Remington RM4040, RM4040B Operating Manual

Operator’s Manual

ORIGINAL INSTRUCTIONS

RM4040 / RM4040B

Cordless Chain Saw

BC

SAVE THESE INSTRUCTIONS

IMPORTANT: Read this manual thoroughly before using this product. Follow all instructions.

769-12208 / 01 03/18

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Essential Terms and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . .12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

NOTE: This operator's manual covers multiple models. Features

may vary by model. Not all features in this manual are applicable

to all models. The model depicted may differ from yours.

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes

he product may vary slightly from the illustrations contained in this

T

manual.

Copyright© 2017 MTD SOUTHWEST INC, All Rights Reserved.

at any time without notice.

SERVICE

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, operation or maintenance of

the unit, please call 1-866-206-2707 (in the United States) or 1-877-

696-5533 (in Canada). Additional information can be found at

www.remingtonpowertools.com.

Warranty service is available through an authorized service center.

To locate a servi

call the number listed above. Service on this unit, both within and

after the warranty period, should only be performed by an

authorized and approved service center. When servicing, use only

identical replacement parts.

ce center in your are

a, please visit our website or

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

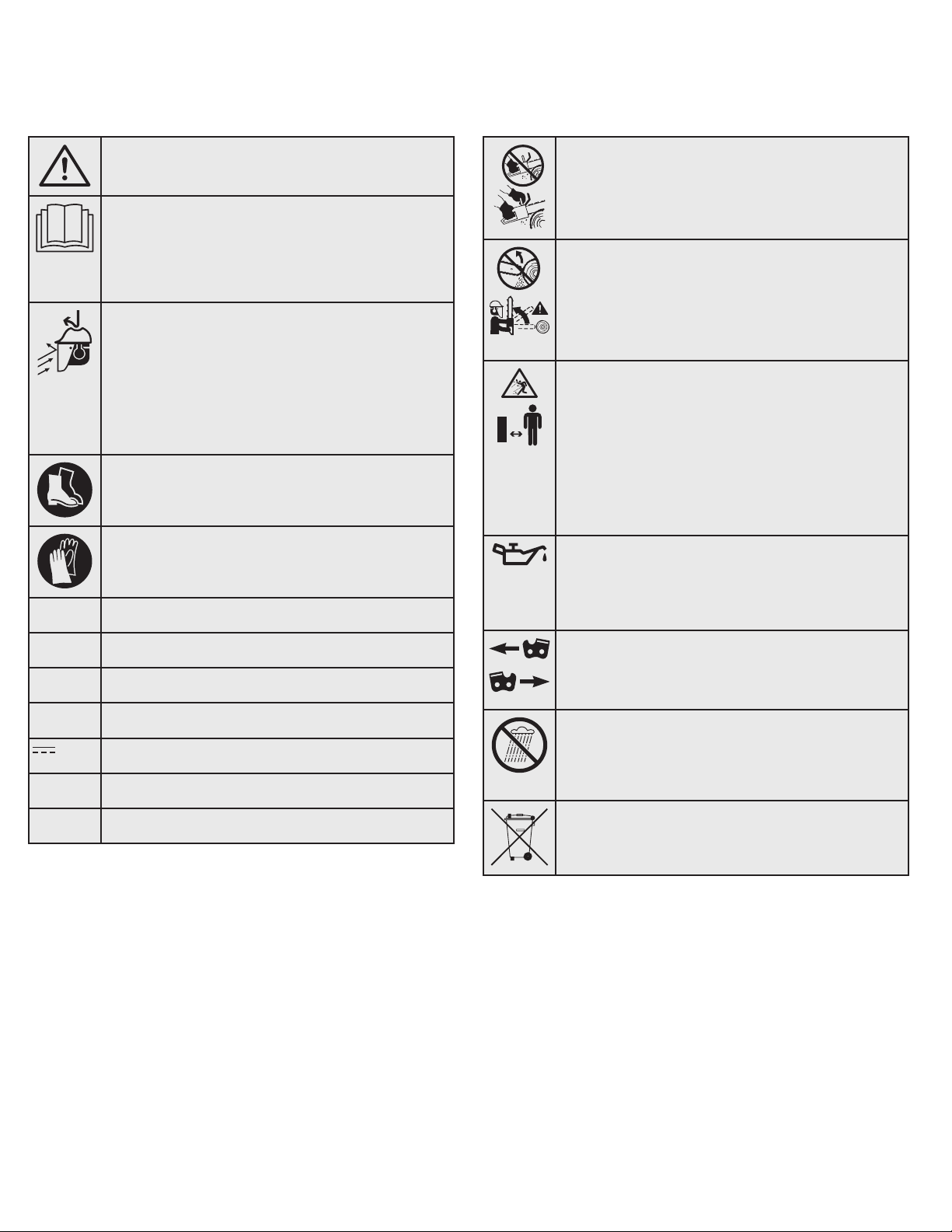

SYMBOL MEANING

DANGER:

Failure to obey a safety DANGER symbol WILL result in

serious injury or death to yourself or to others.

WARNING:

Failure to obey a safety WARNING symbol CAN result in

serious injury to yourself or to others.

Signals an EXTREME hazard.

Signals a SERIOUS hazard.

CAUTION:Signals a MODERATE hazard.

Failure to obey a safety CAUTION symbol MAY result in

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SAFETY

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

CALIFORNIA PROPOSITION 65

WARNING:

chemical known to the State of California to cause cancer,

birth defects or other reproductive harm.

This product contains a

2

• IMPORTANT SAFETY INSTRUCTIONS •

GENERAL POWER TOOL SAFETY WARNINGS

WARNING:

instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres

s in the presence of flammable liquids, gases or dust.

a

Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) Electrical Safety

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified p

atching outlets will reduce risk of electric shock.

m

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use

pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidabl

se a ground fault circuit interrupter (GFCI) protected

u

supply. Use of a GFCI reduces the risk of electric shock.

3) Personal Safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal i

) Use personal protective equipment. Always wear eye

b

protection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source and/or

battery pack, picking up or carrying the tool. Carrying

power to

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in

unexpected situatio

ols with your finger on the switch or energ

ns.

Read all safety warnings and all

, such

lugs and

the cord

for carrying,

njury.

izing power

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) Power Tool Use and Care

a) Do no

b) Do not use the power tool if the switch does not turn it on

c) Disconnect the plug from the power source and/or the

d) Store idle power tools out of the reach of children and do

e) Maintain power

f) Keep cutting tools sharp and clean. Properly maintained

g) Us

e,

5) Battery tool use and care

a) Recharge only with the charger specified by the

b) Use power tools only with specifically designated battery

c) When battery pack is not in use, keep it away from other

d) Under abusive conditions, liquid may be ejected from the

6) Service

a) Have your power tool serviced by a qualified repair person

t forc

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

battery pack from the p

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

f moving parts, breakage of parts and any other

o

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

e the power tool, accessories and tool bits etc. in

ccordance with these instructions, taking into account

a

the working conditions and the work to be performed. Use

of the power tool for operations different from those intended

could result in a hazardous situation.

manufacturer. A charger that is suitable for one type of

battery

pack may cre

battery pack.

packs. Use of any other battery packs may create a risk of

injury and fire.

metal objects, like paper clips, coins, keys, nails, screws

or other small metal objects, that can make a connection

from one terminal to another

together may cause burns or a fire.

battery; avoid contact. If contact accidentally occurs, flush

with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

using only identi

the safety of the power tool is maintained.

e the power tool. Use the correct power tool

ower tool before

tools. Check for misalignment or binding

ate a risk of fire when used with another

horting the battery terminals

. S

cal re

placement parts. This will ensure that

making any

3

Chain saw safety warnings:

• Keep all parts of the body away from the saw chain when

the chain saw is operating. Before you start the chain saw,

make sure the saw chain is not contacting anything. A

moment of inattention while operating chain saws may cause

entanglement of your clothing or body with the saw chain.

• Always hold the chain saw with your right hand on the rear

handle and your left hand on the

chain saw with a reversed hand configuration increases the

risk of personal injury and should never be done.

• Hold the power tool by insulated gripping surfaces only,

because the saw chain may contact hidden wiring. Saw chains

contacting a “live” wire may make exposed metal parts of the

power tool “live” and could give the operator an electric shock.

• Wear safety glasses and hear

protective equipment for head, hands, legs and feet is

recommended. Adequate protective clothing will reduce

personal injury by flying debris or accidental contact with the

saw chain.

• Do not operate a chain saw in a tree. Operation of a chain

saw while up in a tree may result in personal injury.

• Always keep proper footing and operate the chain saw

only when standing on fixed, secur

lippery or unstable surfaces such as ladders may cause a

S

loss of balance or control of the chain saw.

• When cutting a limb that is under tension be alert for

spring back. When the tension in the wood fibers is released

the spring loaded limb may strike the operator and/or throw

the chain saw out of control.

• Use extreme caution when cutting brush and saplings. The

slender material may

oward you or pull you off balance.

t

• Carry the chain saw by the front handle with the chain saw

switched off and away from your body. When transporting

or storing the chain saw always fit the guide bar cover.

Proper handling of the chain saw will reduce the likelihood of

accidental contact with the moving saw chain.

• Follow instructions for lubricating, chain tensioning

hanging accessories. Improperly tensioned or lubricated

c

chain may either break or increase the chance of kickback.

• Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

• Cut wood only. Do not use chain saw for purposes not

intended. For example: do not use chain saw for cutting

plastic, masonry or non-wood building materials. Use of

the chai

result in a hazardous situation.

Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the guide bar touches

an object, or when the wood closes in and pinches the saw chain in

the cut.

Tip contact in some cases may cause a sudden reverse reaction,

kicking the guide bar up and back towards the operator.

Pinching the saw cha

uide bar rapidly back towards the operator.

g

Either of these reactions may cause you to lose control of the saw

which could result in serious personal injury. Do not rely exclusively

upon the safety devices built into your saw. As a chain saw user,

you should take several steps to keep your cutting jobs free from

accident or injury.

Kickback is the result of

procedures or conditions and can be avoided by taking proper

precautions as give below:

n saw for operations diff

catch the saw chain and be whipped

in along the top of the guide bar may push the

tool misuse and/or incorre

nt handle. Holding the

fro

tection. Further

ing pro

e and level surface.

erent than intended could

ct operating

and

• Maintain a firm grip, with thumbs and fingers encircling

the chain saw handles, with both hands on the saw and

position your body and arm to allow you to resist kickback

forces. Kickback forces can be controlled by the operator, if

proper precautions are taken. Do not let go of

o not overreach and do not cut above shoulder height.

• D

This helps prevent unintended tip contact and enables better

control of the chain saw in unexpected situations.

• Only use replacement bars and chains specified by the

manufacturer. Incorrect replacement bars and chains may

cause chain breakage and/or kickback.

• Follow the manufacturer’s sharpening and maintenance

instructions for the sa

height can lead to increased kickback.

w chain. D

ecreasing the depth gauge

the chain saw.

WARNING:Read all safety warnings and all

instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

READ ALL INSTRUCTIONS BEFORE OPERATING

1. SAVE THESE INSTRUCTIONS - This manual contains

important safety and operating instructions.

2. Before using this product, read all instructions and cautionary

markings on the battery, battery charger, and the unit(s) powered

by the battery.

3. Do not handle the charger, including the charger plug and

charger terminals, with wet hands.

4. Do not charge the unit outdoors.

WARNING:

RM4150 batteries with this unit. DO NOT use any other type

of battery, attachment or accessory with this unit. Other

types of batteries, attachments or accessories could lead to

serious injury, property damage or damage to the unit.

NOTE: Although this unit can use the RM4130 battery, it is

not recommended. For best performance, always use an

RM4140 or RM4150 battery with

Only use RM4130, RM4140 or

this unit.

WARNING:Only charge RM4130, RM4140

or RM4150 batteries with an RM4110 battery charger. DO

NOT attempt to use any other battery charger to charge

RM4130, RM4140 or RM4150 batteries. Other types of

battery chargers may cause the batteries to burst, resulting

in fire, personal injury or property damage.

WARNING:

charger to charge RM4130, RM4140 or RM4150 batteries.

DO NOT attempt to charge any other batteries with an

RM4110 battery charger. Other types of batteries may

burst, causing fire, personal injury or property damage.

Only use an RM4110 battery

4

GENERAL SAFETY WARNINGS

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit. Know how to stop the unit and disengage

the controls quickly.

• Stay alert. Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Never allow children to operate the unit. Teens must be trained,

accompanied and supervised by an adult. Never allow

perate the unit without proper instruction.

o

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Check for damaged parts. Make sure

all parts operate properly. Make sure all fasteners are in place

and secure. Make sure all moving parts are properly aligned and

are not bound. Replace parts that are cracked, chipped, or

damaged in

parts repaired or replaced by an authorized service center. Do

not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands and feet.

• Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

• Clear the a

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

• This unit is intended for occasional, household use only.

• Do not allow the unit to be used as a toy.

any way.

a of children, bystanders and pets; keep them

re

Have all damaged or improperly working

adults to

SAFETY WARNINGS FOR ELECTRIC UNITS

General Electric Safety

• Do not expose the unit to rain or wet conditions. Store

indoors.

• Do not handle the unit with wet hands.

• Avoid dangerous environments. Do not operate the unit in the

rain, in wet conditions or on wet surfaces. Moisture is a shock

hazard.

• To reduce the risk of electric shock, avoid body contact with

grounded conductors, such as metal pipes or wire fences.

• Do not operate the unit in explosive atmo

presence of flammable liquids, gases or dust.

Battery Charger Safety

• Follow all charging instructions. Do not charge the battery

outside the temperature range specified in these instructions.

Improperly charging the battery or charging the battery outside

of the specified temperature range may damage the battery and

increase the risk of fire.

• A nameplate on the unit indicates the

onnect the unit to an AC voltage that differs from this voltage.

c

• An extension cord should not be used unless absolutely

necessary. Use of an improper extension cord could result in a

risk of fire, electric shock or electrocution.

• Do not use multiple extension cords.

• Make sure the extension cord is heavy enough to carry the

current drawn by the unit. An undersized extension cord

cause a drop i

overheating. If in doubt, use the next heavier gauge cord. The

smaller the gauge number, the heavier the cord.

n line voltage, resulting in a loss of power and

sphere

voltage used. Never

the unit

s, such as in the

will

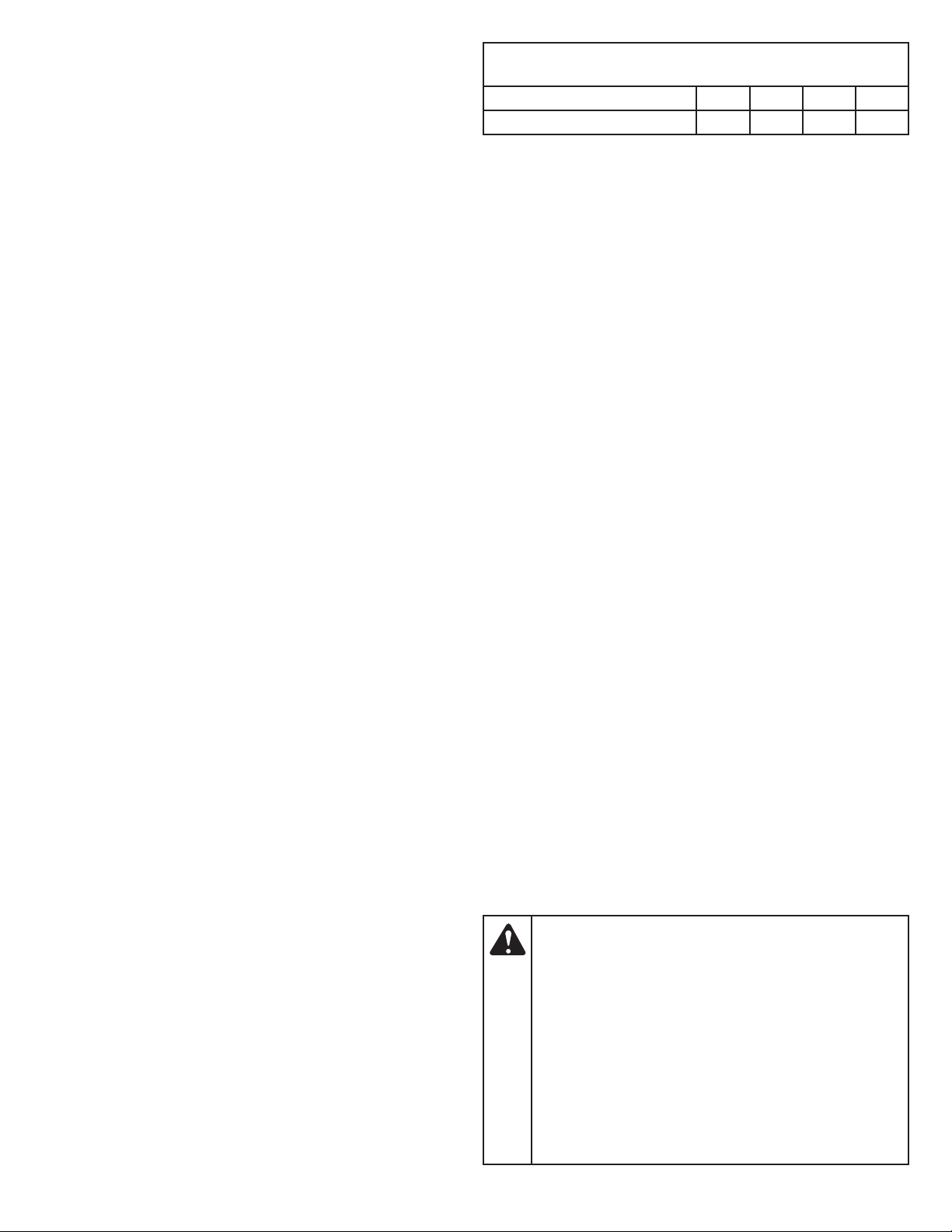

MINIMUM WIRE SIZE FOR EXTENSION CORDS FOR

120 VOLT APPLIANCES USING 0-6 AMPS

Cord Length (ft.) 25 50 100 150

Wire Size (AWG) 16 16 16 14

• Make sure the cords are in good condition. Inspect the power

cord and extension cord periodically. Look closely for

deterioration, cuts or cracks in the insulation. If a cord is

damaged in any manner while plugged in, disconnect the cord

from both the outlet and the unit. Do not use a damaged cord.

Damaged cords should be repaired or replaced.

• Do not abuse cords. Never pull or carry the unit by a cord

ords away from heat, oil, water, sharp edges, and moving

c

objects. Always grasp the plug when disconnecting a cord.

• Never modify a plug, cord or outlet in any way.

• Ground Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used with this unit.

For an extra measure of safety, use receptacles with built-in

GFCI protection.

• Do not place the battery ch

on, tripped over or subjected to damage.

• Do not charge batteries in the rain or in wet conditions. Keep the

battery charger in a cool and dry area.

• Keep the battery charger away from all liquid.

• Do not allow small metal items or material such as steel wool,

aluminum foil or other foreign particles into the charger port.

• Do not probe the charger with conductive mater

risk of electric shock.

• Do not cover the battery charger. The battery charger may

overheat.

• Do not allow the battery or battery charger to overheat. If they

are warm, allow them to cool down. Only charge batteries in

temperatures between 32° and 104° F (0° and 40° C).

• Always unplug the battery charger before cleaning it. Always

unplug the battery charger when it is not in use.

Battery Sa

• Do not expose the battery to fire or to temperatures over 176º F

(80º C). Doing so could cause an explosion.

• Handle batteries with care. Do not short the battery with

conductive materials, such as rings, bracelets, keys, etc.

Shorting the battery may cause personal injury, damage to the

battery or a fire.

• When the battery is not in use, keep it away from small metal

objects, such as paper clips, c

c

• Do not attempt to charge a cracked or damaged battery.

• Do not use a damaged or modified battery. Doing so could result

in a fire, explosion or personal injury.

fety

onnect one terminal to another and short the battery.

WARNING:

fire or chemical burn if mistreated. Do not disassemble,

overheat or incinerate the battery. The battery may develop a

small leak under extreme usage or temperature conditions.

If battery fluid contacts skin:

- Immediately wash the area with soap and water.

- Neutralize the battery fluid with a mild acid (lemon

juice, vinegar, etc.).

- Seek immediate medical attenti

f battery fluid gets in the eyes:

I

- Immediately flush the eyes with clean water for at

least 15 minutes.

- Seek immediate medical attention.

er where cords might be stepped

arg

ial. There

oins, nails, etc. These items could

The battery may present a risk of

on.

. Keep

is a

5

DISPOSING OF DAMAGED OR WORN-OUT BATTERIES

FCC STATEMENT

WARNING:

corrosive material is used in this unit's battery:

LITHIUM-ION, a toxic material.

WARNING:

environment, contact your local waste disposal agency for

specific instructions before disposing of damaged or wornout lithium-ion batteries. Take batteries to a local recycling

and/or disposal center, certified for lithium-ion battery

disposal.

The following toxic and

To prevent contamination of the

WARNING:Do not use broken or cracked

batteries, even if there isn't leakage. Replace damaged or

worn-out batteries with new batteries. DO NOT ATTEMPT

TO REPAIR BATTERIES! Repair attempts may result in

severe personal injury, due to explosion or electrical shock.

To avoid personal injury and damage to the environment:

• Do not attempt to remove or destroy any of the battery

components. Do not open or mutilate the battery. If a leak

develops, released electrolytes are corrosive and toxic. Do not get

the solution in your eyes or on your skin, and do not swallow it.

• Do not dispose of the battery in the regular household trash.

• Do not dispose of the battery in a fi

• Do not dispose of the battery where it will become part of any

waste landfill or municipal solid waste stream.

• Cover the battery terminals with heavy-duty adhesive tape.

• Dispose of the battery according to local, state and federal

regulations.

• Dispose of the battery promptly.

. The cell may explode.

re

CAUTION:

expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more

of the following measures:

— Reorie

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different

— Consult the dealer or an experienced radio/TV technician for help.

ns, may cause harmful interfere

locate the receiving antenna.

nt or re

from that to which the receiver is connected.

Changes or modifications not

nce to radio

WHILE OPERATING

WARNING:

shock, do not expose the unit to rain or wet conditions.

Store the unit indoors.

To reduce the risk of electric

About Call2Recycle Battery Seals

Call2Recycle’s industry steward program helps

battery and product m

re

quirements in the U.S. and Canada, including

compliance with extensive state, provincial and

federal regulations, such as the MercuryContaining and Rechargeable Battery Act (The

Battery Act). Call2Recycle

Stewards, participating battery and product manufacturers and

marketers, purchase the rights to imprint the Call2Recycle Battery

Seals on their rechargeable batteries and products. When you see the

C

all2Recycle Battery Seal, you can feel confident knowing that your

battery or product can be safely and responsibly recycled.

About Call2Recycle

Since 1994, Call2Recycle has diverted more than 75 million pounds

of rechargeable batteries from local landfills and established a

network of 30,000 recycling drop-off locations. More than 200 battery

and/or prod

nited to ensure that batteries are responsibly recycled when they

u

reach their end of life and fund the program that is operated by

Call2Recycle, Inc., a 501(c)4 nonprofit public service organization.

To locate the nearest recycling center, please call 1-800-822-8837.

uct manufacturers, Call2Recycle Industry Stewards, have

anufacturers fulfill recycling

®

Licensees/Industry

• Wear safety glasses or goggles that meet current ANSI / ISEA

Z87.1 standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face mask or dust

mask if the operation is dusty. Use a hard hat or other type of

safety helmet. Falling debris can result in serious personal injury.

• Wear safety boots and protective gloves. Wear heavy, snugfitting clothes,

ot wear loose clothing, jewelry, short pants, sandals or go

n

barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artificial light.

• Avoid starting the unit unintentionally. The operator and unit must be

in a stable position while starting. Refer to Starting and Stopping.

• Use the right tool. Only use this tool for its intend

ut wood. Do not use the unit for cutting plastic, masonry or

c

other non-wood building materials. Only use the unit as

described in this manual.

• Keep hair, face, hands, feet and all other body parts away from

the saw chain when the unit is running. Do not touch or try to

stop moving parts.

• Do not operate the unit faster than the speed needed to do the

job. Do not run the unit at high speed

o not force the unit, especially near the end of a cut. It will do a

• D

better, safer job when used at the intended rate.

• Always turn the unit off when operation is delayed or when

carrying the unit from one location to another.

• Before setting the unit down, always turn the unit off and wait for

all moving parts to come to a complete stop.

including long pants and a long-sleeve shirt. Do

ed purpose: to

when not in use.

6

• Do not operate a unit that is damaged, improperly adjusted or

not completely and securely assembled. Make sure moving

parts stop when the unit is turn

does not turn on and off properly. Have defective parts replaced

by an authorized service center.

• Avoid starting the unit unintentionally. Make sure the trigger

lockout is in the locked position before installing or removing the

battery. Never carry the unit with fingers on the trigger.

• Remove the battery from the unit when it is not in use.

•

Do not use the unit if the trigger and trigger lockout do not start

nd stop the unit.

a

• If the unit strikes or becomes entangled with a foreign object,

stop the motor immediately, remove the battery and allow the

unit to cool. Then, check for damage. If damaged, do not restart

or operate the unit until it is repaired. Do not operate the unit

with loose or damaged parts.

• Use only original equipment manuf

parts and accessories for this unit. These are available from your

authorized service center. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

• Keep the unit clean. Stop the motor, remove the battery and

allow the unit to cool. Carefully remove vegetation and other

debris that could block moving parts.

•

If the unit starts to vibrate abnormally, stop the motor, remove the

battery and allow the unit to cool. I

the vibration. Vibration is generally an indicator of trouble.

ed off. Do not use the unit if it

r (OEM) replacement

acture

nspect the unit for the cause of

CHAIN SAW SAFETY

• Make sure the saw chain is not in contact with anything before

starting the unit.

• When carrying the unit, hold it away from the body, with the

guide bar positioned to the rear. Cover the guide bar and saw

chain with the scabbard when carrying the unit. Hold the unit by

the front handle.

• Keep the work area clean. Cluttered areas invite injuries. Do not

start cutting until the work area

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• For safer, more effective performance, make sure the guide bar

and chain are properly cleaned, lubricated, tightened and

sharpened. Check the guide bar and chain at fre

or proper adjustment.

f

• When cutting a limb that is under tension, use extreme caution.

When the tension is released, the limb could spring back and

strike the operator, causing severe injury or death.

• Use extreme caution when cutting small-sized brush and

saplings, as slender material may catch the saw chain and be

whipped toward the operator or pull the operator off balance.

• This saw i

with CSA Z62.1-03. It is intended for infrequent use by

homeowners, cottagers and campers, and for general

applications such as clearing, pruning, cutting firewood, etc. It is

not intended for prolonged use. If the intended use involves

prolonged periods of operation, this may cause circulatory

problems in the user’s hands due to vibration. Take frequen

reaks and adjust your working position, as needed.

b

• Do not operate the unit in a tree or on a ladder unless

specifically trained to do so.

• Do not use the unit in the presence of flammable liquids or gases.

• Do not attempt operations beyond the operator’s capacity or

experience.

s classified by UL as a Class 2C saw in accord

is clear and fre

e from

quent intervals

ance

t

• Always use the scabbard on the guide bar and saw chain during

transportation and storage.

• Do not remove cut material, or hold material to be cut, when the

unit is running. Always turn the unit off, wait

ome to a complete stop, and remove the battery before

c

clearing jammed material. A moment of inattention can result in

serious personal injury.

for the saw chain to

KICKBACK SAFETY

WARNING:Kickback may occur when the

nose or tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut. In

some cases, tip contact may cause a lightening-fast

reverse action, kicking the guide bar rapidly back to wards

the operator. Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back towards the

operator. Either of these r

control over the saw, which could result in serious injury to

he user. Contact with foreign objects within the wood can

t

also induce a loss of chain saw control.

Understanding Kickback

A basic understanding of kickback can help reduce or eliminate the

element of surprise and the chance of kickback-related injury.

Sudden surprise contributes to accidents.

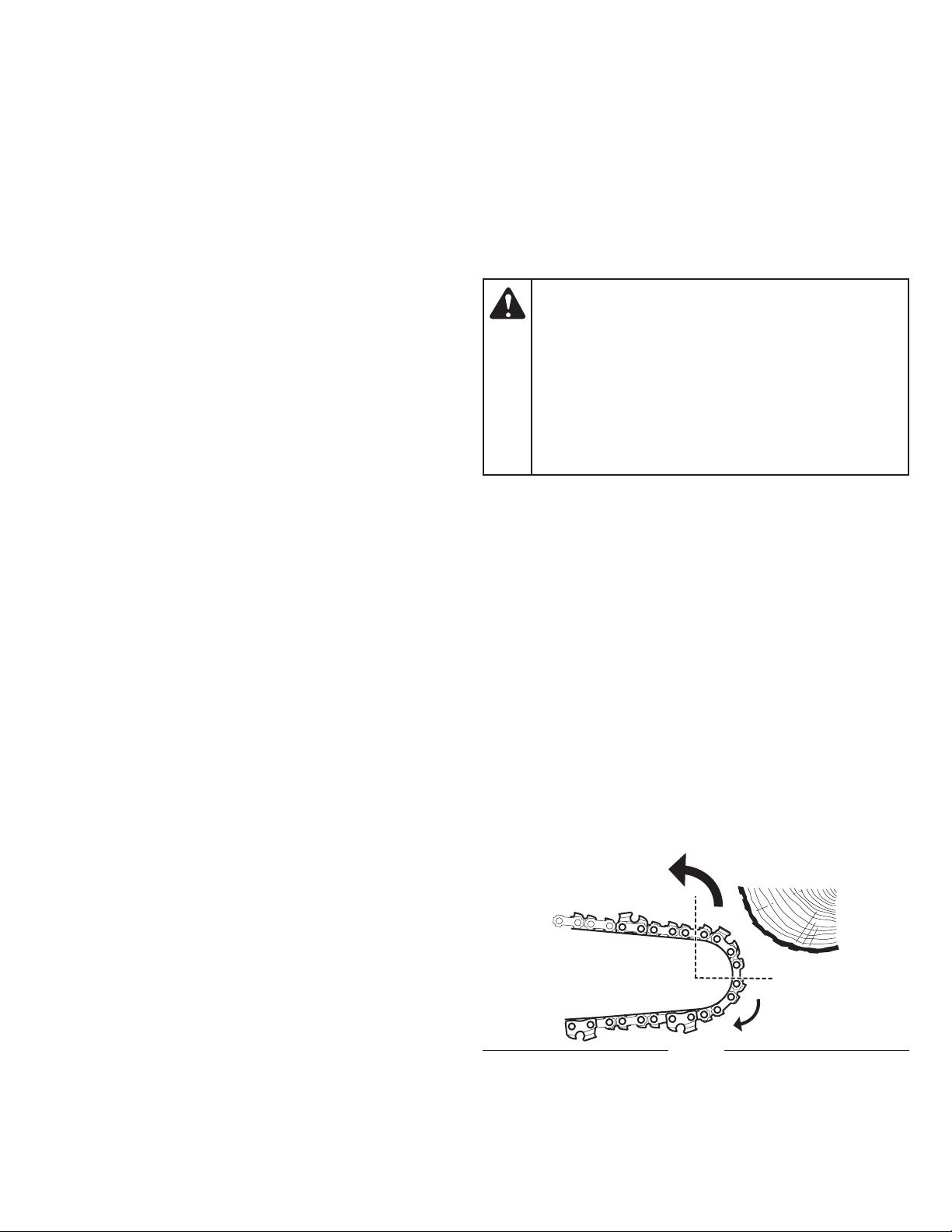

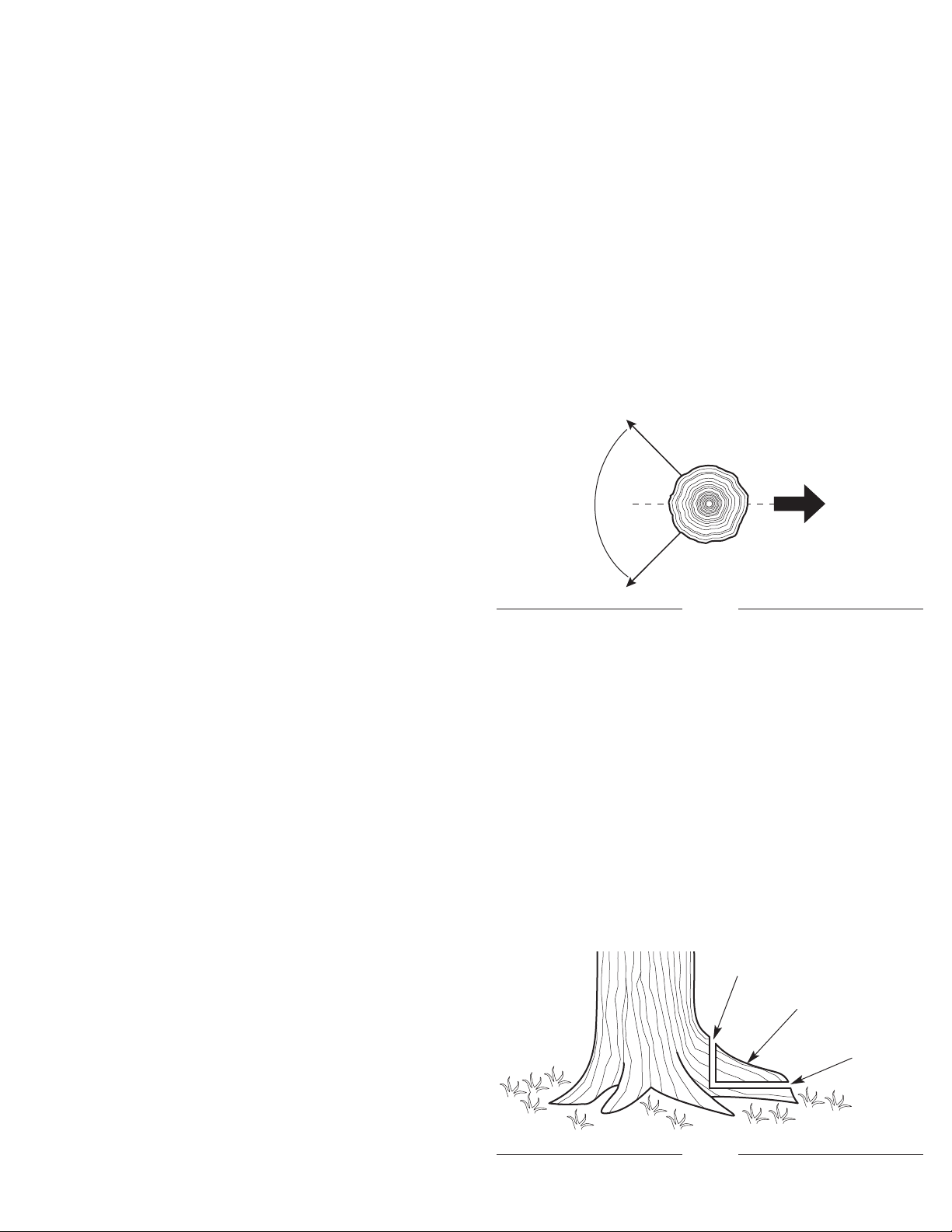

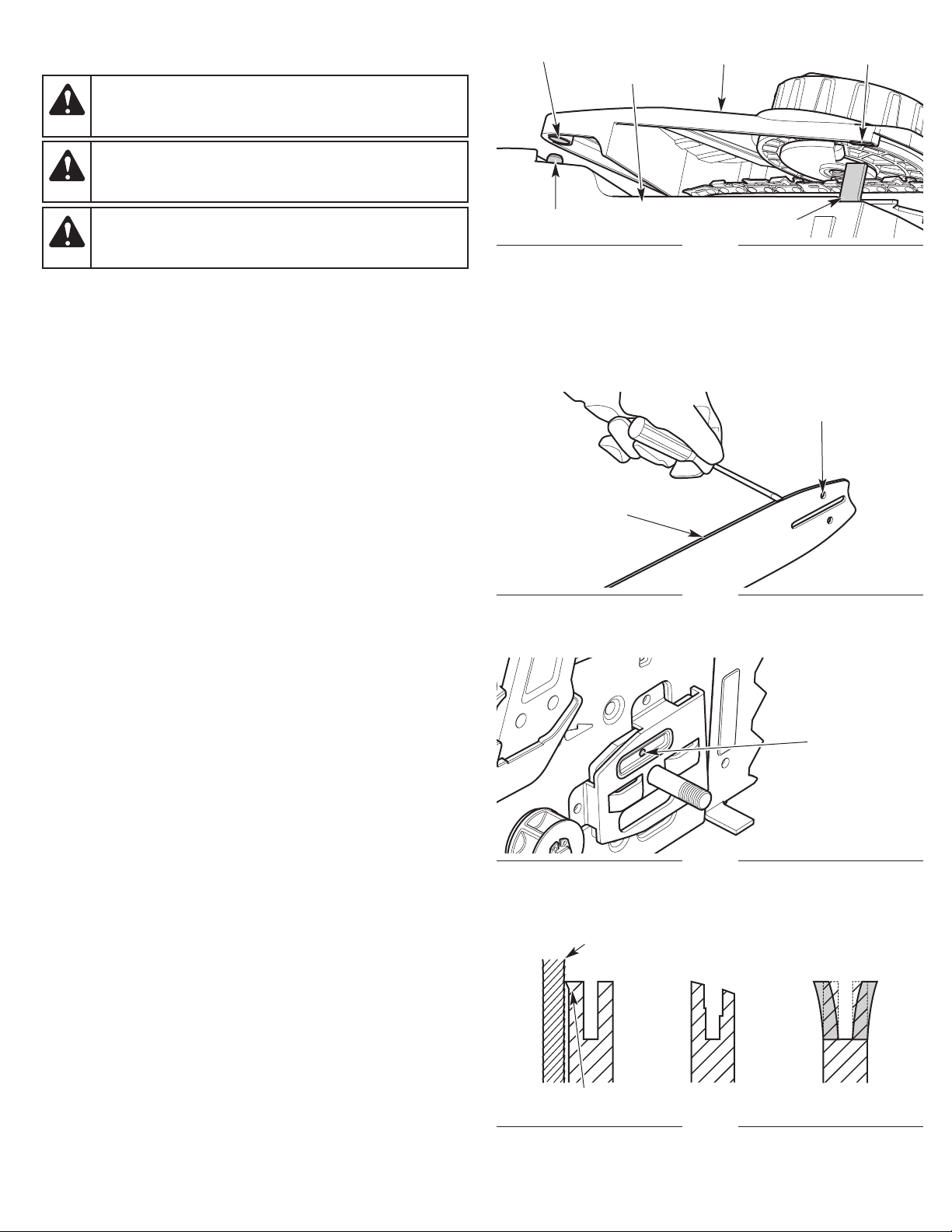

• Rotational Kickback can happen when the upper tip of the

g

uide bar contacts an object while the chain is moving (Fig. A).

This can cause the chain to dig into the object and momentarily

stop moving. The guide bar is then kicked up and back toward

the operator in a lightning-fast reverse reaction.

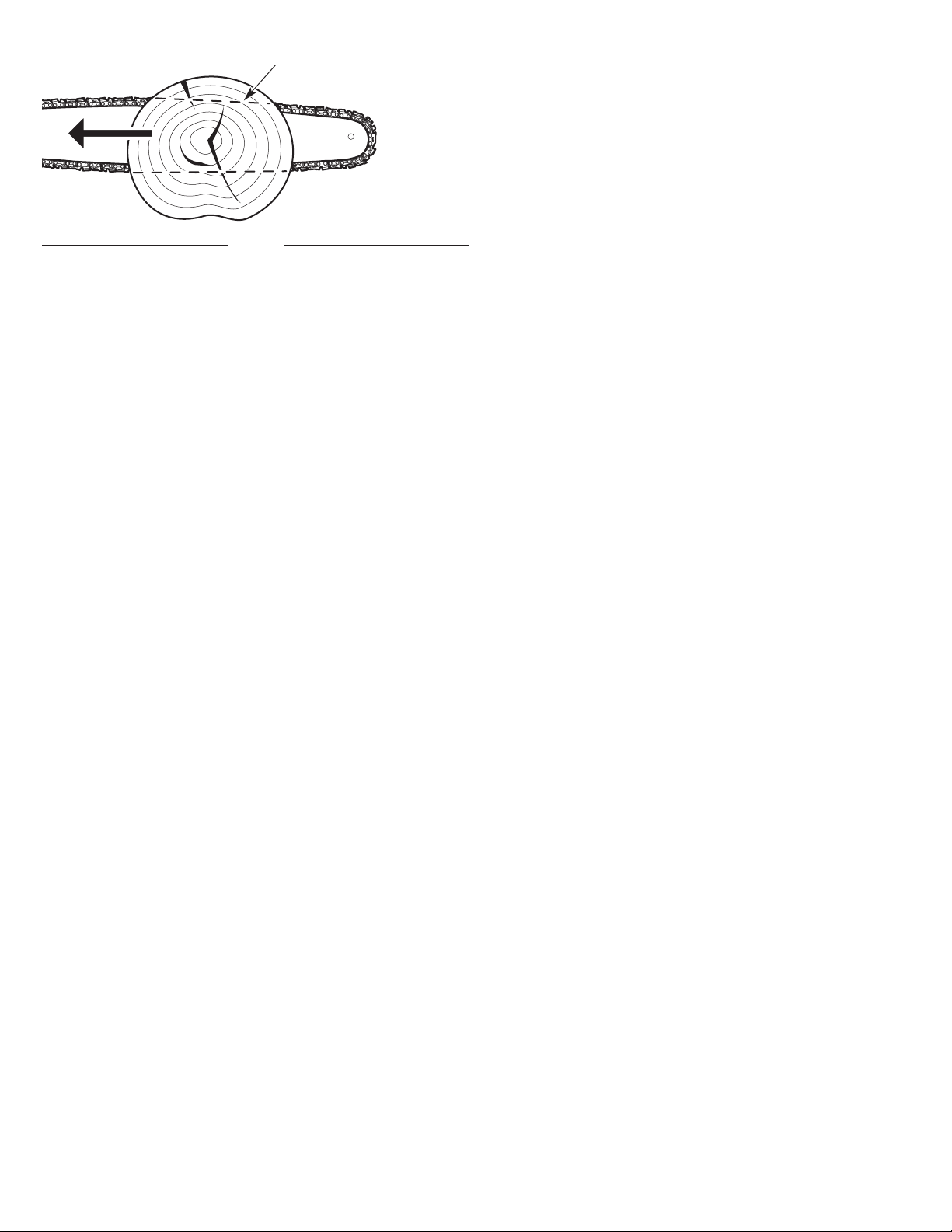

• Linear Kickback can happen when the wood on either side of a

cut closes in and pinches the moving saw chain along the top of

the guide bar (F

he chain force is then reversed, causing the saw to move in the

T

opposite direction, sending the saw straight back toward the

operator.

• Pull-In can happen when the moving chain on the bottom of the

guide bar hits a foreign object inside the wood. This can cause

the chain to suddenly stop. The saw is then pulled forward and

away from the operator, which

of control of the saw.

ig. B). This can cause the chain to instantly stop.

Rotational

Kickback

Kickback

Danger Zone

eactions may cause a loss of

could potentially re

Fig. A

sult in the loss

Saw Chain

Direction

7

Pinch

Linear

Kickback

Fig. B

Kickback Safety Precautions

Take the following steps to reduce the chance of accident or injury:

• Do not rely exclusively upon the safety devices built into the unit.

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on stairs, steep slopes or inclines. Do

not cut above shoulder height.

• Do not make cuts with the tip of the guide bar.

• Make sure the area of operatio

let the tip of the guide bar contact any object, such as a log,

branch, the ground or other obstruction.

• Always inspect the wood before cutting. Foreign objects could

damage the unit or cause serious personal injury. Never cut

through nails, metal rods, railroad ties or pallets.

• Do not operate the unit with one hand! Serious injury to the

operator, helpers or bystan

operation. This unit is intended for two-handed use. Always grip

the unit firmly with both hands when the unit is running. Do not

let go. A firm grip will help maintain control of the unit and

reduce the chance of kickback. Hold the front handle with the

left hand and the rear handle with the right hand. Firmly encircle

the handles with the thumbs and fingers.

• Stand sligh

line of the saw chain.

• Never start the saw when the guide bar is inside an existing cut.

Be extremely careful when re-entering a cut.

• Always begin a cut with the unit running at full speed. Maintain a

steady cutting speed. Slower speeds increase the chance of

kickback.

• Keep the saw housing pressed firmly against the wood.

• Do not cut more than

o not twist the unit when removing the guide bar from a cut.

• D

• Watch out for shifting objects (logs, branches, etc.) that might

pinch or fall onto the saw chain during operation.

• Only use wedges made of wood or plastic. Do not use metal to

hold a cut open.

• Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain.

• Only use replacement bars and ch

anufacturer or the equivalent. These are available from

m

authorized service centers. Use of any unauthorized parts or

accessories could lead to serious injury to the operator or

damage to the unit and will void the warranty.

• Use devices that reduce the risks associated with kickback,

such as low-kickback chains, guide bar nose guards, chain

brakes and low-kickback guide bars. Ther

replacement components for achieving kickback protection in

accordance with CSA Z62.3.

tly to the left of the unit to avoid being in the dire

ders may re

one log or branch at a time.

e from obstructions. Do not

n is fre

sult from one-handed

ains specified by the

no other

e are

ct

• A low-kickback saw chain is a chain that has met the kickback

performance requirements of ANSI/OPEI B175.1-2012 when

tested according to the provisions specified in ANSI/OPEI

B175.1-2012. A low-kickback saw chain is a chain that is also in

accordance with CSA Z62.3. Do not use a replacement saw

chain unless it has met these re

model or has been designated as a low-kickback replacement

saw chain in accordance with ANSI/OPEI B175.1-2012. As saw

chains are sharpened, some of the low-kickback qualities are

lost and extra caution should be used.

• Do not install a bow guide on this unit. Bow guides have larger

kickback zones, which increase the chance of kickback and

serious injury

a low-kickback saw chain. Using a bow guide on this unit is

extremely dangerous.

. This incre

ase is not significantly reduced by using

quirements for this specific

OTHER SAFETY WARNINGS

• Maintain the unit with care. Follow all maintenance instructions

in this manual.

• Do not perform maintenance procedures other than those

described in this manual. Do not attempt to repair the unit; there

are no user-serviceable parts inside. All service, other than the

m

aintenance procedures described in this manual, should be

performed by an authorized service center.

• Do not use the unit if it is not working correctly, has been

dropped, damaged, left outdoors or dropped into water. Have

the unit serviced by an authorized service center.

• Never remove, modify or make inoperative any safety device

furnished with the unit.

• Before inspecting, maintain

placing any parts on the unit:

re

1. Stop the motor. Refer to Starting and Stopping.

2. Wait for all moving parts to stop.

3. Remove the battery.

4. Allow the unit to cool.

• Secure the unit while transporting.

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach of

children.

• Never douse or squirt t

Av

oid getting water in the motor and electrical connections.

Keep handles dry and clean (free from debris, oil and grease).

Clean the unit after each use. Refer to Cleaning and Storage. Do

not use solvents or strong detergents.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these i

nstructions.

ing, cleaning, storing, transporting or

he unit with water or any other liquid.

SAVE THESE INSTRUCTIONS

8

• SAFETY & INTERNATIONAL SYMBOLS •

or DC

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

• USE BOTH HANDS

WARNING:Always use both hands

while operating the unit. Never use only one hand to

operate the unit.

V

A

Hz

AC

WARNING:Read the operator’s

manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious

injury to the operator and/or bystanders.

• WEAR HEAD, EYE AND HEARING PROTECTION

WARNING:

noise can cause severe eye injury and hearing loss.

Wear eye protection meeting current ANSI / ISEA

Z87.1 standards and ear protection when operating

this unit. Wear head protection when operating this

unit; falling objects can cause severe head injury. Use

a full face shield when needed.

• WEAR FOOT PROTECTION

Always wear heavy-duty, non-slip footwear when

operating this unit.

• WEAR HAND PROTECTION

Always wear heavy-duty, non-slip gloves when

handling this unit.

• VOLTS - Voltage

• AMPERES - Current

• HERTZ - Frequency (cycles per second)

• ALTERNATING CURRENT - Type of current

Thrown objects and loud

• KICKBACK

WARNING:

with any object should be avoided. Tip contact may

cause the guide bar to move suddenly upward and

backward, which may cause serious injury.

• KEEP BYSTANDERS AWAY

Contact of the guide bar tip

WARNING:Keep all bystanders,

especially children and pets, at least 50 feet (15 m) from

the operating area.

WARNING:Always keep a clear work

area and retreat path. Be aware of the location of

limbs/branches to avoid falling limbs and debris.

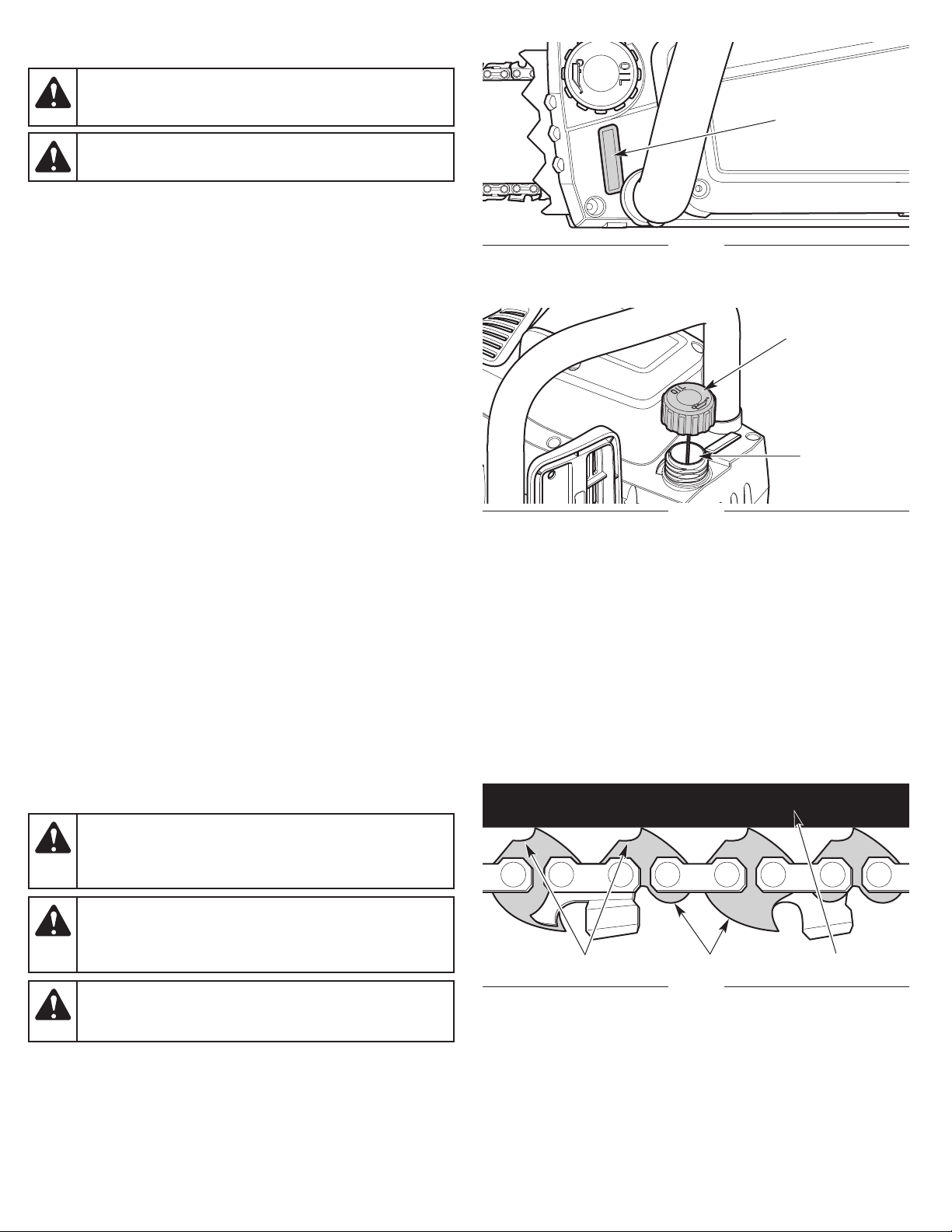

• CHAIN OIL

Make sure the chain oil reservoir is full before

operation. Check the oil level constantly so that it

does not drop below half full. The saw chain must be

continuously coated with oil to function properly.

• CHAIN DIRECTION

Make sure the saw chain faces the direction shown

when installed on the guide bar. Refer to Installing the

Guide Bar and Saw Chain in the Maintenance section.

• DO NOT USE IN THE RAIN

Ah

Wh

• DIRECT CURRENT - Type of current

• AMPERE-HOUR - Measure of charge capacity

• WATT-HOUR - Measure of energy

WARNING:

environments. Never operate the unit in the rain or in

damp or wet conditions. Moisture is a shock hazard.

• DO NOT DISPOSE IN HOUSEHOLD TRASH

Recycle the battery or dispose of the battery

according to local, state and federal regulations.

9

Avoid dangerous

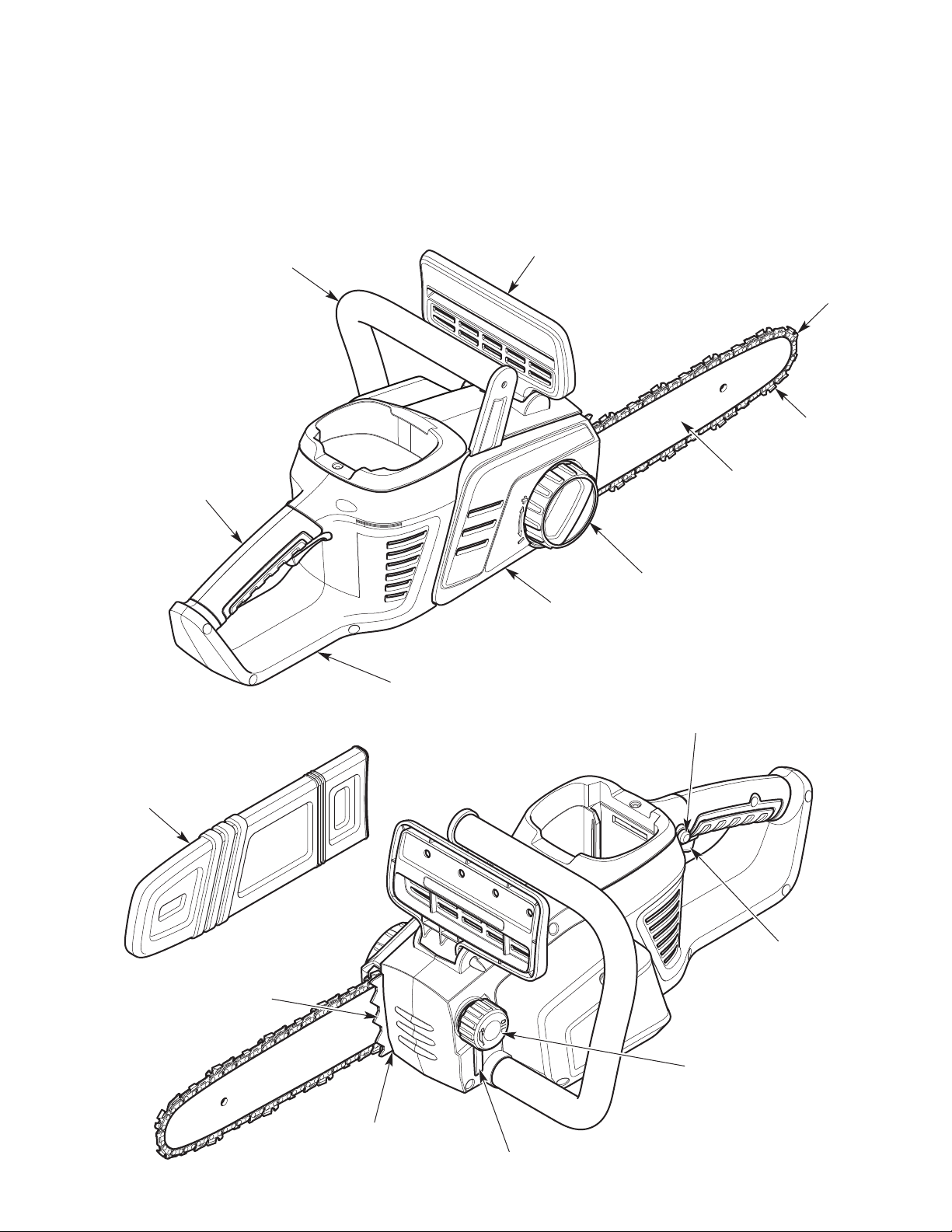

KNOW YOUR UNIT

APPLICATIONS

• Felling and limbing trees

• Cutting logs (bucking)

• Pruning trees

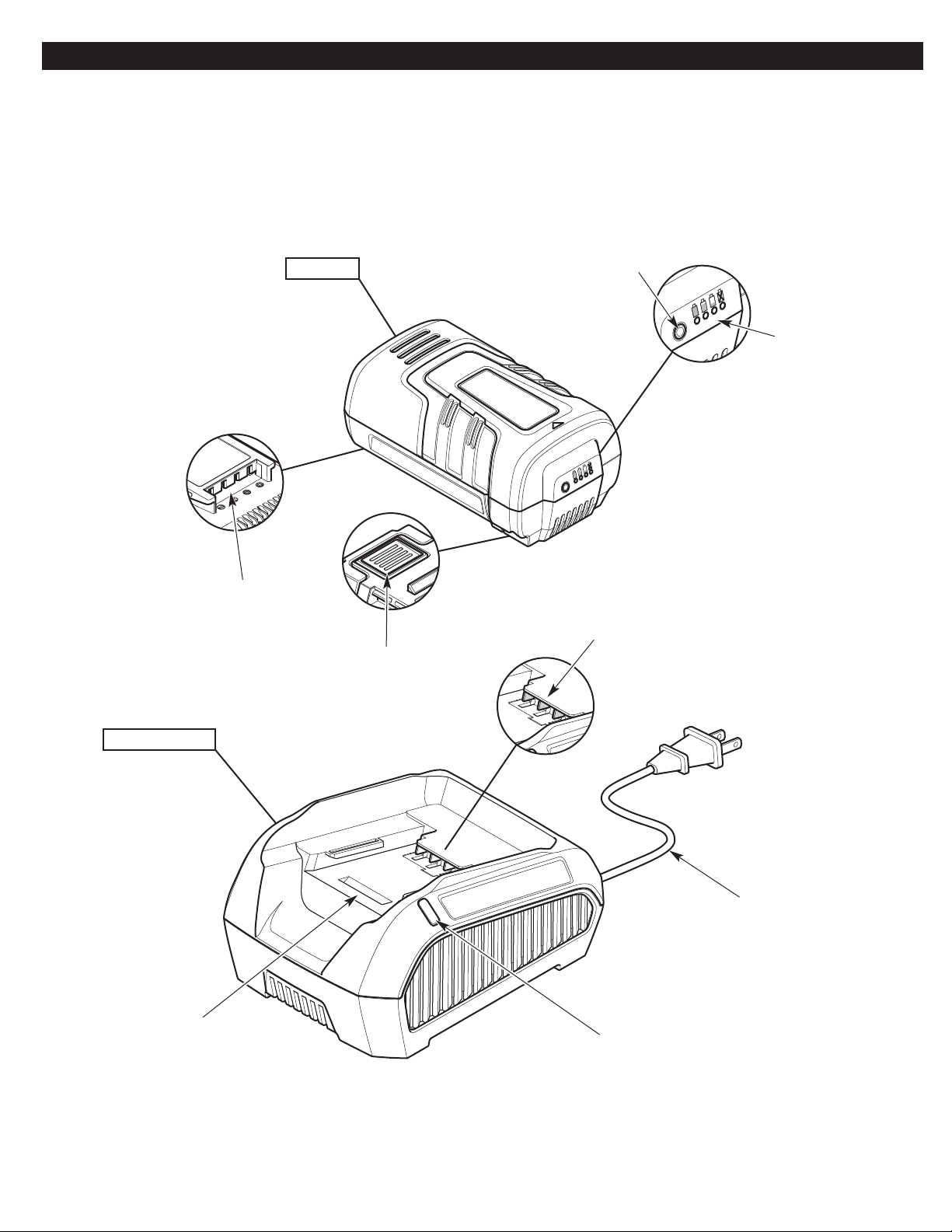

Battery*

NO ASSEMBLY TOOLS REQUIRED

Charge Meter Button

Charge Meter

Lights

Battery Charger*

Charging Dock

Terminals

Terminals

Battery Release

Button

Power Cord

LED

* The battery and battery charger are not included with model RM4040B.

10

Rear Handle

Front Handle

Chain Brake Lever /

Front Hand Guard

Guide Bar Tip

Saw Chain

Guide Bar

Bar Knob / Chain-Tensioning Ring

Bar Cover

Rear Hand Guard

Scabbard

Trigger Lockout

Trigger

Spiked Bumper /

Bucking Spike

Chain Oil Cap

Chain Catcher

Chain Oil Level Window

11

ESSENTIAL TERMS AND DEFINITIONS

• CHAIN SAW - A tool designed to cut wood with a saw chain. A chain saw is an integrated unit comprised of a motor, saw chain, guide

bar, and handles that are designed to be held by two hands during operation.

• CHAIN SAW POWERHEAD - A chain saw without the saw chain and guide bar.

• DRIVE SPROCKET - A toothed wheel that drives the saw chain.

• FRONT HANDLE - A support handle located toward the front of the chain saw.

• R

EAR HANDLE - A support handle located toward the rear of the chain saw.

• FRONT HAND GUARD / CHAIN BRAKE LEVER - A structural barrier between the front handle and the guide bar. The front hand guard

helps protect the operator’s left hand if it slips off the front handle while the unit is running. The front hand guard is also used to activate

the chain brake.

• CHAIN BRAKE - A device use

The chain brake can be activated intentionally by pushing the front hand guard / chain brake lever forward. It can also be activated if the

operator’s hand strikes the front hand guard / chain brake lever during kickback.

• REAR HAND GUARD - A structural barrier below the rear handle. The rear hand guard

chain breaks or disengages from the guide bar during operation.

• GUIDE BAR - A solid railed structure that supports and guides the saw chain.

• GUIDE BAR TIP - The tip or end of the guide bar.

• REDUCED-KICKBACK GUIDE BAR - A guide bar that has been demonstrated to reduce kickback significantly.

• SAW CHAIN - A loop of chain with teeth designed t

chain is composed of drive links, cutters and side links, held together by rivets.

• LOW-KICKBACK SAW CHAIN - A saw chain that complies with the kickback performance requirements of ANSI/OPEI B175.1-2012 when

tested on a representative sample of chain saws. Low-kickback saw chain significantly reduces the chance of kickback and the intensity

o

f kickback, due to specially designed depth gauges and guard links.

• REPLACEMENT SAW CHAIN - A saw chain that complies with the kickback performance requirements of ANSI/OPEI B175.1-2012 when

tested with specific chain saws. It may not meet the ANSI/OPEI performance standards when used with other chain saws.

• SPIKED BUMPER - The pointed tooth (or teeth), at the front of the chain saw,

maintain a stable position while cutting.

• CHAIN CATCHER - A device designed to intercept a whipping chain. The chain catcher reduces the chance of injury if the saw chain

breaks or disengages from the guide bar during operation.

• OILER CONTROL - A system for oiling the saw chain and guide bar.

• SWITCH - A device that, when operated, w

• SWITCH LINKAGE - A mechanism that transfers motion from the trigger to the switch.

• TRIGGER - A device that, when operated in conjunction with the switch lockout (trigger lockout), turns the motor on. Releasing the trigger

immediately turns the motor off. The saw chain will then coast to a stop.

• SWITCH LOCKOUT (TRIGGER LOCKOUT) - A device that pre

unless the switch lockout (trigger lockout) is manually engaged.

• BATTERY RELEASE BUTTON - A device used to disconnect the battery from the battery charger and the unit.

• KICKBACK - A sudden backward and/or upward motion of the guide bar and saw chain. Kickback can occur if the upper portion of the

guide bar tip touches an object while the saw chain is spinning (ro

pinches the saw chain inside the cut (linear kickback).

• ROTATIONAL KICKBACK - A sudden backward and upward motion of the guide bar and saw chain. Rotational kickback can occur if the

upper portion of the guide bar tip touches an object while the saw chain is spinning. The guide bar and saw chain are

back toward the operator in a lightning-fast reverse reaction.

• LINEAR KICKBACK (PINCH KICKBACK) - A sudden backward motion of the guide bar and saw chain. Linear (pinch) kickback can occur

if the wood closes in and pinches the saw chain inside a cut. The saw is then sent straight back toward the operator.

• NORMAL CUTTING POSITION - The positions assumed while making bucking and felling cuts.

• F

ELLING - The process of cutting down a tree.

• NOTCHED UNDERCUT - The first cutting procedure in the tree felling process. A notch is cut on one side of the tree to direct its fall.

• FELLING BACK CUT - The final cut in the tree felling process. The felling back cut is made on the opposite side of the tree from the

notched undercut.

• BUCKING - The process of cutting a fe

• LIMBING - The process of removing branches from a fallen tree.

• PRUNING - The process of cutting limbs from a living tree.

d to stop the chain saw.

ill complete or interrupt an electrical power circ

e or log into lengths.

lled tre

The chain brake helps protect the user by stopping the saw chain in milliseconds.

helps protect the operator’s right hand if the saw

o cut wood, which is driven by the motor and is supported by the guide bar.

used during felling and bucking to help pivot the saw and

uit to the motor.

vents the unit from starting accidentally. The trigger cannot be squeezed

tational kickback). Kickback can also occur if the wood closes in and

then kicked up and

The saw

12

SPECIFICATIONS*

Approximate Unit Weight (without the battery - without chain oil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bar and Chain Oil (not included)

Chain Oil Reservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4 fl. oz. (190 mL)

Guide Bar Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 in. (30.5 cm)

Saw Chain Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8 in. (9.5 mm)

Saw Chain Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.050 in. (1.3 mm)

Battery Type (Model RM4140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40V, 4.0 Ah Lithium-Ion

Battery Type (Model RM4150) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40V, 5.0 Ah Lithium-Ion

Approximate Battery Weight (Model RM4140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9 - 3.4 lbs. (1.3 -

pproximate Battery Weight (Model RM4150) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 - 3.5 lbs. (1.4 - 1.6 kg)

A

Optimum Battery Charging Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32° to 104° F (0° to 40° C)

Optimum Battery Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64° to 73° F (18° to 23° C)

Optimum Battery In-Use Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32° to 113° F (0° to 45° C)

Battery Charger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 V 60 Hz AC only

Battery Charger Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 A 40 V DC

Approximate Charging Time (Model RM4140). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 minutes

App

ximate Charging Time (Model RM4150). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162 minutes

ro

Approximate Battery Charger Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.25 - 1.75 lbs. (0.6 - 0.8 kg)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

9.5 - 10.5 lbs. (4.3 - 4.8 kg)

1.5 kg)

REPLACEMENT PARTS

Please contact the Customer Support Department to order replacement parts.

Part #

713-05074 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

795-00321 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

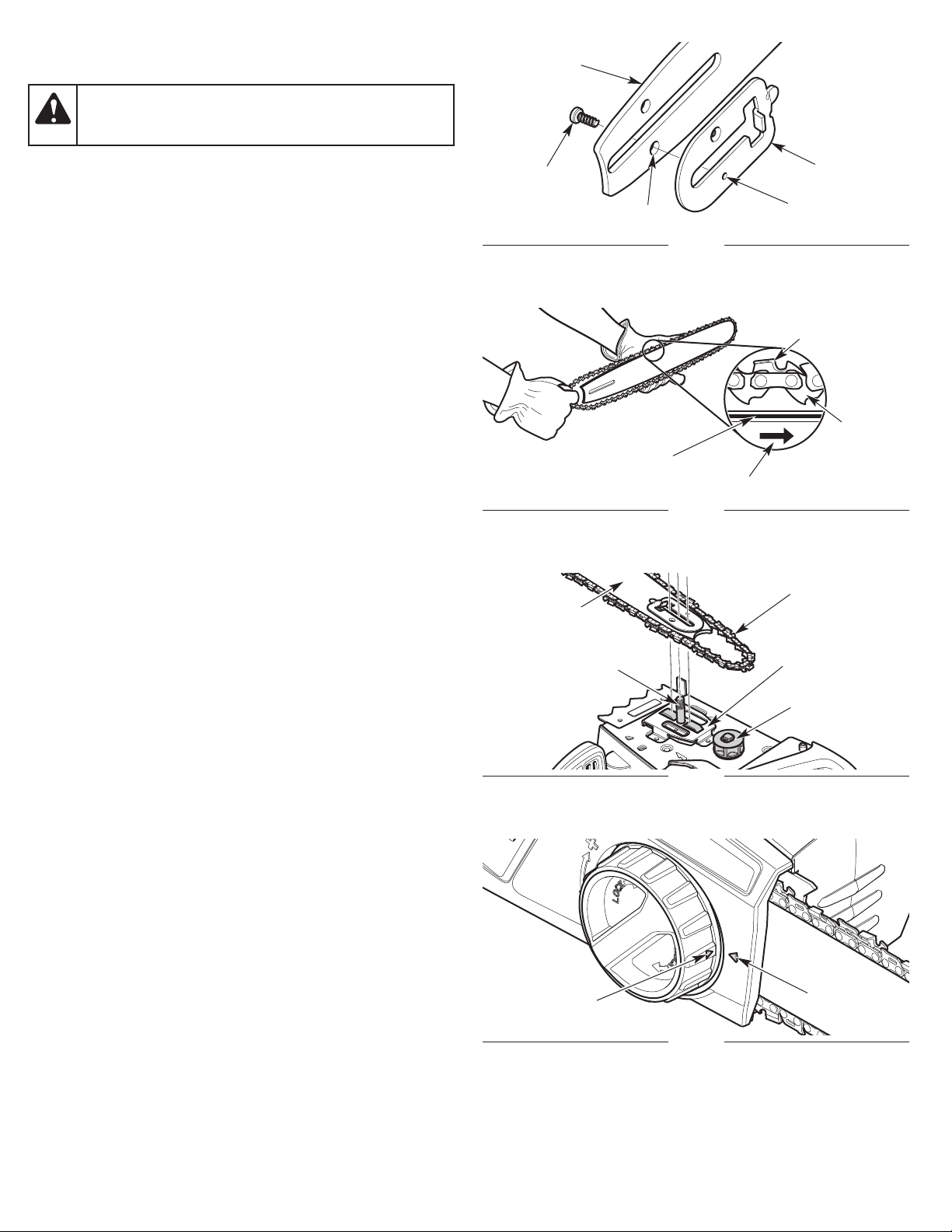

ASSEMBLY

WARNING:

damage to the unit, never assemble, disassemble or adjust

the unit while it is running. Always turn the unit off and

remove the battery to prevent the unit from starting

accidentally. Always allow the unit to cool before

assembling, disassembling or making any adjustments.

ADDING BAR AND CHAIN OIL: INITIAL USE

This unit comes from the factory with the chain oil reservoir empty.

Fill the chain oil reservoir with bar and chain oil before starting or

using the unit. Refer to Adding Bar and Chain Oil instructions in the

Maintenance section.

To prevent serious personal injury and

Description

Saw Chain (12 in. / 30.5 cm)

Guide Bar (12 in. / 30.5 cm)

ADJUSTING THE CHAIN TENSION: INITIAL USE

The saw chain must be properly tensioned before attempting to

start or operate the unit. The saw chain may also re

tensioning as the saw chain heats up during operation. Refer to

Adjusting the Chain Tension instructions in the Maintenance section.

quire additional

13

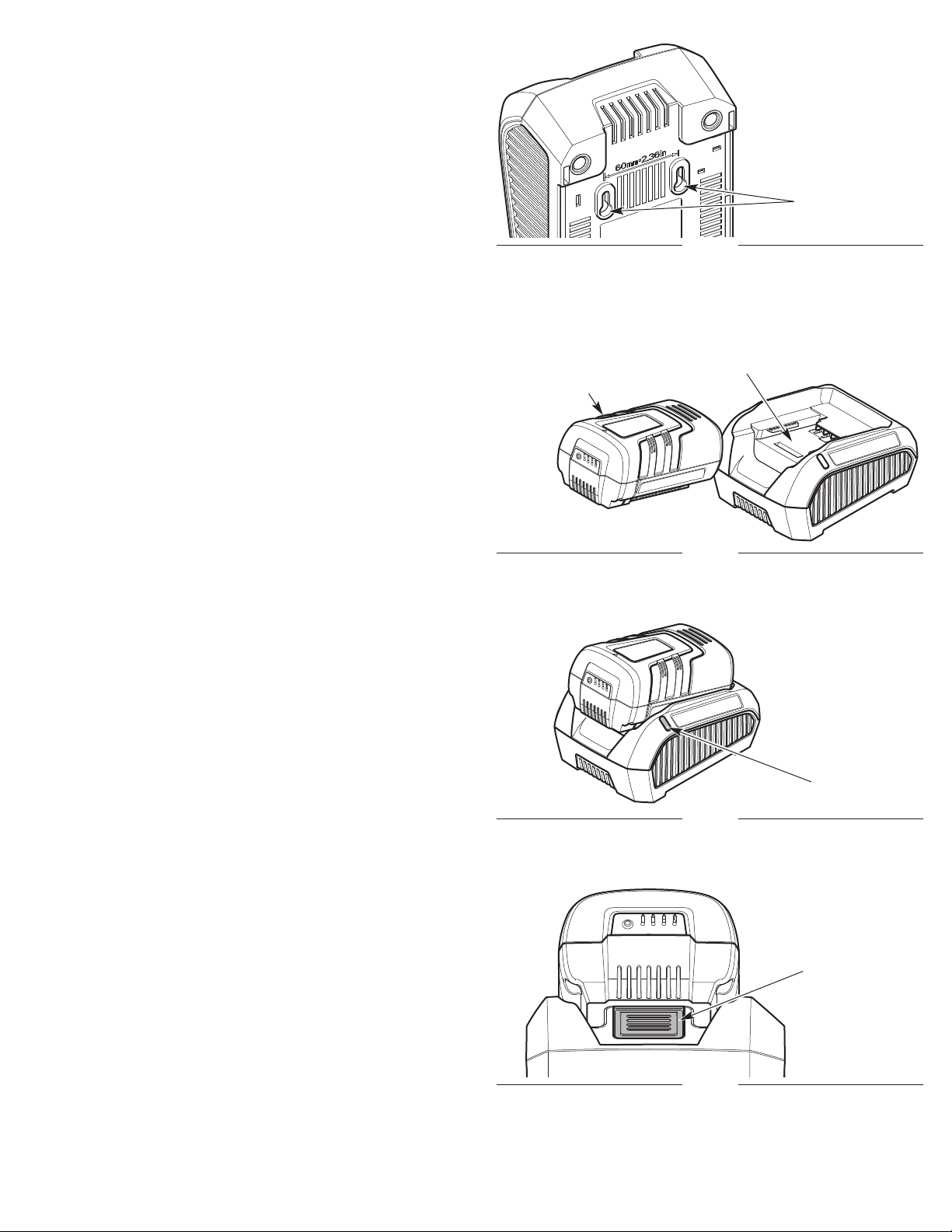

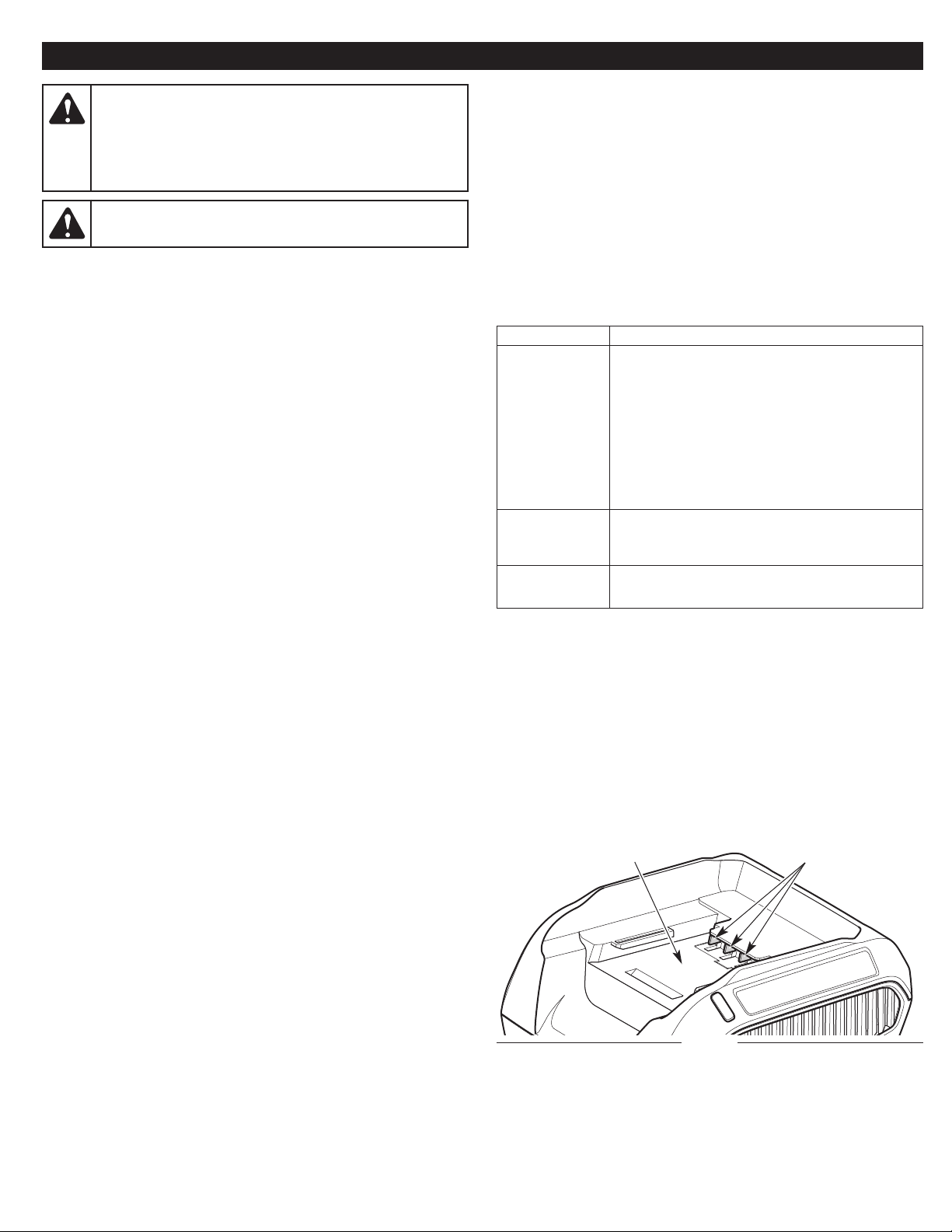

WALL-MOUNTING THE CHARGER (OPTIONAL)

The battery charger can be mounted to a permanent surface, such

as a wall or work bench. Use mounting fasteners (not included)

capable of supporting the combined weight of the battery and

battery charger. Wall-mounting holes are located on the bottom of

the charger (Fig. 10).

Wall-Mounting

Holes

Fig. 10

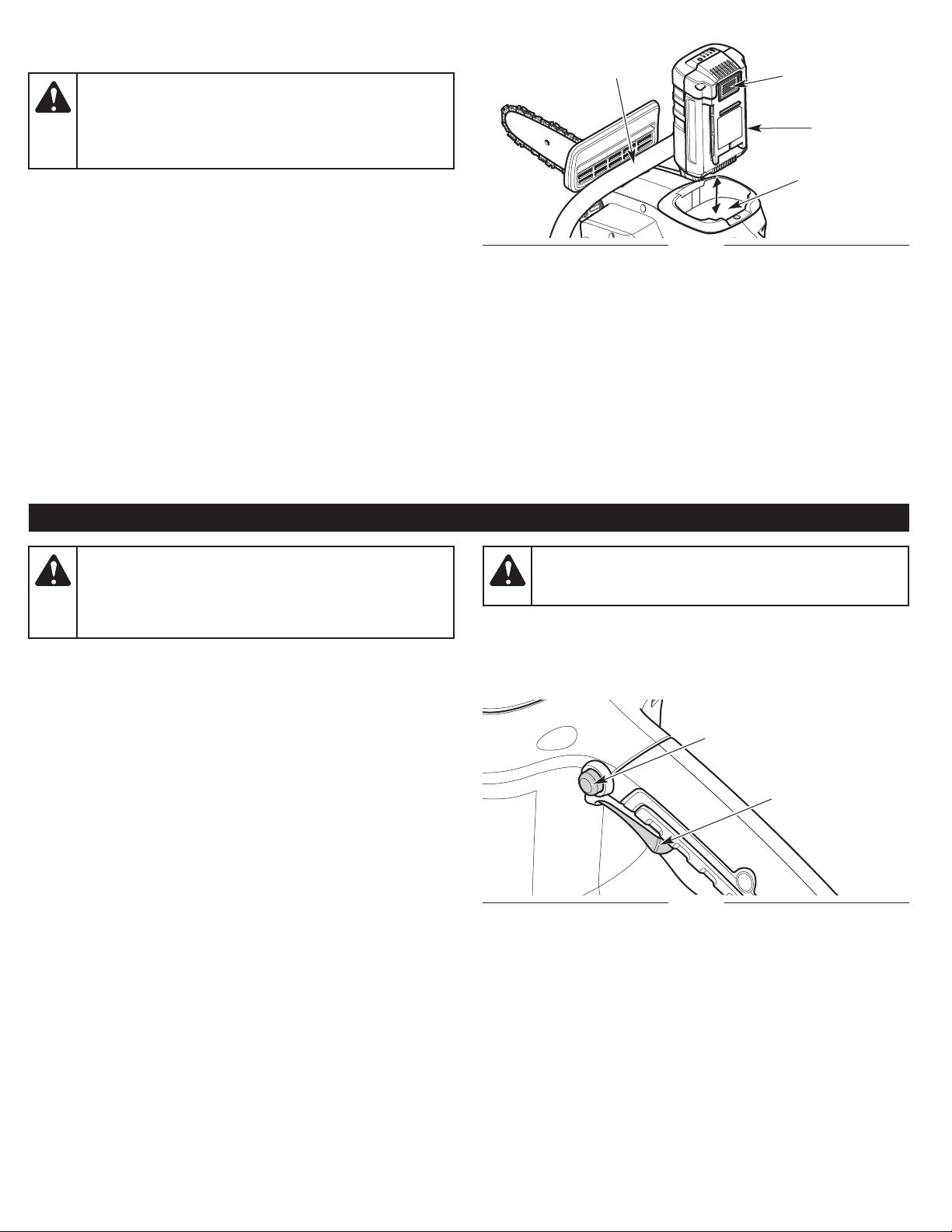

CHARGING THE BATTERY

NOTE: The battery is not shipped fully charged.

NOTE: Lithium-ion batteries will not develop a memory and may be

charged at any time.

For maximum run time, fully charge the battery before each use.

1. Plug the battery charger into an appropriate power outlet. The

LED should turn red (constant) (Fig. 12). If it does not:

• Make sure the battery charger is fully plugged into an

appropriate

ake sure the power outlet is functioning by testing it with

• M

another electrical device.

2. Insert the battery into the charging dock (Fig. 11). Push the

battery firmly until it locks into place.

3. Examine the LED. The LED will indicate the battery status:

• Green (blinking): The battery is charging. Charge the battery

until the green light stops blinking.

• Green (constant): The battery is fully

• Red (blinking - slow): The battery and/or charger are too hot

or too cold. Make sure the battery and charger are in an

environment between 32° and 104° F (0° and 40° C). Allow

time for the battery and/or charger to warm up or cool down.

• Red (blinking - fast): The battery is no longer functional. Refer

to the Warranty section for replacement information.

• Red (constant): The battery is not chargin

attery. Make sure the terminals on the battery and battery

b

charger are clean. Re-insert the battery into the charging dock.

Push the battery firmly until it locks into place.

4. To maximize the life of the battery, the battery charger will turn

off when charging is complete. Once the battery is fully charged,

remove it from the battery charger. Optionally, the battery can be

stored in the

unplugged from the power outlet.

To remove the battery: Hold the battery charger in place with

one hand. Press the battery release button with the other hand

(Fig. 13). Slide the battery out of the charging dock.

power outlet.

battery charg

ed.

charg

g. Remove the

er, but the battery charger should be

Charging Dock

Battery

Fig. 11

LED

Fig. 12

Battery Release

Button

14

Fig. 13

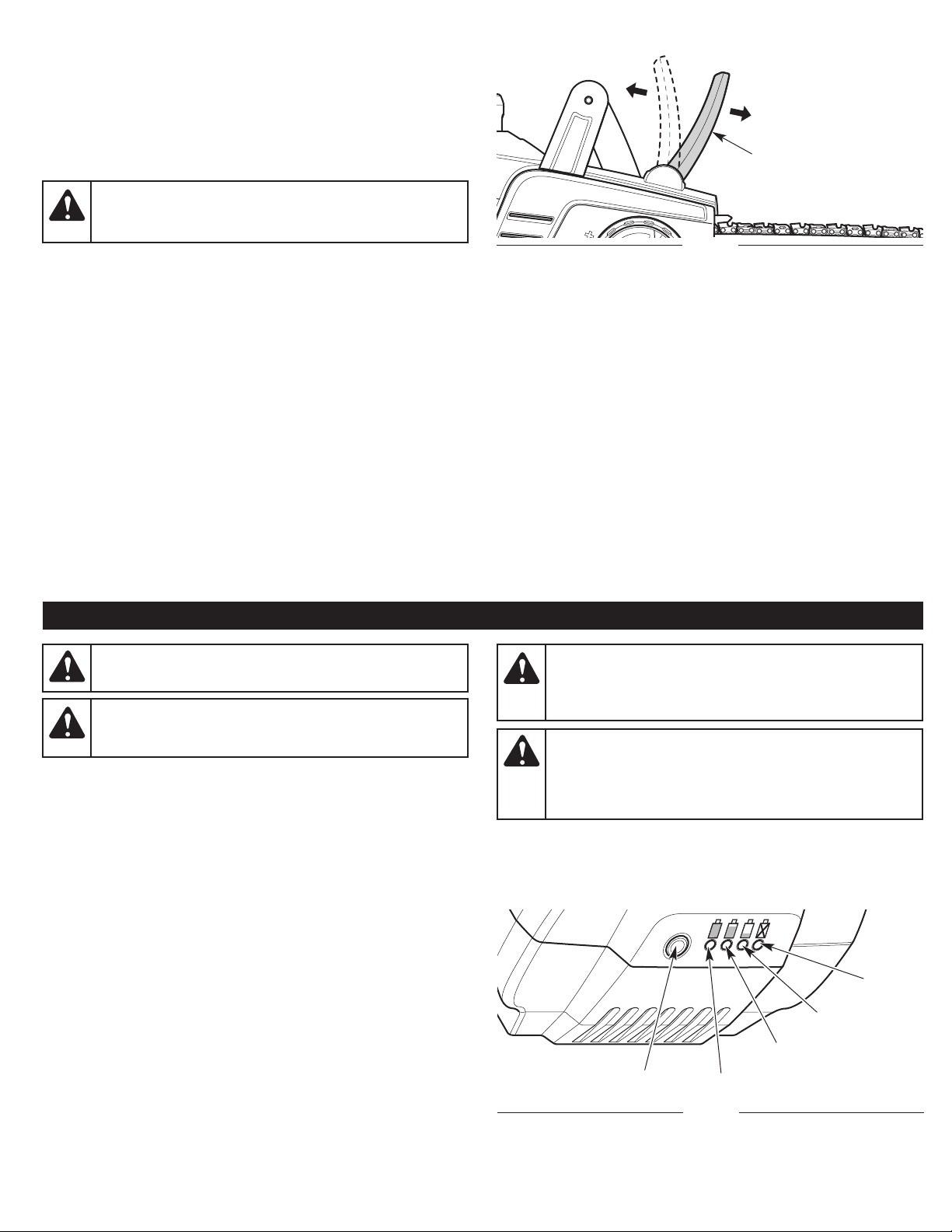

INSTALLING AND REMOVING THE BATTERY

WARNING:

prevent serious injury, DO NOT press the trigger lockout

and DO NOT squeeze the trigger when installing or

removing the battery. Refer to Starting and Stopping.

Remove the battery from the unit when it is not in use.

Avoid accidentally starting the unit. To

Front Handle

Battery

Release Button

Battery

Installing the Battery

1. Grasp the front handle firmly (Fig. 14).

2. Slide the battery into the battery port (Fig. 14). Push the battery

firmly until the battery locks into place (Fig. 14). There should be

an audible “click.”

3. Gently pull the battery to make sure it is securely locked in place.

Removing the Battery

1. Grasp the front handle firmly (Fig. 14).

2. Press the

3. Pull the battery out of the battery port (Fig. 14).

NOTE: It may require a strong pull to remove the battery.

battery re

lease button to unlock the battery (Fig. 14).

STARTING AND STOPPING

WARNING:

and saw chain properly installed. Make sure the guide bar

cover is securely assembled. Make sure the saw chain is

properly tensioned. Refer to Adjusting the Chain Tension

instructions in the Maintenance section.

Never operate the unit without the guide bar

Battery Port

Fig. 14

WARNING:

Keep hands and feet clear of the saw chain and do not

allow the saw chain to contact any object(s).

The saw chain will spin after the unit starts.

BEFORE STARTING THE UNIT

1. Fill the chain oil reservoir with bar and chain oil. Refer to Adding

Bar and Chain Oil in the Maintenance section.

2. Install the battery. Refer to Installing the Battery.

STARTING INSTRUCTIONS

NOTE: To help prevent the motor from starting accidentally, this unit

has a trigger lockout. The trigger lockout and trigger must both

be engaged to start the unit.

1. Press and hold the trigger lockout (Fig. 15).

2

. Continue to hold the trigger lockout. Squeeze and hold the

trigger to start the unit (Fig. 15).

3. Release the trigger lockout, but continue to squeeze the trigger

to the degree needed for the operation.

STOPPING INSTRUCTIONS

1. Release the trigger (Fig. 15).

2. Wait for all moving parts to come to a complete stop.

NOTE: Upon release of the trigger, the trigger lockout will reset to

the locked position.

Trigger Lockout

Trigger

Fig. 15

15

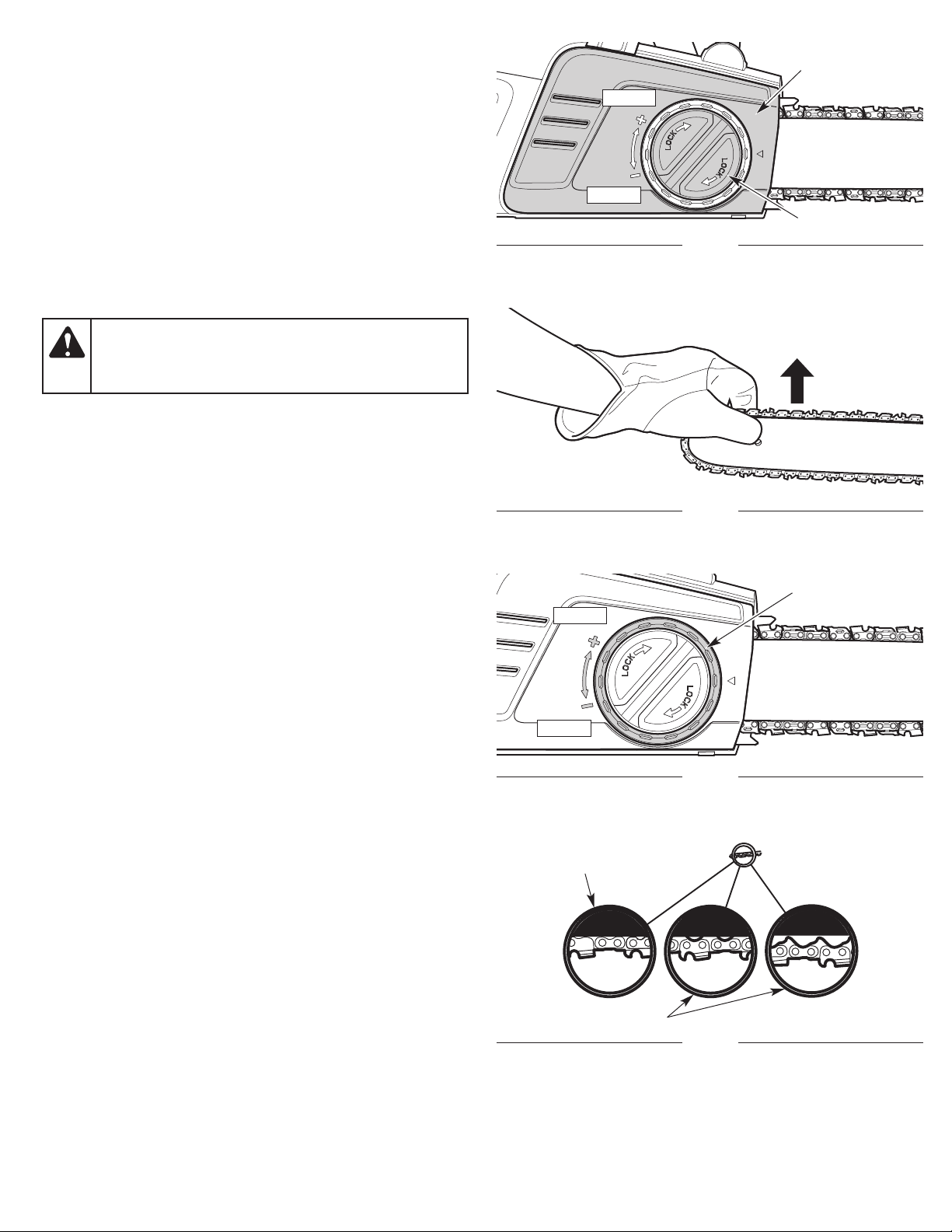

USING THE CHAIN BRAKE

In emergency situations, the saw chain can also be stopped by

engaging the chain brake. The chain brake can be activated

intentionally by pushing the front hand guard / chain brake lever

forward. It can also be activated if the operator’s hand strikes the

front hand guard / chain brake lever during kickback.

Testing the Chain Brake

WARNING:

deliberately. Keep the saw chain from touching anything.

Do not let the chain saw tip forward.

Always test the chain brake before using the unit.

1. S

et the unit on a flat, level surface.

2. Make sure the front hand guard / chain brake lever is pulled

back in the disengaged position (Fig. 16).

3. Grip the unit firmly with both hands. Refer to Holding the Unit in

the Operation section.

4. Start the unit. Refer to Starting Instructions.

5. While the unit is running, engage the chain brake by pushing the

front hand guard / chain brake lever forward with the

Fig. 16). The chain should stop moving abruptly. If it does not,

(

have the unit serviced by an authorized service center.

6. Stop the unit. Refer to Stopping Instructions.

7. Pull the front hand guard / chain brake lever back to the

disengaged position.

Always activate the chain brake slowly and

left hand

Disengaged

Engaged

Chain Brake Lever /

Front Hand Guard

Fig. 16

OPERATION

WARNING:

conditions.

WARNING:

necessary before beginning operation. Refer to Adjusting the

Chain Tension in the Maintenance section.

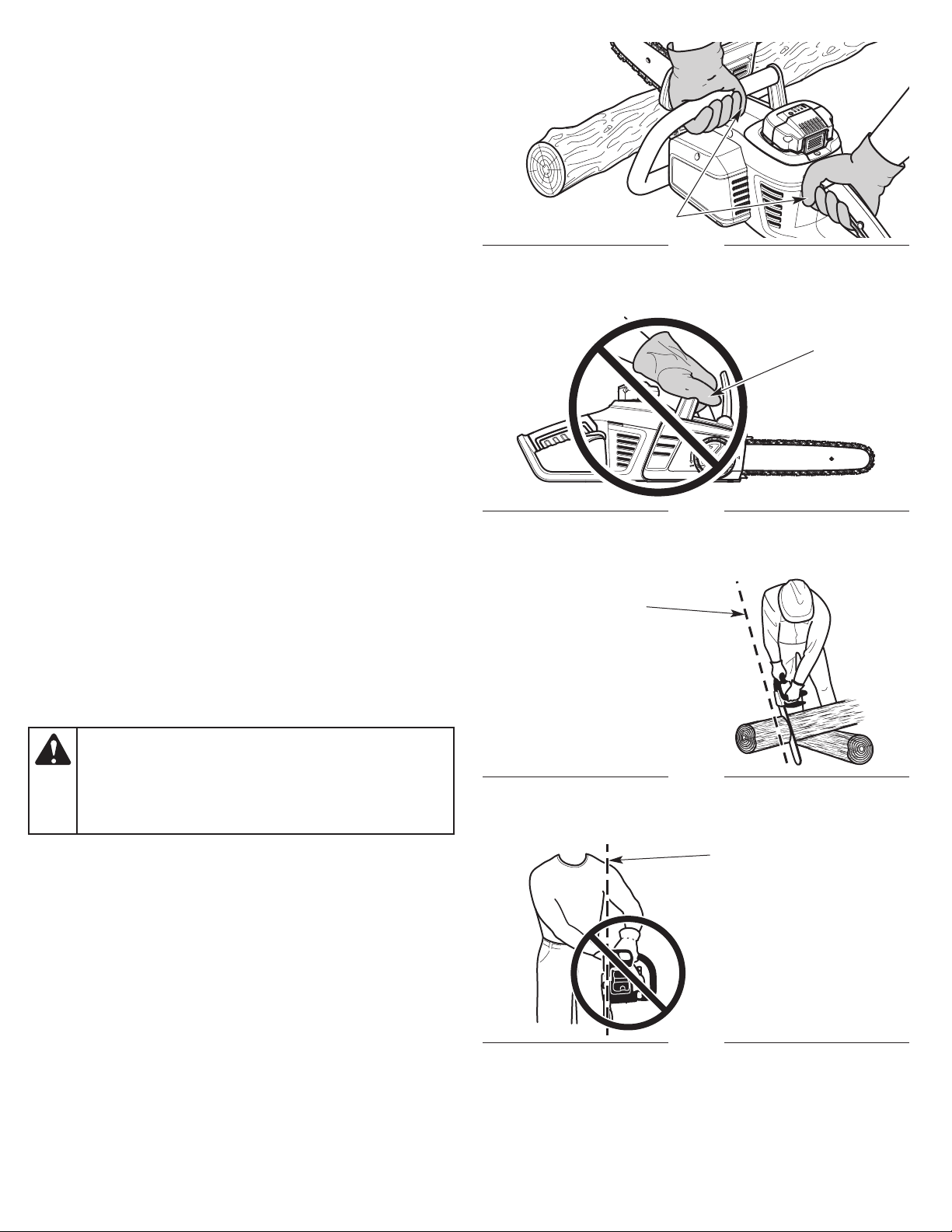

CHECKING THE BATTERY CHARGE LEVEL

1. Press the charge meter button (Fig. 17).

2. One or more of the charge meter lights should illuminate (Fig. 17).

The number and color of the lights will indicate the current

battery charge level:

• 3 Green Lights = 66 - 100% Charge

• 2 Green Lights = 33 - 66% Charge

• 1 Green Light = 1 - 33% Charge

• 1 Red Light = 0% Charge

3. If the red light illuminates, charge the battery

OTE: While in use, lithium-ion batteries provide power with

N

minimal power fade. When the battery is fully discharged, it will

immediately cut power to the unit and require charging.

Do not expose power tools to rain or wet

Always check the chain tension and adjust as

before any further use.

WARNING:

before operation. Check the oil level constantly so that it

does not drop below half full. The saw chain must be

continuously coated with oil to function properly.

WARNING:

foot and body protection to reduce the risk of injury when

operating this unit. Wear head protection. Use a full face

shield when needed. Refer to the Safety section for

appropriate safety equipment information.

Charge Meter Button

Make sure the chain oil reservoir is full

Always wear appropriate eye, hearing, hand,

1% - 33%

33% - 66%

66% - 100%

Fig. 17

0%

16

TIPS FOR BEST RESULTS

• Follow all safety instructions. Refer to the Safety section.

• Only cut wood and materials made of wood. Do not attempt to cut

sheet metal, plastics, masonry or any other non-wood materials.

• Work slowly and maintain careful control.

• Practice cutting a few small logs before beginning a major

cutting operation. First-time users should practice cutting logs

on a sawhorse or cradle b

• Do not attempt to cut trees or logs with diameters larger than 10

in. (25.4 cm).

• When pruning, remove lower branches first to allow clear access

to higher branches and to provide space for falling branches.

• When pruning, remove long branches in stages, not all at once.

undertaking other operations.

efore

Correct Grip

Thumbs Below the Handles

Fig. 18

PREPARING THE WORK AREA

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they

a

re still at risk from thrown objects. Encourage bystanders to

wear eye protection. If you are approached, stop the unit

immediately. When felling, the safe distance is at least twice the

height of the tallest tree in the work area. When bucking, keep

workers at least 15 feet (4.6 m) apart.

• Keep the work area clean. Cluttered areas invite injuries. Do not

start cutting until the work are

a is clear and free from

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• Use the unit only in daylight or good artificial light.

HOLDING THE UNIT

WARNING:

below whether the operator is left-handed or right-handed.

This will help keep the operator slightly to the left of the

unit and out of the direct line of the saw chain if kickback

occurs (Fig. 20 and Fig. 21). Always keep all body parts to

the left of the chain line.

Always use the hand placements specified

Incorrect Grip

Correct Stance

Thumb

Above the

Handle

Fig. 19

Chain Line

Fig. 20

• Always grip the unit firmly with both hands when the unit is

running.

• F

irmly encircle the handles with the thumbs and fingers (Fig. 18).

This will help reduce the chance of losing control of the unit if

kickback occurs. Any grip with thumbs and fingers on the same

side of the handles is dangerous (Fig. 19).

• Stand in a stable position with feet apart and firmly planted.

• Hold the front handle with the left hand. Keep the left arm

straight to help withstand potent

old the rear handle with the right hand. Keep the right arm

• H

ial kickback.

slightly bent.

• Do not cut above shoulder height. Do not overreach.

• When carrying the chain saw from one place to another, hold it

by the front handle, away from the body, and keep the guide bar

pointed to the rear.

Chain Line

Incorrect Stance

Fig. 21

17

CUTTING PROCEDURE BASICS

90°

1. Start the unit. Refer to Starting Instructions in the Starting and

Stopping section.

2. Make sure that oil is flowing onto the guide bar and saw chain. A

small spray should be visible. When using the unit for the first

time, allow 30-60 seconds for the oil to begin flowing.

3. Press the unit against the wood and maintain a firm, steady

pressure through most of the cut. Do not put

unit at the end of the cut.

4. Keep the unit running through the entire cut.

5. Do not try to force the saw through the wood. Allow the saw

chain to do the cutting. Exert only light pressure. Forcing the cut

could result in damage to the unit or personal injury.

6. Release the trigger as soon as the cut is completed. Allow the

saw chain to come to a complete stop. The saw chain, guide bar

a

nd motor may experience unnecessary wear if the unit is run

ithout a cutting load.

w

ssure on the

pre

FELLING: SAFETY

Felling is the process of cutting down a tree. Follow these safety

precautions to reduce the risk of serious injury, property damage

and damage to electrical lines:

• Do not fell trees with an extreme lean. Do not fell trees with

rotten limbs, loose bark or hollow trunks. Have these trees

pushed or dragged do

o not cut trees near buildings or electrical lines. Leave these

• D

operations for professionals. If a felled tree does contact an

electrical line, notify the utility company immediately.

• Check the tree for damaged or dead branches that could fall

and cause serious injury.

• Remove dirt, stones, loose bark, nails, wire and other

obstructions from the portion of the tree that will b

hen bucking and felling operations are performed by two or

• W

more persons in the same general area, they should be

separated from each other by a distance of at least twice the

height of the tree to be felled.

• Consider the force and direction of the wind. Consider the lean

and balance of the tree. Consider the location of large branches.

All of these factors influence the direction that the tree

not try to fell a tree in a direction other than its natural fall line.

o not fell trees during periods of precipitation or high winds.

• D

• Determine a safe and expedient escape route. Clear the area

around the tree and make sure there are no obstructions

blocking the escape route. Establish a 90º corridor of escape,

approximately 135º from the line of fall (Fig. 22).

• Stay uphill from the t

wn with heavy equipment.

e cut.

will fall. Do

ree; it will most likely roll or slide after it falls.

Path of Safe

Retreat

135º From Planned

Line of Fall

Planned

Line of Fall

135º From Planned

Line of Fall

Fig. 22

FELLING: PROCEDURE

Small trees, up to 6 - 7 inches (15 - 18 cm) in diameter, are usually

felled in a single cut. Larger trees require a sequence of two cutting

operations: a notched undercut followed by a felling back cut. It

may also be necessary to remove buttress roots.

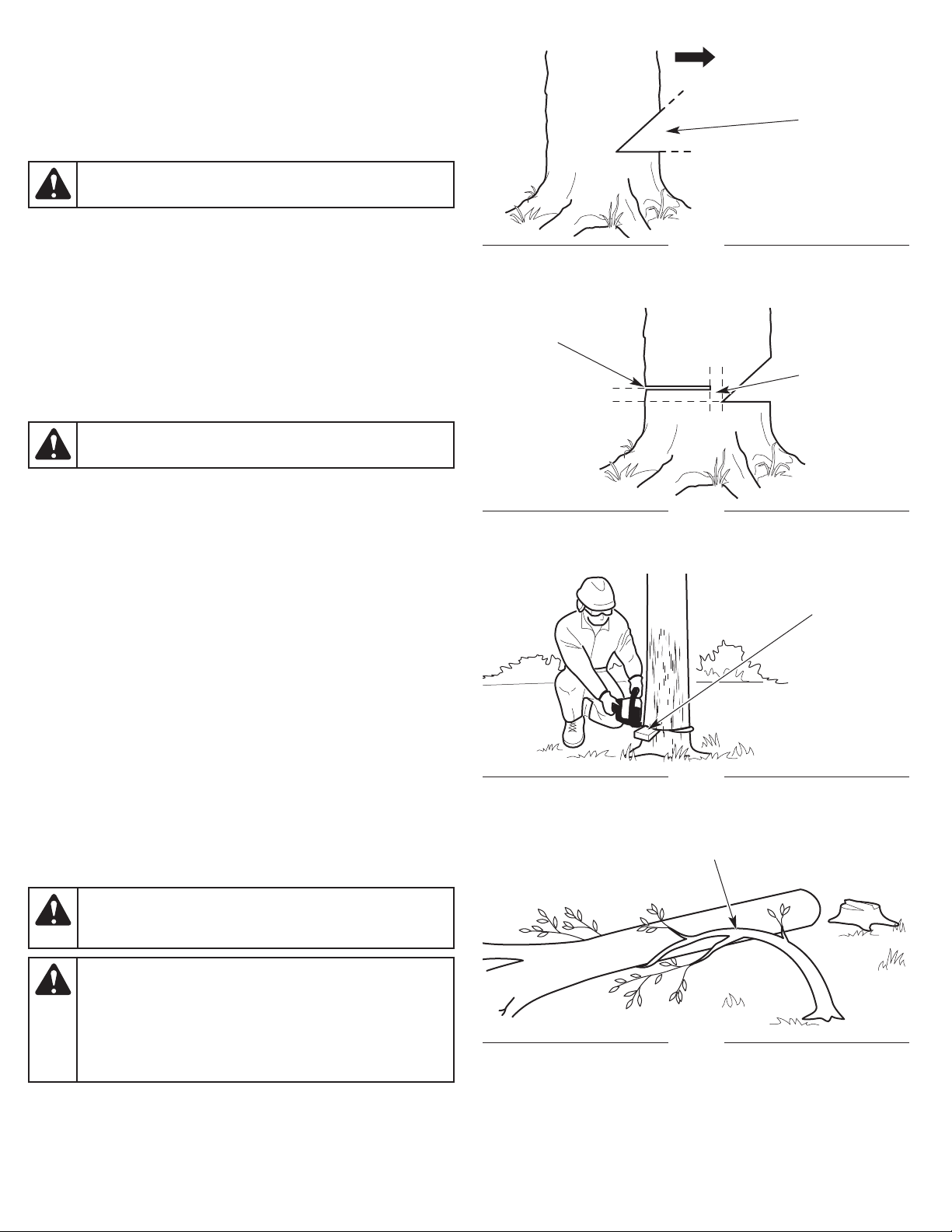

Step 1: Removing Buttress Roots

Buttress roots are large roots that extend above the ground and

help support the tree. If the tree has

impede the felling process, follow these steps to remove them:

e buttress roots that might

larg

Second Cut

Buttress Root

First Cut

Fig. 23

18

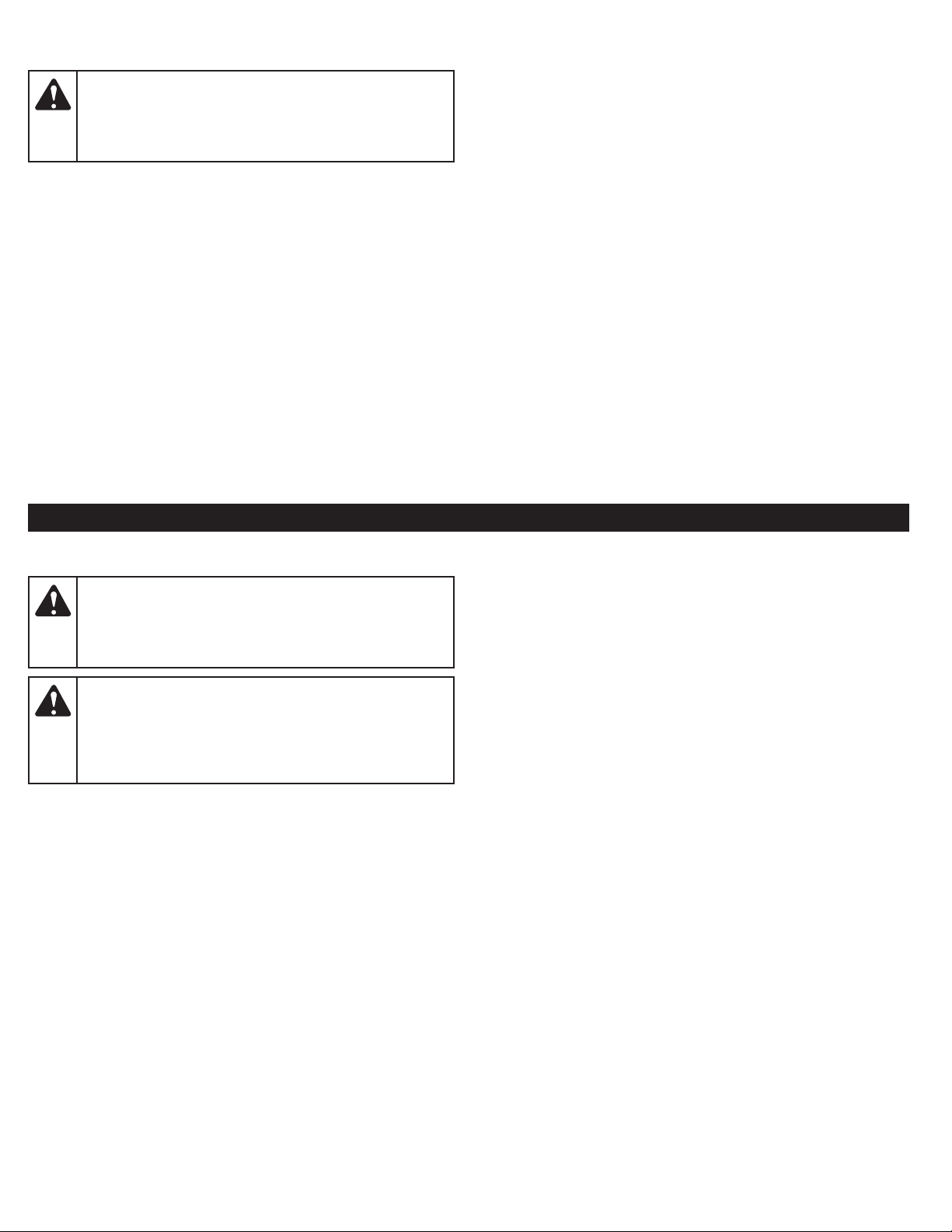

1. Make a horizonal cut into the buttress root (Fig. 23). To prevent

the guide bar from being pinched by the weight of the wood,

always make this cut first.

2. Make a vertical cut into the buttress root (Fig. 23).

3. Remove the loose section from the work area.

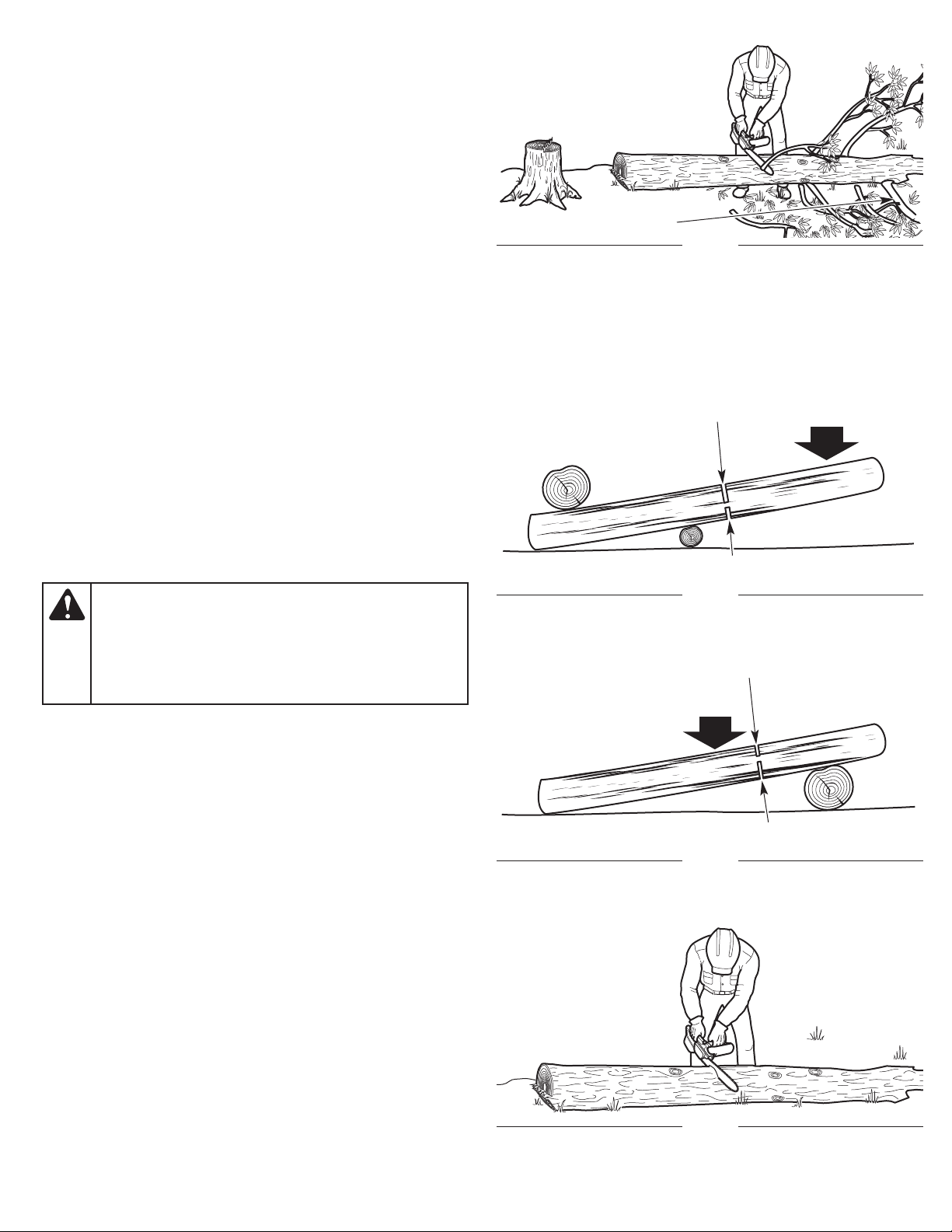

Step 2: Making the Notched Undercut

WARNING:

Never walk in front of a tree with a notched

undercut.

This cut determines which direction the tree will fall. Always make

this cut on the side of the tree facing the dire

ction where the tree

should fall. Make the cut at 90º to the line of fall.

1. Make a horizontal cut into the trunk of the tree (Fig. 24). The cut

should be about 1/3 the diameter of the tree and close to the

ground. To prevent the guide bar from being pinched by the

weight of the wood, always make this cut first.

2. Make a 45º cut into the trunk of the tree, above the first cut (Fig.

24). Continue cutt

. Remove the loose section from the work area.

3

ing until the two cuts meet.

Step 3: Making the Felling Back Cut

Felling

Back Cut

1/3 Diameter

2 inches

(5 cm)

45º

Direction of Fall

Second Cut

Notched

Undercut

First Cut

Fig. 24

2 inches

(5 cm)

Hinge

WARNING:

Always recheck the area for bystanders,

animals and obstacles before making the felling back cut.

This cut fells the tree.

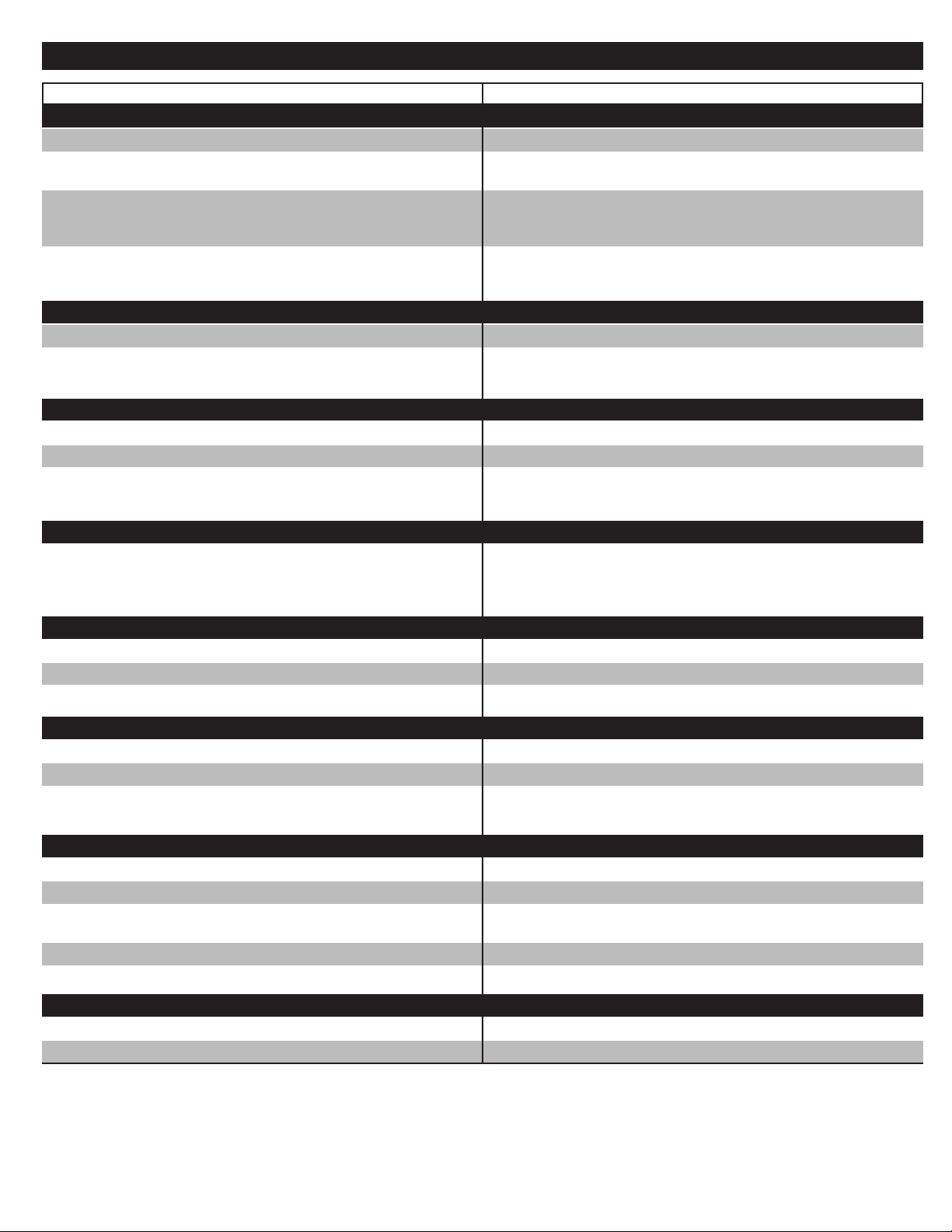

1. Make a horizontal cut into the opposite side of the tree from the

notched undercut (Fig. 25). Make the cut approximately 2 inches

(5 cm) above the bottom of the notched undercut (Fig. 25).

2. As the cut gets close to the notched undercut, only a thin band

of wood will support the tre

e. This band of wood is referred to as

the hinge (Fig. 25). The hinge helps control the fall of the tree.

Leave approximately 2 inches (5 cm) of hinge in place. Do not

cut through the hinge. Cutting through the hinge could cause the

tree to fall in any direction.

3. Periodically glance up during the felling back cut to see if the

tree is going to fall in the correct direction. If there is

hat the tree might not fall in the desired direction, or if the tree

t

a chance

might rock back and bind the chain saw, remove the guide bar

from the cut, stop the unit and use wedges to open the cut and

direct the fall (Fig. 26). Only use soft plastic or wooden wedges.

Drive the wedges into the cut slowly. Once the wedges are in

place and the cut is held open, either carefully reinsert the guide

bar and

p

continue the cut or slowly drive the wedges in further to

ush the tree over.

4. As the hinge gets smaller, the tree should begin to fall. When the

tree begins to fall, remove the chain saw from the cut, stop the

motor and set the unit down immediately. Promptly exit the area

along the retreat path, but keep watching the tree as it falls.

Fig. 25

Wedge

Fig. 26

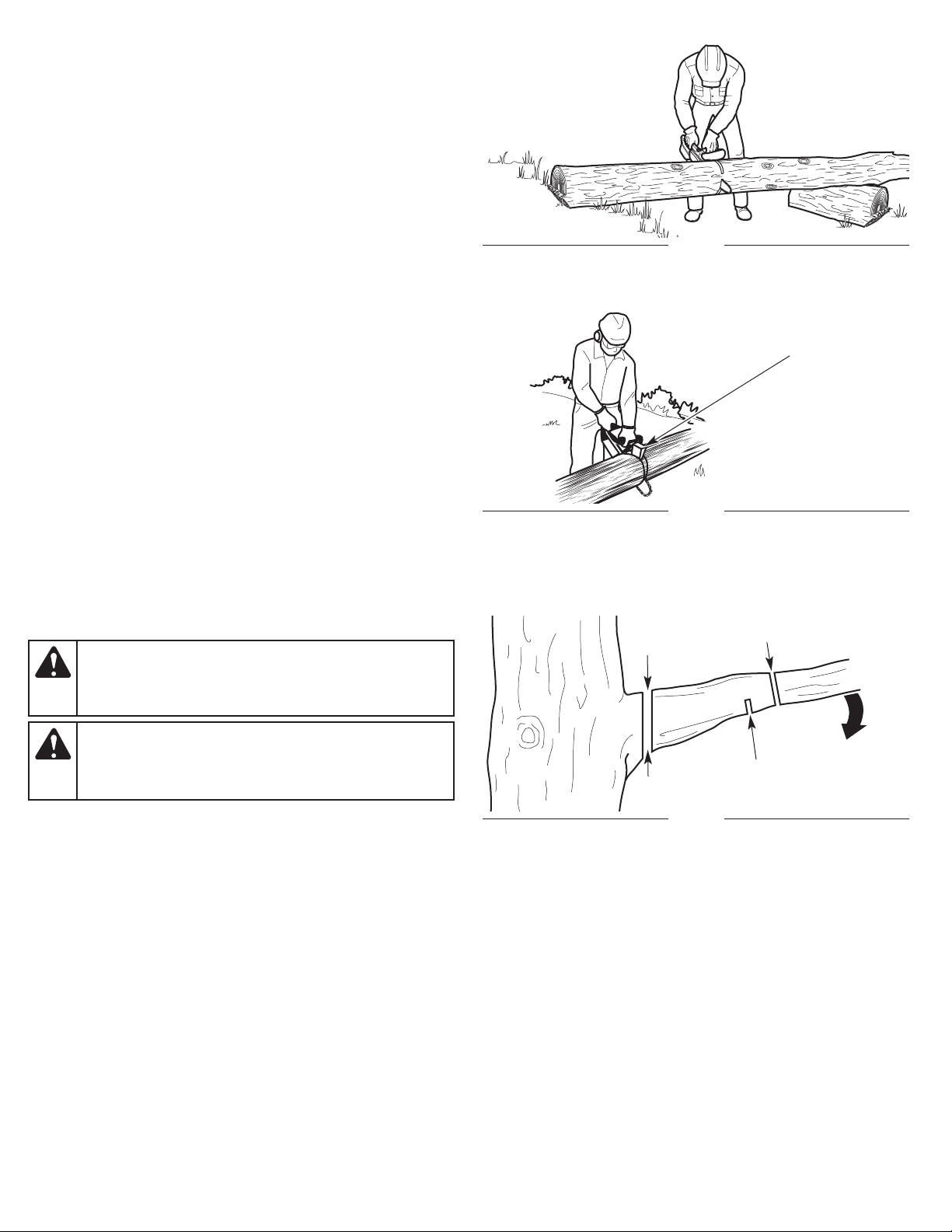

Spring Pole

DANGER:

If the tree starts to fall in the wrong direction

and binds the chain saw, leave the unit and evacuate the

area immediately! Do not try to save the chain saw!

WARNING:

Stay clear of spring poles when operating the

unit. Spring poles are branches, logs, roots or saplings that

are bent under tension by other wood (Fig. 27). When the

tension is released, spring poles can strike the operator,

causing serious injury and potentially knocking the chain

saw into the operator’s body. Use extreme caution when

cutting spring poles or when releasing the cause of tension.

Fig. 27

19

LIMBING

Limbing is the process of removing branches from a fallen tree.

1. Leave the larger support limbs under the tree for last (Fig. 28).

These will keep the tree off the ground during the limbing process.

2. Cut one limb at a time. Stand on the opposite side of the tree

from the limb (Fig. 28). Keep the trunk between the operator and

the chain saw. To avoid binding the chain saw, branches under

tensi

on should be cut fro

m the bottom up.

3. Remove the cut limbs from the work area.

BUCKING: SAFETY

Bucking is the process of cutting a fallen tree into logs of desired

lengths. Follow these safety precautions to reduce the risk of

serious injury:

• Clear the area of objects or obstructions that could contact the

guide bar and result in kickback.

• When bucking on a slope, always stand on the uphill side of the

fallen tree.

• If possible, the end of the tree to be cut should be raised off

he ground. A saw horse is ideal for this purpose. If a saw horse

t

is not available, use other logs or any remaining limb stumps.

Make sure the tree if firmly supported.

• Do not let the saw chain contact the ground or saw horse.

• Cut one log at a time. Release the trigger and allow the saw chain

to come to a complete stop before moving on to the next log.

• Keep feet and all other body parts clear of fa

lling logs.

of

Log Supported

on One End

Support Limb

Fig. 28

Second Cut

First Cut (1/3 Diameter)

Load

DANGER:

Use extreme caution when cutting a fallen

tree that is still attached to the root structure. When the

trunk is separated from the roots, the stump has a high

potential for rocking back into the hole created by the

roots. This can result in serious injury or death. Never

stand in the hole left by the roots. Never allow others to

stand near the root structure.

BUCKING: PROCEDURE

Cutting Logs Under Stress

When logs are supported on one or both ends, the wood tends to

bend during the cutting process. This can cause the chain saw to