Page 1

Operating instructions for sieving m achine

type AS300 control

Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany, 07/02/2012 0002

Page 2

Information on these operating

instructions

The present operating instructions for the model AS300

control analytical sieving machine provide all the necessary information on the headings contained in the table

of contents.

They act as a guide for the reader(s) defined for each

topic necessary for safe use of the AS300 control in accordance with its intended purpose. Familiarity with the

applicable chapters on the part of each target group of

readers is essential for the safe and proper use of the

equipment.

The present technical documentation has been designed

for use both as a learning tool and a source of reference.

Each chapter is a self-contained unit.

These operating instructions do not contain any instructions on repairs. Should repairs ever become necessary,

please contact your supplier or talk directly to Retsch

GmbH.

07/02/2012 Retsch GmbH 2

Page 3

Information on these operating instructions ................ 2

Safety .......................................................................... 4

Safety instructions .................................................... 4

Warnings ................................................................. 5

Repairs ................................................................... 5

Confirmation ............................................................ 5

Technical specifications ............................................... 6

Intended use ........................................................... 6

Emissions ................................................................ 7

Maximum loading ..................................................... 7

Protection systems ................................................... 7

Equipment dimensions .............................................. 7

Base area required ................................................... 7

Transport and assembly ............................................... 8

Packaging ................................................................ 8

Transport ................................................................ 8

Temperature fluctuations........................................... 8

Intermediate storage ................................................ 8

Requirements for the assembly site ............................ 9

Assembly / transport fastening ................................... 9

Re-using the transport fasteners ................................ 9

Electrical connection ................................................. 9

Operation ..................................................................... 10

Operating elements and their use ............................... 10

Installing and tensioning the analytical sieves .............. 11

Operating the AS300 control ...................................... 12

Switching on and off ................................................. 12

Start - Interrupt - Stop ............................................. 12

Setting the time ....................................................... 12

Intermittent – continuous operation ............................ 13

Memory – saving and calling-up sieve parameters ........ 13

Vibration height in "mm" ........................................... 14

Sieve plate acceleration in "g" .................................... 14

Setting the sieve plate acceleration in "g" .................... 14

Signal tone for the end of sieving ............................... 14

Operating hours display ............................................ 15

Information on “memory” display ............................... 15

Information on sieve plate acceleration mode .............. 16

Time correction ........................................................ 17

Acceleration guidelines .............................................. 17

Retsch Analytical sieves ............................................... 18

Sieve accessories ..................................................... 18

Working instructions .................................................... 19

Sieving aids ............................................................. 19

Sieving material quantities ........................................ 19

Wet sieving .................................................................. 20

Required accessories ................................................ 20

Preparations ............................................................ 20

Operation ................................................................ 20

EasySieve ................................................................... 22

Control, evaluation, documentation. ........................... 22

Serial PC connection ................................................. 22

General ........................................................................ 23

Cleaning .................................................................. 23

Maintenance ............................................................ 23

Replacing fuses ........................................................ 23

Accessories .............................................................. 23

Copyright ................................................................ 23

Safety regulations (table) for the AS300 control from the

chapters .................................................................. 24

Changes .................................................................. 24

Parts subject to wear and tear ..................................... 25

Appendix ............................................... following pages

07/02/2012 Retsch GmbH 3

Page 4

Safety

We reject herewith any and all claims relating to personal

injury or material damage which results from failure to

comply with the following safety instructions.

The AS300 control is a modern, high-performance product manufactured by Retsch GmbH. It incorporates the

latest technology. It is entirely safe in operation when

used for the intended purpose and in accordance with the

present technical documentation.

Safety instructions

You, as the owner/operator must ensure that the persons

who are entrusted to work with the AS300 control:

have read and understood all the regulations contained

in the chapter on safety,

have made themselves familiar, prior to starting work,

with all the operating instructions and regulations relevant to that particular target group,

have complete, immediate and unrestricted access to the

technical documentation for this machine,

new personnel must have familiarised themselves with

the safe use of the AS300 control and its intended purpose before starting work with the machine, either

through verbal instruction by a competent person and /

or with the help of the present technical documentation.

Incorrect operation can result in injuries to persons and

damage to property. You bear the responsibility for your

own safety and that of the rest of your staff.

Ensure that no unauthorised persons have access to the

AS300 control.

As a precaution, have your staff certify in writing that

they have received instruction in the operation of the

AS300 control. A draft for such a form can be found at

the end of the chapter on safety.

07/02/2012 Retsch GmbH 4

Page 5

Warnings

Personal injuries

Material damage

Your local Retsch representative

Your supplier

Retsch GmbH direct

The following signs are used to warn of hazards:

Repairs

These operating instructions do not contain any repair instructions. In the interests of your own safety, repairs

should only performed by Retsch GmbH or an authorised

representative (service technician).

In this case, please notify the following:

Your address for service:

Confirmation

I have read and understood the foreword and the

chapter on safety.

__________________________________

Signature of owner/operator

__________________________________

Signature of service technician

07/02/2012 Retsch GmbH 5

Page 6

Technical specifications

Do not make any modifications to the machine and only use

Retsch approved spares and accessories.

The conformity to the European guidelines declared by

Retsch otherwise loses its validity.

It furthermore leads to the nullification of all warranty

claims.

Machine designation:

AS300 control

Intended use

The AS300 control has been specially designed for analytical

sieves with a diameter of 305 mm (12“) to 315mm. This makes

the available sieving area 2.5 times greater than sieves with a

200 mm diameter. The AS300 control thereby allows the average

sieving times to be shortened.

A further benefit is the very high working quantity of material

to be screened (6 kg) which can be separated in one work process. In case of frequently repeated sieve analyses made under the

same conditions, work is considerably simplified by the option of

storing up to 9 parameter combinations direct in the sieving

machine.

To ensure perfectly reproducible results, the AS300 control naturally allows the power frequency independent control drive to

be specified instead of the vibration height. All sieving parameters

are set, displayed and monitored digitally. The amplitude is regulated by a microprocessor-controlled measurement control unit

and is automatically re-adjusted if the loading or voltage changes.

The AS300 control can naturally be calibrated and can be therefore deployed as test equipment for quality control action under

DIN EN ISO 9000 ff. As with all "control" devices, the AS300 control also has an integrated interface.

The sieve can be actuated and adjusted by means of the

EasySieve® evaluation software. EasySieve® displays all sieving

parameters on the screen before and during the sieving process.

This machine is not intended as a production machine nor designed for continuous operation, but rather as laboratory equipment intended for one-shift, 8-hour per day operation.

The AS300 control is suitable for dry sieving of pourable, disperse

products with an input grain of max. 40 mm.

07/02/2012 Retsch GmbH 6

Page 7

Emissions

Characteristic noise values :

Noise measurement according to DIN 45635-031-01-KL3

The characteristic noise values are determined primarily by the

set amplitude width or sieve plate acceleration, the number of

sieves deployed and the nature of the material to be screened.

Example :

Sound power level LWA = 64 dB(A)

Workplace-related emission value L

= 59 dB(A)

pAeq

Operating conditions :

Material to be screened = quartz sand, grain size <1mm, 5

sieves

Amplitude width = 1.5 mm

Maximum loading

Max. quantity of material to be screened = 6 kg

max. sieve stack mass = 10 kg

Protection systems

IP54 or IP20 around the sieve carrier passage

Equipment dimensions

Height: up to approx. 850 mm, Width: 400mm, Depth : 400mm

Weight: approx. 35 kg without sieve stack and

without sieve clamping device

Base area required

400 mm x 400 mm; no safety clearances required.

07/02/2012 Retsch GmbH 7

Page 8

Transport and assembly

Please retain the packaging for the duration of the warranty since, in case of a complaint, returning in unsuitable packaging can jeopardize your warranty claims.

During transportation, do not subject the AS300 control

to impacts, jolts or vibrations. The electronic and mechanical components could otherwise be damaged.

In case of wide temperature fluctuations (during shipment by air, for instance), protect the AS300 control

from condensation. The electronic components could

otherwise be damaged.

Packaging

The packaging used is selected with the shipping mode in

mind. It complies with the generally applicable packaging

guidelines.

Transport

Temperature fluctuations

Intermediate storage

Ensure that the AS300 control is stored in a dry place,

including intermediate storage.

07/02/2012 Retsch GmbH 8

Page 9

Requirements for the assembly site

When the ambient temperature exceeds or falls below that

specified, the electrical and mechanical components may be

damaged, and performance data changed to an unknown

extent.

At a higher humidity, the electrical and mechanical components may be damaged, and performance data changed to an

unknown extent.

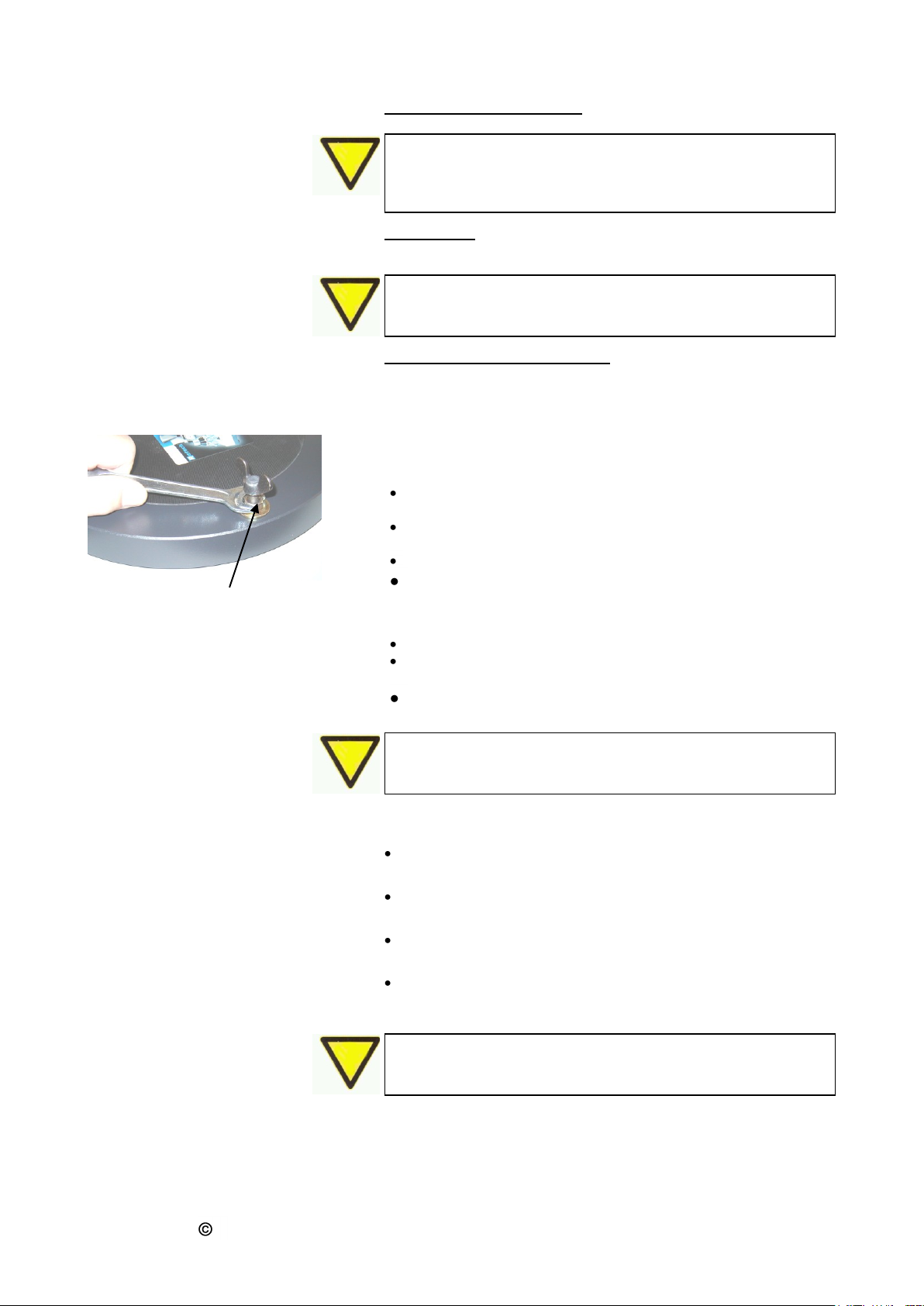

Assembly / transport fastening

SM

Install the AS300 only on a stable laboratory bench to avoid

unpleasant transmission of vibrations.

Undo the hex nut SM with an open-ended spanner until

the sieve disk can be moved freely

Undo the wing screws A (transport fastening) with hex

nuts

Install the appropriate sieve clamping unit

Retain wing screws A with hex nuts (transport fastening)

for transport at a later date.

Re-using the transport fasteners

Screw the hex nuts fully onto the wing screws

Screw the wing screw through the sieve disk into the

housing

Turn the hex nut downwards and tighten with an open-

ended spanner until the sieve disk can no longer move

Mechanical components can be damaged if operated with the

transport fasteners or transported without transport fasteners.

Failure to observe the values on the data plate can cause

damage to the electrical and mechanical components.

Ambient temperature :

5°C to 40°C

Humidity :

Maximum relative humidity 80% at temperatures up to 31°C,

linear decline down to 50% relative humidity at 40°C

Altitude of assembly site :

Max. 2000 m above sea level

Electrical connection

Refer to the data plate for the voltage and frequency at

which the AS300 control is to be operated.

Ensure that the values shown there correspond to those

for the local power supply.

Use the supplied power cord to connect the AS300 con-

trol to the power supply.

When plugging the power cord into the power source,

07/02/2012 Retsch GmbH 9

use an external fuse corresponding to the local regulations.

Page 10

Operation

A Cold device plug combination

C Fuse drawer with glass fuses

B Serial connection

D Protective cap for the serial connection

E ON / OFF switch, left bottom

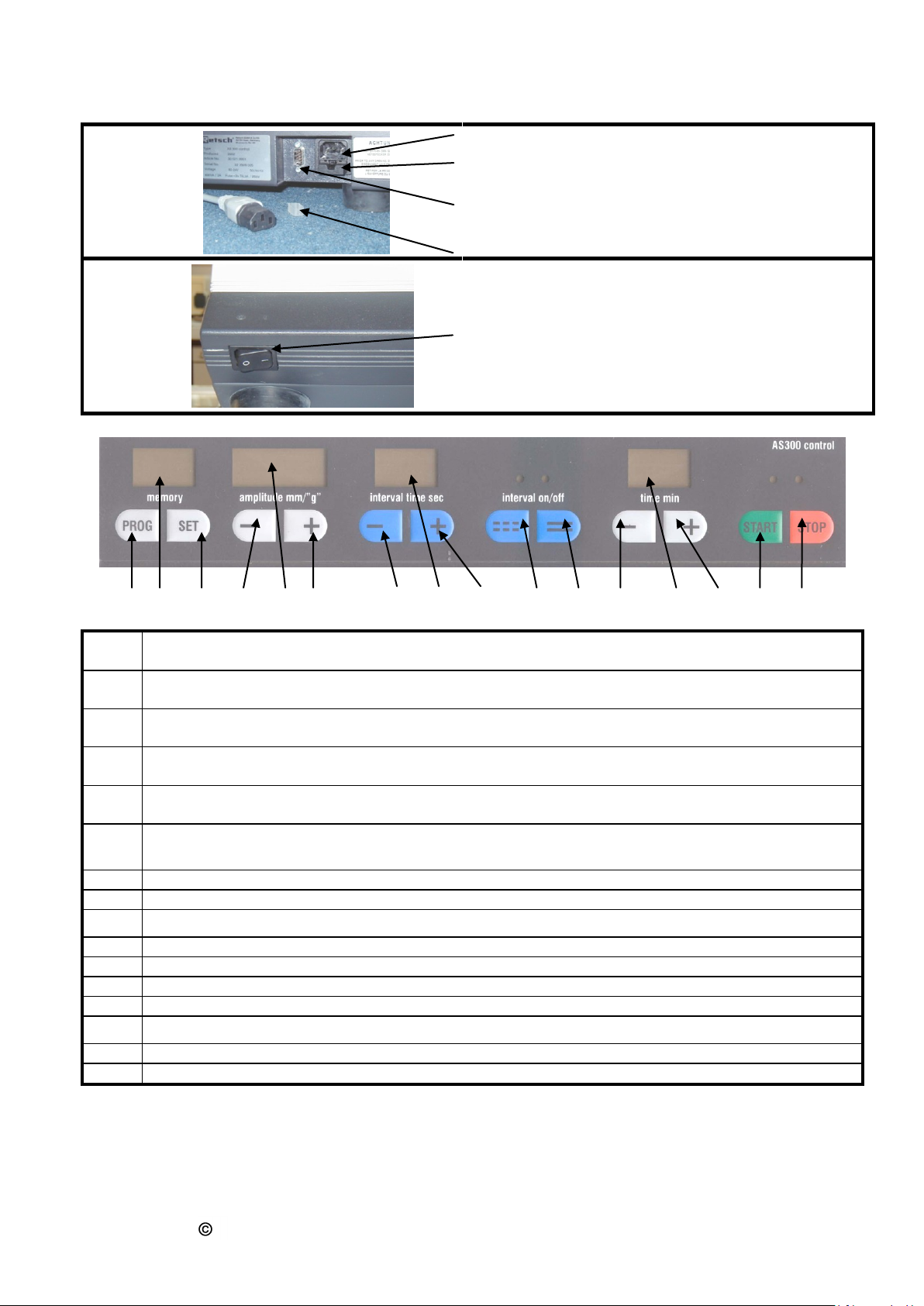

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

PROG – button for calling preset sieving parameters P1-P9 or on and for ending pro-

gramming without storing the parameters.

2

Display memory shows the selected programme P1-P9 or on. If the AS 200 is driven by

the EasySieve® softwear programme ES appears in the display.

3

SET – button for activating the setting mode for the preselected programme positions P1P9 and for storing the parameters after programming.

4

▬ button reduces the amplitude 0.20 – 2.20mm, precision ±0.1mm, or sieve bottom

acceleration in „g“

5

Display amplitude shows the amplitude (2 x amplitude) of 0.20 – 2.20mm or sieve bottom acceleration in „g“.

6

+ button increases the amplitude, 0.20 – 2.20mm, precision ±0.1mm, or sieve bottom

acceleration in „g“.

7

▬ button reduces the interval time, 10 – 99sec.

8

Display interval shows the preselected interval time, 10 – 99sec.

9

+ button increases the interval time, 10 – 99sec.

10

Button switches interval operation ON, left LED lights up.

11

Button switchces interval operation OFF, right LED lights up.

12

▬ button reduces the sieving time, 1 – 99min.

13

Display time shows the preselected sieving time, 1 – 99min.

14

+ button increases the sieving time, 1 – 99min.

15

START button starts the sieving process and the green LED lights up.

16

STOP button stops and ends the sieving process and the red LED lights up.

Operating elements and their use

07/02/2012 Retsch GmbH 10

Page 11

Installing and tensioning the analytical sieves

G

F

H

I

The AS400 control is suitable for use with analytical sieves

with outer diameters of 305-315mm.

Up to 8 analytical sieves plus base pan can be clamped in.

A clamping unit and cover are available for this purpose (see

the accessories listing).

Screw the threaded rods H into the sieve disk screws and

lock with the hex nuts I.

Center the selected sieve stack on the sieve disk

Lay the clamping cover F over the threaded rods on the top

sieve.

Tilt the clamping nuts G to slide them over the stand thread

and down to the clamping cover and fasten securely by

hand.

We recommend the use of talcum powder if the base pan sticks

to the smooth surface of the sieve carrier when removing the

sieve stack.

Shorter rods for the sieve clamping unit are available for

clamping in a maximum of 5 analytical sieves and a base pan

(see accessories.

07/02/2012 Retsch GmbH 11

Page 12

Operating the AS300 control

E

The main switch E is located at the left front of the AS300 control

under the operating element.

Turn the main switch on

On illuminates in the memory display

1,00 illuminates in the amplitude display

The interval off LED illuminates

Two bars illuminate in the time display (- -)

The AS300 control is now ready for operation, without intermittent

mode, in continuous duty, with a vibration height of 1.00mm.

5 15 16

Start:

Press START / key 15

The green LED above key 15 illuminates

Display 5 shows the run-up of the machine to the preset value.

During the sieving time, the vibration height or sieve plate acceleration are kept constant within the stipulated tolerances.

Interrupt (pause function) :

Press STOP / key 16 once

The red LED above key 16 illuminates

The values remain visible

Press START / key 15

The sieving process is resumed

Stop (standby function) :

Press STOP / key 16 twice

The red LED above key 16 illuminates

The entire display goes out

Activate the LED displays = press key 15 once

New values can now be entered

Press START / key 15 a 2nd time

The function as with Start is executed.

12 13 14

When the AS300 control is switched on, the sieving time is still

undetermined = 2 bars in display 13.

Switch on time 1 – 99 min. :

Key 12 reduces the time down to 1 min.

if undershot, two bars appear = undetermined sieving time

Key 14 increases the time up to 99 min.

if overshot, two bars appear = undetermined sieving time

Switching on and off

Start - Interrupt - Stop

Setting the time

07/02/2012 Retsch GmbH 12

Page 13

Intermittent – continuous operation

7 8 9 10 11

When the AS300 control is switched on, intermittent operation is initially disabled.

Enabling intermittent mode of 10-99 sec. :

Press key 10

The LED above key 10 illuminates

Display 8 shows 10 sec.

Pressing key 9 raises the interval period up to 99 sec.

If 99 sec is overshot, start again with 10 sec.

Key 7 reduces the interval period down to 10 sec.

If 10 sec. is undershot, start again with 99 sec.

Disabling intermittent mode :

Press key 11

The LED above key 11 illuminates

Display 8 is extinguished

2 5 8 10 11 13

The memory function, thus saving or calling-up preselected sieve parameters, is only available in standby mode. You are able to change

and overwrite program places P1 to P9 at any time.

After the AS300 control has been turned on, display 2 shows "on".

The next program place P1 to P9 is reached by pressing the PROG

key. on reappears in the display after program place P9.

on = the sieve parameters 5/8/10-11 and 13 can be freely

set here.

or

P1 to P9 = sieve parameters can be stored and called-up here

Start = sieving process is started with the sieve parameters

stored in program place P1 to P9.

Occupying storage space

Press the PROG key until the required storage place P1-P9

has been reached.

Press the SET key, all displays flash

Set sieve parameter 5/8/10-11/13

The programming mode can be aborted by pressing the PROG button

– the values are not stored.

Press SET button – the values are stored

Flashing of the display stops, the adjusting interlock is activated, the

sieving parameters are stored.

If the AS300 control is actuated with a PC and the "EasySieve®"

sieve software, display 2 shows "ES". No manual changes to the sieve

parameters are possible in this mode.

Memory – saving and calling-up sieve parameters

07/02/2012 Retsch GmbH 13

Page 14

Vibration height in "mm"

4 5 6

Reduce :

Key 4 reduces the vibration height down to 0.20 mm

Hold down key 4, after 5 sec. the rapid adjustment function will

commence

If 0.20 mm is undershot, 2.20 mm appears again

Increase :

Key 6 increase the vibration height up to 2.20 mm

Hold down 6, after 5 sec. the rapid adjustment function will com-

mence

If 2.20 mm is overshot, 0.20mm appears again

4 5 6

Reduce :

Key 4 reduces the sieve plate acceleration down to 1g

Hold down key 4, after 5 sec. the rapid adjustment function

will commence

Increase :

Key 6 increase the sieve plate acceleration up to approx. 17g

Hold down 6, after 5 sec. the rapid adjustment function will

commence

11 15 16

If the sieving process runs to the end without interruption, the end

is then signalled by an acoustic tone sounding 5 times.

Disabling the signal tone :

Press keys 11 and 16 simultaneously

confirmed by a signal.

Enabling the signal tone :

Press keys 11 and 15 simultaneously

confirmed by a signal.

A value twice the amplitude is shown as the measured value in display 5 marked amplitude. We refer to this measured value

throughout these instructions as the vibration height.

When the AS300 control is switched on, the vibration height is

preset to 1.00 mm.

Setting the vibration height from 0.20 – 2.20mm :

Sieve plate acceleration in "g"

When the AS300 control is switched on, the vibration height is

preset to 1.00 mm and can be switched to sieve plate acceleration mode by simultaneously pressing and holding down

keys 4+6 for 2s

After switchover, display 5 still does not show any values, this

only happens after the START has been pressed.

The display 5 marked as amplitude mm will show a multiple of

the Earth's gravity "g" as the measured value.

( 1g = 9,81m/s2 )

Setting the sieve plate acceleration in "g"

from 1 – approx.17g

Naturally, your AS300 control can only achieve the sieve

plate acceleration at which, in dependence on the inherent frequency, an amplitude of 2.2 mm is not overshot.

Signal tone for the end of sieving

07/02/2012 Retsch GmbH 14

Page 15

Operating hours display

3 9

If the buttons described below are pressed, the complete running

time of the machine in hours and minutes can be displayed.

Displaying the operating hours:

Press buttons 3 and 9 simultaneously and keep pressed

The indication “bS” appears in the „memory“ display.

hhh hh min 16

Passing out of the operating hours:

Press button 16, STOP.

The following abbreviations can appear:

Display

Description

Button combinations

on

Normal mode – all parameters can be adjusted – also

during sieving.

P1 – P9

Calling and indication of

stored programmes.

Press button „PROG“

ES

Operation with software

EasySieve®

Automatic when starting from EasySieve

bS

Operating hours display

Button combination

“SET” and interval time

„+”

S

Softwear version display

Button combination

“SET” and interval time

„ - ”

Information on “memory” display

07/02/2012 Retsch GmbH 15

Page 16

Information on sieve plate acceleration mode

The AS300 control is a throw sieve which allows you to set

both the amplitude and the sieve plate acceleration as

sieving parameters.

Throw sieves such as the AS300 control are generally based

on a spring/mass system which is exited in inherent frequency.

This means that in contrast to machines exited at mains power

frequency which always oscillate at 50 or 60 Hz, varying sieve

frequencies set in here when loaded with different numbers of

sieves and sieve weights. However, the spring/mass system

has been designed in such a way that the inherent frequency

range is always kept somewhere near 50 and 60 Hz.

As long as sieve analyses are only to be compared with each

other or reproduced within the respective inherent frequency

ranges, setting the same amplitudes and sieving times will

naturally produce comparable results.

However, the increasing globalisation of production processes

nowadays often requires sieve analyses made in both mains

power frequency ranges 50/60Hz to be compared with each

other, and naturally also with the results of your AS300 con-

trol exited at inherent frequency. Even if these sieve analyses

are conducted with the same amplitude and sieving time, the

disparate sieve frequencies are likely to adversely affect the

comparability of results at reasonably short sieving times.

The reason for these differences lies in the fact that the essential parameter in throw sieve analyses is not amplitude, but

rather the sieve plate acceleration, which is crucially influenced by frequency as well as amplitude. Provided that sieving is only carried out at the same frequency, e.g. with the

same mains power frequency, varying the amplitude is naturally the only means of varying the sieve plate acceleration!

In order to take account of these physical facts, your new

AS300 control enables not only the amplitude to be set, displayed and regulated, but also the sieve plate acceleration.

The sieve plate acceleration is shown as a multiple of the

Earth's gravity "g" ( 1g = 9.81 m/s2 ). The functional principle

is based on our German patent No. 19 522 987.

See the chapter on "Operating the AS300 control" and the

paragraph "Sieve plate acceleration" for more details on operation.

Comparative sieve analyses in acceleration mode with direct infeed nevertheless require that the sieve plate acceleration of

the comparative machine (e.g. a AS200 control or another

AS300 control) is known.

If the sieve plate acceleration is unknown, our EasySieve

evaluation software enables you to input comparative data both

much more simply and in a greater scope, thus, for example,

there is also the option of time correction.

07/02/2012 Retsch GmbH 16

R

Page 17

Time correction

K

(„g“)

Movement of charge

Sieve performance

Associated

amplitude at

50 Hz

Associated

amplitude at

60 Hz

1,0

No throw, flow or slip

Very sluggish,

sieve plate clogs up quickly

0.2 mm

0.14 mm

1,5

Gradual lift

Sluggish,

sieve plate clogs up slowly

0.3 mm

0.21mm

1,8

Very flat throw

Very gentle action for material

which is easy to screen

0.36 mm

0.25mm

2,3

Flat to slightly steep

throw

Gentle action for material which is

less easy to screen

0.46 mm

0.32mm

3,5

Steep throw

Brisk action

0.7 mm

0.5 mm

4

Very steep throw

Very brisk action with strong

separation

0.8 mm

0.55 mm

Our investigations have shown that the switch to specifying the

sieve plate acceleration instead of the amplitude is the

most significant influencing variable when sieving at varying

frequencies. Nevertheless, it is clear that an equal sieving time

at 60Hz will involve 20% more sieve strokes than at 50Hz,

which basically is on a par with an extension to the sieving

time. Especially when short sieving times are selected, we accordingly recommend that the sieving time is corrected with

the help of EasySieve

®

Acceleration guidelines

The relevant specialist textbooks, e.g. "Zerkleinerungs- und

Klassiermaschinen" (Crushers and Classifiers) by Prof. Dr. Karl

Höffl, designate sieve plate acceleration in "g" with the letter K

and describe the relationship between this and the sieving effect as follows:

We have added the last two columns to show the associated

amplitudes for the two most common mains power frequencies

in the world.

These particulars should only be regarded as rough values applicable to small charges, when the material to be screened can

generally move around the sieve plate as discrete grains due to

its distribution.

In the laboratory, however, the pulse transmitted by the sieve

plate are usually muffled by thick layers of charge and the

sieve plate of the analytic sieve itself vibrates. Accordingly,

higher K-factors are required in everyday laboratory practice

than those resulting from the dynamics of individual grains.

Thus for everyday practice, the aforesaid recommendations

need to be multiplied by a factor of 1.5 - 2.

07/02/2012 Retsch GmbH 17

Page 18

Retsch Analytical sieves

Sieve plates, frame and labelling executed in compliance with

standards

Tested 5-times with quality certification to DIN ISO, ASTM, BS

On request, with an individual test certificate for control of

test and measuring equipment as per ISO 9000 ff

Sieve plates made of non-rusting wire mesh fabric, 20µm to

125mm

Also available in round or square perforated sheet

RETSCH certificates

Before being delivered, each

sieve is optically gauged and

provided with a works' cer-

tificate.

On request, you receive a

protocol with the acceptance

test certificate which documents the measurement results in tabular form and in

graphics, or a calibration

certificate with more detailed

statistics.

Calibration service

As a special service we

offer to calibrate your

analytical sieve. In doing

so, we record all the relevant information for the

sieve according to standardised gauging methods,

and confirm these in the

requested certificate.

The highest precision for exact results

The accuracy and the reliability of the analysis result are decisively

dependent not only on the sieving machine delivering reproducible

results, but also on the quality of the analytical sieves.

Retsch analytical sieves are high quality measuring instruments for

which only the fabrics and screens which comply with the relevant

standards are used.

Analytical sieves with 305 (12“) and 315mmØ

Sieve accessories

There are base pans, base pans with discharge, intermediate

pans, intermediate rings and sieve covers available which are

compatible with the different analytical sieves. Sieving aids and

sieve stands complete the range of accessories.

Please refer to our price list for details on how to order the analytical sieves and the other available accessories.

Tested quality – black on white

07/02/2012 Retsch GmbH 18

Page 19

Ensure that the fabric of the sieve is not overstretched by overloading with sieving aids as this would have a detrimental effect

on the precision of your analytical sieve.

Overview table

Sieving aids

Quantity per

sieve or charge

Supplier

Area of use

Caution !!

Rubber pearls

5 pcs, Ø20 mm

RETSCH, Haan

Materials to be screened

are fine, dry,

difficult to separate and

throw sieves are used

When using mechanical sieving aids, there

is the danger that soft materials can disintegrate and fine sieve fabrics can be damaged!

Agate pearls

10 pcs, Ø10 mm

RETSCH, Haan

Hard porcelain pearls

approx. 10gr., Ø2

mm

RETSCH, Haan

Vulkollan cubes

5 pcs, 12x12

RETSCH, Haan

Planetary sieving machines

Bristles

3 pcs

RETSCH, Haan

Plastic rings

3 pcs, various Ø

Brushes

Manual sieving

Highly dispersed silicic acids

0.5 to 2%

Degussa, Ffm

Materials to be screened

are fine, sticky, fatty

and electrostatically

charged

Check applicability and compatibility before

adding!

- - Aluminium oxide

0.5 to 1%

Degussa, Ffm

- - active carbon

- - talcum

Latex and rubber powder

Remove grease

Materials to be screened

are very fatty

The granularity of the material to be

screened may not be altered by the solvent

used to remove grease or by the temperature and air used in drying.

Dry

Materials to be screened

are very wet or damp

Guide dry, warm air through the

sieve set

Hygroscopic materials to

be screened

Cleanse with steam

Materials to be screened

are coarse and electrostatically charged

First sieve of the fine sieve then

the coarse sieve

If contamination from

other mechanical aids,

such as rubber pearls, is

to be avoided

The coarse material functions like a mechanical sieving aid (pearls) on the fine

sieves.

Intermittent sieving

RETSCH, Haan

Materials to be screened

are fine, stick easily, or

only fall through the

mesh with difficulty

Intermittent switching is built into the

majority of throw sieves and can be

switched on, if required.

In the case of sieving processes with only 1 to 3 sieves, we recommend the use of short threaded rods ( available as accessories ).

Overly long, protruding rods interfere with the material to be

screened due to their inherent vibration characteristics.

Working instructions

Sieving aids

When dealing with material that is difficult to separate, we recommend the additional use of sieving aids in the individual sieve

fractions. Depending on the width of the sieve meshing and the

preselected vibration intensity, pearls made of agate, rubber, porcelain or nylon bristles and Vulkollan cubes may be used. Also refer to the table below.

Sieving material quantities

The sieve stack required for sieve analyses is composed of analytical sieves arranged one above the other, with progressively

larger holes towards the top, plus the base pan.

To ensure fast separation with exact results, the quantity of the

material to be screened should be adapted to the sieve diameter

and the nominal size of the openings.

The relevant standards on sieve analysis state guideline values in

this context.

07/02/2012 Retsch GmbH 19

Page 20

Wet sieving

Target group: Owner, operator

Dry sieving will be possible in the large majority of cases. There are, however, some materials in which the adhesive forces between the

individual particles can cause difficulties.

These problems can be eliminated by adding

liquid, preferably water, during the sieving operation (in so far as the additives mentioned in

the chapter on “sieving aids” were not successful). One pre-condition for wet sieving,

however, is that the substances to be separated will not swell, dissolve or otherwise interact with the liquid.

Required accessories

Clamping cover with spray nozzle, matching

the sieve diameter.

Base pan with water drain, matching the

sieve diameter.

Preparations

Position your AS200 control “g” near a water

drain.

Use a hose to connect the spray nozzle in

the clamping cover to a water faucet.

Connect the drain from the base pan with

the drain or a suitable container to receive

the liquid.

Operation

Apply the solid in the form of a suspension.

Set the liquid (water) supply rate so that the

spray just covers the sieve surface completely.

Using dispersion agents is advisable. They

reduce the surface tension of the sieve liquids.

When dealing with goods which resist form-

ing a slurry or where more exact separation

is required, spray each individual fraction,

one after the other.

Following the sieving process, the fractions

are to be transferred from the individual

sieves to suitable filters (e.g. filter paper)

and dried in a drying cabinet at 80°C.

Then clean the sieves in an ultrasonic bath

and dry them, too, in the drying cabinet

(without the gaskets).

Do not exceed a maximum drying tempera-

ture of 80°C.

07/02/2012 Retsch GmbH 20

Page 21

Never place the AS200 control “g” directly in

a basin for operation.

Fatal electrical shock hazard.

During wet sieving always connect the AS200

control “g” to a socket which is protected by

a ground fault interrupter.

Adjust the volume of water applied so that it

will just wet the surface of the screen.

Water backing up in the sieve stack can

cause overloading and thus may damage or

destroy the sieve weave.

The loading capacity charts provided in the

Appendix to these operating instructions are

not applicable to wet sieving.

Due to the difficulty in defining the volume of

water in the sieve stack, it is impossible to

make reliable statements for wet sieving.

07/02/2012 Retsch GmbH 21

Page 22

EasySieve

EasySieve , the software package from RETSCH for grain

size analysis, is superior to manual evaluation in many

respects. This is because the software is able to perform

the required measuring and weighing processes automatically – from determining the weights of the sieves to

evaluating the data. And in a much more simple and comfortable manner – thus making life easier.

The software is structured in a self-explanatory way and

follows the logical chain of events involved in analysing

grain sizes. This makes it possible to use it with confidence

in a fairly short time. The multiplicity of evaluation options

additionally provides the utmost flexibility in adapting to

demanding, individual applications.

Parameter input Trend analysis of product processes Comparison with

specification limits

D C

The AS300 control can be connected to the serial interface of a

personal computer for the purpose and transmitting and receiving data. This is done with the normal 9 pole RS232 cable supplied as standard with the AS300 control. This makes it possible to communicate with the EasySieve® evaluation software

available as an accessory.

Remove cap D, if the port is not used, this protects it

from dust and moisture

Connect one end of the serial cable to C and the other to

the PC

Control, evaluation, documentation.

Serial PC connection

07/02/2012 Retsch GmbH 22

Page 23

General

Do not clean the AS300 control with running water.

Danger to life from electrical shock

Only use a rag moistened with water.

Never use solvents.

B

Two glass fuses SPT 6.3A (5x20mm) are required.

Unplug the power at the socket

Pull out fuse holder B

Exchange the fuse

Re-insert fuse holder B

Cleaning

For thorough, gentle and time-saving cleaning of your analytical sieves, we recommend the Retsch ultrasonic baths.

Ask for our special publication "Care and cleaning of analytical

sieves" free-of-charge.

Maintenance

If you use your AS300 control for quality control purposes, it

should then be calibrated regularly in accordance with DIN EN

ISO 9000 ff. In this context, please contact or your dealer or

speak directly to Retsch GmbH.

Otherwise the AS300 control is virtually maintenance-free.

Replacing fuses

07/02/2012 Retsch GmbH 23

Accessories

Sieve clamping unit standard for analytical sieves

305mm (12“)

Standard sieve set 305mm (12“) 50mm high,

consisting of 7 analytical sieves to DIN 3310/1

0.63 + 1.25 + 2.5 + 5 + 10 + 20 and 31.5mm

plus base pan

Standard sieve set 305mm (12“) 50mm high,

consisting of 7 analytical sieves to ASTM

30 + 16 + 8 + 4 mesh + 3/8“ + 3/4“ and 1 1/4“

plus base pan

Software EasySieve

Copyright

Reproducing or distributing this documentation, or utilizing and

distributing the contents is not permitted unless Retsch GmbH

has given express permission to do so.

Violations against this are subject to claims for damages.

Page 24

Safety regulations (table) for the AS300 control from the chapters

Process

Action

Hazards

Safety

Non-compliance with safety instructions leads to material damage and

injuries to people

Any and all claims to damages are excluded

Packaging

Retain the packaging until the warranty time has elapsed

Your warranty claim can be threatened

in case of complaint if a part is returned in inadequate packaging

Transport

Do not subject the AS 300 control to

impacts, jolts or vibrations during

transport

Electronic and mechanical components

can be damaged

Temperature fluctuations

In case of temperature fluctuations,

protect the AS 300 control from

condensation

Electronic components can be damaged

Scope of supply

If the shipment is incomplete and /

or it has been damaged during

transport, you must notify the forwarder and Retsch GmbH immediately (within 24 hours).

Under certain circumstances later complaints may not be considered.

Ambient temperature

Below 5°C

Above 40°C

Electronic and mechanical components

can be damaged.

Performance data can be changed to an

unknown extent.

Humidity

Above 80% at temperatures of up

to 31°C

Electronic and mechanical components

can be damaged.

Performance data can be changed to an

unknown extent.

Transport fastening

Remove transport fasteners before

start up.

Secure the machine with transport

fasteners during transport.

Mechanical parts can be damaged if

operated with transport fasteners or

transporting without transport fasteners.

Electrical connection

Power system does not agree with

the values stated on the data plate

Electronic components can be damaged

Cleaning

Unplug the power at the socket

each time before cleaning.

Danger to life from electric shocks

Never clean with running water

Danger to life from electric shocks

Changes

Technical changes are reserved.

07/02/2012 Retsch GmbH 24

Page 25

Parts subject to wear and tear

Item 11 / Art. No. 03.243.0052

1x rubber disk

Item 37 / Art. No. 05.699.0075

2x fuse insert

Item 701.2 / Art. No. 03.070.0029

2x tightening nut M12

These operating instructions do not contain any repair instructions. In the interests of your own safety, repairs should only performed by Retsch GmbH or an authorised representative (service

technician).

07/02/2012 Retsch GmbH 25

Page 26

Page 27

Page 28

Page 29

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Analytical Sieve Shaker Type AS 300 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

R e t s c h G m b H R e t s c h - A l l e e 1 - 5 4 2 7 8 1 H a a n G e r m a n y w w w . r e t s c h . c o m

ANALYTICAL SIEVE SHAKER

Type AS 300 control

FB-EW-805-044 (E) Änderungsstand D 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN 61000-3-2/-3 Electromagnetic compatibility (EMC)

EN 61236 Electrical measuring, operating, controlling and laboratory equipment – EMC-

requirements in conjunction with EN 61000

EN 55011 Limit values and measuring procedures for noise suppression of industrial,

scientific and medical high frequency devices

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 30

Page 31

Page 32

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...