Page 1

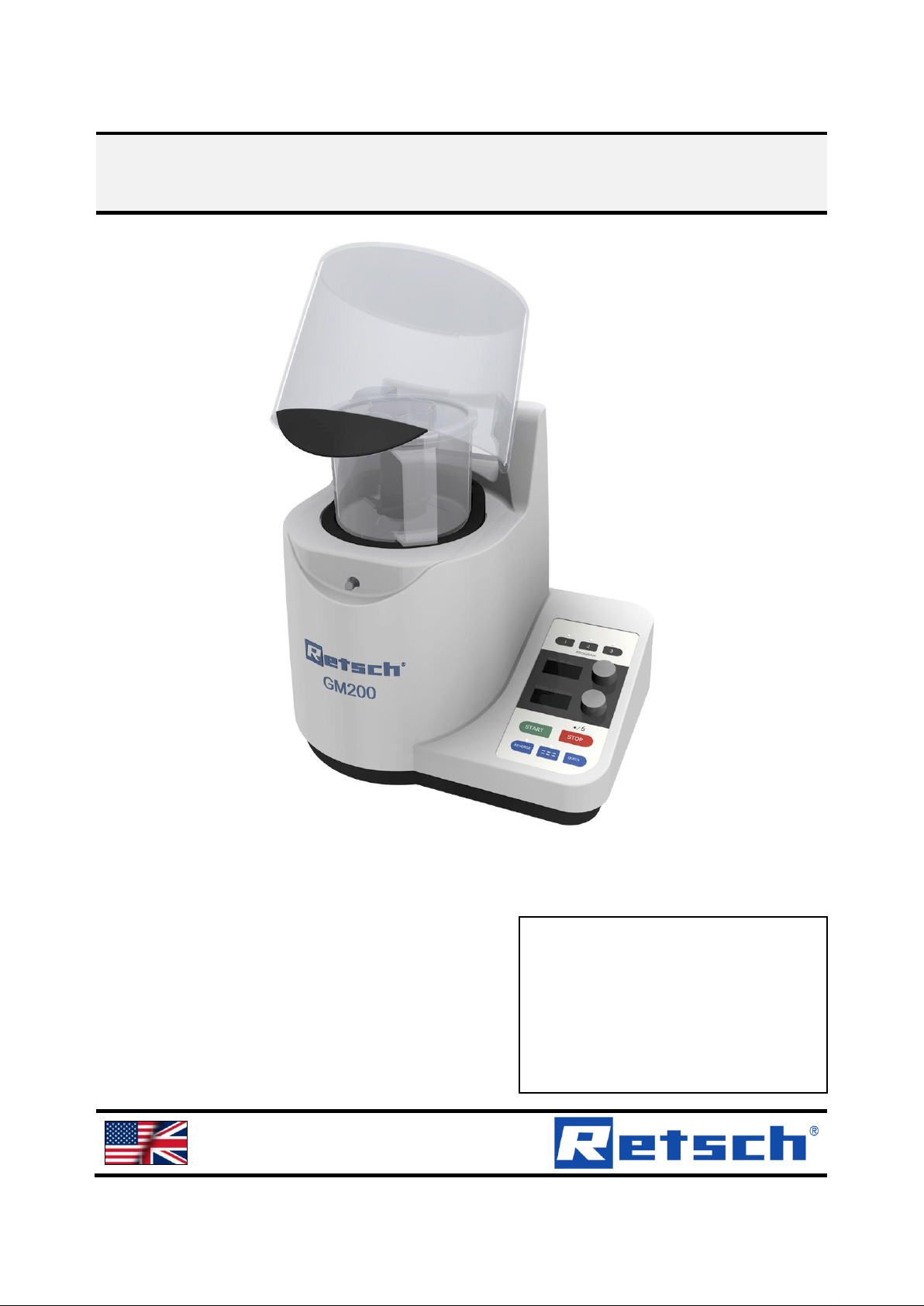

Manual

Knife Mill Grindomix GM200

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 21.12.2012 0010

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

1 Notes on the Operating Manual ............................................................................................................ 5

1.1 Explanations of the safety warnings .................................................................................................. 6

1.2 General safety instructions ................................................................................................................ 7

1.3 Repairs ............................................................................................................................................... 8

2 Confirmation ........................................................................................................................................... 9

3 Transport, scope of delivery, installation .......................................................................................... 10

3.1 Packaging ........................................................................................................................................ 10

3.2 Transport.......................................................................................................................................... 10

3.3 Temperature fluctuations and condensed water ............................................................................. 10

3.4 Conditions for the place of installation ............................................................................................. 10

3.5 Installation of the machine ............................................................................................................... 10

3.6 Electrical connection ........................................................................................................................ 10

3.7 Type plate description ...................................................................................................................... 11

4 Technical data ....................................................................................................................................... 12

4.1 Use of the machine for the intended purpose.................................................................................. 12

4.2 Working instructions ........................................................................................................................ 13

4.3 Protective equipment ....................................................................................................................... 13

4.4 Drive output...................................................................................................................................... 13

4.5 Rated power .................................................................................................................................... 13

4.6 Motor rotation speed ........................................................................................................................ 13

4.7 Rated voltage ................................................................................................................................... 13

4.8 Emissions......................................................................................................................................... 14

4.8.1 Noise measurement Example 1:.................................................................................................. 14

4.8.2 Noise measurement Example 2:.................................................................................................. 14

4.9 Degree of protection ........................................................................................................................ 14

4.10 Dimensions and weight .................................................................................................................... 14

4.11 Required floor space ........................................................................................................................ 15

5 Operating the machine ........................................................................................................................ 16

5.1 Views of the Instrument ................................................................................................................... 16

5.2 Overview table of the parts of the device ........................................................................................ 18

5.3 Overview Table of the Operating Elements and the Display ........................................................... 19

5.4 Operating the Device ....................................................................................................................... 20

5.5 Switching On and Off ....................................................................................................................... 20

5.6 Opening and closing of the grinding chamber ................................................................................. 21

5.7 Inserting the grinding jar .................................................................................................................. 21

5.8 Use of grinding jugs depending on different materials .................................................................... 21

5.8.1 Grinding jars – plastic jugs (PP) .................................................................................................. 22

5.8.2 Grinding jars – glass jugs (borosilicate glass 3.3) ....................................................................... 22

3

Page 4

5.8.3 Grinding jars – stainless steel jugs .............................................................................................. 22

5.9 Lid and jug combinations ................................................................................................................. 22

5.9.1 Lid 1000ml ................................................................................................................................... 23

5.9.2 Lid 500ml ..................................................................................................................................... 24

5.9.3 Gravitation lid ............................................................................................................................... 24

5.10 Filling the vessel .............................................................................................................................. 25

5.10.1 Filling – within the device ......................................................................................................... 25

5.10.2 Fílling – outside the device ...................................................................................................... 26

5.11 Setting the grinding time .................................................................................................................. 27

5.12 Setting the Speed ............................................................................................................................ 28

5.13 Switching on interval or continuous mode ....................................................................................... 28

5.14 Reverse grinding .............................................................................................................................. 29

5.15 Store functions ................................................................................................................................. 30

5.15.1 Saving programs ...................................................................................................................... 30

5.15.2 Starting a saved program ........................................................................................................ 30

5.16 Start – Pause – Stop ........................................................................................................................ 30

5.16.1 Pause function ......................................................................................................................... 30

5.16.2 Premature termination of grinding ........................................................................................... 30

5.17 Resetting the overload protection .................................................................................................... 30

6 Cleaning and service ........................................................................................................................... 31

6.1 Cleaning the Grinding Tools ............................................................................................................ 32

6.2 Check the sealing lip ........................................................................................................................ 33

7 Fault messages ..................................................................................................................................... 34

8 Disposal ................................................................................................................................................. 35

9 Index ...................................................................................................................................................... 36

Appendix ............................................................................................................................... following pages

4

Page 5

Notes on the Operating Manual

Pos: 1.1 /00005 Überschriften/1. Überschri ften/1 Hinweise zur Bedienungsanleitung @ 0\mod_1222347415287_9.doc @ 26 31 @ 1 @ 1

1 Notes on the Operating Manual

Pos: 1.2 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Hinweis zur Bedienungsanleitung @ 0\mod_122 2347341773_9.doc @ 2540 @ @ 1

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

Pos: 1.3 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Änderung en @ 0\mod_1222347341241_9.doc @ 2 526 @ @ 1

www.retsch.com.

Changes

Pos: 1.4 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Urheberrech t @ 0\mod_1222347342038_9.doc @ 2 547 @ @ 1

Subject to technical changes.

Pos: 2.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

5

Page 6

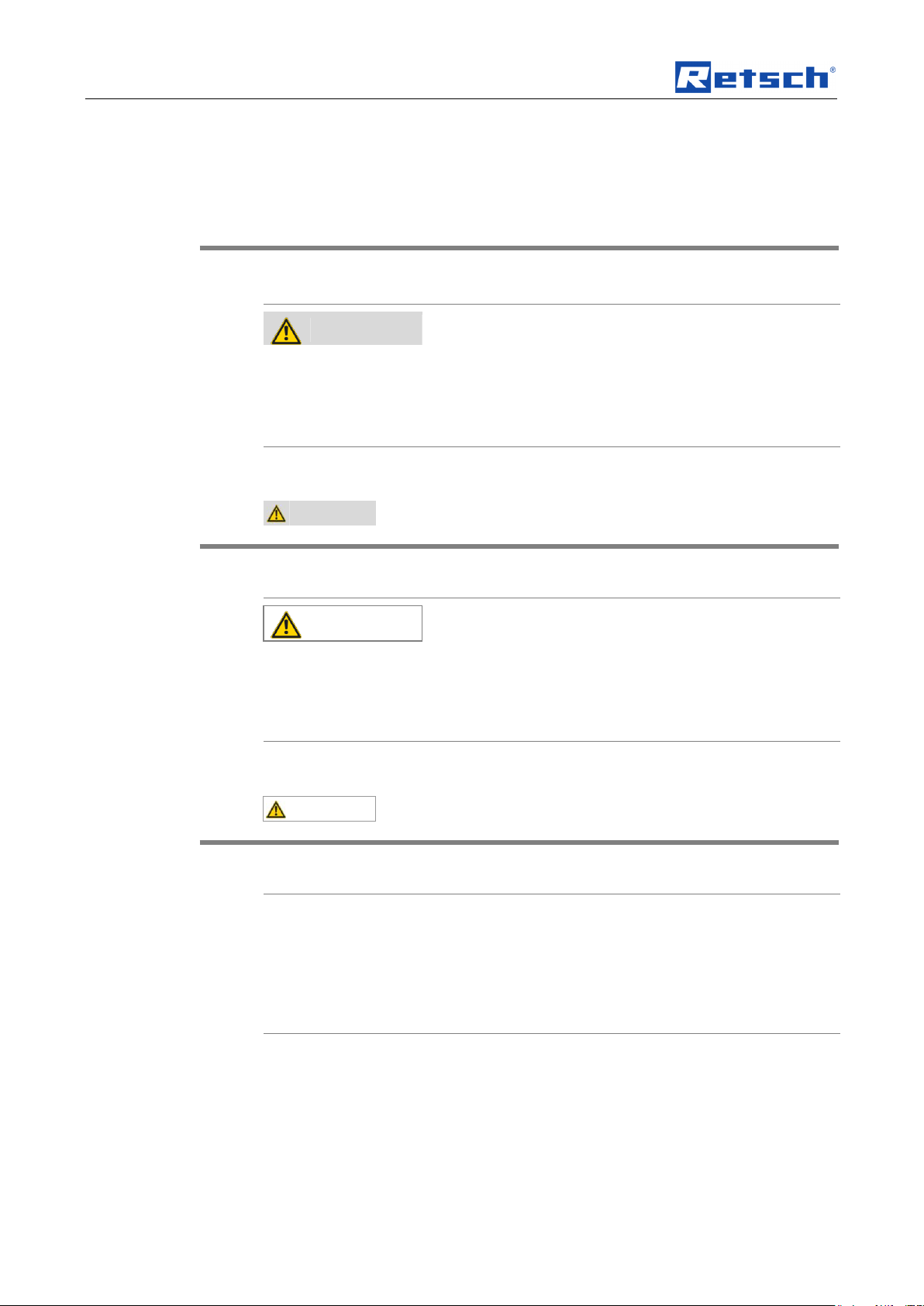

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

Pos: 2.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Erklärunge n zu den Sicherheitswarnungen @ 0\m od_1222344569771_9.doc @ 2484 @ 2 @ 1

1.1 Explanations of the safety warnings

Pos: 2.3 /00003 Standard Kapitel/General Modul Warnhinweise Erklärung neu @ 0\ mod_1234858329746_9.doc @ 6190 @ @ 1

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

Pos: 2.4 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

6

Page 7

Notes on the Operating Manual

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Generelle Sicherheitshinweise @ 0\mod_12223445 68974_9.doc @ 2463 @ @ 1

1.2 General safety instructions

Pos: 2.6 /00004 Warnhinweise/V0002 VORS ICHT Bedienungsanleitung lesen @ 2\ mod_1263894982815_9.doc @ 18630 @ @ 1

Pos: 2.7 /00003 Standard Kapitel/General Modul Zielgruppe und Sicherheit @ 0\mo d_1228722955300_9.doc @ 4100 @ @ 1

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

Pos: 2.8 /00003 Standard Kapitel/General Modul Sicherheitshinweise @ 0\mod_12 28722954800_9.doc @ 4086 @ @ 1

Pos: 2.9 /00004 Warnhinweise/V0015 VORS ICHT + HINWEIS Sach- und Person enschäden @ 1\mod_1236238456676_9.doc @ 7642 @ @ 1

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.10 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.d oc @ 2386 @ @ 1

7

Page 8

Notes on the Operating Manual

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Pos: 2.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Reparat uren @ 0\mod_1223624336511_9.doc @ 2978 @ @ 1

Reperaturen

1.3 Repairs

Pos: 2.12 /00003 Standard Kapitel/Gen eral Modul Reparaturen @ 0\mod_12287229 54535_9.doc @ 4079 @ @ 1

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

Pos: 3.1 /00020 BDA Software/20005 PM GC Kapitelsammlung/- - - - Seitenumbruc h - - - - @ 0\mod_1208857688413_0.doc @ 337 @ @ 1

8

Page 9

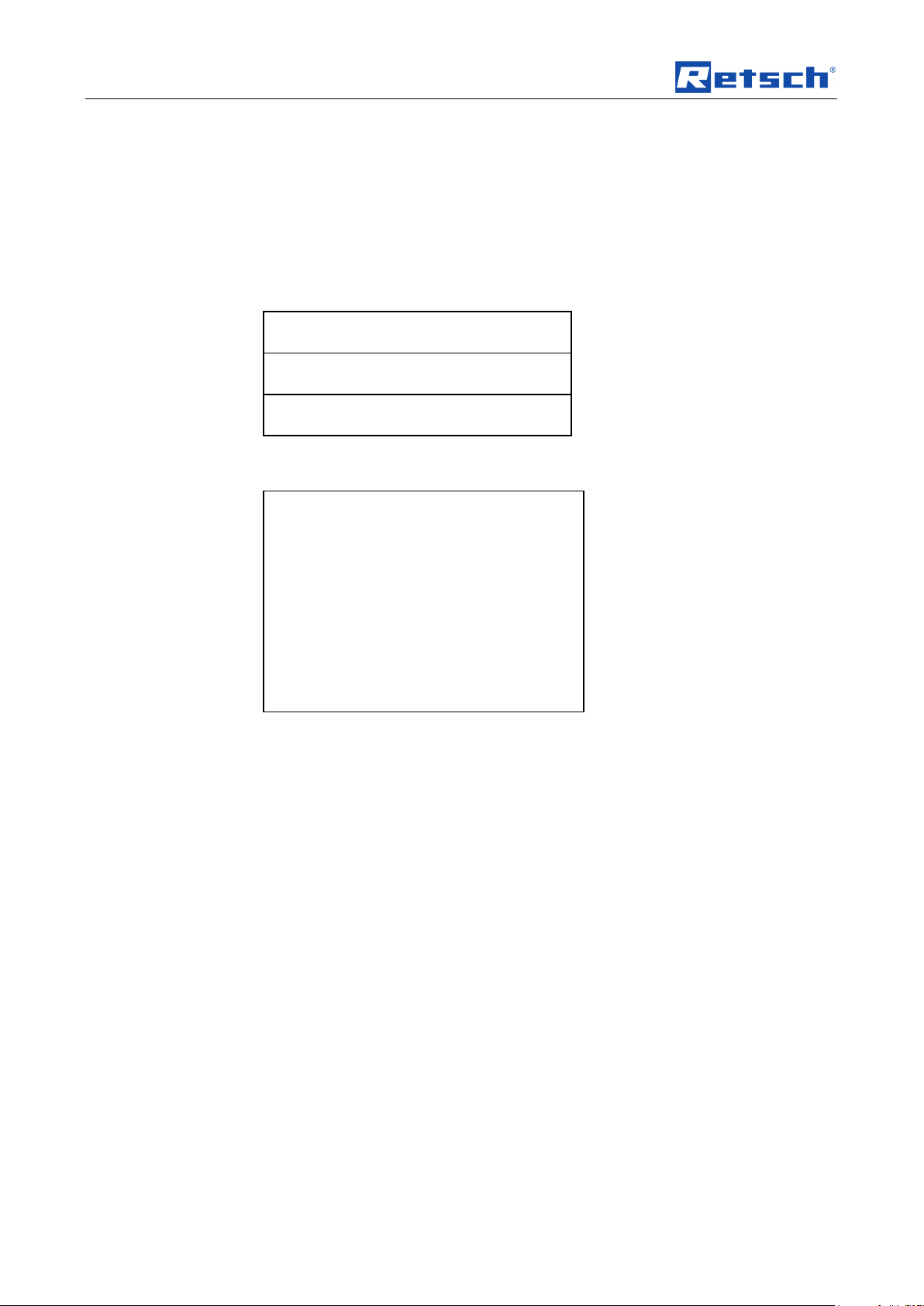

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.2 /00020 BDA Software/20005 PM GC Kapitelsammlung/Überschriften/1. Überschrif ten/1 Bestätigung (Formular für den Be treiber) @ 0\mod_1208870841095_9.d oc @ 430 @ 1 @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /00003 Standard Kapitel/General Modul Bestätigung @ 0\mod_122872296 2707_9.doc @ 4114 @ @ 1

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

Pos: 4.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

9

Page 10

Transport, scope of delivery, installation

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

NOTICE

Ambient temperature

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range of the

machine (5°C to 40°C / ambient temperature).

WARNING

Pos: 4.2 /00005 Überschriften/1. Überschri ften/1 Verpackung, Transport und Aufst ellung @ 0\mod_1226494451893_9.doc @ 3380 @ 1 @ 1

3 Transport, scope of delivery, installation

Pos: 4.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Verpackung @ 0\mod_1226495088973_9.doc @ 33 92 @ 2 @ 1

3.1 Packaging

Pos: 4.4 /00003 Standard Kapitel/General Modul Verpackung @ 0\mod_12289846 18355_9.doc @ 4892 @ @ 1

Pos: 4.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Transport @ 0\mod_1226495164391_9.doc @ 3398 @ 2 @ 1

3.2 Transport

Pos: 4.6 /00004 Warnhinweise/H0017 H INWEIS Transport @ 0\mod_1228918883 019_9.doc @ 4802 @ @ 1

Pos: 4.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Temperatursc hwankungen @ 0\mod_1226495190 738_9.doc @ 3404 @ 2 @ 1

3.3 Temperature fluctuations and condensed water

Pos: 4.8 /00004 Warnhinweise/H0016 H INWEIS Temperaturschwankungen @ 0\ mod_1233564121287_9.doc @ 5570 @ @ 1

The packaging has been adapted to the mode of transport. It complies with the

generally applicable packaging guidelines.

Pos: 4.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Bedingung en für den Aufstellort @ 0\mod_1226497 029322_9.doc @ 3428 @ 2 @ 1

3.4 Conditions for the place of installation

Pos: 4.10 /00003 Standard Kapitel/Gen eral Modul Umgebungstemperatur 5°C - 40°C @ 0\mod_1228918538881_9.doc @ 47 45 @ @ 1

Pos: 4.11 /00004 Warnhinweise/H0021 HIN WEIS Umgebungstemperatur 5°C bis 40°C @ 0\mod_1228918883441_9.doc @ 4 816 @ @ 1

Pos: 4.12 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufstell en des Gerätes @ 0\mod_1226498849756 _9.doc @ 3464 @ 2 @ 1

3.5 Installation of the machine

Pos: 4.13 /00003 Standard Kapitel/Gen eral Modul Aufstellungshöhe @ 0\mod_122 8918538349_9.doc @ 4724 @ @ 1

Pos: 4.14 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ele ktrischer Anschluss @ 0\mod_122656506744 5_9.doc @ 3500 @ 2 @ 1

Installation height: maximum 2000 m above sea level

3.6 Electrical connection

Pos: 4.15 /00003 Standard Kapitel/Gen eral Modul Elektrischer Anschluss @ 0\m od_1228918538521_9.doc @ 4731 @ @ 1

When connecting the power cable to the mains supply, use an external fusethat

complies with the regulations applicable to the place of installation .

• Please check the type plate for details on the necessary voltage and

frequency for the device.

• Make sure the levels agree with the existing mains power supply.

10

Page 11

Transport, scope of delivery, installation

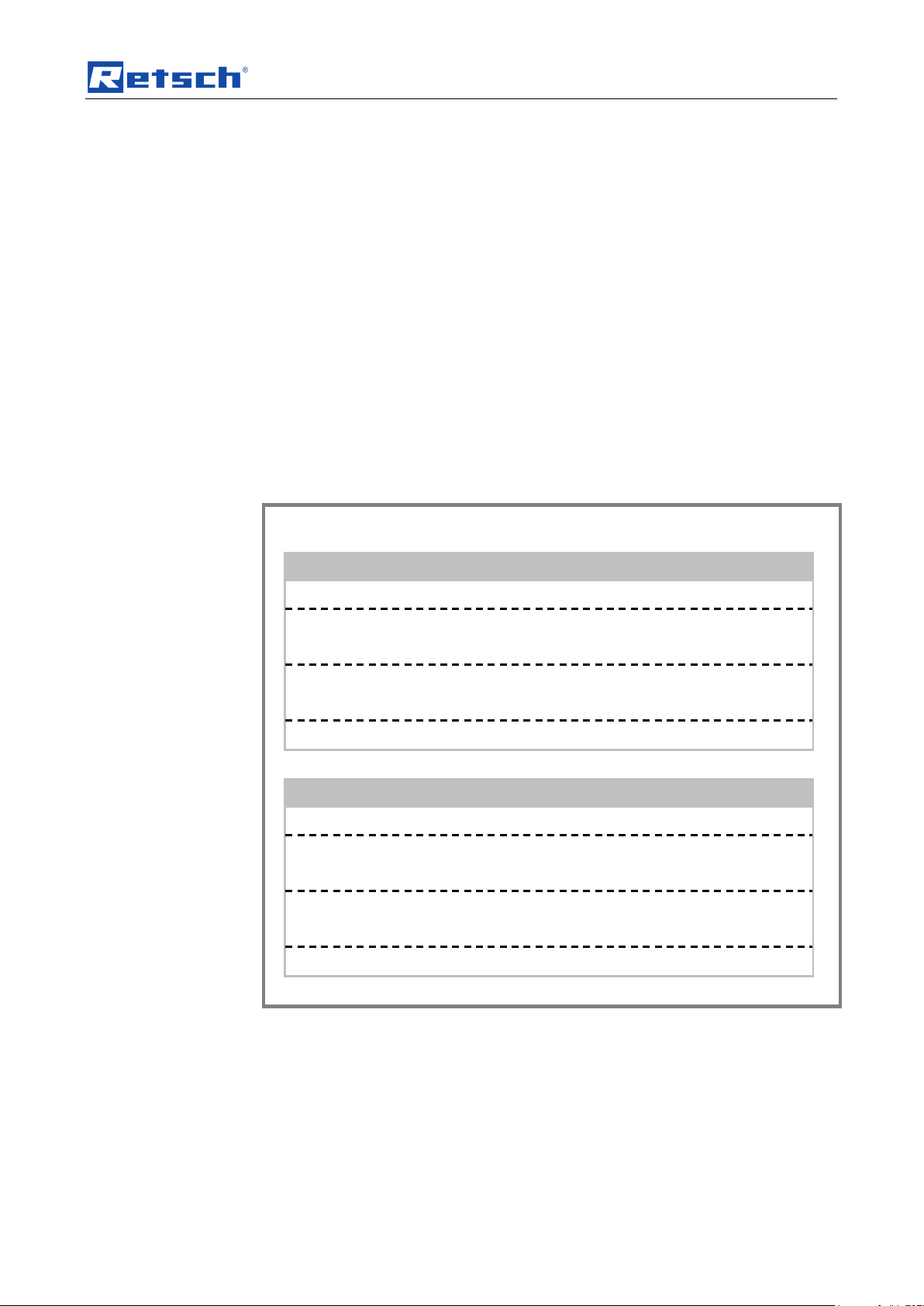

1 2 3 4 5 6 7 8 9

10

11

12

14

13

• Use the supplied connection cable to connect the device to the mains power

Pos: 5.1 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Typenschil d Beschreibung @ 3\mod_1280933953 941_9.doc @ 22302 @ 2 @ 1

supply.

3.7 Type plate description

Pos: 5.2 /00003 Standard Kapitel/General Modul Typenschild @ 3\mod_12809310 92443_9.doc @ 22278 @ @ 1

Fig. 1: Type plate lettering

Pos: 6 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of questions please provide the device designation (1) or the part

number (3) and the serial number (4) of the device.

11

Page 12

Technical data

CAUTION

Risk of explosion or fire

Changing sample characteristics

– Note that the characteristics and accordingly the danger presented by a

sample can change during sieving.

• Do not sieve any potentially explosive or combustible materials in

this device.

CAUTION

Risk of explosion or fire

– On account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

• Do not operate the device in a hazardous atmosphere.

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

Pos: 7.1 /00005 Überschriften/1. Überschri ften/1 Technische Daten @ 0\mod_12 22344525522_9.doc @ 2407 @ 1 @ 1

4 Technical data

Pos: 7.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Einsatz d er Maschine bei bestimmungsgemäßer Ver wendung @ 0\mod_1226476732248_9.do c @ 3243 @ 2 @ 1

4.1 Use of the machine for the intended purpose

Pos: 7.3 /00004 Warnhinweise/V0003 VORS ICHT Explosions- oder Brandgefahr Si eben @ 1\mod_1243924323407_9.doc @ 1 0360 @ @ 1

Pos: 7.4 /00004 Warnhinweise/V0005 VORS ICHT explosionsgefärdete Atmosphäre @ 1\mod_1239868668923_9.doc @ 814 0 @ @ 1

Pos: 7.5 /00004 Warnhinweise/V0006 VORS ICHT Gefahr von Personenschäden Ge fährliche Stoffe @ 1\mod_123623845626 9_9.doc @ 7634 @ @ 1

Pos: 7.6 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0005 GM2 00N Technische Daten/0510 GM200_2 010 Modul Einsatz bei bestimmungsgem äßer Verwendung @ 3\mod_12797027206 57_9.doc @ 20888 @ @ 1

Target group: operators

Machine type designation: GM 200

This device is suitable for analytical grinding, homogenisation and mixing of soft to

medium-hard, aqueous, fatty, fibrous and dry materials in seconds. This device is

designed for quantities of approximately 700ml, large volume materials up to

1000ml.

The feed size is < 30 - 40 mm.

The device is specially designed for the grinding of the following materials :

Fish, meat, vegetables, cheese, preserves, seeds, bacon, sausage, dry baked

goods and pastries, all aqueous, fatty and fibrous products and similar materials.

The device is designed as a laboratory device for 8-hour one-shift operation with a

30% ON duration.

It is not intended for use as production machine and not intended for the mixing

and homogenisation of liquids with low viscosity (emulsions and suspensions) .

12

Page 13

Technical data

Pos: 7.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Funktions weise @ 0\mod_1222344568271_9.doc @ 2442 @ 2 @ 1

Arbeitsweise

4.2 Working instructions

Pos: 7.8 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0005 GM2 00N Technische Daten/0535 GM200_2 010 Modul Funktionsweise @ 3\mod_1279 706968586_9.doc @ 20996 @ @ 1

The grinding process of the device is effected through cutting and, in reverse

operation, through impact effect.

The cutters are straight and are arranged at right-angles to the direction of rotation.

The cutters are slim with a cutting angle of 15° and a pre-cut (pre-grind) of 30°.

With this cutting geometry the entire inertia resulting from the speed difference

between the sample material particles and the cutters can be used as cutting force.

The speed is between 2000 - 10000min-1 and is altered in stages of 500min-1 and

displayed digitally.

The preselected speed is kept constant during grinding by a speed regulator.

Interval operation has proved to be advantageous in the pre-grinding and

homogenisation of large-piece, tough, fibrous and very soft and elastic products.

The grinding duration can be set up to 3 minutes. After expiry of the grinding

duration the motor automatically switches off and the housing lid opens.

3 memories permit the storage and retrieval of frequently used speed/time

Pos: 7.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schutzei nrichtungen @ 0\mod_1226486316130_9 .doc @ 3304 @ @ 1

combinations by the press of a button.

4.3 Protective equipment

Pos: 7.10 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0530 GM200_ 2010 Modul Schutzeinrichtung @ 3\mod_ 1279702722142_9.doc @ 20915 @ @ 1

The grinding chamber of this device is interlocked by a resistant protective hood.

It is only possible to start the device when the protective hood is closed. The motor

must have come to a standstill to open the device.

In the event of fault there is also an electric emergency brake which brings the

cutters to a standstill in fractions of a second from the highest speed.

If the achievable current speed deviates from the setpoint speed by more than 5%

Pos: 7.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Antrieb @ 1\mod_1240475743011_9.doc @ 8557 @ @ 1

due to an overload, this is shown by flashing displays.

4.4 Drive output

Pos: 7.12 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0540 GM200_ 2010 Modul Antrieb @ 3\mod_1279706969 133_9.doc @ 21005 @ @ 1

Pos: 7.13 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Nennleistu ng @ 0\mod_1226491873164_9.doc @ 3334 @ @ 1

Universal electric motor

4.5 Rated power

Pos: 7.14 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/000 5 GM200N Technische Daten/0520 GM200_ 2010 Modul Nennleistung @ 3\mod_1279 702721142_9.doc @ 20897 @ @ 1

Pos: 7.15 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Motordre hzahl @ 1\mod_1241508280705_9.doc @ 8763 @ @ 1

Motor performance: approx. 1000 watts

4.6 Motor rotation speed

Pos: 7.16 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0545 GM200_ 2010 Modul Motordrehzahl @ 3\mod_127 9706969649_9.doc @ 21014 @ @ 1

Pos: 7.17 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Nennspa nnungen @ 1\mod_1240476024494_9.do c @ 8571 @ @ 1

Speed: 2000 rpm-1.... 10,000 rpm-1 ( can be altered in steps of 500 Umin-1)

4.7 Rated voltage

Pos: 7.18 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0550 GM200_ 2010 Modul Nennspannungen @ 3\mod _1279706970164_9.doc @ 21023 @ @ 1

Rated voltages: 230 V 50 Hz (+/- 5%)

100-120V 50/60 Hz (+/- 5%)

13

Page 14

Technical data

CAUTION

Possibility of acoustic signals not being heard

Loud grinding noises

- Acoustic alarms and voice communication might not be heard.

• Consider the volume of the grinding noise in relation to other

acoustic signals in the work environment. You may wish to use

additional visual signals.

Pos: 7.19 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Emmisi onen @ 0\mod_1226487095021_9.doc @ 3310 @ @ 1

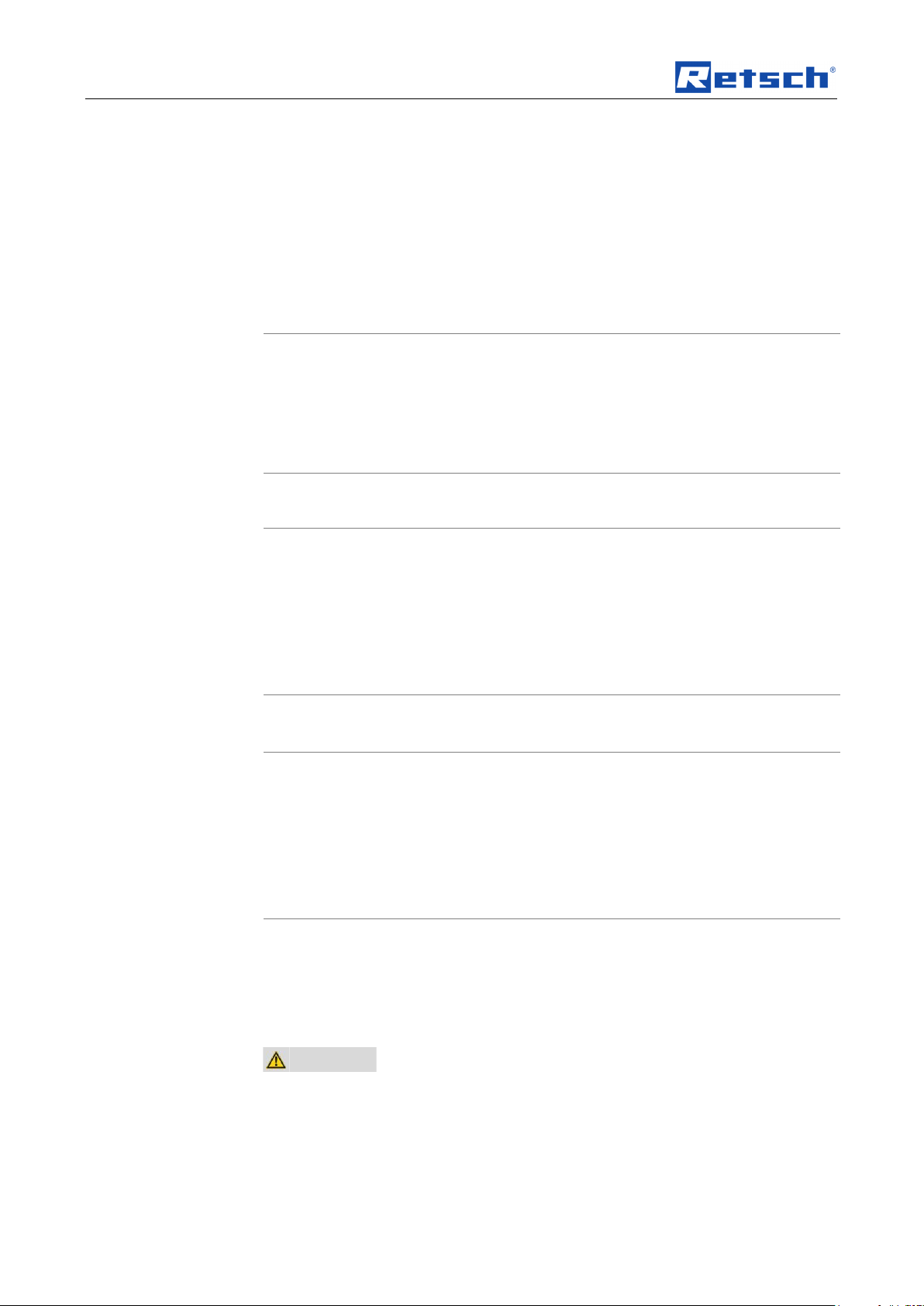

4.8 Emissions

Pos: 7.20 /00004 Warnhinweise/V0020 VOR SICHT Überhören von akustischen Sign alenLaute Mahlgeräusche @ 1\mod_12 48185838858_9.doc @ 11740 @ @ 1

Pos: 7.21 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0510 GM200_ 2010 Modul Emmisionen @ 3\mod_1279 702725923_9.doc @ 20969 @ 33 @ 1

Noise values: ~ 56 dB(A) (without sample material, beaker, cutters)

Noise measurement in accordance with DIN 45635-031-01-KL3

The noise values are also influenced by the properties of the sample medium.

4.8.1 Noise measurement Example 1:

Intensity of sound LWA

Workplace-related emission value LpAeq

Operating conditions:

Jug = glass jug with gravitation lid

Grind unit = cutter made of stainless steel

Feed material = tomatoes, quartered approx. 40 x 25mm

Feed quantity = 100g

4.8.2 Noise measurement Example 2:

Intensity of sound LWA

Workplace-related emission value LpAeq

Operating conditions:

jug = glass jug with gravitation lid

Grind unit = cutter made of stainless steel

Feed material = cheese approx. 20 x 20mm

Pos: 7.22 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Schutzart @ 0\mod_1226491839164_9.doc @ 332 8 @ @ 1

Feed quantity = 100g

4.9 Degree of protection

Pos: 7.23 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0525 GM200_ 2010 Modul Schutzart @ 3\mod_12797027 21626_9.doc @ 20906 @ @ 1

– Grinding chamber and keypad - IP 42

Pos: 7.24 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Abmessu ngen und Gewicht @ 0\mod_1226492 212173_9.doc @ 3352 @ @ 1

– In the area of the ventilation slits - IP 20

4.10 Dimensions and weight

Pos: 7.25 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0505 GM200_ 2010 Modul Abmessungen und Gewicht @ 3\mod_1279702720126_9.doc @ 20879 @ @ 1

Closed:

Height: up to approx. 390mm

Width: 350mm

Depth : 250mm

14

Page 15

Technical data

with open hood:

Height: up to approx. 540mm

Width: 350mm

Depth : 410mm

Pos: 7.26 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Erforderlich e Standfläche @ 0\mod_12264926784 14_9.doc @ 3364 @ 2 @ 1

Weight: approx. 10.1kg (without plastic container and cutter)

4.11 Required floor space

Pos: 7.27 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0005 GM200N Technische Daten/0515 GM200_ 2010 Modul Erforderliche Standfläche @ 3\ mod_1279702726470_9.doc @ 20978 @ @ 1

Pos: 8.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

200 mm x 400 mm; no safety distances required.

15

Page 16

Operating the machine

A B C

D

E

F

H

G J O

Pos: 8.2 /00005 Überschriften/1. Übersc hriften/1 Bedienung des Gerätes @ 0\mod_ 1226565880211_9.doc @ 3519 @ 1 @ 1

5 Operating the machine

Pos: 8.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Ansichte n des Gerätes @ 0\mod_1228990581782_ 9.doc @ 4966 @ 2 @ 1

5.1 Views of the Instrument

Pos: 8.4 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0015 GM2 00N Bedienung/1504 GM200_2010 Mo dul Grafische Ansichten des Gerätes @ 3\ mod_1279722275778_9.doc @ 21703 @ @ 1

Fig. 2: Front view of the machine

16

Page 17

Operating the machine

F

K

L K L1

L3

M

Fig. 3: Rear view of the machine

Fig. 4: Detail view of the socket for non-heating apparatus

Pos: 8.5 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

17

Page 18

Operating the machine

Element

Description

Function

A

Jar lid

Seals the grinding jar

B

Knife cylinder

Cuts and grinds the sample material

C

Grinding jar

Holds the sample material

D

Jar holder

Holder for the grinding jar

E

Operating panel with displays

Start / stop / program memory and displays

F

Grinding chamber hood

Protective hood for safe grinding operations

G

Pin for knife cylinder

Drive shaft for knife cylinder

H

Support for grinding jar

Centres the grinding jar and the jar holder

J

Grinding chamber hood interlock

Locks the grinding chamber hood into place

K

Thermal fuse

Protective switch against overheating

L1

On/off switch

Separates the machine completely from the mains

L3

Socket for non-heating apparatus

Connection for mains cable

M

Vent

Ventilation of motor and inside chamber

O

O ring

Fixes the grinding chamber holder

Pos: 8.6 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Übersichtsta belle der Geräteteile @ 0\mod_122899 0616846_9.doc @ 4972 @ @ 1

5.2 Overview table of the parts of the device

Pos: 8.7 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0015 GM2 00N Bedienung/1505 GM200_2010 Mod ul Tabelle der Geräteteile @ 3\mod_1279 721225379_9.doc @ 21541 @ @ 1

Pos: 8.8 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

18

Page 19

Operating the machine

Element

Description

Function

E1

Program 1

Memory for program function

E2

Program 2

Memory for program function

E3

Program 3

Memory for program function

E4

Time display

Display of the remaining grinding time

E5

Time knob

Grinding time setting (1 second to 3 minutes)

E6

Speed display

Display of the set speed

E7

Speed knob

Speed setting

E8

START button

Start of grinding

E9

STOP / open button

End of grinding / opening of the protective hood

E10

REVERSE button

Direction reversal

E11

INTERVAL button

Grinding with short intervals

E12

QUICK button

Manually controlled grinding

E2

E3

E1

E4

E6

E8

E10

E5

E7

E9

E11

E12

Pos: 8.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Bedien elemente und Funktionen @ 1\mod_12415 10466399_9.doc @ 8819 @ @ 1

Pos: 8.10 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1506 GM200_2010 Mo dul Grafische Ansicht Bedienelemente un d Anzeigen @ 3\mod_1280911038179_9. doc @ 22270 @ @ 1

Fig. 5: Operating elements and displays

Pos: 8.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Übersic htstabelle der Bedienelemente und der Anzeig e @ 0\mod_1228990697273_9.doc @ 4 978 @ @ 1

5.3 Overview Table of the Operating Elements and the Display

Pos: 8.12 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1503 GM200_2010 Mo dul Tabelle Bedienfeldbenennung @ 3\m od_1281606340030_9.doc @ 22310 @ @ 1

Pos: 8.13 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.d oc @ 2386 @ @ 1

19

Page 20

Operating the machine

CAUTION

Device falling down

Incorrect assembly or unsuitable workplace

- The appliance is very heavy and can therefore cause serious personal injuries if

it falls down.

Operate the device only on a sufficiently large, firm, skid-resistant and

steady workplace.

Make sure that all equipment feet are steady.

CAUTION

Damage to hearing

The level of noise can be high depending on the type of material,

the knife used, the speed set and the duration of the grinding

process.

- Noise that is excessive in terms of level and duration can cause

impaired or permanently damaged hearing.

• Ensure suitable sound-proofing measures or wear

hearing protection.

L1

Pos: 8.14 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Bedienung des Gerätes @ 0\mod_12294164657 74_9.doc @ 5052 @ @ 1

5.4 Operating the Device

Pos: 8.15 /00004 Warnhinweise/V0007 VOR SICHT Herabfallen des Gerätes / Stan dfestigkeit @ 1\mod_1248178329919_9.d oc @ 11690 @ @ 1

Pos: 8.16 /00004 Warnhinweise/V0044 VOR SICHT Gehörschaden (GM300, SM200, SM 300) @ 1\mod_1248181519795_9.d oc @ 11731 @ @ 1

Pos: 8.17 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ein- / A usschalten @ 0\mod_1229416527496_9.d oc @ 5058 @ @ 1

5.5 Switching On and Off

Pos: 8.18 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1515 GM200_2010 Mo dul Ein und Ausschalten @ 3\mod_1279 721702190_9.doc @ 21559 @ @ 1

The main switch is located on the reverse side of the device (L1).

• Switch the main switch on.

The grinding time last used appears in the TIME display.

The speed last used appears in the SPEED display.

Fig. 6: Main switch

20

Page 21

Operating the machine

CAUTION

Crushed or bruised fingers

Falling grinding chamber protective hood

– The protective hood of the grinding chamber can cause crushed or bruised

fingers if it falls down.

• Hold the flap tight when closing.

O

E9

Pos: 8.19 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Öffnen und schließen des Gerätes @ 1\mod_1241 510544133_9.doc @ 8826 @ 2 @ 1

5.6 Opening and closing of the grinding chamber

Pos: 8.20 /00004 Warnhinweise/V0008 VOR SICHT Klappe beim Schließen festhalte n (CryoMill) @ 2\mod_1278054213505 _9.doc @ 20549 @ @ 1

Pos: 8.21 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1520 GM200_2010 Mo dul Öffnen und Schließen des Gerätes @ 3\mod_1279721707768_9.doc @ 21640 @ @ 1

• Briefly press the STOP button (E9).

The hood is unlocked and opens.

Pos: 8.22 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahlbe hälter einsetzen @ 0\mod_1226569844414 _9.doc @ 3555 @ @ 1

Fig. 7: Opening hood

5.7 Inserting the grinding jar

Pos: 8.23 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1525 GM200_2010 Mo dul Mahlbehälter einsetzen @ 3\mod_1 279721702862_9.doc @ 21568 @ @ 1

• Open the hood.

• Insert the jug.

Pay attention to the position of the jug when it is inserted.

N.B.

Ensure the correct position of the O ring (O).

Pos: 8.24 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Verwen dungen der Mahlbehälter in Abhängigkeit unters chiedlicher Materialien @ 3\mod_128 3172657446_9.doc @ 22938 @ @ 1

Fig. 8: Inserting jug

5.8 Use of grinding jugs depending on different materials

Pos: 8.25 /00004 Warnhinweise/H0053 HIN WEIS Vermahlung mit flüssigem Stic kstoff (N2) oder Trockeneis (CO2 @ 3\mod_1 283176096576_9.doc @ 22954 @ @ 1

NOTICE

1.H0053

Grinding with liquid nitrogen (LN2) or dry ice (CO2) is not permitted in any

variation of the GM.

Danger from brittleness and breakage of grinding tools or the glass and plastic

Pos: 8.26 /00010 Bedienungsanleitung en Kapitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1526 GM200_2010 Mo dul Verwendungen der Mahlbehälter in Abhä ngigkeit unterschiedlicher Materialien @ 3\mod_1283172508524_9.doc @ 22930 @ 333 @ 1

containers.

21

Page 22

Operating the machine

CAUTION

1.V0028

Danger of injuries caused by cuts

Moving parts – jug, rotor and grinding jar lid

– The jug and the rotor may fall down after removal and cause injury.

• Be aware and put down the components safely.

• Do not place any objects on the device.

5.8.1 Grinding jars – plastic jugs (PP)

Suitable for the following sample materials:

soft, medium-hard, elastic, aqueous, fatty and oily.

Unsuitable for the following sample materials:

hard, hard-brittle,

e.g. cereals, pellets, gelatine sweets.

(increased friction in the plastic jug)

5.8.2 Grinding jars – glass jugs (borosilicate glass 3.3)

Suitable for the following sample materials:

soft, medium-hard, elastic, aqueous, fatty and oily.

Unsuitable for the following sample materials:

hard, hard-brittle,

e.g. cereals, pellets, gelatine sweets.

(glass jugs can break)

5.8.3 Grinding jars – stainless steel jugs

Suitable for the following sample materials:

soft, medium-hard, elastic, aqueous, fatty and oily, hard to medium-hard

Pos: 8.27 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Dec kel und Behälterkombinationen @ 3\mod_12 79714539556_9.doc @ 21437 @ @ 1

e.g. cereals, frozen food, sweets, hard cheese and cold meat/sausage products

5.9 Lid and jug combinations

Pos: 8.28 /00004 Warnhinweise/V0028 VOR SICHT Schnittverletzungen Bewegliche T eile – Behälter, Rotor und Mahlbecherd eckel @ 3\mod_1282896982588_9.doc @ 2 2908 @ @ 1

Pos: 8.29 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1535 GM200_2010 Mo dul Deckel und Behälterkombinationen @ 3 \mod_1279721704065_9.doc @ 21586 @ @ 1

The different lid / jug combinations will accommodate the different tasks.

NOTE

Pay attention to the maximum feed quantity of 300ml.

In the case of aqueous materials the jug may otherwise overflow during grinding.

Exceeding the non-recommended feed quantities.

22

Page 23

Operating the machine

Pos: 8.30 /00005 Überschriften/1.1.1 Ü berschriften/111 Deckel 1000ml @ 3\mod_ 1279716204123_9.doc @ 21445 @ @ 1

5.9.1 Lid 1000ml

Pos: 8.31 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1594 GM200_2010_ keinText_Deckel_Handling @ 5\mod_13558 39207125_0.doc @ 37020 @ @ 1

Pos: 8.32 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1540 GM200_2010 Mo dul Deckel 1000ml @ 3\mod_1279721 704627_9.doc @ 21595 @ @ 1

The 1000ml lid is used for larger quantities of small-piece material. The feed

quantity ranges between 300 and a maximum of 700ml.

The lid is snapped on to the edge of the jug and can be released again by pulling

up the flap.

NOTE

The 1000ml lid may be used both on the plastic and on the glass jug.

Fig. 2: 1000ml lid

23

Page 24

Operating the machine

Pos: 8.33 /00005 Überschriften/1.1.1 Ü berschriften/111 Deckel 500ml @ 3\mod_1 279716246155_9.doc @ 21453 @ @ 1

5.9.2 Lid 500ml

Pos: 8.34 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1545 GM200_2010 Mo dul Deckel 500ml @ 3\mod_12797217 05174_9.doc @ 21604 @ @ 1

The 500ml lid is used for smaller quantities of small-piece material. The feed

quantity is a maximum of 300ml, depending on the material to be ground.

• Position the 500ml lid such that the edge is over the top edge of the jug.

During grinding the 500ml lid is held down by the hood.

NOTE

The 500ml lid can only be used with the plastic jug.

Pos: 8.35 /00005 Überschriften/1.1.1 Ü berschriften/111 Schwerkraftdeckel @ 3\m od_1279716276921_9.doc @ 21461 @ @ 1

5.9.3 Gravitation lid

Pos: 8.36 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1550 GM200_2010 Mo dul Schwerkraftdeckel @ 3\mod_1279 721705752_9.doc @ 21613 @ @ 1

Fig. 3: 500ml lid

The gravitation lids permit an exact adjustment of the useful volume to the

respective feed quantity. They move downwards during grinding, thereby

optimising the grinding chamber volume. The feed quantity is a maximum of 300ml.

The gravitation lid with overcurrent channels ( ) is used for aqueous materials.

Fig. 4: Gravitation lid with overcurrent channels

24

Fig. 5: Graviation lid

Page 25

Operating the machine

CAUTION

2.V0039

Danger of injuries caused by cuts

Sharp cutters

– The cutters are very sharp and may lead to injuries caused by cuts if

handled incorrectly.

• Do not directly take hold of the cutters.

• Only reach into the grinding jar if it is outside the device.

• Do not reach into the grinding jar if the sample material still covers

the cutter.

• Before taking out the cutter remove as much sample material to

safely grip the cutter.

NOTE

The gravitation lids for the plastic jug differ from the gravitation lids for the glass

Pos: 8.37 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Füllen des Behälters @ 2\mod_1267774868556_9. doc @ 18870 @ 2 @ 1

and steel grinding jugs.

5.10 Filling the vessel

Pos: 8.38 /00004 Warnhinweise/V0039 VOR SICHT Schnittverletzung Scharfe Mess erklinge (GM200_2010) @ 3\mod_128289 8421988_9.doc @ 22916 @ @ 1

Pos: 8.39 /00004 Warnhinweise/H0054 HIN WEIS Haube muss sicher in den Verrieg elungsbolzen einrasten @ 3\mod_12831 76291349_9.doc @ 22962 @ @ 1

NOTE

The hood must safely latch into the interlock pin so that the motor can start or so

that no emergency brake is triggered during grinding.

3.H0054

Insert the cutter cylinder before adding the sample material because otherwise it

Pos: 8.40 /00005 Überschriften/1.1.1 Ü berschriften/111 Füllen – innerhalb des Gerät es @ 3\mod_1279716876335_9.doc @ 21 485 @ @ 1

may fall between cutter cylinder and jug.

5.10.1 Filling – within the device

Pos: 8.41 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/001 5 GM200N Bedienung/1560 GM200_2010 Mo dul Füllen innerhalb @ 3\mod_1279721 707174_9.doc @ 21631 @ @ 1

• Insert the jug.

• Position the cutter cylinder and push it down as far as it will go.

• Add the sample material.

• Put on the lid.

• Close the hood until it latches into the interlock pin (J).

25

Page 26

Operating the machine

J

Pos: 8.42 /00005 Überschriften/1.1.1 Ü berschriften/111 Füllen – außerhalb des G erätes @ 3\mod_1279716797287_9.doc @ 2 1477 @ @ 1

Fig. 6: Filling inside the device

5.10.2 Fílling – outside the device

Pos: 8.43 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1555 GM200_2010 Mo dul Füllen außerhalb @ 3\mod_12797217 06643_9.doc @ 21622 @ @ 1

The jug can also be filled before positioning in the device. This means that you can

work without problem with several jugs without intermediate cleaning.

The jugs can only be charged outside the machine with the 500ml and 1000ml lids;

the gravitation lid is not suitable for this purpose.

• Place the cutter cylinder into the jug.

• Add the sample material.

• Position the lid.

• Press the lid in the centre downwards and place the jug into the device.

In the case of the 500ml lid it is essential to push it down so that the cutter cylinder

reaches its final position.

Do not use the gravitation lid when filling the jug outside the machine since

otherwise the cutter will not interlock.

• Close the hood until it latches in the interlock pin.

26

Page 27

Operating the machine

with 1000ml lid

with 500ml lid

Pos: 8.44 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahlda uer einstellen @ 0\mod_1226908456965_9. doc @ 3582 @ @ 1

Fig. 7: Filling outside the device

5.11 Setting the grinding time

Pos: 8.45 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1565 GM200_2010 Mo dul Mahldauer einstellen @ 3\mod_12797 22271278_9.doc @ 21649 @ @ 1

The grinding duration can be set from 1 second to 3 minutes in steps of 1 second.

• Turn the knob (E5) to the left to reduce the grinding duration.

• Turn the knob (E5) to the right to increase the grinding duration.

Turning slowly increases the time in steps of 1 second.

Turning quickly increases the grinding duration in steps of 1 minute.

27

Page 28

Operating the machine

E11

E7

E5

Pos: 8.46 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Drehz ahl einstellen @ 1\mod_1250081022665_9. doc @ 13816 @ @ 1

Fig. 8: Setting grinding duration

5.12 Setting the Speed

Pos: 8.47 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1570 GM200_2010 Mo dul Drehzahl einstellen @ 3\mod_127972 2271888_9.doc @ 21658 @ @ 1

The speed can be set from 2000 min-1 to 10.000 min-1 in steps of 500 min-1.

• Turn the knob (E7) to the left to reduce the speed.

• Turn the knob (E7) to the right to increase the speed.

Slow turning alters the speed in steps of 500 min-1.

Fast turning alters the speed in steps of 3000 min-1.

Pos: 8.48 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Inter vall oder Dauerbetrieb @ 0\mod_122941942 7823_9.doc @ 5094 @ @ 1

Fig. 9: Setting the speed

5.13 Switching on interval or continuous mode

Pos: 8.49 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1575 GM200_2010 Mo dul Intervall oder Dauerbetrieb @ 3\mod_ 1279722272435_9.doc @ 21667 @ @ 1

• Press the interval button (E11).

Fig. 10: Switching on interval operation

28

Page 29

Operating the machine

E12

E10

The LED over the button lights up. The set speed is shown in the display if it is not

larger than 4000 rpm.

• Press the START button.

Grinding now takes places in the interval mode.

• To end interval grinding press the interval button (E11) once again.

The LED above the interval button goes out and the speed maintains the value of

Pos: 8.50 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Reverse - Vermahlung @ 3\mod_12797177236 14_9.doc @ 21493 @ @ 1

4000 rpm. The device is in continuous mode again .

5.14 Reverse grinding

Pos: 8.51 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1580 GM200_2010 Mo dul Reverse - Vermahlung @ 3\mod_12 79722273044_9.doc @ 21676 @ @ 1

• Press the REVERSE button (E10).

Pos: 8.52 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Quick St art - Tastenfunktion @ 1\mod_12403132 33592_9.doc @ 8229 @ 2 @ 1

Pos: 8.53 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1585 GM200_2010 Mo dul Quick Start - Tastenfunktion @ 3\ mod_1279722273888_9.doc @ 21685 @ @ 1

Fig. 11: Switching on interval operation

The LED above the REVERSE button lights up.

• Press the START button.

Grinding takes place in reverse mode and the motor runs against the cutting

direction. Grinding takes place by impact unlike normal mode (cutting).

• Press the REVERSE button (E11) to leave the reverse mode again.

The LED above the REVERSE button lights up. The device is in normal mode once

again – grinding by cutting .

• Press the QUICK button (E12).

Pos: 8.54 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Speicher – Funktionen @ 3\mod_1279718043115_9.doc @ 21517 @ @ 1

Fig. 12: QUICK grinding

The LED above the button lights up and grinding starts immediately.

• Release the QUICK button, grinding is ended immediately and the LED

above the button goes out.

29

Page 30

Operating the machine

E1; E2; E3

5.15 Store functions

Pos: 8.55 /00005 Überschriften/1.1.1 Ü berschriften/111 Programme speichern @ 0\ mod_1229424145211_9.doc @ 5124 @ @ 1

5.15.1 Saving programs

Pos: 8.56 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1590 GM200_2010 Mo dul Programme speichern @ 3\mod_1279 722274919_9.doc @ 21694 @ @ 1

• Keep the button E1, E2 or E3 pressed until the segment displays no longer

flash.

The values for time and speed as well as the setting for REVERSE and INTERVAL

operation are stored in the memory of the corresponding button.

Pos: 8.57 /00005 Überschriften/1.1.1 Ü berschriften/111 Starten eines gespeicherten Programms @ 0\mod_1229424036698_ 9.doc @ 5118 @ @ 1

Fig. 13: Memory buttons

5.15.2 Starting a saved program

Pos: 8.58 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1595 GM200_2010 Mo dul Starten eines gespeicherten Progra mms @ 3\mod_1279722524325_9.doc @ 21 712 @ @ 1

• Press the E1, E2 or E3 button.

The last saved values appear on the “TIME“ and “SPEED“ segment displays. The

LEDs above the REVERSE and INTERVAL buttons light up depending on default.

Pos: 8.59 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Start – Pause – Sto p @ 3\mod_1279719602650_9.doc @ 21525 @ @ 1

Press the START button to start grinding with the default parameters.

5.16 Start – Pause – Stop

Pos: 8.60 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1596 GM200_2010 Mo dul Start - Pause - Stop @ 3\mod_1279 722525044_9.doc @ 21721 @ @ 1

5.16.1 Pause function

• Press the STOP button during grinding.

Grinding is interrupted and the hood remains closed.

It is not possible to move the set parameters (speed, time, interval, reverse). The

current time display is suspended.

• Press the START button to continue grinding.

Grinding is restarted and the time display runs again.

5.16.2 Premature termination of grinding

• Press the STOP button during grinding.

Grinding is interrupted and the hood remains closed.

• Press the STOP button again.

The device is switched off and the hood opens automatically. The parameters

Pos: 8.61 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Überlastsic herung zurücksetzen @ 3\mod_12797 19797635_9.doc @ 21533 @ @ 1

chosen for grinding (speed, time, interval, reverse) are displayed.

5.17 Resetting the overload protection

Pos: 8.62 /00010 Bedienungsanleitungen K apitelsammlungen/GM200 (2010)/0015 GM200N Bedienung/1598 GM200_2010_TM 100_Modul Überlastsicherung zurücksetze n @ 3\mod_1279722532575_9.doc @ 21811 @ @ 1

The overload protection switch (K) is situated on the rear panel.

30

Page 31

Cleaning and service

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

D

Db

K

This overload protection switch disconnects the device from the power supply if the

machine is overloaded.

• After allowing the device to cool down it can be used with the power supply

again by pressing the overload protection switch (K).

Pos: 9.1 /00005 Überschriften/1. Übersc hriften/1 Reinigung und Wartung @ 0\mod_ 1231167007723_9.doc @ 5450 @ @ 1

Fig. 14: Overload protection switch

6 Cleaning and service

Pos: 9.2 /00004 Warnhinweise/W0003 WARNUNG Reinigung Stromstoß neu @ 1\ mod_1236239978437_9.doc @ 7686 @ @ 1

Pos: 9.3 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0025 GM2 00N Reinigung und Wartung/2505 Mod ul Becheraufnahme reinigen @ 4\mod_13 35509265798_9.doc @ 27606 @ @ 1

Fig. 15: Cleaning the jar support

NOTE

Sample material may get underneath the jar support (Db) where the jar support (D)

frequently gets very dirty as a result of liquid or greasy samples.

• Where necessary also clean the area underneath the jar support (Db).

Material may otherwise, under unfavourable circumstances, get inside the device.

31

Page 32

Cleaning and service

Material/device part

Dishwasher-proof

Autoclavable

Knife (stainless steel)

yes

yes

Knife (pure titanium)

yes

yes

Standard lid

yes

yes

Gravitation lid

yes

yes

Gravitation lid with overcurrent

channels

yes

yes

Reduction lid

yes

yes

Plastic container (PP)

yes

no

Plastic container (PC)

yes

yes

Glass container

yes

yes

Stainless steel container

yes

yes

Pos: 9.4 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Reinigung der Mahlwerkzeuge @ 5\mod_1352705 569001_9.doc @ 34940 @ 2 @ 1

6.1 Cleaning the Grinding Tools

Pos: 9.5 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0025 GM2 00N Reinigung und Wartung/2515 GM20 0N Reinigung Mahlwerkzeuge @ 5\ mod_1352705504586_9.doc @ 34950 @ @ 1

NOTICE

• Pay attention to the position of parts in the dishwasher.

H0052

• Do not place the plastic container, plastic lid or the knife near the heating

element. Deformation can otherwise not be ruled out and further use of the

parts will no longer be possible.

32

Page 33

Cleaning and service

Gs

Pos: 9.6 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0025 GM2 00N Reinigung und Wartung/2510 Mod ul Dichtlippe tauschen @ 5\mod_13438208 79046_9.doc @ 32850 @ 2 @ 1

6.2 Check the sealing lip

Fig. 16: Sealing lip (Gs)

Check the sealing lip (Gs) for damage at regular intervals.

• Replace the sealing lip (Gs) if damaged. [No. 05.111.0239]

Notice

Moisture can penetrate the inside of the housing if the sealing lip (Gs) is

damaged.

33

Page 34

Fault messages

F01

Motor is not running

F02

Motor is switched off due to overload

Restart grinding process with small

feed quantity.

F03

Motor speed too low / high

F04

Hood open

F05

Braking time too high

F06

Motor overheated

Allow motor to cool and restart.

F07

Hood monitoring defective

Check the fault message:

Press the START button when the

hood is open.

The “time“ and "speed“ segment

displays flash evenly.

Close the hood to rectify fault.

F08

Overspeed through hardware

Pos: 10.1 /00005 Überschriften/1. Überschrif ten/1 Fehlermeldungen @ 2\mod_1259 056589728_9.doc @ 17580 @ @ 1

7 Fault messages

Pos: 10.2 /00010 Bedienungsanleitungen Kapitelsammlungen/GM200 (2010)/0035 GM200N Fehlermeldungen/3505 GM200_20 10 Modul Fehlermeldungen @ 3\mod_1 279783114219_9.doc @ 21850 @ @ 1

Pos: 11.1 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.d oc @ 2386 @ @ 1

34

Page 35

Disposal

Pos: 11.2 /00005 Überschriften/1. Überschrif ten/1 Entsorgung @ 0\mod_123425874 6831_9.doc @ 6173 @ @ 1

8 Disposal

Pos: 11.3 /00003 Standard Kapitel/Gen eral Modul Entsorgung @ 0\mod_1234269 404935_9.doc @ 6180 @ @ 1

Please observe the respective statutory requirements with respect to disposal.

Information on disposal of electrical and electronic machines in the European

Community.

Within the European Community the disposal of electrically operated devices is

regulated by national provisions that are based on the EU Directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

Accordingly, all machines supplied after 13.08.2005 in the business-to-business

area to which this product is classified, may no longer be disposed of with

municipal or household waste. To document this they have the following label:

=== Ende der Liste für Textmarke Inhalt ===

Fig. 17: Disposal label

Since the disposal regulations within the EU may differ from country to country we

would request you to consult your supplier.

35

Page 36

9 Index

1

1000ml lid ........................................................... 24

5

500ml lid ............................................................. 24

A

Amperage ........................................................... 11

aqueous .............................................................. 22

B

Bar code ............................................................. 11

Borosilicate glass ................................................ 22

C

Capacity .............................................................. 11

CE marking ......................................................... 11

Changes ............................................................... 5

Cleaning and service .......................................... 31

Cleaning the Grinding Tools ............................... 32

E

elastic ................................................................. 22

Electrical connection .......................................... 10

Emissions ........................................................... 14

Emulsions .......................................................... 12

Explanations of the safety warnings .................... 6

External fuse ...................................................... 10

F

F01 ..................................................................... 34

F02 ..................................................................... 34

F03 ..................................................................... 34

F04 ..................................................................... 34

F05 ..................................................................... 34

F06 ..................................................................... 34

F07 ..................................................................... 34

F08 ..................................................................... 34

fatty .................................................................... 22

Conditions for the place of installation ................ 10

Confirmation ......................................................... 9

Connection cable ................................................ 11

Continuous grinding ............................................ 29

Continuous mode ................................................ 29

Copyright .............................................................. 5

D

dB(A) ................................................................... 14

Degree of protection ........................................... 14

Detail view of the socket for non-heating

apparatus ........................................................ 17

Device designation ............................................. 11

Dimensions and weight....................................... 14

DIN 45635-031-01-KL3....................................... 14

Disposal .............................................................. 35

Disposal label ..................................................... 11

Disposal label ..................................................... 35

Drive output ........................................................ 13

Fault messages .................................................. 34

Feed size ........................................................... 12

Filling – outside the device ................................ 26

Filling – within the device ................................... 25

Filling inside the device ...................................... 26

Filling outside the device ................................... 27

Filling the vessel ................................................ 25

Front view of the machine .................................. 16

Fuse strength ..................................................... 11

Fuse type ........................................................... 11

G

General safety instructions .................................. 7

Glass jugs .......................................................... 22

Gravitation lid ..................................................... 24

H

hard .................................................................... 22

hard-brittel .......................................................... 22

36

Page 37

I

Inserting jug ........................................................ 21

Inserting the grinding jar ..................................... 21

Installation height ................................................ 10

Installation of the machine .................................. 10

Interval grinding .................................................. 29

L

Lid 1000ml .......................................................... 23

Lid 500ml ............................................................ 24

Lid and jug combinations .................................... 22

LWA .................................................................... 14

M

Main switch ......................................................... 21

Mains frequency ................................................. 11

Manufacturer’s address ...................................... 11

Materials ............................................................. 12

P

Packaging .......................................................... 10

Part number ....................................................... 11

Pausen function ................................................. 30

Plastic jugs ......................................................... 22

Power version .................................................... 11

Premature termination of grinding ..................... 30

property damage .................................................. 6

Protective equipment ......................................... 13

Q

QUICK grinding .................................................. 29

R

Rated power ....................................................... 13

Rated voltage ..................................................... 13

Rear view of the machine .................................. 17

Regulations for the place of installation ............. 10

medium-hard ....................................................... 22

Memory buttons .................................................. 30

Moderate or mild injury ......................................... 6

Motor rotation speed ........................................... 13

N

Noise measurement ............................................ 14

noise values ........................................................ 14

Notes on the Operating Manual ............................ 5

Number of fuses ................................................. 11

O

oily ....................................................................... 22

Opening and closing of the grinding chamber .... 21

Opening hood ..................................................... 21

Operating elements and displays ....................... 19

Operating the Device .......................................... 20

Operating the machine ....................................... 16

Overcurrent channels ......................................... 24

Overload protection switch ................................. 31

Overview Table of the Operating Elements and

the Display ...................................................... 19

Repairs ................................................................. 8

Required floor space .......................................... 15

Resetting the overload protection ...................... 30

Reverse grinding ................................................ 29

S

Safety warnings ................................................... 6

Sample materials ............................................... 22

Saving programs ................................................ 30

Sealing lip .......................................................... 33

Serial number ..................................................... 11

serious injury ........................................................ 6

Service Address ................................................... 8

Setting grinding duration .................................... 28

Setting the grinding time .................................... 27

Setting the speed ............................................... 28

Setting the Speed .............................................. 28

soft ..................................................................... 22

Sound level ........................................................ 14

Stainless steel jugs ............................................ 22

Start – Pause – Stop .......................................... 30

Overview table of the parts of the device ........... 18

Starting a saved program .................................. 30

Store functions ................................................... 30

37

Page 38

Suspensions ....................................................... 12

Switching On and Off .......................................... 20

Switching on interval operation ..................... 28, 29

Switching on interval or continuous mode .......... 28

T

Target group ......................................................... 7

Technical data .................................................... 12

Temperature fluctuation and condensed water .. 10

Transport ............................................................ 10

Transport, scope of delivery, installation ............ 10

Type plate ........................................................... 10

type plate description .......................................... 11

Type plate lettering ............................................. 11

U

Use of grind jegs depending on different materials

....................................................................... 21

Use of the machine for the intended purpose .... 12

V

Views of the Instrument ..................................... 16

Viscosity ............................................................. 12

W

Working instructions ........................................... 13

Workplace-related emission value ..................... 14

Y

Year of production .............................................. 11

38

Page 39

Page 40

Page 41

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Laboratory Knife Mill GM 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, March 2011

Ralf Eisenbach Dipl.-Ing.

Ret sch Gm bH Retsch-Allee 1-5 427 81 Haan Germany www.retsch. com

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

DIN EN ISO 12852–5.1.1 Food processors and blenders

DIN EN ISO 13849-1 Safety related parts of control systems

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

DIN EN 55011 Emission

DIN EN 61000-3-2 DIN EN 61000-3-3 Emission

DIN EN 61326-1 Immunity

Additional applied standards, in particular

DIN EN 61010-1 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

LABORATORY KNIFE MILL

GM 200 - GRINDOMIX

FB-EW-805-072 (E) Änderungsstand B 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

39

Page 42

Page 43

Page 44

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...