Page 1

Operating Instructions for Tap Sieving Machine

Type AS200 tap

Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany, Doc.Nr. D 98.025.9999

Page 2

Notes on these Operating

Personal injuries

Damage to equipment

Heed instructions for use.

The Retsch agency in your country

Your supplier

Retsch GmbH directly

Instructions

These operating instructions for the AS 200 tap sieving

machine provide all the information you need on the areas

referred to in the table of contents.

For the target group(s) defined for the respective areas

they serve as a guide on how the AS 200 tap can be used

safely in accordance with its intended purpose. It is

essential for the safe and proper use of the equipment that

the respective target group(s) be familiar with the relevant

chapters.

This technical documentation is intended both as a source

of reference and as an instruction manual. The individual

chapters are complete in themselves.

The operating instructions do not contain any repair

instructions. Should repairs ever become necessary,

please contact your supplier or Retsch GmbH directly.

Warnings

The following symbols are used to warn about hazards:

Repairs

These operating instructions do not contain any repair

instructions. For your own safety, repairs should be done

only by Retsch GmbH or an authorised agency.

In such cases, please notify:

Your service address:

8 January 2008 Retsch GmbH 2 Doc. no. D 98.025.9999

Page 3

Notes on these Operating Instructions ................ 2

Warnings ........................................................... 2

Repairs ............................................................. 2

Safety .................................................................. 4

Safety instructions ................................................. 4

Summary of Safety Instructions .......................... 5

Confirmation ....................................................... 6

Technical Data ..................................................... 7

Use in accordance with the intended purpose ................... 7

Emissions ........................................................... 8

Maximum loading .................................................. 8

Systems of protection ............................................. 8

Device dimensions ................................................. 8

Required standing area ........................................... 8

Technical data...................................................... 8

Transport and Installation ................................... 9

Packaging .......................................................... 9

Transport ........................................................... 9

Temperature fluctuations ......................................... 9

Intermediate storage .............................................. 9

Parameters for the place of installation .......................... 9

Installation ......................................................... 10

Alignment .......................................................... 10

Electrical connection ............................................... 10

Operation ............................................................ 11

Operating elements and operation ............................... 11

Operating elements and their functions .......................... 11

Operating elements and their functions .......................... 12

Operating the AS 200 tap ......................................... 13

Switching on and off ............................................... 13

Display and operating element ................................... 13

Setting the time and continuous operation ...................... 14

Starting- interrupting- stopping .................................. 14

Opening the noise insulating hood ............................... 14

Inserting the sieve stack .......................................... 15

Removing the sieve stack ......................................... 16

Retsch Analytical Sieves ...................................... 17

Working Instructions .......................................... 18

Sieving aids ........................................................ 18

Quantities of material to be sieved ............................... 18

EasySieve ........................................................... 19

Control, evaluation, documentation .............................. 19

PC serial connection ............................................... 19

General Points ..................................................... 20

Cleaning ............................................................ 20

Maintenance ........................................................ 20

Safety instructions (table) ........................................ 20

Wearing parts ...................................................... 21

Appendix ....................................... following pages

8 January 2008 Retsch GmbH 3 Doc. no. D 98.025.9999

Page 4

Safety

We herewith exclude any kind of claim relating to personal

injury or material damage arising from a failure to comply with

the following safety instructions.

The AS 200 tap is a very modern highly efficient product

manufactured by Retsch in accordance with the latest technical

developments. It is completely safe if used for its intended purpose

by operators familiar with this technical documentation.

Safety instructions

You, as the owner / managing operator, must ensure that

the people entrusted with working on the AS 200 tap:

have read and understood all rules relating to safety,

have familiarised themselves before starting work with all

the handling instructions and the regulations for the target

group of relevance to their work

have easy access at all times to the technical

documentation for this machine

new personnel must be familiarized with the safe and

appropriate handling of the machine before beginning

work on the AS 200 tap, either by verbal instruction from

a competent person and/or through this technical

documentation

Incorrect operation can result in personal injuries and

damage to equipment. You are responsible for your own

safety and that of your staff.

Make sure that no unauthorised person has access to the

AS 200 tap.

For your own protection have your staff confirm that they

have been instructed in the operation of the AS 200 tap.

You will find a draft of a suitable form at the end of the

section on safety.

8 January 2008 Retsch GmbH 4 Doc. no. D 98.025.9999

Page 5

Summary of Safety Instructions

We herewith exclude any kind of claim for personal injury or material damage arising from a failure to

comply with the following safety instructions.

Do not make any modifications to the machine and use only spare parts and accessories approved by

Retsch. Otherwise, the Declaration of Conformity to the European Directives declared by Retsch will lose its

validity and you will forfeit any right to claims under guarantee.

Please keep the packaging for the duration of the guarantee period because returning the equipment in

unsuitable packaging if you have a complaint can jeopardize your guarantee claims.

The AS 200 tap may not be knocked, shaken or thrown about during transport as this could damage the

electronic and mechanical components.

If the AS 200 tap is subjected to a high level of fluctuations in temperature (e.g. during shipment by air) it

must be protected from condensation in order to prevent damage to the electronic components.

If the shipment is incomplete and / or has been damaged during transport, you must notify the forwarder

and Retsch GmbH immediately (within 24 hours). Complaints lodged at a later date might not be considered

valid.

If the temperature drops below or exceeds the range for ambient temperature, the electrical and mechanical

components may become damaged and performance data may change to an unknown extent.

At high air humidity the electrical and mechanical components can become damaged and performance data

can change to an unknown extent.

To ensure reliable operation, the AS 200 tap must be doweled firmly to the underlying surface by means of

the transport angle piece.

Non-adherence to the levels specified on the type plate can damage electrical and mechanical components.

Ensure that the sieve mesh is not stretched excessively by overloading with sieving aids because this would

impair the precision of your analytical sieves.

The sieves may not be overloaded. Overloading destroys the sieve mesh and impairs sieving results.

The AS 200 tap may not be cleaned with running water. Risk of a fatal electric shock.

Use only a cloth moistened with water. Solvents are not permitted.

These operating instructions do not include repair instructions. For your own safety, repairs may be done only

by Retsch GmbH, an authorised agent or Retsch service technicians.

Safety instructions

Use according to the intended purpose

Packaging

Transport

Temperature fluctuations

Scope of supply

Ambient temperature :

Air humidity :

Installation:

Electrical connection / connecting to the mains supply

Sieving aids

Sieving quantities

Cleaning

Wearing parts

8 January 2008 Retsch GmbH 5 Doc. no. D 98.025.9999

Page 6

Confirmation

I have read the “Notes on these Operating

Instructions” and “Safety” sections.

_________________________________

Signature of the operator

________________________________________

Signature of the owner/managing operator

8 January 2008 Retsch GmbH 6 Doc. no. D 98.025.9999

Page 7

Technical Data

Do not make any modifications to the machine and use only

spare parts and accessories approved by Retsch.

Otherwise the Declaration of Conformity to the European

Directives declared by Retsch will lose its validity.

Furthermore you will forfeit the right to any kind of

claims under guarantee.

The movement of the sieved material in the AS 200 tap can

cause considerable unbalance. It must therefore be installed on

a suitable laboratory table. The net weight of the AS 200 tap

is 68 kg.

Machine type designation: AS 200 tap

Use in accordance with the intended purpose

This device is not designed as a production machine or for

continuous operation, but as laboratory apparatus for

single-shift 8-hour operation.

The RETSCH AS 200 tap is used for dry sieving with

analytical sieves with diameters of up to 203 mm, whereby

the uniform, horizontal circular sieving motion and the

tapping pulse ensure an exact separation of the material

being sieved with a feed grain size of up to a max. 25 mm.

Fine and coarse grained materials, such as those produced

in mills, breweries, and in the chemicals, stone, earth,

wood and plastic industries can be separated exactly with

the AS 200 tap.

The horizontal, rotating movement of the material being

sieved is particularly advantageous for separating products

such as milled grain, wood chips or similar materials.

Accordingly, DIN 53477, for example, specifies a rotating

sieve motion for testing plastics (grainy moulding plastic

material).

The AS 200 tap can be used as testing equipment for

monitoring quality conformance to DIN EN ISO 9000 et

seq.

The required sieving time is digitally set, displayed and

monitored.

The AS 200 tap has an integrated interface for triggering all the

sieving parameters through the EasySieve® software. The

interface cable required for this is included in the scope of supply.

8 January 2008 Retsch GmbH 7 Doc. no. D 98.025.9999

Page 8

Emissions

Noise characteristics:

Measurement of noise in accordance with DIN 45635-031-01-KL3

The noise characteristics depend on the set amplitude or sieve

base acceleration, the number of sieves and the type of the

material being sieved.

Example 1:

Workplace-related emissions LpAeq = = 79 dB(A)

Operating conditions :

Sieved material = quartz sand, grain size <1mm, 5 sieves

Example 2:

Workplace-related emission level LpAeq = 65 dB(A)

Operating conditions :

Sieved material = quartz sand, grain size <1mm, 5 sieves

With noise insulating hood

Maximum loading

max. sieved quantity of sieved material = 3 kg

max. weight of a sieve stack = 6 kg

max. height of a sieve stack: 6 sieves (50 mm) + 1 collecting base

(50 mm)

Systems of protection

IP 54 and IP 20 resp. in the area of the sieve holder passage

Device dimensions

Width: 715 mm, height: approx. 760 mm, depth: 520 mm

Weight: approx. 92 kg (without sieve stack)

Required standing area

800mm x 550mm; no safety spacing needed.

Technical data

Number of oscillations of the sieve plate: 280/min.

Number of tapping pulses: 150/min.

8 January 2008 Retsch GmbH 8 Doc. no. D 98.025.9999

Page 9

Transport and Installation

Please keep the packaging for the duration of the

guarantee period because returning the equipment in

unsuitable packaging if you have a complaint can

jeopardize your guarantee claims.

Lifting above head height is not permissible!

The AS 200 tap may not be knocked, shaken or

thrown about during transport as this could damage the

electronic and mechanical components.

If the AS 200 tap is subjected to a high level of

fluctuations in temperature (e.g. during shipment by

air), it must be protected from condensation in order to

prevent damage to the electronic components.

If the temperature drops below or exceeds the range for

ambient temperature, the electrical and mechanical

components may become damaged and performance data

may change to an unknown extent.

TS

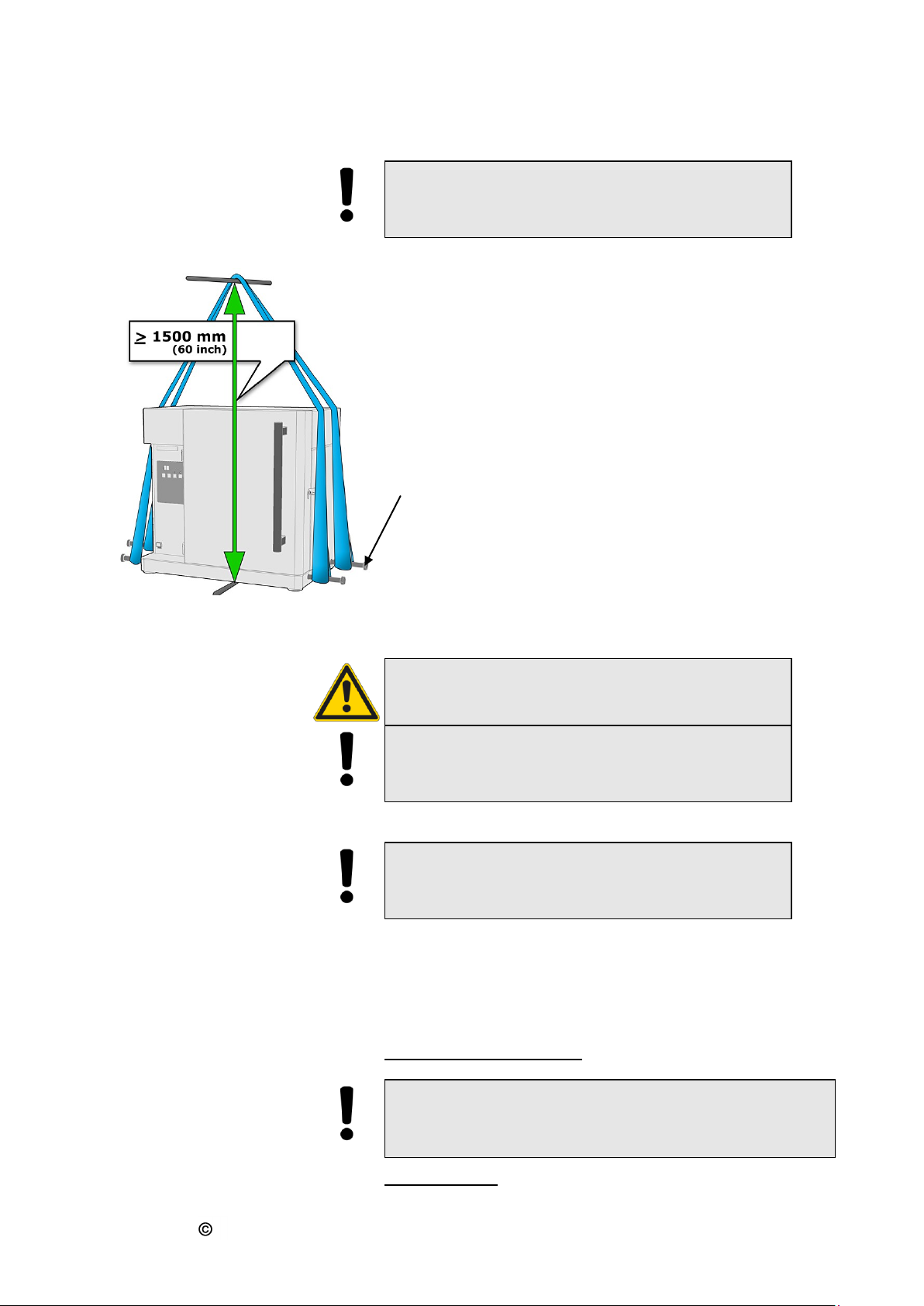

Fig. 1

Packaging

The packaging has been adapted to the transport route

and conforms to the generally applicable packaging

guidelines.

Transport

After unpacking, the AS 200 tap is to be lifted and transported only

with permissible lifting slings and only with the TS transport screws

supplied with the machine. Fig. 1

Net weight: AS 200 tap approx. 92 kg

Temperature fluctuations

Intermediate storage

Make sure that the AS 200 tap is stored in dry conditions

even during intermediate storage.

Parameters for the place of installation

Ambient temperature :

5°C to 40°C

Air humidity:

8 January 2008 Retsch GmbH 9 Doc. no. D 98.025.9999

Page 10

Maximum relative humidity 80% at temperatures up to 31°C, with a

At high air humidity the electrical and mechanical components

can become damaged and performance data can change to an

unknown extent.

Installation

Install the AS 200 tap only on a stable, safe surface in order

to prevent the transmission of undesirable vibrations.

Alignment

To ensure that the AS 200 tap can stand securely, all 4 feet

must be in contact with the installation surface.

Electrical connection

The voltage and frequency for the AS 200 tap are

specified on the type plate.

Make sure that the levels correspond to the available

power supply system.

Connect the AS 200 tap to the power supply system with

the aid of the connection cable included in the scope of

supply.

When connecting the mains cable to the power supply, use

an external fuse in conformance to the regulations

applicable to the place of installation.

Non-adherence to the levels specified on the type plate can

damage electrical and mechanical components.

decrease to 50% relative humidity at 40°C.

Installation height :

max. 2000 m above sea level

8 January 2008 Retsch GmbH 10 Doc. no. D 98.025.9999

Page 11

Operation

Element

Description

Function

A

Tapping arm

Transmits tapping pulses to the material being

sieved.

B

Lock hook

Locks the noise insulating hood

C

Clamping lever

Allows adjustment to the different sieve stack

heights.

D

Sieve plate

Holds the sieve stack

E

Sieve lid

Centres the sieve stack and holds the cork

stopper.

F

Cork stopper

Transmits the tapping pulses to the sieve lid.

G

Display and operating unit:

See below for explanations.

Time preselection and starting/stopping the

machine

M

START press button

No function

A

B

F

E

D C G

M

Operating elements and operation

Operating elements and their functions

Overview table

8 January 2008 Retsch GmbH 11 Doc. no. D 98.025.9999

Page 12

Rear view

Element

Description

Function

H

Device socket

Connection for the device’s power cable

I

ON / OFF switch

For turning the AS 200 tap on and off and serves

as a motor protection switch.

J

RS232 interface

Allows communication with EasySieve

K

Type plate

Information on the device and connected loads

L

BDA information plate

Refers to the operating instructions.

P

Safety switch socket

Activates the door monitoring

I H J

K

L

P

Operating elements and their functions

Overview table

8 January 2008 Retsch GmbH 12 Doc. no. D 98.025.9999

Page 13

Operating the AS 200 tap

The main switch is located on the left side at the

back of the AS 200 tap

Turn on the main switch

- - lights up in the time min display

The STOP LED lights up

The AS 200 tap is now ready for operation without

interval and in continuous operation at a speed of 50

min-1.

The + button increases the sieving time in the range

from 1 – 99 min.

The – button reduces the sieving time, and the range

from 1 – 99 min is shown in the display.

A set continuous operation is shown with - - in the

display.

Press the START button to start the sieving

operation. The green LED lights up during the sieving

process.

Press the STOP button to end the sieving operation.

The red LED lights up.

Switching on and off

Display and operating element

8 January 2008 Retsch GmbH 13 Doc. no. D 98.025.9999

Page 14

Setting the time and continuous

12 13 14

When the AS 200 tap is switched on, the sieving

time still has to be determined.

Two dashes - - appear in the display 13.

Increasing the time:

Button 13 increases the time up to 99 minutes.

Reducing the time:

Button 12 reduces the time down to one minute.

Continuous operation:

If the time drops below one minute, two dashes will

appear in the display. This activates continuous

operation. The same happens when the time

exceeds 99 minutes.

15 16

Starting:

Press the START / Button 15

The green LED over button 15 lights up

Interrupting (pause function):

Press the STOP / button 16 once

The red LED over button 16 lights up

The levels remain visible

Press the START / button 15 at the same time

The sieving process continues

Stopping (stand-by function):

Press STOP / button 16 twice

The red LED over button 16 lights up

The complete display goes out

Activate the LED display by pressing button 15

once

The new levels can be entered now

Press START / button 15 a second time

The function runs as with START

Opening the noise insulating

hood

When the door is opened, the AS 200 tap turns

off automatically and does not start again until

the door is shut.

operation

Starting- interrupting- stopping

8 January 2008 Retsch GmbH 14 Doc. no. D 98.025.9999

Page 15

Inserting the sieve stack

To make it possible to loosen the clamping

screws easily, the position of the KH clamping

lever can be adjusted independently of the

clamping screws.

Then unscrew the two clamping screws C and

push the carriage downwards. Tighten both

clamping screws firmly again.

Place the sieve stack in the centre of the carriage

and loosen the two clamping screws.

Push the carriage upwards until the top edge of

the sieve stack is at the same level as the guide

ring. Then tighten the clamping screws again.

Lift the tapping arm slightly and place the sieve

lid E with cork stopper on the top sieve.

C

E

KH

The AS 200 tap is suitable for analytical sieves with

outside diameters of 200 mm and 203 mm (8“).

8 January 2008 Retsch GmbH 15 Doc. no. D 98.025.9999

Page 16

Removing the sieve stack

To remove the sieve stack, lift it and the lid

upwards slightly and at the same time press the

tapping arm upwards.

Pull the sieve stack forwards and out.

8 January 2008 Retsch GmbH 16 Doc. no. D 98.025.9999

Page 17

Retsch Analytical Sieves

Initially, the new RETSCH sieves will be available in the three

versions that are the most important for sophisticated

laboratory analysis:

200 x 25 mm

200 x 50 mm

203 x 50 mm = 8“ x 2“

Compatibility with other standard sieves is ensured of course.

The new sieves are compatible with the standard RETSCH

range of sieves and can also be combined easily with most

other sieve makes.

This is also important for you:

Every sieve leaves our company with a works certificate or – on

request - a special acceptance test certificate in accordance

with DIN ISO 3310-1.

Calibration certificates guarantee an even greater statistical

reliability and document our aim at perfection.

1. Sieve frame cast in one piece and a seamless mesh

transition prevents cross contamination (no solder, no

residues etc)

2. High degree of resistance to corrosion and easy cleaning

due to the use of high-alloy stainless steel (316L or

1.4435)

3. 15% lighter than traditional sieves but with a larger free

sieving surface

4. Unsurpassed product quality due to fully automatic

production and an uninterrupted optical inspection

5. Innovative resistance welding technology ensures that

the sieve mesh remains taut always.

6. Maximum stability and optimum sealing of the sieve stack

7. Clear sieve marking and traceability due to individual

laser engraving

RETSCH certificates

Before dispatch every sieve is

measured optically and provided

with a works certificate.

On request, you will receive a

report with the acceptance

test certificate with the

measurements recorded in

tabular form and in diagrams

or a calibration certificate

with more detailed statistics.

Calibration service

As a special service, we offer to

recalibrate your analytical

sieves, whereby after

conducting the measurements

in accordance with standards,

all the relevant information is

recorded and confirmed in the

required certificate.

Analytical sieves with diameters of 200 and 203 mm

Sieve accessories

8 January 2008 Retsch GmbH 17 Doc. no. D 98.025.9999

The complete range of accessories for the various

analytical sieves includes the collecting bases, collecting

bases with outlet, intermediate bases, intermediate rings

and sieve lids. Sieve aids and sieve stands round off the

range of accessories offered.

Please refer to our price list for the precise order data for

the analytical sieves and available accessories.

Tested quality – in black and white

Page 18

Make sure that the sieve mesh is not stretched excessively by

overloading with sieving aids, as this would impair the precision

of your analytical sieves.

Overview Table

Sieving aids

Quantity per

sieve or sieved

material

Supplier

Field of application

Caution !!

Vulkollan® cubes

5 pcs., 12x12

RETSCH, Haan

when planar sieve

machines are used

Brushes

3 pcs.

RETSCH, Haan

Plastic rings

3 pcs., various

diameters

Small brushes

with manual sieving

Highly dispersed silicic acid

(Aerosil)

0.5 to 2%

Degussa,

Frankfurt on

Main

with fine, sticky sieve

materials that contain

fat and are

electrostatically charged

Before adding, check usability and

compatibility!

- - Aluminium oxide

0.5 to 1%

Degussa,

Frankfurt on

Main

- - Talcum

with crude rubber and

rubber powder

Drying

with very wet/very

humid sieve materials

Pass dry warm air through the

set of sieves

with hygroscopic sieve

materials

TAP function

for fine materials that

stick easily and fall

through the machine

with difficulty

A TAP function is built into the AS 200

tap tapping sieve machine and can be

switched off at will.

Nominal diameter of

sieve openings

Material quantities in dm3 for

diameters of 200mm

8

0 . 5 0 0

3 . 1 5

0 . 3 0 0

1

0 . 1 4 0

0 . 5

0 . 1 0 0

0 . 2

0 . 0 6 0

0 . 0 6 3

0 . 0 3 5

0 . 0 2 0

0 . 0 2 0

Working Instructions

Sieving aids

For materials that are difficult to separate we recommend the

additional use of sieving aids in the individual sieve fractions. For

this purpose and depending on the mesh size of the sieve and the

preselected oscillation intensity, balls of agate, rubber, porcelain or

nylon brushes and Vulkollan® cubes can be used. See also the table

below.

For recommendations with regard to quantities of material

to be sieved, see the section on “Sieving Quantities”

Quantities of material to be sieved

The stack of sieves required for sieve analysis is made up

of a number of analytical sieves arranged one on top of

the other in ascending order of hole width.

To ensure quick fractioning with an exact result, the

quantity of material to be sieved must be adapted to the

sieve diameter and the nominal diameter of the openings.

Guide levels for this are given in the respective standard

specifications for sieve analysis, e.g. according to DIN

22019/1 the following maximum added quantities are

recommended:

8 January 2008 Retsch GmbH 18 Doc. no. D 98.025.9999

Page 19

EasySieve

EasySieve®, the software for grain size analysis from

RETSCH, is far superior to manual evaluation in many

respects. This is because the software is able to conduct

measuring and weighing operations automatically –

from registering the weights of the sieves to evaluating

the data. This can be accomplished more easily and more

conveniently than ever before, which is why it’s called

“easy”.

The software design is self-explanatory and corresponds to

the logical sequence of grain size analysis. Therefore the

learning phase can be kept very short. The large number

of evaluation possibilities also allows absolute flexibility

with regard to adaptation to sophisticated individual

problems.

Parameter input Trend analysis of product processes Comparison with

specification limits

J

The AS 200 tap can be connected serially to a personal

computer for data transfer in each direction. For this purpose use

a customary 9-pin RS232 cable, included with the AS 200 tap.

This allows communication with the EasySieve® evaluation

software (available as an accessory).

Remove the cap that protects the connection from dust

and moisture when it is not in use

Use the serial cable to link connection J to the PC.

Control, evaluation, documentation

PC serial connection

8 January 2008 Retsch GmbH 19 Doc. no. D 98.025.9999

Page 20

General Points

The AS 200 tap may not be cleaned with running water.

Risk of a fatal electric shock.

Use only a cloth moistened with water.

Solvents are not permitted.

Safety instructions (table)

For the AS 200 tap from the various

chapters

Process

Occurrence

Risks

Safety

Damage to equipment and injury to

people due to a non-observance of

the safety instructions

Rules out all kinds of claims for

compensation.

Packaging

Please keep the packaging for the

duration of the guarantee period.

Returning the equipment in unsuitable

packaging if you have a complaint can

jeopardize your guarantee claims.

Transport

The AS 200 tap may not be

knocked, shaken or thrown about

during transport.

Electronic and mechanical components

can become damaged.

Temperature fluctuations

Protect the AS 200 tap from

condensation if it is subjected to a

high level of fluctuations

Electronic components can become

damaged.

Installation

The AS 200 tap may only be set up

on a suitable laboratory table.

The movement of the sieved material

can cause considerable imbalance.

Scope of supply

If the shipment is incomplete and /

or has been damaged during

transport, you must notify the

forwarder and Retsch GmbH

immediately (within 24 hours).

Complaints lodged at a later date

might not be considered valid.

Ambient temperature

lower than 5°C

higher than 40°C

Electronic and mechanical components

can become damaged.

Performance data can change to an

unknown extent

Air humidity

80% exceeded at temperatures of

up to 31°C

Electronic and mechanical components

can become damaged.

Performance data may change to an

unknown extent.

Electrical Connection

Mains system does not agree with

the levels on the type plate

Electronic components can become

damaged.

Cleaning

Disconnect mains plug before every

cleaning process.

Risk of a fatal electric shock.

Do not clean with running water.

Risk of a fatal electric shock.

Cleaning

We recommend Retsch ultrasonic baths for a thorough but

gentle time-saving cleaning of your analytical sieves.

Please ask for our special leaflet on the “Care and Cleaning

of Analytical Sieves“, which is available free of charge.

Maintenance

Otherwise the AS 200 tap is essentially maintenance-free.

8 January 2008 Retsch GmbH 20 Doc. no. D 98.025.9999

Page 21

Alterations

Item 26 / art. no. 03.382.0024 tapping tool and

item 51 / art. no. 05.114.0090 O ring

Item 41 / Art. no. 03.753.0028 cork stopper

These operating instructions do not contain any repair

instructions. For your own safety, repairs should be done only

by Retsch GmbH or an authorised agency.

Subject to technical alterations without notice.

Copyright

Distributing or duplicating this documentation and

using and passing on the contents are permitted only

with the express permission of Retsch GmbH.

Anyone violating this copyright is liable to pay

damages.

Wearing parts

8 January 2008 Retsch GmbH 21 Doc. no. D 98.025.9999

Page 22

Page 23

Page 24

Page 25

Authorized person for the compilation of technical documents:

Dr. Loredana Di Labio (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Tap Sieving Machine Type AS 200 tap is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, April 2016

Dr.-Ing. Frank Janetta

Manager Development

Retsch GmbH Ret sch-Alle e 1- 5 42781 Haan G erma ny w w w .ret sch.com

Tap Sieving Machine

AS 200 tap 30.025.xxxx

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2014/30/EU

Applied standards, in particular:

EN 61000-3-2/-3 Electromagnetic compatibility (EMC)

EN 61326 Electrical measuring, operating, controlling and laboratory equipment – EMC-

requirements in conjunction with EN 61000

EN 55011 Limit values and measuring procedures for noise suppression of industrial,

scientific and medical high frequency devices

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 26

Page 27

Page 28

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...