Wood Chip Specification

The quality of the fuel used can have a significant impact on the reliability and

the life of the boiler.

The use of contaminated material can lead to breaches of emissions and

waste regulations as well as long term damage to the heating system.

We would recommend using wood chips rather than sh redded wood

De-barked wood for wood chips reduces the ash content of the fuel, therefore

benefits an automated boiler system, reducing the need for human intervention

for servicing.

We recommend as a minimum the fuel should comply with the following

specifications;

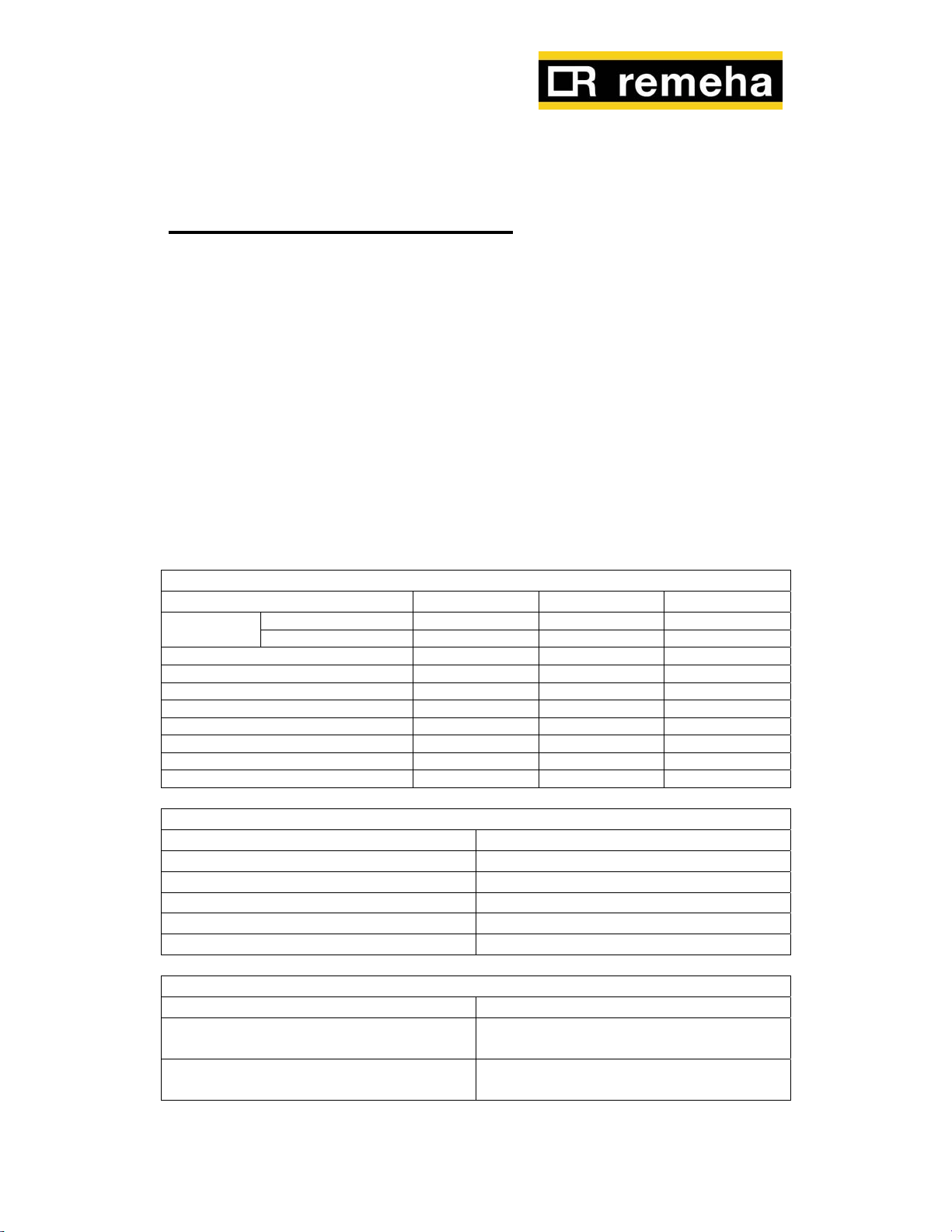

Wood Chips Classification acc. To OENORM M7133

Description

Edge Length Max 85mm 120mm 250mm Single

Pieces

Retained in coarse sieve Max. 20% Max. 20% Max. 20%

Coarse sieve mesh 16 x 16mm 31.5 x 31.5mm 63 x 63mm

Retained in medium sieve 60 to 100% 60 to 100% 60 to 100%

Main Quantity nominal length 30mm 50mm 100mm

Medium sieve mesh 2.8 x 2.8mm 5.6 x 5.6mm 11.2 x 11.2mm

Passing medium s i ev e Max. 20% Max. 20% Max. 20%

Fine sieve me sh 1 x 1mm 1 x 1mm 1 x 1mm

Passing fine si ev e Max. 4% Max. 4% Max.4%

Water Content

Class Class Limits

W20 < 19.99%

W30 20 – 29.99%

W35 30 – 34.99%

W40 35 – 39.99%

W50 40 – 49.99%

Ash Content

Class Class Limits

A1 < 1%

A2 1 – 1.5%

Cross Section Max 3cm

G30 Size G50 Size G100 Size

2

Small Ash Cont ent

Higher Ash Content

5cm2 10cm2

Size Classification

Domestic boilers up to HPK-RA 160: G50 chips, W30

Industrial boilers 150kW to 2000kW: G50 or G100 size depending on transport

system and depending on boiler type the maximum moisture content allowable

is:

HPKI-K 40%, HPKI-R 60%, HPKI-W 45%

Industrial boilers with walking floor fuel transport system may run on G100.

Note

The nominal output for industrial boilers is calculated at 40%

Material Density

For all our boilers we recommend 200kg/m3 i.e. medium density.

Ash Content

Ash content- preferably A2

Contamination

The origin wood must also be free from general contamination such as:slate, stones, metal, rubber, plastic & other unidentified foreign bodi es, heavy

metal compounds as a result of treatment (e.g. Copper chrome Arsenate(CCA)

identified by green colour), halogenated organic compou nds , e.g. lindane

(identified by yellow colour), creosote (identified by dark brown stain and

smell), painted wood, MDF, hardboard and fibreboard.

If the fuel used to operate the boiler(s) does not meet the attached wood chip

specification, Broag Ltd cannot guarantee the performance of the boilers and

physical damage or incapacitation of the boilers and fuel transport system may

result. Furthermore should Broag Ltd be called out to site to intervene as a

result of the boiler(s) being operated using inferior fuel, our labour and any

replacement parts required to rectify the situation will be chargeable items.

Loading...

Loading...