Page 1

Tech Info

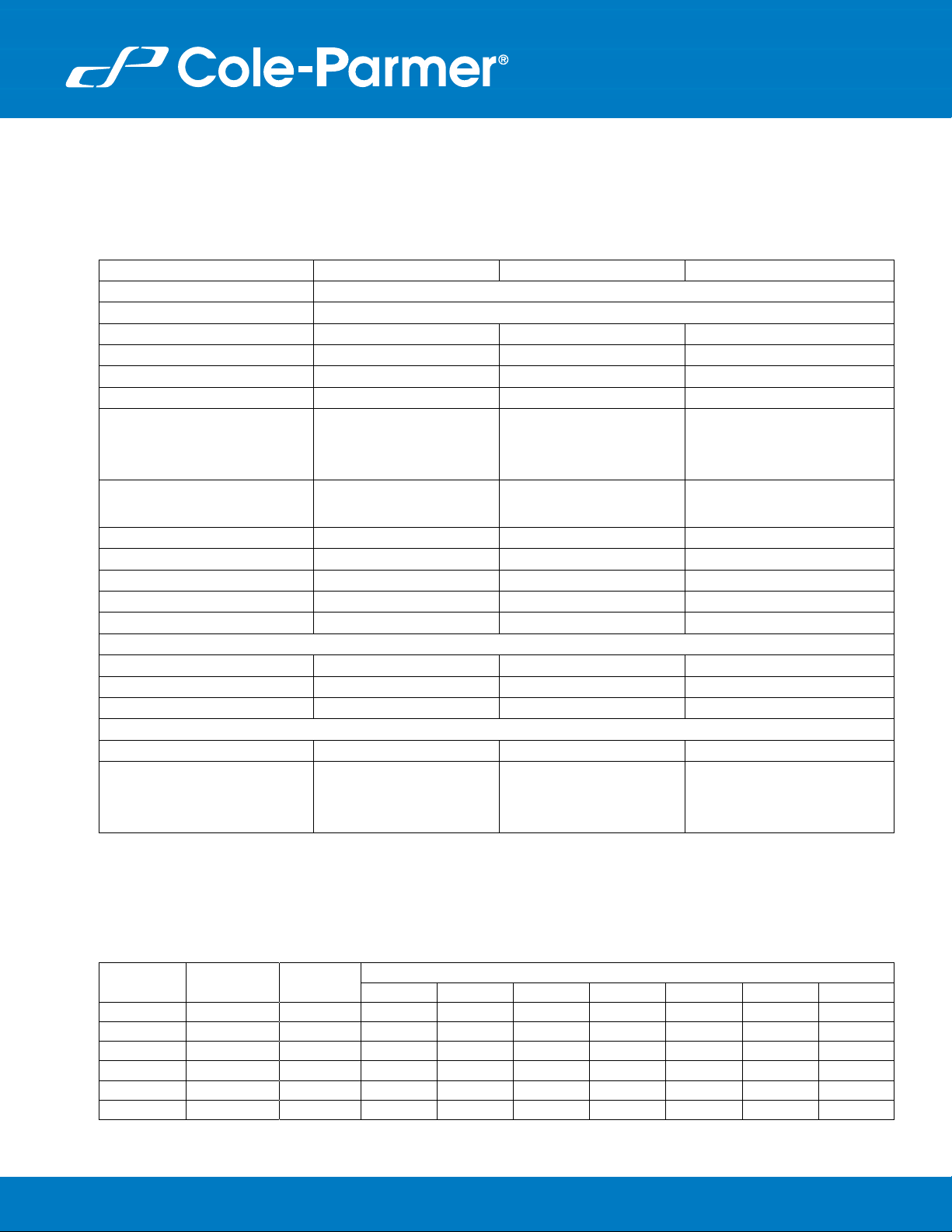

Selection Guide for Retsch® Mixer Jar Mills

Model 04182-01 is mainly used for the

size reduction of small amounts of

sample.

Model 04182-09, with higher energy, can

pulverize samples finer and faster, with

optimum reproducibility. Its convenient

self-locking clamp allows the use of large

jars up to 50 mL.

Performance data Model 04182-01 Model 04182-09 Model 04182-11

Field of application Size reduction, mixing, homogenization, and cell disruption

Feed material Hard, medium-hard, soft, brittle, elastic, fibrous

Feed size* Up to 6 mm Up to 8 mm Up to 8 mm

Grind size* Approx. 10 μm Approx. 5 μm Approx. 5 μm

Batch/Sample volume Max. 2 x 10 mL Max. 2 x 20 mL Max. 1 x 10 mL

Typical mean grinding time 2 minutes 2 minutes Pre-cooling: 10 minutes; Grinding: 4 minutes

Possible applications:

Dry grinding

Wet grinding

Cryogenic grinding

Cell disruption with reaction vials

Suitable grinding jars:

Grinding jar with push-fit lid

Grinding jar with screw-top lid

Self-centering clamping device No Yes —

Number of grinding stations 2 2 1

Digital preselection of vibrational frequency 3 to 25 Hz (180 to 1500 min

Digital preselection of grinding time 10 seconds to 99 minutes 10 seconds to 99 minutes 10 seconds to 99 minutes

Memory for parameter combinations 9 9 1

Technical data

Power consumption 100 W 150 W 160 W

Dimensions (W x H x D) 371 x 266 x 461 mm 371 x 266 x 461 mm 385 x 370 x 570 mm

Net weight Approx. 25 kg Approx. 26 kg Approx. 46 kg

Noise values (Noise measurement according to DIN 45635-31-01-KL3)

Emission value with regard to workplace* L

Measuring conditions:

Feed material 8 mL broken quartz pebbles,

Grinding jars used 2 x 25 mL steel 2 x 25 mL steel 1 x 50 mL steel

Grinding balls used 1 steel ball 20 mm dia. 1 steel ball 20 mm dia. 1 steel ball 25 mm dia.

*Depending on feed material and instrument configuration/settings.

Yes

No

No

Max. 10 x 2.0 mL

1.5 to 25 mL

No

–1

) 3 to 30 Hz (180 to 1800 min–1) 3 to 25 Hz (180 to 1500 min–1)

65 dB(A) L

pAeq

approx. 4.0 to 6.0 mm

Yes

Yes

Yes

Max. 20 x 2.0 mL

No

1.5 to 50 mL

65 dB(A) L

pAeq

8 mL broken quartz pebbles,

approx. 4.0 to 6.0 mm

Model 04182-11 is designed for

grinding samples with liquid nitrogen

which cannot be processed at room

temperature.

Yes

Yes

Yes

Max. 4 x 2.0 mL

No

5 to 50 mL

61 dB(A)

pAeq

8 mL broken quartz pebbles,

approx. 4.0 to 6.0 mm

Table of Guidelines

Grinding jar filling levels—guidelines for sample volume and ball charge. In addition to the instrument settings, the filling level of the

jar is also of crucial importance for the success of the grinding process in mixer mills. A jar filling should consist of about

1

and

⁄3 ball charge. The remaining third is the free jar volume that is necessary for the free movement of the balls. Exceptions to this

are voluminous materials, such as wool, leaves, grasses. In these cases a material filling level of 70 to 80% is necessary. The following

table provides guidelines.

Grinding jar

nominal volume

1.5 mL 0.2 to 0.5 mL 1 mm 1 to 2 pcs. — — — — — —

5.0 mL 0.5 to 2.0 mL 2 mm — 1 to 2 pcs. — — — — —

10.0 mL 2.0 to 4.0 mL 4 mm — — 1 to 2 pcs. 1 to 2 pcs. — — —

25.0 mL 4.0 to 10.0 mL 6 mm — — 5 to 6 pcs. 2 to 4 pcs. 1 to 2 pcs. — —

35.0 mL 6.0 to 15.0 mL 6 mm — — 6 to 9 pcs. 4 to 6 pcs. 2 to 3 pcs. 1 pc. —

50.0 mL 8.0 to 20.0 mL 8 mm — — 12 to 14 pcs. 6 to 8 pcs. 3 to 4 pcs. 1 pc. 1 pc.

Sample

amount

Max. feed

size

5mm Ø 7mm Ø 9/10mm Ø 12mm Ø 15mm Ø 20mm Ø 25mm Ø

Recommended ball charge

U.S. Toll-free: 800-323-4340 • Outside the U.S.: 847-549-7600 • www.coleparmer.com

Canada 800-363-5900 • India 91-22-6716-2222 • UK 0500-345-300

3094MI

1

⁄3 sample

Loading...

Loading...