Page 1

Manual

Dewar LN2 Autofill 50l

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 08.02.2012 0002

Page 2

Copyright

Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

1 Notes on the Operating Manual ............................................................................................................ 5

1.1 Explanations of the safety warnings .................................................................................................. 6

1.2 General safety instructions ................................................................................................................ 7

1.3 Repairs ............................................................................................................................................... 8

2 Confirmation ........................................................................................................................................... 9

2.1 Type plate description ........................................................................................................................ 9

3 Safety and occupational health instructions ..................................................................................... 10

3.1 General ............................................................................................................................................ 11

3.2 Safety instructions on the handling of liquid nitrogen ...................................................................... 12

3.3 Oxygen deficiency ........................................................................................................................... 12

3.3.1 Dangers ....................................................................................................................................... 12

3.3.2 Causes ......................................................................................................................................... 12

3.3.3 Recommendations ....................................................................................................................... 12

3.3.4 General conduct in the case of an accident ................................................................................ 13

3.4 Cryogenic burns ............................................................................................................................... 13

3.4.1 Dangers ....................................................................................................................................... 13

3.4.2 Causes ......................................................................................................................................... 13

3.4.2.1 Burns through splashes ....................................................................................................... 13

3.4.2.2 Burns through contact .......................................................................................................... 14

3.4.3 Recommendations ....................................................................................................................... 14

3.4.4 General rules of conduct for splashes with liquid nitrogen .......................................................... 14

3.4.4.1 To the eyes .......................................................................................................................... 14

3.4.4.2 On the skin ........................................................................................................................... 14

3.5 Danger of explosion ......................................................................................................................... 14

3.5.1 Dangers ....................................................................................................................................... 14

3.5.2 Causes ......................................................................................................................................... 14

3.5.3 Recommendations ....................................................................................................................... 15

3.5.4 General conduct in the case of an accident ................................................................................ 15

3.6 Oxygen enrichment .......................................................................................................................... 15

3.6.1 Dangers ....................................................................................................................................... 15

3.6.2 Causes ......................................................................................................................................... 15

3.6.3 Recommendations ....................................................................................................................... 15

3.7 Surrounding area of the machine .................................................................................................... 16

3.7.1 Rooms .......................................................................................................................................... 16

4 Operating the machine ........................................................................................................................ 17

4.1 Views of the Instrument ................................................................................................................... 17

4.2 Overview table of the parts of the device ........................................................................................ 18

4.3 Technical Data ................................................................................................................................. 19

3

Page 4

4.4 Vacuum closure and safety device .................................................................................................. 19

4.5 Level Display ................................................................................................................................... 19

4.6 Filling the vessel .............................................................................................................................. 20

4.7 Pressure build-up ............................................................................................................................. 21

4.8 Withdrawal of liquid nitrogen............................................................................................................ 21

4.9 Pressure relief .................................................................................................................................. 21

4.10 Transport.......................................................................................................................................... 21

4.11 Admitting the test pressure .............................................................................................................. 22

4.12 Checking the seat tightness............................................................................................................. 22

4.13 Checking the response pressure ..................................................................................................... 22

5 Index ...................................................................................................................................................... 23

4

Page 5

Notes on the Operating Manual

Pos: 1.1 /00005 Überschriften/1. Übersc hriften/1 Hinw eise zur Bedie nungsanleitung @ 0\mod_12223 47415287_9. doc @ 2631 @ @ 1

1 Notes on the Operating Manual

Pos: 1.2 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0001 Hinweise z ur Bedienungsanl eitung/M odul Hinweis zur B edienungsanleit ung @ 0\mod _12223473417 73_9.doc @ 2 540 @ @ 1

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

Pos: 1.3 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0001 Hinweise z ur Bedienungsa nleitung/M odul Änderungen @ 0\mod_122 2347341241_9. doc @ 2526 @ @ 1

www.retsch.com.

Changes

Pos: 1.4 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0001 Hinweise z ur Bedienungsanl eitung/Modul Urh eberrecht @ 0 \mod_1 222347342038_9. doc @ 2547 @ @ 1

Subject to technical changes.

Pos: 2.1 /00010 Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_12223443 73758_0.doc @ 2386 @ @ 1

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

5

Page 6

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

Pos: 2.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften BDA/1 1 Erklärungen zu den Sicher heitswarnunge n @ 0\mod_ 1222344569771 _9.doc @ 2484 @ @ 1

1.1 Explanations of the safety warnings

Pos: 2.3 /00003 Standard Kapitel/General Modul Warnhi nweise Erklär ung neu @ 0\ mod_12348583 29746_9.doc @ 6190 @ @ 1

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

Pos: 2.4 /00010 Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_12223443 73758_0.doc @ 2386 @ @ 1

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

6

Page 7

Notes on the Operating Manual

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften BDA/1 1 Generelle Sic herheitshinweise @ 0\mod_ 12223445689 74_9.doc @ 2 463 @ @ 1

1.2 General safety instructions

Pos: 2.6 /00004 Warnhinweise/V0002 VORS ICHT Bedien ungsanleitung l esen @ 2\ mod_12638949 82815_9.doc @ 18630 @ @ 1

Pos: 2.7 /00003 Standard Kapitel/General Modul Zielgr uppe und Sic herheit @ 0\mo d_12287229553 00_9.doc @ 41 00 @ @ 1

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

Pos: 2.8 /00003 Standard Kapitel/General Modul Sicher heitshinweise @ 0\mod_122 8722954800_ 9.doc @ 4086 @ @ 1

Pos: 2.9 /00004 Warnhinweise/V0015 VORS ICHT + HINW EIS Sach- und Personens chäden @ 1\ mod_12362384 56676_9.doc @ 7642 @ @ 1

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.10 /00010 Bedienungsanleitungen K apitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_1222344 373758_0.doc @ 2386 @ @ 1

7

Page 8

Notes on the Operating Manual

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Pos: 2.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Reparaturen @ 0\mod_ 1223624336511 _9.doc @ 297 8 @ @ 1

Reperaturen

1.3 Repairs

Pos: 2.12 /00003 Standard Kapitel/Gen eral Modul Repar aturen @ 0\m od_122872295 4535_9.doc @ 4 079 @ @ 1

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

Pos: 3.1 /00020 BDA Software/20005 PM GC Kapitelsa mmlung/- - - - S eitenumbruc h - - - - @ 0\mod _12088576884 13_0.doc @ 3 37 @ @ 1

8

Page 9

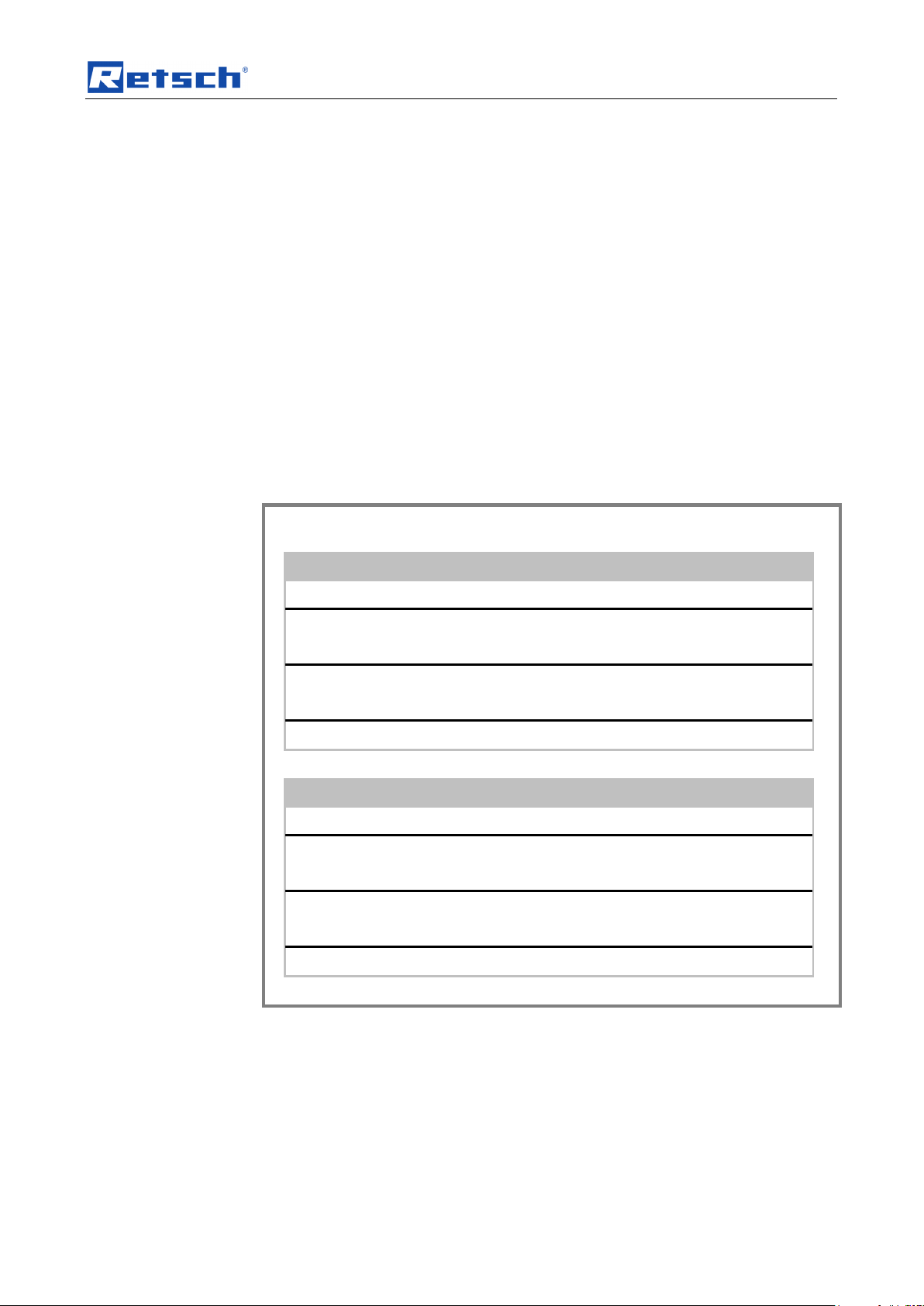

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.2 /00020 BDA Software/20005 PM GC Kapitelsam mlung/Überschrif ten/1. Überschrif ten/1 Best ätigung (Formular f ür den Betrei ber) @ 0\ mod_1208870841 095_9.doc @ 430 @ @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /00003 Standard Kapitel/General Modul Bestätigu ng @ 0\ mod_122872296 2707_9.doc @ 41 14 @ @ 1

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

Pos: 4.1 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften BDA/1 1 Typenschil d Beschreibung @ 3\mod_12 80933953941 _9.doc @ 22302 @ @ 1

2.1 Type plate description

Pos: 4.2 /00003 Standard Kapitel/General Modul Typensc hild Stomlose Ger äte @ 4\ mod_1323077 214627_9.doc @ 26040 @ @ 1

9

Page 10

Safety and occupational health instructions

CAUTION

Danger of injury to eyes and skin

Frostbites through liquid nitrogen

– Liquid nitrogen has a temperature of –196 °C and may cause

injuries similar to burns on skin or eye contact or cause frostbite.

• Always use goggles and wear protective gloves when

opening the cooling casing and the grinding jar.

CAUTION

Use of liquid nitrogen

– Retsch GmbH rules out any liability claims that may arise in the

use of liquid nitrogen or similar cooling agents.

• Please observe the safety regulations of the cooling liquid

supplier.

1 2 3 4 5 6 7

8

Fig. 1: Type plate marking

1 Instrument name

2 Year of manufacture

3 Article number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Waste disposal marking

8 Barcode

When making enquiries, please quote the name of the instrument (1) or the article

Pos: 5.1 /00005 Überschriften/1. Überschri ften/1 Dewar Sicherheits- u nd Arbeitsschut zhinweise @ 0\mod_12337 51785816_9.doc @ 5680 @ @ 1

number (3) and serial number (4) of the instrument.

3 Safety and occupational health instructions

Pos: 5.2 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0101 Warnhinweise/Cr yoMill Ge neral VORSICHT Verletzungsg efahr von Auge n und Haut d urch star ke Erfrierungen @ 0\ mod_122692 7213362_9.doc @ 3750 @ @ 1

Pos: 5.3 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0101 Warnhinweise/Cr yoMill G eneral VORSICH T Verwend ung von flüssige m Stickstoff @ 0\ mod_122692 7515928_9.doc @ 3756 @ @ 1

10

Page 11

CAUTION

Handling liquid nitrogen

General hazardous situations

– The following hazardous situations may arise in the handling of liquid

nitrogen: oxygen deficiency situations, cryogenic burns, danger of

explosion, oxygen enrichment

• All users must be informed about the dangers of working with liquid

nitrogen in order to be able to work safely.

Pos: 5.4 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften BDA/1 1 Allgemeines @ 0\mod_1 22691342152 9_9.doc @ 3723 @ @ 1

3.1 General

Pos: 5.5 /00010 Bedienungsanleitunge n Kapitelsamml ungen/Cr yoMill/0020 Cryo Sich erheitskapitel/Cr yo Kapitel Allg emeines VORSICH T @ 0\ mod_1233906970 969_9.doc @ 5988 @ @ 1

Pos: 5.6 /00010 Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_12223443 73758_0.doc @ 2386 @ @ 1

Safety and occupational health instructions

This section summarises the general occupational health and safety guidelines for

the handling of liquid nitrogen.

11

Page 12

Safety and occupational health instructions

Pos: 5.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften De war/11 Dewar Sic herheitshinweise beim Umgang mit flüssigem Stic kstoff @ 0\ mod_123375 1965302_9.doc @ 5692 @ @ 1

3.2 Safety instructions on the handling of liquid nitrogen

Pos: 5.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften De war/11 Dewar Sau erstoffmangel @ 0 \mod_123 3752064958_9. doc @ 5698 @ @ 1

3.3 Oxygen deficiency

Pos: 5.9 /00010 Bedienungsanleitungen Kapitelsamml ungen/Cr yoMill/0020 Cryo Sich erheitskapitel/Cr yo Kapitel Sauers toffmangel @ 0\mod_123 3907180174_ 9.doc @ 5994 @ @ 1

The main components of air according to volumes are as follows:

– Oxygen O2 21 %

– Nitrogen N2 78 %

– Argon Ar 1 %

The gases contained in the atmosphere are not toxic. However, a change in

concentration (in particular changes to the oxygen concentration) may have effects

on life and burns. It is therefore essential for the air breathed in to contain sufficient

oxygen (> 19 %).

Humans cannot detect changes in the composition of air within the time that will

Pos: 5.10 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Gefahr en @ 0\mod_ 1233906093088 _9.doc @ 5946 @ @ 1

3.3.1 Dangers

Pos: 5.11 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Sauerst offmangel Gefahren @ 0\mod_12339 07181002_9.doc @ 6001 @ @ 1

actually be necessary because the components are colourless and odourless.

A danger of suffocation exists as a result of the normal evaporation of the liquid

nitrogen that pushes out the oxygen in the air. An oxygen deficiency is dangerous

and can cause death through suffocation. The reaction of the organism to oxygen

deficiency will differ greatly depending on the individual. It is not possible to provide

precise and generally applicable information on the symptoms of an oxygen

deficiency.

Example: under normal conditions (20° C; 1013 mbars) 1 l liquid nitrogen

Pos: 5.12 /00005 Überschriften/1.1.1 Ü berschriften/11 1 Dewar Ursache n @ 0\mod_ 12339061241 98_9.doc @ 5952 @ @ 1

evaporates to produce 680 l nitrogen gas.

3.3.2 Causes

Pos: 5.13 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Sauerst offmangel Urs achen @ 0\mod_12339 07185955_9.doc @ 6064 @ @ 1

An oxygen deficiency may arise during the following work or in the following

conditions:

– Nitrogen as liquid or gas

– Natural evaporation of liquid nitrogen

– Refilling of liquid nitrogen

– Leaks in containers for liquid or gaseous nitrogen

– Defect in the air feed or outlet

– Tipping over of the container

Pos: 5.14 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Empfehl ungen @ 0\m od_12339061 48542_9.doc @ 5 958 @ @ 1

This list is not complete.

3.3.3 Recommendations

Pos: 5.15 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Sauerst offmangel Empfehlungen @ 0\mod_12 33907181658_9 .doc @ 6008 @ @ 1

In order to prevent the danger of an oxygen deficiency, the following measures

must be taken.

The vessel:

• must be kept in a vertical position.

12

• must be provided with a suitable insulating lid.

• must be protected from direct sunlight and may not be set up near heat

sources.

Page 13

Safety and occupational health instructions

• may not be transported in vehicles in filled state.

• must be protected from impact, knocks and rapid movements.

• Ventilate all installation rooms constantly and appropriately.

• Wear protective clothing (suitable gloves, goggles or face protection and

safety shoes).

• Check the oxygen content of the room constantly.

• Always carry an oxygen metre.

• Only trained personnel may work with liquid nitrogen.

Pos: 5.16 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Allgem eines Verhalten i m Falle eines U nfalles @ 0\ mod_12339066 62030_9.doc @ 5970 @ @ 1

This list is not complete.

3.3.4 General conduct in the case of an accident

Pos: 5.17 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Sauerst offmangel U nfall @ 0\ mod_123390718 2220_9.doc @ 6 015 @ @ 1

In the case of an accident from oxygen deficiency the following regulations should

be observed.

• Secure the surrounding area to avoid any subsequent accidents.

• Act quickly.

• The rescuers must take measures to protect themselves (respiratory

protection device).

• Move the injured persons from the hazardous area.

• Observe the company instructions for emergencies.

• Ventilate the rooms affected sufficiently.

• Investigate the cause of the accident.

Pos: 5.18 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften Dewar/ 11 Dewar Kr yogene Verbre nnungen @ 0\ mod_123375 2093635_9.doc @ 5704 @ @ 1

This list is not complete.

3.4 Cryogenic burns

Pos: 5.19 /00010 Bedienungsanleitungen K apitelsam mlungen/CryoMill /0020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Verbrennung @ 0\mod_1 23390718278 3_9.doc @ 6022 @ @ 1

Liquid nitrogen is very cold (-196° C).

The surfaces of vessels that were in contact in liquid nitrogen (in particular during

Pos: 5.20 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Gefahr en @ 0\mod_ 1233906093088 _9.doc @ 5946 @ @ 1

3.4.1 Dangers

Pos: 5.21 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Verbrennu ng Gefahr @ 0\ mod_12339071 83314_9.doc @ 6029 @ @ 1

the filling process) may cause skin burns on contact.

Cryogenic liquids may:

– bring about burns to the human body

– make specific materials (metal and plastic) that are not suitable for low

temperatures brittle

Pos: 5.22 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Ursachen @ 0\mod_ 12339061241 98_9.doc @ 5952 @ @ 1

– generate strong misting depending on atmospheric humidity

3.4.2 Causes

Pos: 5.23 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMil l/0020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Verbrennu ng Ursachen @ 0\ mod_123390 7183830_9.doc @ 6036 @ @ 1

There are two types of cryogenic burns:

3.4.2.1 Burns through splashes

When handling samples and in general when handling liquid nitrogen, personnel

must protect themselves from splashes. They can cause cryogenic burns with

serious consequential damage, in particular to eyes and face.

13

Page 14

Safety and occupational health instructions

3.4.2.2 Burns through contact

Contact of the skin with cold material causes frostbite or cryogenic burns.

The interior of vessels or the samples may never be touched or held with bare

Pos: 5.24 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Empfehl ungen @ 0\m od_12339061 48542_9.doc @ 5 958 @ @ 1

3.4.3 Recommendations

Pos: 5.25 /00010 Bedienungsanleitung en Kapitelsam mlungen/CryoMill /0020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Verbrennung Empfehlung @ 0\mod_12339 07184345_9.d oc @ 6043 @ @ 1

hands.

In order to prevent the danger of burning the following points must be observed:

• Never bring cryogenic liquids in contact with the skin.

• Never touch the cold non-isolated or iced walls of a vessel.

• Wear personal protective equipment (suitable gloves, goggles or face

protection and safety shoes).

• Keep the vessel upright.

• Use suitable material (e.g. metal hose or PTFE hose) to refill.

• Train personnel.

Pos: 5.26 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Allgem eine Verhaltensreg eln nach Spritz ern von flüssige m Stickst off @ 0\mod_1 233906744733_ 9.doc @ 5982 @ @ 1

This list is not complete.

3.4.4 General rules of conduct for splashes with liquid nitrogen

Pos: 5.27 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Verbrennung Spritzer @ 0\mod_123 3907184908_ 9.doc @ 6050 @ @ 1

3.4.4.1 To the eyes

• Rinse eyes with much water for 15 min.

• Follow the company instructions for emergencies.

• Consult a doctor

3.4.4.2 On the skin

• Do not rub.

• If possible remove or loosen clothing.

• Slowly and gradually warm the parts affected.

• Do not apply anything to the burnt area.

• Follow the company instructions for emergencies.

• Consult a doctor.

Pos: 5.28 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften Dewar/ 11 Dewar Explosionsgef ahr @ 0\mod_12 33752125798 _9.doc @ 5710 @ @ 1

Both lists are not complete.

3.5 Danger of explosion

Pos: 5.29 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Gefahr en @ 0\mod_ 1233906093088 _9.doc @ 5946 @ @ 1

3.5.1 Dangers

Pos: 5.30 /00010 Bedienungsanleitungen K apitelsammlu ngen/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Explosionsgef ahr Gefahren @ 0\mod_12 33907414909_9.d oc @ 6078 @ @ 1

Pos: 5.31 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Ursachen @ 0\mod_ 12339061241 98_9.doc @ 5952 @ @ 1

3.5.2 Causes

Pos: 5.32 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Explosionsg efahr Ursachen @ 0\mod_12 33907415425_9 .doc @ 6085 @ @ 1

The evaporation of liquid nitrogen may lead to an overpressure in the vessel.

An increase in the vessel may be attributable to:

14

– incorrect set-up (use of a closable lid)

– icing on the neck and on the insulating lid

Page 15

Safety and occupational health instructions

Pos: 5.33 /00005 Überschriften/1.1.1 Ü berschriften/ 111 Dewar Empf ehlungen @ 0\m od_12339061 48542_9.doc @ 5 958 @ @ 1

This list is not complete.

3.5.3 Recommendations

Pos: 5.34 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Explosionsge fahr Empfehl ung @ 0\mod _1233907415909 _9.doc @ 609 2 @ @ 1

To avoid the danger of explosion:

• Always use suitable insulating lids (pay attention to waste gas opening).

• Observe filling levels to avoid the formation of ice on the insulating lid.

• Set up the vessel in dry and roofed rooms.

• Monitor atmospheric humidity in the installation room.

• Check vessel regularly for the collection of condensed water.

• Check vessel regularly for damage to surface or material damage

Pos: 5.35 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Allgem eines Verhalten i m Falle eines U nfalles @ 0\ mod_12339066 62030_9.doc @ 5970 @ @ 1

This list is not complete.

3.5.4 General conduct in the case of an accident

Pos: 5.36 /00010 Bedienungsanleitung en Kapitelsam mlungen/CryoMill /0020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Explosionsg efahr Unfall @ 0 \mod_1233 907416394_9.d oc @ 6099 @ @ 1

In the case of an accident from oxygen deficiency the following regulations should

be observed.

• Secure the surrounding area to avoid any subsequent accidents.

• Act quickly.

• The rescuers must take measures to protect themselves (respiratory

• Move the injured persons from the hazardous area.

• Observe the company instructions for emergencies.

• Ventilate the rooms affected sufficiently.

• Investigate the cause of the accident.

Pos: 5.37 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften Dewar/ 11 Dewar Sa uerstoffanreicheru ng @ 0\ mod_1233752 153835_9.doc @ 5 716 @ @ 1

This list is not complete.

3.6 Oxygen enrichment

Pos: 5.38 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Gefahr en @ 0\mod_ 1233906093088 _9.doc @ 5946 @ @ 1

3.6.1 Dangers

Pos: 5.39 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMil l/0020 Cryo Sic herheitskapitel/Cr yo Kapitel Kr yo Sauerstoffanr eicherung Gefa hren @ 0\ mod_1233907417 378_9.doc @ 6113 @ @ 1

Pos: 5.40 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Ursac hen @ 0\mod_ 12339061241 98_9.doc @ 5952 @ @ 1

3.6.2 Causes

Pos: 5.41 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Sauerstoffanr eicherung Urs achen @ 0\ mod_123390741 7863_9.doc @ 6120 @ @ 1

Pos: 5.42 /00005 Überschriften/1.1.1 Ü berschriften/111 D ewar Empf ehlungen @ 0\m od_12339061 48542_9.doc @ 5 958 @ @ 1

3.6.3 Recommendations

Pos: 5.43 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo Sauerstoffanr eicherung E mpfehlungen @ 0 \mod_123390 7418394_9.d oc @ 6127 @ @ 1

Oxygen enrichment may increase the danger of explosion and fire.

Oxygen may be condensed from the air if liquid nitrogen is used and similarly be

liquefied because the boiling point of oxygen (approx. -183° C) is above that of

nitrogen (-196° C).

The following points must be considered in the case of oxygen enrichment:

protection device).

• Do not smoke.

• Where possible, keep easily inflammable materials away from the vessel.

15

Page 16

Safety and occupational health instructions

• Remove all sources of fire (naked flame and light, spark producers, matches,

lighters etc.).

• Ventilate installation rooms constantly and appropriately.

• Clean floor regularly.

• Train personnel.

• Wear personal protective equipment.

• Check oxygen content constantly.

• Always carry an oxygen metre.

Pos: 5.44 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften Dewar/ 11 Dewar U mgebung des Gerä tes @ 0\m od_123375219 5937_9.doc @ 5 722 @ @ 1

This list is not complete

3.7 Surrounding area of the machine

Pos: 5.45 /00005 Überschriften/1.1.1 Ü berschriften/ 111 Dewar Räu mlichkeiten @ 0\m od_123390671 2889_9.doc @ 5976 @ @ 1

3.7.1 Rooms

Pos: 5.46 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 020 Cryo Sic herheitskapitel/Cr yo Kapitel Kryo U mgebung Räu mlichkeiten @ 0\mod_12 33907185424_9.d oc @ 6057 @ @ 1

The room in which the machine is located must:

• permit operation without danger to the employees

• have a constantly running and appropriate ventilation system

• have a level and non-porous floor that is also able to bear the load of the

vessel

• have safety datasheets on liquid nitrogen visible for all to see

• prevent unauthorised access

• permit the safe filling of the vessel

• permit accessibility to the vessel for inspection, cleaning and maintenance

Pos: 6.1 /00010 Bedienungsanleitungen Kapitelsammlung en/------- Seitenumbruch ----------- @ 0\mod_12223443 73758_0.doc @ 2386 @ @ 1

This list is not complete.

16

Page 17

Operating the machine

V1

PSV

CSV

DM

FA

V3

V2

FA

CSV

PSV

ZF

V3

VV

DM

V1

V2

ZF

KS

KS

SA

SA

Pos: 6.2 /00005 Überschriften/1. Überschri ften/1 Bedie nung des Gerätes @ 0\mod_ 12265658802 11_9.doc @ 3519 @ @ 1

4 Operating the machine

Pos: 6.3 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0016 LN2 Dewar 5 0l/1607 Modul D ewar 50l Beschrei bung @ 2\mod_12677 85565238_9.d oc @ 18900 @ @ 1

The APOLLO ® vessel is a vacuum super-insulated pressure vessel made of

corrosion-resistant stainless steel for storing refrigerated liquid nitrogen in

conformance to the European Pressure Equipment Directive 97/23/EG, Category I

Pos: 6.4 /00005 Überschriften/1.1 Üb erschriften/1.1 Ü berschriften BDA/ 11 Ansichten des Gerätes @ 0\ mod_122899 0581782_9.doc @ 4966 @ 2 @ 1

4.1 Views of the Instrument

Pos: 6.5 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0016 LN2 Dewar 5 0l/1601 Modul Dewar 50l A nsichten der Ger äteteile @ 2\ mod_1267688 670954_9.doc @ 18820 @ @ 1

module A, with CE marking.

Fig. 2: Front view

Fig. 3: Rear view

Pos: 6.6 /00010 Bedienungsanleitunge n Kapitelsamml ungen/------- Seitenumbruch ----------- @ 0\mod_12223443 73758_0.doc @ 2386 @ @ 1

17

Page 18

Operating the machine

Element

Description

Function

V1

Withdrawal valve

Valve for taking out liquid nitrogen

V2

Pressure build-up valve

Valve for building up working pressure quickly

V3

Waste gas valve

Valve for draining liquid nitrogen

CSV

Overflow valve

Safety valve for the feed line to the CryoMill

DM

Pressure indicator

Gas pressure display

PSV

Dewar flask pressure relief valve

KS

Quick-release clamp

Sealing and attachment of the siphon to the Dewar

flask.

VV

Vacuum closure and safety device

Sealing of high vacuum in the intermediate hollow

space

ZF

Withdrawal hose

Liquid nitrogen supply line to the CryoMill

FA

Level display

Shows the liquid nitrogen level

Pos: 6.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Übers chriften BDA/1 1 Übersichtstab elle der Geräteteile @ 0\mo d_122899061 6846_9.doc @ 4 972 @ @ 1

4.2 Overview table of the parts of the device

Pos: 6.8 /00010 Bedienungsanleitungen Kapitelsammlung en/CryoMill/ 0016 LN2 Dewar 5 0l/1602 Modul D ewar 50l Ü bersichtstabelle der Geräteteile @ 2\mod_12 67691643620_ 9.doc @ 1882 7 @ @ 1

Safety valve 1.3 bar of the Dewar flask

Pos: 6.9 /00010 Bedienungsanleitunge n Kapitelsam mlungen/------- Seitenumbr uch ----------- @ 0\mod_1222344373758_ 0.doc @ 2386 @ @ 1

18

Page 19

Operating the machine

Overall height:

80cm

Outside diameter:

50cm

Overall width:

76cm

Immersion depth

58.5cm

Neck diameter:

5.0cm

Weight empty:

44kg

Weight full:

85 kg

Geometrical capacity:

49.5 litres

Stat. rate of evaporation:

2% / day

Operating pressure:

max. 1.3 bar

WARNING

CAUTION

Pos: 6.10 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Technische Da ten @ 0\ mod_12223445 69224_9.doc @ 2470 @ @ 1

4.3 Technical Data

Pos: 6.11 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 016 LN2 De war 50l/1611 Mod ul Dewar 50l Tech nische Date n @ 2\mod _1268230808 121_9.doc @ 1895 0 @ @ 1

Type: APOLLO® 50

Pos: 6.12 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Vakuumversc hluss und Sich erheitseinricht ung @ 2\m od_1268297292 227_9.doc @ 1 8970 @ @ 1

4.4 Vacuum closure and safety device

Pos: 6.13 /00010 Bedienungsanleitungen K apitelsammlu ngen/CryoMill/0 016 LN2 De war 50l/1613 Mod ul Dewar 50l V akuumverschluss u nd Sich erheitseinrichtung @ 2\mod_12 68297689386_ 9.doc @ 1897 7 @ @ 1

Pos: 6.14 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Füllstandsanz eige @ 2\ mod_1268300 595137_9.doc @ 18991 @ @ 1

4.5 Level Display

Pos: 6.15 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMil l/0016 LN2 D ewar 50l/1614 Mo dul Dewar 50l Füllstandskurve Apollo ® 50 @ 2 \mod_1268 298441800_9.d oc @ 18984 @ @ 1

Fig. 3: Vacuum closure and safety device

The vacuum closure and the safety device protect the vacuum space from positive

pressure . Only the manufacturer’s qualified staff may conduct the re-evacuation .

The protective cap (2) retains the valve insert (1) if excessive pressure builds up in

the vacuum space.

• Do not remove the protective cap (2).

• Protect the valve from heat or cooling because embrittlement can lead to the loss

of operating vacuum.

19

Page 20

Operating the machine

Fig. 4: Level Display

Determination of the level in the vessel

• Read the Dewar flask level on the scale in the level display.

• Alternatively, you can use a dipstick to determine the level and compare it

The black area on the level display scale marks 25% of the remaining contents.

Pos: 6.16 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Füllen des B ehälters @ 2 \mod_126777 4868556_9.d oc @ 18870 @ @ 1

Fig. 5: Level curve Apollo ® 50

4.6 Filling the vessel

Pos: 6.17 /00010 Bedienungsanleitung en Kapitelsam mlungen/CryoMill /0016 LN2 De war 50l/1603 Mo dul Dewar 50l B efüllen @ 2\ mod_1267698 001736_9.doc @ 1 8834 @ @ 1

• Close all valves. (V1, V2, V3)

with the level curve (see picture of Apollo® 50 level curve).

20

• Take the withdrawal hose (ZF) off the connection (SA).

• Attach the filling line to the connection (SA).

• Open the waste gas / overflow valve (V3).

• Open the withdrawal valve (V1).

• Fill the Dewar flask until liquid nitrogen comes out of the waste gas /

overflow valve (V3).

• Close the withdrawal valve (V1).

Page 21

Operating the machine

CAUTION

Risks of liquid or gaseous nitrogen

Positive pressure in the vessel

– The introduction of energy during transport can cause a sudden surge in

pressure. Nitrogen is blown off then and this can cause a lack of oxygen,

cryogenic burns, oxygen enrichment and associated risks.

• Make sure the vessel is depressurised before you transport it,

• Remove the siphon and put in the transport plugs.

• Transport the vessel only in an upright position.

• Avoid impacts and vibrations.

• Secure the vessel against falling down, rolling away and damage.

DM

Pos: 6.18 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Druckaufbau @ 1\mod _1240400926229 _9.doc @ 824 0 @ @ 1

• Close the waste gas / overflow valve (V3).

4.7 Pressure build-up

Pos: 6.19 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMil l/0016 LN2 D ewar 50l/1604 Mo dul Dewar 50l Druckaufbau @ 2 \mod_1267 701477789_9.d oc @ 18841 @ @ 1

• Close the withdrawal valve (V1) and the waste gas / overflow valve (V3).

• Open the pressure build-up valve (V2).

• Watch the pressure indicator (DM).

• Close the pressure build-up valve (V2) as soon as the needle reaches the

red marking or nitrogen comes out of the pressure relief valve (PSV).

Pos: 6.20 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BD A/11 Entnahm e von Flüssigstic kstoff @ 2\ mod_126777495 7314_9.doc @ 18 877 @ @ 1

Fig. 6: Pressure gauge

4.8 Withdrawal of liquid nitrogen

Pos: 6.21 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 016 LN2 De war 50l/1605 Mod ul Dewar 50l Entnahme Flüssi gstickstoff @ 2 \mod_1267 709072517_9.d oc @ 18855 @ @ 1

• Attach the liquid nitrogen line to the CryoMill and to the connection (SA).

Pos: 6.22 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Druckentl astung @ 2\ mod_1267777113 490_9.doc @ 18891 @ @ 1

4.9 Pressure relief

Pos: 6.23 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMil l/0016 LN2 D ewar 50l/1606 Mo dul Dewar 50l Dr uckentlastung @ 2\mod_1 267709470983_9. doc @ 18862 @ @ 1

Pos: 6.24 /00005 Überschriften/1.1 Übersc hriften/1.1 Übersc hriften BDA/ 11 Transport @ 0\mod_1 226495164391_ 9.doc @ 3398 @ 2 @ 1

4.10 Transport

Pos: 6.25 /00004 Warnhinweise/V0019 VOR SICHT Überdr uck im Behält er - Gefärdu ng durch LN2 @ 2\mod_126 7775099915_9.doc @ 18884 @ @ 1

• Open the filling and withdrawal valve (V1).

• After taking the liquid, close the filling and withdrawal valve (V1) again.

• Close the pressure build-up valve (V2).

• Open the waste gas valve (V3).

Pos: 6.26 /00005 Überschriften/1. Überschrif ten/1 Prüfa nweisungen @ 1 \mod_1245 230896441_9.d oc @ 11114 @ @ 1

Pos: 6.27 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 016 LN2 De war 50l/1612 Mod ul Dewar 50l Verb oten ist die An wendung f olgender Mittel und @ 2\ mod_126823154047 3_9.doc @ 18 957 @ @ 1

It is impermissible to use the following agents and tools:

• pliers

• striking tools

21

Page 22

Operating the machine

• lubricating spray

• hemp

• open flame

• steam

• leak detection spray

• suds

Pos: 6.28 /00010 Bedienungsanleitungen K apitelsammlung en/CryoMill/0 016 LN2 De war 50l/1610 Mod ul Dewar 50l Prüfu ngen des Sich erheitsve ntiles @ 2\mod_ 126780050589 5_9.doc @ 18 921 @ @ 1

Only the bubble method outlined below may be used to test that the safety valve is

securely in place and has the correct response pressure. This prevents the valve

mechanics becoming dirty and rusty . The response pressure is marked on the

safety valve.

4.11 Admitting the test pressure

Use a suitable test device to introduce the test pressure. Where the safety valves

are not to be removed, the vessel’s inherent pressure is used for the test.

Do not conduct the tests with oxygen or inflammable or corrosive gases.

4.12 Checking the seat tightness

Increase the test pressure to 90% of the response pressure. The valve must

remain leak-tight.

4.13 Checking the response pressure

Slowly increase the test pressure to 100%. The safety valve blows off. The

=== Ende der Liste für Textmarke Inhalt ===

response pressure can deviate from the nominal level by +/- 10%.

22

Page 23

5 Index

A

Article number ..................................................... 10

B

Barcode............................................................... 10

Bubble method .................................................... 22

C

Causes ............................................. 12, 13, 14, 15

CE marking ......................................................... 10

Changes ............................................................... 5

Confirmation ......................................................... 9

Copyright .............................................................. 5

Cryogenic burns .................................................. 13

D

Danger of explosion ............................................ 14

Dangers ........................................... 12, 13, 14, 15

Description .......................................................... 18

L

Level display ...................................................... 20

Level Display ...................................................... 19

Levels in the vessel ............................................ 20

M

Manufacturer’s address ..................................... 10

Moderate or mild injury ........................................ 6

N

Neck diameter .................................................... 19

Nominal level ..................................................... 22

Notes on the Operating Manual ........................... 5

O

Operating pressure ............................................ 19

Operating the machine....................................... 17

Outside diameter ................................................ 19

Overall height ..................................................... 19

Dirt ...................................................................... 22

E

Explanations of the safety warnings ..................... 6

F

Filling the vessel ................................................. 20

Front view ........................................................... 17

Function .............................................................. 18

G

General ............................................................... 11

General conduct in the case of an accident . 13, 15

General rules of conduct for splashes with liquid

nitrogen ........................................................... 14

General safety instructions ................................... 7

Geometrical capacity .......................................... 19

I

Immersion depth ................................................. 19

Inherent pressure ................................................ 22

Instrument name ................................................. 10

Overall width ...................................................... 19

Overview table of the parts of the device........... 18

Oxygen deficiency .............................................. 12

Oxygen enrichment ............................................ 15

P

Positive pressure ............................................... 19

Pressure build-up ............................................... 21

Pressure gauge .................................................. 21

Pressure relief .................................................... 21

Prohibited agents ............................................... 22

Prohibited tools .................................................. 22

property damage .................................................. 6

R

Rear view ........................................................... 17

Recommendations ................................. 12, 14, 15

Re-evacuation .................................................... 19

Repairs ................................................................. 8

Response pressure ............................................ 22

23

Page 24

Rooms................................................................. 16

Rust ..................................................................... 22

S

Safety and occupational health instructions ....... 10

Safety instructions on the handling of liquid

nitrogen ........................................................... 12

Safety warnings .................................................... 6

Seat tightness ..................................................... 22

Serial number ..................................................... 10

serious injury ......................................................... 6

Service Address .................................................... 8

Static rate of evaporation .................................... 19

Surrounding of the machine ............................... 16

T

Target group ......................................................... 7

Technical Data .................................................... 19

Test device ......................................................... 22

Test pressure ...................................................... 22

Transport ............................................................ 21

Type ................................................................... 19

type plate description ........................................... 9

Type plate marking ............................................ 10

V

Vacuum closure and safety device .................... 19

Vacuum closure and safety device .................... 19

Vacuum space ................................................... 19

Valve mechanics ................................................ 22

Views of the Instrument ..................................... 17

W

Waste disposal marking ..................................... 10

Weight empty ..................................................... 19

Weight full .......................................................... 19

Withdrawal of liquid nitrogen .............................. 21

Y

Year of manufacture .......................................... 10

24

Page 25

25

Page 26

Page 27

Page 28

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

28

Loading...

Loading...