Page 1

Operating Manual

DM400 Disc Mill

Original

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 18.07.2014 0001

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Page 3

Page 4

Table of contents

4

1 Basic construction .................................................................................................................................. 7

2 Safety instructions and use ................................................................................................................... 9

2.1 Requirements for the user ................................................................................................................ 9

2.2 Intended use ................................................................................................................................... 10

2.2.1 Operating principle ..................................................................................................................... 10

2.3 Duties of the operating company.................................................................................................... 10

2.4 Hazard warnings and symbols used .............................................................................................. 11

2.5 Device safety instructions ............................................................................................................... 15

2.6 Safety equipment ........................................................................................................................... 17

2.7 Danger areas .................................................................................................................................. 18

2.8 Electrical safety .............................................................................................................................. 18

2.8.1 General information.................................................................................................................... 18

2.8.2 Protection against restarting ...................................................................................................... 19

3 Technical data ....................................................................................................................................... 21

3.1 Dimensions ..................................................................................................................................... 21

3.2 Weight ............................................................................................................................................ 21

3.3 Operating noise .............................................................................................................................. 21

3.4 Voltage, power consumption, power input ..................................................................................... 21

3.5 Fuse ................................................................................................................................................ 21

3.6 Material ........................................................................................................................................... 22

3.7 Final fineness ................................................................................................................................. 22

4 Installation ............................................................................................................................................. 23

4.1 Transport ........................................................................................................................................ 23

4.2 Unpacking ....................................................................................................................................... 23

4.3 Positioning ...................................................................................................................................... 24

4.4 Ambient conditions ......................................................................................................................... 25

4.5 Electrical connection ...................................................................................................................... 26

4.5.1 Adjusting the disc mill to the mains network .............................................................................. 26

4.6 Putting into service ......................................................................................................................... 26

4.7 Switching on for the first time / function test ................................................................................... 27

4.7.1 Switching on ............................................................................................................................... 27

4.7.2 Switching off ............................................................................................................................... 27

5 Working with the disc mill .................................................................................................................... 29

5.1 Display and control panel ............................................................................................................... 30

5.2 Menu navigation ............................................................................................................................. 30

5.3 Specifying the zero point ................................................................................................................ 31

5.4 Adjusting the gap width .................................................................................................................. 32

5.5 Reverse operation .......................................................................................................................... 33

5.6 Adjusting the grinding time ............................................................................................................. 34

5.7 Changing the language .................................................................................................................. 35

5.8 Grinding with zirconium oxide grinding discs ................................................................................. 35

5.9 Material feed ................................................................................................................................... 36

5.10 Sample removal.............................................................................................................................. 38

5.11 Final fineness ................................................................................................................................. 38

6 Cleaning ................................................................................................................................................. 39

6.1 Extracting dust after grinding .......................................................................................................... 39

6.2 Grinding chamber ........................................................................................................................... 39

6.3 Housing .......................................................................................................................................... 40

6.4 Cleaning the hopper ....................................................................................................................... 40

Page 5

Table of Contents

5

7 Servicing ................................................................................................................................................. 41

7.1 Grinding discs ................................................................................................................................. 42

7.2 Replacing the grinding discs (5 + 6)................................................................................................ 42

7.3 Replacing the gear oil ..................................................................................................................... 49

7.3.1 Conducting the gear oil change .................................................................................................. 49

8 Repair ...................................................................................................................................................... 51

8.1 Checklist for troubleshooting ........................................................................................................... 52

9 Disposal .................................................................................................................................................. 54

10 EC Declaration of Conformity ............................................................................................................... 55

11 Index ........................................................................................................................................................ 57

Page 6

Table of contents

6

Page 7

Basic construction

7

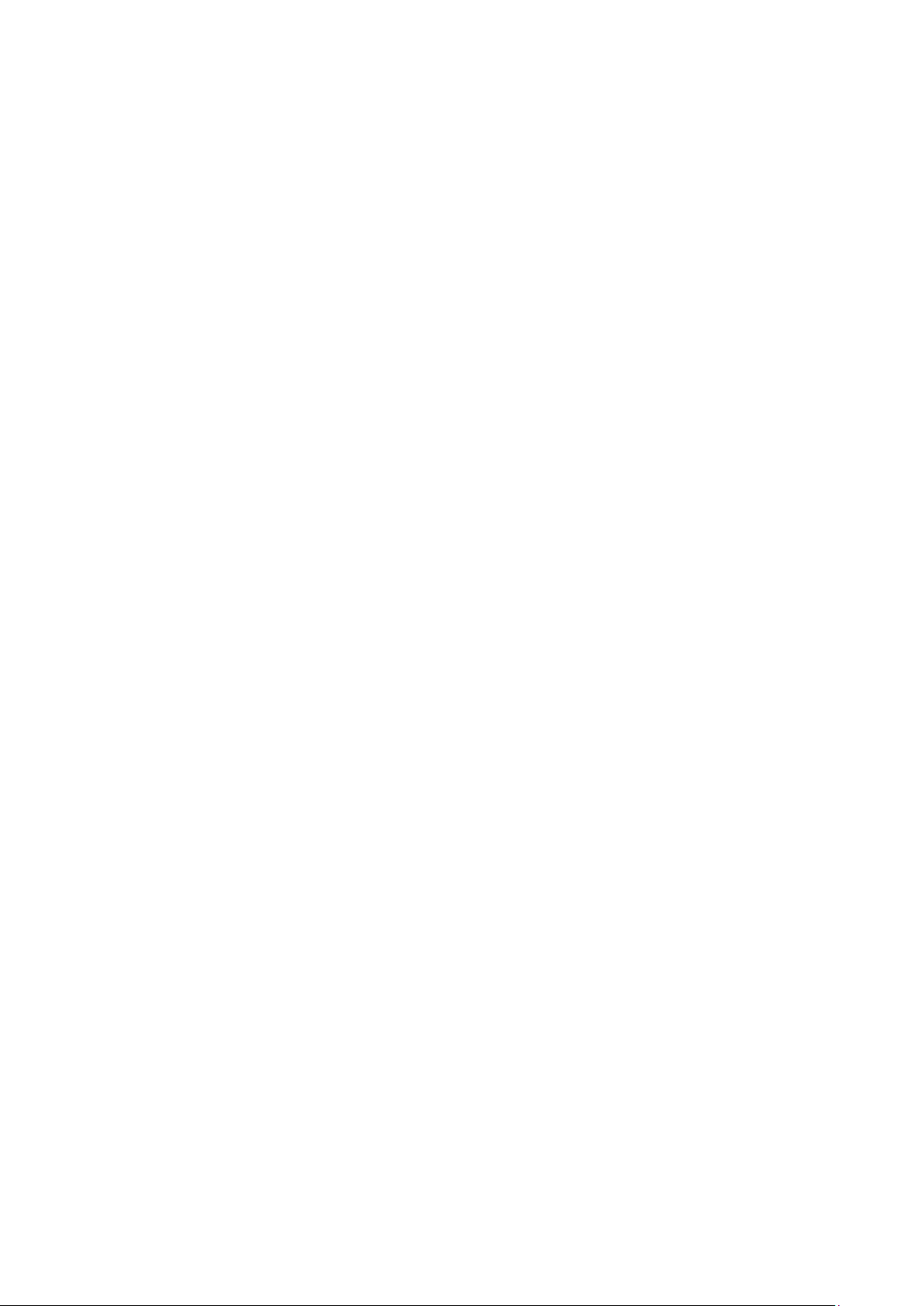

1 Basic construction

1

Display

2

Control panel

3

Main switch

4

Fill hopper

5

Fixed grinding disc

6

Moving grinding disc

7

Gap set screw

8

Grinding chamber closing mechanism

9

Locking bolts sample material container

10

Sample material container

11

Suction flange lid

12

Height adjustable support

13

Interlock switch

14

Housing cover

1

2

12

10

6

13

3

9 5 4

11 7 8

14

Page 8

Basic construction

8

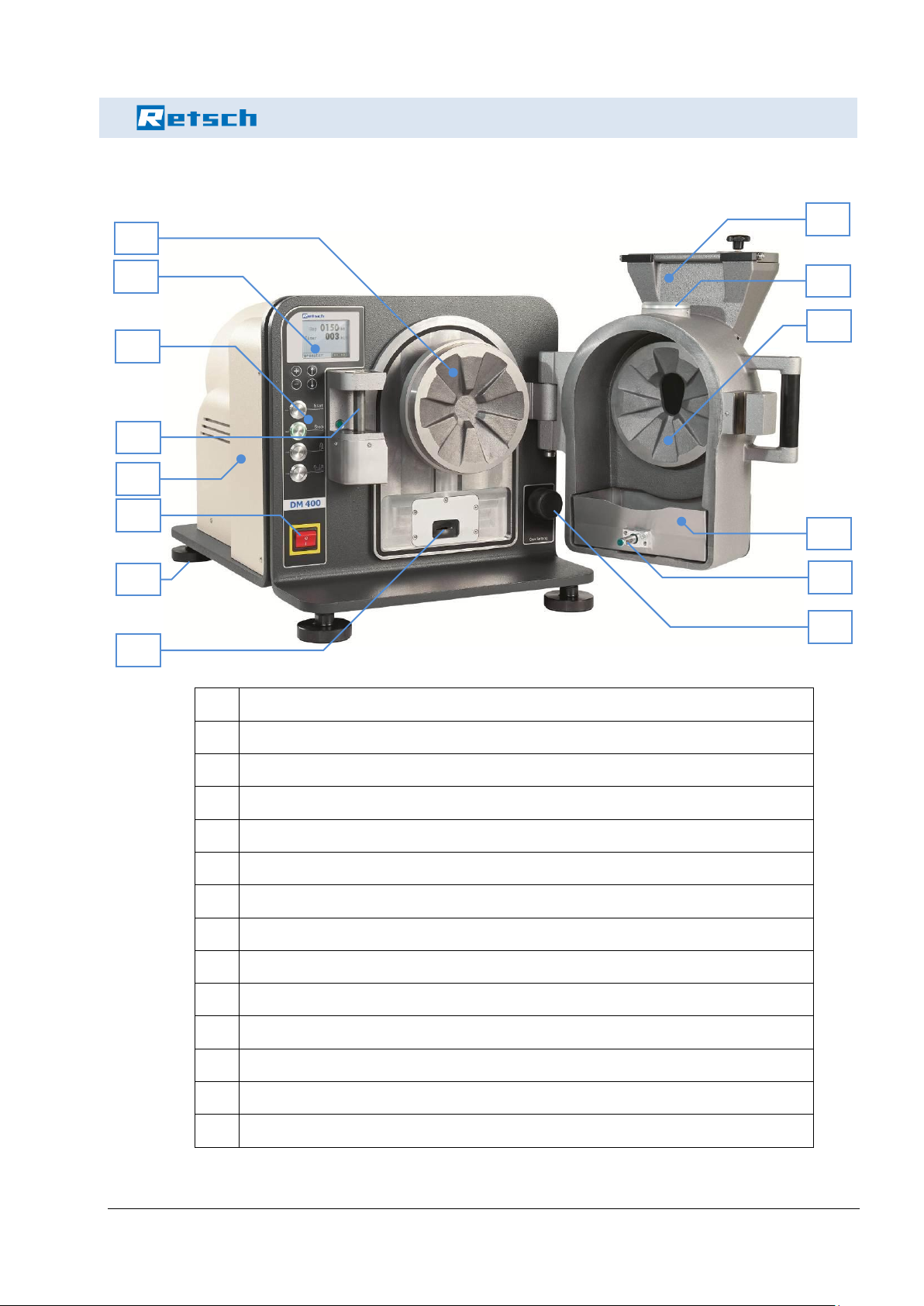

a

+ button (change parameters and gap width, menu navigation)

b

- button (change parameters and gap width, menu navigation)

c

Arrow up button (menu navigation)

d

Arrow down button (menu navigation)

e

Start button

f

Stop button

g

Button dust extraction (on/off)

h

Unlocking and locking the grinding chamber

i

Sensor grinding chamber

a b c d e f g h i

Page 9

Safety instructions and use

9

This Operating Manual is intended for persons commissioned with

the operation and monitoring of the DM400. The Operating Manual,

and in particular the safety instructions, should be heeded by all persons working on or with the equipment. Furthermore the regulations

and provisions on accident prevention applicable at the application

site must be observed. The Operating Manual must always be kept

where the DM400 is used.

Persons with health disorders or who are under the influence of medication, drugs, alcohol or extreme tiredness must not operate the device.

The DM400 may only be operated by authorised persons and serviced and repaired by trained specialists. Technically qualified personnel must conduct all maintenance, servicing and repair work!

Qualified personnel are people who have been authorised by persons

responsible for the safety of the system to execute the required activities and are able to recognise potential dangers and avoid them

based on their training, experience and instruction, as well as their

knowledge of relevant standards, regulations, accident prevention

regulations and operating conditions (definition of skilled personnel

according to IEC 364).

The instructions in this Manual should be followed in order to prevent

danger to the user.

Faults which can impair the safety of persons, the DM400 or other

material assets should be rectified immediately. The following instructions serve both personal safety of operating staff and the safety of

the described products as well as connected equipment: all servicing

and repair work may only be carried out by technically qualified personnel!

This Operating Manual is not a full technical description. It only describes information required for safe operation and maintenance of

serviceability.

Retsch has prepared and checked this Operating Manual very carefully. However no liability can be assumed regarding completeness and

accuracy.

Subject to technical amendments.

2 Safety instructions and use

2.1 Requirements for the user

Page 10

Safety instructions and use

10

2.2 Intended use

The DM400 is a disc mill for batch or continuous fine grinding of hard

brittle to medium hard solids from the areas of mining and metallurgy,

geology and mineralogy and the glass and ceramics industry.

The maximum feed size is 20 mm edge length; the achievable final

fineness level depending on the gap width set is approx. 12 mm (largest gap width) and 0.05 mm (smallest gap width).

The material throughput of the disc mill lies in the range of 20 to 150

kg/h. This depends on the setting of the outlet gap and the bulk

weight and grinding conduct of the sample.

The grinding of the material sample takes place in a grinding

chamber which is dustproof to the outside and in which two

coarsely toothed grinding discs operate against each other.

The moving grinding disc is driven by a powerful, slow running

gear motor.

The sample material is filled through a lockable hopper into the

centre of the upright grinding disc and, after being ground by

compression and shear stress, escapes through the gap between the two discs. The gap width determines the mean particle size of the sample material. The grinding gap can be set to

an accuracy of 0.05 mm using the plus/minus buttons on the

control panel. The gap width can be read off the display (1).

When grinding batches, the sample material is collected in a

sample material container placed in the device (volume: 2l).

The closed design prevents dust escaping. A dust extraction

device may additionally be connected. To clean, the front housing is opened sideways - the grinding chamber is then freely

accessible.

This Manual should be read and understood before using the DM400.

Use of the DM400 demands expert knowledge and should be limited

to commercial users.

Operating personnel must be familiar with the contents of the Operating Manual. It is therefore very important for this Operating Manual to

be actually handed to these persons. It must be ensured that the

Operating Manual always remains with the device.

The DM400 may be used exclusively within the possible uses set out

in this Manual and within the specified regulations in this Manual. In

the event of contravention or incorrect use, the customer assumes full

2.2.1 Operating principle

2.3 Duties of the operating company

Page 11

Safety instructions and use

11

liability for the functionality of the DM400 or for damage arising from

an infringement of this duty.

Through use of the DM400 the customer agrees and recognises that

defects, faults or errors cannot be entirely ruled out. In order to avoid

the risk of personal injury or damage to property arising from this or

otherwise or of other indirect or direct damage, customers must take

adequate and comprehensive safety measures when working with the

device.

It is not possible for Retsch GmbH to monitor compliance with this

Manual or the conditions and methods used in the installation, operation, use and servicing of the DM400. Damage to property leading to

danger to persons may result from incorrect installation. We therefore

assume no responsibility and liability at all for loss, damage or costs

arising from or in any way associated with faulty installation, incorrect

operation or from incorrect use and servicing.

The applicable accident prevention regulations must be complied with.

Generally accepted statutory and other binding regulations on envi-

ronmental protection must be observed.

Safety instructions

Safety instructions are indicated in this Manual by symbols. The safety instructions are introduced by signal words which express the degree of danger.

DANGER!

This combination of symbol and signal word indicates a

direct hazardous situation leading to death or serious

injuries if it is not avoided.

WARNING!

This combination of symbol and signal word indicates a

potentially hazardous situation which can lead to death

or serious injuries if it is not avoided.

2.4 Hazard warnings and symbols used

Page 12

Safety instructions and use

12

CAUTION!

This combination of symbol and signal word indicates a

potentially hazardous situation which can lead to minor

or slight injuries if it is not avoided.

NOTICE!

This combination of symbol and signal word indicates a

potentially hazardous situation which can lead to

damage to property if it is not avoided.

NOTICE!

This combination of symbol and signal word indicates a

potentially hazardous situation which can lead to

damage to the environment if it is not avoided.

Page 13

Safety instructions and use

13

Special safety instructions

The following symbols are used in safety instructions to alert to specific hazards:

DANGER!

This combination of symbol and signal word indicates a

direct hazardous situation through electric current. If a

sign with this symbol is not heeded, serious or fatal

injuries will result.

DANGER!

This combination of symbol and signal word designates

content and instructions for intended use of the machine

in potentially explosive areas. If a sign with this symbol

is not heeded, serious or fatal injuries will result.

DANGER!

This combination of symbol and signal word designates

content and instructions for intended use of the machine

with flammable materials. If a sign with this symbol is

not heeded, serious or fatal injuries will result.

DANGER!

This combination of symbol and signal word designates

content and instructions for intended use of the machine

with potentially explosive substances. If a sign with this

symbol is not heeded, serious or fatal injuries will result.

WARNING!

This combination of symbol and signal word indicates a

direct hazardous situation due to moving parts. If a sign

with this symbol is not heeded, injuries to hands may

result.

Page 14

Safety instructions and use

14

WARNING!

This combination of symbol and signal word indicates a

direct hazardous situation due to hot surfaces. If a sign

with this symbol is not heeded, skin contact with hot

surfaces may cause serious burns to skin.

Safety instructions in

operating instructions

Safety instructions may refer to a specific, individual operating instruction. Such safety instructions are embedded in this operating instruction in order not to interrupt the flow of reading when performing the

action concerned. The signal words described above are used.

Example:

1.

Loosen screw.

2.

CAUTION!

Risk of pinching on the lid.

Close the lid carefully.

3.

Tighten the screw.

Tips and recommendations

This symbol highlights useful tips and recommendations

as well as information for efficient and fault-free

operation.

Other labelling

The following labels are used to emphasise operating instructions,

results, lists, references and other elements in this Manual:

Labelling

Explanation

1., 2., 3. ...

Step-by-step operating instructions

Results of operating steps

Lists without specified order

[Button]

Control elements (e.g. button, switch), indicators (e.g. signalling lamps)

"Display"

Screen elements (e.g. buttons, assignment

of function buttons)

Page 15

Safety instructions and use

15

2.5 Device safety instructions

Please note!

Only use original accessories and original spare parts. Failure to

do so can place the protection of the machine in doubt.

Safe conduct must be strictly followed during all work.

The current applicable national and international accident

prevention regulations must be complied with.

Page 16

Safety instructions and use

16

CAUTION!

Wear hearing protection!

Hearing protection should be worn when a noise level of

85dB (A) is reached or exceeded in order to prevent

damage to hearing.

WARNING!

The maximum workplace concentrations (threshold limit

values - TLV) in valid safety regulations must be

observed, and ventilation must be provided where

necessary or the machine operated under an extractor

hood.

DANGER!

Risk of explosion!

- When grinding oxidable substances (e.g. metals or

coal) there is a risk of spontaneous ignition (dust

explosion) if the fine fraction exceeds a certain

percentage. For this reason special safety measures

must be taken when grinding such substances and

the work must be supervised by a specialist.

- The device is not designed for use in potentially

explosive areas and is not suitable for grinding

explosive materials.

Do not remove signs.

NOTICE!

Replace damaged or illegible signs without delay.

Unauthorised modifications to the device lead to loss of the

conformity to European directives declared by Retsch and to loss

of the warranty claim.

Only use the DM400 in a technically perfect state and as intended,

with an awareness of safety and dangers as specified in the

Operating Manual. In particular have faults which might impair

safety rectified immediately!

If you have any questions or problems after reading the Operating

Manual, please contact our technical staff.

Page 17

Safety instructions and use

17

2.6 Safety equipment

Safety equipment must be used as intended and must

not be rendered unworkable or removed.

All safety equipment must be checked regularly for

completeness and function.

The disc mill has a comprehensive safety system:

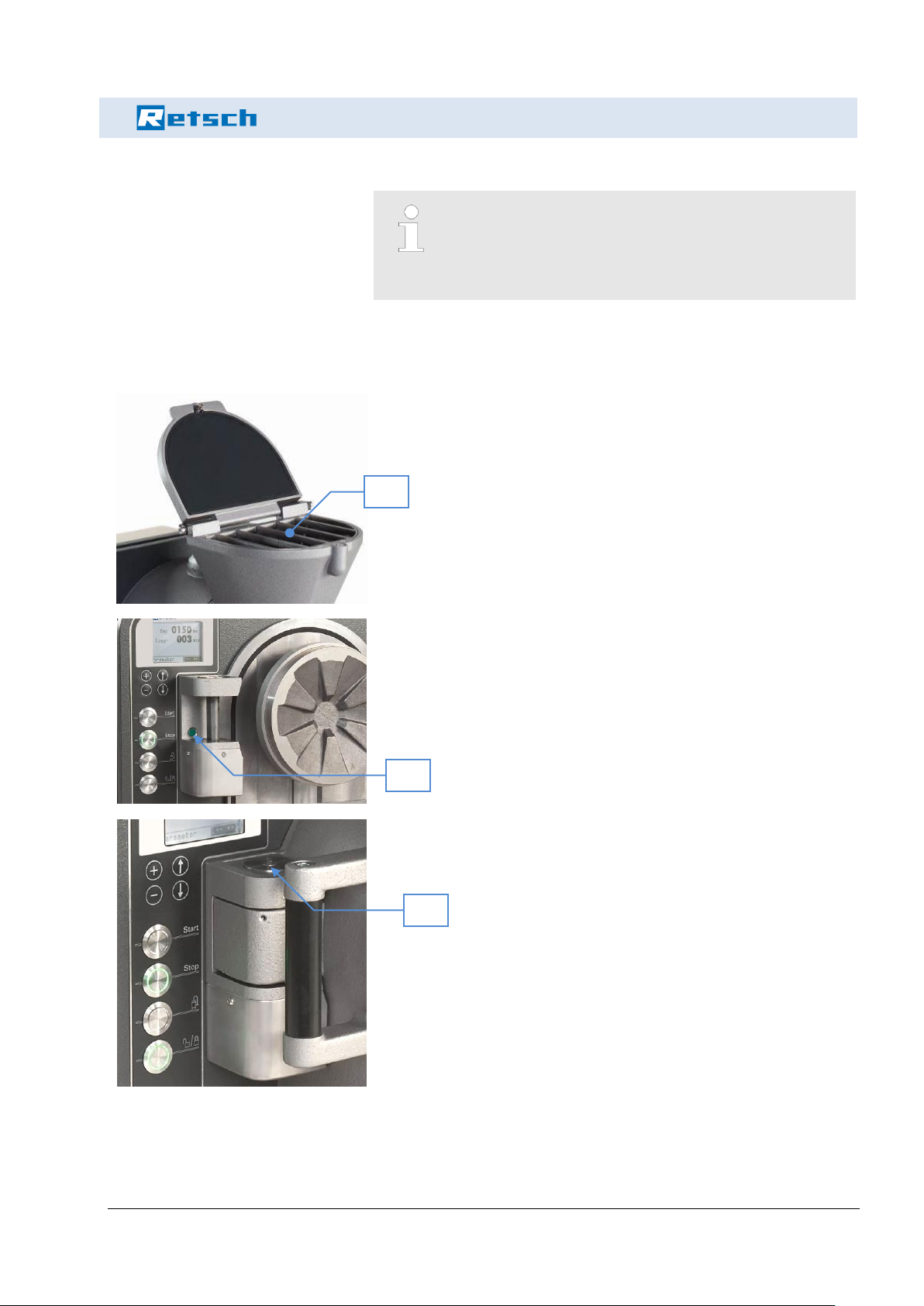

1.

A grille (4G) prevents contact with the fill hopper (4).

2.

A sensor (i) monitors the closing of the grinding chamber before

operation and prevents the disc mill starting up after it has been

opened.

3.

A second safety device checks whether the grinding chamber has

been closed by means of the motorised closing mechanism (8).

4G i 8

Page 18

Safety instructions and use

18

4.

The interlock switch (13) pulls in the sample material container

after the start of grinding and locks it using the locking bolt (9) on

the container. During operation the interlock switch monitors

whether the device is closed correctly. It likewise prevents the

disc mill starting up after it has been opened.

The disc mill does not start if the grinding chamber

is open or the sample material container is missing.

CAUTION!

- Risk of crushing on hopper cover

- Risk of crushing when closing the grinding chamber

- Risk of crushing when cover of dust extraction is

removed during operation!

The disc mill is switched on and off with a main switch (3).

By pressing the switch to I (On):

Disc mill is activated and can be started using the start button (e)

as long as the grinding chamber is closed and the sample material

container is inserted!

By pressing the switch to O (off) during grinding:

The disc mill comes to a halt and is completely deactivated!

Grinding chamber and sample material container remain locked

when switched “off” and cannot be opened.

13

2.7 Danger areas

2.8 Electrical safety

2.8.1 General information

Page 19

Safety instructions and use

19

2.8.2 Protection against restarting

The device switches off in the event of a power failure during operation.

The mill comes to a halt within seconds!

Sample material container can only be opened with the emergency

release (k) inside the device! To do this the housing cover (14)

must be removed as follows (also see chapter “Positioning” )

DANGER!

Pull the plug out and secure the device to prevent

accidental restarting!

Open the housing cover (14) by releasing the quick acting

screws placed on either side.

After releasing the quick acting screws, pull the housing cover

(14) back by a few centimetres. Then lift the housing cover up

and out.

The emergency release (k) inside the device is then visible.

To release the sample material container, pull the emergency

release (k) backwards until the locking bolt (9) on the sample

material container (10) is released.

Considerable force is required to release it.

The emergency release can then be engaged again and the

housing cover closed. The sample material container is pulled in

when grinding next starts.

NOTICE!

Grinding chamber cannot be opened when the grinding

chamber interlock is closed or when switched off.

The disc mill does not start up by itself when supply voltage returns.

The mill has protection against restarting.

The motor is started again by pressing the start button (e), and the

mill begins operation.

Page 20

Safety instructions and use

20

Page 21

Technical data

21

3 Technical data

52 x 105 x 63 cm (width x depth x height)

228 kg (net) without griding discs

246 kg with tungsten carbide grinding discs

Workplace related emissions value in accordance with DIN EN ISO

3746:2005 LPA .

= 68.9 dB (A) The measurement was conducted with sand as sample

material, particle size 0.5 – 2 mm.

Voltage

400V / 3~ 50Hz

230V / 3~ 60Hz

Power consumption

3.2 A

5.6 A

Power input

1830 W

Under high load (significantly

lower in normal use)

1800 W

Under high load (significantly

lower in normal use)

The device may only be operated on a three phase supply network!

Transient electrical surges according to surge category II permissible

(also see chapter “Electrical connection”)

A thermal circuit breaker (motor circuit breaker) is integrated in the

main switch (3) and triggers on overheating; it is operational again

after a brief cooling phase.

3.1 Dimensions

3.2 Weight

3.3 Operating noise

3.4 Voltage, power consumption, power input

3.5 Fuse

Page 22

Technical data

22

3.6 Material

Maximum feed size 20mm (depending on the material)

Minimum feed quantity 20 - 30ml

Batch grinding with collecting container (max. 2l)

Maximum throughput 150kg/h with continuous grinding

The final fineness is between 0.05 and 12mm, depending on the sample material.

3.7 Final fineness

Page 23

Installation

23

4 Installation

The device is supplied on a transport pallet with wooden cover. We

recommend transporting the packaged device with a pallet truck or

forklift.

DANGER!

Do not walk under the transport pallet during transport.

WARNING!

Incorrect lifting can lead to injury or damage to property.

The machine should only be lifted using suitable

equipment and by appropriately qualified personnel!

Damage caused by incorrect transport does not justify any replacement or warranty claims.

Pull out the nails attaching the cover to the transport pallet. The

cover is the wooden box pulled over the transport pallet.

Lift the cover from the transport pallet.

CAUTION!

Risk of crushing!

Always lift with 2 people.

Compare the contents of delivery with your order.

4.1 Transport

4.2 Unpacking

Page 24

Installation

24

4.3 Positioning

DANGER!

Do not walk under the transport pallet during transport.

To position the disc mill you will need a crane or other suitable means

of transport as well as 2 carrying straps (not included with delivery)

with a minimum length of 40cm and loadbearing capacity of 500 kg.

CAUTION!

Weight of the disc mill is approx. 260 kg with grinding

discs (WC) and transport pallet!

NOTICE!

The disc mill must be placed on an even, stable surface.

It can be screwed to this or to a base plate.

1.

The disc mill is screwed to the transport pallet from underneath

using 3 screws. Loosen screws using a spanner wrench (17

mm).

2.

Open the housing cover (14) by unscrewing the quick acting

screws on either side.

14S

Page 25

Installation

25

3.

After unscrewing the quick acting screws, pull the housing cover

(14) back by a few centimetres.

Then lift the housing cover up and out.

4.

Two carrying lugs to attach the carrying straps are then visible.

5.

Attach the carrying straps to a crane or other auxiliary equipment.

6.

Now attach the carrying straps to the 2 carrying lugs provided.

7.

With the help of the crane, position the disc mill in the desired

place. Take care while positioning that the device does not swing

when hanging on the crane.

8.

Remove the carrying straps!

9.

Place the housing cover (14) back on and screw tight.

WARNING!

Mains voltage!

- The device may only be used inside.

- The surrounding air must not contain any conductive

dust.

4.4 Ambient conditions

Page 26

Installation

26

- Maximum relative humidity 80% for temperatures up

to 31°C, decreasing in a linear fashion to 50% relative

humidity at 40°C.

The room temperature must be between 5 and 40°C.

Height up to 2000m above sea level

Degree of pollution 2 in accordance with IEC 664.

Before connection, compare the voltage and current values on the

type plate with the values on the intended mains.

CAUTION!

Electrical as well as mechanical components may be

damaged by failure to heed to values on the type plate.

The DM400 is delivered with supply voltage adapted to suit your country.

The disc mill is supplied with mounted grinding discs. Before grinding

for the first time, check the desired gap width (see chapter “Adjusting

the gap width ”) The device is operational once you have positioned

the disc mill as described under chapter “Positioning“ and have connected the plug to the mains socket.

CAUTION!

- Grinding discs must not touch each other.

- The device may only be operated with mounted and

secured grinding discs.

- Smallest gap width 0.05mm

4.5 Electrical connection

4.5.1 Adjusting the disc mill to the mains network

4.6 Putting into service

Page 27

Installation

27

4.7 Switching on for the first time / function test

Only switch the device on when all work described as from the chapter “Installation” has been carried out!

Set the main switch (3) to I! The display (1) switches on and the

STOP button (f) is lit up in red! If the grinding chamber is locked, the

release and locking button (h) is lit up in green.

When the grinding chamber has been electrically closed and the sample material container is inserted, start using the start button (e). The

disc mill starts up. Then actuate the stop button (f), and the machine

comes to a halt. It is then possible to continue with the chapter “work-

ing with the disc mill”.

Set the main switch (3) to 0. The device switches off completely.

4.7.1 Switching on

4.7.1.1 Function test

4.7.2 Switching off

Page 28

Installation

28

Page 29

Working with the disc mill

29

WARNING!

No warranty or complaint will be accepted in the case of

damage to the device when grinding tools are used

which are not original accessories of the device.

WARNING!

Before starting the machine, ensure that the grinding

discs are correctly mounted and that there are no loose

parts inside the device. If this is not observed, no

warranty or complaint will be accepted for damage to the

device or personal injury that result.

CAUTION!

- Grinding discs must not touch each other.

- The device may only be operated with mounted and

secured grinding discs.

- Smallest gap width 0.05mm

CAUTION!

Ensure that the suction flange lid or adapter to use the

dust extractor are fitted securely. Never reach into the

opening of the suction flange during grinding

NOTICE!

Do not leave the disc mill to run unsupervised.

NOTICE!

Grinding discs wear during grinding. For this reason the

grinding gap must be checked and regulated if

necessary according to use and the degree of wear.

This is carried out as described in chapter 5.3

“Specifying the zero point” and in chapter 5.4 “Adjusting

the gap width”.

5 Working with the disc mill

Page 30

Working with the disc mill

30

5.1 Display and control panel

If the grinding chamber is open, the button (h) to lock the grinding

chamber is not lit up!

During the motorised closing of the grinding chamber, the button

(h) flashes green until the grinding chamber is closed. It is then lit

up in green.

When starting up, the start button (e) flashes green. When the

device has started up, it lights up in green.

After stopping the device, the stop button (f) flashes red until the

disc comes to a standstill. When it is at a standstill it lights up in

red.

When a dust extractor is connected, the button (g) lights up in

green after its activation.

The +/- buttons (a, b) are used to adjust values and for menu

changes.

The arrow buttons (c, d) are used to select menu items and to

make changes in the menu bar.

Menu selection

1.

The Parameter menu is used for the following:

‒ To adjust the gap width between the grinding discs → Gap

‒ To adjust the grinding time in minutes → Time

2.

In the Check/Setup menu you can:

‒ Define the “zero point” → no gap between the grinding discs

‒ Change the direction of rotation of the moving grinding disc (6)

→ Reverse

‒ Set the language → Language

5.2 Menu navigation

Page 31

Working with the disc mill

31

Menu change

1.

To move from the "Parameter" menu to the "Check/Setup" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Check/Setup

menu!

2.

The menu change from the Check/Setup menu to the Parameter

menu takes place in the same way.

Selecting menu items

1.

The menu items within menus are selected using the arrow buttons (c, d).

The zero point is the gap width at which the fixed and the

moving grinding disc rub slightly against each other so

that no gap is present. All other gap widths are actuated

from this zero point.

The zero point must be reset after every time the

grinding discs are changed. Grinding discs can vary in

thickness according to the degree of wear.

1.

To move from the "Parameter" menu to the "Check/Setup" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Check/Setup

menu!

2.

Close the grinding chamber and remove the sample material

container.

5.3 Specifying the zero point

Page 32

Working with the disc mill

32

3.

To change the grinding gap to adjust the zero point, the zero

point line must be selected in the Check / Setup menu using the

arrow buttons (c, d).

4.

Remove the suction flange lid (11). Check both grinding discs

while they are moving together through this opening. It should

only be possible to see a minimal light gap between the two

discs.

During the process of setting the zero point, no gap

information is shown on the display. You can hear a

mechanical noise of the servomotor and see how

the moving grinding disc (6) is aligned through the

suction flange (11)!

5.

CAUTION!

Risk of crushing between the grinding discs!

To check while adjusting the zero point, rotate the moving grinding disc by hand through the opening of the sample material container. While rotating, reduce the gap using the – button (b) until

slight rubbing of the two discs can be felt and heard!

6.

As soon as the smallest gap width has been set and a minimum

rubbing of the discs is registered, this may be defined as zero

point. Only when the zero point is highlighted in black can the

zero point be fixed by simultaneously pressing the stop (f) and +

(a) buttons.

7.

Reinsert the sample material container.

The adjustment of the gap width takes place automatically using the

Parameter menu item. The zero point must be set first (see chapter

“Specifying the zero point) to prevent damage to the grinding discs.

The gap width is adjusted as follows:

5.4 Adjusting the gap width

Page 33

Working with the disc mill

33

1.

To move from the "Check/Setup" menu to the "Parameter" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Parameter

menu

2.

Close the grinding chamber!

3.

In the Parameter menu, press the c button (arrow up) until the

line to enter the gap width is highlighted.

4.

Using the +/- buttons on the control panel, increase (+) or decrease (-) the gap width!

5.

The gap width between the discs adjusts automatically if:

☞the menu item is exited or

☞the grinding process is started using the start button (e).

NOTICE!

Grinding discs wear during grinding. For this reason the

gap width must be checked and possibly adjusted from

time to time. This takes place as described in the

chapter “Specifying the zero point and the chapter

“Adjusting the gap width ”.

CAUTION!

Risk of crushing between the grinding discs!

Reverse operation can be selected in the case of one-sided wear on

grinding discs.

5.5 Reverse operation

Page 34

Working with the disc mill

34

1.

To move from the "Parameter" menu to the "Check/Setup" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Check/Setup

menu!

2.

Select reverse using the arrow buttons (c, d), and activate (on) or

deactivate (off) reverse operation with + (c) or - (d) button.

NOTICE!

Grinding discs are subject to natural wear after

longer periods of use and must be replaced where

necessary. If you ascertain that the grinding discs

are worn on one side, they need not be replaced

immediately. Reverse the direction of rotation of the

drive motor using the reverse setting. The crushing

edges of the grinding discs that had been on the

back are then in use. At this point at the latest you

should order spare grinding discs (see chapter

“Replacing the grinding discs (5 + 6)”)

1.

To move from the "Check/Setup" menu to the "Parameter" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Parameter

menu!

5.6 Adjusting the grinding time

Page 35

Working with the disc mill

35

2.

Select the Time menu item using the arrow buttons (c, d) and

then adjust using the + / - button. If no grinding duration has

been specified, the grinding can be started and ended manually

using the start - (e) and stop- (f) button. The maximum timecontrolled grinding duration that can be set is 60 min!

1.

To move from the "Parameter" menu to the "Check/Setup" menu,

actuate the arrow buttons (c, d) until the - and + signs which are

visible on the bottom right of the display are highlighted in black!

Then use the buttons + (a) or - (b) to move to the Check/Setup

menu!

2.

Select the language line using the arrow buttons (c, d). The language (German or English) can be selected using the +/- button

and then set by exiting the menu item.

A number of points must be observed when grinding using zirconium

oxide grinding discs:

1.

Precise adjustment of the zero gap. Under no circumstances

may the discs touch each other during grinding. The localised

heating leads directly to stress cracks on the perimeter. These

cracks occur in a very short time and are easily identified.

2.

Localised heating can also occur if you add so much material that

high pressure grinding takes place permanently in the grinding

gap on the outer edge of the grinding discs. The leads to stress

cracks on the perimeter of the grinding disc or even to it breaking.

5.7 Changing the language

5.8 Grinding with zirconium oxide grinding discs

Page 36

Working with the disc mill

36

3.

The hardness of the zirconium oxide grinding disc is MOHS 8.5

(HV1350). No sample material that is harder may be ground

because this causes the outer edges of the grinding disc to chip.

Chipping of the edges can also occur with a sample material with

MOHS hardness of 6 or 7.

4.

Proceed very carefully when grinding using zirconium oxide

grinding discs. You should pre-grind your sample material with a

large gap width in the first run before achieving the desired fineness with the smallest gap in a second run. You should proceed

in a similar way if you have no information about the grindability

of your material. The grinding discs have a progressive chipping

geometry. Coarse grinding takes place in the inner area, and fine

grinding in the outer area of the grinding disc. The strain is

greatest in the fine grinding area. The chipping described may

occur here with very hard sample material.

5.

The adhesive used to adhere the securing bolts in the grinding

disc has a temperature resistance up to 80°C. The grinding discs

should therefore not be heated above 80°C in order to guarantee

the secure fit in the support.

6.

Please observe the chapter “Replacing the grinding discs (5 + 6)”

in the Operating Manual when assembling and removing the

grinding discs!

NOTICE!

Retsch GmbH guarantees that only zirconium oxide

grinding discs of the highest quality leave our company.

Used grinding discs which are cracked, chipped or

completely broken on the perimeter, cannot be accepted

as complaint.

DANGER

Risk of explosion

There is a risk of spontaneous ignition (dust

explosion) when grinding substances which oxidise

(e.g. metals or coal) if the fine fraction exceeds a set

percentage. Special safety precautions must

therefore be taken when grinding such materials and

the work must be supervised by a specialist.

The device does not have an ex-protected design

and is not suitable for grinding explosive materials.

5.9 Material feed

Page 37

Working with the disc mill

37

Before switching the device on, care must be taken that

the grinding chamber is locked and the sample material

container is placed straight in the insert and is not

twisted!

CAUTION!

Switch the device on before filling material in the hopper.

1.

The cover of the hopper is secured by a quarter turn quick release fastener. To open the lid, turn the quick release fastener a

quarter turn in an anticlockwise direction!

2.

Fill the sample in the hopper

3.

Add only as much material as will allow the hopper cover to be

closed!

4.

To close the cover you must press the pins on the quick release

fastener into the grooves on the hopper and lock again with a

quarter turn in a clockwise direction!

5.

Monitor the grinding process (grinding noise) and determine the

optimum feed quantity! Repeat this with each new material.

6.

Only add more material once the grinding noise has reduced!

7.

The maximum feed quantity depends on the grindability of the

material and the collecting volume of the sample material container.

8.

Place large lumps of material (max. 20mm edge length) individually in the hopper, close the cover and secure!

Page 38

Working with the disc mill

38

5.10 Sample removal

NOTICE!

The grinding disc support and the housing are made

from ductile cast iron. This cast steel is not rustproof. If

you grind slightly damp sample material, after grinding

you must dry the back of the grinding disc, the inside of

the grinding disc support and all parts of the housing

which come into contact with the sample. If you do not

do so, corrosion can be expected to occur.

Depending on the volume of the ground material, care

must be taken when removing the sample material

container (10) to remove it with both hands. Risk of tipping

over!

The achievable final fineness depends on the property of the sample

and the selected gap width (approx. 0.05 mm to approx. 12 mm).

Only one dimension of the individual particles in the fine material is

determined by the gap width, e.g. the material crushed in platelet form

in the fine product may well contain larger dimensions in an expansion

direction. Normally, however, after a second run with such materials,

the proportion of the sample with larger dimensions in this expansion

direction will have decreased significantly.

5.11 Final fineness

Page 39

Cleaning

39

6 Cleaning

DANGER!

Mains voltage!

- Before starting cleaning work, unplug the device and

protect it from restarting accidentally!

- Do not let liquid run into the device.

- Indicate cleaning work using a warning sign.

- Put safety equipment back into operation after

cleaning work.

NOTICE!

The grinding disc support and the housing are made

from ductile cast iron. This cast steel is not rustproof. If

you grind slightly damp sample material, after grinding

you must dry the back of the grinding disc, the inside of

the grinding disc support and all parts of the housing

which come into contact with the sample. If you do not

do so, corrosion can be expected to occur.

After completion of the grinding process, you can vacuum the dust

created during grinding.

NOTICE!

Do not switch on the dust extraction during grinding as

sample material may otherwise also be extracted.

To clean the grinding chamber, open the chamber. Clean the chamber using a brush and vacuum cleaner. Where necessary you can

also use liquid detergents (alcohol, benzene). However pay attention

to any rust if you use aqueous liquids.

It is important to allow the disc mill to dry completely.

6.1 Extracting dust after grinding

6.2 Grinding chamber

Page 40

Cleaning

40

WARNING!

Risk of poisoning and fire!

When using detergents which are flammable or harmful

to health, it is essential to heed the valid safety

regulations (TLV) and where applicable to clean the disc

mill in a ventilated safety zone.

The machine can be cleaned outside when switched off using a soft

damp cloth. A solution of water and mild detergent may be used here.

No not use a solvent for cleaning.

In special cases the hopper may also be removed and cleaned as

described in the chapter “Replacing the grinding discs (5 + 6)”. When

grinding with the same sample, it is sufficient to clean the hopper of

dirt using a brush and dust extraction. For more intensive cleaning,

the protective grille can be removed by unscrewing 4 M3 countersunk

screws. Clean the hopper with the help of a damp cloth!

CAUTION!

Mount the grille again after cleaning!

Never operate the disc mill without hopper or hopper

grille!

6.3 Housing

6.4 Cleaning the hopper

Page 41

Servicing

41

DANGER!

Mains voltage

- Before starting servicing work, unplug the device and

protect it from restarting accidentally!

- Indicate servicing work using a warning sign.

- Only have servicing carried out by skilled personnel.

- Put safety equipment back into operation after

servicing and repair work.

- We recommend keeping a safety logbook into which

all work (servicing, repairs etc.) to the device are

entered.

- The most important element of servicing is regular

cleaning:

- Cleaning of the entire device must observe the

regulations of the employer’s liability insurance

associations (BGV A3) – in particular when the device

is positioned in a dusty environment or dusty sample

material is processed.

7 Servicing

Page 42

Servicing

42

Function part

Task

Test

Service interval

Grinding chamber sensor

Start inhibitor

Open grinding chamber; start; error message

Always before use

Grinding chamber safety interlock

Start inhibitor

Do not close grinding

chamber electrically;

start; error message

Always before use

Grinding container

protective equipment

Start inhibitor

Sample material container not inserted;

start; error message

Always before use

Grinding disc gap width

Crush function

Check distance

Always before use

The grinding discs wear after a certain period of time according to

sample material. Check the surfaces at specific intervals. Refer to

the information in the chapter “Reverse operation” and the chapter

below “Replacing the grinding discs (5 + 6)” to change the direction of

rotation or to replace the discs.

CAUTION!

The device must be connected to the mains to open the

grinding chamber and to adjust the gap width.

7.1 Grinding discs

7.2 Replacing the grinding discs (5 + 6)

Page 43

Servicing

43

CAUTION!

- Risk of crushing when changing the grinding discs.

- When changing grinding discs, secure them to

prevent them falling down.

CAUTION!

Before inserting the new discs, clean the support and the

back of the discs thoroughly. This is in particular very

important when using the ZrO2 discs and also with

TC+CO discs, so that the discs are positioned without

tension and parallel to each other.

It is also important when tightening the screws that the

tightening torque is not too great (see table) and is the

same for both screws.

Rubber washers (I) which are placed under the steel

washers are used with ZrO2 grinding discs. The nuts are

then tightened until the rubber washer slightly squeezes

out beneath the steel washer. This ensures a tightening

torque of approx. 20Nm.

NOTICE!

When replacing grinding discs, hold them securely and

do not allow them to fall. In the case of zirconium oxide

discs, this can lead to breakage or chipping.

Tools required:

M20 spanner wrench (r)

Motor shaft retainer (s)

30 mm ratchet wrench (t)

6

5

Page 44

Servicing

44

DANGER!

Ensure that the plug is removed from the socket again

after step 5!

1. Connect the device to the power supply!

2.

3.

Switch the main switch (3) to I (ON)!

To ensure that the hexagon screws at the back of

the movable grinding disc can be reached, the

grinding gap should be moved to the smallest width

(see chapter “Adjusting the gap width”)

4.

Then press the release button (h) on the control panel.

5.

The grinding chamber interlock (8) is released! Now open the

grinding chamber. The grinding discs are visible. The moving

grinding disc (6) is screwed at the back with 2x M20 hexagon

screws.

DANGER!

Pull the plug out and secure the device to prevent

accidental restarting!

6.

In order to be able to remove the moving grinding disc, the housing cover (14) must be removed (see chapter “Positioning”)

3

Page 45

Servicing

45

7.

8.

Then hold the motor shaft in place with the help of the motor shaft

retainer (s).

CAUTION!

Do not lock the motor shaft retainer (s) by resting on

the component!

NOTICE!

Hold grinding discs securely when changing them and

do not let them fall. This can lead to breaking or

chipping in the case of zirconium oxide discs.

CAUTION!

Risk of crushing when changing the grinding discs.

Ensure that the grinding disc does not fall on the

floor.

Using the spanner wrench (r), unscrew the hexagon screw on the

moving grinding disc and remove.

Page 46

Servicing

46

9.

The fill hopper (4) must be removed to dismantle the fixed grinding disc (5).

10.

To do this, manually close the grinding chamber and remove the

3 cylinder screws shown.

11.

Remove hopper from the front.

The mounting screws on the fixed grinding disc are then visible!

Page 47

Servicing

47

12.

DANGER!

Risk of crushing when changing the grinding discs.

Ensure that the grinding disc does not fall on the

floor.

Loosen the 2x M20 mounting screws using the ratchet wrench

and open the grinding chamber. Hold the grinding disc in place.

Remove the hexagon screws and remove the grinding disc.

13.

Now take the replacement moving grinding disc and assemble

with the hexagon screws (see Point 5 + 6 in reverse order)

14.

15.

16.

Install the housing cover

Connect the mains plug again.

Switch the device on!

17.

18.

19.

20.

Close the grinding chamber electrically

Adjust the grinding width to at least 12mm as described in the

chapter “Adjusting the gap width”!I

Unlock the grinding chamber and unplug the device!

DANGER!

Pull the plug out and secure the device to prevent

accidental restarting!

Insert the replacement fixed grinding disc and secure with the

hexagon screws. Manually close the grinding chamber and secure the disc using the ratchet wrench (t).

21.

Secure the hopper again in reverse order (see Points 10 and 11)

22.

Plug in and lock the grinding chamber again with the help of the

locking button (h).

Zero point must be specified again (see the chapter

“Specifying the zero point”)

Page 48

Servicing

48

Material

Max. guide

value tightening

torque (Nm)

Density

g/cm³

Abrasion

resistance

Use for sample

material

Hardened steel 1112% Cr

At least 50

7.9

Good

Hard, brittle samples

Manganese steel

12-13% Mn

At least 50

7.9 - 8

Good

Hard, brittle samples

Tungsten carbide

90.3% TC + 9.5%

CO

At least 50

14.8

Very good

Hard, abrasive samples

Zirconium oxide

92.5 ZrO2

Approx. 20

5.9

Extremely good

Medium hard, abrasive

samples for iron-free

grinding

Page 49

Servicing

49

The gearbox of the motor is filled with gear oil on delivery (ISO VG

220). A removable fill screw (o) is present in the top of the gearbox

housing to change the gear oil. To reach this the housing cover must

be removed.

This oil must be changed after approx. 5 years.

1.

Run the DM400 for approx. 15 minutes so that the gear oil inside

warms up and drains off better.

2.

3.

Switch the device off and unplug.

DANGER!

Pull the plug out and secure the device to prevent

accidental restarting!

Unplug the device and remove the cover (see chapter “Position-

ing”)

4.

Remove the motor securing screw (m) under the oil drain plug (n)

using an M10 Allen key!

The gearbox contains approx. 0.22 litres of ISO VG

220 gear box oil!

7.3 Replacing the gear oil

7.3.1 Conducting the gear oil change

Page 50

Servicing

50

5.

Hold a flat container underneath the oil drain plug (n) and unscrew this using an Allen Key No. 5 until oil flows out.

6.

Allow all of the oil to drain from the gearbox (approx. 0.22 l).

Watch the size of the collecting container and empty at intervals

where necessary, screwing the oil drain plug back in to do so.

7.

When the gear oil has been completely emptied, remove the oil

drain plug!

8.

Wipe any spilt gear oil with a paper towel and clean the contact

surface of the oil drain plug.

9.

Screw the oil drain plug with washer tight again.

10.

Assemble the motor securing screw again

11.

The fill screw (o) is then removed!

12.

Place a funnel in the hole and fill the gearbox with 0.22 litres of

gear oil ISO VG 220.

13.

Screw the fill screw (o) with clean sealing ring tight again.

14.

Assemble the housing cover.

Page 51

Repair

51

8 Repair

DANGER!

Mains voltage!

- Before starting repair work, unplug the device and

protect it from restarting accidentally!

- Indicate repair work using a warning sign.

- Have all repair work conducted by skilled personnel.

- Put safety equipment back into operation after

servicing and/or repair work.

Page 52

Repair

52

8.1 Checklist for troubleshooting

Malfunction

Possible cause

Rectification of fault

Mill does not start

No mains connection

Plug in

Mains switch is off

Switch the mains switch on

Grinding chamber safety switch open

Correctly connect the grinding chamber

Sample material container safety switch

open

Correctly insert the sample material container

Thermal circuit breaker has triggered

Wait until the device has cooled down

Fuse in the control circuit has triggered

Have the fuse replaced by qualified specialists.

Discs do not rotate

Gap width set to 0

Adjust the gap width! See chapter “Working with

the disc mill”

Sample is blocking the disc

Open grinding chamber and remove the sample

Mill stands still during operation

Overload! Switch off by motor circuit

breaker switch (main switch)

Allow the mill to cool. Remove sample material,

reduce feed of sample material

Grinding chamber overfilled. Too large /

hard sample material has become stuck

Open the grinding chamber and empty

Mill produces poor grinding

result

Grinding discs are worn

Change the direction of rotation or replace grinding discs. See chapter “Reverse operation” or

chapter “Replacing the grinding discs (5 + 6)“

Grinding discs are not installed in parallel

Remove grinding discs, clean the support and

reinsert (see chapter “Working with the disc mill” )

Sample materials escapes

Grinding chamber seals and sample

material container seals dirty or faulty

Clean or replace seals

Collecting container overfilled (max. 2l)

Remove container and clean the inside

Error message sample material

container

Sample material container not recognised

Slide container in centrally

Soiling of the container guide

Cleaning

No release of the sample

material container after STOP

Release mechanism on sample material

container faulty

Release by emergency actuation inside the

device; see chapter “Protection against restart-

ing”. Contact Retsch!

Automatic gap adjustment not

possible

Control panel is faulty

Replace the control panel

Gap adjustment is faulty

Contact Retsch

Temporary problem solution using the set screw

(7) on the bottom right-hand side at the front!

Adjust the precise gap width manually!

Discs have got stuck

With the help of the set screw (7), loosen! Realign the zero point!

Error message

Gap width, grinding chamber, sample

material container

Actuate the STOP button

Page 53

Repair

53

Page 54

Disposal

54

9 Disposal

Observe the respective statutory regulations when disposing of the device.

Information on disposal of electrical and electronic devices in the European Community:

The disposal of electrical equipment within the European Community is

specified by national regulations based on EU Directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

Accordingly all equipment supplied after 13.08.2005 in the business-tobusiness area may no longer be disposed of with the municipal or

household waste. They are labelled as follows to document this:

Fig. 1: Disposal label

Since the disposal regulations may differ from one country to an-

other within the EU, we ask you to contain your supplier where

necessary.

In Germany this labelling duty has applied since 23.03.2006. As

from this date the manufacturer must offer a reasonable possibility

for returning all equipment supplied as from 13.08.2005. The last

user is responsible for correct disposal for all equipment delivered

before 13.08.2005.

Page 55

EC Declaration of Conformity

55

10 EC Declaration of Conformity

Page 56

EC Declaration of Conformity

56

Page 57

Index

57

11 Index

A

Accident prevention .............................................. 9

Adapting to the mains network ........................... 26

Adjusting the gap width ...................................... 32

Adjusting the grinding time ................................. 34

Authorised persons ............................................... 9

B

Basic construction ................................................ 7

C

Changing the language ...................................... 35

Checklist for troubleshooting .............................. 52

Cleaning after grinding ....................................... 39

Cleaning the grinding chamber .......................... 39

Cleaning the hopper ........................................... 40

Cleaning the housing .......................................... 39

Control panel ...................................................... 30

D

Dimensions ......................................................... 21

Display ................................................................ 30

Disposal label ..................................................... 54

E

Electrical connection ........................................... 26

Electrical safety .................................................. 18

Explanation of signs ........................................... 11

M

Material feed ....................................................... 36

Menu change ...................................................... 31

Menu navigation ................................................. 30

O

Operating noise .................................................. 21

Operating principle .............................................. 10

P

Positioning the device ......................................... 24

Power consumption ............................................ 21

Power input ......................................................... 21

Putting into service ............................................. 26

R

Remove motor cover .......................................... 24

Replacing the gear oil ......................................... 49

Requirements for the user .................................... 9

Reverse operation .............................................. 33

S

Safety equipment ................................................ 17

Safety instructions .............................................. 11

Sample material .................................................. 22

Selecting menu items ......................................... 31

Servicing ............................................................. 41

Specifying the zero point .................................... 31

F

Final fineness ............................................... 22, 38

Function test ....................................................... 27

Fuse .................................................................... 21

H

Hazard symbols used ......................................... 11

Hazard warnings ................................................. 11

L

Locking the hopper cover ................................... 37

T

Timer ................................................................... 34

V

Voltage ................................................................ 21

W

Weight ................................................................. 21

Z

Zirconium oxide grinding discs ........................... 35

Page 58

Index

58

Page 59

FB-EW-805-042 Änderungsstand D 01.2014

Page 60

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...