Page 1

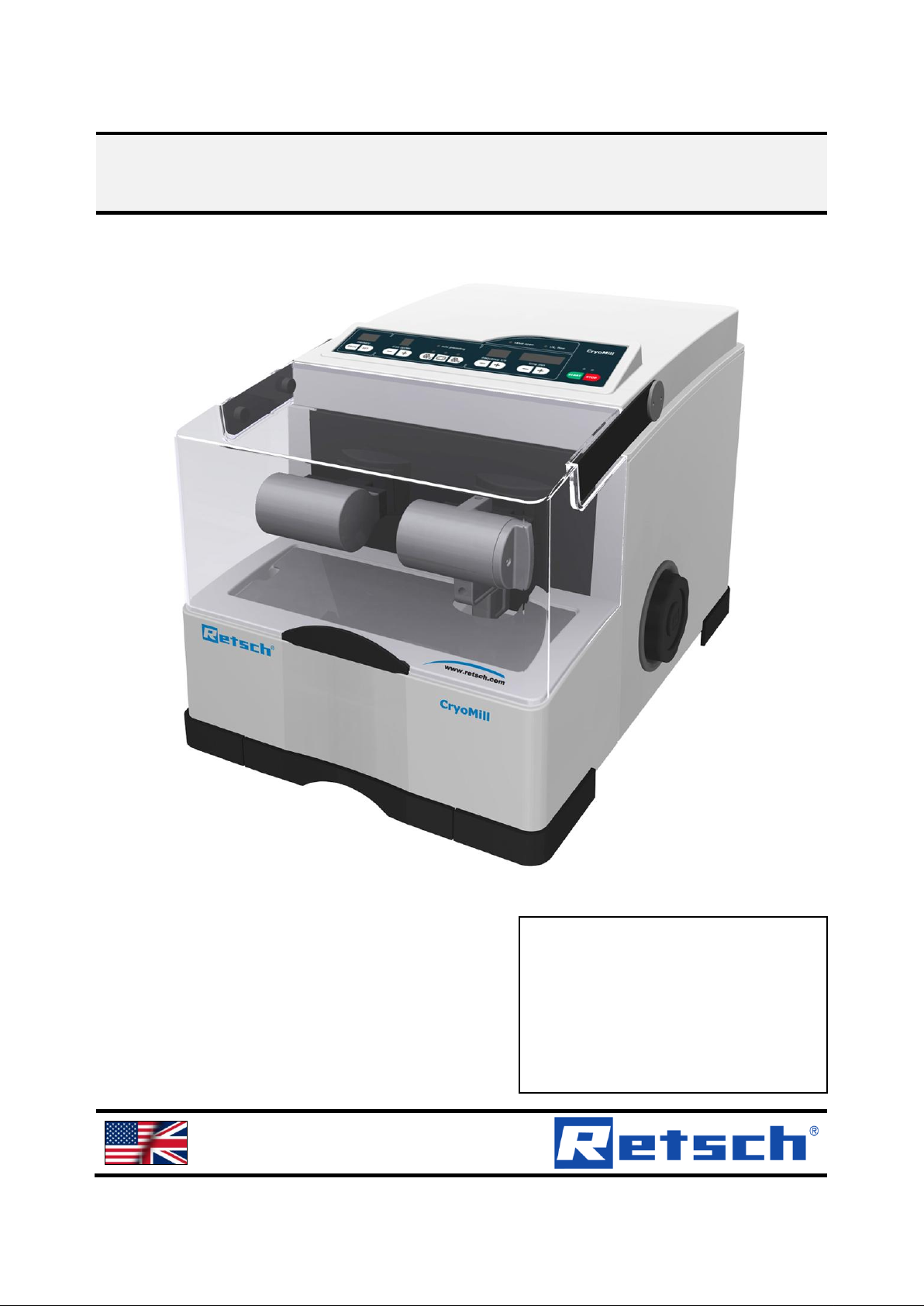

Manual

Mixer Mill CryoMill

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 13.03.2013 0002

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

1 Notes on the Operating Manual ............................................................................................................ 6

1.1 Explanations of the safety warnings .................................................................................................. 7

1.2 General safety instructions ................................................................................................................ 8

1.3 Repairs ............................................................................................................................................... 9

2 Confirmation ......................................................................................................................................... 10

3 Technical data ....................................................................................................................................... 11

3.1 Protective equipment ....................................................................................................................... 11

3.2 Emissions......................................................................................................................................... 11

3.3 Degree of protection ........................................................................................................................ 12

3.4 Rated power .................................................................................................................................... 12

3.5 Dimensions and weight .................................................................................................................... 12

3.6 Required floor space ........................................................................................................................ 12

4 Transport, scope of delivery, installation .......................................................................................... 13

4.1 Packaging ........................................................................................................................................ 13

4.2 Transport.......................................................................................................................................... 13

4.3 Temperature fluctuations and condensed water ............................................................................. 13

4.4 Conditions for the place of installation ............................................................................................. 13

4.5 Installation of the machine ............................................................................................................... 14

4.6 Removing the transport safeguard .................................................................................................. 14

4.7 Type plate description ...................................................................................................................... 18

4.8 Electrical connection ........................................................................................................................ 19

4.9 Connecting the cooling agent feed .................................................................................................. 19

4.10 Removing the liquid nitrogen feed line ............................................................................................ 23

4.11 Cold air outlet ................................................................................................................................... 24

4.12 Mounting the exhaust hose.............................................................................................................. 24

5 Operating the machine ........................................................................................................................ 26

5.1 Use of the machine for the intended purpose.................................................................................. 26

5.2 Operating elements and displays .................................................................................................... 27

5.3 Summary table of device parts ........................................................................................................ 28

5.4 Operating elements and displays .................................................................................................... 29

5.5 Inserting the grinding jar .................................................................................................................. 31

5.5.1 Inserting and removing CryoMill special grinding jar ................................................................... 31

5.5.2 Inserting the cooling jacket sealing plug ...................................................................................... 34

5.5.3 Insert the adapter for 4/2 x 5 ml grinding jar ................................................................................ 35

5.5.4 Insert the adapter for 6 / 4 / 2 x 2-ml Eppendorf reaction vial ..................................................... 36

5.6 Explanations of the grinding cycles ................................................................................................. 37

5.6.1 Grinding without cooling .............................................................................................................. 37

5.6.2 Grinding with cooling ................................................................................................................... 37

3

Page 4

5.7 Programs ......................................................................................................................................... 38

5.7.1 Grinding without program ............................................................................................................ 38

5.7.2 Grinding with program ................................................................................................................. 39

5.7.2.1 Selection of a program ......................................................................................................... 39

5.7.2.2 Display of the program grinding parameters ....................................................................... 39

5.7.2.3 Create/change a program .................................................................................................... 39

5.7.2.4 Delete program .................................................................................................................... 40

5.8 Setting grinding cycles ..................................................................................................................... 40

5.9 Setting the precooling time .............................................................................................................. 41

5.9.1 Precooling with definable precooling time ................................................................................... 41

5.9.2 Automatic precooling ................................................................................................................... 41

5.10 Setting the grinding time .................................................................................................................. 42

5.11 Setting the duration of intermediate cooling .................................................................................... 42

5.12 Setting the grinding frequency ......................................................................................................... 43

5.13 Starting the grinding process ........................................................................................................... 43

5.14 Interrupting and continuing the grinding process ............................................................................ 44

5.14.1 Pausing grinding ...................................................................................................................... 44

5.14.2 Cancelling grinding .................................................................................................................. 44

5.15 Stopping the grinding process ......................................................................................................... 44

5.16 Operating hours display ................................................................................................................... 45

5.17 Operating software display .............................................................................................................. 46

5.18 Replacing the machine fuses........................................................................................................... 46

6 Working instructions............................................................................................................................ 48

6.1 General ............................................................................................................................................ 48

6.2 The grinding process ....................................................................................................................... 48

6.3 Quantities of sample material and feed sizes .................................................................................. 48

6.4 Working instructions ........................................................................................................................ 49

7 Safety functions and fault display ...................................................................................................... 50

7.1 Fault messages ............................................................................................................................... 50

8 Cleaning, wear and service ................................................................................................................. 51

8.1 Cleaning ........................................................................................................................................... 51

8.2 Wear ................................................................................................................................................ 51

8.3 Wearing parts .................................................................................................................................. 51

8.4 Service ............................................................................................................................................. 51

8.5 Checks ............................................................................................................................................. 52

9 Safety and occupational health instructions ..................................................................................... 52

9.1 General ............................................................................................................................................ 52

9.2 Safety instructions on the handling of liquid nitrogen ...................................................................... 54

9.3 Oxygen deficiency ........................................................................................................................... 54

4

Page 5

9.3.1 Dangers ....................................................................................................................................... 54

9.3.2 Causes ......................................................................................................................................... 54

9.3.3 Recommendations ....................................................................................................................... 54

9.3.4 General conduct in the case of an accident ................................................................................ 55

9.4 Cryogenic burns ............................................................................................................................... 55

9.4.1 Dangers ....................................................................................................................................... 55

9.4.2 Causes ......................................................................................................................................... 55

9.4.2.1 Burns through splashes ....................................................................................................... 55

9.4.2.2 Burns through contact .......................................................................................................... 56

9.4.3 Recommendations ....................................................................................................................... 56

9.4.4 General rules of conduct for splashes with liquid nitrogen .......................................................... 56

9.4.4.1 To the eyes .......................................................................................................................... 56

9.4.4.2 On the skin ........................................................................................................................... 56

9.5 Danger of explosion ......................................................................................................................... 56

9.5.1 Dangers ....................................................................................................................................... 56

9.5.2 Causes ......................................................................................................................................... 56

9.5.3 Recommendations ....................................................................................................................... 57

9.5.4 General conduct in the case of an accident ................................................................................ 57

9.6 Oxygen enrichment .......................................................................................................................... 57

9.6.1 Dangers ....................................................................................................................................... 57

9.6.2 Causes ......................................................................................................................................... 57

9.6.3 Recommendations ....................................................................................................................... 57

9.7 Surrounding area of the machine .................................................................................................... 58

9.7.1 Rooms .......................................................................................................................................... 58

10 Disposal ................................................................................................................................................. 59

11 Index ...................................................................................................................................................... 60

Appendix ............................................................................................................................... following pages

5

Page 6

Notes on the Operating Manual

Pos: 1.1 /00005 Überschriften/1. Überschri ften/1 Hinweise zur Bedienungsanleitung @ 0\mod_1222347415287_9.doc @ 2 631 @ 1 @ 1

1 Notes on the Operating Manual

Pos: 1.2 /00003 Standard Kapitel/General Modul Hinweis zur Bedienungsanleitung @ 0\mod_1228722945175_9.doc @ 4058 @ @ 1

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

Pos: 1.3 /00003 Standard Kapitel/General Modul Änderungen @ 0\mod_12287 22944847_9.doc @ 4051 @ @ 1

www.retsch.com.

Changes

Pos: 1.4 /00003 Standard Kapitel/General Modul Urheberrecht @ 0\mod_12287 22945472_9.doc @ 4065 @ @ 1

Pos: 2.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

Subject to technical changes.

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

6

Page 7

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

Pos: 2.2 /00005 Überschriften/1.1 Überschri ften/1.1 Überschriften BDA/11 Er klärungen zu den Sicherheitswarnungen @ 0\ mod_1222344569771_9.doc @ 2484 @ 2 @ 1

1.1 Explanations of the safety warnings

Pos: 2.3 /00003 Standard Kapitel/General Modul Warnhinweise Erklärung neu @ 0\ mod_1234858329746_9.doc @ 6190 @ @ 1

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

Pos: 2.4 /00010 Bedienungsanleitunge n Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

7

Page 8

Notes on the Operating Manual

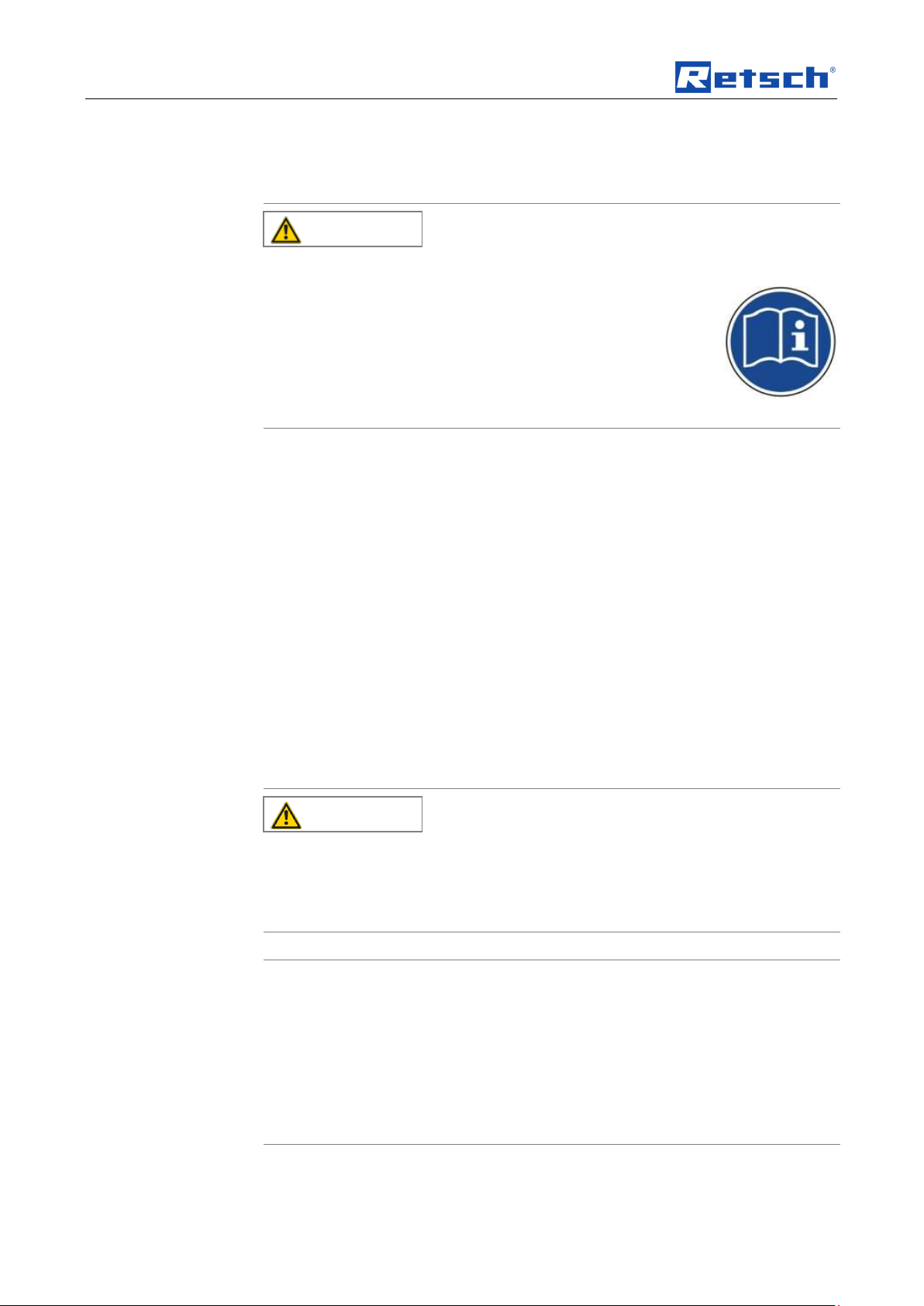

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Generelle Sicherheitshinweise @ 0\mod_122 2344568974_9.doc @ 2463 @ @ 1

1.2 General safety instructions

Pos: 2.6 /00004 Warnhinweise/V0002 V ORSICHT Bedienungsanleitung lesen @ 2\mod_1263894982815_9.doc @ 1863 0 @ @ 1

Pos: 2.7 /00003 Standard Kapitel/General Modul Zielgruppe und Sicherheit @ 0 \mod_1228722955300_9.doc @ 4100 @ @ 1

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

Pos: 2.8 /00003 Standard Kapitel/General Modul Sicherheitshinweise @ 0\mod_ 1228722954800_9.doc @ 4086 @ @ 1

Pos: 2.9 /00004 Warnhinweise/V0015 VORS ICHT + HINWEIS Sach- und Person enschäden @ 1\mod_1236238456676_9 .doc @ 7642 @ @ 1

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.10 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758 _0.doc @ 2386 @ @ 1

8

Page 9

Notes on the Operating Manual

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Pos: 2.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Reparat uren @ 0\mod_1223624336511_9.doc @ 2978 @ @ 1

Reperaturen

1.3 Repairs

Pos: 2.12 /00003 Standard Kapitel/Gen eral Modul Reparaturen @ 0\mod_1228 722954535_9.doc @ 4079 @ @ 1

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

Pos: 3.1 /00020 BDA Software/20005 PM GC Kapitelsammlung/- - - - Seitenum bruch - - - - @ 0\mod_1208857688413_0.doc @ 337 @ @ 1

9

Page 10

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.2 /00020 BDA Software/20005 PM GC Kapitelsammlung/Überschriften/1. Ü berschriften/1 Bestätigung (Formular für den Betreiber) @ 0\mod_1208870841095 _9.doc @ 430 @ 1 @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /00003 Standard Kapitel/General Modul Bestätigung @ 0\mod_122872 2962707_9.doc @ 4114 @ @ 1

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

Pos: 4.1 /00010 Bedienungsanleitunge n Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

10

Page 11

Technical data

Receptacle:

1 50ml steel grinding jar

Grinding component:

1 25mm steel ball each

Feed material:

Quartz gravel particles approx. 4.0 – 6.0mm

Feed quantity:

8ml

Frequency:

30 Hz

Receptacle:

4 5ml steel grinding jar

Grinding component:

2 8mm tungsten carbide balls each

Feed material:

Quartz gravel particles approx. 1.0 – 1.5mm

Feed quantity:

1.5ml

Frequency:

30 Hz

Pos: 4.2 /00005 Überschriften/1. Überschri ften/1 Technische Daten @ 0\mod_12 22344525522_9.doc @ 2407 @ 1 @ 1

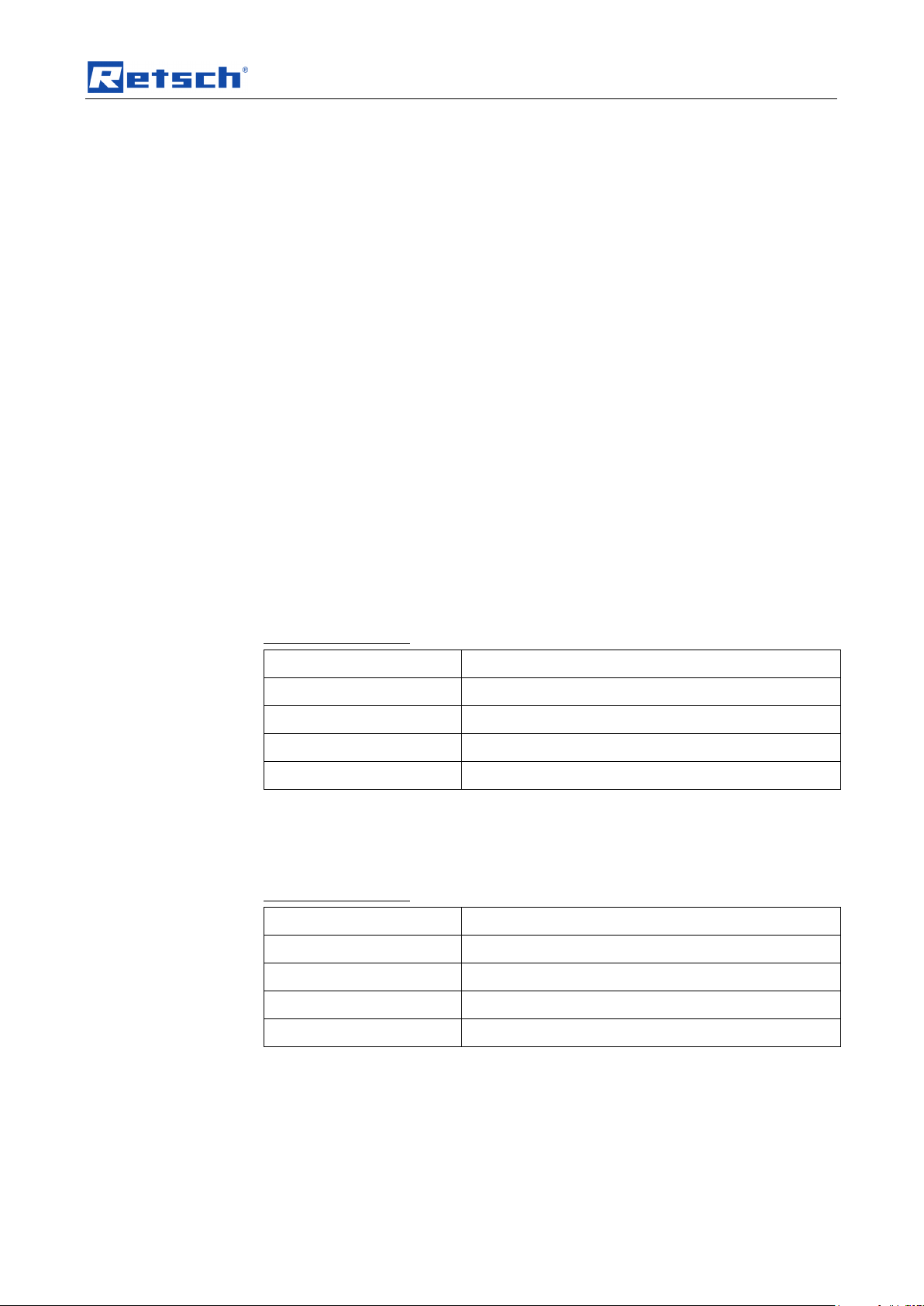

3 Technical data

Pos: 4.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schutzei nrichtungen @ 0\mod_1226486316130 _9.doc @ 3304 @ @ 1

3.1 Protective equipment

Pos: 4.4 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0005 Technisc he Daten/CryoMill II Modul Schutzeinic htung @ 5\mod_1343827811856_9.doc @ 33015 @ @ 1

The grinding chamber of the CryoMill laboratory mill is surrounded by a stable

hood.

Pos: 4.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 E mmisionen @ 0\mod_1226487095021_9.doc @ 3310 @ @ 1

3.2 Emissions

Pos: 4.6 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0005 Technisc he Daten/CryoMill II Modul Emmisionen @ 5\mod_1343827808859_9.doc @ 3 2971 @ @ 1

It is only possible to start the device when the hood is closed.

Noise values:

The noise values are also influenced by the properties of the sample material.

No-load operation:

Emission value with regard

to workplace L

Example 1:

Emission value with regard

to workplace L

Operating conditions:

= 61,4 dB(A)

pAeq

= 75,2 dB(A)

pAeq

Example 2:

Emission value with regard

to workplace L

= 66,3 dB(A)

pAeq

Operating conditions:

11

Page 12

Technical data

CAUTION

Hearing loss

A high sound level may occur depending on the type of material, the

number of balls used, the set grinding frequency and the grinding time.

– Excess noise in terms of intensity and duration can lead to

impairments or permanent damage to hearing.

• Ensure you take suitable soundproofing measures or wear

hearing protection.

Pos: 4.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schutzart @ 0\mod_1226491839164_9.doc @ 3 328 @ @ 1

3.3 Degree of protection

Pos: 4.8 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0005 Technisc he Daten/CryoMill II Modul Schutzart @ 5 \mod_1343827811016_9.doc @ 33 004 @ @ 1

Pos: 4.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Nennleistu ng @ 0\mod_1226491873164_9.doc @ 3334 @ @ 1

IP30

3.4 Rated power

Pos: 4.10 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0005 Tech nische Daten/CryoMill II Modul Nennl eistung @ 5\mod_1343827810260_9.doc @ 32993 @ @ 1

Pos: 4.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Abmessu ngen und Gewicht @ 0\mod_122649 2212173_9.doc @ 3352 @ @ 1

260 watts

3.5 Dimensions and weight

Pos: 4.12 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0005 Tech nische Daten/CryoMill II Modul Abmessu ngen und Gewicht @ 5\mod_13438278 08139_9.doc @ 32960 @ @ 1

Height : 370 to approx. 630 mm with open hood

Width: 385 mm

Depth: 570 mm

Pos: 4.13 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 Erford erliche Standfläche @ 0\mod_122649 2678414_9.doc @ 3364 @ 2 @ 1

Weight: approx. 46 kg without grinding jar

3.6 Required floor space

Pos: 4.14 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0005 Tech nische Daten/CryoMill II Modul Erforderli che Standfläche @ 5\mod_1343827809 560_9.doc @ 32982 @ @ 1

Pos: 5.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

Supporting surface: 500 mm x 650 mm

12

Page 13

Transport, scope of delivery, installation

NOTICE

Storage of packaging

– In the event of a complaint or return, your warranty claims may be

endangered if the packaging is inadequate or the machine has not been

secured correctly.

• Please keep the packaging for the duration of the warranty period.

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

NOTICE

Ambient temperature

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range of the

machine (5°C to 40°C / ambient temperature).

Pos: 5.2 /00005 Überschriften/1. Überschri ften/1 Verpackung, Transport und Aufst ellung @ 0\mod_1226494451893_9.doc @ 3380 @ 1 @ 1

4 Transport, scope of delivery, installation

Pos: 5.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Verpacku ng @ 0\mod_122649508897 3_9.doc @ 3392 @ 2 @ 1

4.1 Packaging

Pos: 5.4 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0006 Trans port, Lieferumfang und Aufstellen /CryoMill II Modul Verpackung @ 5\mod_134 3829055791_9.doc @ 33070 @ @ 1

The packaging is designed for the transport route. It corresponds to generally

Pos: 5.5 /00004 Warnhinweise/H0001 H INWEIS Aufbewahrung der Verpackung @ 0\mod_1228918881595_9.doc @ 475 3 @ @ 1

Pos: 5.6 /00005 Überschriften/1.1 Üb erschriften/1.1 Überschriften BDA/11 Tr ansport @ 0\mod_1226495164391_9.d oc @ 3398 @ 2 @ 1

4.2 Transport

Pos: 5.7 /00004 Warnhinweise/H0017 H INWEIS Transport @ 0\mod_122891888 3019_9.doc @ 4802 @ @ 1

acceptable packaging guidelines.

Pos: 5.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Temperatursc hwankungen @ 0\mod_1226495 190738_9.doc @ 3404 @ 2 @ 1

4.3 Temperature fluctuations and condensed water

Pos: 5.9 /00004 Warnhinweise/H0016 H INWEIS Temperaturschwankungen @ 0\ mod_1233564121287_9.doc @ 5570 @ @ 1

Pos: 5.10 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Bedingu ngen für den Aufstellort @ 0\mod_1 226497029322_9.doc @ 3428 @ 2 @ 1

4.4 Conditions for the place of installation

Pos: 5.11 /00003 Standard Kapitel/Gen eral Modul Umgebungstemperatur 5°C - 40°C @ 0\mod_1228918538881_9.doc @ 4745 @ @ 1

Pos: 5.12 /00004 Warnhinweise/H0021 HIN WEIS Umgebungstemperatur 5°C bis 4 0°C @ 0\mod_1228918883441_9.doc @ 4816 @ @ 1

Pos: 5.13 /00003 Standard Kapitel/Gen eral Modul Luftfeuchtigkeit @ 0\mod_122 8918538693_9.doc @ 4738 @ @ 1

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, decreasing linearly up

Pos: 5.14 /00004 Warnhinweise/H0011 HIN WEIS Luftfeuchtigkeit @ 0\mod_12 28918882628_9.doc @ 4788 @ @ 1

to 50% relative humidity at 40°C

13

Page 14

Transport, scope of delivery, installation

NOTICE

Atmospheric humidity

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed the admissible range for atmospheric humidity.

NOTICE

Property damage

A very cold vapour plume escapes from the nitrogen gas outlet.

– The vapour plume can greatly cool objects. This is why the humidity in the

air condenses.

• The area above the nitrogen gas outlet (B) up to the ceiling must be

kept free.

NOTE

Installation

– Depending on the operating status of the mill, there may be slight

vibrations.

• Place the mill on an even, flat and balanced supporting surface only.

The supporting surface must be stable and must not vibrate.

NOTICE

Installation of the machine

– It must be possible to disconnet the machine from the mains at any time.

• Install the machine such that the connection for the mains cable is

easily accessible.

NOTICE

Transport safeguard

– Components may be damaged.

• Operate the machine only without the transport safeguard or

transport the machine only with transport safeguard.

Pos: 5.15 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufstell en des Gerätes @ 0\mod_12264988 49756_9.doc @ 3464 @ 2 @ 1

4.5 Installation of the machine

Pos: 5.16 /00003 Standard Kapitel/Gen eral Modul Aufstellungshöhe @ 0\mod_ 1228918538349_9.doc @ 4724 @ @ 1

Pos: 5.17 /00004 Warnhinweise/H0055 HIN WEIS CryoMill Dampf-Fahne @ 4\m od_1314082098654_9.doc @ 25428 @ @ 1

Installation height: maximum 2000 m above sea level

Pos: 5.18 /00004 Warnhinweise/H0004 HIN WEIS Boden Aufstellen Vibrationen Bod en @ 0\mod_1228918882236_9.doc @ 4774 @ @ 1

Pos: 5.19 /00004 Warnhinweise/H0002 HIN WEIS Aufstellung Zugang Gerätestec kdose @ 0\mod_1233836960983_9.doc @ 5820 @ @ 1

Pos: 5.20 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Trans portsicherung entfernen @ 0\mod_12275 30921618_9.doc @ 3980 @ 2 @ 1

4.6 Removing the transport safeguard

Pos: 5.21 /00004 Warnhinweise/H0018 HIN WEIS Transportsicherung @ 2\ mod_1278053972635_9.doc @ 20540 @ @ 1

Pos: 5.22 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tr ansport, Lieferumfang und Aufstellen /Cr yoMill II Modul Auspacken und Transportsic herung entfernen @ 5\mod_134382905 3087_9.doc @ 33048 @ @ 1

• Place the device on a stable table.

• Pull the device carefully beyond the edge of the table in order to be able to

14

reach the screw (TA).

Page 15

Transport, scope of delivery, installation

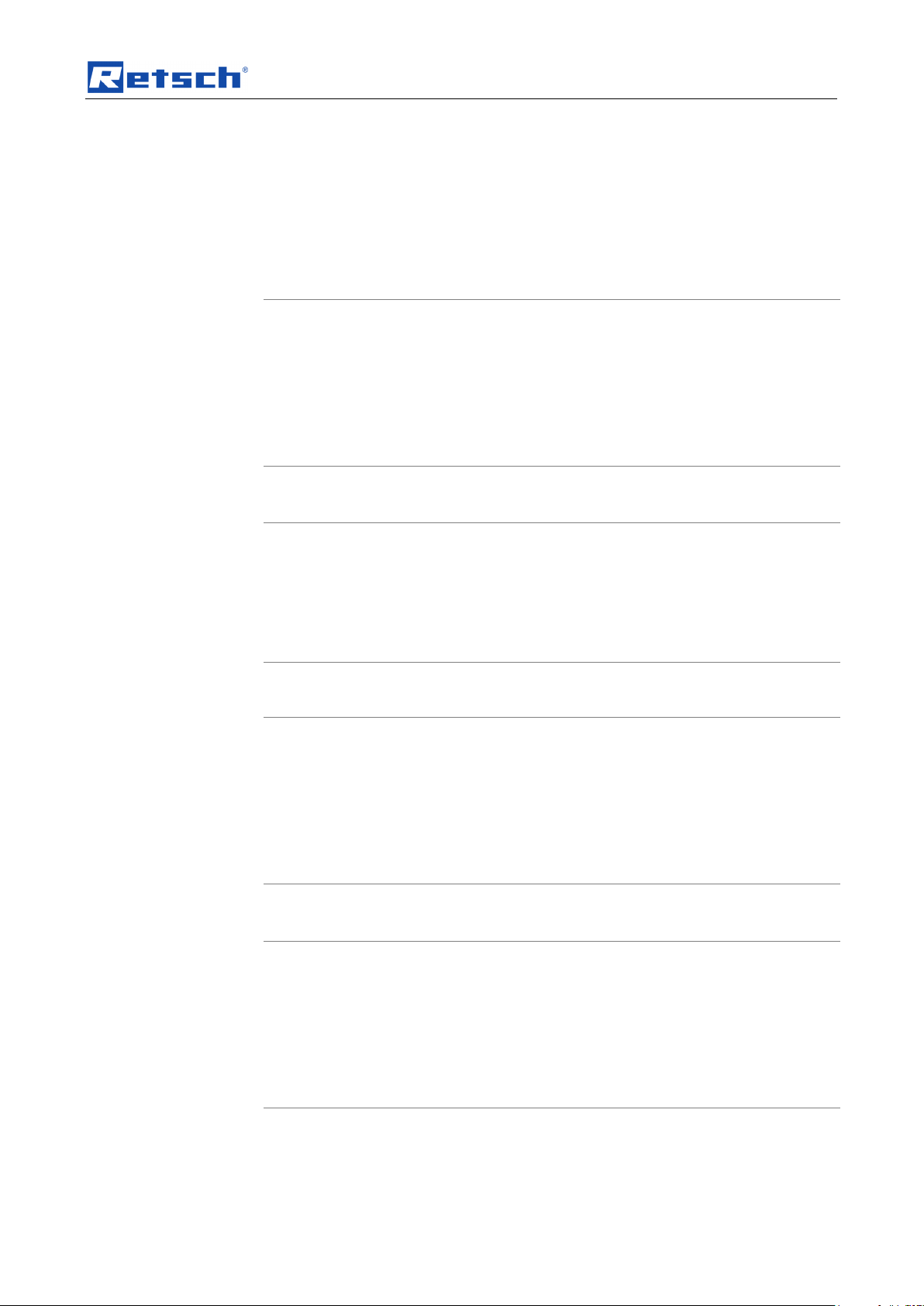

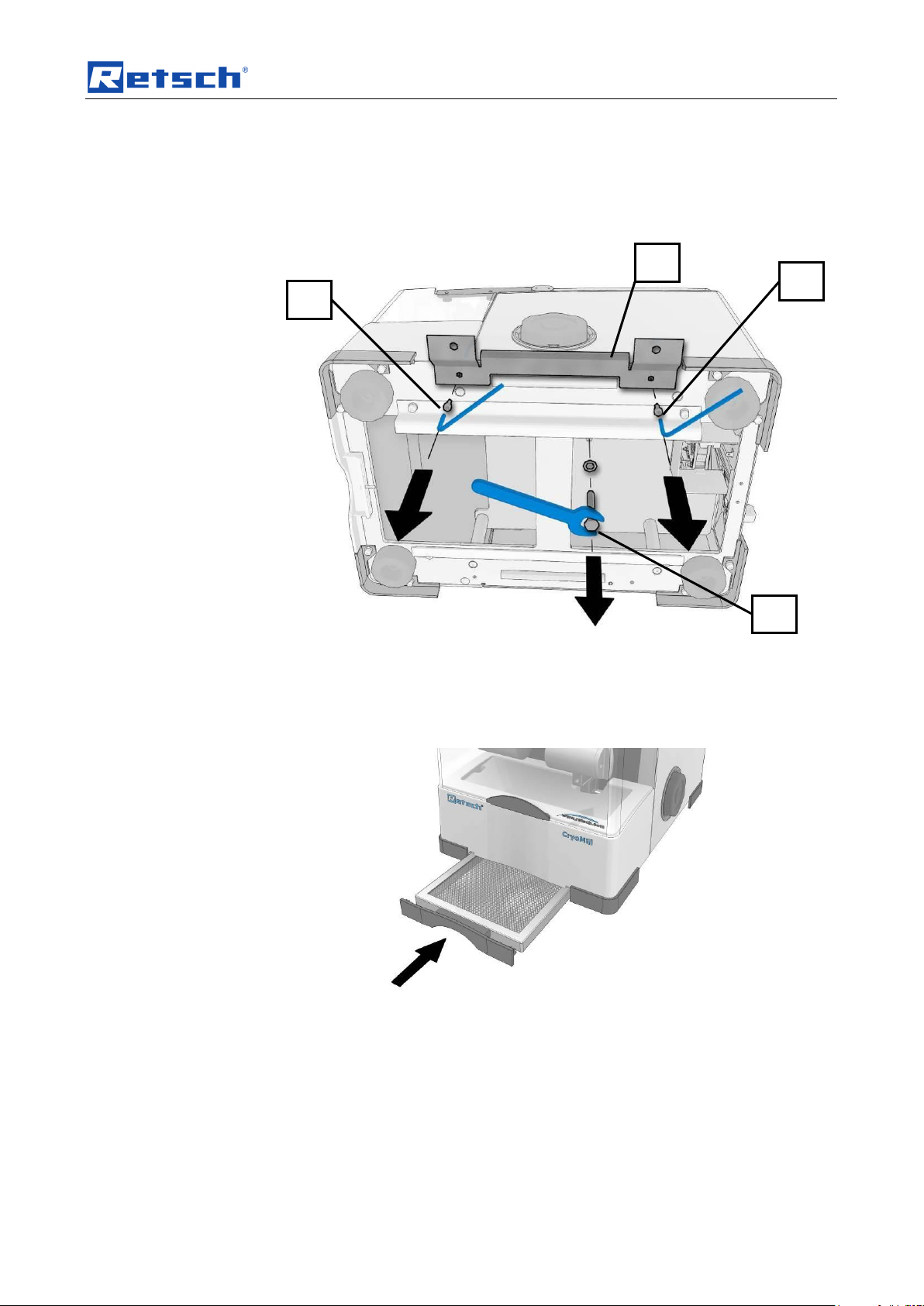

TA

TB

TL1

TL1

Fig. 1: Removing the transport bracket

• Remove the screw (TA) using an Allen key.

Fig. 2:

• Pull the device into the position shown in order to be able to remove

the screw (TB).

• Remove the second screw (TB) and remove the transport bracket

(TL1).

NOTICE

Keep the transport brackets, screws and transport lock for future transport!

15

Page 16

Transport, scope of delivery, installation

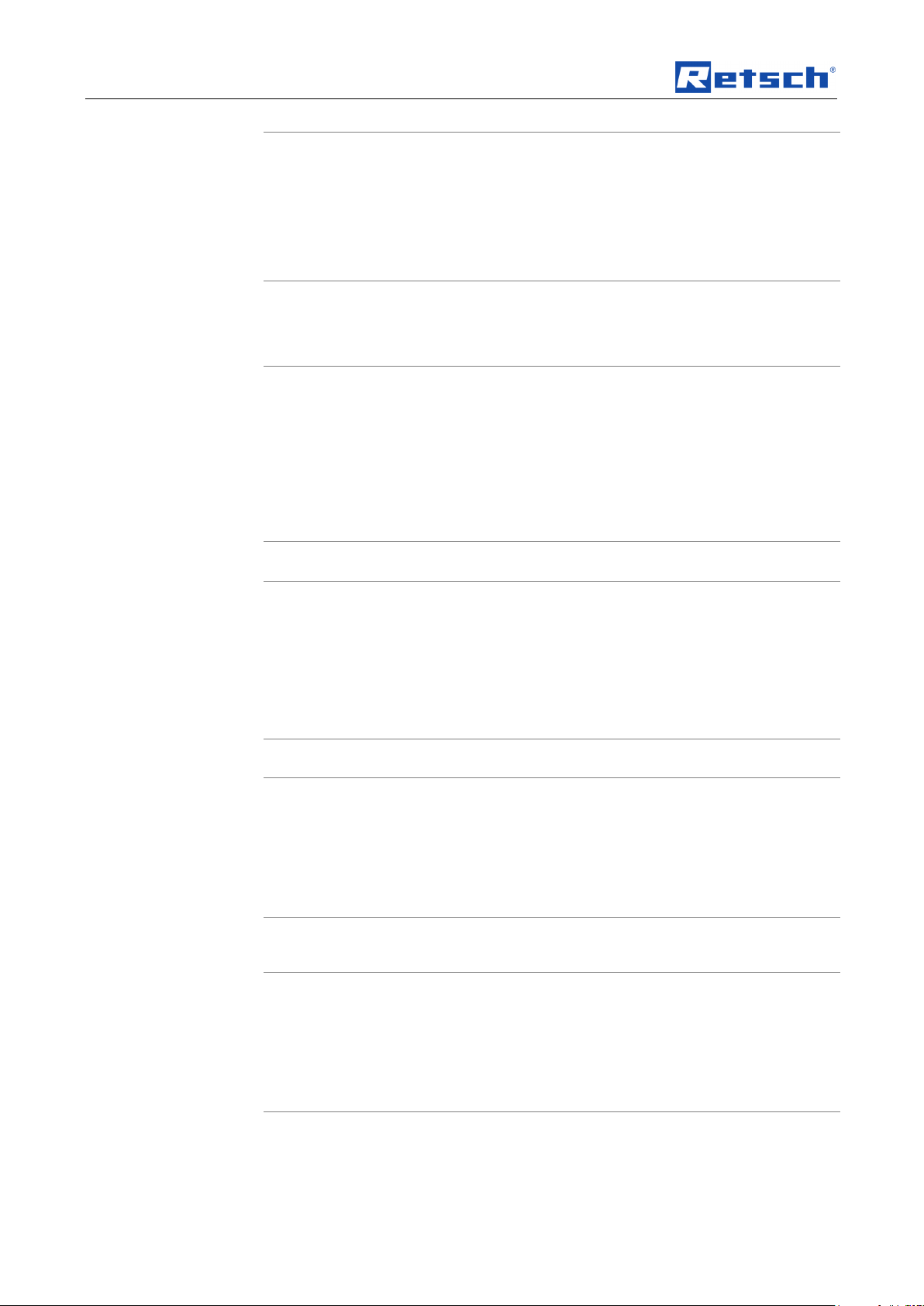

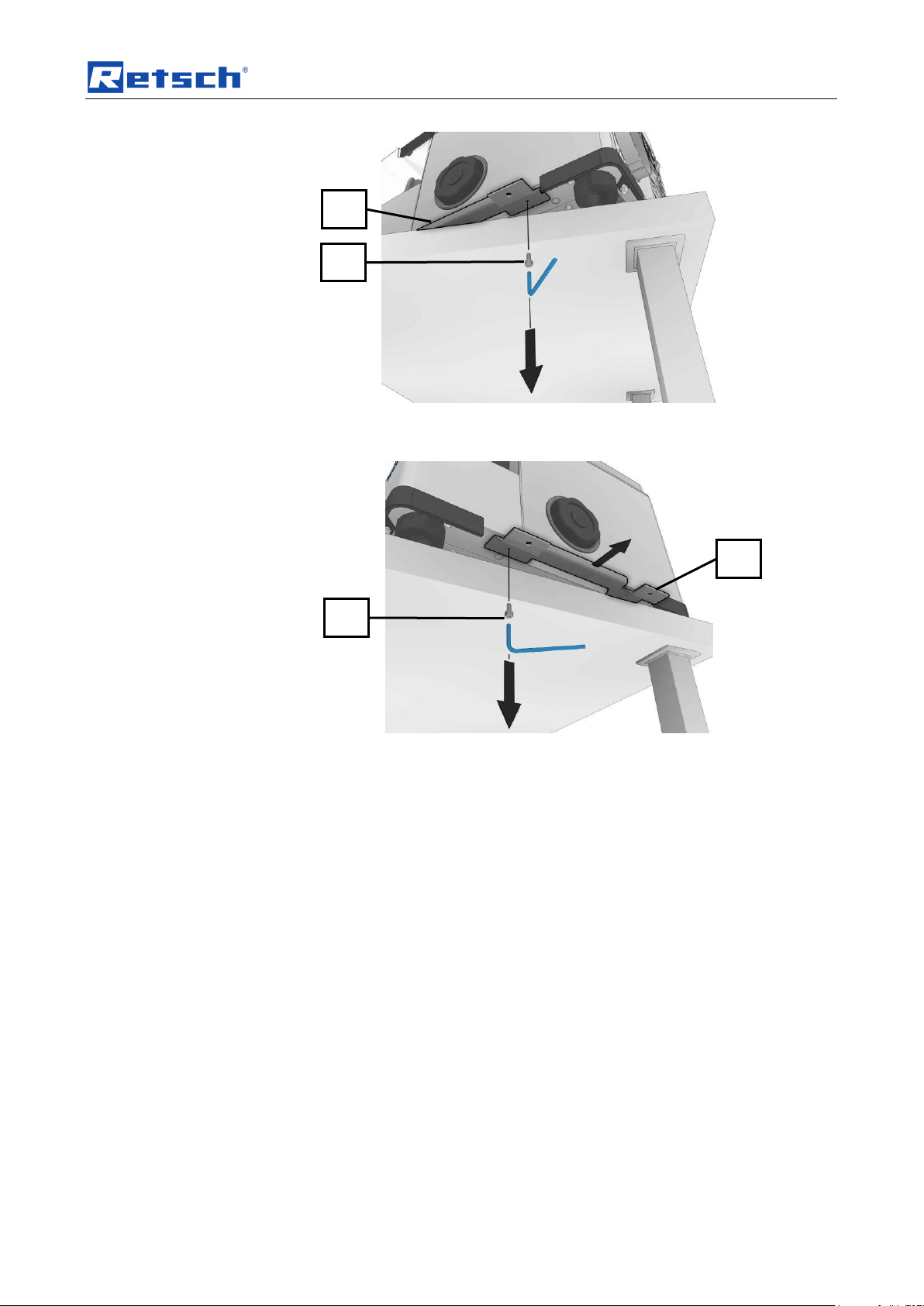

R

F1 U TL2

Fig. 3: Pulling out the condensation collecting filter

• Pull the condensation collecting filter (R) completely out of the device.

• Remove the opening aids (F1) on the side on which you have removed the

transport bracket (TL1).

• Place a soft, clean mat (U) next to the device.

• Tilt the device onto the side on which the transport bracket (TL1)

has been removed.

16

Fig. 4: Tilting the device onto its side

Page 17

Transport, scope of delivery, installation

TS

TC

TD

TL2

The transport lock (TS), which is labelled with an arrow, is situated on the

underneath of the device.

Pos: 5.23 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /0021 Cr yoMill II Modul Griffleiste @ 5\mod_1 355217974441_9.doc @ 36970 @ @ 1

Fig. 5: Removing the transport lock

• Loosen and remove the screw (TS).

• Unscrew the two screws (TC) and (TD).

• Remove the transport bracket (TL2).

Fig. 6:

• Re-insert the condensation collecting filter (R).

NOTICE

Keep the transport brackets, screws and transport lock for future transport!

17

Page 18

Transport, scope of delivery, installation

1 2 3 4 5 6 7 8 9

10

11

12

14

13

GL

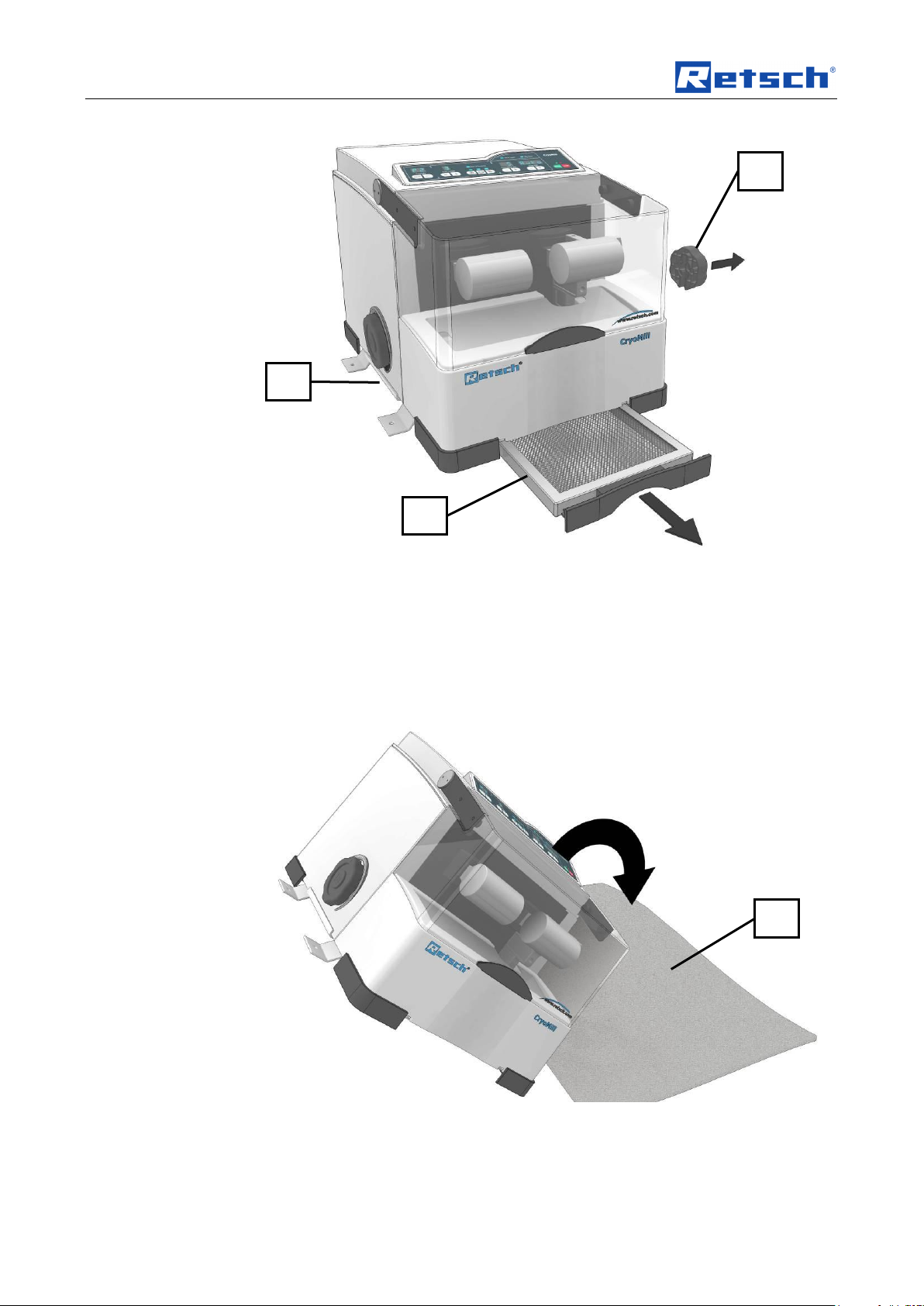

Fig. 7: Grip

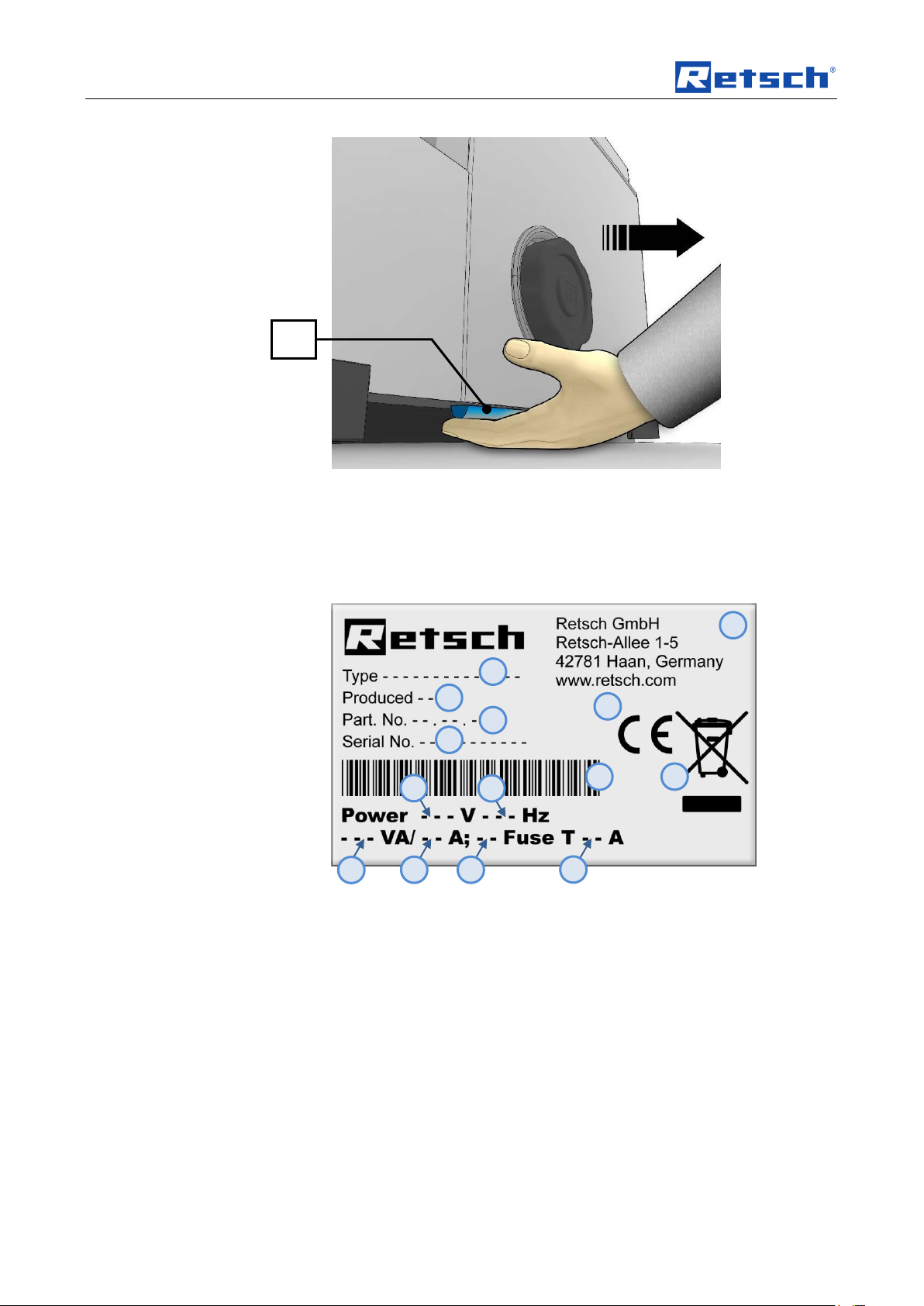

A grip (GL) is situated underneath both sides of the device

Pos: 5.24.1 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 Type nschild Beschreibung @ 3\mod_128093 3953941_9.doc @ 22302 @ 2 @ 1

• Use the grip (GL) to move the device.

4.7 Type plate description

Pos: 5.24.2 /00003 Standard Kapitel/Gen eral Modul Typenschild @ 3\mod_1280 931092443_9.doc @ 22278 @ @ 1

Fig. 8: Type plate lettering

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

18

Page 19

Transport, scope of delivery, installation

WARNING

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

NOTICE

Electrical connection

– Mechanical or electronic components may be damaged.

• Please observe the information on the type plate.

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of questions please provide the device designation (1) or the part

Pos: 5.25 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Elektrisc her Anschluss @ 0\mod_122656506 7445_9.doc @ 3500 @ 2 @ 1

number (3) and the serial number (4) of the device.

4.8 Electrical connection

Pos: 5.26 /00003 Standard Kapitel/Gen eral Modul Elektrischer Anschluss @ 0\ mod_1228918538521_9.doc @ 4731 @ @ 1

When connecting the power cable to the mains supply, use an external fusethat

complies with the regulations applicable to the place of installation .

• Please check the type plate for details on the necessary voltage and

frequency for the device.

• Make sure the levels agree with the existing mains power supply.

• Use the supplied connection cable to connect the device to the mains power

Pos: 5.27 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /CryoMil l II Modul externe Absicherung @ 5\mod_1343829054956_9.doc @ 33059 @ @ 1

Pos: 5.28 /00004 Warnhinweise/W0002 WARNUNG Kabelbruch Stromstoß @ 2\mod_1278055276120_9.doc @ 20557 @ @ 1

supply.

The external fuse must be at least T6.3A (230V) T8A (100/120V).

Pos: 5.29 /00004 Warnhinweise/H0008 HIN WEIS Elektrischer Anschluss @ 0\ mod_1228918882424_9.doc @ 4781 @ @ 1

Pos: 5.30 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 Kü hlmittelzufluss anschließen @ 0\mod_122690 8410419_9.doc @ 3576 @ @ 1

4.9 Connecting the cooling agent feed

Pos: 5.31 /00004 Warnhinweise/H0062 HIN WEIS Risiko der Eisbildung (CryoMill) @ 4\mod_1314082100670_9.doc @ 25 455 @ @ 1

19

Page 20

Transport, scope of delivery, installation

CAUTION

Blocked pipe

Ice formation

– Ice or impurities can block pipes and thereby cause malfunctions.

• Keep the cooling system and supply pipe dry and free from

impurities.

• Do not insert the grinding jar if it is damp or covered with frost.

• Insert the cooling jacket seal (KA) if you will not be using the device

for a long period.

• Do not operate the device unattended.

Pos: 5.32 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /002 0 CryoMill II Modul Kühlmantel Abdichtung @ 5\mod_1344926871592_9.doc @ 34 120 @ @ 1

20

Page 21

Transport, scope of delivery, installation

NOTICE

Damage to the machine

Incorrect cooling agent

– The use of cooling agents other than liquid nitrogen will cause the cooling

system to lose its leak tightness.

• Only liquid nitrogen (LN2) may be used as cooling agent with this

device.

KA

Pos: 5.33 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tr ansport, Lieferumfang und Aufstellen /001 8 CryoMill II Modul Schematische Darstell ung des Kühlsystems @ 5\mod_134451 1088330_9.doc @ 33941 @ @ 1

Fig. 9: Cooling jacket seal

Fig. 10: Connecting the cooling agent supply

21

Page 22

Transport, scope of delivery, installation

CAUTION

The maximum pressure in the external liquid

nitrogen supply line may be a maximum of 1.5

bar.

The use of a safety valve (SV)

is absolutely essential!

B1 (MV)

B2 (TSM)

TSD

TSM

MV

SV

Pos: 5.34 /00010 Bedienungsanleitung en Kapitelsammlungen/CryoMill II/0006 Tr ansport, Lieferumfang und Aufstellen /00 13 CryoMill II Modul Kühlsystem @ 5\ mod_1344511110312_9.doc @ 33952 @ @ 1

Fig. 11: Diagram of the cooling system

Fig. 12: LED displays

The temperature sensor (TSD) in the LN2 outlet controls the solenoid valve (MV).

The LED (B1) lights up when the solenoid valve (MV) is open.

The temperature sensor (TSM), which is downstream of the solenoid valve,

registers whether liquid nitrogen is flowing into the CryoMill. The LED (B2) lights

up when liquid nitrogen flows into the cooling system.

The device must not be moved in a cryogenic state and no additional forces may

act on the cooling agent connection (N). The cooling agent inlet hose must not be

moved while the device is in a cryogenic state.

22

Page 23

Transport, scope of delivery, installation

CAUTION

Risk of injury and danger of frostbite

Bursting of the inlet hose.

– Depending on the operating state of the device, liquid nitrogen may be

enclosed in the supply line. When heated this may lead to the inlet hose

bursting.

• The maximum pressure in the external liquid nitrogen supply line

may be a maximum of 1.5 bar. The use of a safety valve is absolutely

essential!

CAUTION

Risk of injury and danger of frostbite

Uncontrolled escape of liquid nitrogen

– There is a risk of injury in the event of an uncontrolled escape of liquid

nitrogen.

• Stop the liquid nitrogen supply line immediately!

CAUTION

The connection for the liquid nitrogen (LN2) is a G 1/4 inch threaded connector .

The operating pressure in the liquid nitrogen supply line should be at least 0.5 bar.

The lower the pressure of the liquid nitrogen supply line, the longer the precooling

takes. At 0.5 bar supply line pressure and with the system at room temperature,

precooling requires approx. 10 minutes. Depending on the application, you can

execute up to 4 grinding operations with 10 litres of liquid nitrogen.

Throughout the entire duration of cooling, the air humidity in the chamber

condenses on all cooled parts as a layer of ice .

Pos: 5.35 /00004 Warnhinweise/V0070 VOR SICHT LN2 Austritt (CryoMill) @ 4\ mod_1314082103623_9.doc @ 25491 @ @ 1

Pos: 5.36 /00004 Warnhinweise/H0063 HIN WEIS Wasser aus dem Auffangfilter tro pfen (CryoMill) @ 4\mod_13140821013 89_9.doc @ 25464 @ @ 1

After cooling this condensation drips into the collecting filter and evaporates.

NOTICE

Depending on the ambient temperature, air humidity and duration of use, small

Pos: 5.37 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Kühlmittelz ufluss entfernen @ 1\mod_1238053 128286_9.doc @ 7970 @ @ 1

quantities of water may drip from the collecting filter.

4.10 Removing the liquid nitrogen feed line

Pos: 5.38 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /001 2 CryoMill II Modul Kühlmittelzufluss entf ernen @ 5\mod_1344511338025_9.doc @ 33963 @ @ 1

Abb. 13: Removing the liquid nitrogen feed line

Before you remove the liquid nitrogen feed line, the pressure must be relieved for

safety reasons.

23

Page 24

Transport, scope of delivery, installation

CAUTION

Risk of injury to eyes and skin

Outlet for gaseous nitrogen

– Liquid nitrogen has a temperature of –196 °C and can cause burn-like

injuries or frostbite in the case of contact with the skin or eyes.

• Do not keep any parts of the body in front of the outlet for gaseous

nitrogen (B).

B

B10

B13

Abb. 14: pressure relief

• Press the (B10) pre-cooling and (B13) START keys simultaneously for 2

seconds.

Pos: 5.39 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Kaltluft- Austritt @ 0\mod_1232374121848_9.d oc @ 5510 @ @ 1

4.11 Cold air outlet

Pos: 5.40 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /0010 Cr yoMill II Modul Kaltluftaustritt VORSICHT @ 5\mod_1344511373029_9.doc @ 33974 @ @ 1

As long as you keep the keys depressed, the solenoid valve will remain open.

Fig. 15: Outlet for gaseous nitrogen (B)

Pos: 5.41 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Abluftsc hlauch montieren @ 5\mod_134452 2887327_9.doc @ 34030 @ 2 @ 1

4.12 Mounting the exhaust hose

Pos: 5.42 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0006 Tra nsport, Lieferumfang und Aufstellen /0005 Cr yoMill II Modul Abluftschlauch @ 5\ mod_1344519211701_9.doc @ 34020 @ @ 1

24

Page 25

Transport, scope of delivery, installation

B

BS

BR

Fig. 16: Exhaust hose

Pos: 6.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

• Fasten the exhaust hose (BR) with the clamp (BS) to the outlet (B).

– The exhaust hose can be extended up to 1 m

25

Page 26

Operating the machine

NOTICE

Area of use of the machine

– This machine is a laboratory machine designed for 8-hour single-shift

operation.

• This machine may not be used as a production machine nor is it

intended for continuous operation.

Pos: 6.2 /00005 Überschriften/1. Überschri ften/1 Bedienung des Gerätes @ 0\m od_1226565880211_9.doc @ 3519 @ 1 @ 1

5 Operating the machine

Pos: 6.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Einsatz d er Maschine bei bestimmungsgemäßer V erwendung @ 0\mod_122647673224 8_9.doc @ 3243 @ 2 @ 1

5.1 Use of the machine for the intended purpose

Pos: 6.4 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0007 Bedie nung/0023 CryoMill II Modul Zielgruppe Ma schinentyp @ 5\mod_13438292597 04_9.doc @ 33389 @ @ 1

Target group: operating company, operator

Pos: 6.5 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0007 Bedie nung/0007 CryoMill II Modul Einsatz bei besti mmungsgemäße Verwendung Cr yoMill @ 5\mod_1343829239142_9.doc @ 33213 @ @ 1

Name of machine model: CryoMill

This machine is a laboratory device and is suitable for the particularly gentle

grinding and homogenisation of heat-sensitive, soft, fibrous, hard and brittle

materials in a dry and wet state.

The CryoMill is designed exclusively for special grinding jars with screw-top lids (no

standard grinding jars) with steel jacket. It is used for the fast pulverization of up to

six samples simultaneously (dpending on the type of grinding jar).

Available grinding jar volumes :

– 50ml;

– 35ml;

– 25ml;

– 10ml;

– 4 x 5ml including adapter; and

Pos: 6.6 /00004 Warnhinweise/H0007 H INWEIS Einsatzbereich des Gerätes 8 Stün diger @ 1\mod_1236240219096_9.doc @ 7693 @ @ 1

Pos: 6.7 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

– 6 x 2ml Eppendorf vials.

The closed grinding system guarantees complete recovery of the samples . Due to

the extremely short grinding time and the high final fineness of the grinding sample,

the CryoMill is also ideally suitable for sample preparation for all spectral analyses.

Final fineness levels of up to 5 µm can be achieved depending on the grinding time

and the specific properties of the sample material.

The optimal grinding jar filling is generally 1/3 of the grinding jar volume.

Voluminous materials such as wool, leaves, grasses and similar are exceptions to

this. A fill level of 70 - 80% is necessary here.

26

Page 27

Operating the machine

C

F E F A T D FA

R

H

K,L,M

I O U

N P B J S

B

Pos: 6.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Grafisch e Ansichten der Bedienelemente und der Anzeige @ 0\mod_1226566362336_9. doc @ 3537 @ @ 1

5.2 Operating elements and displays

Pos: 6.9 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill II/0007 Bedie nung/0003 CryoMill II Modul Bedienelemente und Bedienung Gafische Ansichte n @ 5\mod_1343829232365_9.doc @ 33 169 @ 2 @ 1

Fig. 17: Front view

27

Page 28

Operating the machine

Element

Description

Function

A

Display and control unit:

See below for explanations

Time preselection, frequency preselection and

starting/stopping the machine

B

Nitrogen gas outlet

Outlet for gaseous nitrogen

C

Counterweight left

Counterweight for the cooling jacket with grinding

jar

D

Cooling jacket

Forms the cooling system together with the

grinding jar (T)

E

Hood

Closes the grinding chamber

F

Opening aid

Can be mounted on the grinding jar cover for

simple removal of the grinding jar

FA

Support for opening aid

Storage of the opening aid

H

Fan

Ventilates the motor and the interior of the mill

I

Caution remove mains plug sign

Safety instruction

J

Type plate

Information about the device and connected loads

K

ON / OFF switch

Switches the device on and off

L

Fuse drawer

Accommodates two glass fuses

M

Connector

Connector for the mains lead of the device

N

Cooling agent connection

Connection for liquid nitrogen

O

RS232 interface

Enables updating of the operating software

P

Observe operating instructions sign

Safety instruction

R

Condensation collecting filter

Collects the condensation from the cooling system

and allows it to evaporate

S

Drip tray

Housing protection

T

Grinding jar

Forms the cooling system together with the cooling

jacket (D)

Fig. 18: Rear view

5.3 Summary table of device parts

Pos: 6.10 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758 _0.doc @ 2386 @ @ 1

28

Page 29

Operating the machine

Element

Description

Function

B1

LED on – valve open

LED off – valve closed

Indicates whether the internal solenoid valve on the

liquid nitrogen supply line is open or closed.

B2

LED on – liquid nitrogen is flowing

LED off – no liquid nitrogen

Indicates that liquid nitrogen is flowing into the device.

B3

LED precooling is running (Vkz)

Precooling is taking place / lights up when values are

set

B4

LED grinding is running (Mz)

The sample is ground / lights up when values are set

B5

LED intermediate cooling is running

(Zkz)

Intermediate cooling is taking plate / lights up when

values are set

B7

Frequency minus button

In setting mode and in operating mode:

reduces the set frequency by 1 Hz (1/s). Continuous

pressing switches on fast scrolling of numbers.

Frequency plus button

In setting mode and in operating mode:

increases the set frequency by 1 Hz (1/s). Continuous

pressing switches on fast scrolling of numbers.

B8

Cooling cycle minus button

Reduces the number of total cycles by 1

Cooling cycle plus button

Increases the number of total cycles by 1

B9

Time minus button

In setting mode and in operating mode:

Reducing the set

• Precooling

• Grinding time

• Intermediate cooling time

B10

B7

B8

B15

B2

B1

B11

B12

B13

B9

B14

B3

B4

B5

Pos: 6.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Bedie nelemente und Anzeigen @ 0\mod_122 6566557086_9.doc @ 3543 @ @ 1

5.4 Operating elements and displays

Pos: 6.12 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0002 CryoMill II Modul Anzeige und Bedieneinheit @ 5\mod_1343829230 960_9.doc @ 33158 @ @ 1

Fig. 19: Control unit

29

Page 30

Operating the machine

Time plus button

In setting mode and in operating mode:

Increasing the set

• Precooling

• Grinding time

• Intermediate cooling time

B10

Setting precooling

Preselection button to set the precooling / switching

automatic precooling on or off)

B11

Setting grinding

Preselection button to set the grinding time

B12

Setting intermediate cooling

Preselection button to set the intermediate cooling time

B13

Start button

Green LED

Starts grinding operation

Indicates grinding operation

Stop button

Red LED and ON

Interrupts or ends grinding operation,

places the machine in stand-by mode

B14

LED - auto precooling

Indicates whether the automatic precooling is switched

on

B15

PROG button

Button to select a program

SET button

Button starts / saves a program editing

Pos: 6.13 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758 _0.doc @ 2386 @ @ 1

30

Page 31

Operating the machine

CAUTION

Danger of injury and frostbite

Escape of liquid nitrogen

– Liquid nitrogen has a temperature of –196 °C and may cause injuries

similar to burns on skin or eye contact or frostbite.

• Never switch the machine on without tightly closed cooling casing.

CAUTION

Crushed or bruised fingers

Falling grinding chamber protective hood

– The protective hood of the grinding chamber can cause crushed or bruised

fingers if it falls down.

• Hold the flap tight when closing.

CAUTION

Clogged piping

Formation of ice

– Ice or foreign matter can clog the pipe and subsequently cause

malfunctioning.

• Do not insert the grinding jar if it is damp or covered with frost.

• Use the cooling jacket sealing plug (KA) if you are not going to use

the device for a long time.

• Do not let the device run without supervision.

Pos: 6.14 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahlbe hälter einsetzen @ 0\mod_1226569844 414_9.doc @ 3555 @ @ 1

5.5 Inserting the grinding jar

Pos: 6.15 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill/0101 Warnhin weise/CryoMill VORSICHT Austritt von fl üssigem Stickstoff @ 0\mod_12287496 57712_9.doc @ 4360 @ @ 1

Pos: 6.16 /00004 Warnhinweise/V0008 VOR SICHT Klappe beim Schließen festhalte n (CryoMill) @ 2\mod_127805421350 5_9.doc @ 20549 @ @ 1

Pos: 6.17 /00005 Überschriften/1.1.1 Ü berschriften/111 CryoMill Spezial Mahlbecher einsetzen @ 0\mod_122751681255 5_9.doc @ 3966 @ @ 1

5.5.1 Inserting and removing CryoMill special grinding jar

Pos: 6.18 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill/0101 Warn hinweise/CryoMill HINWEIS Risiko der Eis bildung @ 0\mod_1234165670129_9. doc @ 6140 @ @ 1

Pos: 6.19 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0014 CryoMill II Modul Mahlbecher Ei nsetzen wechseln @ 5\mod_13438 29248165_9.doc @ 33290 @ @ 1

31

Page 32

Operating the machine

KM

SM

1.

2.

Fig. 20: Dismantling the grinding jar retaining device

• Unscrew the lock nut (KM).

• Remove the screw (SM).

Fig. 21: Inserting the grinding jar

• Insert the special grinding jar filled with the grinding material and grinding

balls into the cooling jacket .

• Twist the grinding jar in completely.

32

Page 33

Operating the machine

CAUTION

Risk of injury to eyes and skin

The cooling jacket and grinding jar reach very low temperatures

during grinding.

– Risk of injury to eyes and skin from severe frostbite

• As a matter of principle, always wear goggles and

protective gloves when opening the cooling jacket and the

grinding jar.

KM

2.

1.

SM

Fig. 22: Securing the grinding jar

• First tighten the screw (SM) by hand (hand-tight).

• Then tighten the lock nut against the cooling jacket. Use the locking pin

provided to do this.

Ensure that the grinding jar is tightly screwed to the cooling jacket, otherwise liquid

nitrogen can escape.

The lock screw (SM) must be screwed tight and secured with the lock nut so that

no sample material escapes from the grinding jar.

Use the opening aid (F) that is kept on the side of the device to remove the

grinding jar .

• Unscrew the lock nut (KM)

• Remove the screw (SM)

• Mount the opening aid (F) on the grinding jar and open it.

33

Page 34

Operating the machine

NOTE

1.H0017

Damage to the PTFE grinding jar

– The threading on the grinding jar can become damaged.

• When it is being inserted into the device, the PTFE grinding jar must

be at room temperature and must not be pre-cooled.

NOTICE

Blocked pipe

Ice formation

– Ice or impurities can block pipes and thereby cause malfunctions.

• Insert the cooling jacket seal (KA) as soon as you are no longer using

the device.

F

Pos: 6.20 /00004 Warnhinweise/H0056 HIN WEIS Cryomill PTFE Mahlbecher nur mit Zimmertemperatur einsetzen - Nicht vorkühlen @ 4\mod_1314082879240_9.d oc @ 25509 @ @ 1

Pos: 6.21 /00005 Überschriften/1.1.1 Ü berschriften/111 Kühlmantel Abdichtung eins etzten @ 2\mod_1266314975785_9.doc @ 18787 @ @ 1

Fig. 23: Using the opening aid

5.5.2 Inserting the cooling jacket sealing plug

Pos: 6.22 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0011 CryoMill II Modul Kühlmantela bdichtung einsetzen @ 5\mod_134 3829244950_9.doc @ 33257 @ @ 1

34

Page 35

Operating the machine

KA

Pos: 6.23 /00005 Überschriften/1.1.1 Ü berschriften/111 Adapter für 4/2 x 5ml Ma hlbecher einsetzen @ 0\mod_1227516748 177_9.doc @ 3960 @ @ 1

Fig. 24: Inserting the cooling jacket seal

5.5.3 Insert the adapter for 4/2 x 5 ml grinding jar

Pos: 6.24 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0001 CryoMill II Modul 5ml Mahlbec her einsetzen @ 5\mod_13438292 29211_9.doc @ 33147 @ @ 1

You can operate the CryoMill with 4 or 2 (5 ml) grinding jars.

• Insert the 5 ml grinding jars into the adapter as shown in the following

diagram.

Fig. 25: Inserting a 5ml grinding jar

Note the positioning of the grinding jars. If you are using two grinding jars, these

must be inserted in opposite openings.

Fig. 26: 5ml grinding jar position

35

Page 36

Operating the machine

NOTICE

Breaking of Eppendorf reaction vials

Changing material properties

– The Eppendorf reaction vials that are available as accessories change

their material properties during the cryogen grinding.

• Do not reuse reaction vials after the cryogen grinding.

• Do not insert reaction vials in centrifuges after the cryogen grinding

• Grinding may take place with a maximum 25Hz.

Pos: 6.25 /00005 Überschriften/1.1.1 Ü berschriften/111 Adapter für 4/2 x 2 ml Epp endorf Reaktionsgefäße einsetzen @ 1\ mod_1243499921893_9.doc @ 10328 @ @ 1

Fig. 27: Inserting the grinding jar adapter

5.5.4 Insert the adapter for 6 / 4 / 2 x 2-ml Eppendorf reaction vial

Pos: 6.26 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill/0101 Warnhin weise/CryoMill HINWEIS Zerbrechen von Eppendorf Reaktionsgefäßen @ 1\m od_1243499975784_9.doc @ 10336 @ @ 1

Pos: 6.27 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0008 CryoMill II Modul Eppendorf G efäße einsetzen @ 5\mod_134382 9240370_9.doc @ 33224 @ @ 1

You can operate the CryoMill with 2, 4 or 6 Eppendorf reaction vials (2ml).

NOTICE

Grinding with Eppendorf reaction vials may only take place with a maximum 25Hz.

(frequency 1/s)

• Insert the 2ml Eppendorf reaction vials into the adapter for reaction vials as

shown in the diagram below.

Fig. 28: Inserting 2ml Eppendorf reaction vials

36

Page 37

Operating the machine

Note the positioning of the Eppendorf reaction vials. If you are using two or four

reaction vials, these must be inserted in opposite openings.

Pos: 6.28 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Erläuter ungen zu den Mahlzyklen @ 0\mod_1 227686930552_9.doc @ 4010 @ @ 1

Fig. 29: Position of 2 ml reaction vials

5.6 Explanations of the grinding cycles

Pos: 6.29 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0009 CryoMill II Modul Erläuterungen zu den Mahlzyklen @ 5\mod_13438 29242206_9.doc @ 33235 @ 33 @ 1

You can deploy the CryoMill for grinding with cooling or grinding without cooling.

5.6.1 Grinding without cooling

• Switch the CryoMill on at the main switch.

• Set the cryo cycles to - .

• Set the desired grinding time (B9)+(B11).

• Press the START button.

The START LED lights up. The remaining grinding time and the set frequency are

displayed.

5.6.2 Grinding with cooling

The following program points can be set when grinding with cooling.

– precooling (Vkz)

– grinding time (Mz)

– intermediate cooling time (Zkz)

– cryo cycles (Number of cooling/grinding cycles)

– frequency 1/s (Grinding frequency)

A single grinding cycle consists of the precooling and the set grinding time. The

intermediate cooling time does not apply in the case of a single grinding cycle.

37

Page 38

Operating the machine

B15

Vkz + Mz = total grinding time

Fig. 30: Sequence of a single grinding cycle

Multiple grinding cycles consist of the precooling, the set grinding time and the

intermediate cooling time.

Number of cryo cycles: n

Vkz + (n-1) (Mz + Zkz) + Mz = total grinding time

Precooling + [(number of set cryo cycles) - 1] x (grinding time + intermediate cooling time) +

grinding time = total grinding time

Pos: 6.30 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Prog ramme @ 5\mod_1344511635554_9.doc @ 33985 @ 2 @ 1

Fig. 31: Sequence of two grinding cycles

5.7 Programs

Pos: 6.31 /00005 Überschriften/1.1.1 Ü berschriften/111 Vermahlung ohne Program m @ 5\mod_1344590601015_9.doc @ 34040 @ 3 @ 1

5.7.1 Grinding without program

Pos: 6.32 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0024 CryoMill II Modul Vermahlu ng ohne Programm @ 5\mod_13445117 04525_9.doc @ 33995 @ @ 1

Fig. 32: Grinding without program

• Press the PROG button (B15) until “- -” is shown in the memory display .

38

Page 39

Operating the machine

B15

B7

B8

B9

B10

B11

B12

The display advances one program each time the button is pressed

- - > P1 > P2 > P3 > P4 > P5 > P6 > P7 > P8 > P9

Pos: 6.33 /00005 Überschriften/1.1.1 Ü berschriften/111 Vermahlung mit Program m @ 5\mod_1344590647615_9.doc @ 34 050 @ 3 @ 1

– The SET button (B15) is blocked in the “- -” mode

5.7.2 Grinding with program

Pos: 6.34 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0025 CryoMill II Modul Vermahlung mit Programm @ 5\mod_1344512 746227_9.doc @ 34005 @ 4444 @ 1

Fig. 33: Grinding with program

5.7.2.1 Selection of a program

• Press the PROG button (B15) until the required program is shown in the

memory display.

– The display advances one program each time the button is pressed .

- - > P1 > P2 > P3 > P4 > P5 > P6 > P7 > P8 > P9

– The buttons B8, B7, B9 are blocked due to the selection of a program.

5.7.2.2 Display of the program grinding parameters

Precooling

• Press the precooling button (B10).

– The set time for precooling appears in the time min (B9) display.

Grinding time

• Press the grinding time button (B11).

– The set time for the grinding time appears in the time min (B9) display.

Intermediate cooling

• Press the intermediate cooling button (B12).

– The set time for the intermediate cooling appears in the time min (B9)

display.

5.7.2.3 Create/change a program

• Press the PROG button (B15) until the required program (memory space) is

displayed in the memory display.

• Press the SET button (B15).

– All displays and the corresponding LEDs for which settings are possible light

up or flash.

39

Page 40

Operating the machine

B8

• Set the parameters for grinding as described in the following chapters:

- Number of grinding cycles

- Precooling

- Grinding time

- Intermediate cooling time

- Grinding frequency

– It is possible to cancel at any time using the PROG button (B15)

• Press the SET button (B15).

– Pressing the SET BUTTON (B15) again stores all parameters in the

program.

5.7.2.4 Delete program

• Press the PROG button (B15) until the program to be deleted is displayed in

the memory display.

• Press the shortcut SET (B15) and - (B8) for at least 5 seconds.

Fig. 34: Deleting a program

– The program is deleted and the parameters are assigned with the values “0”

or “-”.

Pos: 6.35 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahl- Zyklen einstellen @ 0\mod_12271852531 26_9.doc @ 3879 @ @ 1

– It is not possible to start a deleted program.

5.8 Setting grinding cycles

Pos: 6.36 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0017 CryoMill II Modul Mahlzyklen ei nstellen @ 5\mod_1343829253169 _9.doc @ 33323 @ @ 1

Fig. 35: Setting the grinding cycles

40

• Switch the CryoMill on at the main switch.

– After switching on, the last used grinding parameters are displayed and can

be used.

– You can set 0 ("-") to 9 grinding cycles

NOTICE

If 0 ("-") CryoCycles are set, the grinding is conducted without nitrogen. In this

case the buttons B10, B11 and B12 are blocked.

Page 41

Operating the machine

B10

B9

ap

– The first cycle consists of the precooling phase and grinding time

– Cycles 2 to 9 each comprise an intermediate cooling and grinding.

• Press the respective buttons (B8) to set the grinding cycles.

• + Pressing briefly increases the number.

• - Pressing briefly reduces the number.

Pos: 6.37 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Vor kühlzeit einstellen @ 0\mod_12271851066 11_9.doc @ 3867 @ @ 1

– The display runs more quickly when pressed longer.

5.9 Setting the precooling time

Pos: 6.38 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0022 CryoMill II Modul Vorkühlzeit ein stellen @ 5\mod_134382925856 7_9.doc @ 33378 @ 33 @ 1

NOTICE

The machine runs at a fixed frequency of 5 Hz during the precooling and

intermediate cooling.

A range of from 30 seconds to 99 minutes can be set for precooling.

Fig. 36: Setting precooling

After switching on, the last used grinding parameters are displayed and can be

used.

• Switch the CryoMill on at the main switch.

• Press the button (B10) to set precooling

– The precooling LED lights up.

You can choose between two precooling versions:

5.9.1 Precooling with definable precooling time

• Use the buttons (B9) to set precooling.

• + Pressing briefly increases the duration.

• - Pressing briefly shortens the duration.

The display runs more quickly when pressed longer.

5.9.2 Automatic precooling

In the case of automatic precooling the grinding only starts once the entire system

has been sufficiently cooled. This is checked by a sensor (see chapter

>>Connecting the cooling agent supply <<)

Switch automatic precooling on

• Press the button (B10) for at least 2 seconds.

41

Page 42

Operating the machine

B12

B9

LED

B11

B9

LED

– The auto precooling (ap) LED is lit up.

– “Auto” is shown in the time min display.

Switch automatic precooling off

• Press the button (B10) for at least 2 seconds.

– The auto precooling (ap) LED is extinguished.

Pos: 6.39 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahlda uer einstellen @ 0\mod_122690845696 5_9.doc @ 3582 @ @ 1

– “08:00" is shown in the time min display.

5.10 Setting the grinding time

Pos: 6.40 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 B edienung/0015 CryoMill II Modul Mahldauer einstellen @ 5\mod_1343829251134_9. doc @ 33301 @ @ 1

Fig. 37: Setting the grinding time

• Press the button (B11) to set the grinding time.

The grinding time LED lights up.

• Use the buttons (B9) to set the grinding time

(5 to 30 Hz in 1Hz steps).

– + Pressing briefly increases the duration.

– - Pressing briefly shortens the duration.

The display runs more quickly when pressed longer.

NOTICE

In the case of grinding without cooling, the grinding time can be set directly using

Pos: 6.41 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Dauer d er Zwischenkühlung einstellen @ 0\ mod_1227185184595_9.doc @ 3873 @ @ 1

5.11 Setting the duration of intermediate cooling

Pos: 6.42 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0006 CryoMill II Modul Dauer der Z wischenkühlung einstellen @ 5\mod_13 43829237941_9.doc @ 33202 @ @ 1

42

the buttons (B9).

Fig. 38: Setting the intermediate cooling

Page 43

Operating the machine

CAUTION

Danger of injury and frostbite

Escape of liquid nitrogen

– Liquid nitrogen has a temperature of –196 °C and may cause injuries

similar to burns on skin or eye contact or frostbite.

• Never switch the machine on without tightly closed cooling casing.

B7

• Press the button (B12) to set the intermediate cooling .

The intermediate cooling time LED lights up.

• Use the buttons (B9) to set the intermediate cooling time

(30 seconds to 99:00 minutes).

– + Pressing briefly increases the duration.

– - Pressing briefly shortens the duration.

Pos: 6.43 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahlfreq uenz einstellen @ 0\mod_122690855 9789_9.doc @ 3588 @ @ 1

The display runs more quickly when pressed longer.

5.12 Setting the grinding frequency

Pos: 6.44 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0016 CryoMill II Modul Mahlfrequenz einstellen @ 5\mod_1343829252 220_9.doc @ 33312 @ @ 1

Fig. 39: Frequency 1/s

• Switch the CryoMill on at the main switch.

It is only possible to adjust the grinding frequency if the button (B11) for setting the

grinding parameters has been pressed and the LED (B11) is lit up.

• Press the button (B11).

• Press the respective buttons (B7) to set the grinding frequency .

The selectable frequency range is from 3 to 30 Hz.

• + Pressing briefly increases the frequency.

• - Pressing briefly reduces the frequency.

The display runs more quickly when pressed longer.

The frequency of precooling and intermediate cooling is fixed at 5 Hz. The

frequency cannot be adjusted while setting the precooling or intermediate cooling

Pos: 6.45 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahl vorgang starten @ 0\mod_122718500819 0_9.doc @ 3861 @ @ 1

time.

5.13 Starting the grinding process

Pos: 6.46 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill/0101 Warnhin weise/CryoMill VORSICHT Austritt von fl üssigem Stickstoff @ 0\mod_12287496 57712_9.doc @ 4360 @ @ 1

Pos: 6.47 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill/0101 Warnhin weise/CryoMill HINWEIS Der Mahlvorga ng kann nur gestartet werden, wenn die Haube geschlossen ist. @ 0\mod_12 28833855525_9.doc @ 4432 @ @ 1

NOTICE

Pos: 6.48 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0020 CryoMill II Modul Start des Ma hlvorganges @ 5\mod_134382925 6297_9.doc @ 33356 @ @ 1

The grinding process can only be started if the hood is closed.

43

Page 44

Operating the machine

B13

B13

B13

Fig. 40: Starting the grinding process

• Press the START button to start the grinding process.

– The Start LED (green) lights up. At the same time the solenoid valve opens

Pos: 6.49 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 Mahl vorgang unterbrechen und weiterführen @ 1 \mod_1241510629134_9.doc @ 8833 @ @ 1

and liquid nitrogen can flow into the cooling system.

5.14 Interrupting and continuing the grinding process

Pos: 6.50 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0026 CryoMill II Modul Pausenfun ktion @ 5\mod_1345098786153_9.doc @ 34130 @ @ 1

5.14.1 Pausing grinding

Fig. 41: Pausing grinding

• Press the STOP button (B13) once.

– Grinding is interrupted and the LED above the START button flashes.

5.14.2 Cancelling grinding

Fig. 42:

• Press the STOP button (B13) twice.

– The grinding is ended and the two LEDs above the START and STOP

Pos: 6.51 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Mahl vorgang stoppen @ 0\mod_1226909892 231_9.doc @ 3643 @ @ 1

buttons are off.

5.15 Stopping the grinding process

Pos: 6.52 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0021 CryoMill II Modul Stoppen des Ma hlvorganges @ 5\mod_1343829 257317_9.doc @ 33367 @ @ 1

44

Page 45

Operating the machine

K

Fig. 43: Ending the grinding process

• Press the STOP button to end the grinding process.

The STOP LED (red) lights up. At the same time the solenoid valve closes.

In the event that the supply of liquid nitrogen has been interrupted during

operation, this is indicated by the flashing of the remaining time LED (B6) at the

end of the grinding time.

Pressing once interrupts the grinding process, for example to appraise the grinding

sample. The remaining grinding time is still visible on the display.

By pressing the start button again, the mill continues running until the grinding time

has completely expired.

Pressing the stop button twice aborts the grinding process. The machine is now in

start mode.

By pressing the start button, the display is activated again and the grinding time is

reset to the last start setting.

The duration can be changed during the grinding process. The grinding process is

automatically ended on expiry of the grinding time. The display is reset to the last

Pos: 6.53 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Betriebss tunden-Anzeige @ 0\mod_1226909 921463_9.doc @ 3649 @ @ 1

value started.

5.16 Operating hours display

Pos: 6.54 /00010 Bedienungsanleitungen K apitelsammlungen/CryoMill II/0007 Bedi enung/0005 CryoMill II Modul Betriebsstun den anzeigen @ 5\mod_1343829236 125_9.doc @ 33191 @ @ 1

• Switch the device off at the mains switch.

Fig. 44: Switching the device on and off

• Keep the buttons cryo cycles (B8) + and frequency (B7) - pressed

simultaneously and with the buttons pressed, switch the device on at the

mains switch.

45

Page 46

Operating the machine

K

B7

B8

B7

B8

Fig. 45: Display of the operating hours