Page 1

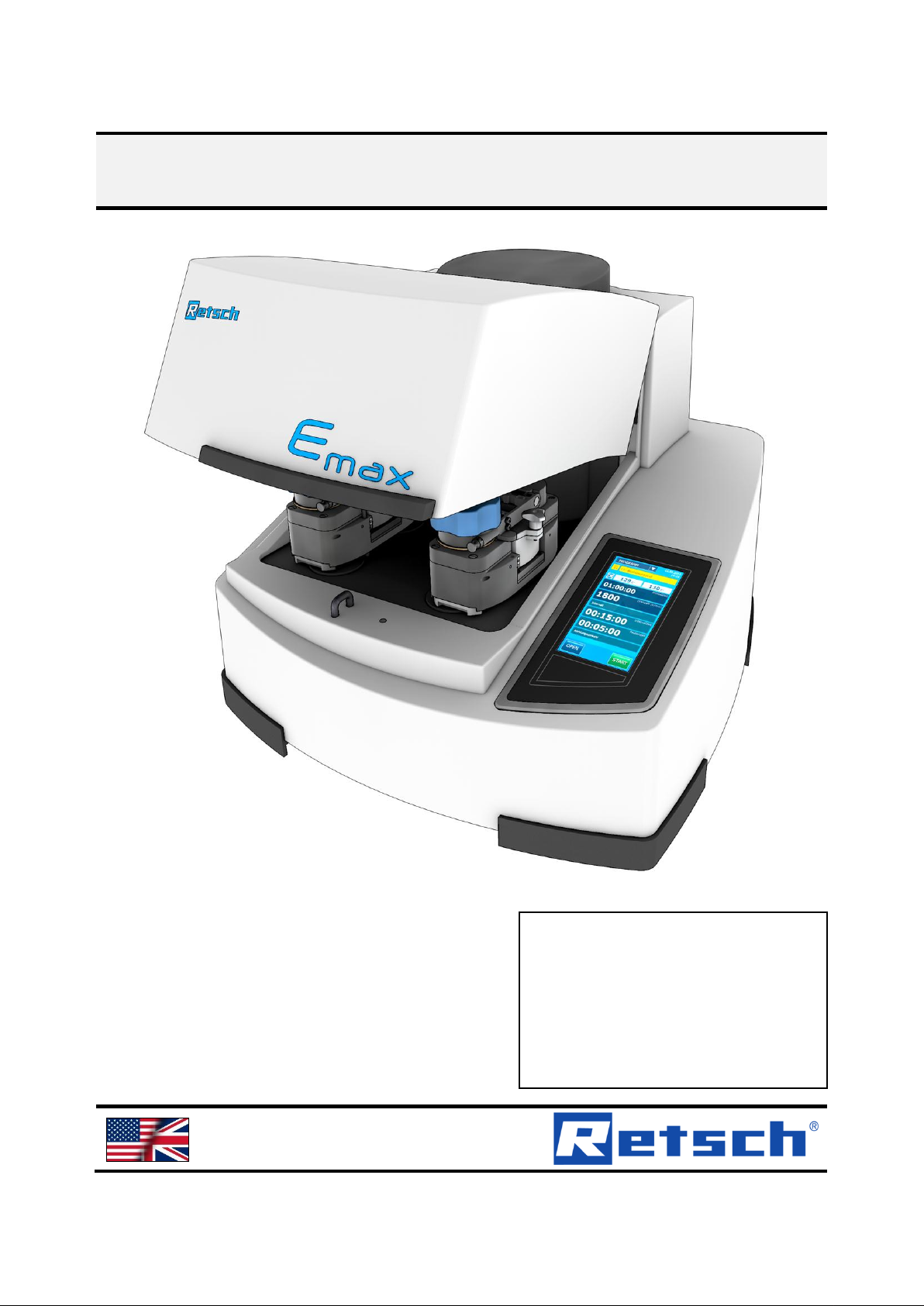

Manual

High Energy Ball Mill Emax

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 17.09.2014 0000

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

3

Page 4

1 Notes on the Operating Manual ............................................................................................................ 7

1.1 Explanations of the safety warnings .................................................................................................. 8

1.2 General safety instructions ................................................................................................................ 9

1.3 Repairs ............................................................................................................................................. 10

2 Confirmation ......................................................................................................................................... 11

3 Technical data ....................................................................................................................................... 12

3.1 Protective equipment ....................................................................................................................... 12

3.2 Degree of protection ........................................................................................................................ 12

3.3 Emissions......................................................................................................................................... 12

3.4 Rated power .................................................................................................................................... 13

3.5 Dimensions and weight .................................................................................................................... 13

3.6 Required floor space ........................................................................................................................ 13

3.7 Receptacle volume .......................................................................................................................... 13

3.8 Feed size ......................................................................................................................................... 14

3.9 Cooling ............................................................................................................................................. 14

3.9.1 Internal ......................................................................................................................................... 14

3.9.2 External ........................................................................................................................................ 14

4 Transport, scope of delivery, installation .......................................................................................... 15

4.1 Packaging ........................................................................................................................................ 15

4.2 Transport.......................................................................................................................................... 15

4.3 Temperature fluctuations and condensed water ............................................................................. 15

4.4 Conditions for the place of installation ............................................................................................. 15

4.5 Installation of the machine ............................................................................................................... 16

4.6 Type plate description ...................................................................................................................... 16

4.7 Electrical connection ........................................................................................................................ 16

4.8 Removing the transport safeguard .................................................................................................. 17

4.9 Removing Transport Safeguards ..................................................................................................... 19

4.10 Cooling ............................................................................................................................................. 20

4.10.1 Cooling agent ........................................................................................................................... 20

4.10.1.1 Connection to an external cooler ..................................................................................... 22

4.10.2 Grinding jar cooling surfaces ................................................................................................... 23

5 Operating the machine ........................................................................................................................ 24

5.1 Use of the machine for the intended purpose.................................................................................. 24

5.2 Views of the Instrument ................................................................................................................... 27

5.3 Opening and closing of the grinding chamber ................................................................................. 30

5.3.1 Opening ....................................................................................................................................... 30

5.3.2 Closing ......................................................................................................................................... 30

5.4 Emergency unlocking ...................................................................................................................... 31

5.5 Opening and closing the grinding jar support .................................................................................. 32

5.5.1 Opening ....................................................................................................................................... 32

5.5.2 Closing ......................................................................................................................................... 33

5.6 Closing the grinding jar .................................................................................................................... 35

5.6.1 Grinding jar and lid identification.................................................................................................. 35

5.6.2 Drying the grinding jars ................................................................................................................ 35

5.7 Ball sizes and speeds ...................................................................................................................... 36

5.7.1 Recommended ball sizes ............................................................................................................. 36

4

Page 5

5.7.2 Recommended speeds ................................................................................................................ 36

5.8 Inserting the grinding jar .................................................................................................................. 36

5.9 Wet grinding with highly flammable materials ................................................................................. 37

6 Control panel software – controlling the device ............................................................................... 39

6.1 Operating elements and displays .................................................................................................... 39

6.2 Functional principle (resistive) of the touchscreen .......................................................................... 41

6.3 Operating modes and navigation ..................................................................................................... 41

6.3.1 Navigation between operating modes ......................................................................................... 41

6.4 Grinding parameters ........................................................................................................................ 42

6.4.1 Adjustable parameters ................................................................................................................. 42

6.4.2 Parameters that can be activated or deactivated ........................................................................ 43

6.5 Manual operation ............................................................................................................................. 43

6.6 Programs ......................................................................................................................................... 44

6.6.1 Program description and heading ................................................................................................ 44

6.6.1.1 Display of the program description ...................................................................................... 44

6.6.1.2 Edit the program description and the heading ..................................................................... 44

6.6.1.3 Saving or cancelling editing of the program description or heading .................................... 45

6.6.2 Selecting saved programs ........................................................................................................... 46

6.6.3 Editing and saving the program ................................................................................................... 46

6.7 Sequences ....................................................................................................................................... 46

6.7.1 Creating or editing a sequence .................................................................................................... 47

6.7.2 Sequence description and heading ............................................................................................. 47

6.7.3 Selecting a saved sequence ........................................................................................................ 47

6.7.4 Editing and saving a sequence .................................................................................................... 48

6.7.4.1 Adding or changing a program to the sequence .................................................................. 48

6.7.4.2 Removing a program from the sequence ............................................................................ 48

6.8 Service menu ................................................................................................................................... 48

6.8.1 Language ..................................................................................................................................... 50

6.8.2 Date and time............................................................................................................................... 50

6.8.3 Timer – setting ............................................................................................................................. 50

6.8.4 Setting temperature limits ............................................................................................................ 51

6.8.5 Automatic opening ....................................................................................................................... 51

6.8.6 Signal tone ................................................................................................................................... 51

6.8.7 Operating hours ........................................................................................................................... 51

6.8.8 Software versions ........................................................................................................................ 51

6.8.9 User information........................................................................................................................... 52

6.8.10 IR sensor calibration ................................................................................................................ 52

6.8.11 Service environment (password protected) ............................................................................. 52

7 Safety functions and fault display ...................................................................................................... 53

7.1 Fault messages ............................................................................................................................... 53

7.2 Returning for service and maintenance ........................................................................................... 54

8 Cleaning, wear and service ................................................................................................................. 55

8.1 Cleaning ........................................................................................................................................... 55

8.2 Wear ................................................................................................................................................ 55

8.3 Wearing parts .................................................................................................................................. 55

8.4 Service ............................................................................................................................................. 55

8.4.1 Replacing the cooling water ......................................................................................................... 56

5

Page 6

8.4.1.1 Removing the cooling water ................................................................................................ 56

8.4.1.2 Rinsing the cooling system .................................................................................................. 57

9 Disposal ................................................................................................................................................. 60

10 Index ...................................................................................................................................................... 61

Appendix .................................................................................................................................. following page

6

Page 7

Notes on the Operating Manual

1 Notes on the Operating Manual

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

www.retsch.com.

Changes

Subject to technical changes.

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

7

Page 8

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

1.1 Explanations of the safety warnings

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

8

Page 9

Notes on the Operating Manual

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

1.2 General safety instructions

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

9

Page 10

Notes on the Operating Manual

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Reperaturen

1.3 Repairs

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

10

Page 11

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Bestätigung

2 Confirmation

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

11

Page 12

Technical data

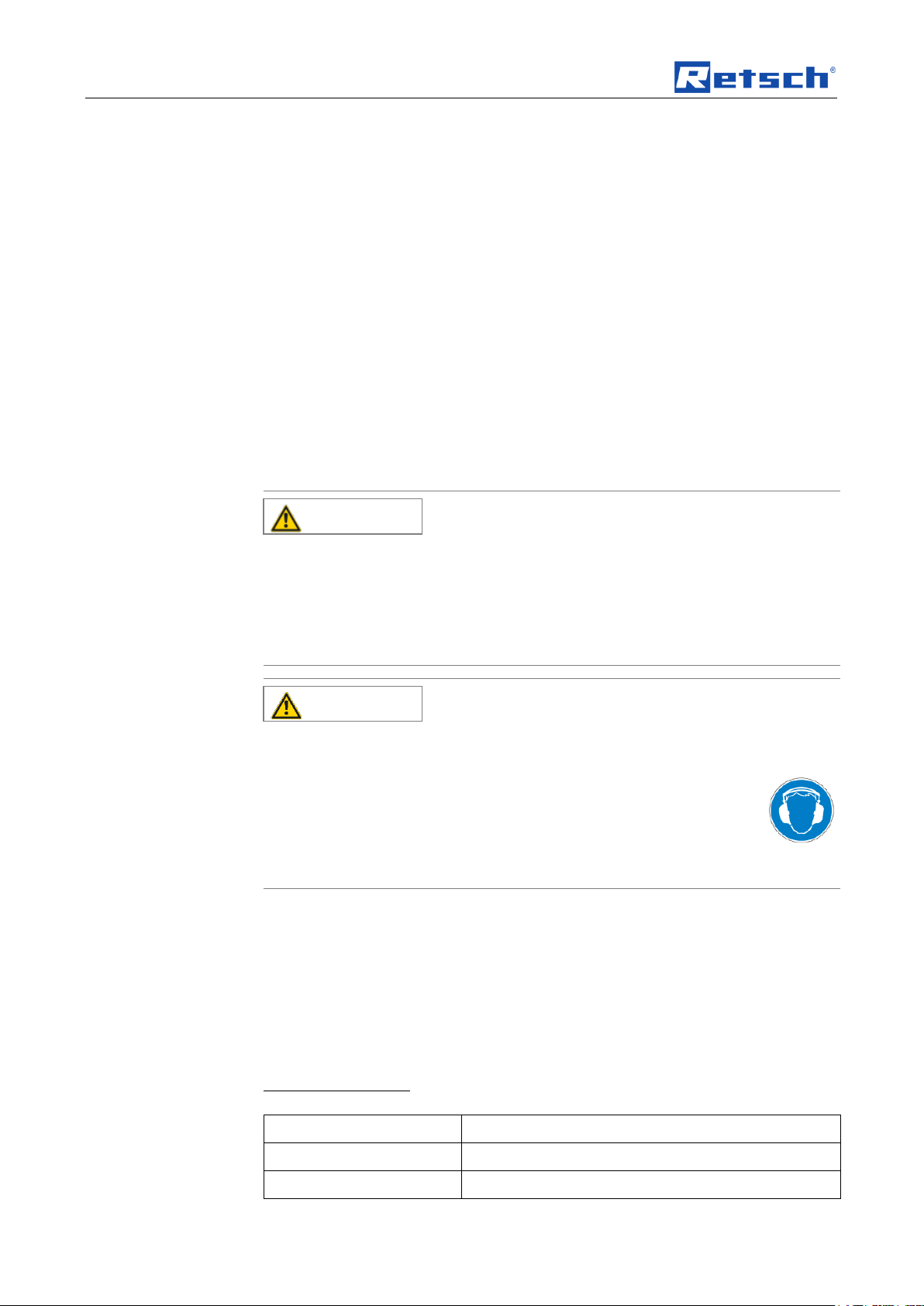

CAUTION

Possibility of acoustic signals not being heard

Loud grinding noises

- Acoustic alarms and voice communication might not be heard.

• Consider the volume of the grinding noise in relation to other

acoustic signals in the work environment. You may wish to use

additional visual signals.

CAUTION

V0077

Damage to hearing

A loud sound level may be generated depending on the type of

material, the number of balls used, the grinding frequency set and the

duration of grinding.

– Excessive noise in terms of level and duration can cause

impairments or permanent damage to hearing.

• Ensure suitable noise protection measures are taken or

wear ear protection.

Container:

2 125ml steel grinding jars

Grinding body:

50 10mm steel balls each

Feed material:

Quartz sand, approx. 0.5mm

3 Technical data

3.1 Protective equipment

– This device is equipped with an automatic lid lock. The lock prevents the

device being started when in an unsafe state.

– The device can only be started when the lid is closed.

– It is only possible to open the lid when the device has come to a halt.

– Monitoring of the grinding jar attachment (clamping lever) before starting and

3.2 Degree of protection

3.3 Emissions

during grinding

IP30

Sound parameters:

The sound parameters are also influenced by the properties of the sample

material.

Example 1:

Workplace-related

equivalent continuous sound level Lep (LIm) = 83dB(A)

Operating conditions:

12

Page 13

Feed quantity:

60ml

Speed:

2,000 rpm

Container:

2 125ml zirconium grinding jars

Grinding body:

275g ZrO2 2mm balls each

Feed material:

Quartz sand, approx. 0.5mm + 35ml H2O

Feed quantity:

40g

Speed:

1,500 rpm

CAUTION

V0047

Device falling down

Incorrect erection or insufficient working space

– Due to its weight, the device can inflict personal injury if it falls down.

• Only operate the device on a sufficiently large, strong and stable

workplace.

• Ensure that all feet of the device are positioned securely.

3.4 Rated power

Technical data

Example 2:

Workplace-related

equivalent continuous sound level Lep (LIm) = 76dB(A)

Operating conditions:

~ 2600W (VA)

3.5 Dimensions and weight

Height : 525mm

Width: 625mm

Depth: 645mm

Weight: approx. 120kg without grinding jar

3.6 Required floor space

Height with open hood : approx. 945mm

Width of the base : 625mm

Depth of the base : 655mm

Location

– The device must be placed on a vibration-free and stable surface.

3.7 Receptacle volume

The batch/feed volume depends on the sample material and on the device

configuration or setting:

Batch/feed volume: max. 2 x 45ml

13

Page 14

Technical data

3.8 Feed size

The feed size depends on the sample material and on the device configuration or

setting.

Feed size: < 5mm

3.9 Cooling

3.9.1 Internal

There is a cooling agent tank at the back which must be filled with water before

putting into operation.

NOTICE Only use clean, lime-free water as cooling agent.

Fill volume: 600ml

3.9.2 External

Cooling agent: clean, lime-free water

You can connect additional cooling at the back of the device.

The maximum pressure must not exceed 6bar.

The minimum temperature of the cooling agent must not be less than 5°C.

Only clean, lime-free water is permitted as cooling agent.

14

Page 15

Transport, scope of delivery, installation

NOTICE

Storage of packaging

– In the event of a complaint or return, your warranty claims may be

endangered if the packaging is inadequate or the machine has not been

secured correctly.

• Please keep the packaging for the duration of the warranty period.

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

HINWEIS

Reklamationen

– Bei Transportschäden müssen Sie den Transporteur und die Retsch

GmbH unverzüglich benachrichtigen. Spätere Reklamationen können

unter Umständen nicht mehr berücksichtigt werden.

• Benachrichtigen Sie Ihren Transporteur und die Retsch GmbH

innerhalb von 24h.

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

4 Transport, scope of delivery, installation

4.1 Packaging

4.2 Transport

The packaging has been adapted to the mode of transport. It complies with the

generally applicable packaging guidelines.

4.3 Temperature fluctuations and condensed water

4.4 Conditions for the place of installation

Ambient temperature: 5°C to 40°C

15

Page 16

Transport, scope of delivery, installation

NOTICE

Ambient temperature

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range of the

machine (5°C to 40°C / ambient temperature).

WARNING

1 2 3

4 5 6 7 8

9

11111

4.5 Installation of the machine

Installation height: maximum 2000 m above sea level

4.6 Type plate description

Fig. 1: Type plate lettering

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of questions please provide the device designation (1) or the part

number (3) and the serial number (4) of the device.

4.7 Electrical connection

16

Page 17

Transport, scope of delivery, installation

WARNING

Serious personal injury

Falling loads

– The appliance is very heavy and can therefore cause serious personal

injuries if it falls down.

• Lifting above head height is not permissible!

TP

When connecting the power cable to the mains supply, use an external fusethat

complies with the regulations applicable to the place of installation .

• Please check the type plate for details on the necessary voltage and

frequency for the device.

• Make sure the levels agree with the existing mains power supply.

• Use the supplied connection cable to connect the device to the mains power

supply.

4.8 Removing the transport safeguard

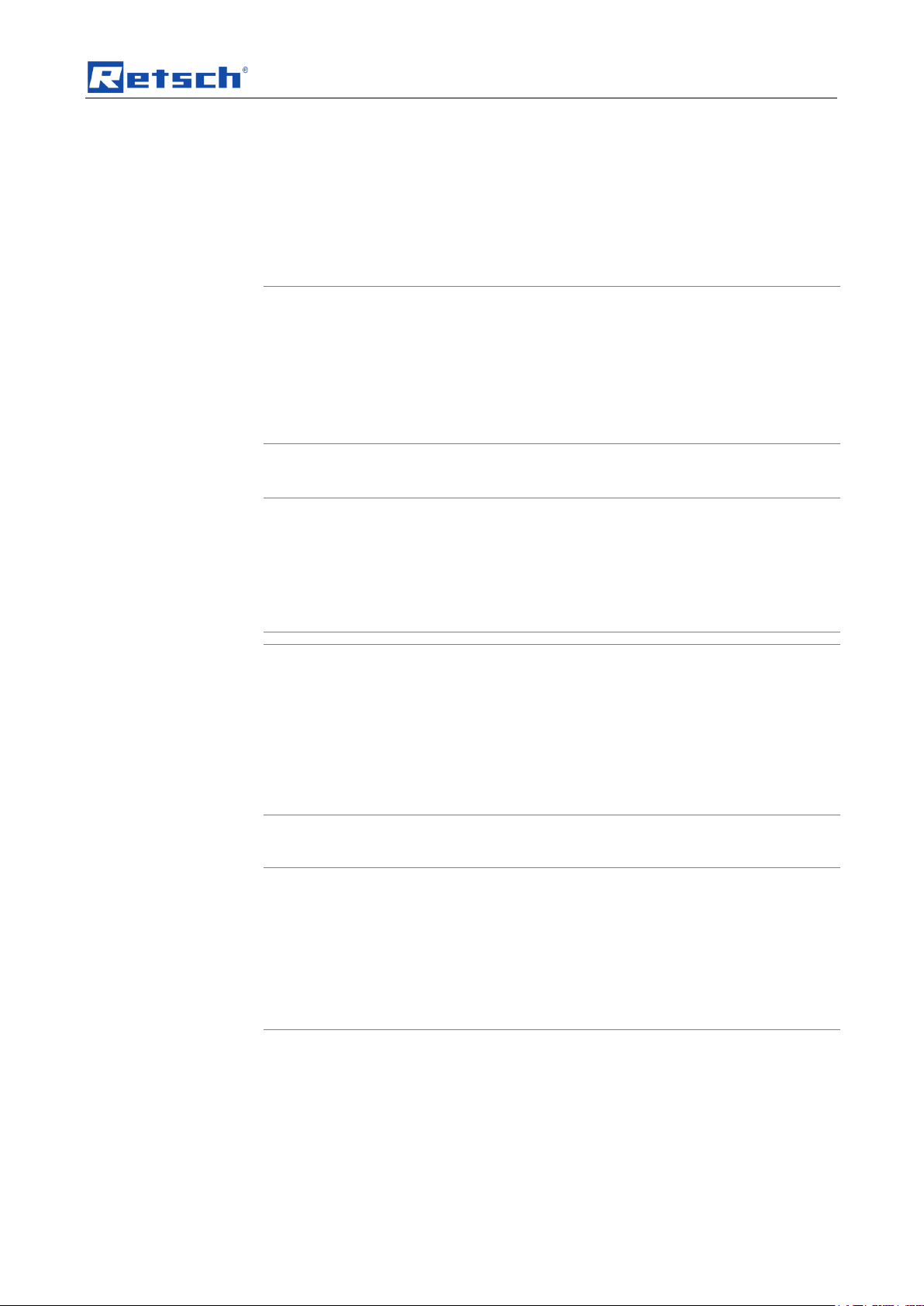

Fig. 1: Unscrewing the transport lock

• Unscrew the screws on either side of the device (TP).

NOTICE

The transport lock can also be used as carrying aid.

17

Page 18

Transport, scope of delivery, installation

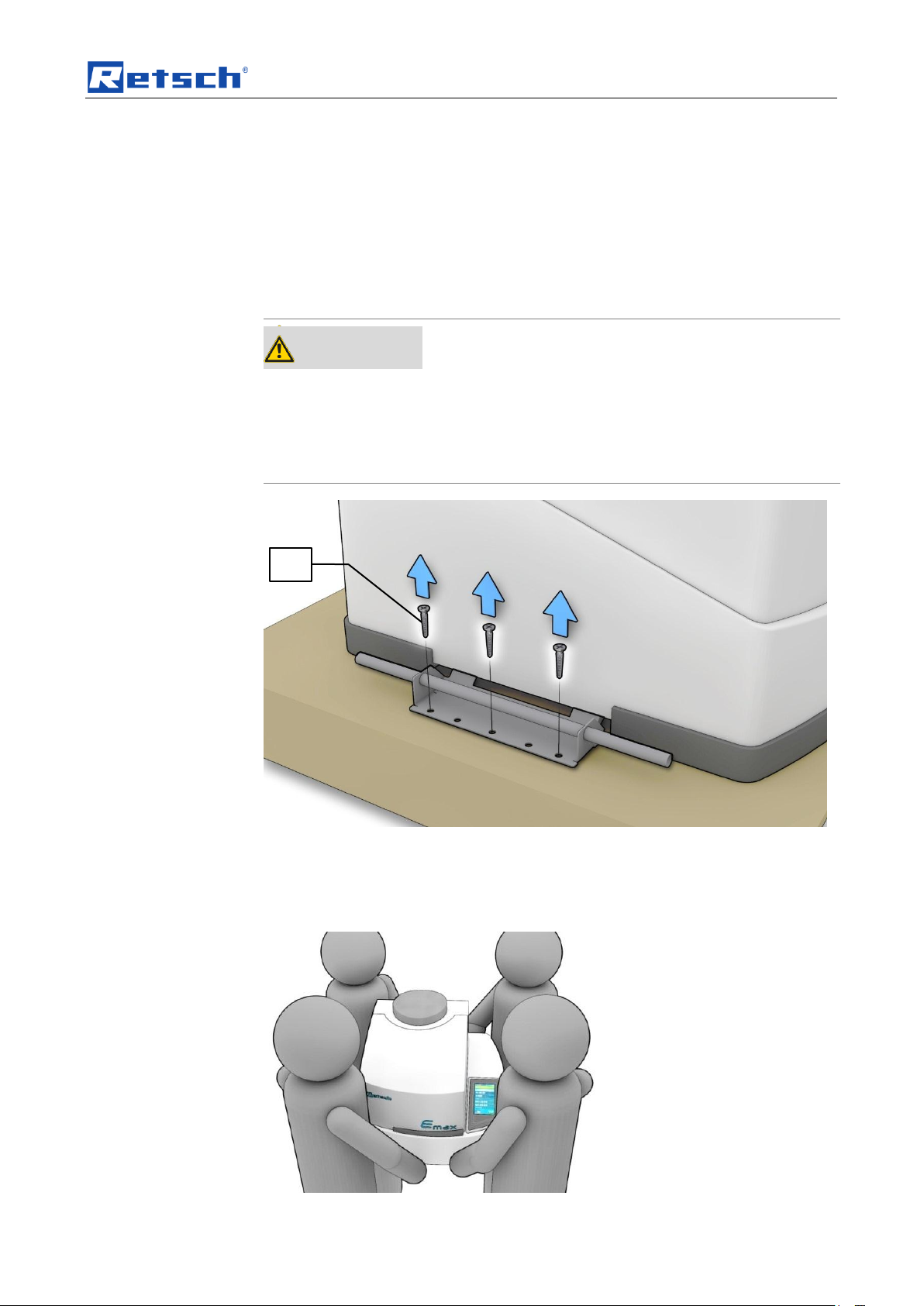

NOTICE

Damage to the feet

Pushing or pulling the device

– The feet oscillate (free-force compensation sockets) and will be damaged if

you pull or push the device across a surface.

• Do not pull or push the device.

• Lift the device to move it.

Fig. 2: Transporting the device

Weight: approx. 120kg without grinding jar

• The device should always be lifted by four people.

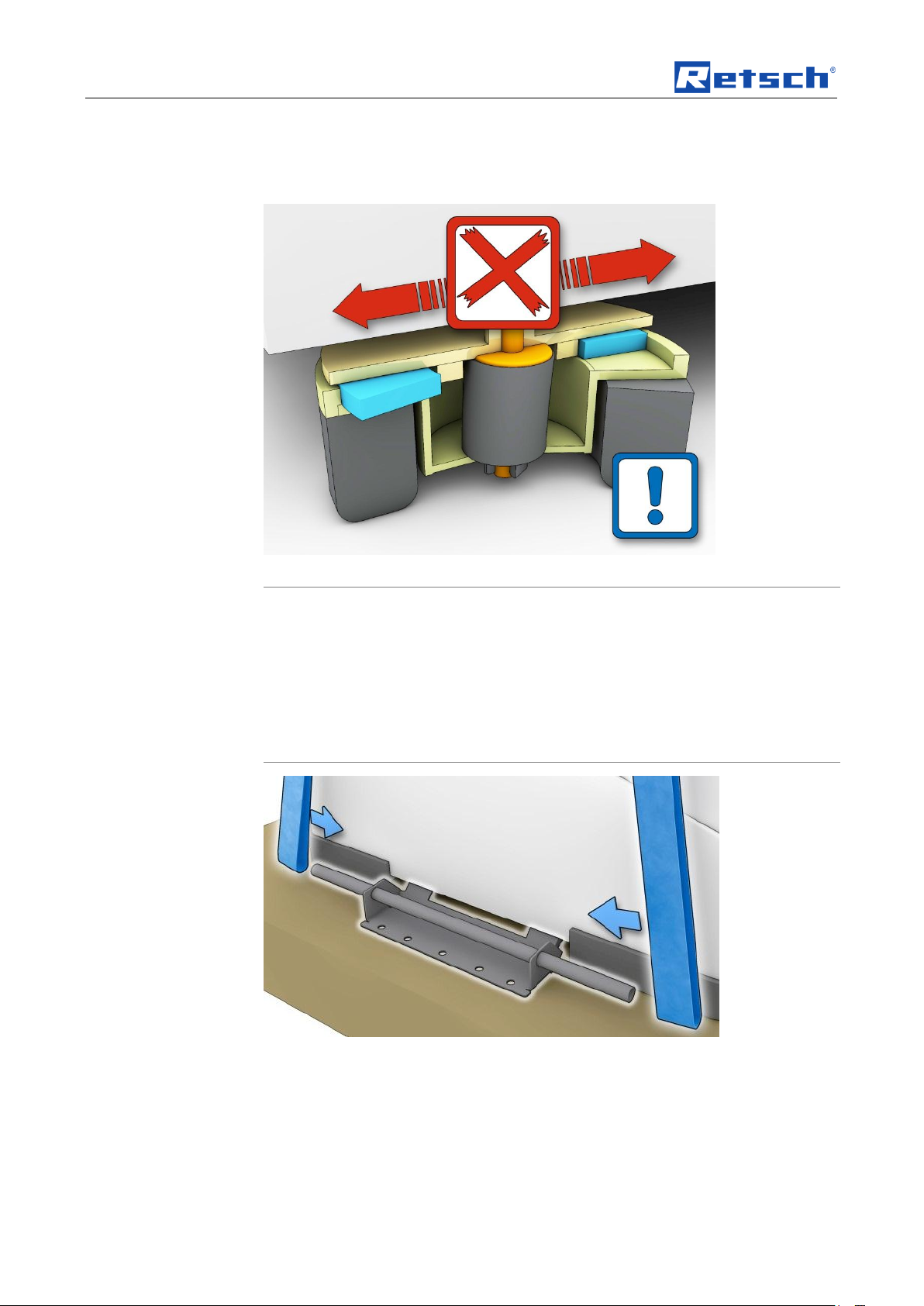

Fig. 3: Oscillating feet– do not push the device

Fig. 4: Attaching lifting gear

You can also use the transport aid for lifting the device with a crane.

• Attach the lifting straps to the two transport aids as shown in the diagram.

NOTICE

The housing can be damaged if the lifting straps are too short.

• Use 4 sufficiently long lifting straps.

• Observe the minimum distance between the device and the lifting gear.

18

Page 19

Transport, scope of delivery, installation

TS

TH

TH

TS

Minimum distance: 100cm

Fig. 5: Minimum distance between housing and lifting gear

4.9 Removing Transport Safeguards

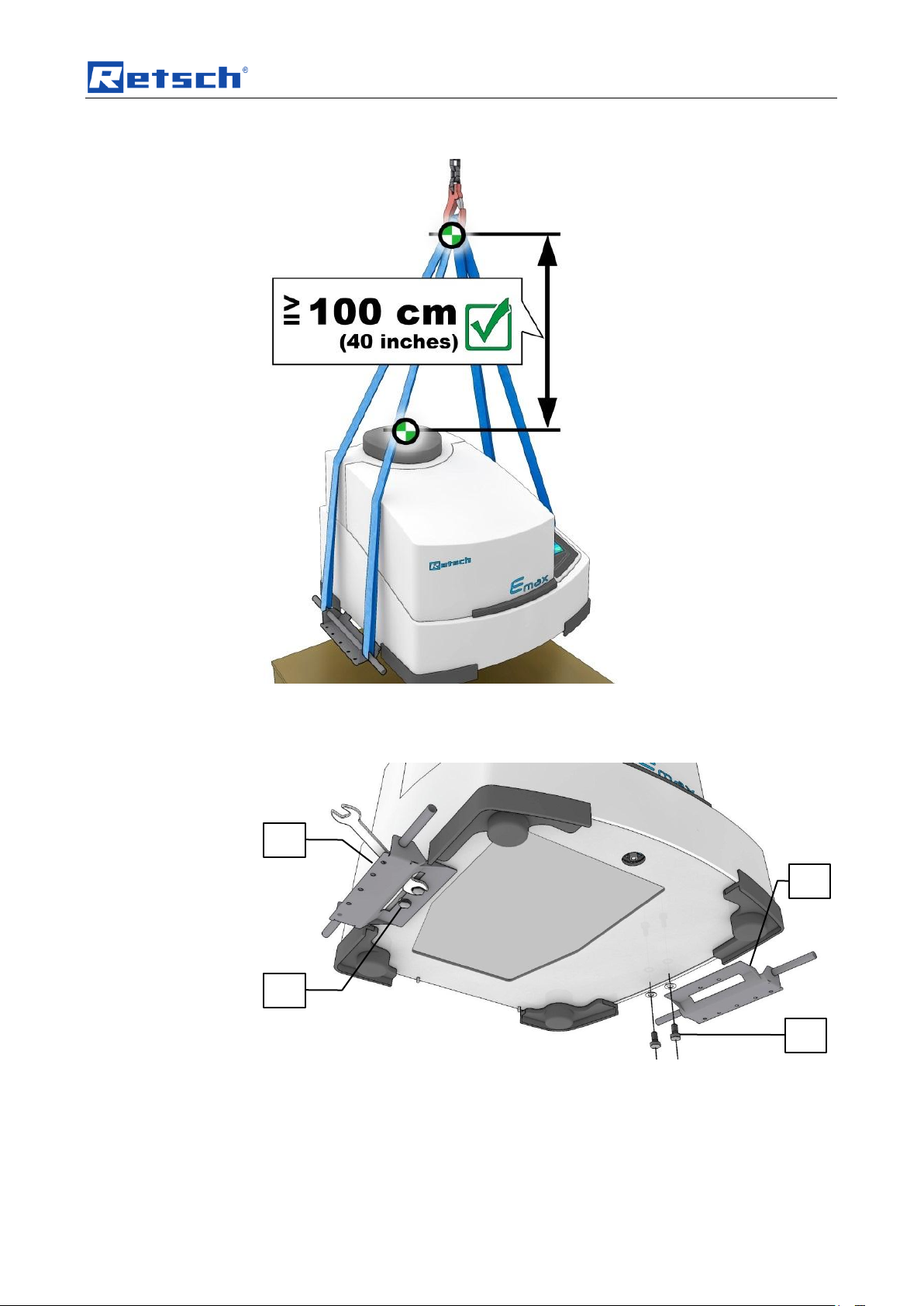

Fig. 6: Transport aid

The transport aid (TH) is fixed to the underneath of the device.

• Use a 13mm wrench to attach and remove the four screws (TS).

19

Page 20

Transport, scope of delivery, installation

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

WARNING

W0008

Risk of death through power surge

Mains plug not completely plugged in

– Water can enter the IEC socket if the IEC is not completely plugged in. An

electric shock can lead to burns and arrhythmia or to respiratory arrest as

well as cardiac arrest.

• Only operate the device with the IEC fully plugged in.

TS

4.10 Cooling

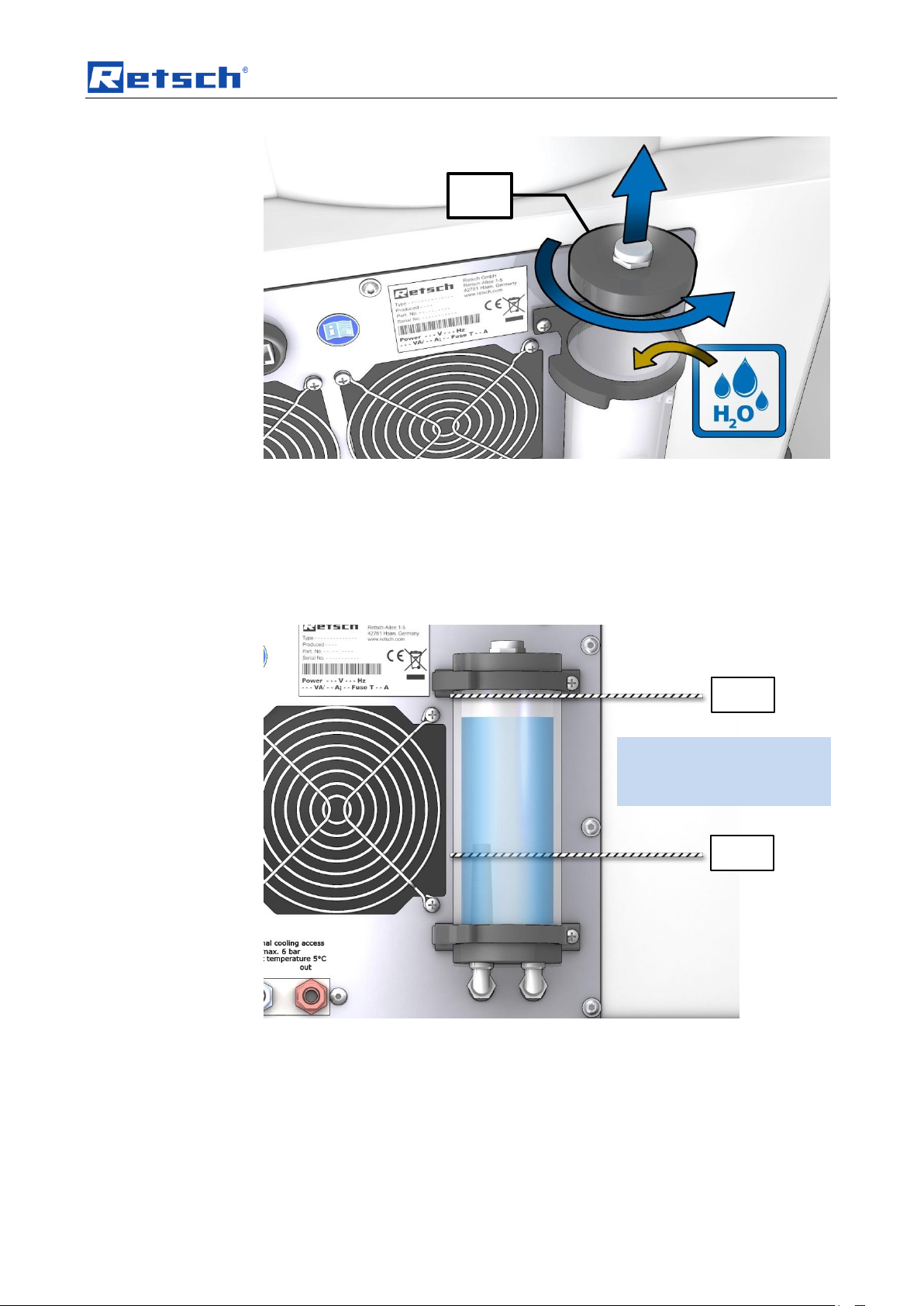

4.10.1 Cooling agent

Fig. 7: Removing the transport aid

There is a cooling agent tank at the back which must be filled with water before

putting into operation. Only clean, lime-free water is permitted as cooling agent.

• Unscrew the lid (TD) to fill the water.

• Start the device up for 2 minutes at a speed of 300 revolutions per minute

(with two grinding jars).

– This activates the internal pump and the cooling agent is distributed in the

cooling system.

• Then close the tank again.

20

Page 21

Transport, scope of delivery, installation

TD

Max

Min

Maximum volume of

cooling agent: 600ml

Fig. 8: Cooling agent tank

Check the supply of cooling agent regularly.

• Only use clean, lime-free tap water when topping up

• Pay attention to dirt in the cooling water. If it is too dirty, the cooling water

must be replaced.

• Maximum volume of cooling agent 600ml.

• Check the cooling system regularly for leaks.

Fig. 9: Maximum and minimum fill level

21

Page 22

Transport, scope of delivery, installation

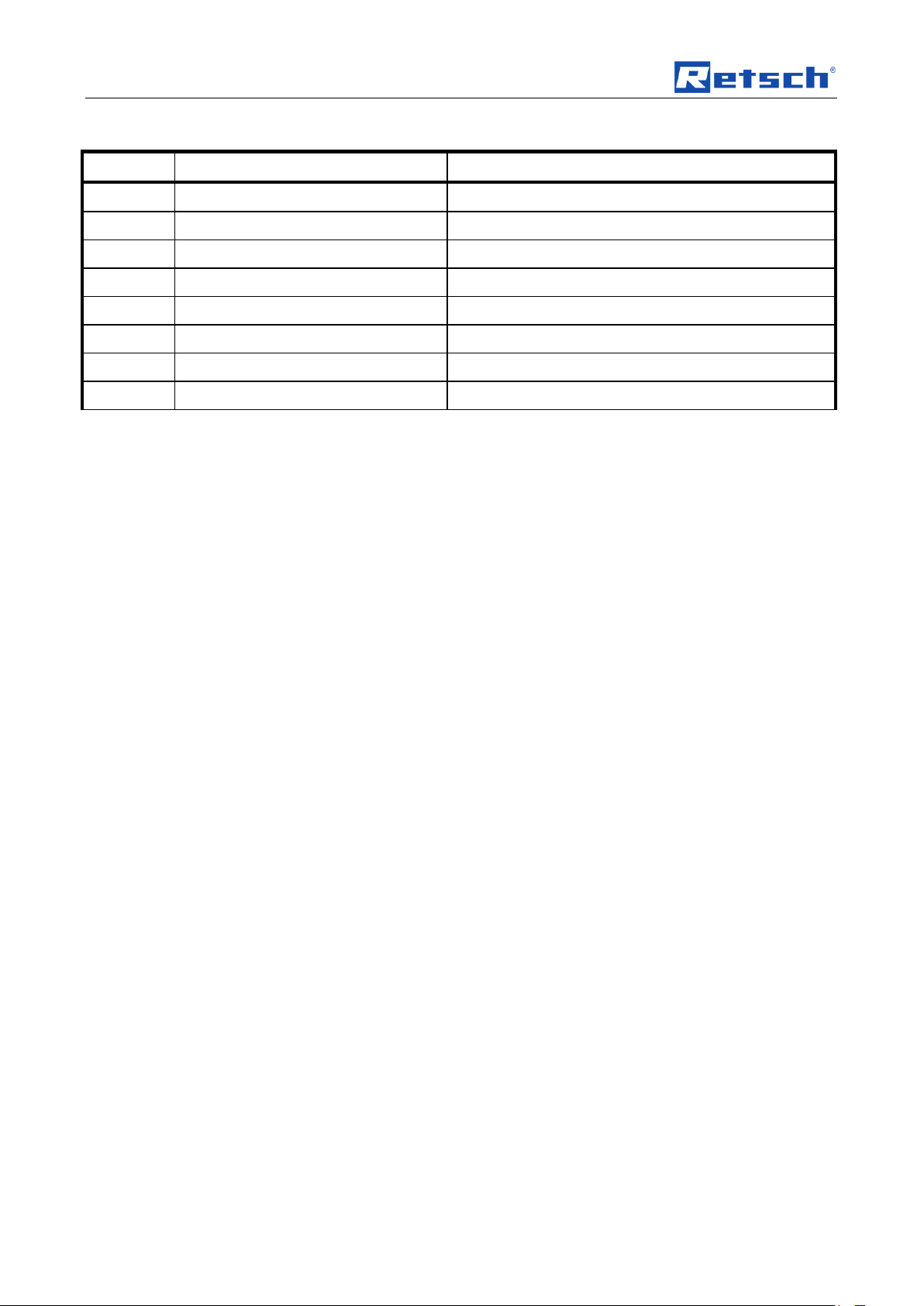

NOTICE

Error message E46

Flowmeter

– The following error sources can lead to an E46 error message:

1. No cooling agent in the cooling system

2. Flowmeter sensor faulty

3. Pump faulty

4. Blockage in the cooling system

• Check whether sufficient cooling water is in the cooling agent tank

(T).

Cooling agent

Clean, lime-free water

Minimum pump pressure

0.6bar

Maximum pump pressure

6bar

Minimum cooling output at 20°C

1kW

Maximum flow rate

10L/min

Working temperature

0° - 40°C

R

P

4.10.1.1 Connection to an external cooler

If the internal cooling is not sufficient for your application, you have the option of

connecting external cooling using the connections (R/P).

The internal cooling is then supported via the heat exchanger by optional external

cooling.

Fig. 10: Connections for external cooling

The maximum pressure in feed and drain pipes must not exceed 6 bar.

The minimum temperature of the cooling agent may not be less than 5°C.

Only clean, lime-free water is permitted as cooling agent.

The type of connection for the hose connection is 10mm x 8mm.

Alternatively own screw connections with a G ¼” thread may be used.

Cooler specifications:

22

Page 23

Transport, scope of delivery, installation

KF

KF

KF

KF

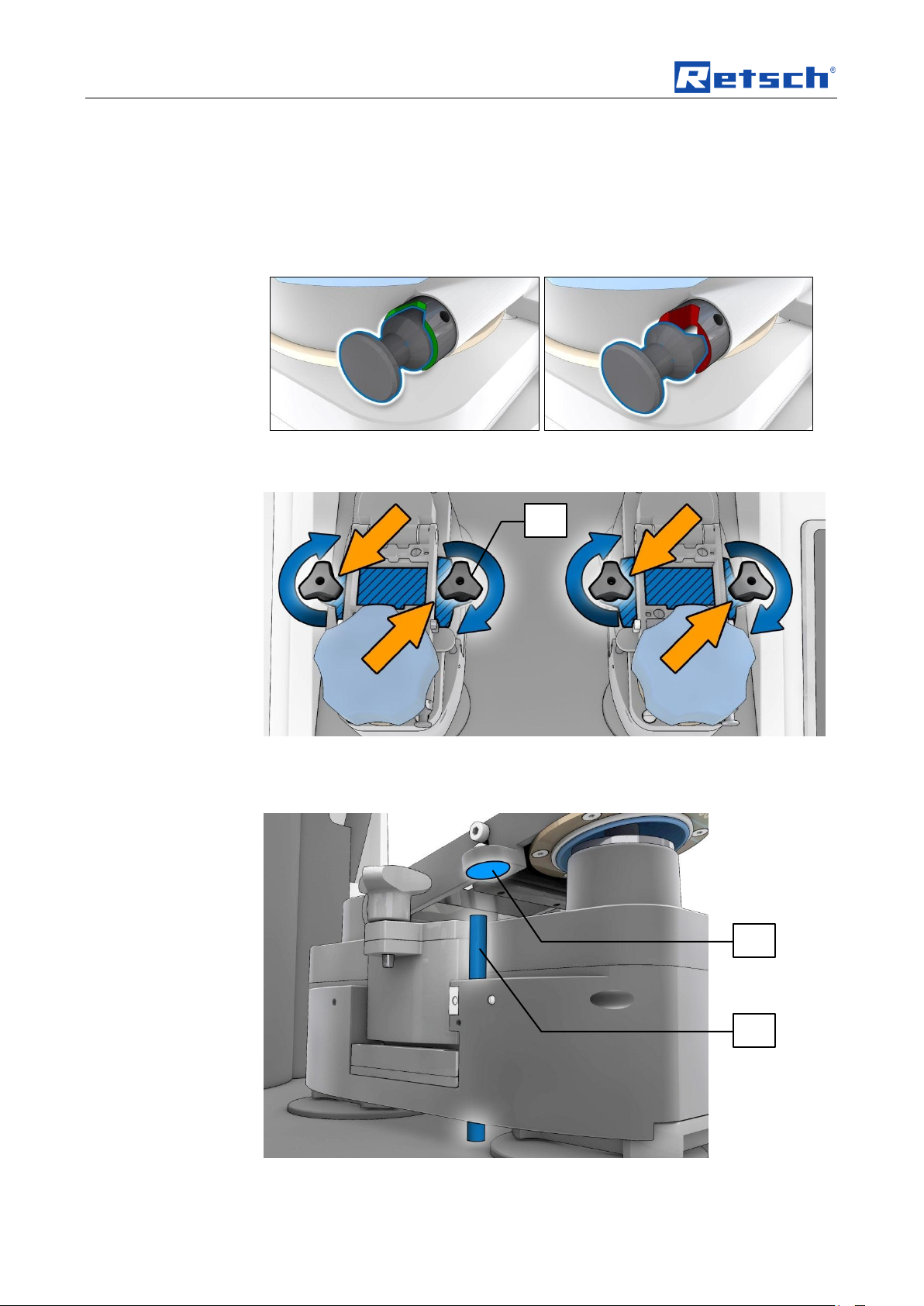

4.10.2 Grinding jar cooling surfaces

Fig. 11: Grinding jar support cooling surfaces

Fig. 12: Grinding jar cooling surfaces

The grinding jar is cooled by the cooling surfaces (KF) in the grinding jar support

(G). For good cooling performance, the surfaces on the grinding jar and support

must be absolutely clean and level.

• Remove any dirt and adhesion from the grinding jar and support.

• Take care that the surfaces are level and undamaged.

23

Page 24

Operating the machine

CAUTION

Risk of explosion or fire

– On account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

• Do not operate the device in a hazardous atmosphere.

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

CAUTION

1.V0004

Risk of explosion or fire

Changing sample properties

– Consider that the properties and therefore also the hazardousness of your

sample can change during the grinding process.

• Do not use any substances in this device which carry the risk of

explosion or fire.

NOTICE

Area of use of the machine

– This machine is a laboratory machine designed for 8-hour single-shift

operation.

• This machine may not be used as a production machine nor is it

intended for continuous operation.

5 Operating the machine

5.1 Use of the machine for the intended purpose

This Retsch ball mill is a laboratory device. It grinds and mixes soft, medium-hard

through to extremely hard, brittle and fibrous materials.

Dry and wet grinding may be conducted.

Minerals, ores, alloys, chemicals, glass, ceramics, plant parts, soil, sewage sludge

and many other substances can be ground easily, quickly and without loss. The

ball mills are successfully deployed in almost all areas of industry and research,

especially where there are high demands regarding cleanliness, speed, fineness

and reproducibility.

Only grinding jars from Retsch GmbH may be used.

Grinding with solvents is permitted. In this case the additional comments in the

“Wet grinding with highly flammable materials” chapter should be taken into

consideration, however.

24

Page 25

Operating the machine

25

Page 26

Operating the machine

26

Page 27

Operating the machine

A

H

E

C

D B F

G

5.2 Views of the Instrument

Fig. 13: Front view of the device

27

Page 28

Operating the machine

Element

Description

Function

A

Locking device

Keeps the device closed

B

Operating touchscreen

Operation of the device, starting, stopping etc.

C

Twist grip grinding jar support

Clamps the grinding jar

D

Twist grip locking pin

Secures the twist grip of the grinding jar support

E

Grinding jar

Grinding container

F

Lock retaining bracket

Retaining dowel for hood

G

Grinding jar support clamping bracket

Clamps the grinding jar

H

Hood

Closes the device

28

Page 29

Operating the machine

Element

Description

Function

I

Power switch

Disconnect the device from the mains, automatic fuse

J

RS232 interface (Ethernet)

Data connection (inactive)

K

USB interface

Data connection

L

Warning sign to disconnect from the

mains

Warning of electric shock

M

Mains connection

Connection for power cable

N

Type plate

Voltage type, serial number, device model

O

Housing fans

Fans for lost heat

P

Cooling water outlet for external

cooling (optional)

Hot water outlet

R

Cooling water inlet for external

cooling (optional)

Cooling water inlet

S

Operating instructions sticker

Reminder to read the operating instructions

T

Cooling agent tank for internal cooling

circuit

Cooling water expansion tank / filling

J I K O P R M L S N T

Fig. 14: Back of the device

29

Page 30

Operating the machine

B3.1

5.3 Opening and closing of the grinding chamber

5.3.1 Opening

When automatic opening is active, the grinding chamber lid is automatically lifted

once grinding has ended (see Service menu chapter).

When deactivated, the grinding chamber lid must be opened manually at the end of

grinding using the OPEN button (B3.1).

• To open the device, tap on the (B3.1) button.

– The display on the button (B3.1) changes to .

5.3.2 Closing

Fig. 15: Opening the hood

• Press the hood down until you notice that the automatic locking has closed

the lid.

– The display on the button (B3.1) changes to .

30

Page 31

Operating the machine

NOTICE

Hood is not closed

Automatic locking has not engaged

– If the hood has not closed sufficiently when it is closed, the automatic lock

cannot engage.

• Open the automatic locking:

To open the device, tap on the OPEN button (B3.1).

• Use a little force to press the hood downwards until you notice that

the automatic locking has closed the lid.

CAUTION

Emergency Unlocking

Drive continuing to run

– There is a substantial risk of injury if the drive and associated device parts

run on a long time without being braked!

• Activate the emergency unlocking only when the machine has come

to a complete stop and is disconnected from the power supply.

Eh

Fig. 16: Closing the hood

5.4 Emergency unlocking

Electrical unlocking is not possible in the case of a power outage.

– Open the hood with the release mechanism (Eh) .

Fig. 17: Position of the emergency release

31

Page 32

Operating the machine

CAUTION

Scalding/burns

Hot grinding jar

– Depending on the grinding process, the material being ground and

accordingly the grinding jar can become very hot.

• Wear appropriate protection always when touching the grinding jar if

it is hot.

Eh D C

DN

Fig. 18: Activating the emergency release

5.5 Opening and closing the grinding jar support

5.5.1 Opening

Fig. 19: Releasing the grinding jar support

The twist grip (C) of the grinding jar support (G) is secured by locking pin (D) to

prevent inadvertent opening.

32

Page 33

Operating the machine

G

DN

C

D

V

• Pull out the locking pin (D) to release from the groove (DN).

• Twist the locking pin 90 degrees to release it permanently.

• Turn the twist grip (C) to open the grinding jar support.

• Only remove the grinding jar with closed lid.

• Only open the grinding jar in a safe position (e.g. extraction device).

• Only open the grinding jar once it has cooled down.

5.5.2 Closing

Fig. 20: Removing the grinding jar

With this grinding device, a very large amount of energy enters the sample

material.

• Therefore make sure that the grinding jar support has been closed properly.

• Before grinding check the lock on the grinding jar support (V).

Fig. 21: Locking the grinding jar support

The twist grip (C) of the grinding jar support (G) is secured by locking pin (D) to

prevent inadvertent opening.

• Twist the locking pin (D) until it engages in the groove (DN).

33

Page 34

Operating the machine

MG

MV

SP

• Turn the twist grip (C) anticlockwise and tighten the twist grip (C) only hand-

tight when closing.

No greater force than “hand-tight” is required because the twist grip is secured by

the locking pin.

NOTICE

As a check that the lock has been activated, when the lock (D) has been closed

correctly a rattling sound can be heard when turning the twist grip (C).

Fig. 22: Securing and opening the locking pin

Fig. 23: Pulling the grinding jar lock tight

• After tightening the grinding jar support (G) with the twist grip (C), check the

tension on the 4 clamping screws (SP).

Fig. 24: Monitoring the grinding jar support

34

Page 35

Operating the machine

Grinding jar material

Temperature

Stainless steel

Up to 200°C

Tungsten carbide

Up to 150°C

Zirconium oxide

Up to 120°C

DM

SP

To avoid operating errors, the correct position of the grinding jar support is queried

using a magnet (MG) via extension (MV) and the corresponding sensor before

each start of the machine and during grinding.

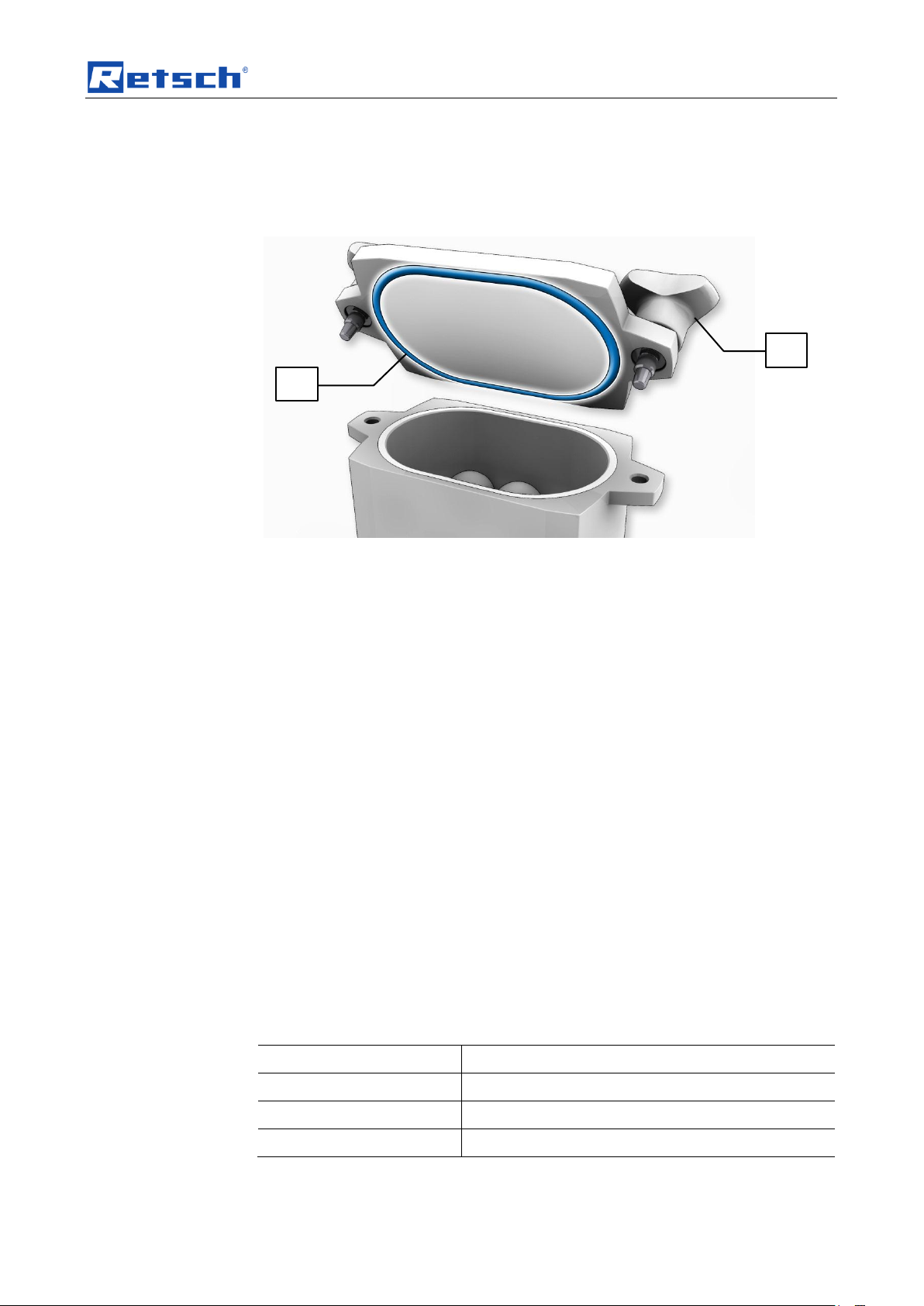

5.6 Closing the grinding jar

Fig. 25: Closing the grinding jar

With this grinding device, a very large amount of energy enters the sample

material.

• Therefore ensure careful closing of the grinding jar.

• When closing the grinding jar, ensure the seal (DM) is firmly in place.

• Tighten the clamping screws (SP) of the locking device so they are hand-

tight.

• Check the tension on the 4 clamping screws (SP) after closing the grinding

jar support (G) with the twist grip (C).

• Please note that the grinding jar can heat up to over 100°C depending on

the grinding jar size, the ball filling, the speed and the grinding duration.

5.6.1 Grinding jar and lid identification

All grinding jars must be identified by the labelling area which shows the grinding

jar material.

Grinding jars, also those with glued ceramic inserts, can be cleaned with alcohol,

petrol or normal household washing-up liquid.

NOTICE

– Ceramic inserts can crack as a result of sudden temperature differences.

• Do not expose grinding jars with ceramic inserts to sudden temperature

differences.

5.6.2 Drying the grinding jars

The grinding jars may be dried in the drying cabinet at the following specified

temperature at any time after cleaning.

35

Page 36

Operating the machine

Grinding jar

Ball size

125ml

Up to 15mm

50ml

Up to 12mm

Grinding jar material

Revolutions per minute

Steel

Up to 1500

Tungsten carbide (WC)

Up to 1200

Zirconium oxide

Up to 1200

NOTICE

H0067

Strong vibrations and noises

Uneven loading

– In the event of uneven loading the device can generate especially strong

vibrations and noises.

• Always use 2 grinding jars.

• Switch the device off immediately in the event of strong vibrations

and noises and check the number and gross weight of the jars.

5.7 Ball sizes and speeds

With this grinding device, a very large amount of energy enters the sample

material. This high amount of energy also acts on the grinding jar and the grinding

balls.

– The following recommendations for the ball sizes used therefore apply

depending on the grinding jar size.

– Likewise note the recommended speeds depending on the grinding jar

material.

5.7.1 Recommended ball sizes

5.7.2 Recommended speeds

The following speed restrictions apply to balls larger than 10mm:

5.8 Inserting the grinding jar

36

Page 37

Operating the machine

G

Fig. 26: Both grinding stations must be loaded

Fig. 27: Inserting the grinding jar

5.9 Wet grinding with highly flammable materials

Wet grinding using highly flammable materials is permissible in this device when

complying with specific precautionary measures.

When using highly flammable materials as grinding aid, such as hexane,

isopropanol, ethanol, petrol or similar, it is to be assumed that the inside of the

grinding jars should be classed as Zone 0 – constantly present explosive mix.

Therefore it is necessary to prevent potentially explosive vapours during the

grinding process - and in particular also from the heating which takes place - from

escaping from the clamped grinding jars and from entering areas in which the

requisite ignition energy is present.

We therefore urgently recommend that the operating company (employer) using

the device assesses the dangers that exist before using corresponding solvents,

taking local conditions into account, as part of a coherent explosion protection

37

Page 38

Operating the machine

concept. Where necessary, supplementary organisational measures should be

recorded in writing in an explosion protection document.

This procedure is regulated in the EU under Articles 118 and 118a of Directive

89/391/EEC.

Please observe comparable provisions in other countries outside the EU.

The following requirements should be assumed here with respect to the device.

• It is necessary to consider the durability of the O-rings (FPM Viton) when

selecting the solvent and the durability of the adhesive used when using

ceramic material inserts.

• Tighten the clamping screws of the locking device so they are hand-tight.

• Please note that the grinding jars can heat up considerably depending on the

grinding jar size, the ball filling, the speed and the grinding duration.

• Check that the lock is firmly in place before removing the grinding jars.

38

Page 39

Control panel software – controlling the device

B1

Navigation

Switching between Manual, Program

and Sequences

Time, Date

B2

Setting and display of parameters

Setting the grinding parameters and

displaying parameters during

grinding

B3

Device controller

Start, Stop, Pause, Lid open

B1

B2

B3

6 Control panel software – controlling the device

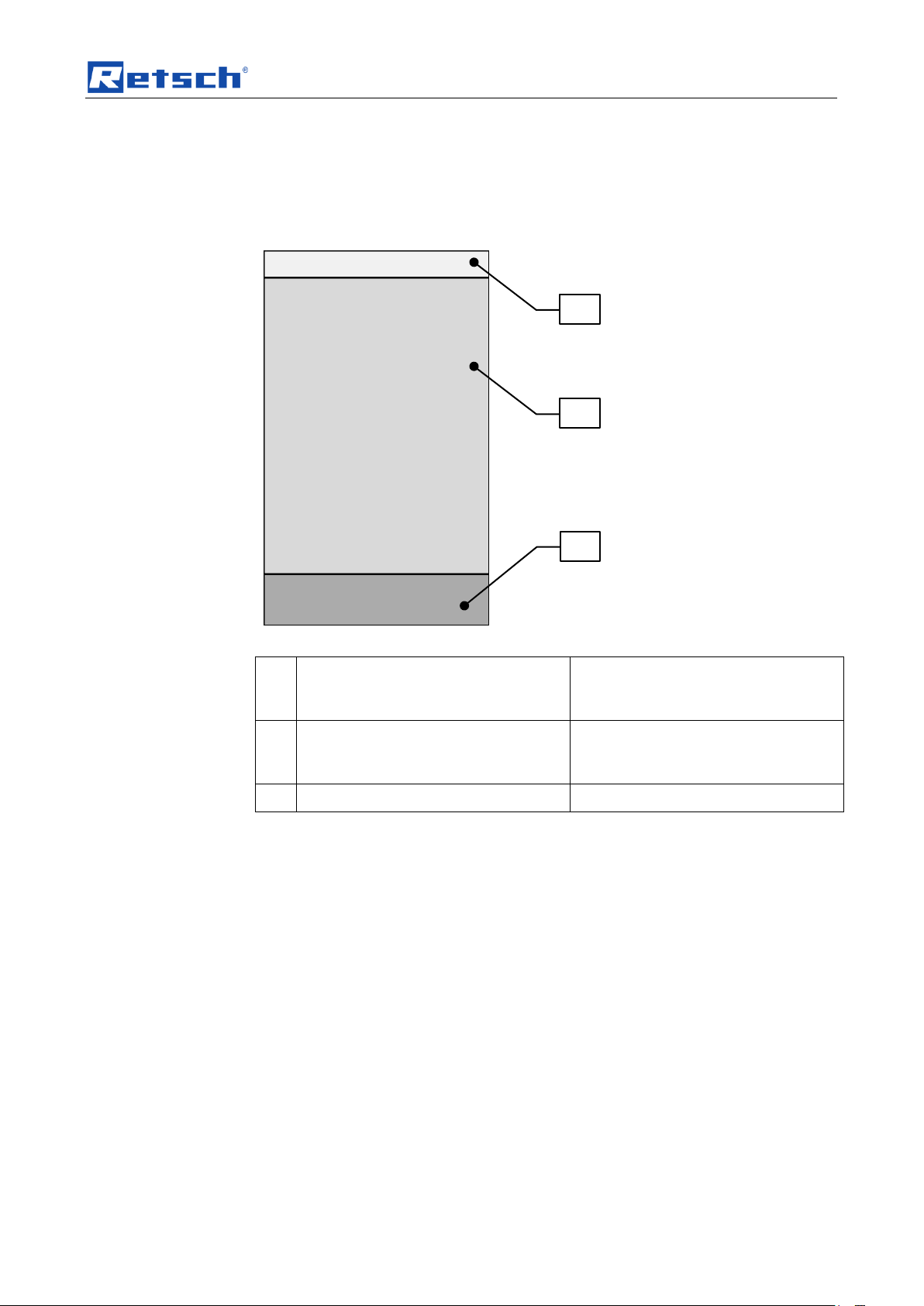

6.1 Operating elements and displays

Fig. 28: Screen areas

39

Page 40

Control panel software – controlling the device

22.04.2014

14:23

PROGRAM

65°C

Temperature

Interval

Reverse direction

01:00:00

Process time

1800

Speed (U/min)

00:15:00

Interval time

00:05:00

Pause time

OPEN

START

10 | Aluminium oxide

B1.1

B2.1

B2.3

B2.5

B2.7

B2.8

B2.9

B3.1

B1.2

B2.2

B2.6

B2.11

B3.2

B2.4

B2.10

70°C

50°C

40

Page 41

Control panel software – controlling the device

Element

Description

Function

B1.1

Navigation

Switching between Manual, Program and

Sequences

B1.2

Display of time

Display of the date and time / access to the device

menu

B2.1

Program information

Retrieval of user data for the current program

B2.2

Edit program

Opens the settings menu for the current program

B2.3

Cooling

Display of the cooling status flow (active / inactive);

upper and lower temperature limit

B2.4

Program designation

Display of the program number and of the saved

program name; selection of the desired program

B2.5

Process time

Display of the grinding duration

B2.6

Display of temperature and

temperature limits

Display of the water temperature in the cooling

system

B2.7

Speed

Display of the speed, reverse grinding

B2.8

Interval

Display of whether interval grinding is active or

inactive

B2.9

Interval time

Display of the interval time

B2.10

Pause time

Display of the pause time

B2.11

Reverse direction

Display of whether the direction reversal is active or

inactive

B3.1

OPEN

Opens the hood

B3.2

START

Starts grinding

6.2 Functional principle (resistive) of the touchscreen

With this resistive touchscreen two electrically conductive layers are connected in

places as a result of pressure in order to determine the position of the pressure

point.

For this reason the operation takes place exclusively using single touch entries.

The advantage of this is that you can also operate the touchscreen when wearing

gloves or using a stylus.

6.3 Operating modes and navigation

The device can be operated entirely using the touchscreen.

The operating software can be divided into three operating modes:

– Manual

– Program

– Sequences

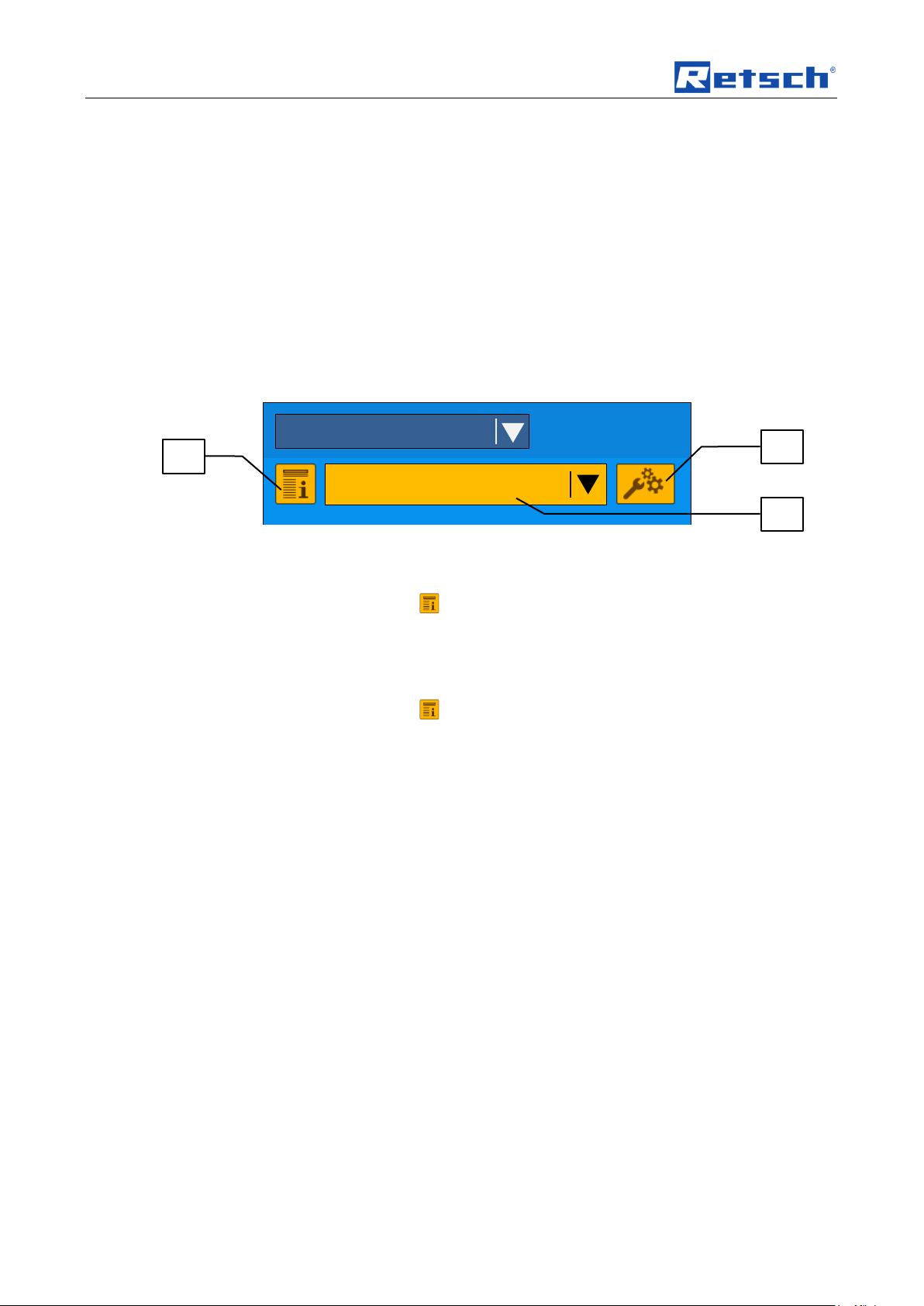

6.3.1 Navigation between operating modes

• Tap on the navigation field (B1.1).

– The navigation menu opens.

– The current mode is marked (by a triangle and coloured lettering)

41

Page 42

Control panel software – controlling the device

22.04.2014

14:23

65 C°

Temperatur

01:00:00

Prozesszeit

10 | Aluminiumoxid

PROGRAM

PROGRAM

MANUAL

SEQUENCE

B1.1

• Tap on the desired mode.

6.4 Grinding parameters

You can change the following grinding parameters.

6.4.1 Adjustable parameters

– Process time 00:00:00 to 99:59:59 (hh:mm:ss)

– Interval time 00:00:00 to 99:59:59 (hh:mm:ss) – only active with interval

– Pause time 00:00:00 to 99:59:59 (hh:mm:ss) – only active with interval

– Speed 300 to 2000 in increments of 100 (revs per minute)

In manual operating mode you can also change some parameters during grinding.

In program mode you can only change parameters when you have activated

editing using the icon (B2.2).

• Tap on the parameter that you wish to edit.

– The window to make entries appears.

• Tap on CANCEL to cancel editing without saving entries.

– The entries are not saved, and the menu displays the previous screen.

• Tap on SAVE to save entries.

The entries are saved, and the menu displays the previous screen.

42

Page 43

Control panel software – controlling the device

Fig. 29: Making entries

6.4.2 Parameters that can be activated or deactivated

– Interval

– Reverse direction

• Tap on the interval line (B2.8)

– Depending on the previous status, interval grinding is then active or inactive.

The parameters for interval time, pause time and reverse direction are

switched to active or inactive according to the activation of interval grinding.

6.5 Manual operation

You can change the following grinding parameters directly in manual operating

mode.

– Process time

– Interval time

– Pause time

– Speed

– Interval

– Reverse direction

The parameters are adjusted as described in the “Grinding parameters” chapter.

43

Page 44

Control panel software – controlling the device

22.04.2014

14:23

PROGRAM

65 C°

Temperatur

Intervall

Richtungsumkehr

01:00:00

Prozesszeit

1800

Drehzahl (U/min)

00:15:00

Intervallzeit

00:05:00

Pausenzeit

OPEN

START

10 | Aluminium oxide

B2.1

B2.2

B2.4

6.6 Programs

You can save up to 10 grinding programs.

You can save the following grinding parameters in a program:

– Process time

– Interval time

– Pause time

– Speed

– Interval

– Reverse direction

Additionally you can allocate every program its own heading and a detailed

description.

6.6.1 Program description and heading

6.6.1.1 Display of the program description

• Tap on the icon (B2.1).

– The program description window opens.

• Tap on the BACK button to return to the previous screen.

6.6.1.2 Edit the program description and the heading

• Tap on the icon (B2.1).

– The program description window opens.

• Tap on the EDIT button to enter or edit the program description or the

heading.

– The window for editing the program description opens.

44

Page 45

Control panel software – controlling the device

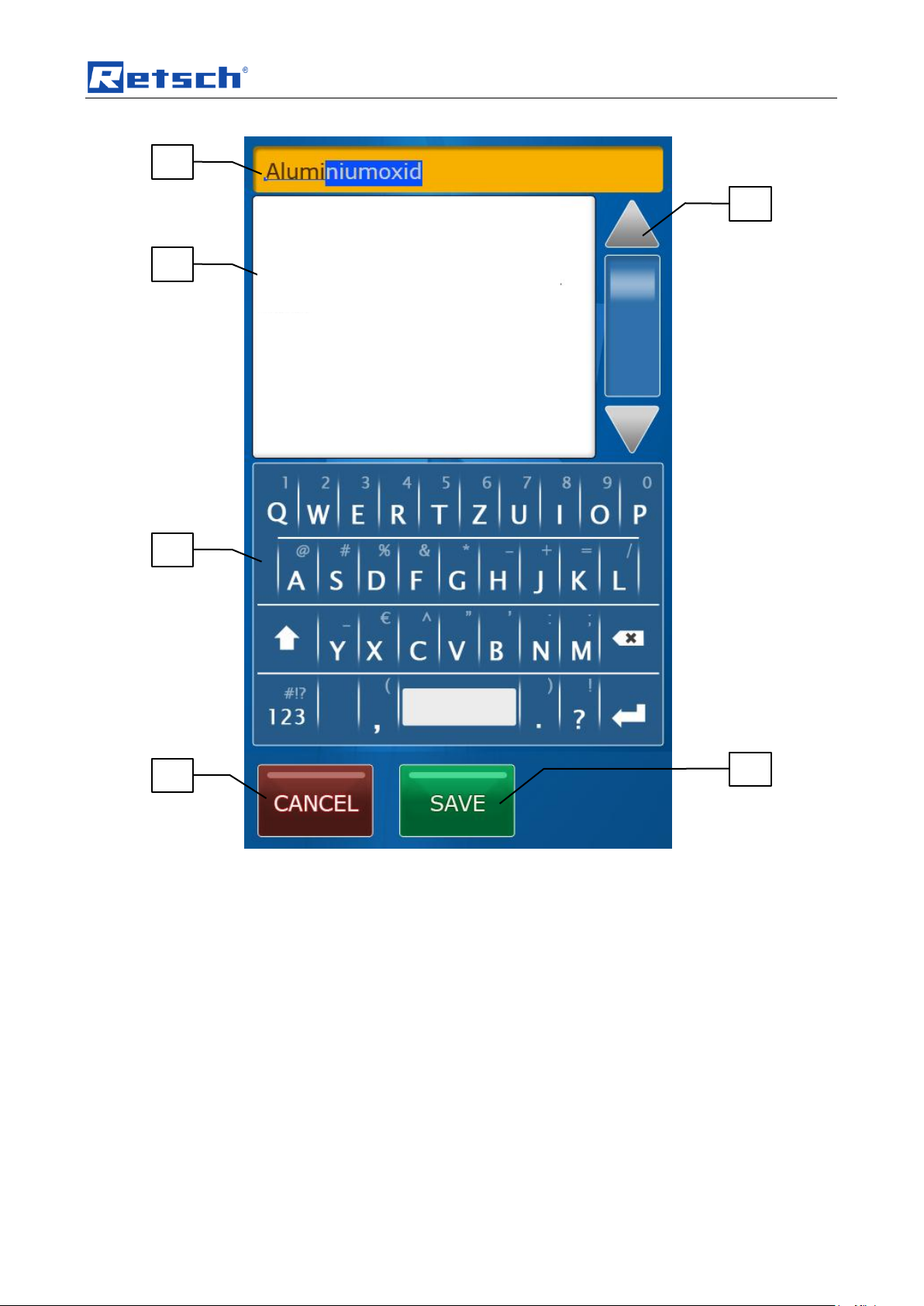

B4.1

B4.6

B4.2

B4.3

B4.5

B4.6

Fig. 30: Window for editing the program description

• To edit the heading, tap the field (B4.1).

– Use the keypad (B4.3) for entries and editing.

• To edit the program description, tap the field (B4.2).

– Use the keypad (B4.3) for entries and editing.

– You can use the arrow keys (B4.6) to scroll up and down longer areas of

text.

6.6.1.3 Saving or cancelling editing of the program description or heading

• Tap on CANCEL to cancel editing without saving the description.

– The entries are not saved, and the menu displays the previous screen

(program description).

• Tap on SAVE to save the description.

– The description is saved, and the menu displays the previous screen

(program description).

45

Page 46

Control panel software – controlling the device

6.6.2 Selecting saved programs

• Tap on the headings field (B2.4).

– The program selection window opens.

– The current program is shown with a grey background.

• Tap on an icon to open the program description of the respective

program.

• Tap on the desired program.

– The program selection window closes and the relevant program is loaded.

6.6.3 Editing and saving the program

In the program mode you can only change parameters if you have activated

editing.

• Tap on the icon (B2.2) to edit the grinding parameters saved in the

program.

The parameters are set as describing in the “Grinding parameters” chapter.

• Tap on CANCEL to cancel editing without saving entries.

– The entries are not saved, and the menu displays the previous screen.

• Tap on SAVE to save the entries.

– The entries are saved, and the menu displays the previous screen.

6.7 Sequences

For special grinding tasks you can collate your previously saved programs into a

sequence in this mode. This enables you to design very complex grinding

processes.

– A sequence is made up of a number of freely selectable programs.

– You can repeat programs.

– You can save up to three sequences.

46

Page 47

Control panel software – controlling the device

22.04.2014

14:23

SEQUENCE

65°C

Temperature

01:00:00

Process time

OPEN

START

1 | Retsch sequence

B5.1

B5.5

B5.8

B5.2

B5.4

70 C°

50 C°

– The grinding parameters of the individual programs cannot be changed in

the sequence mode. To do this, switch to the program mode.

6.7.1 Creating or editing a sequence

1 | Program 5 | P5

2 | Grinding 0001 | P1

3 | Intermediate program | P3

4 | Grinding 0001 | P1

5 | Intermediate program | P3

6 | Intermediate program | P3

7 | Program 5 | P5

6.7.2 Sequence description and heading

You can allocate each of the three sequences its own heading and a detailed

description.

6.7.3 Selecting a saved sequence

• Tap on the icon (B5.1).

All other steps are the same as those explained in the Program description and

heading chapter.

• Tap on the headings field (B5.4).

– The sequence selection window opens.

– The current sequence is shown with a grey background.

47

Page 48

Control panel software – controlling the device

22.04.2014

14:23

PROGRAM

10 | Aluminium oxide

B2.2

• Tap on an icon to open the sequence description of the respective

sequence.

• Tap on the desired sequence.

– The sequence selection is closed and the relevant sequence is loaded.

6.7.4 Editing and saving a sequence

You can only change the program compilation of a sequence if you have activated

editing.

• Tap on the icon (B5.2) to edit the programs saved in the sequence.

The process times of all programs saved in the sequence are added together and

shown in the process time display.

After editing:

• Tap on CANCEL to cancel editing without saving entries.

– The entries are not saved, and the menu displays the previous screen.

• Tap on SAVE to save entries.

– The entries are saved, and the menu displays the previous screen.

6.7.4.1 Adding or changing a program to the sequence

• Tap on the last line in the memory that can be edited and which is shown by

[ – ].

– The list of all saved programs appears.

• Tap on an icon to open the program description of the respective

program.

• Tap on the line for the desired program.

– The program is added to the sequence and the menu displays the previous

screen.

6.7.4.2 Removing a program from the sequence

• Tap on the line in the memory showing the program you wish to remove.

– The list of all saved programs appears.

• Tap on the top line (no program).

– The program is removed from the sequence and the menu displays the

previous screen.

6.8 Service menu

The service menu can be accessed from any operating mode.

• Press and hold the time and date field (B2.2).

– The service menu is displayed full screen.

48

Page 49

Control panel software – controlling the device

22.04.2014

14:23

OPEN

BACK

Language

SETTINGS

Date and time

Signal tone

Automatic opening

Timer setting

IR sensor

Set temperature limits

Operating hours

Software version

User information

Service environment

You can change the following settings in the service menu:

– Language

– Date and time

– Signal tone

– Automatic opening

– Timer setting

– IR sensor calibration

– Set temperature limits

– Operating hours

– Software versions

– User information

– Service environment

49

Page 50

Control panel software – controlling the device

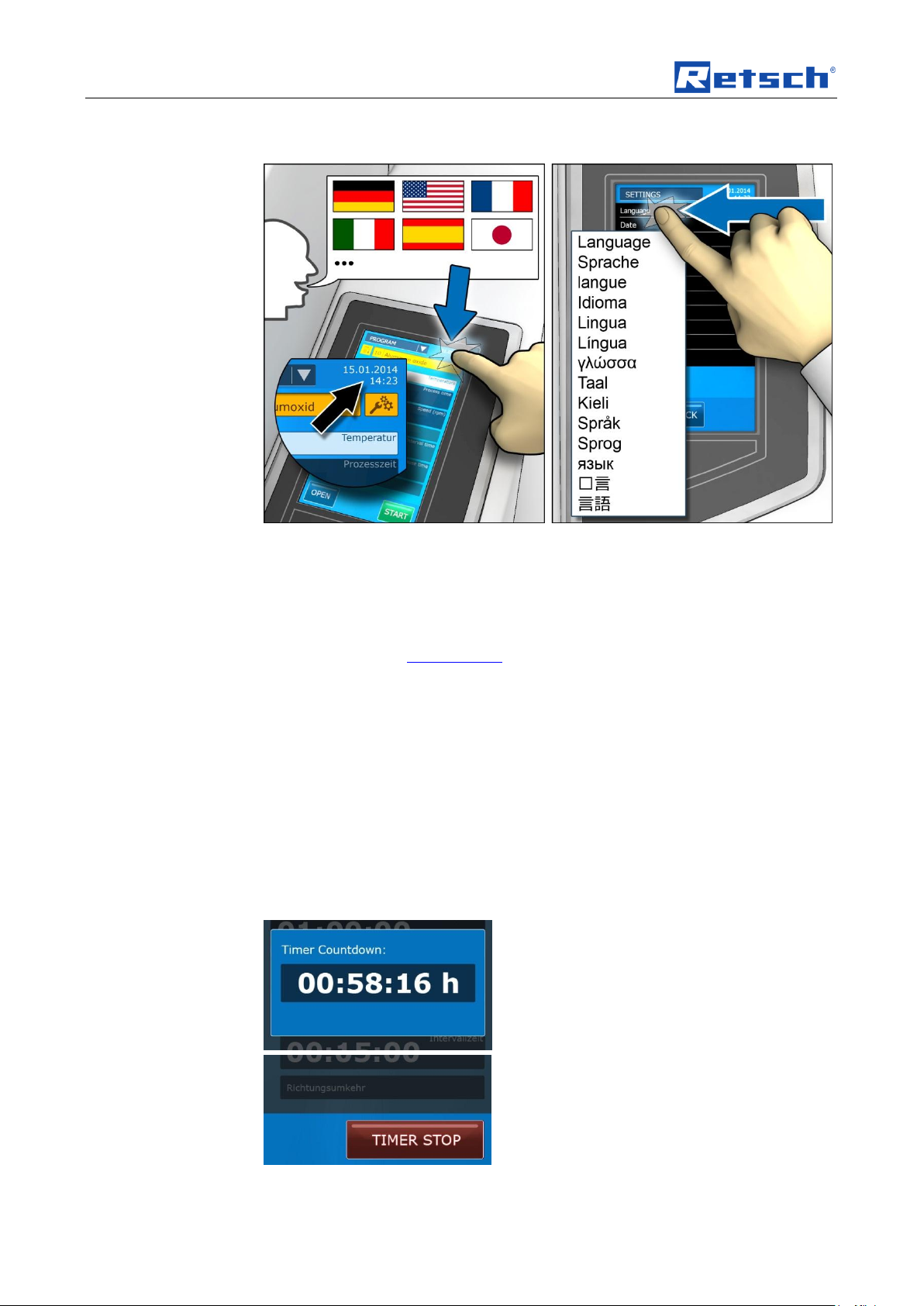

6.8.1 Language

6.8.2 Date and time

6.8.3 Timer – setting

Fig. 31: Accessing the language setting

You can select your language in this menu.

• Tap the desired language on the field.

After selection, the entire menu structure is displayed in the selected language.

NOTICE

The exception is the device control (B3) screen area. The buttons for device

control are displayed in English only.

You can save or change the current date and time under this menu item.

The device can be disconnected from the mains for up to 30 days without losing

the settings.

With the timer function the device can be started with time lag.

The start button is used to confirm the function (the countdown starts running).

• You can interrupt the running down of the start time using the STOP button

and the main switch on the back of the device.

The start time must then be programmed again.

50

Fig. 32: Countdown

Page 51

Control panel software – controlling the device

6.8.4 Setting temperature limits

Fig. 33: Temperature limits

With the temperature limits function you can create grinding pauses in addition to

the actual temperature monitoring.

The grinding is driven at the set speed until it reaches the set max. temperature.

On reaching the maximum temperature, the speed is reduced to 300 rpm until the

minimum temperature is reached. Once the minimum temperature has been

reached, grinding takes place at the set speed again.

NOTICE

After confirming the temperature limits, in addition to the temperature display an

icon and the set temperatures appear on the display (B2.5).

Fig. 34: “Temperature limits active” icon

6.8.5 Automatic opening

With automatic opening the grinding chamber lid is automatically lifted once

grinding has ended.

When deactivated, the grinding chamber lid must be opened manually using the

OPEN button (B3.1).

6.8.6 Signal tone

Error messages in the case of incorrect operation are signalled acoustically by an

alert.

When the function has been turned off, the corresponding pictogram appears

6.8.7 Operating hours

The process times, i.e. the times between START and STOP are counted. The

times cannot be manipulated.

6.8.8 Software versions

In this menu you can update two software areas.

51

Page 52

Control panel software – controlling the device

- Controller (firmware)

- Display

• Tap on the desired update.

NOTICE

A suitable USB data medium with controller and display software must be

connected to the device. The controller and display software must be in the root

directory. The device then automatically recognises the new software.

6.8.9 User information

The following information about the device can be found under user information:

- Accessories

- Spare parts

- User manual

6.8.10 IR sensor calibration

Fig. 35: IR sensor calibration

You can calibrate the IR sensor in this menu.

This is used to measure the temperature of the grinding jar and to adjust it where

necessary.

• Select the field in which you want to adjust the temperature.

6.8.11 Service environment (password protected)

This function can only be accessed by Retsch service technicians.

52

Page 53

Safety functions and fault display

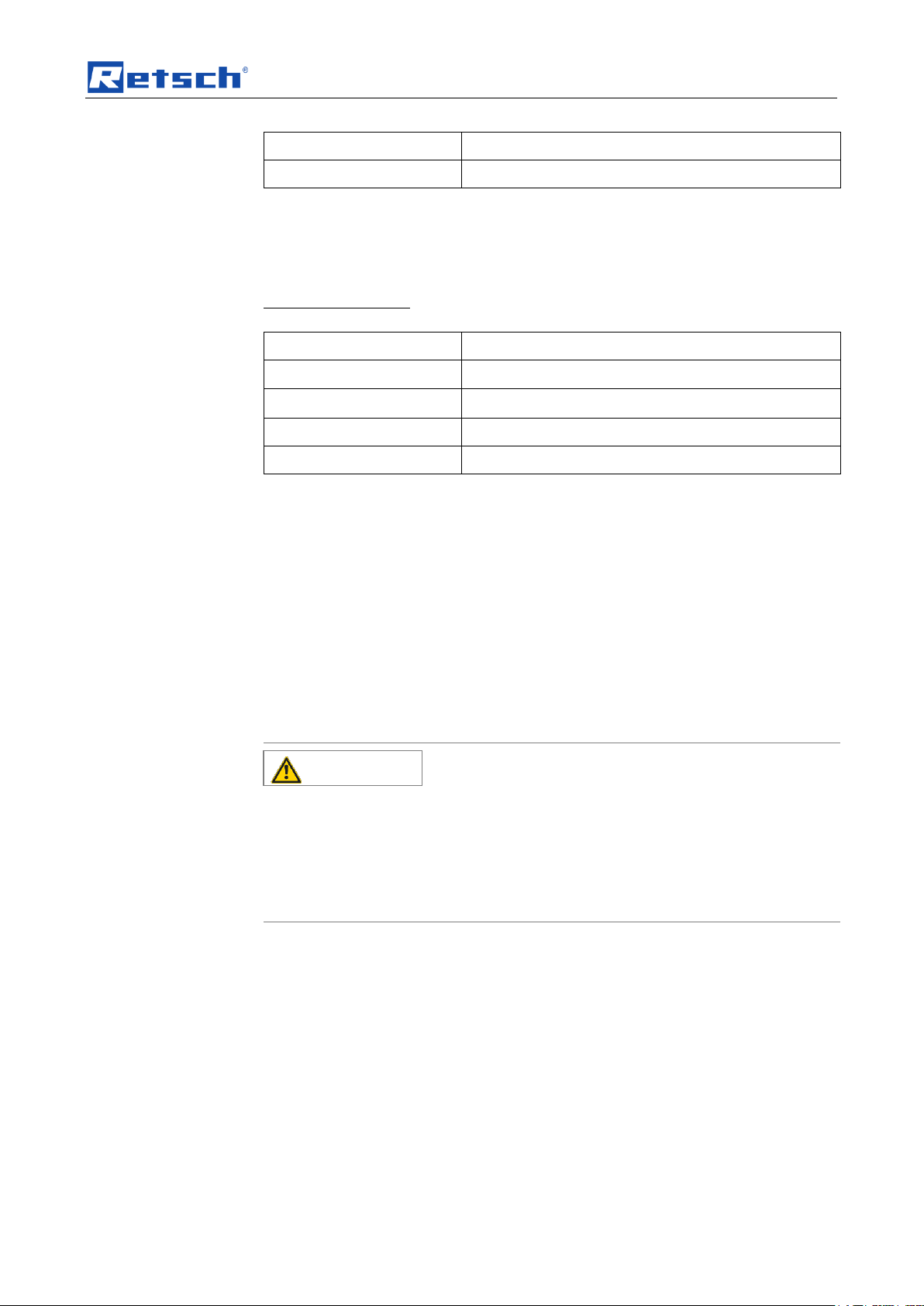

Error code

Description

Measures

E10

Drive overloaded

Press the main switch

E20

Error controller

Press the main switch

E21

Error speed

Press the main switch

E25

Error display

Press the main switch

E26

Error frequency inverter

Press the main switch

E40

Error sensor 1

Confirm message on display

E41

Error speed sensor

Press the main switch

E42

Error temperature sensor 1

Press the main switch

E43

Error temperature sensor 2

Press the main switch

E45

Error sensor 2

Press the main switch

E46

Error sensor 3

Press the main switch

E50

Error safety circuit

Press the main switch

E51

Error safety switch

Press the main switch

E52

Error switch 1

Press the main switch

E53

Error switch 2

Press the main switch

E81

Unbalance

Press the main switch

E87

Unbalance switch

Press the main switch

H10

Allow drive to cool!

Confirm message on display

E100

Temperature limit reached

Confirm message on display

E128

Note temperature limit reached

Confirm message on display

7 Safety functions and fault display

7.1 Fault messages

53

Page 54

Safety functions and fault display

7.2 Returning for service and maintenance

Fig. 2: Returned goods dispatch note

RETSCH devices and accessories can only be accepted for repair, maintenance or

calibration if the returned goods despatch note has been correctly completed in full.

• When returning a device, attach the returned goods dispatch note to the

outside of the packaging.

In order to eliminate any health risk to our employees, we reserve the right to

refuse acceptance and to return the respective delivery at the expense of the

sender.

54

Page 55

Cleaning, wear and service

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

CAUTION

Personal injury

Incorrect repairs

– This operating manual does not include instructions for repair.

• For your own safety repairs should be carried out only by Retsch

GmbH or an authorised representative (service technicians).

8 Cleaning, wear and service

8.1 Cleaning

8.2 Wear

Cleaning

Check at regular intervals whether water or grease are escaping in or beneath the

device.

The grinding tools may become worn, depending on the frequency of the grinding

operation and the sample material. The grinding jars and the balls should be

regularly checked for wear and replaced if necessary.

Check the seals regularly for wear and replace them where necessary.

8.3 Wearing parts

8.4 Service

The grinding tools may become worn, depending on the frequency of the grinding

operation and the sample material. The grinding jars and the balls should be

regularly checked for wear and replaced if necessary.

55

Page 56

Cleaning, wear and service

AG T TD

DS

8.4.1 Replacing the cooling water

8.4.1.1 Removing the cooling water

Fig. 36: Replacing the cooling agent

1. Place a collecting vessel (AG) for the old cooling water under the cooling

agent tank (T).

56

Fig. 37: Removing the lid

2. Unscrew the lid (TD).

3. Remove the sealing screw (DS) to drain the water.

4. Start the device up for 1 minute at a speed of 300 revolutions per minute

(with two grinding jars).

– This activates the internal pump (U) and the remaining cooling agent is

pumped out.

Page 57

Cleaning, wear and service

min.

max.

Maximum cooling agent

volume: 600ml

TR

TB

Fig. 38: Removing the pipe

5. After stopping the device you can remove and clean the pipe (TR).

6. Also clean the base (TB).

7. Reinsert the pipe (TR).

– Ensure the seal is firmly in place.

8. Screw in the sealing screw (DS).

8.4.1.2 Rinsing the cooling system

1. Fill with fresh, clean, lime-free tap water (maximum cooling agent volume

600ml).

Fig. 39: Maximum and minimum fill levels

2. Start the device up for 1 minute at a speed of 300 revolutions per minute

(with two grinding jars).

57

Page 58

Cleaning, wear and service

NOTICE

Error message E46

Flowmeter

– The following error sources can lead to an E46 error message:

1. No cooling agent in the cooling system

2. Flowmeter sensor faulty

3. Pump faulty

4. Blockage in the cooling system

• Check whether sufficient cooling water is in the cooling agent tank

(T).

TD

3. Place an empty collecting vessel (AG) to catch the drained cooling water

under the cooling agent tank (T).

4. Remove the sealing screw to drain the water (DS).

5. Screw the sealing screw (DS) back in.

6. Repeat steps 1 to 5 approx. 3 times.

– A residual cloudiness of the water remains after changing the water several

times. This is quite normal.

1. Only fill with fresh, clean, lime-free tap water (maximum cooling agent

600ml).

• Start the device up for 2 minutes at a speed of 300 revolutions per minute

(with two grinding jars

– This activates the internal pump and the cooling agent is distributed in the

cooling system.

• Screw the lid (TD) back onto the cooling agent tank (T).

Fig. 40: Cooling agent tank

• Ensure that the seal is firmly in place.

• Check the cooling system regularly for leaks.

58

Page 59

Cleaning, wear and service

59

Page 60

Disposal

9 Disposal

Please observe the respective statutory requirements with respect to disposal.

Information on disposal of electrical and electronic machines in the European

Community.

Within the European Community the disposal of electrically operated devices is

regulated by national provisions that are based on the EU Directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

Accordingly, all machines supplied after 13.08.2005 in the business-to-business

area to which this product is classified, may no longer be disposed of with

municipal or household waste. To document this they have the following label:

Fig. 3: Disposal label

Since the disposal regulations within the EU may differ from country to country we

would request you to consult your supplier.

60

Page 61

10 Index

A

Additional cooling 14

Ambient temperature 15

Amount of energy 36

Amperage 16

B

Back of the device 29

Ball size 36

Bar code 16

Base

Depth 13

Width 13

Batch 13

Blockage 22, 58

C

Capacity 16

CE marking 16

Changes 7

Cleaning 55

Cleaning, wear and service 55

Closing 30

Closing the grinding jar 35

Conditions for the place of installation 15

Confirmation 11

Connection cable 17

Control panel 39

Control panel software – Controlling the device 39

Controlling the device 39

Coolant 14

Cooling 14, 20

Cooling agent 20

Cooling surfaces 23

Cooling water

replacement 56

Copyright 7

D

Degree of protection 12

Depth 13

Description 28, 29, 41

Device designation 16

Dimensions and weight 13

Disposal 60

Disposal label 16

Disposal label 60

Drying the grinding jars 35

E

E46 22, 58

Electrical connection 16

Emergency unlocking 31

Emissions 12

Energy input 36

Error message

E46 22, 58

Error messages 53

Explanations of the safety warnings 8

External 14

External fuse 17

F

Fault messages 53

feed size 14

Feed size 14

Feed volume 13

Fill level 21, 57

Front view 27

Function 28, 29, 41

Fuse strength 16

Fuse type 16

G

General safety instructions 9

Grinding jar cooling surfaces 23

Grinding jar support

closing 32

locking 33

opening 32

Grinding parameters 42

H

Height

with open hood 13

Height 13

Hood

closing 31

opening 30

I

Inserting the grinding jar 36

Installation height 16

Installation of the machine 16

Internal 14

Interval 43

Interval time 42

L

Language 50

Locking pin 33

L

12, 13

pAeq

M

Mains frequency 16

Manual operation 43

Manufacturer’s address 16

Maximum pressure 14

Minimum temperature 14

Moderate or mild injury 8

Monitoring 34

61

Page 62

N

Navigation

manual 41

program 41

sequence 41

Notes on the Operating Manual 7

Number of fuses 16

O

Opening 30

Opening and closing of the grinding chamber 30

Operating elements and displays 39

Operating modes 41

Operating the machine 24

Oscillating feet 18

P

Packaging 15

Parameters

setting 42

Part number 16

Pause time 42

Power version 16

Pressure 14

Process time 42

Program

editing 46

saving 46

selecting 46

Program description 44

display 44

edit 44

Programs 44

property damage 8

Protective equipment 12

Pump faulty 22, 58

R

S

Safety functions and fault display 53

Safety warnings 8

Sensor faulty 22, 58

Sequence

editing 48

saving 48

selecting 48

Sequences 46

Serial number 16

serious injury 8

Service 55

Service Address 10

Service menu 48

Sound parameters 12

Speed 36, 42

Speed restriction 36

T

Target group 9

Technical data 12

Temperature fluctuation and condensed water 15

Touchscreen

functional principle 41

resistive 41

Transport 15

Transport, scope of delivery, installation 15

Type plate 17

type plate description 16

Type plate lettering 16

U

Use of the machine for the intended purpose 24

V

Views of the Instrument 27

W

Rated power 13

Receptacle volume 13

Recommended ball size 36

Recommended speed 36

Regulations for the place of installation 17

Removing the transport safeguard 17

Removing Transport Safeguards 19

Repairs 10

Required floor space 13

Return goods dispatch note 54

Returning for service and maintenance 54

Reverse direction 43

62

Wear 55

Wearing parts 55

Weight 13, 18

Wet grinding with highly flammable materials 37

Width 13

Workplace-related emission level 13

Workplace-related emission level 12

Wrench 19

Y

Year of production 16

Page 63

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Planetary Ball Mill Type Emax is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. –Ing. Frank Janetta

Manager Development

Ret sch G mbH Retsch-Allee 1-5 427 81 H aan Germa ny www.retsch .com

PLANETARY BALL MILL

Emax

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN 61236 Electrical equipment for measurement, control and laboratory use in

conjunction with EN 55011 and EN 61000

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 64

Page 65

Page 66

Page 67

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...