Page 1

Operating Instructions - AS200 Analytical Sieve Shakers

basic

digit

Retsch GmbH , 42781 Haan , Retsch-Allee 1-5, Germany 31.07.2012 0007

Page 2

Information on these operating instructions

The present operating instructions for the model AS200

analytical sieve shaker provide all the necessary

information on the topics mentioned in the table of

contents.

These instructions will guide the reader to each topic

necessary for safe use of the AS200, in accordance with

the purpose for which the unit is intended. Familiarity

with the applicable chapters is essential to safe and

proper use of the equipment.

The present technical documentation has been

designed for use both as a learning tool and a reference

source. Each of the chapters represents a selfcontained unit.

These operating instructions do not contain any

information on repairs. If repairs should ever become

necessary, kindly contact your supplier or the Retsch

GmbH.

31.07.2012 Retsch GmbH 2

Page 3

Information on these operating instructions .............. 2

Safety ............................................ 4

Safety notes ................................................. 4

Warnings ................................................... 5

Repairs .................................................... 5

Confirmation ................................................ 5

Technical specifications .............................. 6

Utilization in accordance with the intended purpose .................... 6

Emissions .................................................. 6

Electrical protection class ....................................... 6

Equipment dimensions ......................................... 6

Footprint ................................................... 6

Shipping and installation ............................. 7

Packing .................................................... 7

Shipping ................................................... 7

Intermediate storage .......................................... 7

Requirements for the installation site ............................... 7

Installation / Shipping nuts ...................................... 7

Reusing the shipping nuts ....................................... 8

Electrical connection .......................................... 8

Operation ......................................... 9

Control elements and their use ................................... 9

The operating controls and their functions .......................... 10

Summary table .............................................. 10

The operating controls and their functions .......................... 11

Summary table, part 2 ........................................ 11

Installing and fixing the analytical sieves ........................... 12

Operation for the AS200 digit ................................... 14

Switching on and off .......................................... 14

Start - Interrupt - Stop ......................................... 14

Intermittent - Continuous operation ............................... 15

Vibration height ............................................. 15

Setting the time ............................................. 16

Operation for the AS200 basic .................................. 17

Switching on and off .......................................... 17

Start - Stop ................................................ 17

Vibration height ............................................. 17

Setting the time ............................................. 18

Replacing the fuses – All AS200 models ........................... 18

Working instructions ............................... 19

Supplementary mass ......................................... 19

Sieving aids ................................................ 19

Retsch analytical sieves ....................................... 19

Quantity of product to be sieved ................................. 20

Distribution of the sieved product ................................ 21

Amplitudes as funktion of loaded weight ........................... 22

Explanations of the loading charts ..................... 24

Example 1 : ................................................ 24

Example 2 : ................................................ 25

Example 3 : ................................................ 25

Wet sieving ....................................... 26

Required accessories ......................................... 26

Preparations ............................................... 26

Operation.................................................. 26

General .......................................... 28

Accessories ................................................ 28

Cleaning .................................................. 29

Maintenance ............................................... 29

Copyright .................................................. 29

Modifications ............................................... 29

Safety regulations for the AS200 ................................. 30

Extract from the individual chapters ............................... 30

31.07.2012 Retsch GmbH 3

Page 4

Safety

Target group: Everyone who deals with the

machine in any manner

whatsoever.

The AS200 is a modern, high-performance product

manufactured by the Retsch GmbH; it incorporates the

latest technology. It is entirely safe in operation when

used for the intended purpose and in accordance with

the present technical documentation.

Safety notes

You, as the owner/operator, must ensure that persons

who are entrusted with the operation of the AS200.

* have read and understood all the regulations included in the

chapter on safety,

* have made themselves familiar, prior to starting work, with all

the operating instructions and regulations for the target groups

relevant to them,

* have complete, immediate and unrestricted access to the

technical documentation for this machine,

* new personnel shall have been made familiar with safe and

appropriate use of the AS200 before starting work with the

machine, through instruction by a qualified person and/or with

the help of the present technical documentation.

* Incorrect operation can result in injuries to persons and

damage to property. You bear responsibility for your own

safety and for that of your co-workers.

* Ensure that no unauthorized persons have access to the

AS200.

For your own protection, have your co-workers certify in

writing the fact that they have received instruction in the

operation of the AS200. A suggestion for a printed form

which can be used for this purpose will be found at the

end of the chapter on safety.

We reject herewith any and all claims in conjunction with

personal injury or property damage resulting from failure

to observe the following safety instructions.

31.07.2012 Retsch GmbH 4

Page 5

Warnings

!

Personal injury

Property damage

Local Retsch representative

Your supplier

The Retsch GmbH

_____________________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

The following symbols are used to identify specific

hazard potentials:

Repairs

These operating instructions do not include any repair

instructions. In the interest of your own safety, have

repairs made only by the Retsch GmbH or an authorized

representative (service technician).

In this case, please notify the following:

Your address for service:

Confirmation

I have familiarized myself with the foreword to the operating in-

_______________________________________

_______________________________________

structions and the chapter on safety

Owner/operator signature

Service technician's signature

31.07.2012 Retsch GmbH 5

Page 6

Technical specifications

Do not make any modifications to the machine and use only

RETSCH approved spares and accessories.

Failure to comply will invalidate the CE declaration and

guarantee.

Machine designation: AS200

Utilization in accordance with the intended

purpose

The AS200 is suitable for both dry and wet sieving of

free-flowing, dispersed products where the input product

exhibits grain size of up to a maximum of 25 mm.

Emissions

Characteristic noise values :

Noise measurement according to DIN 45635-31-01-KL3

The characteristic noise values are determined primarily

by the set amplitude value, the number of test sieves

and the characteristics of the sieving material.

Example 1 :

Sound power level: LWA = 71 dB(A)

Workplace-related emission L

Operating conditions:

Sample material: quartz, grain size < 1 mm, 5 sieves

vibration height : 1,5 mm

Example 2 :

Sound power level: LWA = 76 dB(A)

Workplace-related emission L

Operating conditions:

Sample material: quartz, grain size < 1 mm, 5 sieves

vibration height : 3 mm

= 63 dB(A)

pAeq

= 67 dB(A)

pAeq

Electromagnetic compatibility (EMC)

Strong electromagnetic interference fields, such as highpower radio transmitters, can have an adverse influence

on amplitude control in the AS200 model.

Once the source of interference is eliminated, the

AS200 will return to normal operation (self-correction).

Electrical protection class

IP54 and IP20 in the area of the sieve carrier passage.

Equipment dimensions

Height:: up to about 800 mm

Width: 400 mm , Depth: 400 mm

Weight: approx. 40 kg without sieve stack and

without sieve clamping device

Footprint

400 mm x 400 mm; no safety clearances required

31.07.2012 Retsch GmbH 6

Page 7

Shipping and installation

Please retain the packaging for the duration of the

warranty since, in case of a claim, returning in unsuitable

packaging can jeopadize your warranty entitlements

During transportation the AS200 may not be subjected to

impact or vibration; it must not be thrown. The electronic

and mechanical components could otherwise be

damaged.

In case of wide temperature fluctuations (during shipment

by air, for instance) the AS200 will have to be protected

against condensation; the electronic components could

otherwise be damaged.

When the ambient temperature exceeds or falls below that

specified, the electronic and mechanical components may be

damaged, and performance data changed to an unknown

extent.

At higher humidity, the electronic and mechanical components

may be damaged, and performance data changed to an

unknown extent.

Target group: Owner, freight forwarder, operator

Packing

The type of packaging used has been selected in

accordance with the shipping mode. It complies with

generally applicable packaging guidelines.

Shipping

Temperature fluctuations

Intermediate storage

Also ensure that the AS200 is stored in a dry place.

Requirements for the installation site

Ambient temperature

5°C to 40°C

Humidity:

Maximum relative humidity 80% at temperatures up to 31°C;

linear decline down to 50% relative humidity at 40°C.

Installation site – altitude:

max. 2000 m above mean sea level

Installation / Shipping nuts

31.07.2012 Retsch GmbH 7

Page 8

SM

Set up the AS200 only on a stable laboratory bench to avoid unpleasant transmission of vibrations.

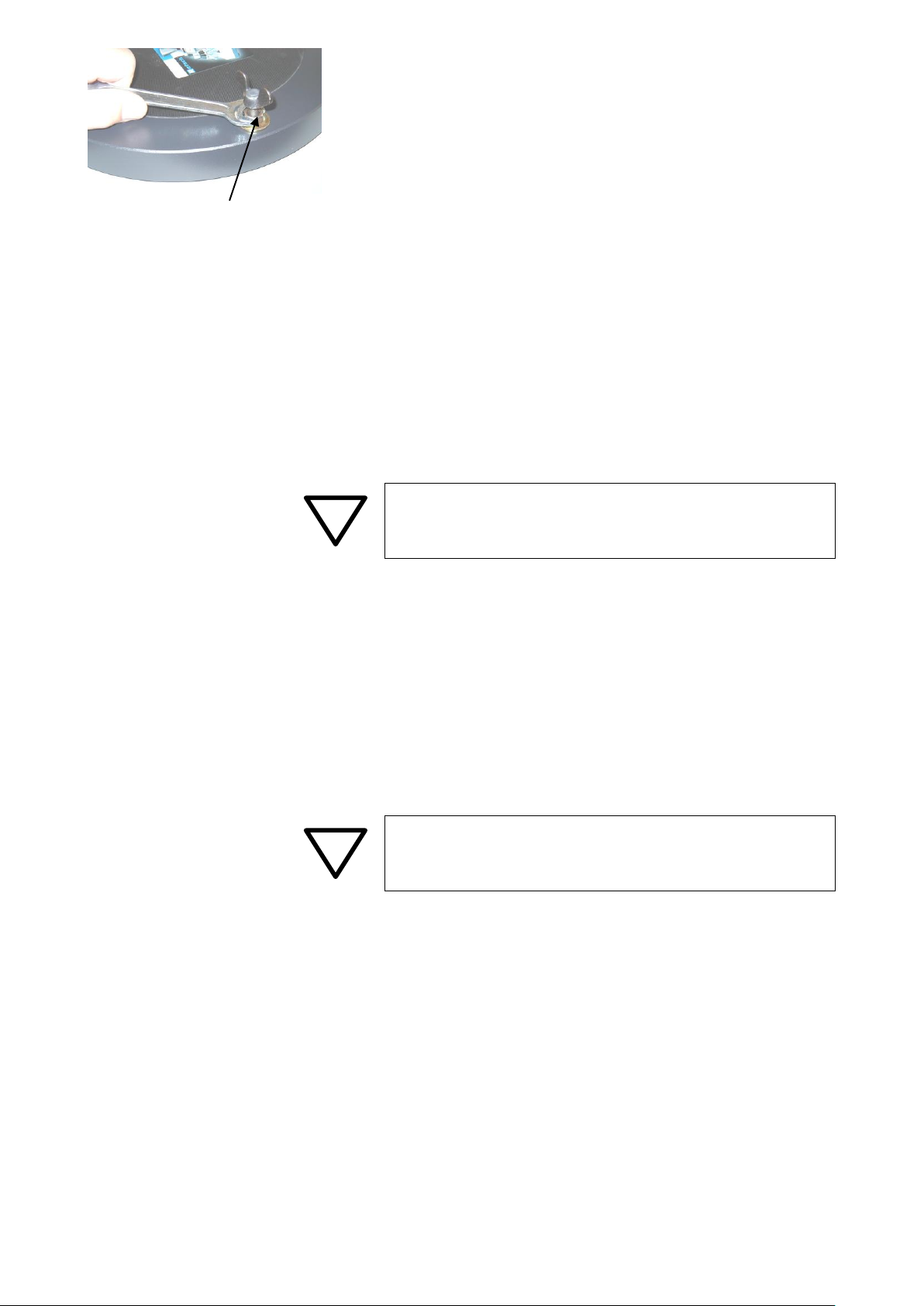

Loosen the hexagonal nuts SM using an open-ended

spanner until the sieve plate moves freely

Unscrew the wing screws A (shipping nuts) with hexagonal

nuts.

Mount the appropriate sieve clamping device (See the

chapter on operation for instructions)

Keep the wing screws A with hexagonal nuts (shipping nuts)

in a safe place for later transportation.

Reusing the shipping nuts

Screw the hexagonal nuts fully onto the wing screws

Screw the wing screws through the sieve plate into the

housing

Twist the hexagonal nuts downwards and tighten until the

sieve plate can no longer move

Operation with these shipping nuts in place, or shipping without

the these nuts installed, could cause damage to mechanical

components.

Electrical connection

Failure to observe the values on the data plate can cause

damage to either the electrical or the mechanical components or both.

* Refer to the data plate for information on the voltage and

frequency at which the AS200 is to be operated.

* Ensure that the values shown there correspond to those for

the local power supply.

* Use the supplied power cord to connect the AS200 to the

power supply.

* When connecting the power cord to the power source, be sure

that the supply circuit is fused in accordance with local codes.

31.07.2012 Retsch GmbH 8

Page 9

Operation

Control elements and their use

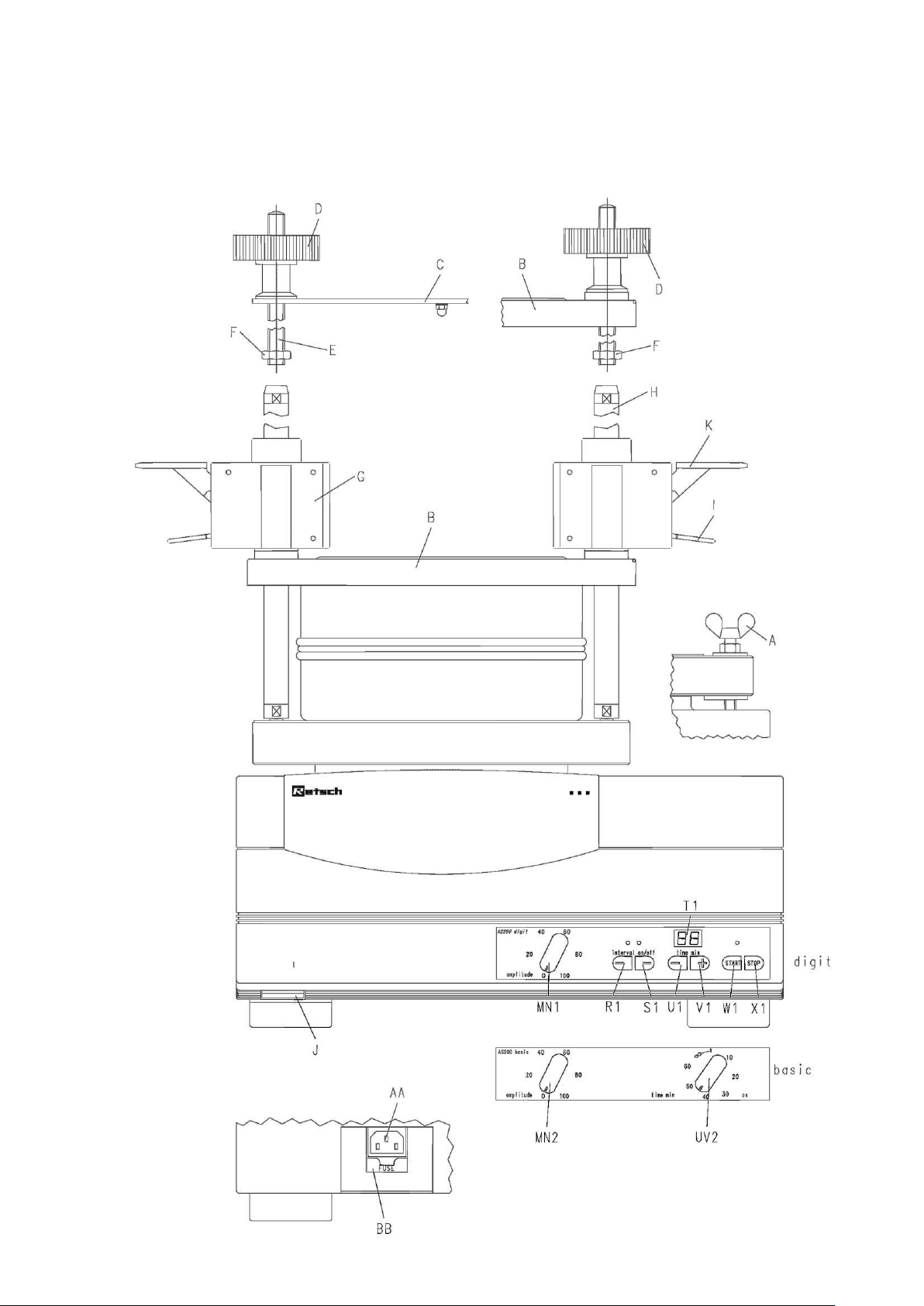

Schematic view of the operating controls:

31.07.2012 Retsch GmbH 9

Page 10

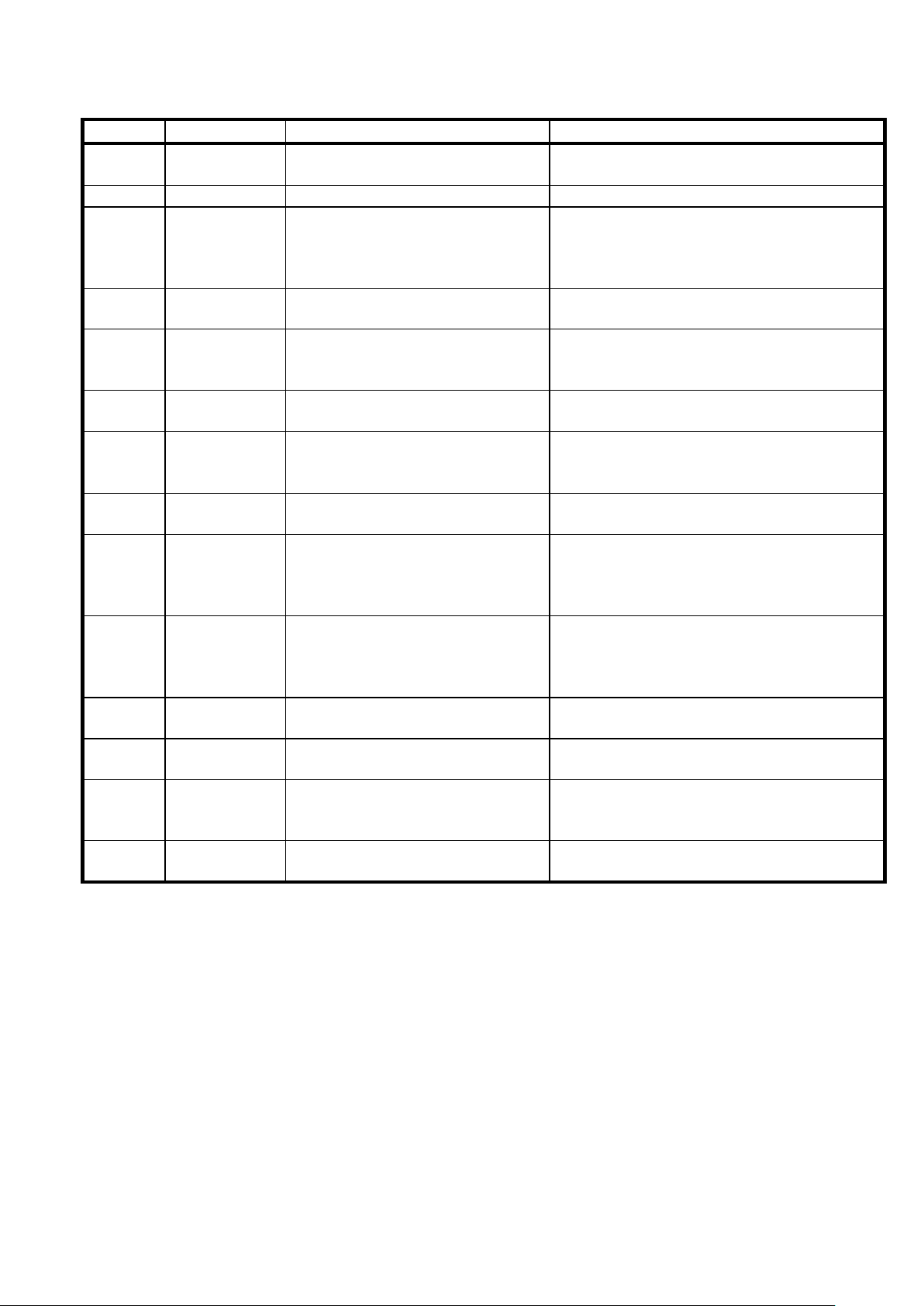

The operating controls and their functions

Element

AS200 model

Description

Function

A

all models

Shipping stabilization; wing

screw with nut and washer

Protects the unit during transportation;

must without fail be removed before use.

AA

all models

Socket

Attachment point for the power cord.

B

Accessories

Sieve fixing cover, standard

Covers the upper analytical sieve; in

conjunction with the retainer nuts D or the

quick-action clamps G it secures the sieve

stack.

BB

all models

Fuse holder

Accepts two glass-tube fuses, 4 A, slowblow

C

Accessory

Sieve fixing cover, economy

Covers the upper analytical sieve; in

conjunction with the retainer nuts D it

secures the sieve stack.

D

Accessory

standard and economy fixing

nuts

In conjunction with the B or C sieve fixing

cover, they secure the sieve stack.

E

Accessory

standard and economy

threaded spindles

Used together with the B or C sieve fixing

cover and the nuts D, they secure the

sieve stack.

F

Accessory

Hex nuts

Locks the threaded spindles E, screwed in

place, on the sieve plate.

G

Accessory

Quick-acting clamps

Permits quick clamping and loosening of

the sieve stack in conjunction with the

sieve fixing cover B and the stationary

rods H.

H

Accessory

comfort stationary rods

Allows for quick clamping and loosening of

the sieve stack in conjunction with the

sieve fixing cover G and the sieve fixing

cover B.

I

Contained in

G

Lever, red

Pressed upwards, it releases the sieve

fixing cover B.

J

all models

ON / OFF switch

Connects and disconnects the unit to the

line power supply.

K

Contained in

G

Lever, green

When pressed repeatedly, it moves the

sieve fixing cover B downward, thus fixing

the sieve stack.

L

AS200

Display: 0.20 to 3.00 mm

Shows the vibration height (twice the

amplitude) from 0.20 to 3.00 mm.

Summary table

31.07.2012 Retsch GmbH 10

Page 11

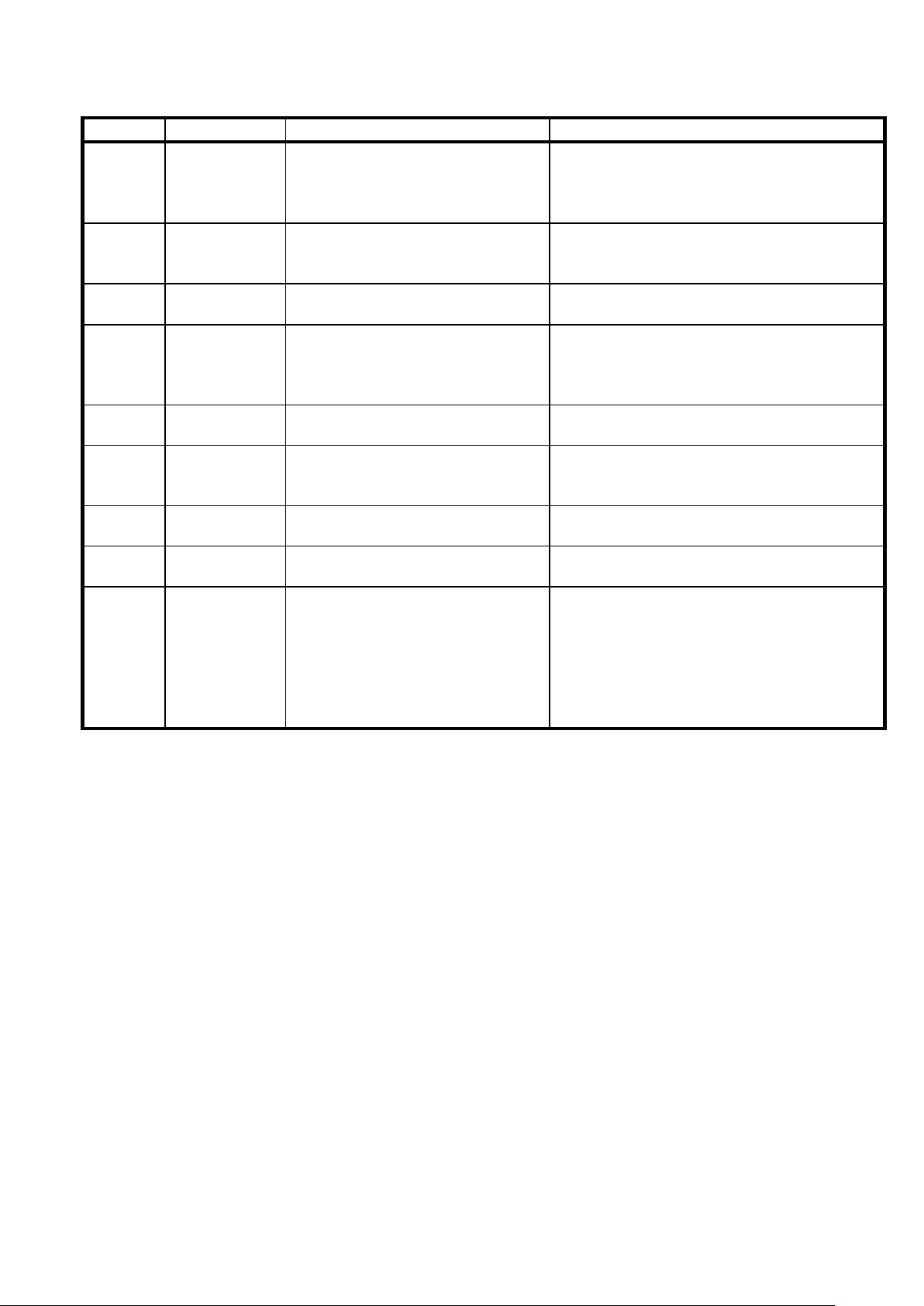

The operating controls and their functions

Element

AS200 Model

Description

Function

MN1

MN2

AS200 digit

AS200 basic

Knob to decrease or increase

vibration height, from 0.00 to

3.00 mm

Turn to the left to decrease, to the right to

increase vibration height. The scale

graduations are not absolute and are to

serve for reference only.

R1

AS200 basic

AS200 digit

Interval ON button

Left-hand LED lights

Switches the AS200 into the interval

mode. Will be disabled when the machine

is first switched on.

S1

AS200 basic

AS200 digit

Interval OFF button

Right-hand LED lights

Switches the AS200 to the continuous

operation mode.

T1

AS200 basic

AS200 digit

Display: 0 to 99 min.

Shows the sieving duration, from 1 to 99

min; two bars, indicating “infinite sieving

duration”, will be seen when the machine

is first switched on.

U1

AS200 basic

AS200 digit

Adjustment button - reduce

sieving period

Reduces the sieving period - 1 to 99 min.

UV2

AS200 basic

Knob for running time:

Reduce/increase or continuous

operation

Reduces or increases the sieving period

0 to 60 min

or sets for infinite sieving period

V1

AS200 basic

AS200 digit

Adjustment button - increase

sieving period

Increases the sieving period - 1 to 99 min.

W1

AS200 basic

AS200 digit

START button

Starts the sieving operation

Green LED lights

X1

AS200 basic

AS200 digit

STOP button

Terminates the sieving process

Press once = Pause – Pause/Display

lights and red LED lights; press the W/W1

button once to restart

Press twice = Standby – Only the red LED

lights; press the W/W1 button twice to

start

Summary table, part 2

31.07.2012 Retsch GmbH 11

Page 12

Installing and fixing the analytical sieves

The AS200 is suitable for use with analytical sieves with

outside diameters of up to 215 mm.

It is possible to install up to 16 analytical sieves 25 mm

high or 8 sieves 50 mm high, plus the base pan in each

case.

A variety of clamping units and covers is available for

use with sieves from 100 to 215 mm O.D. (see the

accessories listing).

Fixing with the sieve clamping unit –

economy or standard

* Screw the threaded rods E into the sieve plate and lock with

the hex nuts F.

* Center the selected sieve stack on the sieve plate.

* Lay the economy C or standard B sieve cover on the top

sieve, around the threaded rods.

* Tilt the clamping nuts D to slide them over the stationary

threaded rod and down to the sieve cover; turn down hand

tight.

We recommend using talcum powder if the base pan

sticks to the smooth surface of the sieve carrier when

removing the sieve stack.

Shorter threaded rods (see accessories listing) are

available to secure a maximum of five analytical sieves

and a base pan; these rods are for use with the

economy and standard sieve clamping units.

Please see also the section on product distribution.

31.07.2012 Retsch GmbH 12

Page 13

Fixing with the sieve clamping unit – comfort

* Screw the stationary rods H into the sieving plate

* Center the selected sieve stack on the sieve plate.

* Slide the comfort clamping cover B over the stationary rods,

pressing the red lever I upward; the green lever K remains in

the upper setting.

* Slide the clamping cover down to the top sieve.

* Press the green lever K downward several times; the red lever

I must not be moved.

* To release, use the thumb to press the red lever I upward; the

sieve cover can now be slid upward.

(Rest the index and middle fingers on the top of the housing

G).

If, after the sieving process, the red lever I proves to be

difficult to move, then the green lever K and the red

lever I are to be pressed simultaneously, briefly, to

release tension.

We recommend using talcum powder if the base pan

sticks to the smooth surface of the sieve carrier when

removing the sieve stack.

31.07.2012 Retsch GmbH 13

Page 14

The main switch J is located at the left-front on the AS200; see

Fig. 8

* Turn the main switch on.

* The interval off LED lights, Fig. 9

* Two bars light in the time display, see Fig. 9

The AS200 is now ready for operation, without the interval

function, in continuous duty.

Fig. 8

Operation for the AS200 digit

Switching on and off

Start - Interrupt - Stop

Fig. 9

Start: Fig. 9

* Press the START button W1.

* The green LED above button W1 lights.

Interruption (pause function): Fig. 9

* Press the STOP button X1 once.

* The red LED above button X1 lights.

* Sieving is suspended; values remain visible in the

display.

* Press the START button W1.

* The sieving process will be resumed.

Stop (standby function): Fig. 9

* Press the STOP button X1 twice

* Red LED above button X1 lights.

* The entire display goes out.

* Activate the LED displays: press button W1 once.

* New values can now be entered.

* Press the START button W1 a second time

* The same function will be executed as with the start

function.

31.07.2012 Retsch GmbH 14

Page 15

Intermittent - Continuous operation

Fig. 10

Intermittent operation is initially disabled when the

AS200 is first switched on.

Enable intermittent mode: Fig. 10

* Press the R1 button.

* The LED above button R1 lights.

Disable intermittent mode: Fig. 10

* Press the S1 button.

* The LED above button S1 lights.

Vibration height

If you desire to work with vibration heights above 2.5

mm, we recommend running the AS200 up to this value

slowly. Depending on the loading situation, resonance

(harmonic reinforcement) effects can be induced,

causing the armature and the yoke of the magnet to

make contact.

Fig. 11

Setting the vibration height (twice the

amplitude), from 0 to 3.00 mm: Fig. 11

* Turn the MN1 knob to the left to reduce the vibration

height, to the right to increase.

The values shown on the potentiometer scale are for

orientation purposes only. There is no absolute

relationship to the actual vibration height and thus this

scale cannot be used as an aid in reproducing previous

values.

Naturally, your AS200 can only achieve the vibration

heights which are within the values shown in the loading

diagram.

31.07.2012 Retsch GmbH 15

Page 16

Reading the vibration height: Fig. 12

The vibration height is shown optically, on the front of

the sieve plate.

The intersection of the two lines shows the vibration

height when the machine is running.

In the illustration at the left the value is 1.8 mm.

Fig. 12

Setting the time

Fig. 13

The AS200 is set for continuous operation when it is first

switched on..

Set the time for 1 to 99 min.: Fig. 13

* Pressing the U1 button will reduce the time down to a

minimum of 1 min.

Once this value has been passed, two bars will appear,

indicating continuous operation.

* Pressing button V1 raises the time, up to 99 min.

When this value is passed, the two bars indicating continuous

operation will appear.

31.07.2012 Retsch GmbH 16

Page 17

Operation for the AS200 basic

The main switch J is located at the left-front on the AS200; see

Fig. 14.

* Turn the main switch on.

* The ON LED lights, Fig. 15.

The AS200 is now ready for operation.

Fig. 14

Switching on and off

Start - Stop

Fig. 15

Start: Fig. 15

* Set knob UV2 for continuous operation .

Stop (standby function): Fig. 15

* Set knob UV2 to I.

Vibration height

If you desire to work with vibration heights above 2.5

mm, we recommend running the AS200 up to this value

slowly. Depending on the loading situation, resonance

(harmonic reinforcement) effects can be induced,

causing the armature and the yoke of the magnet to

make contact.

Setting the vibration height (twice the

amplitude), from 0 to 3.00 mm: Fig. 15

* Turn the MN2 to the left to reduce the vibration height, to

the right to increase.

The values shown on the potentiometer scale are for

orientation purposes only. There is no absolute

relationship to the actual vibration height and thus this

scale cannot be used as an aid in reproducing previous

values.

31.07.2012 Retsch GmbH 17

Page 18

Reading the vibration height: Fig. 16

The vibration height is shown optically, on the front of the sieve

plate.

The intersection of the two lines shows the vibration height when

the machine is running.

In the illustration at the left the value is 1.8 mm.

Naturally, your AS200 can only achieve the vibration heights

which are within the values shown in the loading diagram.

Fig. 16

Setting the time

Fig. 17

Setting the time for 1 to 60 min.: Fig. 17

* Turn the knob UV2 to the right to set the desired running

period.

Switching on continuous operation: Fig. 17

* Turn the knob UV2 to the left to the symbol

Replacing the fuses – All AS200 models

Fig. 18

Two glass tube micro-fuses, 4 A, slow-blow (5 20

mm), will be required for all AS200 models.

Replacement: Fig. 18

* Disconnect the line power cord.

* Pull out the fuse holder BB.

31.07.2012 Retsch GmbH 18

* Replace the fuses.

* Push the fuse holder BB back into normal position.

Page 19

Working instructions

Ensure that the openings in the sieve mesh are not

stretched by overloading with sieving aids as this would

have a detrimental effect on the precision of your

analytical sieve.

Target group: Laboratory technicians

Supplementary mass

The use of a supplementary mass may be required only

for 60 Hz units where, when using a small number of

analytical sieves, insufficient vibration height is attained

for your sieve analysis.

(Refer to chart on page 9.)

The auxiliary mass is mounted below the sieve stack, on

the sieve carrier plate at the AS200, and clamped at the

same time as the sieve stack.

Sieving aids

When dealing with product which is difficult to separate,

for which wet sieving is not possible (see notes in this

chapter), we recommend using sieving aids in the

individual sieve fractions. Depending on the screen size

and the vibration intensity, pearls made of agate,

rubber, china or nylon bristles and Vulkollan cubes may

be used.

Refer to the paragraph on product quantities for

information on suitable charges.

Retsch analytical sieves

Decisive for the accuracy and reliability of analytical

results is, in addition to a sieve shaker which works at

reproducible conditions, the quality of the analytical

sieves themselves.

Retsch analytical sieves are high-quality, high-value

measurement devices which may be used only for

woven and perforated sieves corresponding to the

particular standard. Following final inspection, each

screen is assigned a serial number and a quality

certificate is issued.

31.07.2012 Retsch GmbH 19

Page 20

Retsch analytical sieves are available in versions

Nominal widths of the

screen openings

Material quantity in dm

3

at 200 mm diameter

8

0.500

3.15

0.300

1

0.140

0.5

0.100

0.2

0.060

0.063

0.035

0.020

0.020

complying with all the usual national and international

standards:

* Standards available:

DIN, ISO, ASTM, BS

* Available diameters:

100 mm / 150 mm / 200 mm / 203 mm (8")

* Available woven screens materials:

Woven wire screens made of stainless steel

Perforated plates made of stainless steel

Specifics will be found in the detailed brochure describing

the analytical sieves.

The stack required for sieve analysis is composed of

analytical sieves which are arranged one above the other,

with progressively larger holes toward the top, together

with the base pan.

Quantity of product to be sieved

To ensure fast separation and exact results, the quantity

of the product being examined should be matched to the

sieve diameter and the nominal size of the openings.

The specific standards for sieve analysis (e.g. DIN

22019, Part 1) provide guideline values in which the

following maximum charge quantities are

recommended:

31.07.2012 Retsch GmbH 20

Page 21

Distribution of the sieved product

When carrying out sieving processes with only one to

three sieves, we recommend using the short rods.

Overly long rods, extending above the stack, will interfere

with distribution of the product due to their intrinsic resonance.

Even in procedures with only a single sieve, the AS200

will provide largely uniform distribution of the product

across the sieve screen. Depending on the vibration

height which is selected, the product will be moved

slowly in a circular direction.

Proper leveling of the AS200 is an important factor here.

Leveling can be corrected by screwing the feet CC in or

out as required. Fig. 19

Fig. 19

It is not necessary to lock the feet in position once

adjustment has been made.

31.07.2012 Retsch GmbH 21

Page 22

Amplitudes as funktion of loaded weight

Please refer to the following charts

Tolerances are 5% of the mass of the sieve stack

These charts are to be understood as aids in orientation

and are referenced to the rated voltage as indicated on

the data plate. Fluctuations in line voltage and deviations from the rating will result in higher tolerances.

Chart for the AS200 digit

at 230 V, 50 Hz

Vibration amplitudes from 0 to 3.0 mm

Sieve stack masses = Sieve + collector bottom, without

product being handled from 560 to 6250 grams

Solid line = AS200 with standard / economy sieve

clamping unit

Line with circles = AS200 with “comfort” sieve clamping unit

Chart for the AS200 basic

at 230 V, 50 Hz with clamping unit “economy“

Vibration amplitudes from 0 to 3.0 mm

Sieve stack masses = Sieve + collector bottom, without

product being handled from 560 to 6250 grams

grams

Subject to technical modification without prior notice

31.07.2012 Retsch GmbH 22

grams

Page 23

Chart for the AS200 digit and basic

at 100 V, 50 Hz

Vibration amplitudes from 0 to 3.0 mm

Sieve stack masses = Sieve + collector bottom, without

product being handled from 560 to 6250 grams

grams

Solid line = AS200 with standard / economy sieve

clamping unit

Line with circles = AS200 with “comfort” sieve clamping

unit

To achieve maximum vibration height, the AS200 is to

be operated with a supplementary mass, available as an

accessory, where the sieve stack mass is less than 2

kg.

Subject to technical modification without prior notice

Chart for AS200 , digit and basic

at 110/120 V, 60 Hz

Vibration heights from 0 to 3.0 mm

Sieve stack masses = Sieve + collector bottom, without

product being handled from 560 to 4650 grams

Solid line = AS200 with standard / economy sieve

clamping unit

Crosshatched line =AS200 with “comfort” sieve

clamping unit

Line with circles =AS200 with supplementary weight

and standard sieve clamping unit

Subject to technical modification without prior notice

31.07.2012 Retsch GmbH 23

grams

Page 24

Explanations of the loading charts

The lower loading capacities for the 60 Hz model when

compared with the 50 Hz model are due to physical

factors.

The series AS200 analytical sieving machines are

resonance-type units; the vibration heights (twice the

amplitude) will depend on the loading in the sieve

carrier.

Here the masses which are joined solidly with the sieve

carrier – those in the collector bottom and the sieve

clamping units – play a primary part. The mass of the

product being handled is of subordinate importance and

is thus not taken into account when calculating the

loading capacity.

Once you have determined the mass of your sieve stack

(collector bottom and sieve) you can refer to the appropriate chart (see pages 28 and 30) to read the vibration

height which can be achieved.

When using the comfort clamping unit, its high intrinsic

weight will naturally impart to your sieving machine

different operating characteristics than you will find with

the standard sieve clamping unit.

Refer to the charts on pages 28 and 30 and the following examples.

Utilizing a supplementary mass (available as an accessory component) will make it possible to extend satisfactorily the working range for sieve configurations with

a small number of sieves and consequently with a low

sieve stack mass. This also applies to the 60 Hz

models.

Example 1 :

* You are working with the AS200, 110V-60 Hz model

* The mass of the sieve stack (base pan and sieves)

amounts to 1500 g.

* You are working with the standard sieve clamping unit

The solid line curve shown in the chart applies

The vibration height which can be achieved with your

machine, under these conditions, is approx. 0.7 mm.

31.07.2012 Retsch GmbH 24

Page 25

Example 2 :

Without the supplementary mass it would be possible

only to achieve vibration height of 0.6 mm or less.

In normal applications, vibration heights of between 1

and 2 mm are recommended.

At vibration heights exceeding 2.5 mm it can happen in

the basic and digit models that the armature can

strike the magnets due to resonance effects.

Reduce the vibration height slightly, as mechanical

components could otherwise be damaged.

* You are working with the AS200, 110V-60 Hz model

* The mass of the sieve stack (collector bottom and sieves)

amounts to 1500 g.

* You are working with the comfort sieve clamping unit

The crosshatched curve in the chart applies.

The vibration height which can be achieved with your

machine, under these conditions, is approx. 2.5 mm.

Example 3 :

* You are working with the AS200, 110V-60 Hz model

* The mass of the sieve stack (collector bottom and sieves)

amounts to 560 g.

* You are utilizing the supplementary mass (accessory)

* You are working with the standard sieve clamping unit

The curve in the chart identified with the circles is applicable.

The vibration height which can be achieved with your

machine, under these conditions, is approx. 1,6 mm.

Subject to technical modification without prior notice.

31.07.2012 Retsch GmbH 25

Page 26

Wet sieving

Dry sieving will be possible in the large majority of

cases. There are, however, some materials in which the

adhesive forces between the individual particles can

cause difficulties. These problems can be eliminated by

adding liquid, preferably water, during the sieving

operation (in so far as the additives mentioned in the

chapter on “sieving aids” were not successful). One

pre-condition for wet sieving, however, is that the substances to be separated will not swell, dissolve or otherwise interact with the liquid.

Required accessories

* Clamping cover with spray nozzle, matching the sieve

diameter.

* Base pan with water drain, matching the sieve

diameter.

Preparations

* Position your AS200 near a water drain.

* Use a hose to connect the spray nozzle in the

clamping cover to a water faucet.

* Connect the drain from the base pan with the drain or

a suitable container to receive the liquid.

Operation

* Apply the solid in the form of a suspension.

* Set the liquid (water) supply rate so that the spray just

covers the sieve surface completely.

* Using dispersion agents is advisable. They reduce the

surface tension of the sieve liquids.

* When dealing with goods which resist forming a slurry

or where more exact separation is required, spray

each individual fraction, one after the other.

* Following the sieving process, the fractions are to be

transferred from the individual sieves to suitable filters

(e.g. filter paper) and dried in a drying cabinet at 80°C.

* Then clean the sieves in an ultrasonic bath and dry

them, too, in the drying cabinet (without the gaskets).

Do not exceed a maximum drying temperature of

80°C.

31.07.2012 Retsch GmbH 26

Page 27

!

Never place the AS200 directly in a basin for

operation.

Fatal electrical shock hazard.

!

During wet sieving always connect the AS200 to a

socket which is protected by a ground fault

interrupter.

Adjust the volume of water applied so that it will

just wet the surface of the screen.

Water backing up in the sieve stack can cause

overloading and thus may damage or destroy the

sieve weave.

The loading capacity charts provided in the Appendix

to these operating instructions are not applicable to

wet sieving.

Due to the difficulty in defining the volume of water in

the sieve stack, it is impossible to make reliable

statements for wet sieving.

31.07.2012 Retsch GmbH 27

Page 28

General

Accessories

* Sieve clamping unit – economy

* Sieve clamping unit – standard

* Sieve clamping unit – comfort (quick-action

clamp)

* Universal clamping cover – economy /standard

for sieves 100 / 150 / 200 / 203 mm in diameter

* Universal clamping cover – comfort (quick-action

clamping)

for sieves 100 / 150 / 200 / 203 mm in diameter

* Universal wet sieving clamping cover –

economy/standard

for sieves 100 / 150 / 200 / 203 mm in diameter

* Universal wet sieving clamping cover – comfort

for sieves 100 / 150 / 200 / 203 mm in diameter

* Short threaded rods for shorter sieve stacks

max. 5 analytical sieves, each 50 mm high

* Auxiliary weight, 2100 grams

* Conversion kit, vibration ball mill, for the AS200

basic and digit

* Cover for dust-protected storage of complete

sieve stacks

* Intermediate rings to elevate the sieve frame when

dealing with coarse-grained product

* Intermediate screens to carry out several sieving

cuts in a single step

* SP1000 software

31.07.2012 Retsch GmbH 28

Page 29

Cleaning

!

Never clean the AS200 with running water.

Fatal electrical shock hazard.

Use only a damp rag, moistened with water, for cleaning.

Never use solvents of any kind.

Fig.20

The AS200 requires no routine maintenance. When used

in accordance with the instructions, no maintenance or

adjustment work will have to be carried out.

We recommend cleaning the mounting bars from time to

time when using the comfort sieve clamping unit. In

addition, the comfort sieve clamping unit will produce

unavoidable clamping grooves in the mounting bars after a

certain period of time; this grooving can interfere with

proper clamping.

Consequently it is necessary to examine the mounting rods

occasionally to ascertain whether such grooving has taken

place in the clamping area and, if indicated, to rotate the

mounting rods through 90°. A 17 mm open-end wrench will

be required for this purpose.

Loosen the lock nuts indicated by KM. Fig. 20

Rotate the mounting bars through 90°

Re-tighten the lock nuts firmly.

If rotating the mounting bars through 90° fails to move an

area free of grooving into the engagement area, then we

recommend replacing the mounting bars.

During wet sieving, we recommend checking the water

hoses for leaks every three months.

For thorough, gentle and time-saving cleaning of your

analytical sieves, we recommend using the Retsch UR1

ultrasonic intensive cleaning unit.

Our publication "Care and cleaning of analytical sieve is

available on request, free of charge.

Maintenance

Target group: Operating personnel

31.07.2012 Retsch GmbH 29

Copyright

Reproducing or distributing this documentation, utilizing

or distributing the contents is permitted only with the express consent of Retsch GmbH.

Non-compliance will subject violators to claims for

damages.

Modifications

Subject to modification without prior notice.

Page 30

Safety regulations for the AS200

Subject

Action

Hazards

Vibration height

Vibration height >2.5 mm in the

AS200 basic and digit models

Armature strikes the magnets;

mechanical components could

be damaged.

Shipping

During shipment the AS200 is not

to be subjected to impact or

vibration; do not throw the

package.

Electronic and mechanical

components could be damaged.

Temperature

fluctuation

In case of temperature

fluctuations, protect the AS200

against condensation.

Electronic components could be

damaged.

Scope of supply

If the shipment is not complete or

is damaged, you must notify the

forwarder and Retsch GmbH

immediately (within 24 hours).

Under certain circumstances

compensation cannot be paid

for claims which are lodged

later.

Ambient

temperature

Temperature below 5°C

Temperature above 40°C

Electronic components could be

damaged.

Humidity

Exceeding 80% R.H. at

temperatures up to 31°C

Electronic components could be

damaged.

Installation

Shipping nuts not removed.

Mechanical and electronic

components could be damaged.

Electrical

connection

Local power supply does not

correspond to the values given on

the data plate.

Mechanical and electrical

components could be damaged.

Sieving aids

Stretching the sieve weave due to

excessive charge weight.

The precision of the analytical

sieve can be impaired.

Sieved product

distribution

Use the long threaded rods when

working with only one to three

sieves.

Overly long rods, extending

above the stack, will interfere

with distribution of the product

due to their intrinsic resonance.

Wet sieving

Never place the AS200 directly in

a basin for operation

Fatal electrical shock hazard.

Line power socket not protected

with a ground fault interrupter.

Fatal electrical shock hazard.

Water volume too great.

Water backing up in the sieve

stack can cause overloading

and thus may damage or

destroy the sieve weave.

Cleaning

Never clean the AS200 with

running water.

Fatal electrical shock hazard.

Extract from the individual chapters

31.07.2012 Retsch GmbH 30

Page 31

Page 32

Page 33

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Analytical Sieve Shaker Type AS 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

Retsch Gmb H Re tsch-Allee 1-5 42781 Haan Germany w w w .rets ch.com

ANALYTICAL SIEVE SHAKER

AS 200 basic / digit

FB-EW-805-004 (E) Änderungsstand I 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

DIN EN 50081 Generic standard interference emission - living areas - in conjunction with

EN 55022 and EN 60555

DIN EN 50082 Generic standard interference resistance - living areas

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 34

Page 35

Page 36

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...