REMEHA Quinta Pro series Installation, User And Service Manual

United Kingdom

en

Installation, user and service manual

Wall-hung gas condensing boilers

Quinta Pro

30 – 45 – 65 – 90 – 115

Dear customer,

Thank you for purchasing this appliance.

Please read this manual carefully before using the product and keep it in a safe place for future reference.

In order to ensure continued safe and efficient operation we recommend that the product is regularly maintained. Our Service

and After Sales organization can assist with this.

We hope you will receive many years of satisfactory service.

Remeha B.V.

Postbus 32

7300 AA Apeldoorn

T +31 (0)55 549 6969

I http://nl.remeha.com

E remeha@remeha.com

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.3.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Unit categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1.3 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1.4 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

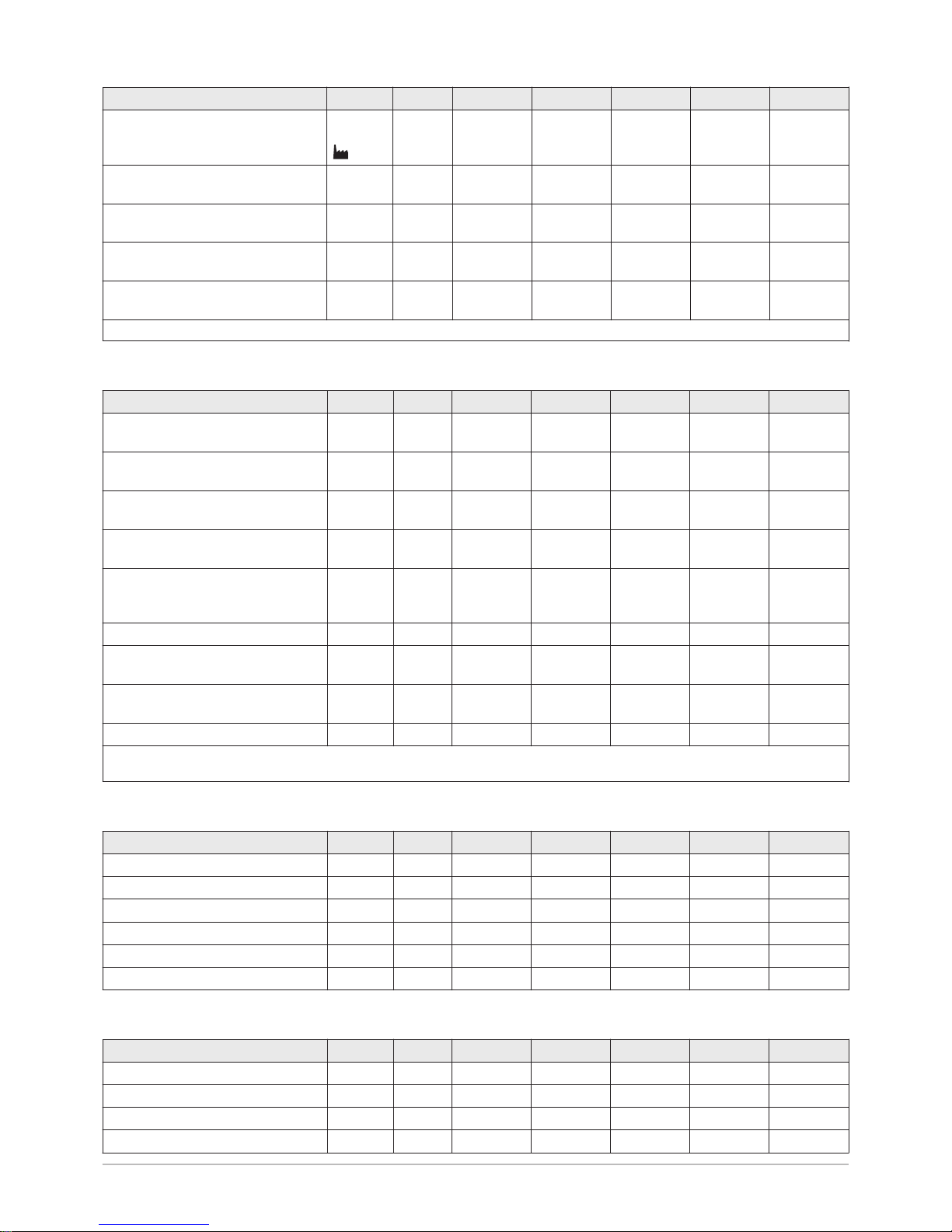

3.3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

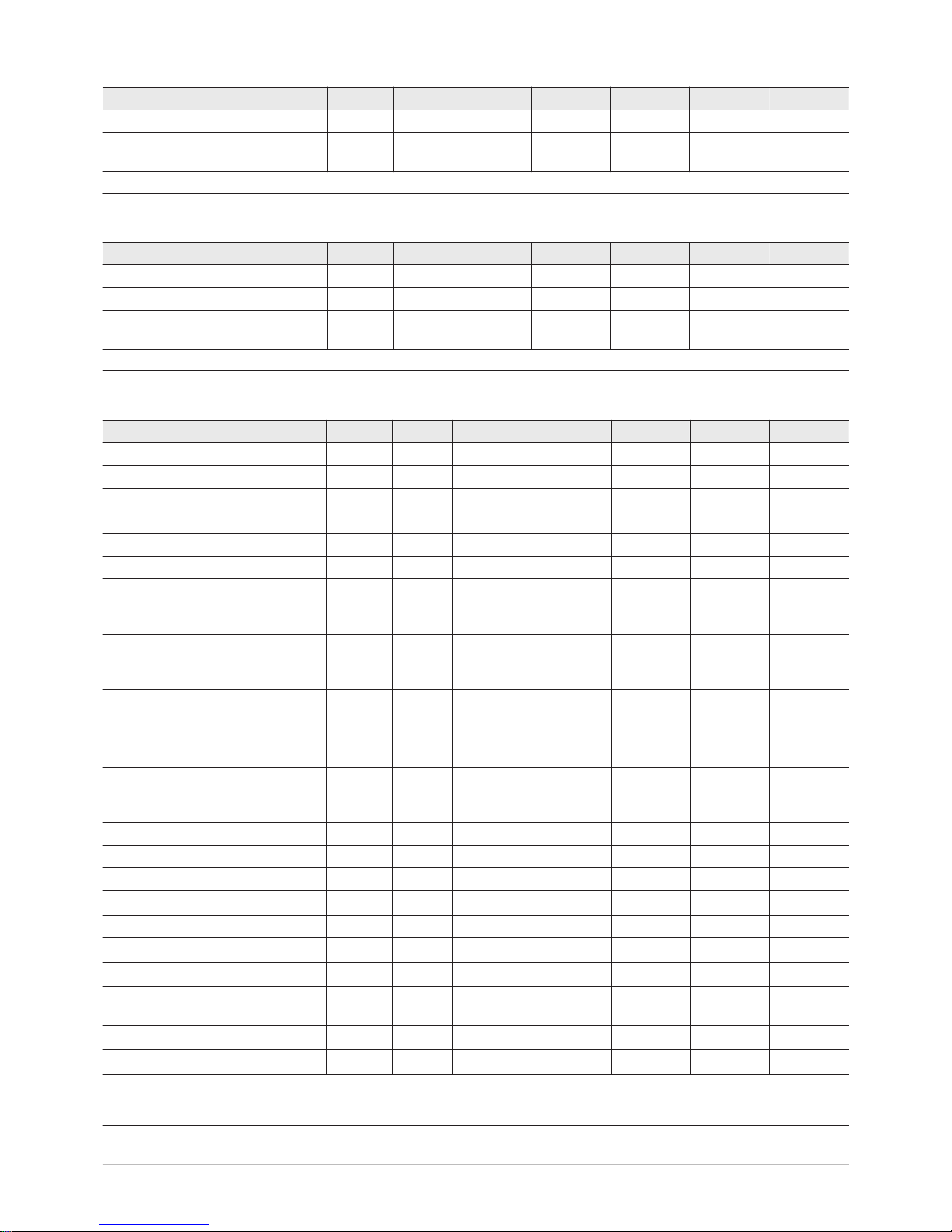

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Cascade system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Water flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.4 Calorifier connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.1 What each key means . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.2 Meaning of the symbols on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

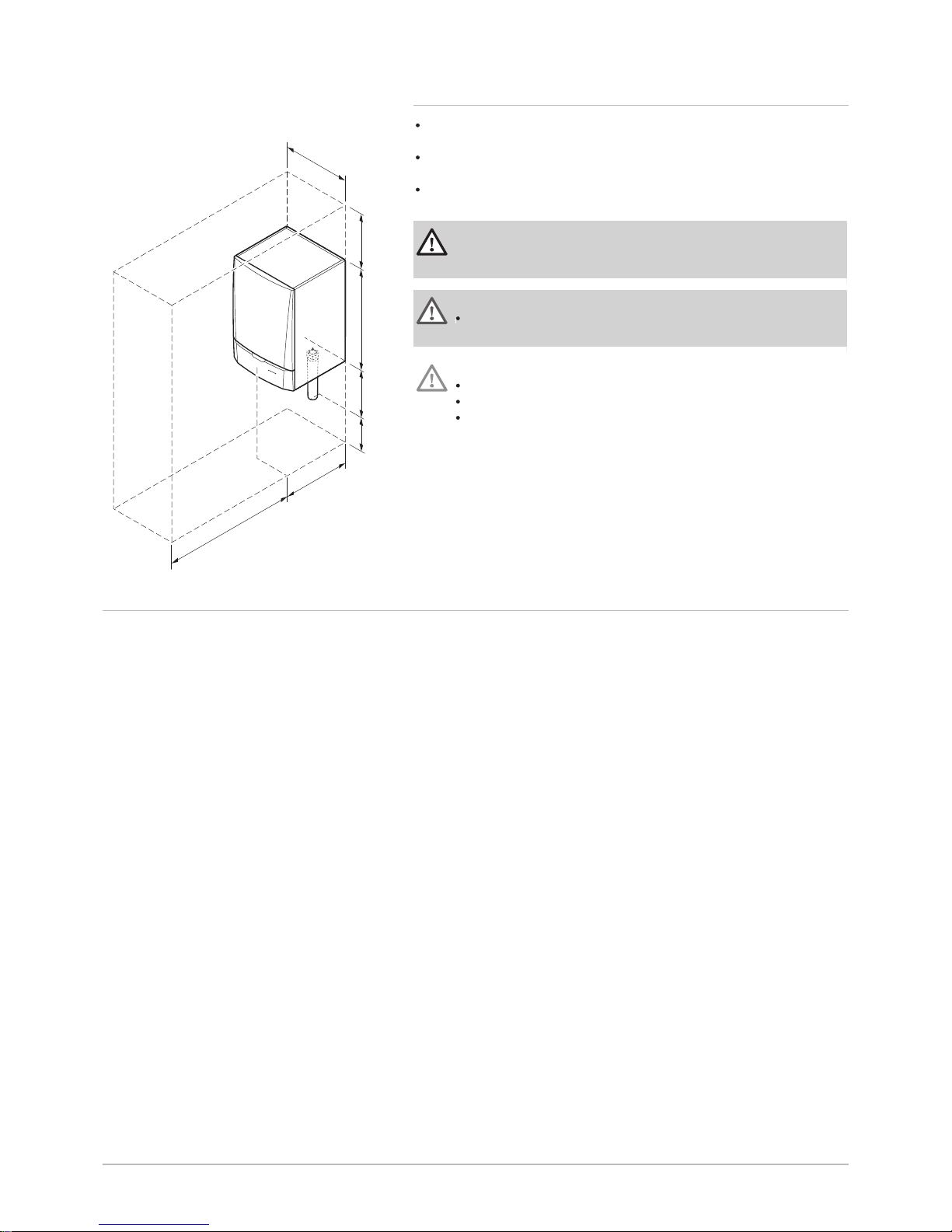

5.2.2 Boiler position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.1 Positioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.1 Rinsing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.2 Connecting the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.3 Connecting the expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.4 Connecting the condensate discharge pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.4 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.5 Air supply/flue gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.5.1 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.5.2 Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5.3 Length of the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.5.4 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.5 Flue gas outlet and air supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contents

123157 - v.06 - 24022015 3

6.6.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.6.3 Access to the connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

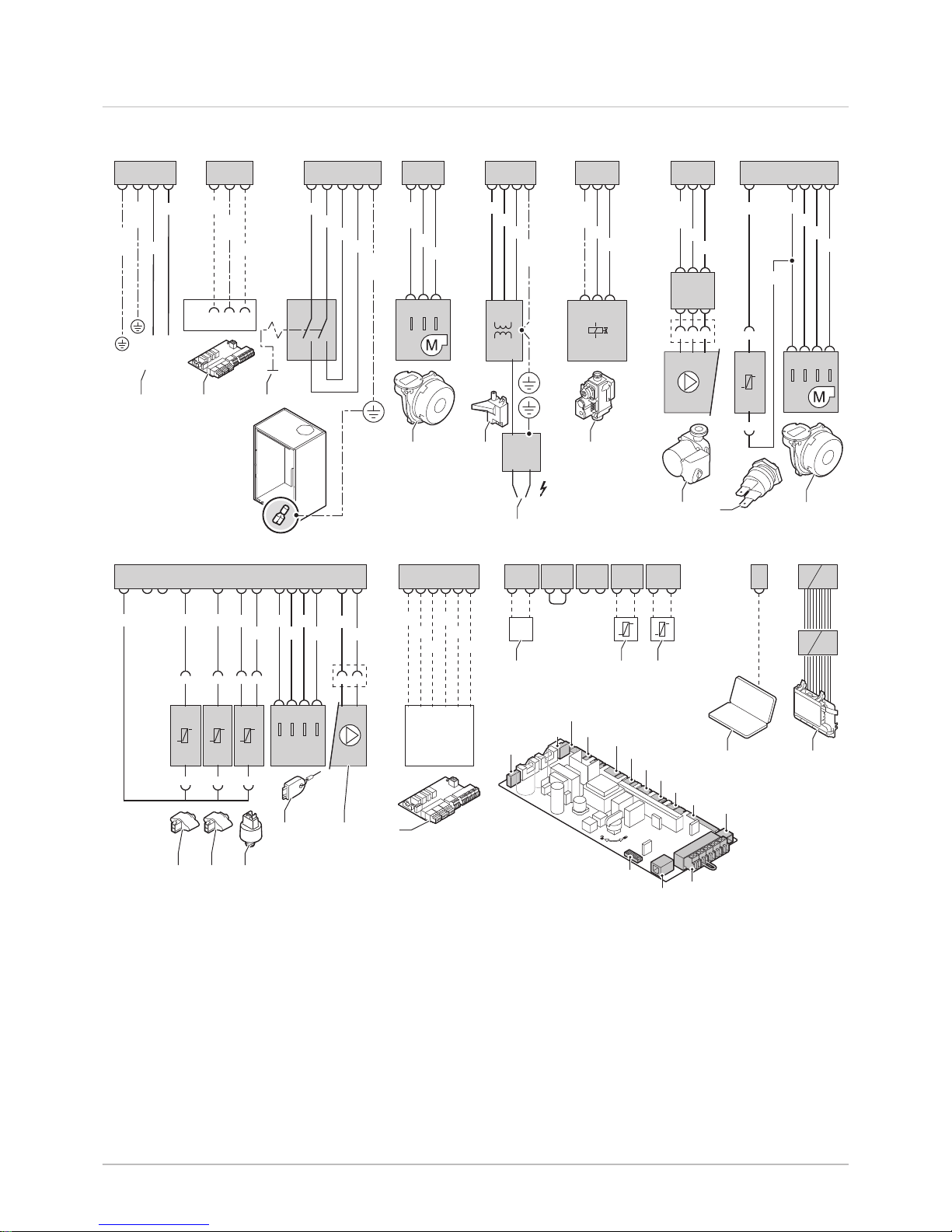

6.6.4 Connection options for the standard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6.5 PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.7.1 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.7.2 Filling the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.7.3 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2 Gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.3 Hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.6 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.6.1 Adaptation to a different gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.6.2 Checking and setting the gas/air ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.7 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.1 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.3 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.1 Parameter descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9.2 Changing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.1 Changing the user-level parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.2 Changing the parameters at installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.3 Setting the maximum load for CH operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.4 Return to the factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.2.5 Carrying out an auto-detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2.6 Setting the manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.3 Displaying the measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.3.1 Reading the various current values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.3.2 Reading out the hour counter and percentage of successful starts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.3.3 Status and sub-status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.2 Service message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

10.2.1 Resetting the service messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.2.2 Starting a new service interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

10.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

10.3.2 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.3 Checking the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.4 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.5 Checking the automatic air vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.3.6 Cleaning the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

10.3.7 Checking the burner and cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.4 Specific maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.4.1 Replacing the ionisation/ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.4.2 Checking the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.4.3 Reassembling the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

11.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.1.1 Blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.1.2 Lock out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.2 Error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.2.1 Reading out the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

11.2.2 Clearing error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Contents

4 123157 - v.06 - 24022015

12.1 Removal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

13 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14.1 ErP information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14.1.1 Product card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14.1.2 Package sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

14.2 EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

14.3 Optional electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

14.3.1 Housing for PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

14.3.2 Connection options for the PCB (SCU-S03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

14.3.3 Connection options for the PCB (SCU-X02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

14.3.4 Connection options for the PCB (SCU-X03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

14.3.5 Connection options for the PCB (c-Mix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Contents

123157 - v.06 - 24022015 5

1 Safety

1.1 General safety instructions

For the installer:

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and do

not operate electrical contacts or switches (door

bell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them off immediate

ly.

5. If the leak is upstream of the gas meter, notify the

gas company.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Trace possible leaks and seal them off immediate

ly.

Caution

After maintenance or repair work, check the entire

heating installation to ensure that there are no leaks.

For the end user:

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and do

not operate electrical contacts or switches (door

bell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Report any leaks immediately.

5. Evacuate the property.

6. Contact a qualified installer.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Report any leaks immediately.

4. Evacuate the property.

5. Contact a qualified installer.

Warning

Do not touch the flue gas pipes. Depending on the

boiler settings, the temperature of the flue gas pipes

can rise to over 60°C.

1 Safety

6 123157 - v.06 - 24022015

Warning

Do not touch radiators for long periods. Depending on

the boiler settings, the temperature of the radiators

can rise to over 60°C.

Caution

Ensure that the boiler is regularly serviced. Contact a

qualified installer or arrange a maintenance contract

for the servicing of the boiler.

Caution

Only genuine spare parts may be used.

Note

Regularly check for the presence of water and pres

sure in the heating installation.

1.2 Recommendations

Danger

This appliance must not be used by people (and chil

dren) with a physical, sensory or mental disability, or

by people with a lack of technical experience, unless

they are supervised by someone who can assure their

safety, or they have been instructed in the correct use

of the appliance. Do not allow children to play with the

appliance.

Warning

Installation and maintenance of the boiler must be car

ried out by a qualified installer in accordance with lo

cal and national regulations.

Warning

Removal and disposal of the boiler must be carried

out by a qualified installer in accordance with local

and national regulations.

Warning

If the mains lead is damaged, it must be replaced by

the original manufacturer, the manufacturer's dealer

or another suitably skilled person to prevent hazard

ous situations from arising.

Warning

Always disconnect the mains supply and close the

main gas tap when working on the boiler.

Warning

Check the entire system for leaks after maintenance

and servicing work.

1 Safety

123157 - v.06 - 24022015 7

Caution

Make sure the boiler can be reached at all times.

The boiler must be installed in a frost-free area.

In the case of a fixed connection to the power cord,

you must always install a main bipolar switch with an

opening gap of at least 3 mm (EN 60335-1).

Drain the boiler and central heating system if you

are not going to use your home for a long time and

there is a chance of frost.

The frost protection does not work if the boiler is out

of operation.

The boiler protection only protects the boiler, not the

system.

Check the water pressure in the system regularly. If

the water pressure is lower than 0.8 bar, the system

must be topped up (recommended water pressure

between 1.5 and 2 bar).

Note

Keep this document near to the boiler.

Note

Casing panels may only be removed for maintenance

and servicing purposes. Refit all panels when mainte

nance work and servicing are complete.

Note

Instruction and warning labels must never be removed

or covered and must be clearly legible throughout the

entire service life of the boiler. Replace damaged or il

legible instruction and warning labels immediately.

Note

Modifications to the boiler require the written approval

of Remeha.

1.3 Liabilities

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the re

quirements of the various Directives applicable. They are

therefore delivered with the marking and any documents

necessary. In the interests of the quality of our products, we

strive constantly to improve them. We therefore reserve the

right to modify the specifications given in this document.

Our liability as manufacturer may not be invoked in the fol

lowing cases:

Failure to abide by the instructions on installing the appli

ance.

Failure to abide by the instructions on using the appliance.

Faulty or insufficient maintenance of the appliance.

1 Safety

8 123157 - v.06 - 24022015

1.3.2 Installer's liability

The installer is responsible for the installation and initial com

missioning of the appliance. The installer must abide by the

following instructions:

Read and follow the instructions given in the manuals pro

vided with the appliance.

Install the appliance in compliance with prevailing legisla

tion and standards.

Carry out initial commissioning and any checks necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the obliga

tion to check the appliance and keep it in good working or

der.

Give all the instruction manuals to the user.

1.3.3 User's liability

To guarantee optimum running of the installation, you must

abide by the following instructions:

Read and follow the instructions given in the manuals pro

vided with the appliance.

Call on a qualified professional to carry out installation and

initial commissioning.

Get your installer to explain your installation to you.

Have the required checks and services done by a qualified

professional.

Keep the instruction manuals in good condition close to the

appliance.

1 Safety

123157 - v.06 - 24022015 9

2 About this manual

2.1 Symbols used

2.1.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special in

structions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations resulting in serious personal injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations resulting in minor personal injury.

Caution

Risk of material damage.

Note

Please note: important information.

See

Reference to other manuals or pages in this manual.

2.2 Abbreviations

DHW Domestic hot water

PCU PCB for managing burner operation

PWM Pulse wide modulation

SCU Control panel PCB

SU Safety PCB

2 About this manual

10 123157 - v.06 - 24022015

3 Technical specifications

3.1 Homologations

3.1.1 Certifications

Tab.1 Certifications

CE identification number PIN 0063CL3333

NOx class 5 (EN 15502–1)

Type of connection B23, B

23P

, B

33

C13, C33, C43, C53, C63, C83, C

93

3.1.2 Unit categories

Category Gas type Connection pressure

(mbar)

II

2H3B/P

G20 (H gas)

G30/G31 (butane/

propane)

20

30-50

3.1.3 Directives

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines speci

fied in this manual.

3.1.4 Factory test

Before leaving the factory, each boiler is optimally set and tested for:

Electrical safety.

Adjustment of (O2/CO2).

Water tightness.

Gas tightness.

Parameter setting.

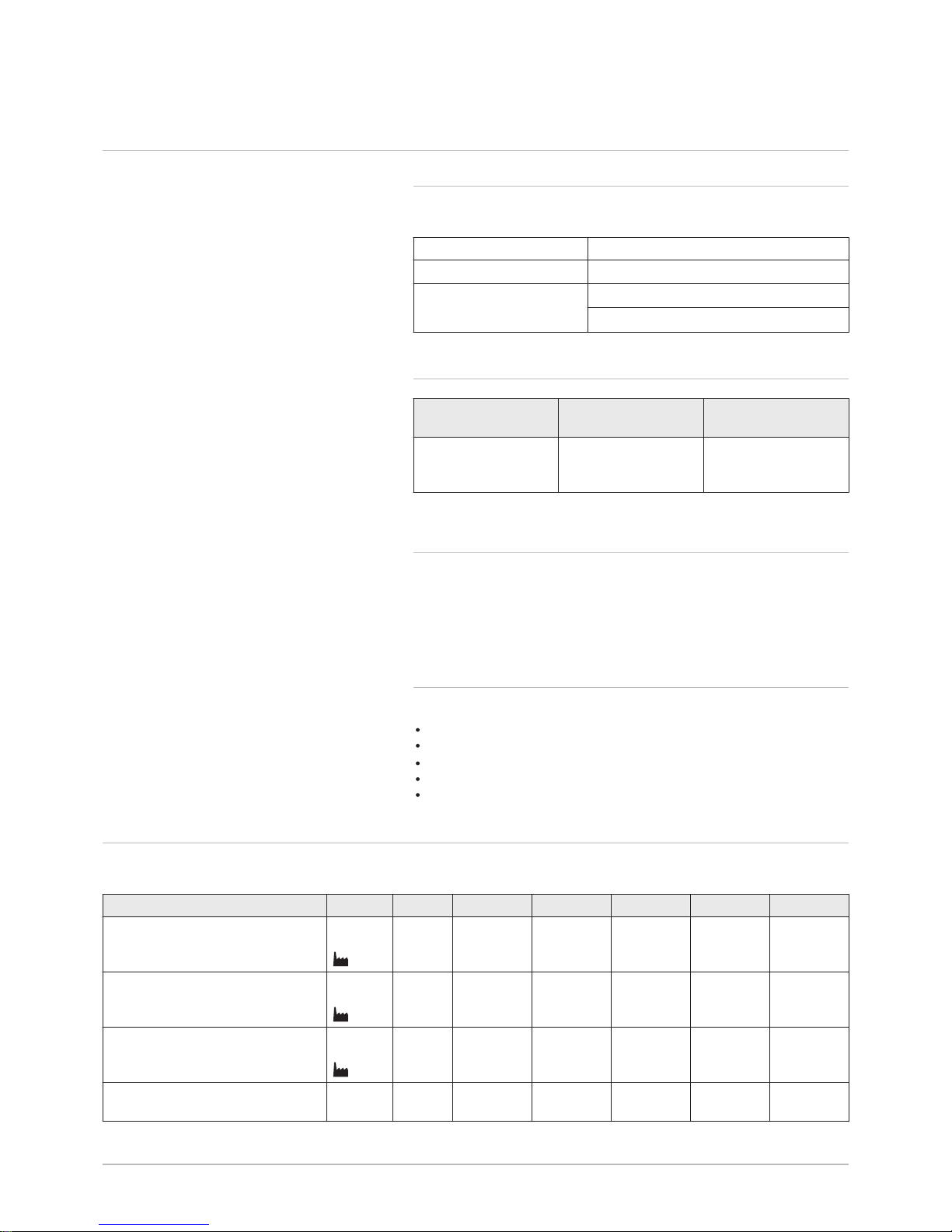

3.2 Technical data

Tab.2 General

Quinta Pro 30 45 65 90 115

Nominal output (Pn)

Central heating operation (80°C/

60°C)

min.–

max.

(1)

kW 8.0–29.3

29.3

8.0–40.0

40.0

12.0–61.0

61.0

14.1–84.2

84.2

20.5–107.0

107.0

Nominal output (Pn)

Central heating operation (50°C/

30°C)

min.–

max.

(1)

kW 8.9–31.4

31.4

8.9–43.0

43.0

13.3–65.0

65.0

15.8–89.5

89.5

22.7–114.0

114.0

Nominal input (Qn)

Central heating operation (Hi)

min.–

max.

(1)

kW 8.2–30.0

30.0

8.2–41.2

41.2

12.2–62.0

62.0

14.6–86.0

86.0

19.6–110.2

110.2

Nominal input (Qn)

CH operation (Hi) G31 (propane)

min kW 8.8 8.8 12.2 22.1 21.2

3 Technical specifications

123157 - v.06 - 24022015 11

Quinta Pro 30 45 65 90 115

Nominal input (Qn)

Central heating operation (Hs)

min.–

max.

(1)

kW 9.1–33.3

33.3

9.1–45.7

45.7

13.6–68.8

68.8

16.2–95.5

95.5

21.9–122.4

122.4

Full load central heating efficiency

(Hi) (80°C/60°C)

% 97.5 97.2 98.3 97.9 97.1

Full load central heating efficiency

(Hi) (50°C/30°C)

% 102.9 102.9 104.6 104.1 102.5

Low load central heating efficiency

(Hi) (return temperature 60°C)

% 97.5 97.5 98.3 96.6 96.5

Partial load CH efficiency (return

temperature 30°C)

% 108.5 108.4 108.9 108.1 108.0

(1) Factory setting

Tab.3 Gas and flue gas data

Quinta Pro 30 45 65 90 115

Gas inlet pressure G20 (H gas) min.–

max.

mbar 17–25 17–25 17–25 17–25 17–25

Gas inlet pressure G31 (propane) min.–

max.

mbar 37–50 37–50 37–50 37–50 37–50

Gas consumption G20 (H gas)

(1)

min.–

max.

m3/h

0.9–3.2 0.9–4.4 1.3–6.6 1.5–9.1 2.0–11.7

Gas consumption G31 (propane)

(2)

min.–

max.

m3/h

0.4–1.2 0.4–1.7 0.5–2.5 0.9–3.5 0.9–4.5

Gas resistance between boiler con

nection and measurement point on

the gas valve unit G20 (H gas)

0.5 1.0 2.0 2.5 3.0

BREAM NOx mg/kWh 37 37 32 29 35

Flue gas quantity min.–

max.

kg/h

g/s

14–50

4.1–15.1

14–69

4.1–20.7

21–104

5.9–30.1

28–138

6.5–39.5

36–178

8.0–52.8

Flue gas temperature min.–

max.

°C 30–65 30–67 30–68 30–68 30–72

Maximum counter pressure Pa 70 150 100 160 220

(1) Gas consumption based on lower heating value under standard conditions: T=288.15 K, p=1013.25 mbar. Gag 30.33; G25 29.25; G31

88.00 MJ/m3

Tab.4 Central heating circuit data

Quinta Pro 30 45 65 90 115

Water content l 6.2 6.2 7.9 11.5 11.5

Water operating pressure min bar 0.8 0.8 0.8 0.8 0.8

Water operating pressure (PMS) max bar 4.0 4.0 4.0 4.0 4.0

Water temperature max °C 110.0 110.0 110.0 110.0 110.0

Operating temperature max °C 90.0 90.0 90.0 90.0 90.0

Hydraulic resistance (ΔT=20K) mbar 70 90 130 140 250

Tab.5 Electrical data

Quinta Pro 30 45 65 90 115

Supply voltage VAC 230 230 230 230 230

Power consumption - full load max W 39 68 88 125 199

Power consumption - low load max W 18 18 23 20 45

Power consumption - standby max W 5 5 6 4 7

3 Technical specifications

12 123157 - v.06 - 24022015

Quinta Pro 30 45 65 90 115

Electrical protection index

(1)

IP

X4D

(3)

X4D

(3)

X4D

(3)

X4D

(3)

X4D

(3)

Fuses Main

PCU

A 6.3

2.0

6.3

2.0

6.3

2.0

6.3

2.0

6.3

2.0

(1) Splashproof; under certain conditions, the boiler may be installed in damp areas, such as bathrooms.

Tab.6 Other data

Quinta Pro 30 45 65 90 115

Total weight (empty) kg 53 53 60 67 68

Minimum mounting weight

(1)

kg 49 49 56 65 65

Average acoustic level at a distance

of one metre from the boiler

dB(A) 38 45 45 52 51

(1) Without front panel.

Tab.7 Technical parameters

Quinta Pro 30 45 65 90 115

Condensing boiler Yes Yes Yes Yes Yes

Low-temperature boiler

(1)

Yes Yes Yes Yes Yes

B1 boiler No No No No No

Cogeneration space heater No No No No No

Combination heater Yes Yes Yes No No

Rated heat output

Prated

kW 29 40 61 84 107

Useful heat output at nominal heat

output and high temperature oper

ation

(2)

P

4

kW 29.3 40.0 61.0 84.2 107.0

Useful heat output at 30% of rated

heat output and low temperature

regime

(5)

P

1

kW 9.8 13.4 20.3 27.9 35.7

Seasonal space heating energy effi

ciency

ƞ

s

% 93 93 93 - -

Useful efficiency at rated heat out

put and high temperature regime

(6)

ƞ

4

% 87.8 87.6 88.6 88.2 87.5

Useful efficiency at 30% of rated

heat output and low temperature

regime

(5)

ƞ

1

% 97.7 97.7 98.1 97.4 97.3

Auxiliary electricity consumption

Full load

elmax

kW 0.039 0.068 0.088 0.125 0.199

Part load

elmin

kW 0.018 0.018 0.023 0.020 0.045

Standby mode

P

SB

kW 0.005 0.005 0.006 0.004 0.007

Other items

Standby heat loss

P

stby

kW 0.101 0.101 0.110 0.123 0.123

Ignition burner power consumption

P

ign

kW - - - - -

Annual energy consumption

Q

HE

kWh

GJ

- - - - -

Sound power level, indoors

L

WA

dB 46 53 53 60 59

Emissions of nitrogen oxides NO

X

mg/kWh 32 33 29 41 41

(1) Low temperature means 30°C for condensing boilers, 37°C for low temperature boilers and 50°C (at heater inlet) for other heating appli

ances.

(2) High temperature operation means 60°C return temperature at heater inlet and 80°C feed temperature at heater outlet.

3 Technical specifications

123157 - v.06 - 24022015 13

See

The back cover for contact details.

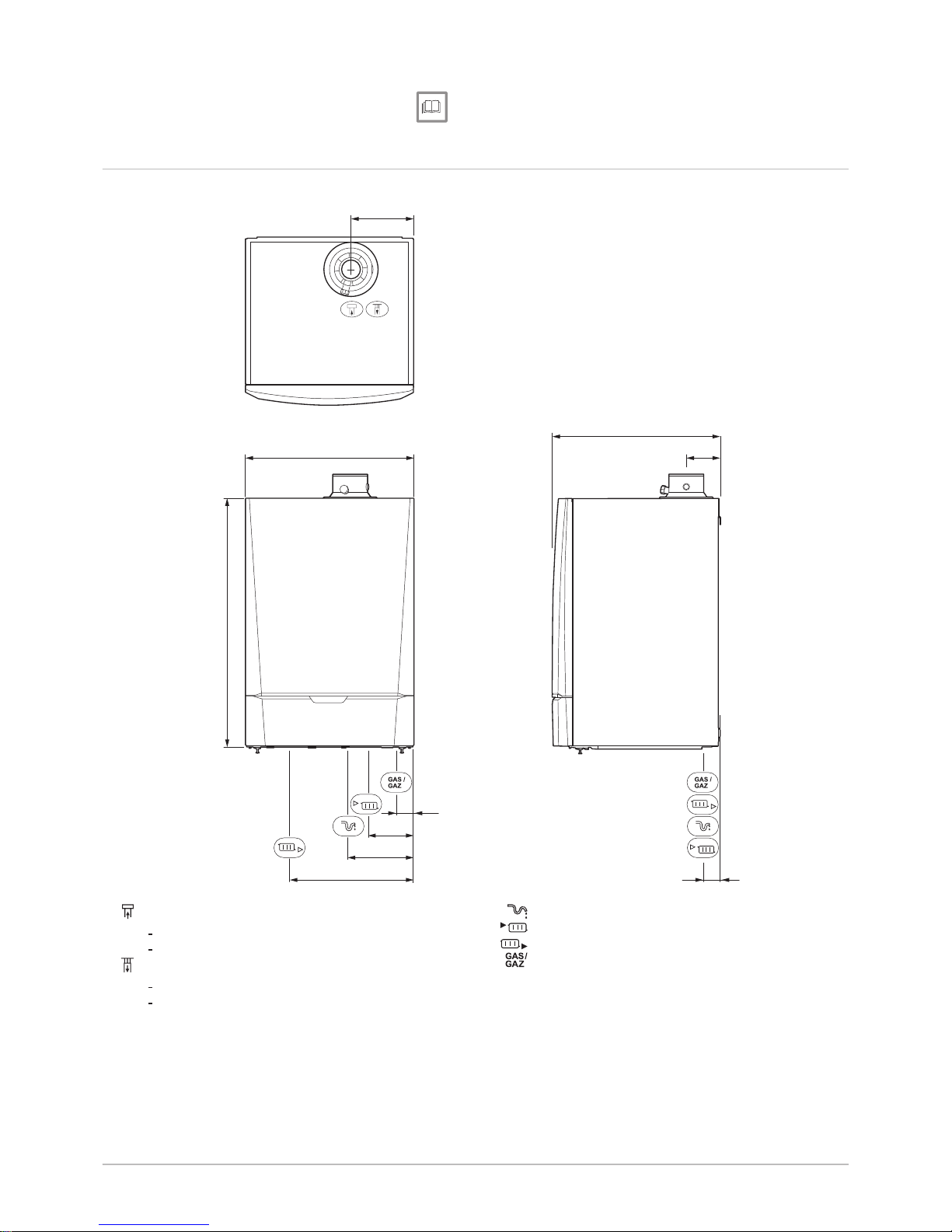

3.3 Dimensions and connections

Fig.1 Dimensions

AD-0000017-01

191

500

750

500

100

50

50

130

191

365

Flue gas outlet connection:

Ø 80 mm (≤ 45 kW)

Ø 100 mm (≥ 65 kW)

Air supply connection:

Ø 125 mm (≤ 45 kW)

Ø 150 mm (≥ 65 kW)

Siphon connection, 32 mm

CH supply connection; 1 ¼ inch male thread

CH return connection; 1 ¼ inch male thread

Gas connection; ¾ inch male thread

3 Technical specifications

14 123157 - v.06 - 24022015

3.4 Electrical diagram

Fig.2 Electrical diagram

AD-0000062-01

X1

X14

X13

X12

X3

X2

X4

X5

X6

X7

X8

X9

X10

X11

X13

1

X6

1 2 3

GN/

YW

WH

BL

153

X21

X8

1 2 3

BR

BL

GN/

YW

2 1 3

X81

3 1 2

X11

1 2 3 4 5 6

WH

GY

OR

RD

GN

YW

X5

2 3 4 1

BK

BL

GN/

YW

GY

1 23

X51

12 13

BK

BK

1 2

X116

9

RD

1

BK

1

2 2

X115

8

BL

1

2

X114

10 11

BK

BK

3 1

X112

2 3

X10

4 5 7 6

X111

BK

BK

BK

BK

1 2 3 4

X9

2 3 4 5

X91

BK

BK

BK

BK

1 2 4 5

1

BK

BK

1

2

X117

X4

1 2 3

X41

BR

BL

GN/

YW

3 1 2

230V, 50Hz

LN

X2

1 32

BL

BR

GN/

YW

2 31

K1

X1

1 32

BR

BL

4

X14

1 10

1 10

X3

4 3 2 15

BR

BL

BR

BL

GN/

YW

3 1

4 2

X51

X12

3 4 5 61 2 7 8

9 1 0

GN/

YW

GN/

YW

1 2 3

4 7

8

13 14

15 16 17

18 19

121110

4

5

6

2

9

1

Power supply (P)

2

Extended PCB (SCU)

3

On/off switch (S)

4

Fan (FAN)

5

Ignition transformer (IT)

6

Ignition pin (E)

7

Gas combination block (GB)

8

Circulating pump (pump A)

9

High limit switch (HLS)

10

Return sensor (RTS)

11

Flow sensor (FTS)

12

Pressure switch (PS)

13

Storage parameter (PSU)

14

Circulating pump (PWM pump)

15

Thermostat (OT)

16

Outside sensor (OS)

17

Calorifier sensor (WS)

18

Computer connection (PC)

19

Display (DIS)

3 Technical specifications

123157 - v.06 - 24022015 15

4 Description of the product

4.1 General description

The Quinta Pro boiler is a high-efficiency wall-hung gas boiler with the fol

lowing properties:

High-efficiency heating.

Option to produce domestic hot water using a separate hot water appli

ance.

Limited emissions of polluted substances.

Ideal choice for cascade configurations.

4.2 Operating principle

4.2.1 Circulating pump

The boiler is supplied without a pump. Take the boiler resistance and sys

tem resistance into account when selecting a pump.

Caution

The pump may have a maximum input of 200 W. Use an auxiliary

relay for a pump with greater power.

See

Technical data, page 11

If possible, install the pump directly under the boiler on the return connec

tion.

For more information, see

Connecting the heating circuit, page 22

4.2.2 Cascade system

The boiler is ideally suited for a cascade system. There are a number of

standard solutions available.

Note

Contact us for more information.

4.2.3 Water flow

The modulating control of the boiler limits the maximum temperature differ

ence between the flow and return and the maximum rise velocity of the

flow temperature. As a result, the boiler is virtually unaffected by low water

flow. In all cases, maintain a minimum water flow of 0.4 m

3

/h. If progres

sive calorifier control is activated with parameter , then maintain a

minimum water flow of 0.8 m

3

/h.

4.2.4 Calorifier connection

A calorifier can be connected to the boiler. Our range includes various cal

orifiers.

Note

Contact us for more information.

Connect the calorifier to the boiler with a calorifier pump. A three-way

valve is not suitable due to the hydraulic resistance. An optional PCB is re

quired to connect a calorifier pump.

4 Description of the product

16 123157 - v.06 - 24022015

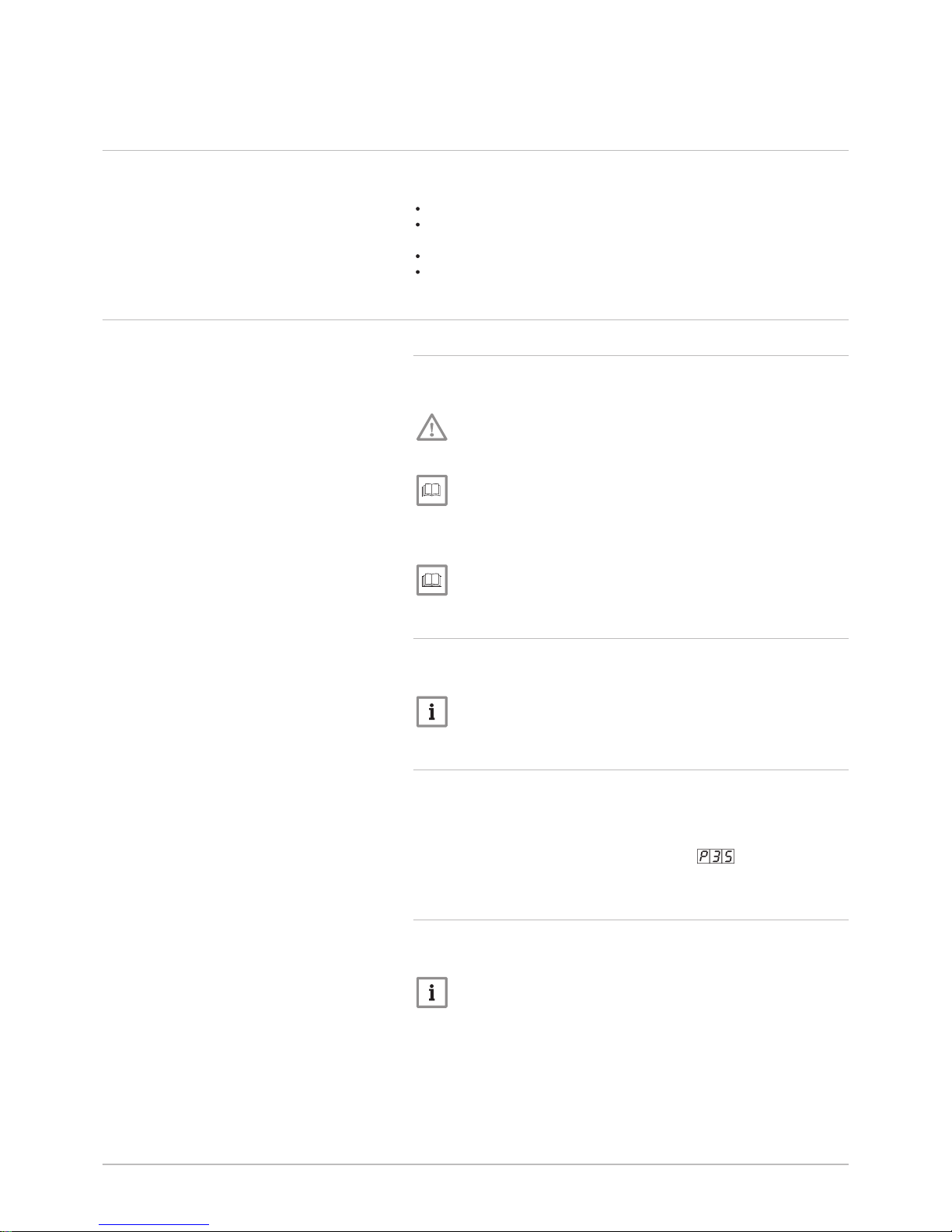

4.3 Main components

1

Flue gas outlet/air supply

2

Casing/air box

3

Heat exchanger (CH)

4

Flue gas measuring point

5

Ionisation/ignition electrode

6

Mixer tube

7

Combined gas valve unit

8

Air intake silencer

9

Instrument box

10

Siphon

11

Housing for PCBs

12

Fan

13

Water flow pipe

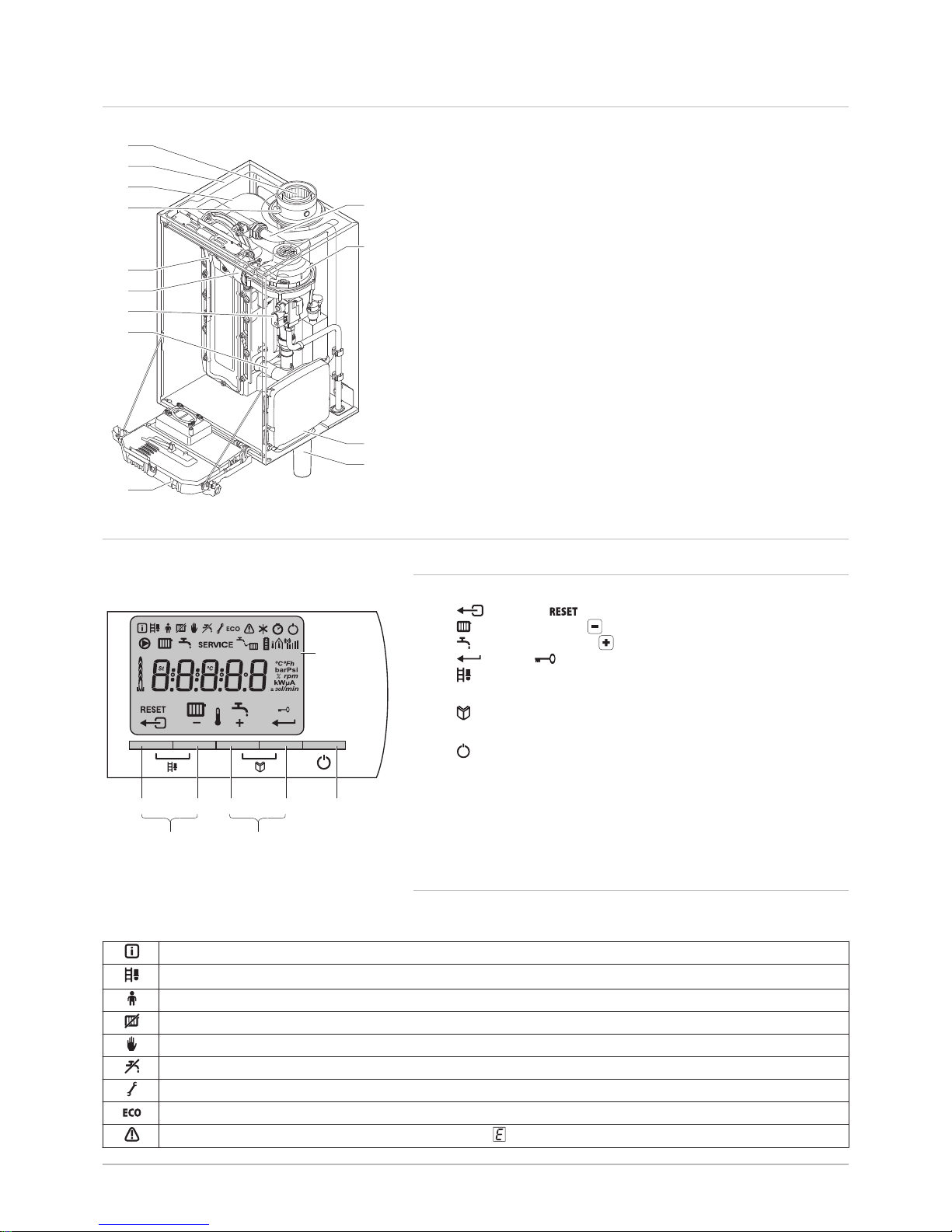

4.4 Control panel description

4.4.1 What each key means

1

Display

2

Escape or key

3

CH temperature or key

4

DHW temperature or key

5

Enter or Cancel key lockout

6

Chimney-sweeping keys

Press the 2 and 3 keys simultaneously.

7

Menu keys

Press the 4 and 5 keys simultaneously.

8

On/off switch

4.4.2 Meaning of the symbols on the display

Tab.8 Symbols on the display

Information menu: Read out various current values.

Chimney-sweeping position: Forced high or low load for O2/CO2 measurement.

User menu: Parameters at user level can be changed.

Central heating function off: The heating function is deactivated.

Manual mode: Boiler is set to manual mode.

DHW function off: The DHW function is switched off.

Service menu: Parameters at installer level can be changed.

ECO setting: The economy setting is activated.

Fault: Boiler indicates a fault. This can be seen from the code and red display.

Fig.3 Main components

AD-0000011-01

8

7

4

5

5

6

2

1

3

9

11

10

12

13

Fig.4 Control panel

AD-0000065-01

1

2 3 4 5 8

6 7

4 Description of the product

123157 - v.06 - 24022015 17

Frost protection: Boiler is running in frost protection mode.

Hour counter menu: Read out the operating hours, number of successful starts and hours on mains supply.

On/off switch: After 5 lockouts, the boiler must be switched off/on again.

Circulating pump: The pump is running.

CH function: Access to CH temperature parameter.

DHW function: Access to DHW temperature parameter.

Yellow display with the symbols: + + (maintenance message).

Water pressure: The water pressure is too low.

Battery symbol: Status of battery in wireless controller.

Signal strength symbol: Signal strength of the wireless controller.

Burner level: Boiler is running at full or part load.

Key lockout: Key lockout is activated.

4.5 Standard delivery

The delivery includes:

The boiler, with mains lead

Suspension bracket and fasteners for wall mounting

Mounting template

Connection cable for pump (Quinta Pro 90/115)

Documentation

This manual only deals with the standard scope of supply. For the installa

tion or mounting of any accessories delivered with the boiler, refer to the

corresponding mounting instructions.

4.6 Accessories and options

Various accessories can be obtained for the boiler.

Note

Contact us for more information.

4 Description of the product

18 123157 - v.06 - 24022015

5 Before installation

5.1 Installation regulations

Warning

The installer must be registered with Gas Safe and have the cor

rect ACS qualifications.

Note

Practical guidelines — see the latest version.

5.2 Choice of the location

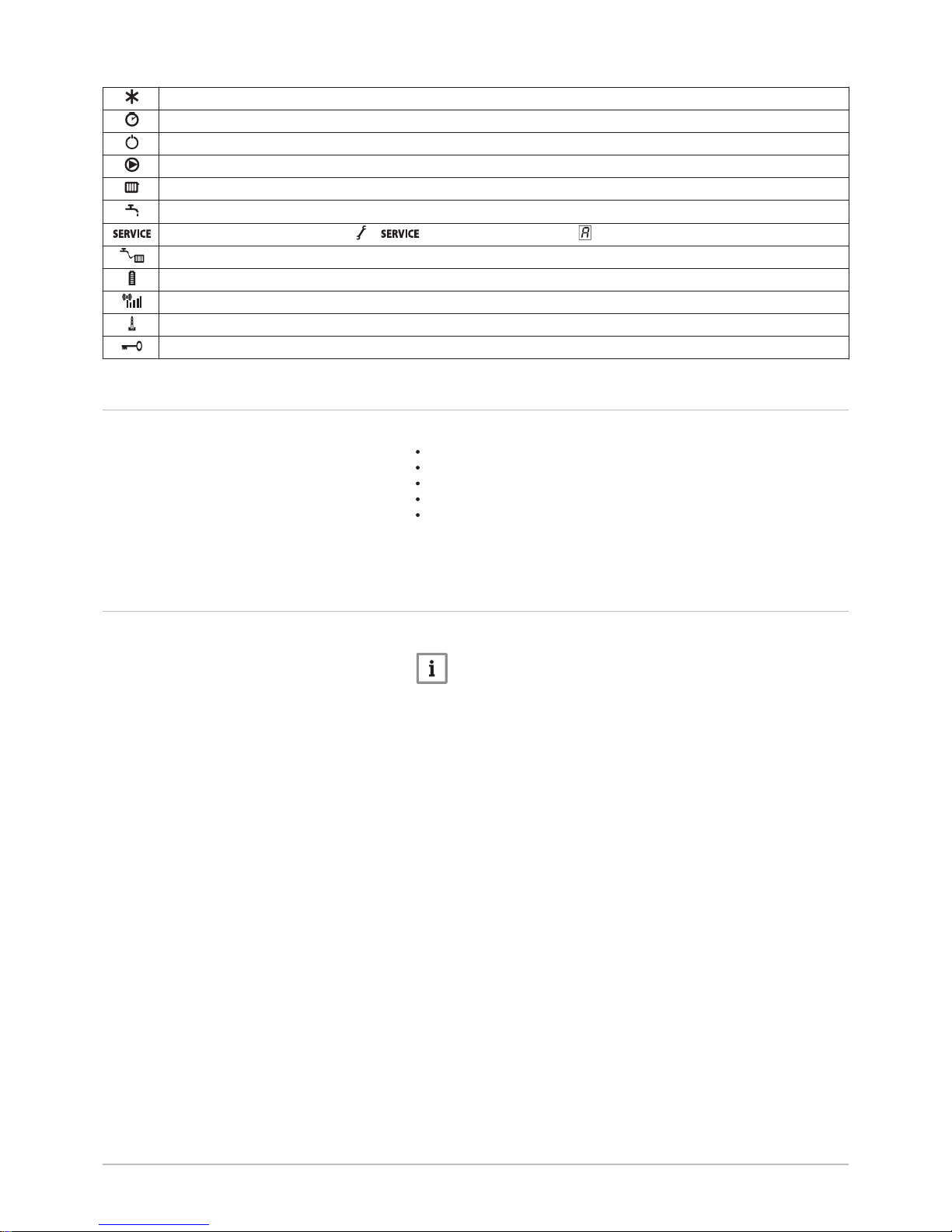

5.2.1 Type plate

The type plate on top of the boiler features the boiler serial number and

important boiler specifications, for example the model and unit category.

The dF and dU codes are also stated on the type plate.

Fig.5

Position of type plate

AD-0000013-01

5 Before installation

123157 - v.06 - 24022015 19

5.2.2 Boiler position

Use the guidelines and the required installation space as a basis for de

termining the correct place to install the boiler.

When determining the correct installation space, take account of the

permitted position of the flue gas discharge and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

Danger

It is forbidden to store, even temporarily, combustible products

and substances in the boiler or near the boiler.

Warning

Fix the appliance to a solid wall capable of bearing the weight of

the boiler when full of water and fully equipped.

Caution

The boiler must be installed in a frost-free area.

The boiler must have an earthed electrical connection.

A connection to the sewer must be present for the condensate

drain close to the boiler.

5.3 Ventilation

The installation must comply with BS 5540 (part 1 + 2), BS 6640 and

IGUP/10.

Fig.6 Installation area

AD-0000014-01

500

min.1000

500

min.

400

350

min.

250

750

5 Before installation

20 123157 - v.06 - 24022015

6 Installation

6.1 General

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

6.2 Preparation

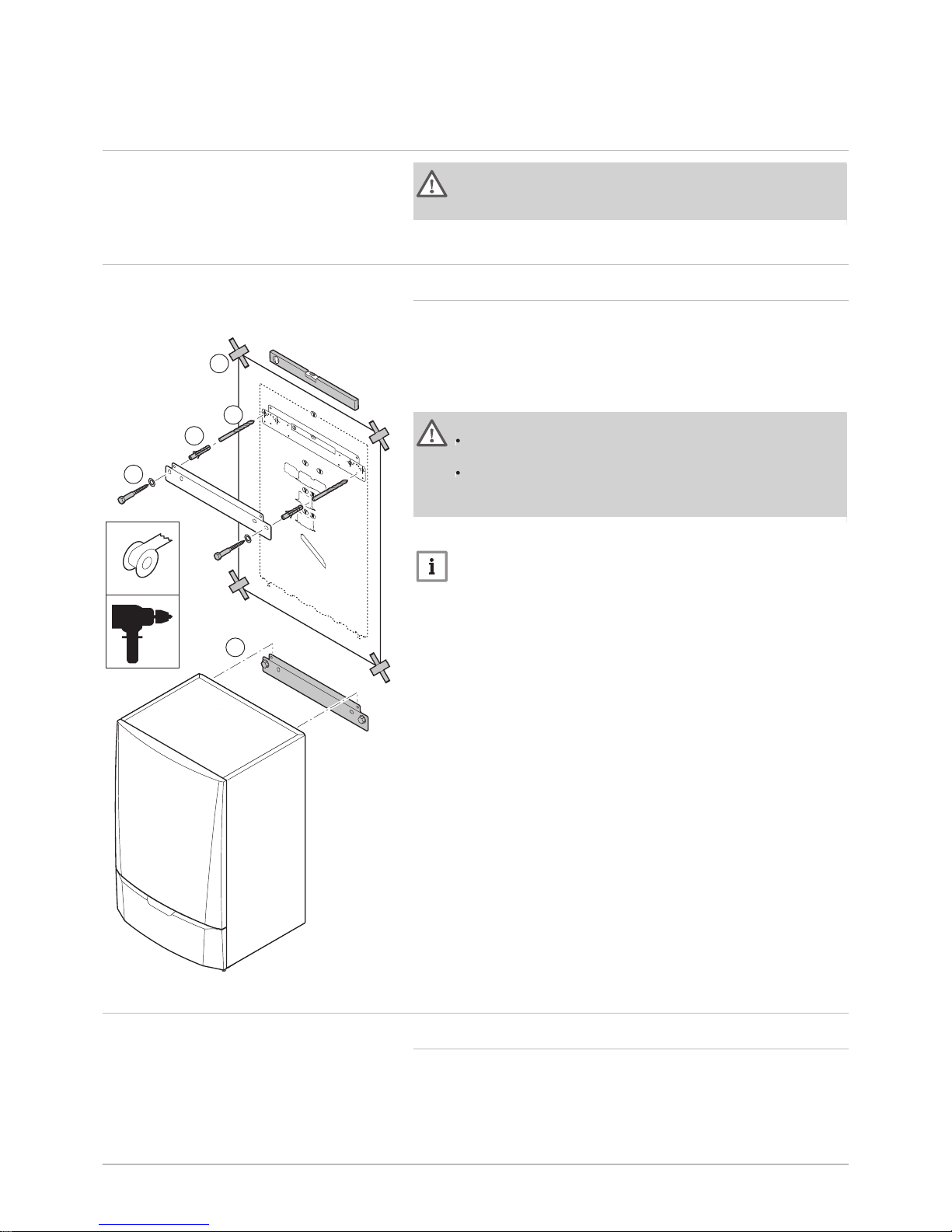

6.2.1 Positioning the boiler

The fitting bracket on the back of the casing can be used to mount the

boiler directly on the suspension bracket.

The boiler is supplied with a mounting template.

1. Attach the mounting template of the boiler to the wall using adhesive

tape.

Warning

Use a level to check whether the mounting template is hanging

perfectly horizontally.

Protect the boiler against building dust and cover the connection

points for the flue gas outlet and air supply. Only remove this

cover to assemble the relevant connections.

2. Drill 2 holes of Ø 10 mm.

Note

The extra holes are intended for use in the event that one of the

two fastening holes is not suitable for correct fastening of the plug.

3. Fit the Ø 10 mm plugs.

4. Attach the suspension bracket to the wall with the Ø 10 mm bolts

supplied.

5. Mount the boiler on the suspension bracket.

6.3 Water connections

6.3.1 Rinsing the system

The installation must be cleaned and flushed in accordance with BS 7593

(2006).

Before a new CH boiler can be connected to an existing or new installa

tion, the entire installation must be thoroughly cleaned and flushed. This

step is absolutely crucial. The flushing helps to remove residue from the

Fig.7 Mounting the boiler

AD-0000018-01

2

1

5

4

3

6 Installation

123157 - v.06 - 24022015 21

installation process (weld slag, fixing products etc.) and accumulations of

dirt (silt, mud etc.)

Note

Flush the CH installation with a volume of water equivalent to at

least three times the volume of the CH installation. Flush the DHW

pipes with at least 20 times the volume of the pipes.

Note

Due to the presence of an aluminium heat exchanger, suitable

chemicals and the correct use of these chemicals should be dis

cussed with specialist water treatment companies.

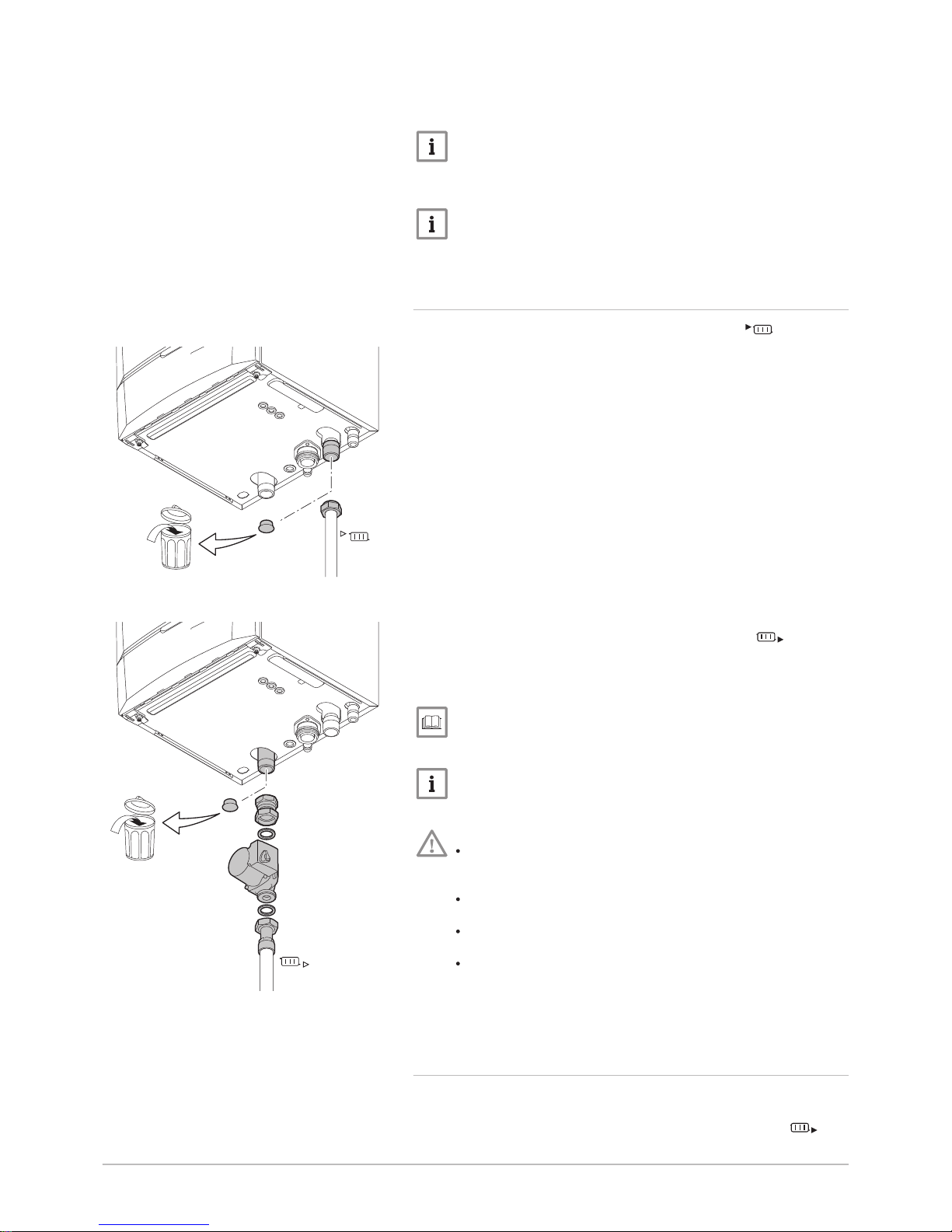

6.3.2 Connecting the heating circuit

1. Remove the dust cap from the CH flow connection at the bot

tom of the boiler.

2. Fit the outlet pipe for CH water to the CH flow connection.

3. For filling and tapping the boiler, install a filling and drain valve in the

system.

4. Remove the dust cap from the CH return connection at the bot

tom of the boiler.

5. Fit the inlet pipe for CH water to the CH return connection.

6. Install the pump in the CH return pipe (if applicable).

See

For the pump's electrical connection: Connecting the pump, page

30

Note

Fit a service shut-off valve in the CH flow pipe and the CH return

pipe to facilitate servicing work.

Caution

When fitting service shut-off valves, position the filling and drain

valve, the expansion vessel and the safety valve between the

shut-off valve and the boiler.

Carry out any welding work required at a safe distance from the

boiler or before the boiler is fitted.

If using synthetic pipes, follow the manufacturer's (connection)

instructions.

When installing open-vented systems, the cold feed and expan

sion tank heights must comply with the requirements laid down

in the Health and Safety Executive publication PM5. The Quinta

Pro boilers require a minimum static height of 3 m (Quinta Pro

30/45/65/90) or 5 m (Quinta Pro 115).

6.3.3 Connecting the expansion vessel

1. Ensure that there is an expansion vessel with the correct volume

and inlet pressure.

2. Fit the expansion vessel on the central heating return pipe

Fig.8 Connecting the CH flow

AD-0000022-01

Fig.9 Connecting the CH return

AD-0000023-01

6 Installation

22 123157 - v.06 - 24022015

6.3.4 Connecting the condensate discharge pipe

1. Fit a plastic drain pipe of Ø 32 mm or larger, terminating in the drain.

2. Insert the flexible condensate drain hose into the pipe.

3. Fit a stench-trap or siphon in the drain pipe.

Danger

The siphon must always be filled with water. This prevents flue

gases from entering the room.

Caution

Never seal the condensate drain.

The drain pipe must slope down at least 30 mm per metre, the

maximum horizontal length is 5 metres.

Condensed water must not be discharged into a gutter.

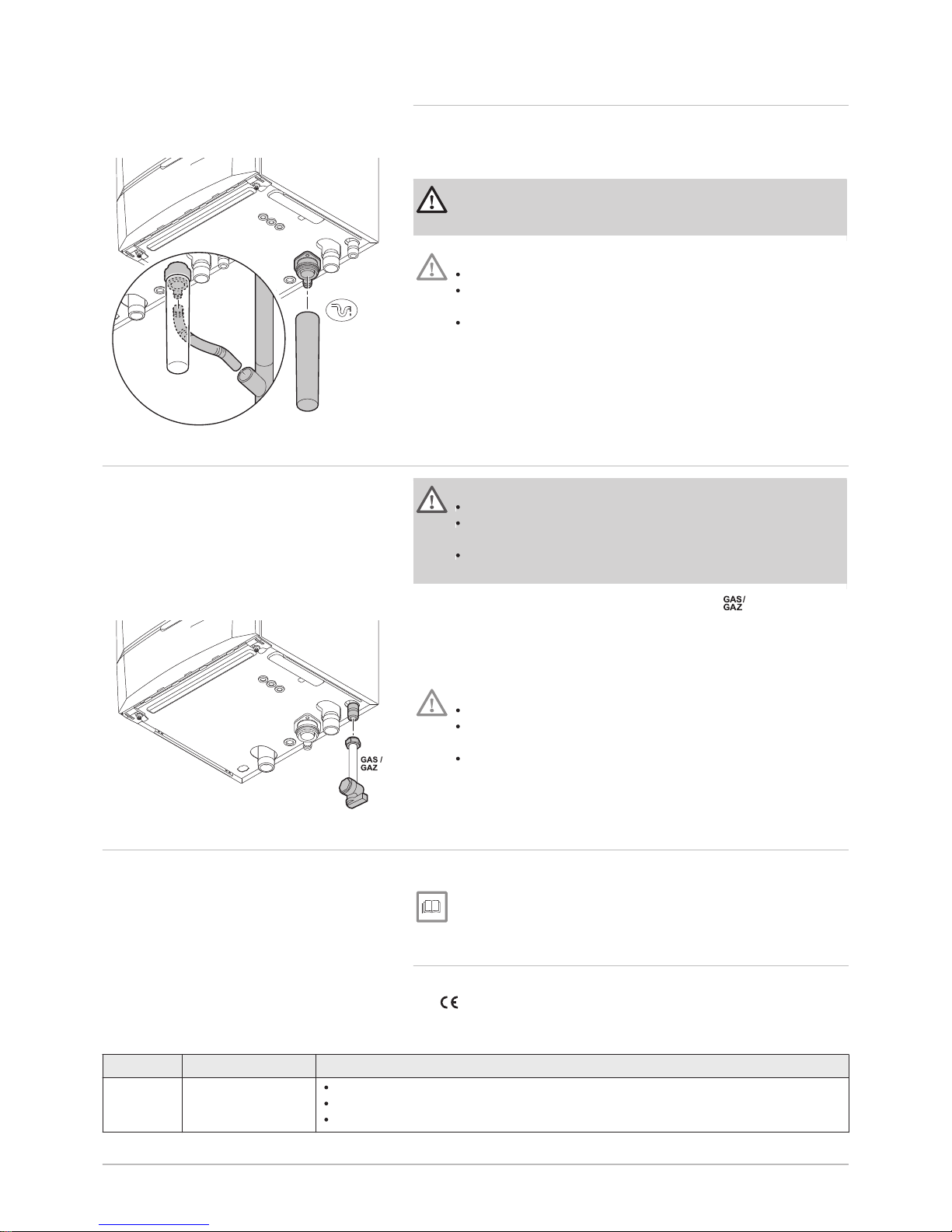

6.4 Gas connection

Warning

Before starting work on the gas pipes, turn off the main gas tap.

Before installing, check that the gas meter has sufficient capaci

ty. Take into account the consumption of all appliances.

Notify the local energy company if the gas meter has insufficient

capacity.

1. Remove the dust cap from the gas supply pipe at the bottom of

the boiler.

2. Fit the gas supply pipe.

3. Fit a gas tap in this pipe, directly underneath the boiler.

4. Fit the gas pipe to the gas tap.

Caution

Remove dirt and dust from the gas pipe.

Always perform welding work at a sufficient distance from the

boiler.

Place a gas filter to prevent pollution of the gas valve unit.

6.5 Air supply/flue gas connections

The boiler is suitable for the following types of flue gas connections:

For more information, see

Certifications, page 11

6.5.1 Classification

This classification is specified in more detail in the table in accordance

with .

Tab.9 Types of flue gas connections

Type Version Description

B23

B23P

(1)

Open Without down-draught diverter.

Flue gas discharge via the roof.

Air from the installation area.

Fig.10 Connecting the condensate dis

charge pipe

AD-0000024-01

Fig.11 Connecting the gas pipe

AD-0000025-01

6 Installation

123157 - v.06 - 24022015 23

Type Version Description

B33 Open Without down-draught diverter.

Joint flue gas discharge via the roof.

Flue gas discharge rinsed with air, air from the installation area (special construction).

C13 Closed Discharge in the outside wall.

Inlet opening for the air supply is in the same pressure zone as the discharge (e.g. a

combined outside wall feed-through).

C33 Closed Flue gas discharge via the roof.

Inlet opening for the air supply is in the same pressure zone as the discharge (e.g. a

concentric roof feed-through).

C43

(2)

Closed/cascade Joint air supply and flue gas discharge duct (CLV system):

Concentric.

Eccentric: air supply from the shaft.

Cascade overpressure

C53 Closed Closed unit.

Separate air supply duct.

Separate flue gas discharge duct.

Discharging into various pressure areas.

C63 Closed This type of unit is supplied by the manufacturer without a supply and discharge sys

tem.

C83

(3)

Closed The appliance can be connected to a semi-CLV system (with common flue gas outlet).

C93

(4)

Closed Air supply and flue gas discharge duct in shaft or ducted:

Concentric.

Eccentric: air supply from the shaft.

Flue gas discharge via the roof.

Inlet opening for the air supply is in the same pressure zone as the discharge.

(1) Also pressure class P1

(2) EN 15502-2-1: 0.5 mbar suction due to depression

(3) 4 mbar depression can occur

(4) See table for minimum dimensions of shaft or duct

Shaft dimensions

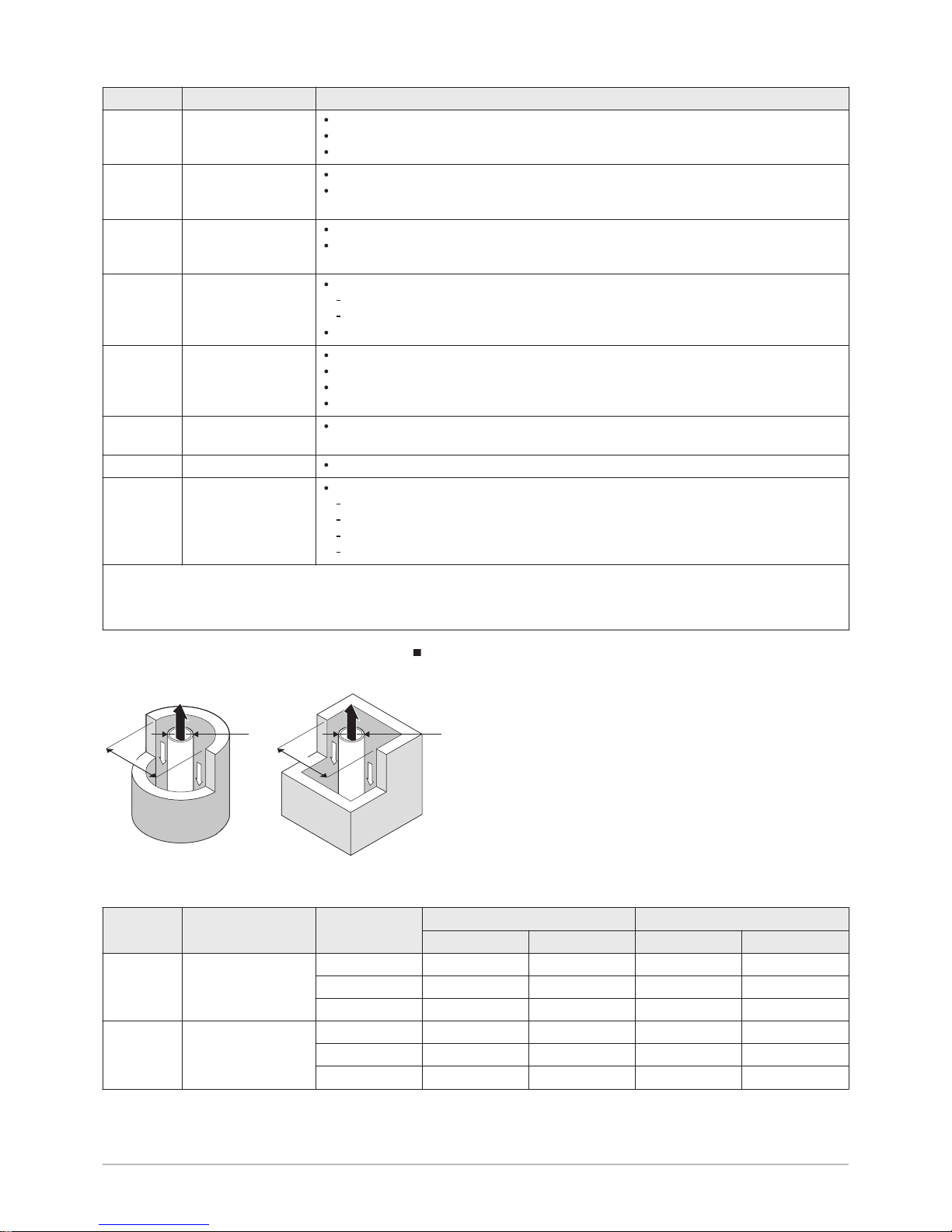

Fig.12

Minimum dimensions of shaft or duct

AD-3000330-01

□

D

Ø

D

Tab.10 Minimum dimensions of shaft or duct

Type Version Diameter (D) Without air supply With air supply

Ø duct □ duct Ø duct □ duct

C93 Rigid 60 mm 110 mm 110 x 110 mm 120 mm 110 x 110 mm

80 mm 130 mm 130 x 130 mm 140 mm 130 x 130 mm

100 mm 160 mm 160 x 160 mm 170 mm 160 x 160 mm

C93 Flexible 60 mm 110 mm 110 x 110 mm 120 mm 110 x 110 mm

80 mm 130 mm 130 x 130 mm 145 mm 130 x 130 mm

100 mm 160 mm 160 x 160 mm 170 mm 160 x 160 mm

6 Installation

24 123157 - v.06 - 24022015

Type Version Diameter (D) Without air supply With air supply

Ø duct □ duct Ø duct □ duct

C93 Concentric 60/100 mm 120 mm 120 x 120 mm 120 mm 120 x 120 mm

80/125 mm 145 mm 145 x 145 mm 145 mm 145 x 145 mm

100/150 mm 170 mm 170 x 170 mm 170 mm 170 x 170 mm

6.5.2 Outlets

Drain systems (roof feed-through and outside wall feed-through) must be

supplied by the following manufacturers:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

Note

Where regulations stipulate that a wire grille must be fitted, use a

suitable grille made from stainless steel. There must be a mini

mum distance of 50 mm between each part of the outlet and the

grille.

Boiler-specific roof and outside wall feed-through kits are also available.

Note

Contact us for more information.

6.5.3 Length of the air and flue gas pipes

Note

When using bends, the maximum chimney length (L) must be

shortened according to the reduction table.

The boiler is also suitable for longer chimney lengths and diam

eters other than those specified in the tables. Contact us for

more information.

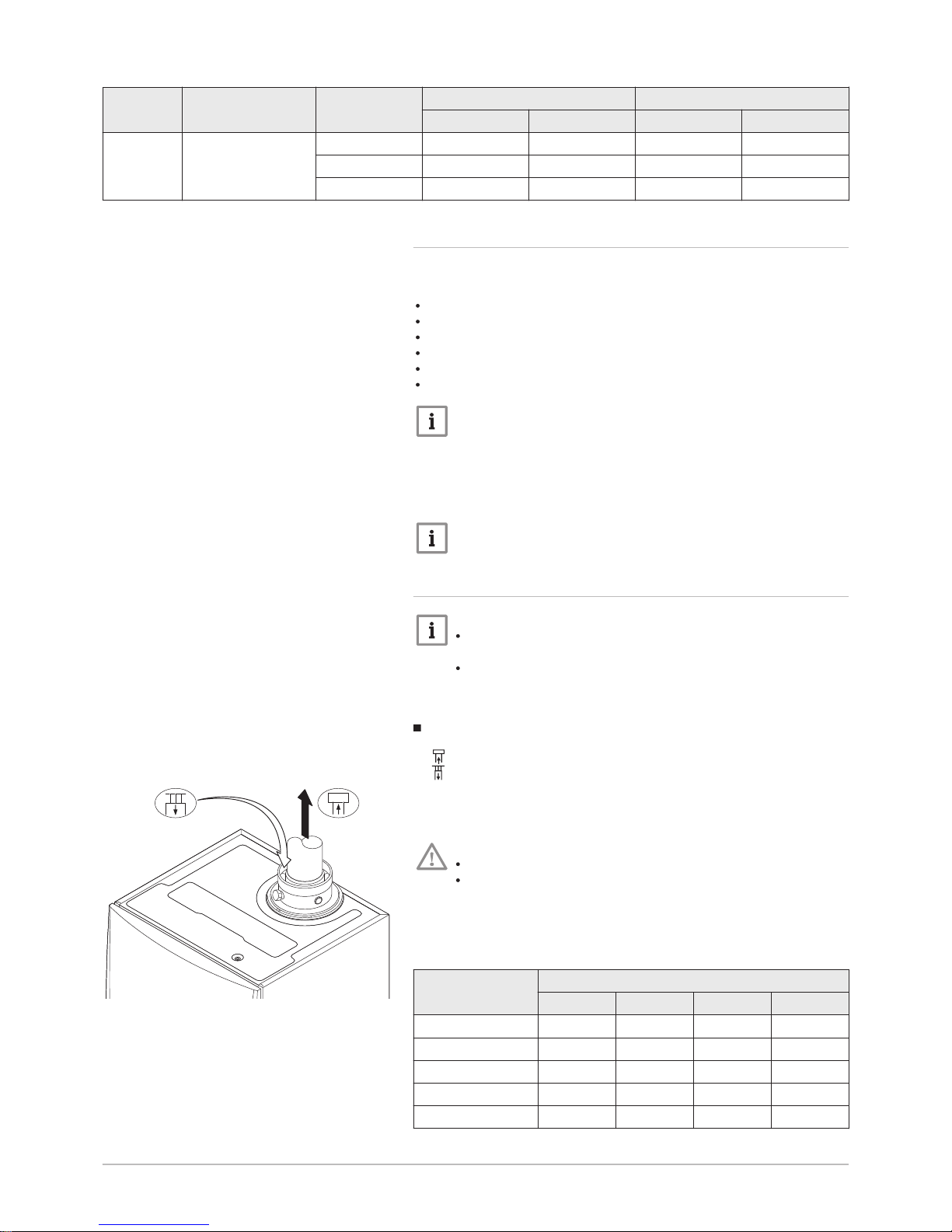

Room-ventilated version (B23, B23P, B33)

Flue gas outlet connection

Air supply connection

With a room-ventilated version, the air supply opening stays open; only the

flue gas outlet opening is connected. This will ensure that the boiler ob

tains the necessary combustion air directly from the installation area.

Caution

The air supply opening must stay open.

The installation area must be equipped with the necessary air

supply openings. These openings must not be obstructed or

shut off.

Tab.11 Maximum chimney length (L)

Quinta Pro Diameter

80 mm 90 mm 100 mm 110 mm

30 40 m 40 m 40 m 40 m

45 33 m 40 m 40 m 40 m

65 10 m 18 m 27 m 40 m

90 9 m 16 m 24 m 40 m

115 8 m 12 m 19 m 37 m

Fig.13 Room-ventilated version

AD-0000028-01

L

=

6 Installation

123157 - v.06 - 24022015 25

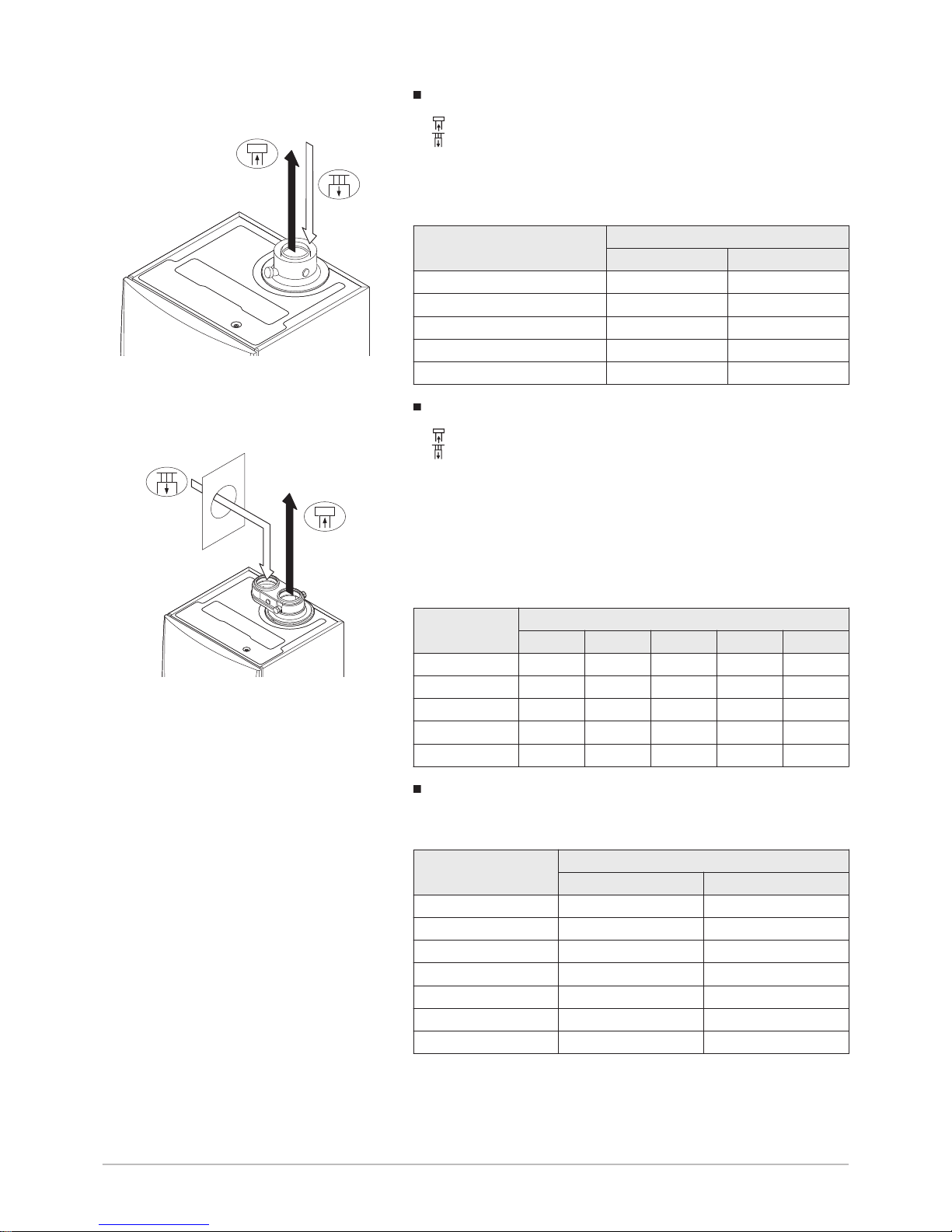

Room-sealed version (C13, C33, C43, C63, C93)

Flue gas outlet connection

Air supply connection

With a closed version, both the flue gas outlet and the air supply openings

are connected (concentrically).

Tab.12 Maximum chimney length (L)

Quinta Pro Diameter

80–125 mm 100–150 mm

30 20 m 20 m

45 16 m 20 m

65 - 13 m

90 - 13 m

115 - 7 m

Connection in different pressure areas (C53, C83)

Flue gas outlet connection

Air supply connection

A 100/100 mm flue gas adapter (accessory) must be fitted for this connec

tion.

Combustion air supply and flue gas discharge are possible in different

pressure areas and semi-CLV systems, with the exception of the coastal

area. The maximum permitted height difference between the combustion

air supply and the flue gas outlet is 36 m.

Tab.13 Maximum chimney length (L) in the various pressure zones

Quinta Pro Diameter

80 mm 90 mm 100 mm 110 mm 130 mm

30 20 m 36 m 36 m 36 m 36 m

45 20 m 36 m 36 m 36 m 36 m

65 - 2 m 8 m 34 m 36 m

90 - - 4 m 32 m 36 m

115 - - - 24 m 36 m

Reduction table

Tab.14 Pipe reduction for each element used (parallel)

Diameter

Pipe reduction

45° bend 90° bend

60 mm 0.9 m 3.1 m

70 mm 1.1 m 3.5 m

80 mm 1.2 m 4.0 m

90 mm 1.3 m 4.5 m

100 mm 1.4 m 4.9 m

110 mm 1.5 m 5.4 m

130 mm 1.6 m 6.2 m

Fig.14 Room-sealed version (concentric)

AD-0000029-01

L

=

Fig.15 Different pressure areas

AD-0000030-01

L

=

+

6 Installation

26 123157 - v.06 - 24022015

Loading...

Loading...