Page 1

G3-PLC Sample Program

User's Manual

Target Device

RX Series/RL78/R9A06G037

www.renesas.com

User’s Manual

All information contained in these materials, including products and product specifications,

represents information on the product at the time of publication and is subject to change by

Renesas Electronics Corp. without notice. Please review the latest information published by

Renesas Electronics Corp. through various means, including the Renesas Electronics Corp.

website (http://www.renesas.com).

Rev.1.01 Jun. 19, 2019

Page 2

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products

and application examples. You are fully responsible for the incorporation or any other use of the circuits, software, and information in the design of your

product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by you or third parties arising from the use of

these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights, or

other intellectual property rights of third parties, by or arising from the use of Renesas Electronics products or technical information described in this

document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics or

others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any

and all liability for any losses or damages incurred by you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for

each Renesas Electronics product depends on the product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home

electronic appliances; machine tools; personal electronic equipment; industrial robots; etc.

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key

financial terminal systems; safety control equipment; etc.

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not intended or authorized for use in products or systems that may pose a direct threat to

human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause serious property damage (space system;

undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics disclaims

any and all liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product that is

inconsistent with any Renesas Electronics data sheet, user’s manual or other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for

Handling and Using Semiconductor Devices” in the reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by

Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation characteristics, installation, etc. Renesas

Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such

specified ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific

characteristics, such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Unless designated as a high reliability

product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics products

are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily injury,

injury or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as safety

design for hardware and software, including but not limited to redundancy, fire control and malfunction prevention, appropriate treatment for aging

degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult and impractical, you are

responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas

Electronics product. You are responsible for carefully and sufficiently investigating applicable laws and regulations that regulate the inclusion or use of

controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics products in compliance with all these

applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance

with applicable laws and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is

prohibited under any applicable domestic or foreign laws or regulations. You shall comply with any applicable export control laws and regulations

promulgated and administered by the governments of any countries asserting jurisdiction over the parties or transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or

transfers the product to a third party, to notify such third party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas Electronics

products.

(Note1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled

subsidiaries.

(Note2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

(Rev.4.0-1 November 2017)

Corporate Headquarters

Contact information

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas.com

For further information on a product, technology, the most up-to-date

version of a document, or your nearest sales office, please visit:

www.renesas.com/contact/.

Trademarks

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trademarks and registered trademarks

are the property of their respective owners.

© 2019 Renesas Electronics Corporation. All rights reserved

Page 3

General Precautions in the Handling of Microprocessing Unit and Microcontroller

Unit Products

The following usage notes are applicable to all Microprocessing unit and Microcontroller unit products from Renesas. For detailed usage notes on the products

covered by this document, refer to the relevant sections of the document as well as any technical updates that have been issued for the products.

1. Precaution against Electrostatic Discharge (ESD)

A strong electrical field, when exposed to a CMOS device, can cause destruction of the gate oxide and ultimately degrade the device operation. Steps

must be taken to stop the generation of static electricity as much as possible, and quickly dissipate it when it occurs. Environmental control must be

adequate. When it is dry, a humidifier should be used. This is recommended to avoid using insulators that can easily build up static electricity.

Semiconductor devices must be stored and transported in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work benches and floors must be grounded. The operator must also be grounded using a wrist strap. Semiconductor devices must not be

touched with bare hands. Similar precautions must be taken for printed circuit boards with mounted semiconductor devices.

2. Processing at power-on

The state of the product is undefined at the time when power is supplied. The states of internal circuits in the LSI are indeterminate and the states of

register settings and pins are undefined at the time when power is supplied. In a finished product where the reset signal is applied to the external reset

pin, the states of pins are not guaranteed from the time when power is supplied until the reset process is completed. In a similar way, the states of pins in

a product that is reset by an on-chip power-on reset function are not guaranteed from the time when power is supplied until the power reaches the level

at which resetting is specified.

3. Input of signal during power-off state

Do not input signals or an I/O pull-up power supply while the device is powered off. The current injection that results from input of such a signal or I/O

pull-up power supply may cause malfunction and the abnormal current that passes in the device at this time may cause degradation of internal elements.

Follow the guideline for input signal during power-off state as described in your product documentation.

4. Handling of unused pins

Handle unused pins in accordance with the directions given under handling of unused pins in the manual. The input pins of CMOS products are

generally in the high-impedance state. In operation with an unused pin in the open-circuit state, extra electromagnetic noise is induced in the vicinity of

the LSI, an associated shoot-through current flows internally, and malfunctions occur due to the false recognition of the pin state as an input signal

become possible.

5. Clock signals

After applying a reset, only release the reset line after the operating clock signal becomes stable. When switching the clock signal during program

execution, wait until the target clock signal is stabilized. When the clock signal is generated with an external resonator or from an external oscillator

during a reset, ensure that the reset line is only released after full stabilization of the clock signal. Additionally, when switching to a clock signal produced

with an external resonator or by an external oscillator while program execution is in progress, wait until the target clock signal is stable.

6. Voltage application waveform at input pin

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the CMOS device stays in the area between VIL (Max.)

and VIH (Min.) due to noise, for example, the device may malfunction. Take care to prevent chattering noise from entering the device when the input level

is fixed, and also in the transition period when the input level passes through the area between VIL (Max.) and VIH (Min.).

7. Prohibition of access to reserved addresses

Access to reserved addresses is prohibited. The reserved addresses are provided for possible future expansion of functions. Do not access these

addresses as the correct operation of the LSI is not guaranteed.

8. Differences between products

Before changing from one product to another, for example to a product with a different part number, confirm that the change will not lead to problems.

The characteristics of a microprocessing unit or microcontroller unit products in the same group but having a different part number might differ in terms of

internal memory capacity, layout pattern, and other factors, which can affect the ranges of electrical characteristics, such as characteristic values,

operating margins, immunity to noise, and amount of radiated noise. When changing to a product with a different part number, implement a systemevaluation test for the given product.

Page 4

Table of Contents

1. Introduction ........................................................................................................................ 1

1.1 List of Abbreviations and Acronyms .......................................................................................................... 1

1.2 Reference .................................................................................................................................................. 1

2. Software Structure ............................................................................................................. 2

2.1 Development Environment......................................................................................................................... 3

2.1.1 Hardware .......................................................................................................................................... 3

2.1.2 Software ........................................................................................................................................... 3

2.2 File structure .............................................................................................................................................. 4

3. Project Settings ............................................................................................................... 11

3.1 Start e2studio ............................................................................................................................................ 11

3.1.1 Workspace settings ........................................................................................................................ 11

3.1.2 Import project ................................................................................................................................. 12

3.1.3 Building project ............................................................................................................................... 13

3.2 Built Environment ..................................................................................................................................... 14

3.3 Macro Definition ....................................................................................................................................... 15

3.3.1 R_DEFINE_APP_MODE ............................................................................................................... 15

3.3.2 R_RL78_PLC ................................................................................................................................. 16

3.3.3 R_DEFINE_APP_BOOT ................................................................................................................ 16

3.4 Memory Map ............................................................................................................................................ 19

3.4.1 RX631 ............................................................................................................................................ 19

3.4.2 RX651 ............................................................................................................................................ 21

3.4.3 RL78G13 ........................................................................................................................................ 23

4. Sample Program .............................................................................................................. 25

4.1 G3-PLC Sample Application .................................................................................................................... 25

4.1.1 Application Control Parameters ..................................................................................................... 28

4.1.2 Command Processing Unit ............................................................................................................ 33

4.1.3 G3 Processing Unit ........................................................................................................................ 37

4.1.4 G3 API Wrapper ............................................................................................................................. 49

4.1.5 Flash control unit ............................................................................................................................ 52

4.1.6 IPv6 unit ......................................................................................................................................... 63

4.2 CPX3 SAP ............................................................................................................................................... 69

4.3 Common Process .................................................................................................................................... 69

4.3.1 CRC control .................................................................................................................................... 69

4.3.2 LED control ..................................................................................................................................... 69

4.3.3 Memory management .................................................................................................................... 69

4.3.4 Queue control ................................................................................................................................. 69

4.3.5 Console control .............................................................................................................................. 69

4.3.6 Soft timer control ............................................................................................................................ 70

4.3.7 Data operation ................................................................................................................................ 70

4.4 BSP .......................................................................................................................................................... 71

4.4.1 FIT .................................................................................................................................................. 71

4.4.2 API Functions ................................................................................................................................. 71

4.4.3 Library ............................................................................................................................................ 73

4.4.4 Startup ............................................................................................................................................ 73

4.5 Framework ............................................................................................................................................... 78

4.5.1 Sequence ....................................................................................................................................... 78

4.5.2 Process Flow .................................................................................................................................. 83

5. Resources Used .............................................................................................................. 86

5.1 Hardware Resources ............................................................................................................................... 86

5.1.1 RX631 ............................................................................................................................................ 86

5.1.2 RX651 ............................................................................................................................................ 87

Page 5

5.1.3 RL78G13 ........................................................................................................................................ 88

5.2 ROM/RAM Usage Amount ....................................................................................................................... 89

Page 6

R11UM0114EJ0101 Rev.1.01 Page 1 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

1. Introduction

This document is a user’s manual for a sample program to perform power line communication using

R9A06G037.

1.1 List of Abbreviations and Acronyms

Table 1-1 shows an abbreviation used this document .

Table 1-1 List of Abbreviations and Anonyms

Acronym

Description

CPX3

It refers to R9A06G037.

FIT

Abbreviation for "Firmware Integration Technology"

IB

Abbreviation for "Information Base"

NVM

Abbreviation for "Non-Volatile Memory"

SROM

Abbreviation for "Serial flash ROM"

1.2 Reference

Table 1-2 References

No

References

Number

[1]

G3-PLC Sample API Specification for Renesas RX Series

R11UM0041EJ0105

[2]

G3-PLC Sample Application Start Guide for GCPX3 board

R11QS0003EJ0102

[3]

G3-PLC Serial Command Specification

R11UM0042EJ0112

[4]

Serial Boot Operating Manual

R11UM0059EJ0102

[6]

GCPX3 Evaluation Kit J70D1

R30UZ0081EJ0100

[7]

BCPX3 Evaluation Kit J80D1

R30UZ0098EJ0100

[8]

BCPX3 Evaluation Kit J80D2

R30UZ0099EJ0100

Page 7

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 2 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

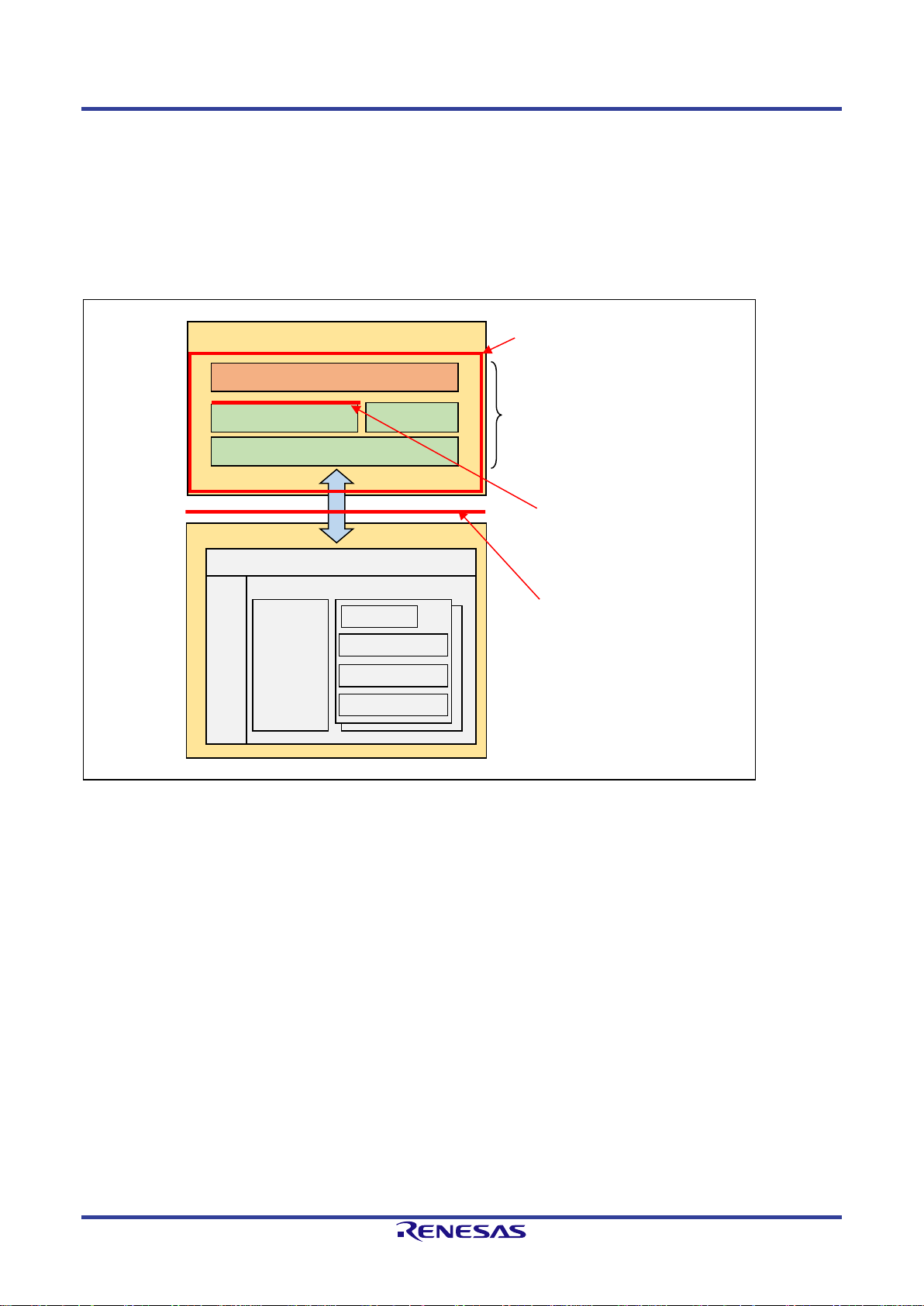

2.Software Structure

This sample program consists of the G3-PLC sample application unit, BSP unit, CPX3 SAP unit, and common

processing unit. The sample program is implemented on the host controller (microcontroller) and accesses to

the system block and the G3 block within R9A06G037 by using serial commands. By using API functions

provided by CPX3 SAP, it is possible to access each block within R9A06G037 without considering the serial

commands. All source codes for this sample program are open to the public. Figure 2-1 shows the software

configuration diagram. For details on specifications in red lines, refer to corresponding documents such as the

API specification and the serial command specification.

Figure 2-1 Software structure

Sample program

G3-PLC sample application

R9A06G037

UART I/F

G3 Block

G3

Controller

Open source codes

BSP

Sample API specification

Target of this document

System

Block

G3-PLC serial command specification

System block serial command

EAP Layer

ADP Sub Layer

MAC Sub Layer

PHY Layer

CPX3 SAP

Common part

Page 8

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 3 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

2.1 Development Environment

2.1.1 Hardware

Table 2-1 shows evaluation boards supported in this sample program.

Table 2-1 List of evaluation board

Evaluation board

MCU

Note

J70D1/J70D2

RX631

RX631 represents R5F5631EDD FP.

(ROM:2Mbytes / RAM:128Kbytes / E2 Data Flash:32Kbytes)

Refer to the manual "GCPX3 Evaluation Kit J70D1" for board setting.

J80D1

RX651

RX651 represents R5F56519AD FP.

(ROM:1Mbytes / RAM:256Kbytes / Data Flash:none)

Refer to the manual "BCPX3 Evaluation Kit J80D1" for board setting.

J80D2

RL78G13

RL78G13 represents R5F100GLAFB.

(ROM:512Kbytes / RAM:32Kbytes / Data Flash:8Kbytes)

Refer to the manual "BCPX3 Evaluation Kit J80D2" for board setting.

2.1.2 Software

The projects on this sample program are operationally tested on the following integrated development

environments.

Table 2-2 List of integrated development environments

Integrated development environment

Details

e2studio

e2studio Ver 7.3.0

Compiler (RX631/RX651)

GCC for Renesas 4.8.4.201803-GNURX

Compiler (RL78G13)

CC-RL Ver 1.8.00

Page 9

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 4 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

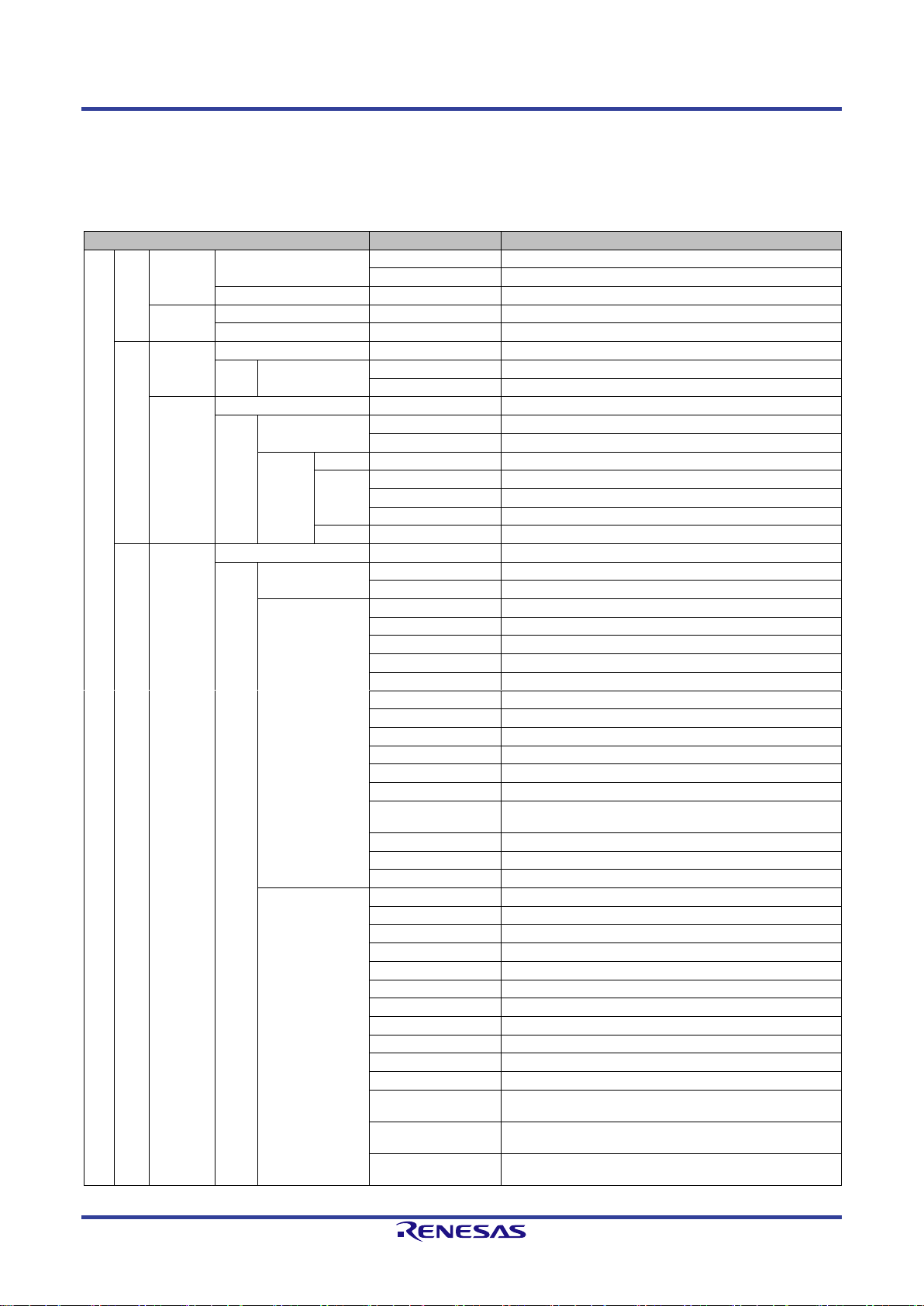

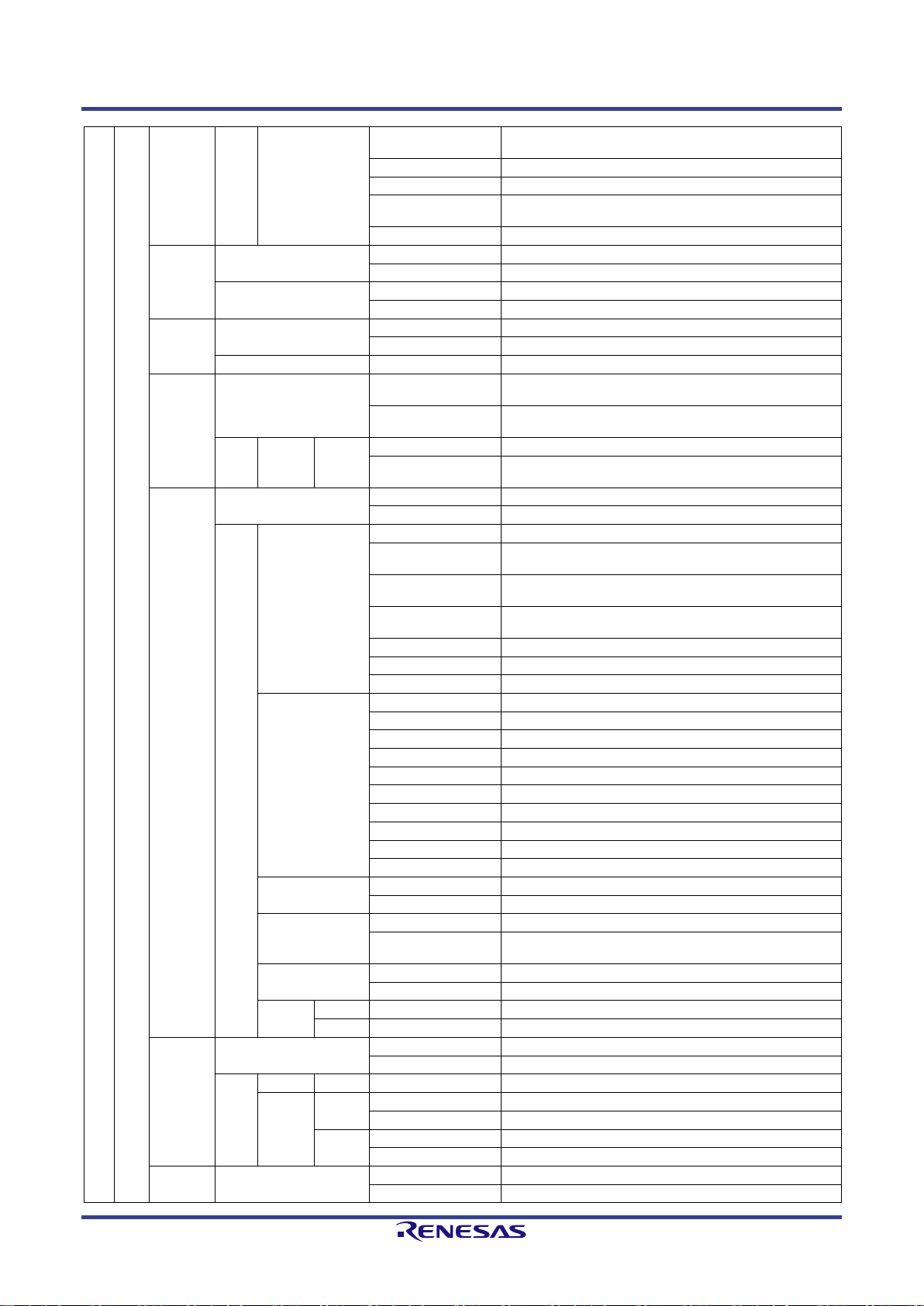

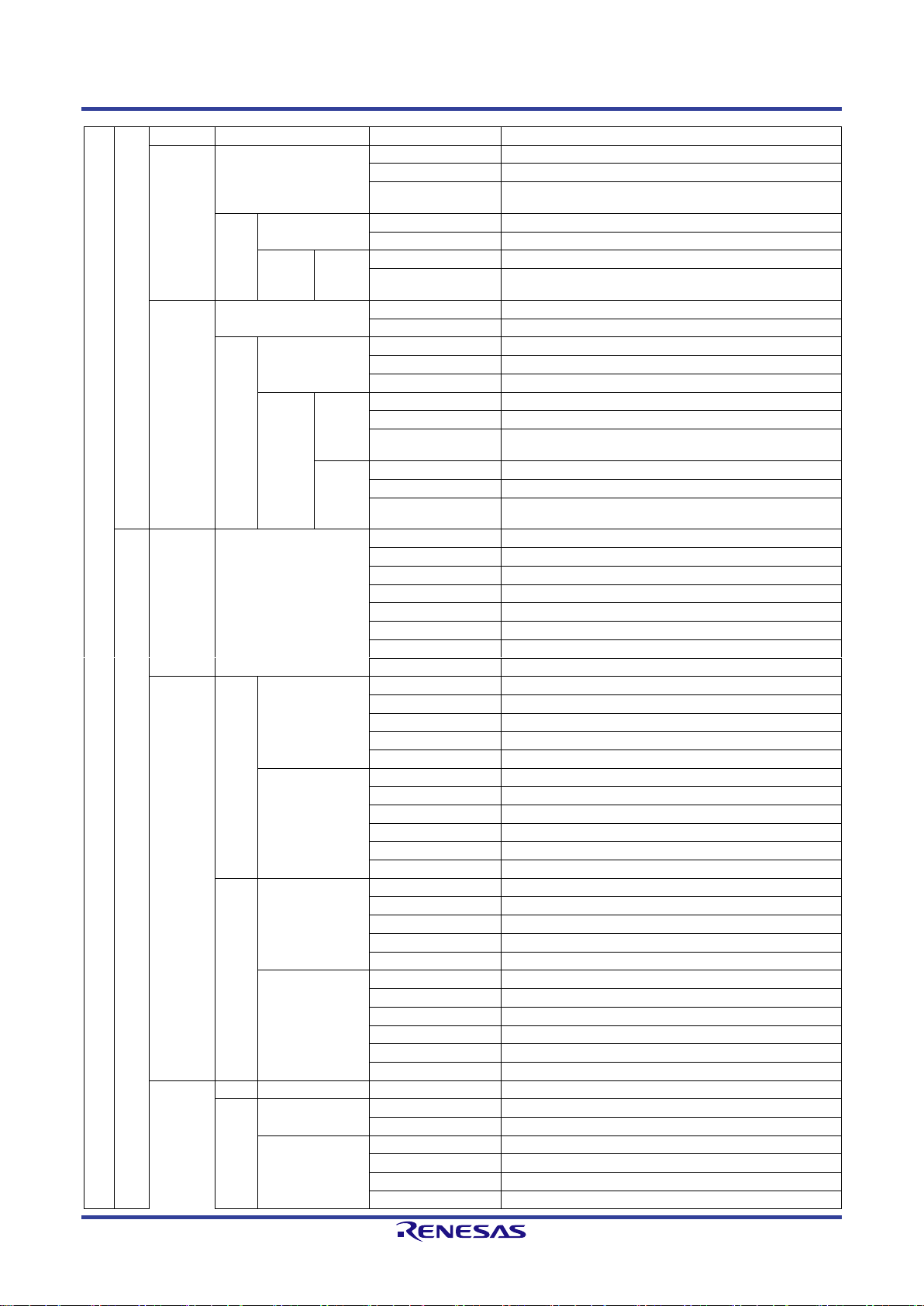

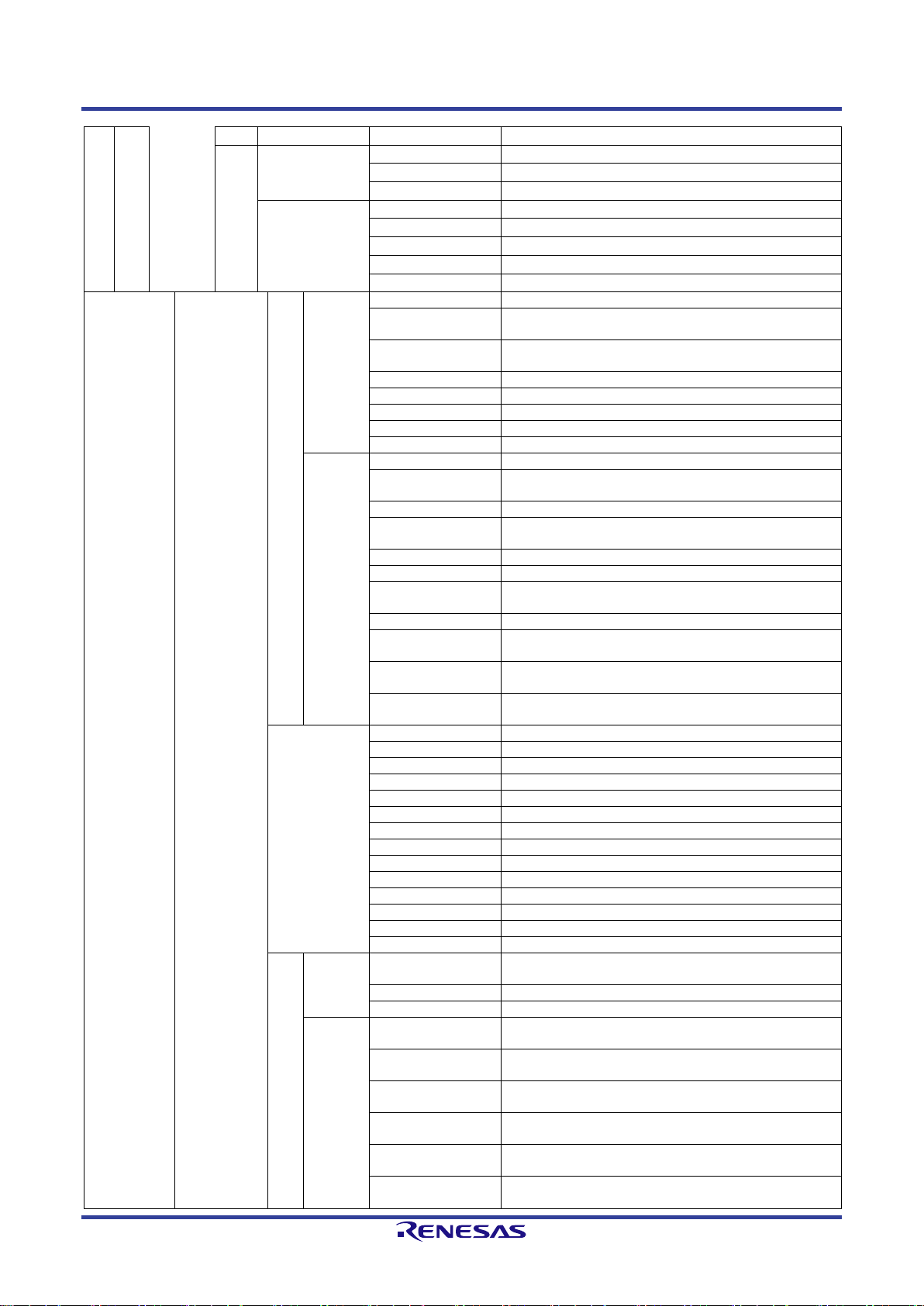

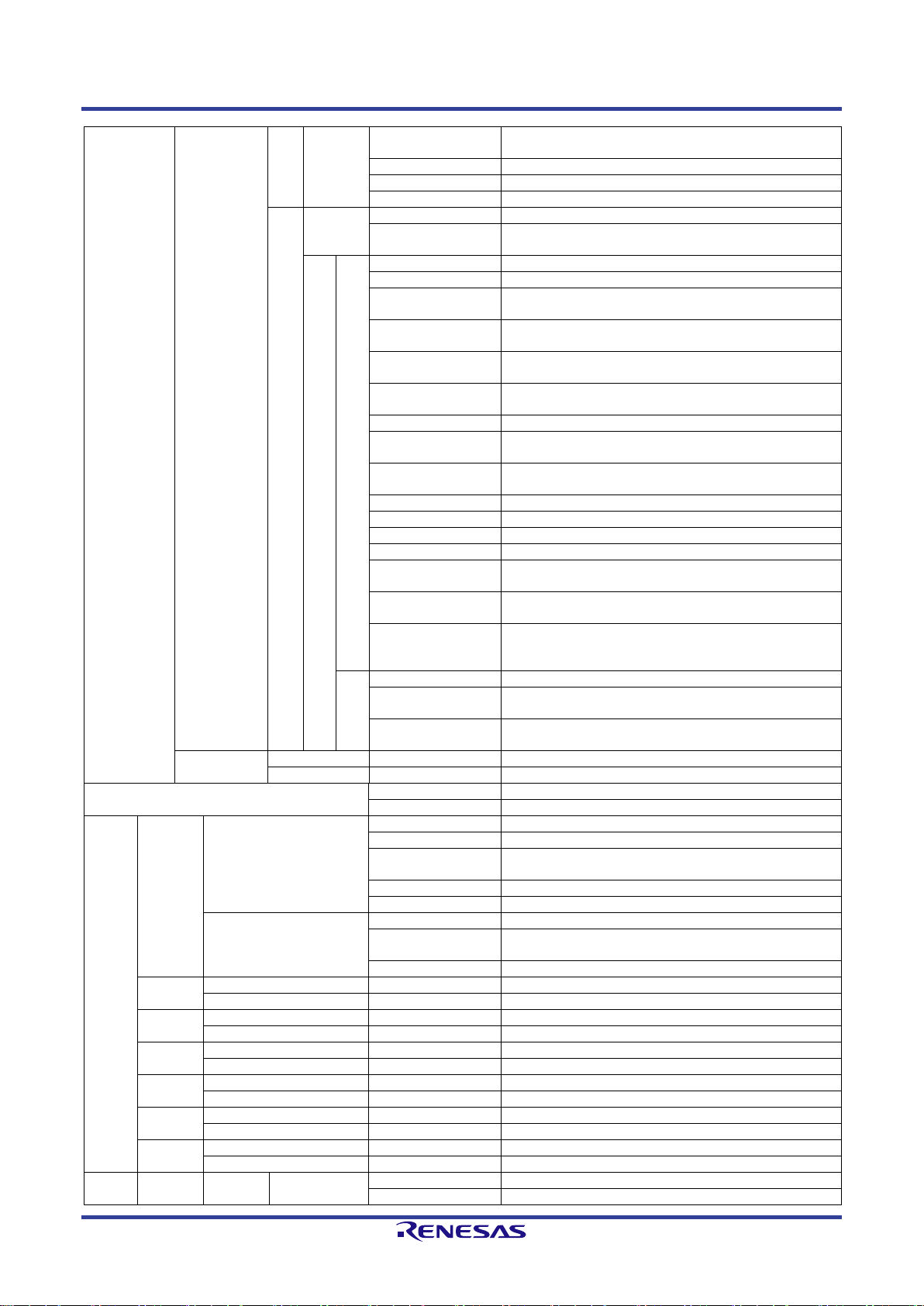

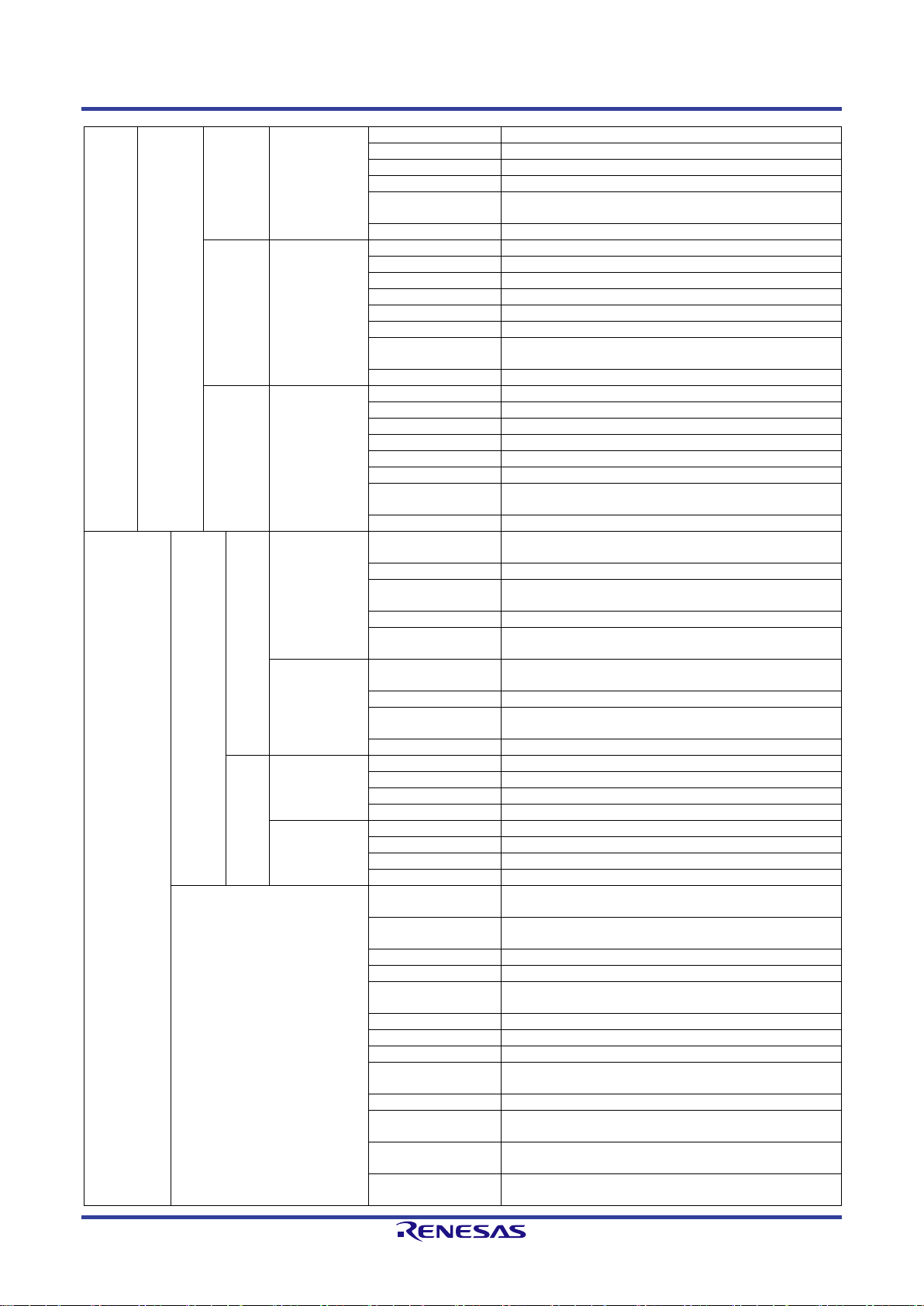

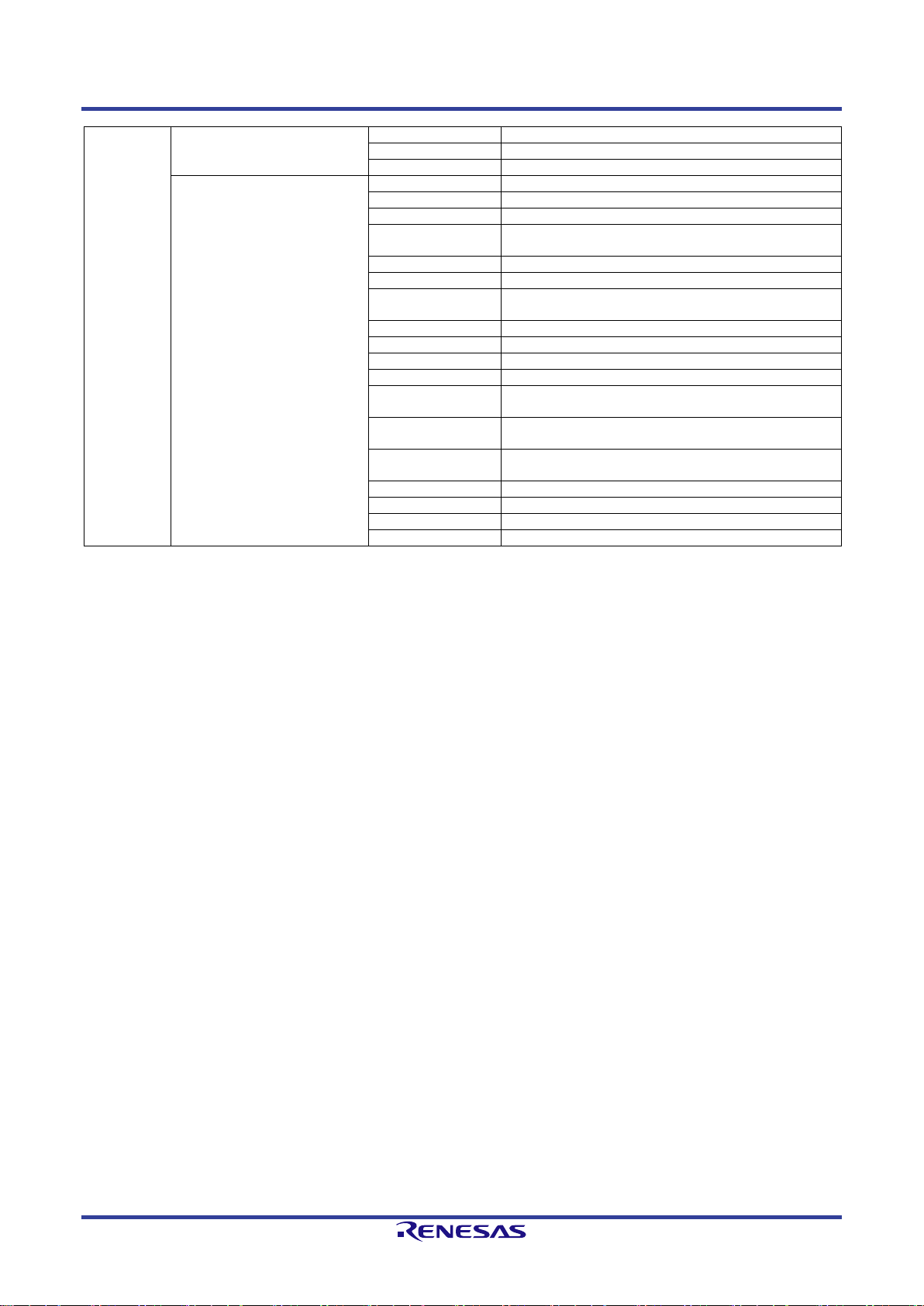

2.2 File structure

Table 2-3 shows file configuration of this sample application.

Table 2-3 File structure

Folder Name

File Name

Description

bsp

api

rl

inc

r_bsp_api.h

Header file for RL78 BSP API function

r_bsp_int.h

Header file for RL78 BSP interrupt function

src

r_bsp_api.c

RL78 BSP API function

rx

inc

r_bsp_api.h

RX BSP API function

src

r_bsp_api.c

RX BSP API function

rl_fit

r_bsp

platform.h

RL BSP common definition file

mcu

rl78g13

cpu.c

RL78-dedicated function

cpu.h

Header file for RL78-dedicated function

r_flash_rl

inc

r_flash_rl_if.h

Header file for FLASH API function open to the public

src

r_flash_rl.c

FLASH API function

r_flash_rl.h

Header file for FLASH API function

flash_ty

pe_4

r_flash_rl78.h

Header file for FLASH_TYPE_4 FLASH API function

incrl78

pfdl.h

Header file for flash data library(PicoFDL)

pfdl.inc

Flash data library(PicoFSL) include file

pfdl_types.h

Flash data library(PicoFDL) definition file

librl78

pfdl.lib

Flash data library(PicoFDL)

rx_fit

r_bsp

platform.h

RX BSP common definition file

mcu

all

r_bsp_common.c

MCU common function

r_bsp_common.h

Header file for MCU common function

rx631

cpu.c

RX631-dedicated function

cpu.h

Header file for RX631-dedicated function

locking.c

Header file for RX631 exclusive control function

locking.h

Header file for RX631 exclusive control function

mcu_clocks.c

RX631 clock control function

mcu_info.h

RX631 configuration

mcu_init.c

RX631 initial function

mcu_init.h

Header file for RX631 initial function

mcu_interrupts.c

RX631 interrupt function

mcu_interrupts.h

Header file for RX631 interrupt function

mcu_locks.c

RX631 exclusive control function by resource

mcu_locks.h

Header file for RX631exclusive control function by

resource

r_bsp.h

RX631 BSP header file

r_bsp_config.h

RX631 BSP configuration file

r_mcu_config.h

FLASH configuration when not using FIT

rx651

cpu.c

RX651-dedicated function

cpu.h

Header file for RX651-dedicated function

locking.c

RX651 exclusive control function

locking.h

Header file for RX651 exclusive control function

mcu_clocks.c

RX651 clock control function

mcu_info.h

RX651 configuration

mcu_init.c

RX651 initial function

mcu_init.h

Header file for RX651 initial function

mcu_interrupts.c

RX651 interrupt function

mcu_interrupts.h

Header file for RX651 interrupt function

mcu_locks.c

RX651 exclusive control function by resource

mcu_locks.h

Header file for RX651 exclusive control function by

resource

mcu_mapped_interr

upts.c

Interrupt function mapped to RX651

mcu_mapped_interr

upts.h

Header file for interrupt function mapped to RX651

Page 10

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 5 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

mcu_mapped_interr

upts_private.h

Definition file for mapped interrupt function

r_bsp.h

Header file for RX651 BSP header file

r_bsp_config.h

RX651 BSP configuration file

r_bsp_interrupt_con

fig.h

Mapped interrupt function configuration

r_mcu_config.h

FLASH configuration when not using FIT

r_byteq

r_byteq_config.h

Queue configuration

r_byteq_if.h

Header file for external public queue API function

src

r_byteq.c

Queue API function

r_byteq_private.h

Queue API definition file

r_cmt

r_cmt_rx_config.h

CMT configuration

r_cmt_rx_if.h

Header file for external public CMT

src

r_cmt_rx.c

CMT API function

r_eeprom

_riic_rx

r_eeprom_riic_rx_co

nfig.h

EEPROM configuration

r_eeprom_riic_rx_if.

h

Header file for external public EEPROM API function

src

targets

eeprom

_riic

r_eeprom_riic_rx.c

EEPROM API function

r_eeprom_riic_rx_pr

ivate.h

EEPROM API definition file

r_flash_rx

r_flash_rx_config.h

FLASH configuration

r_flash_rx_if.h

Header file for external public FLASH API function

src

r_flash_fcu.c

FLASH_TYPE_3/FLASH_TYPE_4 common function

r_flash_fcu.h

Header file for FLASH_TYPE_3/FLASH_TYPE_4

common function

r_flash_group.c

FLASH_TYPE_1, FLASH_TYPE_3/FLASH_TYPE_4

common function

r_flash_group.h

Header file for FLASH_TYPE_1,

FLASH_TYPE_3/FLASH_TYPE_4 common function

r_flash_rx.c

FLASH API function

r_flash_rx.h

Header file for FLASH API function

r_flash_targets.h

FLASH API definition file

flash_type_1

r_codeflash.c

E2 code flash control function

r_codeflash.h

Header file for E2 code flash control function

r_codeflash_extra.c

Access window control function

r_codeflash_extra.h

Header file for access window control function

r_dataflash.c

E2 data flash control function

r_dataflash.h

Header file for E2 data flash control function

r_flash_common.h

Flash common definition file

r_flash_type1.c

FLASH_TYPE_1 API function

r_flash_type1_if.h

Header file for FLASH_TYPE_1 API function

r_flash_utils.c

FLASH API for RX11x series-dedicated section

flash_type_2

r_flash_type2.c

FLASH_TYPE_2 API function

r_flash_type2_if.h

Header file for FLASH_TYPE_2 API function

flash_type_3

r_flash_type3.c

FLASH_TYPE_3 API function

r_flash_type3_if.h

Header file for Header file for FLASH_TYPE_3 API

function

flash_type_4

r_flash_type4.c

FLASH_TYPE_4 API function

r_flash_type4_if.h

Header file for FLASH_TYPE_4 API function

targets

rx63n

r_flash_rx63n.h

RX631 FLASH definition file

rx65n

r_flash_rx65n.h

RX651 FLASH definition file

r_gpio

r_gpio_rx_config.h

GPIO configuration

r_gpio_rx_if.h

Header file for external public GPIO API function

src

r_gpio_rx.c

GPIO API function

targets

rx631

r_gpio_rx631.c

RX631 data file

r_gpio_rx631.h

RX631 definition file

rx651

r_gpio_rx651.c

RX651 data file

r_gpio_rx651.h

RX651 definition file

r_mpc

r_mpc_rx_config.h

MPC configuration

r_mpc_rx_if.h

Header file for external public MPC API function

Page 11

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 6 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

src

r_mpc_rx.c

MPC API function

r_riic_rx

r_riic_rx_config.h

IIC configuration

r_riic_rx_if.h

Header file for external public IIC API function

r_riic_rx_pin_config.

h

PIN configuration for IIC use

src

r_riic_rx.c

IIC API function

r_riic_rx_private.h

IIC API definition file

targets

rx65n

r_riic_rx65n.c

RX651 IIC function

r_riic_rx65n_private.

h

RX651 definition file

r_sci

r_sci_rx_config.h

SCI configuration

r_sci_rx_if.h

Header file for external public SCI API function

src

r_sci_rx.c

SCI API function

r_sci_rx_platform.h

RX BSP SCI common definition

r_sci_rx_private.h

SCI API definition file

rx631

r_sci_rx631.c

RX631 SCI function

r_sci_rx631_data.c

RX631 data file

r_sci_rx631_private.

h

RX631 definition file

rx65n

r_sci_rx65n.c

RX651 SCI function

r_sci_rx65n_data.c

RX651 data file

r_sci_rx65n_private.

h

RX651 definition file

setu

p

ccrl

rl78g13

bin_include.asm

Binary file for include

cstart.asm

Startup routine

hwsetup.c

Hardware setting file

intprg.c

RL78G13 interrupt function

iodefine.h

RL78G13 register definition

machine.h

Header file for hardware control function

stkinit.asm

Stack area setting

vect.h

RL78G13 vector prototype

ccrx

rx631

inc

iodefine.h

RX631 I/O register definition

sbrk.h

Heap size definition

stacksct.h

Stack area setting

typedefine.h

Type definition

vect.h

RX631 vector prototype

src

dbsct.c

B/R section setting

hwsetup.c

Hardware setting file

intprg.c

RX631 interrupt function

resetprg.c

Startup routine

sbrk.c

Heap memory setting

vecttbl.c

RX631 vector table

rx651

inc

iodefine.h

RX651 ICU register definition

sbrk.h

Heap size definition

stacksct.h

Stack area setting

typedefine.h

Type definition

vect.h

RX651 vector prototype

src

dbsct.c

B/R section setting

hwsetup.c

Hardware setting file

intprg.c

RX651 interrupt function

resetprg.c

Startup routine

sbrk.c

Heap memory setting

vecttbl.c

RX651 vector table

gcc

rx631

inc

interrupt_handlers.h

Header file for RX631 interrupt function

iodefine.h

RX631 I/O register definition

machine.h

Header file for hardware control function

src

hardware_setup.c

Hardware setting file

interrupt_handlers.c

RX631 interrupt function

machine.c

Hardware control function

resetprg.c

Startup routine

Page 12

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 7 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

vector_table.c

RX631 vector table

rx651

inc

interrupt_handlers.h

Header file for RX651 interrupt function

iodefine.h

RX651 I/O register definition

machine.h

Header file for hardware control function

src

hardware_setup.c

Hardware setting file

interrupt_handlers.c

RX651 interrupt function

machine.c

Hardware control function

resetprg.c

Startup routine

vector_table.c

RX651 vector table

cpx3_api

cpx3_sap

g3

inc

r_adp_binstruct.h

Header file for ADP layer binary command

r_c3sap_g3_buffsiz

e.h

Buffer and stack definition file

r_c3sap_g3_depend

.h

Environmental dependent part definition file

r_c3sap_g3_if.h

Header file for G3 layer API function

r_eap_binstruct.h

Header file for EAP layer binary command

r_g3ctrl_binstruct.h

Header file for G3 layer binary command

r_g3mac_binstruct.h

Header file for MAC layer binary command

r_g3_cmd.h

G3 block command ID definition file

src

r_c3sap_adp.c

ADP layer API function

r_c3sap_adp_conve

rt.c

ADP layer convert function

r_c3sap_eap.c

EAP layer API function

r_c3sap_eap_conve

rt.c

EAP layer convert function

r_c3sap_g3.c

G3 layer API function

r_c3sap_g3.h

G3 layer definition file

r_c3sap_g3ctrl_con

vert.c

G3 layer convert function

r_c3sap_g3mac.c

MAC layer API function

r_c3sap_g3mac_co

nvert.c

MAC layer convert function

r_c3sap_g3_convert

.h

Header file for G3 block convert function

r_c3sap_g3_depend

.c

API function for environment dependent G3 layer

inc

r_adp_sap.h

ADP layer definition file

r_adp_statistics.h

Definition file for ADP layer statistics information

r_c3sap_api.h

CPX3 SAP API definition file

r_c3sap_config.h

CPX3 SAP configuration

r_eap_sap.h

EAP layer definition file

r_eap_statistics.h

Definition file for EAP layer statistics information

r_g3mac_sap.h

MAC layer definition file

r_g3mac_statistics.h

Definition file for MAC layer statistics information

r_g3_api.h

Header file for G3 layer API header file

r_g3_sap.h

G3 layer definition file

r_lml_statistics.h

Definition file for LMAC layer statistics information

r_sys_api.h

Header file for SYSTEM layer API header file

r_sys_sap.h

SYSTEM layer definition file

r_uif_statistics.h

Definition file for UART-IF statistics information

sys

inc

r_c3sap_sys_depen

d.h

Definition file for environment dependent system block

r_c3sap_sys_if.h

Header file for system block API function

r_constants.h

Definition file(handler) for SAP layer constant

src

r_c3sap_sys.c

System block API function

(not depending on environment)

r_c3sap_sys.h

Header file for system block API function(not

depending on environment )

r_c3sap_sys_conve

rt.c

System block convert function

r_c3sap_sys_conve

rt.h

Header file for system block convert function

r_c3sap_sys_depen

d.c

System block API function

(environment dependent)

r_c3sap_sys_thread

.c

CPX3 SAP pseudo thread function

Page 13

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 8 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

r_c3sap_sys_thread

.h

Header file for CPX3 SAP pseudo thread function

r_c3sap_sys_ver.h

CPX3 SAP version definition file

r_sys_binstruct.h

Header file for system block binary command

r_sys_cmd.h

System block command ID definition file

uif

inc

r_uif_sap_if.h

Header file for external public UIF API function

r_uif_thread_if.h

Header file for UIF API function

(IF/core)

src

core

r_uif_base.h

UIF core-based header file

r_uif_base_param.h

UIF core parameter definition file

r_uif_buff_declared.

c

UIF core buffer management function

r_uif_buff_declared.

h

Header file for UIF core buffer management function

r_uif_data_manage.

c

UIF core data management function

r_uif_data_manage.

h

Header file for UIF core data management function

r_uif_hdlc.h

HDLC packet definition file

r_uif_hdlc_process.

c

HDLC packet control function

r_uif_hdlc_process.

h

Header file for HDLC packet control

r_uif_intc.c

UIF transfer interrupt function

r_uif_intc.h

Header file for UIF transfer interrupt function

r_uif_rx_process.c

UIF reception control function

r_uif_rx_process.h

Header file for UIF reception control function

r_uif_statistics_inter

nal.h

UIF statistics information internal definition file

r_uif_tx_process.c

UIF transmission

control function

r_uif_tx_process.h

Header file for UIF

transmission control

function

if

r_c3sap_uif.c

UIF API function

r_c3sap_uif_drv.c

Part function within

UIF

r_c3sap_uif_drv.h

Header file for part

function within UIF

fw_download

inc

r_fw_download.h

Header file for R9A06G037 boot function

src

r_fw_download.c

R9A06G037 boot function

cpx3_fw

cpx3_fw_release.bin

Binary file for R9A06G037 firmware

cpx3_fw_release.h

Header file for R9A06G037 firmware

extern

common

inc

r_byte_swap.h

Header file for array/integer data convert function

r_config.h

Sample program setting configuration

r_io_vec.h

Header file for function connecting distributed data to

1 stream

r_mem_tools.h

Header file for memory tool function

r_typedefs.h

Type definition

src

r_byte_swap.c

Array/Integer data convert function

r_io_vec.c

Header file for function connecting distributed data to

1 stream

r_mem_tools.c

Memory tool function

crc

inc

r_crc32_api.h

Header file for CRC32 API function

src

r_crc32_api.c

CRC32 API function

led

inc

r_led_api.h

Header file for LED control API function

src

r_led_api.c

LED control API function

memory

inc

r_memory_api.h

Header file for memory management API function

src

r_memory_api.c

Memory management API function

queue

inc

r_queue_api.h

Header file for queue management API function

src

r_queue_api.c

Queue management API function

stdio

inc

r_stdio_api.h

Header file for console I/O API function

src

r_stdio_api.c

Console I/O API function

timer

inc

r_timer_api.h

Header file for software timer API function

src

r_timer_api.c

Software timer API function

project

e2s

rl78g13

G3PLC

.Certificationlinker

Linker file for certification build

.cproject

Tool chain setting file

Page 14

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 9 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

.Demolinker

Linker file for demo build

.info

Development environment information

.project

Project setting file

.Releaselinker

Linker file for release build

G3PLC

Release.launch

Debug setting file

makefile.init

Makefile initial setting

rx631

G3PLC

.Certificationlinker

Linker file for certification build

.cproject

Tool chain setting file

.Demolinker

Linker file for demo build

.info

Development environment information

.project

Project setting file

.Releaselinker

Linker file for release build

G3PLC

Release.launch

Debug setting file

makefile.init

Makefile initial setting

rx651

G3PLC

.Certificationlinker

Linker file for certification build

.cproject

Tool chain setting file

.Demolinker

Linker file for demo build

.info

Development environment information

.project

Project setting file

.Releaselinker

Linker file for release build

G3PLC

Release.launch

Debug setting file

makefile.init

Makefile initial setting

sample_app

extern

flash

inc

r_demo_nvm_proce

ss.h

Header file for NVM management function

r_demo_print.h

Header file for string operation function

r_demo_status2text.

h

Header file for status information and string convert

function

r_flash_lib.h

Header file for FLASH driver wrapper function

r_flash_usage_map.

h

Macro definition file for address acquisition in NVM

area

src

r_demo_nvm_proce

ss.c

NVM management function

r_demo_print.c

String operation function

r_demo_status2text.

c

Status information and string convert function

r_flash_lib.c

FLASH driver wrapper function

ipv6

inc

r_check_sum.h

Header file for checksum calculation function

r_icmp_v6.h

icmp v6 definition file

r_ipv6_headers.h

IPv6 packet definition file

r_udp_headers.h

UDP packet definition file

src

r_check_sum.c

Checksum calculation function

r_icmp_v6.c

ICMP v6 packet control function

r_ipv6_headers.c

IPv6 packet control function

r_udp_headers.c

UDP packet control function

inc

r_cpx3_scramble_m

atrix.h

Encryption matrix definition file

r_demo_api.h

Header file for wrapper function of calling CPX3

SAP(MAC,ADP)

r_demo_app.h

Header file for main application

r_demo_app_eap.h

Header file for CPX3 SAP wrapper function (EAP)

r_demo_app_thread

.h

Header file for application pseudo thread

r_demo_app_ver.h

Version definition file of sample application

r_demo_common.h

Header file for IPv6 packet control API function

r_demo_config.h

Header file for configuration of application

r_demo_ib_access.

h

Header file for IB access API function

r_demo_main.h

Header file for main function

r_demo_metric_com

putation.h

Header file for link cost calculation

r_demo_os_wrapper

.h

Header file for OS wrapper function

r_demo_parameters

.h

Configuration parameter definition file

Page 15

G3-PLC Sample Program User's Manual 2. Software Structure

R11UM0114EJ0101 Rev.1.01 Page 10 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

r_demo_statistics.h

Header file for statistics information /log acquisition

r_demo_sys.h

Header file for system menu API function

r_demo_tools.h

Header file for string control API function

src

main.c

Main function

r_demo_api.c

CPX3 SAP wrapper function (MAC,ADP)

r_demo_app.c

Main function for sample application

r_demo_app_thread

.c

Pseudo thread for applications

r_demo_bootstrap.c

Network start function

r_demo_common.c

API function for IPv6 packet control

r_demo_config.c

API function for configuration information

management

r_demo_eap.c

CPX3 SAP wrapper function (EAP)

r_demo_g3_cb.c

CPX3 SA callback function

r_demo_ib_access.c

API function for IB access

r_demo_main.c

Sample application start

r_demo_metric_com

putation.c

API function for link cost calculation

r_demo_os_wrapper

.c

OS wrapper function

r_demo_parameters

.c

Configuration parameter

r_demo_statistics.c

API function for statistics information / log acquisition

r_demo_sys.c

API function for system menu

r_demo_sys_cb.c

Callback function for system menu

r_demo_tools.c

String control API function

Page 16

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 11 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

3.Project Settings

3.1 Start e2studio

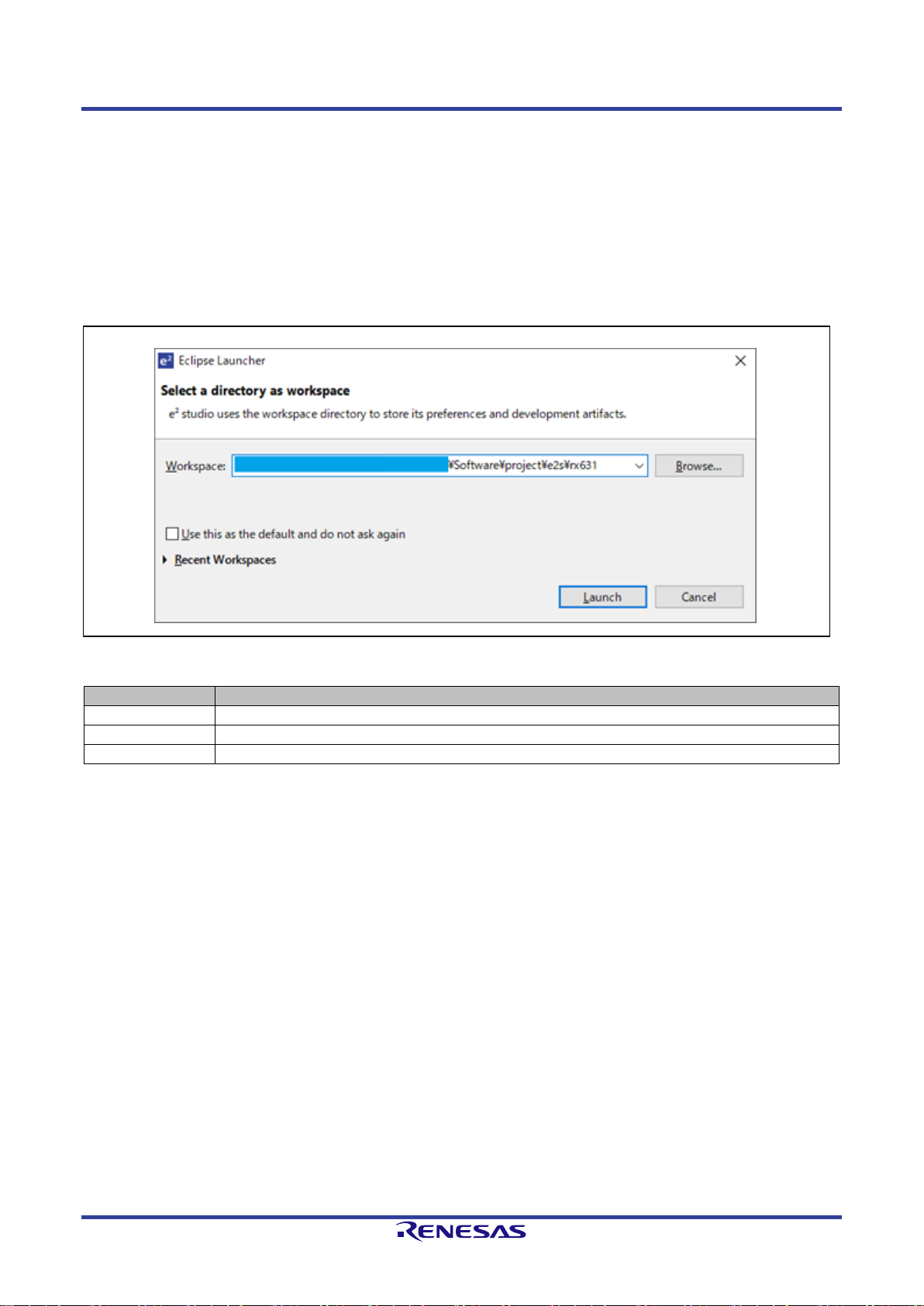

3.1.1 Workspace settings

Start e2studio and set up the following workspace. For this sample program, a project is prepared for each

evaluation board.

Figure 3-1 Select workspace

Evaluation board

Workspace path

J70D1/J70D2

(Installed directory path)\Software\project\e2s\rx631

J80D1

(Installed directory path)\Software\project\e2s\rx651

J80D2

(Installed directory path)\Software\project\e2s\rl78g13

Page 17

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 12 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

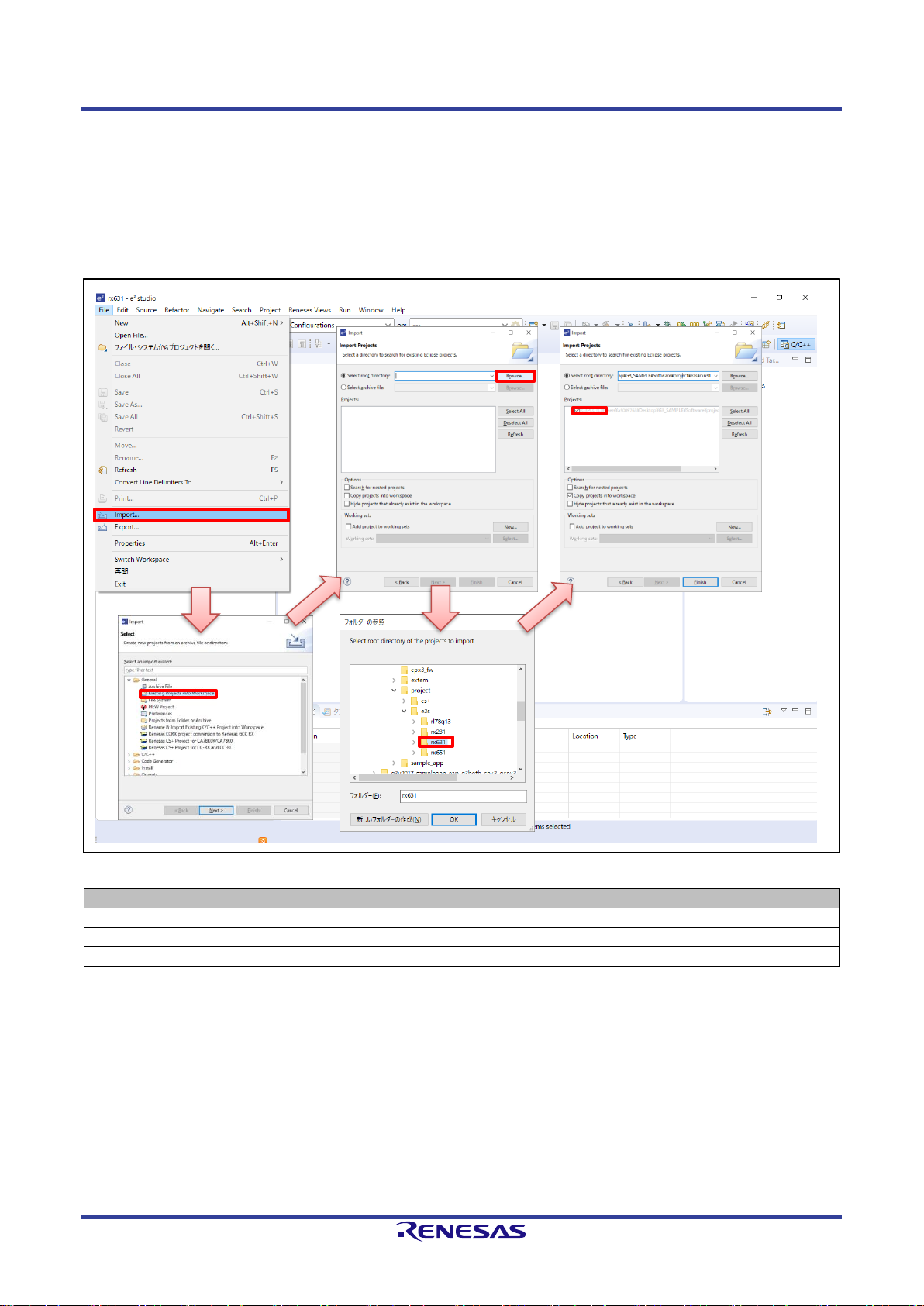

3.1.2 Import project

The project will be imported by the following procedure.

1. File -> Import

2. Existing Project into Workspace

3. Set the following path in the root directory

4. Select G3PLC

Figure 3-2 Import Project

Evaluation board

Root directory path

J70D1/J70D2

(Installed directory path)\Software\project\e2s\rx631

J80D1

(Installed directory path)\Software\project\e2s\rx651

J80D2

(Installed directory path)\Software\project\e2s\rl78g13

G3PLC

[1]

[2]

[3]

[4]

Page 18

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 13 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

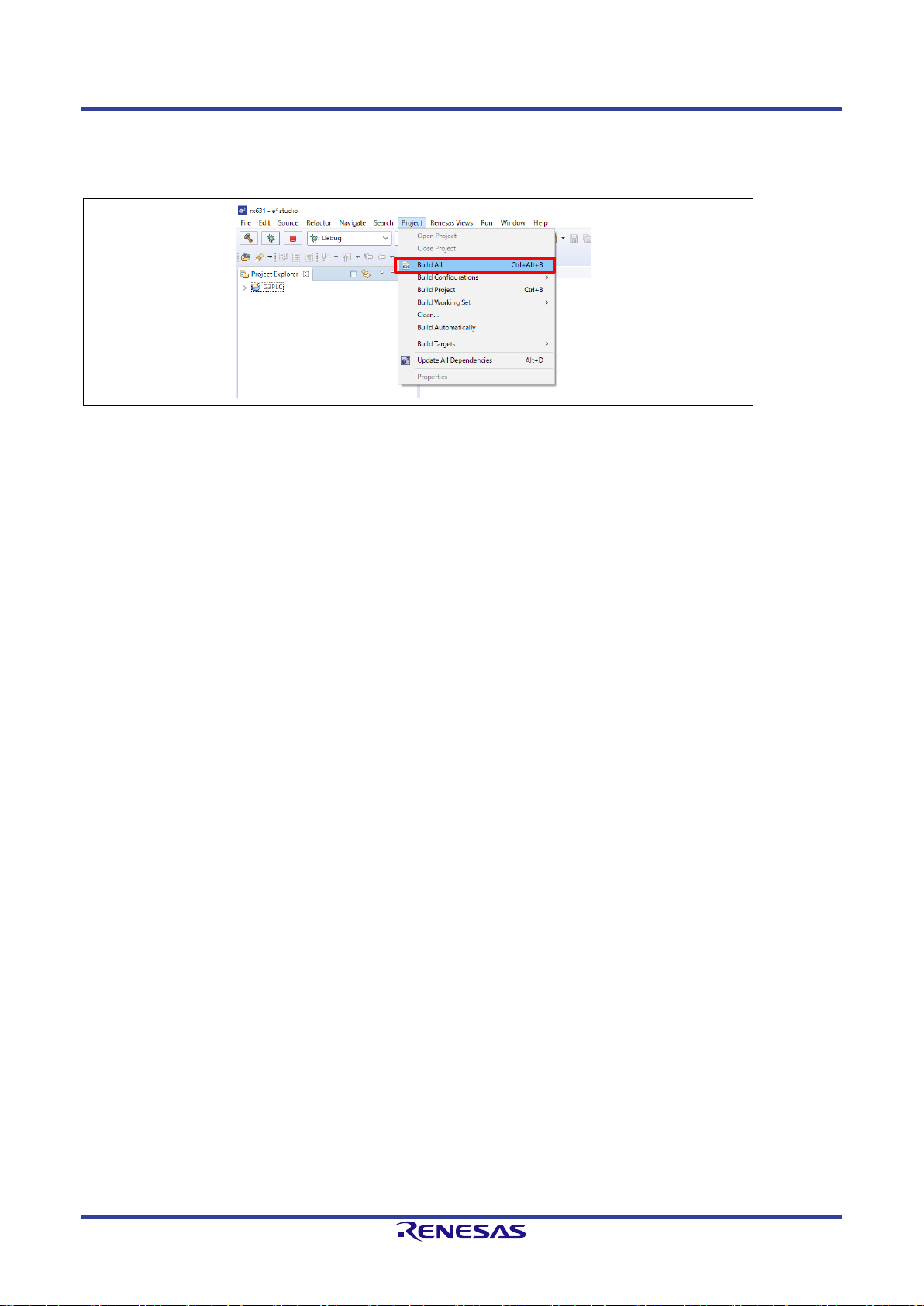

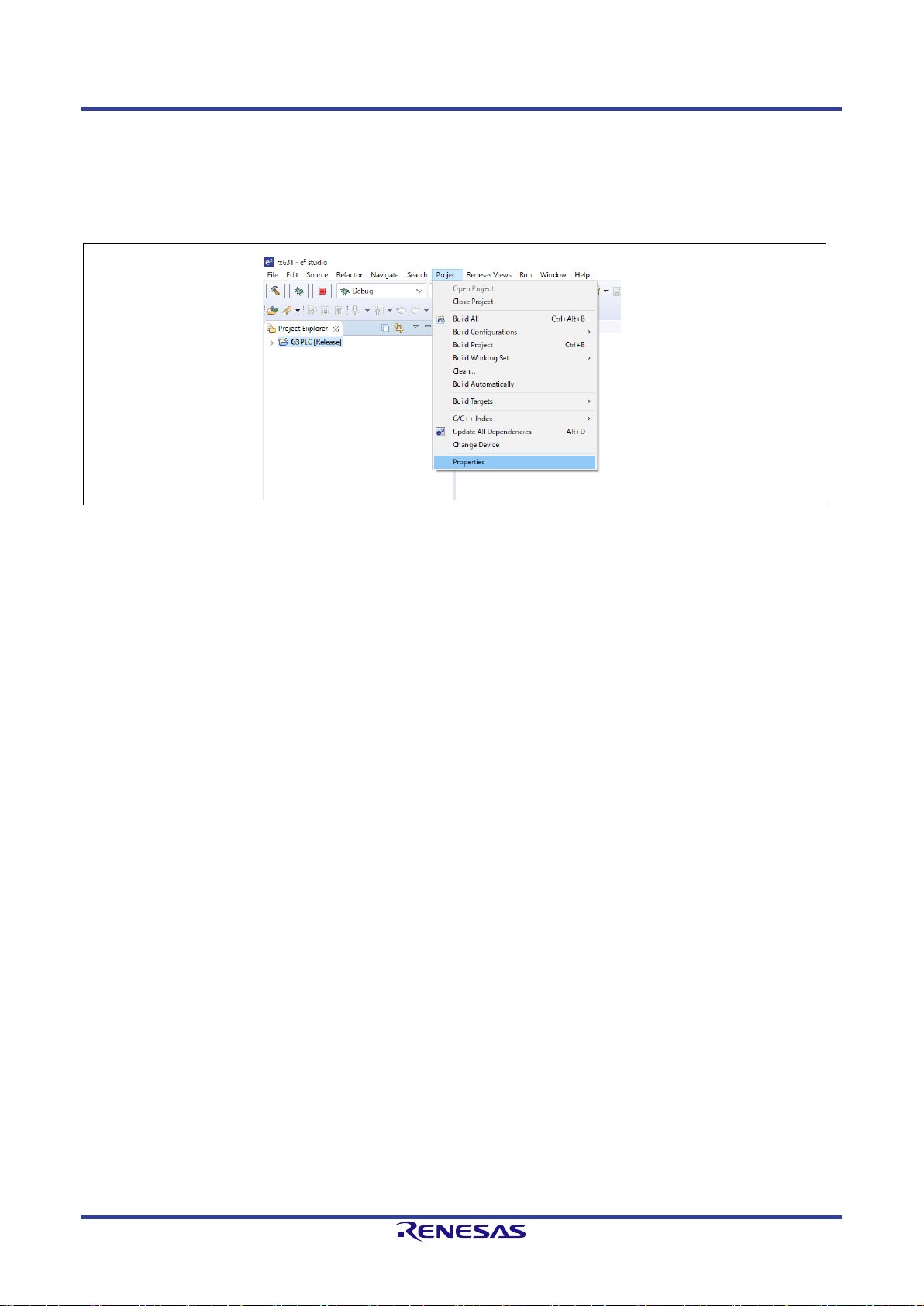

3.1.3 Building project

Select Project -> Build All and do the build.

Figure 3-3 Build project

Page 19

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 14 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

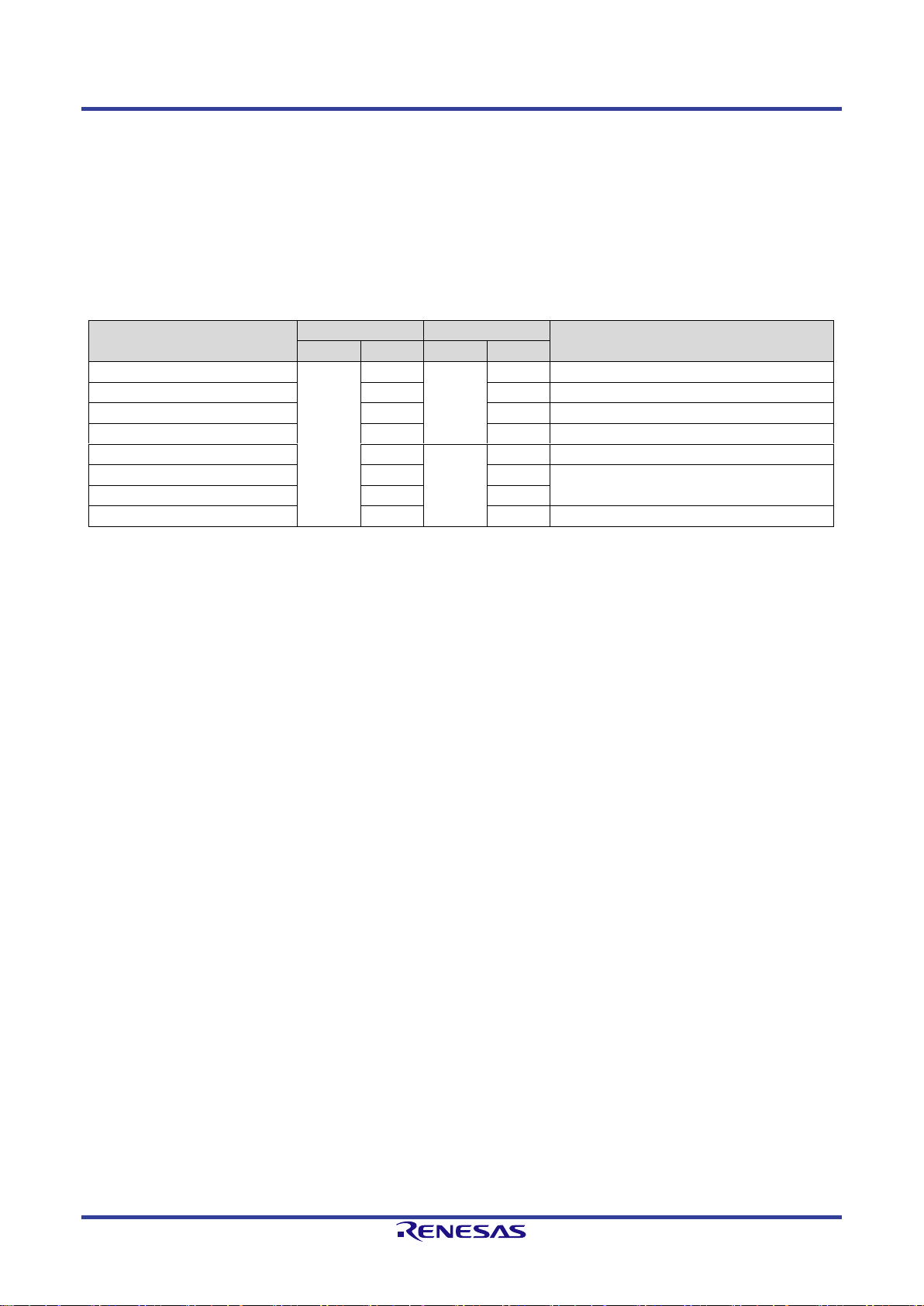

3.2 Built Environment

There are 3 types of built environments for 1 project, and the parameter to be set can be switched at startup.

The Macro definitions to be defined vary depending on the built environment. For some built environments,

the setting can be changed by DipSw. The DipSw-bit is assigned as PORT_ID and managed by common

control as DipSw allocation varies depending on the evaluation board type. Table 3-1 shows the relationship

between DipSw and PORT_ID. Refer to the start guide (G3-PLC Sample Application Start Guide for GCPX3

board) for functions in detail.

Table 3-1 DipSw setting

PORT ID

J70D1/J70D2

J80D1/J80D2

Function

SW

No

SW

No

PORT_ID_AUTO_MODE

SW1

1

SW9

1

Application mode (Refer to 3.3) setting

PORT_ID_CERT_MODE

2

2

Application mode (Refer to 3.3) setting

- 3 3

-

- 4 4

-

PORT_ID_ROUTE_TYPE

5

SW8

1

Route type setting

PORT_ID_BANDPLAN_1

6

2

BandPlan setting

PORT_ID_BANDPLAN_0

7

3

PORT_ID_DEVICE_TYPE

8

4

Device type (Coordinator/Peer) setting

This program provides 3 types of built environments.

・Release build :When ”Release” is selected for the build configuration of the development

environment. This manual is based on this built environment if not explicitly stated.

The parameters to be set at startup will be reflected by the DipSw setting.

・Demo build :When “Demo” is selected for the build configuration of the development environment.

The parameters will be reflected based on data recorded in NVM. The memory used

for NVM varies depending on the evaluation board, yet NVM is accessed from via the

flash control unit(Chapter 4.1.5) in this program. The following macro is defined in the

project file. R_DEFINE_APP_MODE=1

・Certification mode :When “Certification” is selected for the build configuration of the development

environment. This configuration is used to execute the authentication test by

connecting to an authentication device supporting G3. After power supply, the sample

application will automatically work and start test communication with the authentication

device. This mode is driven by the G3 authentication parameters, and therefore it is

not possible to communicate with the evaluation board running on the Release/Demo

build. The following macro is defined in the project file. R_DEFINE_APP_MODE=2

Details on macros are explained in Chapter 3.3.

Page 20

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 15 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

3.3 Macro Definition

This section describes the macro definitions to be set on the project.

3.3.1 R_BOARD_TYPE

This is the definition for determining the evaluation board that will work the sample application.

Table 3-2 R_BORAD_TYPE description

Define name

Value

Description

R_BOARD_NOT_SET

0

Do not use

R_BOARD_G_CPX3

5

J70/D1 and J70/D2 evaluation board.

R_BOARD_J80D1

9

J80/D1 evaluation board.

R_BOARD_J80D2

10

J80/D2 evaluation board.

3.3.2 R_DEFINE_APP_MODE

By defining this macro, it is possible to change the parameter to be set at startup . Table 3-3 shows setting

values for this macro.

Table 3-3 R_DEFINE_APP_MODE setting value

Definition

Value

R_DEMO_APP_MODE_NORMAL

0u

R_DEMO_APP_MODE_DEMO

1u

R_DEMO_APP_MODE_CERT

2u

Table 3-4 shows parameters to be set at startup.

Table 3-4 Relationship between R_DEFINE_APP_MODE and parameters

Parameter

R_DEFINE_APP_MODE

R_DEMO_APP_MODE_NORM

AL

R_DEMO_APP_MODE_DEMO

R_DEMO_APP_MODE_CERT

bandPlan

Select by DipSw

(PORT_ID_BANDPLAN_0,

PORT_ID_BANDPLAN_1)

Data value recorded in NVM

R_G3_BANDPLAN_

CENELEC_A when no effective

data exist

Select by DipSw

(PORT_ID_BANDPLAN_0,

PORT_ID_BANDPLAN_1)

deviceType

Select by DipSw

(PORT_ID_DEVICE_TYPE)

Data value recorded in NVM

R_ADP_DEVICE_

TYPE_PEER when no effective

data exist

Select by DipSw

(PORT_ID_DEVICE_TYPE)

startMode

(appMode)

*1

Select by DipSw

(PORT_ID_AUTO_MODE,

PORT_ID_CERT_MODE)

Data value recorded in NVM

R_DEMO_MODE_CUI when no

effective data exist

Set R_DEMO_MODE_CERT

routeType

Select by DipSw

(PORT_ID_ROUTE_TYPE)

Data value recorded in NVM

R_G3_ROUTE_TYPE_NORMA

L when no effective data exist

R_G3_ROUTE_TYPE_JP_B for

ARIB depending on bandPlan

R_G3_ROUTE_TYPE_NORMA

L for other than the above

*1 application mode

Page 21

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 16 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

The sample program defines the following 3 modes as an application mode.

・CUI mode(R_DEMO_MODE_CUI) :Coordinator or Peer selectable by the user.

・AUTO mode(R_DEMO_MODE_AUTO) :Start operation according to PORT_ID_DEVICE_TYPE.

・CERT mode(R_DEMO_MODE_CERT) :Start test communication with the authentication device by

automatically starting the sample application.

3.3.3 R_RL78_PLC

This macro definition is used to switch the process depending on the microcontroller type (RL78/RX series).

Table 3-5 shows parameters to be changed by this macro definition.

Table 3-5 Parameter to be changed by the definition R_RL78_PLC.

Parameter

Defined (RL78G13)

Not defined (RX)

Far modifier

Yes

No

Timer

16-bit timer

8-bit timer and

compare match timer

The number of stages in the queue

3 8 Data size to be saved in 1 stage of the queue

1400 bytes

1500 bytes

Refer to 4.5.2 for the queue usage.

3.3.4 R_DEFINE_APP_BOOT

This macro definition is used to switch the CPX3 boot mode. Table 3-6 shows setting values for this macro.

Table 3-6 R_DEFINE_APP_BOOT setting value

Definition

Value

R_DEMO_APP_UART_BOOT

0u

R_DEMO_APP_SROM_BOOT

1u

Table 3-7 shows parameters to be changed by this macro definition.

Table 3-7 Parameter to be changed by definition R_DEFINE_APP_BOOT

Parameter

R_DEMO_APP_UART_BOOT

R_DEMO_APP_SROM_BOOT

R_DEFINE_APP_BOOT

Boot by downloading FW via UART from

the host microcontroller.

Boot by downloading FW saved in the

serial flash memory connecting to CPX3.

Page 22

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 17 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

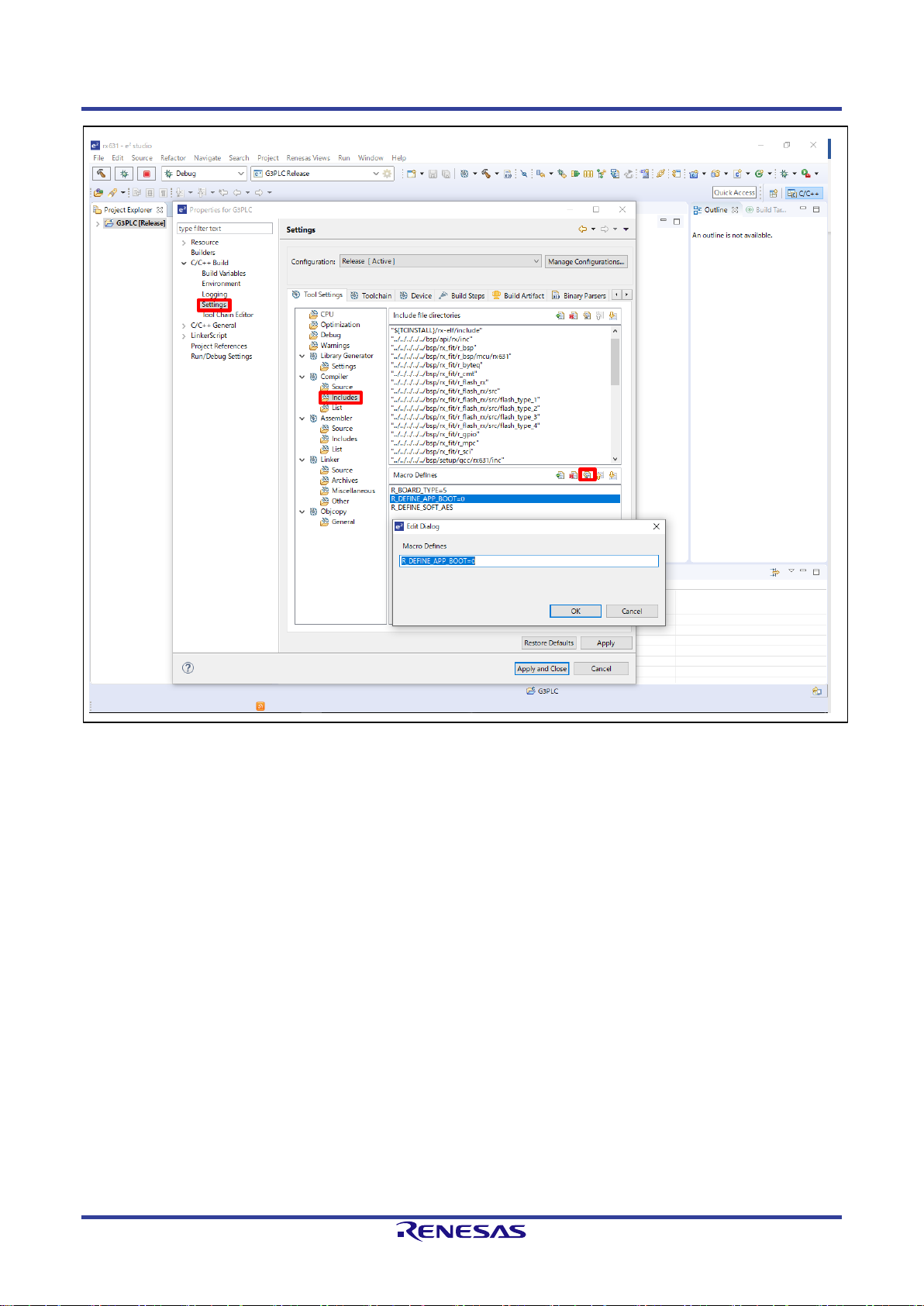

In the e2studio project, the procedure to change the macro definition is as follows.

1. Project -> Properties

2. C++ Build -> Settings

3. Tool Settings Tab-> Compiler -> Includes

4. Change Macro define value

Figure 3-4 Change macro definition (1/2)

Page 23

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 18 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Figure 3-5 Change macro definition (2/2)

Page 24

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 19 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

3.4 Memory Map

The section layouts for each MCU are shown below.

3.4.1 RX631

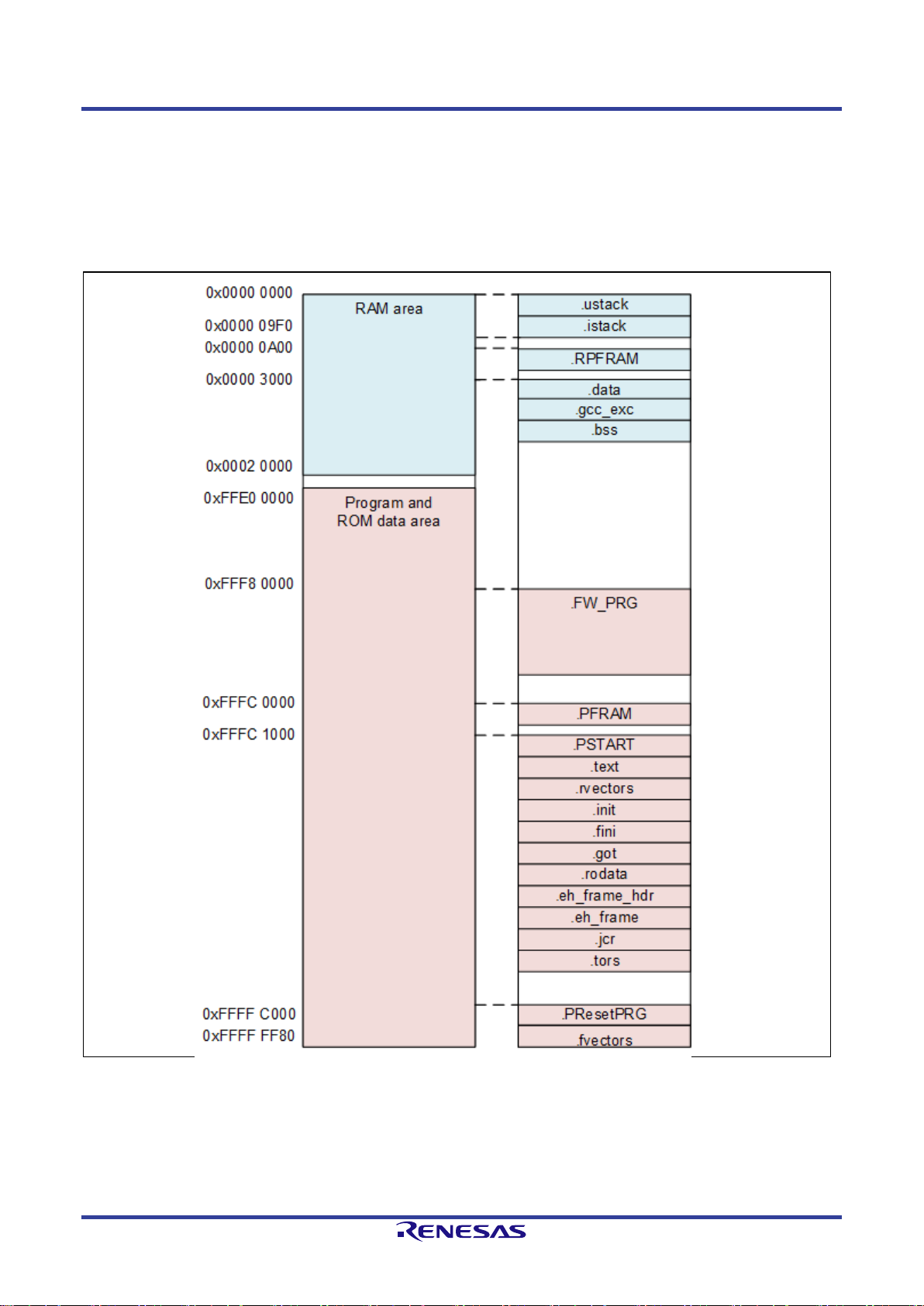

Figure 3-6 shows the section layout for the sample program and Table 3-8 describes each section in detail.

Figure 3-6 Section layout (RX631(R5F5631EDxFP))

Page 25

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 20 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Table 3-8 Section list (RX631)

Section

Section start address

Description

.ustack

0x00000000

User stack section.

Allocation size is 0 as it is not used.

.istack

0x000009F0

Interrupt stack section.

.RPFRAM

0x00000A00

Section for expanding sections of the PFRAM section to RAM.

.data

0x00003000

Section for variables with the initial value.

.gcc_exc

Located after.data

Section for GCC exceptions.

.bss

Located after.gcc_exc

Section for variables without the initial value.

.FW_PRG

0xFFF80000

Section for CPX3 FW

.PFRAM

0xFFFC0000

Section to mapping Flash driver to operate in RAM

.PSTART

0xFFFC1000

Section for startup code.

.text

Located after .PSTART

Section for program codes.

.rvectors

Located after .text

Section for variable (interrupt) vector table.

.init

Located after.rvectors

Section for initial setting codes.

.finit

Located after.init

Section for end codes.

.got

Located after.finit

Section for global offset table.

.rodata

Located after.got

Section for ROM data.

.eh_frame_hdr

Located after.rodata

Section for exceptional handler data.

.eh_frame

Located after.eh_frame_hdr

Section for exceptional handler frame.

.jcr

Located after.eh_frame

Java section.

.tors

Located after.jcr

Section for C++ constructor/ destructor.

.PResetPRG

0xFFFFC000

Section assigned with the function to be executed after reset.

.fvectors

0xFFFFFF80

Section for fixed(exceptional)vector table.

Page 26

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 21 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

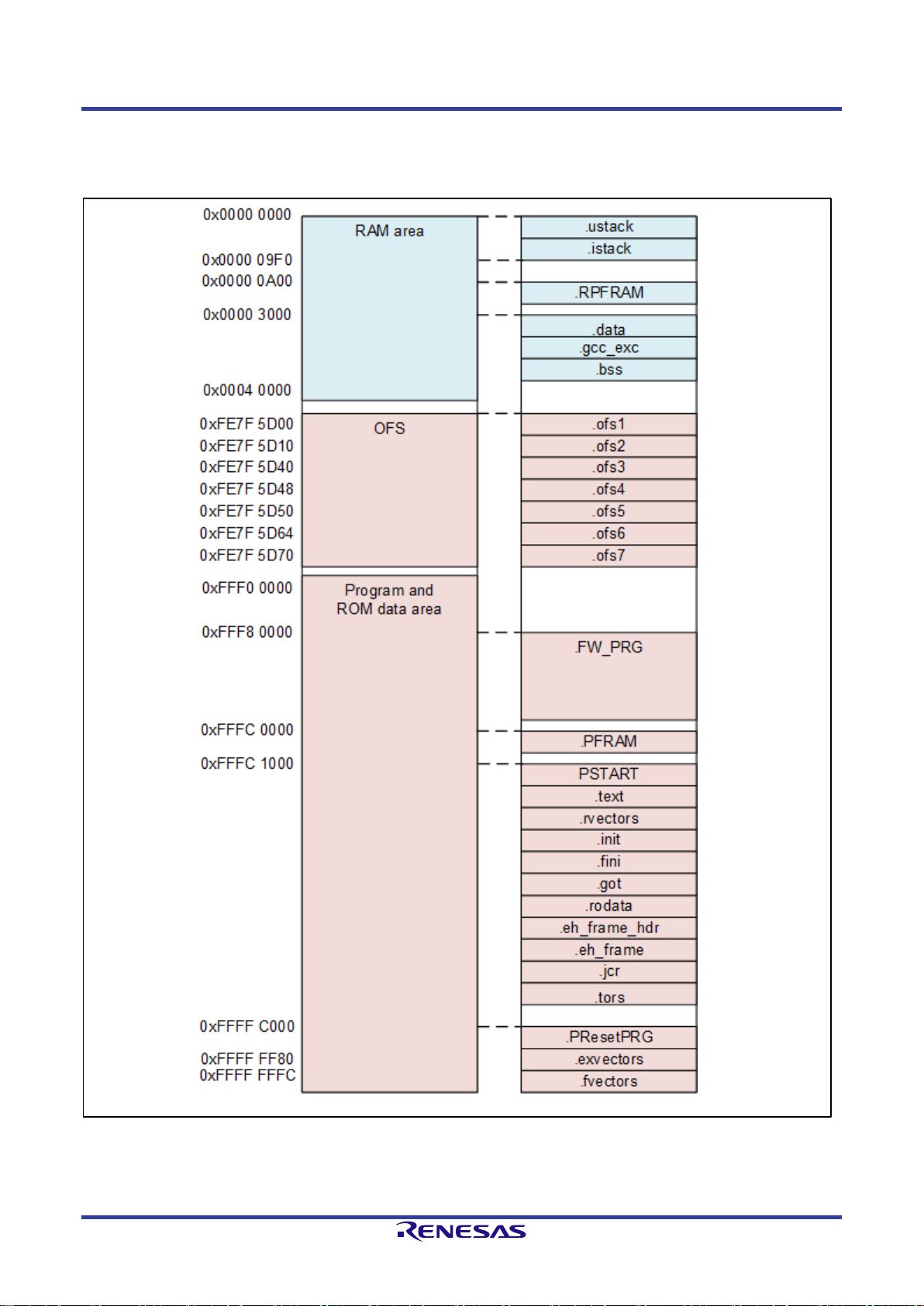

3.4.2 RX651

Figure 3-7 shows the section layout for the sample program, and Table 3-9 describes each section in detail.

Figure 3-7 Section layout (RX651(R5F56519AxFP))

Page 27

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 22 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Table 3-9 Section list (RX651)

Section

Section start address

Description

.ustack

0x00000000

User stack section.

Allocation size is 0 as it is not used.

.istack

0x000009F0

Interrupt stack section.

.RPFRAM

0x00000A00

Section for expanding sections of the PFRAM section to RAM.

.data

0x00003000

Section for variables with the initial value.

.gcc_exc

Located after.data

Section for GCC exceptions.

.bss

Located after.gcc_exc

Section for variables without the initial value.

.ofs1

0xFE7F5D00

Option setting memory section.

.ofs2

0xFE7F5D10

Option setting memory section.

.ofs3

0xFE7F5D40

Option setting memory section.

.ofs4

0xFE7F5D48

Option setting memory section.

.ofs5

0xFE7F5D50

Option setting memory section.

.ofs6

0xFE7F5D64

Option setting memory section.

.ofs7

0xFE7F5D70

Option setting memory section.

.FW_PRG

0xFFF80000

Section for CPX3 FW

.PFRAM

0xFFFC0000

Section to mapping Flash driver to operate in RAM

.PSTART

0xFFF00000

Section for startup code.

.text

Located after .PSTART

Section for program codes.

.rvectors

Located after .text

Section for variable (interrupt) vector table.

.init

Located after.rvectors

Section for initial setting codes.

.finit

Located after.init

Section for end codes.

.got

Located after.finit

Section for global offset table.

.rodata

Located after.got

Section for ROM data.

.eh_frame_hdr

Located after.rodata

Section for exceptional handler data.

.eh_frame

Located after.eh_frame_hdr

Section for exceptional handler frame.

.jcr

Located after.eh_frame

Java section.

.tors

Located after.jcr

Section for C++ constructor/ destructor

.PResetPRG

0xFFFFC000

Section assigned with the function to be executed after reset.

.exvectors

0xFFFFFF80

Section for exceptional vector table.

.fvectors

0xFFFFFFFC

Section for fixed vector table.

Page 28

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 23 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

3.4.3 RL78G13

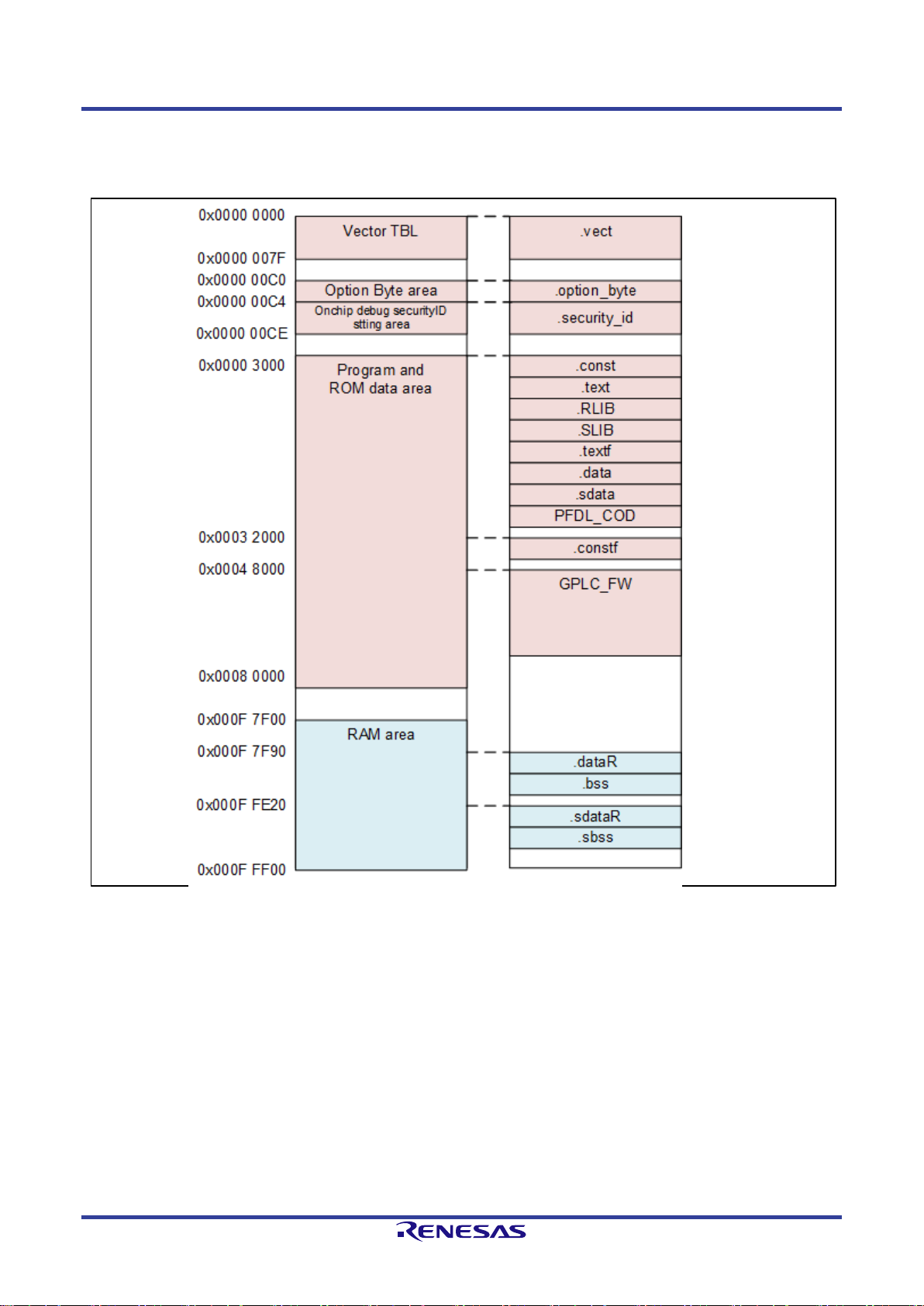

Figure 3-8 shows the section layout for the sample program, and Table 3-10 describes each section in detail.

Figure 3-8 Section layout (RL78G13(R5F100GL))

Page 29

G3-PLC Sample Program User's Manual 3. Project Settings

R11UM0114EJ0101 Rev.1.01 Page 24 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Table 3-10 Section list (RL78G13)

Section

Section start address

Description

.vect

0x00000000

Section for vector table.

.option_byte

0x000000C0

Section for optional bytes.

.security_id

0x000000C4

Section for security ID.

.const

0x0000300

Section for ROM data(near area allocation).

.text

Located after .const

Section for program codes(near area allocation).

.RLIB

Located after.text

Section for Runtime/Library codes.

.SLIB

Located after.RLIB

Section for standard library codes.

.textf

Located after.SLIB

Section for program codes(far area allocation).

.data

Located after.textf

Section for variables with the near initial value.

.sdata

Located after.data

Section for variables with the initial value( variables of saddr

allocation ).

.PFDL_COD

Located after.sdata

Section for data flash library codes.

.constf

0x00032000

Section for ROM data(far area allocation).

.GPLC_FW

0x00048000

Section for CPX3 FW.

.dataR

0x000F7F90

Section to be mapped from ROM to RAM.

.bss

Located after.dataR

Section for variables without the initial value ( near area

allocation).

.sdataR

0x000FFE20

Section to be mapped from ROM to RAM.

.sbss

Located after.sdataR

Section for variables without the initial value(variables of saddr

allocation ).

Page 30

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 25 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

4.Sample Program

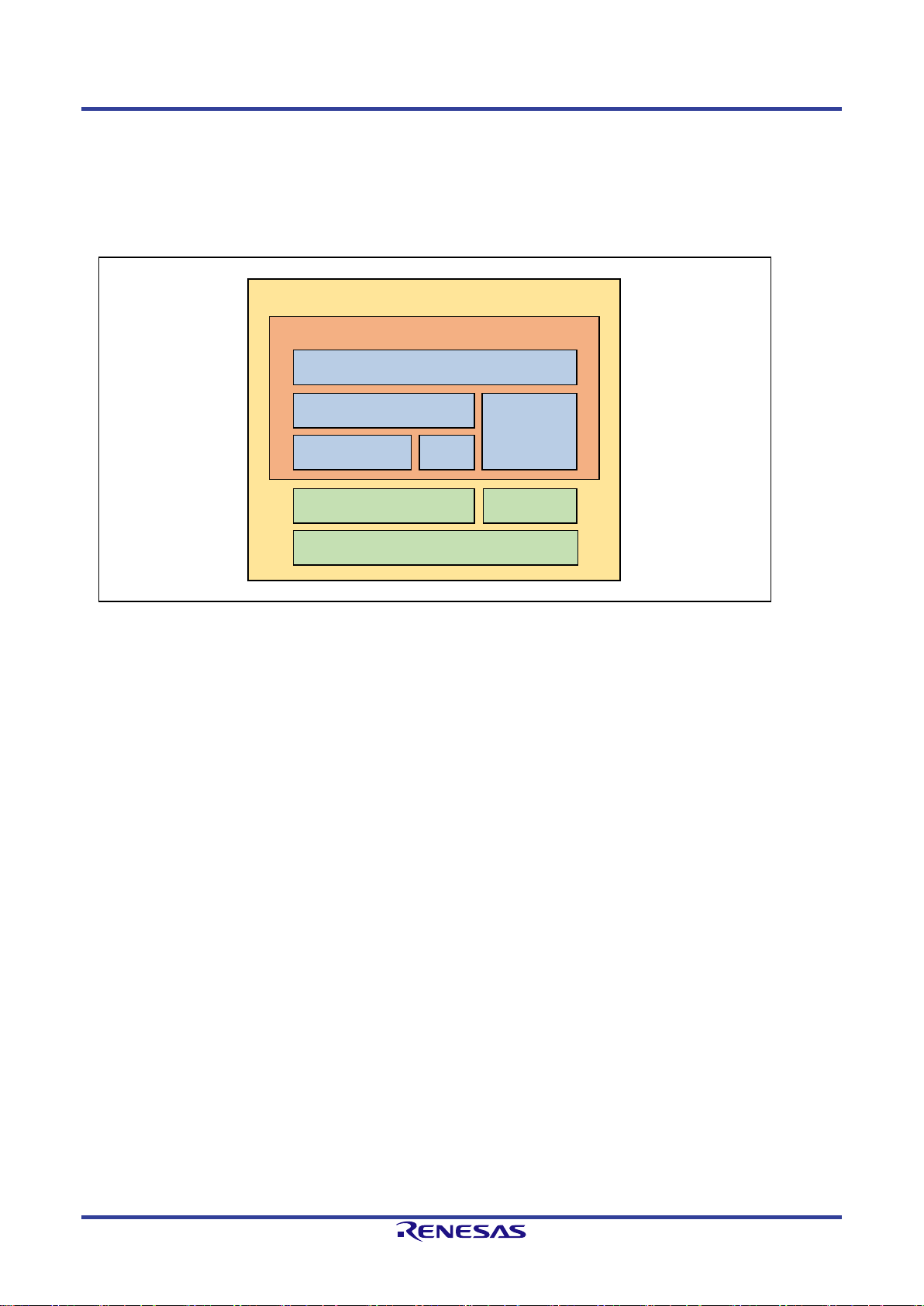

This sample program consists of the G3-PLC sample application unit, BSP unit ,CPX3 SAP unit, and common

processing unit and operates on the framework using timer interrupts after startup sequence initialization.

Refer to Chapter 4.5 for the framework in detail.

Figure 4-1 Sample program block diagram

4.1 G3-PLC Sample Application

The G3-PLC sample application consists of process blocks from the command processing unit,G3 processing

unit,G3 API wrapper unit,IPV6 unit and flash control unit. The overview of each process block is as below:

(1) Command processing unit :provides user interface(CUI) to control sample applications.

(2) G3 processing unit :provides functions used for G3-PLC communication process.

(3) G3 API wrapper :provides the wrapper layer to convert CPX3 SAP API from asynchronous to

synchronous.

(4) IPV6 unit :provides function to generate/analyze IPV6 packets.

(5) Flash control unit :provides function to manage communication parameters.

The sample application performs initialization in the main function and calls the function R_DEMO_Main().

The function R_DEMO_Main() executes command process and G3 process for user interfaces. Figure 4-2

and Figure 4-3 show process flows of the main function and the function R_DEMO_Main() respectively.

Sample program

G3-PLC sample application

Command processing unit

G3 processing unit

CPX3 SAP

G3 API wrapper

BSP

IPV6

Flash control

unit

Common

processing

Page 31

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 26 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Figure 4-2 Main function process flow

(1) Preform initialization to control LED on the evaluation board

(2) Set the CPX3FW boot mode(Setting CPX3 BOOT0 terminal level ).

(3) Perform standard I/O initialization such as terminal software(PC) and debug output(PC) etc.

(4) Initialize the software timer.

(5) Execute demo application main process.

Page 32

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 27 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Figure 4-3 The function R_DEMO_Main process flow

(1) Initialize CPX3 SAP and boot CPX3.

(2) Initialize the flash driver.

(3) Startup the thread for applications.

(4) Check the validity of the NVM area (check presence/absence of SyncWord). When it is judged as invalid,

the default value will be written into the NVM area.

(5) Set the communication parameter. Note that the setting value varies depending on the built environment.

Refer to 4.1.1.1 for details.

(6)(7) When the application mode (appMode) is AUTO mode/CERT mode, the function R_DEMO_App() will

be executed. For the CUI mode, the function R_DEMO_AppMainMenu() will be executed.

Page 33

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 28 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

4.1.1 Application Control Parameters

The sample application has control parameters such as table size and LQI threshold values retained internally

for G3-PLC communication. It also has management information as a configuration such as whether operating

on Coordinator or Peer and BandPlan etc.

4.1.1.1 Control Parameters

There are 3 types of control parameters for CPX3 or for applications. By defining R_PROFILE_DEFAULT,

R_PROFILE_METERING or R_PROFILE_NO_HOP as a header file r_demo_parameters.h, the parameter

setting value changes partly. In the sample application, R_PROFILE_METERING is defined for parameter

setting for meter applications. For no hop application define R_PROFILE_NO_HOP and the other application

define R_PROFILE_DEFAULT. Table 4-1 and Table 4-2 show parameters to be set for CPX3. Table 4-3 show

parameters used only for applications.

Table 4-1 CPX3 setting parameters(when r_demo_parameters.h: Common profile)

Parameter

Definition

Value

Neigbour table size

R_DEMO_G3MAC_NEIGBOUR_TABL

E_SIZE

500

Device table size

R_DEMO_G3MAC_DEVICE_TABLE_S

IZE

500

adpdBuffNum

R_DEMO_ADP_ADPD_DATA_QUEUE

_SIZE

2

Routing table size

R_DEMO_ADP_ROUTING_TABLE_SI

ZE

500

The maximum PAN descriptor value

R_DEMO_ADP_MAX_PAN_DESCRIP

TORS

64

LBP buffer size

R_DEMO_EAP_LBP_BUFF_SIZE

8

Client Info table size

R_DEMO_EAP_CINFO_TABLE_SIZE

64

Interval for frame counter indications

R_FRAMECOUNT_INTERVAL

0x100

SNR offset (CENELEC-A)

R_VAL_MAC_OFFSET_SNR_CA

0xFD

SNR offset (ARIB)

R_VAL_MAC_OFFSET_SNR_ARIB

0xFA

SNR offset (FCC)

R_VAL_MAC_OFFSET_SNR_FCC

0xFA

TMR Indication enable/disable setting

R_VAL_MAC_TMR_IND_ENABLE

R_TRUE

Route Indication enable/disable setting

R_VAL_ADP_ROUTE_IND_ENABLE

R_TRUE

RREP Indication enable/disable setting

R_VAL_ADP_RREP_IND_ENABLE

R_TRUE

SATT enable / disable setting

R_VAL_PHY_SATT_CTRL_DISABLE

R_FALSE

Page 34

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 29 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Table 4-2 CPX3 setting parameters(when r_demo_parameters.h: Individual profile )

Parameter

Definition

Value

Default

Metering

The maximum number of hops

R_VAL_ADP_MAX_HOPS

8

14

Whether to enable default route to Coordinator or not

R_VAL_ADP_DEFAULT_COO

RD_ROUTE_ENABLED

R_TRUE

R_TRUE

The maximum join process wait time

R_VAL_ADP_MAX_JOIN_WA

IT_TIME

20

180

Threshold value to judge the communication status.

When the LQI(Link quality indicator) becomes lower

than this value, the communication is judged as

disconnected.

R_VAL_ADP_LOW_LQI

0

52

Threshold value to judge the communication status.

When the LQI(Link quality indicator) becomes higher

than this value, the communication is judged as fully

established.

R_VAL_ADP_HIGH_LQI

255

100

Threshold value to judge the communication status.

When the LQI(Link quality indicator) becomes lower

than this value, the communication is judged as Weak

Link.

R_VAL_ADP_WEAK_LQI

52

58

Kq value

R_VAL_ADP_KQ

10

30

Krt value

R_VAL_ADP_KRT

0

8

Controls the default disable routing when

routeType=ROUTE_TYPE_NORMAL

R_VAL_ADP_DEFAULT_ROU

TING_DISABLE

R_FALSE

R_FALSE

adpNetTraversalTime to be used

R_VAL_ADP_NET_TRAVERS

AL_TIME

20

40

adpRREPWait to be used

R_VAL_ADP_RREP_WAIT

4 8 macMaxBe to be used

R_VAL_MAC_MAX_BE

8 9 macMinBe to be used

R_VAL_MAC_MIN_BE

3 3 macA to be used

R_VAL_MAC_A

8

3

macBeaconRandomizationWindowLength to be used

R_VAL_MAC_BEACON_RAN

D_WIDTH

12

45

macBroadcastDataTxTimeout to be used

R_VAL_MAC_BCAST_TX_TI

MEOUT

30 5 macRetryMaxCw to be used

R_VAL_MAC_RETRY_MAC_

CW

R_FALSE

R_FALSE

Table 4-3 Application setting parameter (when r_demo_parameters.h: Individual profile)

Parameter

Definition

Value

Default

Metering

The minimum LQI value during the initial scanning

R_MIN_JOIN_LQI_START

80

80

LQI decreasing step width after the second scanning

R_MIN_JOIN_LQI_STEP

5

5

Wait time after completing the route scanning to the

next scanning

R_WAIT_BETWEEN_DISCOVE

RIES

3000

3000

Route scanning duration

R_SCAN_DURATION

15

90

The number of re-transmissions when joining the

same LBA

R_JOIN_RETRYNUM_TO_SAM

E_LBA

2 2 The maximum number of retries when joining the

same PAN

R_JOIN_RETRYNUM_PER_DIS

COVERY

3

3

Wait time to rejoining

R_WAIT_BETWEEN_JOINREQ

5000

5000

LQI threshold value for the initial scanning

R_WEAK_LQI_TH

60

60

Whether to execute route scanning after joining or not

R_ROUTE_DISCOVERY_AFTE

R_JOIN

R_FALSE

R_TRUE

Page 35

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 30 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

4.1.1.2 Configration

The management information is retained in global variable g_demo_config which is of type r_demo_config_t

as a sample application configuration. The information to be retained after power off will be saved regularly in

NVM area. Refer to Chapter 4.1.5 for details. The setting value varies depending on the define

macro(R_DEFINE_APP_MODE) after initialization processing. The setting values for each mode is shown

below. The configuration can be changed by the user command input. Table 4-4, Table 4-5 and Table 4-6

shows the list of menu commands and change methods.

Table 4-4 Sample application configuration (Release build)

Item

Setting value after initialization processing

Change method

PLC communication modem

R_PLATFORM_TYPE_CPX3

None

Evaluation board

R_BOARD_TYPE_G_CPX3

None

Band plan

Refer to Table 3-4

1. BandPlan menu

2. DipSw

(PORT_ID_BANDPLAN_0,

PORT_ID_BANDPLAN_1)

Device type

Refer to Table 3-4

1. Start menu

1 - Demo Application

2. DipSw

(PORT_ID_DEVICE_TYPE)

Route type

Refer to Table 3-4

1. DipSw

(PORT_ID_ROUTE_TYPE)

Verbose mode setting

R_TRUE

1. Start menu

7 - Toggle Verbose Mode

2. Coordinator/Peer main menu,G3

common menu

8 - Toggle verbose mode

Mac promiscuous mode

setting

R_FALSE

1. Start menu, Coordinator/Peer main

menu

4 - Toggle Mac promiscuous mode

Application mode

Refer to Table 3-4

1. DipSw

(PORT_ID_AUTO_MODE,

PORT_ID_CERT_MODE)

Quality of Service

R_G3MAC_QOS_NORMAL

1. G3 common menu

1 - Send data frame

-> Priority (0:normal/1:high)

Auto Route Discovery setting

R_TRUE

1. G3 common menu

1 - Send data frame

-> Allow route discovery (1:yes/0:no)

EUI64 address

0xFF0102FFFE000000

1. Data flash menu

1 - edit dev config and reboot MCU

PAN ID

0x781D

Automatically set by the EUI64 address

Coordinator short address

0x0000

None

PSK

0x00112233445566778899AABBCCDDEEF

F

None

GMK[0]

0xAF4D6DCCF14DE7C1C4235E6FEF6C15

1F

None

GMK[1]

0x123456789ABCDEF0FFEEDDCCBBAA99

88

None

Active key

0

None

Peer device reset wait time

0x00000000

None

Tone mask

0xFFFFFFFFFFFFFFFFFF

None

ExtID length(Peer)

0x10u

None

ExtID (Peer)

0x48454D530001030405060708090A0B0C

None

ExtID length (Coordinator)

0x10u

None

ExtID (Coordinator)

0x534D0001030405060708090A0B0C0D0E

None

Page 36

G3-PLC Sample Program User's Manual 4. Sample Program

R11UM0114EJ0101 Rev.1.01 Page 31 of 89

Jun. 19, 2019

RENESAS CONFIDENTIAL

Table 4-5 Sample application configuration (Demo build)

Item

Setting value after initialization processing

Change method

PLC communication modem

R_PLATFORM_TYPE_CPX3

None

Evaluation board

R_BOARD_TYPE_G_CPX3

None

Band plan

Refer to Table 3-4

1. BandPlan menu

Device type

Refer to Table 3-4

1. Start menu

Route type

Refer to Table 3-4

1 - Demo Application

Verbose mode setting

R_TRUE

None

Mac promiscuous mode

setting

R_FALSE

1. Start menu

Application mode

Refer to Table 3-4

7 - Toggle Verbose Mode