SIC / 24.04.2012

:

:

The quality of the fuel used can have a significant impact on the reliability and the life of the boiler.

Off –specification pellets can contaminate stocks of good material and maybe difficult to dispose

of.

The use of contaminated material can lead to breaches of emissions and waste regulations as well as

long term damage to the heating system.

The European standards have been developed based on the work of CEN’s TC335 solid biofuels

committee.

As a minimum the fuel should comply with the following specification acc. to OENORM M 7135

and ENplus Class A1.

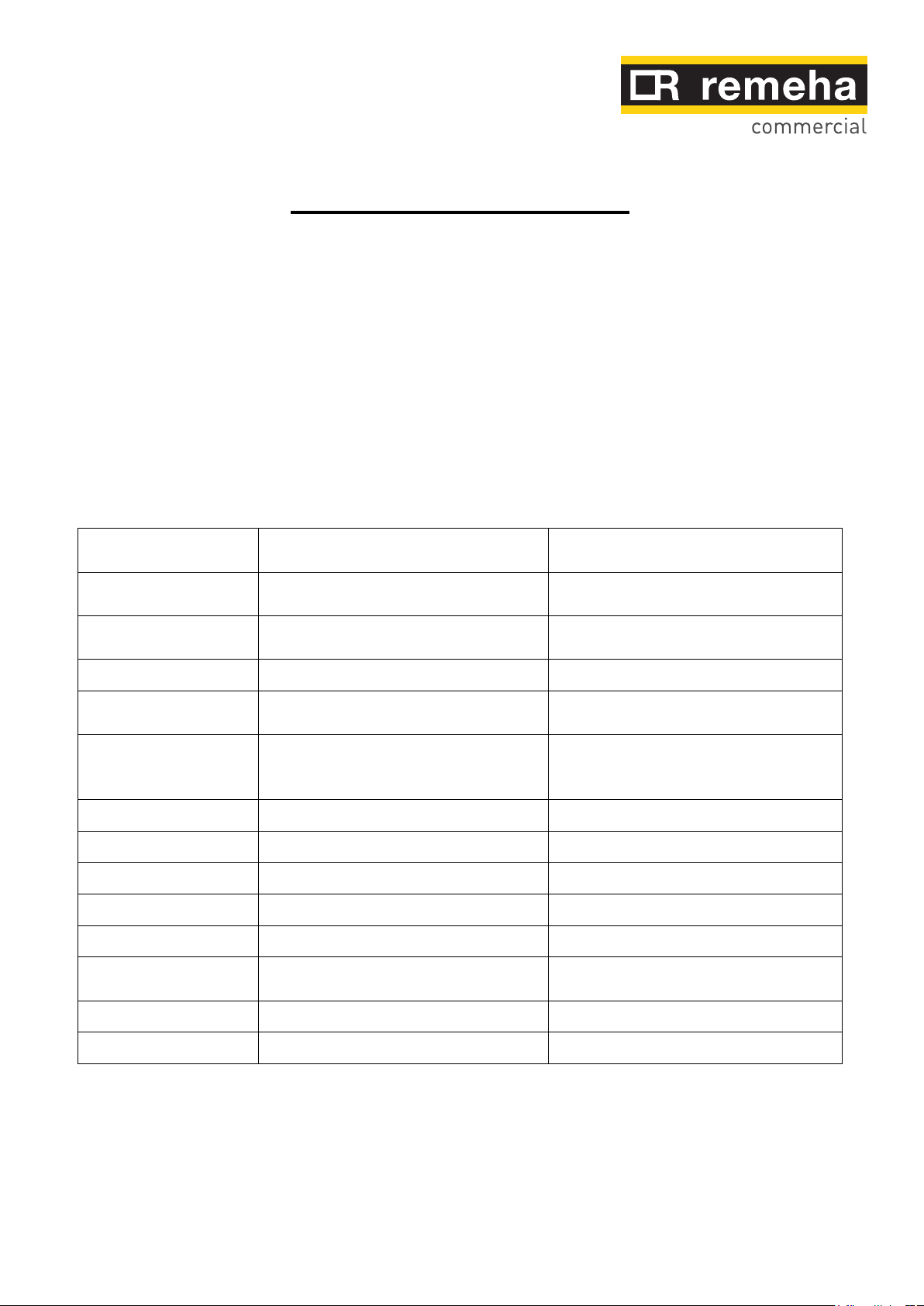

Energy density

Diameter

Length:

Wood Pellet Specification

OENORM M 7135 ENplus Class A1

4.9kWh/kg.

4mm ≤ D ≥ 10mm

4 X D 3,15≤ L ≤ 40

4.5kWh/kg.

6mm (±1)

Bulk density:

Origin

Moisture content

Ash content

Sulphur content

Chlorine content

Nitrogen content

Mechanical

durability

Amount of fines

Additives

min. 650kg/m³ ≥ 600 kg/m³

Chemically untreated wood without

bark

≤ 10 % ≤ 10 %

≤ 0.5 % ≤ 0.7 %

≤ 0.04 % ≤ 0.05 %

≤ 0.02 % ≤ 0.02 %

≤ 0.30 % ≤ 0.30 %

≥ 97.7% ≥ 97.5%

≤1,00% ≤1,00%

< 2 w-% of dry basis < 2 w-% of dry basis

Chemically untreated wood without

bark,

Stem wood

If the fuel used to operate the boiler(s) does not meet the attached pellet specication,

Remeha Commercial cannot guarantee the performance of the boilers and physical damage

or incapacitation of the boilers and fuel transport system may result. Furthermore should

Remeha Commercial be called out to site to intervene as a result of the boiler(s) being

operated using inferior fuel, our labour and any replacement parts required to rectify the

situation will be chargeable items.

Loading...

Loading...