Page 1

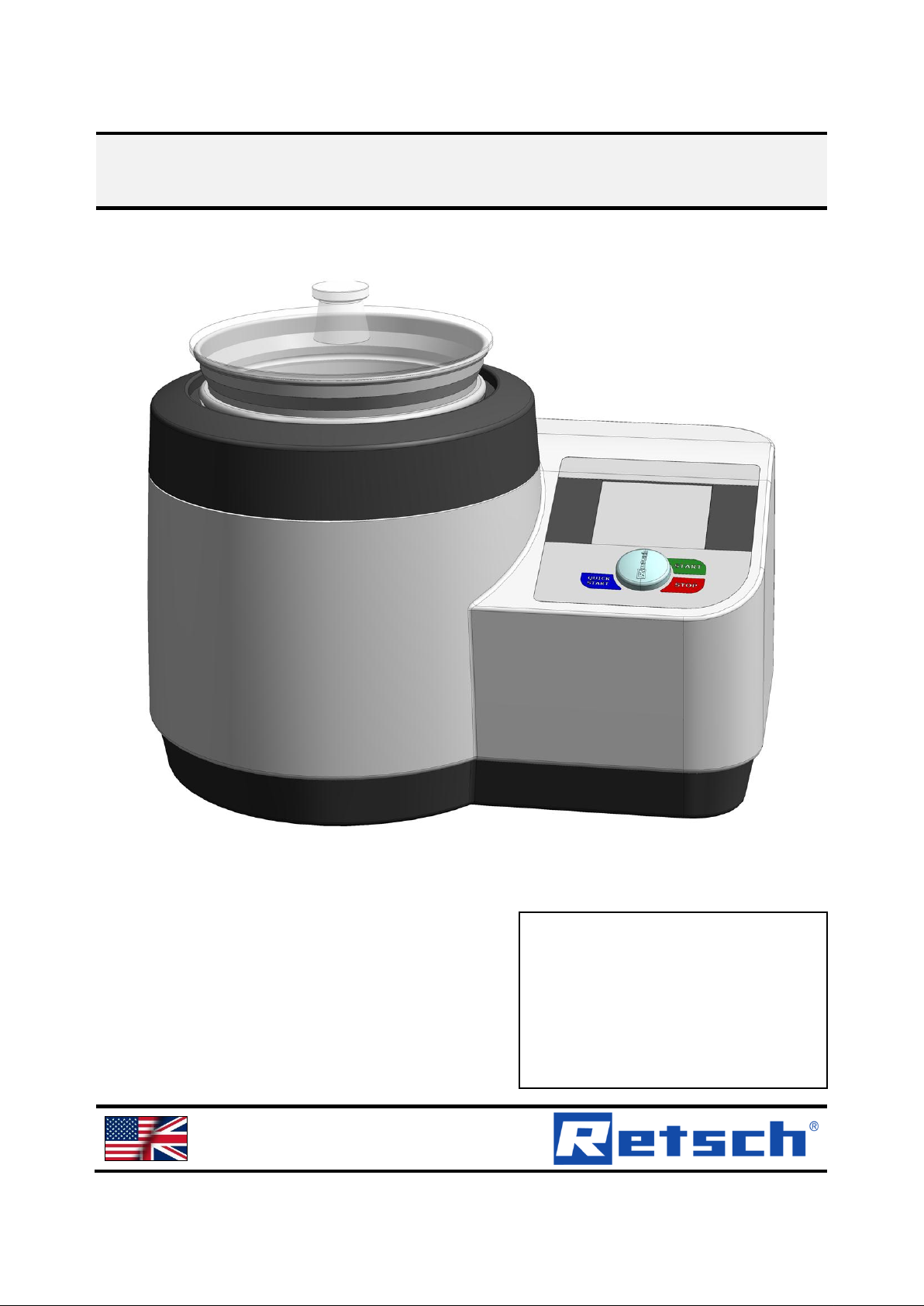

Manual

Air Jet Sieving Machine AS200jet

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 18.09.2014 0011

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

3

Page 4

1 Notes on the Operating Manual ............................................................................................................ 6

1.1 Explanations of the safety warnings .................................................................................................. 7

1.2 General safety instructions ................................................................................................................ 8

1.3 Repairs ............................................................................................................................................... 9

2 Confirmation ......................................................................................................................................... 10

3 Technical data ....................................................................................................................................... 11

3.1 Use of the machine for the intended purpose.................................................................................. 11

3.2 Emissions......................................................................................................................................... 12

3.3 Maximum Load ................................................................................................................................ 13

3.4 Degree of protection ........................................................................................................................ 13

3.5 Dimensions and weight .................................................................................................................... 13

3.6 Required floor space ........................................................................................................................ 13

3.7 Rated power .................................................................................................................................... 13

3.8 Type plate description ...................................................................................................................... 14

4 Transport, scope of delivery, installation .......................................................................................... 15

4.1 Packaging ........................................................................................................................................ 15

4.2 Transport.......................................................................................................................................... 15

4.3 Temperature fluctuations and condensed water ............................................................................. 15

4.4 Conditions for the place of installation ............................................................................................. 15

4.5 Installation of the machine ............................................................................................................... 15

4.6 Electrical connection ........................................................................................................................ 16

5 Operating the machine ........................................................................................................................ 18

5.1 Views of the Instrument ................................................................................................................... 18

5.2 Operating elements and displays .................................................................................................... 20

5.3 Overview table of the parts of the device ........................................................................................ 21

5.4 Working procedure .......................................................................................................................... 22

5.5 Switching On and Off ....................................................................................................................... 22

5.6 Inserting the test sieve ..................................................................................................................... 22

5.6.1 Sieve lid for 50--mm/25--mm sieve height ................................................................................... 23

5.7 Soft-faced mallet – Application and Use .......................................................................................... 23

5.8 Connecting the external Industrial Vacuum cleaner ........................................................................ 23

5.8.1 Vacuum cleaner function ............................................................................................................. 24

5.8.1 Setting options using the display menu ....................................................................................... 27

5.8.2 Navigation between operating modes ......................................................................................... 27

5.9 Symbols in the Display Unit ............................................................................................................. 28

5.10 Direct access to the language menu ............................................................................................... 29

5.11 Menu structure ................................................................................................................................. 30

5.12 Operating modes ............................................................................................................................. 31

5.12.1.1 Manual ............................................................................................................................. 31

5.12.1.2 Program 01 to 09 ............................................................................................................ 31

5.12.1.3 Quick Start ....................................................................................................................... 31

5.12.1.4 Basic settings ................................................................................................................... 31

5.13 Manual operation ............................................................................................................................. 32

5.13.1 Sieve duration .......................................................................................................................... 32

5.13.2 Speed ....................................................................................................................................... 32

5.13.3 Vacuum .................................................................................................................................... 32

4

Page 5

5.13.4 Open Mesh .............................................................................................................................. 32

5.13.5 Save parameters ..................................................................................................................... 32

5.13.6 Suction apparatus .................................................................................................................... 32

5.14 Programs ......................................................................................................................................... 33

5.14.1 Sieve duration .......................................................................................................................... 33

5.14.2 Speed ....................................................................................................................................... 33

5.14.3 Vacuum .................................................................................................................................... 33

5.14.4 Open Mesh .............................................................................................................................. 33

5.14.4.1 Change program .............................................................................................................. 33

5.14.4.2 Delete program ................................................................................................................ 34

5.15 Quick Start ....................................................................................................................................... 34

5.16 Basic settings ................................................................................................................................... 34

5.16.1 Vacuum .................................................................................................................................... 34

5.16.2 Languages ............................................................................................................................... 34

5.16.3 Brightness ................................................................................................................................ 34

5.16.4 Date ......................................................................................................................................... 35

5.16.5 Time ......................................................................................................................................... 35

5.16.6 Signal tone ............................................................................................................................... 35

5.16.7 Interface ................................................................................................................................... 35

5.16.8 Service ..................................................................................................................................... 35

5.16.8.1 Operating hours ............................................................................................................... 35

5.16.8.2 Software version display .................................................................................................. 35

5.16.8.3 Software version controller .............................................................................................. 35

5.16.8.4 Update software ............................................................................................................... 35

5.16.8.4.1 Display ......................................................................................................................... 35

5.16.8.4.2 Controller ..................................................................................................................... 36

5.16.8.5 Sensor calibration ............................................................................................................ 36

5.16.9 Service level ............................................................................................................................. 36

5.17 Starting, Interrupting, Stopping .................................................................................................... 36

5.18 Stand-by ....................................................................................................................................... 36

5.19 Controlled suction force adjuster ................................................................................................. 37

5.20 Cyclone assembly ........................................................................................................................ 37

6 EasySieve® ........................................................................................................................................... 42

6.1 Control, evaluation, documentation................................................................................................... 42

6.2 Serial PC connection ......................................................................................................................... 42

7 Cleaning and service ........................................................................................................................... 44

7.1.1 Cleaning ....................................................................................................................................... 44

7.1.2 Vacuum cleaner – changing the vacuum cleaner bag ................................................................ 44

7.1.3 Maintenance ................................................................................................................................ 44

7.2 Calibrating the pressure sensor (checking of the differential pressure) ............................................ 44

8 Fault messages ..................................................................................................................................... 46

9 Index ...................................................................................................................................................... 47

Appendix .................................................................................................................................. following page

5

Page 6

Notes on the Operating Manual

Pos: 1.1 /0005 RETSCH/0015 RETSCH R eparatur- und Montageanleitungen/0 0000 Überschriften/1. Überschriften/1 Hinw eise zur Bedienungsanleitung @ 0\ mod_1222347415287_9.docx @ 2631 @ 1 @ 1

1 Notes on the Operating Manual

Pos: 1.2 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlu ngen/CryoMill/0001 Hinweise zur Bedienu ngsanleitung/Modul Hinweis zur Bedienungs anleitung @ 0\mod_1222347341773 _9.docx @ 2540 @ @ 1

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

Pos: 1.3 /0005 RETSCH/0005 RET SCH Bedienungsanleitungen Kapitelsam mlungen/CryoMill/0001 Hinweise zur Bedi enungsanleitung/Modul Änderungen @ 0\mod_1222347341241_9.docx @ 2526 @ @ 1

Pos: 1.4 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlu ngen/CryoMill/0001 Hinweise zur Bedienu ngsanleitung/Modul Urheberrecht @ 0\ mod_1222347342038_9.docx @ 2547 @ @ 1

Pos: 2.1 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

www.retsch.com.

Changes

Subject to technical changes.

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

6

Page 7

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

Pos: 2.2 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Erkläru ngen zu den Sicherheitswarnungen @ 0 \mod_1222344569771_9.docx @ 2484 @ 2 @ 1

1.1 Explanations of the safety warnings

Pos: 2.3 /0010 RETSCH Standard Kapitel General Modul Warnhinweise Erklärung neu @ 0\mod_1234858329746_9.doc x @ 6190 @ @ 1

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

Pos: 2.4 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

7

Page 8

Notes on the Operating Manual

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.5 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Generell e Sicherheitshinweise @ 0\mod_1222 344568974_9.docx @ 2463 @ 2 @ 1

1.2 General safety instructions

Pos: 2.6 /0025 Warnhinweise/V0002 VOR SICHT Bedienungsanleitung lesen @ 2 \mod_1263894982815_9.docx @ 186 30 @ @ 1

Pos: 2.7 /0010 RETSCH Standard Kapitel General Modul Zielgruppe und Sicherheit @ 0\mod_1228722955300_9.docx @ 4100 @ @ 1

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

Pos: 2.8 /0010 RETSCH Standard Kapitel General Modul Sicherheitshinweise @ 0\mod_1228722954800_9.docx @ 4086 @ @ 1

Pos: 2.9 /0025 WarnhinweiseV0015 VORS ICHT + HINWEIS Sach- und Person enschäden @ 1\mod_1236238456676_9.d ocx @ 7642 @ @ 1

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.10 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

8

Page 9

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Pos: 2.11 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Reparatur en @ 0\mod_1223624336511_9.doc x @ 2978 @ 2 @ 1

Reperaturen

1.3 Repairs

Pos: 2.12 /0010 RETSCH Standard KapitelG eneral Modul Reparaturen @ 0\mod _1228722954535_9.docx @ 4079 @ @ 1

Notes on the Operating Manual

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

Pos: 3.1 /0005 RETSCH/0010 RETSCH Software Anleitungen/PMGrindControl- - - - Seitenumbruch - - - - @ 0\mod_120 8857688413_0.docx @ 337 @ @ 1

9

Page 10

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.2 /0010 BDA Software/Überschrift en/1. Überschriften/1 Bestätigung (Formular für den Betreiber) @ 0\mod_120887 0841095_9.docx @ 430 @ 1 @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Bestätig ung @ 0\mod_1228722962707_9.docx @ 4114 @ @ 1

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

Pos: 4 /0005 RETSCH/0005 RETSCH Be dienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

10

Page 11

Technical data

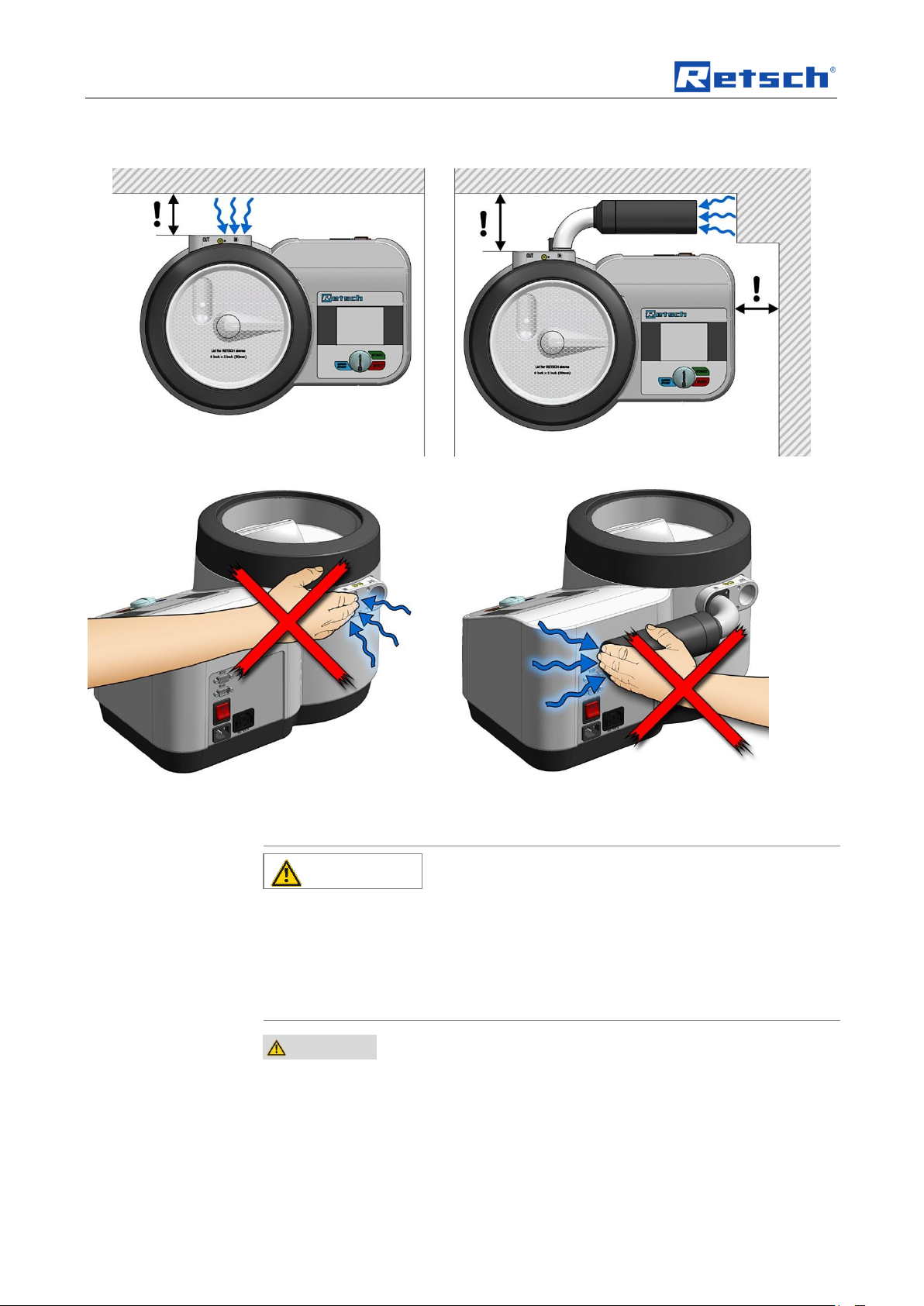

CAUTION

Risk of explosion or fire

– On account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

• Do not operate the device in a hazardous atmosphere.

CAUTION

Risk of explosion or fire

Changing sample characteristics

– Note that the characteristics and accordingly the danger presented by a

sample can change during sieving.

• Do not sieve any potentially explosive or combustible materials in

this device.

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

Pos: 5.1 /0020 Überschriften/1. Überschrift en/1 Technische Daten @ 0\mod_122 2344525522_9.docx @ 2407 @ 1 @ 1

3 Technical data

Pos: 5.2 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Einsatz der Maschine bei bestimmungsgemäßer Verwendung @ 0\mod_1226476732248 _9.docx @ 3243 @ 2 @ 1

3.1 Use of the machine for the intended purpose

Pos: 5.3 /0025 Warnhinweise/V0005 VOR SICHT explosionsgefärdete Atmosphäre @ 1\mod_1239868668923_9.doc x @ 8140 @ @ 1

Pos: 5.4 /0025 Warnhinweise/V0003 VOR SICHT Explosions- oder Brandgefahr Sieben @ 1\mod_1243924323407_9.doc x @ 10360 @ @ 1

Pos: 5.5 /0025 Warnhinweise/V0006 VOR SICHT Gefahr von Personenschäden G efährliche Stoffe @ 1\mod_123623845 6269_9.docx @ 7634 @ @ 1

Pos: 5.6 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlunge n/AS200Jet/0005 AS200Jet Technische Da ten/AS200Jet Modul Einsatz bei bes timmungsgemäße Verwendung @ 1\m od_1236585801365_9.docx @ 7778 @ @ 1

Target group: Owner/managing operator, operator

Machine Type Designation: AS200jet

The AS200jet is specially designed for the dry sieving and the particle size

determination of fine-grained, dry, pourable and dispersed bulk materials. The

sieve holder is particularly suitable for the Retsch 203-mm-diameter test sieves.

This device offers user-friendly operation with rotary knob control and a large

graphic display. All sieve parameters are set, indicated and monitored digitally.

Work is also made easier by the possibility of storing up to 9 and 10 (QUICK

START) parameter combinations directly in the sieve shaker for frequently

repeated sieving operations under the same conditions. The QUICK START key

allows direct access to a combination of parameters.

The device can be controlled and adjusted with the EasySieve® evaluation

software. With EasySieve® all sieve parameters are displayed on the screen

before and during the sieving procedure.

The AS200jet can then reduce the average sieving times in samples with a high

fine fraction.

11

Page 12

Technical data

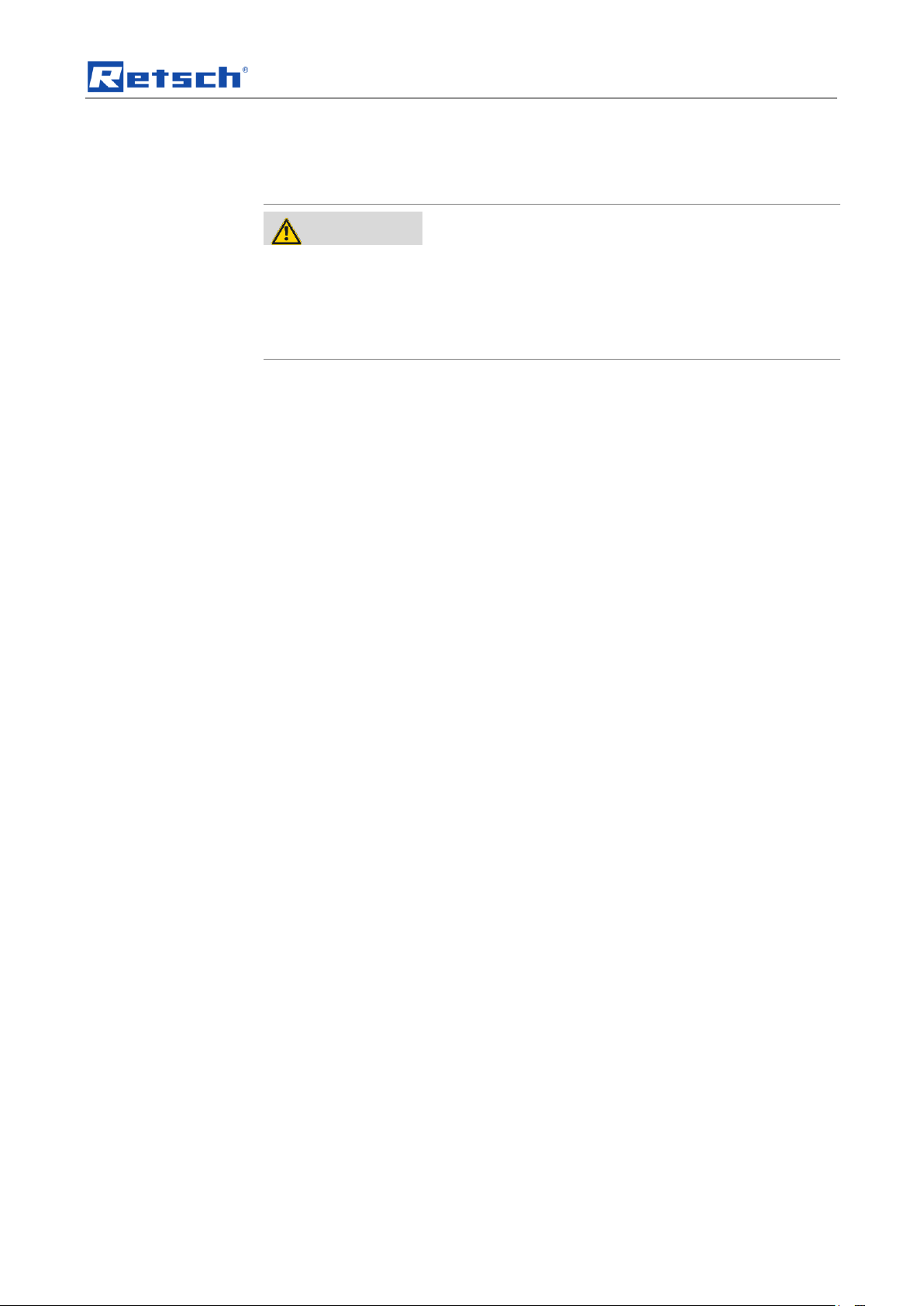

NOTICE

Area of use of the machine

– This machine is a laboratory machine designed for 8-hour single-shift

operation.

• This machine may not be used as a production machine nor is it

intended for continuous operation.

NOTE

Defects in components due to liquids

Penetration of liquids inside the housing

– Components are damaged and the correct functioning of the device is no

longer assured.

• Do not use this device for any wet sieving.

CAUTION

Hearing damage or hearing loss

Suction noise at the suction opening

– The volume and/or force of drawn-in air can damage

hearing or cause hearing loss.

• Keep your ears away from the air inlet in the channel.

Use hearing protection.

CAUTION

V0050

Failure to hear acoustic signals

Loud suction noise on the air inlet

– It is possible that some acoustic warnings and voice communication may

not be noticed.

• Take the strength of the suction noise into consideration when

designing your acoustic signals in the working environment.

Possibly additionally use visual signals.

Pos: 5.7 /0025 Warnhinweise/H0007 HIN WEIS Einsatzbereich des Gerätes 8 Stündig er @ 1\mod_1236240219096_9.doc x @ 7693 @ @ 1

Pos: 5.8 /0025 Warnhinweise/H0005 HIN WEIS Defekt von Bauteilen durch Flüssig keiten Nassiebung @ 1\mod_12439 25266971_9.docx @ 10369 @ @ 1

Pos: 5.9 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Emmision en @ 0\mod_1226487095021_9.doc x @ 3310 @ 2 @ 1

3.2 Emissions

Pos: 5.10 /0025 Warnhinweise/V0046 VORS ICHT Gehörschaden Gehörverlust (AS 200Jet) @ 3\mod_1282734262384 _9.docx @ 22771 @ @ 1

Pos: 5.11 /0025 Warnhinweise/V0050 VORS ICHT Überhören akustischer Signale ( AS200Jet) @ 3\mod_1282734265322 _9.docx @ 22798 @ @ 1

Pos: 5.12 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0005 AS200Jet Technische D aten/AS200Jet Modul Emmisionen @ 1\mod_1236585801662_9.docx @ 77 86 @ @ 1

Noise characteristics:

The noise is measured in accordance with DIN 45635-031-01-KL3

The AS 200 jet itself is constructed in a manner that prevents any significant

development of noise.

The noise characteristics of the connected industrial vacuum cleaner depend on

the set suction force and suction load.

When the NILFISK HDS2000 is used at max. suction stage II, the average sound

pressure level without sample filling is 72dB.

To reduce the suction noise, the provided sound absorber (IS) can be connected to

the air inlet channel (I).

12

Page 13

Pos: 5.13 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Maxi male Belastung @ 0\mod_12289835289 05_9.docx @ 4880 @ 2 @ 1

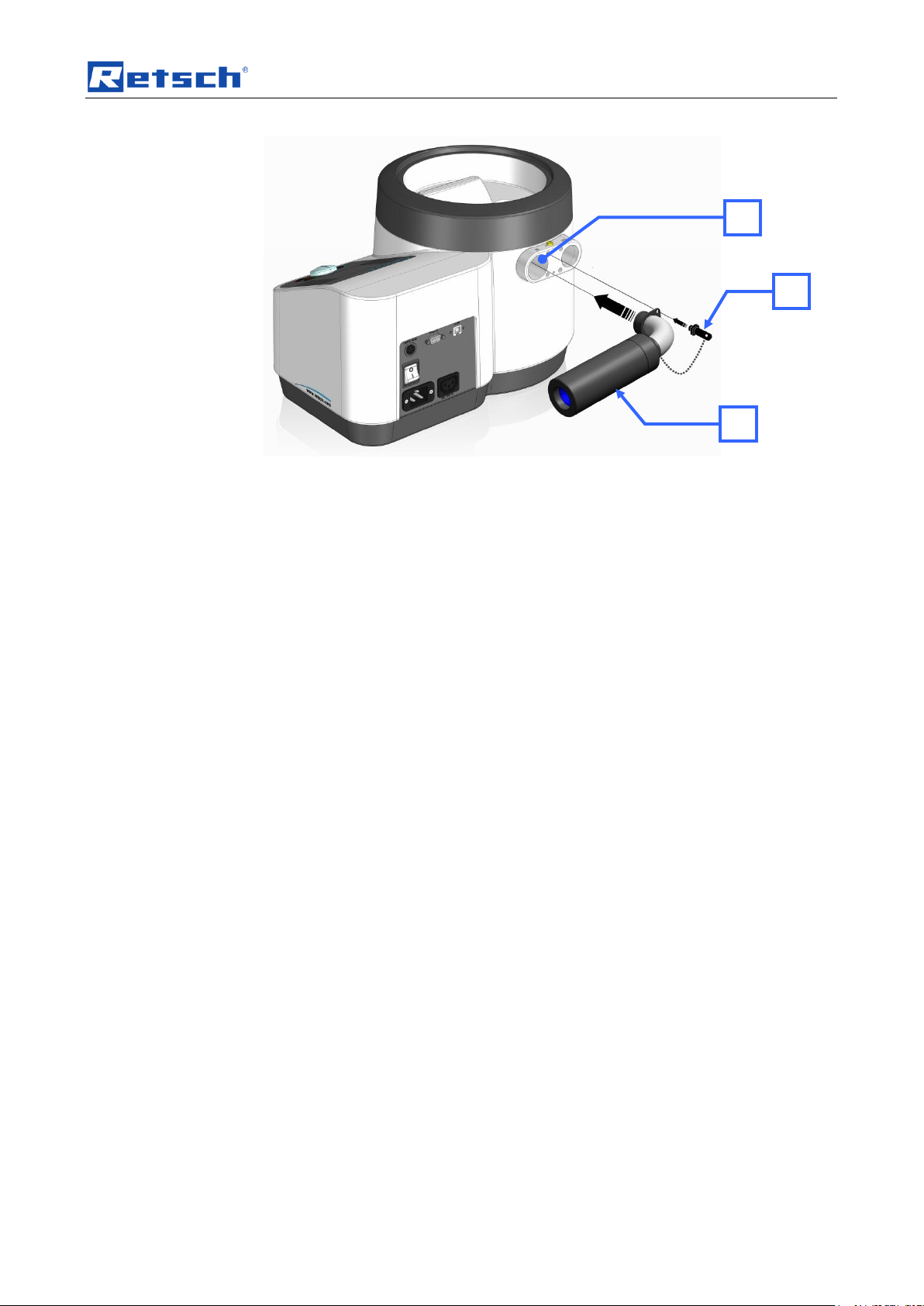

I

IS

IB

Technical data

Fig. 1: Connecting the sound absorber

Put the position pin (IB) into the opening marked in the picture in order to lock the

sound absorber in a horizontal position.

3.3 Maximum Load

Pos: 5.14 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0005 AS200Jet Technische D aten/AS200Jet Modul Siebgutmenge M aximale Siebturmmasse @ 1\mod_12 36585803100_9.docx @ 7826 @ @ 1

NOTICE

Ensure that the differential pressure or vacuum generated by your vacuum cleaner

or the suction is not greater than 100 mbar (9999 Pa).

The maximum quantity of material to be sieved depends on the mesh size and

Pos: 5.15 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Schutzart @ 0\mod_1226491839164_9.doc x @ 3328 @ 2 @ 1

sieve size.

3.4 Degree of protection

Pos: 5.16 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0005 AS200Jet Technische D aten/AS200Jet Modul Schutzart @ 1 \mod_1236585802584_9.docx @ 781 0 @ @ 1

Pos: 5.17 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Abmess ungen und Gewicht Retsch @ 0\mo d_1226492212173_9.docx @ 3352 @ 2 @ 1

– IP40

3.5 Dimensions and weight

Pos: 5.18 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsamml ungen/AS200Jet/0005 AS200Jet Technisch e Daten/AS200Jet Modul Abmessunge n und Gewicht @ 1\mod_1236585800975 _9.docx @ 7770 @ @ 1

Height : 288 mm (without lid)

Width: 460 mm

Depth: 305 mm

Pos: 5.19 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Erforderlic he Standfläche @ 0\mod_1226492 678414_9.docx @ 3364 @ 2 @ 1

Weight: approx. 14 kg

3.6 Required floor space

Pos: 5.20 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0005 AS200Jet Technische D aten/AS200Jet Modul Erforderliche S tandfläche @ 1\mod_1236585801975 _9.docx @ 7794 @ @ 1

Pos: 5.21 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Nennl eistung @ 0\mod_1226491873164_9.doc x @ 3334 @ 2 @ 1

460 mm x 320 mm; no safety spacing required

3.7 Rated power

Pos: 5.22 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0005 AS200Jet Tech nische Daten/AS200Jet Modul Nennleistung @ 1\mod_1236585802287_9.docx @ 7 802 @ @ 1

• AS200jet: maximum 50 watts

• AS200jet + HDS200 or GM80 vacuum cleaner: maximum 1450 watts

13

Page 14

Technical data

1 2 3

4 5 6 7 8 9 10

11

12

14

13

Pos: 6.1 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Type nschild Beschreibung @ 3\mod_12809339 53941_9.docx @ 22302 @ 2 @ 1

3.8 Type plate description

Pos: 6.2 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Typenschild @ 3\mod_1280931092443_9.doc x @ 22278 @ @ 1

Fig. 2: Type plate lettering

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of questions please provide the device designation (1) or the part

Pos: 7 /0005 RETSCH/0005 RETSCH Be dienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

number (3) and the serial number (4) of the device.

14

Page 15

Transport, scope of delivery, installation

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

NOTICE

Ambient temperature

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range of the

machine (5°C to 40°C / ambient temperature).

CAUTION

V0047

Device falling down

Incorrect erection or insufficient working space

– Due to its weight, the device can inflict personal injury if it falls down.

• Only operate the device on a sufficiently large, strong and stable

workplace.

• Ensure that all feet of the device are positioned securely.

Pos: 8.1 /0020 Überschriften/1. Überschrift en/1 Verpackung, Transport und Aufst ellung @ 0\mod_1226494451893_9.d ocx @ 3380 @ 1 @ 1

4 Transport, scope of delivery, installation

Pos: 8.2 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Verpac kung @ 0\mod_1226495088973_9.docx @ 3392 @ 2 @ 1

4.1 Packaging

Pos: 8.3 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Verpacku ng @ 0\mod_1228984618355_9.doc x @ 4892 @ @ 1

Pos: 8.4 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Transport @ 0\mod_1226495164391_9.docx @ 3398 @ 2 @ 1

4.2 Transport

Pos: 8.5 /0025 Warnhinweise/H0017 HIN WEIS Transport @ 0\mod_1228918883 019_9.docx @ 4802 @ @ 1

Pos: 8.6 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Temperat urschwankungen @ 0\mod_122649 5190738_9.docx @ 3404 @ 2 @ 1

4.3 Temperature fluctuations and condensed water

Pos: 8.7 /0025 Warnhinweise/H0016 HIN WEIS Temperaturschwankungen @ 0\ mod_1233564121287_9.docx @ 5570 @ @ 1

The packaging has been adapted to the mode of transport. It complies with the

generally applicable packaging guidelines.

Pos: 8.8 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Bedingu ngen für den Aufstellort Retsch @ 0\ mod_1226497029322_9.docx @ 3428 @ 2 @ 1

4.4 Conditions for the place of installation

Pos: 8.9 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Umgebungst emperatur 5°C - 40°C @ 0\mod_1 228918538881_9.docx @ 4745 @ @ 1

Pos: 8.10 /0025 Warnhinweise/H0021 H INWEIS Umgebungstemperatur 5°C bis 40 °C @ 0\mod_1228918883441_9.doc x @ 4816 @ @ 1

Pos: 8.11 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufstelle n des Gerätes Retsch @ 0\mod_12 26498849756_9.docx @ 3464 @ 2 @ 1

Ambient temperature: 5°C to 40°C

4.5 Installation of the machine

Pos: 8.12 /0025 Warnhinweise/V0047 VORS ICHT Herabfallen des Gerätes / Sta ndfestigkeit @ 3\mod_1282734263400_ 9.docx @ 22780 @ @ 1

15

Page 16

Transport, scope of delivery, installation

CAUTION

V0048

Parts connected to voltage

The power supply is suddenly switched on

– When you switch the device on there is danger of an electrical shock at the

electrical connection for the external suction device.

• Do not touch the electrical connection for the external suction device

and do not insert any parts into the openings.

WARNING

Pos: 8.13 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Aufstell ungshöhe @ 0\mod_1228918538349_9. docx @ 4724 @ @ 1

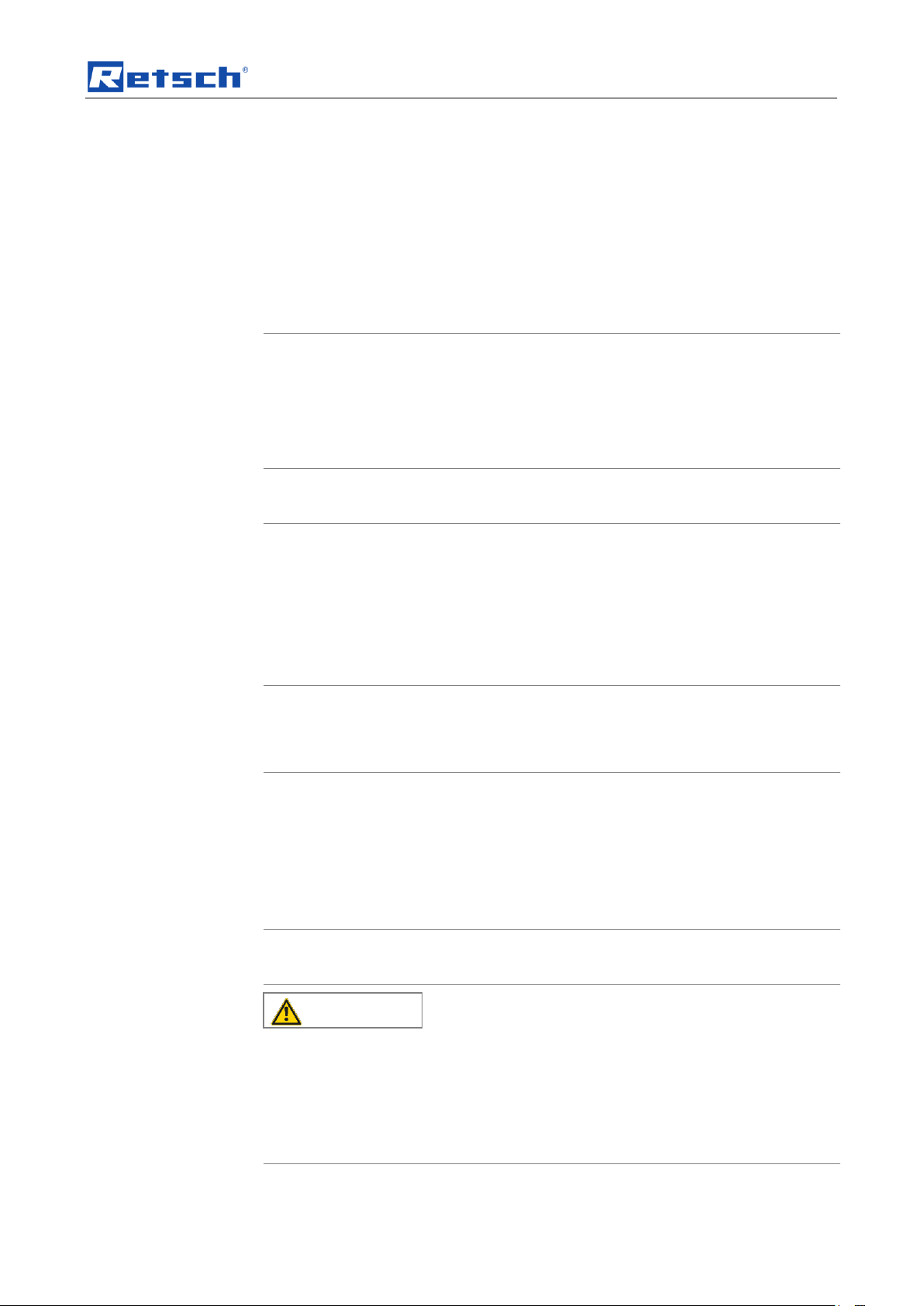

Pos: 8.14 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsamml ungen/AS200Jet/0006 AS200Jet Transport, Lieferumfang und Aufstellen/AS200Jet M odul Grafiken Lufteinlass offen halten @ 3\mod_1307347943605_9.docx @ 2 5260 @ @ 1

Installation height: maximum 2000 m above sea level

Pos: 8.15 /0020 Überschriften/1.1 Üb erschriften/1.1 Überschriften BDA/11 Elektri scher Anschluss @ 0\mod_1226565067 445_9.docx @ 3500 @ 2 @ 1

4.6 Electrical connection

Pos: 8.16 /0025 Warnhinweise/V0048 VORS ICHT Unter Stromspannung stehende Teile (AS200Jet) @ 3\mod_1282734 266259_9.docx @ 22807 @ @ 1

Pos: 8.17 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Elektrisc her Anschluss @ 0\mod_122891853 8521_9.docx @ 4731 @ @ 1

When connecting the power cable to the mains supply, use an external fusethat

complies with the regulations applicable to the place of installation .

• Please check the type plate for details on the necessary voltage and

frequency for the device.

• Make sure the levels agree with the existing mains power supply.

16

Page 17

Pos: 8.18 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/AS200Jet/0006 AS200Jet Transport, Li eferumfang und Aufstellen/AS200J et Modul externe Absicherung @ 1\mod _1243926769314_9.docx @ 10385 @ @ 1

WARNING

W0002

Danger to life through electric shock

– An electric shock can lead to burns and to cardiac arrhythmias or to

respiratory arrest and cardiac arrest.

• The device may only be operated with plugs that have a protective

conductor (earthed).

Pos: 8.19 /0025 Warnhinweise/W0015 WARNUNG Kabelbruch Stromstoß Erdung @ 4\mod_1334064762171_9.docx @ 27560 @ @ 1

Pos: 9.1 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

Transport, scope of delivery, installation

• Use the supplied connection cable to connect the device to the mains power

supply.

The external fuse must be at least T15A (230V) T15A (100/120V).

17

Page 18

Operating the machine

A

B

C

D G F

E

Pos: 9.2 /0020 Überschriften/1. Überschrift en/1 Bedienung des Gerätes @ 0\ mod_1226565880211_9.docx @ 3519 @ 1 @ 1

5 Operating the machine

Pos: 9.3 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ansic hten des Gerätes Retsch @ 0\mod_122 8990581782_9.docx @ 4966 @ 2 @ 1

5.1 Views of the Instrument

Pos: 9.4 /0005 RETSCH Bedienungsanlei tungen Kapitelsammlungen/AS200Jet/00 07 AS200Jet Bedienung/AS200Jet M odul Grafische Ansichten des Gerätes @ 1\ mod_1239699996835_9.docx @ 8127 @ @ 1

Fig. 3: Front view

18

Page 19

Operating the machine

H

I

J K M O P H R

S T L

Fig. 4: Rear view

Fig. 5: View of the sieve compartment (without sieve)

19

Page 20

Operating the machine

C D G F E

Pos: 9.5 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ansichten der Bedienelemente und der Anzeige @ 0\mod_1226566362336_9.docx @ 3 537 @ 2 @ 1

5.2 Operating elements and displays

Pos: 9.6 /0005 RETSCH Bedienungsanlei tungen Kapitelsammlungen/AS200Jet/00 07 AS200Jet Bedienung/AS200Jet Modul Ansicht der Displayeinheit @ 1\mod _1236682005889_9.docx @ 7916 @ @ 1

Fig. 6: View of the display unit

Pos: 9.7 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

20

Page 21

Operating the machine

Element

Description

Function

A

Lid for air jet sieving

Lid for the test sieve

B

Test sieve

Sieve for the dry sieving and/or particle size

determination

C

Display

Displays the control functions and parameters

D

Start button

Starts sieving

E

Stop button

Stops sieving

F

Operating knob

Dial for changing the device settings

G

Quick start button

Starts quick sieving

H

Air outlet channel

Connection for external exhaust

I

Air inlet channel

Opening for air inlet

J

Connection for automatic air flow

regulation

Connector socket for external air flow regulation

K

Serial PC - Port (RS232)

PC connection for data communication with

EasySieve®

L

USB interface

PC connection for data communication with

EasySieve®

M

On/Off switch

Disconnects the device from the mains / including

thermal and switchable power fuse

O

IEC C14 appliance inlet

Mains connection

P

IEC C13 connector

Power connection for the external vacuum cleaner

R

Cover for differential pressure sensor

Protects the differential pressure sensor

S

Air nozzle

Conducts the air jet upwards onto the sieve

T

Nozzle compartment

Feeds the material to be sieved to the air outlet

channel

Pos: 9.8 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Übersichtst abelle der Geräteteile @ 0\mod_12 28990616846_9.docx @ 4972 @ 2 @ 1

5.3 Overview table of the parts of the device

Pos: 9.9 /0005 RETSCH Bedienungsanlei tungen Kapitelsammlungen/AS200Jet/00 07 AS200Jet Bedienung/AS200Jet Modul T abelle der Geräteteile @ 1\mod_12 39875152197_9.docx @ 8150 @ @ 1

Pos: 9.10 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

21

Page 22

Operating the machine

T

A

Pos: 9.11 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Arbeits weise Retsch @ 0\mod_1228990496 537_9.docx @ 4960 @ 2 @ 1

5.4 Working procedure

Pos: 9.12 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200Jet Mo dul Arbeitsweise @ 1\mod_1243413970 772_9.docx @ 9550 @ @ 1

The AS 200 jet has an air nozzle, which is set rotating. The sieve with lid is put on

top of that. A vacuum unit generates a jet of air, which disperses the particles

through the air nozzle on the sieve. The material, which is smaller than the sieve’s

mesh size is transported by the backflow of the air into the cyclone or directly into

the vacuum cleaner. The jet of air de-agglomerates the particles and cleans the

Pos: 9.13 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ein- / Ausschalten @ 0\mod_1229416527496_ 9.docx @ 5058 @ 2 @ 1

sieve mesh constantly.

5.5 Switching On and Off

Pos: 9.14 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200Jet Mo dul Ein und Ausschalten @ 1\mod_1239 194085237_9.docx @ 8018 @ @ 1

• Press the on/off switch (M) at the back to turn on the device.

When the switch is in the "off" position, the device must be disconnected

Pos: 9.15 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Einsetze n des Analysesiebes @ 1\mod_1236 591586574_9.docx @ 7875 @ 2 @ 1

completely from the mains power supply.

5.6 Inserting the test sieve

Pos: 9.16 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Einsetzen des Analysesiebes @ 1\ mod_1239194012458_9.docx @ 8004 @ 3 @ 1

The AS200jet is intended for Retsch test sieves with a diameter of 203mm (8

inches) and a height of 25mm (1 inch) or 50mm (2 inches). The range of mesh

fineness extends from 10µm to approx. 4mm.

Fig. 7: Inserting the test sieve

Place the sieve in the nozzle compartment (T).

Close the sieve with the air jet sieve lid (A) intended for the respective sieve height.

NOTE

The AS200jet cannot be started until the sieve has been inserted and the lid put

on.

22

Page 23

Operating the machine

WARNING

W0007

Electric shock

Faulty power cable

– When you switch the device on there is danger of an electrical shock if the

power cable for the external suction device is damaged.

• Before use, check the power cable between the sieve device and the

suction device for possible damage.

• Never use a damaged power cable!

2

1

5.6.1 Sieve lid for 50--mm/25--mm sieve height

Fig. 8: Sieve lid

The sieve lid for 50-mm (2-inch) sieves lies on the top edge of the sieve (1).

Pos: 9.17 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Schonha mmer – Anwendung und Gebrauch @ 2\mod_1256728342926_9.docx @ 174 60 @ 2 @ 1

The sieve lid for 25-mm (1-inch) sieves lies on the ledge inside the sieve (2).

5.7 Soft-faced mallet – Application and Use

Pos: 9.18 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Schonhammer verwenden @ 2\ mod_1256728441363_9.docx @ 17467 @ @ 1

Any caking that has built up during the sieving process is knocked off the inside of

the lid by means of the soft-faced mallet.

Tap lightly, striking the centre of the knob as far as possible.

Pos: 9.19 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Anschluss des externen Industrie-Saugers R etsch @ 1\mod_1239966706099_9.docx @ 8160 @ 2 @ 1

Fig. 9: Using the soft-faced mallet

5.8 Connecting the external Industrial Vacuum cleaner

Pos: 9.20 /0025 Warnhinweise/W0007 WARNUNG Stromschlag Defektes Stromka bel (AS200Jet) @ 3\mod_128273426 7244_9.docx @ 22816 @ @ 1

23

Page 24

Operating the machine

CAUTION

Objects thrown-out or falling down

Connection of compressed air instead of vacuum cleaner

– If compressed air is connected to one of the two air openings, the sieve lid

and the sieve will be hurled out.

• This device may not be operated with compressed air.

CAUTION

H

P

Pos: 9.21 /0025 Warnhinweise/V0049 V ORSICHT Herausgeworfenen Gegenstä nde (AS200Jet) @ 3\mod_128273426436 9_9.docx @ 22789 @ @ 1

Pos: 9.22 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Anschluss Industrie Staubsauger @ 1\mod_1239966838301_9.docx @ 8167 @ 3 @ 1

The AS200jet can be operated only with a suction extractor, such as for example a

vacuum cleaner. We recommend the use of the Retsch industrial vacuum cleaner,

which is available as an accessory.

Before starting to use the Retsch industrial vacuum cleaner, read the

accompanying operating manual.

Fig. 10: Connection of the Retsch industrial vacuum cleaner

• As required, connect the manual suction force adjuster to the

air outlet channel (H).

• Connect your vacuum cleaner’s suction tube to the air outlet

channel (H) or to the manual suction force adjuster.

• Insert the type F IEC C14 connector on the vacuum cleaner

into the IEC C13 panel-mounted outlet (P).

The power for the Retsch industrial vacuum cleaner is supplied from the AS200jet.

5.8.1 Vacuum cleaner function

By means of the vacuum cleaner menu item, the industrial vacuum cleaner

connected to the IEC C13 panel-mounted outlet (P) can be used for cleaning the

device too.

• Pull the industrial vacuum cleaner’s suction hose out of the air outlet channel

(H).

• Navigate to the menu item Manual suction apparatus.

• Press the start button.

24

Page 25

Pos: 9.23 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Steueru ng der Luftstrom-Stärke @ 1\mod_12 40308048818_9.docx @ 8180 @ 2 @ 1

NB

H0051

Objects are sucked in

Vacuum in the sieve area

– Small objects can be sucked into the inside of the machine.

• No small objects or parts of the body may be placed near the suction

opening.

CAUTION

V0050

Failure to hear acoustic signals

Loud suction noise on the air inlet

– It is possible that some acoustic warnings and voice communication may

not be noticed.

• Take the strength of the suction noise into consideration when

designing your acoustic signals in the working environment.

Possibly additionally use visual signals.

U

1

1

2

3 4

V

U

V

Pos: 9.24 /0020 Überschriften/1.1.1. Übersc hriften/111 Manuelle Steuerung der Luftstr omstärke @ 1\mod_124030929594 3_9.docx @ 8201 @ 3 @ 1

Pos: 9.25 /0025 Warnhinweise/H0051 H INWEIS Gegensstände werden anges augt (AS200Jet) @ 3\mod_1282734261369 _9.docx @ 22762 @ @ 1

Pos: 9.26 /0025 Warnhinweise/V0050 VORS ICHT Überhören akustischer Signale ( AS200Jet) @ 3\mod_1282734265322 _9.docx @ 22798 @ @ 1

Operating the machine

• To turn the vacuum cleaner off, press the STOP button or use the turn-andpush dial.

Pos: 9.27 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul manuelles Verstellen des Luftstro mes (Querschnitt) @ 1\mod_12403096044 54_9.docx @ 8222 @ @ 1

Fig. 11: Air jets through the manual suction force adjuster

Fig. 12: Manual adjustment of the air jet (cross section)

25

Page 26

Operating the machine

The air jet can be changed by turning the manual air jet setting (U).

[1] Air entry opening (V) closed maximum air jet

[2] Air entry opening (V) open minimum air jet

The difference in air pressure (differential pressure) between the air inlet and air

Pos: 9.28 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Anschließen Manuelle Saugkraft verstellung @ 3\mod_1290606663037_9.doc x @ 24030 @ @ 1

outlet at a given moment is displayed on the screen.

Pos: 9.29 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

Fig. 13: connecting the manual suction force adjuster

26

Page 27

Operating the machine

to .

to .

Pos: 9.30 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Displa yeinheit - Bedienung des Gerätes @ 1\ mod_1236677049299_9.docx @ 7890 @ 2 @ 1

Pos: 9.31 /0005 RETSCH/0099 RETSCH Standard Kapitel/General Modul Displa yeinheit - Bedienung des Gerätes @ 1\m od_1236681950483_9.docx @ 7908 @ 33 @ 1

This device offers a new, very convenient operator guidance. All relevant data can

be entered or retrieved by means of a graphics display with one-button operation.

The menu guidance is in several languages.

5.8.1 Setting options using the display menu

The selection bar in the display should be operated as follows:

Rotation function I)

• Turn the operating button to get to the various menu points. The selected

menu points are marked by the dark selection bar. Areas which cannot be

changed are skipped.

Rotation function II)

• Turn the operating button to change figures and decisions in the menu

points.

Press I)

• Press the operating button to open selected menu points.

Press II)

• Press the operating button to confirm settings.

Press III)

• Keeping the operating button pressed takes you back to the basic screen

(level 1).

5.8.2 Navigation between operating modes

• Turn the operating button clockwise until the dark line cursor is in the

navigation menu (C1).

• Press the operating button (F).

– The icon for scrolling direction (C4) changes from

• By turning the operating button, switch between the operating modes

manual, Program 01 to 09, Quick Start and basic settings.

• To activate the selected operating mode, press the operating button (F).

– The icon for scrolling direction (C4) changes from

• By turning the operating button, switch to the sub-points of the selected

menu point.

27

Page 28

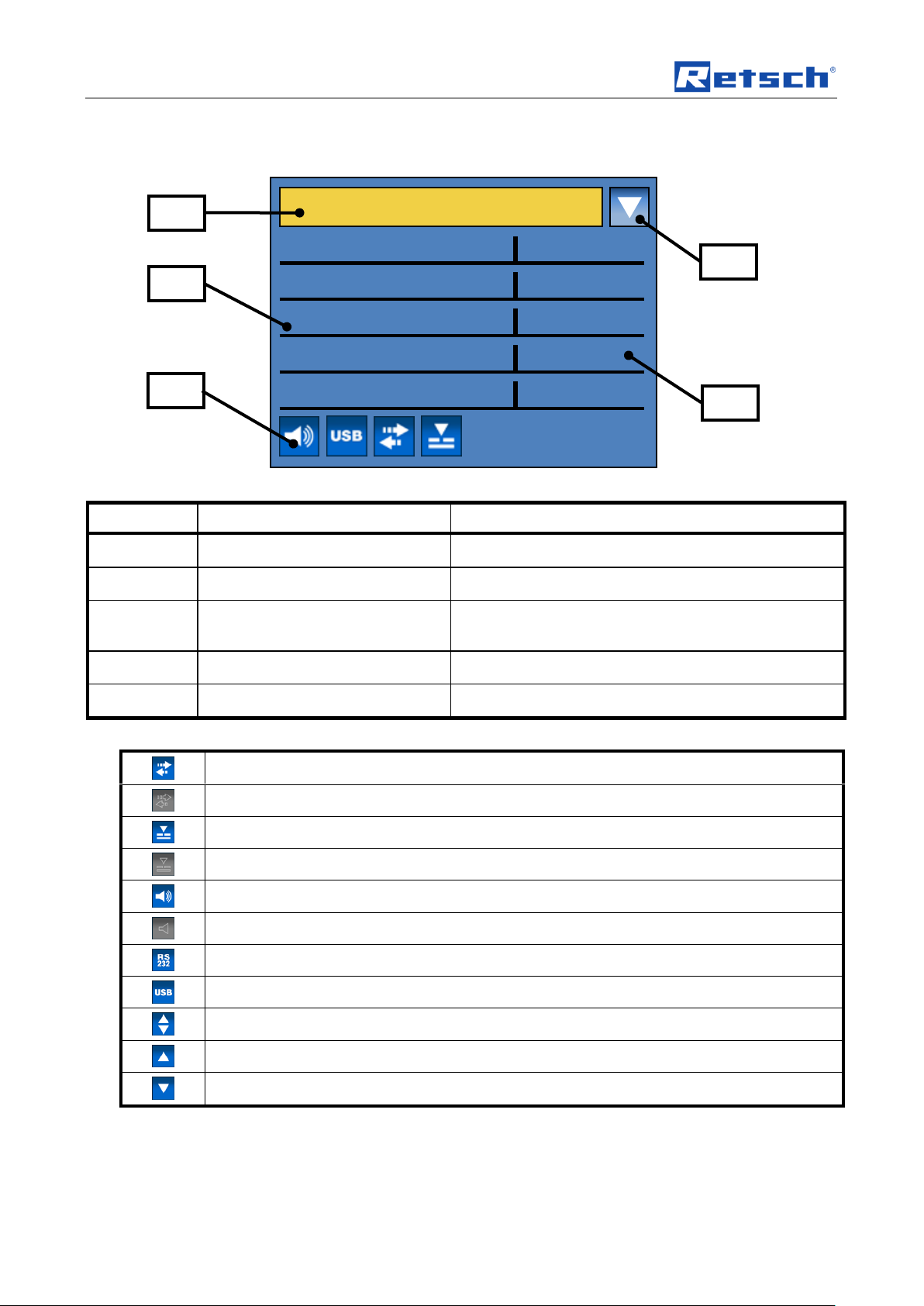

Operating the machine

Element

Description

Function

C1

Menu navigation

Switch between manual, program and basic settings

C2

Specification of sieve parameters

Sieve parameter display and adjustment

C3

Icons for device functions

Display of function statuses of sound, interface, Open

Mesh and automatic vacuum force adjustment

C4

Icon for scrolling direction

Shows possible scrolling directions

C5

Sieve parameters

Display of values

Open Mesh switched on (see Open Mesh chapter)

Open Mesh switched off

Automatic vacuum adjustment connected

No automatic vacuum adjustment

Signal tone on

Signal tone off

RS232 interface active

USB interface active

Scrolling up or down possible

Scrolling up only is possible

Scrolling down only is possible

MANUAL

SIEVE DURATION

SPEED

VACUUM

OPEN MESH

SAVE PARAMETERS

00:10 mm:ss

05 rpm

0000 Pa

ON

C4

C1

C5

C2

C3

Pos: 9.32 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Symbol e in der Displayeinheit @ 1\mod_12499 91350589_9.docx @ 13770 @ 2 @ 1

5.9 Symbols in the Display Unit

Pos: 9.33 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200Jet Mo dul Grafikdisplay Menü neu @ 7\mod_ 1386159686424_9.docx @ 53360 @ @ 1

Fig. 1: View of the menu in the display unit

Pos: 9.34 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200Jet Mo dul Symbole in der Displayeinheit neu @ 1 \mod_1239194092534_9.docx @ 809 8 @ @ 1

Pos: 9.35 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsamml ungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

28

Page 29

Operating the machine

Pos: 9.36 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Direktz ugriff auf das Sprachenmenü @ 7\mod_ 1386851099017_9.docx @ 53612 @ 2 @ 1

5.10 Direct access to the language menu

Pos: 9.37 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Spracheinstellungen extra @ 7\mod _1386769736915_9.docx @ 53474 @ @ 1

If you have inadvertently set the wrong language you can go straight to the

language menu using the following steps.

• Switch the device off by the main switch.

• Switch the device on, simultaneously pressing the buttons START - STOP -

QUICK START.

• After selecting the correct language, switch the device off and immediately

back on.

• Confirm your selection by pressing the operating button.

The device has now been permanently set to your language and you are in the

main menu.

Pos: 9.38 /0005 RETSCH/0005 RETSCH Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

29

Page 30

Operating the machine

Manual

Sieve duration

Speed

Vacuum

Open Mesh

Save parameters

Program

Save

Back Suction apparatus

Program [01 - 09]

Sieve duration

Speed

Vacuum

Open Mesh

Change program

Program

Sieve duration

Speed

Vacuum

Open Mesh

Save

Back Delete program

Program

Delete

Back

Quick Start

Sieve duration

Speed

Vacuum

Open Mesh

Change program

Program

Sieve duration

Speed

Vacuum

Open Mesh

Save

Back

Delete program

Basic settings

Vacuum

Languages

Brightness

Date Time Signal tone

Interface

Service

Operating hours

Display software version

Controller software version

Software updates

Display

Start

Back Controller

Start

Back Back

Calibrate sensor

Service level

Calibrate rotation speed

Test motor

Back

Back

Pos: 9.39 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Menüstr uktur @ 1\mod_1239699858524_9.doc x @ 8120 @ 2 @ 1

5.11 Menu structure

Pos: 9.40 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Gesamtmenüstruktur 01 @ 7\mod _1386754070774_9.docx @ 53451 @ @ 1

Overview of all menu points:

30

Page 31

Operating the machine

G

Pos: 9.41 /0020 Überschriften/1.1 Üb erschriften/1.1 Überschriften BDA/11Betri ebsmodi @ 7\mod_1386851520343_9.doc x @ 53623 @ 2 @ 1

5.12 Operating modes

Pos: 9.42 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Betriebsmodi @ 7\mod_13867699 49365_9.docx @ 53496 @ 2444 @ 1

You can select the following operating modes using the menu navigation (C1):

5.12.1.1 Manual

If this function has been set, all parameters and functions can be retrieved and

changed at any time. This is also possible while sieving.

5.12.1.2 Program 01 to 09

In programs 01 to 09 the previously set parameters such as sieve duration, speed,

vacuum (only with connected automatic suction force adjustment) and Open Mesh

can be saved in a memory.

5.12.1.3 Quick Start

Under the Quick Start menu point, as with a program you can save previously set

parameters such as sieve duration, speed, vacuum (only with connected automatic

suction force adjustment) and Open Mesh in a memory.

The Quick Start sieving can also be started directly using

the Quick Start button (G).

– The Quick Start button has no function if you are in a settings menu.

Fig. 2: Quick Start button

5.12.1.4 Basic settings

In this settings menu, you can perform the following device settings:

– Vacuum

– Languages

– Brightness

– Date

– Time

– Signal tone

– Interface

– Service

31

Page 32

Operating the machine

Open Mesh switched on

Open Mesh switched off

P

Pos: 9.43 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Manueller Betrieb @ 7\mod_1386773101603_ 9.docx @ 53507 @ 3 @ 1

5.13 Manual operation

Pos: 9.44 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Manueller Betrieb @ 7\mod_138677 4886925_9.docx @ 53540 @ 233333 @ 1

5.13.1 Sieve duration

00:01 to 99:59 (minutes : seconds)

5.13.2 Speed

5 to 55 revolutions per minute (10 revolutions per minute “Open Mesh”

5.13.3 Vacuum

You can adjust the vacuum when the automatic suction force adjustment has been

connected. (Pa; mbar; psi)

5.13.4 Open Mesh

Display whether Open Mesh is active: YES / NO

The air nozzle is moved two steps in the direction of rotation and then one step

back. The speed is fixed when Open Mesh is switched on to 10 revolutions per

minute.

5.13.5 Save parameters

All previously set parameters such as sieve duration, speed, vacuum (only with

connected automatic suction force adjustment) and Open Mesh can be saved in a

memory here.

• Set the desired parameters.

• By turning the operating button (F), switch to the menu point Save

• Press the operating button (F).

– The Save parameters menu opens and the dark line cursor is on Program.

• Press the operating button (F) to select a program memory location or Quick

• By turning the operating button (F) switch to the desired memory location.

• Press the operating button (F) to exit the memory location selection.

• Select either

– Save to save settings or

– back to cancel without saving.

5.13.6 Suction apparatus

parameters.

Start.

32

Fig. 3: Connector (electrical connection for the external suction apparatus)

Using the suction apparatus menu point, you can switch on the vacuum cleaner

connected to the connector (P) independently of sieving.

• By turning the operating button (F) switch to the suction apparatus menu

point.

Page 33

Operating the machine

Open Mesh switched on

Open Mesh switched off

• Press the operating button (F).

– The Off display appears in the suction apparatus menu point.

• Press the START button to switch the power on.

• Press the STOP button to turn the power off.

• Press the operating button (F) to exit the suction apparatus menu point.

Pos: 9.45 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Program m @ 5\mod_1344511635554_9.docx @ 33985 @ 2 @ 1

5.14 Programs

Pos: 9.46 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200jet Mo dul Programme @ 7\mod_1386774927 066_9.docx @ 53551 @ 233344 @ 1

5.14.1 Sieve duration

Display of the stored sieve duration:

00:01 to 99:59 (minutes : seconds)

5.14.2 Speed

Display of the stored speed:

5 to 55 revolutions per minute (10 revolutions per minute “Open Mesh”)

5.14.3 Vacuum

Display of the vacuum with connected automatic vacuum force adjustment.

5.14.4 Open Mesh

Display whether Open Mesh is active: YES / NO

NOTE

The air nozzle is moved two steps in the direction of rotation and then one step

back. The speed is fixed when Open Mesh is switched on to 10 revolutions per

minute.

5.14.4.1 Change program

In this menu you can change the stored parameters of each program incl. Quick

Start.

• By turning the operating button (F) switch to the Change program menu

• Press the operating button (F).

– The Save parameters menu opens and the dark line cursor is on Program.

NOTE

You can change the active or any other program.

• Press the operating button (F) to activate the program selection.

• By turning the operating button (F) switch to the desired memory location.

• Press the operating button (F) to exit the memory location selection.

• Set the desired sieve parameters.

• Finally select either

point.

- Save to save the settings or

33

Page 34

Operating the machine

- Back to cancel without saving.

– This returns you to the program level.

NOTE

A program which has not been saved cannot be started.

5.14.4.2 Delete program

In this menu you can delete the stored parameters of each program.

NOTE

Only the parameters saved in the respective program are deleted. The program

memory location remains in place. The parameters in the Quick Start program

cannot be deleted.

• By turning the operating button (F) switch to the Delete program menu point.

• Press the operating button (F).

– The Delete program menu opens and the dark line cursor is on Program.

• Press the operating button (F) to activate the program selection.

• By turning the operating button (F) switch to the desired program.

• Press the operating button (F) to exit the program selection.

• Finally select either

– Delete to delete the settings or

– Back to cancel without deleting.

Pos: 9.47 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Quick Start @ 7\mod_1386773204943_9.doc x @ 53518 @ 2 @ 1

– You return to the program level.

5.15 Quick Start

Pos: 9.48 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Quick Start @ 7\mod_138677493167 6_9.docx @ 53563 @ @ 1

Pos: 9.49 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Grundein stellungen neu @ 7\mod_138753561 4794_9.docx @ 53850 @ 2 @ 1

5.16 Basic settings

Pos: 9.50 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Grundeinstellungen @ 7\mod_1386 774936450_9.docx @ 53575 @ 33333333 44445543 @ 1

5.16.1 Vacuum

Fig. 4: Quick Start button

Using the QUICK START button you can start sieving directly with the parameters

saved in the Quick Start program location.

(see programs)

NOTE

No sieving can be started while the basic settings menu is active.

You can set the display unit for the vacuum in this menu:

– Pa

– mbar;

– psi

5.16.2 Languages

5.16.3 Brightness

34

You can selecte the languages menu here. After selecting and pressing the

operating button, the entire menu structure is displayed in your language.

The brightness can be adjusted to the respective user or environment (sunshine,

glare etc.).

Page 35

5.16.4 Date

Signal tone on

Signal tone off

RS232 interface active

USB interface active

K

L

5.16.5 Time

5.16.6 Signal tone

5.16.7 Interface

Operating the machine

The current date can be entered here.

The device can be disconnected from the mains for up to 30 days without losing

the settings.

The time can be entered here.

The time then appears in the stand-by screen.

The device can be disconnected from the mains for up to 30 days without losing

the settings.

The error messages on incorrect operation can be supported by an acoustic signal

tone. When the function is switched off, the corresponding pictogram appears

Fig. 5: Interfaces

In this menu you can switch from using the RS232 (K) or the USB (L) interface.

5.16.8 Service

5.16.8.1 Operating hours

The hours counted are sieving hours, i.e. the total times between START and

STOP. The times cannot be manipulated.

5.16.8.2 Software version display

Shows the software version of the display.

5.16.8.3 Software version controller

Shows the software version of the controller.

5.16.8.4 Update software

5.16.8.4.1 Display

– The target display unit is selected on the PC via a software update selection

menu.

35

Page 36

Operating the machine

– The data are sent by the connected PC via interface cable (RS232 or USB)

to the controller PCB. The controller PCB forwards the data on to the boot

loader of the display unit.

5.16.8.4.2 Controller

– The target device controller is selected on the PC via a software update

selection menu.

– The data are sent by the connected PC via interface cable (RS232 or USB)

to the controller PCB. The controller PCB forwards the data on to the boot

loader of the display unit.

5.16.8.5 Sensor calibration

See chapter “pressure sensor calibration”

5.16.9 Service level

NOTE

Access to this menu point is exclusively permitted for service employees or

Pos: 9.51 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Starten, Un terbrechen, Stoppen @ 0\mod_12 29417133049_9.docx @ 5070 @ 3 @ 1

authorised service personnel.

5.17 Starting, Interrupting, Stopping

Pos: 9.52 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Starten Stoppen @ 1\mod_12391 94086237_9.docx @ 8026 @ @ 1

• Switch the device on by pressing the on/off switch at the back.

• Use the operating knob (F) to set the sieving parameters you want.

• Put the test sieve with the sample onto the nozzle compartment.

• Place the lid on the sieve.

NOTE

The sieving will not start if the lid is not on.

• Start sieving by pressing the START button (D).

• You can also start the air jet sieving directly by pressing the QUICK START

Pos: 9.53 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Quick S tart - Tastenfunktion @ 1\mod_1240 313233592_9.docx @ 8229 @ 2 @ 1

Pos: 9.54 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Quick Start Tastenfunktion @ 1\mod _1239194087706_9.docx @ 8042 @ @ 1

Pos: 9.55 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Stand-b y @ 7\mod_1386841122969_9.doc x @ 53601 @ 2 @ 1

key (G). (see chapter on Quick Start key functions)

The QUICK START (G) key can be used to start a pre-programmed sieving

process directly without accessing the menu.

5.18 Stand-by

Pos: 9.56 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Stand-By-Monitor @ 7\mod_1386841015177_ 9.docx @ 53590 @ @ 1

36

After the device has been inactive for 15 minutes (time after a STOP command),

the stand-by screen switches on automatically.

By pressing one of the buttons or touching the operating button, the stand-by

screen disappears without executing the command given.

If you were in a sub-menu when the stand-by screen was activated, you return

automatically to this selection window.

NOTE

The stand-by screen cannot be deactivated.

Page 37

Operating the machine

Automatic vacuum force adjustment connected

No automatic vacuum force adjustment

WARNING

W0002

Danger to life through electric shock

– An electric shock can lead to burns and to cardiac arrhythmias or to

respiratory arrest and cardiac arrest.

• The device may only be operated with plugs that have a protective

conductor (earthed).

SK

J IS

H

Pos: 9.57 /0020 Überschriften/1.1.1. Übersc hriften/11 Anschluss der geregelten S augkrauftsteuerung @ 1\mod_1240308 097272_9.docx @ 8187 @ 1 @ 1

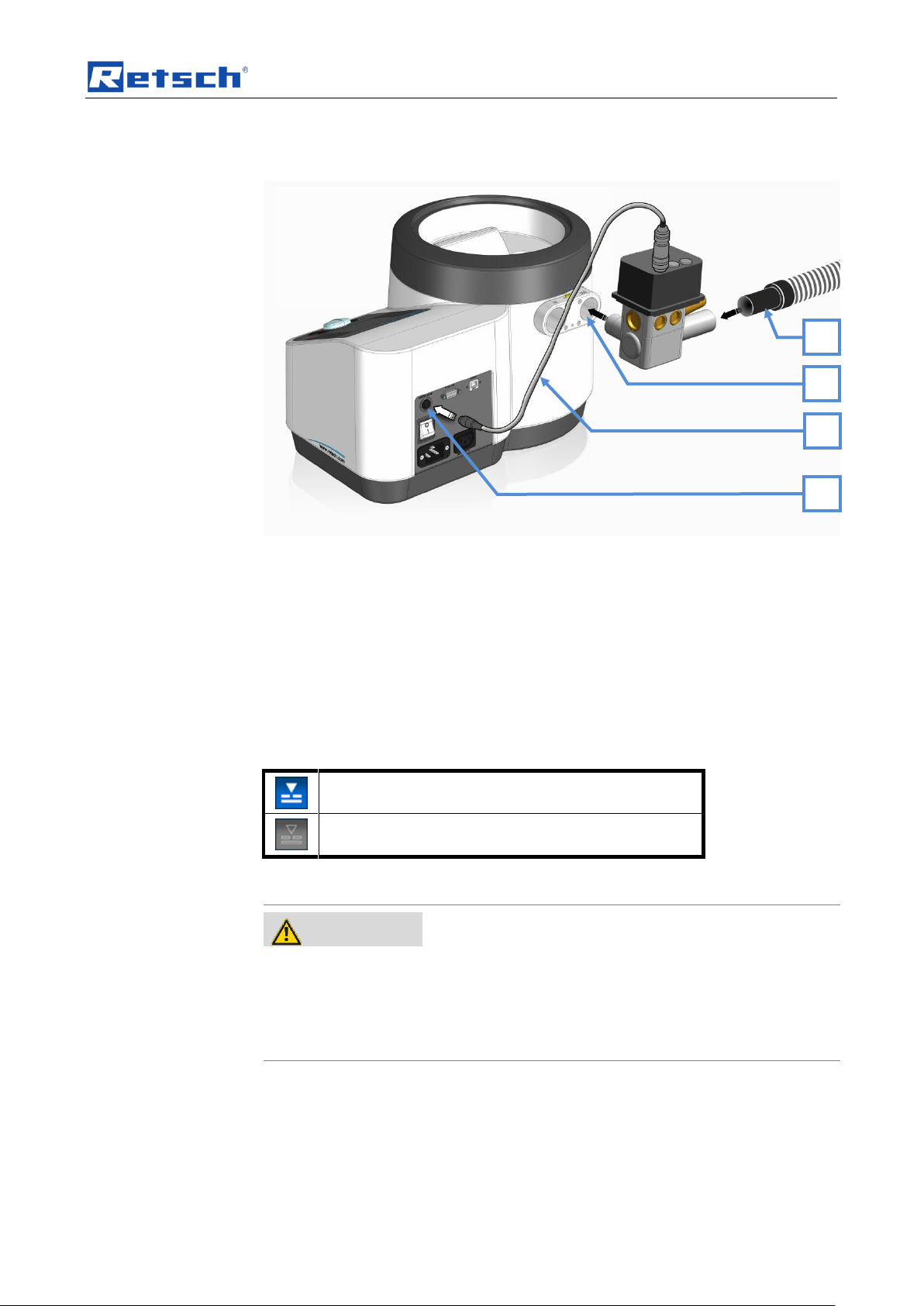

5.19 Controlled suction force adjuster

Pos: 9.58 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200Jet Modul Anschluss des Motor-Regelventils @ 1\mod_1240309232193_9.docx @ 8194 @ @ 1

Fig. 14: Connecting the automatic suction force adjuster

The automatic suction force adjuster available as a Retsch accessory allows the air

jet force to be controlled automatically. The AS200jet measures the momentary

differential pressure and controls the automatic suction force adjuster accordingly.

• Insert the automatic suction force adjuster into the air outlet channel (H) as

• Connect the automatic suction force adjuster’s control cable (SK) to the

• Connect the industrial vacuum cleaner’s suction tube to the opening (IS).

As long as the automatic suction force adjuster’s control cable is connected, the

following symbol appears in the display:

Pos: 9.59 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Zyklon M ontage @ 2\mod_1277451406744_9. docx @ 20490 @ 3 @ 1

5.20 Cyclone assembly

Pos: 9.60 /0025 Warnhinweise/W0015 WARNUNG Kabelbruch Stromstoß Erdung @ 4\mod_1334064762171_9.docx @ 27560 @ @ 1

shown in the picture.

control connection (J).

37

Page 38

Operating the machine

CAUTION

Risk of explosion or fire

Changing sample characteristics

– Note that the characteristics and accordingly the danger presented by a

sample can change during sieving.

• Do not sieve any potentially explosive or combustible materials in

this device.

Element

Description

Function

Z1

Knurled head screw

Fastens the cyclone

Z2

Pin

Anti-rotation device for support Z3

Z3

Housing support for cyclone

Cyclone support

Z4

Fixing screw

Fastens the cyclone support

Z5

Manual suction power adjuster

To adjust the air current

Z1

Z3

Z4

Z5

Z6

Z9

Z2

Z7

Z8

Pos: 9.61 /0025 Warnhinweise/V0003 VORS ICHT Explosions- oder Brandgefa hr Sieben @ 1\mod_1243924323407_9.d ocx @ 10360 @ @ 1

Pos: 9.62 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet/0 007 AS200Jet Bedienung/AS200jet Mo dul Hinweis Elektrostatische Aufladung @ 4\mod_1338364384983_9.docx @ 29490 @ @ 1

Electrostatic charge inside the devices is prevented by earthing the device via the

protective conductor on the electrical connection. Ensure the correct assembly of

the cyclone in order to guarantee sufficient earthing.

NOTICE

Despite this, electrostatic charge separation may however still occur between the

sample and receptacle wall inside the collecting receptacle (Z9) depending on the

Pos: 9.63 /0005 RETSCH Bedienungsa nleitungen Kapitelsammlungen/AS200Jet /0007 AS200Jet Bedienung/AS200Jet Mo dul Zyklon Anschließen @ 2\mod_127 7131181425_9.docx @ 20450 @ @ 1

sample property, flow speed and air humidity.

Fig. 15: Individual cyclone parts

38

Page 39

Operating the machine

Z6

Air outlet

Connection for the industrial vacuum cleaner

Z7

Cyclone cover

Removable cover with air outlet

Z8

Cyclone

Separates sample material from air current

Z9

Collecting vessel

Collecting tank for sieved sample material

Z2

Z3

Fig. 16: Connection of the cyclone

Fig. 17: Steps 1 and 2

1. Push the pin (Z2) into the upper opening on the outer edge of the housing.

2. Push the cyclone support (Z3) onto the pin.

39

Page 40

Operating the machine

Z4

Z5

H

Z1

Fig. 18: Steps 3 and 4

3. Screw the screw (Z4) in.

4. Push the manual suction power adjuster (Z5) into the air outlet‘ (H).

40

Fig. 19: Steps 5 and 7

5. Push the cyclone with cover into the manual suction power adjuster.

Position the cyclone with cover such that the support on the cyclone fits into

the housing support (Z3).

6. Screw the knurled head screw (Z1) into the housing support.

Page 41

Pos: 10 /0005 RETSCH/0005 RETSCH B edienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

Operating the machine

Fig. 20: Connect the vacuum cleaner

7. Place the hose of the vacuum cleaner in the upper opening of the cyclone.

41

Page 42

EasySieve®

K

L

Pos: 11.1 /0005 RETSCH/0015 RETSCH Reparatur- und Montageanleitungen/ 00000 Überschriften/1. Überschriften/1 E asySieve® @ 0\mod_1229520770280_9.d ocx @ 5246 @ 2 @ 1

6 EasySieve®

Pos: 11.2 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften Software BDA1 1 Steuern, auswerten, dokumentieren @ 0 \mod_1231151811461_9.docx @ 5357 @ 2 @ 1

6.1 Control, evaluation, documentation

Pos: 11.3 /0010 RETSCH Standard KapitelG eneral Modul EasySieve @ 0\mo d_1231151891210_9.docx @ 5363 @ @ 1

EasySieve®, the software package from RETSCH for grain size analyses, is

superior to manual evaluation in many respects. This is because the software is

able to perform the required measuring and weighing processes automatically –

from determining the weights of the sieves to evaluating the data. And in a much

more simple and comfortable manner – thus making life “easier”.

The software is structured in a self-explanatory way and follows the logical chain of

events involved in analysing grain sizes. This makes it possible to use it with

confidence in a fairly short time. The multiplicity of evaluation options additionally

provides the utmost flexibility in adapting to demanding, individual applications.

Abb. 21: Parameter input – Trend analysis of product processes - Comparison with specification limits

Pos: 11.4 /0020 Überschriften/1.1 Übersc hriften/1.1 Überschriften Software BDA1 1 PC - Anschluss seriell @ 0\mod_123 1157519470_9.docx @ 5369 @ 3 @ 1

6.2 Serial PC connection

Pos: 12 /0005 RETSCH Bedienungsanleit ungen Kapitelsammlungen/AS200Jet/00 091 AS200Jet PC Anschluss Seriell/AS200 Jet Modul PC Anschluss Seriell @ 1\ mod_1249992786844_9.docx @ 13787 @ @ 1

The AS200jet can be connected in series with a personal computer for data

migration and data transfer. Either use a standard 9-pole RS232 cable or a type B

USB cable. This enables analysis communication between sieving and the

EasySieve ® software which is available as an accessory.

Depending on the model, connect either

• the 9-pole RS232 cable to the RS232 interface (K) or

• the USB type B cable to the USB interface (L).

42

Fig. 22: Schnittstellen

Page 43

EasySieve®

Pos: 13 /0005 RETSCH/0005 RETSCH B edienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.docx @ 2386 @ @ 1

43

Page 44

Cleaning and service

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

Pos: 14.1 /0020 Überschriften/1. Überschri ften/1 Reinigung und Wartung @ 0\m od_1231167007723_9.docx @ 5450 @ 1 @ 1

7 Cleaning and service

Pos: 14.2 /0025 Warnhinweise/W0003 WARNUNG Reinigung Stromstoß neu @ 1\mod_1236239978437_9.docx @ 7686 @ @ 1

Pos: 14.3 /0001 Bedienungsanleitungen/ 00106 Kapitelsammlung AS200Jet/001 0 AS200Jet Reinigung und Wartung/AS20 0Jet Modul Reinigung und Wartung @ 1 \mod_1235638688043_9.docx @ 7479 @ 33 @ 1

7.1.1 Cleaning

We recommend Retsch ultrasonic baths for thorough, gentle and time-saving

cleaning of your test sieves.

Ask for our free special publication “Looking after and cleaning test sieves”.