REMEHA Gas 460 S Technical Instructions

Remeha Gas 460 S

Gas-fired boilers

English

06/02/06

Technical

instructions

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 Furnace operation equipped with safety box RV 00 54 / 000 00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adapting to another gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2 Changing the ignition burner injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Changing the burner injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Setting the injector pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5 Checking the minimum gas pressure switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6 Attaching the label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Commissionning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1 Pressure settings and calibrated injector markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2 Final checks before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1 Checking and cleaning the main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Spare parts Gas 460 S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Remeha Gas 460 S 06/02/06 - 300005247-001-B

Introduction

This product will be marketed in the following European Union

member states:

GB - HU - ES

Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

1 Regulations

It is in any case imperative to conform to the local

regulations in force.

2 Symbols used

Caution danger

Specific information Information must be kept in mind to maintain comfort

The boilers and hot water tanks are designed and manufactured in

accordance with the sound engineering practice, as requested in

article 3.3 of the directive 97/23/EC; it is certified by compliance with

the directives 90/396/EC, 92/42/EC, 73/23 EC and 89/336/EC.

We would draw your attention to the danger of corrosion in

boilers located in or close to premises in which the atmosphere

may be polluted by chloride or fluoride compounds.

For example: Hairdressing salons, industrial premises

(solvents), refrigeration units.

In this event, we cannot uphold the warranty.

Risk of injury and damage to equipment. Attention must be paid to the warnings on

safety of persons and equipment

Z

Reference Refer to another manual or other pages in this instruction manual

06/02/06 - 300005247-001-B Remeha Gas 460 S

3

1Introduction

Description

Gas 460 S boilers are made of cast iron:

- with atmospheric gas burners

- with 2 operating stages

- with electronic ignition via the ignition burner for hot water central

heating

- with a useful output of between 119 and 380 kW

2 Certifications

2.1 Introduction

It is CE approved under the following number : 0085BL0187

The boilers are in compliance with the EC directives:

- Royal Decree dated 8th January 2004

- 90/396/EEC Gas Appliance Directive

- 73/23/EEC Low Voltage Directive

Reference Standard : EN 60.335.1

- 89/336/EEC Electromagnetic Compatibility Directive

Reference Standard : EN 50.081.1 ; EN 50.082.1 ; EN 55.014

- 92/42/EEC Efficiency Directive **

Low temperature gas boiler

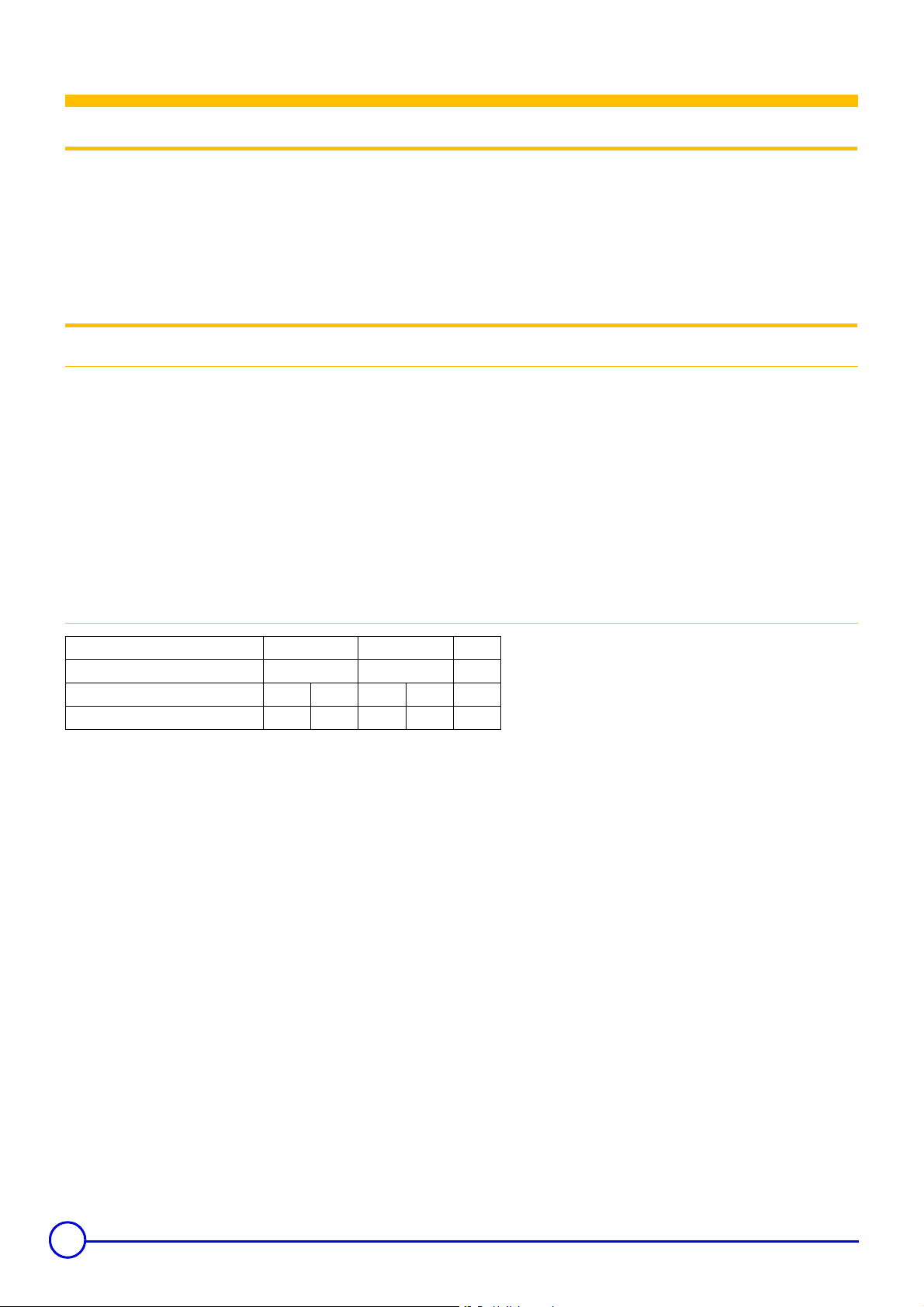

2.2 User country

1

,

They are designed to be connected to a chimney.

The figure given after Gas 460 S indicates the number of sections

which make up the boiler.

Gas 460 S boilers are delivered with a K control panel. They can be

fitted with an optional RC4 and RC5 control unit (master-slave control

unit options).

- Type B11 (B11

discharge control system).

France:

Performance class III boiler according to ATG B 84

recommendations.

Belgium:

The boilers comply with the specifications of the HR+ quality label.

The boilers should be fitted with a 160 VA circuit separation

transformer (delivered with the documentation package).

if fitted with the optional combustion products

BS

User country ES HU GB

Category II

Gas type G20G31G20G31G20

Distribution pressure (mbar) 20 37 25 50 20

The boilers leave the factory operating with H natural gas.

2H3P

II

2H3P

II

2H3P

4

Remeha Gas 460 S 06/02/06 - 300005247-001-B

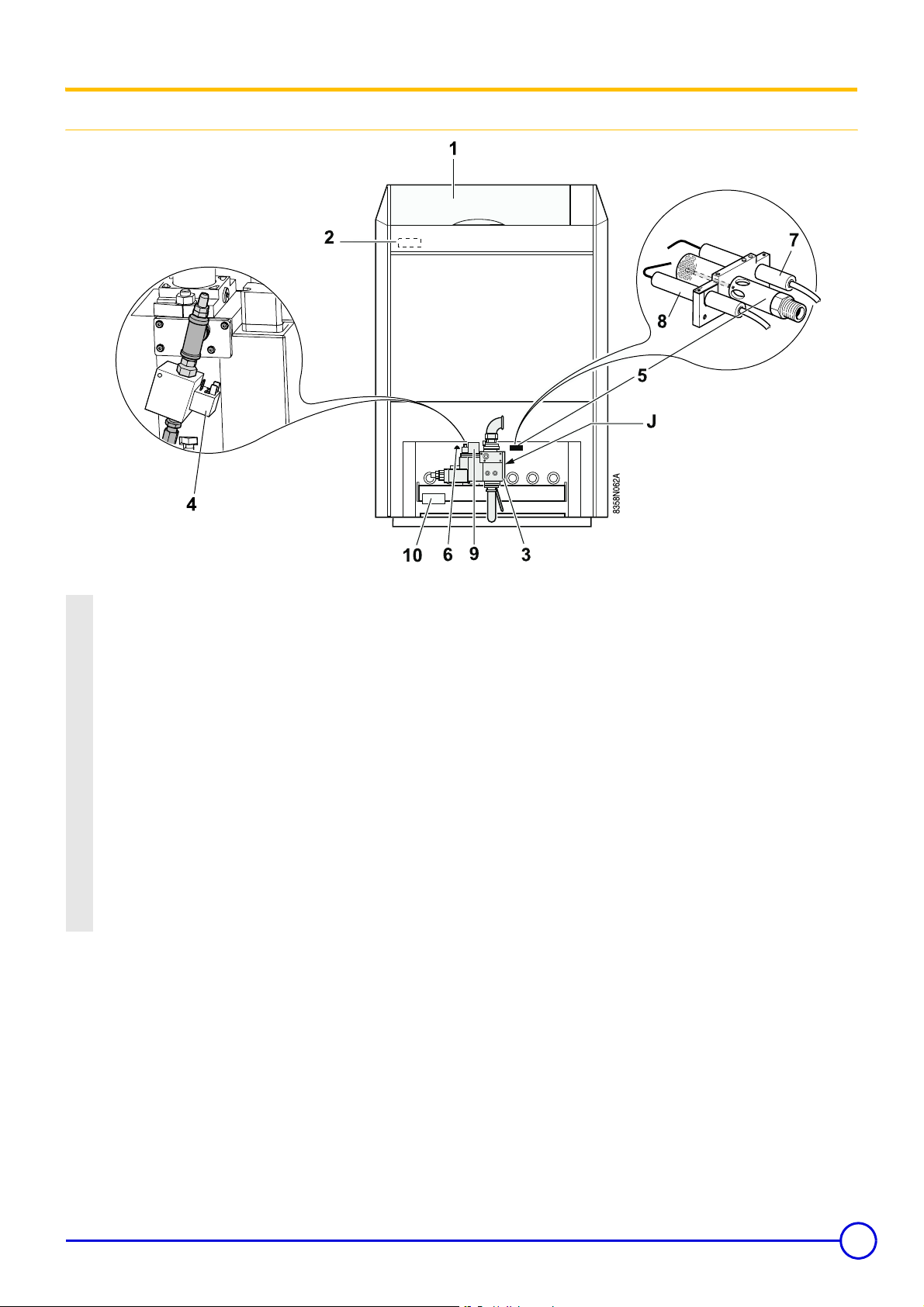

3Main parts

3.1 Boiler

1 Control panel

2 Safety box

The safety control box is fitted to the control panel and controls the

burner ignition, function and extinction sequences.

3 Multivalve gas unit:

It includes a safety valve and a 2-stage principal valve with filter and

minimum gas pressure switch.

4 Ignition burner valve

5 Ignition burner

6 Flame inspection window

7 Ionisation probe: It detects flame presence on the ignition burner by

flame ionisation.

8 Ignition electrode: This ensures ignition burner ignition using a high

voltage spark.

9 Minimum gas pressure switch

(Minimum pressure: 12.5 mbar)

10 Ignition box

06/02/06 - 300005247-001-B Remeha Gas 460 S

5

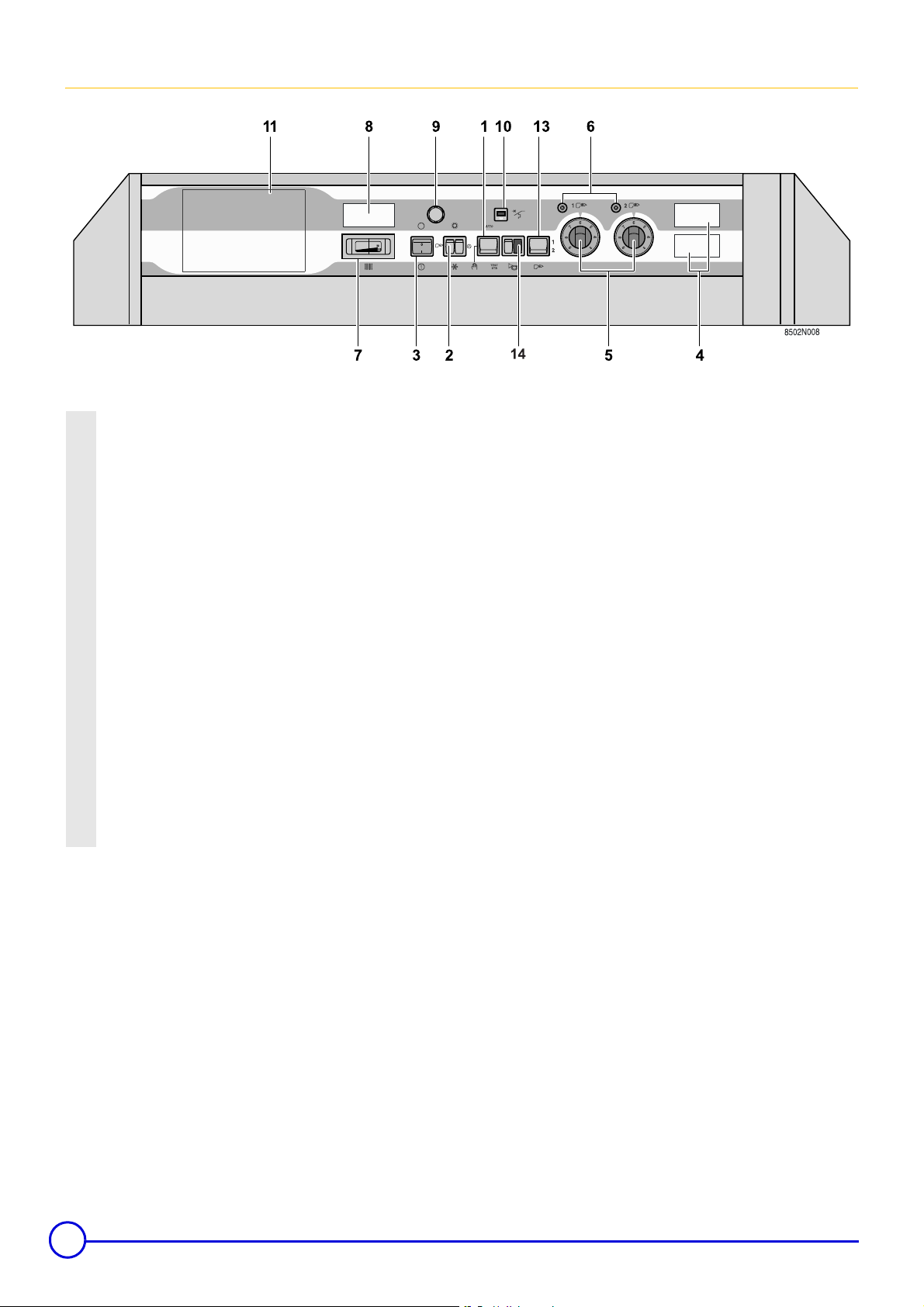

3.2 Control panel

13-position switch Auto / Manual ! / TEST STB

- The switch may be left on either position manual ! or automatic AUTO.

- STB TEST: Temporary action to test the safety thermostat.

- Press the TEST STB switch and set pump shut-off switch (2) 9 to the “Summer” position %.

2 Switch Burner / Heating pump:

This button is used to control the burner and the heating pump.

Both buttons are in “Winter” . position: Heating and hot water production systems operate (if a hot water tank is included).

Both buttons are in “Summer” % position: The burner and the heating pump don't operate.

If the boiler is fitted with a control unit, both buttons must be left on the Winter . position.

3 Main ON/OFF switch

4 Location for hour run meter for the first and second stage (optional)

5 Boiler thermostat (30 to 90 °C):

A factory-set stop limits the maximum temperature to 75 °C. The stop may be moved if necessary.

6 Stage one or stage two indicators:

These only go on if the relevant thermostat or control unit require heating and if the safety contact is closed.

7 Boiler thermometer

8 Location for flue gas thermometer (optional)

9 Safety thermostat with manual reset (set to 110 °C).

10 10 A Circuit-breaker: with delayed action and manual reset.

11 Location for optional features or a RC4/RC5 control unit

13 Switch for selecting the number of burner stages

14 Burner alarm indicator + Reset button

6

Remeha Gas 460 S 06/02/06 - 300005247-001-B

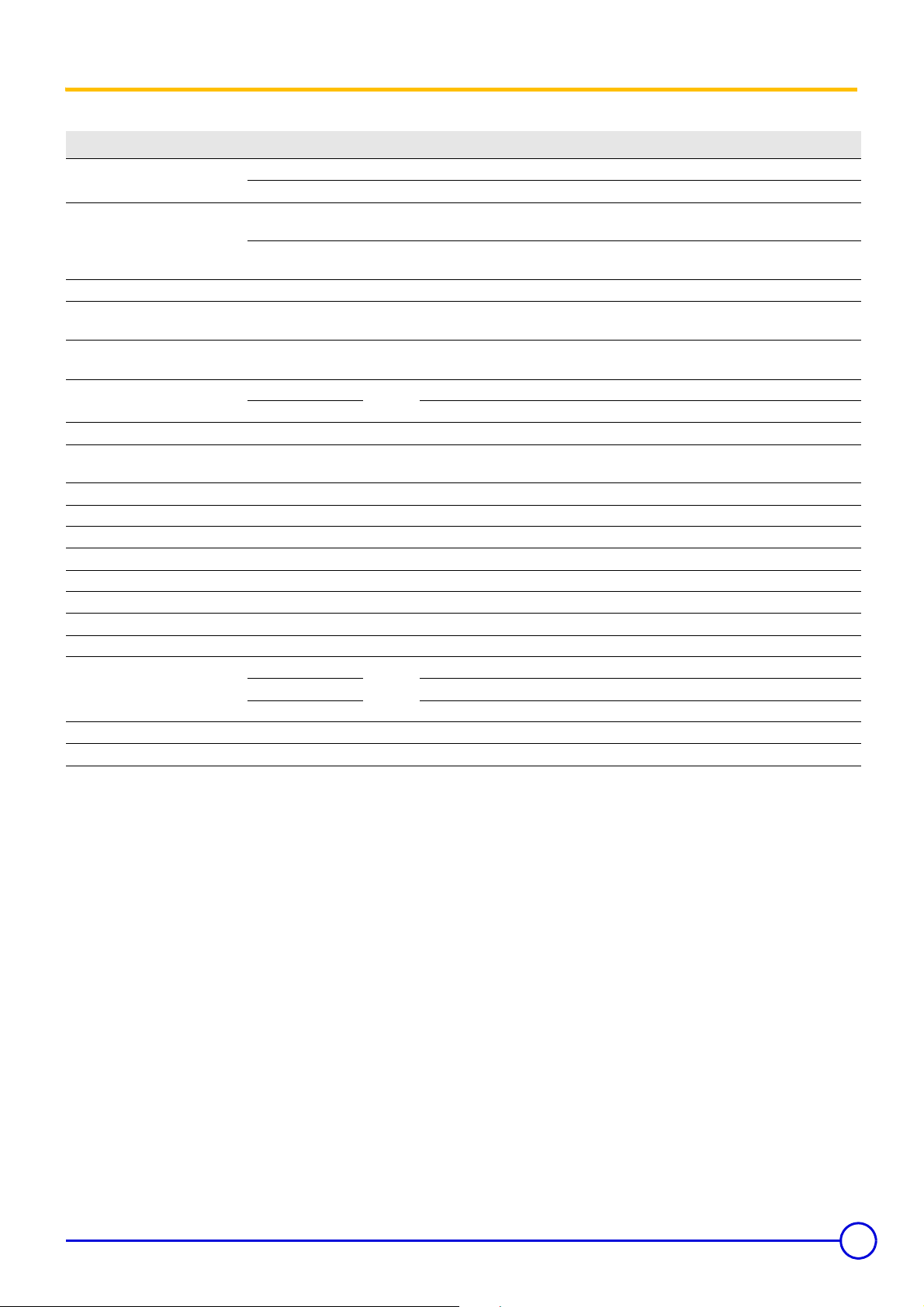

4 Technical characteristics

The boilers can operate on natural gases type H/L.

Boiler Gas 460 S / 8 10 12 14 16 18 20

Useful efficiency

Power input

Number of sections Part 8 101214161820

Mass flue gas flow rate

(1)

Flue gas temperature Tf

Boiler temperature 80°C

CO

2

Ionisation current µA 1.0

Required depressurisation at the

nozzle

Minimum outlet temperature °C 40

Maximum outlet temperature °C 90

Maximum operating pressure bar 6

Electrical connection V/Hz 230/50

Electrical output W 108 / 114 maximum

Gas connection 20 mbar inch 1" 1" 1" 1"1/4 1"1/4 1"1/4 1"1/2

Heating connection inch 2"

Internal diameter flue gas nozzle mm 250 300 300 350 350 350 400

Water resistance

(1)

Water capacity* l 61 76 91 106 122 137 154

Shipping weight kg 668 807 934 1096 1227 1364 1476

(1)

at 2nd stage

1st stage kW 83-98 107-126 131-154 155-182 179-210 202-238 226-266

2nd stage kW 119-140 153-180 187-220 221-260 255-300 289-340 323-380

1st stage kW

93.1-

108.9

2nd stage kW 131.1-153

kg per

sec

0.097 0.127 0.144 0.177 0.191 0.203 0.258

119.4-

139.7

168.2-

196.3

145.6-

170.4

205.2-

239.4

171.9-

201.1

242.2-

282.6

197.9-

231.5

278.8-

325.4

224-262.1

315.7-

368.4

250.1-

292.6

352.4-

411.3

°C 125 123 130 126 133 140 126

1st stage

2nd stage 5.4-6.4 5.3-6.3 5.8-6.8 5.5-6.5 6.0-7.0 6.5-7.5 5.5-6.5

%

3.9-4.9 3.8-4.8 4.3-5.3 4.0-5.0 4.5-5.5 5.0-6.0 4.0-5.0

daPa 0.7

∆ T = 10K

∆ T = 15K 36 59 88 123 164 211 263

mbar

80 133 198 277 369 484 592

∆ T = 20K 20 33 50 69 92 118 148

1 mbar = 10 mmCE = 10 daPa = 100 Pa

06/02/06 - 300005247-001-B Remeha Gas 460 S

7

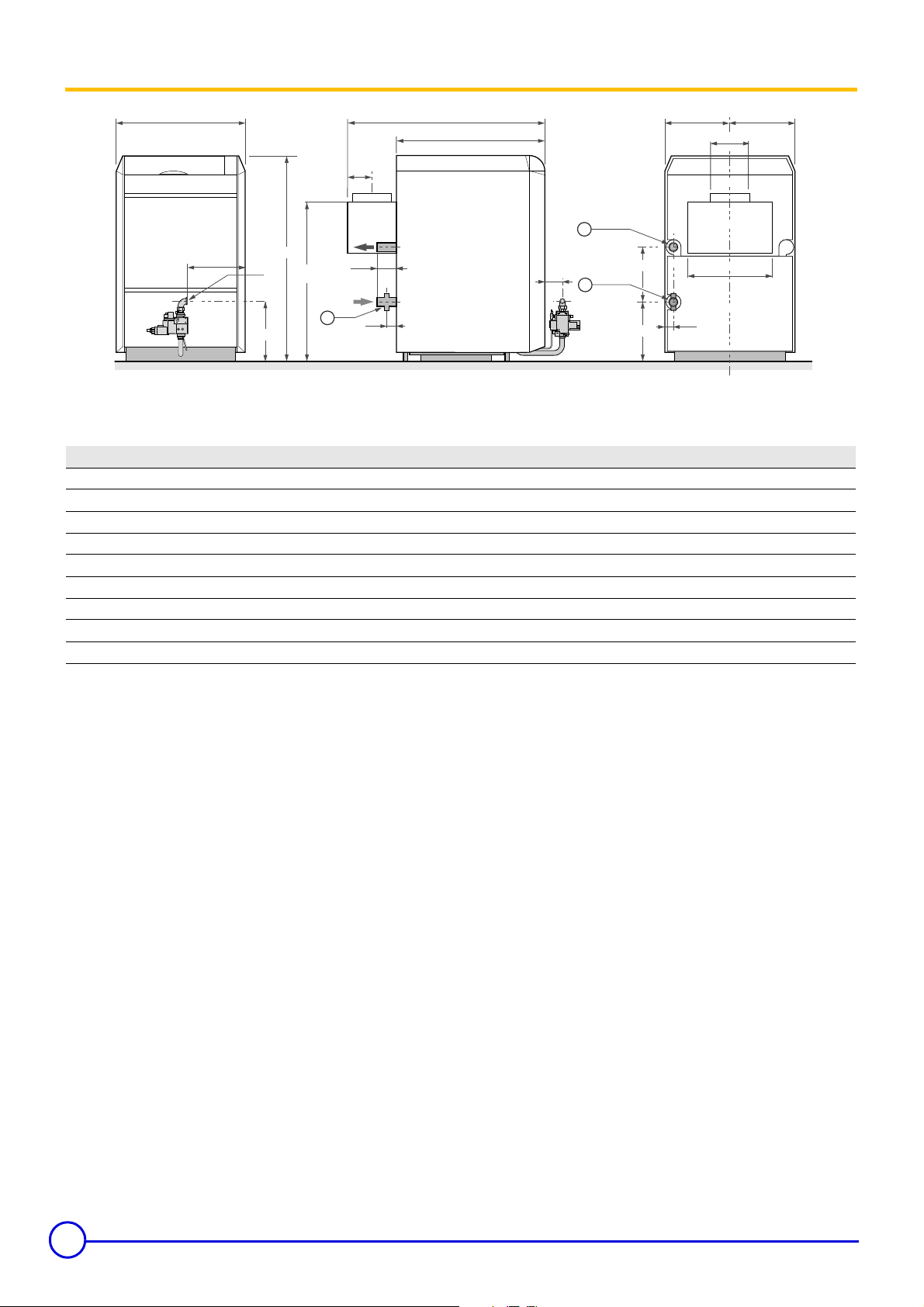

5 Main dimensions

Heating outlet R 2

Heating return R 2

8358N061A

B

E

ø F

1406

J

H

130

3

60

G

A

1006

1

375

410

130

2

Draining Rp 3/4

= =

ø C

D

64

Boiler Gas 460 S /8 /10 /12 /14 /16 /18 /20

A (mm) 1362 1362 1362 1412 1412 1412 1462

B (mm) 970 1146 1322 1498 1674 1850 2026

Ø C (mm) 250 300 300 350 350 350 400

D (mm) 632 808 984 1160 1336 1512 1688

E (mm) 165 165 165 190 190 190 220

Ø F (mm) (20/25 mbar) Rp1 Rp1 Rp1 Rp1 1/4 Rp 1 1/4 Rp 1 1/4 Rp 1 1/2

Ø F (mm) (300 mbar) Rp 3/4

G 447 535 623 704 792 880 963

H 445 445 445 454 454 454 507

J 1094 1094 1094 1194 1194 1194 1194

8

Remeha Gas 460 S 06/02/06 - 300005247-001-B

Operation

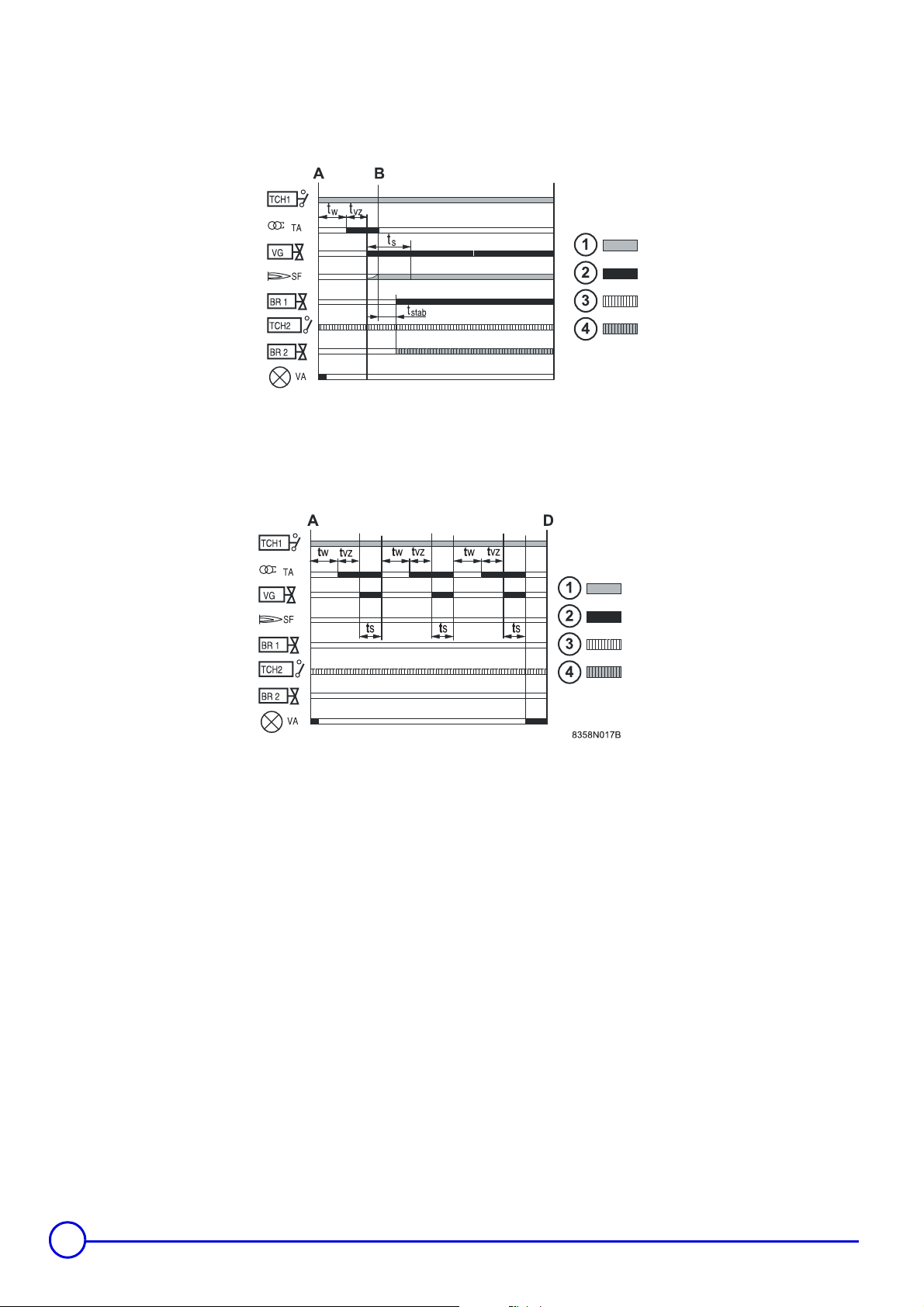

1 Furnace operation equipped with safety box RV 00 54 / 000 00

Operating principle

The boiler can operate at either 2nd stage or 1st stage depending on

the thermal needs of the installation.

The ignition and burner surveillance sequences are ensured by the

safety box.

Behaviour in normal conditions

The box closes the TCH contact when there is a requirement for

heat1. The safety control box runs an auto-check of around 1

second(s) by lighting the alarm warning light VA.

In the case of an offset alarm, it is necessary to use a timed

relay in order to prevent an unjustified alarm signal.

After a waiting time tw, the ignition transformer TA produces a series

of sparks at the ignition electrode. After a pre-ignition period tvz, the

ignition burner valve VG and the safety valve VS open. Formation of

flame in ignition burner. The ionisation sensor SF shows a flame

signal with a minimum ionisation current of 1 µA and ignition is shut

down. After a period of stabilisation tstab, the principal burner ignites

at 1st stage BR1 (or at 2nd stage if the 2nd stage thermostat TCH2

is needed).

Behaviour in abnormal conditions

- If a flame is not detected before the safety time ts, the box makes

2 more ignition attempts. If, at the end of the last attempt, there is

still no flame signal, the box goes into safety and the safety

indicator comes on. To restart the heater, press the reset button on

the safety box.

- If there is a loss of flame in normal operation, the box automatically

repeats the start up sequence.

Resetting

The box is reset after going into safety by pressing the reset button.

If the reset button does not work, wait at least 15 seconds before

trying a second time. After activating the reset button, the warning

light goes out and the safety control box restarts after a waiting time

of around 1 minute.

Note 1: The box may be on safety on its first start up: press the reset

button to release it.

Note 2: If the reset button is pressed in normal operation, the gas

valves close and the box starts a new ignition sequence.

06/02/06 - 300005247-001-B Remeha Gas 460 S

9

Normal operating cycle

Operating cycle on safety (start up without flame signal)

8358N016A

Required input signals

Box output signals

Thermostatic request at 2nd stage

Operation 2nd stage

A Start of operation

B Formation of flame in ignition burner

BR1 1st stage

BR2 2nd stage

SF Burner flame signal

TA Ignition transformer

TCH1 Boiler thermostat 1 Speed

TCH2 Boiler thermostat 2 Speed

VA Safety lockout warning light

VG Ignition burner valve + Safety valve VS

ts Safety time: maximum 10 seconds

tstab Flame stabilisation time: 5 seconds

tvz Pre-ignition time: 10 seconds

tw Waiting time: 0 seconds

10

Remeha Gas 460 S 06/02/06 - 300005247-001-B

Adapting to another gas

These actions must be carried out by a qualified

technician.

1 Changing gas

The boilers are factory-set to operate on natural gas H (G20 - 20

mbar). To convert it to natural gas L, use the gas L conversion kit

(optional). Carry out the operations described below.

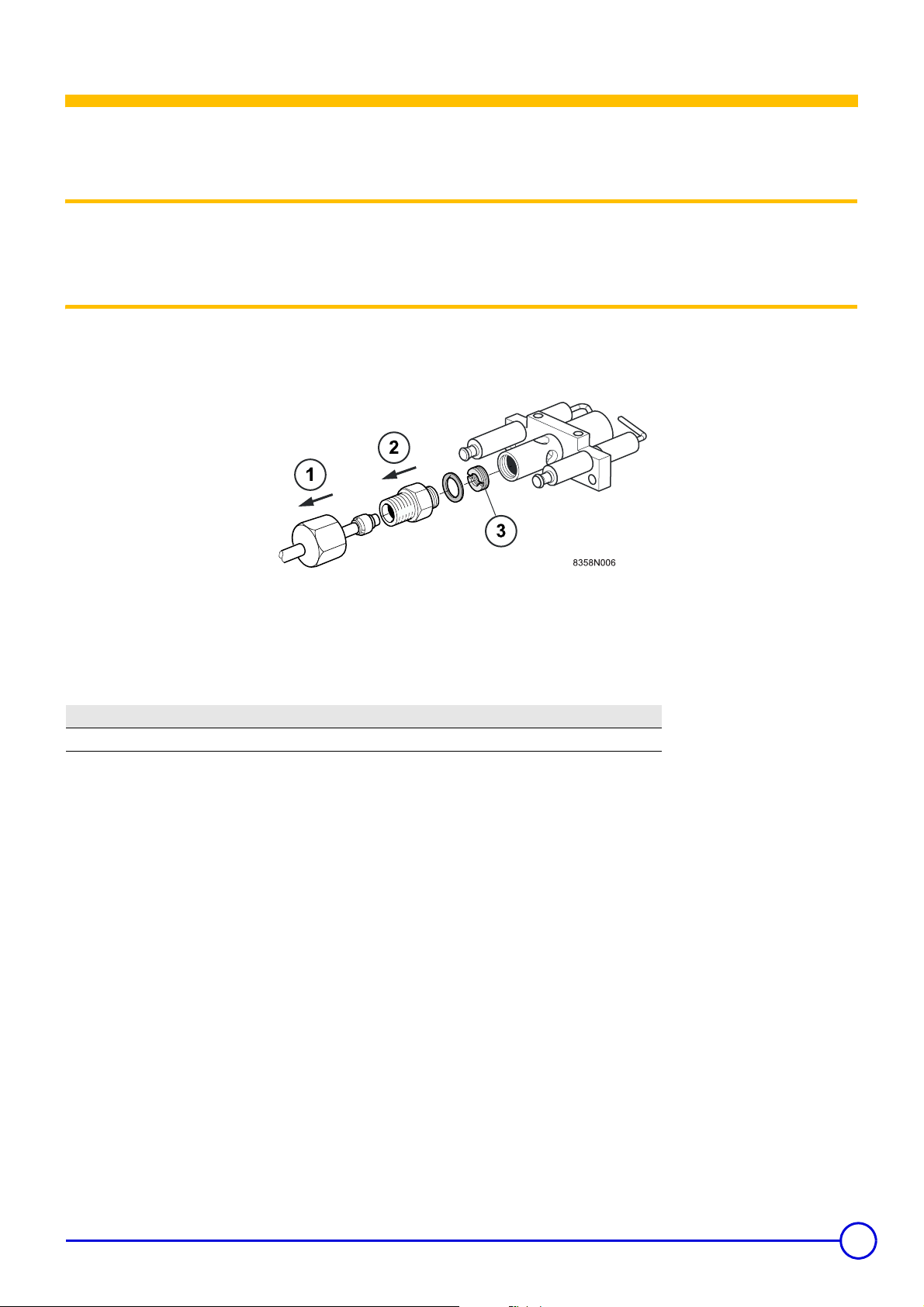

2 Changing the ignition burner injector

Operations to be carried out to convert from natural gas H to natural

gas L and vice versa:

Belgium: The operations required to switch from one gas

to another must be carried out by a SERV'elite technician.

Remove the gas supply pipe from the ignition burner (13 mm

spanner).

Remove the nozzle + seal.

Natural gas H Natural gas L

Nozzle marking 80 100

Nozzle diameter 0.80 mm 1.00 mm

Unscrew the nozzle using a screwdriver and screw in the new

injector.

- Reassemble the parts

- Carry out a leak tightness check

06/02/06 - 300005247-001-B Remeha Gas 460 S

11

Loading...

Loading...