Page 1

POWDER ACTUATED TOOL

MANUFACTURERS´ INSTITUTE INC.

™

REMINGTON R300

S F

®

Model R300

Operating

Instructions

IMPORTANT:

Read all instructions and warnings found in this manual

and on power load packaging before operating your

powder actuated tool. This manual should always accompany the tool and be transferred with it upon change

of ownership.

Page 2

S F

REMINGTON R300

S F

Index

Warning: Safety Precautions ............................................3-11

Why A Fastener Holds .........................................................12

Selecting Fasteners and Power Loads ................................13

Operation ....................................................................... 14-16

Parts List ..............................................................................17

Accessories .........................................................................17

Barrel Replacement .............................................................18

Troubleshooting Guide ..................................................19, 20

Application Chart ...........................................................20, 21

Replacement Parts and Accessories ...................................22

Technical Service .................................................................22

Repair Service .....................................................................22

Parts Centrals ......................................................................23

Limited Warranty .................................................................24

REMINGTON

®

Model R300

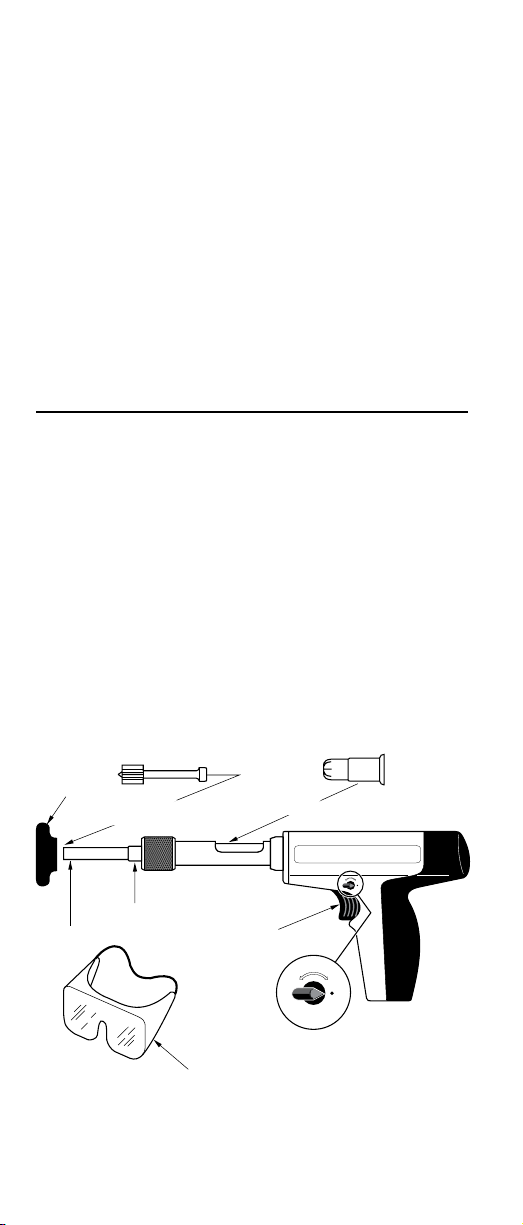

The Remington® Model R300 is designed for use with Remington® .22 caliber, Type A, neck-down crimped power loads and

Remington® Power Fasteners. Remington® Power Fasteners

are manufactured from special steel and heat treated to produce a very hard, yet ductile, fastener.

The Remington® Model R300 is equipped with two safety

devices; a safety ON/OFF switch next to the trigger and a

spring-compression muzzle that must be fully depressed for

the tool to fire.

Spall

Shield*

Power Fastener*

Barrel Assembly

Muzzle

* Not provided with tool.

Power Load*

Trigger

Safety ON/OFF

Switch

Recommended

Approved Eye

Protection*

2

119586

Page 3

Warning: Safety

?

?

S F

S F

S F

D

E

FEC

TIVE

Precautions

The following pages contain detailed warnings, cautions, and

rules of safe operation. Read carefully and become familiar

before operating to avoid serious injury. We expressly disclaim

any liability for any injury to persons or damage to property

which result from your failure to take the precautions contained

in this manual.

WARNING: This tool is designed only for use by qualified

operators. Qualification is obtained through a thorough understanding of the Safety Precautions and operating instructions

as defined in this operating manual. NOTE: The labor regulations of many states require that the operator of this tool on

a job site be thoroughly trained and certified for competence

prior to operating this tool. For certification procedures, call:

DESA Power Tools™ Technical Services Department, 1-800858-8501 (English only) or visit www.desatech.com.

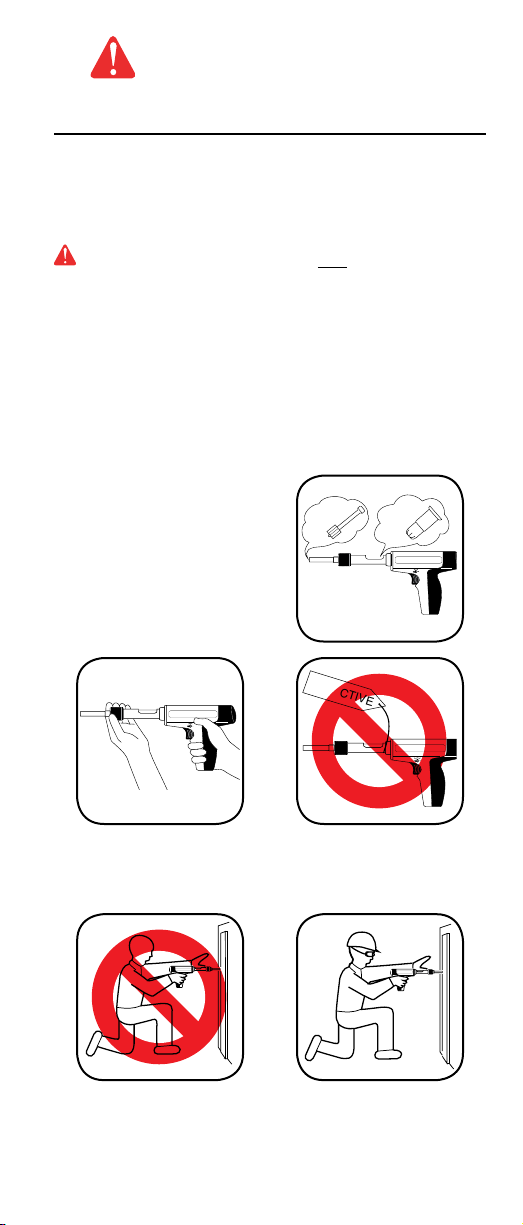

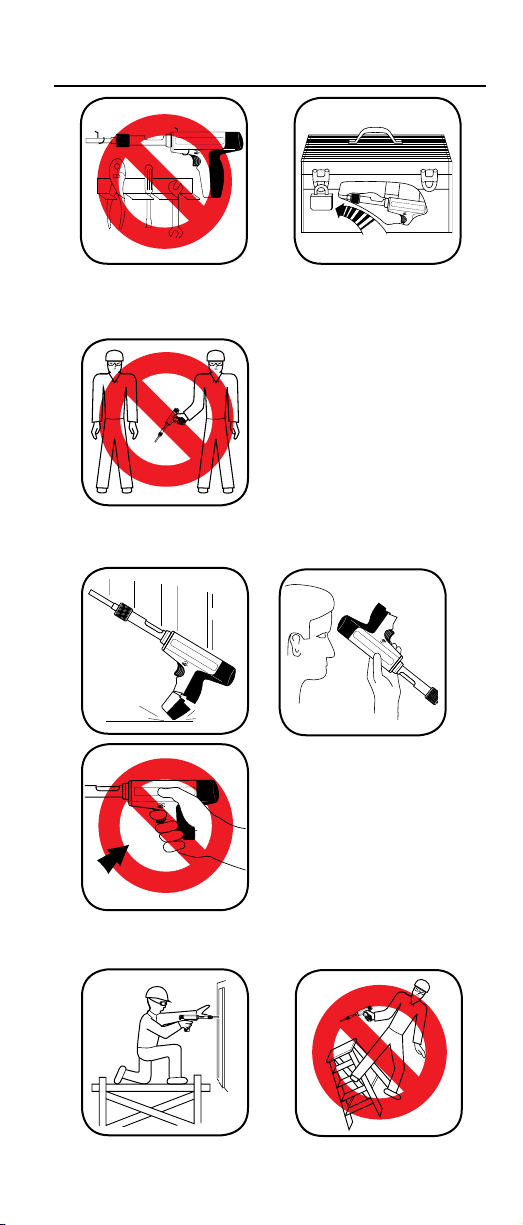

BEFORE USING

1. ALWAYS handle the tool

as if it were loaded. Before

starting work, check that

the tool is unloaded and

the muzzle is clear. NEVER

load a tool unless it is going

to be used.

2. ALWAYS

If the tool does not work properly, remove from service and

tag DEFECTIVE. DO NOT use the tool again until it has

been properly repaired.

3. Operators and bystanders must ALWAYS wear goggles

and ear protection which meet or exceed the accepted

standards for adequate protection in your country. In the

USA, refer to ANSI standards. In Canada, refer to CSA

standards.

119586

inspect to make sure the tool is working properly.

3

Page 4

S F

S F

POWDER

ACTUATED

TOOLS

IN USE

WARNING

!

S F

Safety Precautions

S

F

S F

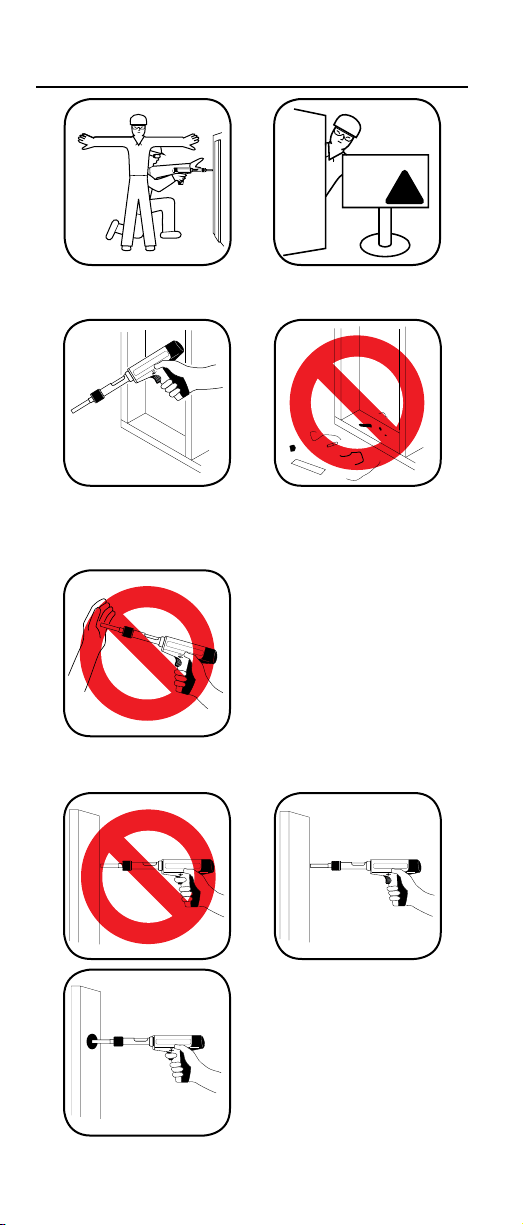

4. ALWAYS

clear the work area on all sides and post appropri-

ate warning signs on job sites.

5. ALWAYS make sure the work area is clean from loose

material and debris.

HANDLING THE TOOL

1. NEVER

place your hand over the muzzle. Accidental dis-

charge can cause serious injury.

2. NEVER place your finger on the trigger until the muzzle of

the tool is against the work surface.

4

119586

Page 5

P

O

W

E

R

L

O

A

D

S

P

O

W

E

L

O

A

D

S

F

S

F

S

F

Safety Precautions

S F

S F

S

F

S

F

3. ALWAYS

store UNLOADED powder actuated tool and

power loads in a locked container. Keep power loads of

different power levels in separate containers.

4. NEVER carry or pass a loaded powder actuated tool.

NEVER point a powder actuated tool at anyone.

5. If the tool is dropped, inspect for damage and repair it before

continuing to work. NEVER use a damaged tool.

6. ALWAYS

operating a powder actuated tool.

119586

take precautions to maintain your balance while

5

Page 6

?

?

?

?

?

?

?

CENTER

PUNCH TEST

TOO SOFT

Sinks in

with

average

hammer

blow

Start

1

GRAY

3

GREEN

4

YELLOW

2

BROWN

Safety Precautions

TOO HARD

Point

flattens

TOO BRITTLE

Surface

shatters

7. An operator taking medi-

cation should take extra

precautions while handling

the tool. NEVER drink alcoholic beverages or take

medications which impair

your vision, balance, or

judgement before using a

powder actuated tool.

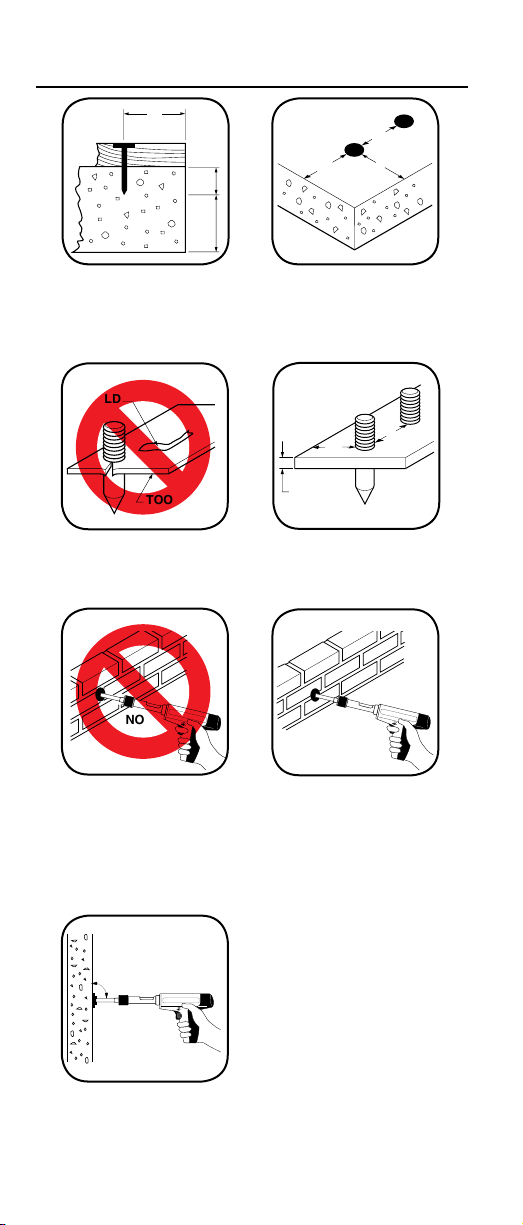

KNOW YOUR FASTENING BASE MATERIAL

1. ALWAYS know the thickness and type of base material

into which you are fastening. NEVER GUESS. Test the

base material by using the Center Punch Test. The Center

Punch Test is performed by using a hammer to test drive

the particular power fastener to be used into the material.

If the point penetrates easily, the material is too soft. If the

point becomes blunt, the material is too hard. If the material

fractures, cracks or shatters, the material is too brittle. Test

fastenings can be made if the material shows a clear power

fastener impression and the power fastener point is not

blunted. ALWAYS start with the lowest power load (Gray-

Level 1) and proceeding with the order shown in the lower

right-hand figure above. Operators and bystanders must

ALWAYS wear goggles and ear protection which meet or

exceed the accepted standards for adequate protection

in your country. In the USA, refer to ANSI standards. In

Canada, refer to CSA standards.

6

119586

Page 7

S F

Safety Precautions

S F

CAST IRON GLASS

S F

TILE

BRICK

S F

S F

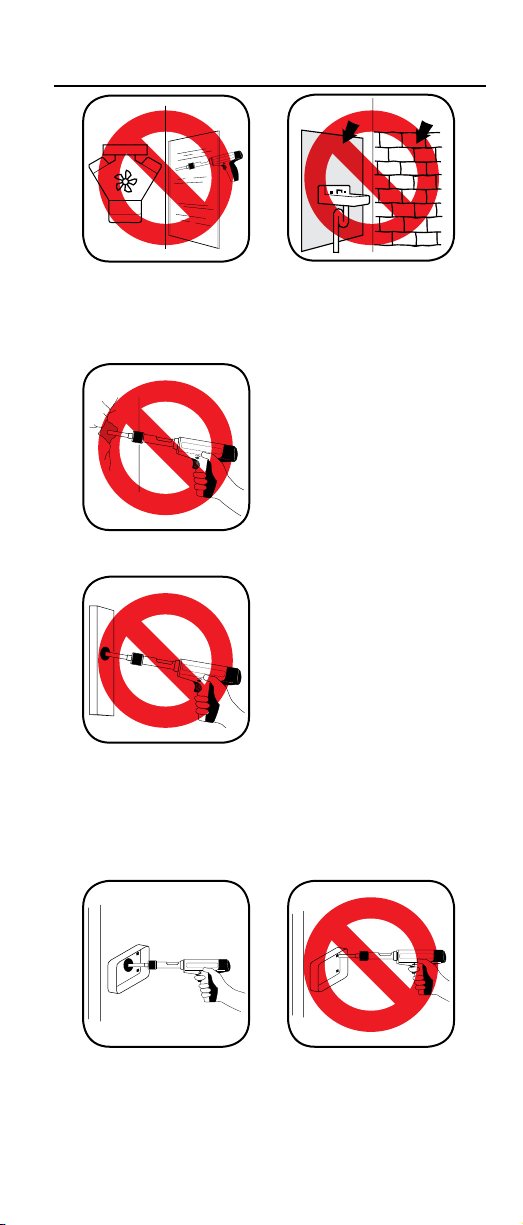

2. NEVER

attempt to drive power fasteners into very hard or

brittle materials including, but not limited to cast iron, glass,

tile, stone, brick, or hardened steel. Materials of this type

tend to shatter and create hazard from flying particles.

3. NEVER make fastenings in spalled or cracked areas.

4. NEVER drive power fasteners into thin or easily penetrated

material unless it is backed by concrete or steel. When in

doubt, such as when base material is concealed, conduct

a Center Punch Test (See page 6). Check continually to

avoid fastening into unsuitable material, especially in older

buildings.

5. DO NOT fasten through or within 1/2" of predrilled or pre-

punched holes.

119586

7

Page 8

3"

3"

3"

3"

3X

1X

3/16" MIN

1/2"

1"

YES

S

F

90˚

S F

Safety Precautions

TOO THIN

WELD

NO

S

F

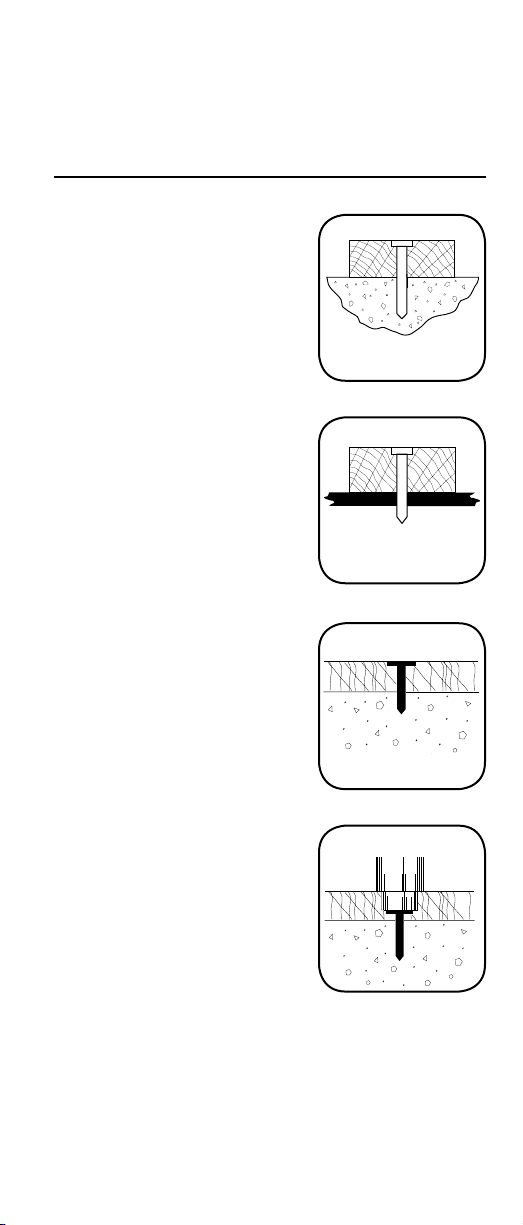

6. DO NOT drive power fasteners into concrete less than three

times as thick as the intended power fastener penetration,

within 3" of the edge, within 3" of another power fastener,

or within 3" of a failed power fastener.

7. DO NOT drive power fasteners into steel base material

less then 3/16" thick, within 2" of a weld, within 1/2" of the

edge, or within 1" of another power fastener.

8. When fastening into masonry walls, always drive into

horizontal mortar joints, NEVER into vertical mortar joints.

BE CAREFUL, a poorly laid joint may permit too much

penetration and/or unsatisfactory holding power.

OPERATING THE TOOL

1. ALWAYS hold tool perpendicular to work surface.

8

119586

Page 9

WATER

S

F

30

S F

S F

Safety Precautions

S F

GASOLINE

GAS

OLINE

POWER

LOADS

POWER

LOADS

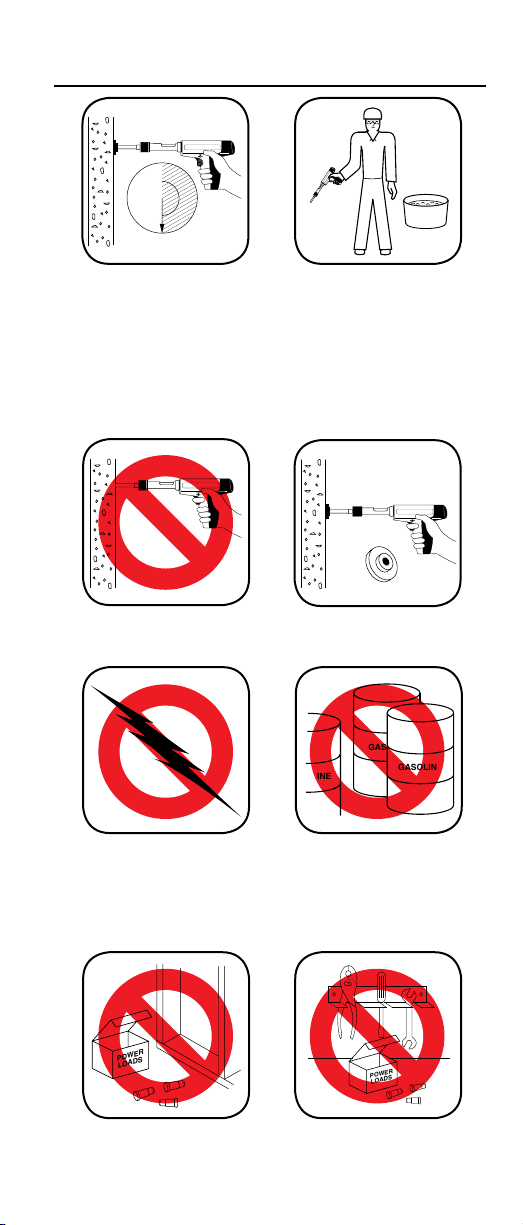

2. Should the tool fail to fire, hold the muzzle firmly against

the work surface for 30 seconds. Release the trigger and

remove pressure on the tool while holding the muzzle

against the work surface. Again press the tool firmly against

the work surface and pull the trigger. If the tool still fails to

fire, hold the tool firmly against the work surface for another

30 seconds before unloading and carefully discarding the

misfired power load into water or oil.

Spall

Shield

3. ALWAYS use the spall shield when driving directly into

concrete or steel. ALWAYS wear eye protection.

4. NEVER

use a powder actuated tool in an explosive or

flammable atmosphere or when non-sparking tools are

required.

POWER LOADS AND POWER FASTENERS

1.

NEVER leave unfired power loads on floors or work surfaces.

119586

9

Page 10

1

2

3

4

5

6

7

8

9

10

11

12

1

22

L

E

K

C

I

N

B

R

A

S

S

C

A

L

I

B

E

R

POWER

LOADS

ONLY

Start

1

GRAY

3

GREEN

4

YELLOW

2

BROWN

Safety Precautions

YELLOW?

BROWN?

GREEN?

GRAY?

POWER

LOADS

POWER

LOADS

NOTE:

Failure to start with

the lowest power level

can result in overdrive

condition and will result in damage to tool

(see page 13).

2.

Remington® Power Loads are available in four power levels with

gray (1) being the lowest power level and yellow (4) being the

highest power level. start with the lowest power level (graylevel 1) and increase until a proper fastening is made (see page

13, Selecting Power Fasteners and Power Loads).

3. NEVER use power loads in firearms.

4. NEVER carry power fasteners or other hard objects in the

same pocket or container with power loads.

5. A color blind person must take extra precautions to prevent

10

the chance of mixing the power loads of various levels.

119586

Page 11

Plastic Flute

Shank

Head

1 2

LOAD

S F

2 1

UNLOAD

S F

Safety Precautions

6. Power fasteners are a permanently installed fixture. An

act of demolition is required for their removal. Appropriate

safety precautions must be taken.

7. NEVER use common nails or other materials as fasten-

ers. Remington® Power Fasteners are manufactured from

special steel and heat treated to produce a very hard, yet

ductile, fastener.

8. NEVER pry a power load out of the chamber. Prying can

discharge the load causing serious injury (see Trouble-

shooting Guide on pages 19 and 20).

9. ALWAYS

insert the power fastener first, then the power

load. If work is interrupted for any reason, ALWAYS remove

the power load before removing the power fastener (see

page 15, item 8).

119586

11

Page 12

Why a Power

Fastener Holds

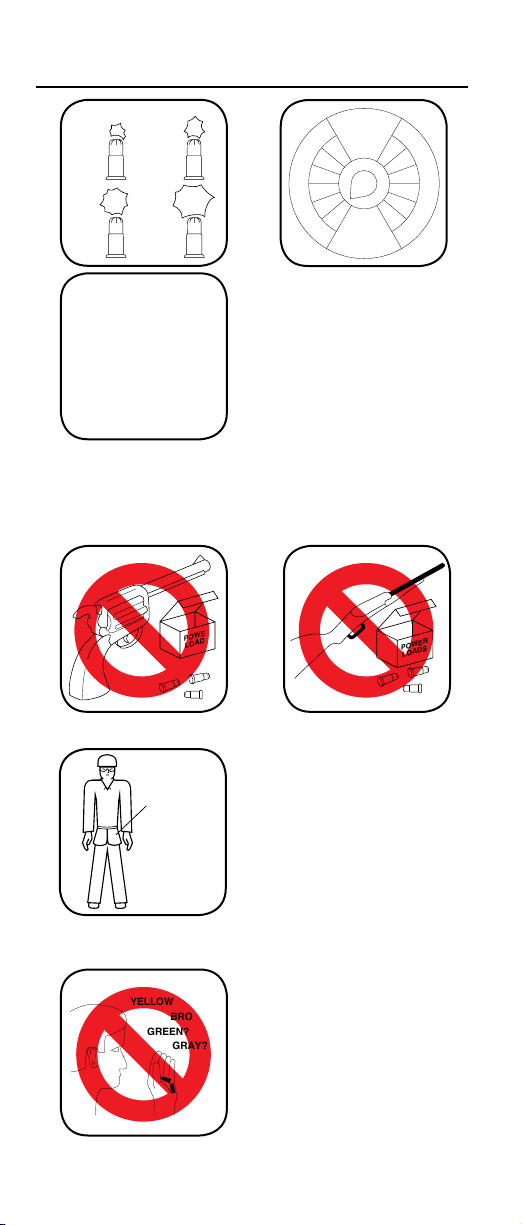

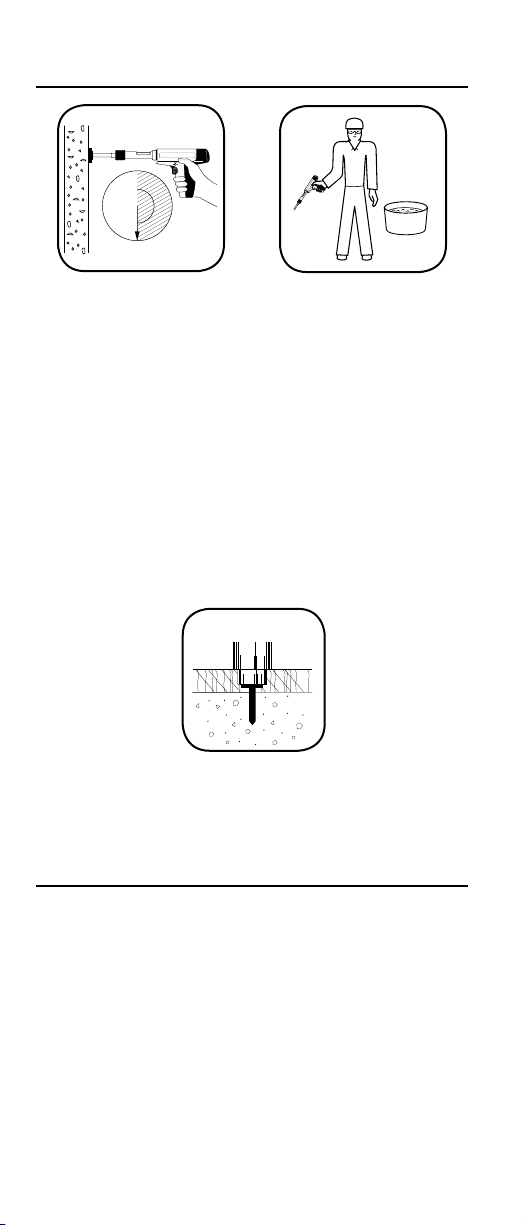

WHY A POWER FASTENER HOLDS

IN CONCRETE

The compression bond of the concrete to the power fastener accounts

for the majority of the holding power.

The power fastener displaces the concrete which tries to return to its original

form causing a squeezing effect.

Maximum holding power is achieved

when the depth of penetration produces a bond on the power fastener

equal to the strength of the concrete.

As a general rule, penetration should be approximately 1" to 1 1/4"

into the base concrete. Make sure the concrete is at least three

times as thick as the intended power fastener penetration. NEVER

have the power fastener point protrude thru the concrete.

NOTE: Concrete needs to cure for 28 days before maxi

mum fastening holding power will be achieved.

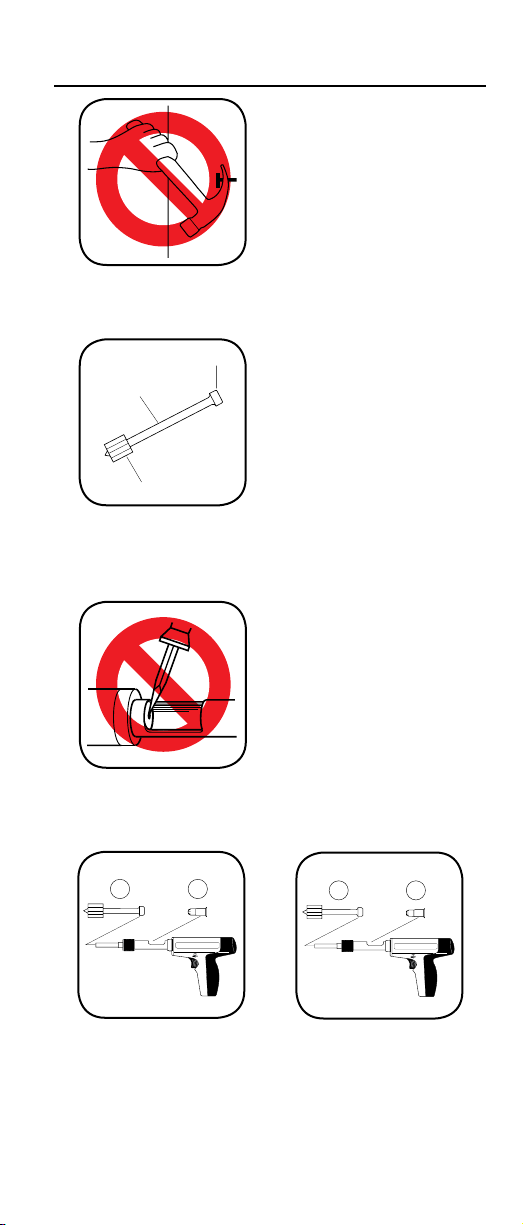

WHY A POWER FASTENER HOLDS IN STEEL

Holding power in steel depends on

the elasticity of the steel. The steel

pushes back on the shank of the

power fastener.

Drop a marble into water; the water

parts, the marble continues down,

the water closes back. This is similar

to the reaction when a power fastener penetrates steel.

In steel, the point of the power fastener must penetrate completely through for highest holding power. If the power fastener

does not penetrate, the spring action of the steel pushes back

on the point and tends to force the power fastener out.

Recommended applications are between 3/16-3/8" steel.

NOTE:

When fastening in steel be sure the point goes thru

the steel.

-

12

119586

Page 13

Selecting Power

OVERDRIVE

Fasteners and

Power Loads

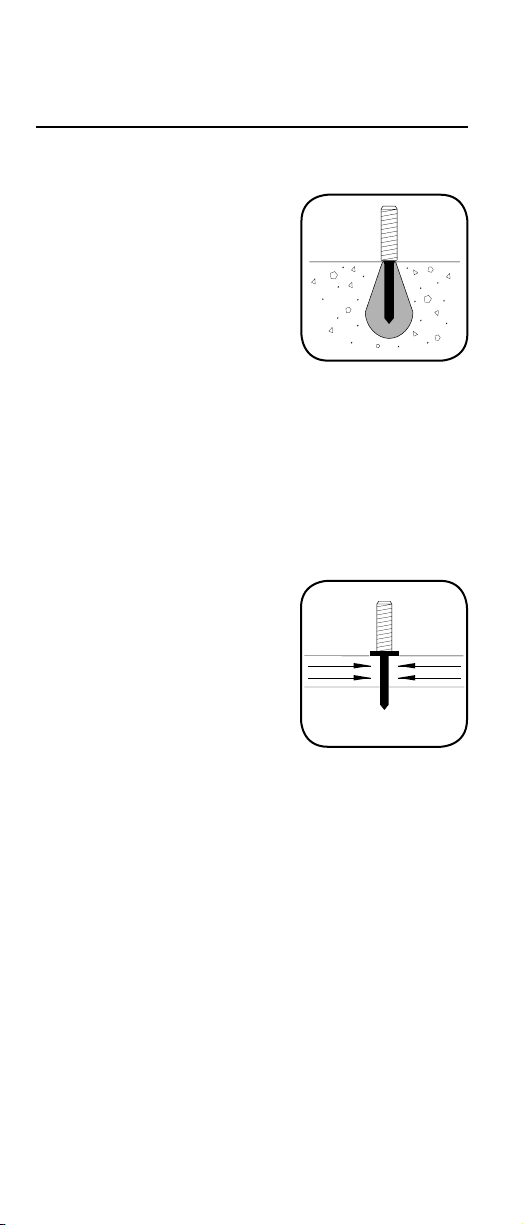

FASTENING INTO CONCRETE

The proper power fastener length

can be determined by adding the

thickness of the material to be

fastened and the amount of power

fastener that will actually penetrate

the concrete. The concrete must be

three times as thick as the intended

power fastener penetration. In most

cases, penetration should be approximately 1" to 1 1/4" into the base

concrete material.

FASTENING INTO STEEL

The proper power fastener length can

be determined by adding the thickness of the material to be fastened

and the thickness of the steel. The

point of the power fastener must go

completely through the steel.

POWER LOADS

Always start with the lowest power

level (gray-level 1). If the first test

power fastener does not penetrate to

the desired depth, move to the next

highest power level (brown-level 2).

Increase until a proper fastening is

made. IMPORTANT: Damage to the

tool will result if the above instructions are not followed (see illustrations to right and lower right).

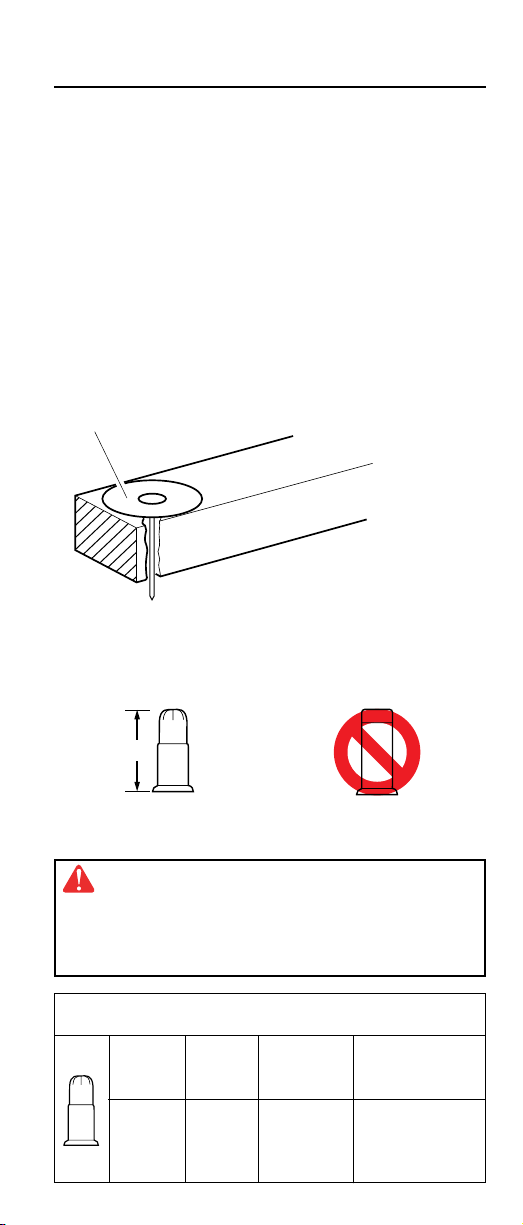

OVERDRIVEN POWER

FASTENERS AND PISTON

An overdriven power fastener results when too strong of a power

load is used causing the piston to

extend past the muzzle. Move to the

next lightest power load. Repeated

overdrive will damage your tool. By

avoiding overdrive, you can extend

the life of your tool considerably.

NOTE: NEVER

a power fastener. This can damage

the tool and/or cause possible injury

to the operator.

fire the tool without

Wood or Non-Metals

To Concrete

Wood or Non-Metals

To Steel

RIGHT

Flush With Surface

Piston Extended

Out of Muzzle

119586

13

Page 14

S F

S F

Operation

S F

Safety ON

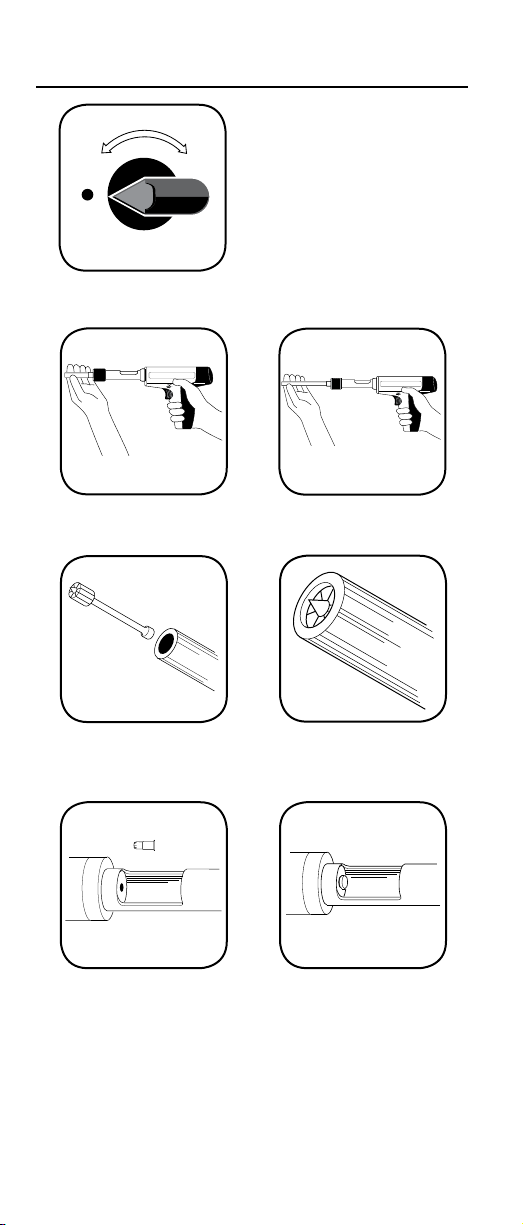

1.

ALWAYS place safety ON/OFF switch in the SAFETY ON

position before inserting power fastener and power load.

2.

Grasp muzzle and slide barrel forward rapidly until it stops.

This sets piston into firing position and opens the chamber.

3. Insert power fastener into muzzle of tool, head end first.

Push the power fastener until point is even with end of tool.

ALWAYS load the power fastener first, then the power load.

4. Select the proper Remington® Power Load (see Application

Chart on pages 20 and 21) and insert into the chamber until

it stops. NOTE: Failure to start with the lowest power level

can result in overdrive condition and will result in damage

to the tool (see page 13).

14

119586

Page 15

S F

S F

S F

S F

90˚

S F

Operation

S F

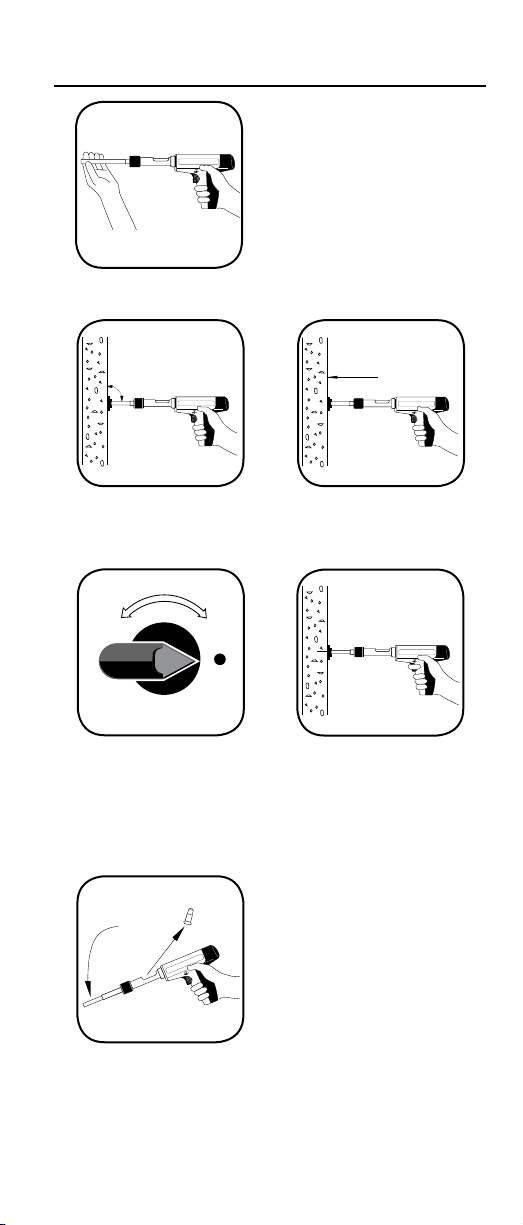

5. Push barrel into housing to the closed position.

6. Place the muzzle of tool perpendicular to work surface

without tilting the tool. Push tool against work surface until

sliding action of barrel stops.

Safety OFF

7. Before squeezing trigger, rotate safety ON/OFF switch to

the SAFETY OFF position. Squeeze trigger to set power

fastener. Be sure to keep pressure on tool during this operation.

IMPORTANT: When tool is not in use, ALWAYS rotate

safety ON/OFF switch to the SAFETY ON position.

8. After fastening is made, slide barrel forward rapidly. This

motion ejects the spent power load and resets the piston

for the next fastening. Make sure spent load has ejected

from tool.

119586

15

Page 16

Operation

WATER

S

F

30

S F

9. Should the tool fail to fire, hold the muzzle firmly against

the work surface for 30 seconds. Release the trigger and

remove pressure on the tool while holding the muzzle

against the work surface. Again press the tool firmly against

the work surface and pull the trigger. If the tool still fails to

fire, hold the tool firmly against the work surface for another

30 seconds before unloading and carefully discarding the

misfired power load into water or oil.

PISTON OVERDRIVE

If the tool does not open after firing and the piston is 1/2 inch or

more out of the muzzle:

1. Strike muzzle end of R300 against hard surface to force

piston back into muzzle.

2. Eject the power load (See step 8 of Operation).

OVERDRIVE

CARE OF YOUR R300

Clean your R300 after each day’s use. Clean chamber with

accessory wire brush, part number 056485 (Not included with

tool). Apply good quality penetrating lubricant spray (such as

WD-40) sparingly and wipe dry.

NOTE: The labor regulations of many states require that the

operator of this tool on a job site be thoroughly trained and certified for competence prior to operating this tool. For certification

procedures, call: Technical Services Department, 1-800-8588501 (English only) or visit www.desatech.com.

16

119586

Page 17

1

5

4

8

17

16

7

6

9

3

2

10

18

11

13

12

20

15

14

21

19

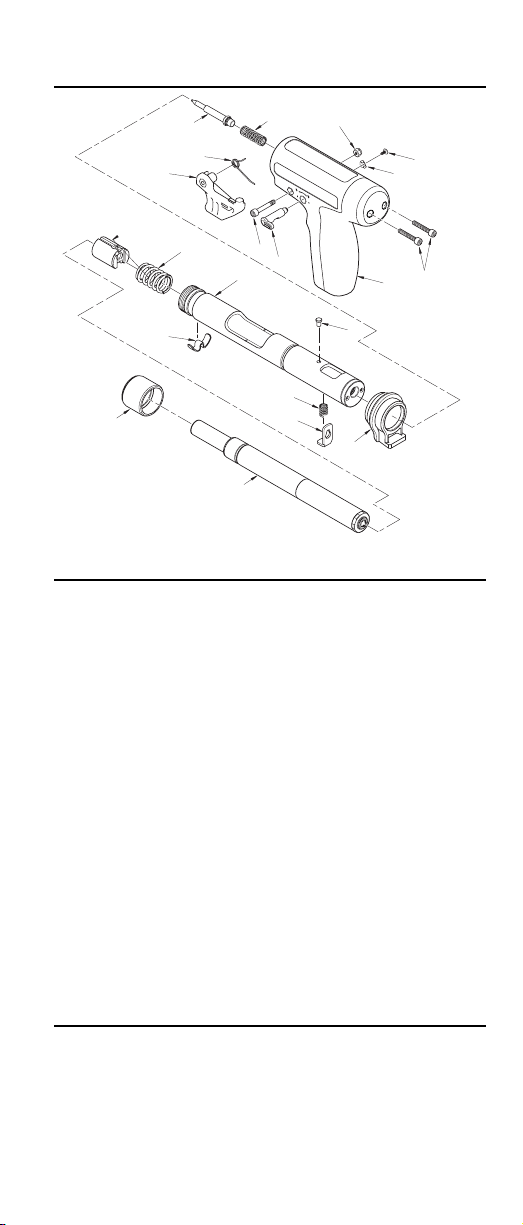

Parts List

Key

No. Part No. Description Qty.

1 300001 Handle Screw 2

2 300110 Handle 1

3 300101 Safety Switch 1

4 300103 Lock Washer 1

5 300104 Safety Switch Screw 1

6 300105 Trigger 1

7 300106 Trigger Spring 1

8 300107 Trigger Lock Nut 1

9 300108 Trigger Screw 1

10 300201 Receiver Stop 1

11 300210 Receiver 1

12 479601 Breech 1

13 479602 Breech Spring 1

14 479603 Sear 1

15 250604 Sear Spring 1

16 479605 Firing Pin 1

17 479606 Firing Pin Spring 1

18 479607 Pin Stip 1

19 479300 Barrel Assembly 1

20 479205 Tang 1

21 300010 Tang Cap Screw 1

ACCESSORIES

Part No. Description

101320-01 Spall Sheild

056415 Goggles

056485 Brush, 1/4"

056486 Brush, 5/8"

501801 Hex Wrench, 3mm

IMPORTANT: Do not use key numbers when ordering service

parts. Always order components by part number and description. Include Model and Serial numbers.

119586

17

Page 18

Barrel Replacement

B

E

S F

DB

B

G

S F

B

D

S F

A

F

B

C

A

S F

B

C

WARNING: NEVER disassemble, replace barrel, clean,

or assemble a powder actuated tool while it is loaded.

1. Unscrew knurled tang nut

(A). Slide barrel assembly

(B) out and remove tang (C),

then remove barrel assembly (B) from receiver (D).

2. If tool has been overdriven, tap piston (E) on a hard surface

until the piston is pushed back into the muzzle. Inspect the

barrel assembly (B) and replace if damaged.

3. To assemble, push piston

(E) all the way into barrel

(B) using a screwdriver (G).

Slide the barrel assembly

(B) into the receiver (D).

Turn barrel (B) to line up

tang slot (F) with tang (C).

Insert tang (C) into tang slot

(F). Firmly tighten knurled

tang nut (A).

18

119586

Page 19

Troubleshooting Guide

POSSIBLE

PROBLEM

Pisto n h angs

out of muzzle.

CAUSE

Tool overdriven.

REMEDY

Tap piston on a hard

surface until piston is

pushed back into the

muzzle (see Overdriven

Fastener, below).

Overdriven fastener.

Piston jammed.

Expended load

will not extract.

Piston not properly

assembled in relation to barrel screw.

Broken piston.

Excessive power.

Overdriving of fastener (see above).

Dirty or damaged

chamber.

Broken ejector.

Remove barrel assembly. Follow instructions

for barrel replacement

(see page 18). Replace

all damaged or missing

parts.

Replace barrel assembly or take tool to your

distributor.

Change either to next

lower powder load or next

longer length fastener.

Remove barrel assembly. Follow instructions

for barrel replacement

(see page 18). Replace

other parts if damaged.

Clean chamber. If loads

will not chamber with

slip-fit or extraction difficulties continue, take

tool to your distributor.

Replace barrel assembly or take tool to your

distributor.

Re duction or

loss of power

Tool does not

completely depress.

119586

Piston not returning

to full rear position.

Worn piston ring or

broken piston.

Misassembled or

damaged breech

and firing pin parts.

19

Barrel must be snapped

to the full extended position to properly position

piston against breech.

Replace barrel assembly or take tool to your

distributor.

Remov e breech a nd

check all parts for correct

fit assembly.

Page 20

Troubleshooting Guide

PROBLEM

Tool does not

fire.

Opening and

closing of barrel or pushing

down on the

tool, etc. is not

smooth but is

rough or binds.

POSSIBLE

CAUSE

Failu r e o f t o o l

to depress completely.

Dirt build-up on

breech not allowing proper penetration of firing

pin.

Safety Switch is in

ON position

Lac k o f p r oper

cleaning.

REMEDY

See data listed under

Tool does not completely

depress, above.

Check firing pin indentation on cartridge. Clean

breech, breech face, sear

and firing pin. Replace

worn or damaged parts.

Rotate Safety Switch to

OFF position.

Inspect and clean complete tool. Replace worn

or damaged parts.

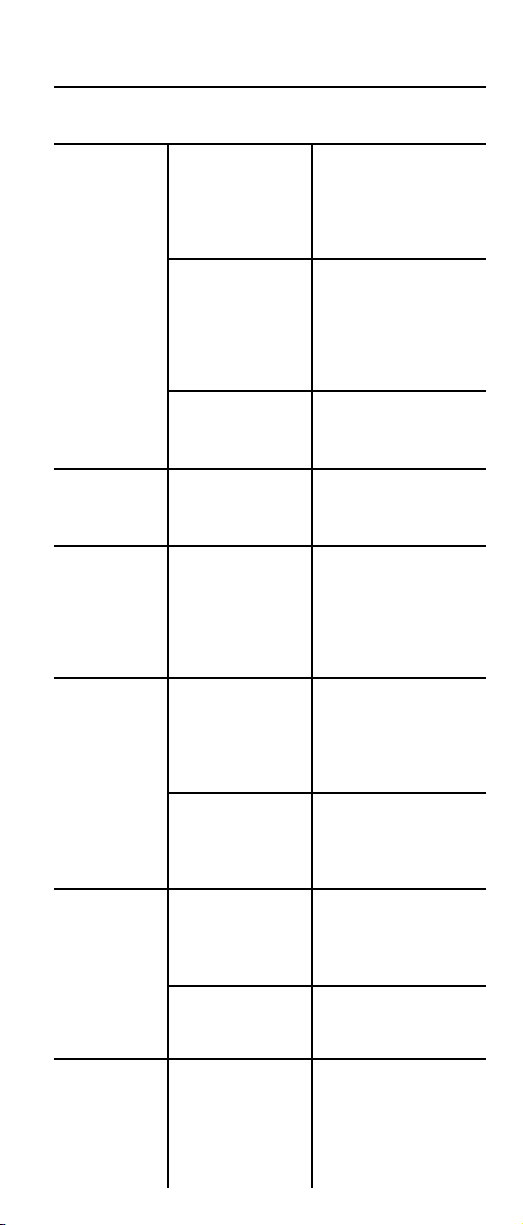

Application Chart

Power load and power fastener application information.

For fastening

this:

to this:

Power fastener

length

Power load

color

20

119586

Page 21

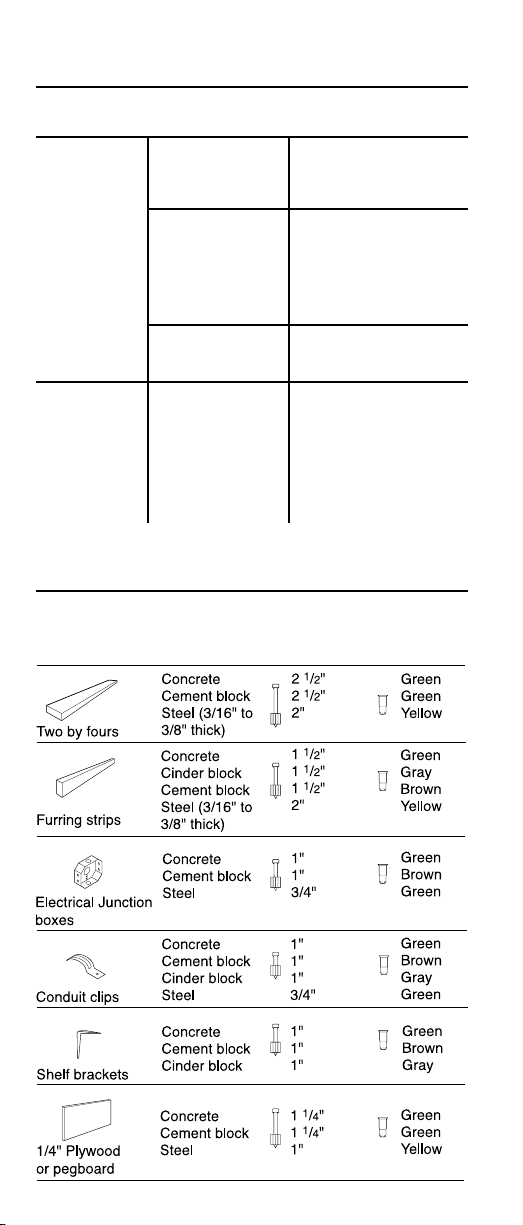

Application Chart

5/8"

Power load listings are recommendations only. If you are in

doubt, try a test fastening using the next lightest power load.

Power fasteners and power loads are available in blister packs

of 25 and cartons of 100.

IMPORTANT

• Recommended for use with Remington® power loads and

power fasteners.

• If power fastener goes below the top surface of the board,

use penetrating control disc (see illustration below) or washered SPW-type power fasteners.

• Operators and bystanders must ALWAYS wear goggles and

ear protection which meet or exceed the accepted standards

for adequate protection in your country. In the USA, refer to

ANSI standards. In Canada, refer to CSA standards.

* Use power fastener with penetration control disc, part

number 015549.

IMPORTANT

This tool is designed to use .22 caliber neck-down crimped

loads, power levels 1 (gray) through 4 (yellow).

Neck-Down Crimped

Power Load

Straight Wadded

Power Load

CAUTION: Do not use any load other

than the .22 caliber neck-down crimped load.

Other types of loads will cause load-ejection

problems.

.22 CALIBER Type A, neck-down crimp loads for powder

actuated tools

Load Color Code

Stock Level Load Case

Number Number Strength Body Head

A22C1 1 light brass Gray

A22C2 2 medium brass Brown

A22C3 3 heavy brass Green

119586

A22C4 4 extra heavy brass Yellow

21

Page 22

Replacement Parts

And Accessories

WARNING: Use only replacement parts and acces

sories described in this manual. Use of other parts or

accessories could damage tool or injure operator.

For original replacement parts and accessories, contact your

nearest Authorized Dealer or Authorized Service Center for this

product. If they can not supply the part or accessory, contact

your nearest Parts Central listed on page 23. Each Authorized

Dealer, Authorized Service Center, and Parts Central is independently owned and operated.

See page 17 for an Illustrated Parts List.

If you need additional referral information, contact our Technical

Service Department (see Technical Service).

In Canada call 1-800-561-3372 for parts information.

Technical Service

You may have further questions about assembling, operating,

or maintaining this product. If so, you can visit our Technical

Service web site at www.desatech.com or contact our Technical Service Department at 1-800-858-8501 (English Only).

You may also write to:

DESA Power Tools™

P.O. Box 90004

Bowling Green, KY 42102-9004

ATTN: Technical Service Power Tools

When contacting DESA Power Tools™, have ready

• Your Name

• Your Address

• Your Phone Number

• Model Number of Product

• Date of Purchase (Include copy of receipt for written requests).

-

Repair Service

Note: Only use original replacement parts. This will protect your

warranty coverage for parts replaced under warranty.

Each Authorized Service Center is independently owned and

operated.

WARRANTY SERVICE

If product requires warranty service, return it to nearest Authorized

Service Center. You must show proof of purchase. If faulty materials

or workmanship caused damage, we will repair or replace product

without charge. Note: Normal wear, misuse, abuse, neglect, or

accidental damage is not covered under warranty.

NON-WARRANTY SERVICE

If product requires service, return it to nearest Authorized Service

Center. Repairs will be billed to you at regular repair list prices.

For additional Service Center or warranty information, call

1-800-858-8501 (English only) or visit our Technical Service

web site at www.desatech.com.

22

119586

Page 23

Parts Centrals

Ray’s Portable Heater Service

3191 Myers Road

Camino, CA 95709-9550

530-644-7716

Tool & Equipment Service

Solutions, LLC

5 Manila Drive

Hamden, CT 06514-0322

203-248-7553

1-800-397-7553

Grainger Parts Operations

1657 Shermer Road

Northbrook, IL 60062-5362

708-498-5900

1-800-323-0620

www.grainger.com

Portable Heater Parts

342 North County Road 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-800-362-6951

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

franktalk@aol.com

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Master Part Distributors

1251 Mound Avenue NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

www.masterparts.net

Hance Distributors, Inc.

12795 16th Avenue North

Plymouth, MN 55441-4556

763-559-2299

www.hanceco.com

Automotive Equipment Service

1651 E. Kansas City Road

Olathe, MO 66061

816-531-9144

1-800-843-3546

www.aes-lawnparts.com

Bowden Electric Motor Service

1681 S. Wesleyan Blvd.

Rocky Mount, NC 27803

252-446-4203

East Coast Energy

10 East Route 36

West Long Branch, NJ 07764-1501

1-800-755-8809

Forrest Lytle and Sons, Inc.

740 West Galbraith Road

Cincinnati, OH 45231-6002

513-521-1464

Bortz Chain Saw Shop

Road #2, Box 64A

Oley, PA 19547-9412

610-987-6452

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

1-800-325-4828

La Ports

2444 N 5th Street

Hartsville, SC 29550-7704

843-332-0191

MTA Distributors

555 Hickory Hills Blvd.

Nashville, TN 37189-9244

615-299-8777

1-800-264-0225

Webbs Appliance Center

1519 Church Street

Nashville, TN 37203-3004

615-329-4079

1-800-899-4079

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324-1403

804-543-2232

1-800-788-0008

catatem@erols.com

Mills Lawn and Garden

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

www.mills-parts.com

Tuco Industrial Products

5223 180th Street SW

Suite 4A-1

Lynnwood, WA 98037-4506

425-743-9533

1-800-735-1268

www.tucoheat.com

119586

23

Page 24

Limited Warranty

DESA Power Tools™ warrants the Remington® Model R300

against defects in materials and workmanship for a period of

one (1) year (90 days for reconditioned unit) from the date of

purchase. The bill of sales or proof of purchase must be presented at the time a claim is made under this warranty.

If within one (1) year from the purchase date this Powder Actuated Tool fails due to a defect in material or workmanship,

DESA Power Tools™ will repair or replace the tool at DESA

Power Tools™ option. To obtain service under this warranty,

contact DESA Power Tools™ at the number/address listed below. You must have the Serial Number, Model Number, date of

purchase and indicate the type of problem being experienced.

DESA Power Tools™ will send replacement part(s), repair,

or replace the tool at DESA Power Tools™ option. However,

this warranty does not cover failures caused by misusing or

abusing the product (for proper use of this product, read and

understand the operating instructions in this owners manual).

Repairs made because of misuse, abuse, negligence, or accident will be charged for at regular repair prices. Power loads

and power fasteners are not covered.

This express and limited warranty is the only warranty on this

product, and to the full extent permitted by law there are no

other warranties, express or implied, including warranties of

merchantability and/or fitness for a particular purpose which extend beyond the terms of this express and limited warranty.

To the full extent permitted by law, the liability of DESA Power

Tools™ for personal injury, property damage, or any other

damage whatsoever, including consequential and incidental

damages, arising from the sale or use of this product shall not

exceed the purchase price of this product.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

In U.S.A., contact:

P.O. Box 90004

Bowling Green, KY

www.desatech.com

For Technical Assistance on Your

Remington® Powder Actuated Tool Or

For Certification Procedures, Call

Technical Services Department

1-800-858-8501 (English only)

Or Visit www.desatech.com.

42102-9004

U.S.A. ONLY

24

In Canada, contact:

82 Akron Road

Toronto, Ontario

M8W 1T2

1-800-561-3372

Fax: 1-800-561-8003

119586

Page 25

REMINGTON R300

S F

POWDER ACTUATED TOOL

MANUFACTURERS´ INSTITUTE INC.

™

®

Modelo R300

Instrucciones

de operación

IMPORTANTE:

Antes de operar su herramienta accionada con pólvora

lea las instrucciones y advertencias de este manual y las

del paquete de carga explosiva. Este manual debería

siempre acompañar a la herramienta y ser transferido

con ésta cuando haya cambio de propietario.

119586

25

Page 26

S F

REMINGTON R300

S F

El Índice

ADVERTENCIA: Precauciones de seguridad ............... 27-35

¿Porque Un Sujetador De Potencia Sostiene? ...................36

Selección de los sujetadores de potencia y

de las cargas explosivas ...................................................37

Operación ...................................................................... 38-40

Lista de partes .....................................................................41

Accesorios ...........................................................................41

Reemplazo del cañón ..........................................................42

Guia de Investigacion de Averias ..................................43, 44

Tabla de utilización ........................................................44, 45

Accesorios y piezas de repuesto .........................................46

Servicio Técnico ..................................................................46

Servicio de Reparación .......................................................46

Centros de repuestos ..........................................................47

Garantía Limitada ................................................................48

REMINGTON

®

Modelo R300

La Remington® Modelo R300 está diseñada para usarse con

cargas explosivas Remington® calibre .22 encapsuladas de

cuello bajo tipo A y con los sujetadores de potencia Remington®

no mayores de 2 1/2 pulgadas o sujetadores de potencia con

arandela no mayores de 3 pulgadas. Los sujetadores Remington® de Potencia están fabricados con un acero especial

y tienen un tratamiento térmico lo cual produce sujetadores

muy duros y a la vez dúctiles.

La Remington® Modelo R300 está equipada con dos dispositivos de seguridad. Un interruptor de seguridad ON/OFF

(ENCENDIDO/APAGADO junto al gatillo y una boca de cañón

de compresión por resorte que debe presionarse totalmente

para que la herramienta dispare.

Escudo

contra

esquirlas*

Sujetador de potencia*

Conjunto

Boca del

cañón

*No se provee con la herramienta.

cañón

Protección visual

aprobada y recomendada*

Carga explosiva*

Gatillo

Interruptor

ENCENDIDO/APAGADO

de seguridad

26

119586

Page 27

?

?

S F

S F

S F

D

E

FEC

TIVE

ADVERTENCIA:

Precauciones de Seguridad

Las páginas siguientes contienen advertencias, precauciones y reglas detalladas para una operación segura. Léalas cuidadosamente

y familiarícese antes de operar para evitar lesiones graves. Renunciamos expresamente cualquier responsabilidad por cualquier lesión a personas o daño a la propiedad que resulten de su negligencia

en seguir las precauciones contenidas en este manual.

ADVERTENCIA: Esta herramienta está diseñada para ser

usada solamente por operadores calificados. La calificación se

obtiene a través de un entendimiento completo de las Precau-

ciones de Seguridad e instrucciones de operación según se

explica en este manual. NOTA: Los reglamentos de trabajo de

muchos estados exigen que antes de operar esta herramienta

en el sitio de trabajo el operador esté completamente entrenado

y acreditado como competente. Para los procedimientos de

certificación, llame al departamento de servicios técnicos de

DESA Power Tools™ al 1-800-858-8501 (Inglés solamente) o

visite la página web www.desatech.com.

ANTES DE USAR

1.

SIEMPRE maneje la herra-

mienta como si estuviera

cargada. Antes de empezar

el trabajo, revise que la herramienta esté descargada

y que la boca del cañón esté

despejada. NUNCA cargue

la herramienta a no ser que

la vaya a utilizar.

DEFECTUOSO

2. Inspeccione SIEMPRE para asegurarse que la herramien-

ta esté trabajando apropiadamente. Si la herramienta no

trabaja apropiadamente, retírela del servicio e identifíquela

como DEFECTUOSA. NO use la herramienta de nuevo

hasta que haya sido reparada apropiadamente.

3. Los operadores y los que miran deben usar SIEMPRE pro-

tección visual y auditiva iguales o mejores que lo indicado

en las normas establecidas en su país para una protección

correcta. Para Estados Unidos, vea las normas ANSI. Para

Canadá, vea las normas CSA.

119586

27

Page 28

S F

S F

S F

S

F

S F

Precauciones de Seguridad

SE TRABAJA CON

HERRAMIENTAS

ACCIONADAS

CON

PÓLVORA

ADVERTENCIA

!

4. Despeje SIEMPRE el área de trabajo en todo el contorno y

coloque en los sitios de trabajo las señales de advertencia

apropiadas.

5. SIEMPRE asegúrese que el área de trabajo esté limpia de

materiales sueltos y desechos.

MANIPULACIÓN DE LA HERRAMIENTA

1. NUNCA ponga su mano sobre la boca del cañón. Una

descarga accidental podría ocasionar una grave lesión.

2. NUNCA

coloque sus dedos en el gatillo hasta que la boca

del cañón de la herramienta esté contra la superficie de

trabajo.

28

119586

Page 29

P

O

W

E

R

L

O

A

D

S

P

O

W

E

L

O

A

D

S

F

S

F

S F

S

F

S

F

S

F

S F

Precauciones de Seguridad

3. Guarde la herramienta accionada con pólvora y las cargas

en un contenedor asegurado bajo llave. La herramienta

debe guardarse SIEMPRE DESCARGADA. Guarde las

cargas explosivas de diferente nivel de potencia en contenedores separados.

4. NUNCA lleve o pase la herramienta accionada con pólvora cuando esté cargada. NUNCA apunte la herramienta

accionada con pólvora a ninguna persona.

5. Si la herramienta se cae, inspeccione algún daño y repare

antes de continuar trabajando. NUNCA use una herramien-

ta dañada.

6. Tome SIEMPRE precauciones para mantener su equilibrio

mientras opera una herramienta accionada con pólvora.

119586

29

Page 30

?

?

?

Precauciones de Seguridad

?

?

?

?

PRUEBA DEL

PUNZÓN

Empiece

1

GRIS

3

VERDE4AMARILLO

2

MARRÓN

DEMASIADO SUAVE

Se hunde

con un

golpe

normal

de martillo

DEMASIADO DURA

La punta

se aplana

DEMASIADO

FRÁGIL

La

superficie

se destroza

7. Un opera dor que esté

tomando medicamentos

debería tomar precauciones adicionales cuando

maneje la herramienta.

Cuando vaya a usar la

herramienta accionada con

pólvora NUNCA ingiera be-

bidas alcohólicas ni tome

medicamentos que disminuyan su visión, equilibrio

o juicio.

CONOZCA EL MATERIAL DE LA BASE DE

SUJECIÓN

1. SIEMPRE conozca el espesor y el tipo del material de la base

en el cual usted va a sujetar. NUNCA ADIVINE. Pruebe el ma-

terial de la base mediante la prueba del punzón. La prueba del

punzón se realiza usando un martillo para probar la penetración

del sujetador de potencia que va a usarse en el material. Si la

punta penetra fácilmente, entonces el material es muy suave.

Si la punta se vuelve roma entonces el material es muy duro.

Si el material se fractura, se agrieta o se destroza, entonces el

material es muy frágil. La prueba de sujeción puede hacerse si el

material muestra una impresión clara del sujetador de potencia

y si la punta del sujetador de potencia no está roma. SIEMPRE

empiece con la carga explosiva más baja (gris-nivel 1) y proceda

con el orden mostrado arriba en la figura inferior derecha.

operadores y los que miran deben usar SIEMPRE protec-

ción visual y auditiva iguales o mejores que lo indicado en

las normas establecidas en su país para una protección

correcta. Para Estados Unidos, vea las normas ANSI. Para

Canadá, vea las normas CSA.

30

Los

119586

Page 31

S F

S F

HIERRO

FUNDIDO

VIDRIO

S F

S F

S F

Precauciones de Seguridad

BALDOSA

LADRILLO

2. NUNCA

trate de clavar los sujetadores de potencia en

materiales muy duros o frágiles incluidos pero no limitados

a hierro fundido, vidrio, baldosa, piedra, ladrillo o acero

endurecido. Materiales de este tipo tienden a destrozarse

y los pedazos que se desprenden generan un peligro.

3. NUNCA realice sujeciones en zonas fragmentadas o

agrietadas.

4. NUNCA

clave los sujetadores de potencia en materiales

delgados o de fácil penetración a no ser que por detrás

esté concreto o acero. Cuando tenga dudas, como es el

caso en que el material de la base esté oculto, realice la

prueba del punzón (Vea la página 30). Revise continuamente para evitar la sujeción en materiales inadecuados,

especialmente en edificios viejos.

5. NO sujete a través o en orificios de 13 mm (1/2 pulg.)

taladrados o punzonados previamente.

119586

31

Page 32

90˚

S F

NO

S

F

YES

S

F

Precauciones de Seguridad

76mm

76mm

76mm

76 mm

3X

1X

MÍNIMO 5 mm

13 mm

25 mm

DEMASIADO

DELGADO

SOLDADURA

6. NO clave los sujetadores de potencia en concreto que

tengan menos de tres veces el espesor de la penetración

proyectada del sujetador de potencia, cuando esté dentro

de 76 mm (3 pulg.) del borde, dentro de 76 mm (3 pulg.)

de otro sujetador de potencia, o dentro de 76 mm (3 pulg.)

de otro sujetador de potencia fallido.

7. NO clave los sujetadores de potencia en materiales a

base de acero que tengan menos de 5 mm (3/16 pulg.)

de espesor, o en el intervalo de 51 mm (2 pulg.) de una

suelda, o 13 mm (1/2 pulg.) del filo o 25,5 mm (1 pulg.) de

otro sujetador de potencia.

SÍ

8. Cuando sujete en paredes de hormigón, clave siempre en

las juntas horizontales de argamasa, NUNCA en las juntas

verticales. TENGA CUIDADO, una junta mal colocada

puede permitir demasiada penetración y/o un poder de

sujeción insatisfactorio.

OPERACIÓN DE LA HERRAMIENTA

1. SIEMPRE sostenga la herramienta perpendicular a la

superficie de trabajo.

32

119586

Page 33

30

S F

S F

S F

WATER

S

F

Precauciones de Seguridad

GASOLINA

GAS

OLINA

CARGAS

EXPLOSIVES

CARGAS

EXPLOSIVES

AGUA

2. Si la herramienta no dispara, sostenga firmemente la boca del

cañón por 30 segundos contra la superficie de trabajo. Suelte

el gatillo y retire la presión en la herramienta mientras sostiene

la boca del cañón contra la superficie de trabajo. Presione

firmemente de nuevo la herramienta contra la superficie de

trabajo y hale el gatillo. Si la herramienta aún no dispara, sosténgala firmemente contra la superficie de trabajo por otros 30

segundos antes de descargarla y deseche cuidadosamente

en agua o aceite las cargas explosivas fallidas.

Escudo

Contra

Esquirlas

3. Use SIEMPRE el escudo contra esquirlas cuando clave

directamente en concreto o en acero. SIEMPRE use protección visual.

4. NUNCA

use la herramienta accionada con pólvora en una

atmósfera explosiva o inflamable o cuando se requieran

herramientas que no arrojen chispas.

CARGAS EXPLOSIVAS Y SUJETADORES DE

POTENCIA

1. NUNCA deje sobre el piso o las superficies de trabajo las

cargas explosivas aún no disparadas.

119586

33

Page 34

Precauciones de Seguridad

Empiece

1

GRIS

3

VERDE4AMARILLO

2

MARRÓN

1

2

3

4

5

6

7

8

9

10

11

12

1

2

2

C

A

L

I

B

R

E

L

A

T

Ó

N

N

Í

Q

U

E

L

¡SOLAMENTE

CARGAS

EXPLOSIVAS!

CARGAS

EXPLOSIVES

CARGAS

EXPLOSIVE

S

¿AMARILLO?

¿MARRON?

¿VERDE?

¿GRIS?

NOTA:

Si usted no empieza con el nivel de potencia más

bajo puede generarse una condición de clavado

excesivo que podría dañar la herramienta (Vea la

página 37).

2. Las cargas explosivas Remington® están disponibles en

cuatro niveles de potencia siendo la gris la del nivel más

bajo de poder y la amarilla la que tiene el nivel más alto.

Empiece SIEMPRE con el nivel de poder más bajo (gris

– nivel 1) y aumente hasta que se realice una apropiada

sujeción (Vea en la página 37, Selección de los sujetadores

de potencia y de las cargas explosivas).

3. NUNCA use las cargas explosivas en armas de fuego.

4. En el mismo bolsillo o contenedor NUNCA transporte los

sujetadores de potencia u otros objetos duros con las

cargas explosivas.

5. Una persona que no distingue bien los colores debe tener

mayor precaución para evitar que se mezclen cargas explosivas que tengan diversos niveles.

34

119586

Page 35

2 1

UNLOAD

S F

1 2

LOAD

S F

Precauciones de Seguridad

6. Los sujetadores de potencia son aparatos instalados per-

manentemente. Para retirarlos se requiere una demolición.

Deben tomarse en consideración las precauciones de

seguridad apropiadas.

Cabeza

Eje

Flauta

Plástica

7. NUNCA use clavos comunes u otros materiales como su-

jetadores. Los sujetadores Remington® de Potencia están

fabricados con un acero especial y tienen un tratamiento

térmico lo cual produce sujetadores muy duros y a la vez

dúctiles.

8. NUNCA

saque una carga de la cámara usando una

palanca. Al hacer palanca puede descargarse la carga

ocasionando una lesión grave (Vea Guia de Investigacion

de Averias en las páginas 43 y 44).

CARGA

9. SIEMPRE

la carga explosiva. Si por alguna razón se interrumpe el

trabajo, SIEMPRE retire la carga explosiva antes de retirar

inserte primero el sujetador de potencia y luego

DESCARGA

el sujetador de potencia (Vea la página 39, punto 8).

119586

35

Page 36

¿Porque Un Sujetador De

Potencia Sostiene?

¿PORQUÉ UN SUJETADOR DE POTENCIA

SE SOSTIENE EN EL CONCRETO?

La adhesión por compresión del

concreto hacia el sujetador de potencia explica la mayoría del poder

de sujeción. El sujetador de potencia

desplaza al concreto el cual tiende a

volver a su forma original ocasionando un efecto de apretamiento.

El máximo poder de sujeción se

obtiene cuando la profundidad de

penetración produce una adhesión en el sujetador de potencia

igual a la resistencia del concreto. Por regla general, la penetración debería ser aproximadamente de 25 mm a 32 mm (1 a 1 1/4

pulg.) en la base de concreto. Asegúrese que el concreto sea al

menos tres veces el espesor de la penetración proyectada del

sujetador de potencia. NUNCA haga que la punta del sujetador

de potencia sobresalga del concreto.

NOTA: El concreto necesita de 28 días para fraguar para

que el sujetador alcance su poder máximo de sujeción.

¿PORQUÉ UN SUJETADOR DE POTENCIA

SE SOSTIENE EN EL ACERO?

El poder de sujeción en el acero

depende de la elasticidad del acero.

El acero presiona contra la espiga

del sujetador de potencia.

Deje caer una canica en el agua, el

agua se separa, la canica continua

bajando y el agua se cierra tras

de ella. Este ejemplo es igual a la

reacción del sujetador de potencia

cuando penetra en el acero.

Para lograr el mayor poder de sujeción, la punta del sujetador

de potencia debe penetrar completamente en el acero. Si

el sujetador de potencia no penetra la reacción del acero

presiona contra la punta y tiende a empujar al sujetador de

potencia hacia fuera.

Se recomienda usar aceros de entre 5 mm a 9.5 mm (3/16

a 3/8 pulg.)

NOTA: Cuando sujete en acero asegúrese que la punta traspase el acero.

36

119586

Page 37

Selección de los

sujetadores de potencia y

de las cargas explosivas

SUJECIÓN EN CONCRETO

La longitud apropiada del sujetador de

potencia puede determinarse añadiendo al

espesor del material a ser sujetado, la longitud del sujetador de potencia que realmente

penetra en el concreto. El espesor del

concreto debe ser tres veces la penetración

proyectada del sujetador de potencia. En la

mayoría de los casos, la penetración en el

material a base de concreto debe ser aproximadamente de 1 a 1 1/4 de pulgada.

SUJECIÓN EN ACERO

La longitud apropiada del sujetador

de potencia puede determinarse añadiendo al espesor del material a ser

sujetado, el espesor del acero. La punta

del sujetador de potencia debe traspasar

completamente el acero.

CARGAS EXPLOSIVAS

Siempre empiece con el nivel explosivo

más bajo (gris-nivel 1) Si el sujetador de

potencia de la primera prueba no penetra

la profundidad deseada, mueva al nivel

explosivo inmediato superior (marrónnivel 2). Aumente hasta obtener una

sujeción apropiada. IMPORTANTE: Un

daño en la herramienta será consecuencia de no seguir las instrucciones

anteriores (Vea las ilustraciones de la

posición correcta e incorrecta).

CLAVADO EXCESIVO DE LOS SUJETADORES

DE POTENCIA Y DEL PISTÓN

Un sujetador de potencia clavado excesivamente resulta cuando se usa una

carga explosiva muy fuerte, lo que hace

que el pistón se extienda pasando la boca

del cañón. Mueva a la carga más ligera de

potencia. Un clavado excesivo repetido

dañará a su herramienta. Si evita el clavado excesivo la vida de su herramienta

puede extenderse considerablemente.

NOTA: NUNCA dispare la herramienta sin un sujetador de potencia.

Esto puede dañar la herramienta y/o

ocasionar una posible lesión al operador.

Madera o no

metales con

concreto

Madera o no

metales con acero

CORRECTO

A ras con la

superficie

IMPULSO

EXCESIVO

Pistón extendido

fuera de la boca

del cañón

119586

37

Page 38

S F

S F

S F

Operación

Seguridad

ENCENDIDA

1. Coloque SIEMPRE el interruptor ON/OFF de seguridad en

la posición SAFETY ON antes de insertar el sujetador y la

carga explosiva.

2. Sujete la boca del cañón y deslice rápidamente el cañón

hacia adelante hasta que tope. Esto coloca al pistón en

posición de disparo y abre la cámara.

3.

Inserte el sujetador de potencia en la boca del cañón de la

herramienta, inserte primero el extremo que lleva la cabeza.

Empuje el sujetador de potencia hasta que la punta esté a

nivel con el extremo de la herramienta. SIEMPRE cargue pri-

mero el sujetador de potencia y luego la carga explosiva.

4. Seleccione la carga explosiva Remington® apropiada (Vea

la Tabla de utilización en las páginas 44 y 45) e insértela

en la cámara hasta que tope. NOTA: Si usted no empieza

con el nivel de potencia más bajo puede generarse una

condición de clavado excesivo que podría dañar la herramienta (Vea la página 37).

38

119586

Page 39

S F

S F

S F

S F

90˚

S F

S F

Operación

5. Empuje el cañón hacia la carcasa a la posición cerrada.

6. Coloque la boca del cañón perpendicular a la superficie de

trabajo sin inclinar la herramienta. Empuje la herramienta

contra la superficie de trabajo deslizándola hasta que tope.

Seguridad

APAGADA

7. Antes de apretar el gatillo, gire el interruptor ON/OFF de

seguridad a la posición SAFETY OFF. Apriete el gatillo para

fijar el sujetador de potencia. Esté seguro de mantener

presionada a la herramienta durante esta operación.

IMPORTANTE: Cuando no use la herramienta, gire

SIEMPRE el interruptor ON/OFF de seguridad a la posición

SAFETY ON.

8. Luego de hacer la sujeción, deslice rápidamente el cañón

hacia delante. Este movimiento expulsa la carga explosiva

usada y vuelve a colocar al pistón listo para la siguiente

sujeción. Asegúrese que la carga usada haya sido expulsada de la herramienta.

119586

39

Page 40

30

S F

WATER

S

F

Operación

AGUA

10. Si la herramienta no dispara, sostenga firmemente la boca del

cañón por 30 segundos contra la superficie de trabajo. Suelte

el gatillo y retire la presión en la herramienta mientras sostiene

la boca del cañón contra la superficie de trabajo. Presione

firmemente de nuevo la herramienta contra la superficie de

trabajo y hale el gatillo. Si la herramienta aún no dispara, sosténgala firmemente contra la superficie de trabajo por otros 30

segundos antes de descargarla y deseche cuidadosamente

en agua o aceite las cargas explosivas fallidas.

IMPULSO EXCESIVO DEL PISTÓN

Si la herramienta no se abre luego del disparo y el pistón está

a 13 mm (1/2 pulg.) o más fuera de la boca del cañón:

1. Golpee el extremo de la boca del cañón del R300 contra

una superficie dura para forzar al pistón a que entre en la

boca del cañón.

2. Expulse la carga explosiva (Vea en Operación, el paso 8).

IMPULSO

EXCESIVO

CUIDADO DE SU R300

Limpie su R300 luego de cada uso diario. Limpie la cámara

con un cepillo de alambre que viene como accesorio, número

de parte 56485 (No se incluye con la herramienta). Aplique un

poco de pulverizador lubricante y penetrante de buena calidad

(como el WD-40) y séquelo con un paño.

NOTA: los reglamentos de trabajo en muchos estados requieren que el operador de esta herramienta, en un sitio de trabajo,

esté completamente entrenado y certificado como competente

antes de operar esta herramienta. Para procedimientos de

certificación llame al Departamento de Servicios Técnicos

al 1-800-858-8501 (Inglés solamente) o visite la página web

www.desatech.com.

40

119586

Page 41

1

5

4

8

17

16

7

6

9

3

2

10

18

11

13

12

20

15

14

21

19

Lista de partes

Nº Nº

clave de parte Descripción Cantidad

1 300001 Tornillo del mango 2

2 300110 Mango 1

3 300101 Interruptor de seguridad 1

4 300103 Arandela de seguridad 1

5 300104 Tornillo del interruptor de seguridad 1

6 300105 Gatillo 1

7 300106 Resorte del gatillo 1

8 300107 Contratuerca del gatillo 1

9 300108 Tornillo del gatillo 1

10 300201 Tope del recibidor 1

11 300210 Recibidor 1

12 479601 Recámara 1

13 479602 Tornillo de la recámara 1

14 479603 Fiador 1

15 250604 Tornillo del fiador 1

16 479605 Espiga de disparo 1

17 479606 Tornillo de la espiga de disparo 1

18 479607 Tope de la espiga 1

19 479300 Conjunto cañón 1

20 479205 Lengüeta 1

21 300010 Tornillo tapón de la lengüeta 1

ACCESORIOS

Nº

de parte Descripción

101320-01 ESCUDO contra esquirlas

056415 GAFAS DE SEGURIDAD

056485 CEPILLO de 1/4 de pulgada

056486 CEPILLO de 5/8 de pulgada

501801 LLAVE HEXAGONAL

de 3/16 de pulgada

IMPORTANTE: Cuando solicite repuestos no use los números

clave. Siempre pida repuestos por el número de parte y la

descripción. Incluya los números de modelo y serie.

119586

41

Page 42

S F

A

S F

B

D

S F

B

C

F

B

C

A

S F

DB

Reemplazo del cañón

B

E

B

G

ADVERTENCIA: NUNCA desarme, cambie el cañón,

limpie, ensamble una herramienta activada con pólvora cuando esté cargada.

1. Desenrosque la tuerca

moleteada de la lengüeta

(A). Deslice hacia fuera el

conjunto cañón (B) y retire

la lengüeta (C), luego retire

el conjunto cañón (B) del

recibidor (D).

2. Si la herramienta ha sido impulsada en exceso, golpee

con suavidad el pistón (E) contra una superficie dura hasta

que el pistón entre en la boca del cañón. Inspeccione el

conjunto cañón (B) y reemplácelo si está dañado.

3. Para ensamblar, empuje

fondo el pistón (E) en el cañón (B) con un destornillador (G). Deslice l conjunto

cañón (B) insertándolo en

el recibidor (D). Gire el cañón (B) para alinearlo con

la ranura de la lengüeta (F)

con la lengüeta (C), Inserte

(C) en la ranura (F) de la

lengüeta. Apriete con firmeza la tuerca moleteada

(A) de la lengüeta.

42

119586

Page 43

Guia de Investigacion de

PROBLEMA

El pistón cuelga

fuera de la boca

del cañón.

Sujetador clavado en exceso.

Pistón atascado.

No se extrae la

carga utilizada.

Red u c ción o

pérdida de potencia.

No se puede

presionar completamente a la

herramienta.

CAUSA

PROBABLE

Herramienta impulsada excesivamente.

El pistón no está

bien ensamblado

con relación al tornillo del cañón.

Pistón roto.

Potencia excesiva.

Clavado excesivo

del sujetador (ver

arriba).

Cámara s ucia o

dañada.

Expulsor roto.

Las espigas que

se están usando

tienen más de 2 1/2

pulgadas de largo.

El pistón no regresa

a su posición completamente atrás.

Anillo desgastado

del pistón o pistón

roto.

Partes de la cámara

y de la espiga de

disparo mal ensambladas o dañadas.

REMEDIO

Golpee con suavidad el

pistón contra una superficie dura hasta que el pistón

sea empujado hacia atrás

hacia la boca del cañón.

(Vea abajo sujetador cla-

vado en exceso).

Retire el conjunto cañón.

Siga las instrucciones para

el reemplazo del cañón

(vea las página 42). Re

emplace todas las partes

dañadas o faltantes.

Reemplace el conjunto cañón o lleve la herramienta

donde su distribuidor.

Cambie ya sea a la carga

explosiva inmediata inferior o al sujetador más

largo que sigue.

Retire el conjunto cañón.

Siga las instrucciones para

el reemplazo del cañón

(Vea las página 42). Reemplace otras partes que

estén dañadas.

Limpie la cámara. Si las

dificultades de deslizamiento o extracción de las

cargas en la cámara continúan, lleve la herramienta

donde su distribuidor.

Reemplace el conjunto cañón o lleve la herramienta

donde su distribuidor.

Use la espiga del tamaño apropiado.

El cañón debe estar sujeto a presión en la posición

completamente extendida para que el pistón se

ubique adecuadamente

contra la recámara.

Reemplace el conjunto cañón o lleve la herramienta

donde su distribuidor.

Retire la recámara y revise que todas las partes

estén bien ensambladas.

Averias

-

119586

43

Page 44

Guia de Investigacion de

Tablón de dos

por cuatro

Tiras de

recubrimiento

Cajas de empalme

eléctricas

Abrazaderas de

tubería

Soportes para

anaqueles

Aglomerado de

1/4 de pulgada o

tableros perforados

Concreto

Bloque de cemento

Acero (con espesor

de 3/16 a 3/8 de

pulgada)

2 1/2 pulg.

2 1/2 pulg.

2 1/2 pulg.

1 1/2 pulg.

1 1/2 pulg.

1 1/2 pulg.

2 pulg.

Verde

Gris

Marrón

Amarillo

Verde

Verde

Amarillo

Concreto

Bloque de cemento y

ceniza

Bloque de cemento

Acero (con espesor

de 3/16 a 3/8 de

pulgada)

Concreto

Bloque de cemento

Bloque de cemento y

ceniza

Acero

Concreto

Bloque de cemento

Bloque de cemento y

ceniza

1 pulg.

1 pulg.

1 pulg.

Verde

Marrón

Gris

1 pulg.

1 pulg.

1 pulg.

3/4 pulg.

Verde

Marrón

Gris

Verde

Concreto

Bloque de cemento

Acero

Concreto

Bloque de cemento

Acero

1 1/4 pulg.

1 1/4 pulg.

1 pulg.

Verde

Verde

Amarillo

1 pulg.

1 pulg.

3/4 pulg.

Verde

Marrón

Verde

Averias

PROBLEMA

La herramienta

no dispara.

CAUSA

PROBABLE

No es posible presionar completamente a la herramienta.

La suciedad acumulada en la recámara no permite la

penetración apropiada de la espiga

de disparo.

El interruptor de

seguridad está en

la posición ON

REMEDIO

Vea ar riba l os datos

listados en No se puede

presionar completamente a la herramienta.

Revise en el cartucho la

muesca de la espiga disparo. Limpie la recámara,

la cara de la recámara, el

fiador y la espiga de disparo. Reemplace las partes

desgastadas o dañadas.

Gire el interruptor de

seguridad a la posición

OFF

El abrir y cerrar

del cañón o

Falta de limpieza

adecuada.

empujar hacia

abajo en la herramienta, etc.

no es suave

sino dura o se

remuerde.

Tabla de utilización

Información sobre el uso de cargas explosivas y

Para sujetar

esto:

sujetadores de potencia.

A esto:

44

Inspeccione y limpie completamente la herramienta. Reemplace las partes

desgastadas o dañadas.

Color de la

carga

explosiva

119586

Longitud del

sujetador de

potencia

Page 45

Tabla de utilización

Las cargas explosivas de esta lista son sólo recomendaciones.

Si tiene duda, haga una prueba de sujeción usando la siguiente

carga explosiva más ligera.

Los sujetadores de potencia y las cargas explosivas están

disponibles en paquetes pequeños de 25 y en cartones de 100

unidades.

IMPORTANTE

• Recomendado para usar con cargas explosivas y sujetadores de potencia Remington®.

• Si el sujetador de potencia penetra por debajo de la superficie superior de la tabla, use el disco de control de penetración (vea la ilustración más abajo) o use sujetadores de

potencia tipo SPW con rodela incorporada.

• Los operadores y los que miran deben usar SIEMPRE protección visual y auditiva iguales o mejores que lo indicado

en las normas establecidas en su país para una protección

correcta. Para Estados Unidos, vea las normas ANSI. Para

Canadá, vea las normas CSA.

* Use sujetadores de potencia con disco de control de pe-

netración, número de parte 015549.

IMPORTANTE

Esta herramienta está diseñada para usarse con cargas encapsuladas de cuello bajo calibre .22, niveles de potencia 1

(gris) hasta el 4 (amarillo).

15.9 mm

Carga explosiva encapsulada

de cuello bajo

Carga explosiva

empaquetada recta

PRECAUCIÓN: No use ninguna carga

que no sea la carga explosiva encapsulada

de cuello bajo calibre .22. Otros tipos de

cargas explosivas ocasionarán problemas

de expulsión de la carga.

Cargas encapsuladas de cuello bajo tipo A CALIBRE .22

para herramientas accionadas con pólvora

Número Número Código de

del del nivel Poder de colores

artículo de carga la carga Cuerpo Cabeza

A22C1 1 Ligero Latón Gris

A22C2 2 Medio Latón Marrón

A22C3 3 Fuerte Latón Verde

A22C4 4 Muy fuerte Latón Amarillo

119586

45

Page 46

Accesorios y piezas de

repuesto

ADVERTENCIA: Use sólo repuestos y accesorios descritos en este manual. El uso de otros repuestos o accesorios podría dañar la herramienta o lesionar al operador.

Para accesorios y piezas de repuesto originales llame al Distribuidor Autorizado o al Centro Autorizado de Servicio para este

producto. Si ellos no tienen la pieza o accesorio, llame a la Central de Piezas más cercana a usted que se lista en la página 47.

Cada Distribuidor Autorizado, Centro Autorizado de Servicio y

Central de Piezas es y opera independientemente.

Vea la página 41 para una lista ilustrada de piezas.

Si necesita referencia adicional informativa, llame a nuestro

departamento de servicio técnico (vea Servicio Técnico).

En el Canadá llame al 1-800-561-3372 para obtener informa

ción sobre las piezas.

Servicio Técnico

Usted puede tener más preguntas sobre cómo ensamblar,

utilizar o mantener este producto. Si es así, usted puede visitar

nuestro sitio Web de servicio técnico en www.desatech.com o

llamar al departamento de servicio técnico al 1-800-858-8501

(sólo en inglés). Usted puede también escribir a:

DESA Power Tools™

P.O. Box 90004

Bowling Green, KY 42102-9004

ATTN: Technical Service Power Tools

Cuando llame a DESA Power Tools™ tenga listo:

• Su nombre

• Su dirección

• Su número de teléfono

• El número de modelo del producto

• Fecha de compra (incluya un copia del recibo para solicitudes por escrito).

-

Servicio de Reparación

Nota: Use sólo piezas de repuesto originales. Esto protegerá la

cobertura de su garantía de las piezas repuestas bajo garantía.

Cada Centro Autorizado de Servicio es y opera independientemente.

SERVICIO CON GARANTÍA

Si el producto necesita servicio bajo garantía, envíelo al centro

de servicio autorizado más cercano a usted. Usted debe mostrar prueba de compra. Si el daño fue causado por materiales

imperfectos o por mano de obra, repararemos o cambiaremos

el producto sin cobrarle a usted. Nota: Esta garantía no cubre

desgaste, mal uso, abuso, negligencia o daño accidental.

SERVICIO SIN GARANTÍA

Si el producto necesita servicio, envíelo al centro de servicio

autorizado más cercano a usted. Se le enviarán las facturas

por reparación a los precios normales de reparación.

Para información adicional sobre centros de servicio o de garantía, llame al -800-858-8501 (sólo en inglés) o visite nuestro

sitio Web de servicio técnico en www.desatech.com.

46

119586

Page 47

Centros de repuestos

Ray’s Portable Heater Service

3191 Myers Road

Camino, CA 95709-9550

530-644-7716

Tool & Equipment Service

Solutions, LLC

5 Manila Drive

Hamden, CT 06514-0322

203-248-7553

1-800-397-7553

Grainger Parts Operations

1657 Shermer Road

Northbrook, IL 60062-5362

708-498-5900

1-800-323-0620

www.grainger.com

Portable Heater Parts

342 North County Road 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-800-362-6951

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

franktalk@aol.com

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Master Part Distributors

1251 Mound Avenue NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

www.masterparts.net

Hance Distributors, Inc.

12795 16th Avenue North

Plymouth, MN 55441-4556

763-559-2299

www.hanceco.com

Automotive Equipment Service

1651 E. Kansas City Road

Olathe, MO 66061

816-531-9144

1-800-843-3546

www.aes-lawnparts.com

Bowden Electric Motor Service

1681 S. Wesleyan Blvd.

Rocky Mount, NC 27803

252-446-4203

East Coast Energy

10 East Route 36

West Long Branch, NJ 07764-1501

1-800-755-8809

Forrest Lytle and Sons, Inc.

740 West Galbraith Road

Cincinnati, OH 45231-6002

513-521-1464

Bortz Chain Saw Shop

Road #2, Box 64A

Oley, PA 19547-9412

610-987-6452

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

1-800-325-4828

La Ports

2444 N 5th Street

Hartsville, SC 29550-7704

843-332-0191

MTA Distributors

555 Hickory Hills Blvd.

Nashville, TN 37189-9244

615-299-8777

1-800-264-0225

Webbs Appliance Center

1519 Church Street

Nashville, TN 37203-3004

615-329-4079

1-800-899-4079

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324-1403

804-543-2232

1-800-788-0008

catatem@erols.com

Mills Lawn and Garden

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

www.mills-parts.com

Tuco Industrial Products

5223 180th Street SW

Suite 4A-1

Lynnwood, WA 98037-4506

425-743-9533

1-800-735-1268

www.tucoheat.com

119586

47

Page 48

Garantía Limitada

DESA Power Tools™ garantiza a la modelo R300 de Remington® de defectos en materiales y mano de obre por un período

de un (1) año (90 días para productos recondicionados) a

partir de la fecha de compra. Al realizarse un reclamo según

la garantía debe presentarse la factura o el comprobante de

compra.

Si dentro de un (1) año a partir de la fecha de compra esta

herramienta activada con pólvora falla debido a defectos en

materiales y mano de obra, DESA Power Tools™, según lo

estime, reparará o reemplazará la herramienta. Para obtener

el servicio bajo esta garantía, póngase en contacto con DESA

Power Tools™ al número/dirección indicados abajo. Debe tener

el número de serie, número de modelo, fecha de compra e

indicar el tipo de problema que tiene. DESA Power Tools™, a

su criterio, enviará la parte(s) de repuesto, reparará o reemplazara la herramienta. Sin embargo esta garantía no cubre fallas

ocasionadas por mal uso o abuso del producto (para el uso

apropiado de este producto lea y entienda las instrucciones de

operación de este manual del propietario). Las reparaciones debidas al mal uso, abuso, negligencia o accidente serán cobradas

a los precios regulares de reparación. Las cargas explosivas

y sujetadores de potencia no están cubiertos.

Esta garantía expresa y limitada es la única garantía de este

producto, y según lo permitido por la ley no hay otras garantías

expresas o implícitas, incluyendo garantías de comerciabilidad

y/o adecuación para un propósito particular lo cual está fuera del

alcance de los términos de esta garantía expresa y limitada.

Según lo permitido por la ley, la responsabilidad de DESA

Power Tools™ por daño personal, daño a la propiedad u otro

daño cualesquiera, incluyendo daños incidentales o consecuentes, que resultan de la venta o uso de este producto no

excederá el precio de compra de este producto.

Esta garantía le da derechos legales específicos, y usted puede

también tener otros derechos que varían de estado a estado.

En Estados Unidos,

contáctese con:

P.O. Box 90004

Bowling Green, KY

www.desatech.com

42102-9004

En Canadá,

contáctese con:

82 Akron Road

Toronto, Ontario

M8W 1T2

1-800-561-3372

Fax: 1-800-561-8003

SÓLO PARA ESTADOS UNIDOS

Para asistencia técnica de su herramienta

Remington® accionada con pólvora o para

procedimientos de certificación, llame al

departamento de servicios técnicos al

1-800-858-8501 (Inglés solamente) o visite

la página Web www.desatech.com.

48

119586

Page 49

REMINGTON R300

S F

POWDER ACTUATED TOOL

MANUFACTURERS´ INSTITUTE INC.

™

®

Modèle R300

Mode

d’emploi

IMPORTANT:

Lire toutes les directives et tous les avertissements apparaissant dans le présent guide et sur l’emballage des cartouches

explosives avant d’utiliser l’outil actionné par explosif. S’assurer que le guide accompagne de tout temps le pistolet et lors

d’un changement de propriétaire, il est à remettre au nouveau

propriétaire.

119586

49

Page 50

S F

REMINGTON R300

S F

Index

Avertissement : Mesures de précaution ........................ 51-59

Ancrage d’un goujon d’ancrage ...........................................60

Sélection des goujons d’ancrage et des

cartouches explosives .......................................................61

Utilisation ....................................................................... 62-64

Liste des pièces ...................................................................65

Accessoires .........................................................................65

Remplacement du tube .......................................................66

Guide de Dépannage ....................................................67, 68

Tableau des applications ...............................................68, 69

Pièces de rechange et accessoires .....................................70

Service Techique .................................................................70

Service de Réparation ...................................................70, 71

Centres de pièces ................................................................71

Garantie Limitée ........................................ Couverture arrière

REMINGTON

MD

Modèle R300

Le Modèle R300 de RemingtonMD est conçu pour être utilisé avec

des cartouches à extrémité gaufrée de type A, calibre .22, et avec

des goujons d’ancrage RemingtonMD d’une longueur maximum

de 2 1/2 po ou des goujons avec limiteur d’enfoncement de 3 po

tout au plus. Les goujons d’ancrage RemingtonMD sont fabriqués

à partir d’acier spécial et traités thermiquement afin de les rendre

à la fois très durs et ductiles.

Le modèle R300 de RemingtonMD est doté de deux dispositifs