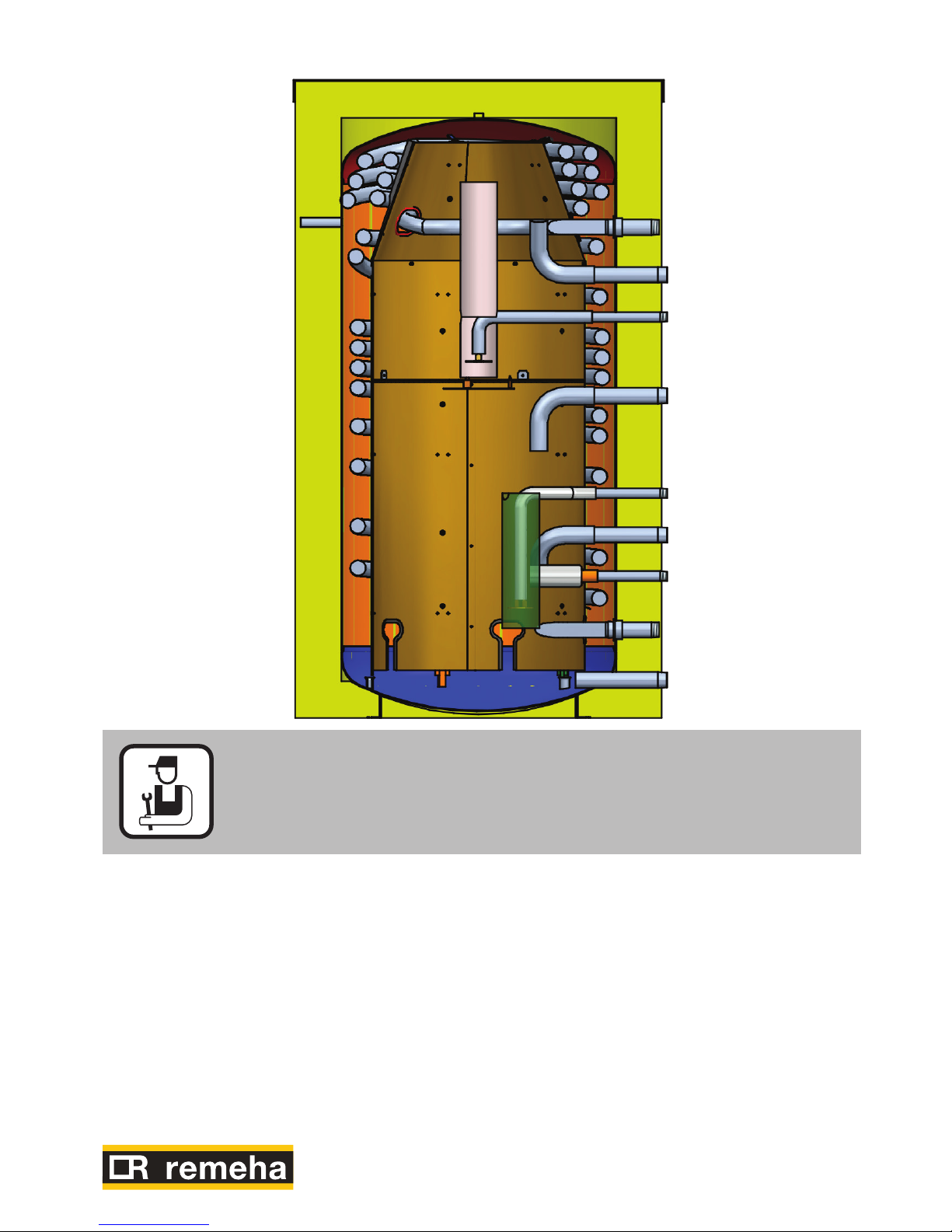

REMEHA HFS 600, HFS 750 Installation And Service Manual

HFS

600 - 750

Installation and service manual

Powerful domestic water boiler

Great Britain

en

Dear customer,

Thank you for purchasing this appliance.

Be sure to read this manual carefully before using the product and keep it in a safe place for future use.

To ensure continued safe and proper operation, we recommend having the product serviced regularly. Our service and

customer service organisation can assist you with this.

We hope you will continue to enjoy the product for many years to come.

37651255 - v.01 - 23052016 HFS 650 / HSF 700

Table of contents

Table of contents

1 Introduction .......................................................................................4

1.1 Symbols used .................................................................................4

1.2 General information .............................................................................4

2 Safety instructions and recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Technical description................................................................................6

3.1 General description .............................................................................6

3.2 Technical data .................................................................................6

3.3 Description of operation ..........................................................................7

3.3.1 Filling the hot water boiler.................................................................7

3.3.2 Installation of a recirculation line............................................................8

4 Installation .......................................................................................10

4.1 Installation instructions..........................................................................10

4.1.1 Domestic water quality .....................................................................10

4.2 Scope of delivery ..............................................................................12

4.3 Placement ...................................................................................12

4.4 Main dimensions – Connections ..................................................................12

4.5 Mounting the appliance .........................................................................13

4.5.1 Installation of a recirculation line set........................................................13

4.5.2 Mounting the boiler .....................................................................14

4.6 Hydraulic examples ............................................................................16

4.7 Connections on the domestic water side ............................................................21

4.7.1 Special precautions ....................................................................21

4.7.2 Combination inlet group .................................................................21

4.7.3 Shut-off valves ........................................................................21

4.7.4 Cold water/domestic water connection ......................................................21

4.7.5 Tap water mixing valve ..................................................................21

4.7.6 Hot water recirculation line ...............................................................21

4.7.7 Measures to prevent backflow of heated water ...............................................22

4.8 Connection of the expansion vessels to the collector and heating circuit ...................................22

4.8.1 Boiler circuit ..........................................................................22

4.8.2 Collector circuit (on the boiler side) ........................................................22

4.9 Electrical connection ...........................................................................22

4.10 Commissioning ...............................................................................22

5 Inspection and maintenance.........................................................................23

5.1 Switching off during the summer: Safety through Steam Back ...........................................23

5.2 Maintenance .................................................................................23

6 Commissioning report..............................................................................24

6.1 System description.............................................................................24

6.2 Inspection of collector circuit supply and return lines...................................................24

6.3 Control station, verification of operation RemaSOL C2 .................................................24

6.4 System inspection .............................................................................25

6.5 Resetting ....................................................................................25

6.6 Remarks.....................................................................................26

7 Maintenance report ................................................................................27

7651255 - v.01 - 230520164 HFS 650 / HSF 700

1 Introduction

1 Introduction

1.1 Symbols used

This manual uses various danger levels to draw attention to the special

instructions. We do this to increase the safety of the user, to prevent

problems and to ensure the technical reliability of the device.

Danger

Chance of dangerous situations that can cause severe personal

injury.

Danger of electric shock

Danger of electric shock

Warning

Chance of dangerous situations that can cause minor personal

injury.

Attention

Chance of property damage.

Explanation

Attention, important information.

See

Reference to other manuals or other pages in this manual.

HW: hot water

1.2 General information

Congratulations! You have chosen a quality product. We advise you

to read the instructions below in order to ensure the optimal operation

of your installation. We are confident that this product will meet your

expectations. The manufacturer cannot be held liable for damage resulting

from incorrect use of the appliance, deficient or inadequate maintenance

or incorrect installation of the appliance (it is your responsibility to have

the installation performed by an authorised heating installer).

57651255 - v.01 - 23052016 HFS 650 / HSF 700

2 Safety instructions and recommendations

2 Safety instructions and recommendations

Attention

Installation, commissioning and maintenance must be performed by

a competent technician and in accordance with the applicable legal

requirements and supplied instructions.

Attention

Heating water and domestic water may not come into contact with

each other.

Regular maintenance of the appliance is necessary to ensure reliable and

safe operation. If the hot water boiler is modified in any way, the warranty

will be void.

7651255 - v.01 - 230520166 HFS 650 / HSF 700

3 Technical description

3 Technical description

3.1 General description

The HFS 600 / HFS 750 is a powerful hot water boiler for legionella-free

heating of domestic water based on continuous recirculation with heating

boiler and solar energy installation. The hot water boiler is suitable for

use where there is a high demand for hot water, in the types of situations

found in:

• Hotels

• Carecomplexes

• Apartmentcomplexes

• Campsites

• Sportsaccommodations

• Farm/cattleranches

• Processindustry

etc.

Description of the product:

• Steelboilervesselwithavolumeof600and750litresrespectively

• Boilervesselexternallyprotectedbyarust-inhibitinglayer,black

• Domesticwatercoilmadeofcorrugatedstainlesssteelpipe,

grade 1.4404

• Insulationofpolyesterfibre(120mm)withNeoporwhiteoutercovering.

• Incl.thermometermetimmersionsleeve

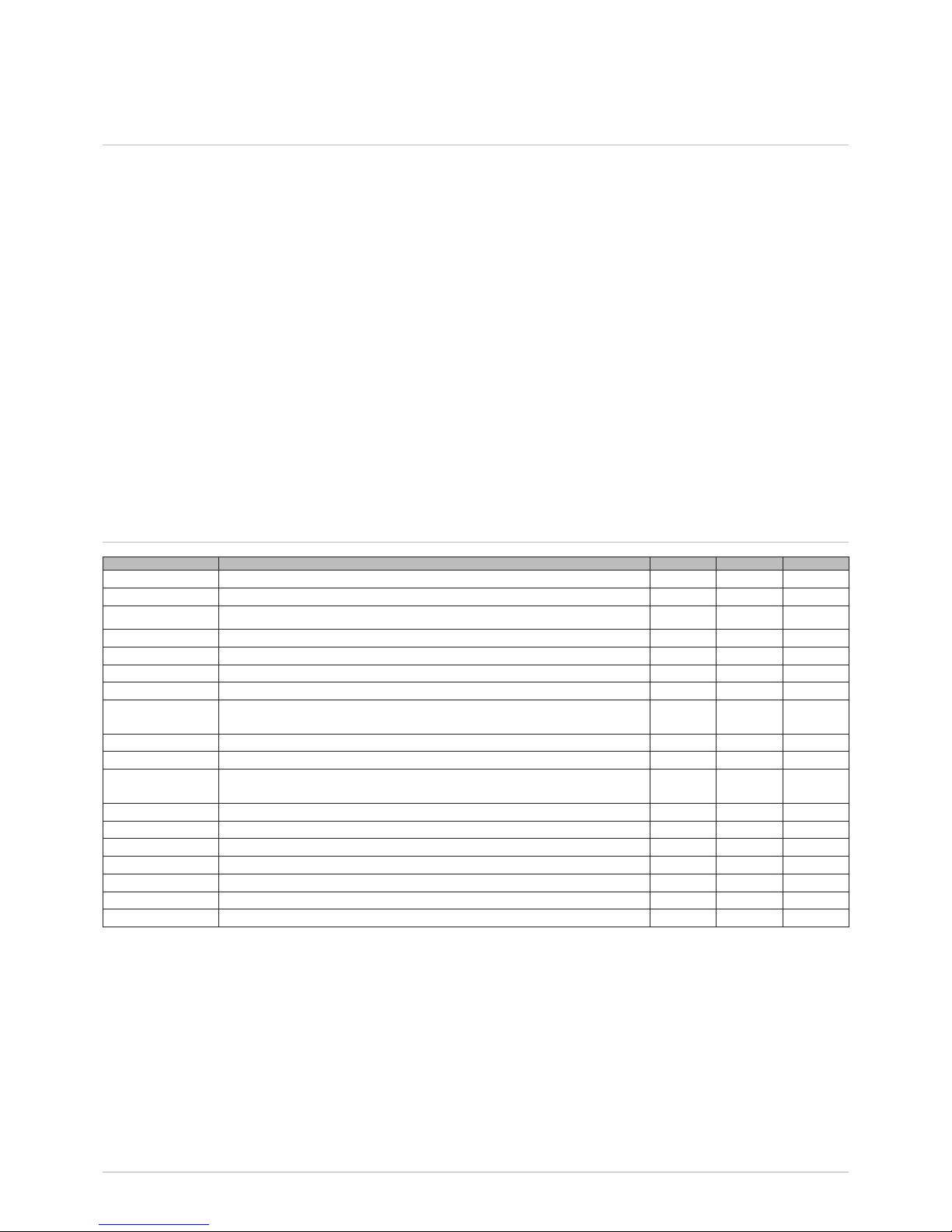

3.2 Technical data

Type HFS 600 750

Buffer vessel Nominalvolume Litre 620 750

Max. operating overpressure bar 6 6

Max. operating temperature °C 95 95

Heat exchanger Corrugated stainless steel coil Litre 46 52

Max. operating overpressure bar 8 8

Consumed energy at 35 K kW 150 195

Continuous capacity 35 K l/hr 3000 4800

Situation 1: Return line from the heating boiler connected to the upper

connection (connection 3 + 6, page 7)

Flow in 10 min. at 35 K (mixed) (1) l/10 min 750 990

Power index 18 45

Situation 2: Return line from the heating boiler connected to the lower

connection (connection 8, page 7)

Flow in 10 min. at 35 K (mixed) (1) l/10 min 900 1200

Power index(1) 25 62

Stand-by losses Vtotal = 55 °C (primary temperature) kWh/24 h 2.7 3

Cooling constant Cr 0.13 0.14

ErP data

Boiler volume V I 653 742

Standby heat loss S W 113 125

(1) Temperature cold water supply: 10 °C - Outlet temperature hot water unit: 45 °C - Primary temperature 80 °C

Target value hot water unit: 70 °C

77651255 - v.01 - 23052016 HFS 650 / HSF 700

3 Technical description

3.3 Description of operation

3.3.1 Filling the hot water boiler

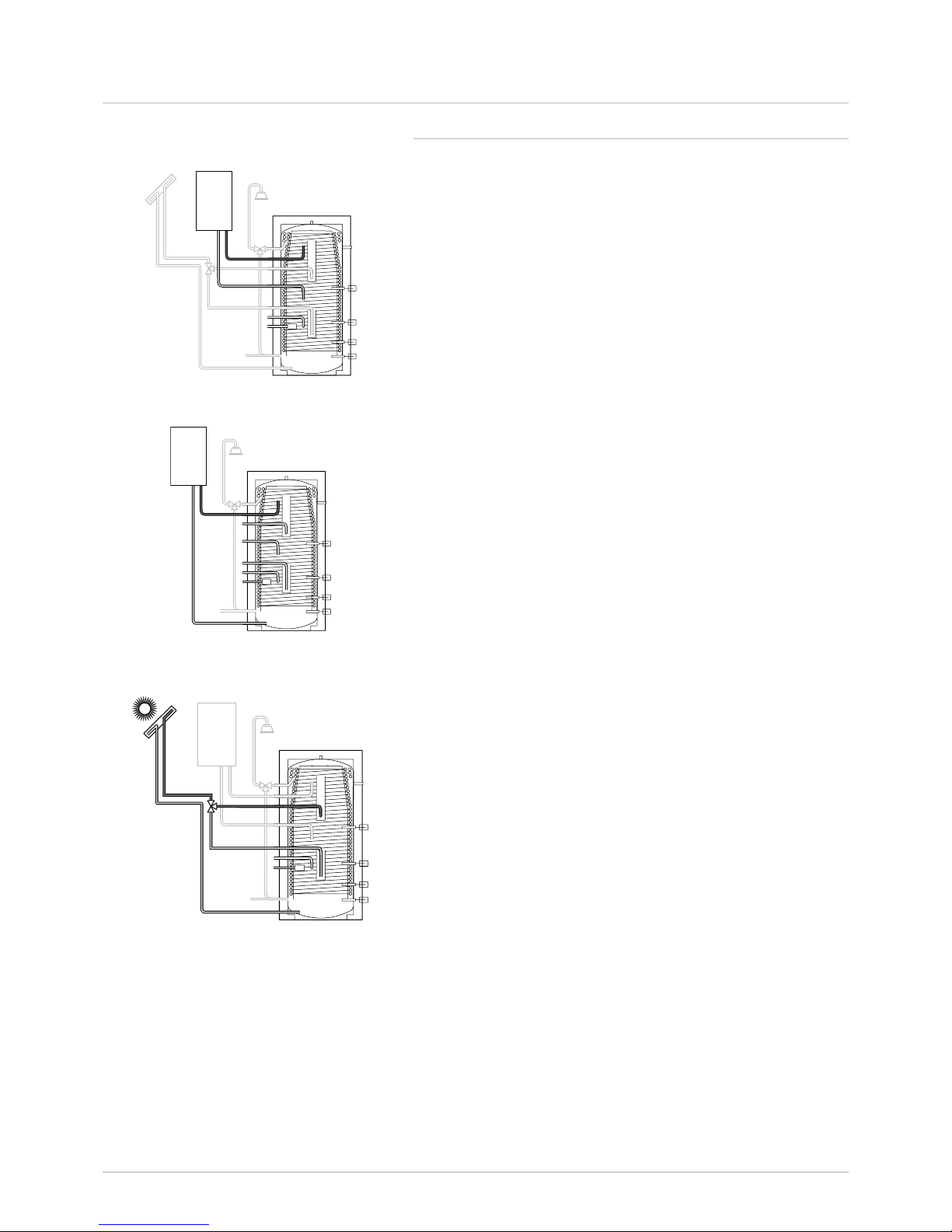

Q Situation 1: Heating boiler + collector circuit

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 2: Only heating boiler

HW: Boiler sensor

Q Situation 3a: Charging via the solar energy installation, at

top, with boiler

S2: Solar boiler sensor

Stb: Boiler sensor

WW

S2

Stb

KW

L000017-C

WW

KW

L000016-C

Stb

WW

S2

KW

L000019-C

7651255 - v.01 - 230520168 HFS 650 / HSF 700

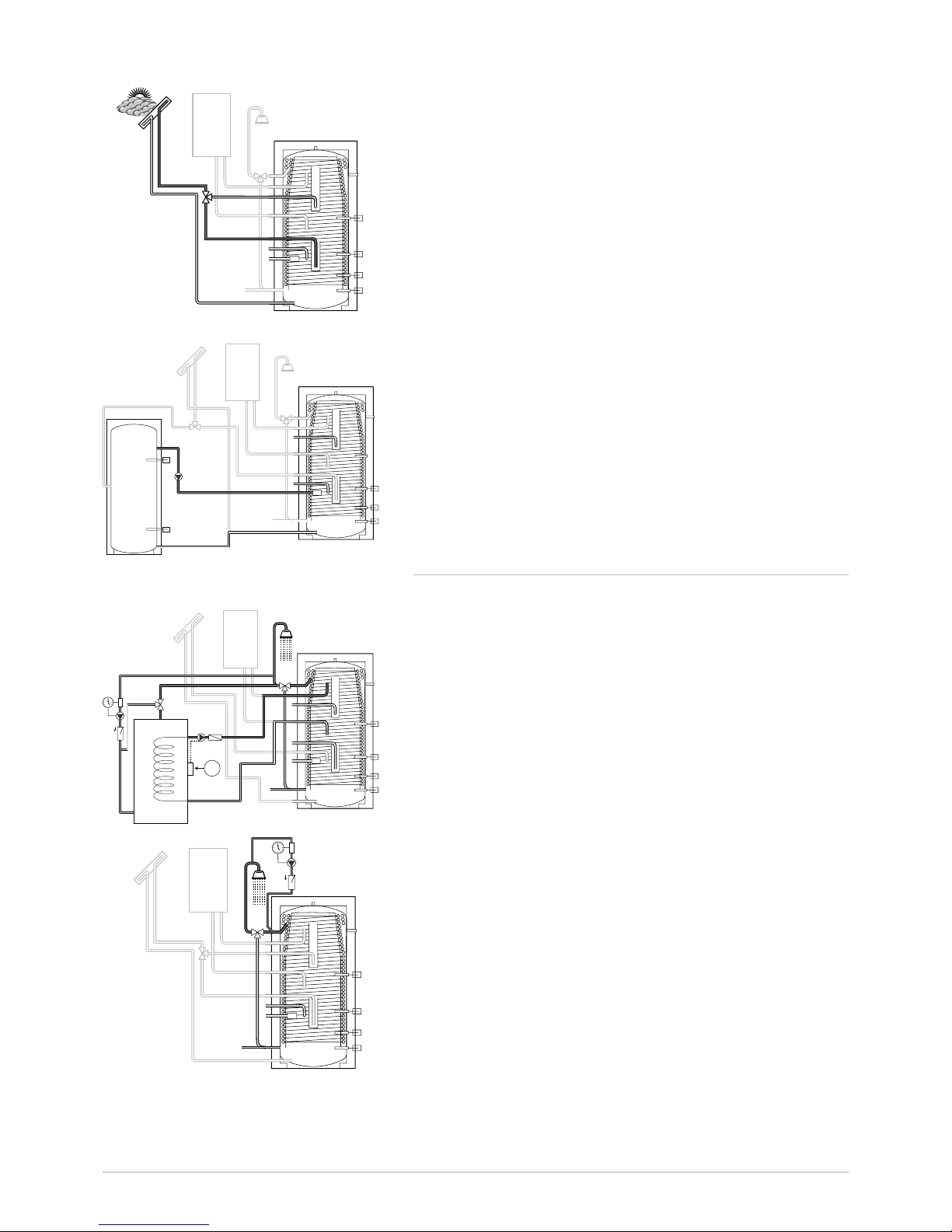

Q Situation 3b: Charging via the solar energy installation, at

bottom, with boiler

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 4: Filling / draining via buffer

S2: Solar boiler sensor

S4: Buffer - bottom

HW: Boiler sensor

S5: Buffer - top

3.3.2 Installation of a recirculation line

Q Situation 1: Recirculation: use of a separate recirculation

buffer (with a flow rate loss of more than 250 l/hr: see

ISSO publication 55.1 section 4.2.3 Thermal management

concept).

Thermostat x °C

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 2: Recirculation: use of optional recirculation

connection set 100020184 at a flow rate loss of up to

250 l/hr (see ISSO publication 55.1 section 4.2.3 Thermal

management concept).

S2: Solar boiler sensor

S4: Boiler sensor CH boiler

Stb

WW

S2

KW

L000020-C

WW

S2

KW

S5

S4

L000021-C

Stb

WW

S2

KW

1

L000024-C

Stb

WW

S2

KW

L000022-C

3 Technical description

97651255 - v.01 - 23052016 HFS 650 / HSF 700

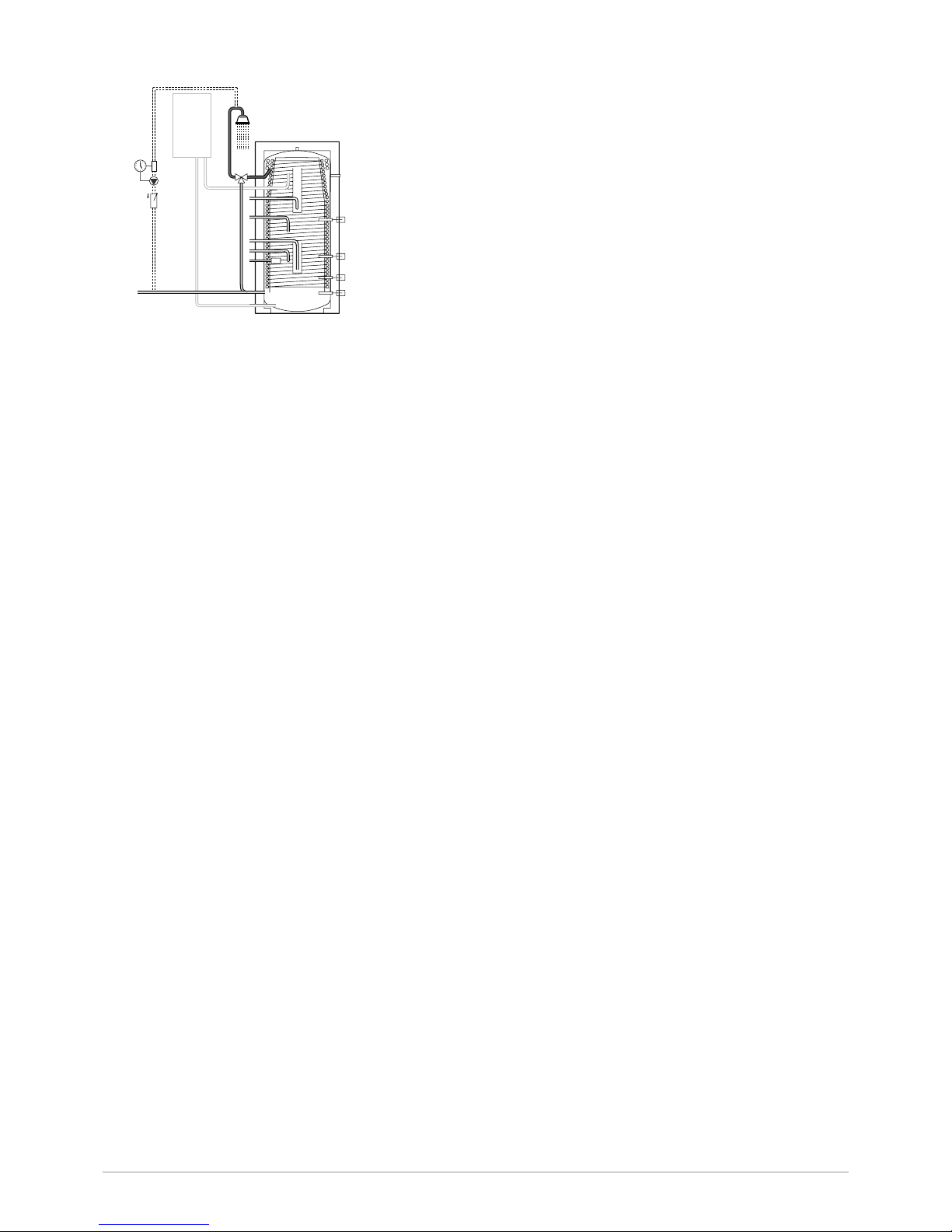

Q Situation 3: Recirculation without collector circuit (at a

flow rate loss of more than 250 l/hr: see ISSO publication

55.1 section 4.2.3 Thermal management concept).

HW: Boiler sensor

WW

KW

L000025-D

3 Technical description

7651255 - v.01 - 2305201610 HFS 650 / HSF 700

4 Installation

4 Installation

4.1 Installation instructions

All aspects of the installation must be carried out in accordance with the

current regulations for work performed and technical systems in private,

public or other buildings.

Attention

The installation must be carried out in accordance with the current

regulations, best practices for technical work, and the instructions in

this manual.

4.1.1 Domestic water quality

Self-cleaning effect

Boilers with corrugated stainless steel coil for heating of domestic water

are insusceptible to deposits of pure lime (pure calcium). Pressure

differences in the pipe during opening and closing of the taps cause

pressure surges in the corrugated stainless steel coil. This causes the coil

to stretch slightly and then contract again.

These movements in the coil are sufficient to cause ‘normal’ lime deposits

(calcium) to flake off. The dissolved lime is flushed away when a tap is

opened.

Attention

This self-cleaning effect of the corrugated stainless steel coil in HFS

boilers is no longer sufficient when in addition to the lime (calcium)

there are also other substances such as free carbonic acid and

magnesium present in the water. When lime and free carbonic acid

are present in the water, these substances react to form ‘scale’.

The presence of magnesium in the water at a filling temperature

> 60 °C promotes the formation of scale.

Boiler scale, in contrast to lime, is not broken loose by the selfcleaning effect of the corrugated stainless steel coil but rather forms

larger deposits. When the pressure is relieved from the corrugated

stainless steel coil in the boiler, during maintenance for example,

boiler scale in solid form may break loose and clog the coil (heat

exchanger).

For domestic water containing these substances, the corrugated stainless

steel coil must be inspected regularly and decalcified with a softening

agent as necessary or a decalcification system must be installed in the

cold water supply line of the HFS domestic water boiler.

Loading...

Loading...