Remington RM1015P, RM0815P Owner’s Manual

EIVIIN

TELESCOPING ELECTRIC

CHAiNSAW/POLESAW

®

MODELS: RM0815P_ RMI015P

iMPORTANT: Read and understand this manuaJ before assembling or

operating this appliance, improper use of this appliance can cause

severe injury or death. Keep this manuaJ for future reference.

0Q0s

LISTED

PART NO. 769-05152 P00 (06/09)

Please call the Customer Support Department or visit our website for assistance:

Llame al Departamento de Atenci6n al Cliente o visite nuestro sitio Web para solicitar asistencia:

Pour obtenir de I'aide, veuillez appeler le service a la clientele ou visitez notre site web :

U.S. - EE.UU. - aux I_tats Unis Canada - Canada - au Canada

1-866-206-2707 or - o - ou 1-877-696-5533

www.remingtonpowertools.com

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS. OTHER PATENTS PENDING.

For assistance regarding the assembly, controls, operation or maintenance of the unit, please call the Customer

Support Department. Additional information about the unit can be found on our website.

For service, please call the Customer Support Department to obtain a list of authorized service dealers near

you. Service on this unit, both within and after the warranty period, should only be performed by an authorized

and approved service dealer. When servicing, use only identical replacement parts.

NO DEVUELVA ESTA UNIDAD AL VENDEDOR. PARA SOLICITAR SERVICIO POR LA GARANTIA, DEBERA

PRESENTAR PRUEBA DE SU COMPRA.

ESTE PRODUCTO ESTA CUBIERTO POR UNA O MAS PATENTES DE EE.UU., OTRAS PATENTES ESTAN

PENDIENTES.

Para solicitar asistencia en relaci6n con el ensamblaje, los controles, la operaci6n o el mantenimiento de la

unidad, Ilame al Departamento de Atenci6n al Cliente. Puede encontrar mas informaci6n sobre la unidad en

nuestro sitio Web.

Para mantenimiento, Ilame al Departamento de Apoyo al Cliente para obtener una lista de distribuidores de

servicio autorizados de su Iocalidad. El mantenimiento y reparaci6n de este equipo, ya sea durante o despues

del periodo cubierto per la garantia, deben ser realizados solamente per un proveedor de servicios autorizado

y aprobado. Cuando vaya a dar mantenimiento al equipo, utilice solo piezas de repuesto originales.

NE RAMENEZ PAS CET APPAREIL CHEZ LE DI_TAILLANT. UNE PREUVE D'ACHAT SERA EXIGI_E POUR

TOUTE PRISE EN CHARGE DANS LE CADRE DE LA GARANTIE.

CE PRODUIT EST COUVERT PAR UN OU PLUSIEURS BREVETS AUX ETATS UNIS. AUTRES BREVETS EN

INSTANCE.

Si vous eprouvez des difficultes h assembler ce produit ou si vous avez des questions sur les commandes,

I'utilisation ou I'entretien de cet appareil, veuillez contacter le service h la clientele. Des informations

supplementaires sent disponibles sur notre site web.

Pour un entretien ou une reparation, veuillez appeler le service b.la clientele pour obtenir une liste complete des

concessionnaires agrees pres de chez vous. L'entretien de cet appareil doit _tre confie exclusivement h un

concessionnaire agree pendant et apres la periode de garantie. Lors de I'entretien, utilisez uniquement des

pieces de rechange identiques.

Before beginning, locate the unit's model plate, which lists the model and serial numbers of your unit. Refer to

the sample plate below and copy the information for future reference.

Antes de comenzar, Iocalice la placa correspondiente al modelo de la unidad, la cual indica el modelo y los

ndmeros de serie de la misma. Vea la placa de muestra debajo y copie la informaci6n para consultarla en el future.

Avant de commencer, cherchez la plaque mentionnant le modele et le numero de serie de votre appareil.

Reportez-vous b. I'exemple ci-dessous et notez-y les informations pour pouvoir vous y referer ulterieurement.

Model Number - NOmero del modelo - Numero de modele

Parent Part Number

Numero de serie _ S/N _TEM

Se i , um e 1

Nt_mero de la pieza del

Numero de piece mere

fabricante

Copy the model and parent part numbers here:

Copie el modelo y los nt_meros de piezas del fabricante aqui:

Copiez ici le mod61e ainsi que le n ° de I'article :

Copy the serial number here:

Copie el numero de serie aqui:

Copiez ici le n° de serie :

iNTRODUCTiON

Your Remington Telescoping Pole Saw is a dual purpose product. The electric chain saw is a separate

operating unit when not assembled to the telescoping pole. Before operating either the chain saw or

the pole saw, make certain you read and understand all Important SafEty |nfbrmation.

Contents

IMPORTANT SAFETY INFORMATION ................................................................................ 4

Before Operating Saw ........................................................................................................................ 4

While Operating Saw .......................................................................................................................... 4

Kickback ............................................................................................................................................. 5

Maintenance and Storage of Saw ...................................................................................................... 6

Pole Saw Trimming Precautions ....................................................................................................... 7

UNPACKING ......................................................................................................................... 7

PRODUCT iDENTiFiCATiON .............................................................................................. 8

CHAIN SAW TERMS AND DEFiNiTiONS ........................................................................... 9

CHAIN SAW iNFORMATiON ............................................................................................. 10

Chain Saw Hardware ....................................................................................................................... t0

Chain Saw Assembly ........................................................................................................................ t0

Saw Chain Tension Adjustment ........................................................................................................ t t

Extension Cords ............................................................................................................................... 12

Filling Oil Tank .................................................................................................................................. 12

Oiling Chain ...................................................................................................................................... 12

Cutting withe the Chain Saw ............................................................................................................ 12

Felling a Tree .................................................................................................................................... 13

Limbing a Tree .................................................................................................................................. t 5

Bucking a Log ................................................................................................................................... 15

Trimming a Tree (Pruning) ................................................................................................................ 16

POLE SAW INFORMATION .............................................................................................. 17

Pole Saw Assembly .......................................................................................................................... 17

Adjusting Pole Length ...................................................................................................................... 18

Cutting with the Pole Saw ................................................................................................................ 18

CLEANING AND MAINTENANCE .................................................................................... 19

Cleaning Saw Body .......................................................................................................................... 19

Care of Guide Bar ............................................................................................................................ 19

Sharpening Saw Chain ..................................................................................................................... 20

Replacement Chain .......................................................................................................................... 21

STORAGE .......................................................................................................................... 21

REPLACEMENT PART AND ACCESSORIES .................................................................. 21

TROUBLESHOOTING ....................................................................................................... 22

REPAIR SERVICE ............................................................................................................. 22

WARRANTY INFORMATION ............................................................................................. 23

SAVE THESE INSTRUCTIONS

All information, illustrations and specifications in this manual are based on the latest

product information available at the time of printing. We reserve the right to make changes

at any time without notice.

Copyright© 2009 MTD SOUTHWEST INC, All Rights Reserved.

3

iMPORTANT SAFETY iNFORMATiON

A

WARNING: When using an electric

chain saw, basic safety precautions

should always be followed to reduce

the risk of fire, electric shock, and injury

to persons, including the following:

READ ALL iNSTRUCTiONS

Make sure you read and understand all

instructions in Important Safety Infor-

mation on pages 4 through 7. improper

use of this chain saw can cause severe

injury ordeath from fire, electrical shock,

body contact with moving chain, or fall-

ing wood.

BEFORE OPERATING SAW

1. Read and understand this owner's manual

before operating saw.

2. Watch what you are doing. Use common sense.

Do not operate saw when you are tired.

3. Use saw for cutting wood only.

• Do not use chain saw tk)rpurpose not in-

tended.

• Do not use for cutting non-wood items.

4. Only well-instructed adults should operate saw.

Never allow children to operate saw.

5. Use only electrical voltage noted on model

plate of saw.

6. Use only extension cords marked for outdoor

use. See page 21 lk)rextension cord require-

ments.

7. Do not operate saw

• while under the influence of alcohol, medica-

tion, or drugs

• in rain or in damp or wet areas

• where highly flammable liquids or gases are

present

• if pole or saw is damaged, adjusted wrong, or

not fully and securely assembled

• if trigger does not turn saw on and off. Chain

must stop moving when you release trigger.

Have faulty switch replaced by authorized

service center.

• while in ahurry

• while in tree or on a ladder

• while on aerial booms, buckets, or platforms

8. Wear snug-fitting clothes when operating chain

saw. Do not wear loose clothing or ,jewelry.

They can get caught in moving saw chain.

9. Wear the following safety gear when operating

saw:

10.

11.

12.

13.

WHILE OPERATING

1.

2.

3.

4. Keep children, animals, and bystanders away

5. Do not use the pole saw to cut down trees. Use

6. Do not use near power lines. Keep at least 10

7. If two or more persons perform bucking and

8. Secure wood you are cutting by using clamps

• heavy-duty gloves (wear rubber gloves when

working outdoors)

• steel-toed safety footwear with non-skid

soles

• eye protection such as safety glasses,

goggles, or face screen

• safety hard hat

• ear mufflers or ear plugs

• hair covering to contain long hair

• face or dust mask (if working in dusty ar-

eas)

Before cutting, always provide the follow-

ing:

• clear work area

• secure footing

• planned retreat path from falling limbs

Inspect tree before trimming or cutting

down. Make sure there are no dead limbs or

branches that may fall on you. Make allow-

ance for branches to fall freely to the ground.

Do not use pole saw to fell saplings. Use

the chain saw without pole attachment.

To reduce the risk of electric shock, this

saw has a polarized plug (one blade is wider

than the other). This plug will fit in a polar-

ized outlet only one way. If the plug does

not fit fi]lly in the outlet of your extension

cord, reverse the plug. If it still does not fit,

a polarized extension cord will be neces-

sary. Do not change the plug in any way.

SAW

Stay alert. Use common sense while operating

saw.

Keep work area clean. Cluttered areas invite

injuries.

Be aware of extension cord while operating

chain saw. Be careful not to trip over cord.

Keep cord away Dora chain and operator at

all times.

from chain saw and extension cord. Only chain

saw user should be in work area.

the chain saw without pole attachment and

only if you are trained or have expert help.

feet away Dora electrical lines.

felling operations at the same time, provide

plenty of distance between operations. Provide

distance of at least twice the height of tree being

felled.

or chocks.

IMPORTANT SAFETY INFORMATION

9. Grip chain saw firmly with both hands. Never

operate chain saw with one hand. Never use

hand guard as handle.

10. Grip pole saw securely. Place one hand on the

pole and the other on the handle.

11. Keep finger off trigger until ready to make

cut.

12. Before starting chain saw, make sure chain is

not touching anything.

13. To guard against electrical shock, avoid body

contact with grounded objects such as pipes,

fences, and metal posts.

14. Keep all parts of body away from chain when

saw is running.

15. Do not force saw while cutting. Apply light

pressure. It will do the job better and safer at

the rate for which it was intended.

16. Do not cut small brush and saplings with the

pole saw. Use the chain saw only, with extreme

care. Slender matter may catch in the chain and

be whipped toward you. This could also pull

you off balance.

17. When cutting limb or tree trunk that is under

tension, use extreme caution. Be alert for

wood springing back. When wood tension is

released, limb could spring back and strike

operator causing severe injury or death.

18. Carry saw from one place to another

• with saw stopped and unplugged

• Chain saw - by holding front handle (never

use hand guard as handle)

• Pole saw - with telescoping pole returned to

shortest position

• Pole saw - by holding the pole atthe balance

point (close to saw end)

• with finger off trigger

• with guide bar and chain to rear

_ WARNING: This product contains

chemicals known to the State of Cali-

fornia to cause cancer or birth defects,

or other reproductive harm.

_ WARNING: Some dust created by

fects, or other reproductive harm. Some

type of work. To reduce your exposure

to these chemicals: work in a well venti-

that are specially designed to filter out

KICKBACK

KICKBACK SAFETY DEVICES ON

THiS SAW

This saw has a low-kickback chain and reduced

kickback guide bar. Both items reduce the chance

of kickback. Kickback can still occur with this

saw.

Follow assembly instructions on page 10. Do not

remove front hand guard. Do not replace front

hand guard with substitute.

The following steps will reduce the risk of kick-

back:

power sanding, sawing, grinding, drill-

ing, and other construction activities

contains chemicals known (to the state

of California) to cause cancer, birth de-

examples of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and ce-

ment and other masonry products

• arsenic and chromium from chemi-

cally-treated [umber

Your risk from these exposures varies,

depending on how often you do this

lated area, and workwith approved safety

equipment, such as those dust masks

microscopic particles.

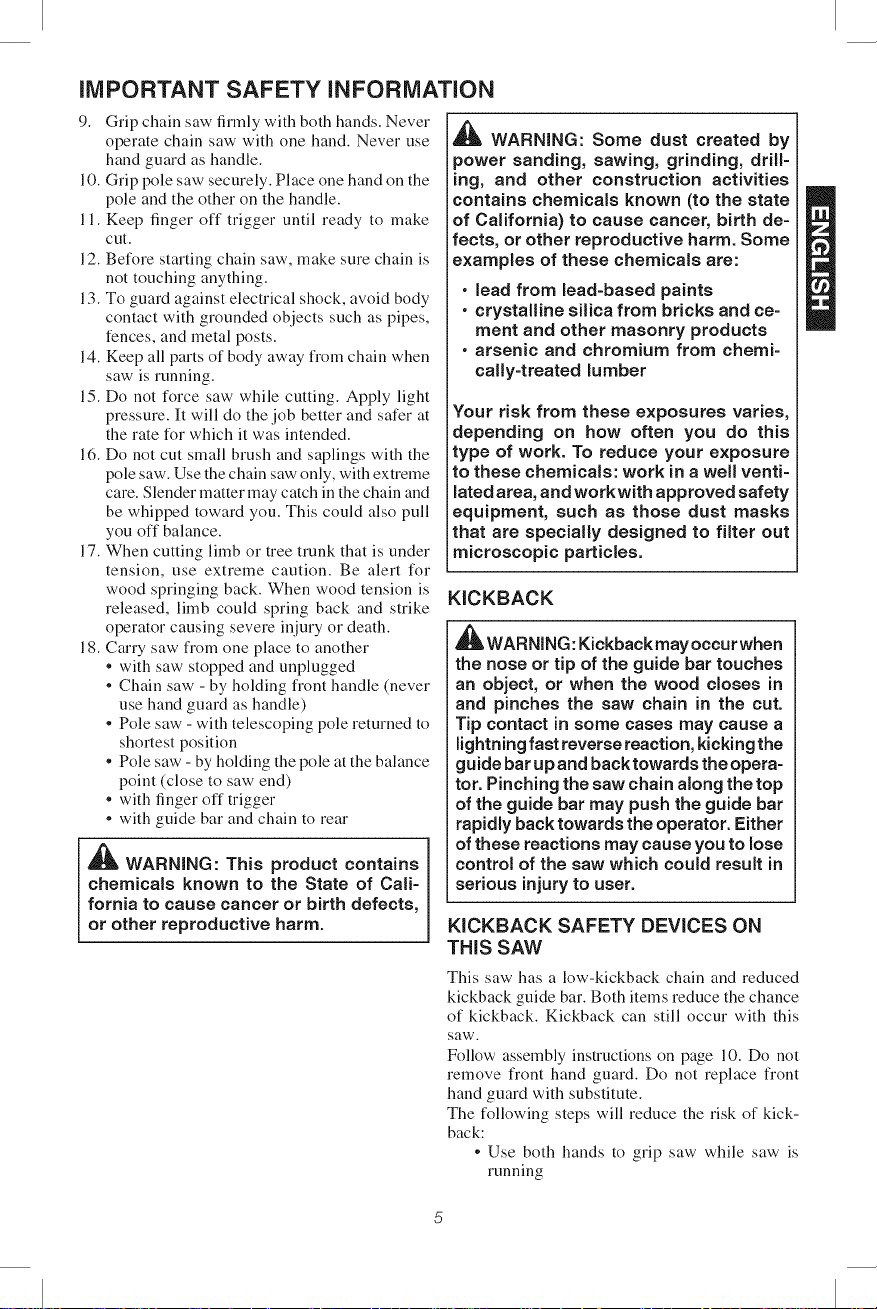

A

WARNING: Kickback mayoccur when

the nose or tip of the guide bar touches

an object, or when the wood closes in

and pinches the saw chain in the cut.

Tip contact in some cases may cause a

lightning fast reverse reaction, kicking the

guide bar up and backtowards the opera-

tor. Pinching the saw chain along the top

of the guide bar may push the guide bar

rapidly back towards the operator. Either

of these reactions may cause you to lose

control of the saw which could result in

serious injury to user.

• Use both hands to grip saw while saw is

running

iMPORTANT SAFETY iNFORMATiON

• For chain saw, use firm grip. Thumbs and

fingers must wrap around saw handles.

• For pole saw, have one hand gripping the

handle and the other gripping the pole. Use

firm grip. Thumbs and fingers must wrap

around pole and handle.

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and fingers

must wrap around saw handles.

• Keep all safety items in place on saw. Make

sure they work properly.

• Chain saw - do not overreach or cut above

shoulder height.

• Pole saw - do not overreach or extend arms

above shoulder height.

• Keep solid footing and balance at all

times.

• Stand slightly to left side of saw. This keeps

your body from being in direct line with

chain.

• Do not let guide bar nose touch anything

when chain is moving (see Figure l ).

• Never try cutting through two branches at

same time. Only cut one log at a time.

• Do not bury guide bar nose or try plunge cut

(boring into wood using guide bar nose).

• Watch for shifting of wood or other forces

that may pinch chain.

- Use extreme caution when reentering aprevious

cut.

• Use low-kickback chain and guide bar sup-

plied with this chain saw. Only replace these

parts with chains and guide bars listed in this

manual.

• Never use dull or loose chain. Keep chain

sharp with proper tension.

Saw Maintenance and Kickback

Safety

Follow maintenance instructions in this manual.

Proper cleaning of saw and chain and guide bar

maintenance can reduce chances of kickback.

Inspect and maintain saw after each use. This will

increase the service life of your saw.

Note: Even with proper sharpening, risk of kick-

back can increase with each sharpening.

Direction

90 °

Do Not Let

Guide Bar

Touch Here

MAINTENANCE AND STORAGE OF

SAW

1. Unplug saw from power source:

2. Inspect saw befbre and after each use. Check

3. Maintain saw with care:

4. When servicing, use only identical replace-

5. When not in use, always store saw:

Save these instructions. It is your guide to safe

and proper operation of this saw.

• when not in use

• before moving fi'om one place to an

other

• before servicing

• befbre changing accessories or attachments,

such as saw chain and guard

saw closely if guard or other part has been dam-

aged. Check fbr any damage that may affect

operator safety or operation of saw. Check for

alignment or binding of moving parts. Check

for broken or damaged parts. Do not use saw

if damage affects safety or operation. Have

damage repaired by authorized service center.

• Never expose saw to rain.

• Keep chain sharp, clean, and lubricated

for better and safer performance.

• Follow steps outlined in this manual to

sharpen chain.

• Keep handles dry, clean, and free of oil

and grease.

• Keep all screws and nuts tight.

• Inspect power cord often. If damaged,

have repaired by authorized service cen

ter.

• Never carry saw by power cord.

• Never yank power cord to unplug it.

• Keep power cord finm heat, oil, m_d sharp

edges.

• Inspect extension cords often and re

place if damaged.

ment parts.

• in a high or locked place, out of children's

reach

• in a dry place

• in a cm'rying case or with scabb_ud over guide

bar

• drain oil after each use and befbre storing saw

to prevent oil leakage.

Figure 1 - Kickback Hazard Example: Do Not

Let Nose of Guide Bar Touch Object While

Chain is Moving

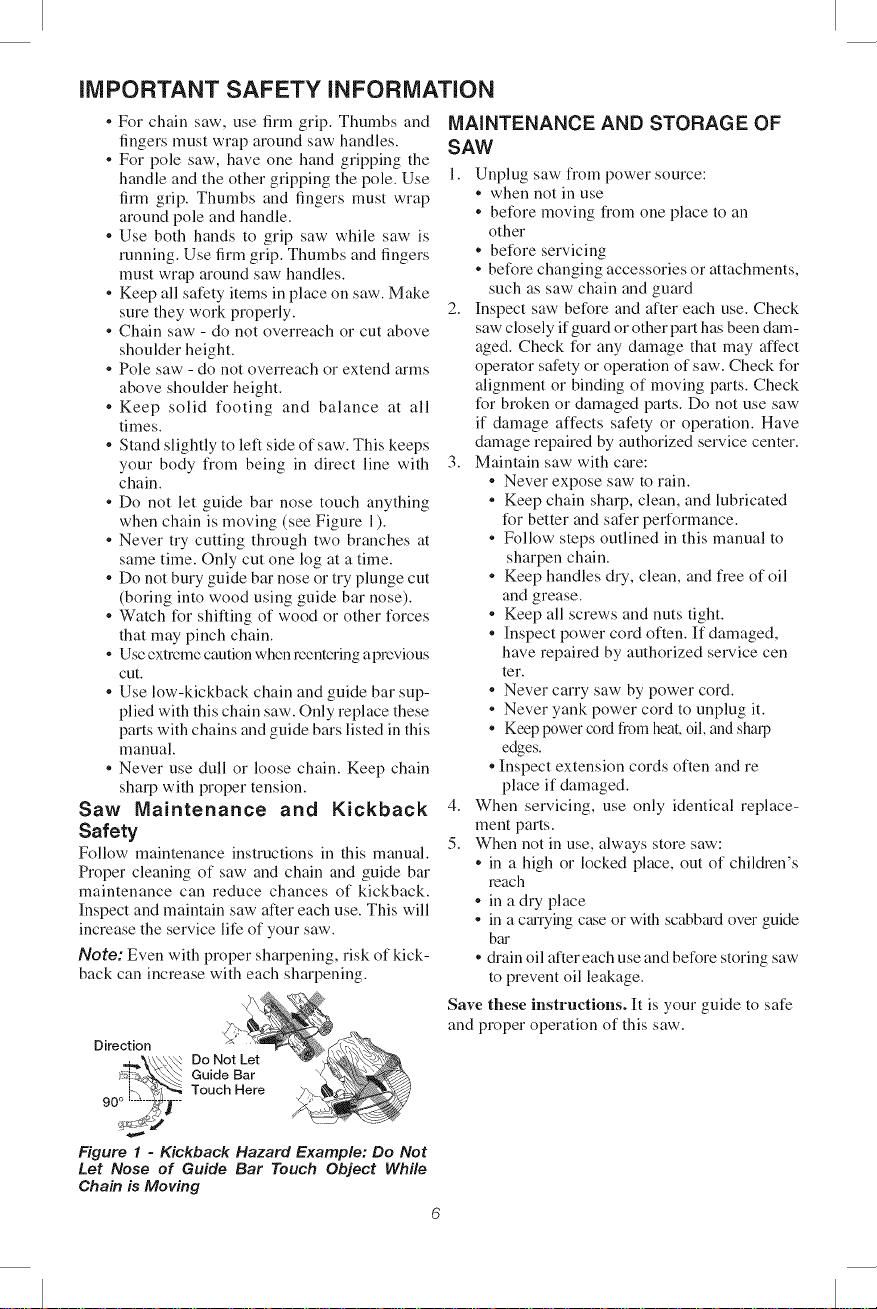

iMPORTANT SAFETY iNFORMATiON

POLE SAW TRiMMiNG

PRECAUTIONS

Do not use the pole saw to cut limbs

larger in diameter than the length of the

guide bar.

Never stand directly under the limb you

are trimming. Always position yourself out

of the path of failing debris.

Never stand on a ladder or other type of

unstable support while using the pole

SaW.

Always use both hands to operate pole

saw. Keep a firm, steady pressure on the

pole saw while cutting but do not try to

force the saw through the wood.

Keep other persons away from cutting end

of pole saw and at a safe distance from

work area.

Do not use pole saw near cable, electric

power or telephone lines. Maintain a mini=

mum clearance of 10 feet from all power

lines.

IMPORTANT: Read and understand this

manual before assembling or operating

this chain saw. Improper use of saw can

cause severe injury. Keep this manual

for future reference.

UNPACKING

1. Remove all items from carton.

2. Check all items t_r any shipping damage. If

you find any damage or if any parts are missing,

call 1-866-206-2707 (in Canada, call 1-877-

696-5533).

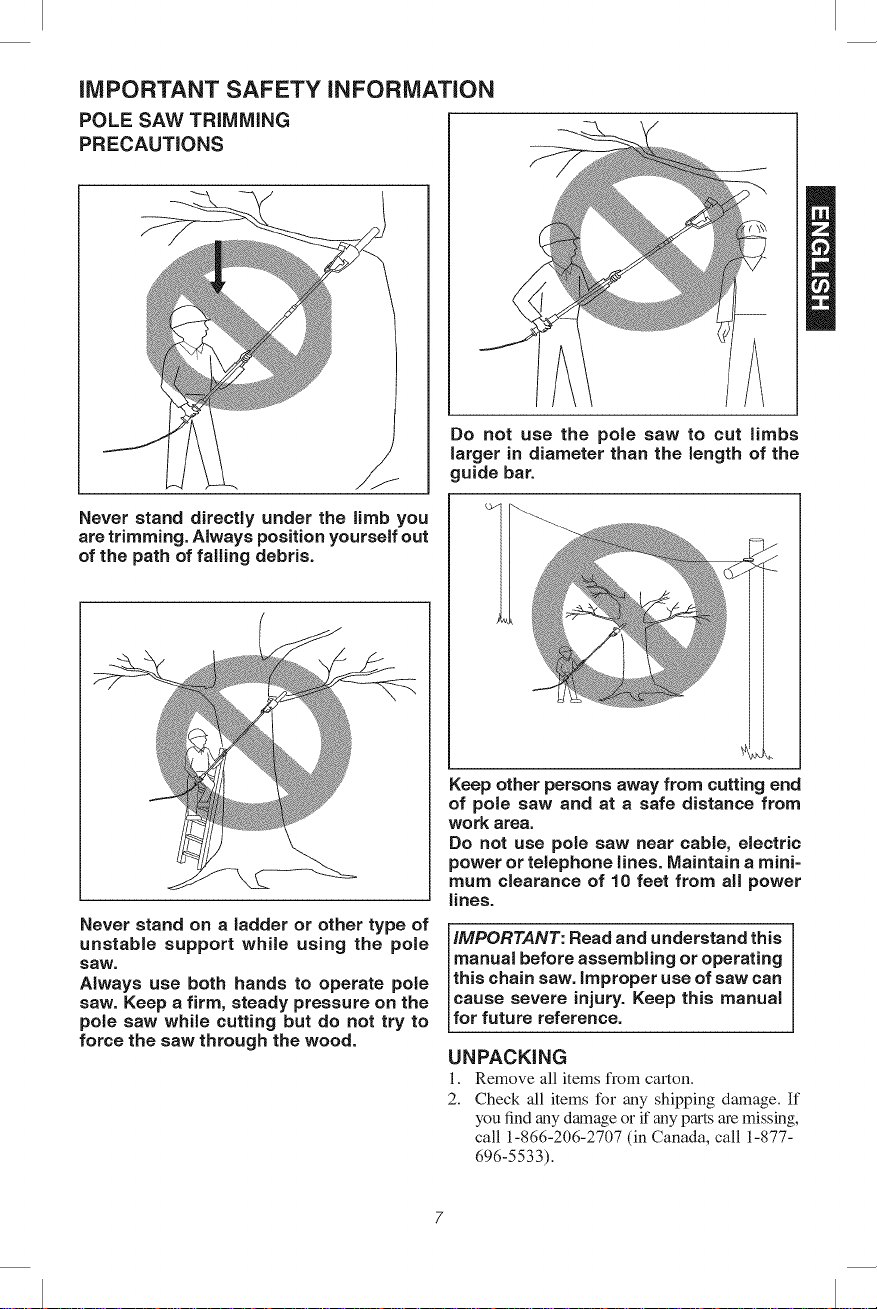

PRODUCT IDENTIFICATION

CHAIN SAW - ALL MODELS

Rear

Handle

Rear Hand

Guard

Power

Cord

Front

Handle

POLESAW

MODELS: RM0815P, RMI015P

\" Sprocket

Cover

Front Hand

Guard

Chain

Spike

Guide Bar Nose

/

/

/

Guide Bar

Oil Level Sight Hole (located on

_left side of saw body, between

front handle and front hand

Cap With Squeeze

Bulb

Lockout

Hand Guard Chain

Oil Cap

\

Scabbard

Tr_igger

Saw

Trigger Outer Pole

Lockout

Trigger

Handle

Power

Cord

Power Cord

Clamping

Lever

Grip

Area

Tighten

\

Guide Bar

Pole Bracket,

Inner Pole Lock Washer,

Loosen

Adjustment

Knob

CHAIN SAW TERMS AND DEFiNiTiONS

Bucking Process of cutting a felled tree or log

into lengths.

Clamping Lever Lever is loosened to allow

inner pole to be adjustd and tighted to hole pole

in position.

Felling Process of cutting down a tree.

Felting Cut Final cut when felling a tree. Make

this cut on opposite side of tree from notching

cut.

Front Handle Located at front of saw body.

Front Hand Guard Shield between front

handle and guide bar. Protects left hand while

using saw.

Guide Bar Metal bar that extends from saw

body. The guide bar supports and guides chain.

Guide Bar Nose Tip or end of guide bar.

Inner Pole The moveable section of tubing to

which the saw is attached.

Kickback Quick backward and upward motion

of guide bar. Kickback may occur when tip of

guide bar touches an ohject while chain is mov-

ing. The guide bar will kick up and back towards

operator.

Limbing Process of cutting limb(s) from a

felled tree.

Low-Kickback Chain Chain that reduces chance

of kickback as required by ANSI B175.1.

Normal Cutting Position Stance used while

making bucking and felling cuts.

Notching Cut Notch cut in tree that directs

fall of tree.

Oiler Control System for oiling guide bar and

chain.

Outer Pole Retains the moveable inner pole.

Power Head Chain saw without chain and guide

bar. Also known as saw body.

Pushback (Kickback, Pinch) Rapid pushback

of chain saw. Pushback may occur if chain along

top of guide bar is pinched, caught, or contacts a

foreign ohject.

Rear Handle Handle located at rear of saw

body.

Reduced Kickback Guide Bar Guide bar that

reduces chance of kickback.

Replacement Chain Chain that complies with

ANSI B175.1 when used with a specific saw. It

may not meet ANSI requirements when used with

other saws.

Saw Chain (Chain) Loop of chain having

cutting teeth for cutting wood. The motor drives

chain. The guide bar supports chain.

Spiked Bumper (Spike) Pointed teeth at front

of saw body beside guide bar. Keep spiked bumper

in contact with wood when felling or bucking. It

helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts

electrical circuit to motor of saw.

Switch Linkage This device connects switch

to trigger. It moves switch when you squeeze

trigger.

Trigger Switch Lockout Device that reduces

accidental starting of saw.

Trigger Device that turns saw on and off. Squeez-

ing trigger turns saw on. Releasing trigger turns

saw off.

Trimming (Pruning) Process of cutting limb(s)

from a living tree.

Undercut An upward cut from underside of log

or limb. This is done while in normal cutting posi-

tion and cutting with top of guide bar.

CHAIN SAW iNFORMATiON

CHAIN SAW HARDWARE

The plastic hardware bags should include the

lMlowing:

* (2) Guidebar bolts

* (2) Guidebar nuts

* (1) Phillips self tapping screw

. (1) Saw chain

* (1) Guide bar

* (1) Hand guard

* (1) Scabbard

CHAIN SAW ASSEMBLY

Assemble the chain saw before assembling the

pole.

Note: Some models are pre-assembled. Assembly

is not needed on these models.

See Stay gT_ainTension Adjustment, page I I.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

IMPORTANT: Do not clamp chain saw in

vise during assemNy.

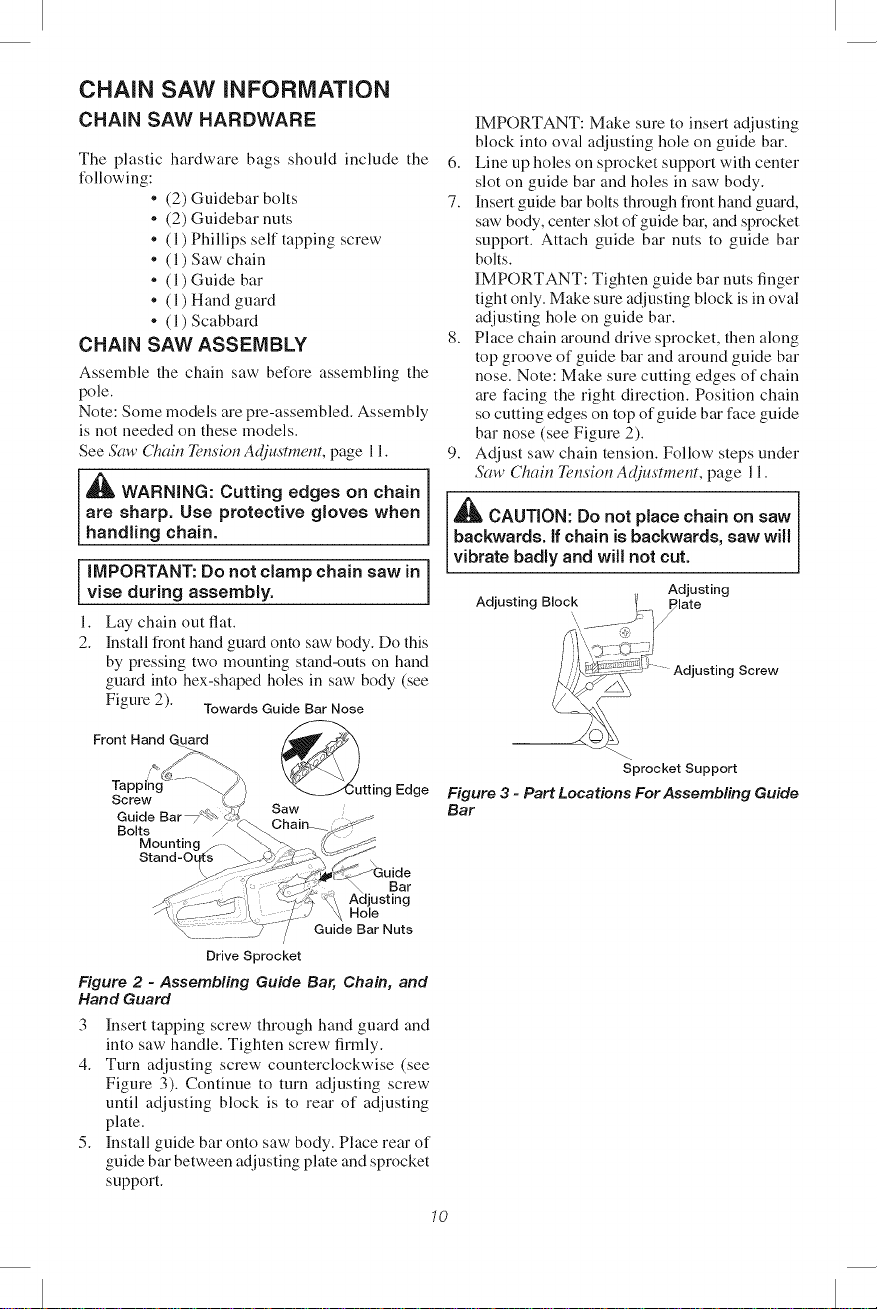

Lay chain out fiat.

2. Install fi'ont hand guard onto saw body. Do this

by pressing two mounting stand-outs on hand

guard into hex-shaped holes in saw body (see

Figure 2). Towards Guide Bar Nose

IMPORTANT: Make sure to insert adjusting

block into oval adjusting hole on guide bar.

6. Line up holes on sprocket support with center

slot on guide bar and holes in saw body.

7. Insert guide bar bolts through fi'ont hand gum'd,

saw body, center slot of guide bar, and sprocket

support. Attach guide bar nuts to guide bar

bolts.

IMPORTANT: Tighten guide bar nuts finger

tight only. Make sure adjusting block is in oval

adjusting hole on guide bar.

8. Place chain around drive sprockeL then along

top groove of guide bar and around guide bar

nose. Note: Make sure cutting edges of chain

are facing the right direction. Position chain

so cutting edges on top of guide bar face guide

bar nose (see Figure 2).

9. Adjust saw chain tension. Follow steps under

Saw Chain Tension Adjustment, page 11.

backwards. If chain is backwards, saw will

_ CAUTION: Do not place chain on saw

vibrate badly and will not cut.

Adjusting Bloc k _late

Adjusting

Screw

Front Hand C__uard

Tapping

Screw

Guide Bar /+%.

Bolts

Mounting

Stand-OI

\ ................ )

Drive Sprocket

Figure 2 - Assembling Guide Bag Chain, and

Hand Guard

3 Insert tapping screw through hand guard and

into saw handle. Tighten screw firmly.

4. Turn adjusting screw counterclockwise (see

Figure 3). Continue to turn adjusting screw

until adjusting block is to rear of adjusting

plate.

5. Install guide bar onto saw body. Place rear of

guide bar between adjusting plate and sprocket

support.

_utting Edge

Saw

Bar

Hole

Guide Bar Nuts

Sprocket Support

Figure 3 - Part Locations For Assembling Guide

Bar

10

CHAIN SAW iNFORMATiON

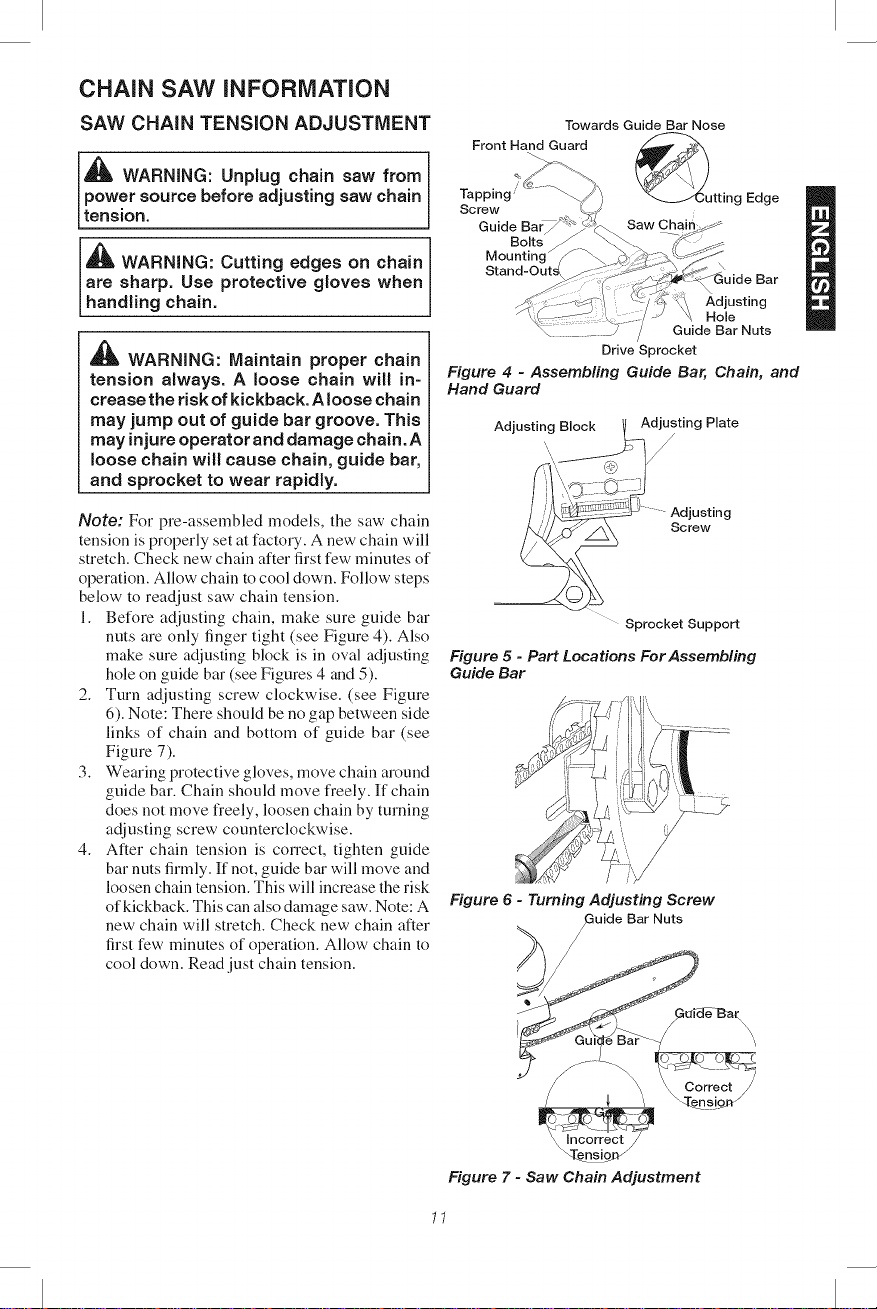

SAW CHAIN TENSION ADJUSTMENT

power source before adjusting saw chain

_ WARNING: Unptug chain saw from

tension.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

£k

WARNING: Maintain proper chain

tension always. A loose chain will in-

crease the risk of kickback. AIoose chain

may jump out of guide bar groove. This

may injure operator and damage chain. A

loose chain will cause chain, guide bar,

and sprocket to wear rapidly.

Note: For pre-assembled models, the saw chain

tension is properly set at factory. A new chain will

stretch. Check new chain after first few minutes of

operation. Allow chain to cool down. Follow steps

below to readjust saw chain tension.

1. Before adjusting chaim make sure guide bar

nuts are only finger tight (see Figure 4). Also

make sure adjusting block is in oval adjusting

hole on guide bar (see Figures 4 and 5).

2. Turn adjusting screw clockwise. (see Figure

6). Note: There should be no gap between side

links of chain and bottom of guide bar (see

Figure 7).

3. Wearing protective gloves, move chain around

guide bar. Chain should move freely. If chain

does not move freely, loosen chain by turning

adjusting screw counterclockwise.

4. After chain tension is correct, tighten guide

bar nuts firmly. If not, guide bar will move and

loosen chain tension. This will increase the risk

of kickback. This can also damage saw. Note: A

new chain will stretch. Check new chain after

first few minutes of operation. Allow chain to

cool down. Read .just chain tension.

Towards Guide Bar Nose

Front Hand, Guard _u

Tapping / tting

Screw

Bolts

Mounting j

Figure 4 = Assembling Guide Bar, Chain, and

Hand Guard

Adjusting _ ting Plate

Figure 5 - Part Locations For Assembling

Guide Bar

Figure 6 =Turning Adjusting Screw

Saw Chain

Guide Bar Nuts

Drive Sprocket

.........Adjusting

_ Screw

Sprocket Support

Guide Bar Nuts

\

Adjusting

Hole

Edge

Figure 7 - Saw Chain Adjustment

11

\ Correct

_T._0_o_/

CHAIN SAW iNFORMATiON

EXTENSION CORDS

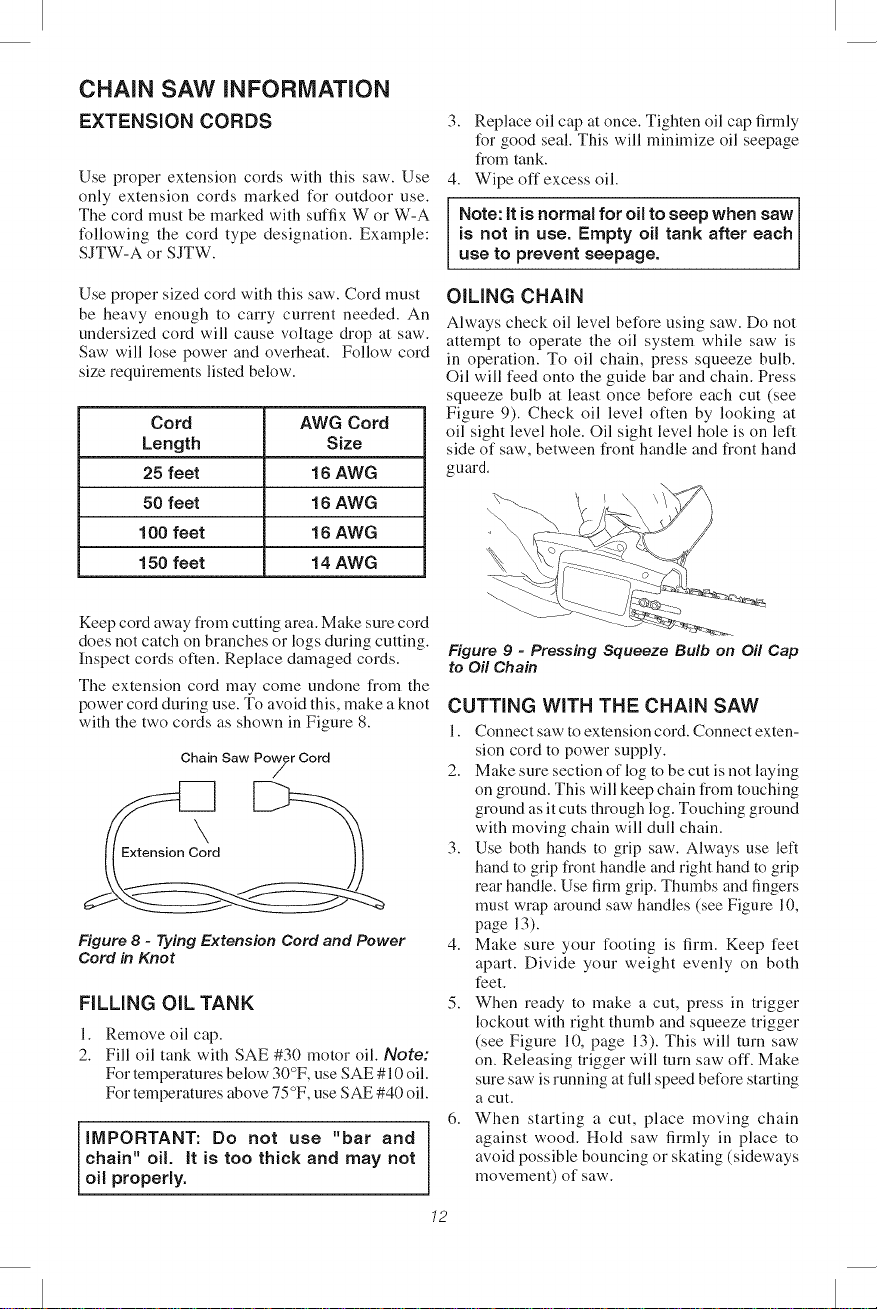

Use proper extension cords with this saw. Use

only extension cords marked for outdoor use.

The cord must be marked with suffix W or W-A

following the cord type designation. Example:

SJTW-A or SJTW.

3. Replace oil cap at once. Tighten oil cap firmly

for good seal. This will minimize oil seepage

fi'om tank.

4. Wipe off excess oil.

Note: it is normal for oil to seep when saw

is not in use. Empty oil tank after each

use to prevent seepage.

Use proper sized cord with this saw. Cord must

be heavy enough to carry current needed. An

undersized cord will cause voltage drop at saw.

Saw will lose power and overheat. Follow cord

size requirements listed below.

Cord AWG Cord

Length Size

25 feet 16 AWG

50 feet 16 AWG

100 feet 16 AWG

150 feet 14 AWG

Keep cord away from cutting area. Make sure cord

does not catch on branches or logs during cutting.

Inspect cords often. Replace damaged cords.

The extension cord may come undone fi'om the

power cord during use. To avoid this, make a knot

with the two cords as shown in Figure 8.

Chain Saw PoTr Cord

Figure 8 - Tying Extension Cord and Power

Cord in Knot

FILLING OIL TANK

1.

Remove oil cap.

2.

Fill oil tank with SAE #30 motor oil. Note:

For temperatures below 30°F, use SAE # I 0 oil.

For temperatures above 75°F, use SAE #40 oil.

IMPORTANT: Do not use "bar and

chain" oil. R is too thick and may not

oil properly.

OiLiNG CHAIN

Always check oil level before using saw. Do not

attempt to operate the oil system while saw is

in operation. To oil chain, press squeeze bulb.

Oil will feed onto the guide bar and chain. Press

squeeze bulb at least once before each cut (see

Figure 9). Check oil level often by looking at

oil sight level hole. Oil sight level hole is on left

side of saw, between front handle and front hand

guard,

Figure 9 - Pressing Squeeze Bulb on Oil Cap

to Oil Chain

CUTTING WiTH THE CHAIN SAW

1. Connect saw to extension cord. Connect exten-

sion cord to power supply.

2. Make sure section of log to be cut is not laying

on ground. This will keep chain fi'om touching

ground as it cuts through log. Touching ground

with moving chain will dull chain.

3. Use both hands to grip saw. Always use left

hand to grip front handle and right hand to grip

rear handle. Use firm grip. Thumbs and fingers

must wrap around saw handles (see Figure 10,

page 13).

4. Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both

feet.

5. When ready to make a cut, press in trigger

lockout with right thumb and squeeze trigger

(see Figure 10, page 13). This will turn saw

on. Releasing trigger will turn saw off. Make

sure saw is running at full speed befbre starting

a cut.

6. When starting a cut, place moving chain

against wood. Hold saw firmly in place to

avoid possible bouncing or skating (sideways

movement) of saw.

12

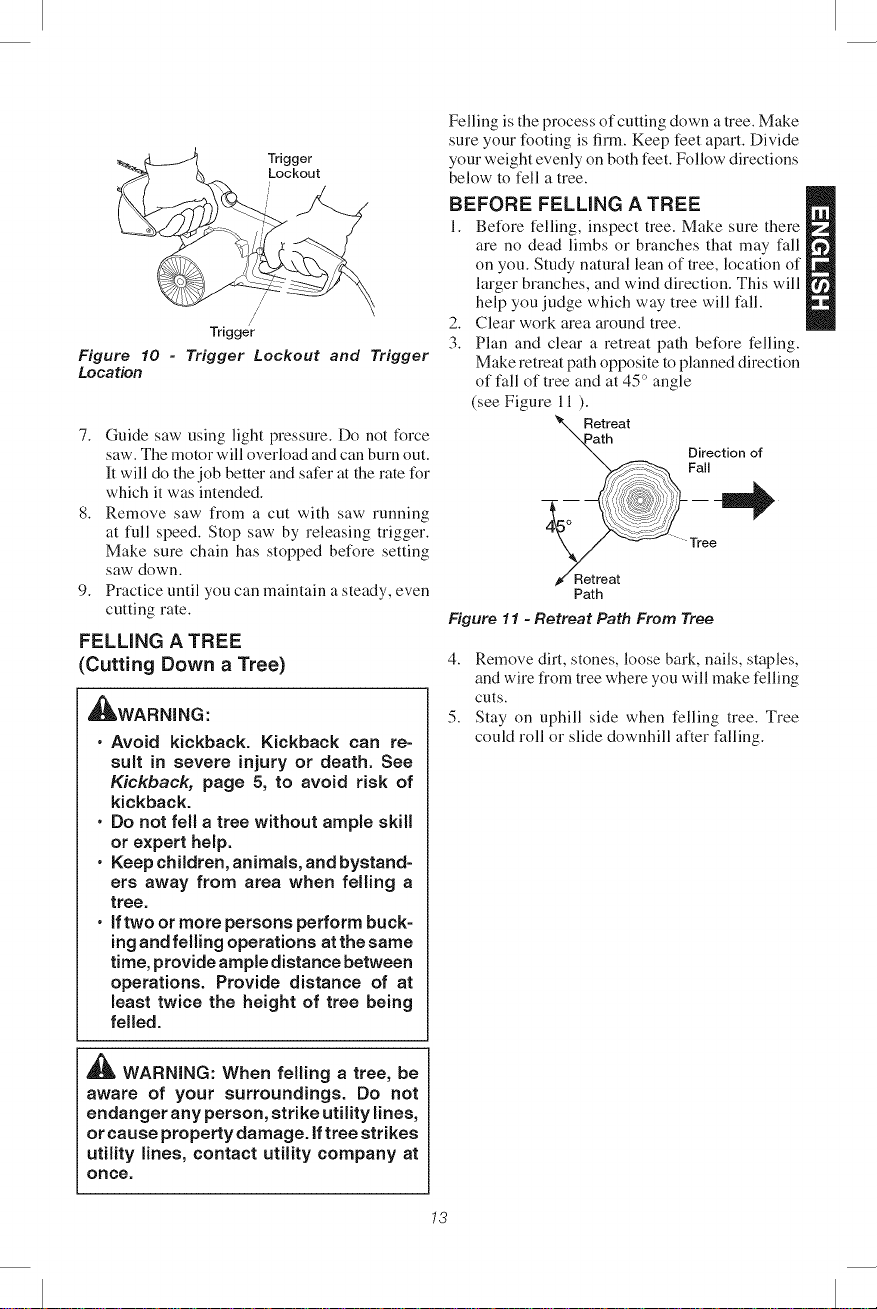

Trigger

Lockout

/

/

/

Trigge'r

Figure 10 - Trigger Lockout and Trigger

Location

7. Guide saw using light pressure. Do not %rce

saw. The motor will overload and can burn out.

It will do the job better and safer at the rate for

which it was intended.

8. Remove saw from a cut with saw running

at full speed. Stop saw by releasing trigger.

Make sure chain has stopped before setting

saw down.

9. Practice until you can maintain asteady, even

cutting rate.

FELLING A TREE

(Cutting Down a Tree)

_IbWARNING:

• Avoid kickback. Kickback can re-

sult in severe injury or death. See

Kickback, page 5, to avoid risk of

kickback.

• Do not fell a tree without ampte skill

or expert help.

• Keep children, animals, and bystand-

ers away from area when felling a

tree.

• Iftwo or more persons perform buck-

ing and felling operations at the same

time, provide ample distance between

operations. Provide distance of at

least twice the height of tree being

felled.

Felling is the process of cutting down a tree. Make

sure your footing is firm. Keep feet apart. Divide

your weight evenly on both feet. Follow directions

below to fell a tree.

BEFORE FELLING A TREE

1. Bef_)re felling, inspect tree. Make sure there

are no dead limbs or branches that may fall

on you. Study natural lean of tree, location of

larger branches, and wind direction. This will

help you judge which way tree will fall.

2. Clear work area around tree.

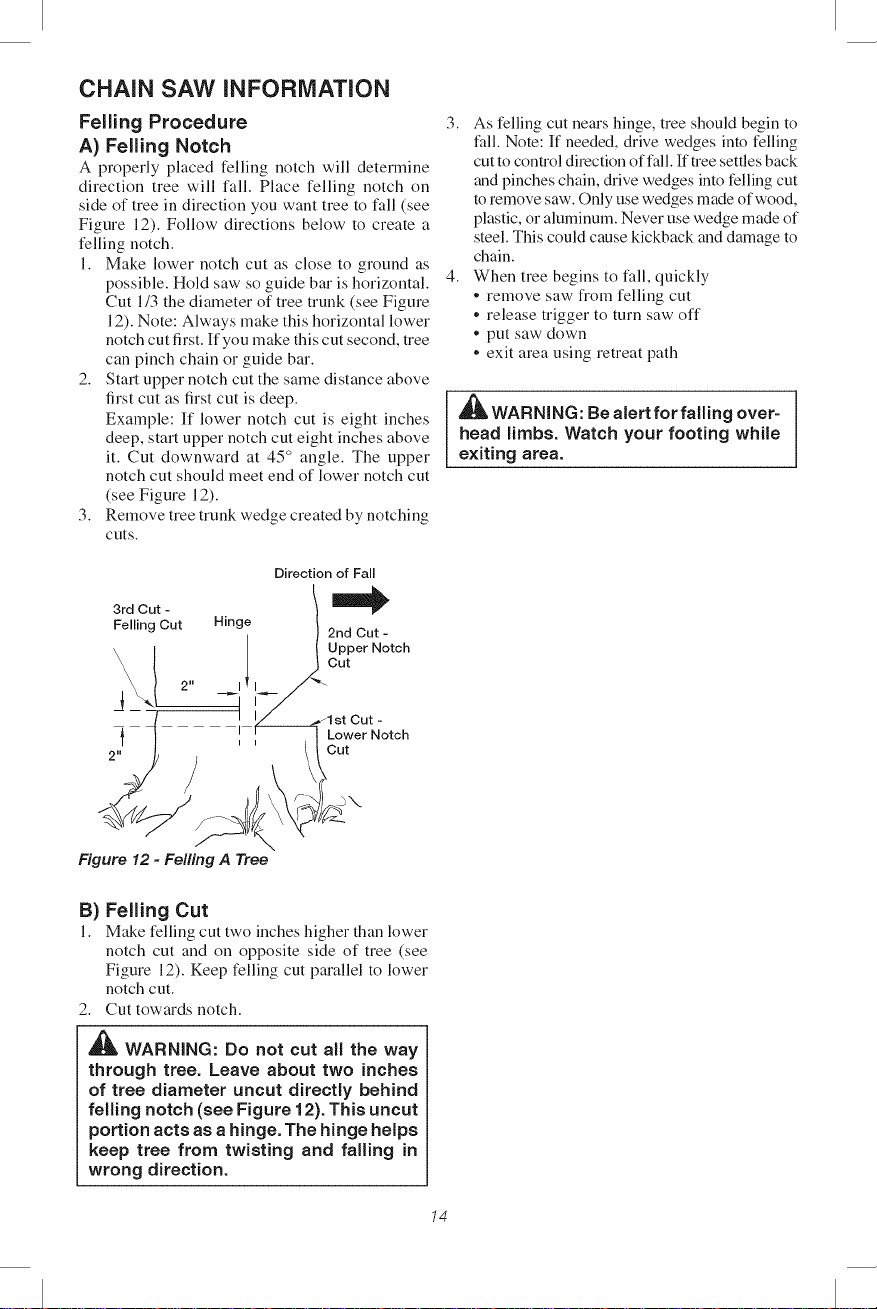

3. Plan and clear a retreat path bef_)re felling.

Make retreat path opposite to planned direction

of fall of tree and at 45° angle

(see Figure l 1 ).

etreat

th

Path

Figure 11 - Retreat Path From Tree

4. Remove dirt, stones, loose bark, nails, staples,

and wire from tree where you will make felling

cuts.

5. Stay on uphill side when felling tree. Tree

could roll or slide downhill after falling.

Direction of

Fall

WARNING: When felling a tree, be

aware of your surroundings. Do not

endanger any person, strike utility lines,

or cause property damage, iftree strikes

utility lines, contact utility company at

once.

13

CHAIN SAW iNFORMATiON

Felling Procedure

A) Felling Notch

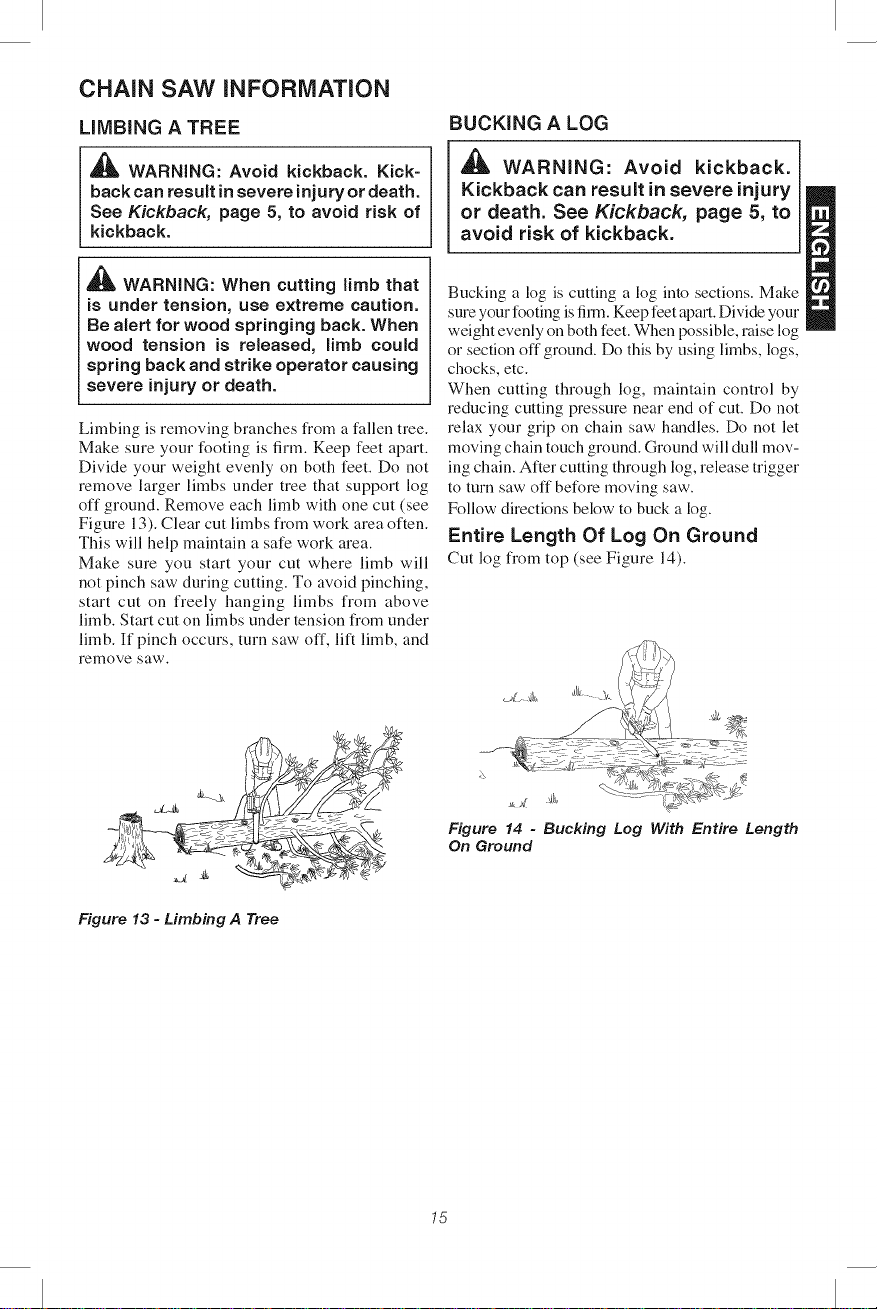

A properly placed felling notch will determine

direction tree will fall. Place felling notch on

side of tree in direction you want tree to fall (see

Figure 12). Follow directions below to create a

telling notch.

1. Make lower notch cut as close to ground as

possible. Hold saw so guide bar is horizontal.

Cut 113the diameter of tree trunk (see Figure

12).Note: Always make this horizontal lower

notch cut first. If you make this cut second, tree

can pinch chain or guide bar.

2. Start upper notch cut the same distance above

first cut as first cut is deep.

Example: If lower notch cut is eight inches

deep, start upper notch cut eight inches above

it. Cut downward at 45 ° angle. The upper

notch cut should meet end of lower notch cut

(see Figure 12).

3. Remove tree trunk wedge created by notching

cuts.

Direction of Fall

Felling Cut Hinge

_[ | Upper Notch

2" Cut

2" I

2nd Cut -

) Cut

Cut -

Lower Notch

3. As telling cut nears hinge, tree should begin to

fall. Note: If needed, drive wedges into telling

cut to control direction of fall.If tree settles back

and pinches chain, drive wedges into felling cut

to remove saw.Only use wedges made of wood,

plastic, or aluminum. Never use wedge made of

steel. This could cause kickback and damage to

chain.

4. When tree begins to fall, quickly

* remove saw from felling cut

* release trigger to turn saw off

* put saw down

* exit area using retreat path

£t

WAR NI NG: Be alert for falling over-

head limbs. Watch your footing while

exiting area.

Figure 12- Felling A Tree

B) Felling Cut

1. Make felling cut two inches higher than lower

notch cut and on opposite side of tree (see

Figure 12). Keep telling cut parallel to lower

notch cut.

2. Cut towards notch.

_ WARNING: Do not cut aH the way

through tree. Leave about two inches

of tree diameter uncut directly behind

felling notch (see Figure 12). This uncut

portion acts as a hinge. The hinge helps

keep tree from twisting and falling in

wrong direction.

14

CHAIN SAW iNFORMATiON

LIMBING A TREE

BUCKING A LOG

WARNING: Avoid kickback. Kick-

back can resuR in severe injury or death.

See Kickback, page 5, to avoid risk of

kickback.

_, WARNING: When cutting limb that

is under tension, use extreme caution.

Be alert for wood springing back. When

wood tension is released, limb could

spring back and strike operator causing

severe injury or death.

Limbing is removing branches fi"om a fallen tree.

Make sure your footing is firm. Keep feet apart.

Divide your weight evenly on both feet. Do not

remove larger limbs under tree that support log

off ground. Remove each limb with one cut (see

Figure 13). Clear cut limbs from work area often.

This will help maintain a safe work area.

Make sure you start your cut where limb will

not pinch saw during cutting. To avoid pinching,

start cut on freely hanging limbs from above

limb. Start cut on limbs under tension fi'om under

limb. If pinch occurs, turn saw off, lift limb, and

remove saw.

WARNING: Avoid kickback.

Kickback can result in severe injury

or death. See Kickback, page 5, to

avoid risk of kickback.

Bucking a log is cutting a log into sections. Make

sure your footing is finn. Keep feet apart. Divide your

weight evenly on both feet. When possible, raise log

or section off ground. Do this by using limbs, logs,

chocks, etc.

When cutting through log, maintain control by

reducing cutting pressure near end of cut. Do not

relax your grip on chain saw handles. Do not let

moving chain touch ground. Ground will dull mov-

ing chain. After cutting through log, release trigger

to turn saw off before moving saw.

Follow directions below to buck a log.

Entire Length Of Log On Ground

Cut log from top (see Figure 14).

Figure 13 - Limbing A Tree

Figure 14 - Bucking Log With Entire Length

On Ground

15

CHAIN SAW iNFORMATiON

WARNING:

• if on slope, make sure log will not

roll down hitL Secure log by using

wooden stakes. Drive wooden stakes

into ground on downhill side of log.

Stand on uphill side of log while cut-

ting. Log may roll after cutting.

• Never try cutting through two logs

at same time. This could increase

the risk of kickback.

• While cutting log, never hold logwith

your hand, leg, or foot.

• While cutting log, never allow an-

other person to hold log.

• Turn off and unplug saw before mov-

ing from one place to another.

Log Supported On One End

1. Make first cut on underside of log (see Figure

15). Use top of guide bar to make this cut. Cut

113through diameter of log. This cut will keep

section fl'om splintering when cut.

2. Make second cut directly above first cut. Cut

down to meet first cut. This cut will keep log

from pinching guide bar and chain.

1st Cut

Figure15 - Bucking Log WhenLogIs Supported

On One End

Log Supported On Both Ends

1. Make first cut fi'om above log (see Figure 16).

Cut 113 through diameter of log. This cut will

keep section fi'om splintering when cut.

2. Make second cut on underside of log, directly

under first cut. Use top of guide bar to make

this cut. Cut up to meet first cut. This will keep

log from pinching guide bar and chain.

TRiMMiNG A TREE (PRUNING)

WARNING:Avoid kickback. Kickback

can result in severe injury or death.

See Kickback, page 5, to avoid risk of

kickback.

_ WARNING: Do not operate pole

saw while:

• in a tree

• on a ladder or any other unstable

surface

• in any awkward position

You may lose control of pole saw caus-

ing severe injury.

_, WAR NING: Donot extend arms above

shoulders when using pole saw.

_, CAUTION: Seek professional help if

facing conditions beyond your ability.

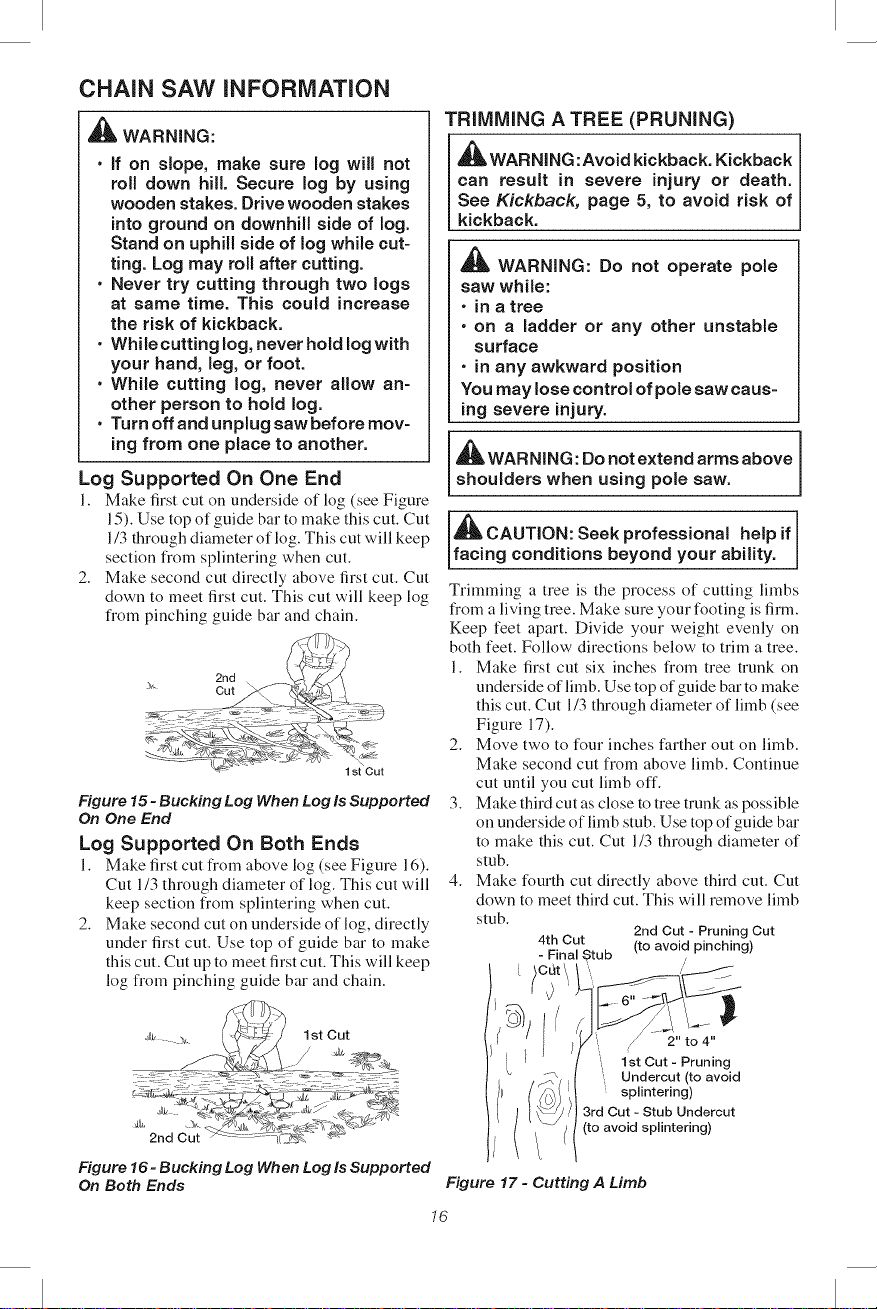

Trilnlning a tree is the process of cutting limbs

fl'om a living tree. Make sure your footing is firm.

Keep feet apart. Divide your weight evenly on

both feet. Follow directions below to trim a tree.

1. Make first cut six inches fi'om tree trunk on

underside of limb. Use top of guide bar to make

this cut. Cut 113through diameter of limb (see

Figure 17).

2. Move two to four inches farther out on limb.

Make second cut from above limb. Continue

cut until you cut limb off.

3. Make third cut as close to tree trunk as possible

on underside of limb stub. Use top of guide bar

to make this cut. Cut 113through diameter of

stub.

4. Make fburth cut directly above third cut. Cut

down to meet third cut. This will remove limb

stub.

4th Cut (to avoid pinching)

- Final Stub

2nd Cut - Pruning Cut

' /

Figure 16 - Sucking Log When Log is Supported

On Both Ends

l

Figure 17 - Cutting A Limb

16

3rd Cut - Stub Undercut

(to avoid splintering)

2" to 4"

1st Cut - Pruning

Undercut (to avoid

splintering)

POLE SAW iNFORMATiON

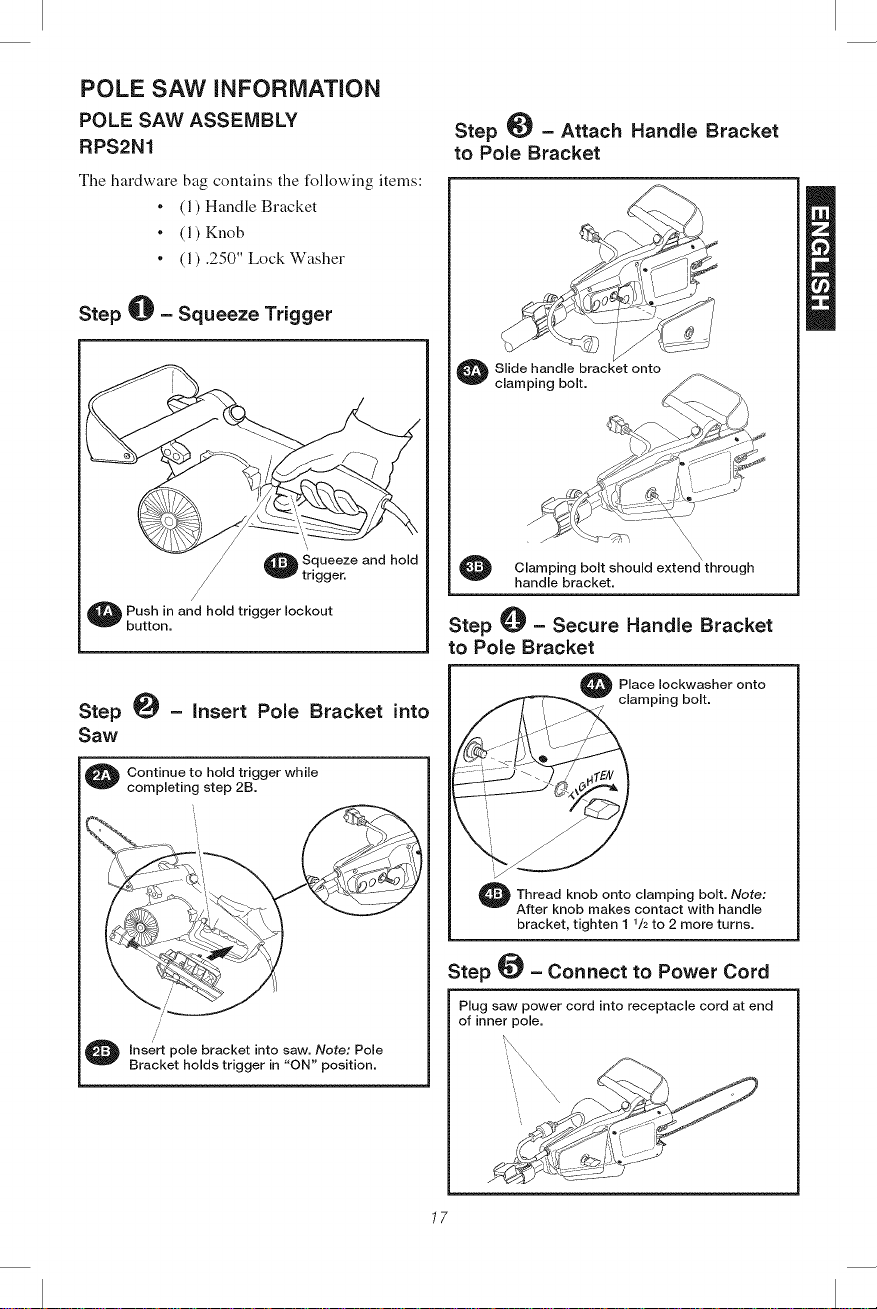

POLE SAW ASSEMBLY

RPS2N1

The hardware bag contains the following items:

* (1) Handle Bracket

* (1) Knob

* (1) .250" Lock Washer

Step O = Squeeze Trigger

Step _=7-Attach Handle Bracket

to Pole Bracket

O lide handle bracket onto

clamping bolt.

Squeeze and hold

j _ trigger.

/

Q ush in and hold trigger lockout

button.

Step _ = insert Pole Bracket into

Saw

O ontinue to hold trigger while

completing step 2B.

/'

/'

O nsert pole bracket into saw. Note: Pole

Bracket holds trigger in "ON" position.

Clamping bolt should extend through

handle bracket.

A

Step _ = Secure Handle Bracket

to Pole Bracket

Place Iockwasher onto

clamping bolt.

O Thread knob onto bolt. Note:

After knob makes contact with handle

bracket, tighten 1 1/2to 2 more turns.

clamping

Step _ = Connect to Power Cord

Plug saw power cord into receptacle cord at end

of inner pole.

\

17

POLE SAW iNFORMATiON

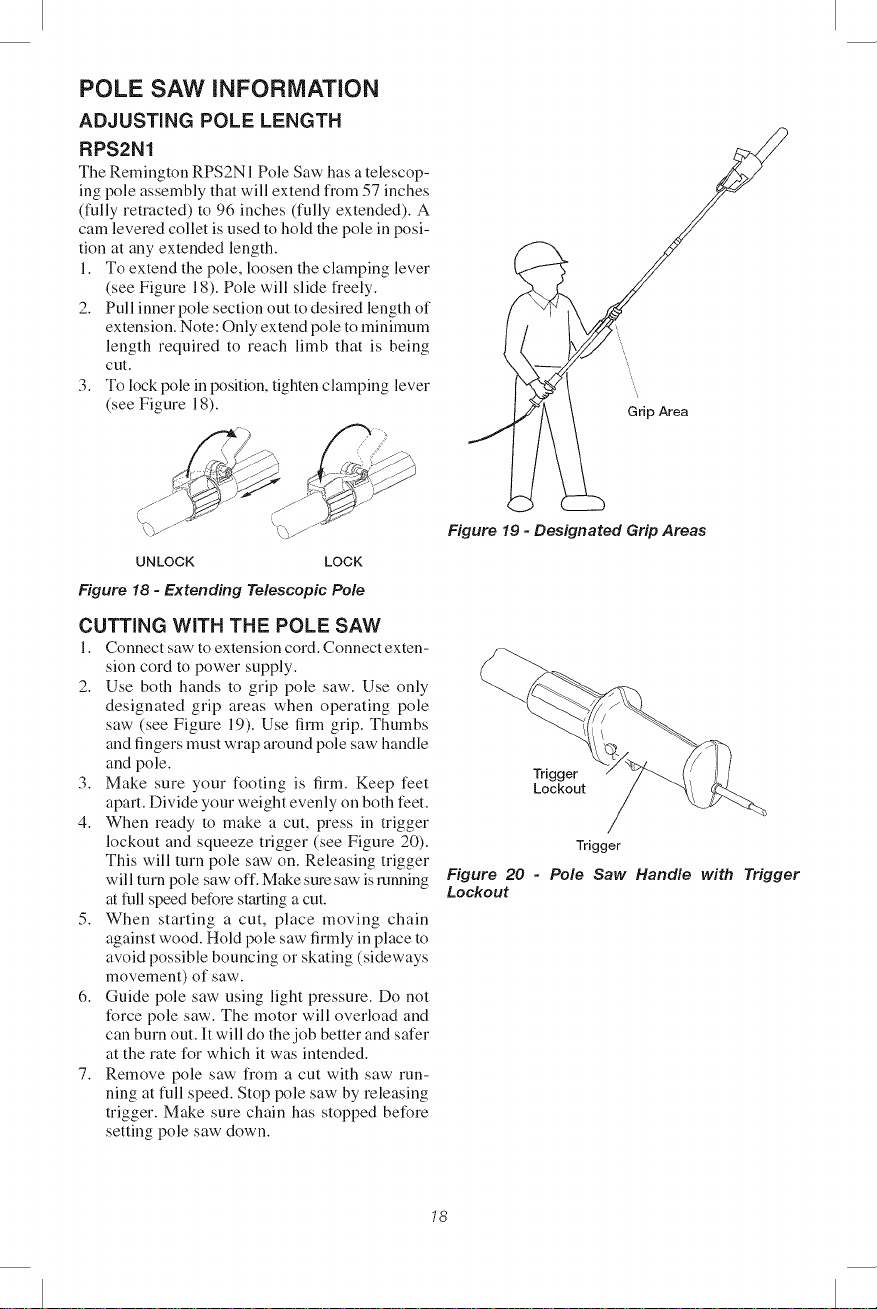

ADJUSTING POLE LENGTH

RPS2N1

The Remington RPS2N l Pole Saw has a telescop-

ing pole assembly that will extend from 57 inches

(fully retracted) to 96 inches (fully extended). A

cam levered collet is used to hold the pole in posi-

tion at any extended length.

1. To extend the pole, loosen the clamping lever

(see Figure 18). Pole will slide freely.

2. Pull inner pole section out to desired length of

extension. Note: Only extend pole to minimum

length required to reach limb that is being

cut.

3. To lock pole in position, tighten clamping lever

(see Figure 18).

\

'\

Grip Area

"% '_/

UNLOCK LOCK

Figure 18 - Extending Telescopic Pole

CUTTING WiTH THE POLE SAW

1. Connect saw to extension cord. Connect exten-

sion cord to power supply.

2. Use both hands to grip pole saw. Use only

designated grip areas when operating pole

saw (see Figure 19). Use firm grip. Thumbs

and fingers must wrap around pole saw handle

and pole.

3. Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both feet.

4. When ready to make a cut, press in trigger

lockout and squeeze trigger (see Figure 20).

This will turn pole saw on. Releasing trigger

will turn pole saw off. Make sure saw is running

at full speed before stm'ting a cut.

5. When starting a cut, place moving chain

against wood. Hold pole saw firmly in place to

avoid possible bouncing or skating (sideways

movement) of saw.

6. Guide pole saw using light pressure. Do not

force pole saw. The motor will overload and

can burn out. It will do the job better and safer

at the rate for which it was intended.

7. Remove pole saw from a cut with saw run-

ning at full speed. Stop pole saw by releasing

trigger. Make sure chain has stopped beh_re

setting pole saw down.

Figure 19 - Designated Grip Areas

Trigger

Lockout

Trigger

Figure 20 - Pole Saw Handle with Trigger

Lockout

1S

CLEANING AND MAINTENANCE

NOTICE: These are instructions for ser-

vicing your chain saw. Any servicing

not mentioned should be done by an

authorized service center.

CLEANING SAW BODY

A

WARNING: Unplug chain saw from

power source before servicing. Severe

injury or death could occur from electri-

cal shock or body contact with moving

chain.

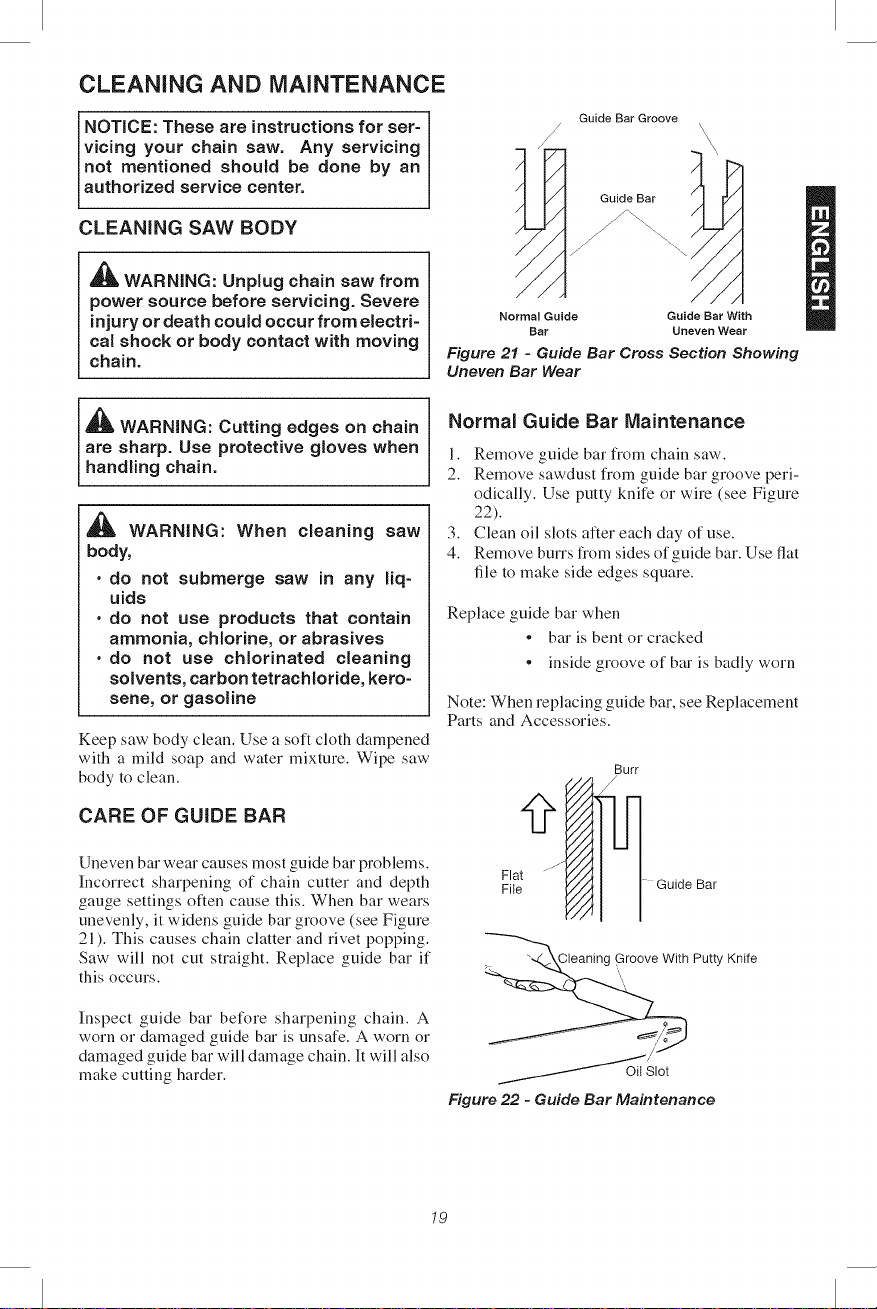

Guide Bar Groove

Guide Bar

Normal Guide Guide Bar With

Bar Uneven Wear

Figure 21 - Guide Bar Cross Section Showing

Uneven Bar Wear

A

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

WARNING: When cleaning saw

body,

• do not submerge saw in any liq-

uids

• do not use products that contain

ammonia, chlorine, or abrasives

• do not use chlorinated cleaning

solvents, carbon tetrach[oride, kero-

sene, or gasoline

Keep saw body clean. Use a soft cloth dampened

with a mild soap and water mixture. Wipe saw

body to clean.

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems.

Incorrect sharpening of chain cutter and depth

gauge settings often cause this. When bar wears

unevenly, it widens guide bar groove (see Figure

21). This causes chain clatter and rivet popping.

Saw will not cut straight. Replace guide bar if

this occurs.

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove peri-

odically. Use putty knife or wire (see Figure

22).

3. Clean oil slots after each day of use.

4. Remove burrs fl_omsides of guide bar. Use fiat

file to make side edges square.

Replace guide bar when

* bar is bent or cracked

* inside groove of bar is badly worn

Note: When replacing guide bar, see Replacement

Parts and Accessories.

Burr

/

/

Guide Bar

Putty Knife

Inspect guide bar before sharpening chain. A

worn or damaged guide bar is unsafe. A worn or

damaged guide bar will damage chain. It will also

make cutting harder.

Figure 22 - Guide Bar Maintenance

19

CLEANING AND MAINTENANCE

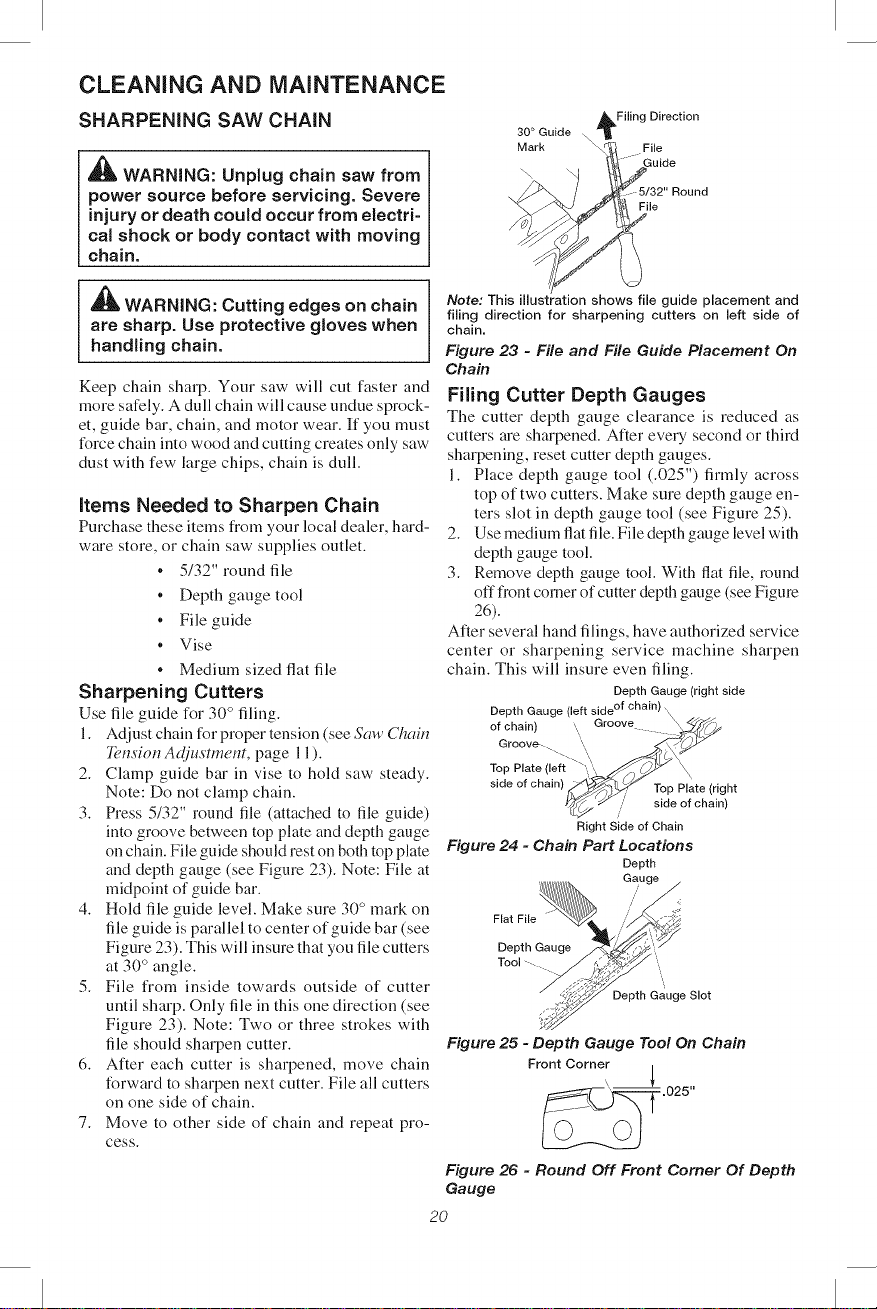

SHARPENING SAW CHAIN

A

_l, WARNING: Unplug chain saw from

power source before servicing. Severe

injury or death could occur from electri-

cal shock or body contact with moving

chain.

30° Guide \ _l_l Filing

Mark _ - File

File

Direction

3uide

A

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

Keep chain sharp. Your saw will cut faster and

more safely. A dull chain will cause undue sprock-

et, guide bar, chain, and motor wear. If you must

force chain into wood and cutting creates only saw

dust with few large chips, chain is dull.

items Needed to Sharpen Chain

Purchase these items from your local dealer, hard-

ware store, or chain saw supplies outlet.

* 5/32" round file

* Depth gauge tool

* File guide

* Vise

. Medium sized flat file

Sharpening Cutters

Use file guide for 30 ° filing.

1. Adjust chain for proper tension (see Stay Clulin

Tensiotl Adjustment, page I l ).

2. Clamp guide bar in vise to hold saw steady.

Note: Do not clamp chain.

3. Press 5/32" round file (attached to file guide)

into groove between top plate and depth gauge

on chain. File guide should rest on both top plate

and depth gauge (see Figure 23). Note: File at

midpoint of guide bar.

4. Hold file guide level. Make sure 30 ° mark on

file guide is parallel to center of guide bar (see

Figure 23). This will insure that you file cutters

at 30 ° angle.

5. File trom inside towards outside of cutter

until sharp. Only file in this one direction (see

Figure 23). Note: Two or three strokes with

file should sharpen cutter.

6. After each cutter is sharpened, move chain

forward to sharpen next cutter. File all cutters

on one side of chain.

7. Move to other side of chain and repeat pro-

cess.

Note: This illustrationshows file guide placement and

filing direction for sharpening cutters on left side of

chain.

Figure 23 - File and File Guide Placement On

Chain

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as

cutters are sharpened. After every second or third

sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") firmly across

top of two cutters. Make sure depth gauge en-

ters slot in depth gauge tool (see Figure 25).

2. Use medium flat file. File depth gauge level with

depth gauge tool.

3. Remove depth gauge tool. With fiat file, round

off front comer of cutter depth gauge (see Figure

26).

After several hand filings, have authorized service

center or sharpening service machine sharpen

chain. This will insure even filing.

Depth Gauge (right side

Depth Gauge (left side °f chain)

of chain) , Groove ___/_._

o.........,,

Top Plate (left "'2S_S_'J

side of chain) _./_/)_ Top Plate (right

/_%,,' side of chain)

Right Side of Chain

Figure 24 - Chain Part Locations

Figure 25 - Depth Gauge Tool On Chain

Front Corner

i_ "025''

Figure 26 - Round Off Front Corner Of Depth

Gauge

2O

Depth

Gauge /

CLEANING AND MAINTENANCE

REPLACING SAW CHAIN

Replace chain when cutters are too worn to

sharpen or when chain breaks. Only use replace-

ment chain noted in this manual. Always include

new drive sprocket when replacing chain. This

will maintain proper driving of chain. Note: For

proper chain and drive sprocket, see Replacement

Parts and Accessories.

STORAGE

If storing saw tk)rmore than 30 days, follow steps

below:

1. Drain oil tank after each use.

2. Remove and clean guide bar and chain. Clean

guide bar and chain by soaking in petroleum

based solvent or mild soap and water mix-

ture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil. This

will prevent rust.

5. Wit_ a thin coating of oil over surface of guide

b_u'.

6. Wipe off outside of saw body. Do this with soft

cloth daml_ned with amild soap ;rod water mix-

ture.

7. Store chain saw

* in a high or locked place, out of chiMren's

math

* in a dry place

REPLACEMENT PARTS

AND ACCESSORIES

,_k WARNING: Use only replacement

parts and accessories described in this

manual. Use of other parts or accessories

could damage saw or injure operator.

For original replacement parts and accessories,

call 1-866-206-2707 (in Canada call 1-877-696-

5533) or visit www.remingtonpowertools.com.

21

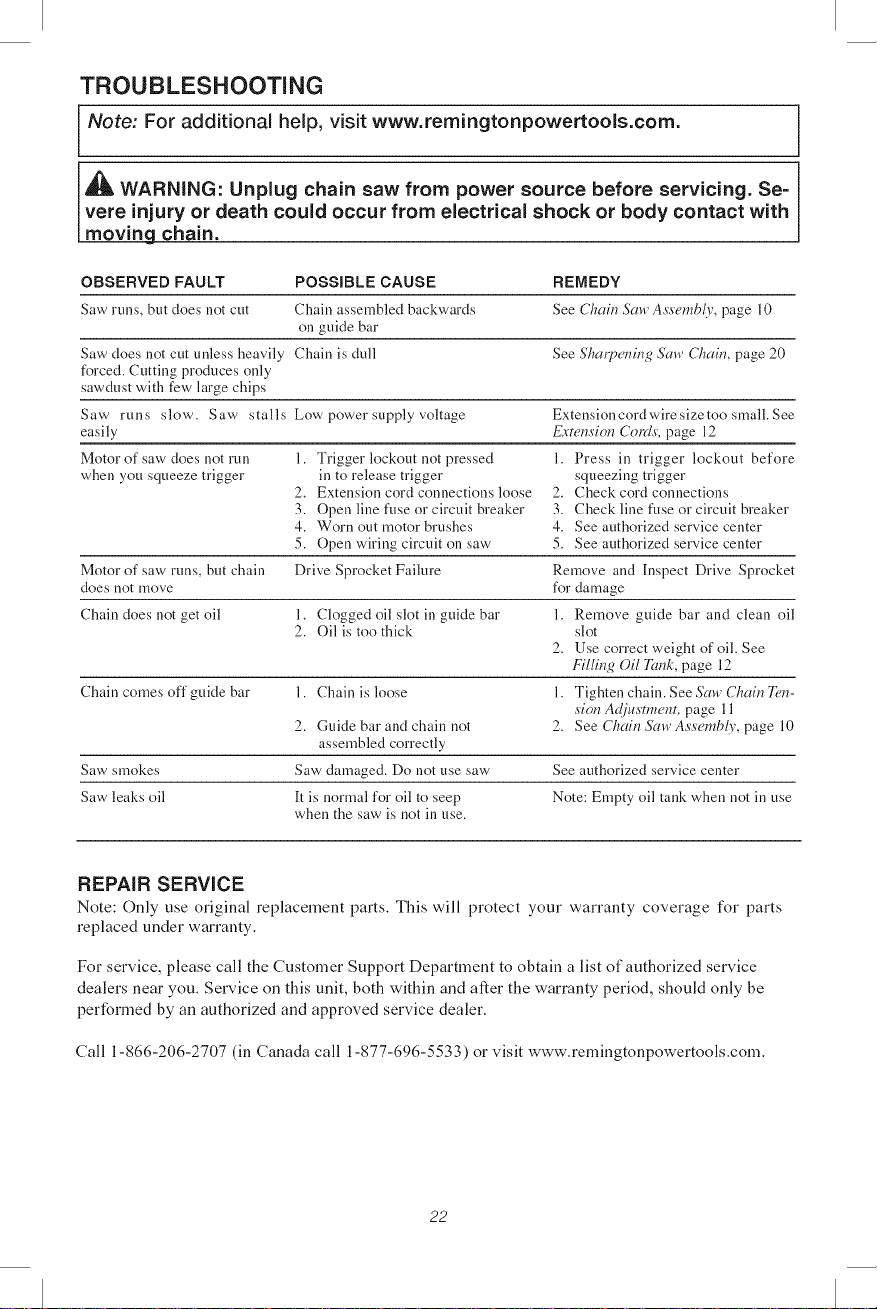

TROUBLESHOOTING

Note: For additional help, visit www.remingtonpowertools.com.

WARNING: Unplug chain saw from power source before servicing. Se-

vere injury or death could occur from electrical shock or body contact with

moving chain.

OBSERVED FAULT POSSIBLE CAUSE REMEDY

Saw runs, but does not cut Chain assembled backwaMs See Chain 3'aw A<v_'mb/y, page 10

Saw does not cut unless heavily Chain is dull See Shawening 5'awChain, page 20

forced. Cutting produces only

sawdust with few large chips

Saw runs slow. Saw stalls Low powersupplyvoltage Extensioncordwiresizetoosmall. See

easily Exr_,nsion CoMs, page 12

Motor of saw does not run

when you squeeze trigger

Motor of saw runs, but chain Drive Sprocket Failure Remove and Inspect Drive Sprocket

does not move for damage

Chain does not get oil 1. Clogged oil slot in guide bar 1. Remove guide bar and clean oil

Chain coines off guide bar 1. Chain is loose 1. Tighten chain. See Saw Chain Tg,n-

Saw smokes Saw damaged. Do not use saw See authorized service center

Saw leaks oil It is normal for oil to seep Note: Empty oil tank when not in use

on guide bar

1. Trigger lockout not pressed

in to release trigger

2. Extension cord connections loose

3. Open line fuse or circuit breaker

4. Worn out motor brushes

5. Open wiring circuit on saw

2. Oil is too thick slot

2. Guide bar and chain not 2. See Chain 5'aw Assembly, page 10

assembled correctly

when the saw is not in use.

1. Press in trigger lockout before

squeezing trigger

2. Check cord connections

3. Check line fuse or circuit breaker

4. See authorized service center

5. See authorized service center

2. Use correct weight of oil. See

Filling Oi! Tank, page 12

sion Ac!jusm_enr, page 11

REPAIR SERVICE

Note: Only use original replacement parts. This will protect your warranty coverage for parts

replaced under warranty.

For service, please call the Customer Support Department to obtain a list of authorized service

dealers near you. Seiwice on this unit, both within and alter the warranty period, should only be

perfbrmed by an authorized and approved service dealer.

Call 1-866-206-2707 (in Canada call 1-877-696-5533) or visit www.remingtonpowertools.coln.

22

WARRANTY iNFORMATiON

MANUFACTURER'S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Remington LLC ("Remington") with respect with new

merchandise purchased and used in the United States, its possessions and territories.

Remington warrants this product against defects in material and workmanship for a period of one (1)year

commencing on the date of original purchase and will, at its option, repair or replace, free of charge, any

part found to be defective in material or workmanship. This limited warranty shall only apply if this product

has been operated and maintained in accordance with the Operator's Manual furnished with the product,

and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of other peril or natural disaster. Damage

resulting from the installation or use of any accessory or attachment not approved by Remington for

use with the product(s) covered by this manual will void your warranty as to any resulting damage.

This warranty is limited to ninety (90) days from the date of original retail purchase for any Remington

product that is used for rental or commercial purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE THROUGH

YOUR LOCAL AUTHORIZED SERVICE DEALER. To locate the dealer in your area, please check for a

listing in the Yellow Pages or contact the Customer Service Department of Remington by calling 1-866-

206-2707 or writing to RO. Box 361032, Cleveland, OH 44136 or if in Canada call 1-877-696-5533. No

product returned directly to the factory will be accepted unless prior written permission has been

extended by the Customer Service Department of Remington.

This limited warranty does not provide coverage in the following cases:

A. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley, Starter Ropes,

Drive Belts

B. Remington does not extend any warranty for products sold or exported outside of the United

States of America, its possessions and territories, except those sold through Remington's

authorized channels of export distribution

Remington reserves the right to change or improve the design of any Remington Product without

assuming any obligation to modify any product previously manufactured.

No implied warranty, including any implied warranty of merchantability or fitness for a particular

purpose, applies after the applicable period of express written warranty above as to the parts as

identified. No other express warranty or guaranty, whether written or oral, except as mentioned

above, given by any person or entity, including a dealer or retailer, with respect to any product shall

bind Remington. During the period of the Warranty, the exclusive remedy is repair or replacement

of the product as set forth above. (Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole and exclusive remedy arising from

the sales. Remington shall not be liable for incidental or consequential loss or damages

including, without limitation, expenses incurred for substitute or replacement lawn care

services, for transportation or for related expenses, or for rental expenses to temporarily

replace a warranted product. (Some states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the amount of the purchase price of the product

sold. Alteration of the safety features of the product shall void this Warranty. You assume the risk and

liability for loss, damage, or injury to you and your property and/or to others and their property arising

out of the use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purchaser, original lessee or the

person for whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

To locate your nearest service dealer dial 1-866-206-2707 in the United States or 1-877-696-5533 in

Canada.

REMINGTON LLC

RO. Box 361032

Cleveland, OH 44136

23

Loading...

Loading...