Page 1

Operator’s Manual

2-Cycle Chain Saw

RM4218 / RM4620

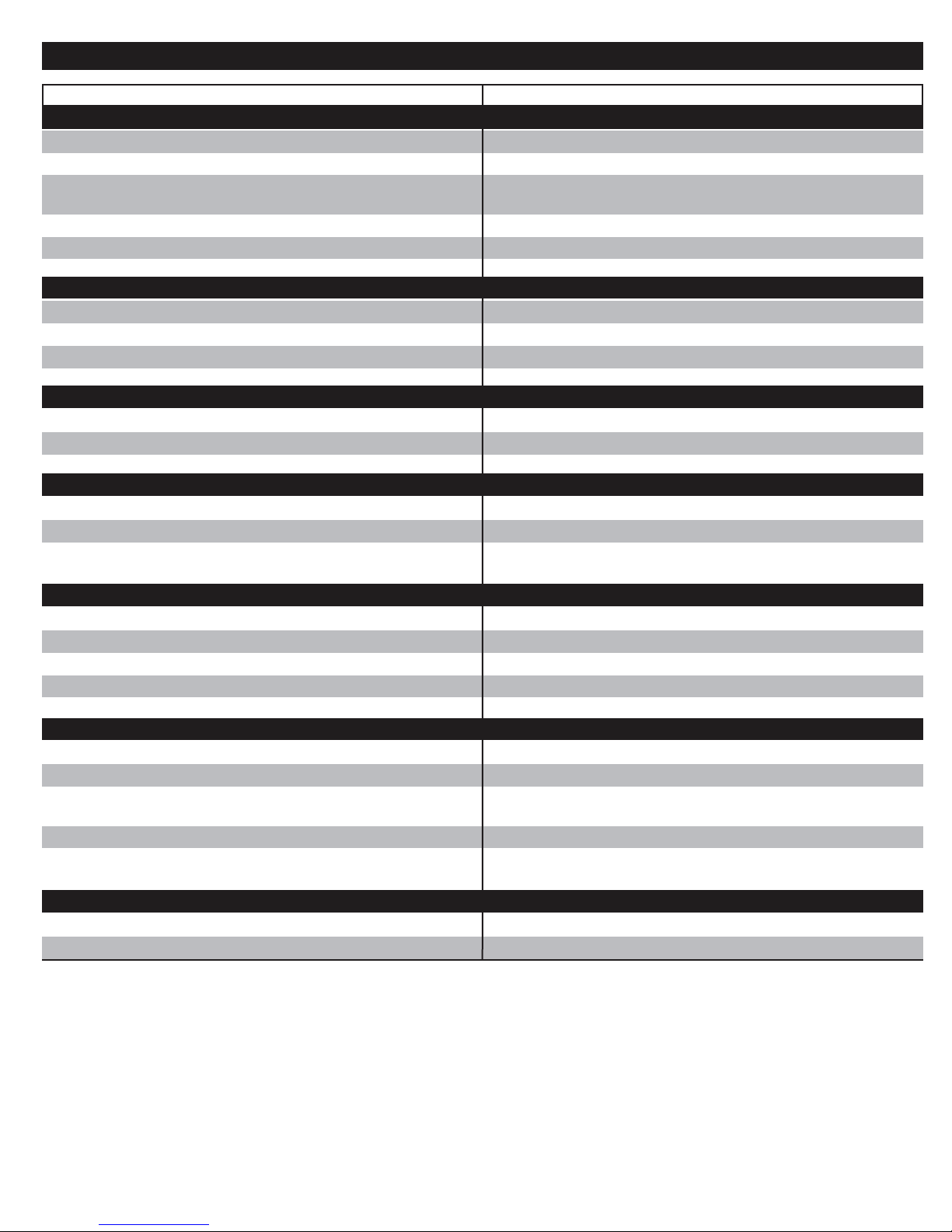

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SAVE THESE INSTRUCTIONS

SERVICE

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or

maintenance of the unit, please call the Customer Support Department

at 1-866-206-2707 in the United States or 1-877-696-5533 in Canada.

Additional information about the unit can be found on our website at

www.remingtonpowertools.com.

For service, please call the Customer Support Department to obtain

a list of authorized service dealers near you. Service on this unit,

both within and after the warranty period, should only be performed

by an authorized and approved service dealer. When servicing, use

only identical replacement parts.

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

Copyright© 2013 MTD SOUTHWEST INC, All Rights Reserved.

IMPORTANT: Read this manual thoroughly before using this product. Follow all instructions.

769-08938 / 00 09/13

Page 2

SAFETY

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

DANGER:Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in

serious injury or death to yourself or to others.

WARNING:Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in

serious injury to yourself or to others.

CAUTION:Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. If it requires

replacement, ask your LOCAL SERVICE DEALER to install the

Accessory Part #753-08106 Muffler Assembly.

CALIFORNIA PROPOSITION 65

WARNING:This product contains a chemical

known to the state of California to cause cancer, birth defects

or other reproductive harm.

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

WARNING:When using the unit, all safety rules

must be followed. Please read these instructions before

operating the unit in order to ensure the safety of the

operator and any bystanders. Please keep these

instructions for later use.

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit. Know how to stop the unit and disengage

the controls quickly.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Never allow children to operate the unit. Never allow adults to

operate the unit without proper instruction.

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands and feet.

• Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or

repairs before using the unit.

SAFETY WARNINGS FOR GAS UNITS

WARNING:Use caution when handling fuel.

Gasoline is highly flammable and its vapors can explode if

ignited. Take the following precautions:

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

• Always mix and add fuel in a clean, well-ventilated outdoor area

where there are no sparks or flames. DO NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

2

Page 3

WHILE OPERATING

• Wear safety glasses or goggles that meet current ANSI Z87.1

standards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face mask or dust mask if the

operation is dusty. Use a hard hat or other type of safety helmet.

• Wear safety boots and protective gloves. Wear heavy, snugfitting clothes, including long pants and a long-sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• Make sure the saw chain is not in contact with anything before

starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting and Stopping.

• Use the right tool. Only use this tool for its intended purpose: to

cut wood. Do not use the unit for cutting plastic, masonry or

other non-wood building materials. Only use the unit as

described in this manual.

• Keep all body parts away from the saw chain when the unit is

running. Do not touch or try to stop moving parts.

• Do not touch the engine or muffler. These parts get extremely hot

from operation, even after the unit is turned off.

• Do not operate the unit faster than the speed needed to do the job.

Do not run the unit at high speed when not in use.

• Do not force the unit, especially near the end of a cut. It will do a

better, safer job when used at the intended rate.

• Always turn the engine off when operation is delayed, when

setting the unit down or when carrying the unit from one location

to another. Make sure all moving parts come to a complete stop.

• Carry the unit by the front handle with the muffler positioned

away from the body and the guide bar positioned to the rear.

Cover the guide bar and saw chain with the scabbard when

carrying the unit.

• If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the unit

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are available from your

authorized service dealer. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

• Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

• Keep the work area clean. Cluttered areas invite injuries. Do not

start cutting until the work area is clear and free from

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• For safer, more effective performance, make sure the guide bar

and chain are properly cleaned, lubricated, tightened and

sharpened. Check the guide bar and chain at frequent intervals

for proper adjustment.

• When cutting a limb that is under tension, use extreme caution.

When the tension is released, the limb could spring back and

strike the operator, causing severe injury or death.

• Use extreme caution when cutting small-sized brush and

saplings, as slender material may catch the saw chain and be

whipped toward the operator or pull the operator off balance.

• This saw is classified by UL as a Class 1C saw in accordance

with CSA Z62.1-03. It is intended for infrequent use by

homeowners, cottagers and campers, and for general

applications such as clearing, pruning, cutting firewood, etc. It is

not intended for prolonged use. If the intended use involves

prolonged periods of operation, this may cause circulatory

problems in the user’s hands due to vibration.

• Do not operate the unit in a tree or on a ladder unless

specifically trained to do so.

• Never remove, modify or make inoperative any safety device

furnished with the unit.

• Do not use the unit in the presence of flammable liquids or gases.

• Do not attempt operations beyond the operator’s capacity or

experience.

• Do not operate a unit that is damaged, improperly adjusted or

not completely and securely assembled. Make sure moving

parts stop when the unit is turned off. Do not use the unit if it

does not turn on and off properly. Have defective parts replaced

by an authorized service dealer.

KICKBACK SAFETY

WARNING:Kickback may occur when the

nose or tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut. In

some cases, tip contact may cause a lightening-fast

reverse action, kicking the guide bar rapidly back to wards

the operator. Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back towards the

operator. Either of these reactions may cause a loss of

control over the saw, which could result in serious injury to

the user. Contact with foreign objects within the wood can

also induce a loss of chain saw control.

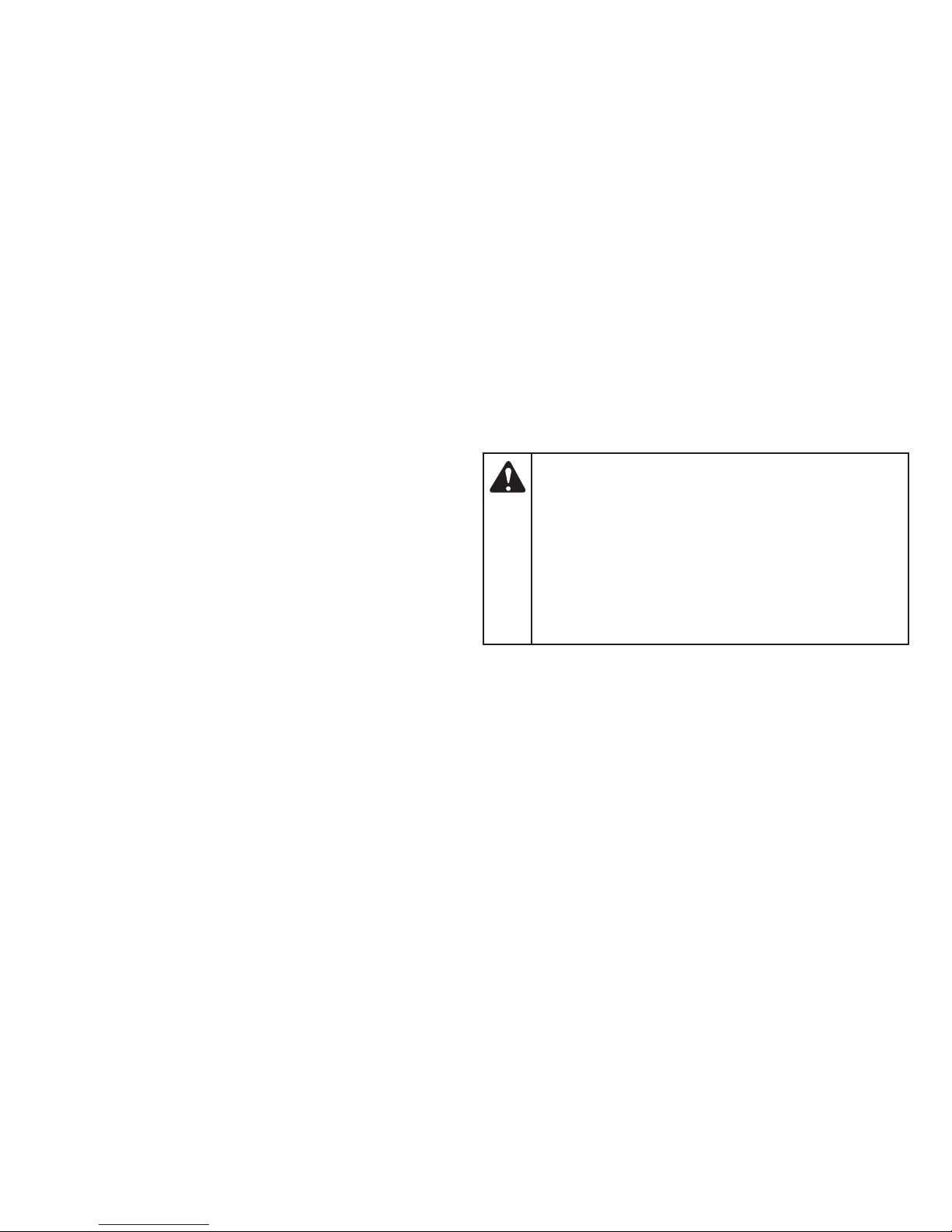

Understanding Kickback

A basic understanding of kickback can help reduce or eliminate the

element of surprise and the chance of kickback-related injury.

Sudden surprise contributes to accidents.

• Rotational Kickback can happen when the upper tip of the

guide bar contacts an object while the chain is moving (Fig. A).

This can cause the chain to dig into the object and momentarily

stop moving. The guide bar is then kicked up and back toward

the operator in a lightning-fast reverse reaction.

• Linear Kickback can happen when the wood on either side of a

cut closes in and pinches the moving saw chain along the top of

the guide bar (Fig. B). This can cause the chain to instantly stop.

The chain force is then reversed, causing the saw to move in the

opposite direction, sending the saw straight back toward the

operator.

• Pull-In can happen when the moving chain on the bottom of the

guide bar hits a foreign object inside the wood. This can cause

the chain to suddenly stop. The saw is then pulled forward and

away from the operator, which could potentially result in the loss

of control of the saw.

3

Page 4

Rotational

Kickback

Kickback

Danger Zone

Fig. A

Fig. B

Pinch

Saw Chain

Direction

Linear

Kickback

• Only use wedges made of wood or plastic. Do not use metal to

hold a cut open.

• Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain.

• Only use replacement bars and chains specified by the

manufacturer or the equivalent. These are available from

authorized service dealers. Use of any unauthorized parts or

accessories could lead to serious injury to the operator or

damage to the unit and will void the warranty.

• Use devices that reduce the risks associated with kickback,

such as low-kickback chains, guide bar nose guards, chain

brakes and low-kickback guide bars. There are no other

replacement components for achieving kickback protection in

accordance with CSA Z62.3.

• A low-kickback saw chain is a chain that has met the kickback

performance requirements of ANSI/OPEI B175.1-2012 when

tested according to the provisions specified in ANSI/OPEI

B175.1-2012. A low-kickback saw chain is a chain that is also in

accordance with CSA Z62.3. Do not use a replacement saw

chain unless it has met these requirements for this specific

model or has been designated as a low-kickback replacement

saw chain in accordance with ANSI/OPEI B175.1-2012. As saw

chains are sharpened, some of the low-kickback qualities are

lost and extra caution should be used.

• Do not install a bow guide on this unit. Bow guides have larger

kickback zones, which increase the chance of kickback and

serious injury. This increase is not significantly reduced by using

a low-kickback saw chain. Using a bow guide on this unit is

extremely dangerous.

Kickback Safety Precautions

Take the following steps to reduce the chance of accident or injury:

• Do not rely exclusively upon the safety devices built into the unit.

• Do not cut above shoulder height.

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on steep slopes or inclines.

• Do not make cuts with the tip of the guide bar.

• Make sure the area of operation is free from obstructions. Do not

let the tip of the guide bar contact any object, such as a log,

branch, the ground or other obstruction.

• Always inspect the wood before cutting. Foreign objects could

damage the unit or cause serious personal injury. Never cut

through nails, metal rods, railroad ties or pallets.

• Do not operate the unit with one hand! Serious injury to the

operator, helpers or bystanders may result from one-handed

operation. This unit is intended for two-handed use. Always grip

the unit firmly with both hands when the unit is running. Hold the

front handle with the left hand and the rear handle with the right

hand. Firmly encircle the handles with the thumbs and fingers.

Do not let go. A firm grip will help maintain control of the unit

and reduce the chance of kickback.

• Stand slightly to the left of the unit to avoid being in the direct

line of the saw chain.

• Never start the saw when the guide bar is inside an existing cut.

Be extremely careful when re-entering a cut.

• Always begin a cut with the unit running at full speed. Fully

squeeze the throttle control and maintain a steady cutting

speed. Slower speeds increase the chance of kickback.

• Keep the saw housing pressed firmly against the wood.

• Do not cut more than one log or branch at a time.

• Do not twist the unit when removing the guide bar from a cut.

• Watch out for shifting objects (logs, branches, etc.) that might

pinch or fall onto the saw chain during operation.

OTHER SAFETY WARNINGS

• Follow all maintenance instructions in this manual.

• All service, other than the maintenance procedures described in

this manual, should be performed by an authorized service dealer.

• Do not use the unit if it is not working correctly, has been

dropped, damaged, left outdoors or dropped into water. Have

the unit serviced by an authorized service dealer.

• Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

• Secure the unit while transporting.

• Always use the scabbard on the guide bar and saw chain during

transportation and storage.

• Always store the unit and fuel in a cool, dry and well-ventilated

space. Do not store fuel, or a unit with fuel in the tank, indoors

where fumes may reach open flames (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach of

children.

• Never douse or squirt the unit with water or any other liquid. Keep

handles dry, clean and free from debris, oil, fuel and grease. Clean

the unit after each use. Refer to Cleaning and Storage. Do not use

solvents or strong detergents.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

4

Page 5

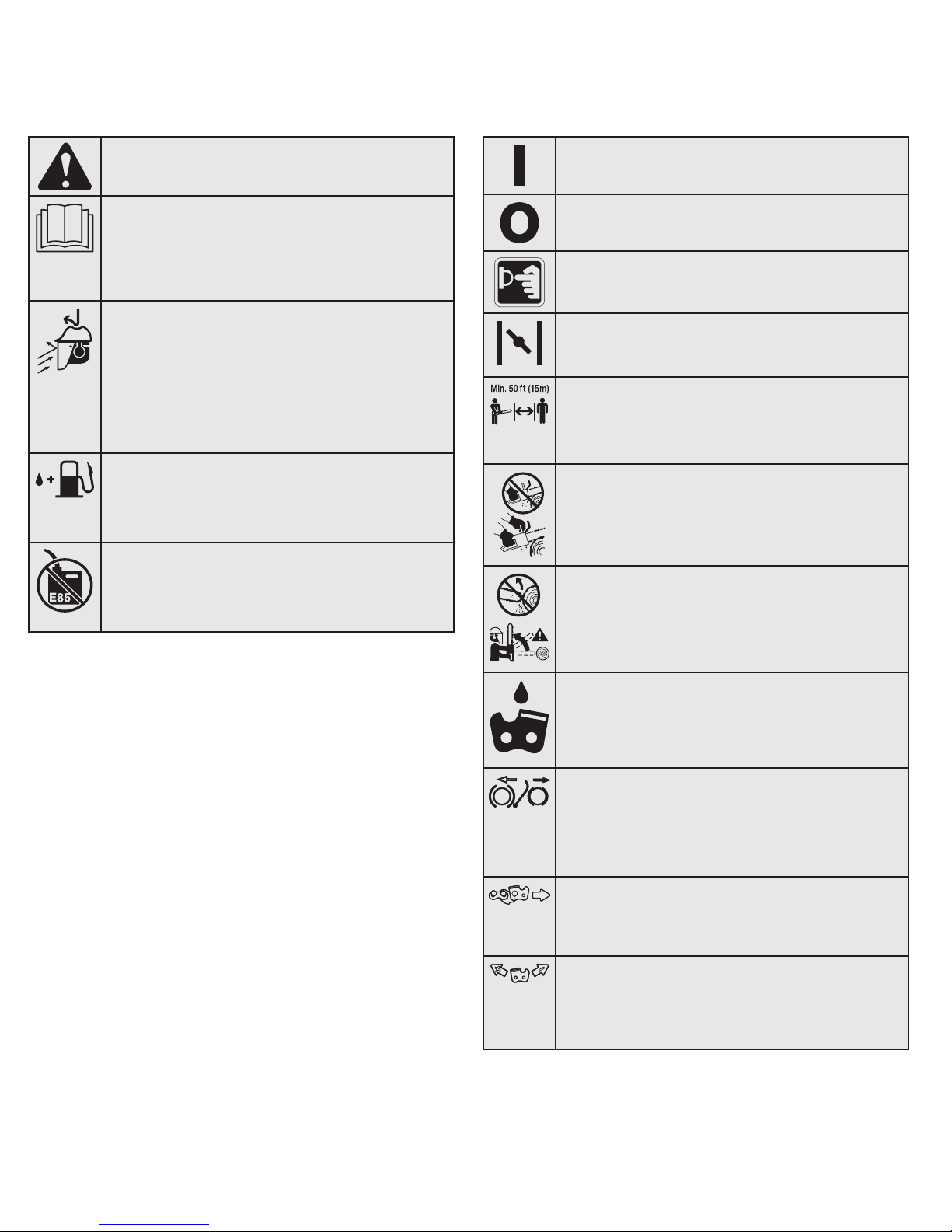

• SAFETY & INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

WARNING: Read the operator’s manual(s)

and follow all warnings and safety instructions. Failure

to do so can result in serious injury to the operator

and/or bystanders.

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• WEAR HEAD, EYE AND HEARING PROTECTION

WARNING:Thrown objects and loud noise

can cause severe eye injury and hearing loss. Wear

eye protection meeting current ANSI Z87.1 standards

and ear protection when operating this unit. Wear

head protection when operating this unit; falling

objects can cause severe head injury. Use a full face

shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING:It has been proven that fuel

containing greater than 10% ethanol will likely

damage this engine and void the warranty.

• CHOKE CONTROL

• Pulled Out - FULL choke position

• Pushed In - RUN position

• KEEP BYSTANDERS AWAY

WARNING:Keep all bystanders, especially

children and pets, at least 50 feet (15 m) from the

operating area.

• USE BOTH HANDS

WARNING: Always use both hands while

operating the unit. Never use only one hand to

operate the unit.

• KICKBACK

WARNING: Contact of the guide bar tip

with any object should be avoided. Tip contact may

cause the guide bar to move suddenly upward and

backward, which may cause serious injury.

• CHAIN OIL ADJUSTMENT INDICATOR

The chain must be continously coated with oil to

function properly. Make sure to set the oil adjustment

screw to allow a sufficient amount of oil to flow

continuously onto the chain.

• CHAIN BRAKE

The chain brake immediately stops the moving saw

chain in emergency situations. To manually engage

the chain brake, push the chain brake lever forward

completely. To disengage the chain brake, pull the

chain brake lever back completely.

• CHAIN DIRECTION

Make sure the saw chain faces the direction shown

when installed on the guide bar. Refer to Installing the

Guide Bar and Saw Chain in the Maintenance section.

• CHAIN TENSIONING

Always keep the saw chain properly tensioned. Turn

the chain-tensioning screw clockwise to tighten the

saw chain. Turn the chain-tensioning screw

counterclockwise to loosen the saw chain.

5

Page 6

APPLICATIONS

• Felling and limbing trees

• Cutting logs (bucking)

• Pruning trees

ASSEMBLY TOOLS REQUIRED:

• Flat-head screwdriver or multi-purpose tool

(provided)

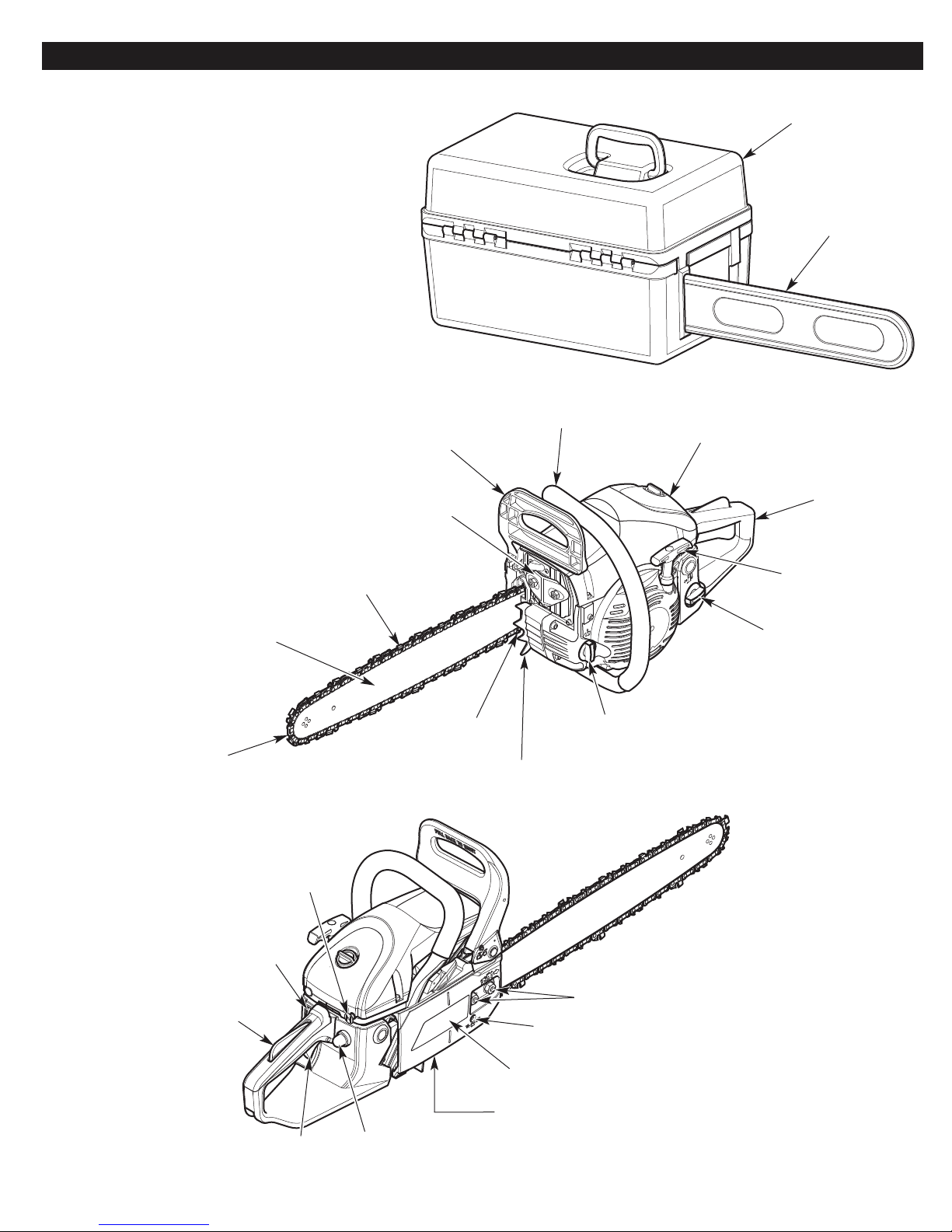

KNOW YOUR UNIT

Carrying Case

Scabbard

Guide Bar Tip

Guide Bar

Chain Brake Lever /

Front Hand Guard

Low-Kickback

Saw Chain

Muffler

Chain Catcher

Front Handle

Spiked Bumper /

Bucking Spike

Air Filter Cover

(Spark Plug and Air Filter)

Rear Handle /

Boot Loop

Starter Rope Grip

Fuel Cap

Chain Oil

Reservoir Cap

Choke Knob

On/Off Switch

Throttle Lockout

Throttle Control

Bar-Retaining Nuts

Chain-Tensioning

Screw

Bar Cover

Chain Oil

Adjustment Screw

Primer Bulb

6

Page 7

SAFETY FEATURES

• LOW-KICKBACK SAW CHAIN significantly reduces the chance of kickback and the intensity of kickback, due to specially designed

depth gauges and guard links.

•The SPARK ARRESTER SCREEN retains carbon and other flammable particles over 0.023 inches (0.6mm) in size from the engine

exhaust flow. Compliance with local, state and federal laws and/or regulations governing the use of a spark arrester screen is the user’s

responsibility. Refer to Spark Arrestor Note in the Safety section for additional information.

•The CHAIN BRAKE LEVER / FRONT HAND GUARD helps protects the operator’s left hand if it slips off the front handle while the unit is

running. The chain brake lever is also used to manually engage the chain brake.

•The CHAIN BRAKE reduces the chance of injury if kickback occurs, by stopping the saw chain in milliseconds. The chain brake is

designed to engage automatically in response to kickback. The chain brake can also be activated by pushing the chain brake lever

forward, either intentionally or if the operator’s hand strikes the lever during kickback.

•The ON/OFF SWITCH immediately stops the engine when moved to the OFF position. The On/Off switch must be moved to the On

position to start the engine.

•The THROTTLE LOCKOUT prevents accidental acceleration of the engine. The throttle control cannot be squeezed unless the throttle

lockout is depressed.

•The CHAIN CATCHER reduces the chance of injury if the saw chain breaks or derails during operation. The chain catcher is designed to

intercept a whipping chain.

SPECIFICATIONS*

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement (RM4218). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 cc (2.56 cu. in.)

Displacement (RM4620). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 cc (2.8 cu. in.)

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Spark Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RCJ6Y or equivalent plug

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bar and Chain Oil

Fuel/Oil Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Fuel Tank Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 oz. (650 mL)

Chain Oil Reservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.45 oz. (250 mL)

Approximate Unit Weight (without fuel or chain oil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 15 lbs. (6.3 - 6.8 kg)

Guide Bar Length (RM4218) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 in. (45.7 cm)

Guide Bar Length (RM4620) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 in. (50.8 cm)

Saw Chain Pitch (RM4218) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8 in. (9.5 mm)

Saw Chain Pitch (RM4620) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.325 in. (8.3 mm)

Saw Chain Guage (RM4218) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.050 in. (1.3 mm)

Saw Chain Guage (RM4620) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.050 in. (1.3 mm)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

REPLACEMENT PARTS

Please contact the Customer Support Department to order replacement parts.

Part #

753-08104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

Saw Chain (18 in. / 45.7 cm)

Guide Bar (18 in. / 45.7 cm)

Saw Chain (20 in. / 50.8 cm)

Guide Bar (20 in. / 50.8 cm)

Bar-Retaining Nuts

7

Page 8

ASSEMBLY

ADDING BAR AND CHAIN OIL: INITIAL USE

This unit comes from the factory with the chain oil reservoir empty.

Use the bottle of bar and chain oil that is included with the unit.

Refer to Adding Bar and Chain Oil instructions in the Maintenance

section.

ADJUSTING THE CHAIN TENSION: INITIAL USE

The saw chain must be properly tensioned before attempting to

start or operate the unit. The saw chain may also require additional

tensioning as the saw chain heats up during operation. Refer to

Adjusting the Chain Tension instructions in the Maintenance section.

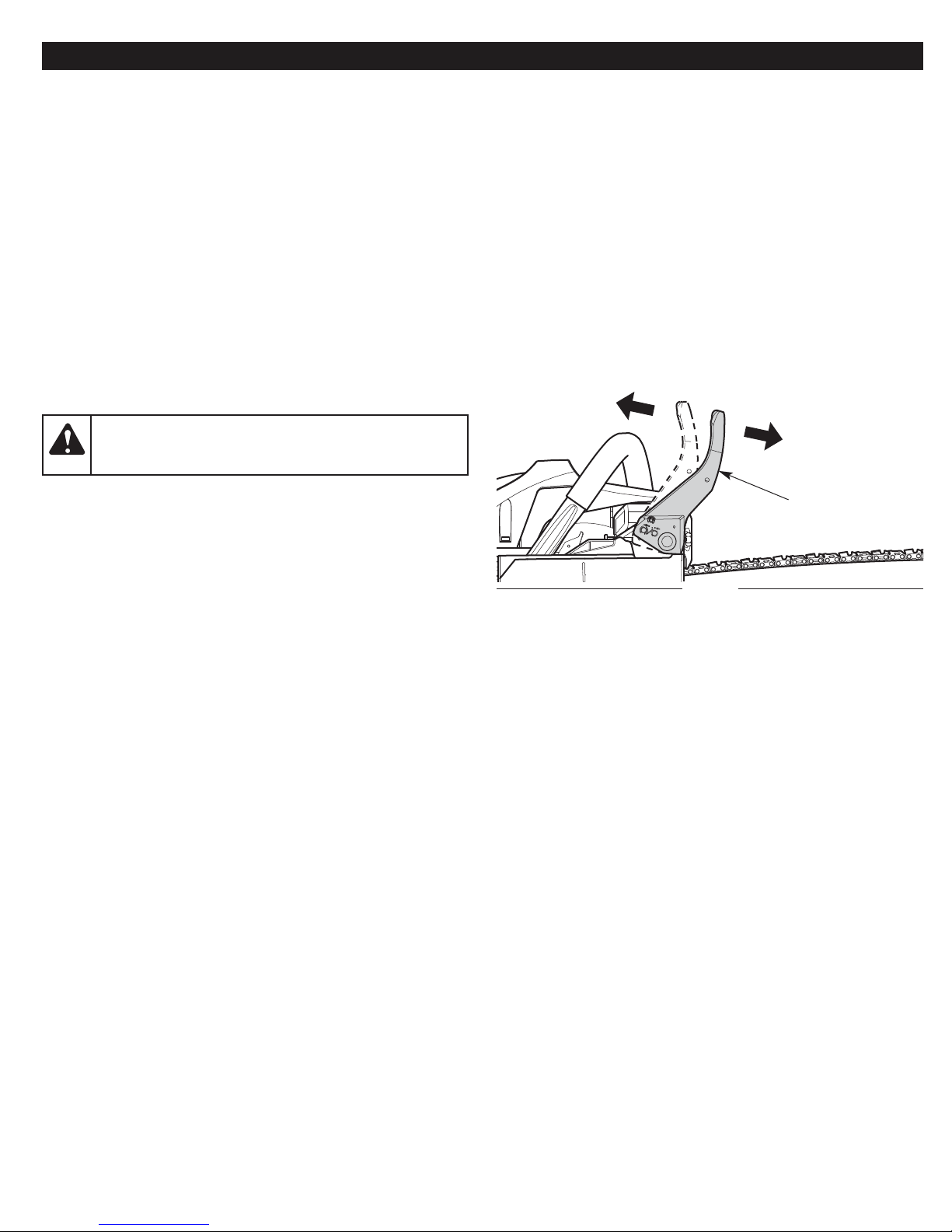

TESTING THE CHAIN BRAKE

WARNING: Always activate the chain brake slowly and

deliberately. Keep the saw chain from touching anything.

Do not let the chain saw tip forward.

Always test the chain brake before using the unit.

1. Set the unit on a flat, level surface.

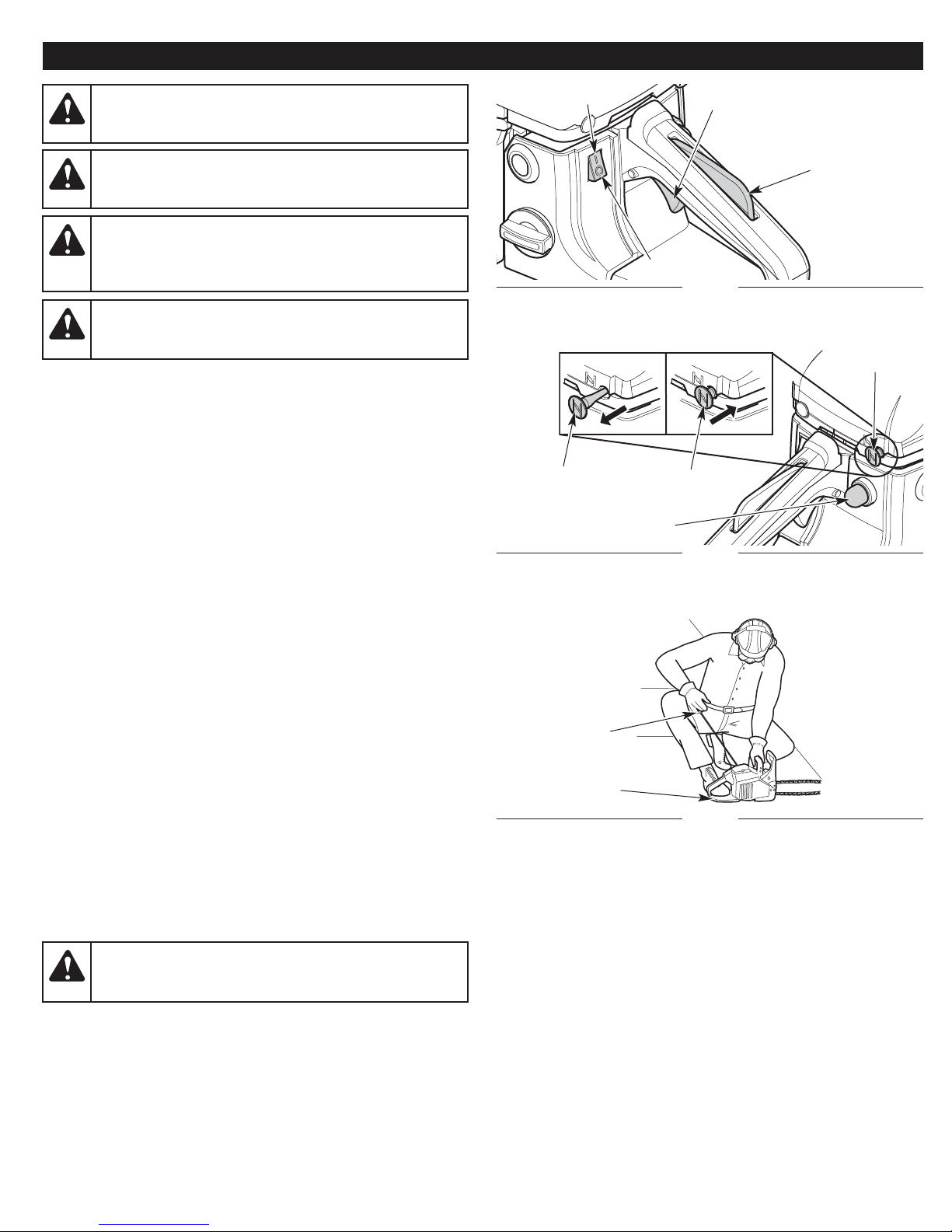

2. Make sure the chain brake lever is pulled back in the

disengaged position (Fig. 1).

3. Start the unit. Refer to Starting Instructions in the Starting and

Stopping section. Maintain a proper grip. Refer to Holding the

Unit in the Operation section.

4. While the unit is running, squeeze the throttle control to 1/3

throttle and then engage the chain brake by pushing the chain

brake lever forward with the left hand (Fig. 1). The chain should

stop moving abruptly.

IF... If the chain stops moving, the chain brake is working correctly.

IF... If the chain does not stop moving, have the unit serviced by an

authorized service dealer.

5. Stop the engine and return the chain brake to the disengaged

position. Refer to Stopping Instructions in the Starting and

Stopping section.

Disengaged

Engaged

Chain Brake Lever

Fig. 1

8

Page 9

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

The use of old and/or improperly mixed fuel is the most common cause

of performance problems. Use only fresh, clean unleaded gasoline.

Follow the instructions carefully for the proper gasoline/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate, forming acids when stored. ALWAYS use fresh fuel (less

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

• Always use the fresh fuel mix explained in your operator's manual

• Use the fuel additive STA-BIL® or an equivalent

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

WARNING: DO NOT USE E85 FUEL IN THIS UNIT. It

has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

Using Fuel Additives

The bottle of 2-cycle oil provided with this unit contains a fuel

additive to help inhibit corrosion and minimize gum deposits.

Always use the brand of 2-cycle oil that came with this unit. If this is

unavailable, use a 2-cycle oil designed for air-cooled engines and

mix it with a fuel additive, such as STA-BIL Fuel Stabilizer or an

equivalent. Add 0.8 oz. (23 mL) of fuel additive per gallon of fuel,

according to the instructions on the container. NEVER add fuel

additives directly to the unit's fuel tank.

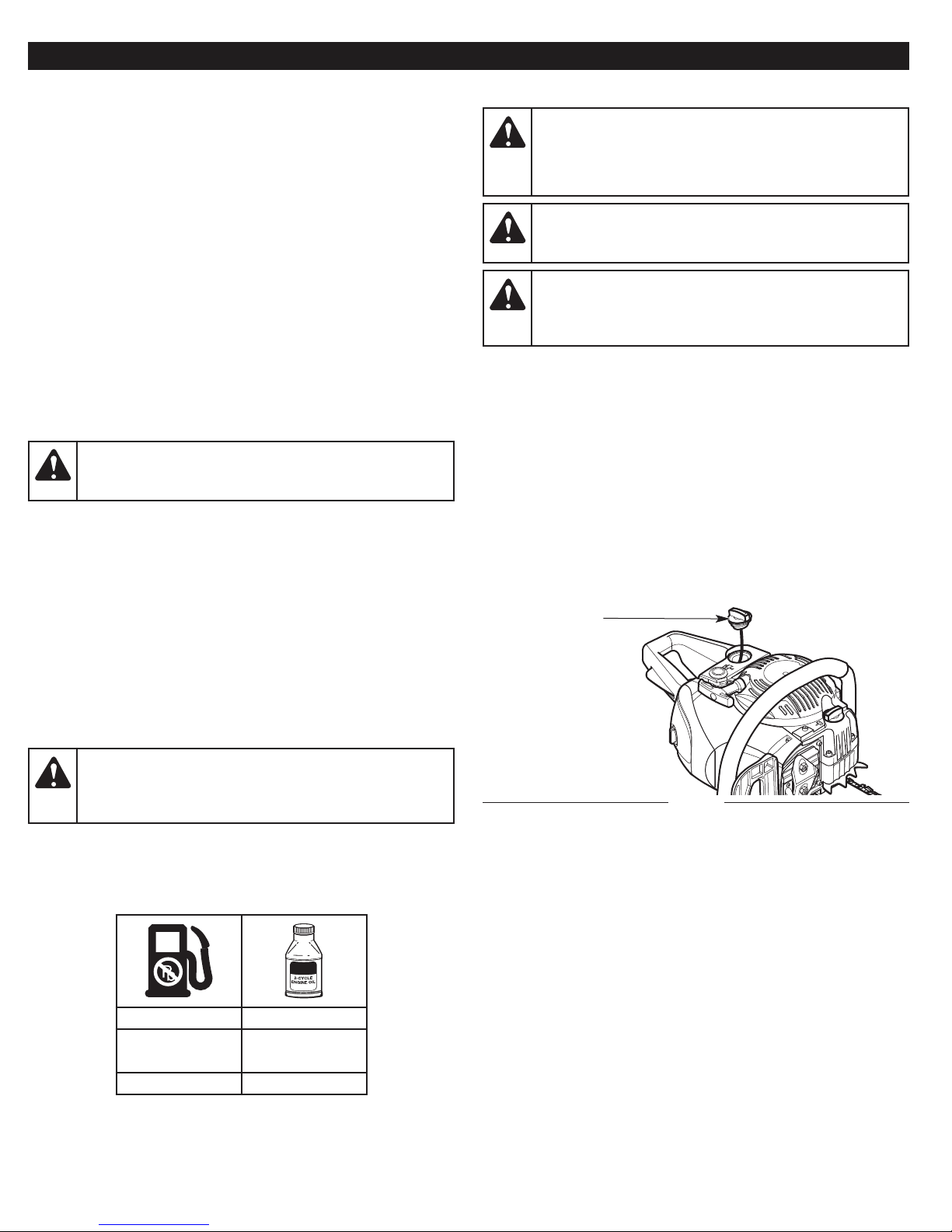

Mixing the Fuel

NOTE: This unit comes with a 3.2 oz. (95 mL) bottle of 2-cycle oil.

To obtain the correct fuel mixture described below, pour the

entire bottle into one gallon of unleaded gasoline.

FUELING THE UNIT

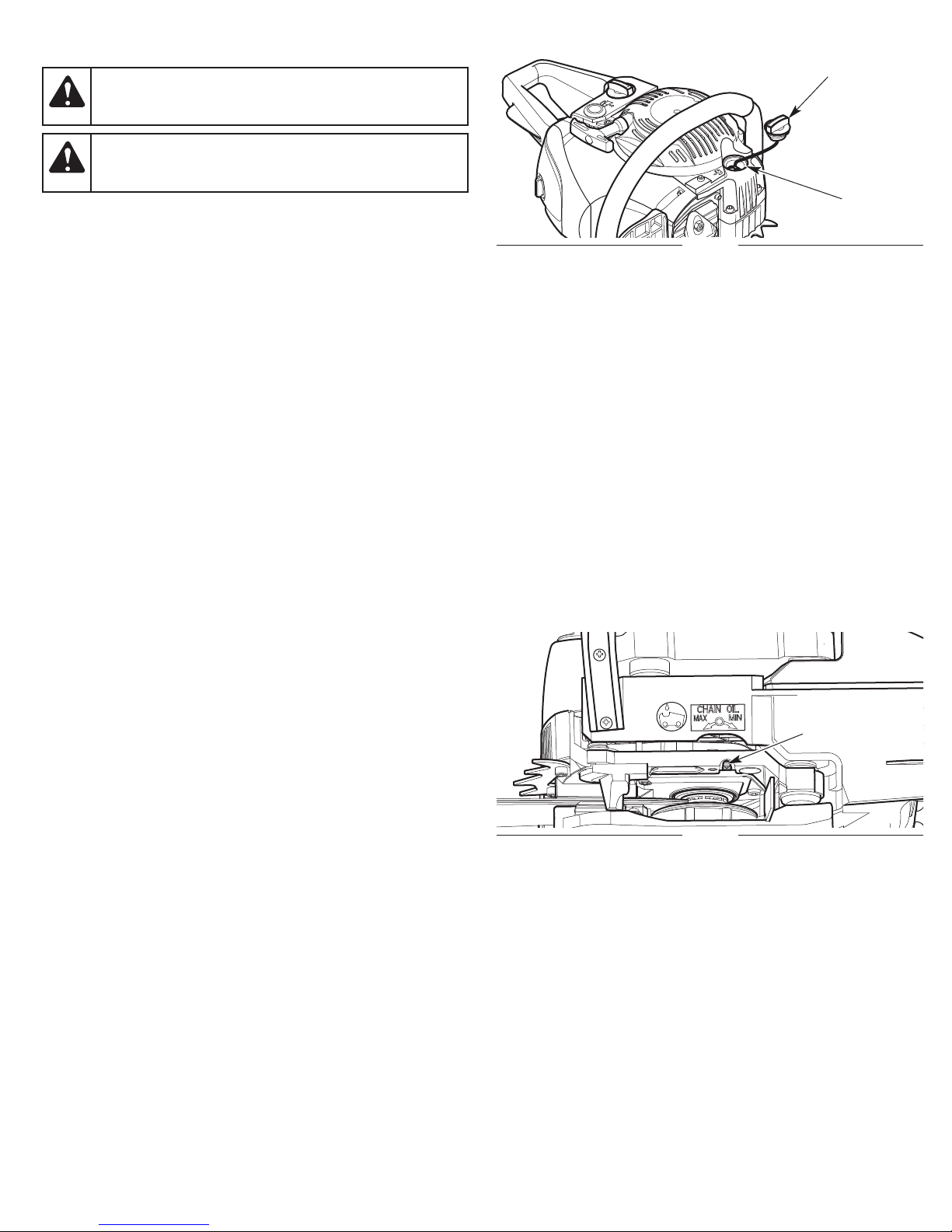

WARNING:

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

Gasoline is extremely flammable. Ignited

WARNING: Remove the fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING: Add fuel in a clean, well ventilated outdoor

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

1. Position the unit with the fuel cap facing up.

2. Remove the fuel cap (Fig. 2).

3. Place the fuel container spout into the fill hole on the fuel tank

and fill the tank.

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

the fueling site before starting the engine.

Fuel Cap

CAUTION: For proper engine operation and maximum

reliability, pay strict attention to the gasoline and oil mixing

instructions on the 2-cycle oil bottle. Using improperly

mixed fuel can severely damage the engine.

Thoroughly mix the proper ratio of unleaded gasoline with 2-cycle

engine oil. Do not mix them directly in the unit’s fuel tank. Use a

separate fuel can. Use a 40:1 gasoline/oil ratio. See the table below

for specific gasoline and oil mixing ratios.

Unleaded gasoline 2-cycle oil

1 gallon U.S.

(3.8 L)

1 L 25 mL

MIXING RATIO - 40:1

3.2 fl. oz.

(95 mL)

Fig. 2

9

Page 10

STARTING AND STOPPING

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING: Avoid accidentally starting the unit. To avoid

serious injury, the operator and the unit must be in a stable

position when pulling the starter rope (Fig. 5).

WARNING: Never operate the unit without the guide bar

and saw chain properly installed. Make sure the bar-retaining

nuts are tight and the guide bar cover is securely assembled.

Make sure the saw chain is properly tensioned.

WARNING: The saw chain will spin after the engine

starts. Keep hands and feet clear of the saw chain and do

not allow the saw chain to contact any object(s).

STARTING INSTRUCTIONS

1. Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

2. Fill the fuel tank. Refer to Fueling the Unit.

3. Fill the chain oil reservoir with bar and chain oil. Refer to Adding

Bar and Chain Oil in the Maintenance section.

4. Make sure the chain brake is disengaged. Refer to Testing the

Chain Brake in the Assembly section.

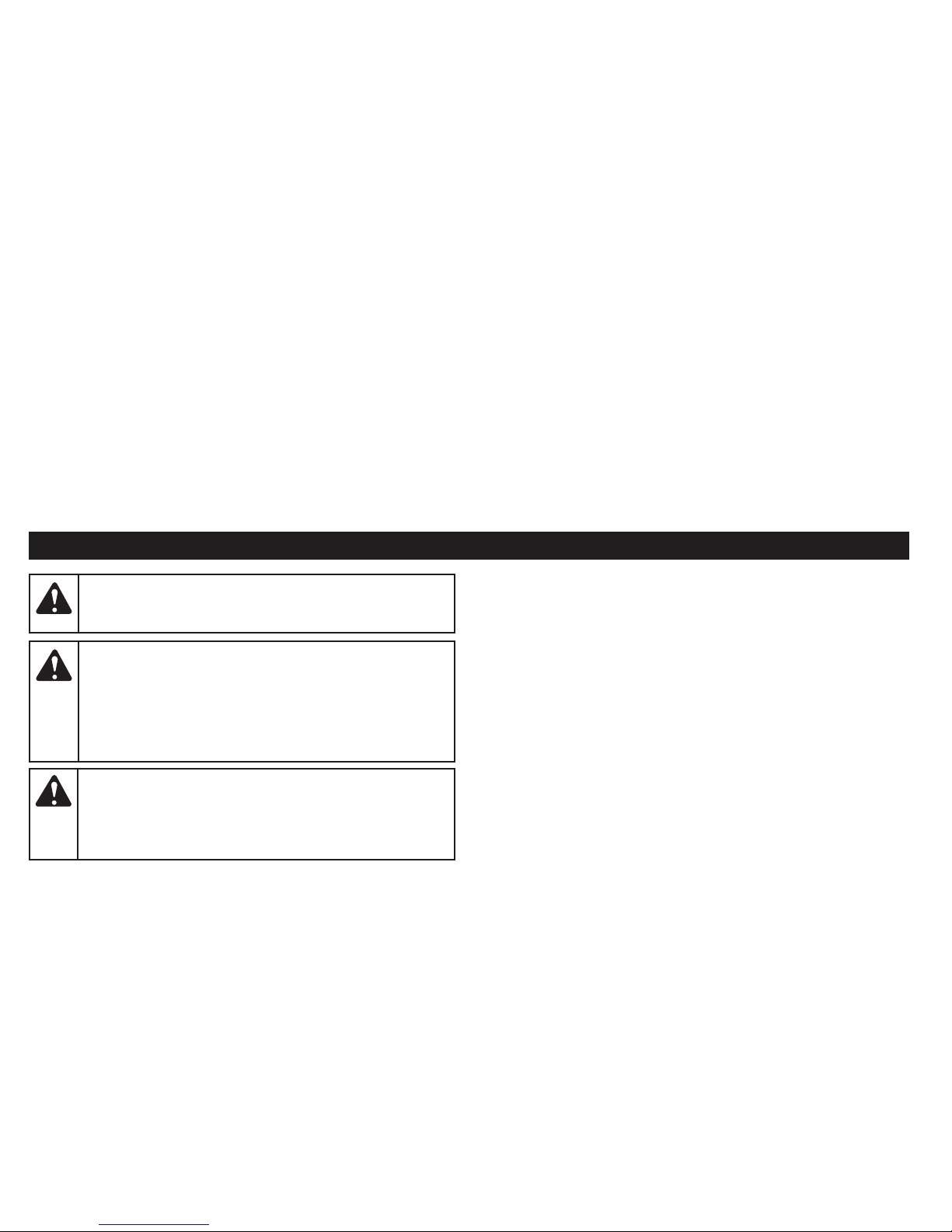

5. Move the On/Off switch to the On position (Fig. 3).

6. Slowly press and release the primer bulb 10 times (Fig. 4). If fuel

cannot be seen in the primer bulb, press and release the primer

bulb until fuel is visible.

7. Pull the choke knob out to Position 1 (Fig. 4).

NOTE: DO NOT touch the throttle control until step 14 (Fig. 3).

8. DO NOT touch the throttle control (Fig. 3). Set the unit on a flat,

level surface. Clear the area of any objects that could contact

the saw chain.

9. DO NOT touch the throttle control. Crouch in the starting

position (Fig. 5). Hold the front handle with the left hand. Hold

the starter rope grip with the right hand. Insert the right foot into

the boot loop to help hold the unit firmly in place.

10. DO NOT touch the throttle control. Pull the starter rope with a

controlled and steady motion 5 times (Fig. 5).

11. DO NOT touch the throttle control. Push the choke knob in to

Position 2 (Fig. 4).

12. DO NOT touch the throttle control. Pull the starter rope with a

controlled and steady motion 3 to 5 times to start the engine.

13. DO NOT touch the throttle control. Allow the engine to warm up

for 30 to 60 seconds.

14. Press and hold the throttle lockout. Lightly squeeze and release

the throttle control to idle the engine.

On ( I ) / Start

Position 1

Starter

Rope Grip

Boot Loop

Throttle Control

Throttle Lockout

Off (O) / Stop

Fig. 3

Choke Knob

Position 2

Primer Bulb

Fig. 4

Starting

Position

Fig. 5

WARNING: The saw chain should not move when the

engine runs at idle. If it does move, refer to Adjusting the

Idle Speed in the Maintenance section.

15. To reduce the chance of injury, engage the chain brake until you

are ready to begin operation. When ready, disengage the chain

brake. Then press the throttle lockout and squeeze the throttle

control to accelerate the engine, as needed.

NOTE: The engine is properly warmed up when it accelerates

without hesitation.

IF... the engine hesitates, continue the warm-up.

IF... the engine does not start, begin the starting procedure with

step 4.

10

Page 11

IF... the engine fails to start after a few attempts, move the choke

knob to Position 2, press the throttle lockout and squeeze the

throttle control. Pull the starter rope with a controlled and steady

motion 3 to 8 times. The engine should start. If it does not,

repeat this instruction.

IF... the engine is already warm, make sure the On/Off switch is in

the On position, crouch in the starting position, pull the choke

knob out to Position 1 and then push the choke knob back in to

Position 2. Begin the starting procedure with step 12.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to idle.

2. Move the On/Off switch to the Off position (Fig. 3). Wait for the

saw chain to come to a complete stop.

Emergency Stopping

1. Push the chain brake lever forward to engage the chain brake.

Refer to Testing the Chain Brake in the Assembly section.

2. Move the On/Off switch to the Off position.

OPERATION

WARNING: Always check the chain tension and adjust as

necessary before beginning operation. Refer to Adjusting the

Chain Tension in the Maintenance section.

WARNING:

before operation. Check the oil level constantly so that it

does not drop below half full. Make sure the chain oil

adjustment screw is set appropriately. Refer to Setting the

Chain Oil Adjustment Screw in the Maintenance section.

The saw chain must be continuously coated with oil to

function properly.

WARNING:

foot and body protection to reduce the risk of injury when

operating this unit. Wear head protection. Use a full face

shield when needed. Refer to the Safety section for

appropriate safety equipment information.

TIPS FOR BEST RESULTS

• Follow all safety instructions. Refer to the Safety section.

• Only cut wood and materials made of wood. Do not attempt to

cut sheet metal, plastics, masonry or any other non-wood

materials.

• Practice cutting a few small logs before beginning a major

cutting operation.

• Do not attempt to cut trees or logs with diameters larger than:

- 16” (RM4620)

- 14” (RM4218)

Make sure the chain oil reservoir is full

Always wear appropriate eye, hearing, hand,

11

Page 12

PREPARING THE WORK AREA

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they

are still at risk from thrown objects. Encourage bystanders to

wear eye protection. If you are approached, stop the unit

immediately. When felling, the safe distance is at least twice the

height of the tallest tree in the work area. When bucking, keep

workers at least 15 feet (4.6 m) apart.

• Keep the work area clean. Cluttered areas invite injuries. Do not

start cutting until the work area is clear and free from

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• Use the unit only in daylight or good artificial light.

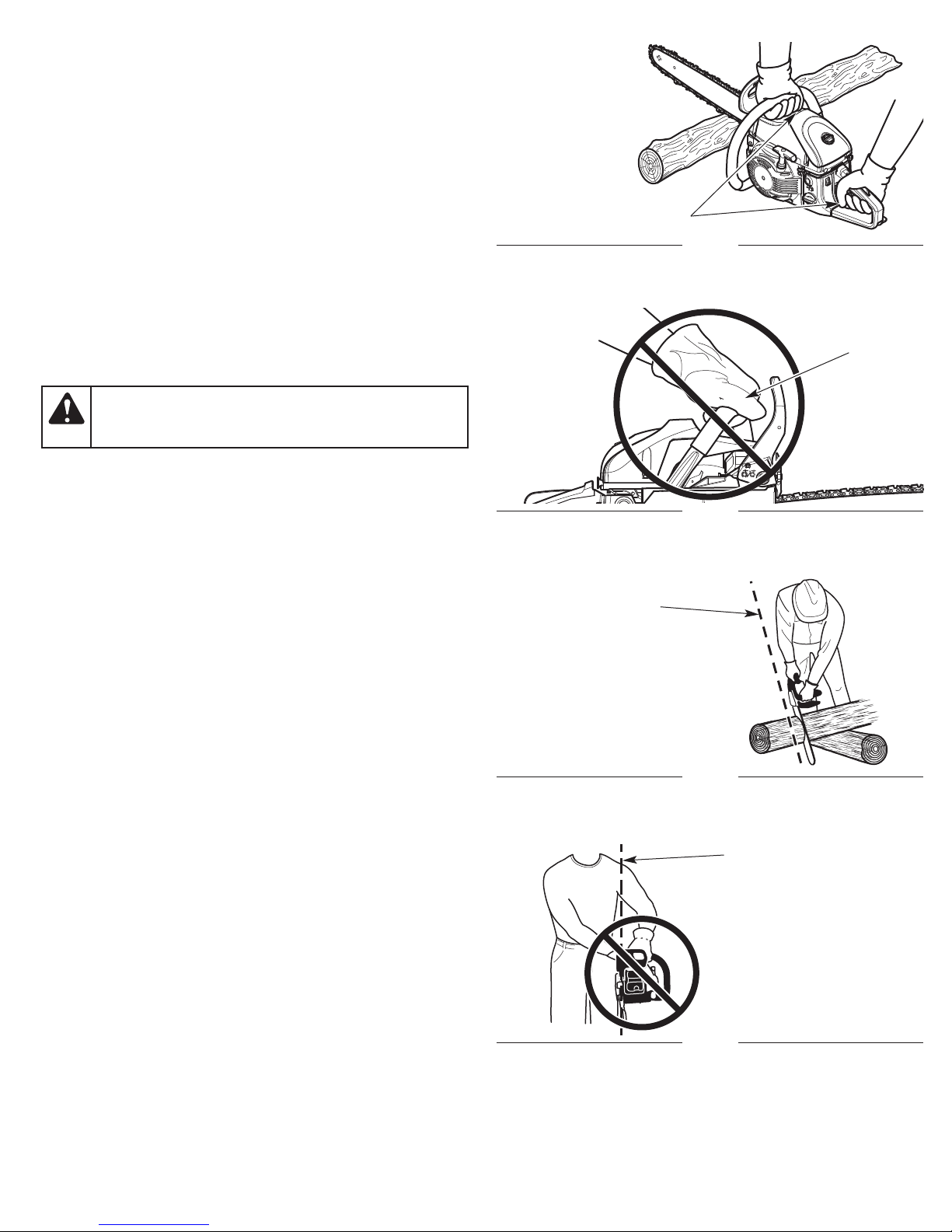

Correct Grip

Thumbs Below the Handles

Fig. 6

HOLDING THE UNIT

WARNING: Always hold the front handle with the left

hand and the rear handle with the right hand. Always keep

all body parts to the left of the chain line.

• Firmly encircle the handles with the thumbs and fingers (Fig. 6).

This will help reduce the chance of losing control of the unit if

kickback occurs. Any grip with thumbs and fingers on the same

side of the handles is dangerous (Fig. 7).

• Always grip the unit firmly with both hands when the unit is

running.

• Hold the front handle with the left hand. Keep the left arm

straight to help withstand potential kickback.

• Hold the rear handle with the right hand. Keep the right arm

slightly bent.

• Use these hand placements whether the operator is left-handed

or right-handed. This will help keep the operator slightly to the

left of the unit and out of the direct line of the chain saw if

kickback occurs (Fig. 8 and Fig. 9).

• Stand in a stable position with feet apart and firmly planted.

• Do not cut above shoulder height. Do not overreach.

Incorrect Grip

Correct Stance

Thumb

Above the

Handle

Fig. 7

Chain Line

CUTTING PROCEDURE BASICS

1. Start the unit. Refer to Starting Instructions in the Starting and

Stopping section.

2. Keep your fingers off the throttle control until you are ready to

make a cut.

3. Accelerate the unit to full speed before cutting.

4. Press the unit against the wood and maintain a firm, steady

pressure through most of the cut. Do not put pressure on the

unit at the end of the cut.

5. Maintain a steady speed throughout the cut. Keep the unit

running through the entire cut.

6. Do not try to force the saw through the wood. Allow the saw

chain to do the cutting. Exert only light pressure. Forcing the cut

could result in damage to the unit or personal injury.

7. Release the throttle control as soon as the cut is completed.

Allow the saw chain to come to a complete stop. The saw chain,

guide bar and engine may experience unnecessary wear if the

unit is run without a cutting load.

Fig. 8

Chain Line

Incorrect Stance

Fig. 9

12

Page 13

FELLING: SAFETY

Felling is the process of cutting down a tree. Follow these safety

precautions to reduce the risk of serious injury, property damage

and damage to electrical lines:

• Do not fell trees with an extreme lean. Do not fell trees with

rotten limbs, loose bark or hollow trunks. Have these trees

pushed or dragged down with heavy equipment.

• Do not cut trees near buildings or electrical lines. Leave these

operations for professionals. If a felled tree does contact an

electrical line, notify the utility company immediately.

• Check the tree for damaged or dead branches that could fall

and cause serious injury.

• Remove dirt, stones, loose bark, nails, wire and other

obstructions from the portion of the tree that will be cut.

• When bucking and felling operations are performed by two or

more persons in the same general area, they should be

separated from each other by a distance of at least twice the

height of the tree to be felled.

• Consider the force and direction of the wind. Consider the lean

and balance of the tree. Consider the location of large branches.

All of these factors influence the direction that the tree will fall. Do

not try to fell a tree in a direction other than its natural fall line.

• Do not fell trees during periods of precipitation or high winds.

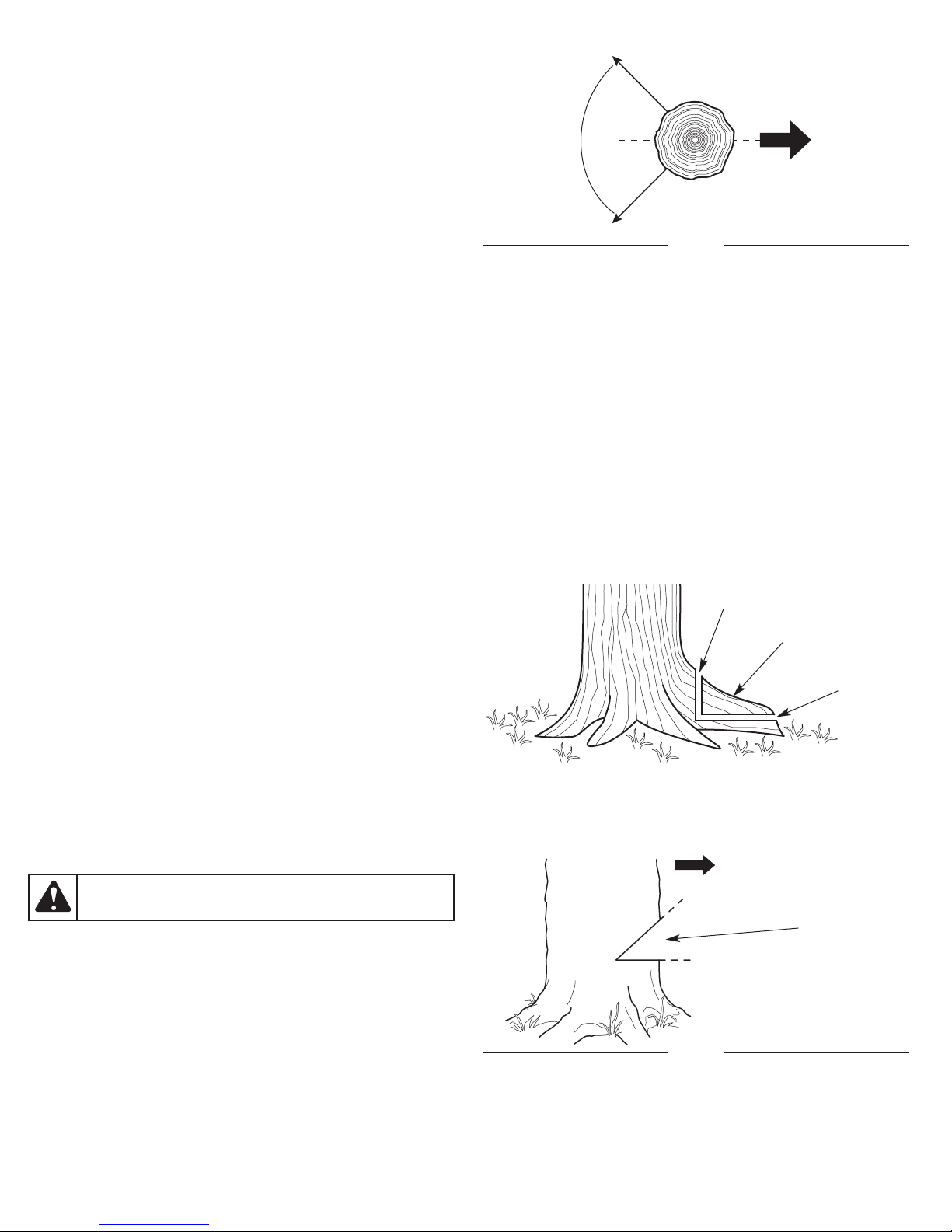

• Determine a safe and expedient escape route. Clear the area

around the tree and make sure there are no obstructions

blocking the escape route. Establish a 90º corridor of escape,

approximately 135º from the line of fall (Fig. 10).

• Stay uphill from the tree; it will most likely roll or slide after it falls.

Path of Safe

Retreat

90°

135º From Planned

Line of Fall

Planned

Line of Fall

135º From Planned

Line of Fall

Fig. 10

FELLING: PROCEDURE

Small trees, up to 6 - 7 inches (15 - 18 cm) in diameter, are usually

felled in a single cut. Larger trees require a sequence of two cutting

operations: a notched undercut followed by a felling back cut. It

may also be necessary to remove buttress roots.

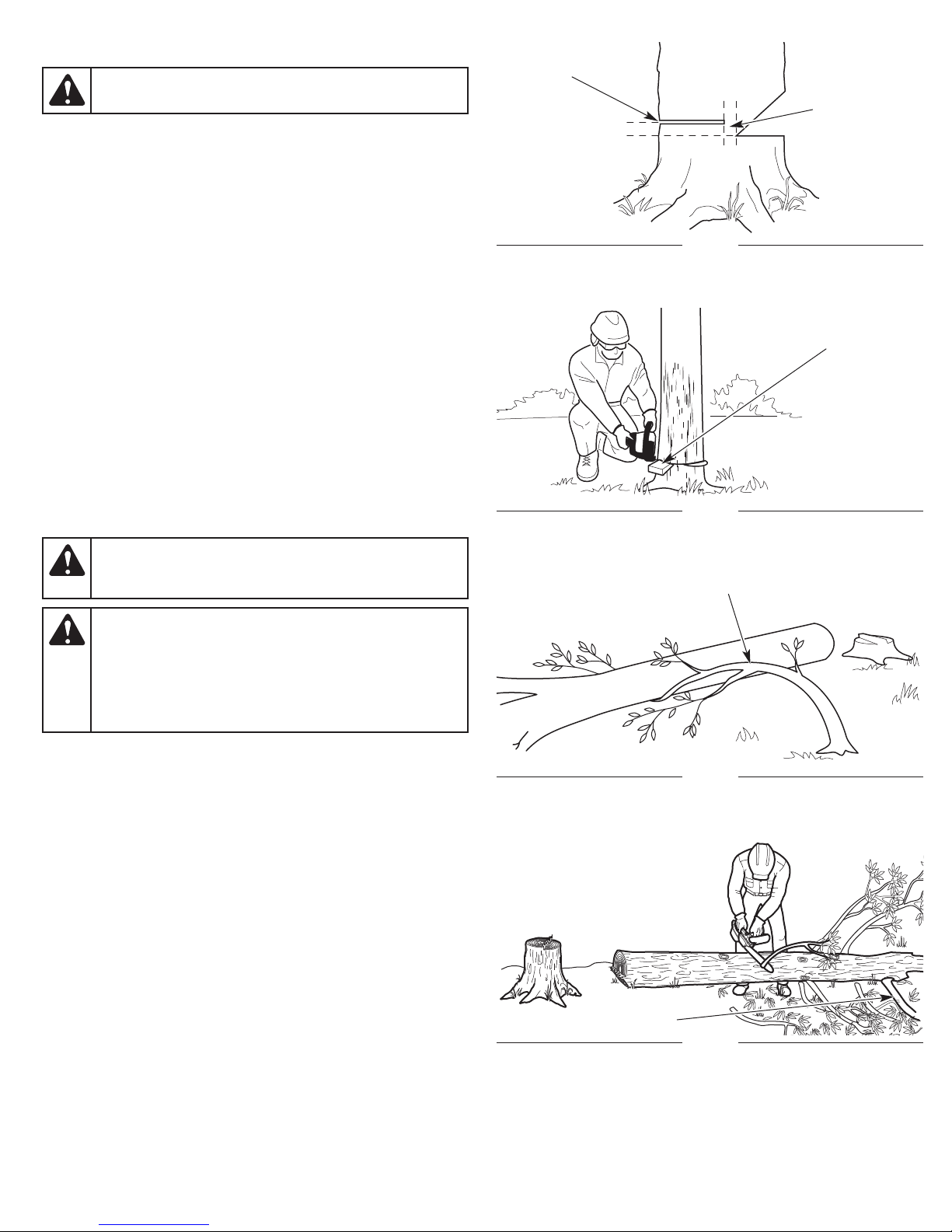

Step 1: Removing Buttress Roots

Buttress roots are large roots that extend above the ground and

help support the tree. If the tree has large buttress roots that might

impede the felling process, follow these steps to remove them:

1. Make a horizonal cut into the buttress root (Fig. 11). To prevent

the guide bar from being pinched by the weight of the wood,

always make this cut first.

2. Make a vertical cut into the buttress root (Fig. 11).

3. Remove the loose section from the work area.

Step 2: Making the Notched Undercut

WARNING: Never walk in front of a tree with a notched

undercut.

This cut determines which direction the tree will fall. Always make

this cut on the side of the tree facing the direction where the tree

should fall. Make the cut at 90º to the line of fall.

1. Make a horizontal cut into the trunk of the tree (Fig. 12). The cut

should be about 1/3 the diameter of the tree and close to the

ground. To prevent the guide bar from being pinched by the

weight of the wood, always make this cut first.

2. Make a 45º cut into the trunk of the tree, above the first cut (Fig.

12). Continue cutting until the two cuts meet.

3. Remove the loose section from the work area.

1/3 Diameter

Second Cut

Buttress Root

First Cut

Fig. 11

Direction of Fall

Second Cut

Notched

Undercut

First Cut

Fig. 12

13

Page 14

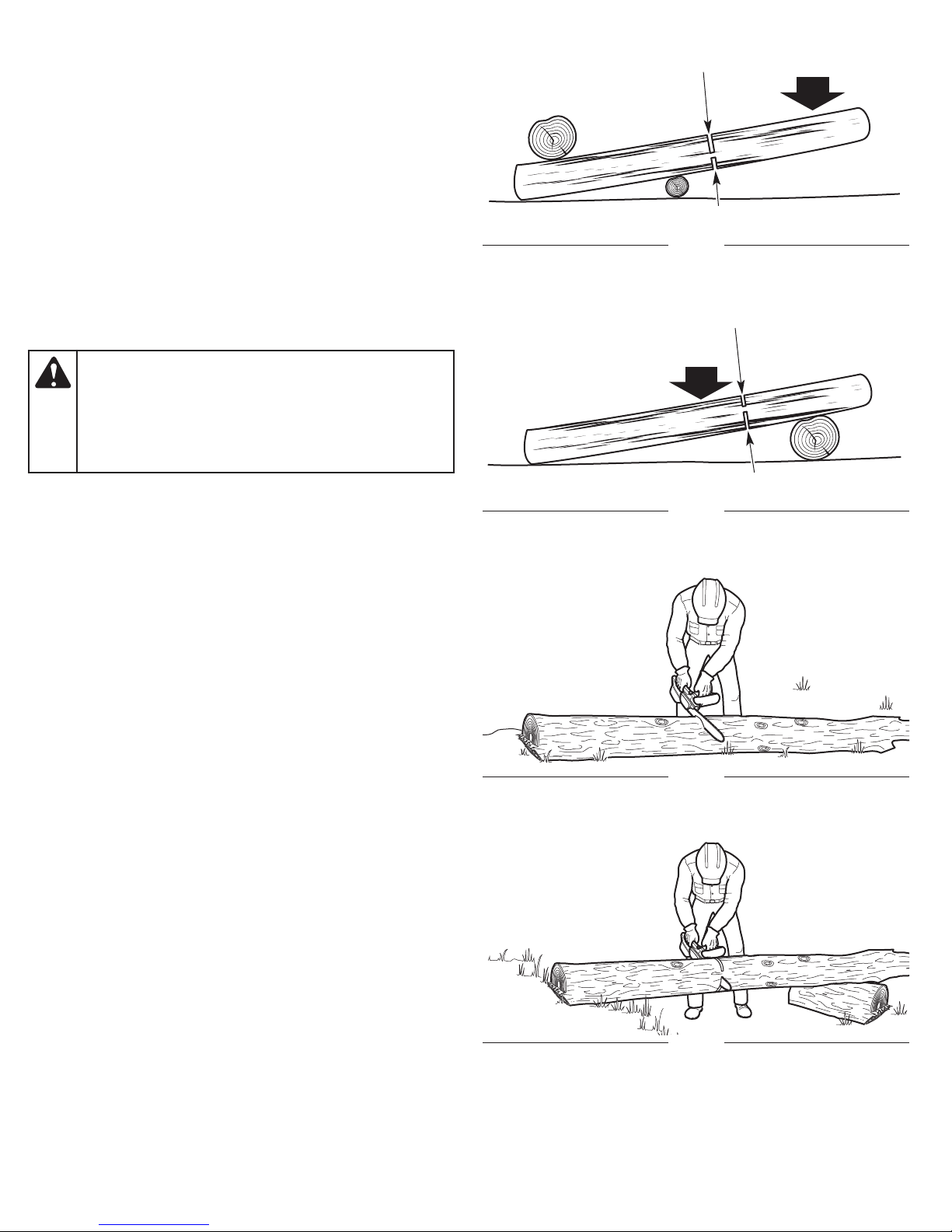

Step 3: Making the Felling Back Cut

WARNING: Always recheck the area for bystanders,

animals and obstacles before making the felling back cut.

This cut fells the tree.

1. Make a horizontal cut into the opposite side of the tree from the

notched undercut (Fig. 13). Make the cut approximately 2 inches

(5 cm) above the bottom of the notched undercut (Fig. 13).

2. As the cut gets close to the notched undercut, only a thin band

of wood will support the tree. This band of wood is referred to as

the hinge (Fig. 13). The hinge helps control the fall of the tree.

Leave approximately 2 inches (5 cm) of hinge in place. Do not

cut through the hinge. Cutting through the hinge could cause the

tree to fall in any direction.

3. Periodically glance up during the felling back cut to see if the

tree is going to fall in the correct direction. If there is a chance

that the tree might not fall in the desired direction, or if the tree

might rock back and bind the chain saw, remove the guide bar

from the cut, stop the unit and use wedges to open the cut and

direct the fall (Fig. 14). Only use soft plastic or wooden wedges.

Drive the wedges into the cut slowly. Once the wedges are in

place and the cut is held open, either carefully reinsert the guide

bar and continue the cut or slowly drive the wedges in further to

push the tree over.

4. As the hinge gets smaller, the tree should begin to fall. When the

tree begins to fall, remove the chain saw from the cut, stop the

engine and set the unit down immediately. Promptly exit the area

along the retreat path, but keep watching the tree as it falls.

Felling

Back Cut

2 inches

2 inches

(5 cm)

Hinge

(5 cm)

Fig. 13

Wedge

Fig. 14

DANGER: If the tree starts to fall in the wrong direction

and binds the chain saw, leave the unit and evacuate the

area immediately! Do not try to save the chain saw!

WARNING: Stay clear of spring poles when operating the

unit. Spring poles are branches, logs, roots or saplings that

are bent under tension by other wood (Fig. 15). When the

tension is released, spring poles can strike the operator,

causing serious injury and potentially knocking the chain

saw into the operator’s body. Use extreme caution when

cutting spring poles or when releasing the cause of tension.

LIMBING

Limbing is the process of removing branches from a fallen tree.

1. Leave the larger support limbs under the tree for last (Fig. 16).

These will keep the tree off the ground during the limbing process.

2. Cut one limb at a time. Stand on the opposite side of the tree

from the limb (Fig. 16). Keep the trunk between the operator and

the chain saw. To avoid binding the chain saw, branches under

tension should be cut from the bottom up.

3. Remove the cut limbs from the work area.

Spring Pole

Fig. 15

Support Limb

Fig. 16

14

Page 15

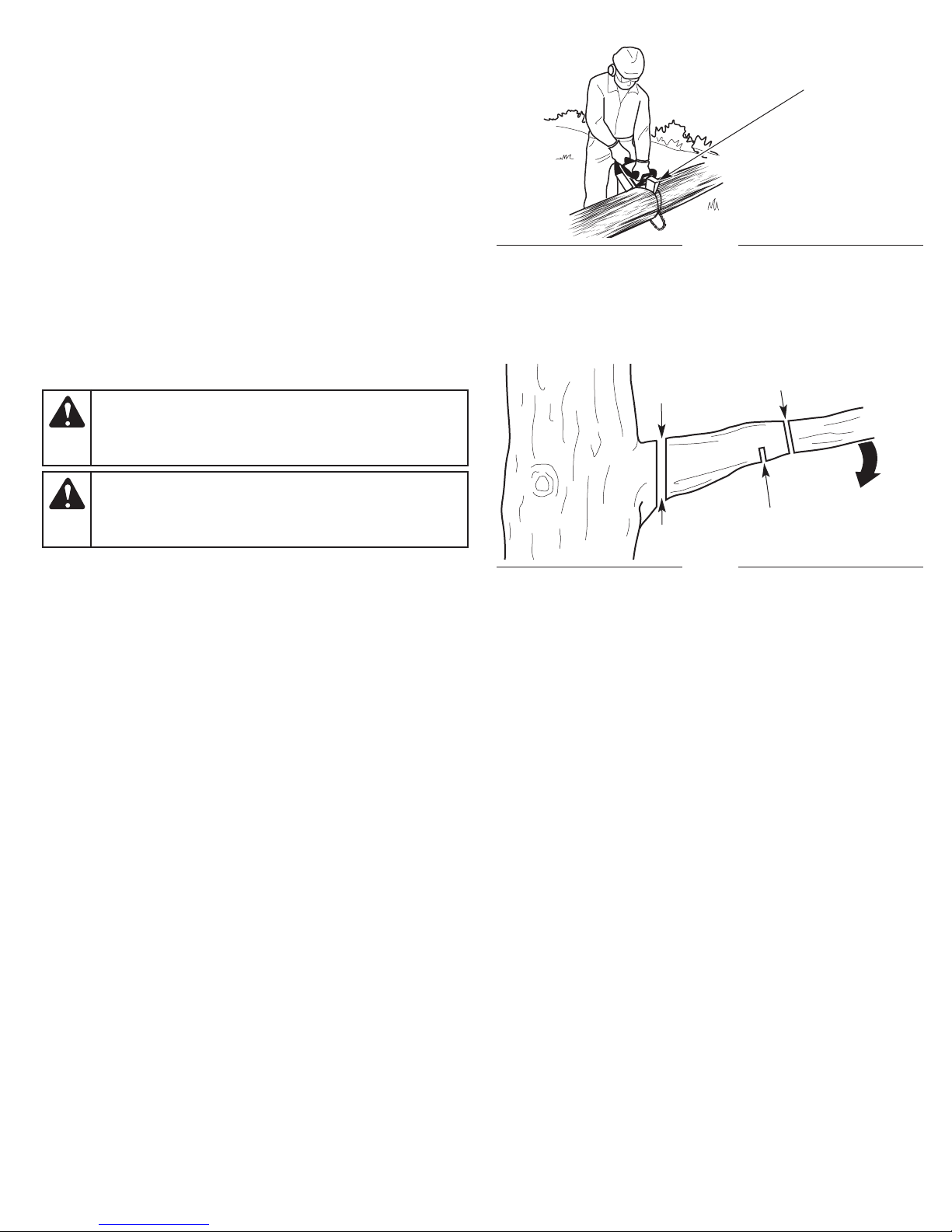

BUCKING: SAFETY

Bucking is the process of cutting a fallen tree into logs of desired

lengths. Follow these safety precautions to reduce the risk of

serious injury:

• Clear the area of objects or obstructions that could contact the

guide bar and result in kickback.

• When bucking on a slope, always stand on the uphill side of the

fallen tree.

• If possible, the end of the tree to be cut should be raised off of

the ground. A saw horse is ideal for this purpose. If a saw horse

is not available, use other logs or any remaining limb stumps.

Make sure the tree if firmly supported.

• Do not let the saw chain contact the ground or saw horse.

• Cut one log at a time. Release the throttle control and allow the

saw chain to come to a complete stop before moving on to the

next log.

• Keep feet and all other body parts clear of falling logs.

DANGER: Use extreme caution when cutting a fallen

tree that is still attached to the root structure. When the

trunk is separated from the roots, the stump has a high

potential for rocking back into the hole created by the

roots. This can result in serious injury or death. Never

stand in the hole left by the roots. Never allow others to

stand near the root structure.

Log Supported

on One End

Log Supported

Two Ends

Second Cut

First Cut (1/3 Diameter)

Fig. 17

First Cut (1/3 Diameter)

Load

Second Cut

Fig. 18

Load

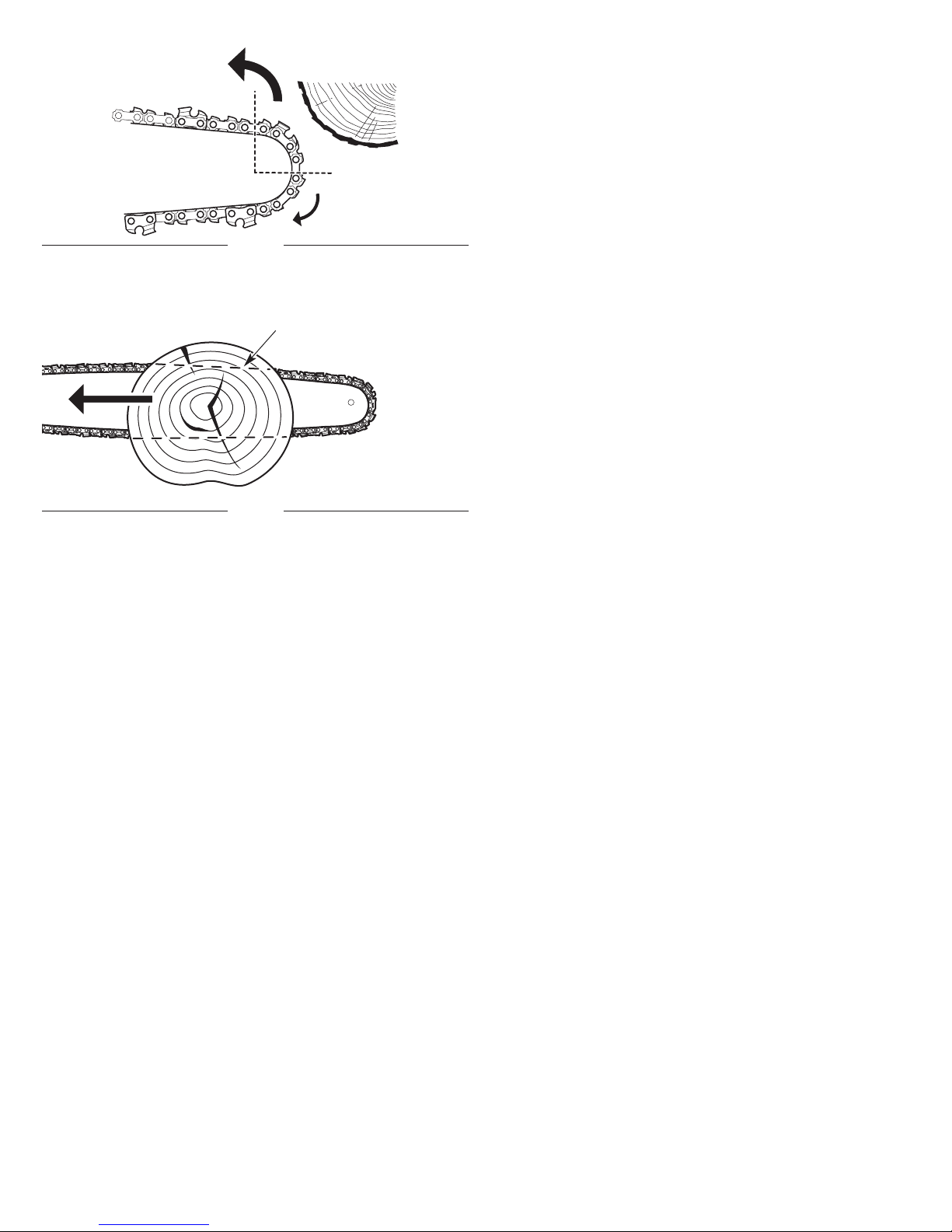

BUCKING: PROCEDURE

Cutting Logs Under Stress

When logs are supported on one or both ends, the wood tends to

bend during the cutting process. This can cause the chain saw to

become pinched between the two sides. Pay extra attention.

1. Make the first cut approximately 1/3 the diameter of the log. Do

not cut deeper than 1/3.

• If the log is supported on one end (Fig. 17), make the first cut

from below (underbucking). Refer to Underbucking.

• If the log is supported on two ends (Fig. 18), make the first cut

from above (overbucking). Refer to Overbucking.

2. Make the second cut from the opposite side until the two cuts

meet. If the diameter of the wood is large enough, insert soft plastic

or wooden wedges to hold the cut open and prevent pinching (Fig.

21). Take care not to touch the wedges with the saw chain.

Cutting Fully-Supported Logs

When logs are supported along the entire length, extra care should

be taken to make sure the saw chain does not contact the ground

or other support structure (Fig. 19).

1. Cut through the log as much as possible, without cutting into the

ground or support structure. Cut from above (overbucking).

Refer to Overbucking.

2. Roll the log over and finish cutting through the log from above

(overbucking).

Overbucking

Fig. 19

Underbucking

Fig. 20

15

Page 16

Overbucking

1. Begin cutting from above, with the bottom of the saw chain

against the top of the log (Fig. 19).

2. Exert light, downward pressure. The saw will tend to pull away

from the operator. Be prepared and hold the saw firmly to

maintain control.

Underbucking

1. Begin cutting from below, with the top of the saw chain against

the bottom of the log (Fig. 20).

2. Exert light, upward pressure. The saw will tend to push toward the

operator. Be prepared and hold the saw firmly to maintain control.

Wedge

Fig. 21

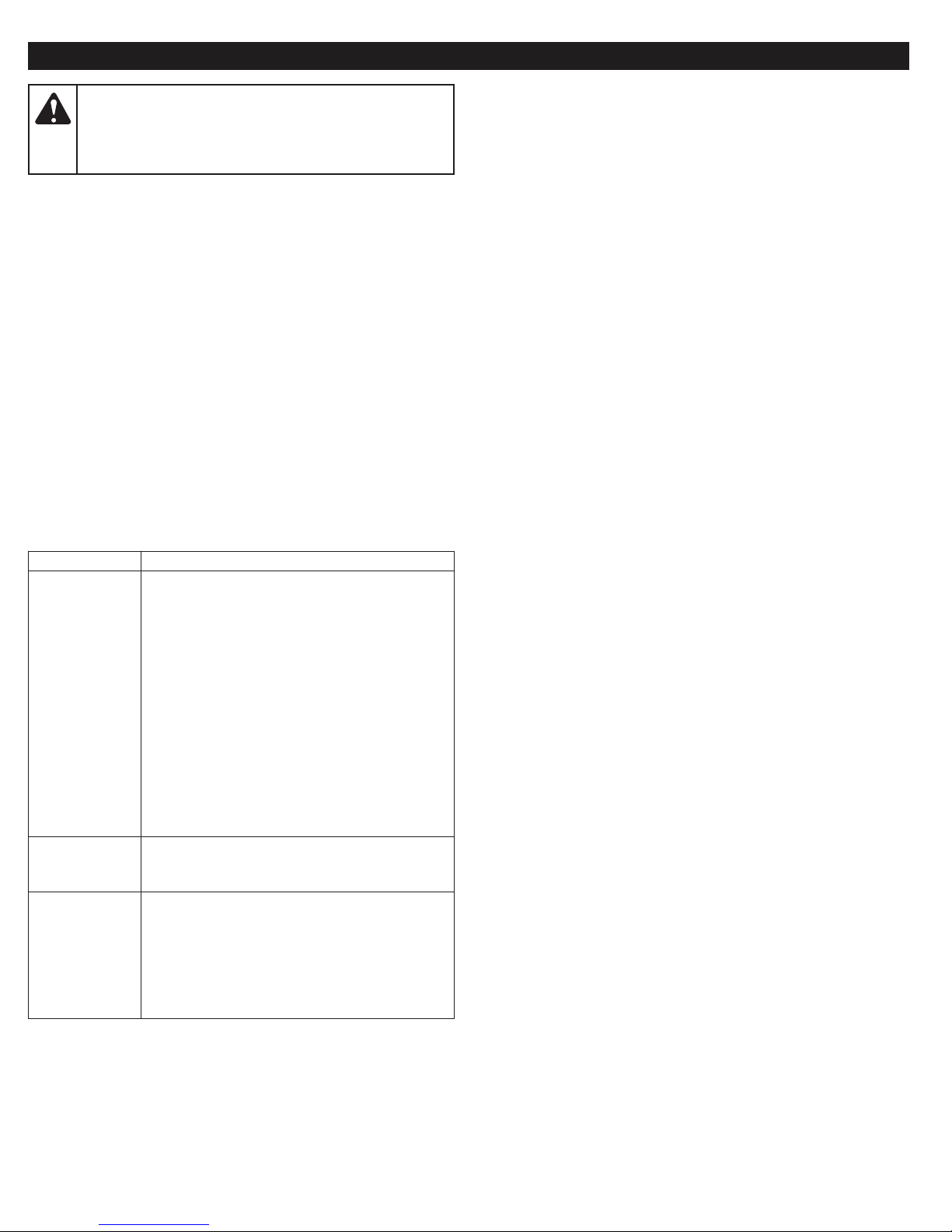

PRUNING

WARNING: Do not cut above shoulder height. Use a

pole saw to cut limbs above shoulder height or hire a

professional. Do not operate the unit in a tree or on a

ladder unless specifically trained to do so.

WARNING: Falling branches can cause serious injury.

Always wear appropriate head protection. Plan an escape

route away from falling limbs. Do not position any body

parts directly below the limb when cutting.

Pruning is the process of cutting limbs from a living tree.

1. Make the first cut approximately 6 inches (15 cm) from the tree

trunk. Cut upward, from the underside of the limb. Use the top

of the guide bar to make this cut. Cut a third of the way through

the diameter of the limb (Fig. 22).

2. Make the second cut 2 - 4 inches (5 - 10 cm) farther out on the

limb. Cut downward, from the top of the limb. Use the bottom of

the guide bar to make this cut. Cut completely through the limb

(Fig. 22).

3. Make the third cut as close to the tree trunk as possible. Cut

upward, from the underside of the limb stub. Use the top of the

guide bar to make this cut. Cut a third of the way through the

diameter of the limb (Fig. 22).

4. Make the fourth cut directly above the third cut. Cut downward,

from the top of the limb stub. Use the bottom of the guide bar to

make this cut. Cut completely through the limb stub to meet the

third cut (Fig. 22). This will remove the limb stub.

Fourth Cut

Second Cut

First Cut

Third Cut

Fig. 22

16

Page 17

MAINTENANCE

WARNING:

maintenance or repairs while the unit is running. Always

allow the unit to cool before servicing or repairing the unit.

Disconnect the spark plug wire to prevent the unit from

starting accidentally.

To prevent serious injury, never perform

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

All service, other than the maintenance procedures described in

this manual, should be performed by an authorized service dealer.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take the unit to

an MTD authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by an MTD authorized

service dealer.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the emissions

control devices, such as the spark arrestor, muffler, carburetor, etc.

CUSTOMER RESPONSIBILITY

FREQUENCY MAINTENANCE REQUIRED

Before each

use

After each use • Clean the unit and inspect decals. Refer to

Every 10 hours • Check the spark plug condition and gap.

• Check for loose screws, nuts or bolts

(tighten as needed)

• Check for damaged or worn parts*

• Check the saw chain sharpness. Refer to

Sharpening the Saw Chain.

• Test the chain brake*. Refer to Testing the

Chain Brake.

• Check the chain tension (adjust as needed).

Refer to Adjusting the Chain Tension.

• Fill the chain oil reservoir (refill frequently).

Refer to Adding Bar and Chain Oil.

• Fill the fuel tank with fresh, properly mixed

fuel. Refer to the Oil and Fuel section.

• Clean the air filter. Refer to Maintaining the

Air Filter.

Cleaning in the Cleaning and Storage

section.

Refer to Maintaining the Spark Plug.

• Clean the guide bar groove and oil

passages. Lubricate the sprocket tip. Refer

to Maintaining the Guide Bar.

• Clean the cylinder fins. Refer to Cleaning in

the Cleaning and Storage section.

* If maintenance or replacement is required, have the unit serviced

by an MTD authorized service dealer.

17

Page 18

ADDING BAR AND CHAIN OIL

DANGER:

irreparable damage to the unit. Make sure the chain oil

reservoir is always filled. Always use bar and chain oil.

Failure to fill the chain oil reservoir will cause

Chain Oil

Reservoir Cap

WARNING:

Oil constantly flows from the chain oil

reservoir to oil the saw chain. Check the chain oil level

frequently so that it does not drop below half full.

The guide bar and saw chain require lubrication to minimize friction.

Never starve the guide bar and chain of lubricating oil. Running the

unit without enough oil will decrease cutting efficiency, shorten the

life of the saw chain, cause rapid dulling of the saw chain and

excessive wear to the guide bar from overheating. An insufficient

amount of lubricating oil is evidenced by smoke, guide bar

discoloration or pitch build-up.

Only use bar and chain oil that is formulated to perform over a wide

range of temperatures with no diluting required in the chain oil

reservoir. Do not use motor oil or any other petroleum-based oil. Do

not use dirty, used or contaminated oil. Damage may occur to the

guide bar or saw chain. Dispose of old oil according to federal, state

and local regulations.

1. Set the unit on a flat, level surface.

2. To prevent debris from entering the chain oil reservoir, use a damp

cloth to clean the chain oil reservoir cap and surrounding area.

3. Unscrew the chain oil reservoir cap (Fig. 23).

4. Carefully pour the oil into the chain oil reservoir. DO NOT overfill.

5. Reinstall the chain oil reservoir cap.

6. Wipe up any oil that may have spilled.

Chain Oil

Reservoir

Fig. 23

ADJUSTING THE BAR AND CHAIN OIL FLOW

Bar and chain oil will slowly flow from the chain oil reservoir onto the

chain. Approximately one tank of bar and chain oil is used for every

tank of fuel.

1. To increase the oil flow, turn the automatic oiler adjustment

screw counterclockwise with a flat-head screwdriver (Fig. 24).

2. To decrease the oil flow, turn the automatic oiler adjustment

screw clockwise with a flat-head screwdriver (Fig. 24).

Chain Oil

Adjustment Screw

Fig. 24

18

Page 19

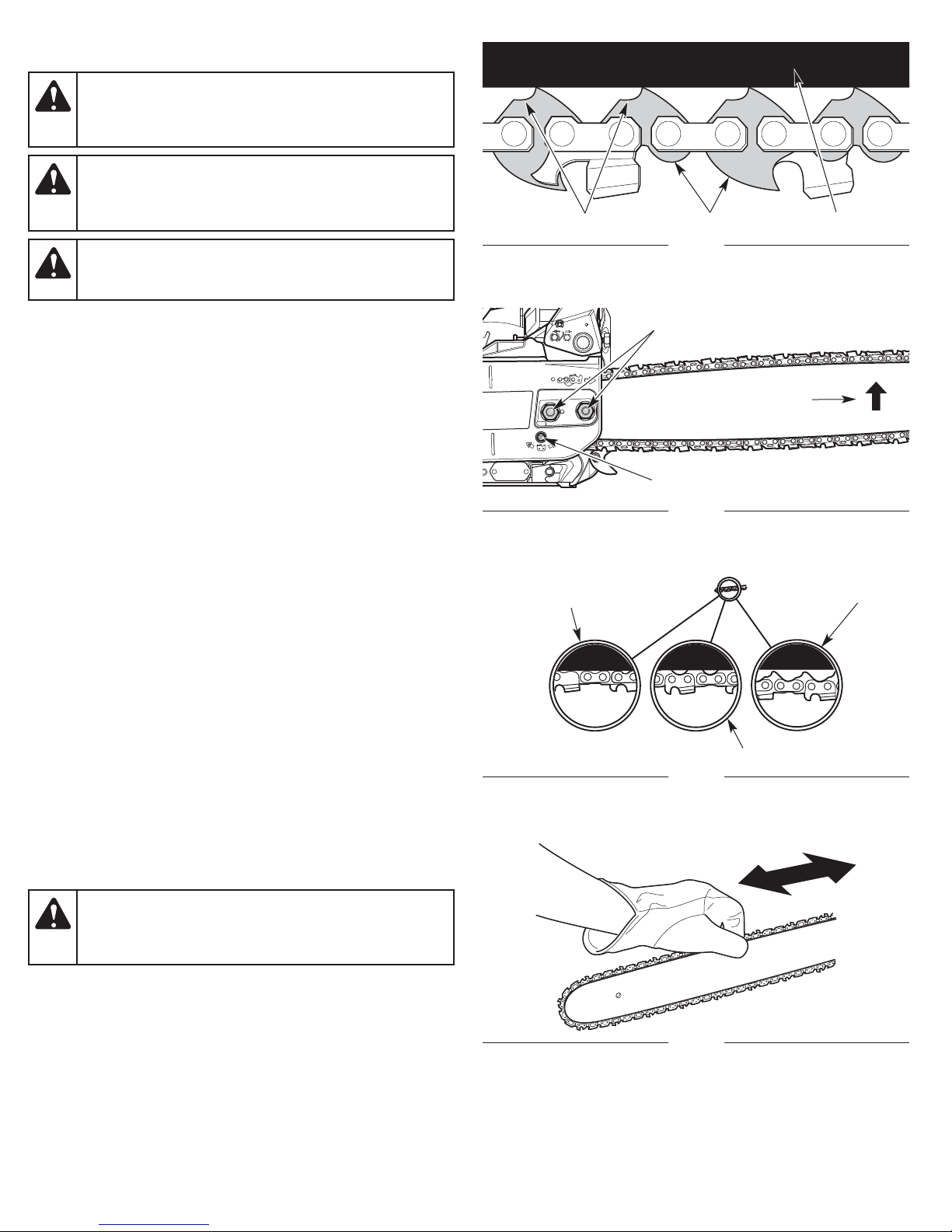

ADJUSTING THE CHAIN TENSION

CAUTION:

The guide bar, saw chain, and saw bearings

will wear more rapidly if the saw chain is not properly

tensioned. Maintaining proper chain tension will improve

cutting performance and prolong the life of the saw chain.

WARNING: To prevent serious injury, never touch the

saw chain or adjust the chain tension while the unit is

running. Disconnect the spark plug wire to prevent the unit

from starting accidentally.

WARNING: The saw chain is very sharp. Always wear

heavy-duty protective gloves when handling or performing

maintenance on the saw chain.

Check the chain tension before and during operation. Adjust the

chain tension whenever the flats on the saw chain hang out of the

bar groove (Fig. 25).

NOTE: A new saw chain tends to stretch and will need readjustment

after as few as five (5) cuts. This is normal during the break-in

period. The interval between future adjustments will lengthen

quickly.

1. Make sure the chain brake is disengaged. Refer to Testing the

Chain Brake in the Assembly section.

2. Use the multi-purpose tool or a 1/2 inch (13 mm) wrench to

slightly loosen the bar-retaining nuts (Fig. 26).

3. Hold the guide bar tip up and use a flat-head screwdriver to turn

the chain-tensioning screw (Fig. 26).

• Turn the chain-tensioning screw clockwise to tighten the saw

chain.

• Turn the chain-tensioning screw counterclockwise to loosen

the saw chain.

The desired chain tension depends upon the temperature of the

saw chain (Fig. 27).

• Cold Chain Tensioning - The saw chain should fit snuggly

against the underside of the guide bar. There should be no sag

(Fig. 27).

• Warm Chain Tensioning - The saw chain will expand as it

heats up during operation. The drive links should hang

approximately 1/16 inch (1.3 mm) out of the guide bar groove

(Fig. 27).

4. Hold the guide bar tip up and move the saw chain back and

forth along the guide bar (Fig. 28). Make sure the saw chain

moves freely and is in proper mesh with the sprocket. If the saw

chain does not move easily, slowly turn the chain-tensioning

screw counterclockwise to loosen the saw chain.

NOTE: The saw chain will not move if the chain brake is engaged.

5. Hold the guide bar tip up and securely tighten the bar-retaining nuts.

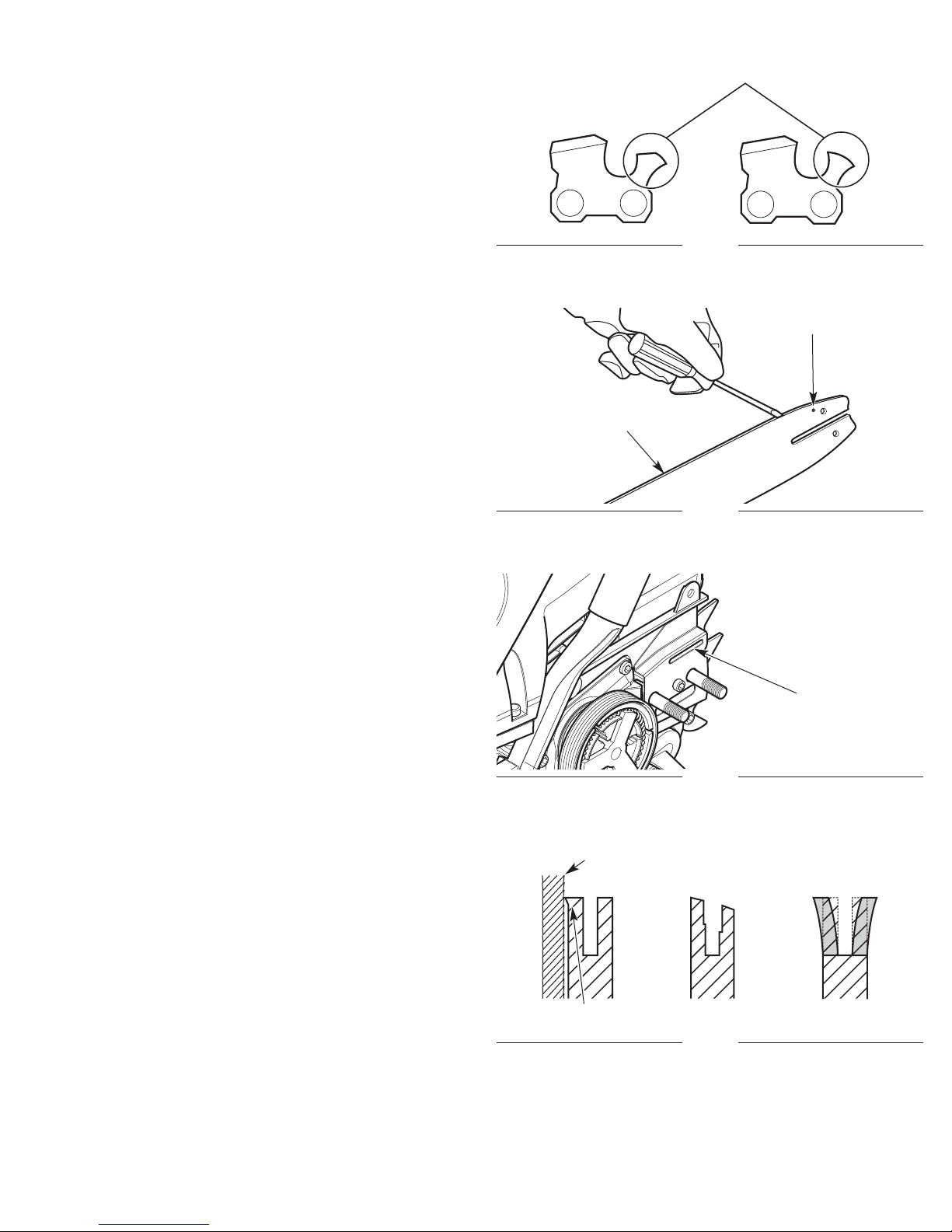

Flats

Drive Links

Fig. 25

Bar-Retaining Nuts

Guide Bar Tip

Chain-Tensioning Screw

Fig. 26

Correct Warm Tension

Fig. 27

Guide Bar

Too LooseCorrect Cold Tension

CAUTION: If the saw chain was tensioned while warm, it

may become too tight when cooled. Loosen the chain

tension after operation and check the chain tension before

the next use.

Fig. 28

19

Page 20

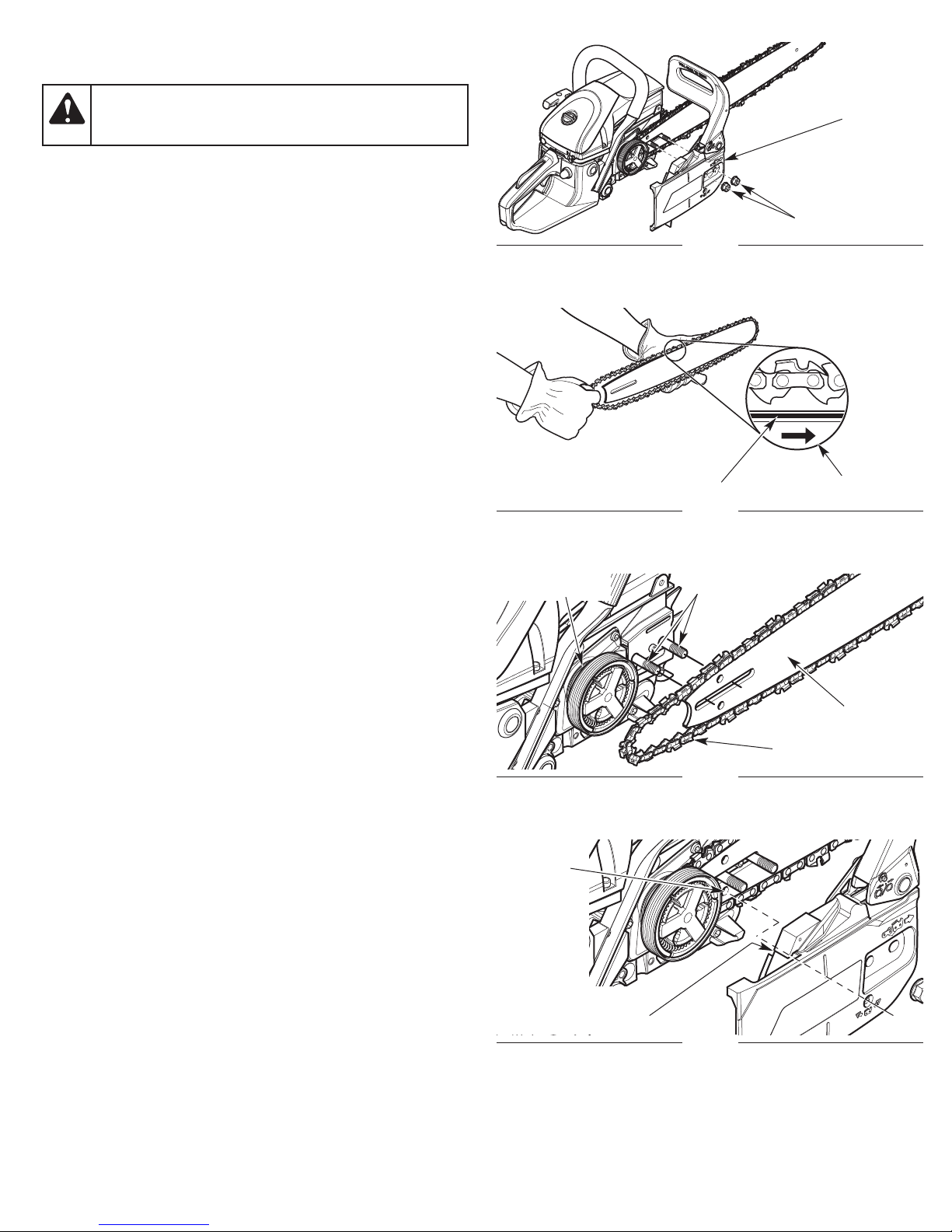

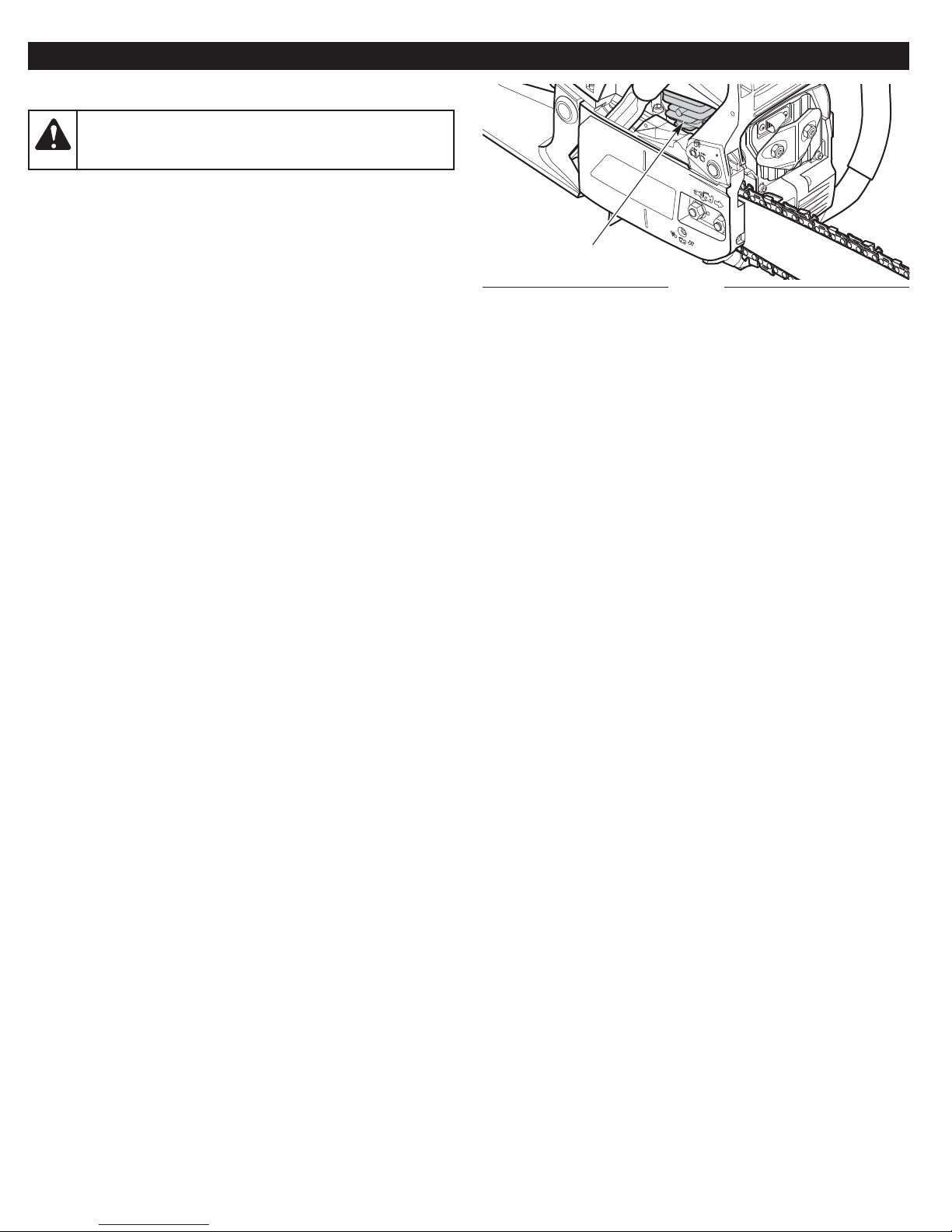

REMOVING AND INSTALLING THE GUIDE BAR AND SAW

CHAIN

WARNING:

The saw chain is very sharp. Always wear

heavy-duty protective gloves when handling or performing

maintenance on the saw chain.

The guide bar and saw chain need to be removed when certain

maintenance procedures are performed, such as when rotating the

guide bar. When replacing old guide bars and saw chains with new

parts, always use the manufacturer’s specified replacement parts.

Refer to Replacing the Guide Bar and Saw Chain.

Removing the Guide Bar and Saw Chain

1. Make sure the chain brake is disengaged. Refer to Testing the

Chain Brake in the Assembly section.

2. Use the multi-purpose tool or a 1/2 inch (13 mm) wrench to

loosen the bar-retaining nuts (Fig. 29).

3. Remove the bar-retaining nuts and bar cover (Fig. 29).

4. Loosen the saw chain. Refer to Adjusting the Chain Tension.

5. Remove the guide bar and saw chain from the guide bar bolts

(Fig. 31).

6. Remove the saw chain from the guide bar.

Installing the Guide Bar and Saw Chain

1. Set the saw chain on a clean, flat surface and straighten out any

kinks.

2. Fit the saw chain into the guide bar groove (Fig. 30). Make sure

the cutters point in the correct direction of rotation (Fig. 30). Keep a

loop of saw chain at the back end of the guide bar (Fig. 30).

3. Hold the saw chain and guide bar together in position over the

unit. Loop the saw chain around the drive sprocket and install the

guide bar onto the guide bar bolts (Fig. 31). Make sure the guide

bar is flush against the mounting surface. Make sure the flats on

the saw chain are in the grooves on the drive sprocket.

4. Install the bar cover. Make sure the chain-tensioning pin is in the

pin hole on the guide bar (Fig. 32).

5. Place the bar-retaining nuts onto the guide bar bolts and tighten

them hand tight.

6. Make sure the saw chain is still in the guide bar groove, then

tighten the saw chain. Refer to Adjusting the Chain Tension.

7. Hold the guide bar tip up and securely tighten the bar-retaining nuts.

Drive Sprocket

Fig. 29

Guide Bar Groove

Fig. 30

Guide Bar Bolts

Bar Cover

Bar-Retaining Nuts

Direction of Rotation

Guide Bar

Saw Chain

MAINTAINING THE SAW CHAIN

For safe, efficient operation, the saw chain must be maintained

properly.

The saw chain will wear with use, causing the chain to stretch. This

is normal. When it is no longer possible to obtain a correct chain

tension adjustment, the saw chain will need to be repaired by an

authorized service dealer or replaced. Refer to Replacing the Guide

Bar and Saw Chain.

Always keep the saw chain sharp. During operation, look for the

following indicators of a dull saw chain:

• Wood chips are small and powdery.

• The saw chain must be forced through the wood.

• The saw chain cuts to one side.

If any of these conditions exist, sharpen or replace the saw chain.

Refer to Sharpening the Saw Chain or Replacing the Guide Bar and

Saw Chain.

NOTE: If you do not fully understand the sharpening procedure after

reading the instructions, have the saw chain sharpened by an

authorized service dealer or replace the saw chain.

Fig. 31

Pin Hole

Chain-Tensioning Pin

Fig. 32

20

Page 21

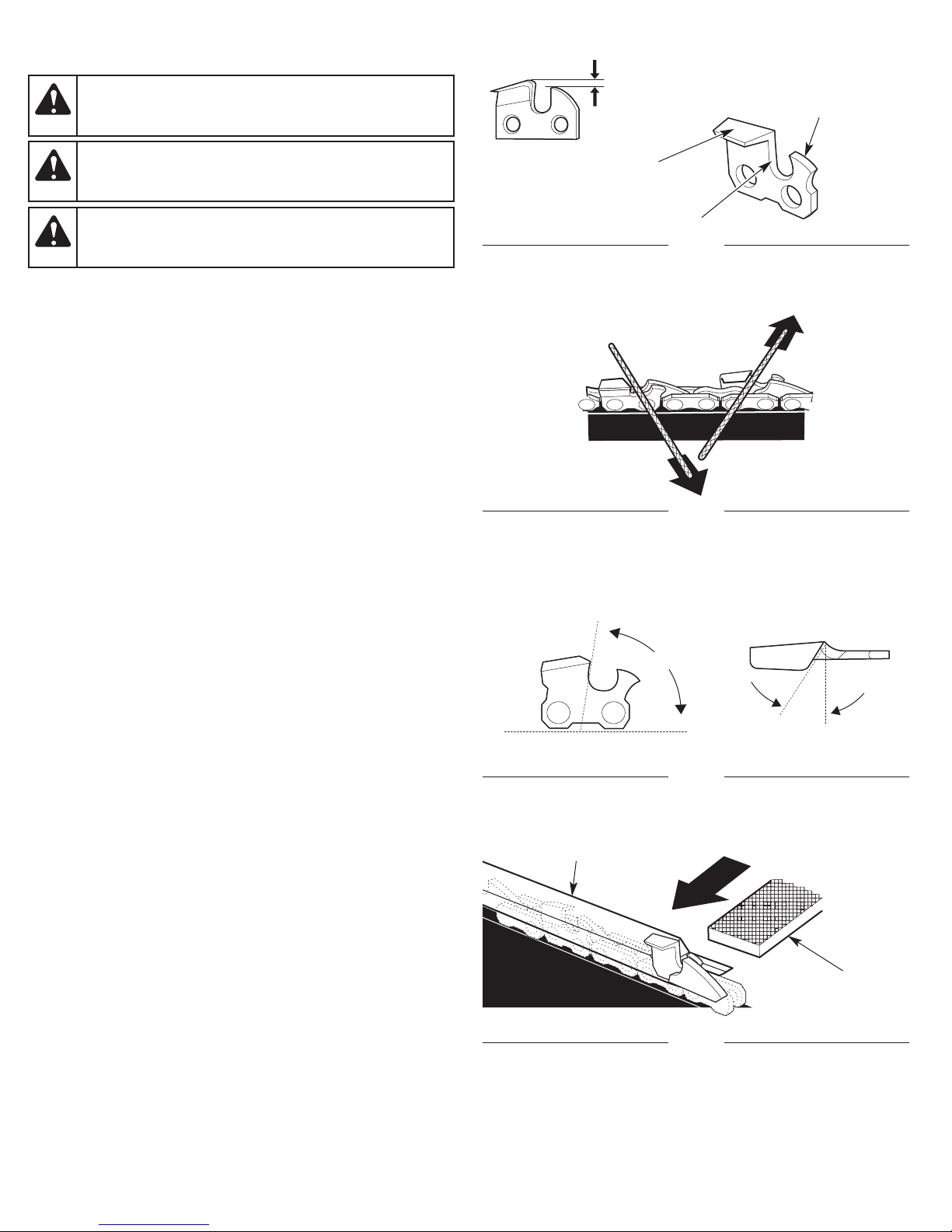

SHARPENING THE SAW CHAIN

WARNING:

heavy-duty protective gloves when handling or performing

maintenance on the saw chain.

The saw chain is very sharp. Always wear

Depth Gauge Clearance

1/32 inch (0.6 mm)

Depth Gauge

WARNING: An improperly sharpened saw chain

increases the chance of kickback. Failure to replace or

properly maintain the saw chain can cause serious injury.

CAUTION: A dull or improperly sharpened saw chain

can cause excessive engine speed during operation, which

can result in severe engine damage.

If the saw chain was damaged by contacting hard objects, such as

nails or stones, or was abraded by mud or sand on the wood, have

an authorized service dealer sharpen the saw chain.

When sharpening the saw chain, file all cutters to the specified

angles and measurements. Other angles or measurements can

cause excessive wear to the guide bar and saw chain, cause the

chain to dull quickly and increase the chance of kickback. Fast

cutting can be obtained only when all cutters are uniform.

1. Tighten the chain tension so that the saw chain is taut and does

not wobble. Refer to Adjusting the Chain Tension.

• Always file the saw chain at the midpoint of the guide bar.

2. Use a round file and file holder (tools not included) to sharpen

the top plate and side plate of each cutter.

• Use a 5/32 inch (4 mm) diameter file when sharpening the 18

inch saw chain (RM4218). Use a 3/16 inch (4.8 mm) diameter

file when sharpening the 20 inch saw chain (RM4620).

• Keep the file level with the top plate of the cutter (Fig. 33). Do

not let the file dip or rock. Use light, but firm pressure.

• File toward the front corner of the cutter (Fig. 34). Lift the file

away from the cutter at the end of the forward stroke. Only file

on the forward stroke.

• Apply a few firm strokes to each tooth. When filed correctly,

the top plate will be at a 30º angle and the side plate will be at

an 80º angle (Fig. 35). Using the correct file and file holder will

automatically produce the correct angles.

• File all the left-hand cutters in one direction (Fig. 34). Then

move to the other side of the saw chain and file all of the righthand cutters in the opposite direction (Fig. 34).

• Occasionally remove filings with a wire brush.

3. Use a depth gauge tool (not included) to measure the depth

gauge clearance (Fig. 36) of each cutter. The depth gauge

clearance must be maintained at 1/32 inch (0.6 mm). The depth

gauge clearance determines the depth at which the cutter enters

the wood during operation and the size of the wood chips

produced. Too much clearance increases the chance of

kickback. Too little clearance decreases the size of the wood

chips, thus deceasing the ability to cut.

• Use a 1/32 inch (0.6 mm) depth gauge jointer and a flat file

(tools not included) to lower the depth gauge to the correct

clearance (Fig. 36).

• After lowering the depth gauge, use the flat file to restore the

original rounded shape to the depth gauge (Fig. 37). Take care

not to damage the cutting edges or nearby links.

Top Plate

Side Plate

Fig. 33

Filing Angle

Left-Hand

Cutters

Right-Hand

Cutters

Fig. 34

Correct Filing Angles

Top Plate

80º

30º

Side Plate

Fig. 35

Depth Gauge Jointer

Flat File

Fig. 36

21

Page 22

Restore original rounded shape

Fig. 37

MAINTAINING THE GUIDE BAR

1. Rotate the guide bar frequently, at regular intervals (for example,

after every 5 hours of operation), to ensure even wear on the top

and bottom of the guide bar. Refer to Removing and Installing

the Guide Bar and Saw Chain.

2. Clean the guide bar groove and oil passages whenever the saw

chain is removed, when the unit has been used heavily or when

the saw chain appears dirty. Use a screwdriver, putty knife, wire

brush or similar instrument to remove debris from the guide bar

groove (Fig. 38). Use a small, soft wire to remove any debris

from the chain oil discharge hole (Fig. 39).

NOTE: If the oil passages are clear, the saw chain will give off a

spray of oil shortly after it begins to rotate during operation.

3. Frequently check the guide bar for damage (Fig. 40). Feathering

and burring of the guide bar rails (the ridges on either side of the

bar groove) is a normal process of guide bar wear. Such faults

should be smoothed with a file as soon as they occur (Fig. 40). A

guide bar with the following faults should be replaced:

• Wear inside the guide bar rails that permits the chain to lay

sideways

• Bent guide bar

• Cracked or broken rails

• Spread rails

Refer to Replacing the Guide Bar and Saw Chain.

Lubricating the Guide Bar Sprocket Tip

The guide bar sprocket tip was lubricated at the factory, but requires

regular lubrication. Failure to lubricate the guide bar sprocket tip will

result in poor performance, damage to the unit and will VOID the

warranty.

NOTE: This procedure can be performed while the guide bar and

saw chain are still assembled on the unit.

1. Clean the guide bar sprocket tip thoroughly with a damp cloth

(Fig. 41).

2. Use a guide bar tip lube gun (not included) to inject grease into

the lubrication hole (Fig. 41). Inject grease until it appears on the

outer edge of the guide bar sprocket tip.

3. Rotate the saw chain by hand. Always wear heavy-duty

protective gloves. Make sure the chain brake is disengaged.

4. Repeat the lubrication process until the entire guide bar

sprocket tip is lubricated.

Guide Bar Groove

Flat File

Bur Spread Rails

Oil Passage

Fig. 38

Chain Oil

Discharge Hole

Fig. 39

Uneven Wear

Fig. 40

22

Page 23

REPLACING THE GUIDE BAR AND SAW CHAIN

WARNING:

which significantly reduces the danger of kickback. Lowkickback saw chain does not completely eliminate

kickback. A low-kickback or “safety chain,” should never

be regarded as total protection against injury.

When replacing the guide bar and saw chain, only use the

replacement parts specified by the manufacturer or their

equivalents. Refer to Replacement Parts. Use of any unauthorized

parts or accessories could lead to serious injury to the operator or

damage to the unit and will VOID the warranty.

Always use a replacement saw chain designated as “low-kickback”

or a saw chain that meets the low-kickback performance

requirements. A standard saw chain (a chain that does not have the

kickback-reducing guard links) should only be used by an

experienced professional chain saw operator.

Always use a low-kickback saw chain,

Lubrication Hole

Guide Bar Tip Lube Gun

Guide Bar Sprocket Tip

Fig. 41

MAINTAINING THE AIR FILTER

WARNING: To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit.

Failure to maintain the air filter can result in poor performance or

can cause permanent damage to the engine. Engine failure due to

improper air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

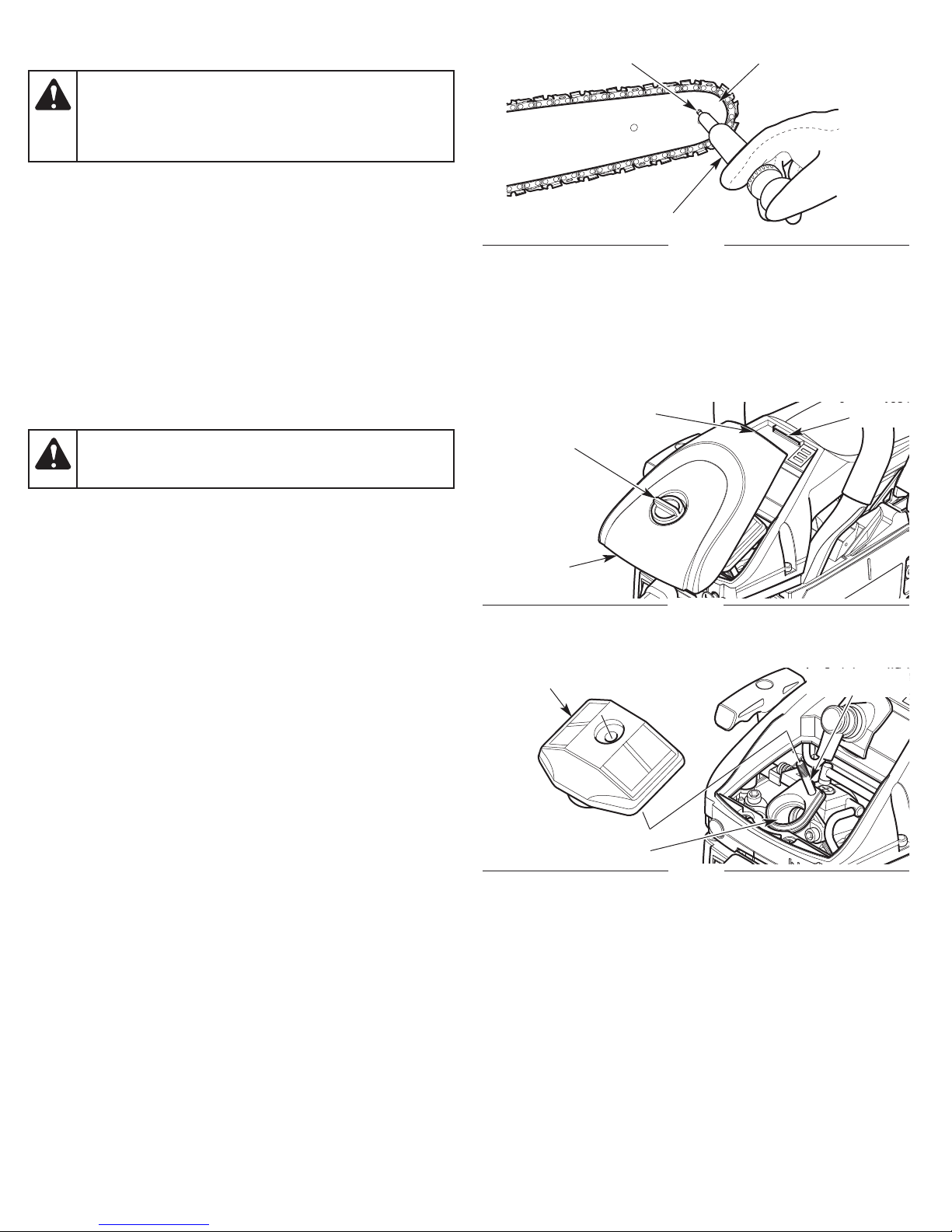

1. Turn the knob on the air filter cover counterclockwise to loosen

the air filter cover (Fig. 42).

2. Remove the air filter cover (Fig. 42).

3. Remove the air filter (Fig. 43).

4. Wash the air filter in mild detergent and water. Rinse the air filter

thoroughly and allow it to dry.

5. Reinstall the air filter onto the mounting post (Fig. 43). Make sure

the opening in the air filter sits securely in the air intake (Fig. 43).

NOTE: Operating the unit without the air filter and air filter cover will

VOID the warranty. Keep a supply of spare air filters.

6. Place the air filter cover back onto the unit. Insert the tab on the

air filter cover into the slot on the chain saw housing (Fig. 42).

7. Turn the knob clockwise to tighten the air filter cover securely.

Knob

Air Filter

Cover

Air Filter

Ta b

Air Intake

Slot

Fig. 42

Mounting Post

Fig. 43

23

Page 24

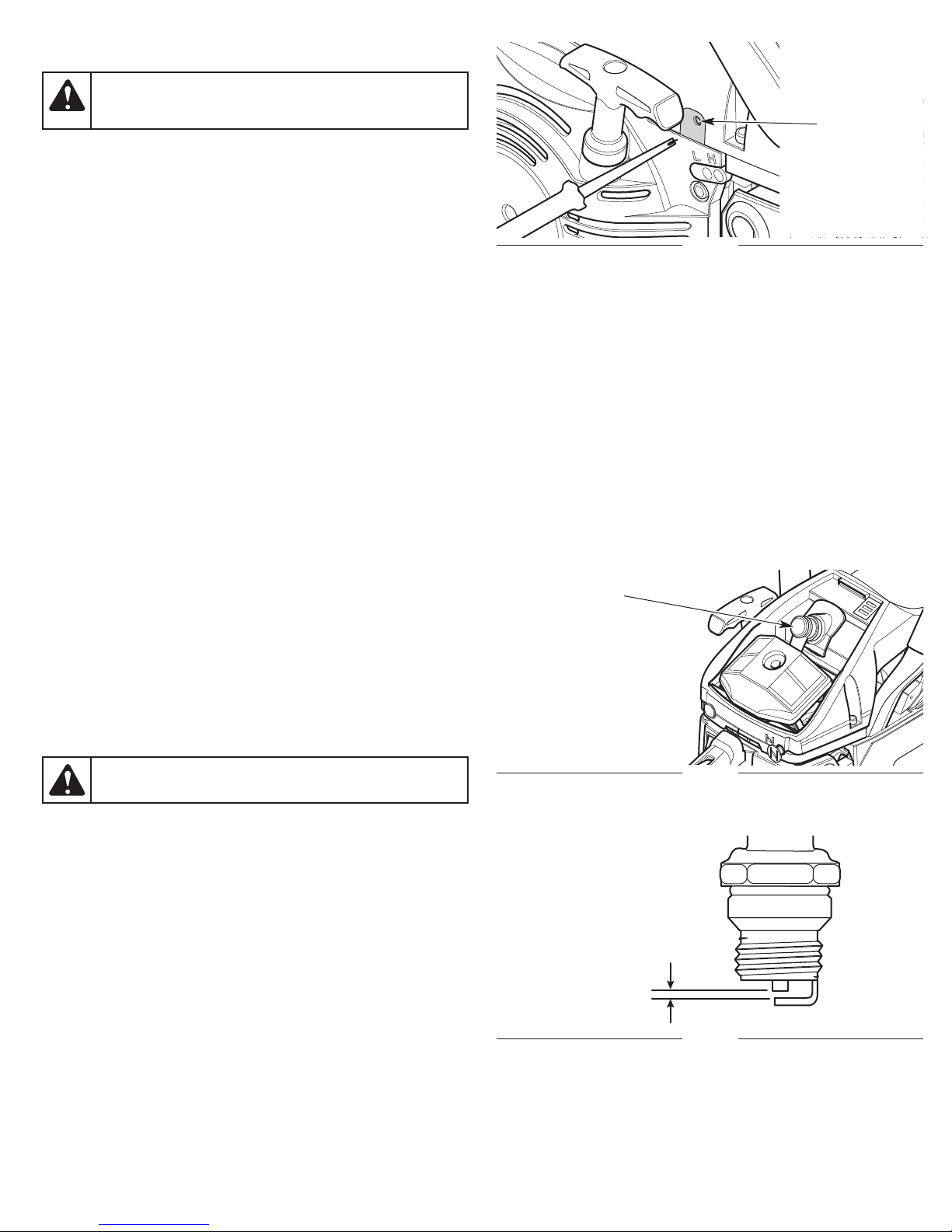

ADJUSTING THE IDLE SPEED

WARNING:

The saw chain may spin during idle speed

adjustments. Wear protective clothing and observe all

safety instructions to prevent serious personal injury.

NOTE: Careless adjustments can seriously damage the unit. An

authorized service dealer should make carburetor adjustments.

If, after checking the fuel and cleaning the air filter, the engine still

will not idle, adjust the idle speed screw as follows:

1. Start the engine. Refer to Starting and Stopping.

2. Release the throttle control and let the engine idle.

• If the engine stops, use a small Phillips or flat-head screwdriver

to turn the idle speed screw clockwise, 1/8 of a turn at a time

(as needed) until the engine idles smoothly (Fig. 44).

• If the engine idles too quickly, turn the idle speed screw

counterclockwise, 1/8 of a turn at a time (as needed) to reduce

the idle speed (Fig. 44).

NOTE: The saw chain should not spin when the engine idles. If it

does, reduce the idle speed until the saw chain stops moving.

Checking the fuel, cleaning the air filter, and adjusting the idle speed