Page 1

Operating Instructions for Oscillating Mill MM400

Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 2/8/2012 0002

Page 2

Notes on these operating

instructions

These operating instructions for the oscillating mill, type MM400,

give all the necessary information on the areas mentioned in the

contents.

They instruct the target group(s) for each of the defined areas, in

order to ensure safe handling of the MM 400 when used for the

intended purpose. Knowledge of the relevant section is an

essential precondition for safe, proper use of the machine.

This technical documentation is a reference work and also a set of

teaching instructions. The individual sections are complete in

themselves.

These operating instructions do not include instructions for

repairs. In case of possible defects or necessary repairs please

contact your suppliers or Retsch GmbH direct:

Retsch GmbH, www.retsch.de/

2/8/2012 2 Retsch GmbH

Page 3

Contents

Notes on these operating instructions ..................................... 2

Contents .................................................................................. 3

Safety ...................................................................................... 4

Safety instructions ............................................................................ 4

Warning signs ................................................................................... 5

Repairs ............................................................................................ 5

Confirmation .................................................................................... 8

Technical data ......................................................................... 9

Use according to the intended purpose ................................................ 9

Protective equipment ................................................................ 10

Emissions ....................................................................................... 10

Protective systems .................................................................... 11

Rated power: .................................................................................. 11

Machine dimensions ........................................................................ 11

Required floor space ........................................................................ 11

Transport and installation ..................................................... 11

Packing .......................................................................................... 11

Transport ....................................................................................... 11

Intermediate storage ....................................................................... 11

Conditions for the place of installation ............................................... 12

Installation ..................................................................................... 12

Electrical connection ........................................................................ 12

Operation .............................................................................. 14

Operating elements and operation ..................................................... 14

Graphical representation .................................................................. 14

General table .................................................................................. 15

Display and operating unit ................................................................ 16

Inserting / replacing the milling cups ................................................. 17

Setting the milling time ................................................................... 17

Setting the frequency ...................................................................... 18

Starting the milling process .............................................................. 18

Stopping the milling process ............................................................. 18

Storing the milling parameters .......................................................... 19

Operating hours display ................................................................... 19

Operating software display ............................................................... 20

Replacing the machine fuses ............................................................. 20

Working instructions ............................................................. 20

General .......................................................................................... 20

The milling process.......................................................................... 21

Quantities of milling material and grain sizes ...................................... 21

Safety instructions for handling liquid nitrogen.................................... 22

Safety functions and fault displays ........................................ 23

Safety functions .............................................................................. 23

General ................................................................................. 24

Cleaning ........................................................................................ 24

Maintenance ................................................................................... 24

Wear ............................................................................................. 24

Wearing parts ................................................................................. 24

Checks ........................................................................................... 24

Copyright ....................................................................................... 24

Alterations ..................................................................................... 25

Accessories for MM 400 .................................................................... 25

Safety regulations for the MM 400 - summary ..................................... 26

Appendix .......................................................... following pages

2/8/2012 3 Retsch GmbH

Page 4

We exclude any claims for damages of any kind for

injury to persons and damage to equipment arising

from non-observance of the following safety

instructions.

Safety

Target group: All persons concerned with the

machine in any way

The MM 400 is a modern, highly efficient product of Retsch

GmbH, corresponding to state of the art. If the machine is

used according to the intended purpose with a knowledge of

this technical documentation it is completely safe and reliable

to operate.

Safety instructions

As the operating authority it is your duty to ensure that all

persons charged with working on the MM 400:

have read and understood all the instructions on

safety,

before beginning work know all the instructions

and regulations for the target group relevant to

their work,

have access to the technical documentation for

this machine at all times, without problems.

New personnel should be familiarized with safe,

proper handling of the machine before beginning

work on the MM 400, either by verbal instruction

from a competent person or through this

technical documentation.

Improper operation can cause injury to persons

or damage to the equipment. You are responsible

for your own safety and that of your employees.

Ensure that no unauthorised persons have access

to the MM 400.

For your own protection have your employees confirm that

they have been instructed in operation of the MM 400. The

draft of a suitable form is given at the end of the section on

safety.

2/8/2012 4 Retsch GmbH

Page 5

Warning signs

Injury to persons

Damage to equipment

Observe instructions for use

The Retsch agency in your country

Your supplier

Retsch GmbH directly

____________________________________

____________________________________

____________________________________

____________________________________

Warnings are given by the following signs:

Repairs

These operating instructions do not include repair instructions.

For your own safety repairs must be carried out only by Retsch

GmbH or an authorised agent (service technicians).

In this case please contact:

Your service address:

2/8/2012 5 Retsch GmbH

Page 6

Safety instructions

We exclude any liability for claims for damages in any form whatsoever for injury to persons or damage

to the machine caused through non-observance of the following safety instructions.

Do not make any alterations to the machine and use only spare parts and accessories approved by

Retsch. Otherwise the Declaration of Conformity with European directives made by Retsch will lose its

validity. Furthermore this will also lead to the loss of any guarantee claims.

Please keep the packing material for the duration of the guarantee period, since, in case of a complaint

and return of the machine in unsuitable packing material your guarantee claim will be at risk.

The MM 400 must not be jolted, shaken or thrown during transport. Otherwise the electronic and

mechanical components may be damaged.

If subjected to high temperature variations (e.g. during transport by aircraft) the MM 400 must be

protected against condensed water. Otherwise the electronic components may be damaged.

If the delivery is incomplete and/or transport damage is found, you must inform the transporter and

Retsch GmbH immediately (within 24 hrs). Later complaints may possibly be no longer considered.

If the temperature drops below or exceeds the ambient temperature the electronic and mechanical

components may be damaged; the performance data are then altered to an unknown extent.

At high atmospheric humidity the electronic and mechanical components may be damaged and the

performance data are altered to an unknown extent.

If the values on the rating plate are not observed the electrical and mechanical components may be

damaged.

Ensure that the milling cups are inserted correctly in the milling cup holder – otherwise they can become

damaged when starting the machine.

Both milling positions must always be used since otherwise this will cause considerable unbalance.

When removing and opening hot milling cups always wear protective gloves.

Danger of burning the hands.

Observe the relevant regulations and directives of your country for handling chemicals and hazardous

materials.

Apply these when working with the MM 400.

Milling of materials with the MM 400 which give a risk of fire or explosion is prohibited.

Please take the necessary measures, depending on the hazardous nature of your sample, to prevent

danger to persons.

Note also that the properties, and therefore the hazardous nature of your sample, can change during the

milling process.

Use according to the intended purpose

Packing materials

Transport

Temperature variations

Supply schedule

Conditions for the place of installation

Electrical connection

Inserting / replacing the milling cups

General

Materials

2/8/2012 6 Retsch GmbH

Page 7

Safety instructions for handling liquid nitrogen

Always wear protective goggles and protective gloves when handling liquid nitrogen.

Liquid nitrogen has a temperature of –196°C and can cause frostbite or injury similar to burns if it comes

into contact with the skin or eyes.

Follow the safety regulations of the cooling liquid supplier.

Retsch GmbH accepts no liability whatsoever arising from the use of liquid nitrogen or similar materials.

Do not clean the MM 400 under running water. Danger to life through current surge.

Use only a cloth moistened with water. Cleaning agents and solvents should not be used – not for

cleaning the milling tools either.

Do not make any alterations to the machine and use only spare parts and accessories approved by

Retsch.

Otherwise the Declaration of Conformity with European directives made by Retsch will lose its validity.

Furthermore this will also lead to the loss of any guarantee claims.

These operating instructions do not include any repair instructions. For your own safety repairs should be

carried out only by Retsch GmbH or an authorised agent (service technicians).

Cleaning

Accessories for the MM 400

Wearing parts

2/8/2012 7 Retsch GmbH

Page 8

Confirmation

I have taken note of the sections „Notes on these

operating instructions” and “Safety”

_______________________________________

Signature of operating authority

_______________________________________

Signature of service technician

2/8/2012 8 Retsch GmbH

Page 9

Technical data

The sample quantity should not be less than 25% of the

milling cup volume.

The milling ball/s may otherwise damage the

milling cups.

The milling cup materials and milling ball materials

must always be identical.

The milling ball/s may otherwise damage the

milling cups.

Do not make any alterations to the machine and use

only spare parts and accessories approved by Retsch.

Otherwise the Declaration of Conformity with the

European directives by Retsch loses its validity.

Futhermore this will result in the loss of any kind

of guarantee claim.

Do not clamp any ceramic milling cups of the MM 2/200

or any milling cups without a complete steel casing.

Clamping by the metallic components of the

milling cup holder of the MM 400 can cause

damage to the ceramic parts.

Target group: Operating authority, operator

Machine type designation: MM 400

Use according to the intended purpose

The MM 400 is a laboratory machine and is suitable for milling

and homogenising soft, fibrous, hard and brittle materials in

the wet and dry state.

The MM 400 is designed for use with screw-type milling cups

with a steel casing and a milling set with clamping centerings

of dia. 36 mm and a min. clamping length of 60 mm. It is used

for fast, super fine milling of 2 samples simultaneously.

Ceramic milling cups without a complete steel casing must not

be used.

The closed milling system guarantees complete recovery of the

samples. Owing to the extremely short milling time and the

high final fineness of the material to be milled the MM 400 is

also ideally suitable for sample preparation for all spectral

analyses.

Final finenesses of down to 1 µm can be achieved, depending

on the milling time and the specific properties of the sample

material. The optimum milling cup filling is as a rule 1/3 of the

milling cup volume.

Exceptions to this are voluminous materials, such as wool,

leaves, grasses and suchlike. In these cases a filling level of

70-80% is necessary.

2/8/2012 9 Retsch GmbH

Page 10

Do not use ceramic or natural stone milling cups for

milling graphite or graphite mixtures.

The high lubricating properties of graphite cause high

milling ball speeds, the energy of which cannot be

absorbed by the material owing to its low density.

For this reason there is a danger that the ceramic

or natural stone inserts of the milling cups will be

destroyed by the ball/s.

For further information our application laboratory will

Container:

2 steel milling cups of 25 ml

Milling organ:

1 steel ball 20 mm

Material charged:

Quartz crushed pebbles approx.

4.0 – 6.0 mm

Charged quantity:

8ml

Container:

2 steel milling cups of 5 ml

Milling organ:

2 tungsten carbide balls 8 mm

Material charged:

Quartz crushed pebbles approx.

1.0 – 1.5 mm

Charged quantity:

1.5ml

be pleased to assist you.

Protective equipment

The milling chamber of the laboratory mill MM 400 is

enclosed by a strong covering hood.

Starting the machine is possible only with the hood

closed.

Emissions

Noise characteristic values :

The noise characteristic values are also influenced by

the properties of the material to be milled.

Example 1:

Intensity of sound LWA = 71.4 dB(A)

Emission value related to

workplace L

Operating conditions:

= 61 dB(A)

pAeq

Example 2:

Intensity of sound LWA = 76 dB(A)

Emission value related to

workplace L

Operating conditions:

2/8/2012 10 Retsch GmbH

= 65 dB(A)

pAeq

Page 11

Protective systems

Please keep the packing material for the duration of the

guarantee period since if there is a complaint and the

machine is returned with inadequate packing your

guarantee claim will be at risk.

The MM 400 must not be knocked, shaken or thrown

during transport. Otherwise the electronic and

mechanical components can become damaged.

If temperature variations are high (e.g. during air

transport) the MM 400 must be protected against

condensed water. Otherwise the electronic components

can become damaged.

IP30

Rated power:

150 Watt

Machine dimensions

Height: 266 mm up to approx. 524 mm with hood opened

Width: 371 mm

Depth: 461 mm

Weight: approx. 26 kg without milling cups

Required floor space

400 mm x 500 mm; no safety distance required.

Transport and installation

Target group: operating authority, transporter,

operators

Packing

Packing is adapted to the transport route and

conforms to generally applicable packaging guidelines.

Transport

Temperature variations

Intermediate storage

Ensure that the MM 400 is also stored dry during

intermediate storage.

2/8/2012 11 Retsch GmbH

Page 12

Conditions for the place of installation

If the ambient temperature drops below or exceeds

these values the electronic and mechanical components

can become damaged and performance data are

changed to an unknown extent.

At higher atmospheric humidity the electronic and

mechanical components can become damaged and

performance data are changed to an unknown extent.

Remove transport safeguard:

A transport safeguard, which is marked with an arrow,

is located on the underside of the MM 400.

Unscrew the screw and remove.

Keep the transport safeguard device for transport at

a later date.

Operation with the transport safeguard or transport

without the transport safeguard can cause damage to

the mechanical components.

Ambient temperature:

5°C to 40°C

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up

to 31°C,

decreasing linearly down to 50% relative humidity at

40°C.

Installation height:

max. 2000 m above sea level

Installation

Mount the MM 400 on a firm, stable laboratory bench

since otherwise vibrations can be transmitted.

Electrical connection

The voltage and frequency for the MM 400 are

given on the type plate.

Ensure that these values correspond to the

available power supply system.

Connect the MM 400 to the power supply system

using the supplied connection cable.

2/8/2012 12 Retsch GmbH

Page 13

Protection by external fusing is to be used when

If the values on the type plate are not observed this can

result in damage to the electrical and mechanical

components.

connecting the mains cable to the power supply,

according to the regulations at the place of

installation.

2/8/2012 13 Retsch GmbH

Page 14

Operation

A C B

D

Target group: operators

Operating elements and operation

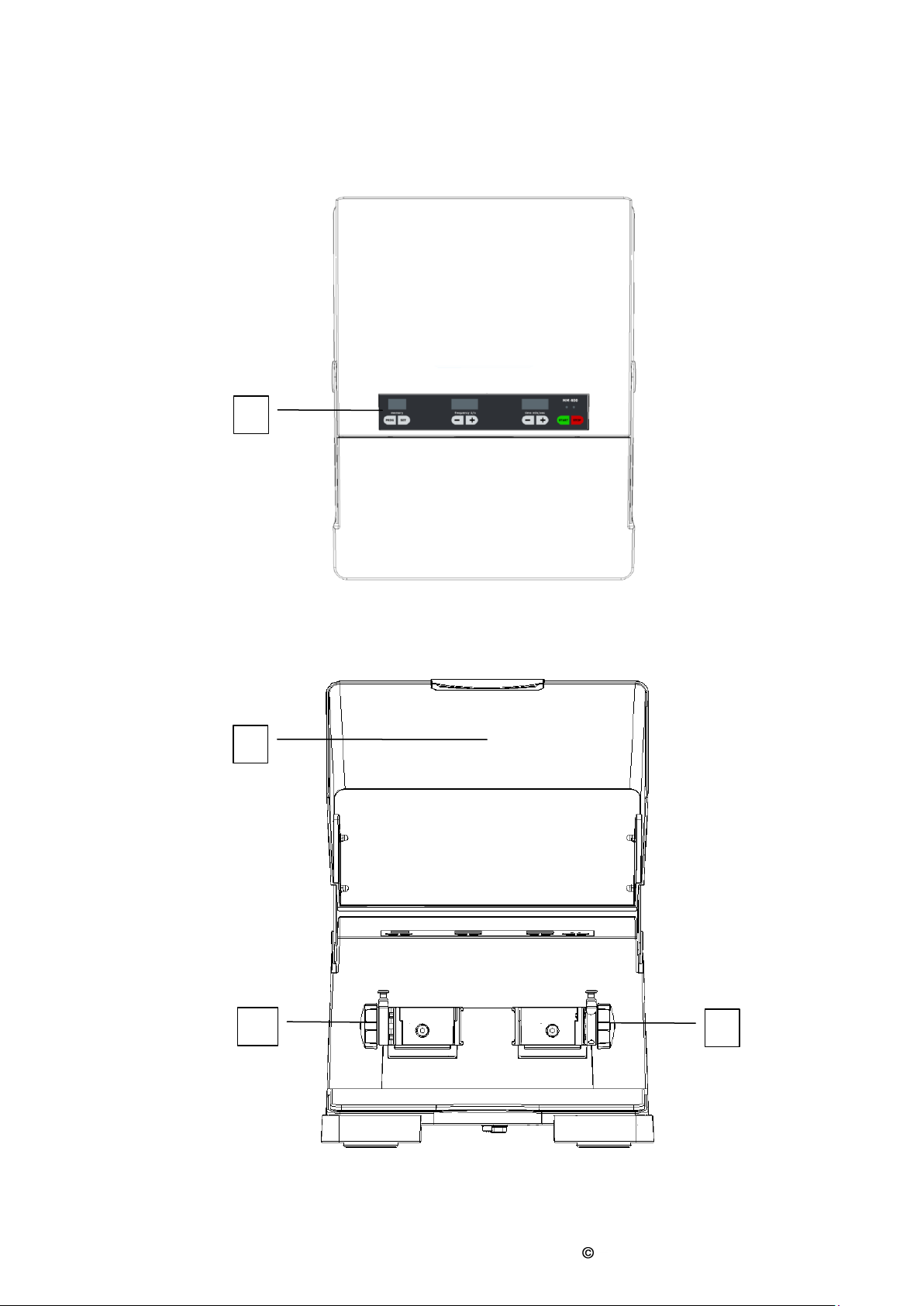

Graphical representation

Plan view

Front view

2/8/2012 14 Retsch GmbH

Page 15

Rear view

Element

Description

Function

A

Display and operating unit: for

explanation see below

Time preselection, frequency preselection,

programme and starting / stopping the

machine

B

Hood

Closes the milling chamber

C

Milling cup holder - left

Holds the milling cup

D

Milling cup holder - right

Holds the milling cup

E

Switch ON / OFF

For switching the MM 400 on and off

F

Fuse compartment

Takes two visible type fuses

G

Machine socket

Connection for power cable of machine

H

Interface RS232

Enables operating software to be updated

I

Sign – Caution! unplug mains

plug

Safety instruction

J

Type plate

Information on the machine and connected

loads

K

Sign – Follow operating

instructions

Safety instruction

J

F

G K I

E

H

General table

2/8/2012 15 Retsch GmbH

Page 16

Display and operating unit

Element

Description

Function

L

Memory , operating mode and

stand-by

The various operating modes, such as on,

programme and stand-by are displayed here.

PROG

Calls the stored programmes

SET

Stores the set milling parameters

M

Frequency display

The frequency can be set continuously from 3 to

30 Hz here.

Frequency – minus button

In the on mode and in the operating mode:

Reduction of the set frequency by 0.1

oscillaltions. Continuous pressing switches

on the digits fast running.

Frequency – plus button

In the setting mode and operating mode:

Increase of the set freuqency by 0.1

oscillations. Continuous pressing switches

on the digits fast running.

N

Time display

Shows the set milling time or, during operation,

the milling time still remaining.

Setting range: 10 seconds to 99 minutes.

Time – minus button

In the on mode and operating mode:

Reduction of the set milling time by one

second. Continuous pressing switches on

the digits fast running.

Time – plus button

In the on mode and operating mode:

Increase of the set milling time by one

second. Continuous pressing switches on

the digits fast running.

P

Start – button

Green LED

Starts the milling operation

Indicates milling operation

O

Stop – button

Red LED and ON

Interrupts or ends the milling operation,

Puts the machine into stand-by mode

L M N

P

O

2/8/2012 16 Retsch GmbH

Page 17

Inserting / replacing the milling cups

Place the milling cups, filled with the material to be milled and

the milling balls, into the centering points Z of the clamping

device and clamp firmly. Fig.1/2

Remove the locking pin SB upwards from the groove and

turn through 90°. Fig.1/2

This unlocks the locking device.

Turn the handwheel HD counterclockwise until the max.

clamping range is reached. Fig.1/2

Turn the locking pin SB back through 90° until it engages in

the groove again.

Insert milling cup and press lightly into the centering point Z

Turn the handwheel HD clockwise with two fingers until the

milling cup just fits, free of play, in the holder. Then

continue to turn the handwheel clockwise through 6 – 8

easily audible “clicks”, while at the same time the locking

pin SB is raised and lowered with clearly audible “clicks”.

The engaged locking pin reliably prevents automatic opening of

the milling cup holder.

If the locking pin SB cannot be pulled upwards to release it,

unlocking should not be forced with a hammer or similar tool.

Otherwise the hardened locking pin can break off.

Briefly retension the handwheel HD in the clockwise direction –

the locking pin can then move freely again.

To remove the milling cup lift the locking pin and turn the

handwheel in the opposite direction to tighten.

In order to guarantee quiet running of the MM 400 both milling

positions must be loaded with approximately the same mass.

Ensure that the milling cups are inserted correctly in the

guides.

Otherwise the milling cup will be damaged when the machine is

started.

When removing and opening hot milling cups always wear

protective gloves.

Danger of burning the hands.

Setting the milling time

• Switch on the MM 400 with switch D

Preselect time:

• Set required milling time with + / - buttons N+ and N-

• Short pressing of N+ or N- adjusts the time by one second or

one minute. When pressed for longer the display runs

continuously without a pause.

If 99.0 minutes is exceeded the display L shows 0.10

seconds again.

Z

SB

HD

N -

N +

Abb.1

Abb.2

Z

SB

2/8/2012 17 Retsch GmbH

Page 18

Setting the frequency

• Set the frequency with + / - buttons M+ and M-.

• Short pressing of + or – adjusts the frequency in single steps.

With longer pressing the display runs faster. Selectable

frequency range is from 3 to 30 Hz.

Starting the milling process

• Shut the hood.

• Set the frequency.

• Set the time.

• The milling operation is started with start button P.

• The milling time is recorded and the milling time still

remaining is shown in display N.

The milling process can be started only when the hood is

closed.

Stopping the milling process

• Press the stop button O.

• Pressing once interrupts the milling process, for example in

order to assess the milled material. The milling time still

remaining is still visible in the display N. By repressing the

start button the mill continues to run until the milling time

has completely elapsed.

• Pressing the stop button twice stops the milling process. The

machine is now in the stand-by mode.

• Pressing the start button reactivates the display and the

milling time is reset to the last starting value.

During the milling process the time can be adjusted by pressing

the N+ or N- button.

When the milling time has elapsed the milling process is

automatically ended. The display is reset to the last started

value.

M-

M+

P

O

N

2/8/2012 18 Retsch GmbH

Page 19

Storing the milling parameters

Storing or calling the preselected milling parameters can be

carried out only in the on mode.

After switching on the MM 400 “on” appears in the display L.

By pressing the button PROG the next programme position P1

to P9 can be obtained. After programme position P9 „on“

reappears in the display. In the PROG mode all buttons, apart

from PROG, START and STOP are blocked.

When the display shows on

the frequency M and time N are freely adjustable.

When the display shows P1 to P9

milling parameters can be stored and called

Start = the milling process is started with the selected

programme or the parameters freely selected under

„on“ .

Allocating the storage location

Press button PROG once or several times until the

required storage location P1-P9 has been reached.

Press SET button – all displays flash.

Set frequency M and time N.

The programming mode can be discontinued by pressing the

button PROG – the values are not stored.

Press SET button – the values are stored.

Flashing of the display stops, the adjustment interlock is

activated and the milling parameters are stored.

If the buttons described below are pressed in the stand-by mode

the complete running time of the machine is shown in hours and

minutes.

Display operating hours :

Press buttons - "frequency 1/s" (- M) and SET

simultaneously and keep pressed.

“bS” appears in the display “memory”.

hhh hhh

Leave operating hours :

Press STOP button.

PROG

SET

L

Operating hours display

2/8/2012 19 Retsch GmbH

Page 20

Operating software display

When the buttons described below are pressed in the stand-by

mode the actual software version is displayed.

Display operating software:

Press buttons + "frequency 1/s" (+ M) and SET

simultaneously and keep pressed.

„S“ appears in the display „memory“ and the actual software

version appears in the display “frequency 1/s”.

Leave operating software display :

Press STOP button.

Replacing the machine fuses

The following visible type fuses are required for the MM 400:

2 MT 3.15 A fuses

Replacing the fuses

• Unplug mains plug from the machine socket A

• By pressing the locking devices on the side of the fuse

compartment B these are released and can be pulled out.

• Replace fuses

• Insert fuse holder B so that it engages.

B

A

Working instructions

Target group: operators

General

The MM 400 is an ultramodern, high performance product

from Retsch GmbH.

Owing to the large selection of accessories the oscillation

mill, type MM 400, is a machine with many different

application possibilities in laboratories in industry and

research. It is used mainly in the chemical and

pharmaceutical sectors and in mineralogical and biological

applications etc.

2/8/2012 20 Retsch GmbH

Page 21

The milling process

Clamp the machine filled with material to be milled, together with

the milling ball/s in the milling cup holder as described.

Close the hood.

Set the milling parameters.

Start the MM 400.

Do not open the hood during the milling process.

Although the milling cups are brought to a standstill immediately

by the built-in brake, the millling process can no longer be

continued with the remaining running time.

The MM 400 must be restarted and the initial parameters are then

again available.

In order to guarantee quiet running of the MM 400 we recommend

that milling cups with the same mass as far as possible are

clamped in both milling positions.

Do not open the plexiglass hood during the milling process.

Although the milling cups are brought to a standstill immediately

by the built-in brake, the milling process can no longer be

continued with the remaining running time.

The MM 400 must be restarted and the initial parameters are then

again available.

Milling cup

volume in ml

Milling material

quantity in ml

min – max

Ball filling

optional

Number dia. in mm

max. charging grain

size in mm

25

4 – 10

1

15

6

35

6 – 15

1

20

6

50

8 – 20

1

25

8

Milling of materials which can cause a fire or explosion in

the MM 400 is prohibited.

Please take any necessary measures to prevent danger to

persons, depending on the dangerous nature of your

sample.

Please note that the properties, and therefore the

dangerous nature of your sample, can change during the

milling process.

Quantities of milling material and grain sizes

2/8/2012 21 Retsch GmbH

Page 22

Safety instructions for handling liquid nitrogen

The MM 400 is also designed for cryogenic milling.

As an accessory for cold milling we also supply a cryo kit for

cooling the milling cups with liquid nitrogen.

Cryo kit order number: 22.354.0001.

When handling liquid nitrogen always wear protective

goggles and protective gloves.

Liquid nitrogen has a temperature of – 196°C and can cause

injury similar to burns or frostbite in contact with the skin

or eyes.

Protective goggles also protect the eyes against serious

injuries through flying glass splinters, which may be caused

through bursting of glass containers as a result of low

temperature tension.

Please follow the safety regulations of the cooling

liquid supplier.

Retsch GmbH excludes any liability claims whatsoever

which may arise through the use of liquid nitrogen or

similar materials.

2/8/2012 22 Retsch GmbH

Page 23

Safety functions and fault displays

F01

F03

F04

F05

F07

F02

F06

Safety functions

F01 - Overloading

In order to avoid overloading of the drive motor and resulting

endangerment to the user the MM 400 is fitted with a load monitoring

device.

In case of overloading the monitoring function switches the machine

off in good time.

At the end of the cooling time it is only necessary to switch the

machine off and on again in order to be able to operate it normally

again.

F02 – Speed recognition, zero speed

If the drive does not start up after pressing the start button there is a

fault in the system. Possible causes: drive blocked, motor or speed

sensor defective.

F03 – Speed recognition, overspeed

If the specified frequency is exceeded after starting, „F3” appears in

the display and the machine is switched off.

Possible cause of fault: defective speed sensor.

F04 – Hood open

The drive must not run when the hood is open. This serves to protect

the operator against injury. If the hood is opened when the machine

is running the control unit switches the drive off immediately and

“F04” appears in the display. If the start button is pressed with the

hood open in order to start the milling process “F04” is also displayed

and the drive is not started.

This alarm can be cancelled by pressing the stop button.

F05 –Keyboard monitor

If one or more buttons are pressed for longer than 15 seconds the

control unit switches the drive off and displays “F05”.

This function is intended to prevent unintentional faulty operation if

any object accidentally presses on the keyboard.

In order to cancel this fault alarm switch the machine off and on

again once.

F06 – Magnetic speed monitoring sensor

If one of the magnets that monitors speed is missing or defective,

this will be detected by the control, which will then switch off the

machine. “F06” will appear in the display. To eliminate this fault, it

must be repaired by authorised Retsch service technicians.

F07 – Magnetic switch – hood monitoring

If the magnetic switch which monitors hood opening has a defect in

the supply line this is recognised by the control unit and causes the

machine to be switched off. “F07” appears in the display. To eliminate

this fault repair by an authorised Retsch service agent is necessary.

2/8/2012 23 Retsch GmbH

Page 24

General

Do not clean the MM 400 with running water.

Danger to life through current surge

Use only a cloth moistened with water. Cleaning agents

and solvents must not be used – not for cleaning the

milling tools either.

Do not make any alterations to the machine and use only spare

parts and accessories approved by Retsch.

Otherwise the declared conformity with the European

directives by Retsch will lose its validity. Furthermore

this will lead to loss of any kind of guarantee claims.

These operating instructions do not include instructions for

repair. For your own safety repairs should be carried out only

by Retsch GmbH or an authorised representative (service

technicians).

Cleaning

Maintenance

The MM 400 is maintenance-free. When used properly

no maintenance and setting work need be carried out.

Wear

The milling tools can become worn, depending on the

frequency of the milling operation and the material to

be milled. The milling cups and ball(s) should be

regularly checked for wear and replaced if necessary.

Wearing parts

Checks

Correct functioning of the hood switch must be checked

regularly:

• Switch on the machine with switch E.

• Start milling operation with start button P.

• Lift the hood.

• If there is an opening gap of a few cm the machine is

switched off and F4 appears in the display.

• Cancel F4 with stop button O.

If this switching off function does not take place the MM 400

must be checked immediately by Retsch service.

Copyright

Distribution or duplication of this documentation, using

or passing on the contents, is allowed only with the

express permission of Retsch GmbH.

Anyone violating is liable to pay damages.

2/8/2012 24 Retsch GmbH

Page 25

Designation

Material

Article no.

Milling cup 25 ml

Hardened steel

01.462.0237

Milling cup 1.5 ml

Stainless steel

01.462.0230

Milling cup 5 ml

01.462.0231

Milling cup 10 ml

01.462.0236

Milling cup 25 ml

02.462.0213

Milling cup 35 ml

01.462.0214

Milling cup 50 ml

01.462.0216

Milling cup 10 ml

Tungsten carbide

01.462.0235

Milling cup 25 ml

01.462.0217

Milling cup 5 ml

Agate

01.462.0232

Milling cup 10 ml

01.462.0233

Milling cup 10 ml

Zirconium oxide

01.462.0234

Milling cup 25 ml

02.462.0201

Milling cup 35 ml

01.462.0215

Milling cup 25 ml

Teflon

01.462.0238

Milling cup 35 ml

01.462.0244

Milling balls dia.

5,7,9,12,15 mm

Hardened steel

Milling balls dia.

5,7,9,12,20,25 mm

Stainless steel

Milling balls dia.

5,7,9,12,15 mm

Tungsten carbide

Milling balls dia.

5,7,9,12 mm

Agate

Milling balls dia.

12,15,20 mm

Zirconium oxide

Milling balls dia.

10,12,20 mm

Teflon with steel core

Milling balls dia.

5,7,9,12 mm

Polyamide for mixed

vessels

Alterations

Subject to technical alterations without notice.

Accessories for MM 400

2/8/2012 25 Retsch GmbH

Further accessories are given in our price list or in

internet under www.retsch.de

Page 26

Safety regulations for the MM 400 - summary

Subject

Action

Danger

Safety

Danger to persons and damage to the

equipment caused through non-observance

of the safety instructions

Claims for damages in any form are

excluded

Transport

Do not knock, shake or throw the MM 400

during transport

Electronic and mechanical components

can be damaged

Keep the packing material for the duration of

the guarantee period

Complaint and return of the goods in

inadequate packing puts your

guarantee claim at risk

Temperature

variations

Protect the MM 400 from condensed water if

there are temperature variations

Electronic components can be

damaged

Supply schedule

If the delivery is incomplete and / or there is

transport damage you must inform the

transporter and Retsch GmbH immediately

(within 24 hrs).

Later complaints may possibly no

longer be considered.

Ambient

temperature

Temperature drops below 5°C

Temperature exceeds 40°C

Electronic and mechanical components

can be damaged.

Performance data are changed to an

unknown extent.

Atmospheric

humidity

Exceeds 80% at

temperatures up to 31°C

Electronic and mechanical components

can be damaged.

Performance data are changed to an

unknown extent.

Electrical

connection

Mains power supply does not agree with

values on type plate

Fault-current circuit breaker must be

incorporated into the power supply.

Mechanical and electronic components

can be damaged.

Prevents electric shock if machine has

an electrical defect.

Inserting milling

cups

Ensure that the milling cups are positioned

correctly in the guides.

Milling cups and holder can be

damaged.

Checks

Check hood switch regularly

Danger of injury if defective and

machine open during operation.

Cleaning

Do not clean with running water

Danger to life through current

surge

2/8/2012 26 Retsch GmbH

Page 27

Page 28

Page 29

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Mixer Mill Type MM 400 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

R e t s c h G m b H R e t s c h - A l l e e 1 - 5 4 2 7 8 1 H a a n G er m a n y w ww . r e t s c h . c o m

Mixer MILL

MM 400

FB-EW-805-057 (E) Änderungsstand D 01/2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN 61000-3-2/-3 Electromagnetic compatibility (EMC)

EN 61236 Electrical measuring, operating, controlling and laboratory equipment – EMC-

requirements in conjunction with EN 61000

EN 55011 Limit values and measuring procedures for noise suppression of industrial,

scientific and medical high frequency devices

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 30

Page 31

Page 32

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...