Page 1

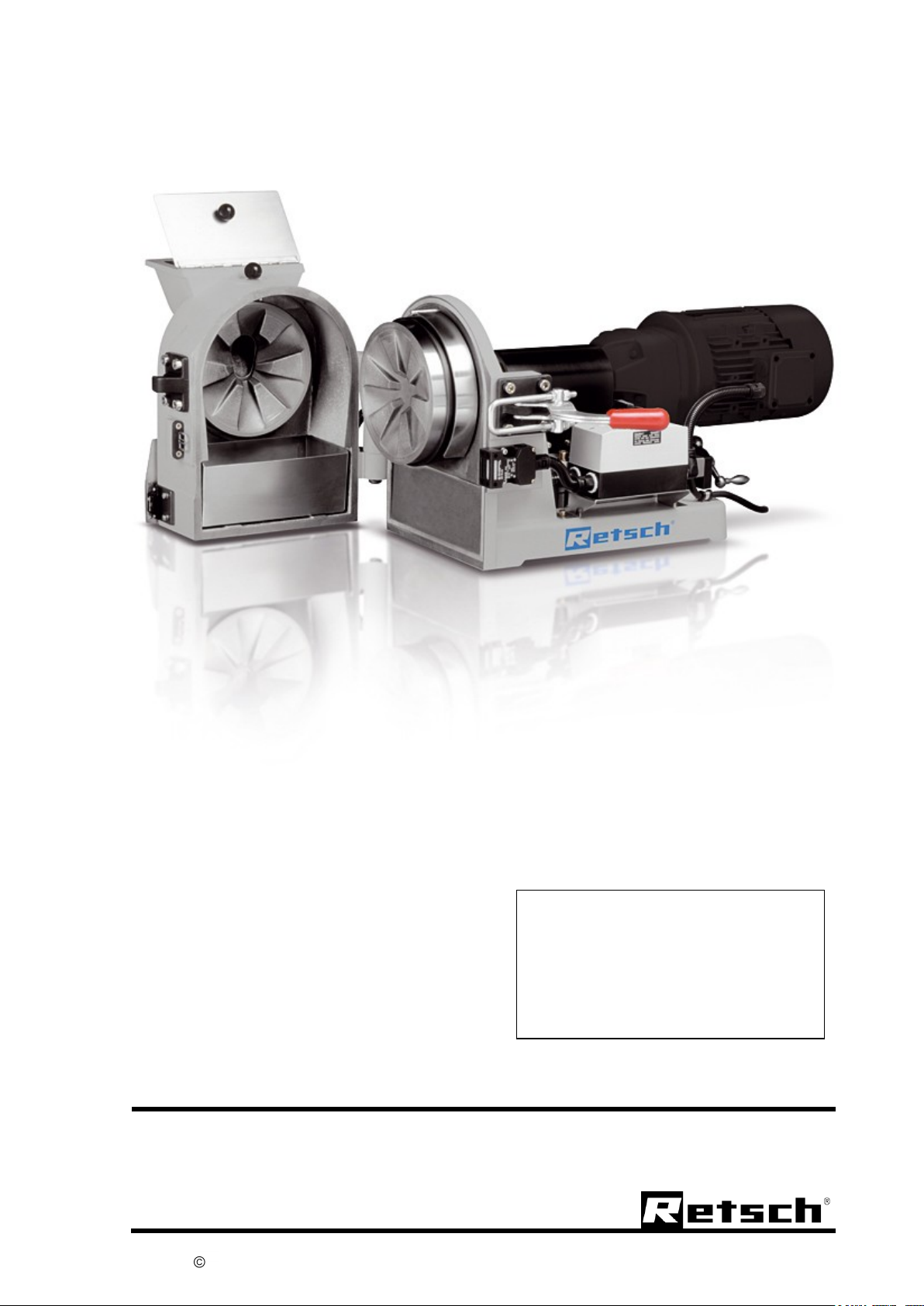

Operating Instructions for the

Disk Mill Model DM200

Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany, 2/8/2012 0002

Page 2

Information on these Operating

Instructions

The present operating instructions for the laboratory

model DM200 disk mill provides you with all of the

necessary information on the areas specified in the

table of contents.

It is an instruction for the target group(s) defined for

each of these areas in the safe and intended use of

the DM200. The prerequisite of each of the target

group(s) being able to use it safely and as intended is

having a knowledge of the relevant sections.

The present technical documentation is a reference

work and instructions for learning and each of the sections is closed in and of itself.

These operating instructions are not instructions for

repair. If repairs should be necessary, please consult

your vendor or get in contact with Retsch GmbH directly.

16.11.2006 Retsch GmbH 2 Doc.Nr. GB 98.740.9999

Page 3

Information on these Operating Instructions

.................................................................... 2

Safety .......................................................... 4

Safety Information ..................................... 4

Warning Signs ........................................... 4

Repairs ..................................................... 5

Confirmation ............................................. 5

Technical Data ............................................. 6

Use as intended ......................................... 6

Functional Description ................................ 6

Protective Equipment ................................. 7

Drive ........................................................ 7

Motor Output ............................................ 7

Rated Voltages .......................................... 7

Rpm's ...................................................... 7

Protective Types ........................................ 7

Emissions ................................................. 8

Machine Dimensions ................................... 8

Floor Space Required ................................. 8

Transportation and Installation ................... 9

Packaging ................................................. 9

Transportation ........................................... 9

Intermediate Storage ................................. 9

The Parameters for the Place of Installation .. 10

Installation................................................ 10

Electrical Connection .................................. 10

Operation ..................................................... 11

The Operating Elements and Operation ......... 11

Adjusting the Gap Width ............................. 12

Starting the Machine .................................. 12

Feeding the Material to be Crushed .............. 12

Changing the direction of

rotation, replacing the milling disks .............. 13

General Information .................................... 15

Accessories ............................................... 15

Cleaning ................................................... 15

Service ..................................................... 15

Necessary Safety Tests............................... 15

Copyright .................................................. 15

Modifications ............................................. 15

Safety Regulations (Table) .......................... 16

Appendix .............................. following pages

16.11.2006 Retsch GmbH 3 Doc.Nr. GB 98.740.9999

Page 4

Safety

We will not be liable for any claims to compensation

whatsoever for property damage or personal injury

that were caused by not observing the following safety

information.

!

personal injury

property damage

The DM200 laboratory disk mill is a highly modern

high-performance product from Retsch GmbH and is

state-of-the-art. If the machine is used as intended

and if the user has a knowledge of the technical

documentation here, it is completely safe when operated.

Safety Information

You as the operator have to ensure that the persons

entrusted with working at the DM200:

have taken notice of and understood all of the

regulations in the area of safety,

know all of the instructions for use and regula-

tions of the target group relevant for them before commencing work,

have access to the technical documentation of

this machine at any time and without any problems.

Before work is commenced on the DM200, ensure

that new personnel has been made familiar with its

safe and intended use either by having a competent

person introduce it to them orally and / or based upon

the present technical documentation.

Improper operation may lead to personal injury, property damage or injury. You are responsible for your

own safety and that of your employees.

Ensure that no unauthorised persons have access to

the DM200 laboratory disk mill.

For your own protection, have your employees confirm

that they have been instructed in the operation of the

DM200. You will find the draft of the appropriate form

after the section on safety.

Warning Signs

we give warnings with the following signs:

16.11.2006 Retsch GmbH 4 Doc.Nr. GB 98.740.9999

Page 5

Repairs

The Retsch agency in your country

your vendor

Retsch GmbH directly

These operating instructions are not instructions for

repair. For your own safety, repairs may only be done

by Retsch GmbH or an authorised agency or service

technicians.

In this case, please notify:

your service address:

Confirmation

I have taken notice of the foreword and the section on

safety.

_______________________________________

________

the signature of the operators

_______________________________________

________

the signature of the service technician

16.11.2006 Retsch GmbH 5 Doc.Nr. GB 98.740.9999

Page 6

Technical Data

!

The DM200 is not designed to be explosion protected and therefore it is not suited to milling explosive self-igniting or fire-promoting substances.

!

If oxidised materials are milled such as metals,

organic materials, wood, plastics, etc., there is the

danger of self-ignition (dust explosion) if the proportion of fines exceeds a certain percentage. It is

necessary to observe the appropriate safety

guidelines when materials such as these are

crushed.

Do not modify the machine and only use the spare

parts and accessories approved by Retsch.

Otherwise the conformity with European directives declared by Retsch shall be rendered

invalid.

Furthermore, this leads to a loss of all warranty claims.

The material sample is crushed by two milling

discs coarsely meshed on the inside working

against one another in a milling space sealed

against dust from the outside. One of these is

driven by a powerful and slow moving gear motor.

The material to be milled is filled into the centre

of the stationary milling disc through a closable

funnel and it escapes from the gap between the

two disks after being crushed by compressing and

shearing force. The width of the gap can be adjusted and controlled from outside and determines

the mean granulation of the material to be milled.

machine model designation: DM200

Use as intended

The DM200 laboratory disk mill is suited for finely

milling soft to hard materials (up to 8 Mohs) in sets or

continuously from the fields of mining and metallurgy,

rocks and earth, the glass industry or soil research.

Our applications laboratory would be glad to give you

further information upon request.

The DM200 is designed for quantities from 20 to approximately 150 Kg/h depending upon the setting of

the discharge gap and the piled density and crushing

behaviour of the sample. The feed size may not exceed an edge length of a maximum of 20 mm.

16.11.2006 Retsch GmbH 6 Doc.Nr. GB 98.740.9999

Functional Description

Page 7

Protective Equipment

The following safety equipment reliably prevents persons

from unintentionally putting their hands in the machine

when it is running.

funnel tube designed in conformity with EN 294.

This prevents persons from putting their hands into

the milling space when the flap is opened

safety limit switch.

This prevents the machine from starting up when the

milling space is open.

It also stops the motor within a safe period of time

when the milling space is opened during operation

safety limit switch.

This prevents the machine from starting up when the

collecting container is drawn out.

It also stops the motor within a safe period of time

when drawing out the collecting container.

protective motor switch, ON/OFF switch.

This switches off the machine automatically if there is

a defect or if the motor is overloaded.

position [ I ] the machine starts.

position [ 0 ] the machine stops.

This prevents the machine from starting up independently if there is an electrical defect or power failure.

3~ 230 V

50 /

60Hz

approx. 5.7 A

3/N~ 400 V

50 /

60Hz

approx. 3.3 A

3~115 V

50 /

60Hz

approx. 11.4

A

3~ 200 V

50 /

60Hz

approx. 6.5 A

gear motor

IP 55

safety limit switch for the door

IP 67

safety limit switch for the collecting

container

IP 67

protective motor switch, ON-OFF

switch

IP 55

Drive

standard three-phase gear motor

Motor Output

1,500 Watt

Rated Voltages

Rpm's

50Hz = Rpm's 440 min-1

60Hz = Rpm's 528 min-1

Protective Types

16.11.2006 Retsch GmbH 7 Doc.Nr. GB 98.740.9999

Page 8

Emissions

Characteristic Noise Values :

Noise measurement in conformity with DIN 45635031-01-KL3

The properties of the material to be crushed also has

an effect upon the characteristic noise values.

sound level LWA = 81 dB(A)

emission read at the workpiece L

= 69,4 dB(A)

pAeq

Machine Dimensions

height: 400 mm, 500 mm with the vertical flap on

the funnel.

width: 430 mm, 900 mm with door opened at 180°.

depth : 890 mm, 1,000 mm with door opened at 90°

weight: approximately 140 kg

Floor Space Required

430 mm x 1000 mm; a safety distance is not necessary.

16.11.2006 Retsch GmbH 8 Doc.Nr. GB 98.740.9999

Page 9

Transportation and Installation

Please store the packaging for the duration of the

warranty period because your warranty claim

would be endangered if there were a complaint

and it were returned in insufficient packaging.

In order to be able to transport the DM200 in a

crane of a minimum load-bearing capacity of 250

kp, it should be hoisted with the hoisting equipment as shown in the adjacent figure.

The DM200 may not be shocked, shaken or

thrown during transportation. Otherwise, the electronic and mechanical component parts could be

damaged.

If there are strong temperature fluctuations (for

instance, when being transported by aeroplane),

the DM200 should be protected from condensation

water. Otherwise, there could be damage to the

electronic component parts.

Packaging

Packaging is in accordance with the transportation

path and satisfies the generally recognised packaging

guidelines.

Transportation

Temperature Fluctuations

Intermediate Storage

Please also ensure that the DM200 is stored dry if it is

placed in intermediate storage.

16.11.2006 Retsch GmbH 9 Doc.Nr. GB 98.740.9999

Page 10

The Parameters for the Place of Installation

If the temperature is above or below the ambient

temperature, the electronic and mechanical component parts may be damaged changing the performance data in an unpredictable fashion.

If the humidity is higher, the electronic and mechanical component parts may be damaged changing

the performance data in an unpredictable fashion.

Only place the DM200 on a solid and sturdy foundation.

Electrical and mechanical component parts may be

damaged if the values on the nameplate are not

complied with.

!

Modifications or rebuilding it to a supply voltage

other than stated on the machine nameplate should

only be done by an electrician.

Danger of Current Surge!

ambient temperature :

5°C to 40°C

humidity :

The maximum relative humidity is 80% at temperatures up to and including 31°C, decreasing linearly to

50% relative humidity at 40°C

Installation Altitude:

a maximum of 2,000 m above sea level

Installation

Electrical Connection

The mains fusing should be designed as follows:

at 3~ 230 and 3/N~ 400V = 16A

at 3~ 115 and 3~ 200V = 20A

you may find the voltage and frequency of the

DM200 on the nameplate.

please ensure that the values agree with the ex-

isting power mains.

only connect the DM200 to the power mains with

the aid of the cable connector supplied.

You may have the connection made directly with a

change-over switch to avoid having to call in an electrician. This has the benefit that the milling disc teeth

may be used by both sides. This is described in the

section "Changing the Direction of Rotation and

Replacing the Milling Disc".

16.11.2006 Retsch GmbH 10 Doc.Nr. GB 98.740.9999

Page 11

Operation

A B C D E F G H I J K

C L D H J K

item

element

function

A

door

seals the milling space dustproof

B

funnel tube

receives the material to be milled

C

window milling gap

enables you to check the milling gap by means of blade gauge

D

collecting container

receives the crushed material to be milled

E

milling disc doors

crushes the material to be milled fed into it together with F

F

milling disc housing

crushes the material to be milled fed into it together with E

G

safety switch for the door

prevents the machine from starting up when the door is open

H

lubrication point

enables you to relubricate the coupling

I

door lock

enables you to open and safely close the doors

J

protective motor switch

disconnect the motor from the mains if there is an overload

position [I] the machine is switched on

position [0] the machine is stopped

K

gap adjustment crank

enables you to adjust the gap together with C

graduation line = 0.01 mm

L

safety switch for the collecting container

prevents the machine from starting up when the collecting

container is drawn out

The Operating Elements and Operation

16.11.2006 Retsch GmbH 11 Doc.Nr. GB 98.740.9999

Page 12

Adjusting the Gap Width

You may adjust the gap width between the milling disc in

the housing and in the door just by adjusting the graduated rotating crank mounted below the motor. 1 graduation line = 0.01 mm.

You may adjust the gap from 0.1 to approximately 5 mm.

Rotating Crank

Caution! Do not go below the minimum gap width of 0.1

mm.

You may control check the gap width setting through a

window behind the funnel tube by means of a sensing

gauge.

Window

You may also adjust the gap width when the machine is

running.

Material that is difficult to mill should be milled at least

twice. Select a larger gap width as pre-crushing for the

first pass and then you achieve the desired final fineness

with the small gap in the second milling pass.

Caution !

The smallest gap width is 0.1 mm.

The milling discs may not touch one another because otherwise

this could damage the milling discs.

It is only possible to start the DM200 when the door is

closed and the collecting container has been inserted.

The ON-OFF switch is on the right-hand side of the

DM200.

ON-OFF switch

position [I] DM200 starts

position [0] DM200 stops

The ON-OFF switch also acts as a protective motor

switch.

If the motor is overloaded or if there is another electrical

fault, this switch disconnects the DM200 from the mains.

The DM200 can only start up when the DM200 is

manually started with the ON-OFF switch.

After the gap has been set and the DM200 has been

started, you commence material feed. Do not exceed a

maximum edge length 20 mm. Open the lid of the funnel

tube for this purpose.

the lid of the funnel tube

When feeding the material to be crushed, please ensure

that the funnel tube lid is closed because otherwise the

material to be crushed could fall back.

Furthermore, the quantity of fed material to be crushed

depends upon its millability. Therefore, note the decreasing intensity of the milling sound to ascertain the optimum feed quantity.

Caution!

Only feed the material to be crushed after having started the

DM200.

If the DM200 starts up filled with material to be crushed, this

may lead to damage in the mechanical component parts.

Starting the Machine

Feeding the Material to be Crushed

16.11.2006 Retsch GmbH 12 Doc.Nr. GB 98.740.9999

Page 13

Changing the direction of rotation, re-

The milling disks are subject to natural wear after use over

a long period.

However, before they need to be replaced by new ones the

direction of rotation of the motor can be changed so that

the opposite side of the gear teeth can be used. By this

means the service life of the milling disks can be extended.

Changing the direction of rotation:

By reversing the phases of the mains supply the direction of

rotation of the motor can be changed. Since this necessitates intervention in the electrical connecting line of the

DM200 the change in direction of rotation should be carried

out only by a qualified electrician.

However, it is possible to install a direction of rotation

change-over switch when connecting up to the mains supply

for the first time. It is then no longer necessary for an electrician to intervene when the the direction of rotation has to

be changed again.

Replacing the milling disk in the door:

Disconnect the mains plug

Remove the collecting vessel

Keep the door closed

Slightly unscrew the hexagon bolts or hexagon nuts with

an open-jawed spanner

Open the door

Keep a firm hold on the milling disk while unscrewing

both hexagon bolts with washers

Remove the milling disk

Clean the mounting of the milling disk in the door

Insert a new milling disk so that its contact surface is

level

Screw in the hexagon bolts again – for zirconium oxide

hexagon nuts are used

placing the milling disks

16.11.2006 Retsch GmbH 13 Doc.Nr. GB 98.740.9999

Page 14

Replacing the milling disk in the housing:

Disconnect the mains plug

Remove the collecting vessel

Open the door

Lift up the cover

Unscrew the hexagon bolts or hexagon nuts with an SW

30 open-jawed spanner

Remove the milling disk

Clean the mounting of the milling disk

Place a new milling disk in position

The milling disk must have a level contact surface

Screw in the hexagon bolts with washers – for zirconium

oxide hexagon nuts are used.

GS SS

Caution

It is essential that the milling disks have a level contact

surface.

There should be no unevenness or other components under

the milling disk.

For zirconium oxide disks it is absolutely necessary that the

rubber washer GS is placed under the steel washer SS.

Caution

Milling disks of zirconium oxide should be tightened with a

torque of only 20-30 Nm. Do not forget the rubber washer

GS.

Milling disks of steel and tungsten carbide are tightened

with a torque of 50-100 Nm.

16.11.2006 Retsch GmbH 14 Doc.Nr. GB 98.740.9999

Page 15

General Information

!

Do not clean the DM200 with flowing water.

Danger from Current Surge

Only use moistened rags.

Solvents are not permitted.

The protection type of DM200 is IP 55

The DM200 does not require service, although it should

be relubricated on the lubricating nipple of the shifting

sled.

Conventional lubricating grease may be used for this

purpose.

A grease gun is also available as an accessory under

the order no. 05.185.0006.

!

If the machine is not functioning properly, do not continue to operate it and get in contact with our customer

service.

Accessories

Cleaning

You may pull out the collecting container for cleaning purposes.

Open the door to clean the milling discs, the milling space

and the funnel tube.

You may now conveniently clean the entire area that has

come into contact with the material to be crushed with the

aid of a brush or vacuum cleaner.

Service

Necessary Safety Tests

The safety limit switches on the door and the collecting

container should be checked on a monthly basis to see if

they are in perfect working order:

open the door:

It may not be possible to switch on the DM200 any more

with the ON/OFF switch.

close the door:

It must be possible to start the DM200 with the ON/OFF

switch again.

pull out the collecting container:

It may not be possible to switch on the DM200 any more

with the ON/OFF switch.

push in the collecting container:

It must be possible to start the DM200 with the ON/OFF

switch again.

Copyright

It is only allowed to pass on or copy this documentation

or utilise and pass on its content with the express permission of Retsch GmbH.

Non-compliance engages the obligation of compensa-

16.11.2006 Retsch GmbH 15 Doc.Nr. GB 98.740.9999

tion for damage.

Modifications

We reserve the right to make technical modifications.

Page 16

Safety Regulations (Table)

for the DM200 from the sections

process

action

hazards

safety information

property damage and personal

injury may be incurred if the safety

information is not observed.

no claims to compensation for damage

shall be accepted whatsoever

intended use

do not mill any explosive selfigniting or fire-promoting materials

danger to life and limb because of

explosion because the DM200 is not

designed to be explosion protected.

do not mill materials whose fine

proportion at a certain percentage

may lead to an explosion.

danger to life and limb because of

explosion because the DM200 is not

designed to be explosion protected.

do not modify the machine and

only use the spare parts and accessories approved by Retsch.

otherwise the conformity with European directives declared by Retsch

shall be rendered invalid.

Furthermore, this leads to the loss of

all warranty claims.

packaging

please store the packaging for the

warranty period.

if there is a complaint and it is returned in insufficient packaging, this

may jeopardise your warranty claims.

temperature fluctuations

protect the DM200 from condensate water forming if there are

temperature fluctuations.

electronic component parts may be

damaged.

transportation

do not shock, shake or throw the

DM200 during transportation

electronic and mechanical component

parts may be damaged.

scope of delivery

if the delivery is incomplete and /

or if there is damage from transportation, you have to inform the

transporter and Retsch GmbH

without delay (within 24h).

under certain circumstances later

complaints may not be recognised.

ambient temperature

should not fall below 5°C

should not go above 40°C

electronic and mechanical component

parts may be damaged and performance data may change unpredictably.

humidity

do not exceed a relative humidity

of 80% at 31°C or 50% (descending linearly) at 40°C.

higher humidity may damage the electronic and mechanical component

parts and performance data may

change unpredictably.

electrical connection

the network does not agree with

the values on the nameplate.

electronic and mechanical component

parts may be damaged.

adjusting the gap

width

do not adjust a gap width < 0.1

mm

if the milling discs come into contact

with one another, they may be damaged.

feeding the material

to be crushed

only feed material to be crushed

when the DM200 is operating.

if the DM200 starts up filled with material to be crushed, this may damage

the mechanical component parts.

cleaning

do not clean the DM200 with flowing water.

danger from current surge.

the protection type of the DM200 is

IP55

safety tests

get in contact with customer service if the safety equipment functions improperly..

if defects are improperly repaired, this

may lead to danger to life and limb.

16.11.2006 Retsch GmbH 16 Doc.Nr. GB 98.740.9999

Page 17

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

R e t s c h G m b H R e t s c h - A l l e e 1 - 5 4 2 7 8 1 H a a n G er m a n y w w w . r e t s c h . c o m

DISC MILL

DM 200

FB-EW-805-042 (E) Änderungsstand D 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

THIS MACHINE CONFORMS TO THE FOLLOWING STANDARD SPECIFICATIONS AND DIRECTIVES:

The EC Directive for Machines „Directive 89/392/EEC“, Appendix 1, Subsection 1 Fundamental Safety and

Health Requirements for Machine Design and Construction,

The EC Directive for Electromagnetic Compatibility (EMC) „Directive 89/336/EEC (May 3, 1989) of the

Council for Alignment of the Laws of the Member States for Electromagnetic Compatibility“ (including modifi-

cations till July 22, 1993),

The Requirements on „ Electrical Equipment of Machines“ (IEC 204-1 1992, modified)

German Version EN 60 204-1 : 1992.

In case of a modification to the machine not previously discussed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

We affirm herewith that the certification process was conducted exclusively in accordance with Directive

89/392/EEC (Jun. 14, 1989), Amendment 91/368/EEC (Jun. 20, 1991),, Modification 93/44/EEC (Jun. 14,

1993), Modification 93/68/EEC (July 22, 1993), Directive of the Council for Alignment of the Laws of the

Member States for Machines.

Page 18

Page 19

Page 20

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...