Page 1

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany | 07.10.2019 Version 0001

Manual

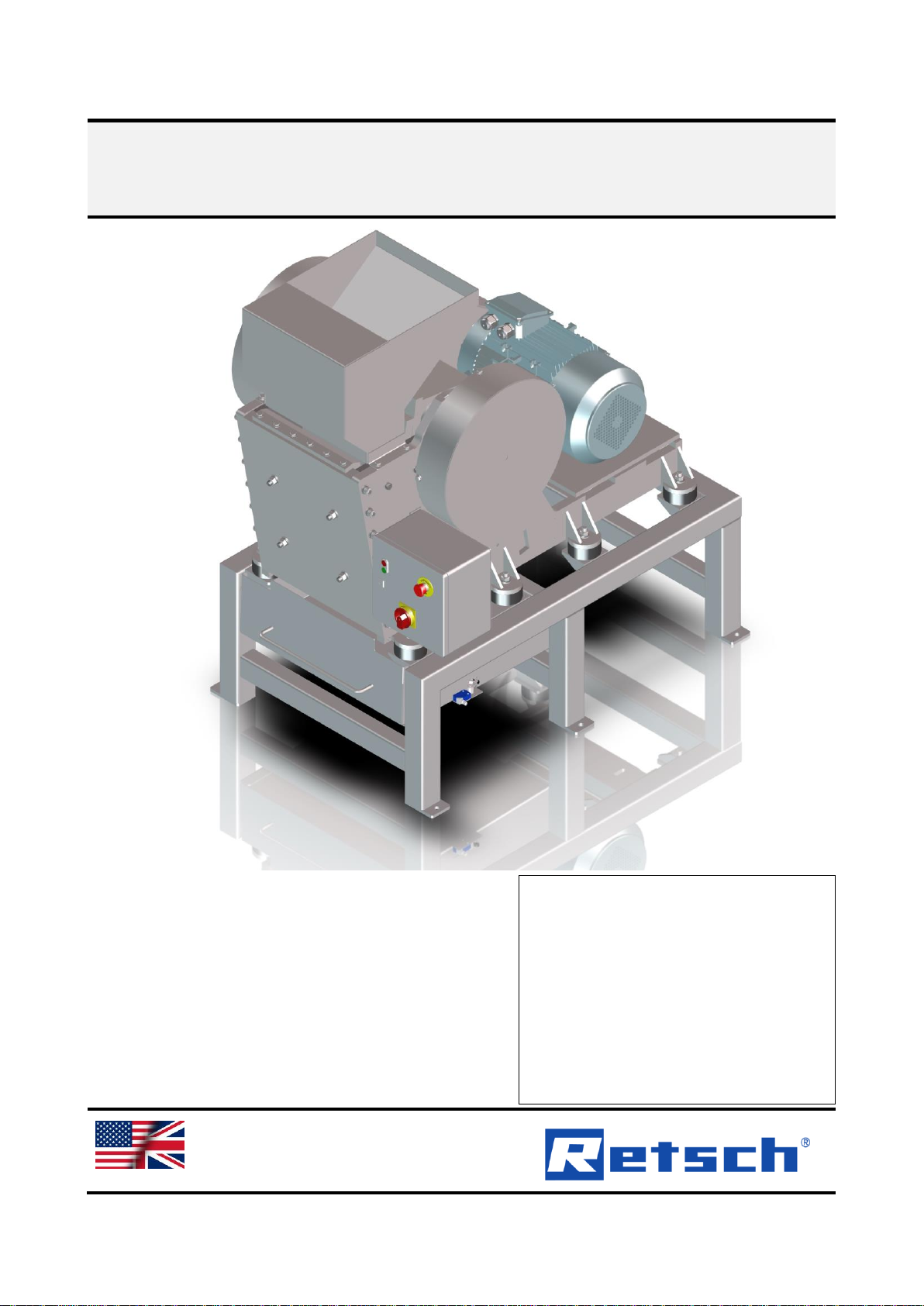

Jaw Crusher BB 600

Translation

Page 2

2

Copyright

© Copyright by

Retsch GmbH

Retsch-Allee 1-5

42781 Haan

Germany

Page 3

3

Table of Contents

1 Notes on the manual ........................................................................................................................ 5

1.1 Disclaimer .................................................................................................................................... 5

1.2 Copyright ...................................................................................................................................... 5

1.3 Repairs ......................................................................................................................................... 6

2 Safety ................................................................................................................................................ 7

2.1 Explanations of the Safety Instructions .......................................................................................... 8

2.2 General Safety Instructions ........................................................................................................... 9

2.3 Protective Equipment .................................................................................................................. 10

2.4 Intended use............................................................................................................................... 10

2.5 Improper use .............................................................................................................................. 10

2.6 Confirmation Form for the Managing Operator ............................................................................ 11

3 Technical Data................................................................................................................................ 12

3.1 Use of the Device for the Intended Purpose ................................ ................................................ 12

3.2 Principle of Operation ................................................................................................................. 12

3.3 Dimensions and Weight .............................................................................................................. 12

3.4 Required Floor Space ................................................................................................................. 13

3.5 Installation drawing ..................................................................................................................... 14

3.6 Rated Power............................................................................................................................... 15

3.7 Degree of Protection ................................ ................................................................ ................... 15

3.8 Emissions ................................................................................................................................... 15

3.9 Electromagnetic Compatibility (EMC) .......................................................................................... 16

3.10 Feed Grain Size.......................................................................................................................... 16

3.11 Degree of hardness of the sample material ................................................................ ................. 16

3.12 Gap width ................................ ................................................................ ................................ ... 16

4 Packaging, Transport and Installation .......................................................................................... 17

4.1 Packaging .................................................................................................................................. 17

4.2 Transport .................................................................................................................................... 17

4.3 Temperature Fluctuations and Condensation .............................................................................. 19

4.4 Conditions for the Installation Site ............................................................................................... 19

4.5 Electrical Connection .................................................................................................................. 20

4.6 Type Plate Description ................................................................................................................ 21

5 Views of the device ........................................................................................................................ 22

5.1 Front........................................................................................................................................... 22

5.2 Back ................................................................................................ ................................ ........... 23

5.3 View of the control unit................................................................................................................ 24

6 First Commissioning...................................................................................................................... 25

6.1 Installation of the Device ................................................................................................ ............. 26

6.2 Establishing the power supply ..................................................................................................... 27

7 Operating the Device ..................................................................................................................... 28

7.1 Switching On / Off ....................................................................................................................... 29

7.2 Adjusting the gap width ............................................................................................................... 30

7.3 Adding sample material .............................................................................................................. 32

7.4 Removing sample material after grinding .................................................................................... 33

8 Cleaning, Wear and Maintenance .................................................................................................. 35

8.1 Cleaning ................................................................................................................................ ..... 35

8.1.1 Cleaning the machine housing ................................................................................................ 36

8.1.2 Cleaning the feed hopper and grinding chamber ..................................................................... 36

8.2 Wear .......................................................................................................................................... 37

8.2.1 Replacing the breaking jaws ................................................................................................... 37

8.2.2 Replacing the wearing plates .................................................................................................. 40

8.3 Maintenance ............................................................................................................................... 42

Page 4

4

8.3.1 Lubricating the device ............................................................................................................. 42

8.3.2 Checking the limit switch ......................................................................................................... 43

8.4 Return for Service and Maintenance ........................................................................................... 44

9 Accessories.................................................................................................................................... 45

10 Disposal.......................................................................................................................................... 46

11 Index ................................................................ ................................................................ ............... 47

Page 5

Notes on the manual

5

1 Notes on the manual

This manual provides technical guidelines for the safe operation of the device. Read this

manual through carefully before installing, putting into service and operating the device.

Reading and understanding this manual is essential for handling the device safely and as

intended.

This manual does not contain any repair instructions. Please contact your supplier or contact

Retsch GmbH directly if anything is unclear or you have questions about these guidelines or the

device, or in the case of any faults or necessary repairs.

You can find further information about your device at http://www.retsch.com on the pages for

the specific device concerned.

Amendment status:

The document amendment 0001 of the "Jaw Crusher BB 600" manual has been prepared in

accordance with the Machinery Directive 2006/42/EC.

1.1 Disclaimer

This manual has been prepared with great care. We reserve the right to make technical

changes. We assume no liability for personal injuries resulting from the failure to follow the

safety information and warnings in this manual. No liability will be assumed for damage to

property resulting from the failure to follow the information in this manual.

1.2 Copyright

This document or parts of it or its content may not be reproduced, distributed, edited or copied

in any form without prior written permission of Retsch GmbH. Damage claims shall be asserted

in the case of infringements.

Page 6

Notes on the manual

6

1.3 Repairs

This manual does not contain any repair instructions. For safety reasons, repairs may only be

carried out by Retsch GmbH or an authorised representative or by qualified service technicians.

In case of repair, please inform…

…the Retsch GmbH representative in your country,

…your supplier, or

…Retsch GmbH directly.

Service address:

Page 7

Safety

7

2 Safety

Safety Officer

The operating company itself must ensure the following with respect to persons authorised to

work on the device:

− that they have read and understood all regulations contained in the chapter on safety;

− that they are aware before they start work of all instructions and regulations for the target

group related to the work;

− that they have easy access to the manual for this device at all times;

− that they have been familiarised with the safe and correct handling of the device before

starting work on it, by means of a verbal introduction by a competent person and/or using

this manual.

Improper operation can lead to personal injuries. The operating company itself is

responsible for its safety and that of its staff. The operating company itself must ensure that no

unauthorised persons have access to the device.

Target group

All those operating, cleaning or working with or on the device.

This device is a modern, powerful product from Retsch GmbH and has been developed in line

with the state-of-the art. The device is safe to use when operated correctly and when following

the instructions in this manual.

People under the influence of intoxicating substances (medications, drugs, alcohol) or who

are overtired may not operate the device or work on the device.

Page 8

Safety

8

2.1 Explanations of the Safety Instructions

The following warnings in this manual warn of possible risks and damage:

DANGER

D1.0000

Risk of fatal injuries

Source of danger

− Possible consequences if the danger is ignored.

• Instructions and information on how to avoid the risk.

Fatal or serious injuries may result if the “Danger” sign is disregarded. There is a very high

risk of a life-threatening accident or lasting personal injury. The signal word DANGER is

additionally used in the running text or in instructions.

WARNING

W1.0000

Risk of life-threatening or serious injuries

Source of danger

− Possible consequences if the danger is ignored.

• Instructions and information on how to avoid the risk.

Life-threatening or serious injuries may result if the “Warning” sign is disregarded. There is

an increased risk of a serious accident or of a possibly fatal personal injury. The signal word

WARNING is additionally used in the running text or in instructions.

CAUTION

C1.0000

Risk of injuries

Source of danger

− Possible consequences if the danger is ignored.

• Instructions and information on how to avoid the risk.

Average to slight injuries may result if the “Caution” sign is disregarded. There is an average

or slight risk of an accident or personal injury. The signal word CAUTION is additionally

used in the running text or in instructions.

Page 9

Safety

9

NOTICE

N1.0000

Type of damage to property

Source of the damage to property

− Possible consequences if the information is ignored.

• Instructions and information on how to avoid the damage to

property.

Damage to property may result if the information is disregarded. The signal word NOTICE is

additionally used in the running text or in instructions.

2.2 General Safety Instructions

CAUTION

C2.0002

Risk of injury

Lack of knowledge of the manual

− The manual contains all safety-related information. Disregarding the

manual can therefore lead to injuries.

• Read the manual carefully before operating the device.

CAUTION

C3.0015

Risk of injury

Improper modifications to the device

− Improper modifications to the device can result in injuries.

• Do not make any unauthorised changes to the device.

• Only use the spare parts and accessories approved by Retsch

GmbH!

NOTICE

N2.0012

Changes to the device

Improper modifications

− The conformity declared by Retsch GmbH with the European Directives

will lose its validity.

− Any warranty claims will be terminated.

• Do not make any modification to the device.

• Use spare parts and accessories that have been approved by Retsch

GmbH exclusively.

Page 10

Safety

10

2.3 Protective Equipment

• The Jaw Crusher BB 600 can only be started when the collecting receptacle has been

inserted into the base frame.

• A limit switch behind the collecting receptacle prevents the machine starting in an unsafe

state.

• Removing the collecting receptacle results in the grinding process stopping immediately.

• The motor protection switch turns the drive motor off when the jaws are blocked.

• In the event of danger, the machine can be shut down at any time by pressing the

emergency stop button .

2.4 Intended use

The Jaw Crusher BB 600 is suitable for grinding medium to extremely hard substances and for

brittle and hard ductile materials.

The machine has been designed for 8-hour single shift operation. Use is only permitted in the

laboratory by appropriately trained and qualified staff.

2.5 Improper use

The Jaw Crusher BB 600 is not designed for continuous operation. Use in the private sphere

and for applications other than those set out in the “Intended use” chapter is not permitted.

Repairs and modifications may only be carried out by Retsch GmbH by an authorised

representative, or by qualified service technicians.

Page 11

Safety

11

2.6 Confirmation Form for the Managing Operator

This manual contains essential instructions for operating and maintaining the device which must

be strictly observed. It is essential that they be read by the user and by the qualified staff

responsible for the device before the device is commissioned. This manual must be available

and accessible at the place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that he has received

sufficient instructions about the operation and maintenance of the system. The user has

received the manual, has read and taken note of its contents and consequently has all the

information required for safe operation and is sufficiently familiar with the device.

The managing operator should for legal protection have the user confirm the instruction about

the operation of the device.

I have read and taken note of the contents of all chapters in this manual as well as all

safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Place, date and signature

Managing operator or service technician

Surname, first name (block letters)

Position in the company

Place, date and signature

Page 12

Technical Data

12

3 Technical Data

3.1 Use of the Device for the Intended Purpose

Das

The Jaw Crusher BB 600 is suitable for grinding medium to medium-hard substances and brittle

and hard ductile materials.

The machine can be used to grind the following materials:

• Concrete

• Ores

• Rocks

• Glass

• Ceramics

• Coal

• Minerals

• Slag

• Cement clinker

NOTICE

N3.0007

Range of application of the device

Long-term operation

− This laboratory device is designed for eight-hour single-shift operation

with a duty cycle of 30 %.

• This device may not be used as a production machine nor is it

intended for continuous operation.

3.2 Principle of Operation

The Jaw Crusher BB 600 is tough and powerful.

The feed material passes through the splash-free hopper and into the grinding chamber.

Grinding takes place in the wedge-shaped shaft between the jaws. The feed material is

crushed and moved downwards by the elliptical motion.

The sample falls into a removable collecting receptacle as soon as it is finer than the smallest

discharge gap width.

The infinitely variable adjustment of the gap width ensures an optimum setting for the feed

material and for the desired final fineness level.

3.3 Dimensions and Weight

Height: ~1,575 mm

Width: ~1,073 mm

Depth: ~1,456 mm

Weight: ~1,300 kg net

Page 13

Technical Data

13

3.4 Required Floor Space

Width of floorspace: 1,080 mm

Depth of floorspace: 1,500 mm

No safety distance is required!

A space of around 50 cm should be planned on the left-hand side of the machine for better

operability.

Page 14

Technical Data

14

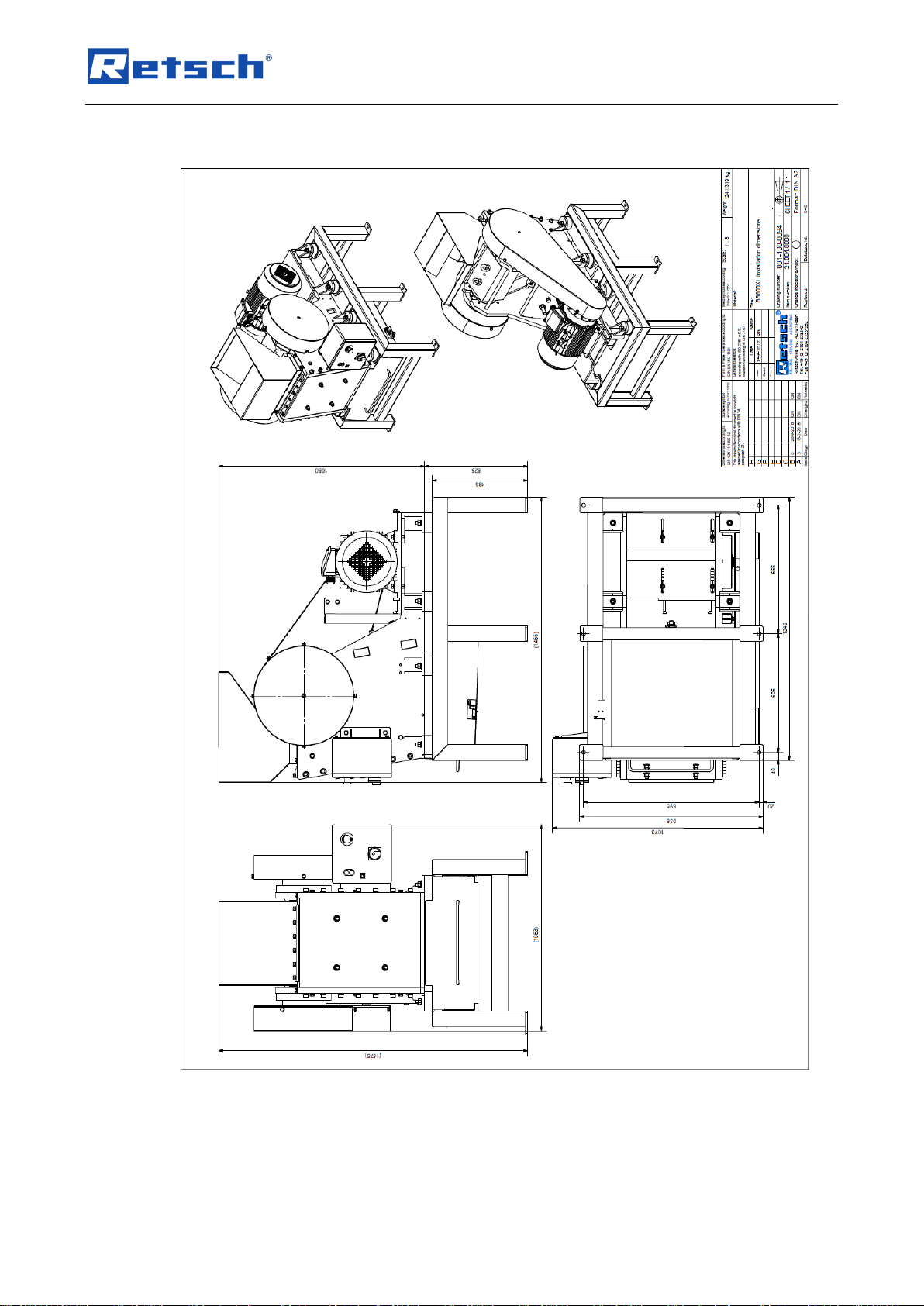

3.5 Installation drawing

Fig. 1: Installation drawing

Page 15

Technical Data

15

3.6 Rated Power

15000 watts

3.7 Degree of Protection

− IP 55

3.8 Emissions

Noise data

Noise measurement in accordance with DIN 45635-31-01-KL3

Noise levels are significantly influenced by the properties of the sample material.

Example 1:

Sound power level LWA = 101.7 dB(A)

Workplace-related emissions value L

pAeq

= 89.5 dB(A)

Operating conditions :

Feed material : marble pebbles, particle size <90 mm

Set gap width: < 6 mm

Final particle size: < 10 mm

Fill level of the grinding chamber: approx. 65 %

Example 2:

Sound power level LWA = 102 dB(A)

Workplace-related emissions value L

pAeq

= 90 dB(A)

Operating conditions:

Feed material: quartz pebbles, particle size <55 mm

Set gap width: < 6 mm

Final particle size: < 10 mm

Fill level of the grinding chamber: approx. 65 %

CAUTION

C4.0045

Damage to hearing

A high noise level may arise depending on the type of the material, the jaws

used and the duration of grinding

− Excessive noise in terms of level and duration can cause impairments or

lasting damage to hearing.

• Suitable sound insulation measures must be provided or hearing

protection worn.

Page 16

Technical Data

16

3.9 Electromagnetic Compatibility (EMC)

− EMC class in accordance with DIN EN 55011: B

3.10 Feed Grain Size

Feed size: < 350x170 mm

Final fineness: < 6 mm

3.11 Degree of hardness of the sample material

The degree of hardness of the sample material should be above 3 on the Mohs’ scale to

achieve effective grinding. The degree jaws should be harder than the sample material to

prevent increased wear on the jaws.

3.12 Gap width

The spacer plates permit a gap width adjustment of between 6 mm and approx. 60 mm:

Spacer plates [mm]

Gap opening [mm]

-

62 5 58

10

47

15

38

20

33

25

25

30

18

35

12

37 (maximum)

6

Page 17

Packaging, Transport and Installation

17

4 Packaging, Transport and Installation

4.1 Packaging

The packaging has been adapted to the mode of transport. It complies with the generally

applicable packaging guidelines.

NOTICE

N4.0001

Complaint or return

Keeping the packaging

− Inadequate packaging and insufficient securing of the device can

jeopardise the warranty claim in the event of a complaint or return.

• Keep the packaging for the duration of the warranty period.

4.2 Transport

DANGER

D2.0001

Serious personal injury

Suspended loads

− If dropped, the great weight of the device would result in serious injuries

or death.

• People must never stand below suspended loads!

WARNING

W2.0011

Serious injuries

Excessive weight

• The machine is extremely heavy, weighing 1300 kg, and can lead to

serious injuries when lifted.

• The machine may only be lifted and transported using lifting gear!

NOTICE

N5.0017

Damage to components

Transport

− Mechanical or electronic components may be damaged during transport.

• The device must not be knocked, shaken or thrown during transport.

Page 18

Packaging, Transport and Installation

18

NOTICE

N6.0014

Complaints

Incomplete delivery or transport damage

− The forwarding agent and Retsch GmbH must be notified immediately in

the event of transport damage. It is otherwise possible that subsequent

complaints will not be recognised.

• Please check the delivery on receipt of the device for its

completeness and intactness.

• Notify your forwarding agent and Retsch GmbH within 24 hours.

Fig. 2: Transport bolts

The Jaw Crusher BB 600 can be transported using a crane or other suitable means of transport:

• To do this, wind ropes through the two transport bolts (TS) on the machine.

CAUTION Only use suitable lifting gear that has been approved for the weight of the device.

The BB 600 has a base frame (Z) using which the device can be lifted and transported with the

help of lifting gear.

Move lifting gear such as a forklift under the base frame (Z).

Slowly lift the device using the lifting gear and stabilise it to prevent it from toppling over.

Fig. 3: Base frame

TS

TS

Z

Page 19

Packaging, Transport and Installation

19

4.3 Temperature Fluctuations and Condensation

NOTICE

N7.0016

Damaged components due to condensation

Temperature fluctuations

− The device may be exposed to substantial fluctuations in temperature

during transport. The ensuing condensation can damage electronic

components.

• Wait until the device has acclimatised before putting it into service.

Temporary storage:

Also in case of an interim storage the device must be stored dry and within the specified

ambient temperature range.

4.4 Conditions for the Installation Site

− Installation height: max. 2 000 m above sea level

− Ambient temperature: 5 °C – 40 °C

NOTICE

N8.0021

Ambient temperature

Temperatures outside the permitted range

− Electronic and mechanical components may be damaged.

− The performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range (5 °C to

40 °C ambient temperature) of the device.

− Maximum relative humidity < 80 % (at ambient temperatures ≤ 31 °C)

For ambient temperatures UT between 31 °C and 40 °C, the maximum relative humidity value LF

linearly decreases according to LF = –(UT – 55) / 0.3:

Ambient temperature

Max. rel. humidity

≤ 31 °C

80 %

33 °C

73.3 %

35 °C

66.7 %

37 °C

60 %

39 °C

53.3 %

40 °C

50 %

Page 20

Packaging, Transport and Installation

20

NOTICE

N9.0015

Humidity

High relative humidity

− Electronic and mechanical components may be damaged.

− The performance data alter to an unknown extent.

• The relative humidity in the vicinity of the device should be kept as

low as possible.

4.5 Electrical Connection

WARNING

W3.0005

Danger to life due to electric shock or fire

Incorrect connection to the power supply may result in parts of the housing or

cables being live and in fires starting.

− Serious injuries or death due to an electric shock.

− Serious injuries or death due to fires.

• The device may only be connected by a qualified electrician.

NOTICE

N10.0022

Electrical connection

Failure to observe the values on the type plate

− Electronic and mechanical components may be damaged.

• Connect the device only to a mains supply matching the values on

the type plate.

− Information about the required voltage and frequency of the device can be found on the

type plate .

− The device may only be connected to the power supply using the connection cable

supplied.

− The circuit breaker for connecting the power cable to the power supply at the installation

site should be suitable for higher start-up current and correspond to a type C

characteristic (slow blow fuse).

NOTICE

N11.0005

Electrical connection

Wrong direction of rotation on drive motor

− Electronic and mechanical components may be damaged.

− Insufficient grinding of the sample material.

• Before putting into operation for the first time, check whether the

direction of rotation of the motor (fan direction of rotation) complies

with the direction arrow on the belt cover.

Page 21

Packaging, Transport and Installation

21

4.6 Type Plate Description

Fig. 1: Type plate

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of queries please provide the device designation (1) or part number (3), as well

as the serial number (4) of the device.

1

2

3

4

5

6

7 8 9

10

11

12

14

13

Page 22

Views of the device

22

5 Views of the device

5.1 Front

Fig. 4: Front view

Element

Description

Function

A

Feed hopper

For adding material.

B

Control element

For operating and controlling the machine.

C

Collecting receptacle

Collects the sample material.

The limit switch in the base frame actuates if the

collecting receptacle is removed during operation.

A

B

C

Page 23

Views of the device

23

5.2 Back

Fig. 5: Rear view

Element

Description

Function

D

Lock nuts

Counter the spacer plates when adjusting the gap

E

Spring

For adjusting the gap

E

D

Page 24

Views of the device

24

5.3 View of the control unit

Fig. 6: Control element

Element

Description

Function

F

On/Off switch

Switches the jaw crusher on or off.

G

Emergency stop button

Stops the machine in the event of danger.

H

Main switch

Switches the machine on or off.

F G H

Page 25

First Commissioning

25

6 First Commissioning

WARNING

W4.0002

Danger to life through electric shock

Damaged power cable

− Operating the device with a damaged power cable or plug can lead to lifethreatening injuries caused by an electric shock.

• Before operating the device, check the power cable and plug for

damage.

• Never operate the device with damaged power cable or plug!

WARNING

W5.0004

Danger to life due to electric shock

Electrically conductive parts of the housing due to contact with live cables inside

the housing

− An electric shock can result in burns, cardiac arrhythmia, respiratory

arrest and cardiac arrest.

• Always operate the device using a mains socket protected by a

residual current circuit breaker (RCCB).

NOTICE

N12.0002

Setting up the device

Disconnecting the device from the mains

− A separation of the device from the mains must be possible at any time.

• Set up the device in such a way, that the connection for the power

cable is always easily accessible.

NOTICE

N13.0004

Setting up the device

Vibrations during operation

− Depending on the operating mode of the device, slight vibrations may

occur.

• Set up the device only on a vibration-free, plane and stable surface.

Page 26

First Commissioning

26

6.1 Installation of the Device

Fig. 7: Securing to the transport pallet

On delivery, the Jaw Crusher BB 600 is screwed to the transport pallet.

• Remove the hex screws (SC) from the transport pallet.

• Using a forklift, lift the machine up.

• Secure the supplied stands (vibration absorbers) to the base frame.

• Place the machine onto the intended installation surface.

If the machine is installed without the stands (vibration absorbers), it must be screwed to a level,

firm base.

• Screw the machine firmly onto the base using suitable hex screws (SC).

Fig. 2: Device feet: do not push or pull device

NOTICE

N14.0002

Damage to the device feet

Pushing or pulling the device

− If the device is pushed or pulled across a surface, this can damage the

device feet (vibration dampers).

• Do not pull or push the device.

• Lift the device if you need to move it.

SC

Page 27

First Commissioning

27

6.2 Establishing the power supply

WARNING

W6.0005

Danger to life due to electric shock or fire

Incorrect connection to the power supply may result in parts of the housing or

cables being live and in fires starting.

− Serious injuries or death due to an electric shock.

− Serious injuries or death due to fires.

• The device may only be connected by a qualified electrician.

The Jaw Crusher BB 600 is connected to the power supply as follows:

• Ensure that the machine has been securely installed; see “Installation of the Device”.

• Using the connecting cable provided, connect the machine to the operator’s power supply.

Also see “Electrical Connection”.

• When doing so comply with local regulations and safety measures.

Page 28

Operating the Device

28

7 Operating the Device

CAUTION

C5.0005

Risk of injury

Potentially explosive atmosphere

− The device is not suitable for use in potentially explosive atmospheres.

Operating the device in a potentially explosive atmosphere can lead to

injuries caused by an explosion or fire.

• Never operate the device in a potentially explosive atmosphere!

CAUTION

C6.0006

Risk of injury

Sample material that is harmful to health

− Sample material that is harmful to health can injure people (illness,

contamination).

• Use suitable extraction systems with sample material that is

harmful to health.

• Use suitable personal protective equipment with sample material

that is harmful to health.

• Take note of the safety data sheets for the sample material.

CAUTION

C7.0010

Risk of burns or poisoning

Varying sample properties

− The properties and therefore also the chemical reactivity of the sample

can change during the grinding process and can cause burns or poisoning

as a result.

• Do not process any substances in this device whose chemical

reactivity is so changed by grinding that there is a risk of explosion

or poisoning.

• Take note of the safety data sheets for the sample material.

CAUTION

C8.0004

Risk of injury

Explosive or flammable samples

− Samples can explode or catch fire during the grinding process.

• Do not use any samples in this device that carry a risk of explosion

or fire.

• Take note of the safety data sheets for the sample material.

Page 29

Operating the Device

29

NOTICE

N15.0007

Range of application of the device

Long-term operation

− This laboratory device has been designed for 8-hour single shift operation.

• This device must not be used as a production machine or deployed

in continuous operation.

NOTICE

N16.0000

Selection of suitable materials

− You might be using unsuitable materials.

• Use the manufacturer’s application database to check whether

your sample material is suitable for use.

7.1 Switching On / Off

NOTICE The Jaw Crusher BB 600 may only be started up with an empty crushing chamber.

Grinding material placed in the crushing chamber or the feed hopper before starting the

machine will result in a blockage and possibly damage to mechanical components.

The control unit is located on the front of the Jaw Crusher BB 600, see “View of the control unit”.

Start the machine as follows:

• Turn the main switch (H) to the “ON” position and release the emergency stop button (G)

where applicable.

• Switch the machine on using the green button (F).

The motor is started up and the moving crusher arm is set in motion.

The grinding process can only be started if the drawer on the collecting receptacle (C) (see

“Front view”) has been completely pushed in. Please ensure that you close and lock the drawer

in order to prevent it slipping out due to vibrations.

When open, a limit switch prevents the machine starting (also see (C) in “Front view.

NOTICE Stop the Jaw Crusher BB 600 when there is no longer any grinding material in the

crushing chamber.

Mechanical components may be damaged by a possible blockage.

The control unit is on the front of the Jaw Crusher BB 600, see “View of the control unit”.

The machine is switched off as follows:

• Switch the machine off using the red knob (F).

• Turn the main switch (H) to the “OFF” position.

In an emergency: the machine is shut down immediately when the emergency stop button (G)

is pressed.

The motor is disconnected from the power supply and the moving crusher arm comes to a halt.

Page 30

Operating the Device

30

7.2 Adjusting the gap width

Fig. 8: Adjusting the gap width

The gap width can be adjusted as follows:

• Turn the Jaw Crusher BB 600 off at the main switch (H) (see “View of the control element“).

• Disconnect the machine from the power supply and secure to prevent it restarting.

• Unscrew the outer lock nuts (DML) and (DMR).

Wrench opening SW 36.

• Unscrew the middle lock nut (DMM).

Wrench opening SW 30.

• Screw in the middle screw (DSM), wrench opening SW 30.

Ensure that the spring (E) is tensioned at all times.

• Insert the desired combination of spacer plates (DB).

The gap will be wider when you remove the spacer plates and will be narrower when you

insert the spacer plates. Also see “Gap width”.

Fig. 9: Spacer plates

DSM

DML

DMM

DMR

DB

E

Page 31

Operating the Device

31

• Unscrew the middle screw (DSM).

Ensure that the spring (E) is tensioned at all times.

• Tighten the outer lock nuts (DML) and (DMR).

Torque approx. 190 Nm.

• Tighten the middle lock nut (DMM).

Torque approx. 110 Nm.

• Adjust the spring pre-load so that the spring is 55 mm long.

Wrench opening SW 30.

Fig. 10: Spring pre-load

Page 32

Operating the Device

32

7.3 Adding sample material

CAUTION

C9.0045

Damage to hearing

A high noise level may arise depending on the type of the material, the jaws

used and the duration of grinding

− Excessive noise in terms of level and duration can cause impairments or

lasting damage to hearing.

• Suitable sound insulation measures must be provided or hearing

protection worn.

NOTICE

N17.0003

Damage to mechanical components

Overfilling the feed hopper and the grinding chamber

− Feeding too much sample material can result in increased wear to the

jaws and wearing plates and to blockages.

• Do not use the feed hopper for storing sample material.

• Do not fill the grinding chamber to over 65% full.

• Do not exceed the specified maximum feed size for the sample

material.

• Fill larger and firmer sample material slowly and gradually into the

feed hopper.

• Pre-grind larger and firmer sample material with a larger gap where

necessary.

NOTICE Filling the crushing chamber to more than 2/3 full may damage the guide plates on the

feed hopper (A) and will result in sample material being conveyed by the activated crusher arm

into the crusher housing behind the crusher arm.

The fill volume also influences the fine share in the pre-ground sample. The fuller the crushing

chamber, the higher the fine share may be.

NOTICE With respect to the fill level, attention should also always be paid to the volume of the

collecting receptacle (D). The fill quantity must not exceed the volume of the collecting

receptacle (D).

NOTICE Only fill the feed hopper (A) and the crushing chamber when the machine is in operation.

The feed hopper (A) is not intended for storing sample material, rather its sole purpose is for

feeding the material into the crushing chamber. It furthermore prevents inadvertent access to the

crushing chamber and holds back any splashing sample material.

Page 33

Operating the Device

33

7.4 Removing sample material after grinding

CAUTION

C10.0005

Burns

Heating of the sample material during grinding

− Hot surfaces on the collecting receptacle or the grinding chamber can

cause burns.

− Hot sample material in the collecting receptacle can cause burns.

• Allow the hot sample material to cool down before removing the

collecting receptacle and opening the door.

• Wear protective gloves.

CAUTION

C11.0010

Heavy collecting receptacle

Depending on the density of the sample material or the filling level, the filled

collecting receptacle may be very heavy.

− Due to its weight, a filled collecting receptacle can cause personal injuries

when lifted out from the base frame.

• As a general rule, always use both hands to pull the collecting

receptacle out of the base frame.

• Two people should always remove a heavy collecting receptacle

from the base frame.

• Wear safety shoes.

NOTICE

N18.0004

Damage to mechanical components

Jaw blockage with the motor shutting down

− Due to the size and geometry of the grinding chamber, blockages may

occur when feeding a large quantity of big pieces of firmer sample

material. If the machine is not switched off in time in the event of

blockages, a motor protection switch turns the overloaded drive motor off.

• Switch the machine off immediately when there is a blockage and

remove the sample material causing the blockage.

• Reduce the feed of sample material to the feed hopper.

• Fill larger and firmer sample material slowly and gradually into the

feed hopper.

• If necessary, pre-grind larger and firmer sample material using a

larger gap width.

Page 34

Operating the Device

34

Fig. 11: Collecting receptacle

• Switch the Jaw Crusher BB 600 off.

• Pull the collecting receptacle (C) out of the base frame.

• Remove the ground sample material from the collecting receptacle (C).

C

Page 35

Cleaning, Wear and Maintenance

35

8 Cleaning, Wear and Maintenance

CAUTION

C12.0013

Risk of injury

Improper repairs

− Unauthorised and improper repairs can cause injuries.

• Repairs to the device may only be carried out by the Retsch GmbH ,

an authorised representative or by qualified service technicians.

• Do not carry out any unauthorised or improper repairs to the device!

8.1 Cleaning

WARNING

W7.0003

Risk to life caused by an electric shock

Cleaning live parts with water

− Cleaning the device with water can lead to life-threatening injuries caused

by an electric shock if the device has not been disconnected from the

power supply.

• Only carry out cleaning work on the device when it has been

disconnected from the power supply.

• Use a cloth moistened with water for cleaning.

• Do not clean the device under running water!

CAUTION

C13.0031

Risk of injury

Cleaning with compressed air

− When using compressed air for cleaning purposes dust and remnant of

the sample material can be flung around and injure eyes.

• Always wear safety glasses when cleaning with compressed air.

• Observe the material safety data sheets of the sample material.

NOTICE

N19.0009

Damage to the housing and device

Use of organic solvents

− Organic solvents may damage plastic parts and the coating.

• The use of organic solvents is not permitted.

Page 36

Cleaning, Wear and Maintenance

36

8.1.1 Cleaning the machine housing

The machine is best cleaned using an industrial vacuum cleaner and brush with a long handle:

• Clean the housing of the Jaw Crusher BB 600 with a damp cloth and standard household

detergent.

• Ensure that no water or detergent gets inside the machine.

8.1.2 Cleaning the feed hopper and grinding chamber

WARNING

W8.0003

Serious personal injury

Contact between moving jaws in the grinding chamber

− Accidentally reaching into the grinding chamber and between moving jaws

can cause serious injuries to hands.

• Always operate the device with the feed hopper installed.

Fig. 12: Feed hopper

• Turn the Jaw Crusher BB 600 off by the main switch (H) (see “View of the control unit”).

• Disconnect the machine from the power supply and secure to prevent it restarting.

• Unscrew the four hex screws (S) around the feed hopper (A).

• Lift the feed hopper (A) up and off.

• Clean the feed hopper (A) using a damp cloth and household detergent.

• Clean the grinding chamber and jaws with a brush and vacuum the loosened material

residue with an industrial vacuum cleaner.

• The grinding chamber may alternatively be carefully cleaned with compressed air.

• After cleaning, replace the feed hopper above the grinding chamber.

• Secure the feed hopper (A) again using the four hex screws (S).

A

S

Page 37

Cleaning, Wear and Maintenance

37

8.2 Wear

CAUTION

C14.0013

Risk of injury

Improper repairs

− Unauthorised and improper repairs can cause injuries.

• Repairs to the device may only be carried out by the Retsch GmbH ,

an authorised representative or by qualified service technicians.

• Do not carry out any unauthorised or improper repairs to the device!

Jaws may wear depending on the frequency of grinding and the property of the sample material.

The jaws and the wearing plates should be inspected regularly for wear and replaced where

necessary.

8.2.1 Replacing the breaking jaws

The jaws on the Jaw Crusher BB 600 are replaced as follows:

• Turn the machine off by the main switch (H) (see “View of the control unit”).

• Disconnect the machine from the power supply and secure to prevent it restarting.

Fig. 13: Feed hopper

• Unscrew the four hex screws (S) for the feed hopper (A).

• Lift the feed hopper (A) up and off.

• Set the gap width to maximum.

To do this, unscrew the lock nuts and remove the spacer plates (see “Adjusting the gap

width”).

A

S

Page 38

Cleaning, Wear and Maintenance

38

Fig. 14: Removing the cover plates

• Loosen the screws (AS) and remove the cover plates (P).

Fig. 15: Unscrewing the fixing screws

• Unscrew the four fixing screws (FS) on both jaws.

• Gently tap the surface of the jaws so that they come away from the support and slide

downwards.

P

P

AS

AS

FS

Page 39

Cleaning, Wear and Maintenance

39

Fig. 16: Removing the jaws

• Remove the jaws using the supplied lifting pins (TH).

The worn jaws have been removed and the new jaws can be inserted in reverse order.

TH

Page 40

Cleaning, Wear and Maintenance

40

8.2.2 Replacing the wearing plates

Proceed as follows to replace the wearing plates:

• Remove the feed hopper, see “Cleaning the feed hopper and grinding chamber”.

Fig. 17: Wearing plate fastening

• Unscrew the four fixing screws (SBS) on each wearing plate (SB).

Fig. 18: Wearing plate fastening

• Screw one eyebolt (RS) into each designated drill hole at the top of the wearing plate (RS).

• Lift the wearing plates (SB) slightly to release them.

SB

SBS

RS

SB

Page 41

Cleaning, Wear and Maintenance

41

• Using a crane, lift the wearing plates out from the crushing chamber by the eyebolts.

The wearing plates have been removed and the new wearing plates can be inserted in

reverse order.

Page 42

Cleaning, Wear and Maintenance

42

8.3 Maintenance

CAUTION

C15.0013

Risk of injury

Improper repairs

− Unauthorised and improper repairs can cause injuries.

• Repairs to the device may only be carried out by the Retsch GmbH ,

an authorised representative or by qualified service technicians.

• Do not carry out any unauthorised or improper repairs to the device!

8.3.1 Lubricating the device

The Jaw Crusher BB 600 must be lubricated again after around 60 operating hours:

Fig. 19: Lubrication points

• Apply a sufficient amount of grease (approx. 4 to 7 g) to the marked lubrication points (SP).

• Use natural coloured, lithium saponified and graphite-free grease, such as Shell Gadus S2

V220 2 or BP Energrease LS-EP 2 as lubricant.

• Apply the grease to the lubrication points using a standard grease press.

SP

SP

Page 43

Cleaning, Wear and Maintenance

43

8.3.2 Checking the limit switch

A functional inspection of the limit switch must be conducted every 6 months.

Check the function of the limit switch as follows:

• Start the Jaw Crusher BB 600.

• Open the draw on the collecting receptacle (D), see “Front view”.

The limit switch must activate, and the machine must stop or coast to a halt.

• Close the drawer on the collecting receptacle (D).

The machine must not start up.

• Turn the machine on by the main switch (H).

The machine starts and runs normally.

Page 44

Cleaning, Wear and Maintenance

44

8.4 Return for Service and Maintenance

Fig. 20: Return form

The acceptance of devices and accessories of the Retsch GmbH for repair, maintenance or

calibration can only be effected, if the return form including the decontamination declaration

service has been correctly and fully completed.

Download the return form located in the download section "Miscellaneous" on the Retsch

GmbH homepage (http://www.retsch.com/downloads/miscellaneous/).

When returning a device, attach the return form to the outside of the packaging.

In order to eliminate any health risk to the service technicians, Retsch GmbH reserves the right

to refuse the acceptance and to return the respective delivery at the expense of the sender.

Page 45

Accessories

45

9 Accessories

Information on available accessories as well as the respective manuals are accessible directly

on the Retsch GmbH homepage (http://www.retsch.com) under the heading "Downloads" of the

device.

Information on wear parts and small accessories can be found in the Retsch GmbH general

catalogue also available on the homepage.

In case of any questions concerning spare parts please contact the Retsch GmbH

representative in your country, or Retsch GmbH directly.

Page 46

Disposal

46

10 Disposal

In the case of a disposal, the respective statutory requirements must be observed. In the

following, information on the disposal of electrical and electronic devices in the European

Community are given.

Within the European Community the disposal of electrically operated devices is regulated by

national provisions that are based on the EU Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE).

Accordingly, all devices supplied after August 13th 2005 in the business-to-business area, to

which this product is classified, may no longer be disposed of with municipal or household

waste. To document this, the devices are provided with the disposal label.

Fig. 3: Disposal label

Since the disposal regulations worldwide and also within the EU may differ from country to

country, the supplier of the device should be consulted directly in case of need.

This labelling obligation is applied in Germany since March 23rd 2006. From this date on, the

manufacturer must provide an adequate possibility of returning all devices delivered since

August 13th 2005. For all devices delivered before August 13th 2005 the end user is responsible

for the proper disposal.

Page 47

Index

47

11 Index

A

Accessories ......................................................46

Adjusting the gap width .....................................31

Adjusting the gap width .....................................30

Ambient temperature.........................................20

Amendment status ..............................................6

Amperage .........................................................22

B

Back .................................................................24

Bar code ................................ ...........................22

Base frame .......................................................19

Burns ................................................................34

C

Calibration ........................................................45

Capacity ...........................................................22

CE marking .......................................................22

Circuit breaker ..................................................21

Cleaning ...........................................................36

Cleaning the feed hopper ..................................37

Cleaning the grinding chamber ..........................37

Cleaning the machine housing ..........................37

Collecting receptacle ................................... 23, 35

Complaints.................................................. 18, 19

Condensation....................................................20

Confirmation form for the managing operator ....12

Control element .......................................... 23, 25

Copyright ............................................................6

D

Damage to hearing ..................................... 16, 33

Degree of hardness of the sample material .......17

Degree of protection .........................................16

Description

Back ..............................................................24

Front .............................................................23

Device designation............................................22

Device feet........................................................27

Dimensions .......................................................13

Depth ............................................................13

Height ...........................................................13

Weight ...........................................................13

Width.............................................................13

direction arrow ..................................................21

Disclaimer ...........................................................6

Disconnection from the mains ...........................26

Disposal............................................................47

label ........................................................ 22, 47

regulations ....................................................47

E

Electrical connection .........................................21

Electromagnetic compatibility ............................17

EMC .................................................................17

Emergency stop button .....................................11

Emissions .........................................................16

Establishing the power supply ...........................28

Explanations of the safety instructions .................9

F

Feed grain size .................................................17

Feed hopper ................................... 23, 33, 37, 38

First commissioning ..........................................26

Fixing screws for jaws .......................................40

Floorspace

Depth ............................................................14

Width.............................................................14

Frequency.........................................................21

Front .................................................................23

Front view .........................................................23

Fuse strength ....................................................22

Fuse type ..........................................................22

G

Gap width .........................................................17

General catalogue.............................................46

General safety instructions ................................10

H

Humidity ...........................................................21

I

Improper use ....................................................11

Installation ........................................................18

Establishing the power supply........................28

Installation drawing ...........................................15

Installation drawing ...........................................15

Installation height ..............................................20

Installation of the device ....................................27

Installation site

conditions ................................ ......................20

Intended use ................................ ..................... 11

L

Lift

with lifting gear ..............................................19

Limit switch .......................................................11

Checking .......................................................44

Long-term operation ..........................................30

Long-term operation ..........................................13

Lubrication points ..............................................43

M

Mains frequency ...............................................22

Mains supply .....................................................21

Maintenance ................................... 12, 36, 43, 45

lubricating......................................................43

Manual................................................................6

Manual..............................................................10

Manual..............................................................12

Manufacturer’s address .....................................22

Motor protection switch .....................................11

Page 48

Index

48

N

Noise level .................................................. 16, 33

Notes on the manual ...........................................6

Number of fuses ...............................................22

O

Operating instructions .......................................12

Operating the device .........................................29

P

Packaging .........................................................18

Part number ................................ ......................22

Power version ...................................................22

Principle of operation ........................................13

Protective equipment ........................................11

R

Range of application of the device .....................13

Range of application of the device .....................30

Rated power .....................................................16

Rear view..........................................................24

Relative humidity

maximum ......................................................20

Releasing the jaws ............................................39

Removing the cover plates ................................39

Repair ......................................... 7, 36, 38, 43, 45

Repair instructions ..............................................7

Replacing the breaking jaws..............................38

Replacing the wearing plates ............................41

Required floor space .........................................14

Return...............................................................18

for service and maintenance ..........................45

Return device....................................................47

Return form.......................................................45

S

Safety .................................................................8

Safety Officer ......................................................8

Sample material

adding ........................................................... 33

heated ...........................................................34

removing .......................................................34

Serial number ................................................... 22

Service address ..................................................7

Small accessories .............................................46

Spacer plates ....................................................31

Spare parts .......................................................46

Spring pre-load .................................................32

Switching on / off ..............................................30

T

Target group .......................................................8

Technical data ................................ ..................13

Temperature fluctuations...................................20

Temperature range ...........................................20

Temporary storage............................................20

Transport ..........................................................18

Transport bolts ..................................................19

Transport damage.............................................19

Transport pallet

Securing ........................................................27

Type C characteristic ........................................21

Type plate ................................................... 21, 22

description .....................................................22

U

Use of the device for the intended purpose........13

V

Vibrations .........................................................26

View of the control unit ......................................25

Views of the device ...........................................23

Voltage .............................................................21

W

Warning ..............................................................9

Information ................................ ....................10

Warranty claim ..................................................18

Warranty claims ................................................10

Wear ........................................................... 36, 38

Wear parts ........................................................46

Wearing plate fastening ....................................41

Wearing plate fastening ....................................41

Wearing plates ..................................................38

Weight ..............................................................13

Wrong direction of rotation motor ......................21

Y

Year of production.............................................22

Page 49

49

Page 50

Copyright

© Copyright by

Retsch GmbH

Retsch-Allee 1-5

42781 Haan

Germany

Loading...

Loading...