Page 1

User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 1 of 54

2020.11.06

Evaluation System for Stepping Motor with Resolver

User's Manual

Safety Precautions

Be sure to read this manual before using the Evaluation System for Stepping Motor with Resolver

(RTK0EMX270S01020BJ) (Called "this product" below).

・ Follow the instructions in this manual when using this product.

・ Keep this manual near this product so you can refer to it whenever necessary.

・ Transfer or sale of this product to third parties is prohibited without written approval.

・ The purchaser or importer of this product shall ensure compliance with local regulations. In addition, the

customer is responsible for ensuring that this product is handled correctly and safely, in accordance with the laws

of the customer's country (region).

・ The manuals and specifications related to this product (called "the documents, etc." below) are tools that were

developed for the function and performance evaluation of Renesas Electronics semiconductor devices (called

"Renesas Electronics devices" below) mounted on this product and do not guarantee the quality, function, and

performance equivalent to Renesas Electronics products.

・ By purchasing this product or downloading the documents, etc. from Renesas Electronics website, the support

services provided from Renesas Electronics are not guaranteed.

・ All information contained in this manual represents information on products at the time of publication of this

manual. Note that the product data, specifications, contact for inquiries, contents of website, address, etc., are

subject to change by Renesas Electronics Corporation without notice. Confirm the latest information on Renesas

Electronics website, etc.

In this manual, items related to the safe use of the product are indicated as described below.

■The degree of injury to persons or damage to property that could result if the designated instruction in this manual

is not followed is indicated as follows.

Danger

Indicates a thing that, if not followed, could result in

death or serious injury(*1) to the user, and which is

highly imminent.

Warning

Indicates a thing that, if not followed, could result in

death or serious injury to the user.

Caution

Indicates a thing that, if not followed, could result in

injury(*2) to persons or physical damage(*3).

*1 Serious injury refers to conditions resulting in persistent after-effects and for which treatment would

necessitate hospitalization or regular hospital visits, such as loss of eyesight, burns (high- or low-

temperature), electric shock, bone fracture, poisoning, or other injuries.

*2 Injury refers to conditions for which treatment would necessitate hospitalization or regular hospital visits.

*3 Physical damage refers to damage affecting the wider surroundings, such as the user's home or property.

Meaning of Notations

R12UZ0065EJ0110

Rev.1.10

2020.11.06

Page 2

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 2 of 54

2020.11.06

■Requirements related to the handling of the product are classified into the following categories.

・Marks indicating that an action is prohibited

General prohibition

The indicated action is prohibited.

(Example) Do not touch.

Touching the specified location could

result in injury.

・Marks indicating that an action requires caution.

General caution

Indicates a general need for caution

that is not specified.

(Example) High temperature

Indicates the possibility of injury due to

high temperature.

・Marks directing that the specified action is required

General instruction

The specified action is required.

(Example) Turn off (disconnect) power.

Instructs the user to turn off (disconnect)

the power to the product.

Danger

・The product should be used only by persons having a thorough knowledge of electrical and mechanical

components and systems, a full knowledge of the risks associated with handling them, and training in

inverter motor control and handling motors, or equivalent skills (called "users" below). Users should be

limited to persons who have carefully read the Caution Items contained in this manual.

・Unlike typical equipment, this product has no protective case to ensure safety, and it contains moving

parts and high-temperature components that could be dangerous. Do not touch the evaluation board or

cables while power is being supplied.

・Carefully check to make sure that there are no pieces of conductive materials or dust adhering to the

board, connectors, and cables.

・There are moving parts, driven by a motor. Do not touch the motor while power is being supplied.

・Ensure that the motor is insulated and placed in a stable location before supplying power.

Do not connect load to motor.

・This could cause fire, burns, or injury.

Warnings Regarding Use of the Product

■Danger Items

Page 3

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 3 of 54

2020.11.06

Warning

Caution - Rotating parts

・The system includes a motor. Touching the rotating shaft could cause high-temperature burns or injury.

Insert plugs, connectors, and cables securely, and confirm that they are fully inserted.

・Incomplete connections could cause fire, burns, electric shock, or failures.

Use the power supply apparatus specified in the manual.

・Failure to do so could cause fire, burns, electric shock, injury, or failures.

Stop supplying power and unplug all cables when the product will not be used for a period of time or when

moving the product.

・Failure to do so could cause heat, fire, burns, electric shock, or failures.

・This will protect the product against damage due to lightning.

Use a mechanism (switch, outlet, etc.) located within reach to turn off (disconnect) the power supply.

・If an abnormality occurs, it may be necessary to cut off the power supply quickly.

Stop supplying power immediately if you notice abnormal odor, smoke, abnormal sound, or overheating.

・Continuing to use the product in an abnormal condition could cause fire, burns, or electric shock.

Do not disassemble, modify, or repair the product.

・Doing so could cause fire, burns, electric shock, injury, or failures.

Do not use this product for any purpose other than initial evaluation of motor control in a testing room or

laboratory.

Do not integrate the product or any part of it into other equipment.

Do not insert or remove cables or connectors when the product is powered on.

・The product has no safety case.

・Failure to observe the above could cause fire, electric shock, burns, or failures.

・The product may not perform as expected if used for other than its intended purpose.

Caution

High temperature

・The motor gets hot. Touching it could cause high-temperature burns.

Follow the procedure specified in the manual when turning the power to each system on or off.

・Failure to do so could cause overheating or failures in devices.

Attention to static charge

Before using this product, wear an antistatic wrist strap. If you touch this product with a static

charge on your body, a device failure may occur or operation may become unstable.

Before using this product, mount the ferrite core near this product on each cable for connecting

this product and stabilized power supply.

・Failure to do so could interfere with operation of other devices or cause failures in the devices.

■Warning Items

■Caution Items

Page 4

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 4 of 54

2020.11.06

Information Related to Regulations

European Union regulatory notices

This product complies with the following EU Directives. (These directives are only valid in the European Union.)

CE Certifications:

・Electromagnetic Compatibility (EMC) Directive 2014/30/EU

EN61326-1 : 2013 Class A

WARNING: This is a Class A product. This equipment can cause radio frequency noise when used in the

residential area. In such cases, the user/operator of the equipment may be required to take

appropriate countermeasures under his responsibility.

・Information for traceability

・Authorised representative

Name: Renesas Electronics Corporation

Address: Toyosu Foresia, 3-2-24, Toyosu, Koto-ku, Tokyo 135-0061, Japan

・Manufacturer

Name: Renesas Electronics Corporation

Address: Toyosu Foresia, 3-2-24, Toyosu, Koto-ku, Tokyo 135-0061, Japan

・Person responsible for placing on the market

Name: Renesas Electronics Europe GmbH

Address: Arcadiastrasse 10, 40472 Dusseldorf, Germany

・Trademark and Type name

Trademark: Renesas

Product name: Evaluation System for Stepping Motor with Resolver

Type name: RTK0EMX270S01020BJ

Environmental Compliance and Certifications:

・Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU

Page 5

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 5 of 54

2020.11.06

Overview of This Product

The Evaluation System for Stepping Motor with Resolver is a motor control evaluation kit.

This product has a resolver/digital converter IC manufactured by Renesas Electronics, which enables high resolution

position control in combination with the motor with a resolver supplied with this product.

The product is equipped with various external device interfaces, which enables you to start the evaluation of the

stepping motor with a resolver immediately by connecting a general motor control device.

In addition, this product supports the support tool for motor control development manufactured by Renesas

Electronics (Renesas Motor Workbench). Renesas Motor Workbench can display internal variables of a microcontroller

in waveform in real time and automatically extract vector control parameters, which enables efficient software

development.

This user's manual describes how to handle this product. On this product, the connectors other than those required for

quick start are not basically mounted at the factory. To use an interface described in this user's manual, it may be

necessary to mount a required connector.

Mounted devices

Microcontroller: R5F524TEADFP

Resolver/digital converter: RAA3064002GFP

Gate driver: HIP4082IBZ

RS-485 driver: ISL3156EIUZ

CAN driver: R2A25416SP

MOSFET: RJK1054DPB

Regulator: ISL9001AIRNZ, ISL9005AIRNZ

Related documents

⚫ Related to 48V 2A inverter board for stepping motor

➢ Circuit diagram: R12TU0083

➢ Parts list: R12TU0085

➢ PCB pattern diagram: R12TU0087

⚫ Related to RX24T CPU card with RDC-IC

➢ Circuit diagram: R12TU0082

➢ Parts list: R12TU0084

➢ PCB pattern diagram: R12TU0086

⚫ Related to the support tool for motor control development "Renesas Motor Workbench"

➢ User's Manual: R21UZ0004

⚫ Sample code

➢ Application note: R03AN0014

Included items

Refer to the "Included Items" supplied with this product.

Page 6

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 6 of 54

2020.11.06

Abbreviations

Abbreviation

Formal name

Remarks

this product

Evaluation System for Stepping Motor with

Resolver

Model name: RTK0EMX270S01020BJ

inverter board

48V 2A inverter board for stepping motor

Model name: RTK0EM0000B11020BJ

CPU card

RX24T CPU card with RDC-IC

Model name: RTK0EMX270C02000BJ

RMW

Support tool for motor control development

"Renesas Motor Workbench"

Support tool for motor control

development manufactured by Renesas

Electronics

MCU

microcontroller

Microcontroller mounted on this product

(Model name: R5F524TEADFP)

RDC IC

resolver/digital converter IC

Resolver/digital converter IC mounted

on this product

(Model name: RAA3064002GFP)

Page 7

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 7 of 54

2020.11.06

Contents

Safety Precautions .................................................................................................................... 1

Information Related to Regulations ........................................................................................... 4

Overview of This Product .......................................................................................................... 5

Overview of the Product ..................................................................................................... 8

1.1 Specifications ................................................................................................................................ 8

1.2 Block Diagram ............................................................................................................................... 9

1.3 Layout .......................................................................................................................................... 10

Using This Product ........................................................................................................... 11

2.1 Quick Start 1 Connection and Board Operations ..................................................................... 11

2.2 Quick Start 2 GUI Operations ................................................................................................... 15

2.3 Initial Software Specifications ..................................................................................................... 23

2.4 Writing to Flash Memory ............................................................................................................. 24

2.5 Troubleshooting .......................................................................................................................... 25

Kit Specifications .............................................................................................................. 27

3.1 Specification List ......................................................................................................................... 27

3.2 Stepping Motor with Resolver ..................................................................................................... 28

3.3 Power Supply .............................................................................................................................. 29

3.4 Inverter Circuit ............................................................................................................................. 30

3.5 Sensor Interfaces ........................................................................................................................ 34

3.6 External Device Interfaces .......................................................................................................... 37

3.7 User Interfaces ............................................................................................................................ 44

3.8 Pin Assignments ......................................................................................................................... 46

How to Flash Program MCU ............................................................................................ 51

Website and Support ............................................................................................................... 54

Revision History ....................................................................................................................... 55

General Precautions in the Handling of Microprocessing Unit and Microcontroller Unit

Products ........................................................................................................................... 56

Notice ...................................................................................................................................... 57

Page 8

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 8 of 54

2020.11.06

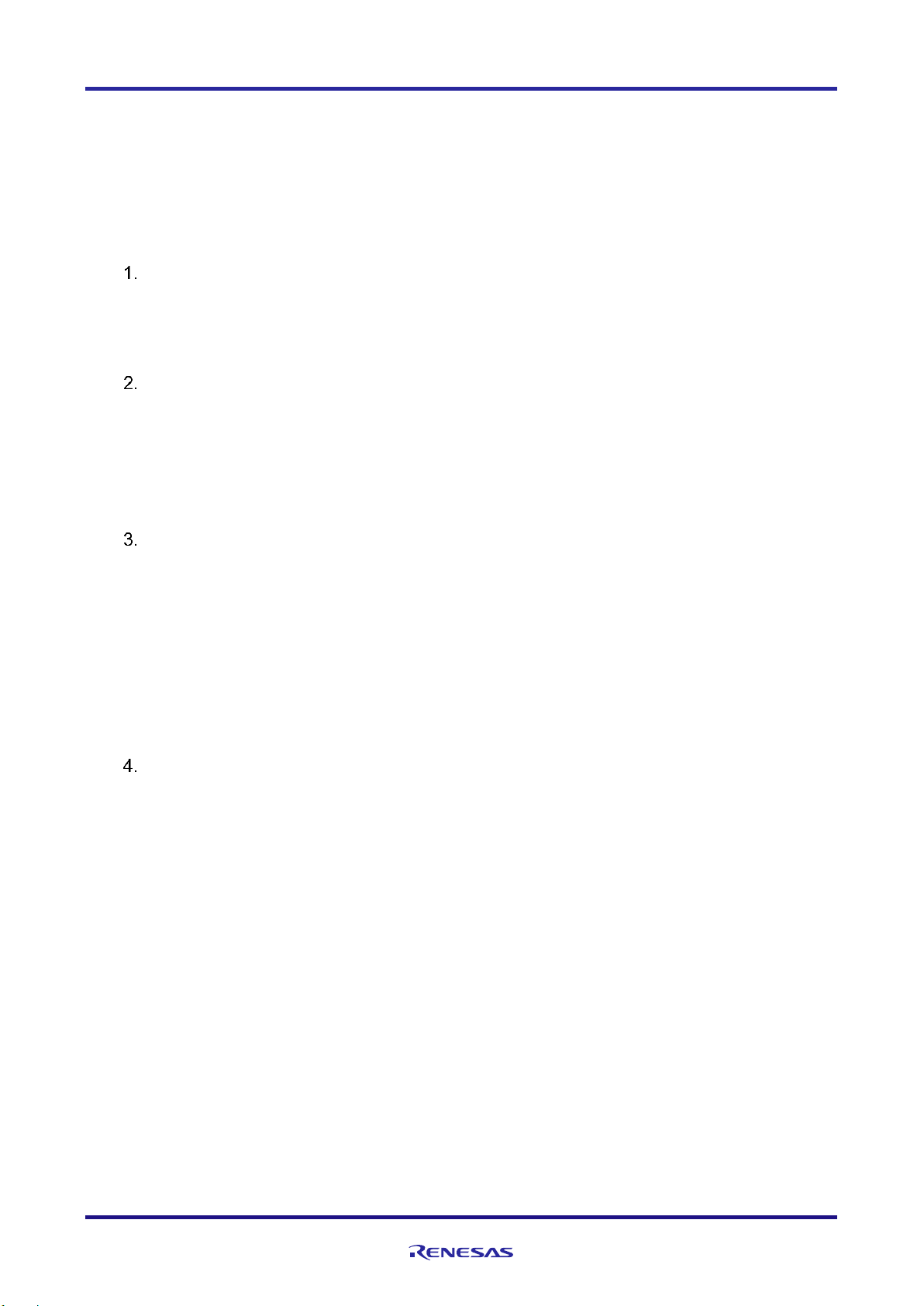

Overview of the Product

1.1 Specifications

Table 1-1 Overview of Specifications

Item

Specification

Kit name

Evaluation System for Stepping Motor with Resolver

Kit model name

RTK0EMX270S01020BJ

Kit configuration

48V 2A inverter board for stepping

motor

RTK0EM0000B11020BJ

RX24T CPU card with RDC-IC

RTK0EMX270C02000BJ

Stepping motor with resolver

R17PMK440CNVA4438

(manufactured by MinebeaMitsumi Inc.)

Rated current: 2 Apeak/Phase

With a resolver

Inverter

specifications

• Applicable motor: Stepping motor

• Rated voltage: 48 V

• Rated output: 100 W

• Detection function: Phase current, bus voltage

• Protection function: Overcurrent protection

Interface

specifications

• Applicable sensors: Resolver, encoder(*1)

• External device interfaces: RS-485(

*1

), CAN(*1), pulse train command(*1),

general-purpose in/out(

*1

)

Development

support functions

• Compatible with support tool for motor control development, Renesas Motor

Workbench

• With an on-board emulator circuit (flash programming circuit)

External view

Note: The actual product may differ from this photo.

Operating

temperature

Room temperature

Operating humidity

No condensation allowed.

Compliance: EMC

directive

Europe: EN61326-1: 2013 Class A

*1 The connector is not mounted.

Page 9

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 9 of 54

2020.11.06

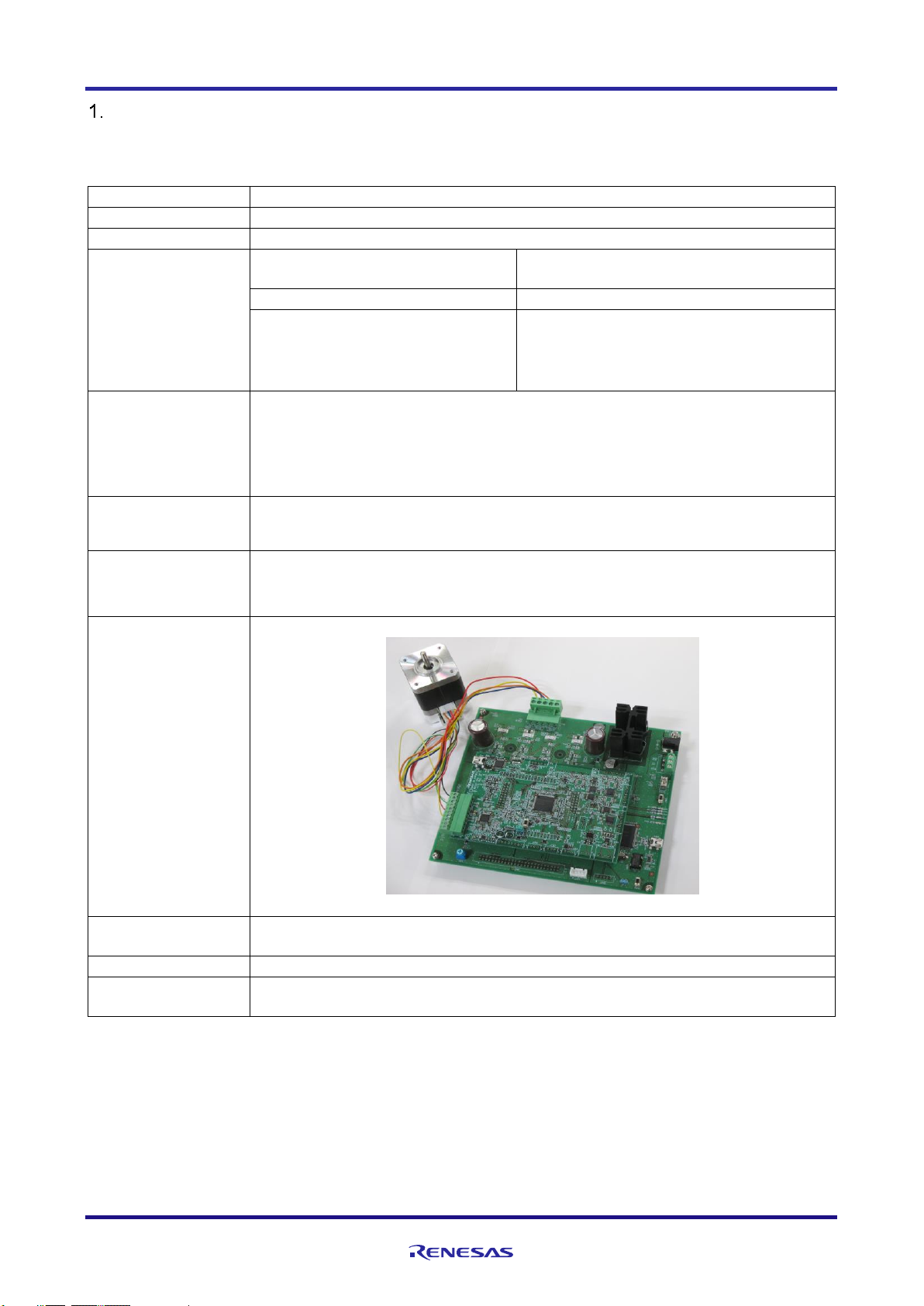

1.2 Block Diagram

Power

connector

Variable

resistor

Toggle switch/

push switch

12-V voltage

generation function

Overcurrent

detection

function

5-V voltage

generation

function

Inverter circuit

Gate Driver

Motor

connector

Board-to-

board

connector

24-48V

12V

Overcurrent detection

4-phase

compensation PWM

5V

MCU

RX24T

Origin sensor/limit

sensor interface (not

installed)

USB connector (not

installed)

Crystal

oscillator

Reset switch

LED * 3

RDC IC

Output voltage

divider

Resolver

connector

E2 On Board

RS485

CAN

Buffer

Communication circuit for motor development support tool, Renesas Motor Workbench

USB

connector

Digital

Isolator

Current detection

amplifier

LED * 2

Inverter board

Encoder/pulse train

command connector

(not installed)

CAN communication

connector (not

installed)

RS-485

communication

connector (not

installed)

General-purpose

output connector (not

installed)

General-purpose

input analog

command connector

(not installed)

Buffer

Buffer

CPU card

Shunt resistor

MOSFETs

Resolver motor

Figure 1-1 Block Diagram

Current

detection

MTU0

RDC

TMR4

MTU3

MTU4

UART6

MTU

RSCAN

A/D

ICU

Origin sensor

Limit sensor

MTU2

POE

I/O

Inverter

Upper device

RS485

Upper device

CAN

Upper device

Sequence input

Upper device

Sequence output

I/O

Supply voltage

Phase

voltage

Overcurrent

detection

Variable resistor

Switch

Analog command

Analog monitor

D/A

Resolver

Motor

LED

UART1

RMW

PE5/IRQ0

P00/IRQ2

P24/DA0

I/O

LED3

LED2

LED1

SW1

SW2

DOG

N-OT, P-OT

P33/MTCLKA

P32/MTCLKB

PA5/MTIOC1A

SPON

PD1

PA3/MTIOC2 A

PB2/TXD6

PB1/RXD6

I/O

P02

RS485_TX

RS485_RX

RS485_DE

PA0/CTXD0

PA1/CRXD0

CAN_TX

CAN_RX

P10

SVON

P65

PB7

GPINPUT

GPINPUT

PB6

PB5

PB4

PB3

PD4

PD2

COIN

ORG

GPOUTPUT

RDY

ERROR

GPOUTPUT

ICS_RX

ICS_TX

PD5/RXD1

PD3/TXD1

I/O

P64/AN204

P92/MTIOC6 D

P55/AN211

AIN

VR1

VDC

P54/AN210

VA-

VB-

VB+

VA+

P53/AN209

P52/AN208

P51/AN207

P75/MTIOC4C

P74/MTIOC3D

P72/MTIOC4A

P72/MTIOC3B

B+L

A+L

B+H

A+H

P70/POE0#

PA2

P81

P80

P61

P62

Analog_Mon

P43

P11/TMO3

PB0/TMO0

P82/TMO4

P31/MTIOC0A

TMR0

TMR3

MTU9

P21/MTIOC9A

PE0/MTIOC9B

P95/MTIOC6B

RSPI

P23/MOSI A

PA4/RSPCKA

PD6/SSLA0

P22/MISOA

HISEDE_OC

RDC_RESET

RDC_CLK

RDC_PWMINA

RDC_PWMINB

RDC_CC

RDC_CARR IER1

RDC_CARR IER2

RDC_COUT

SPI_MOSI

SPI_MISO

SPI_SCLK

SPI_SCS

P50/AN206

P47/AN103

MNTOUT_DC

MNTOUT_AC

RDC_ALARM

P01/POE12#

POE

Shunt resistor

A/D

P60/AN200

A/D

A-H

A-L

B-L

B-H

P91/MTIOC7 C

MTU6

MTU7

P94/MTIOC7 A

P44/AN100

P45/AN101

P46/AN102

P40/AN000

IA-

IA+

IB+

IB-

Encoder

Upper device

Pulse command

ENC_A

ENC_B

ENC_Z

PULSE/UP

DIR/DOWN

CLR

PE4/MTCLK C

PE3/MTCLK D

PA3/MTIOC2 A

Figure 1-2 Connection Destinations of RX24T Pins by Function

Page 10

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 10 of 54

2020.11.06

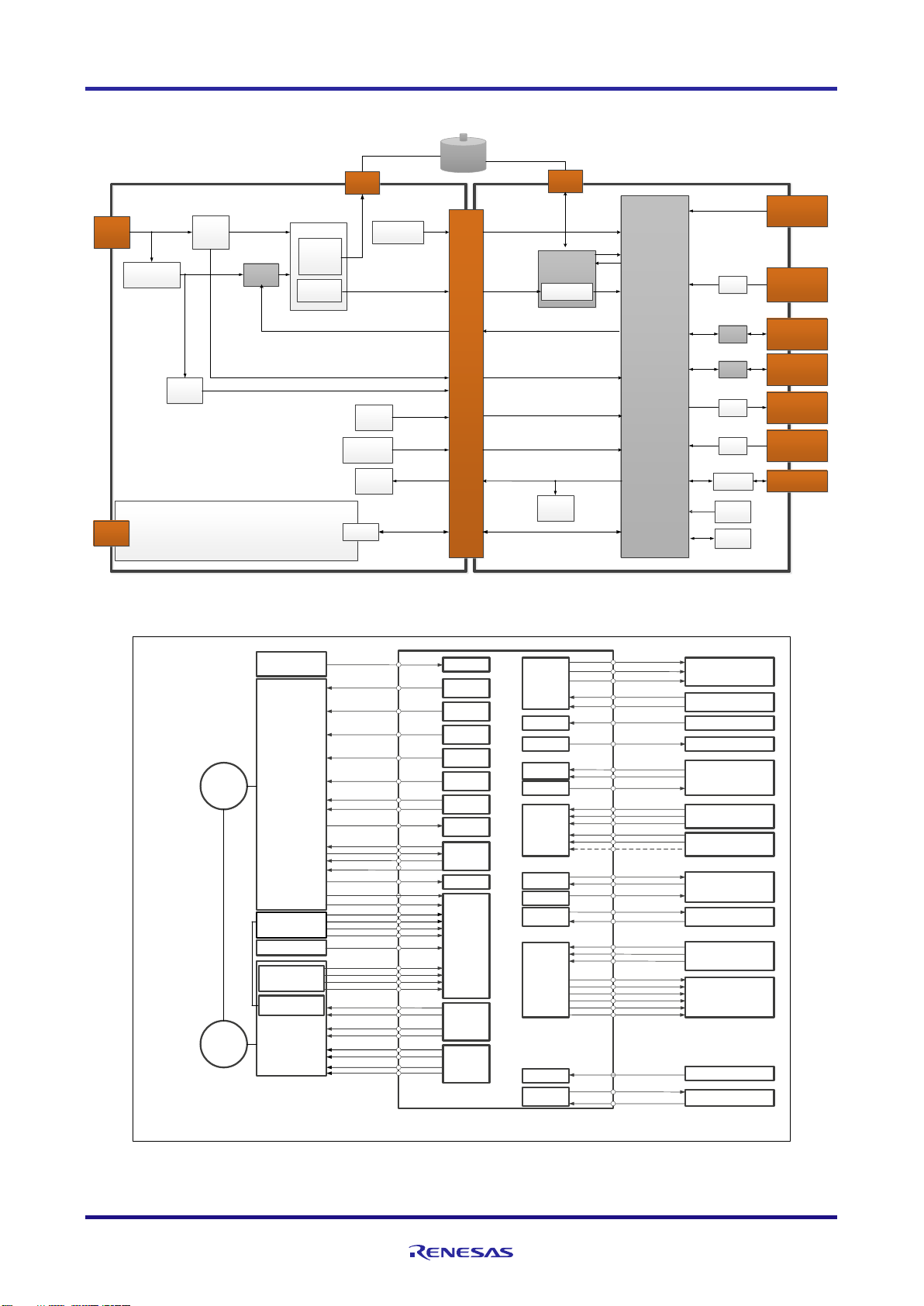

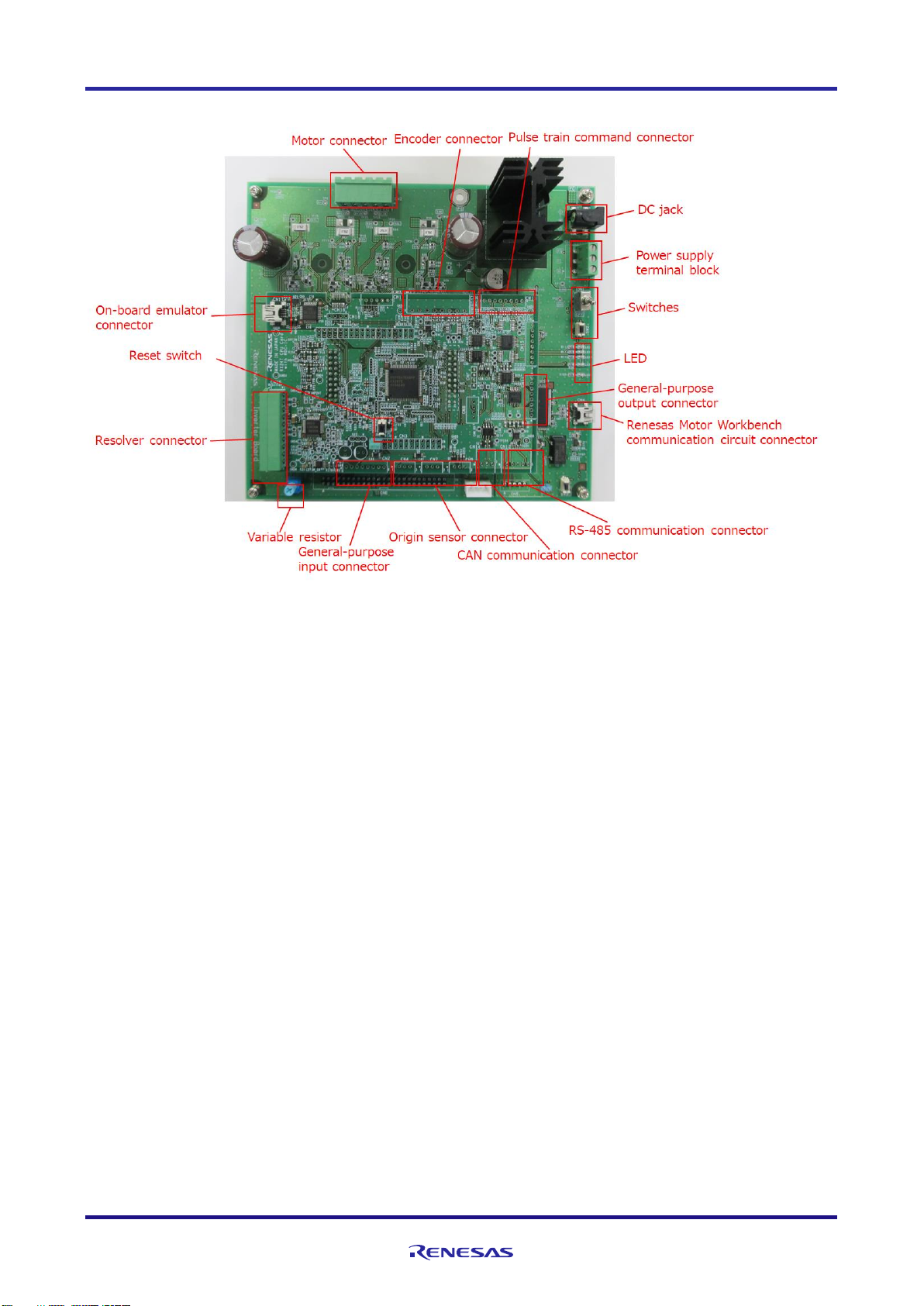

1.3 Layout

Figure 1-3 Layout

* All connectors other than the resolver connector and on-board emulator connector are not mounted on the CPU card.

* The actual product may differ from this photo.

Page 11

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 11 of 54

2020.11.06

Using This Product

2.1 Quick Start 1 Connection and Board Operations

This section describes a quick start procedure of this product. Perform steps (1) to (9) in this order.

A stepping motor with resolver (called a motor below) manufactured by MinebeaMitsumi Inc. is supplied with this

product. Use the supplied motor in the procedure described in this section.

Before using this product, wear an antistatic wrist strap. If you touch this product with a static charge on your body, a

device failure may occur or operation may become unstable.

Procedure of quick start 1

Step

Operation

(1)

Connecting the motor and board

(2)

Checking the variable resistor

(3)

Connecting the stabilized power supply and board

(4)

Supplying the power

(5)

Executing the calibration

(6)

Enabling the rotation of the motor

(7)

Checking that the motor speed changes

(8)

Stopping the rotation of the motor

(9)

Stopping supplying the power

Preparation

Prepare the following items.

・Stabilized power supply: 24 VDC or higher output voltage, 1 A or higher output current

・Two power cables: Cables through which 1 A or higher current can flow (for connecting the stabilized

power supply and inverter board)

Page 12

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 12 of 54

2020.11.06

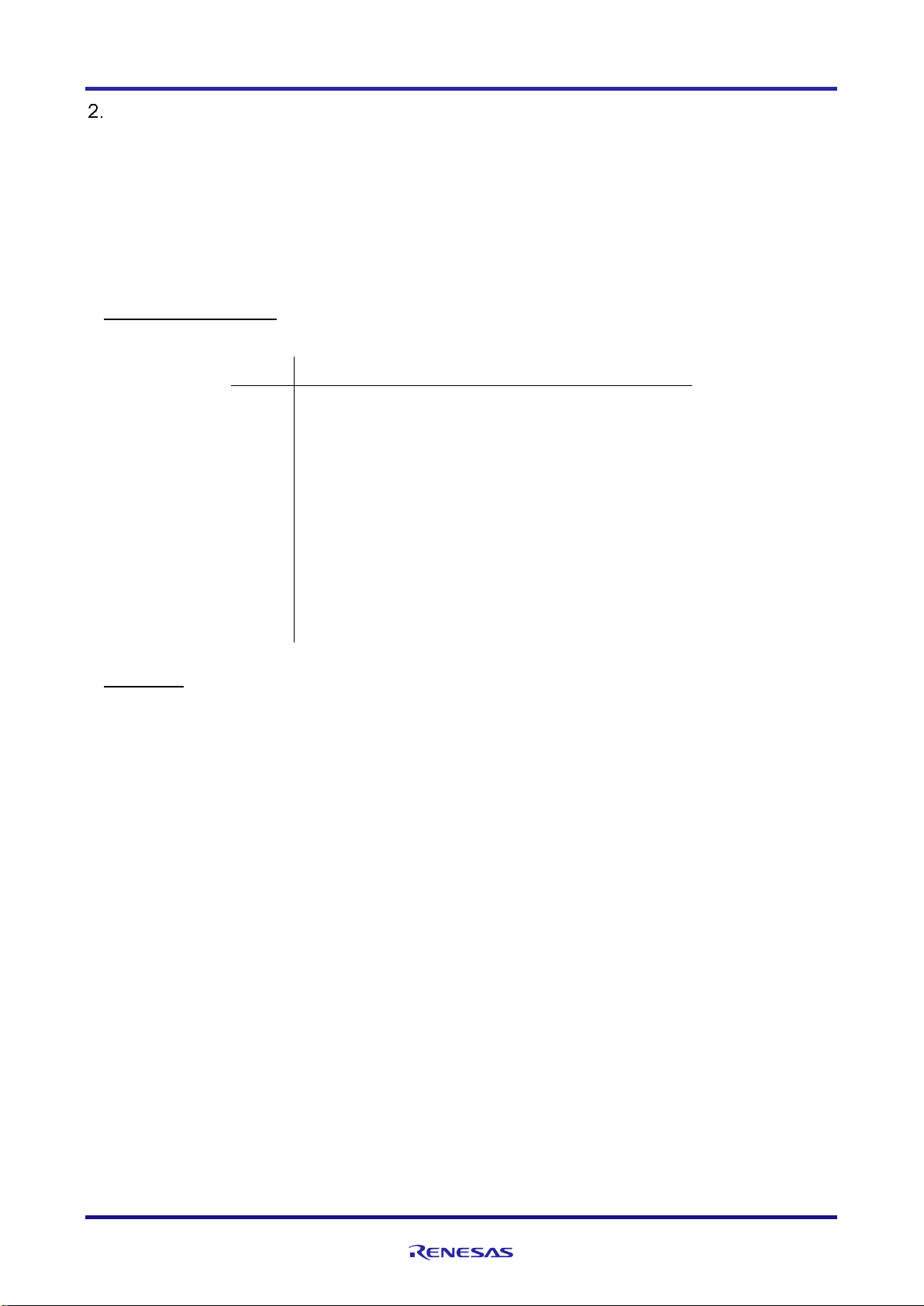

(1) Connecting the motor and board

First, connect the motor cable and the resolver cable to the supplied motor as shown in Figure 2-1. Then, connect the

motor cable to the inverter board and the resolver cable to the CPU card as shown in Figure 2-2.

Figure 2-1 Connecting the Cables to the Motor

Figure 2-2 Connecting the Cables to the Boards

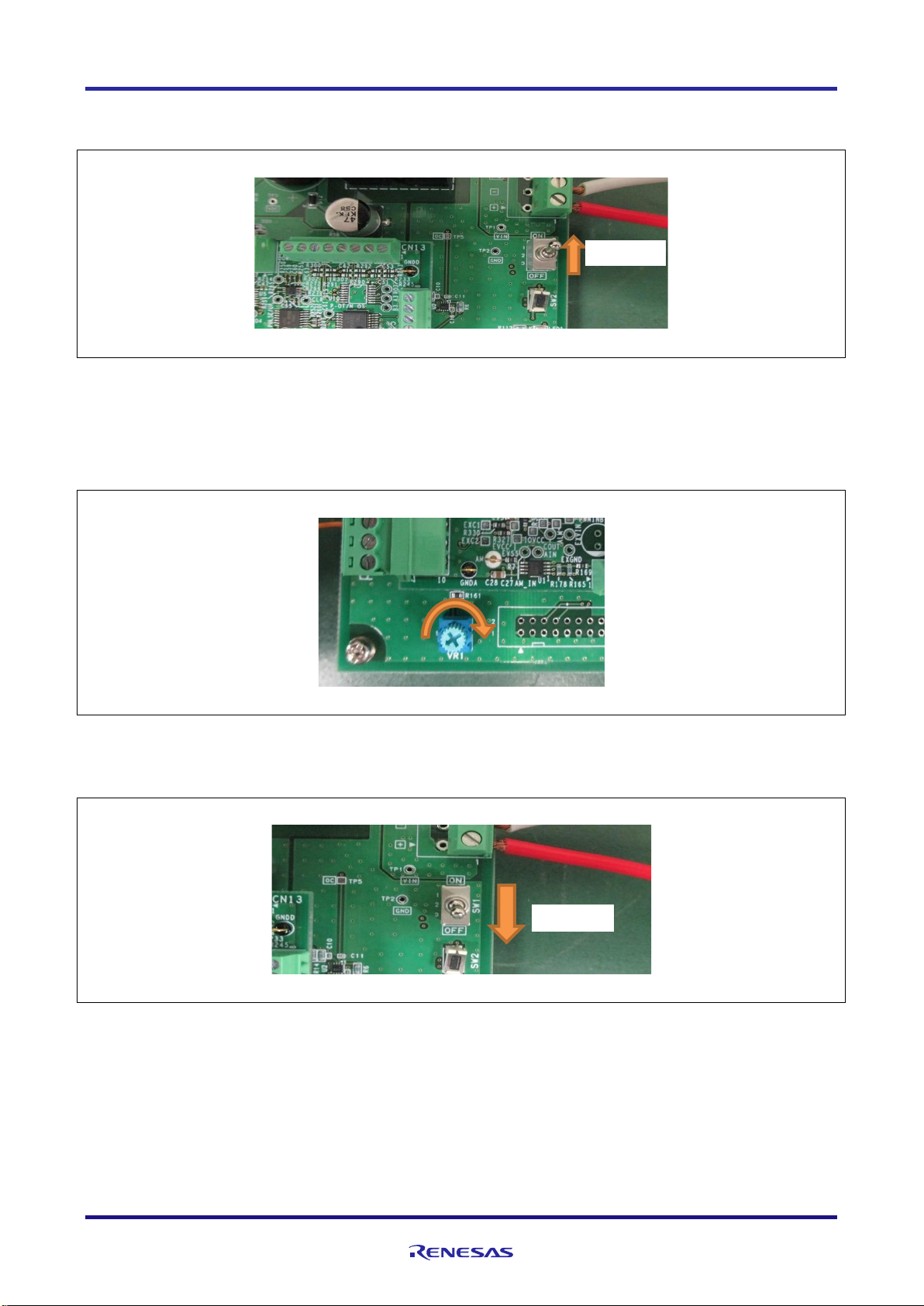

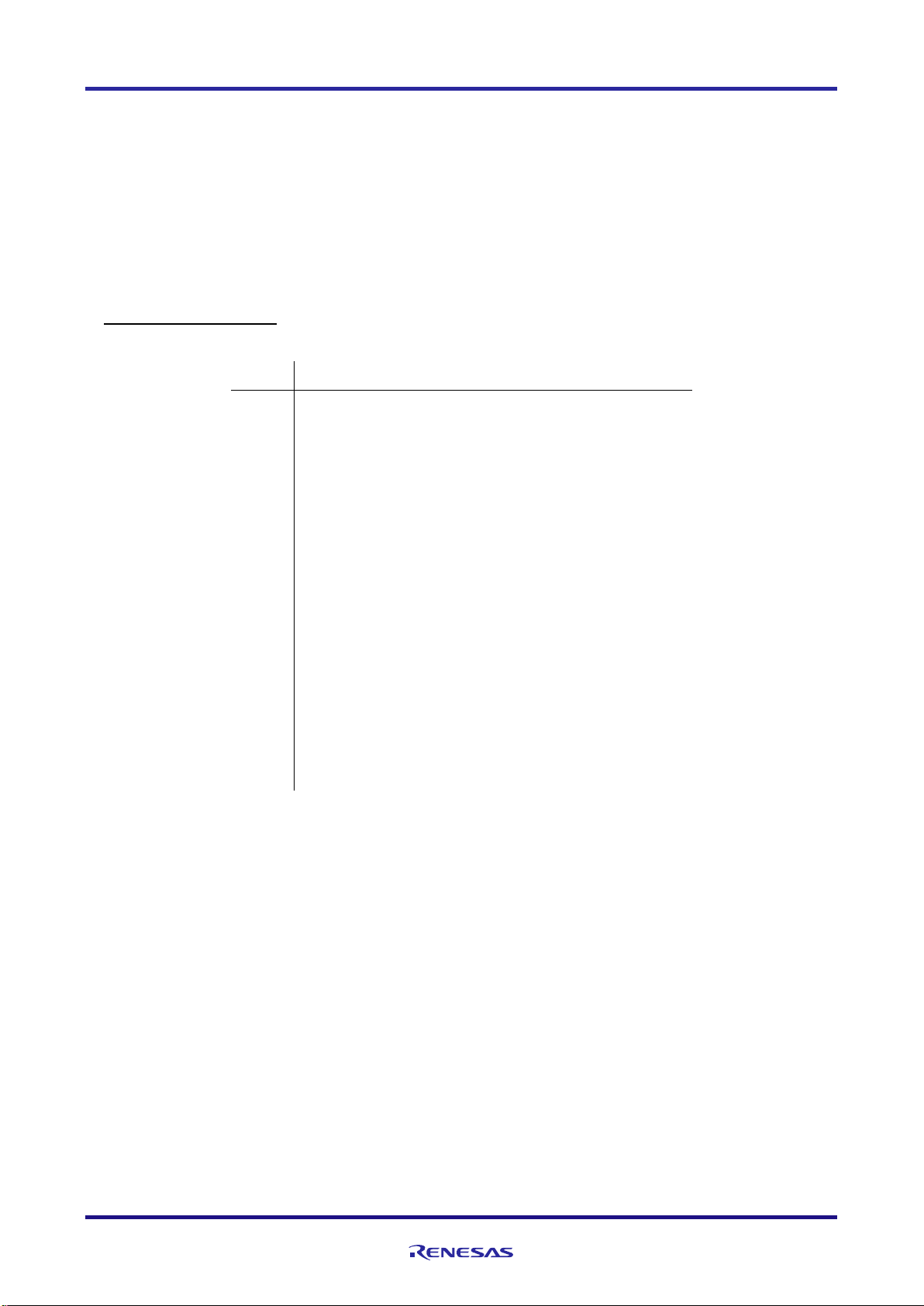

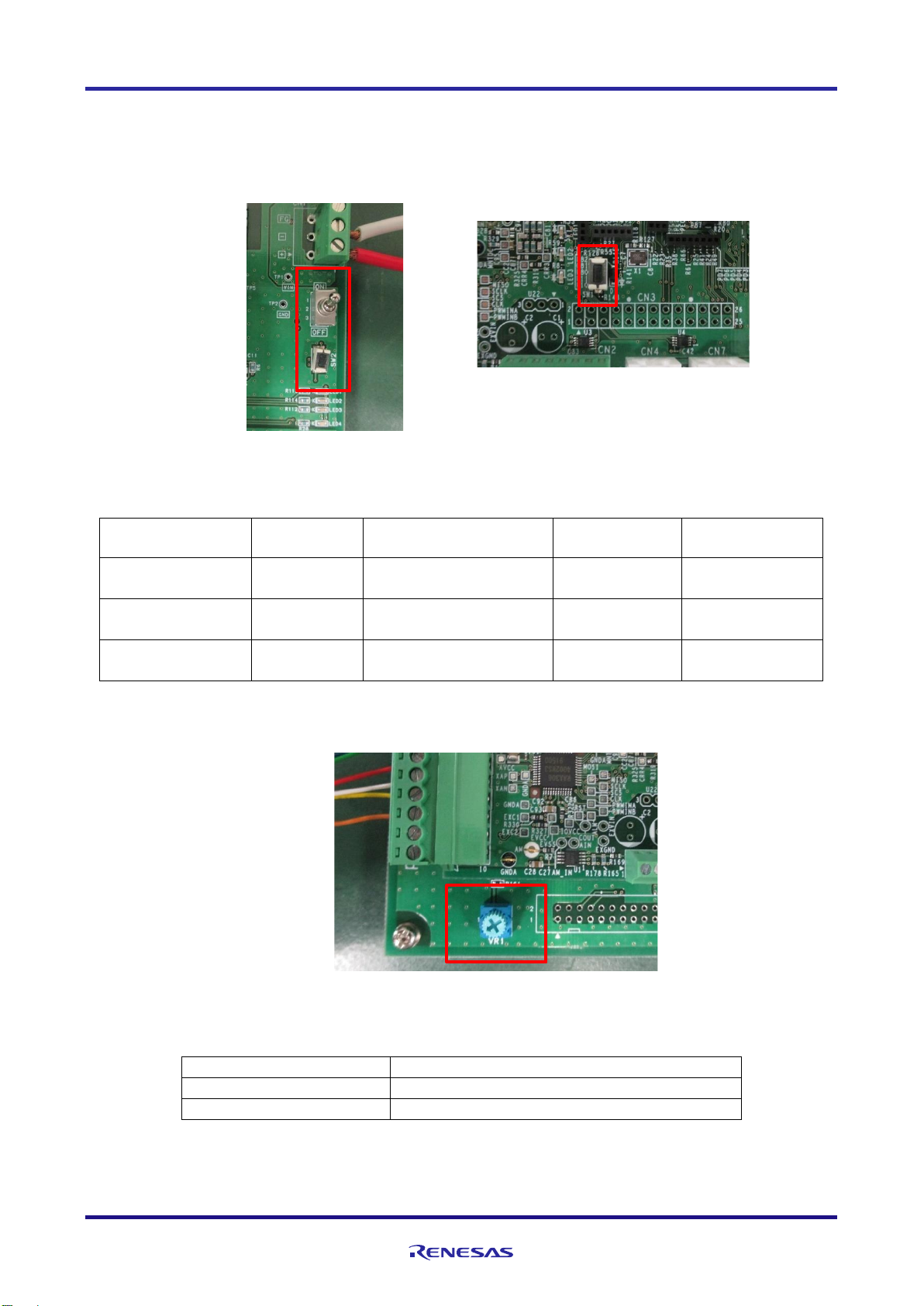

(2) Checking the SW1 and the variable resistor

While referencing Figure 2-3, check that the SW1 is OFF and the variable resistor (VR1) is in the center position. If

the VR1 is not in the center position, adjust it in the center position with an ESD safe slotted screwdriver.

Figure 2-3 Checking the SW1 and the Variable Resistor

Page 13

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 13 of 54

2020.11.06

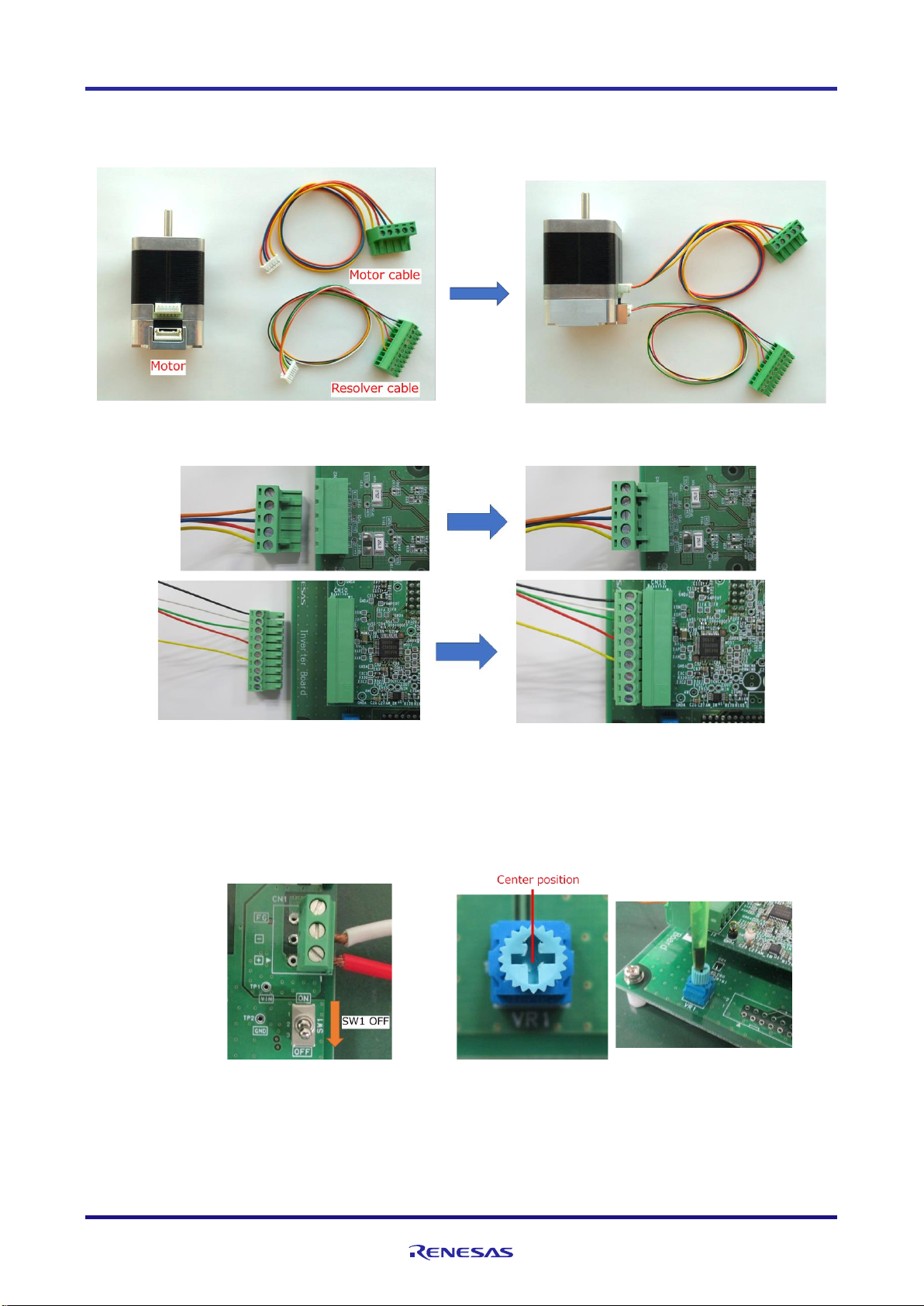

(3) Connecting the stabilized power supply and board

This product provides a terminal block and DC jack as connectors for supplying the power to the board. The

following explains an example of connecting the board to the terminal block using a stabilized power supply. Connect

the power supply to the board as shown in Figure 2-4.

Figure 2-4 Power supply to the power connector

(4) Supplying the power

Use a stabilized power supply as the power supply, set the output voltage to 24 V and the limit current to 1 A, and

start output. If the voltage drops even momentarily, a reset occurs since the voltage of the power supplied to the MCU

also drops, which causes the program to be halted.

(5) Executing the calibration

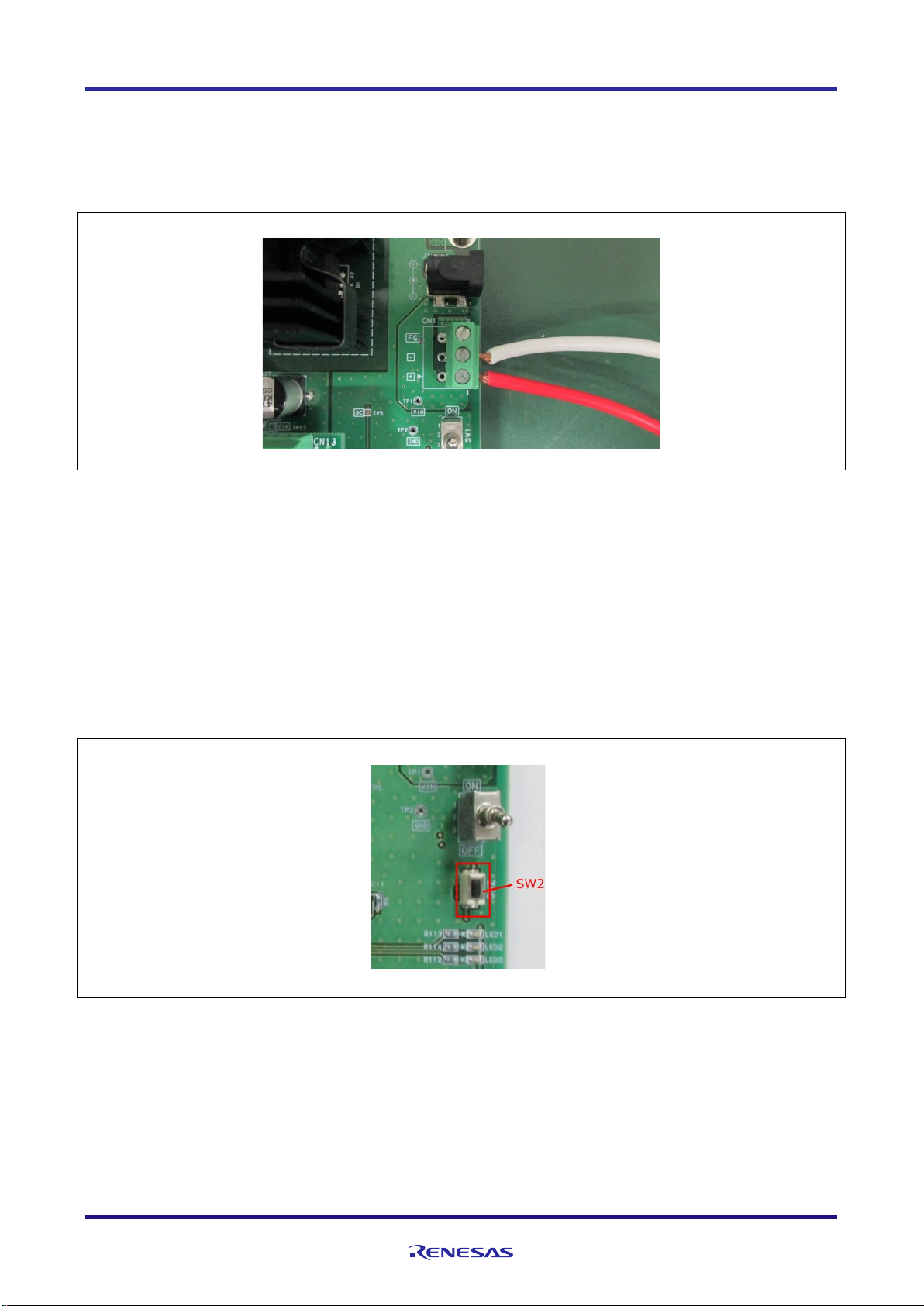

For calibratin the motor parmaters, push and release SW2 and wait for 30~40 seconds. The motor starts rotating in

20~30 seconds. It stops rotating when the calibration finishes.

Figure 2-5 Push SW2 for the Calibration

Page 14

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 14 of 54

2020.11.06

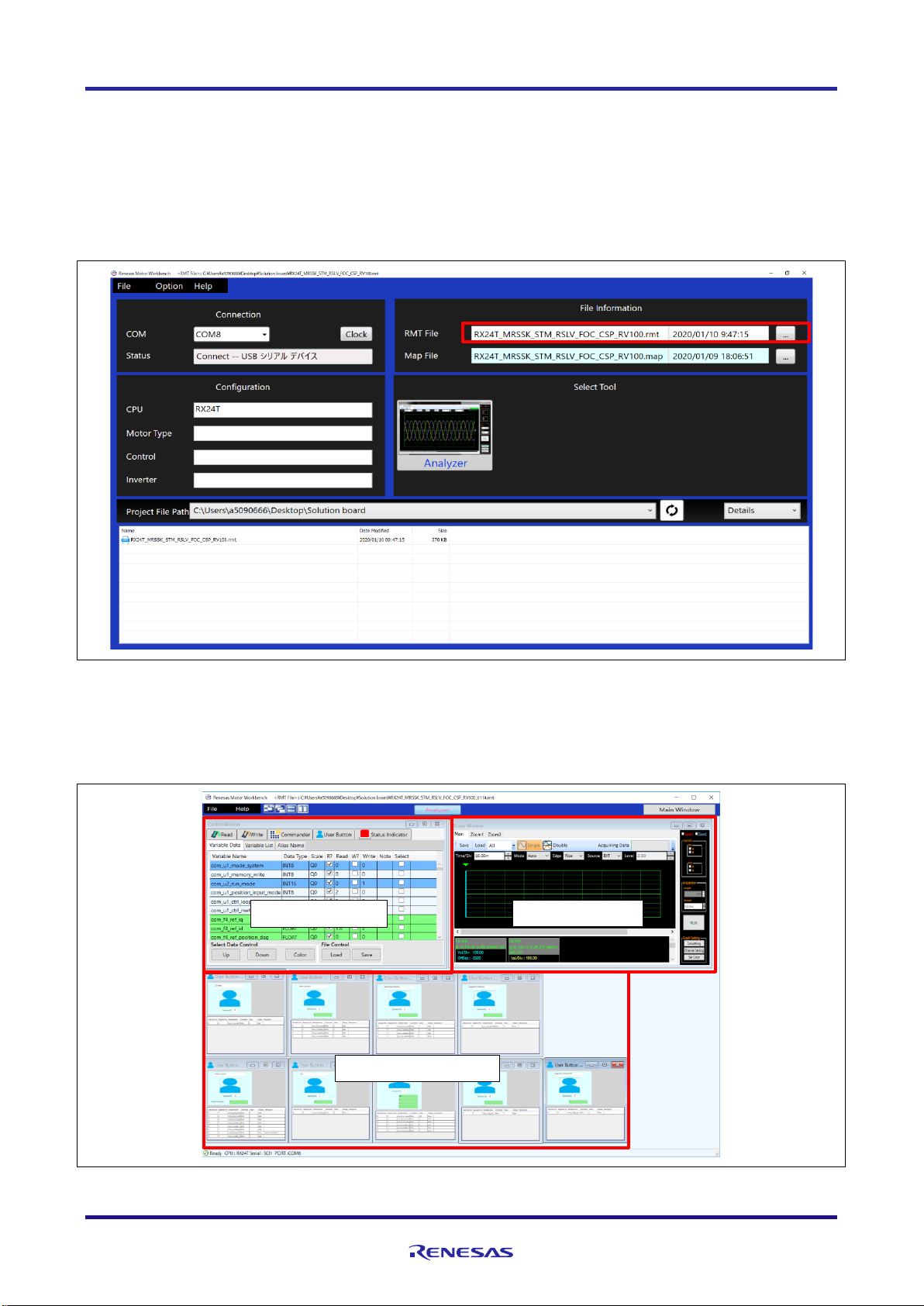

(6) Enabling the rotation of the motor

To enable the rotation of the motor, turn the toggle switch (SW1) on as shown in Figure 2-6.

Figure 2-6 Enabling the Rotation of the Motor

(7) Checking that the motor speed changes

Check that the motor speed changes when you turn the rotor of the variable resistor (VR1).

Figure 2-7 Changes of the Motor Speed

(8) Stopping the rotation of the motor

To stop the rotation of the motor, turn toggle switch SW1 off.

Figure 2-8 Stopping the Rotation of the Motor

(9) Stopping supplying the power

Check that the rotation stops and stop the output from the stabilized power supply.

SW1 ON

SW1 OFF

Page 15

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 15 of 54

2020.11.06

2.2 Quick Start 2 GUI Operations

This section describes an operation procedure using Renesas Motor Workbench, support tool for motor control

development which is an application running on a PC.

Before starting this operation procedure, make connections and confirm SW setting according to steps (1) to (3) in

quick start 1. In addition, it is necessary to download the sample program “Vector Control of a Two-Phase Stepping

Motor Incorporating a Resolver Sensor”(R03AN0014) from the product page linked from the following URL and write

the program to the CPU card according to the procedure described in Chapter 4.

URL: http://japan.renesas.com/rssk/motor

Procedure of quick start 2

Step

Operation

(1)

Connecting a PC and this product

(2)

Connecting Renesas Motor Workbench

(3)

Loading the configuration file

(4)

Switching to the Analyzer tool

(5)

Changing the user interface

(6)

Executing offset calibration

(7)

Executing gain and phase calibration

(8)

Executing angle error calibration

(9)

Setting the command value of position control

(10)

Operating the motor in the position control mode

(11)

Turning the servo off

(12)

Sending a speed command

(13)

Stopping rotation

(14)

Stopping supplying the power

Page 16

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 16 of 54

2020.11.06

(1) Connecting a PC and this product

Connect the USB cable supplied with this product to the USB connector on a PC and USB connector CN4 on the

inverter board. After that, turn the power to the board on as instructed in step (4) of quick start 1.

Figure 2-9 Connecting a PC

(2) Connecting Renesas Motor Workbench

Start up Renesas Motor Workbench and check that the relevant COM number is displayed.

For details of the methods of RMW operations described below, refer to "Support Tool for Motor Control

Development, Renesas Motor Workbench User's Manual (R21UZ0004JJ)".

Figure 2-10 Checking the COM Number

Page 17

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 17 of 54

2020.11.06

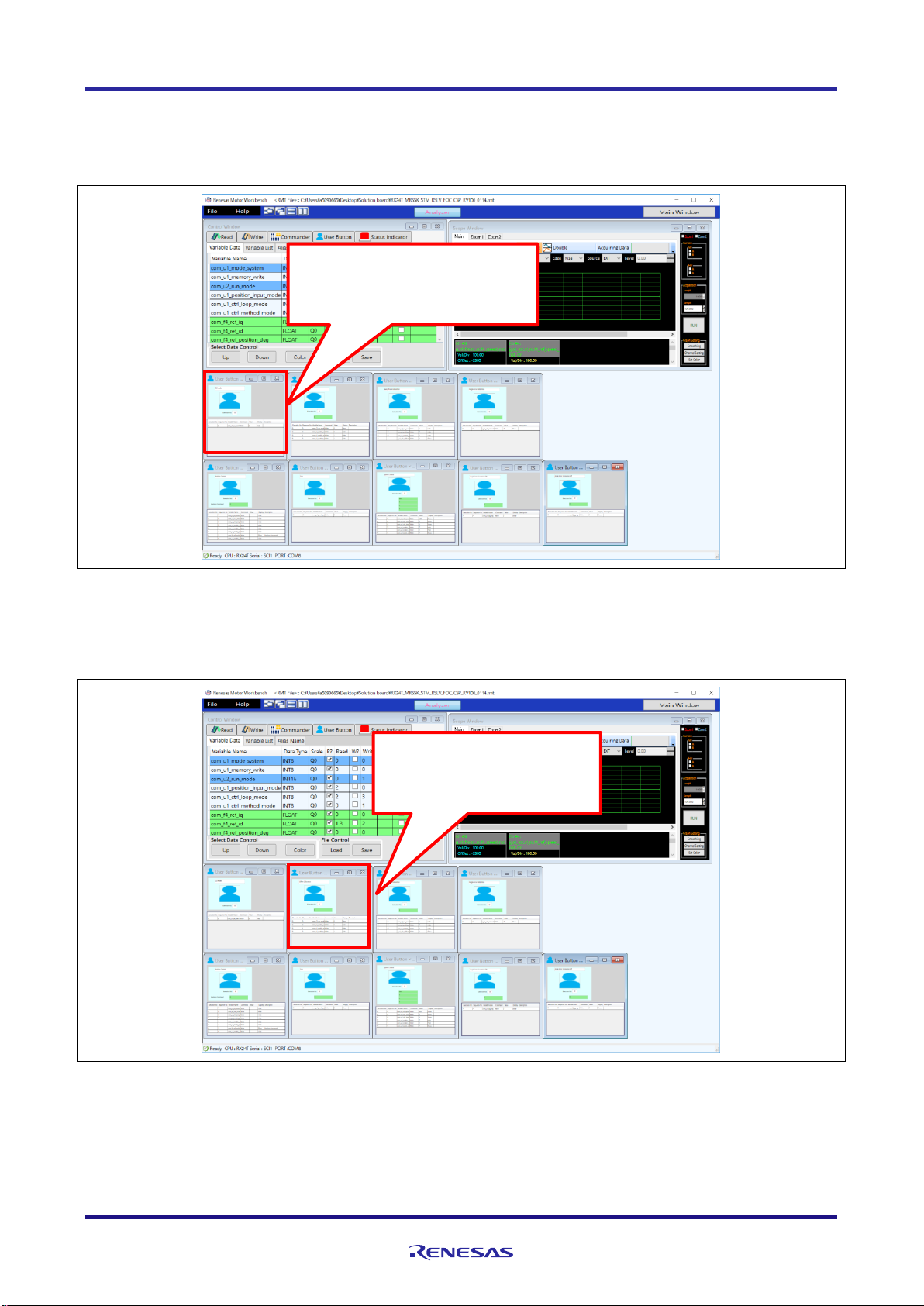

(3) Loading the configuration file

Download the sample code “Vector Control of a Two-Phase Stepping Motor Incorporating a Resolver

Sensor”(R03AN0014) and load the configuration file " RX24T_MRSSK_STM_RSLV_FOC_CSP_RVxxx.rmt " on

Renesas Motor Workbench.

Note that the capture screens in this manual may be different from the actual ones.

URL: http://japan.renesas.com/rssk/motor

Figure 2-11 Reading the Configuration File

(4) Switching to the Analyzer tool

In the Main window, click the Analyzer button. Renesas Motor Workbench displays the windows for the Analyzer

tool, Scope, User Button, and Control windows.

Figure 2-12 Display for the Renesas Motor Workbench Analyzer Tool

Scope window

Control window

User button window

Page 18

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 18 of 54

2020.11.06

(5) Changing the user interface

Change the user interface from the switches and variable resistor on the board to Renesas Motor Workbench. On

Renesas Motor Workbench, click the "GUI mode" User Button. Variable com_u1_sw_userif is rewritten from 1 to 0

and the interface changes.

Figure 2-13 Changing the User Interface

(6) Executing offset calibration

Click the "Offset Calibration" User Button to execute offset calibration.

Figure 2-14 Starting the Execution of Offset Calibration

User Button "GUI mode"

Changes the user interface.

User Button "Offset Calibration"

Execute offset calibration.

Page 19

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 19 of 54

2020.11.06

(7) Executing gain and phase calibration

Click the "Gain/Phase Calibration" User Button to execute gain and phase calibration.

Figure 2-15 Starting the Execution of Gain/Phase Calibration

(8) Executing angle error calibration

Click the "Angle error Calibration" User Button to execute angle error calibration. The motor starts rotating in 20~30

seconds. It stops rotating when the calibration finishes.

Figure 2-16 Starting the Execution of Angle Error Calibration

User Button " Gain/Phase Calibration"

Execute gain and phase calibration.

User Button " Angle error Calibration "

Execute angle error calibration.

Page 20

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 20 of 54

2020.11.06

(9) Setting the command value of position control

Set the command value of position control in the "Position Control" User Button.

Figure 2-17 Write Command Value in the Position Control Mode

(10) Operating the motor in the position control mode

Click the "Position Control " User Button. The motor starts rotating and stops at the posision set in the step (9).

Figure 2-18 Position Control Mode

Write command

value "100".

User Button " Position Control "

The motor starts rotating and stops.

Expansion

Page 21

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 21 of 54

2020.11.06

(11) Turning the servo off

Click the "Stop" User Button. The tool enters the stop mode from the position control mode and the servo is turned

off. (The motor shaft is released.)

Figure 2-19 Turning the Servo Off

(12) Sending a speed command

Click the "Speed Control" User Button. The motor rotates in the speed control mode and a waveform is displayed in

the Scope window.

Figure 2-20 Setting a Speed Command

User Button "Stop"

Puts the tool in the stop

mode.

User Button "Speed

Control"

Sends a speed

command.

The waveform in the

Scope window changes.

Push the "run" Button.

Page 22

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 22 of 54

2020.11.06

(13) Stopping rotation

Click the "Stop" User Button. The motor stops.

Figure 2-21 Stopping the Motor

(14) Stopping supplying the power

Check that the rotation stops and stop the output from the stabilized power supply.

User Button "Stop"

Puts the tool in the stop

mode.

Page 23

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 23 of 54

2020.11.06

2.3 Initial Software Specifications

Software for resolver vector control is factory-written on the RX24T. The specifications of the software are as

follows.

Table 2-1 Initial Software Specifications

Item

Specification

Control method

Resolver vector control

VR1

Turned clockwise: Rotates the motor counterclockwise.

Turned counterclockwise: Rotates the motor clockwise.

SW1

ON: Enables the rotation of the motor.

OFF: Disables the rotation of the motor.

SW2

Error occurs : cancels the error status

Motor rotates : N/A

Motor stops : calibration

LED1

On: SW1 in the ON state and normal operating status

Off: SW1 in the OFF state or error status

LED2

On: Error status

Off: Normal operating status

Renesas Motor Workbench

Available

Page 24

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 24 of 54

2020.11.06

2.4 Writing to Flash Memory

Since this product has an on-board emulator circuit (flash programming circuit), you can write data to the flash

memory without separately preparing a tool product. Connect the supplied USB cable to CN17 (USB mini-B connector)

on the CPU card and the USB connector on the PC and write data using an application such as Renesas Flash

Programmer or e2studio. With Renesas Flash Programmer and e2studio, the on-board emulator circuit is recognized as

E2Lite. Make the connection setting for E2Lite.

For details of how to use each application, refer to the relevant user's manual.

Figure 2-22 Connecting the Cable

Page 25

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 25 of 54

2020.11.06

2.5 Troubleshooting

・A connector is not mounted.

CN2, CN 4, CN 6, CN 7, CN 9, CN 11, CN 12, CN 13, and CN 14 are not mounted on the CPU card. Mount

required connectors.

・A cable is not connected (the number of connected cables is insufficient).

In the normal status, four motor cables and five resolver cables are connected.

・Some accessories are missing.

Check the accessory list. If any accessory is missing, contact the supplier from which you purchased this

product or Renesas Support.

・The motor does not operate.

Check whether power is supplied. Check whether the cable is connected.

・The rotation speed is unstable.

Execute auto calibration as instructed in quick start 2.

・The motor stops (the error status occurs).

Check whether the output current limitation of the power supply is proper. To rotate the supplied motor with

no load, set the current limitation to 1 A or higher. Also, see 2.5.1 and 2.5.2.

・This product cannot be connected with Renesas Motor Workbench (COM is not recognized).

Check that the version of Renesas Motor Workbench is 2.0 or later. When multiple COM numbers are

displayed, try to connect this product with another COM number.

・This product cannot be connected with Renesas Motor Workbench (The MCU (RX24T) is not recognized).

Check that the CPU card is correctly mounted on the inverter board and power is supplied to the inverter

board. The power to the CPU card is supplied from the inverter board.

・Software cannot be written to the MCU.

Check that the write setting is correct (see 2.4).

・Resetting this product to the factory settings

You can find the factory-set software in the product website. Download and write the software.

Page 26

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 26 of 54

2020.11.06

2.5.1 When the Rotation of the Motor Stops

When the motor is driven, if any predetermined limit value is exceeded, the initial software assumes that an error

occurred, turns LED2 on the inverter board and CPU card, and stops the rotation.

To recover from the error, press SW2 when the toggle switch SW1 is in the OFF position. When the error status is

canceled, LED2 goes off.

Figure 2-23 Error Notification LED and SW2

2.5.2 Checking the Status (Renesas Motor Workbench)

If LED2 is still on even after you perform the operation described in 2.5.1, you can possibly find the cause by

checking the status with Renesas Motor Workbench. Click Read in the Control window of RMW to check the status.

The value of variable _g_st_foc.u2_error_status, which indicates the status may correspond to an error listed in Table

2-2.

Figure 2-24 Checking the Status in the Control Window

Table 2-2 Values of the Variable and Corresponding Error Statuses

Variable _g_st_foc.u2_error_status

Error status

0x0001

Overcurrent

0x0002

Overvoltage

Page 27

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 27 of 54

2020.11.06

Kit Specifications

3.1 Specification List

Table 3-1 Specification List of the Evaluation System for Stepping Motor with Resolver

Major item

Item

Specification

MCU

Model name

R5F524TEADFP

Operation clock

20-MHz crystal oscillator (PLL-multiplied internal frequency: 80

MHz)

Power supply

Input voltage

24 VDC (-5%) to 48 VDC (+5%)

Connectors

・ Terminal block

・ DC jack (PL03B, center-positive)

Supplied motor

Type

Stepping motor

Size

42 mm square

Rated current

2 Apeak/phase

Holding torque

0.51 N m

Inverter circuit

Maximum output

100 W

Switching frequency

20 kHz or lower

Dead time

0.5 s or longer *1

PWM logic

Positive logic with both upper and lower arms

Current detection

Method

Voltage detection with a shunt resistor (-4 to +4 A)

Current detection method

Phase current detection (phase A, phase B)

Shunt resistor

25 m

Current detection amplifier

gain

Bain: 20

Bias: 2.5 V

A/D input range

0.25 to 4.75 V

(A/D input pin with an independent sample-and-hold circuit)

Sensors

Resolver

Method: Single-phase excitation two-phase output

Excitation frequency: 20 kHz

Encoder

Open-collector output, 200 kp/s applicable

Voltage detection

DC bus voltage detection

(Bus voltage detection)

Detection by resistance division

Phase voltage detection

Detection by resistance

Protection circuit

Overcurrent detection

When the current is 5 A, the overcurrent detection signal is

output and the inverter circuit stops*2.

Fuse

Rated current: 8 A

Reverse current

prevention diode

Repetitive peak reverse voltage: 75 V or higher

External device

interfaces

Communication interfaces

・ Renesas Motor Workbench communication circuit

・ RS-485 communication circuit

・ CAN communication circuit

Other interfaces

・ Pulse train command input circuit

・ General-purpose input/output circuits

User interfaces

Input

・ One toggle switch, one push switch

・ Variable resistor

Display

・ Three LEDs (Two of three are synchronized with LEDs on

the CPU card.)

・ LED for the power supply of the inverter control circuit

・ LED for the power supply of the CPU card

*1 It is not the dead time guaranteed with hardware. A dead time must be set with software. The dead time in the

initial program is factory-set to 0.5 s.

*2 To stop the inverter circuit, the POE function of the MCU is used.

Page 28

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 28 of 54

2020.11.06

3.2 Stepping Motor with Resolver

Table 3-2 lists the specifications of the stepping motor with resolver in this product. Figure 3-1 shows the external

view of the motor.

Table 3-2 Specifications of the Stepping Motor with Resolver

Model No.

R17PMK440CNVA4438

Rated current (Apeak/Phase)

2.0

Winding resistance (ohm)

1.2

Holding torque (Nm)

0.51

Inductance (mH)

2.6

Rotor inertia (kgm2)

75.0

Detent torque (Nm)

0.017

Figure 3-1 External View of the Stepping Motor with Resolver

Figure 3-2 Motor and Resolver Cable Wiring

Page 29

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 29 of 54

2020.11.06

3.3 Power Supply

To operate this product, it is necessary to apply 24 to 48 VDC externally. As connectors, the following items are

provided: Terminal block for connecting a stabilized power supply or switching power supply and a DC jack for

connecting an AC adapter. A voltage of 12 V for the gate driver and a voltage of 5 V for the MCU and other ICs are

generated on the inverter board.

A frame ground is provided on the terminal block. In addition, one of spacer mounting holes is connected to a frame

ground. When it is necessary to connect a frame ground, use either of them.

Figure 3-3 shows the connector. Table 3-3 lists the power input specifications. Table 3-4 lists the pin assignments of

the terminal block.

Figure 3-3 Power Connector

Table 3-3 Power Input Specifications

Power supply terminal block

DC jack

Input voltage

24 to 48 V 5%

24 V 5%

Input current

5 A (max)

3.5 A (max)

Applicable

cable

Cross section: 0.20 to 1.50 mm2

AWG: 16 to 30

Center-positive

Center diameter: 2 Barrel diameter: 6.5

Table 3-4 Power Supply Terminal Block

Connector

Signal name

Description

Inverter board CN1.1

VIN

Positive power input

Inverter board CN1.2

GND

Reference power input

Inverter board CN1.3

FG

Frame ground

A protection circuit is provided at the power input section, which consists of an overcurrent detection circuit,

overcurrent protection fuse, and reverse current prevention diode. The overcurrent detection circuit outputs the

overcurrent detection signal when the input current reaches 5 A. The rated current of the fuse is 8 A. Table 3-5 lists the

specifications of the protection circuit.

Table 3-5 Specifications of the Protection Circuit

Overcurrent detection threshold

5 A

Destinations of the overcurrent

detection signal

CNA.5, U2 (P70/POE0#) on the CPU card

Fuse characteristics

Rated current: 8 A. Blown at twice the

rated current within 5 seconds.

Page 30

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 30 of 54

2020.11.06

3.4 Inverter Circuit

This product has an inverter circuit for driving a 2-phase stepping motor and a connector for connecting the motor.

3.4.1 Connector

The plug of the connector for connecting the motor is separated from the socket. The connector is located at the

position shown in Figure 3-4.

Figure 3-4 Connector for Connecting the Motor

Page 31

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 31 of 54

2020.11.06

3.4.2 Inverter, Gate Driver

As the gate driver, the HIP4082 manufactured by Renesas Electronics Corporation is used. As the MOSFET, the

RJK1054DPB is used. Table 3-6 and Figure 3-5 show the configuration and connection of the inverter circuit.

Table 3-6 Inverter Drive Signal Board-to-Board Connection

CPU card

Board-to-

board

connector

Inverter board

Connection destination

(RX24T)

Gate driver

input

Gate driver

output

MOSFET

Motor pin

U2.56 (P71/MTIOC3B)

CNA.12

U4.7 (AHI)

U4.10 (AHO)

Q3

CN2.4

(phase A+)

U2.53 (P74/MTIOC3D)

CNA.9

U4.4 (ALI)

U4.13 (ALO)

Q4

U2.55 (P72/MTIOC4A)

CNA.11

U10.2 (BHI)

U10.16 (BHO)

Q5

CN2.3

(phase B+)

U2.52 (P75/MTIOC4C)

CNA.8

U10.3 (BLI)

U10.14 (BLO)

Q6

U2.45 (P95/MTIOC6B)

CNA.6

U4.2 (BHI)

U4.16 (BHO)

Q1

CN2.5

(phase A-)

U2.48 (P92/MTIOC6D)

CNA.4

U4.3 (BLI)

U4.14 (BLO)

Q2

U2.46 (P94/MTIOC7A)

CNA.10

U10.7 (AHI)

U10.10 (AHO)

Q7

CN2.2

(phase B-)

U2.49 (P91/MTIOC7C)

CNA.7

U10.4 (ALI)

U10.13 (ALO)

Q8

A

A

B

B

HIP4082A

+12V

AHO

ALO

FG

Inverter board

CPU card

RX24T

MTIOC3B

MTIOC3D

MTIOC4A

MTIOC4C

AA+

B+

B-

FG

HIP4082A

BHO

BLO

BHO

BLO

AHO

ALO

U4

MTIOC6D

MTIOC6B

MTIOC7A

MTIOC7C

BLI

BHI

ALI

AHI

ALI

AHI

U10

BLI

BHI

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

CN2

CNA

U2

Figure 3-5 Inverter Circuit

Page 32

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 32 of 54

2020.11.06

3.4.3 Current Detection

This product has a current detection circuit for measuring the motor current. The current detection circuit converts

phase currents to voltage signals and inputs them to the A/D converter. Figure 3-6 shows the circuit configuration.

Table 3-7 shows the connection.

Inverter board

RX24T

ADC

CPU card

S&H

S&H

AN100

AN101

x20

2.5V Center

OUT

-IN

+IN

OUT

-IN

+IN

Motor

AA+

B+

B-

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

R27

R67

U5

U9

CNB

U2

CN2

Figure 3-6 Current Detection Circuit

Table 3-7 Motor Current Detection Signal Board-to-Board Connection

Inverter board

Board-to-

board

connector

CPU card

Measurement target

Current detection amplifier

Connection

destination (RX24T)

Input

Output

Phase A shunt R27+

U5.8 (IN+)

U5.5 (OUT)

CNB.5

U2.91

(P40/AN100)

Phase A shunt R27-

U5.1 (IN-)

CNB.3

Phase B shunt R67+

U9.8 (IN+)

U9.5 (OUT)

CNB.6

U2.89

(P41/AN101)

Phase B shunt R67-

U9.1 (IN-)

CNB.4

The relationship between the current value of the shunt resistor

in the current detection circuit and the A/D

conversion value

is expressed by Equation 1. Table 3-8 lists typical values.

Equation 1

A

Current value of the shunt resistor

Shunt resistance

G

V/V

Current detection amplifier gain

V

Analog supply voltage

LSB

A/D conversion value

Table 3-8 Motor Phase Current and Corresponding Output Voltage of the Current Detection Amplifier

Current value

4 A

2 A (rated)

0 A

-2 A (rated)

-4 A

Potential difference across

shunt resistor

0.2 V1%

0.1 V1%

0.0 V1%

-0.1 V1%

-0.2 V1%

Output voltage

4.5 V2%

3.5 V2%

2.5 V2%

1.5 V2%

0.5 V2%

A/D conversion value

(*1)

3685 LSB

2866 LSB

2048 LSB

1228 LSB

409 LSB

*1 Reference value in which the error of the A/D converter is not included

Page 33

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 33 of 54

2020.11.06

3.4.4 Voltage Detection

This product has a voltage divider for measuring the supply voltage and voltage of each phase of the motor. The

output of the voltage divider is connected to the A/D converter on the RX24T. Figure 3-7 shows the circuit

configuration. Table 3-9 lists the connection destinations.

Inverter board

RX24T

ADC

CPU card

AN211

AN209

Motor

AA+

B+

B-

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

CNB

U2

CN2

AN208

AN207

AN210

S&H

Figure 3-7 Voltage Detection Circuit

Table 3-9 Voltage Detection Signal Board-to-Board Connection

Inverter board

Board-to-board

connector

CPU card

Measurement target

Connection destination

(RX24T: U2)

Inverter supply voltage

CNB.8

U2.78 (P55/AN211)

Phase A+ voltage

CNB.10

U2.82 (P51/AN207)

Phase B+ voltage

CNB.11

U2.81 (P52/AN208)

Phase B- voltage

CNB.12

U2.80 (P53/AN209)

Phase A- voltage

CNB.13

U2.79 (P54/AN210)

The relationship between the supply voltage and A/D conversion result is expressed by Equation 2. Table 3-10 lists

typical values.

Equation 2

V

Input voltage value

V

Analog supply voltage

LSB

A/D conversion value

Table 3-10 Relationships among the Input Voltage, Output Voltage, and A/D Conversion Value

Supply

voltage

A/D input

voltage

A/D conversion

value *1

24 V

1.077 V

882 LSB

36 V

1.616 V

1323 LSB

48 V

2.155 V

1765 LSB

*1 Reference value in which the error of the A/D convertor is not included

Page 34

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 34 of 54

2020.11.06

3.5 Sensor Interfaces

3.5.1 Resolver

This product has a resolver/digital converter IC (RDC IC). The RDC IC converts the analog signal output from the

resolver to the phase-modulated digital signal output. For the specifications of the RDC IC, refer to "RDC IC User's

Manual (r03uz0002)".

The connector for connecting the resolver is of a plug/socket type, which allows you to connect and disconnect the

resolver easily. Figure 3-8 shows the location of the resolver connector supplied with this product. Table 3-11 lists

connection information of the resolver motor and resolver connector.

Figure 3-8 Connector for Connecting the Resolver

Table 3-11 Resolver Connector Connection

Connector

Signal

name

Connection destination

Resolver

cable color

CN10.1

cos-

RDC IC

U21.28 (EXCOUT2) via U21.17 (XBN) and R335

Black

CN10.2

EXOUT1

RDC IC

U21.26 (EXCOUT1) and U29 (EXCFBP) via R335

White

CN10.3

cos+

RDC IC

U21.28 (EXCOUT2) via U21.18 (XBP) and R335

Green

CN10.4

EXOUT1

RDC IC

U21.26 (EXCOUT1) and U29 (EXCFBP) via R335

-

CN10.5

sin+

RDC IC

U21.28 (EXCOUT2) via U21.23 (XAP) and R335

Red

CN10.6

EXOUT1

RDC IC

U21.26 (EXCOUT1) and U29 (EXCFBP) via R335

-

CN10.7

sin-

RDC IC

U21.28 (EXCOUT2) via U21.24 (XAN) and R335

Yellow

CN10.8

EXOUT1

RDC IC

U21.26 (EXCOUT1) and U29 (EXCFBP) via R335

-

CN10.9

shield

Power

supply

GND_A

-

CN10.10

shield

Power

supply

GND_A

-

Page 35

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 35 of 54

2020.11.06

3.5.2 Encoder

This product supports encoder A/B/Z signal input. The signals are input to the MCU via the 5-V pull-up resistor, RC

filter, and buffer IC. Figure 3-9 shows the location of the encoder connector. Table 3-12 lists connection information of

the encoder and connector. Table 3-13 lists the specifications of the input signals. The connector is not mounted at the

factory. To use an encoder, mount a 2.54 mm pitch connector.

Figure 3-9 Encoder Connector

Table 3-12 Encoder Signal Connector Connection Information

Connector

Pin function

Connection destination (RX24T)

CN6.1

5 V

Power

supply

+5V_D

CN6.2

Phase A

RX24T

U2.58 (P33/MTCLKA)*1

CN6.3

GND

Power

supply

GND_D

CN6.4

Phase B

RX24T

U2.59 (P32/MTCLKB)*1

CN6.5

GND

Power

supply

GND_D

CN6.6

Phase Z

RX24T

U2.36 (PA5/MTIOC1A)*1

CN6.7

GND

Power

supply

GND_D

CN6.8

GND

Power

supply

GND_D

*1 Via the positive logic buffer IC

Table 3-13 Encoder Signal Input Specifications

Pulse rate

200 kp/r (max)

Input signal type

Open collector

Connector applicable wire

Cross section: 0.14 to 0.5 mm²

AWG: 20 to 26

Connector type

3.5 mm pitch plug/socket terminal block

Page 36

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 36 of 54

2020.11.06

3.5.3 Origin/Limit Sensors

This product supports the photoelectric sensor signal input for origin/limit sensors. It has a pull-up resistor on the

board for supporting NPN sensors. The input signals are connected to the MCU all via the buffer IC. Figure 3-10 shows

the locations of the origin/limit sensor connectors. Table 3-14 lists the input specifications. Table 3-15 lists connector

connection information. The connectors are not mounted at the factory. To use a sensor, mount a 2.5 mm pitch

connector.

Figure 3-10 Origin/Limit Sensor Connectors

Table 3-14 Origin/Limit Sensor Input Specifications

Input signal type

Open collector

Connector

B3B-XH-A (J.S.T. Mfg. Co., Ltd.)

Table 3-15 Origin/Limit Sensor Signal Input Connector Connection Information

Connector

Signal

Connection destination

CN4.1

5V

+5V_D

CN4.2

DOG

U2.1 (PE5/IRQ0)*1

CN4.3

GND

GND_D

CN7.1

5V

+5V_D

CN7.2

N-OT

U2.7 (P00/IRQ2) *2

CN7.3

GND

GND_D

CN9.1

5V

+5V_D

CN9.2

P-OT

U2.7 (P00/IRQ2) *2

CN9.3

GND

GND_D

*1 Via the positive logic buffer IC

*2 A wired OR connection is made between N-OT and P-OT on the CPU card.

Page 37

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 37 of 54

2020.11.06

3.6 External Device Interfaces

This product has various types of external device interfaces, which allows the connection of general motor control

devices.

3.6.1 Renesas Motor Workbench Communication Circuit

This product is equipped with a USB connection interface and supports support tool for motor control development

Renesas Motor Workbench (RMW). RMW, an application program running on a PC, can display internal variables of a

target microcontroller in waveform in real time, read and write them, and automatically extract each parameter. For

details of the operation method, refer to "RMW Operation Manual (r21uz0004)".

Figure 3-11 Renesas Motor Workbench Communication Circuit Connector

RX24T

Inverter board CPU card

Rene sas Motor

Workbench

communication

circuit

Digital Isolator

PD5/RXD1

PD3/TXD1

Power supply isolation

USB

Figure 3-12 Renesas Motor Workbench Communication Circuit

Page 38

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 38 of 54

2020.11.06

3.6.2 RS-485 Communication

This product is equipped with an RS-485 communication interface, which enables asynchronous serial

communication using differential signals at a maximum of 5 Mbps. It also supports a multidrop system, which enables

control over transmission enable. For communication, the UART function built in the mounted MCU

(R5F524TEADFP) is used. As a transceiver, the ISL3156E manufactured by Renesas Electronics Corporation is

mounted. Figure 3-13 shows the location of the connector. Table 3-16 lists the communication specifications. Table

3-17 lists the connection information from the connector to the RX24T. The connector is not mounted at the factory. To

use RS-485 communication, mount a 2.54 mm pitch connector.

Figure 3-13 RS-485 Communication Connector

Table 3-16 RS-485 Communication Specifications

Baud rate

5 Mbps (max)

Half-/full-duplex

Full-duplex

Common-mode voltage

-7 to +12 V

Terminating resistor

100 , 0.1 F (AC termination)

ISL3156E

RS48 5

100

0.1u

RO

DI

Z

Y

A

B

DE

RE#

AC termination

Connector applicable wire

Cross section: 0.2 to 0.5 mm²

AWG: 20 to 24

Table 3-17 RS-485 Communication Connector Connection Information

Connector

Signal

Connection destination (RS-485

transceiver differential side)

CN12.1

Differential input +

RS-485 transceiver

U9.9 (A)

CN12.2

Differential input -

RS-485 transceiver

U9.8 (B)

CN12.3

GND

Power supply

-

CN12.4

Differential output -

RS-485 transceiver

U9.8 (Z)

CN12.5

Differential output +

RS-485 transceiver

U9.6 (Y)

Table 3-18 Connection between the RS-485 Transceiver and MCU

RS-485 transceiver CMOS level side

Connection with RX24T

Processing on the

board

U9.1 (RO)

U2.34 (PB1/RXD6)

10-k pull-up

U9.2 (RE#)

No connection with U2

10-k pull-down

U9.3 (DE)

U2.2 (P02)

10-k pull-down

U9.4 (DI)

U2.33 (PB2/TXD6)

-

Page 39

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 39 of 54

2020.11.06

3.6.3 CAN Communication

This product is equipped with a CAN communication interface, which enables communication at a maximum of 1

Mbps. For communication, the RSCAN function built in the mounted MCU (R5F524TEADFP) is used. Figure 3-14

shows the location of the connector. Table 3-19 lists the communication specifications. Table 3-20 lists the connection

information from the connector to the RX24T. The connector is not mounted at the factory. To use CAN

communication, mount a 2.54 mm pitch connector.

Figure 3-14 CAN Communication Connector

Table 3-19 CAN Communication Specifications

Baud rate

1 Mbps (max)

Half-/full-duplex

Half-duplex

Terminating resistance

120

Connector applicable wire

Cross section: 0.2 to 0.5 mm²

AWG: 20 to 24

Table 3-20 CAN Communication Connection Information

Connector

Connection

destination

CN14.1

U13.6 (CANL)

CN14.2

GND

CN14.3

U13.7 (CANH)

Transceiver connection

destination

RX24T connection

destination

U13.1 (Txd)

U2.41 (PA0/CTXD0)

U13.4 (Rxd)

U2.40 (PA1/CRXD0)

Page 40

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 40 of 54

2020.11.06

3.6.4 Pulse Train Command

This product is equipped with an input interface for pulse train commands, which enables the input of pulse train

commands at a maximum of 200 kp/r. The input signals are connected to the MCU all via the buffer IC. Figure 3-15

shows the location of the connector. Table 3-21 lists the input specifications. Table 3-22 lists connection information.

The connector is not mounted at the factory. To use pulse train commands, mount a 2.54 mm pitch connector.

Figure 3-15 Pulse Train Command Connector

Table 3-21 Pulse Train Command Input Specifications

Pulse rate

200 kp/r (max)

Input signal type

Open collector

Connector applicable wire

Cross section: 0.14 to 0.5 mm²

AWG: 20 to 26

Table 3-22 Pulse Train Command Input Connection Relationship

Connector

Signal name

Connection destination (RX24T)

CN13.1

5V

Power

supply

+5V_D

CN13.2

PULSE/UP

RX24T

U2.8 (PE4/MTCLKC)*1

CN13.3

GND

Power

supply

GND_D

CN13.4

DIR/DOWN

RX24T

U2.9 (PE3/MTCLKD)*1

CN13.5

GND

Power

supply

GND_D

CN13.6

CLR

RX24T

U2.38 (PA3/MTIOC2A)*1

CN13.7

GND

Power

supply

GND_D

CN13.8

GND

Power

supply

GND_D

*1 Via the positive logic buffer IC

Page 41

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 41 of 54

2020.11.06

3.6.5 General-Purpose Output

This product has a general-purpose output interface for outputting various notification signals to external devices.

The interface has an open-collector buffer output with a withstand voltage of 30 V and is applicable for control devices

operating at 24 V. The output signals from the MCU are connected to the connector all via the buffer IC. Figure 3-16

shows the location of the connector. Table 3-23 lists the output specifications. Table 3-24 lists the connection

information. The connector is not mounted at the factory. To use the general-purpose output, mount a 2.54 mm pitch

connector.

Figure 3-16 General-Purpose Output Connector

Table 3-23 General-Purpose Output Specifications

Logic

Positive

Output type

Open collector

Withstand voltage

30 V

Connector applicable wire

Cross section: 0.14 to 0.5 mm²

AWG: 20 to 26

Table 3-24 General-Purpose Output Connector Connection Information

Connector

Signal name

Connection destination

(RX24T)

CN11.1

5V

Power

supply

+5V_D

CN11.2

General-purpose

output (RDY)

RX24T

U2.32 (PB3)*1

CN11.3

General-purpose

output (COIN)

RX24T

U2.27 (PB6) *1

CN11.4

General-purpose

output (ORG)

RX24T

U2.28 (PB5) *1

CN11.5

General-purpose

output (ERROR)

RX24T

U2.23 (PD2) *1

CN11.6

General-purpose

output

RX24T

U2.21 (PD4) *1

CN11.7

General-purpose

output

RX24T

U2.30 (PB4) *1

CN11.8

GND

Power

supply

GND_D

*1 Via the open-collector output IC with a withstand voltage of 30 V

Page 42

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 42 of 54

2020.11.06

3.6.6 General-Purpose Input

This product has a general-purpose input interface for inputting various notification signals from external devices.

The interface has a pull-up circuit, assuming that open-collector signals are input. The input signals are connected to the

MCU all via the buffer IC. The connector is also used for the analog input. Figure 3-17 shows the location of the

connector. Table 3-25 lists the input specifications. Table 3-26 lists the connection information. The connector is not

mounted at the factory. To use the general-purpose input, mount a 2.54 mm pitch connector.

Figure 3-17 General-Purpose Input Connector

Table 3-25 General-Purpose Input Specifications

Logic

Positive

Input type

Pull-up/hysteresis input buffer

Withstand voltage

0 to 5 V

Connector applicable wire

Cross section: 0.14 to 0.5 mm²

AWG: 20 to 26

Table 3-26 General-Purpose Input Connector Connection Information

Connector

Signal name

Connection destination (RX24T)

CN2.4

GND

Power supply

GND_D

CN2.5

General-purpose

input

RX24T

U2.69 (P65)*1

CN2.6

General-purpose

input

RX24T

U2.26 (PB7)*1

CN2.7

General-purpose

input (SVON)

RX24T

U2.100 (P10)*1

CN2.8

5V

Power supply

+5V_D

*1 Via the positive logic buffer IC

Page 43

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 43 of 54

2020.11.06

3.6.7 Analog Input

This product has an analog input circuit for inputting analog commands from external devices or general-purpose

analog signals. When the input end is open, a voltage of AVCC/2 = 2.5 V is input to the MCU. The connector is also

used for the general-purpose input. Figure 3-18 shows the location of the connector. Table 3-27 lists the input

specifications. Table 3-28 lists the connection information. The connector is not mounted at the factory. To use the

analog input, mount a 2.54 mm pitch connector.

Figure 3-18 Analog Input Connector

Table 3-27 Analog Input Specifications

Input voltage range [V]

0 to 5 V

Input characteristics

Two pull-up/pull-down resistors with a

resistance of 470 k 1%

When the input end is open: 2.5 V

CPU card

MCU

P64/AN204

1k

0.1u

470k

470k

Analog co mma nd

input

Connector applicable wire

Cross section: 0.14 to 0.5 mm²

AWG: 20 to 26

Table 3-28 Analog Input Connection Information

Connector

Signal name

Connection destination

CN2.1

GND

Power supply

GND_A

CN2.2

Analog input

RX24T

U2.70 (P64/AN204) *1

CN2.3

5V

Power supply

+5V_A

*1 Via the buffer configuration op-amp

Page 44

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 44 of 54

2020.11.06

3.7 User Interfaces

3.7.1 LEDs

This product has four LEDs on the inverter board and three LEDs on the CPU card. Two LEDs on the CPU card are

connected to the same MCU pins to which LEDs on the inverter board are connected. Figure 3-19 shows the locations

of the LEDs. Table 3-29 lists the connection information.

Figure 3-19 LEDs

Table 3-29 LED On Conditions and Connection Information

LED

On condition

Off condition

Board-to-board

connector

Connection

destination

Inverter board: LED1

Port output: Low

Port output: High

CNA.1

CPU card: U2.97

(RX24T P81)

Inverter board: LED2

Port output: Low

Port output: High

CNA.2

CPU card: U2.98

(RX24T P80)

Inverter board: LED3

Port output: Low

Port output: High

CNA.3

CPU card: U2.39

(RX24T PA2)

Inverter board: LED4

5-V supplied

5-V supply stopped

-

5-V power supply

(+5V_D)

CPU card: LED1

Port output: Low

Port output: High

-

CPU card: U2.97

(RX24T P81)

CPU card: LED2

Port output: Low

Port output: High

-

CPU card: U2.98

(RX24T P80)

CPU card: LED3

5-V supplied

5-V supply stopped

-

5-V power supply

(+5V_D)

Page 45

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 45 of 54

2020.11.06

3.7.2 Switches

This product has an MCU reset switch and two switches connected to MCU pin functions. Figure 3-20 shows the

locations of the switches. Table 3-30 lists the connection information.

Figure 3-20 Locations of the Switches

Table 3-30 Switch Input Levels and Connection Information

Switch

Switch type

Input

Board-to-board

connector

Connection

destination

Inverter board:

SW1

Toggle switch

Lever OFF position: High

Lever ON position: Low

CNA.13

CPU card: U2.76

(RX24T P61)

Inverter board:

SW2

Tact switch

Released: High

Pressed: Low

CNA.14

CPU card: U2.10

(RX24T P62)

CPU card: SW1

Tact switch

Released: High

Pressed: Low

-

CPU card: U2.10

(RX24T RES#)

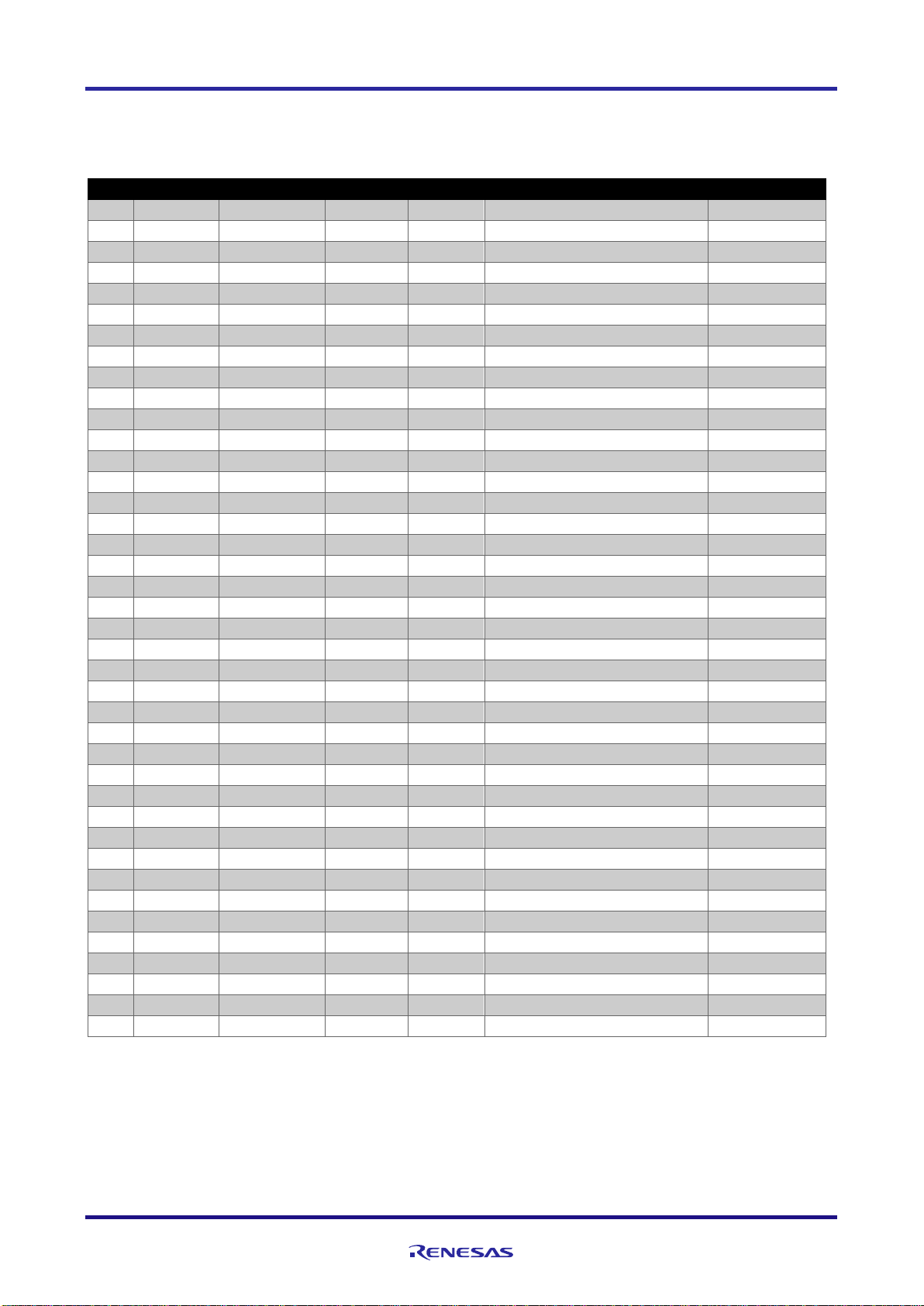

3.7.3 Variable Resistor

This product has a variable resistor. Figure 3-21 shows the location. Table 3-31 lists the specifications.

Figure 3-21 Location of the Variable Resistor

Table 3-31 Specifications and Connection Information of the Variable Resistor

Output voltage range

0 to AVCC

Board-to-board connector

CNB.15

Connection destination

CPU card: U2.77 (RX24T P60/AN200)

Page 46

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 46 of 54

2020.11.06

3.8 Pin Assignments

3.8.1 MCU Pin Function Assignments

Table 3-32 MCU Pin Function Assignments (1/3)

#

Port

Module

Function

IN/OUT

Connection destination

Signal name

1

PE5

ICU

IRQ0

IN

Sensor (origin)

DOG

2

P02

Port

P02

OUT

Upper device (RS-485)

RS485_DE-

3

VSS

Power

VSS

-

Power supply

GND_D

4

P00

ICU

IRQ2

IN

Sensor (limit)

N-OT, P-OT

5

VCL

Power

VCL

-

Power supply

VCL

6

MD

System

MD

IN/OUT

E2 on board

FINE

7

P01

POE

POE12#

IN

RDC IC

RDC_ALARM

8

PE4

MTU

MTCLKC

IN

Upper device (Pulse command)

PULSE/UP

9

PE3

MTU

MTCLKD

IN

Upper device (Pulse command)

DIR/DOWN

10

RES#

System

RES#

IN

Reset circuit/E2 on board

MCU_RESET

11

XTAL

System

XTAL

-

Oscillator

XTAL

12

VSS

Power

VSS

-

Power supply

GND_D

13

EXTAL

System

EXTAL

-

Oscillator

EXTAL

14

VCC

Power

VCC

-

Power supply

VCC_D

15

PE2

Not used

- - - - 16

PE1

Not used

- - - - 17

PE0

MTU9

MTIOC9B

OUT

RDC IC

CARRIER2

18

PD7

Not used

- - - - 19

PD6

RSPI

SSLA0

OUT

RDC IC

SPI_SCS

20

PD5

UART1

RXD1

IN

RMW communication circuit

ICS_RX

21

PD4

Port

PD4

OUT

Upper device (sequence output)

GPOUTPUT

22

PD3

UART1

TXD1

OUT

RMW communication circuit

ICS_TX

23

PD2

Port

PD2

OUT

Upper device (sequence output)

ERROR

24

PD1

Port

PD1

OUT

Sensor power ON/OFF

SPON

25

PD0

Not used

- - - - 26

PB7

Port

PB7

IN

Upper device (sequence input)

GPINPUT

27

PB6

Port

PB6

OUT

Upper device (sequence output)

COIN

28

PB5

Port

PB5

OUT

Upper device (sequence output)

ORG

29

VCC

Power

VCC

-

Power supply

VCC_D

30

PB4

Port

PB4

OUT

Upper device (sequence output)

GPOUTPUT

31

VSS

Power

VSS

-

Power supply

GND_D

32

PB3

Port

PB3

OUT

Upper device (sequence output)

RDY

33

PB2

UART6

TXD6

OUT

Upper device (RS-485)

RS485_TX

34

PB1

UART6

RXD6

IN

Upper device (RS-485)

RS485_RX

35

PB0

TMR

TMO0

OUT

RDC IC

PWMINA

36

PA5

MTU1

MTIOC1A

IN

Encoder

ENC_Z

37

PA4

RSPI

RSPCKA

OUT

RDC IC

SPI_SCLK

38

PA3

MTU2

MTIOC2A

IN

RDC IC

COUT

39

PA2

Port

PA2

OUT

LED

LED3#

40

PA1

RSCAN

CRXD0

IN

Upper device (CAN)

CAN_RX

Page 47

Evaluation System for Stepping Motor with Resolver User's Manual

R12UZ0065EJ0110 Rev.1.10 Page 47 of 54

2020.11.06

Table 3-33 MCU Pin Function Assignments (2/3)

#

Port

Module

Function

IN/OUT

Connection destination

Signal name

41

PA0

RSCAN

CTXD0

OUT

Upper device (CAN)

CAN_TX

42

VCC

Power

VCC

-

Power supply

VCC_D

43

P96

Not used

- - - - 44

VSS

Power

VSS

-

Power supply

GND_D

45

P95

MTU67

MTIOC6B

OUT

Gate driver

A-H

46

P94

MTU67

MTIOC7A

OUT

Gate driver

B-H

47

P93

Not used

- - - - 48

P92

MTU67

MTIOC6D

OUT

Gate driver

A-L

49

P91

MTU67

MTIOC7C

OUT

Gate driver

B-L

50

P90

Not used

- - - - 51

P76

Not used

- - - - 52

P75

MTU34

MTIOC4C

OUT

Gate driver

B+L

53

P74

MTU34

MTIOC3D

OUT

Gate driver

A+L

54

P73

Not used

- - - - 55

P72

MTU34

MTIOC4A

OUT

Gate driver

B+H

56

P71

MTU34

MTIOC3B

OUT

Gate driver

A+H

57

P70

POE

POE0#

IN

Overcurrent detection circuit

HISEDE_OC#

58

P33

MTU

MTCLKA

IN

Encoder phase A

ENC_A

59

P32

MTU

MTCLKB

IN

Encoder phase B

ENC_B

60

VCC

Power

VCC

-

Power supply

VCC_D

61

P31

MTU0

MTIOC0A

OUT

RDC IC

CC

62

VSS

Power

VSS

-

Power supply

GND_D

63

P30

Not used

- - - - 64

P24

D/A

DA0

OUT

Analog monitor

Analog_Mon

65

P23

RSPI

MOSIA

OUT

RDC IC

SPI_MOSI

66