Page 1

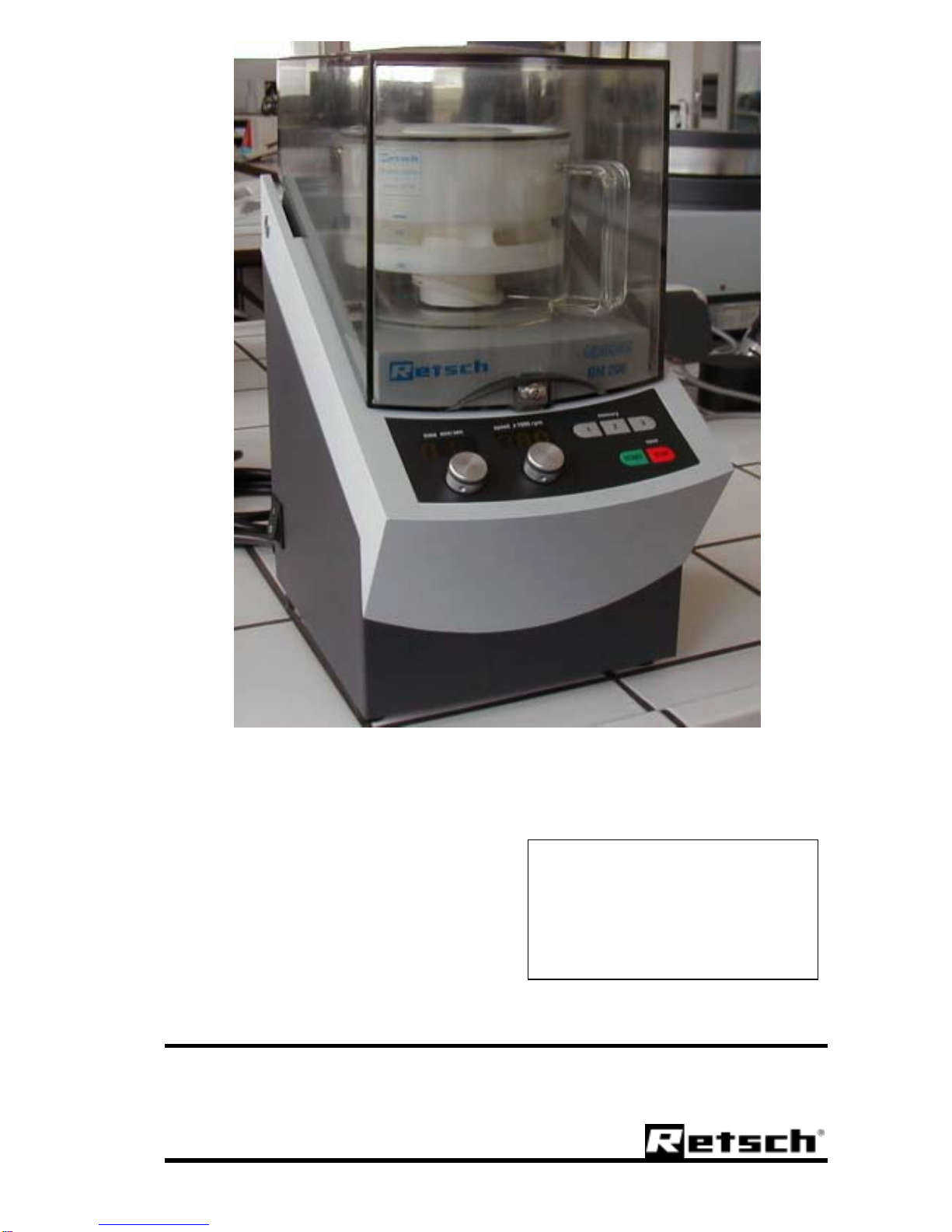

Operating Instructions for the Cutting Mill

Type

GRINDOMIX GM 200

Retsch GmbH & Co. KG, 42781 Haan, Rheinische Str.36, Germany, Doc.no. GB 98. 251.9999 C

Page 2

22.02.2002 Retsch GmbH & Co. KG 2 Doc.no. GB 98.251.9999 C

Notes on the operating instructions

These operating instructions for the laboratory knife mill type

GRINDOMIX GM 200 provide all the necessary information on the

topics named in the table of conte nts.

They guide the defined target group(s) for the relevant fields towards

safe and correct procedures for handling the GRINDOMIX GM 200.

Safe and correct handling is only possible when the relevant target

group(s) are familiar with the chapters concerned.

This technical docume ntation constitutes both a refere nce work and a

tutorial. The individual chapters are self-contained units.

These operating instructions do not contain any instructions for repairs. Should any repair s become necessary, please contact your su pplier or contact Retsch GmbH dir ect.

Page 3

22.02.2002 Retsch GmbH & Co. KG 3 Doc.no. GB 98.251.9999 C

Notes on the operating instructions....................................................... 2

Safety ........................................................................................... 4

Notes on safety.................................................................................4

Warning notes ..................................................................................5

Repairs ........................................................................................... 5

Confirmation ...................................................................................5

Technical Data................................................................................ 6

Use for the intended purpose................................................................ 6

Description of function....................................................................... 6

Protection systems.............................................................................7

Drive .............................................................................................8

Motor power....................................................................................8

Rated voltage ................................................................................... 8

Speed.............................................................................................8

Emissions........................................................................................8

IP rating .........................................................................................8

Dimensions ..................................................................................... 8

Installation area required......................................................................8

Transport and installation................................................................... 9

Packaging........................................................................................ 9

Transport........................................................................................9

Temporary storage.............................................................................9

Scope of supply.................................................................................9

Parameters for the installation point........................................................ 10

Installation ......................................................................................10

Electrical connection.......................................................................... 10

Operation ...................................................................................... 11

Controls and operation........................................................................11

Table of controls............................................................................... 12

Operating the GRINDOMIX GM 200....................................................13

Switching ON and OFF ...................................................................... 13

Opening the cover.............................................................................13

Inserting the vessel ............................................................................. 13

Using Grinding Containers with Different Materials..................................... 14

Lid and vessel combinations .................................................................15

The 1000 ml lid.................................................................................15

The 500 ml lid .................................................................................. 15

The gravity lid ..................................................................................15

Loading the machine ..........................................................................16

Setting the time.................................................................................17

Setting the speed...............................................................................17

Interval mode...................................................................................17

Memory buttons ...............................................................................18

Loading a program............................................................................. 18

Starting - Interrupting - Stopping ...........................................................18

Replacing fuses................................................................................. 19

Setting Back the Overload Fuse.............................................................19

Notes on Operation .......................................................................... 20

General .......................................................................................... 20

Notes on sample milling ......................................................................20

General ......................................................................................... 23

Accessories...................................................................................... 23

Cleaning .........................................................................................24

Cleaning of the milling tools, vessel and lid ............................................... 24

Maintenance ....................................................................................24

Necessary safety tests..........................................................................24

Copyright........................................................................................24

Modifications ...................................................................................24

Fault display.....................................................................................25

Safety regulations (Table)..................................................................... 26

Safety regulations (Table 2)...................................................................27

Warranty conditions.......................................................................... 28

Page 4

22.02.2002 Retsch GmbH & Co. KG 4 Doc.no. GB 98.251.9999 C

Safety

Target group: All persons dealing with the machine in any way.

The GRINDOMIX GM 200 laboratory knife mill is a highly modern,

efficient product from Retsch GmbH. Its engineering is state of the art.

When handled correctly by persons familiar with the machine and this

technical documentation, the GRINDOMIX GM 200 is perfectly safe

and reliable in operation.

Notes on safety

You, as the operator, are responsible for ensur ing that the persons appointed to work with the GRINDOMIX GM 200:

• have read and understood all the regulations concerning

safety,

• are familiar with all procedures and instructions for their relevant target group before starting work,

• have access to the technical documentation for this machine

at any time and without problems.

You should ensure that new pe rsonnel are instructed in safe and correct handling either orally by a competent person and/or by this technical documentation before sta rting work with the GRINDOMIX GM

200.

Incorrect operation can lead to d amage or injury. You are responsible

for your own safety and that of your staff.

Please ensure that no unauthorised persons have access to the

GRINDOMIX GM 200.

For your own protection, have your staff confirm their instruction in

the operation of the GRINDOMIX GM 200. You will find an appropriate draft form at the e nd of the chapter on safety.

We accept no liability whatsoever for any damage or injury resulting

from non-observance of the f ollowing notes on safety.

Page 5

22.02.2002 Retsch GmbH & Co. KG 5 Doc.no. GB 98.251.9999 C

Warning notes

We use the following symbols to warn agai nst:

!

Personal injury

Damage to property

Repairs

These operating instructions do not c ontain a ny instr uc tions on repairs.

For your own safety, only ha ve re pairs per formed by Re tsch GmbH or

an authorised representative (service technicians).

In such cases, please notify:

The Retsch agency in your country

Your supplier

Retsch GmbH direct

Your service address:

Confirmation

I have read and noted the chapters entitled Foreword and Safety.

_________________________________________

Operator’s signature

_________________________________________

Service technician’s signature

Page 6

22.02.2002 Retsch GmbH & Co. KG 6 Doc.no. GB 98.251.9999 C

Technical Data

Target group: Operators

Machine type designation: GRINDOMIX GM 200

Use for the intended purpose

The GRINDOMIX GM 200 laboratory knife mill is suitable for the

comminution, homogenisation and mixing of soft to mediu m-hard, water and grease containing, fibrous and dry materials ready for analysis in

a matter of seconds. The GRINDOMIX GM 200 is designed for quantities up to approx. 700 ml, and up to 1000 ml for large volume materials. The input particle size is <30 - 40 mm.

It is particularly designed for the milling of the following materials:

Fish, meat, vegetables, cheese, preserves, seeds, bacon, sausage, dry

bread and pastry pr oducts, all products containing wate r or rich in fat,

fibrous products and similar materials.

The GRINDOMIX GM 200 is not designed as a production machine,

but as a laboratory instrume nt intended for 8 hour single shift operation at a continuous duty fa ctor of 30%.

This machine is not suitable for the mixing and homogenisation of liquids or low viscosity emulsions and suspensions.

For further information, please contact our applications labora tory

staff, who will be pleased to help.

Do not modify the machine in any way, and use only spare parts

and accessories approved by Retsch.

The conformity with European Directives declared by

Retsch will otherwise be invalidated.

Furthermore, this will lead to all warranty claims being rendered null and void.

Description of function

The comminution process in the GRINDOMIX GM 200 takes place

by cutting.

The knife blades are straight and arranged at a right angle to the direction of rotation.

The knives are slim, with a cutting edge angle of 15° and a 30° leading

facet.

With this cutting edge geometry, the entire momentum resulting from

the difference in velocity between the particles of process material and

the blades can be used as the cutting force.

The speed is between 2000 and 10000 rpm, and is set and digitally displayed in steps of 500 rpm.

The selected speed is kept c onstant by a controller during milling.

Page 7

22.02.2002 Retsch GmbH & Co. KG 7 Doc.no. GB 98.251.9999 C

Interval mode is started by holding the start button depressed. It has

proven advantageous to start milling in interval mode for pregranulation and homogenisation of coarse, tough, fibrous, very soft or

highly elastic products.

The milling duration can be set at up to 3 min., and on completion of

milling the motor switches off automatically and the housing cover

opens.

3 memory locations facilitate the saving and loading of frequently used

speed/time combinations at the touch of a button.

The milling result is also influenced by the relationship between the

milling chamber volume and the quantity of material to be processed.

Various vessel/lid combinations are therefore available to the user:

For the plastic vessels, plastic lids for 500 and 700/1000 ml and a gravity lid are available.

The 700/1000 ml plastic lid is used for large quantities of small grained

materials such as seeds, pepper corns and cheese. The input quantity is

between 300 and max. 700 ml.

The 500 ml plastic lid is used for smaller quantities of small grained

materials such as seeds, pepper corns and cheese. The input quantity is

max. 300 ml.

The gravity lid is used for large volume materials and materials containing water, such as lettuce and tomatoes. Under the force of its own

weight, the lid automatically adapts to fit the milling chamber volume

during the milling operation.

700/1000 ml plastic lids and a separate gravity lid are available for the

glass vessels.

Protection systems

The milling chamber of the GRINDOMIX GM 200 is secured by an

especially robust housing cov er.

The machine can only be started when the cover is closed, and the

cover can only be opened when the motor is at a standstill.

In case a fault should occur, there is also an electrical emergency brake

which brings the blade to a standstill in a fraction of a second, even

from its maximum speed.

Should an overload cause the actual speed to deviate by more than 5 %

from the specified speed set, this is indicated by flashing displays.

Page 8

22.02.2002 Retsch GmbH & Co. KG 8 Doc.no. GB 98.251.9999 C

Drive

Series-wound motor

Motor power

750 watts

Rated voltage

230V 50 Hz and

100 - 110V 50 / 60Hz

Speed

Knife speed variable from 2000 to 10000 rpm

Emissions

Noise characteristics:

Noise measurement to DIN 45635-031-01-KL3

The noise levels are also infl uenced by the properties of the material to

be milled.

Example 1:

Sound power level L

WA

= 79.2 dB(A)

Workplace related emission level L

p eq

= 66.9 dB(A)

Service conditions:

Vessel = Glass vessel with gravity lid

Milling unit = Knife in stainless steel

Input material = Tomatoes, quartered, approx. 40 x 25mm

Input quantity = 100g

Example 2:

Sound power level L

WA

= 86.2 dB(A)

Workplace related emission level L

p eq

= 73.9 dB(A)

Service conditions:

Vessel = Glass vessel with gravity lid

Milling unit = Knife in stainless steel

Input material = Cheese, approx. 20 x 20mm

Input quantity = 100g

IP rating

Milling chamber and keyboard IP42

In the area of the ventilation slots IP20

Dimensions

Height: up to approx. 370mm, Width: 200mm, Depth: 270mm

with cover open

Height: up to approx. 450mm, Width: 200mm, Depth: 400mm

Weight: approx. 7.5 kg without plastic vessel and knife

Installation area required

200 mm x 400 mm; no safety clearances are necessary.

Page 9

22.02.2002 Retsch GmbH & Co. KG 9 Doc.no. GB 98.251.9999 C

Transport and installation

Target group: Operators, carriers

Packaging

The packaging is suitable for the particular me ans of transpor t. It complies with the general packaging regulations.

Please keep the packaging for the duration of the guarantee period, as your guarantee claim may be invalidated if there is a complaint and the unit is returned in inad e quate packaging.

Transport

The GRINDOMIX GM 200 must not be jarred, shaken or

thrown during transport. This could damage the electronic and

mechanical components.

Temperature fluctuations

When subjected to major temperature fluctuations (e.g. during air

transport) the GRINDOMIX GM 200 is to be protected from

condensation. Damage to the ele ctronic components may otherwise result.

Temporary storage

Ensure that the GRINDOMIX GM 200 is stored in a dry place even

when storage is temporary.

Scope of supply

• 1 GRINDOMIX GM 200

• 1 plastic vessel

• 1 lid, 1000 ml

• 1 knife cylinder

• 1 instruction manual

Check that the delivery is complete, including any accessories ordered

in addition.

Check that the GRINDOMIX GM 200 functions perfectly (see the

chapter on operation).

In cases of incomplete delivery and/or transport damage, you

must notify the forwarding agent and Retsch GmbH without

delay (within 24 hours). It may not be possible to accept subsequent complaints.

Page 10

22.02.2002 Retsch GmbH & Co. KG 10 Doc.no. GB 98.251.9999 C

Parameters for the installation point

Ambient temperature:

5°C to 40°C

If the ambient temperature is above or below that specified, the

electronic and mechanical components may be damaged and performance data change to an unknown extent.

Humidity:

Maximum relative humidity 80% at temperatures up to 31°C, declining

in a straight line to 50% relative humidity at 40°C

Higher humidity can cause damage to the electronic and mechanical

components, and performanc e data can change to an unknown e x tent.

Site altitude:

max. 2000 m above sea level

Installation

Always set up the GRINDOMIX GM 200 on a firm and stable base,

e.g. a laboratory bench.

Electrical connection

• See the type plate for the voltage and frequency of the

GRINDOMIX GM 200.

• Ensure that the values agree with those of the available power

supply.

• Connect the GRINDOMIX GM 200 to the power supply using

the connecting cable supplied.

Failure to observe the values on the type plate can lead to damage to

electrical and mec ha nical components.

Page 11

22.02.2002 Retsch GmbH & Co. KG 11 Doc.no. GB 98.251.9999 C

Operation

Target group: Operators

Controls and operation

Graphical display of the contr ols:

J

C

D

E

F

G

H

A

K

Front view Side view

B

Rear view

L

Page 12

22.02.2002 Retsch GmbH & Co. KG 12 Doc.no. GB 98.251.9999 C

Table of controls

Item Element Illustration Function

A Main switch Connects the GRINDOMIX GM 200 to and isolates it from

the mains

B Fuse holder

Contains two glass fuses

(See type plate for further details)

C START button

Starts the milling process

Switches interval mode on

D STOP button

Stops the milling process

Opens the cover

E Display of machine run-

ning time

Displays the selected machine running time of

1 sec - 3 min

F Knob for time setting

Allows the desired machine running time to be set.

G Speed display

Displays the selected speed of

2000 - 10000 rpm

H Knob for speed setting

Allows the desired speed to be set

J Memory function Allows up to three time and speed combinations to be saved

and loaded

K Housing cover not shown Screens the milling chamber off

L Overload protection

switch

If the motor is overloaded, cuts the GM 100's power off

If pressed, restore s the connection to the power supply after

the motor has cooled down

Page 13

22.02.2002 Retsch GmbH & Co. KG 13 Doc.no. GB 98.251.9999 C

Operating the GRINDOMIX GM 200

Target group: Operators

Switching ON and OFF

Fig.1

Fig.2

The main switch A is located at the bottom left side of the GRINDOMIX

GM 200. Fig.1

• Turn on the main switch.

• The time display indicates the last milling du ration used.

• The speed display shows the last speed used.

Opening the cover

Fig.3

• Press STOP button D brief l y. Fig.3

The cover is released and springs open.

Inserting the vessel

Fig.4.1

Fig.4.2

• Open the cover.

• Insert the vessel.

Ensure that the vessel is correctly positioned when inserted. Use the left or

right guide slot. Fig.4.1 and 4.2

Page 14

22.02.2002 Retsch GmbH & Co. KG 14 Doc.no. GB 98.251.9999 C

Using Grinding Containers with Different Materials.

The material properties specified here primarily r elate to products from

the targeted market of foodstuffs or animal feed because the Grindomix should be classified in its main application.

Grinding Cup – Plastic Container (PP)

suited for: material consistency soft, medium-hard, elastic, containing

water, fatty and oily.

not suited for:: material consistency hard, hard to brittle such as cereals, pressed parts and pellets, gelatine candies. Increased abrasion in the

plastic container.

Warning!

The plastic container and the plastic covers are only resistant to

cleaning in a dishwasher.

If using a dishwasher, ensure the correct positioning!

Never place close to the heating helix, otherwise deformation might

occur which could prevent further use with the GM .

Sterilising and heating in a n autoclave is not possible!

Grinding Cup – Glass Container (Borosilicate Glass 3.3)

suited for: material consistency soft, medium-hard, elastic, containing

water, fatty and oily.

not suited for:: material consistency hard, hard to brittle such as cereals, pressed parts and pellets, ge latine candies. Glass containers may

break.

Grinding Cup – Stainless Steel Containers (1.4435

x2CrNiMo 18-14-3)

suited for: material consistency soft, medium-hard, elastic, containing

water, fatty and oily, hard to medium hard such as cereals, furthermore

for deep-frozen foods, chewable candy, hard cheese and sausage products,

Caution!

It is not allowed to grind with liquid nitrogen (fl. N

2

) or dry ice

(CO

2

) in any GM option. There is danger resulting from grinding

tools or the glass or plastic container becoming brittle or breaking.

Page 15

22.02.2002 Retsch GmbH & Co. KG 15 Doc.no. GB 98.251.9999 C

Lid and vessel combinations

The various lid/vessel combinations allow the machine to be adapted

for various functions.

The 1000 ml lid

Fig.5

The 1000 ml lid is used for large quantities of small grained materials such

as seeds, pepper corns and cheese, etc.

The input quantity is between 300 and max. 700 ml. Fig.5, see also the

chapter Notes on operation.

The lid is clamped onto the lip of the vessel, and can be released with the

tab.

Note:

The 1000 ml lid can be used with both plastic and glass vessels.

The 500 ml lid

Fig.6

The 500 ml lid is used for smaller quantities of small grained materials such

as seeds, pepper corns and cheese, etc.

The input quantity is max. 300 ml. Fig.6, depending on the material to be

processed. See a l so the chapter on Notes on operation.

The 500 ml lid is merely laid on the vessel with its edge on the top of the

vessel. During milling, the 500 ml lid is held down by the cover.

Note:

The 500 ml lid can only be used with plastic vessels.

The gravity lid

Fig.7

The gravity lid allows the vessel volume to be adjusted precisely to suit the

input quantity. It simply moves with the material during milling, and thus

optimises the milling chamber volume.

It is used for materials c ontaining water, such as potatoes, paprika, le ttuce

or tomatoes. Fig.7, see also Notes on operation.

The input quantity is max. 300 ml.

Note:

There are two gravity lids, one for the glass vessel and one for the plastic

vessel.

Caution! Ensure that the input quantity does not exceed the maximum of

300 ml.

If the recommended input quantities are exceeded with materials containing water, the vessel may overflow during the milling proce ss.

Page 16

22.02.2002 Retsch GmbH & Co. KG 16 Doc.no. GB 98.251.9999 C

Loading the machine

Filling the vessel in the machine

• Insert the vessel.

• Fit the knife cylinder, sliding it up to the stop.

• Pour in the material to be processed.

• Fit the lid.

• Close the cover and ensure that its interlock pin engages.

!

The cover must engage securely with the interlock pin, so that the motor

can start and no emergency braking operation is triggered off during milling.

Caution! Always insert the knife cylinder before feeding the process material in, as otherwise process material may be deposited between the knife

cylinder and the vessel.

Filling the vessel outside the machine

The vessel can also be filled before it is inserted in the mac hine . You can

thus easily work with several vessels – without stopping to clean them.

Vessels can only be loaded outside the machine when the 500 ml and 1000

ml lids are used. The gravity lid is not suitable for this purpose.

The sequence is then:

• Fit the knife cylinder into the vessel.

• Feed in the process material.

• Fit the lid.

• Insert the vessel in the GRINDOMIX GM 200, holding the lid down at

the centre (absolutely necessary with the 500 ml lid) so that the knife

cylinder definitely reaches its limit position. Fig.8 and Fig.9

• Close the cover so that the interlock pin engages.

Fig. 8 with 1000 ml lid

Fig. 9 with 500 ml lid

We recommend you to hold the lid down at the centre (absolutely necessary with the 500 ml lid) so that the knife cylinder definitely reaches its

limit position. Fig. 8 and 9

!

The cover must engage securely with the interlock pin, so that the motor

can start and no emergency braking operation is triggered off during milling.

When filling the vessel outside the machine, do not use the gravity lid, as it

cannot hold the knife down when the vessel is inserted in the machine.

Page 17

22.02.2002 Retsch GmbH & Co. KG 17 Doc.no. GB 98.251.9999 C

Setting the time

Fig.10

When the machine is switched on, display E shows the last time set.

Select a time between 1 second and 3 minutes: Fig.10

• Turn knob F anti-clockwise: the time can be reduced to 1 sec.

• Turn knob F clockwise: the time can be increased to 3 min.

The time is freely selectable between 1 sec. and 3 min.

Turning speed

• Slow turning = steps of 1 sec.

• Up to 10 sec. in 1 sec. steps only

• Fast turning = steps of 30 sec. (from 10 sec. onwards)

Setting the speed

Fig.11

When the machine is switched on, display G shows the last speed set.

Set the speed between 2000 and 10000 rpm: Fig.11

• Turn knob H anti-clockwise: the speed can be reduced to 2000 rpm.

• Turn knob H clockwise: the speed can be increased to 10000 rpm.

The speed is freely selectable between 2000 and 10000 rpm.

Turning speed

• Steps of 500 rpm.

Interval mode

Fig.12

Fig.12a

The interval mode is advantageous for coarse input material of 30 - 40mm

in size, large volume sample material such as lettuce, sample material containing water such as tomatoes, coarse, tough fibrous material like salami,

and very soft or tough and elastic sample material like cheese.

The interval mode is activate d with the START button C and remains

active as long as the START button C is held depressed, up to a maximum

of the set milling duration.

If the set speed is >4000 rpm, the machine runs at the set speed in the first

interval. All further intervals are run at 4000 rpm.

If the set speed is <4000 rpm, all intervals are run at the set speed.

If interval operation is supposed to be maintained during the entire period

of grinding, it can be permane ntly switched on by simultaneously pressing

the buttons START + memory 1.

Page 18

22.02.2002 Retsch GmbH & Co. KG 18 Doc.no. GB 98.251.9999 C

Memory buttons

Fig.13

The GRINDOMIX GM 200 has three memory buttons J, which can be

used to save paramete r combinations of time and speed. Fig.13

• Turn the main switch on.

• Displays E and G indicate the last parameters set.

• Set the time with knob F.

• Set the frequency with knob H.

• Hold one of the three memory buttons J depressed. After 1.5 seconds,

displays E and G flash.

• When the displays stop flashing, the parameters are stored under the

memory key which was presse d.

Loading a program

• Press the corresponding memory button J, Fig.13, briefly.

The saved parameters then appear on displays E and G.

• Start the GRINDOMIX GM 200.

Starting - Interrupting - Stopping

Fig.14

Starting: Fig. 14

• Press the START button C.

During the milling period, the speed is kept constant within a specified

tolerance.

Interrupting: Fig.14

• Press the STOP button D.

The milling process is interrupted and can be resumed for the re maining

running time by pressing the START button C again.

Stopping: Fig.14

• Press the STOP button D twice.

The milling process is stopped, the cover springs open and the original

machine running time is displayed.

Page 19

22.02.2002 Retsch GmbH & Co. KG 19 Doc.no. GB 98.251.9999 C

Replacing fuses

Fig.10

[This is] only possible with machine up to the c ha nge symbol “B” behind

the serial number of the machine's nameplate. Refer to the chapter on

“Setting Back the Overload Fuse” from sy mbol “B”

Two glass fuses are required:

T 4 A (6.3x32mm) for 230V -50Hz

T 8 A (6.3x32mm) for 100/110V -50/60Hz

Replacement: Fig.10

• Disconnect the mains plug.

• Push in fuse holder B with a screwdriver and turn it ¼ turn in the anti-

clockwise direction.

• Draw out the fuse holder.

• Replace the fuses.

• Slide the fuse holder back in.

• Lock the fuse holder.

Setting Back the Overload Fuse

Fig.10a

This is only possible with machines with a „C“ behind the serial number of

the machine nameplate.

Figure 10a

There is the overload protective switch on the right-hand side of the rear

wall.

If the machine overloads, this disconnects the GM from the power supply.

You may re-connect the GM with the power supply by pressing the

switch after a period of cooling off. This can be ascertained empirically.

Page 20

22.02.2002 Retsch GmbH & Co. KG 20 Doc.no. GB 98.251.9999 C

Notes on Operation

Target group: Operators

General

The GRINDOMIX GM 200 laboratory knife mill is a highly modern,

powerful product from Retsch GmbH & Co. KG.

With its broad selection of accessories, the GRINDOMIX GM 200 is a

machine with a variety of applications, predominantly in the foodstuffs

sector.

The GRINDOMIX GM 200 is suitable for preparation of products

with a high water, oil and fat content, which can also be soft, tough and

fibrous. Materials, then, su ch as are to be found in foodstuffs laboratories and have to be prepared there for a wide range of different analysis

processes.

The aim of all comminution tests is to reduce the size of an input material to such an extent that it is suitable for analysis. Analysis fineness

and homogeneity are of paramount importance. In the preparation of

laboratory samples, more material is always milled than is actually necessary for the analysis. The final product therefore has to exhibit a degree of homogeneity which pe rmits random, but nevertheless representative, sampling.

Notes on sample milling

Almost any material-specific degree of fineness can be achieved by setting various milling parameters and by the combination of particular

vessels and lids.

All the milling parameters listed in the following tables are

guideline values only. Depending on the product properties and

the corresponding analysis requirements, the milling duration

and speed in particular will have to be determined by experimentation.

Doubling the input quantity also necessitates a doubling of the milling

duration for many produ cts, if the same degree of homogenisation is to

be achieved. An increase in the speed with double the input quantity is

not, however, to be recommend ed.

Products with a high water content,

predominantly fruit and vegetables,

deep-frozen products and packaged meals, preserves up to 300

ml

For these products, the glass or plastic vessel is to be used with a corresponding gravity lid.

The gravity lid has the function of adapting the milling chamber volume to correspond to the vary ing sample volume during the milling

process. The input volume must not exceed 300 ml. The sample material is to be cut in advance to a size of around 30 mm and fed into the

mill vessel. Then set the gravity lid on the sample material in the vessel.

Page 21

22.02.2002 Retsch GmbH & Co. KG 21 Doc.no. GB 98.251.9999 C

When the mill is started, the milling chamber volume required changes

as a result of circulation effects and of the centrifugal forces acting on

liquefied process material. The gravity lid moves with the material and

thus constantly optimises the milling chamber.

This only functions, however, with prod ucts with a high water content.

When the gravity lid is used, we recommend that the max. input volume

be determined on the basis of the input material.

If the input volume is > 300 ml, sample liquid can emerge from the mill

vessel.

If the input volume is > 300 ml, the amount of input material either has

to be reduced, or multiple milling operations performed.

Sample material Sample quantity Particle size Speed Time

Potatoes 200 g 20-30 mm 7000 rpm 20 sec.

Tomatoes 250 g 30 mm 8000 rpm 10 sec.

Cucumbers 200 g 30 mm 8000 rpm 15 sec.

Apples 200 g 30 mm 7000 rpm 15 sec.

Mandarin oranges 180 g up to 30 mm 8000 rpm 10 sec.

Mushrooms 230 g up to 30 mm 8000 rpm 20 sec.

Greens 300 g up to 20 mm 8000 rpm 30 sec.

Peas and carrots 265 ml up to 15 mm 10 000 rpm 15 sec.

Stew 200 ml up to 20 mm 10 000 rpm 20 sec.

Canned pet food 350 g as contents 10 000 rpm 20 sec.

Products with a high fat content,

predominantly meat and fish

Tough, fibrous, heterogeneous products such as meat and sausages,

fish and other marine products should be prepared in the glass or plastic vessel with a simple lid (1000 ml). Cut the sample material to a size

of around 10 - 20 mm in advance, and feed it into the vessel. Fit the lit

and press it onto the lip of the vesse l.

If the input volume exceeds 300 ml, always start the machine in interval mode, i.e. hold the start button down for 10 - 15 secs., or an overload may occur and the fuses will blow.

Sample material Sample quantity Particle size Speed Time

Salami 120 g 10 mm 6000 rpm 20 sec.

Meat chop without bone 100 g 10 - 15 mm 6000 rpm 20 sec.

Smoked bacon 100 g 15 mm 7000 rpm 15 sec.

Tuna fish 100 g as contents 7000 rpm 20 sec.

Rollmops 150 g as contents 7000 rpm 20 sec.

If the input volume of tough, fibrous products is > 300 ml, the machine

may be overloaded and the fuses blow. Therefore start the

GRINDOMIX GM 200 in interval mode first.

Page 22

22.02.2002 Retsch GmbH & Co. KG 22 Doc.no. GB 98.251.9999 C

Products of very soft and/or tough and elastic consistency

Dairy products, in this case predominantly cheeses, with different fat

contents and strengths, and tough and elastic fruits, are processed with

a plastic vessel and a simple lid (1000 ml). While the fruit can be put

into the vessel whole, cheese, e.g. camembert, has to be chopped into

eighths.

For products with a tough and e l astic consistency, the GRINDOMIX

GM 200 must always be started in interval mod e. Hold the start button down for 10 - 15 secs.

The milling duration is the fundamental factor determining the degree

of fineness. If no experie nce has been gained, start with a short time

setting, e.g. 10 sec., and approach the desired degre e of fineness step by

step.

Sample material Sample quantity Particle size Speed Time

Camembert 200 g 30 mm 5000 rpm 30 sec.

Gouda 100 g 10 - 15 mm 5000 rpm 10 sec.

Parmesan 175 g 10 mm 5000 rpm 20 sec.

Figs 100 g 30 - 35 mm 8000 rpm 15 sec.

Dried fruits 100 g 20 - 30 mm 7000 rpm 10 sec.

Chocolate bars (Mars) 100 g 30 mm 6000 rpm 15 sec.

When products with a tough and elastic consistency are processed, the

fuses can blow. Therefor e always start the GRINDOMIX GM 200 in

interval mode first.

Products in the form of pourable grains

All cereals, seeds, mixed feed and pellets are preferably to be granulated gently in a steel vessel with a simple lid (1000 ml).

Grains containing grease and oil, e.g. cocoa beans, oil seeds and nuts,

can be processed into paste by increasing the milling duration accordingly.

Sample material Sample quantity Particle size Speed Time

Corn 120 g 5 - 7 mm 6000 rpm 20 sec.

Feed pellets 200 g 5 - 10 mm 6000 rpm 20 sec.

Pepper corns 100 g 5 mm 7000 rpm 30 sec.

Cocoa beans 80 g 20 mm 5000 rpm 25 sec.

Peanuts 120 g 10 mm 6000 rpm 30 sec.

The 500 ml lid can be used with all the above products if the input quantity is small.

Page 23

22.02.2002 Retsch GmbH & Co. KG 23 Doc.no. GB 98.251.9999 C

General

Target group: Operators

Accessories

• Glass vessel, 1000ml,

borosilicate glass 3.3

Transparent, smooth surface, high

quality material.

• 500ml lid in plastic

Used for max. 300 ml, e.g. seeds,

pepper corns, cheese etc.

• Gravity lid for the standard

plastic vessel

Infinitely variable milling chamber

from approx. 0.4 to 1 litre, automatic

adjustment to the varying milling

chamber volume at different stages of

the milling process.

• Gravity lid for the glass vessel

Infinitely variable milling chamber

from approx. 0.4 to 1 litre, automatic

adjustment to the varying milling

chamber volume at different stages of

the milling process.

• Scraper

For easier removal of pasty samples.

Page 24

22.02.2002 Retsch GmbH & Co. KG 24 Doc.no. GB 98.251.9999 C

Cleaning

!

Do not clean the GRINDOMIX GM 200 under running water.

Danger of fatality from electric shock.

Use a moist cloth only.

Use no solvents.

The ingress protection rating of the GRINDOMIX GM 200 is:

IP42 in the milling chamber and keyboard.

IP30 in the area of the ventilation slots.

Cleaning of the milling tools, vessel and lid

The milling tools, vessels and the various lids are dishwasher-proof.

The glass vessel can be sterilised.

The knife cylinder can be sterilised up to 130°C.

Maintenance

The GRINDOMIX GM 200 is maintenance-free.

When used in accordance with the manufacturer's instructions the machine requires no mainte nance or adjustment.

Necessary safety tests

Check the cover interlock monthly for correct function:

• Close the cover:

The cover must close in re sponse to a light pressure, and the interlock

pin spring into the interlocked position immediately. It must not be

possible to open the cover manually.

• Open the cover:

A short press on the STOP button must be sufficient to release the interlock pin and allow the cov er to spring open.

Warning!

The plastic container and the plastic covers are only resistant to

cleaning in a dishwasher.

If using a dishwasher, ensure the correct positioning!

Never place close to the heating helix, otherwise deformation might

occur which could prevent further use with the GM .

Sterilising and heating in a n autoclave is not possible!

Copyright

Dissemination or duplication of this documentation, utilisation and dissemination of its contents will only be permitted with the express approval of Retsch GmbH & Co. KG. Contraventions will give rise to liability for damages.

Modifications

The right is reserved to modify any specification without notice.

Page 25

22.02.2002 Retsch GmbH & Co. KG 25 Doc.no. GB 98.251.9999 C

Fault display

The GRINDOMIX GM 200 is equipped with an error display.

In the case of a fault, various fault codes are issued on the speed display or by flashing seque nces of the time and speed displays.

Fault code

(flashing sequence)

Cause

Remedy

F02 Motor switched off due to overload. Re start the milling process with a

smaller quantity of input mater i a l .

F06 Motor overheated. Allow the motor to cool down and

restart.

Both displays flash continuously The cover is still open. Close the cover.

Minor motor overload with speed

deviation >5%.

Restart the milling process with a

slightly smaller quantity of input

material.

Other flashing sequences indicate an electrical fault, and these codes are

primarily intended to facilitate the work of service personnel. We recommend you to contact our after sales service staff.

Page 26

22.02.2002 Retsch GmbH & Co. KG 26 Doc.no. GB 98.251.9999 C

Safety regulations (Table)

for the GRINDOMIX GM 200 from the individual chapters

Subject Action Hazard

Safety

Failure to observe the notes on safety can lead

to damage to property and personal injury.

We accept no liability whatsoever for any damage

or injury resulting from non-observance of the

notes on safety.

Use for the intended purpose

Do not modify the machine in any way, and

use only spare parts and accessories approved

by Retsch.

The conformity with European Directives declared by Retsch will otherwise be invalidated.

Furthermore, this will lead to all warranty claims

being rendered null and void.

Packaging

Please keep the packaging for the duration of

the guarantee period.

Your guarantee claim may be invalidated if there is

a complaint and the unit is returned in inadequate

packaging.

Temperature fluctuations

When subjected to major temperature fluctuations, the GRINDOMIX GM 200 is to be

protected from condensation.

Damage to the electronic components may otherwise result.

Transport

The GRINDOMIX GM 200 must not be

jarred, shaken or thrown during transport.

This could damage the electronic and mechanical

components.

Scope of supply

In cases of incomplete delivery and/or transport damage, you must notify the forwarding

agent and Retsch GmbH without delay (within

24 hours).

It may not be possible to accept subsequent complaints.

Ambient temperature

Not below 5°C.

Not above 40°C.

Electronic and mechanical components may be

damaged and performance data change to an

unknown extent.

Humidity

Maximum relative humidity 80% at temperatures up to 31°C, d eclining in a straight line to

50% relative humidity at 40°C.

Higher humidity can cause damage to the electronic and mechanical components, and performance data can change to an unknown extent.

Electrical connection

Mains power differs from the values on the

type plate.

Electrical and mechanical components may be

damaged.

Handling the gravity lid

Recommended input quantities or max. inpu t

volume of 300 ml exceeded.

If the recommended input quantities are exceeded

with materials containing water, the vessel may

overflow during the milling process.

Filling the vessel in the machine

The cover must engage securely with the

interlock pin.

The motor cannot otherwise start or an emergency

braking operation may be triggered off during

milling.

Caution! Always insert the knife cylinder

before feeding the process material in.

Otherwise process material may be deposited

between the knife cylinder and the vessel.

Filling the vessel outside the

machine

Hold the lid down at the centre when inserting

the vessel into the machine (absolutely necessary with the 500 ml lid).

The knife cylinder must definitely reach its limit

position.

The cover must engage securely with the

interlock pin.

The motor cannot otherwise start or an emergency

braking operation may be triggered off during

milling.

When filling the vessel outside the machine,

do not use the gravity lid.

It cannot hold the knife down when the vessel is

inserted in the machine.

Page 27

22.02.2002 Retsch GmbH & Co. KG 27 Doc.no. GB 98.251.9999 C

Safety regulations (Table 2)

for the GRINDOMIX GM 200 from the individual chapters

Subject Action Hazard

Notes on sample milling

If the input volume is > 300 ml, sample liquid

can emerge from the mill vessel(concerns the

gravity lid).

The amount of input material either has to be

reduced, or multiple milling operations performed.

If the input volume of tough, fibrous produ ct s

is > 300 ml, the machine may be overloaded

and the fuses blow.

Therefore start the GRINDOMIX GM 200 in

interval mode first.

When products with a tou gh and elastic consistency are processed, the fuses can blow.

Therefore always start the GRINDOMIX GM

200 in interval mode first.

Cleaning

Do not clean the GRINDOMIX GM 200

under running water.

Use a moist cloth only.

Use no solvents.

Danger of fatality from electric shock.

Necessary safety tests

In the case of malfunction, do not continue to

operate the machine.

Contact our after sales service staff!

Fault display

Fault code displays which are not listed. Contact our after sales service staff.

Page 28

22.02.2002 Retsch GmbH & Co. KG 28 Doc.no. GB 98.251.9999 C

Warranty conditions

1. In the case of justified complaints, we will repair or r epla c e the defective parts at no cha r ge.

The purchaser shall only be entitled to withdraw from the contract or reduce the purchase price

when, at our decision, repair is impractical or impossible or replacements cannot be supplied or

cannot be supplied in due time, or when a reasonable period of grace of at least six weeks set

by the customer has expired without result due to circumstances within our control.

Should the attempt to repair or replace defective parts finally fail, the customer may at his

option require a reduction of the purchase price or withdraw from the contract. Further claims,

in particular such for damages not suffered by the object itsel f, such as loss of production, shall

be excluded unless caused by intent or negligence on our part. We pass on the liability of the

manufacturer(s) for bought-in products.

2. We shall bear the direct costs of repair or replacement on condition that the complaint has

proven to be justified. This also applies to the costs o f shipment and reasonable costs for dismantling and installation. The customer shall however be obliged to bear the costs of providing

his own fitters and ancillary personnel at site. Should our customer operate abroad, we shall in

contrast be entitled to bear the co sts of recti fication, and in particular transport , travel and material costs, ex-German border.

3. The warranty term for newly manufactured goods is two years, for used it is one year.

The guarantee refers to deployment in a laboratory in 1-shift operation. In case of multi-shift

operation or other areas of application, the guarantee term is shortened accordingly.

No warranty is given for parts subject to wear and tear.

4. We warrant that our goods are free of manufacturing defects. The suitability, classification and

function of our goods shall be exclusively determined by the specifications in the acknowledgement of order, even if these deviate from the order. In such cases, the customer shall have the

option of drawing our attention to any deviations from the order within two weeks of receipt of

our acknowledge ment, and reaching agree ment with us. Should no obje ction be raised to the

specifications in the acknowledgement of order, these shall be deemed accepted.

In the lack of any agreement to the contrary, we shall accept no liability for the suitability of the

object supplied for the purpose intended by the customer. The same shall apply to performance

data expected by the customer, unless we have been able to perform appr opr ia te, r ealistic laboratory trials in advance and declared the corresponding performance data to be firm an d binding

in writing in our acknowledgement of order.

5. Our warranty shall also become null and void if person s other than those appointed by ourselves

perform repairs or other work on or modifications to goods we have supplied or use unsuitable

accessories, provided that their is a causal relat ionship between such actions and the defects

which appear. For the rest, our warranty is dependent on compliance with our operatin g instructions.

6. If the goods are installed in other systems or production facilities by the customer without our

prior approval, or connected to, linked with or processed on such systems or production facilities, our warranty is exclusively limited to the parts we have supplied.

7. Repair or replacement of defective parts shall be effected at our option either at the point of

installation of the object purchased, or at our corporate location. When repairs take place at the

point of installation, the customer is to afford our representative unimpeded access for as long

as required to the object purchased. The customer may for the rest only require the performance of the warranty work during normal local business hours. Should warranty work be performed at the customer’s request outside our normal business hours, the customer is to pay the

additional costs. Should he require further special work over and above the warranty work,

these costs are also to be borne on the basis of our current prices.

Loading...

Loading...