When it comes to sustainability,

we think from the ground up.

GILLES BIOMASS BOILER

The most efficient way to heat on a low to zero carbon fuel

CONTENTS

page

Introduction 2

Biomass and climate change 3

Fuel choices 4

Fuel storage 5

Fuel calculator 6

Transport systems 7

HPK-RA 9

HPKI-L 199 27

HPKI-K 180-550kW 29

HPKI-R 999 34

Important information 36

Notes 38

REMEHA COMMERCIAL HIGH

PERFORMANCE, HIGH EFFICIENCY

BIOMASS BOILER TECHNOLOGY

Remeha Commercial has been manufacturing and supplying

high performance low-carbon and energy-efficient heating

products since 1935. Climate change is globally considered to be

one of the most pressing and challenging issues of our time.

As a company, Remeha is committed to creating a more

sustainable future with new products that will support businesses

and organisations in meeting our UK environmental and

legislative targets and the nation in achieving decarbonisation.

Climate change is caused by the emission of harmful greenhouse gases

which act like a blanket over the Earth’s surface, trapping heat in the

atmosphere and raising surface and atmospheric temperatures with

devastating results to the planet. Carbon dioxide (CO

primary greenhouse gases.

Heating currently accounts for almost half of the UK’s carbon

emissions. Using biomass as a fuel to produce deliver low carbon

heating and hot water from a renewable source could significantly

reduce this. The Carbon Trust suggests that lifetime CO

for woodchip biomass are in the range of 10-23 kg CO

with 263-302 kgCO

biomass boilers now offer greater ease of use and flexibility making

them one of the most popular of all renewable technologies.

Remeha’s range of high performance biomass boilers provide

controllable, environmentally-friendly, low-carbon heating with

efficiencies of up to 96% GCV and emission levels significantly below

the new minimum levels of Building Regulations. Biomass boilers are

often specified in conjunction with gas condensing boilers. The Remeha

range of biomass boilers is fully-compatible with our market-leading,

renewable-ready, high-efficiency gas condensing boilers, offering a

quality solution to energy-efficient, low to zero carbon heating from a

single supplier. With our technologically-advanced range of biomass

boilers, our knowledgeable team and our experience of around 600

installations across the UK, when the heat is required on demand,

Remeha Commercial can help.

/MWh for natural gas. As technology advances,

2

) is one of the

2

emissions

2

/MWh compared

2

BIOMASS AND CLIMATE CHANGE

One of the most important environmental benefits of using

sustainably produced wood for energy in place of fossil fuels

is its positive impact in helping moderate long-term global

climate change.

Fossil fuel combustion takes carbon that was locked away

underground (as crude oil, gas, or coal) millions of years ago and

transfers that carbon to the atmosphere as new CO

burned, on the other hand, it recycles carbon that was already in the

natural carbon cycle, which is recaptured through sustainable forest

growth. Consequently, the net long-term effect of burning wood fuel

is considerably less, as long as the sources from which the wood came

are sustainably managed.

Biomass offers three key advantages over fossil fuel alternatives:

Carbon savings: using solid biomass for heating typically gives

reductions in carbon of around 80 to 90 per cent compared with fossil

fuel alternatives.

Fuel price savings: biomass is up to 80% cheaper than heating oil.

RHI funding: Government support through the Renewable Heat

Incentive means that biomass generates considerable annual

payments for the amount of heat it generates and uses.

This funding is dependent on boiler size and heat output

The Remeha range of fully-automated wood chip and wood pellet

biomass boilers uses advanced combustion technology to achieve

an outstanding combustion efficiency of up to 96%, resulting in lower

fuel consumption and reduced ash of just 0.5-1%.

With emission levels significantly below the new minimum levels of

Building Regulations, Remeha biomass boilers meet all environmental

regulations and are eligible for RHI funding.

. When wood is

2

BIOMASS AND CLIMATE CHANGE

2

3

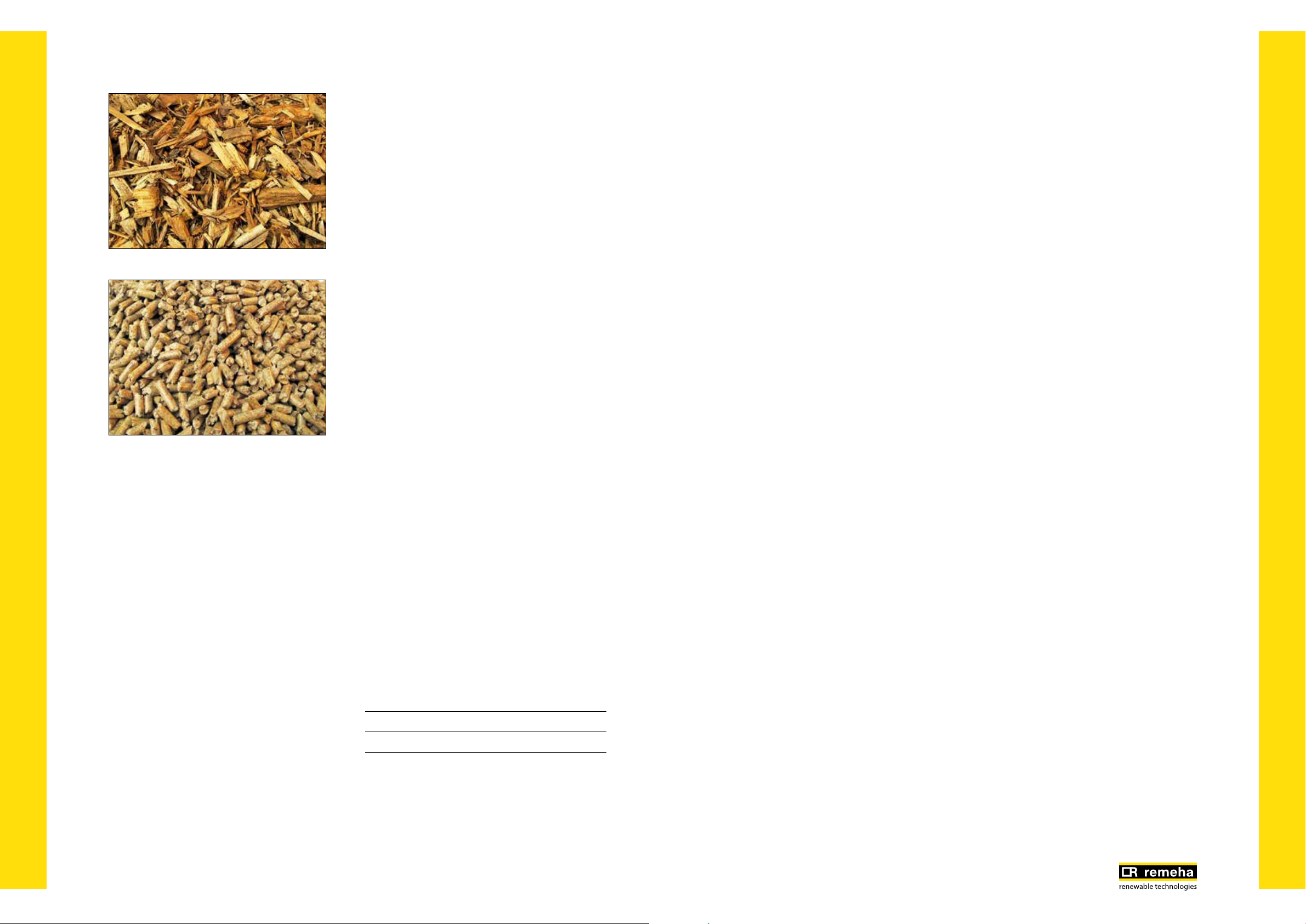

REMEHA GILLES BIOMASS BOILER FUEL CHOICES

FUEL CHOICES

REMEHA GILLES BIOMASS BOILER FUEL STORAGE

WOOD FUEL STORAGE

This guide is to help the designer decide which

wood fuel to choose and assumes that the choice

to burn wood chips or pellets as a fuel has been

made and that the different characteristics of the

fuel need to be considered before making a

final decision.

Wood pellets have a calorific value and a higher

bulk density than Wood chip, this could make them

more suitable for installations with a limited storage

capacity or where frequent fuel deliveries are not

viable (the calorific value of 5m³ of Wood pellet is

equivalent to approximately 18m³ of Wood chip).

Wood pellets Vs Wood chips

n

Pellets flow freely whereas chips do not

n

Pellets are a more dense form of fuel than chips

therefore take less storage space per kW/hr

n

Pellets are generally more expensive per kW/hr

than chips

n

A wood chip boiler can burn pellets whereas a pellet

boiler can’t burn wood chip

Summary

At the time of writing chips are about 60% of the cost

per kW/hr of Natural Gas and pellets are about the

same as Natural Gas, therefore chips do have the

possibility of giving a payback as well. Pellets are

about 50% the cost of Gas Oil per kW/hr.

If fuel storage space, on site labour or a local supply

of chips are unavailable, it is evident that pellets will

give a significant carbon reduction over traditional

heating fuels.

Wood pellet Wood chip

Density kg/m³ approx 650 200

Heat output kW hr/m³ approx 3000 800

Consideration now needs to be given to the type of

fuel store suitable for the different fuels as each has a

different requirement. There is however one overriding

consideration to bear in mind for both fuels: it is easier

to move the heating system water than wood fuel,

so try to keep the fuel store as close to the wood boiler

as possible. The simpler the fuel route the better!

What capacity does the fuel store need to be?

Calculation of the fuel store capacity is dependent

upon a number of factors:

n

What output is the boiler in kW?

n

How many hours per week will it be in operation?

n

Which type of fuel is being used – pellet or chip?

n

How often are fuel deliveries feasible?

n

What is the capacity of the delivery vehicle?

Wood chip example

A 160kW boiler in a school working 6hrs per day at

full output burning wood chip will burn the following

amount of fuel per week.

160kW x 6hrs per day x 5 days per week = 4800 kW/hrs

per week.

4800 divided by 800 (the amount of kW/hrs per m³

of chips) = 6m³ per week.

Most fuel delivery vehicles carry approximately 30m³

of fuel so in this instance if a 36/38m³ store could be

created a delivery would be required approximately

every 6 weeks without the store needing to be fully

empty to receive a full load.

Wood pellet example

A 100kW boiler in a sports centre working

approximately 12hrs per day at full output burning

pellets will burn the following amount of fuel per week.

100kW x12hrs per day x 7 days per week = 8400kW/hrs

per week.

8400 divided by 3000 (the amount of kW/hrs per m³

of pellets) = 2.8m³ per week.

CALCULATIONS AT A GLANCE:

Wood chip

Boiler output (kW) x hrs run per day x day run per

week = kW/hrs produced per week.

kW/hrs per week divided by 800 (kW/hrs per m³

of chips) = m³ required per week.

Wood pellet

Boiler output (kW) x hrs run per day x day run per

week = kW/hrs produced per week.

kW/hrs per week divided by 3000 (kW/hrs per m³

of Pellet) = m³ required per week.

Wood chip storage

As mentioned previously, chips do not free flow so are

not suitable for the sort of storage used for pellets.

To move chips from the store to the transport system,

a Sweep Auger needs to be used.

In operation the auger, which is driven by an electric

motor, transfers its drive into a gearbox underneath

the circular disc which then makes the arms rotate and

drag the fuel to the auger. The fuel is then transported

to the boiler via auger(s) like wood pellets.

Choose the largest diameter sweep collector that will

fit between the fuel store walls to minimise fuel left

around the edges.

Sweep collector operation undermines fuel causing it

to fall inwards and then be fed into the feed auger.

One motor drives the sweep collector and feed auger.

The wood chip store should be as square as possible to

minimise the fuel left in the corners.

Wood pellet storage

As previously mentioned, pellets will flow freely so

they can be kept in a fuel store with a sloping floor to a

central feed auger (ideal slope of 40 degrees or more).

The fuel can then be moved using augers to the boiler

or feed another auger to take the fuel further using

extra augers. Alternatively, if no fuel storage room is

available or you do not want to adapt one, other pellet

storage options are available.

That would require a full load approximately every

10 weeks or a half load every month or so.

4

5

32

32

32

32

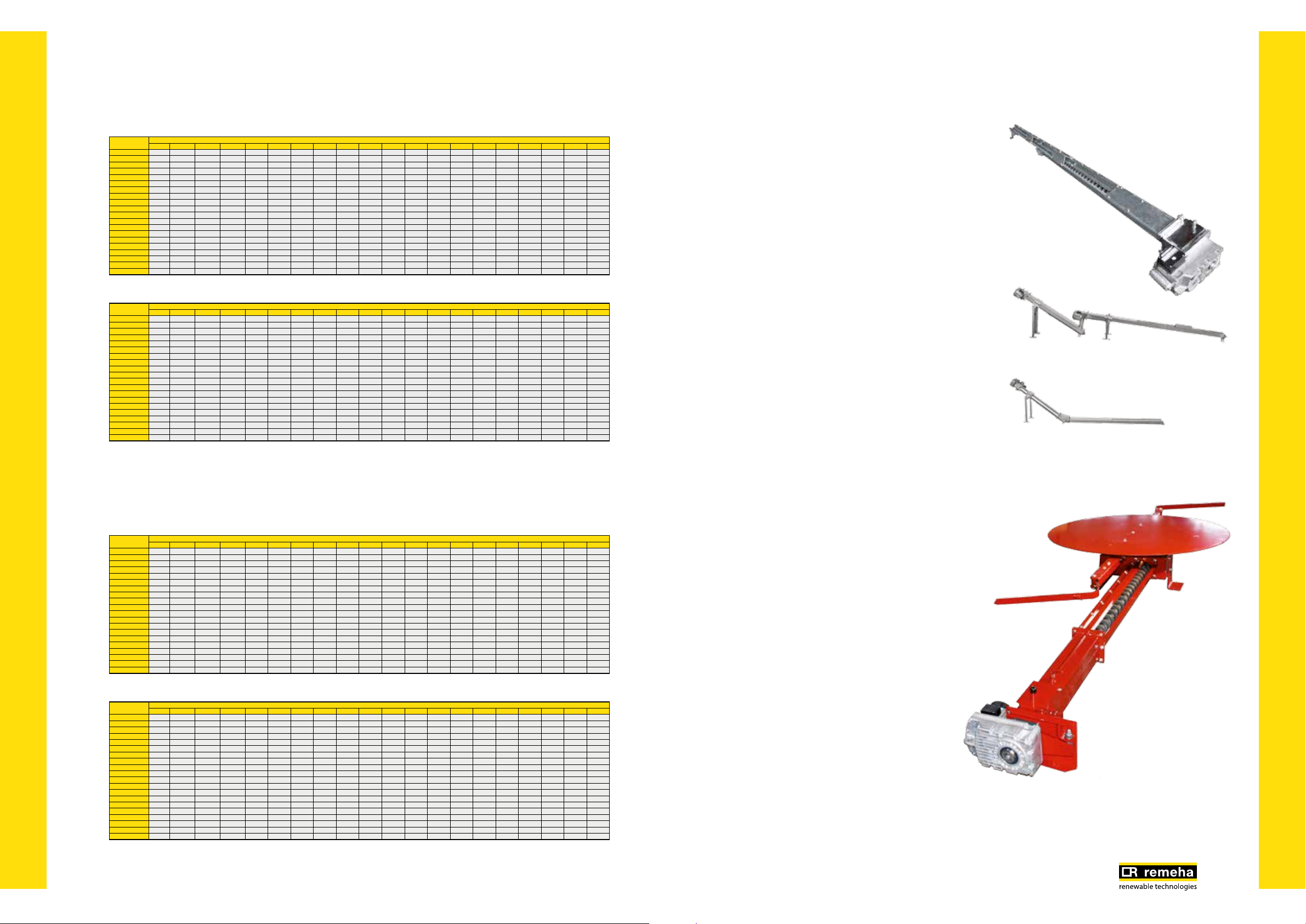

REMEHA GILLES BIOMASS BOILER FUEL CALCULATOR

BIOMASS FUEL CALCULATOR FOR 5 DAY WEEK

REMEHA GILLES BIOMASS BOILER TRANSPORT SYSTEMS

TRANSPORT SYSTEMS

Chip (800kW/hrs/m3 @ 200kgs)

Boiler Output kW

Pellet (3000kW/hrs/m

Boiler Output kW

5 6789101112131415161718192021222

25 0.78 0.94 1.09 1.25 1.41 1.56 1.72 1.88 2.03 2.19 2.34 2.50 2.66 2.81 2.97 3.13 3.28 3.44 3.59 3.75

50 1.56 1.88 2.19 2.50 2.81 3.13 3.44 3.75 4.06 4.38 4.69 5.00 5.31 5.63 5.94 6.25 6.56 6.88 7.19 7.50

75 2.34 2.81 3.28 3.75 4.22 4.69 5.16 5.63 6.09 6.56 7.03 7.50 7.97 8.44 8.91 9.38 9.84 10.3110.78 11.25

100 3.13 3.75 4.38 5.00 5.63 6.25 6.88 7.50 8.13 8.75 9.38 10.0010.63 11.2511.88 12.5013.13 13.7514.38 15.00

125 3.91 4.69 5.47 6.25 7.03 7.81 8.59 9.38 10.16 10.9411.72 12.50 13.28 14.06 14.8415.63 16.4117.19 17.9718.75

150 4.69 5.63 6.56 7.50 8.44 9.38 10.31 11.25 12.1913.13 14.06 15.0015.94 16.8817.81 18.7519.69 20.6321.56 22.50

175 5.47 6.56 7.66 8.75 9.84 10.9412.03 13.1314.22 15.3116.41 17.5018.59 19.6920.78 21.8822.97 24.06 25.1626.25

200 6.25 7.50 8.75 10.0011.25 12.5013.75 15.00 16.25 17.5018.75 20.00 21.2522.50 23.7525.00 26.25 27.5028.75 30.00

225 7.03 8.44 9.84 11.2512.66 14.0615.47 16.8818.28 19.6921.09 22.50 23.9125.31 26.7228.13 29.5330.94 32.3433.75

250 7.81 9.38 10.9412.50 14.0615.63 17.1918.75 20.3121.88 23.44 25.00 26.5628.13 29.6931.25 32.8134.38 35.9437.50

275 8.59 10.31 12.0313.75 15.4717.19 18.9120.63 22.34 24.0625.78 27.50 29.2230.94 32.6634.38 36.0937.81 39.5341.25

300 9.38 11.2513.13 15.0016.88 18.7520.63 22.50 24.38 26.2528.13 30.00 31.8833.75 35.6337.50 39.3841.25 43.1345.00

325 10.16 12.19 14.2216.25 18.2820.31 22.3424.38 26.41 28.4430.47 32.50 34.53 36.56 38.5940.63 42.6644.69 46.7248.75

350 10.94 13.13 15.3117.50 19.6921.88 24.0626.25 28.44 30.6332.81 35.00 37.19 39.38 41.5643.75 45.9448.13 50.3152.50

375 11.72 14.0616.41 18.75 21.0923.44 25.7828.13 30.47 32.8135.16 37.50 39.84 42.19 44.5346.88 49.2251.56 53.9156.25

400 12.50 15.00 17.5020.00 22.5025.00 27.5030.00 32.50 35.0037.50 40.00 42.50 45.00 47.5050.00 52.5055.00 57.5060.00

425 13.28 15.9418.59 21.2523.91 26.5629.22 31.88 34.53 37.1939.84 42.50 45.16 47.81 50.4753.13 55.7858.44 61.0963.75

450 14.06 16.8819.69 22.5025.31 28.1330.94 33.75 36.56 39.3842.19 45.00 47.81 50.63 53.4456.25 59.0661.88 64.6967.50

475 14.84 17.8120.78 23.7526.72 29.6932.66 35.63 38.59 41.5644.53 47.50 50.47 53.44 56.4159.38 62.3465.31 68.2871.25

500 15.63 18.7521.88 25.0028.13 31.2534.38 37.50 40.63 43.7546.88 50.00 53.13 56.25 59.3862.50 65.6368.75 71.8875.00

3

@ 650kgs)

5 6789101112131415161718192021222

25 0.21 0.25 0.29 0.33 0.38 0.42 0.46 0.50 0.54 0.58 0.63 0.67 0.71 0.75 0.79 0.83 0.88 0.92 0.96 1.00

50 0.42 0.50 0.58 0.67 0.75 0.83 0.92 1.00 1.08 1.17 1.25 1.33 1.42 1.50 1.58 1.67 1.75 1.83 1.92 2.00

75 0.63 0.75 0.88 1.00 1.13 1.25 1.38 1.50 1.63 1.75 1.88 2.00 2.13 2.25 2.38 2.50 2.63 2.75 2.88 3.00

100 0.83 1.00 1.17 1.33 1.50 1.67 1.83 2.00 2.17 2.33 2.50 2.67 2.83 3.00 3.17 3.33 3.50 3.67 3.83 4.00

125 1.04 1.25 1.46 1.67 1.88 2.08 2.29 2.50 2.71 2.92 3.13 3.33 3.54 3.75 3.96 4.17 4.38 4.58 4.79 5.00

150 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00 5.25 5.50 5.75 6.00

175 1.46 1.75 2.04 2.33 2.63 2.92 3.21 3.50 3.79 4.08 4.38 4.67 4.96 5.25 5.54 5.83 6.13 6.42 6.71 7.00

200 1.67 2.00 2.33 2.67 3.00 3.33 3.67 4.00 4.33 4.67 5.00 5.33 5.67 6.00 6.33 6.67 7.00 7.33 7.67 8.00

225 1.88 2.25 2.63 3.00 3.38 3.75 4.13 4.50 4.88 5.25 5.63 6.00 6.38 6.75 7.13 7.50 7.88 8.25 8.63 9.00

250 2.08 2.50 2.92 3.33 3.75 4.17 4.58 5.00 5.42 5.83 6.25 6.67 7.08 7.50 7.92 8.33 8.75 9.17 9.58 10.00

275 2.29 2.75 3.21 3.67 4.13 4.58 5.04 5.50 5.96 6.42 6.88 7.33 7.79 8.25 8.71 9.17 9.63 10.0810.54 11.00

300 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 8.00 8.50 9.00 9.50 10.0010.50 11.0011.50 12.00

325 2.71 3.25 3.79 4.33 4.88 5.42 5.96 6.50 7.04 7.58 8.13 8.67 9.21 9.75 10.2910.83 11.3811.92 12.4613.00

350 2.92 3.50 4.08 4.67 5.25 5.83 6.42 7.00 7.58 8.17 8.75 9.33 9.92 10.5011.08 11.6712.25 12.8313.42 14.00

375 3.13 3.75 4.38 5.00 5.63 6.25 6.88 7.50 8.13 8.75 9.38 10.0010.63 11.2511.88 12.5013.13 13.75 14.38 15.00

400 3.33 4.00 4.67 5.33 6.00 6.67 7.33 8.00 8.67 9.33 10.0010.67 11.3312.00 12.6713.33 14.00 14.6715.33 16.00

425 3.54 4.25 4.96 5.67 6.38 7.08 7.79 8.50 9.21 9.92 10.6311.33 12.0412.75 13.4614.17 14.88 15.5816.29 17.00

45

0 3.75 4.50 5.25 6.00 6.75 7.50 8.25 9.00 9.75 10.50 11.25 12.0012.75 13.5014.25 15.00 15.7516.50 17.2518.00

475 3.96 4.75 5.54 6.33 7.13 7.92 8.71 9.50 10.2911.08 11.8812.67 13.46 14.25 15.0415.83 16.6317.42 18.2119.00

500 4.17 5.00 5.83 6.67 7.50 8.33 9.17 10.00 10.8311.67 12.5013.33 14.1715.00 15.8316.67 17.5018.33 19.1720.00

Full Load Operating Hours/Day

Full Load Operating Hours/Day

BIOMASS FUEL CALCULATOR PER DAY

3

Chip (800kW/hrs/m

Boiler Output kW

25 0.16 0.19 0.22 0.25 0.28 0.31 0.34 0.38 0.41 0.44 0.47 0.50 0.53 0.56 0.59 0.63 0.66 0.69 0.72 0.75

50 0.31 0.38 0.44 0.50 0.56 0.63 0.69 0.75 0.81 0.88 0.94 1.00 1.06 1.13 1.19 1.25 1.31 1.38 1.44 1.50

75 0.47 0.56 0.66 0.75 0.84 0.94 1.03 1.13 1.22 1.31 1.41 1.50 1.59 1.69 1.78 1.88 1.97 2.06 2.16 2.25

100 0.63 0.75 0.88 1.00 1.13 1.25 1.38 1.50 1.63 1.75 1.88 2.00 2.13 2.25 2.38 2.50 2.63 2.75 2.88 3.00

125 0.78 0.94 1.09 1.25 1.41 1.56 1.72 1.88 2.03 2.19 2.34 2.50 2.66 2.81 2.97 3.13 3.28 3.44 3.59 3.75

150 0.94 1.13 1.31 1.50 1.69 1.88 2.06 2.25 2.44 2.63 2.81 3.00 3.19 3.38 3.56 3.75 3.94 4.13 4.31 4.50

175 1.09 1.31 1.53 1.75 1.97 2.19 2.41 2.63 2.84 3.06 3.28 3.50 3.72 3.94 4.16 4.38 4.59 4.81 5.03 5.25

200 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00 5.25 5.50 5.75 6.00

225 1.41 1.69 1.97 2.25 2.53 2.81 3.09 3.38 3.66 3.94 4.22 4.50 4.78 5.06 5.34 5.63 5.91 6.19 6.47 6.75

250 1.56 1.88 2.19 2.50 2.81 3.13 3.44 3.75 4.06 4.38 4.69 5.00 5.31 5.63 5.94 6.25 6.56 6.88 7.19 7.50

275 1.72 2.06 2.41 2.75 3.09 3.44 3.78 4.13 4.47 4.81 5.16 5.50 5.84 6.19 6.53 6.88 7.22 7.56 7.91 8.25

300 1.88 2.25 2.63 3.00 3.38 3.75 4.13 4.50 4.88 5.25 5.63 6.00 6.38 6.75 7.13 7.50 7.88 8.25 8.63 9.00

325 2.03 2.44 2.84 3.25 3.66 4.06 4.47 4.88 5.28 5.69 6.09 6.50 6.91 7.31 7.72 8.13 8.53 8.94 9.34 9.75

350 2.19 2.63 3.06 3.50 3.94 4.38 4.81 5.25 5.69 6.13 6.56 7.00 7.44 7.88 8.31 8.75 9.19 9.63 10.0610.50

375 2.34 2.81 3.28 3.75 4.22 4.69 5.16 5.63 6.09 6.56 7.03 7.50 7.97 8.44 8.91 9.38 9.84 10.3110.78 11.25

400 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 8.00 8.50 9.00 9.50 10.0010.50 11.0011.50 12.00

425 2.66 3.19 3.72 4.25 4.78 5.31 5.84 6.38 6.91 7.44 7.97 8.50 9.03 9.56 10.0910.63 11.1611.69 12.2212.75

450 2.81 3.38 3.94 4.50 5.06 5.63 6.19 6.75 7.31 7.88 8.44 9.00 9.56 10.1310.69 11.2511.81 12.3812.94 13.50

475 2.97 3.56 4.16 4.75 5.34 5.94 6.53

500 3.13 3.75 4.38 5.00 5.63 6.25 6.88 7.50 8.13 8.75 9.38 10.0010.63 11.2511.88 12.5013.13 13.7514.38 15.00

Pellet (3000kW/hrs/m

Boiler Output kW

25 0.04 0.05 0.06 0.07 0.08 0.08 0.09 0.10 0.11 0.12 0.13 0.13 0.14 0.15 0.16 0.17 0.18 0.18 0.19 0.20

50 0.08 0.10 0.12 0.13 0.15 0.17 0.18 0.20 0.22 0.23 0.25 0.27 0.28 0.30 0.32 0.33 0.35 0.37 0.38 0.40

75 0.13 0.15 0.18 0.20 0.23 0.25 0.28 0.30 0.33 0.35 0.38 0.40 0.43 0.45 0.48 0.50 0.53 0.55 0.58 0.60

100 0.17 0.20 0.23 0.27 0.30 0.33 0.37 0.40 0.43 0.47 0.50 0.53 0.57 0.60 0.63 0.67 0.70 0.73 0.77 0.80

125 0.21 0.25 0.29 0.33 0.38 0.42 0.46 0.50 0.54 0.58 0.63 0.67 0.71 0.75 0.79 0.83 0.88 0.92 0.96 1.00

150 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 0.65 0.70 0.75 0.80 0.85 0.90 0.95 1.00 1.05 1.10 1.15 1.20

175 0.29 0.35 0.41 0.47 0.53 0.58 0.64 0.70 0.76 0.82 0.88 0.93 0.99 1.05 1.11 1.17 1.23 1.28 1.34 1.40

200 0.33 0.40 0.47 0.53 0.60 0.67 0.73 0.80 0.87 0.93 1.00 1.07 1.13 1.20 1.27 1.33 1.40 1.47 1.53 1.60

225 0.38 0.45 0.53 0.60 0.68 0.75 0.83 0.90 0.98 1.05 1.13 1.20 1.28 1.35 1.43 1.50 1.58 1.65 1.73 1.80

250 0.42 0.50 0.58 0.67 0.75 0.83 0.92 1.00 1.08 1.17 1.25 1.33 1.42 1.50 1.58 1.67 1.75 1.83 1.92 2.00

275 0.46 0.55 0.64 0.73 0.83 0.92 1.01 1.10 1.19 1.28 1.38 1.47 1.56 1.65 1.74 1.83 1.93 2.02 2.11 2.20

300 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60 1.70 1.80 1.90 2.00 2.10 2.20 2.30 2.40

325 0.54 0.65 0.76 0.87 0.98 1.08 1.19 1.30 1.41 1.52 1.63 1.73 1.84 1.95 2.06 2.17 2.28 2.38 2.49 2.60

350 0.58 0.70 0.82 0.93 1.05 1.17 1.28 1.40 1.52 1.63 1.75 1.87 1.98 2.10 2.22 2.33 2.45 2.57 2.68 2.80

375 0.63 0.75 0.88 1.00 1.13 1.25 1.38 1.50 1.63 1.75 1.88 2.00 2.13 2.25 2.38 2.50 2.63 2.75 2.88 3.00

400 0.67 0.80 0.93 1.07 1.20 1.33 1.47 1.60 1.73 1.87 2.00 2.13 2.27 2.40 2.53 2.67 2.80 2.93 3.07 3.20

425 0.71 0.85 0.99 1.13 1.28 1.42 1.56 1.70 1.84 1.98 2.13 2.27 2.41 2.55 2.69 2.83 2.98 3.12 3.26 3.40

450 0.75 0.90 1.05 1.20 1.35 1.50 1.65 1.80 1.95 2.10 2.25 2.40 2.55 2.70 2.85 3.00 3.15 3.30 3.45 3.60

475 0.79 0.95 1.11 1.27

500 0.83 1.00 1.17 1.33 1.50 1.67 1.83 2.00 2.17 2.33 2.50 2.67 2.83 3.00 3.17 3.33 3.50 3.67 3.83 4.00

@ 200kgs)

Full Load Operating Hours/Day

5 6789101112131415161718192021222

7.13 7.72 8.31 8.91 9.50 10.0910.69 11.2811.88 12.4713.06 13.6614.25

3

@ 650kgs)

5 6789101112131415161718192021222

1.43 1.58 1.74 1.90 2.06 2.22 2.38 2.53 2.69 2.85 3.01 3.17 3.33 3.48 3.64 3.80

Full Load Operating Hours/Day

Standard, rising and kinked pellet augers

4

Pellet auger with gear motor, multiple bearings and

support feet for stability.

Auger channel for conveying the pellets with

progressive pitch auger flights. After the system

starts the augers convey the pellets from the storage

room towards the boiler into the cell wheel on the

pellet burner. The special layout of the auger ensures

smooth and trouble-free fuel transport.

Standard auger

Special features

4

Transport auger with progressive pitch (for gentle and

easy transport of the pellets to the burner)

Gear box protection coupling prevents the auger and

gear box from overload

Rising auger

Standard hinged sweep collector

for woodchip

The main components are the spur gears used

specifically by GILLES. They have a torque of 5000Nm

and special seals that effectively and continuously

prevent the penetration of dust and cuttings.

The robust design of the double-arm telescopic

collector is also unmatched. This technology used by

GILLES is the first to allow safe, fully automatic and

4

convenient wood combustion. Two standard hinged

arms make working in a small space radius possible.

The ripping hook prevents blockages in that larger

wood chips are automatically pushed down and cut

in the cell wheel. Included is the pressure disc, the

gear motor and the pre-tensioning device.

Max. delivery height for wood chip: 5m.

Includes safety device.

Over heat protection valve (OPV) for automatic

extinguishing. By means of the controlled overrun of

4

the stoker auger, the fuel supply chain is interrupted

and eliminates back burning.

Incl. diameter adjustment.

- Massive auger shaft.

- 8 mm strong auger flights.

- Continuously welded progressive pitch auger flights.

- Suitable for material size of G50 at maximum.

Kinked auger

6 7

REMEHA GILLES BIOMASS BOILER TRANSPORT SYSTEMS

Ripping hook

Special features

Ripping hook prevents blockages in that larger wood

chips are automatically pushed down to then be cut

in the cell wheel.

Transport auger with continuously welded 8mm auger

flights and progressive pitch (prevents blockages)

Cell wheel and combustion chamber

The cell wheel is a multi tested full-metal cell wheel

reliably interrupts the boiler with the storage room

and thus provides 100% protection against burnback.

The blades attached to the running wheel are slightly

curved which prevents noise generation and reduces

compressive forces. From HPK-RA 75 these blades

are running at an offset angle to the rotary axis to

enhance the cutting action with a fixed cutting edge

integrated in the stable noise-damping cast enclosure.

REMEHA GILLES BIOMASS BOILER HPKRA OVERVIEW

HPKRA

PELLET

Continuously welded 8 mm auger flights

Cell wheel

Combustion chamber

High combustion temperatures guaranteed in all

performance ranges and the best possible use of your

fuel. Well designed air guidance is a precondition for

highest quality of combustion. Years of experience,

high tech development, resistant materials guarantee

clean combustion and long service life.

HPKRA

WOOD CHIP

Transport direction

Transport auger with continuously progressive 8mm auger flights (stops that material getting stuck)

8 9

REMEHA GILLES BIOMASS BOILER HPKRA OVERVIEW

OVERVIEW

BOILER CONTROLS

REMEHA GILLES BIOMASS BOILER HPKRA OVERVIEW

HPKRA

Gilles HPK-RA boilers are suitable for both pellet and

woodchip, the high-performance boiler is produced as

a tension-free welded construction to maximise the

strength and durability of the boiler. Welded highperformance multiple-draught boiler in thick-walled

boiler plate S235JR 6mm width. Horizontal heat

exchanger tubes in seamless drawn thick-wall boiler

pipe. 70mm thick external insulation.

Suitable for automatic combustion of wood chip and

pellets and without any adjustments suitable for using

pieces of wood in emergency operation, thanks to an

additional combustion chamber opening and grate.

n

Operational pressure max 3 bar

n

Boilers have efficiency of >90%

n

Modulation down to 30% of nominal output

n

Automatic Ignition, Heat Exchanger cleaning

and Ash removal

n

‘Cell Wheel’ burn back protection device

n

Gilles touch heating control

n

Bespoke fuel storage and transport system design

The Gilles Touch control panel incorporates

state of the art programming and instrumentation.

Alongside conventional sensors the boiler benefits

from independently controlled primary and secondary

combustion zones managed by the control system.

This enables clean and complete burning of the fuel

and achieves 95% efficiency, optimising emissions.

The Gilles Touch, via an internet connection, allows

access and maintenance of the system from any

computer, Smartphone or tablet device, this allows

adjustment of the specific heatload without being in

the vicinity of the boiler allowing you to change the

requirements as and when needed. The advanced

control system and high capacity heat exchangers

in the boiler enables unrivalled modulation according

to your specific demands.

Benefits

n

Settings for different fuels

n

Setting and alteration of all heating requirements

via PC/Mac, Smartphone or tablet

n

Modulation of the boiler

PELLET

2

Key Features

1 Pellet burner in highly heat-resistant steel for

HPK-RA 12.5 – 60 or ceramic for HPK-RA 75 – 160

6

7

8

5

4

9

3

1

11

10

2

2 Ash removal via ash agitator with special drive

technology – ash compression resulting in long

emptying intervals – rolling ash container

3 Combustion chamber door for log wood operation

(no changeover required)

4 Horizontal pipe heat exchanger with automatic

cleaning

5 Flue gas fan for optimal ignition process and

permanent negative pressure in the boiler

6 Lambda probe for fuel detection and optimised,

clean combustion process

7 Overheat protection

8 Welded multiple-draught boiler in 6 mm

boiler plate

9 Shunt circuit with pump and mixing valve available

10 Primary air modulating variable

11 Secondary air modulating variable

Suitable fuel characteristics:

Wood Chip

G50, W30 as per EN 14961-4 Property Class A1

Pellet

6mm ø as per EN 14961-2 Property Class A1

n

Remote servicing of the boiler via internet

n

Cascade control of up to 5 boilers

n

Trend logging over 6 months (exportable to USB stick

and can be shown in Excel)

n

Automatic error notification via email

n

Password protected

Optional

n

Automatic error notification via SMS

n

Status request and alterations possible via SMS

(current boiler temperature, operating mode,

boiler status, etc.)

HPKRA

WOOD CHIP

10

4

3

Key Features

1 Cell wheel

2 Wood chip burner in high-quality heat-resistant

ceramic

3 Ash removal via ash agitator with special drive

technology – ash compression resulting in long

8

9

7

5

11

1

13

6

2

12

3

emptying intervals

4 Combustion chamber door for log wood operation

(no changeover required)

5 Horizontal pipe heat exchanger with automatic

cleaning

6 Ceramic-lined afterburning chamber with

individually offset heat-resistant fire bricks

7 Flue gas fan for optimal ignition process and

permanent negative pressure in the boiler

8 Lambda probe for fuel detection and optimised,

clean combustion process

9 Overheat protection

10 Welded multiple-draught boiler in 6 mm

boiler plate

11 Shunt circuit with pump and mixing valve available

12 Primary air modulating variable

13 Secondary air modulating variable

10 11

REMEHA GILLES BIOMASS BOILER HPKRA OVERVIEW

HPKRA

REMEHA GILLES BIOMASS BOILER HPKRA 49 TECHNICAL SPECIFICATION

HPKRA 49

OUTPUT 49 - 153kW

PELLET & WOOD CHIP

Boiler Model HPK-R A 49 HPK-R A 49

Wood Pellet Wood Chip

Product Code 401011 401028

Full Load kW 49 49

Part Load kW 15 15

Boiler Dry Weight kg 724 724

Dimensions L x W x H mm 1430 x 765 x 1445 1430 x 765 x 1445

Hydraulic Pressure Drop mb ar 11K 36.5 36.5

Water Flow Rate l/s 10k 1.17 1.17

Thermal Efficiency Full Load % 93.7 91,7-93,1

Thermal Efficiency Part Load % 93.7 92.8

Flow Temperature Max °C 95 95

Return Temperature Min °C 55 55

Maximum Working Pressure bar 3 3

Fuel Type Pellets acc. to EN14961-2/OENORM M7135/DIN CEN/TS 14961 (P16, P45)

Burner Type Forward fired Forward fired ceramic

Consumption @ Full Load*

1

Burner Control On/Off Modulating Modulating

Burner Noise Level n/a n/a

Max Electric Power Input kW 3 3

Max Current Consumption A 4.6 4.6

Electrical Supply ~3/400V 50Hz 16A 5x2,5mm

Flue Size Ø mm 180 180

Height Central Line Flue Gas Outlet mm 1325 1325

Flue Gas Volume Full Load m

Flue Gas Volume Part Load m

Flue Gas Temperature High °C 126 154

Type Tested and Seal of Approval by TÜV-Süd TÜV-Süd

Test Procedure According to test report Range tested

NOX Full Load*2*3*

NOX Part Load*

Organic “C” Full Load*

Organic “C” Part Load*

Dust Full Load*

Dust Full Load*

CO Full Load*

CO Par t Load*

NOX Full Load*

NOX Part Load*

Organic “C” Full Load*

Organic “C” Part Load*

Dust Full Load*

Dust Full Load*

CO Full Load*

CO Par t Load*

4

2*3*4

2*4

2*4

2*4

2*4

2*4

2*4

2*3

2*3

2

2

2

2

2

2

PM10 N/A N/A

Delivery Dimensions mm

Residual Fan Pressure Full Load Pa 9 7

Residual Fan Pressure Part Load Pa 7 8

Boiler Volume (Water) Litre 150 15 0

Ash Container Volume Litre 43 43

Flow Connection 1 1/2" 1 1/2”

Return Connection 1 1/2” 1 1/2”

Overheat Protection Valve Connection 1/2” 1/2”

Burner Position Left or right Left/right or rear

Ignition Method Electric/Automatic Electric/Automatic

Feature Log wood operation possible Log wood operation possible

Performance and Combustion Control Programmable logic controller Programmable logic controller

Back Burn Protection by Full-metal cell wheel Full-metal cell wheel

Ventilation Dependent Operation Yes Ye s

Type of Fans Radial fan Radial fan

mbar 20K 11 11

l/s 20k 0.59 0.59

kg/hr ~10 ~12

2

3

/hr 86 101

3

/hr 32.3 37.1

~3/400V 50Hz 16A 5x2,5mm

2

Low °C 94 84

13% Vol-% 02 10% Vol-% 02 13% Vol-% 02 10% Vol-% 02

mg/m382 113 94105 129145

mg/m377 106 101 138

mg/m35 8 1 12

mg/m32 3 5 7

mg/m315 20 1129 1540

mg/m319 26 19 26

mg/m333 45 1953 2473

mg/m322 31 16 3224 224

mg/MJ 54 66 72

mg/MJ 50 6996

mg/MJ 4 1

mg/MJ 1 4

mg/MJ 10 819

mg/MJ 12 13

mg/MJ 21 1236

mg/MJ 15 112

12

*1 base d on wood chips 20% moisture, 800kWh/kg, 20 0kg/m3

*2 referring to 0°C and 1013mbar, dry fume, 13% Vol-% O

*3 calculated as NO

*4 referring to 0°C and 1013mbar, dry fume, 10% Vol-% O

2

2

2

13