HFS

600 - 750

Installation and service manual

Powerful domestic water boiler

Great Britain

en

Dear customer,

Thank you for purchasing this appliance.

Be sure to read this manual carefully before using the product and keep it in a safe place for future use.

To ensure continued safe and proper operation, we recommend having the product serviced regularly. Our service and

customer service organisation can assist you with this.

We hope you will continue to enjoy the product for many years to come.

37651255 - v.01 - 23052016 HFS 650 / HSF 700

Table of contents

Table of contents

1 Introduction .......................................................................................4

1.1 Symbols used .................................................................................4

1.2 General information .............................................................................4

2 Safety instructions and recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Technical description................................................................................6

3.1 General description .............................................................................6

3.2 Technical data .................................................................................6

3.3 Description of operation ..........................................................................7

3.3.1 Filling the hot water boiler.................................................................7

3.3.2 Installation of a recirculation line............................................................8

4 Installation .......................................................................................10

4.1 Installation instructions..........................................................................10

4.1.1 Domestic water quality .....................................................................10

4.2 Scope of delivery ..............................................................................12

4.3 Placement ...................................................................................12

4.4 Main dimensions – Connections ..................................................................12

4.5 Mounting the appliance .........................................................................13

4.5.1 Installation of a recirculation line set........................................................13

4.5.2 Mounting the boiler .....................................................................14

4.6 Hydraulic examples ............................................................................16

4.7 Connections on the domestic water side ............................................................21

4.7.1 Special precautions ....................................................................21

4.7.2 Combination inlet group .................................................................21

4.7.3 Shut-off valves ........................................................................21

4.7.4 Cold water/domestic water connection ......................................................21

4.7.5 Tap water mixing valve ..................................................................21

4.7.6 Hot water recirculation line ...............................................................21

4.7.7 Measures to prevent backflow of heated water ...............................................22

4.8 Connection of the expansion vessels to the collector and heating circuit ...................................22

4.8.1 Boiler circuit ..........................................................................22

4.8.2 Collector circuit (on the boiler side) ........................................................22

4.9 Electrical connection ...........................................................................22

4.10 Commissioning ...............................................................................22

5 Inspection and maintenance.........................................................................23

5.1 Switching off during the summer: Safety through Steam Back ...........................................23

5.2 Maintenance .................................................................................23

6 Commissioning report..............................................................................24

6.1 System description.............................................................................24

6.2 Inspection of collector circuit supply and return lines...................................................24

6.3 Control station, verification of operation RemaSOL C2 .................................................24

6.4 System inspection .............................................................................25

6.5 Resetting ....................................................................................25

6.6 Remarks.....................................................................................26

7 Maintenance report ................................................................................27

7651255 - v.01 - 230520164 HFS 650 / HSF 700

1 Introduction

1 Introduction

1.1 Symbols used

This manual uses various danger levels to draw attention to the special

instructions. We do this to increase the safety of the user, to prevent

problems and to ensure the technical reliability of the device.

Danger

Chance of dangerous situations that can cause severe personal

injury.

Danger of electric shock

Danger of electric shock

Warning

Chance of dangerous situations that can cause minor personal

injury.

Attention

Chance of property damage.

Explanation

Attention, important information.

See

Reference to other manuals or other pages in this manual.

HW: hot water

1.2 General information

Congratulations! You have chosen a quality product. We advise you

to read the instructions below in order to ensure the optimal operation

of your installation. We are confident that this product will meet your

expectations. The manufacturer cannot be held liable for damage resulting

from incorrect use of the appliance, deficient or inadequate maintenance

or incorrect installation of the appliance (it is your responsibility to have

the installation performed by an authorised heating installer).

57651255 - v.01 - 23052016 HFS 650 / HSF 700

2 Safety instructions and recommendations

2 Safety instructions and recommendations

Attention

Installation, commissioning and maintenance must be performed by

a competent technician and in accordance with the applicable legal

requirements and supplied instructions.

Attention

Heating water and domestic water may not come into contact with

each other.

Regular maintenance of the appliance is necessary to ensure reliable and

safe operation. If the hot water boiler is modified in any way, the warranty

will be void.

7651255 - v.01 - 230520166 HFS 650 / HSF 700

3 Technical description

3 Technical description

3.1 General description

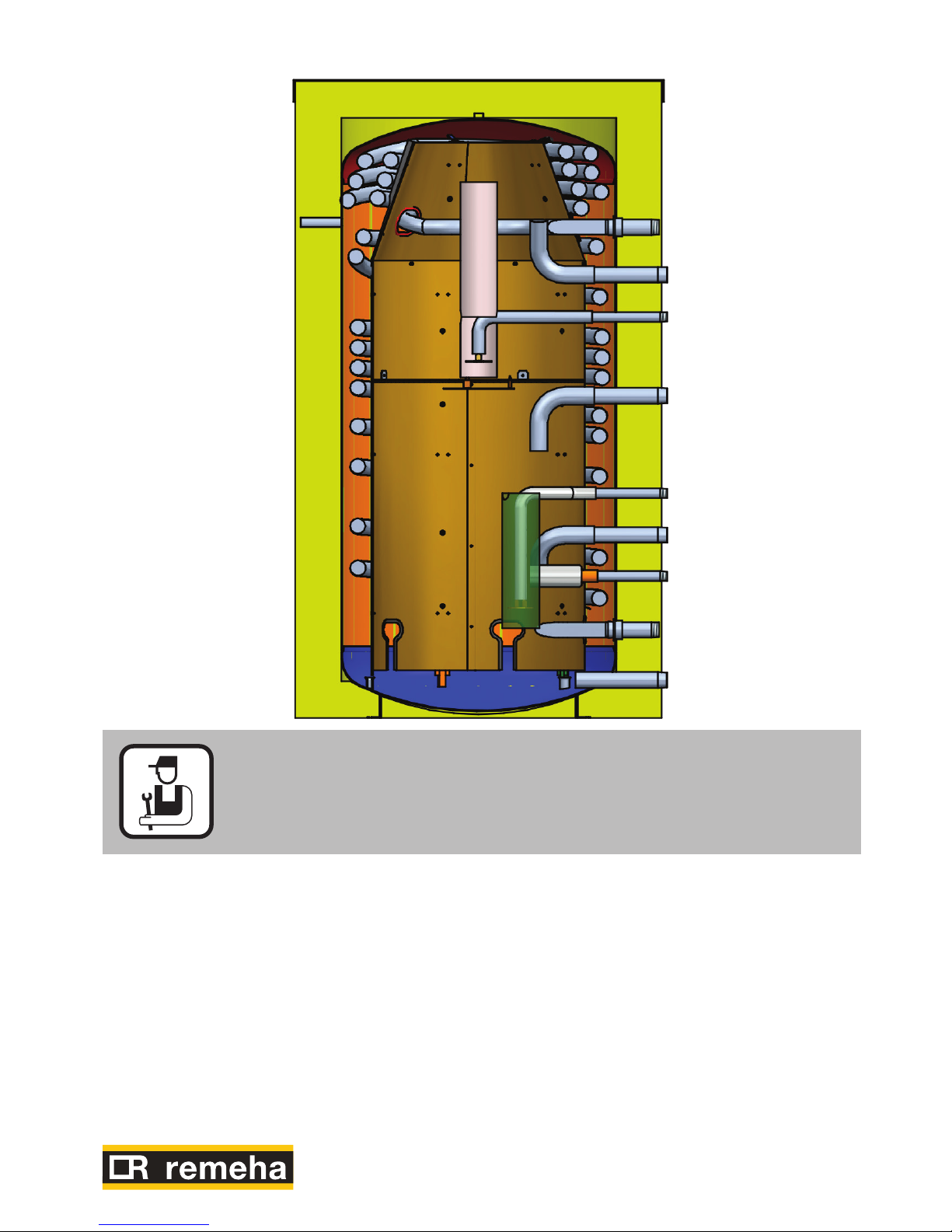

The HFS 600 / HFS 750 is a powerful hot water boiler for legionella-free

heating of domestic water based on continuous recirculation with heating

boiler and solar energy installation. The hot water boiler is suitable for

use where there is a high demand for hot water, in the types of situations

found in:

• Hotels

• Carecomplexes

• Apartmentcomplexes

• Campsites

• Sportsaccommodations

• Farm/cattleranches

• Processindustry

etc.

Description of the product:

• Steelboilervesselwithavolumeof600and750litresrespectively

• Boilervesselexternallyprotectedbyarust-inhibitinglayer,black

• Domesticwatercoilmadeofcorrugatedstainlesssteelpipe,

grade 1.4404

• Insulationofpolyesterfibre(120mm)withNeoporwhiteoutercovering.

• Incl.thermometermetimmersionsleeve

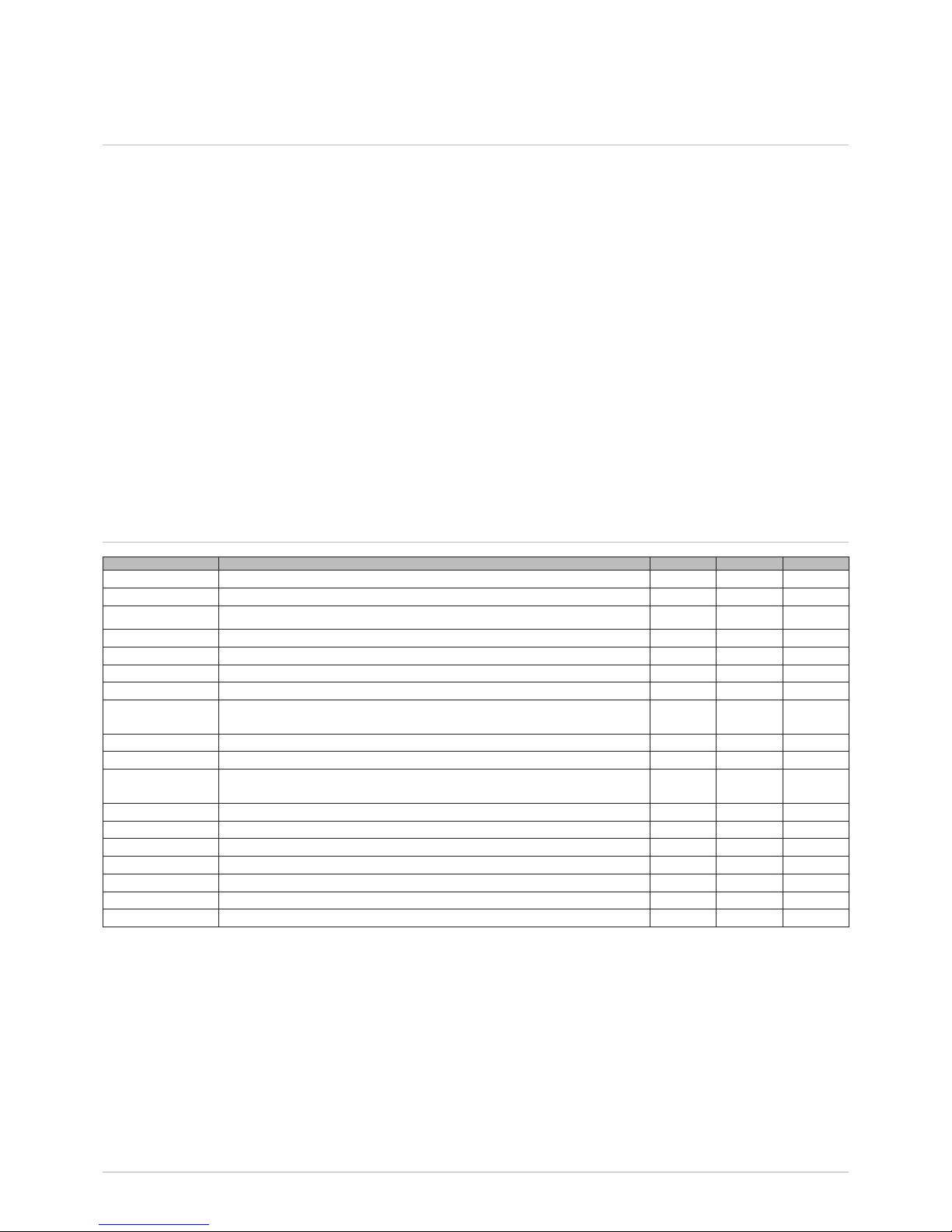

3.2 Technical data

Type HFS 600 750

Buffer vessel Nominalvolume Litre 620 750

Max. operating overpressure bar 6 6

Max. operating temperature °C 95 95

Heat exchanger Corrugated stainless steel coil Litre 46 52

Max. operating overpressure bar 8 8

Consumed energy at 35 K kW 150 195

Continuous capacity 35 K l/hr 3000 4800

Situation 1: Return line from the heating boiler connected to the upper

connection (connection 3 + 6, page 7)

Flow in 10 min. at 35 K (mixed) (1) l/10 min 750 990

Power index 18 45

Situation 2: Return line from the heating boiler connected to the lower

connection (connection 8, page 7)

Flow in 10 min. at 35 K (mixed) (1) l/10 min 900 1200

Power index(1) 25 62

Stand-by losses Vtotal = 55 °C (primary temperature) kWh/24 h 2.7 3

Cooling constant Cr 0.13 0.14

ErP data

Boiler volume V I 653 742

Standby heat loss S W 113 125

(1) Temperature cold water supply: 10 °C - Outlet temperature hot water unit: 45 °C - Primary temperature 80 °C

Target value hot water unit: 70 °C

77651255 - v.01 - 23052016 HFS 650 / HSF 700

3 Technical description

3.3 Description of operation

3.3.1 Filling the hot water boiler

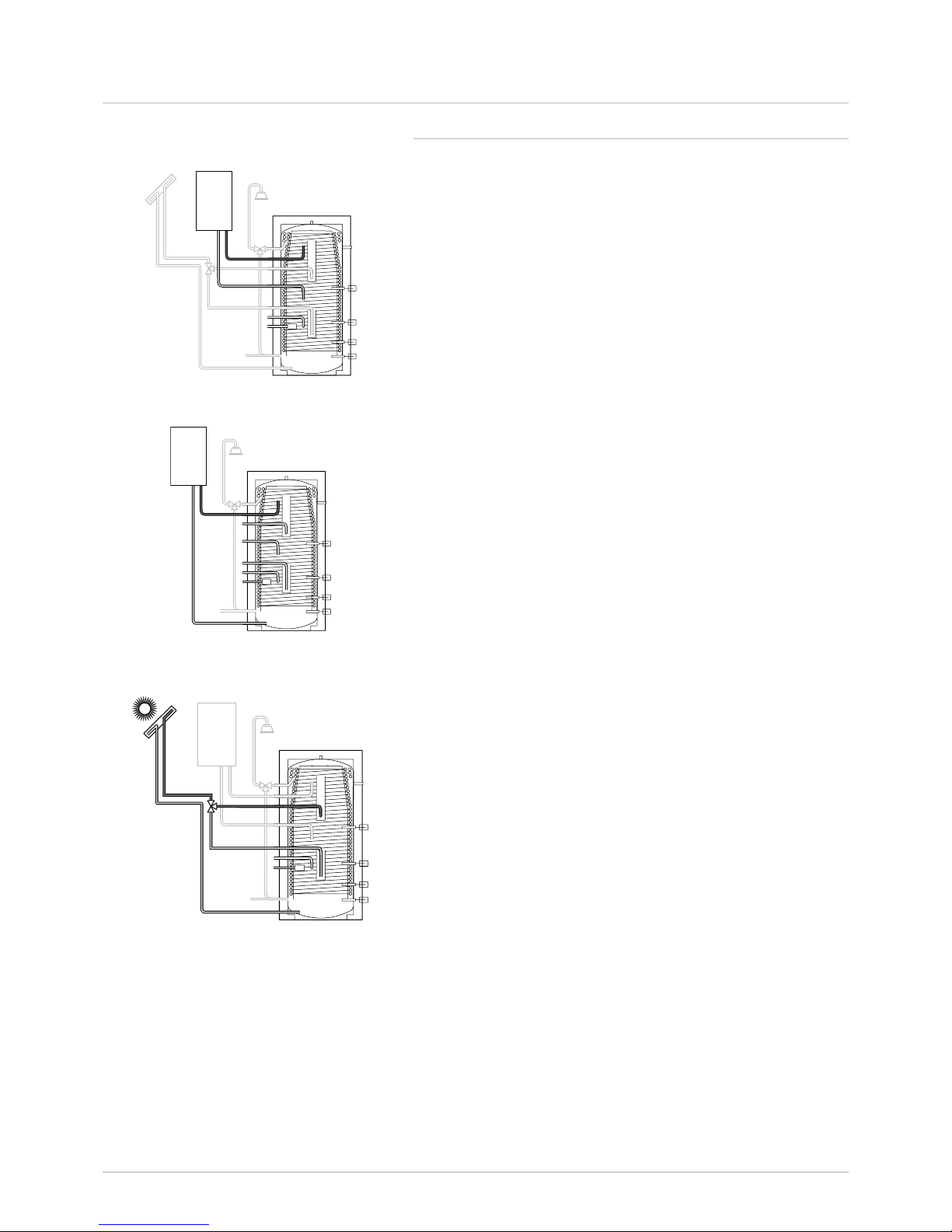

Q Situation 1: Heating boiler + collector circuit

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 2: Only heating boiler

HW: Boiler sensor

Q Situation 3a: Charging via the solar energy installation, at

top, with boiler

S2: Solar boiler sensor

Stb: Boiler sensor

WW

S2

Stb

KW

L000017-C

WW

KW

L000016-C

Stb

WW

S2

KW

L000019-C

7651255 - v.01 - 230520168 HFS 650 / HSF 700

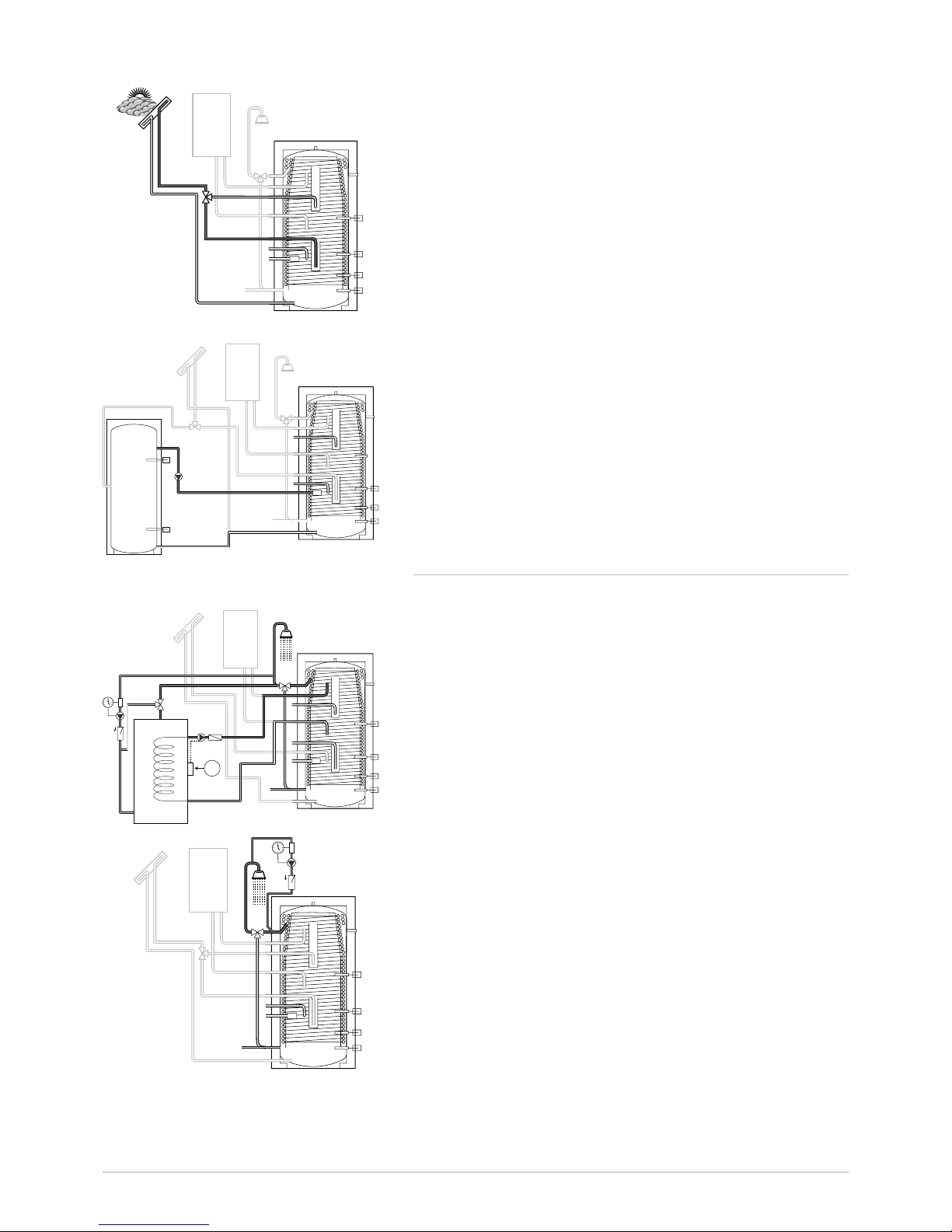

Q Situation 3b: Charging via the solar energy installation, at

bottom, with boiler

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 4: Filling / draining via buffer

S2: Solar boiler sensor

S4: Buffer - bottom

HW: Boiler sensor

S5: Buffer - top

3.3.2 Installation of a recirculation line

Q Situation 1: Recirculation: use of a separate recirculation

buffer (with a flow rate loss of more than 250 l/hr: see

ISSO publication 55.1 section 4.2.3 Thermal management

concept).

Thermostat x °C

S2: Solar boiler sensor

Stb: Boiler sensor

Q Situation 2: Recirculation: use of optional recirculation

connection set 100020184 at a flow rate loss of up to

250 l/hr (see ISSO publication 55.1 section 4.2.3 Thermal

management concept).

S2: Solar boiler sensor

S4: Boiler sensor CH boiler

Stb

WW

S2

KW

L000020-C

WW

S2

KW

S5

S4

L000021-C

Stb

WW

S2

KW

1

L000024-C

Stb

WW

S2

KW

L000022-C

3 Technical description

97651255 - v.01 - 23052016 HFS 650 / HSF 700

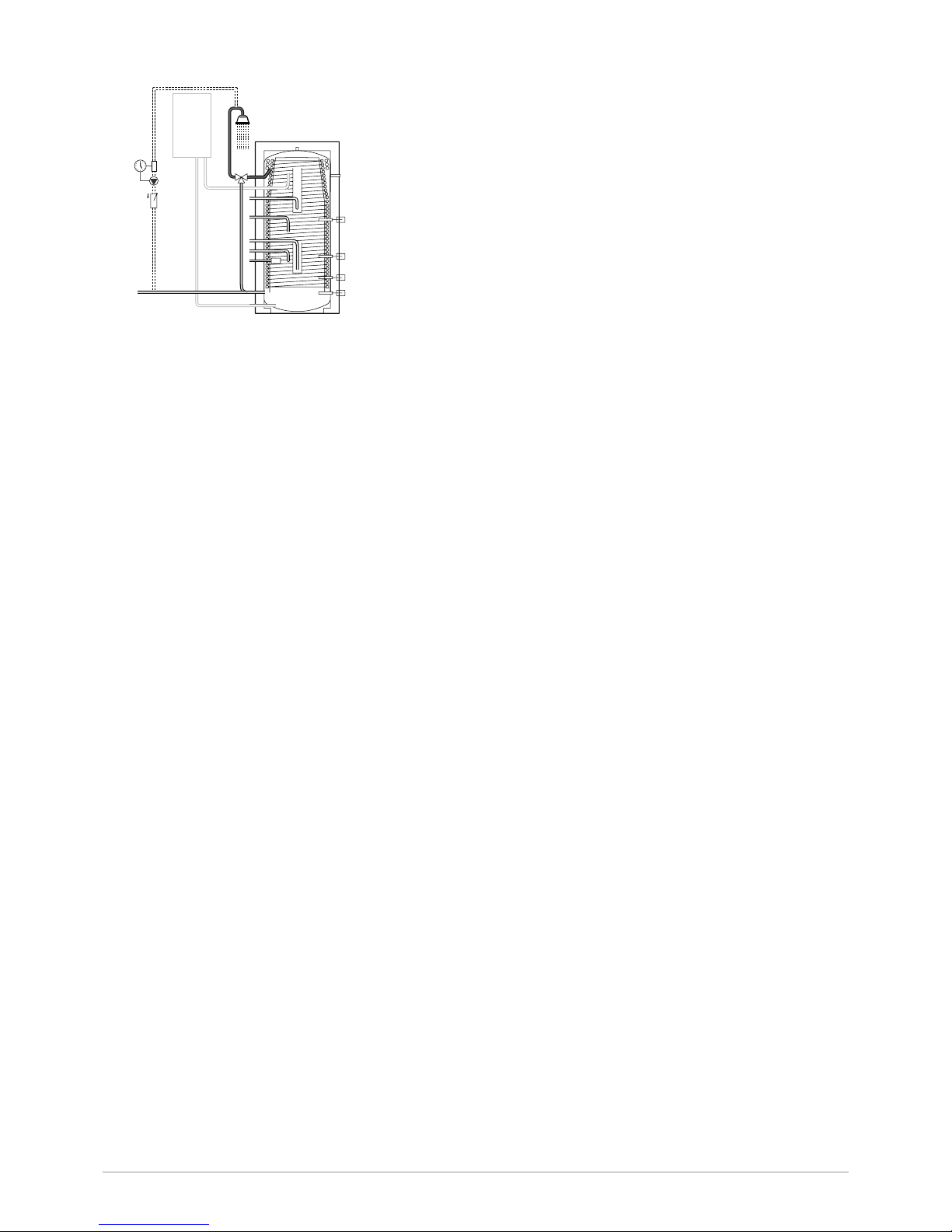

Q Situation 3: Recirculation without collector circuit (at a

flow rate loss of more than 250 l/hr: see ISSO publication

55.1 section 4.2.3 Thermal management concept).

HW: Boiler sensor

WW

KW

L000025-D

3 Technical description

7651255 - v.01 - 2305201610 HFS 650 / HSF 700

4 Installation

4 Installation

4.1 Installation instructions

All aspects of the installation must be carried out in accordance with the

current regulations for work performed and technical systems in private,

public or other buildings.

Attention

The installation must be carried out in accordance with the current

regulations, best practices for technical work, and the instructions in

this manual.

4.1.1 Domestic water quality

Self-cleaning effect

Boilers with corrugated stainless steel coil for heating of domestic water

are insusceptible to deposits of pure lime (pure calcium). Pressure

differences in the pipe during opening and closing of the taps cause

pressure surges in the corrugated stainless steel coil. This causes the coil

to stretch slightly and then contract again.

These movements in the coil are sufficient to cause ‘normal’ lime deposits

(calcium) to flake off. The dissolved lime is flushed away when a tap is

opened.

Attention

This self-cleaning effect of the corrugated stainless steel coil in HFS

boilers is no longer sufficient when in addition to the lime (calcium)

there are also other substances such as free carbonic acid and

magnesium present in the water. When lime and free carbonic acid

are present in the water, these substances react to form ‘scale’.

The presence of magnesium in the water at a filling temperature

> 60 °C promotes the formation of scale.

Boiler scale, in contrast to lime, is not broken loose by the selfcleaning effect of the corrugated stainless steel coil but rather forms

larger deposits. When the pressure is relieved from the corrugated

stainless steel coil in the boiler, during maintenance for example,

boiler scale in solid form may break loose and clog the coil (heat

exchanger).

For domestic water containing these substances, the corrugated stainless

steel coil must be inspected regularly and decalcified with a softening

agent as necessary or a decalcification system must be installed in the

cold water supply line of the HFS domestic water boiler.

117651255 - v.01 - 23052016 HFS 650 / HSF 700

4 Installation

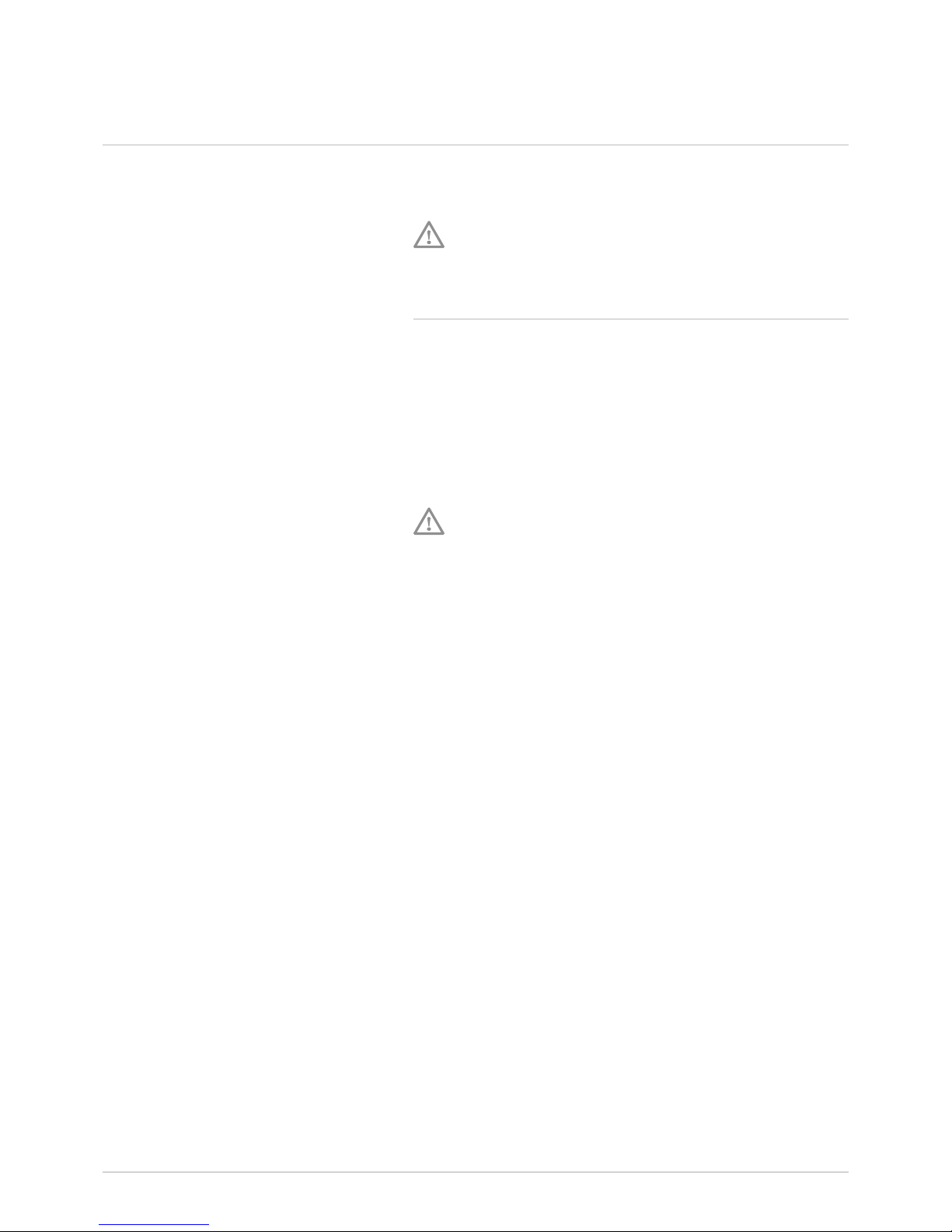

Operation:

Flushing connection set HFS 600-750 for flushing the corrugated stainless

steel coil to remove deposits of boiler scale

Flushing provisions on the HFS:

The flushing provisions on the HFS must, in accordance with regulations,

consist of the following parts:

2 T-fittings, 2 shut-off valves

Installation: in the cold water line before the inlet on the HFS boiler and

on the hot water outlet.

The extra valves makes it possible to shut off the cold and hot water lines,

empty and inspect the corrugated stainless steel coil in the HFS boiler

and flush it with a suitable flushing agent if necessary.

After completion of these tasks, the cold water valve must be opened first

and the corrugated stainless steel coil must be flushed with clean water.

Only after flushing may the hot water line be opened again.

a) Cold water line

b) Hot water line

c) Recirculation line

d) Flush valve cold

e) Flush valve hot

s) combination inlet group

See ISSO publication

55.1 section 4.2.3

Thermal management

concept

Hot water outlet

Cold water supply

Flush connection supply

max. 65 °CkW

7651255 - v.01 - 2305201612 HFS 650 / HSF 700

4.2 Scope of delivery

Name

Buffer vessel 1

Cover 1

Options:

- Connection set recirculation line set 100020184

4.3 Placement

The device:

• Installinalocationprotectedfromfreezingtemperatures

• Placeonaconcretepadtomakeiteasiertocleanthespace

• Installascloseaspossibletoatappointtokeepheatlossinthepipes

to a minimum.

4.4 Main dimensions – Connections

A mm B mm C mm D mm E mm F mm G mm H mm I mm

HFS 600 W 100 237 383 495 609 875 1000 1755 1090

HFS 750 W 100 237 596 708 822 1088 1000 1970 1303

J mm K mm L mm M mm N mm O mm P mm Q mm T mm

HFS 600 W 1205 1335 1348 215 350 480 848 1631 750

HFS 750 W 1418 1547 1561 231 405 646 1061 1844 750

4 Installation

a

Domestic hot water outlet R 1 1/4 (corrugated stainless

steel coil)

b

Heating boiler supply R 1 1/4

c

Heating boiler return line - with modulating heating

boiler R 1 1/4

d

Collector circuit connection - supply line 1 R 3/4

e

Fill/drain connection R 3/4

f

Heating boiler return line 2 - with modulating heating

boiler R 1 1/4

g

Cold water supply R 1 1/4 (corrugated stainless steel

coil)

h

Collector circuit return line connection R 1 1/4 heating

boiler return line (without collector circuit)

i jkImmersion sleeve Ø16 mm

l

Thermometer connection Rp 1/2

m

Manual air bleed Rp 1/2

n

Supply – collector circuit 2 R 3/4

o

Immersion sleeve Ø7 mm

Boiler dimensions

Diameter: Ø750 mm

Height HFS 600/750: 1755-1970 mm

Tilting dimension HFS 600/750: 1740/1950 mm

R = male thread

Rp = female thread

137651255 - v.01 - 23052016 HFS 650 / HSF 700

4.5 Mounting the appliance

4.5.1 Installation of a recirculation line set

To ensure that hot water is available at the taps, an inline recirculation

system can be connected to the HFS. The inline recirculation system

is not part of the boiler and must be ordered separately. Be aware that

the boiler temperature is reduced by the complete recirculation line. The

following hydraulic configurations can be used.

The recirculation set is connected to the outlet of the hot water boiler,

directly in series with the outlet or as diversion through use of a T-fitting

(depending on the flow). The hose must be inserted in the hot water outlet

over a length of at least three meters and connected to the return line

of the recirculation line and the cold water supply of the thermostatic tap

water mixing valve. A timer must be installed for the recirculation line.

See

Thermal management concept ISO publication 55.1, section 4.2.3

(1)

(7)

(9)

(10)

(8)

(6)

(2)

(3)

(5)

(4)

(10)

(11)

(7)

(9)

(8)

(6)

(1)

(2)

(3)

(5)

(4)

(10)

(7)

(9)

(8)

(1)

(6)

(2)

(3)

(5)

(4)

Recirculation connection via the cold water line

Recirculation connection via the recirculation

buffer

Recirculation connection through use of the inline

recirculation connection set (without tap water mixing valve)

4 Installation

Legend:

1) return – CH boiler

2) supply – CH boiler

3) -

4) supply – collector circuit

5) return – collector circuit

6) Domestic hot water

7) timer

8) sensor

9) domestic water pump

10) supply – cold water

11) inline recirculation line

7651255 - v.01 - 2305201614 HFS 650 / HSF 700

4.5.2 Mounting the boiler

Attention

The installation must be carried out in accordance with the current

regulations, best practices for technical work, and the instructions in

this manual.

Danger of electric shock

Solar collectors must be protected against lightning strikes and be

earthed.

Stb

WW

S2

M001070D

S2, Stb: Before proceeding with the installation the sensors must be

placed in the corresponding immersion sleeves.

See

Page 5

Stb

WW

S2

M001070D

M001071C

4 Installation

157651255 - v.01 - 23052016 HFS 650 / HSF 700

4 Installation

Fit a manual

bleed valve

7651255 - v.01 - 2305201616 HFS 650 / HSF 700

4.6 Hydraulic examples

1. Quinta Pro + HFS + DKC + collector field

4 Installation

Select diagram SC514000.SET from the SD card (see control station doc section 2.4)

The components enclosed in a green rectangle are used.

Legend CH boiler

1 CH supply

2 CH return

TB Mount boiler sensor S43.946 on boiler terminal Tdhw (see boiler doc)

Legend Quadro HFS vessel

1 Domestic hot water out R1

1

/

4

”

2 Supply – CH boiler connection R1

1

/

4

”

3 Return – CH boiler connection R1

1

/

4

”

4 Solar supply R3/4”

5 Fill R3/4”

6 2nd return – CH boiler connection R1

1

/

4

”

7 Domestic cold water in R1

1

/

4

”

8 Solar return/CH boiler return line (without collector circuit) 1

1

/

4

”

9, 10, 11 immersion sleeve Ø16 mm

12 Thermometer R1/2”

13 Manual air bleed Rp

1

/

2

” (not included)

14 2nd supply – solar connection R

3

/

4

”

15 Immersion sleeve Ø 7 mm

S2 Boiler sensor bottom – HFS vessel in no. 9

TB boiler sensor part no. S43.946 CH boiler in no. 11

Legend Solar station/collector DKC

1 Supply – solar collector

2 Return – solar collector

3 Supply to boiler

4 Return to boiler

S1 Collector sensor

S3 Primary sensor plate heat exchanger

S9 Primary sensor return

R1 Primary solar pump

R3 Secondary solar pump

See section 4.2.3 Thermal management

concept ISSO publication 55.1

#

Legionella circuit

Timer with pump for legionella prevention

(not supplied by Remeha)

$

Install domestic water portion in

accordance with the applicable domestic

water installation standards. For more

information about the recirculation

connection options, see the documentation

for the recirculation connection set.

Terminal strip RemaSOL C/2

Max. 5 kW loss

from 10 to 100 m

2

collectors

177651255 - v.01 - 23052016 HFS 650 / HSF 700

2. Quinta Pro + HFS + P-buffer + DKC + collector field

4 Installation

Select diagram SC514000.SET from the SD card (see control station doc section 2.4)

The components enclosed in a green rectangle are used.

Legend CH boiler

1 CH supply

2 CH return

TB Mount boiler sensor S43.946 on boiler terminal Tdhw (see boiler doc)

Legend Quadro HFS vessel

1 Domestic hot water out R1

1

/

4

”

2 Supply – CH boiler connection R1

1

/

4

”

3 Return – CH boiler connection R1

1

/

4

”

4 Supply – solar R3/4”

5 Fill R3/4”

6 2nd return – CH boiler connection R1

1

/

4

”

7 Domestic cold water in R1

1

/

4

”

8 Solar return/CH boiler return line (without collector circuit) 1

1

/

4

”

9, 10, 11 immersion sleeve Ø16 mm

12 Thermometer R1/2”

13 Manual air bleed Rp

1

/

2

” (not included)

14 2nd supply – solar connection R

3

/

4

”

15 Immersion sleeve Ø 7 mm

S2 Boiler sensor bottom – HFS vessel in no. 9

TB boiler sensor part no. S43.946 CH boiler in no. 11

Legend Solar station/collector DKC

1 Supply – solar collector

2 Return – solar collector

3 Supply to boiler

4 Return to boiler

S1 Collector sensor

S3 Primary sensor plate heat exchanger

S9 Primary sensor return

R1 Primary solar pump

R3 Secondary solar pump

Legend P vessel

1 Air bleed (not included) Rp ½”

2 Supply – CH installation 1/drain R1 ¼”

3 Supply – CH installation 2, R1 ¼”

4 Supply – boiler R1 ¼”

5 Immersion sleeve Ø16 mm

6 Return/supply – CH installation 3, R1 ¼”

7 Supply – boiler / buffer / heat pump

8 Supply line – collector G1”

9 Return – CH installation-2 R1 ¼”

10 Return – boiler / buffer / heat pump R1 ¼”

11 Return – low temp. system R1 ¼”

12 Return – boiler / draining

13 Return – CH system-1 / draining

14 Return line – collector

15 Thermometer connection Rp ½”

S4Slideboilersensoronvesselterminalstrip.Nearno.12

S7 Boiler sensor top in no. 5

R4 Drain pump

See section 4.2.3 Thermal management

concept ISSO publication 55.1

$

Install domestic water portion in

accordance with the applicable domestic

water installation standards. For more

information about the recirculation

connection options, see the documentation

for the recirculation connection set.

#

Legionella circuit

Timer with pump for legionella prevention

(not supplied by Remeha)

Terminal strip RemaSOL C/2

Max. 5 kW loss

Port A

Port B

From 10 to 100 m

2

collectors

7651255 - v.01 - 2305201618 HFS 650 / HSF 700

3. CWH + HFS + DKC + collector field

4 Installation

Select diagram SC514000.SET from the SD card (see control station doc section 2.4)

The components enclosed in a green rectangle are used.

Legend CH boiler

1 Domestic cold water in

2 Domestic water recirculation return

3 Domestic supply/recirculation

Legend Quadro HFS vessel

1 Domestic hot water out R1

1

/

4

”

2 Supply – CH boiler connection R1

1

/

4

”

3 Return – CH boiler connection R1

1

/

4

”

4 Supply – solar R3/4”

5 Fill R3/4”

6 2nd return – CH boiler connection R1

1

/

4

”

7 Domestic cold water in R1

1

/

4

”

8 Solar return/CH boiler return line (without collector circuit) 1

1

/

4

”

9, 10, 11 immersion sleeve Ø16 mm

12 Thermometer R1/2”

13 Manual air bleed Rp

1

/

2

” (not included)

14 2nd supply – solar connection R

3

/

4

”

15 Immersion sleeve Ø 7 mm

S2 Boiler sensor bottom – HFS vessel in no. 9

Legend Solar station/collector DKC

1 Supply – solar collector

2 Return – solar collector

3 Supply to boiler

4 Return to boiler

S1 Collector sensor

S3 Primary sensor plate heat exchanger

S9 Primary sensor return

R1 Primary solar pump

R3 Secondary solar pump

See section 4.2.3 Thermal management

concept ISSO publication 55.1

%

Install domestic water portion in

accordance with the applicable domestic

water installation standards.

Terminal strip RemaSOL C/2

Max. 5 kW loss

From 10 to 100 m

2

collectors

197651255 - v.01 - 23052016 HFS 650 / HSF 700

4. CWH + HFS + P-buffer + DKC + collector field

4 Installation

Select diagram SC514000.SET from the SD card (see control station doc section 2.4)

The components enclosed in a green rectangle are used.

Legend CWH

1 Domestic cold water in

2 Domestic water recirculation return

3 Domestic supply/recirculation

Legend Quadro HFS vessel

1 Domestic hot water out R1

1

/

4

”

2 Supply – CH boiler connection R1

1

/

4

”

3 Return – CH boiler connection R1

1

/

4

”

4 Supply – solar R3/4”

5 Fill R3/4”

6 2nd return – CH boiler connection R1

1

/

4

”

7 Domestic cold water in R1

1

/

4

”

8 Solar return/CH boiler return line (without collector circuit) 1

1

/

4

”

9, 10, 11 immersion sleeve Ø16 mm

12 Thermometer R1/2”

13 Manual air bleed Rp

1

/

2

” (not included)

14 2nd supply – solar connection R

3

/

4

”

15 Immersion sleeve Ø 7 mm

S2 Boiler sensor bottom – HFS vessel in no. 9

Legend Solar station/collector DKC

1 Supply – solar collector

2 Return – solar collector

3 Supply to boiler

4 Return to boiler

S1 Collector sensor

S3 Primary sensor plate heat exchanger

S9 Primary sensor return

R1 Primary solar pump

R3 Secondary solar pump

%

Install domestic water portion in

accordance with the applicable

domestic water installation standards.

See section 4.2.3 Thermal

management concept ISSO

publication 55.1

Terminal strip RemaSOL C/2

Max. 5 kW loss

From 10 to 100 m

2

collectors

Legend P vessel

1 Air bleed (not included) Rp ½”

2 Supply – CH installation 1/drain R1 ¼”

3 Supply – CH installation 2, R1 ¼”

4 Supply – boiler R1 ¼”

5 Immersion sleeve Ø16 mm

6 Return/supply – CH installation 3, R1 ¼”

7 Supply – boiler / buffer / heat pump

8 Supply line – collector G1”

9 Return – CH installation-2 R1 ¼”

10 Return – boiler / buffer / heat pump R1 ¼”

11 Return – low temp. system R1 ¼”

12 Return – boiler / draining

13 Return – CH system-1 / draining

14 Return line – collector

15 Thermometer connection Rp ½”

S4Slideboilersensoronvesselterminalstrip.Nearno.12

S7 Boiler sensor top in no. 5

R4 Drain pump

Port A

Port B

7651255 - v.01 - 2305201620 HFS 650 / HSF 700

5. Quinta Pro + HFS

4 Installation

Legend CH boiler

1 CH supply

2 CH return

TB Mount boiler sensor S43.946 on boiler terminal Tdhw (see boiler doc)

Legend Quadro HFS vessel

1 Domestic hot water out R1

1

/

4

”

2 Supply – CH boiler connection R1

1

/

4

”

3 Return – CH boiler connection R1

1

/

4

”

4 Supply – solar R3/4”

5 Fill R3/4”

6 2nd return – CH boiler connection R1

1

/

4

”

7 Domestic cold water in R1

1

/

4

”

8 Solar return/CH boiler return line (without collector circuit) 1

1

/

4

”

9, 10, 11 immersion sleeve Ø16 mm

12 Thermometer R1/2”

13 Manual air bleed Rp

1

/

2

” (not included)

14 2nd supply – solar connection R

3

/

4

”

15 Immersion sleeve Ø 7 mm

S2 Boiler sensor bottom – HFS vessel in no. 9

TB boiler sensor part no. S43.946 CH boiler in no. 11

Max. 5 kW loss

See section 4.2.3 Thermal

management concept ISSO

publication 55.1

Legionella circuit via boiler controller

(see boiler doc.)

#

Install domestic water portion in

accordance with the applicable

domestic water installation standards.

For more information about the

recirculation connection options,

see the documentation for the

recirculation connection set.

217651255 - v.01 - 23052016 HFS 650 / HSF 700

4.7 Connections on the domestic water side

This must be done in accordance with the current standards and local

regulations.

The maximum operating pressure of the heat exchanger in the hot water

boiler is 8 bar.

4.7.1 Special precautions

For the hydraulic connection it is absolutely essential that the supply lines

be flushed to prevent metal filings or other particles from entering the

boiler.

4.7.2 Combination inlet group

Attention

According to the safety regulations, a combination inlet group must

be installed on the cold water inlet of the domestic water heating

circuit.

Maximum pressure of the combination inlet group: 8 bar

Include the combination inlet group in the cold water circuit.

4.7.3 Shut-off valves

The primary and secondary circuits must include shut-off valves so

they can be isolated for convenient maintenance of the domestic water

heating circuit. Through use of these shut-off valves it is possible to

perform maintenance on the boiler and the components without having

to empty the entire system. Moreover, these shut-off valves make it

possible to isolate the domestic water heating circuit in the installation to

perform pressure testing at pressures higher than the permitted operating

pressure.

Attention

When connecting to copper pipes, a coupling made of steel, cast

metal or an insulating material must be used between the hot water

outlet of the boiler and this pipe to fully eliminate the possibility of

corrosion of the connection.

4.7.4 Cold water/domestic water connection

The connection to the cold water supply must be made as shown in the

diagram on page 11. A drain and a funnel for the safety fittings must be

present in the boiler room. The parts used for connection to the cold

water supply must comply with the local standards and regulations. A

combination inlet group must be installed in the cold water supply.

4.7.5 Tap water mixing valve

In combination with solar collectors, we recommend the installation of a

thermostatic tap water mixing valve.

4.7.6 Hot water recirculation line

See

Page 13.

4 Installation

7651255 - v.01 - 2305201622 HFS 650 / HSF 700

4 Installation

4.7.7 Measures to prevent backflow of heated water

A non-return valve must be installed in the cold water supply.

4.8 Connection of the expansion vessels to the collector and heating circuit

4.8.1 Boiler circuit

The expansion vessel must be connected directly to the boiler.

The installation must be carried out in accordance with the applicable

technical guidelines.

4.8.2 Collector circuit (on the boiler side)

See

Manual accompanying the solar energy station

4.9 Electrical connection

See

• Manualaccompanyingthecontrolstationforthesolarenergy

system

• Technicalmanualaccompanyingtheheatingboiler.

4.10 Commissioning

See

• Manualaccompanyingthesolarenergystations(DKC).

• Manualaccompanyingthecontrolstationforthesolarenergy

system

• Technicalmanualaccompanyingtheheatingboiler.

237651255 - v.01 - 23052016 HFS 650 / HSF 700

5 Inspection and maintenance

5 Inspection and maintenance

5.1 Switching off during the summer: Safety through Steam Back

Remeha solar installations with RemaSOL control stations include threeway protection that prevents damage to the solar energy system itself and

that potentially caused by the system (particularly when it is switched off).

See

The manual accompanying the control station.

Explanation

The installation has been designed so that no special safety

measures are required in the summer when the user will be away

for a longer period of time.

Attention

The control station may not be switched off and the heat conducting

liquid may not be drained.

The control station for the solar energy system keeps the system in

operation as long as mains electricity is available and the circulation pump

is working. With the functions for boiler protection, collector protection,

night-time cooling and complete shutdown, the system is always kept

within the desired parameters without the system entering the steam

phase. In the event of a pump failure, Steam Back also ensures that no

problems develop for the house owner when the steam temperature of

> 140 °C is reached. When a temperature of 145 °C is reached and a

pressure of approximately 2.5 bar is exceeded in the installation, one

drop of collector liquid evaporates in the collector for every two litres

of saturated vapour (steam). Within a tenth of a second the resulting

pressure increase forces the liquid out of the collector and into the

expansion vessel provided for this purpose. This all happens very quickly,

without noise and without steam pressure. The solar energy system is

now empty. There is no load on the system, because the collectors no

longer contain any collector liquid.

The collector liquid is not affected, because it is not in the collector. When

the temperature in the collector drops below 135 °C again, the two litres

of steam in each condenser condenses to one drop of collector liquid.

The collector liquid stored in the expansion vessel is released back to the

collector. The installation is filled automatically. During the next start of

the solar energy system the collector circuit is opened for three minutes.

If micro-bubbles have formed, these are now separated via the Airstop

in the station. At the end of the three minutes the installation starts

completely again. Steam Back ensures safe operation of the installation,

completely automatically, without the need for manual intervention. For a

collector surface area of 10 m2 or greater, in addition to a regular expansion

vessel a buffer vessel must be installed to provide storage capacity for

larger quantities of collector liquid. Steam Back protects all components of

the solar energy system. The solar energy station with integrated Airstop,

the special expansion vessel, the safety valve, the collectors with single pipe

and the control station for the system.

5.2 Maintenance

We recommend entering a maintenance contract that includes annual or

biannualinspectionoftheliquidlevel,anti-freezingprotectionandsystem

pressure as well as a leak check and overall check for correct operation.

7651255 - v.01 - 2305201624 HFS 650 / HSF 700

6 Commissioning report

6.1 System description

6.2 Inspection of collector circuit supply and return lines

6.3 Control station, verification of operation RemaSOL C2

Installation location ................................................................. Company name .....................................................................

Customer ................................................................................ Street .....................................................................................

Street ...................................................................................... Postal code/city .....................................................................

Postal code/city ...................................................................... Tel. ....................................... Fax ..........................................

Tel. ..................................... Fax ............................................ Mobile ....................................................................................

Mobile ..................................................................................... Email ......................................................................................

Email....................................................................................... Technician ..............................................................................

Solar energy installation for: £Domestic hot water £Supplemental heating £Swimming pool heating

Solar collectors: Type: ................................................................. Quantity: ..................................

.

Mounting type: £On the roof £Flush with the roof £Flat roof

Line: £Duo-Tube £Cu 15 £Cu 18

£Other line: ø .........................................mm Length ........................m

Insulation: ...................mm Type/Manufacturer ................................................................

Boiler: Type: ...............................................................................................

Solar energy station: £Installation integrated in the collector £Other: ............................

Solarheat-transferuid: £LS £Othersolaruid.................. Volumeinlitres:................

Installation pressure: ................................bar

Expansion vessel pre-charge

collector: ................................bar

- Return line (cold) connected Return line £OK

- Supply line (hot) connected to collector line Supply line £OK

- Sensor installed on the side where the hot collector line exits the collector (supply line) Sensor position £OK

Purging 10 min, £ OK Temperature buffer bottom S4 = .......... °C

Thenmatched-owoperation £ OK Temperature buffer top S5 = .......... °C

Collectortemperature(TC) S1 = .......... °C Temperaturecollectoreld2 S6 = .......... °C

Temperature boiler 1 bottom (TS) S2 = .......... °C Collector temperature return or S9 = .......... °C

Supply temperature exchanger (TE) S3 = .......... °C temperature buffer

6 Commissioning report

257651255 - v.01 - 23052016 HFS 650 / HSF 700

6.4 System inspection

6.5 Resetting

Commissioning

Pump primary circuit, speed-controlled R1

□

Yes□No

Three-way diverting valve R2

□

Yes□No

Pump secondary circuit, speed-controlled R3

□

Yes□No

Pump biomass boiler R4

□

Yes□No

Switchingvalvellinganddraining R5

□

Yes□No

Drain pump / swimming pool pump R8

□

Yes□No

Filling pump for the boiler R9

□

Yes□No

Legionella prevention pump R10

□

Yes□No

Heat capacity = .............. kW

∆ Ttarget = .............. K

Min. switching point = .............. °C

Collector temperature max. = .............. °C

Self-calibration phase tu = .............. min.

Minimum speed R1 = .............. rpm

Minimum speed R3 = .............. rpm

Domestic water heating, desired values of the

supplemental heating:

- Boiler circuit .............. °C

Components on the roof:

All mounting screws tightened £ yes

All plumbing connections checked, no leaks £ yes

Solar energy station:

Correctly connected to the supply and return lines £ yes

Thermometer supply and return temperature placed and checked £ yes

Boiler:

Combination inlet group installed £ yes

Pressure reducer set at ........ bar £ yes

Hot water mixer with thermosiphon U connected to the solar boiler £ yes

Thermostatic mixer set to ..............°C £ yes

Insulation on the boiler checked £ yes

All connections lines installed £ yes

Expansion vessel:

Pre-charge pressure of the expansion vessel checked £ yes

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

Installation manuals (solar collector, boiler, complete station, controller) given to the customer £ yes

Operation of the solar energy system via the display on the control station explained to the customer £ yes

6 Commissioning report

7651255 - v.01 - 2305201626 HFS 650 / HSF 700

6 Commissioning report

6.6 Remarks

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................

Place: .......................................................................................... Date: .............................................................................

Customer’s signature Technician’s signature

277651255 - v.01 - 23052016 HFS 650 / HSF 700

7 Maintenance report

7 Maintenance report

Maintenance number: .........................................

System description

Inspection

Three-way diverting valve R3

Temporary inlet heat regulation S10 = .............. °C

Temporary outlet heat regulation S11 = .............. °C

Pump primary circuit, speed-controlled R1

□

Yes□No

Three-way diverting valve R2

□

Yes□No

Pump secondary circuit, speedcontrolled

R3

□

Yes□No

Pump biomass boiler R4

□

Yes□No

Switchingvalvellinganddraining R5

□

Yes□No

Drain pump / swimming pool pump R8

□

Yes□No

Filling pump for the boiler R9

□

Yes□No

Legionella prevention pump R10

□

Yes□No

Installation pressure checked .......................... bar pH value ......................

Pre-charge pressure of the collector

expansion vessel .......................... bar

Freezeprotectionchecked ..........................°C

Noleaks: Visualinspection:

Collector £ OK £ OK

Pipe £ OK £ OK

Solar energy station £ OK £ OK

Domestic water heating £ OK £ OK

Controlstation Vericationofoperation £ OK

Collector temperature (TC) S1 = ............°C

Temperature boiler 1 bottom (TS) S2 = ............°C

Exchanger supply temperature (TE) S3 = ............°C

Temperature boiler 1 top S4 = ............°C

Temperature buffer bottom S4 = ............°C

Temperature buffer top S5 = ............°C

Temperaturecollectoreld2 S6=............°C

Collector temperature return or S9 = ............°C

temperature buffer

Enamelledboiler: Sacricialanodechecked £issufcient £ must be replaced

Thermostatic tap water mixer Setting ...............°C

Customer ................................................................................ Company name .....................................................................

Street ...................................................................................... Street .....................................................................................

Postal code/city ...................................................................... Postal code/city .....................................................................

Tel. ...................................... Fax ........................................... Tel. ....................................... Fax ...........................................

Mobile .................................................................................... Mobile .....................................................................................

Email....................................................................................... Email .....................................................................................

Technician ..............................................................................

Solar energy installation for: £ Domestic hot water £ Supplemental heating £ Swimming pool heating

Solar collectors: ................................................... Surface area .................................m

2

Domestic water heating: .............................................. Solar energy station: . ..............................................................

7651255 - v.01 - 2305201628 HFS 650 / HSF 700

7 Maintenance report

Complete installation checked

Functional inspection £ OK £ must be replaced

Swimming pool = ............°C Biomass = ............°C

Min. temp. Sp. = ............°C Min. temp. boiler = ............°C

Max. temp. Schw. = ............°C Max. temp. Sp. = ............°C

ΔTin =............°C ΔTin =............°C

ΔTuit =............°C ΔTuit =............°C

Place: ......................................................................... Date: ...............................................................

Customer’s signature Technician’s signature

£ Installation OK

£Installationhasdeciencies

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

297651255 - v.01 - 23052016 HFS 650 / HSF 700

7 Maintenance report

7651255 - v.01 - 2305201630 HFS 650 / HSF 700

7 Maintenance report

© Copyright

All technical and technological information contained in these technical instructions, as well as any drawings and technical

descriptions supplied, remain our property and shall not be multiplied without our prior consent in writing. Specifications subject

to change without notice.

7651255 - v.01 - 23052016

REMEHA BV

Kanaal Zuid 110,

NL-7332BDApeldoorn

THENETHERLANDS

Tel: +31 55 5496969

Fax: +31 55 5496496

Internet: www.remeha.nl

E-mail: remeha@remeha.com

Loading...

Loading...