REMEHA W40, W60-m ECO Installation And Maintenance Instructions Manual

remeha

W40/60-m ECO

Installation and

maintenance instructions

High-efficiency

condensing boiler

for free standing (frame

mounted) or wall

mounted installation

Suitable for room sealed

fanned flue or open flue

fan assisted operation

2

remeha W40/60-m ECO

CONTENTS

Preface 4

1. General description of the boiler 4

2. Construction 4

3. Technical data and dimensions 5

3.1 Dimensions 5

3.2 Technical data 6

3.3 Delivery package 6

4. Efficiency information 7

4.1 Annual efficiency 7

4.2 Heat to water efficiency 7

5. Installation applications 7

5.1 General 7

5.1.1 Installation of single boilers 7

5.1.2 Installation of multiple boilers 8

6. Boiler layout 9

6.1 Equipment diagram 9

6.2 Operating principle 10

6.3 Control panel 10

6.4 Control system 11

6.4.1 General 11

6.4.2 Operating mode 12

6.4.3 Setting mode (with dot) 13

6.4.4 Read-out mode (with blinking dot) 14

6.4.5 Forced 'HIGH' mode 14

6.4.6 Forced 'LOW' mode 14

6.4.7 Speed mode (half digits) 14

6.4.8 Failure mode (blinking 'code' display)15

6.4.9 Service code 15

6.4.10 User settings 16

7. Installation instructions 17

7.1 General 17

7.2 Location 17

7.3 Dimensions of wall mounting bracket 17

7.4 Ventilation requirements 18

7.5 Flue gas discharge and air supply 19

7.5.1 General 19

7.5.2 Single boiler,

non room sealed applications 20

7.5.3 Single boiler,

room sealed applications 21

7.5.4 Cascade configurations 21

7.6 Installation details 22

7.6.1 Condensate discharge 22

7.6.2 Cold feed and expansion tank

height for open vented systems 22

7.6.3 Water treatment 22

7.6.4 Safety valve 23

7.6.5 Circulation pump 23

7.7 D.H.W. application 23

7.7.1 D.H.W. control 23

7.7.2 Schematic sketch of connections 24

3

8. Electrical installation 25

8.1 General 25

8.2 Electrical supply 25

8.3 Connection to the control system 25

8.3.1 Modulating control 25

8.3.2 Room thermostat 24V 26

8.3.3 Room thermostat in combination

with an outdoor temperature sensor 26

8.3.4 Two-stage external weather

compensator 26

8.3.5 D.H.W. control 26

8.3.6 Frost protection 27

8.3.7 Signals 27

8.4 Water temperature control 28

8.5 Low-water protection 28

8.6 High limit temperature protection 28

8.7 Differential air pressure switch (LD2) 28

8.8 Control box 28

8.9 Fuse specification 28

8.10 Electrical wiring diagram 29

9. Installation instructions for the gas Installer 30

9.1 Gas connection 30

9.2 Gas pressures 30

9.3 Gas/air ratio control 30

10. Commissioning 31

10.1 Initial lighting 31

10.2 Shut-down 32

10.3 Settings 33

10.3.1 General 33

10.3.2 Setting the required flow

temperature 33

10.3.3 Setting the required flow

temperature when using an

outdoor sensor 33

10.3.4 Changing the cut-in temperature

differential 33

10.3.5 Setting the pump control 33

10.3.6 Setting the burner control 33

10.3.7 Setting D.H.W. temperature 34

10.3.8 Switching D.H.W. operation

on and off 34

10.3.9 Changing D.H.W. operating cut-in

differential (service level) 34

10.3.10 Changing maximum flow

temperature during D.H.W.

operation 34

10.3.11 Changing three-way valve/boiler

pump setting 34

11. Fault-finding 35

11.1 General 35

11.2 Faults in appliances in combination with

the

rematic

®

weather-compensated

boiler control 35

11.3 Faults in appliances without a modulating

rematic

®

weather-compensated

boiler control 35

11.4 Fault codes 35

12. Inspection and servicing instructions 37

12.1 General 37

12.2 Inspection 37

12.3 Maintenance 38

12.4 Draining and filling 39

12.5 Venting 39

4

remeha W40/60-m ECO

If you have any questions, or if you need more information about specific subjects relating to this boiler,

please do not hesitate to contact us.

The data published in these technical instructions is

based on the latest information and is subject to revisions.

We reserve the right to modify the design and/or configuration of our products at any moment without being

obliged to adjust earlier supplies accordingly.

PREFACE

These technical instructions contain useful and impor tant

information for the correct operation and maintenance of

the remeha central heating boiler, models W40/60-m

ECO.

Furthermore, impor tant instr uctions are given to ensure

safe and trouble free boiler operation.

Read these instructions carefully before putting the boiler into operation, familiarize yourself with its operation

and control and strictly observe the instructions given.

The remeha W40/60-m ECO can be easily programmed

and controlled using the built in microprocessor. Actual

and set values can be checked from the read-out display.

Gas and water connections are sited at the bottom of

the boiler whilst combustion air inlet and flue discharge

connections are located at the top of the casing.

For multiple boiler applications refer to the Technical

Information "Multiple units".

The boiler meets the requirements of the EC regulations

of the directives:

- 90-m/396/EEC Gas appliances directive

- 92/42/EEC Efficiency directive

- 73/23/EEC Electrical low voltage directive

- 89/392/EEC Machiner y directive

- 89/336/EEC E.M.C. directive

W40-m ECO - PIN-number: 63/AO/6520.

W60-m ECO - PIN-number: 63/AP/6520.

For further advice or information contact Broag Ltd.

1. GENERAL DESCRIPTION OF THE BOILER

The remeha W40/60-m ECO is a condensing boiler

which may be installed free standing on a frame or wall

mounted on a bracket.The boiler is suitable for room

sealed fanned flue or open flue fan assisted applications.

The boiler is designed for central heating and indirect

hot water supply at working pressures not exceeding 3

bar.It should be installed on a pumped water circulation

system and is suitable for both open and unvented system operation.

The remeha W40/60-m ECO is fitted with a top mounted

premix gas burner firing downwards into an aluminium

heat exchanger. The application of the premix burner,

with its carefully controlled gas/air ratio, water heating

efficiencies of 110.4% (NCV) are obtained in the condensing mode with very low CO and NOx emissions.

A condensate collector and a siphon for the condensate

drain is fitted at the bottom of the boiler.

Quick connect latches on the air box cover make the

unit easy to service and maintain.

2. CONSTRUCTION

A DC fan has been mounted on the combustion air

supply side, which guarantees the supply of the correct

quantity of combustion air. Gas injection takes place in a

special mixing section at the inlet of the fan.

As a result, the optimum mixture of gas and air is

achieved in the fan. A pre-mix burner, placed in the top

of the appliance, guarantees optimum combustion.

The remeha W40/60-m ECO heat exchanger is manufactured in aluminium, and equipped with conducting

panels for optimum heat transfer.

At the bottom of the appliance, a condensate collector

tray and a siphon are responsible for discharging

condensed water.

The closed air box increases safety, and facilitates

installation in practically any room.

Through the use of microprocessor technology, the

remeha W40/60-m ECO is simple to set and control.

Display windows make it possible to check the current

and target settings.

The gas and water connections are clearly mounted on

the underside of the appliance.The combustion air

supply and flue gas discharge are mounted on the top

of the boiler (100 mm I/D socket).

By using quick connect latches on the air box cover (no

screws), the appliance is also easy to service and

maintain.

5

3. TECHNICAL DATA AND DIMENSIONS

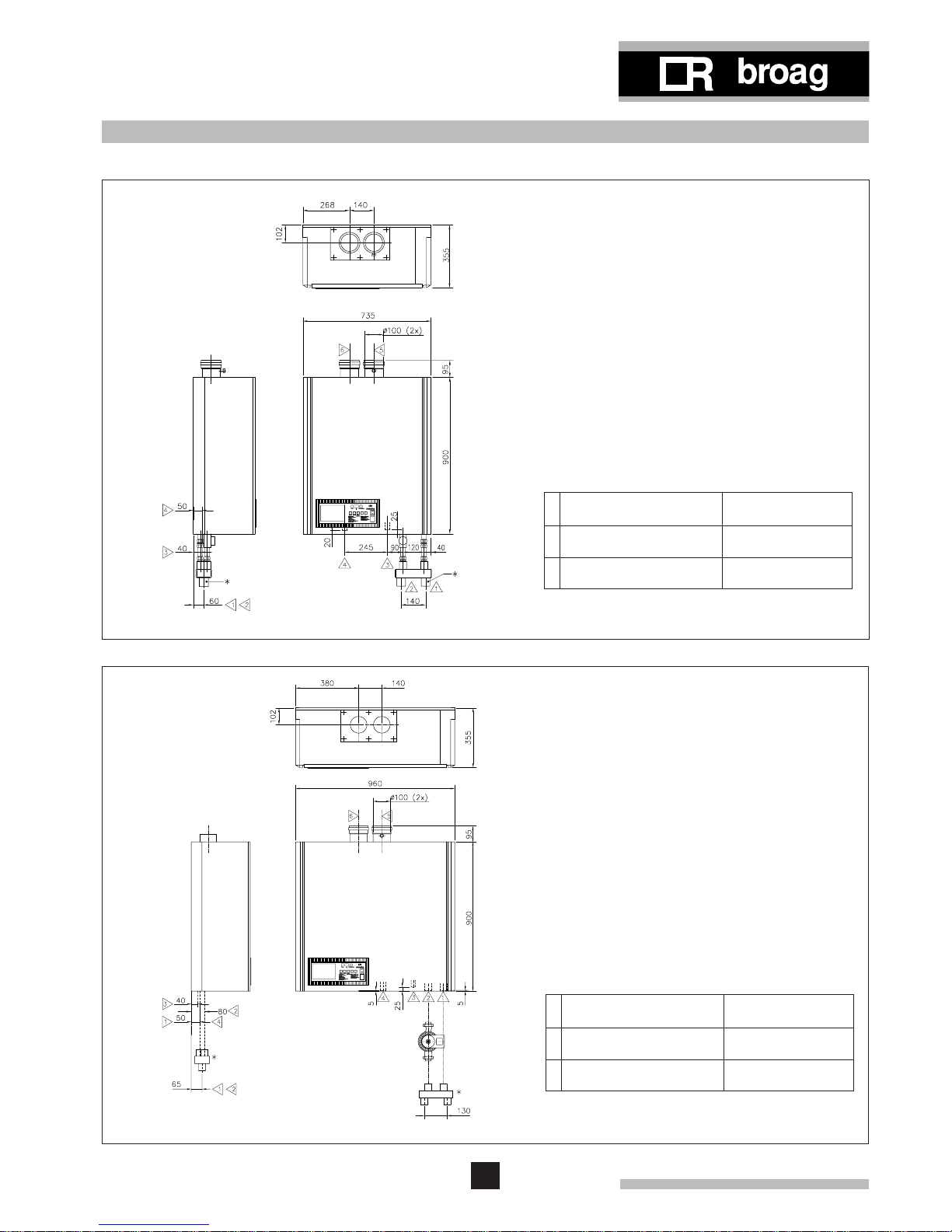

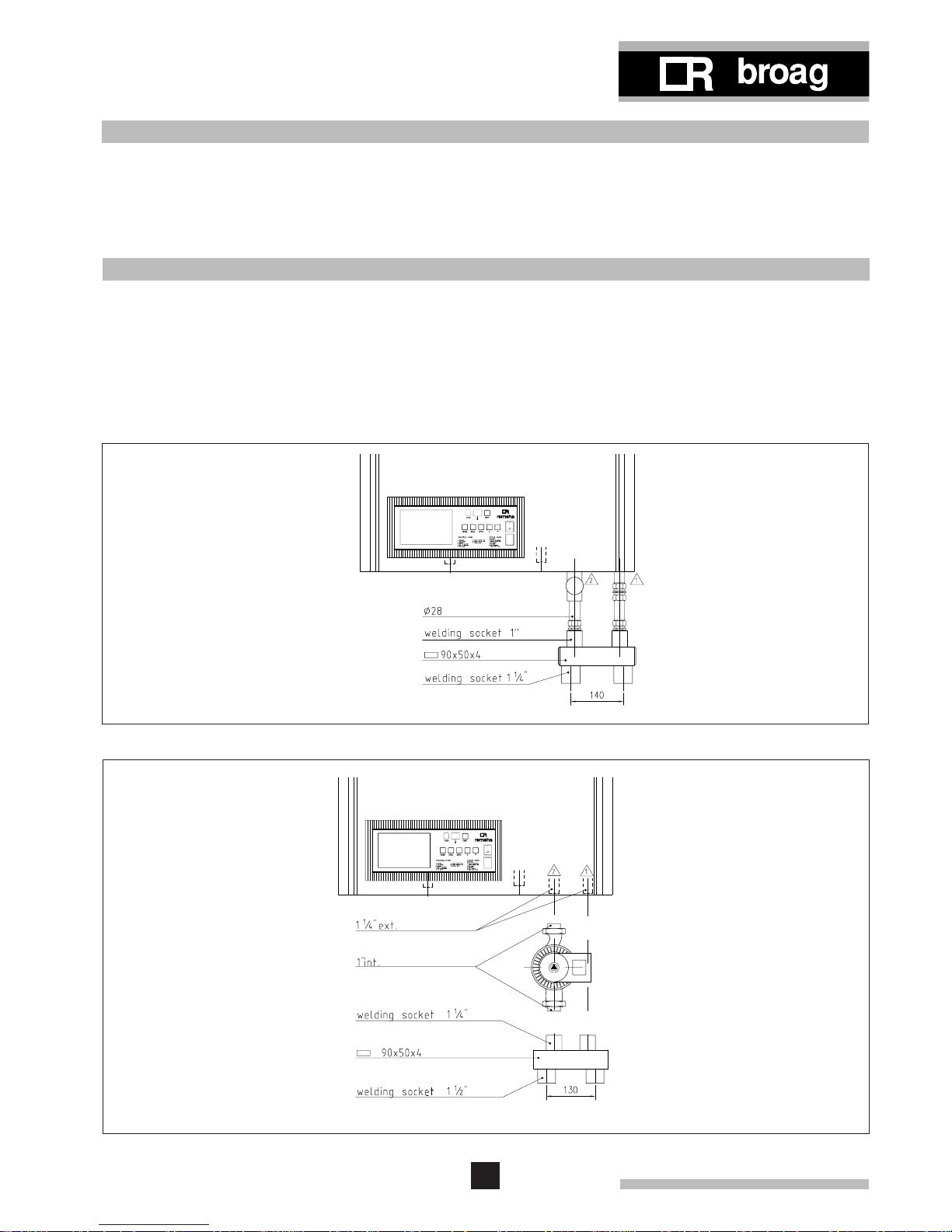

3.1 Dimensions

Top

view

remeha W40-m ECO

Side view

Front view

Fig. 01 remeha W40-m ECO

remeha W60-m ECO

1 Flow boiler 28 mm dia.

2 Return boiler 28 mm dia.

3 Gas

3/4

" male thread

4 Condensate discharge 32 mm dia.

5 Flue gas discharge 100 mm dia.

6 Combustion air supply 100 mm dia.

* Low loss header for single boiler only

Flow/return connections 1

1/4

BSP (F)

Fig. 02 remeha W60-m ECO

Front view

Side view

Top

view

1 Flow boiler 1

1/4

" male thread

2 Return boiler 1

1/4

" male thread

3 Gas

3/4

" male thread

4 Condensate discharge 32 mm dia.

5 Flue gas discharge 100 mm dia.

6 Combustion air supply 100 mm dia.

* Low loss header for single boiler only

Flow/return connections 1

1/2

BSP (F)

6

remeha W40/60-m ECO

modulating

high - low

on - off

18.2

60.5

20.3

66.4

20.7

69.0

18.6

62.1

II

2H 3P

17 - 30

2.0 - 6.6

18

10

0,8

104

B23, C13, C33,

C43, C53, C63

240/50

100

2

20

100

20 - 90

0.3

3

6

900

not applicable

75

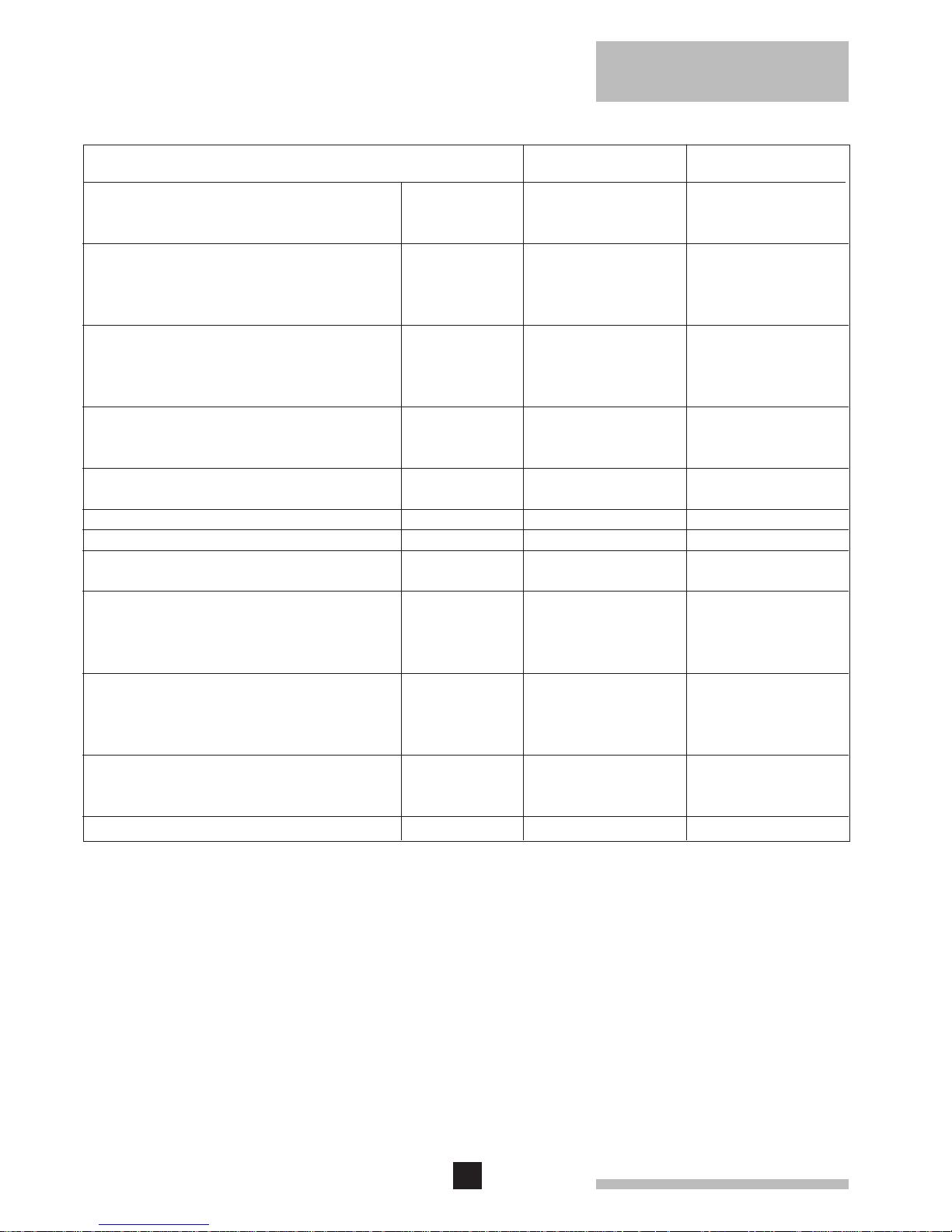

3.2 Technical data

Boiler type

Load control: adjustable

Output (80/60˚C) - min.

- max.

(40/30˚C) - min.

- max.

Input (GCV) - min.

- max

Input (NCV) - min.

- max

Category

Inlet pressure gas

Gasrate (natural gas)

NOx emission

Residual fan duty

Mass flue rate

Appliance (flue) type

Main supply

Electric rating

Fuse rating

Isolation class

Watertemperature - max.

- control

Operating pressure - min.

- max.

Water contents

Waterresistance (∆T = 10˚C)

Residual pump duty (∆T = 20˚C)

Assembly weight

modulating

high - low

on - off

12,4

41.0

14.0

44.3

14.1

47.0

12.7

42.3

II

2H 3P

17 - 30

1.3 - 4.5

51

29

0,8

71

B23, C13, C33,

C43, C53, C63

240/50

150

2

20

100

20 - 90

0.3

3

5

400

350

67

kW

kW

kW

kW

kW

kW

kW

kW

mbar

m3/h

mg/kWh

ppm

mbar

kg/h

V/Hz

VA

A

IP

°C

°C

bar

bar

ltr

mbar

mbar

kg

remeha

W40-m ECO

remeha

W60-m ECO

3.3 Delivery package

- circulation pump

- low loss header

- pressure gauge

- filling and drain cock

- air supply fan

- electronic control and protection equipment: 24V

- interface for

rematic

®

weather-compensated boiler

control

- temperature regulation: adjustable from 20 to 90°C

- differential air pressure switch

- low-water protection via temperature sensors

- aluminium heat exchanger

- red spray-coated sheet steel casing

- pump switch

- frost protection

- easy-to-read control panel with display

- siphon trap

- hanging bracket

- automatic vent.

Accessories

- conversion set for propane

- connection set for calorifier

- outdoor temperature sensor

- modulating

rematic

®

weather-compensated boiler

control

- interface for modulating room control (Honeywell

Chronotherm Modulation).

7

4. EFFICIENCY INFORMATION

4.1 Annual efficiency

a. 103.3% (NCV), 93.0% (GCV) at an average water

temperature of 45˚C (55/35˚C).

4.2 Heat to water efficiency

a. Up to 99.0% (NCV), 89.1% (GCV) at an average

water temperature of 76.5˚C.

b.Up to 110.4% (NCV), 99.4% (GCV) at an average

water temperature of 45˚C.

5. INSTALLATION APPLICATIONS

5.1 General

The boiler may be used with a fully pumped sealed or

open vented central heating system and pumped heating combined with pumped indirect domestic hot water

supply systems.

The remeha W40/60-m ECO is not suitable for systems

which include any gravity circulation, bathroom installations or connection to unlined brick chimneys.

5.1.1 Installation of single boilers

The low noise level emission of 48 dBA measured at 1

m from the boiler makes the remeha W40/60-m ECO

ideal for installation as a single boiler in large domestic

dwellings and smaller commercial premises.

The single boiler should be supplied with a header

(available from Broag).

Fig. 03 Header dimensions remeha W40-m ECO

Fig. 04 Header dimensions remeha W60-m ECO

8

remeha W40/60-m ECO

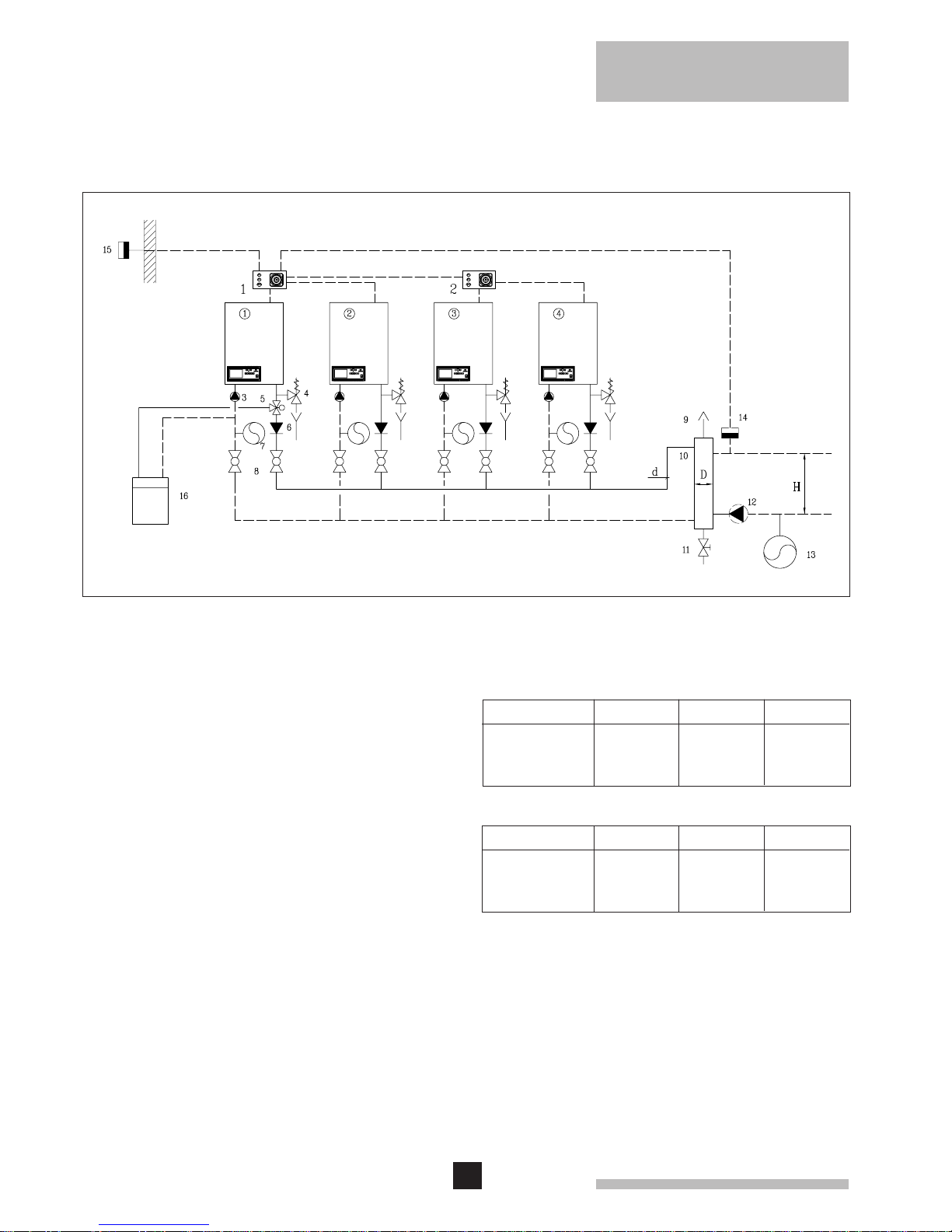

5.1.2 Installation of multiple boilers

Multiple boilers are idealy suited for use in larger commercial buildings and offer a wide variety of application

possibilities (see principle drawing).

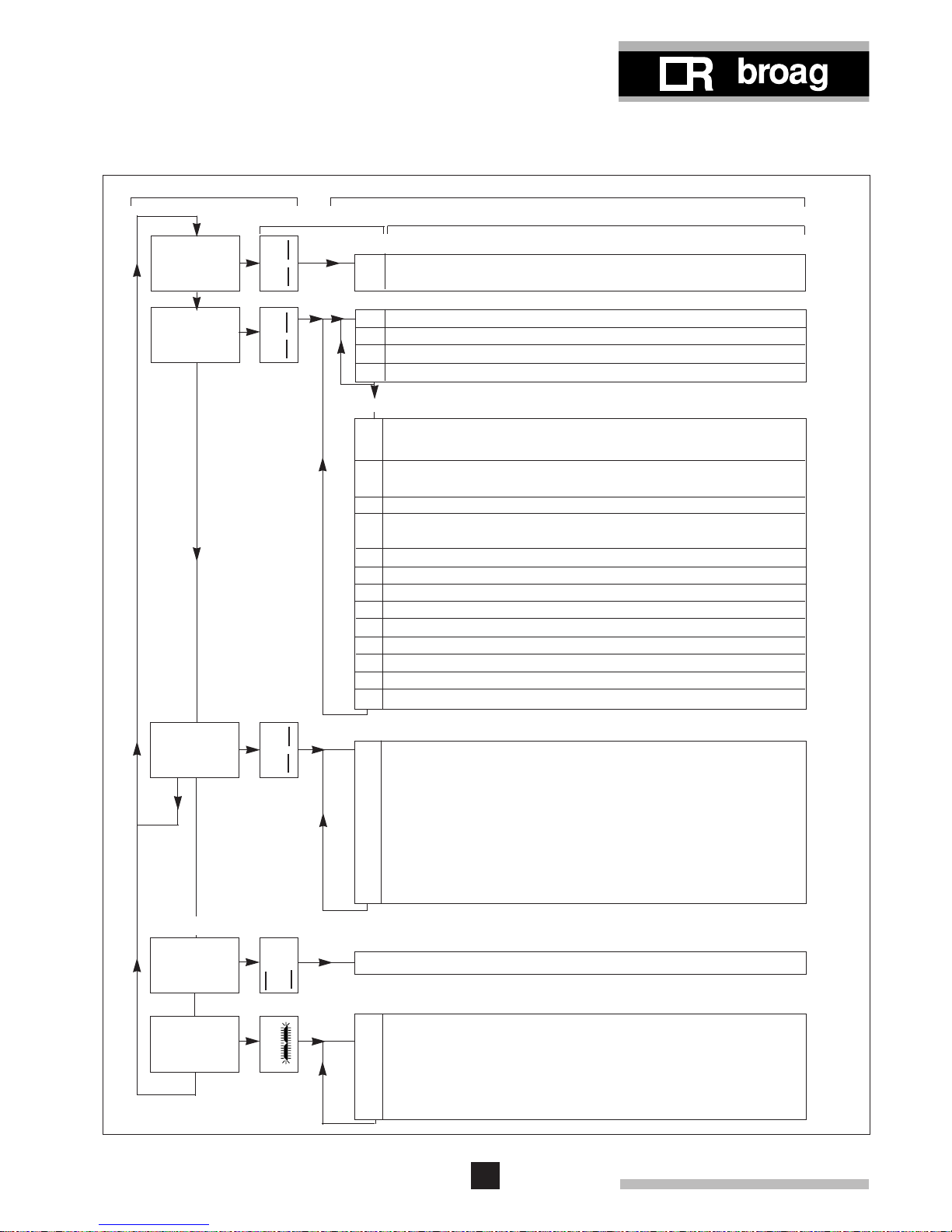

Fig. 05 Principle drawing multiple boilers

For further advice or information refer to the Technical

Information "Multiple Units".

Contact Broag Ltd.

Table

1. rematic®4-step weather compensator (Master)

Step 1 till 4

2. rematic®4-step modular controller (Slave)

Step 5 till 8

3. Pump (to be set at position 1)

4. Safety valve

5. Three-way valve, 230 V (D.H.W.)

6. Non-return valve

7. Expansion vessel (if required)

8. Manual isolating valve

9. Automatic vent

10. Open header (neutral header)

11. Drain cock

12. Installation pump

13. Installation expansion vessel

14. Flow sensor

15. Outdoor sensor

16. D.H.W. storage

D.H.W.

No. of units

2

3

4

'D'

'd'

80

100

125

32

38

50

remeha W40-m ECO

250

250

300

H

No. of units

2

3

4

'D'

'd'

100

125

150

50

63

63

remeha W60-m ECO

300

400

500

H

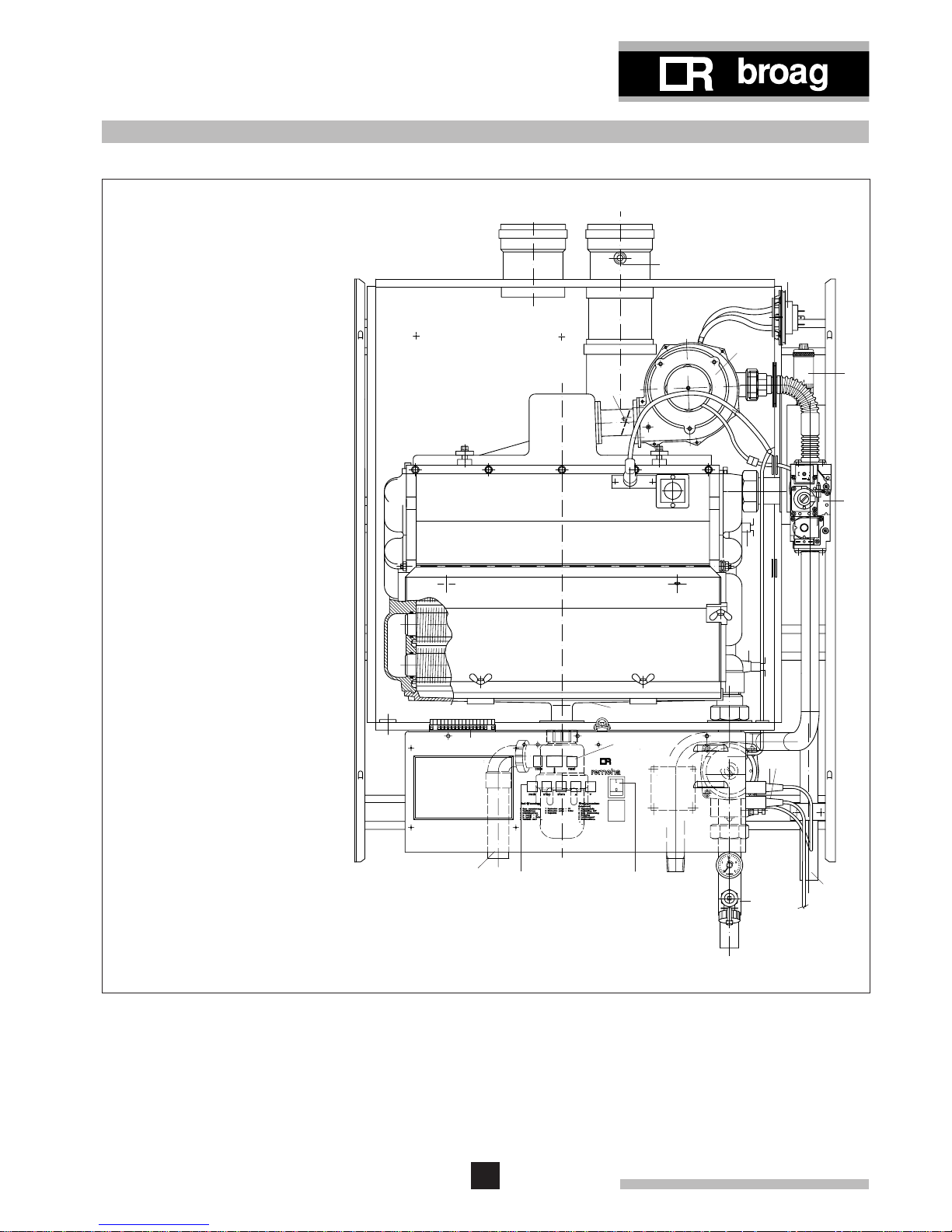

9

1

2

3

4

11

12

16

18

21

23

25

26

31

33

30

29

24

6

7

8

10

5

9

15

20

22

28

27

32

35

17

19

34

14

Fig. 06 Boiler layout remeha W40-m ECO

6. BOILER LAYOUT

6.1 Equipment diagram

1. Air supply

2. Flue gas discharge

3. Measure point O2 /CO

2

4. Air box

5. Slide connector

6. Differential air pressure switch

7. Spring loaded damper

8. Gas injector (behind fan)

9. Fan

10. Automatic vent

11. Burner

12. Ignition/ionisation probe

13. Sight glass

14. Manual air vent

15. Gas combi-block

16. Heat exchanger

17. Flow temperature sensor

18. Inspection cover

19. Return temperature sensor

20. Condense collector

21. Instrument panel

22. Electrical connection strip (X15)

23. Facility for incor porating a

rematic®weather compensated

boiler control

24. Condensate discharge

25. Setting keys

26. Read-out display and reset key

27. Burner switch

28. Interface for rematic®weather

compensated boiler control

29. Gas connection

30. Pump (only W40-m ECO)

31. Pressure gauge

32. Filling and drain cock

33. Return connection

34. Electrical connection pump and

three-way valve

35. Flow connection

13

10

remeha W40/60-m ECO

6.2 Operating principle

The appliance is equipped with a closed air box.Via a

fan, air is drawn in.On the intake side of the fan, an intake unit has been mounted where the gas is injected.

Depending on the settings and the ambient temperatures measured by the temperature sensors, the fan

speed is regulated.The gas/air ratio control adjusts the

quantity of gas to the quantity of air.

The gas/air mixture is achieved in the fan, and then

transported to the burner.

Following combustion, the hot flue gases are conducted

via the aluminium heat exchanger. At the heat exchanger, the flue gases give off heat to the central heating

water in the heat exchanger. The water vapour in the flue

gases condenses against the finned pipes at the base.

The heat released during this condensation process (the

so-called latent or condensation heat) is also transferred

to the central heating water.

The condensed water thus formed is discharged via a

siphon at the base of the heat exchanger.

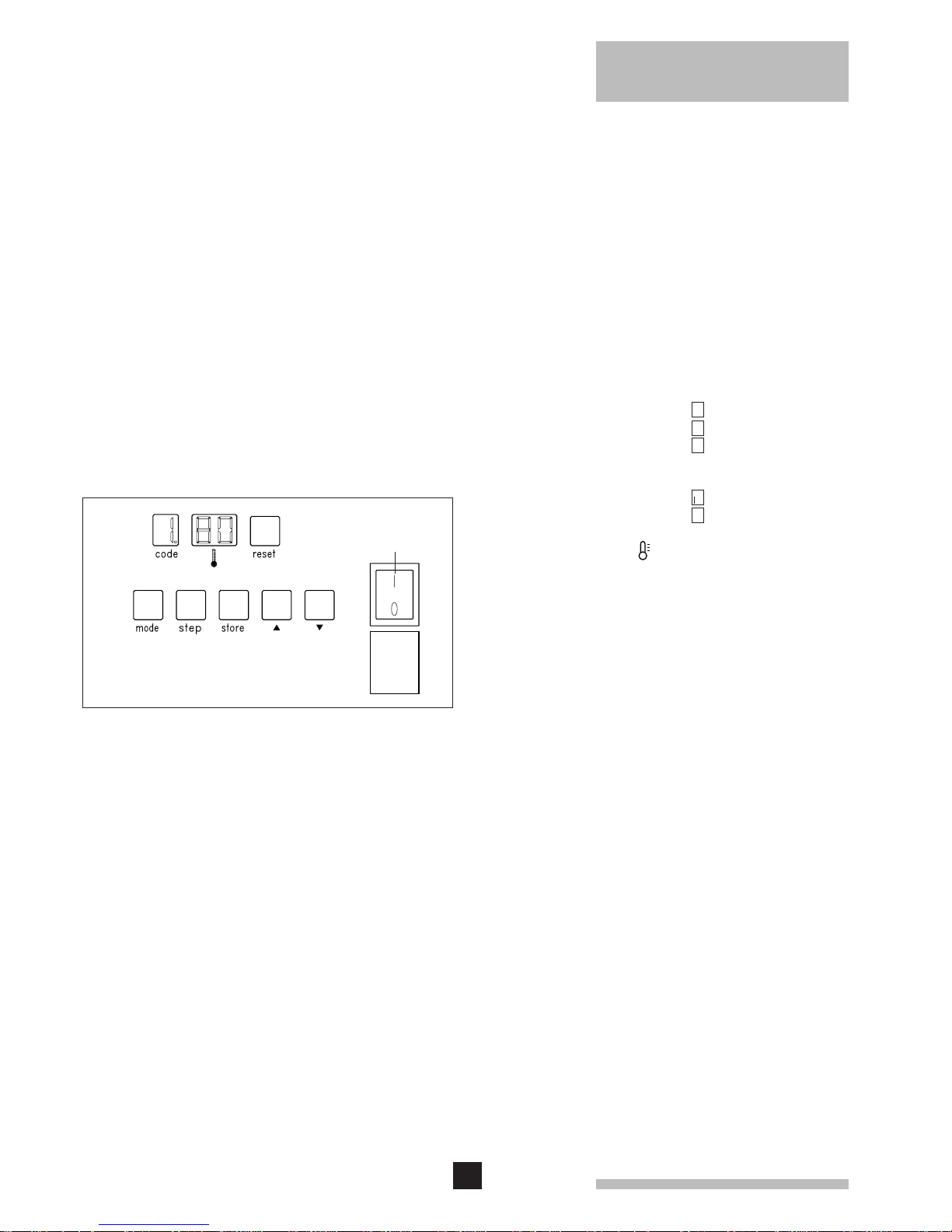

6.3 Control panel

The remeha W40/60-m ECO is equipped with an

advanced control system comprising:

a. an automatic microprocessor control system

b.a control panel with setting keys and read-out display.

Various values can be set and read, using the setting

keyboard and read-out displays.

The two levels for setting and read-out are:

- user level - free access

- service level - access by service code.

The control panel accommodates the following compo-

nents

(fig. 07)

:

a.'code'-display

display of:- operating mode 1 digit

- setting mode 1. digit and dot

- read-out mode 1. digit and blinking dot

in service level:

- speed mode half digits

- failure mode 1 blinking digit

b.temperature display ( )

display of:- temperatures

- settings

- malfunctions

c. 'reset'-key:

- to reset after a malfunction

d.'mode'-key:

- key to select the required mode

e.'step'-key:

- key to select the required program within the

selected mode

f. 'store'-key:

- key to save the settings

g.'▲'-key

- to select a higher setting

h.'▼'-key:

- to select a lower setting

i. burner switch:

- to switch the boiler on/off.

c

g h

f

ed

a

b

Fig. 07 Control panel

i

11

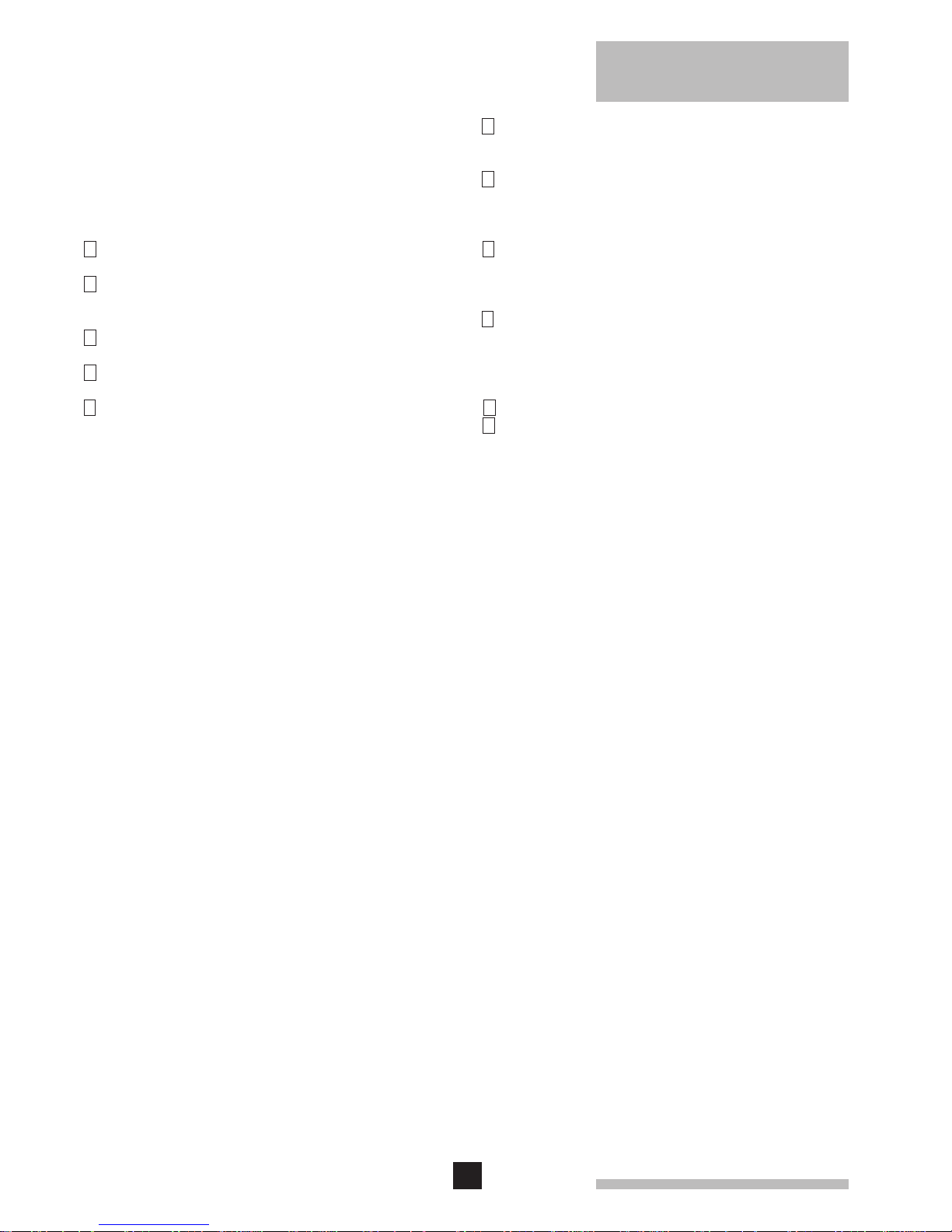

Fig. 08 Flow diagram microprocessor

6.4 Control system

6.4.1 General

digit and

dot

.

0-9

H,L

digit

Temperature display

'Code'-display

Press the 'step'-key

Press the 'mode'-key

1. Required flow temperature

2. Pump setting

3. D.H.W. setting

A. Boiler control operation

On service level (C 12):

6. Fan speed at full load (hundreds)

7. Fan speed at full load (units)

8. Fan speed at part load (hundreds)

9. Fan speed at part load (units)

b. D.H.W. cut-in temperature differential

C. Max. fan speed D.H.W.

d. Max. fan speed D.H.W.

E. Not applicable

F. Monitoring fan speed LD2

G. Forced par t load after star t

H. Fan speed at start

I. Max. flow temperature D.H.W.

J. D.H.W. control

L. Reser ve

n. Heating cut-in temperature differential

P. Security type

1. Flow temperature

2. Retur n temperature

3. D.H.W. temperature

4. Outdoor temperature

5. Not applicable

6. Flow temperature (setpoint)

7. Room ther mostat status and air pressure switch status

8. Reser ve

9. Not applicable

.

Fan speed

blinking

digit

1 Failure code

2 Operating mode during failure

3 Flow temperature during failure

4 Return temperature during failure

5 D.H.W. temperature during failure

6 Outdoor temperature during failure

half digits

Flow temperature

or

Operating

mode (see

para. 6.4.2)

Setting

mode (see

para. 6.4.3)

Read-out

mode (see

para. 6.4.4)

Speed

mode (see

para. 6.4.7)

Failure

mode (see

para. 6.4.8)

digit and

blinking dot

On service level (C 12):

12

remeha W40/60-m ECO

6.4.2 Operating mode

During operation the 'code'-display shows the status

(position in cycle) of the boiler, while the temperature

displays indicates the measured water temperature.

The digits in the 'code'-display have the following meaning:

0 Standby; there is no heat demand from the heating or

hot water controls.

1 Pre-purging; before start-up, the boiler is purged for

0,3 seconds.When the heat demand has been met,

the fan continues to operate for another 10 seconds.

2 Ignition: ignition is activated for 2.4 seconds while the

gas valve is opened.

3 Central heating mode; the boiler operates in the cen-

tral heating mode.

4 D.H.W. operation: the boiler operates when the three-

way valve serving the calorifier is actuated by a

demand from the D.H.W. temperature sensor.

5 Waiting mode; the fan runs and the boiler waits until

this has been proved or waits until the three-way

valve has returned to the central heating position.

7 Continued pump operation in the central heating

mode: after heat demand is met, the pump continues

to operate for the time selected (if continuous pump

operation has not been selected).

8 Continued pump operation in the D.H.W. mode; after

D.H.W. demand is met, the three-way valve will be

energized for another 5 minutes and the pump keeps

running.

9 Control stop

- flow temperature > 95˚C

- flow temperature > setpoint +5˚C

- return temperature > max. flow temp.-10˚C

- rise in flow temperature exceeded.

HForced full load.

L Forced part load.

Loading...

Loading...