Remeha Gas 310-610 Brochure

THE

SMARTER

WAY TO

REDUCE

EMISSIONS

REMEHA

CONDENSING

BOILER

RANGE

The most efficient way to

reduce your carbon footprint.

GAS 310/610 ECO PRO

2 3

INTRODUCTION

60% of the buildings that will be

standing in 2050 are already here with

us today. So tomorrow, there will be

a great need for intelligent heating

technology specifically designed

for refurbished buildings. This is

where Remeha’s advanced thinking

is leading the way. To a future where

our highly efficient heating systems

help to improve the overall energy

efficiency of refurbished buildings.

Giving them new life and a more

sustainable future.

The Remeha Gas 310 ECO PRO and

the Remeha Gas 610 ECO PRO are

compact, floor standing condensing

boilers. Their small footprint and

ability to be installed side to side

makes them ideally suited for

modular configuration. An optional

Optimising Weather Compensating

control package is available to ensure

maximum efficiency. The boilers are

suitable for both new and retrofit

applications. With conventional and

room sealed capability, they can be

installed in most situations.

CONTENTS

Introduction 2

Boiler description 2

Application information 3

Advantages at a glance 3

Typical boiler construction 4-5

Operating principle 6-7

Dimensions 8-11

Maintenance areas 12-13

Technical data 14-15

Flue data 16-19

Controls 20-21

Electrical connections 22-24

Safety interlocks 25-27

REMEHA GAS 310/610 ECO PRO

OVERVIEW

BOILER DESCRIPTION

The Remeha Gas 310/610 ECO PRO boilers are fully assembled, free

standing, gas fired (Natural gas only), fully modulating, high efficiency

condensing boilers and are supplied on wheels for easy manoeuvrability

into the boiler house.

The sectional cast aluminium heat exchanger and other major

components are contained within a rigid steel frame with removable

casing parts for maintenance purposes. The Remeha Gas 310 ECO PRO

and each Remeha Gas 610 ECO PRO module frame is fitted with a set of

wheels to enable the assembled unit to be easily manoeuvred into position

within the plant room on site with the minimum of effort. All major

electrical and electronic controls are contained within the instrument

panel mounted on top of the boiler at the opposite end to the connections

facing to the front (long side) but can be rotated 90˚ towards the short

side to suit site location. The Remeha Gas 310 ECO PRO boiler is available

with flow and return connections on the left or right hand end of the boiler

(this must be decided at time of order), with the gas connection on the top

of the boiler. The flue gas outlet, complete with a condensate connection,

is at low level on the same end as the F/R connections. The combustion

air inlet is located at the top of the boiler. The Remeha Gas 610 ECO PRO

boiler has two flows and returns at one end of the boiler with a combined

flue gas outlet. The boiler is not available with a choice between left or

right hand versions, but the control panel can easily be rotated to enable

the boiler connections to be on the left or right hand side.

The boilers are suitable for room sealed or conventional flue applications

and have been designed for central heating and indirect hot water

production at working pressures not exceeding 7 bar. They must be

installed on a fully pumped system and are designed for operating

pressures between 0.8 and 7 bar.

The pre-mix gas burner (NG only) with its gas/air ratio control system

ensures clean, trouble-free operation with higher than average annual

efficiencies of up to 109.35% Hi (NCV) in the condensing mode combined

with ultra low NOx and minimum CO

package allows for external On/Off, High Low (volt free switch/s) or

Modulating control (0-10V input). The built-in digital display shows normal

operating/fault code indication and allows actual and set values to be read

and adjusted.

The intelligent, advanced boiler control (‘abc

boiler operating conditions, varying the heat output to suit the system load.

The control is able to react to external “negative” influences in the rest of

the system (flow rates, air/gas supply problems) maintaining boiler output

for as long as possible without resorting to a lockout condition. At worst,

the boiler will reduce its output and/or shut down (shut off mode) awaiting

the “negative” conditions to return to normal before restarting. The ‘abc

control cannot override the standard flame safety controls.

All Remeha Gas 310/610 ECO PRO boilers are tested after assembly to

ensure the boiler and controls comply to our strict quality policy.

emissions. The standard control

2

®

’) continuously monitors the

®

’

APPLICATION INFORMATION

The Remeha Gas 310/610 ECO PRO boilers can be used on all new

and refurbishment projects in both single and multiple configurations.

Conventional and room sealed flue system capability means that the boiler

can be sited almost anywhere within a building.

The Remeha iSense and “OpenTherm” weather compensators (option) are

able to communicate directly with the boilers’ controls to make full use of

their fully modulating features, ensuring that the boiler closely matches

the system demand at all times.

External control systems (BMS) can be interfaced with the boiler to provide

on/off - or modulating (0-10V) control options.

A key benefit of the Remeha Gas 310/610 Eco Pro is that it is Renewable

Energy Ready. Most renewable energy products need to be backed up by

a condensing boiler during periods of peak demand.

The secondary return feature on the new Remeha Gas 310/610 Eco Pro

makes this boiler particularly suitable for use with renewable energy

technologies that use low grade heat such as heat pumps or underfloor

heating circuits.

Bivalent systems such as this combine the best of renewable and

conventional heating technologies to maximise the seasonal efficiency

of the system as a whole over the course of the year.

REMEHA GAS 310/610 ECO PRO

OVERVIEW

ADVANTAGES

AT A GLANCE

Inspected for compliance

Lightweight construction

Easy disassembly

Supplied with wheels for quick

and easy installation

High efficiency - 106.8%

at 50°C/30°C (NCV)

Boiler controls -

on/off high/low or fully

modulating over 20%-100% (1:5)

Low NOx ≥ 35

Ultra quiet > 65 dBA

Digital Diagnostic Display

Cast - sectional aluminium

heat exchanger

Cylindrical, stainless steel,

premix burner

Control adjustable 20˚C-90˚C

Air pressure differential

sensor (LDS)

Temperature sensors for low

water level protection

Gas/air mixing system

with venturi

Electronic control and

protection equipment

Frost protection

Conventional or room

sealed capability

Menu controlled microprocessor

boiler control

Enhanced failure functionality

Compact at only 72cm wide -

fit through a standard door

Left or right hand version

Gas 310 ECO PRO

4 5

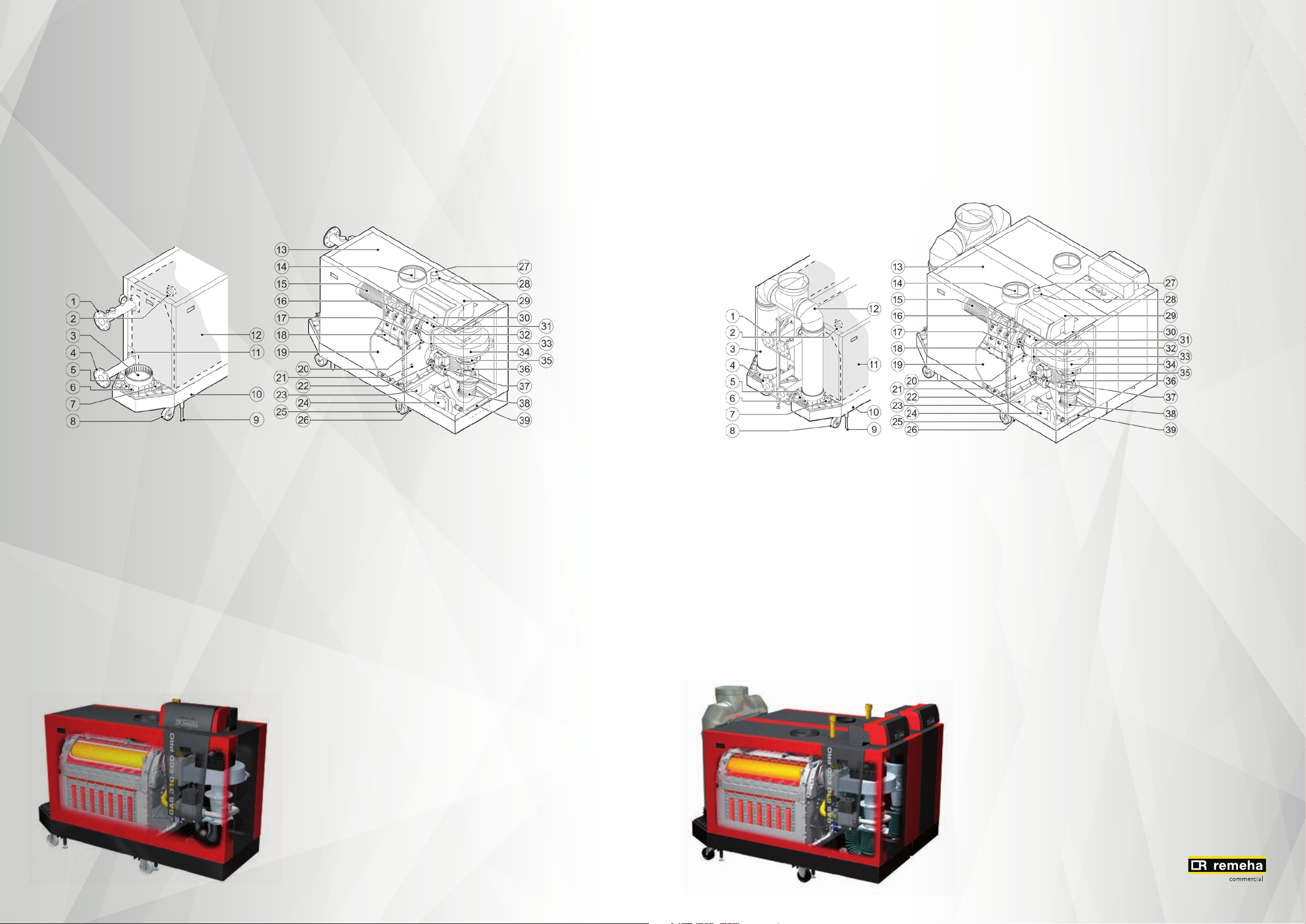

REMEHA GAS 310/610 ECO PRO

TYPICAL REMEHA GAS 310 ECO PRO

BOILER CONSTRUCTION

The unit has been inspected for compliance with the essential requirements of the following directives:

CE identification number (PIN): 0063CL3613

NOx Class: 5

OVERVIEW

REMEHA GAS 310/610 ECO PRO

OVERVIEW

TYPICAL REMEHA GAS 610 ECO PRO

BOILER CONSTRUCTION

The unit has been inspected for compliance with the essential requirements of the following directives:

CE identification number (PIN): 0063CL3613

NOx Class: 5

1 Flow connection

2 Air differential

pressure switch

3 Flue gas discharge pipe

4 Return connection

5 Outlet for measuring

combustion gases

6 Flue gas thermostat (option)

7 Condensate collector

sealant cap

8 Pivoting castor

9 Jacking bolt

10 Base frame

11 Connection for second

return (optional)

12 Heat exchanger

insulation kit (option)

13 Boiler casing

14 Air inlet 34 Fan

15 Burner

16 Adapter

17 Ignition/ionization electrode

18 Heat exchanger

19 Inspection hatch

20 Heat exchanger sensor

21 Return sensor

22 Gas filter

23 Data plate

24 Siphon

25 Fixed castor

EFFICIENCY INFORMATION

Average Annual Efficiency DIN 4702 Part 8

Up to 109.35% at Hi

a. Up to 98.4% at Hi at an average water

temperature of 70°C (80°C/60ºC)

b. Up to 106.8% at Hi at an average water

temperature of 40°C (50°C/30°C)

26 Jacking bolt

27 Gas connection

28 Gas pressure

measurement point

29 Control panel

30 Location for optional

features or a control unit

31 Pressure measurement point

32 Sight glass

33 Non-return valve

35 Extension piece

36 Venturi

37 Gas block

38 Air inlet hose

39 Document holder

1 Flow connection

2 Air differential

pressure switch

3 Flue gas discharge pipe

4 Return connection

5 Outlet for measuring

combustion gases

6 Flue gas thermostat (option)

7 Condensate collector

sealant cap

8 Pivoting castor

9 Jacking bolt

10 Base frame

11 Heat exchanger

insulation kit (option)

12 Flue gas collector

13 Boiler casing

14 Air inlet

15 Burner

16 Adapter

17 Ignition/ionization electrode

18 Heat exchanger

19 Inspection hatch

20 Heat exchanger sensor

21 Return sensor

22 Gas filter

23 Data plate

24 Siphon

25 Fixed castor

26 Jacking bolt

27 Gas connection

28 Gas pressure

measurement point

29 Control panel

30 Location for optional

features or a control unit

31 Pressure measurement point

32 Sight glass

33 Non-return valve

34 Fan

35 Extension piece

36 Venturi

37 Gas block

38 Air inlet hose

39 Document holder

Maintenance Consumption

Average 0.15 at 30K

∆T = Boiler temp - Ambient temperature

NOTE: NCV = Hi, GCV = Hs

6 7

OPERATING PRINCIPLE

Combustion air is drawn into the inlet connection

from the plant room (conventionally flued)

or from outside via the eccentric flue system

(room sealed) by an air supply fan.

On the inlet side of the fan is a specially designed

chamber (venturi unit) which takes gas from

the multiblock and mixes it in the correct

proportions with the incoming air. This mixing

system ensures that the correct gas/air ratio is

delivered to the pre-mix burner at all times.

Depending on demand (under the dictates of flow/

return sensor and other external/internal control

inputs) the ‘abc

boiler output. The ‘abc

speed of the air supply fan which alters the volume

of air being drawn into the venturi. This change in

volume is measured using air pressure differential

which directly controls the volume of gas also being

delivered to the venturi. The resultant controlled

mixture is delivered to the premix burner.

®

’ system determines the required

®

’ control then varies the

REMEHA GAS 310/610 ECO PRO

This mixture is initially ignited by the combined

ignition/ionisation probe, which monitors the

state of the flame. Should the flame be unstable

or not ignite within the pre-set safety time cycle,

the controls will (after 5 attempts) shut the boiler

down requiring manual intervention to reset the

boiler. The digital display will indicate a flashing

fault code confirming the reason for the failure.

The products of combustion in the form of hot

flue gases are forced through the heat exchanger

transferring their heat to the system water (the flue

gas temperature is reduced to approximately 5°C/8°C

above the temperature of the system return water)

then discharged via the condensate collector, to the

flue gas outlet connection, to the atmosphere.

OVERVIEW

There will be a vapour cloud formed at the flue

gas terminal, because of the low flue gas exit

temperature - this is not smoke, simply water

vapour formed during the combustion process.

When the flue gas temperature falls below dew

point (55°C), water vapour (created during the

combustion process) will begin to condense out

in the boiler, transferring its latent heat into the

system water, thereby increasing the output of the

boiler without increasing the gas consumption.

Condensation formed within the boiler and flue

system is discharged from the boiler to an external

drain via the drain pan and siphon supplied.

REMEHA GAS 310/610 ECO PRO

OVERVIEW

The boiler can be supplied as an option with

a second (constant temperature) return

connection. This additional connection enables

the boiler to make full use of its condensing

ability whilst accepting both fixed and variable

temperature returns from the same system.

8 9

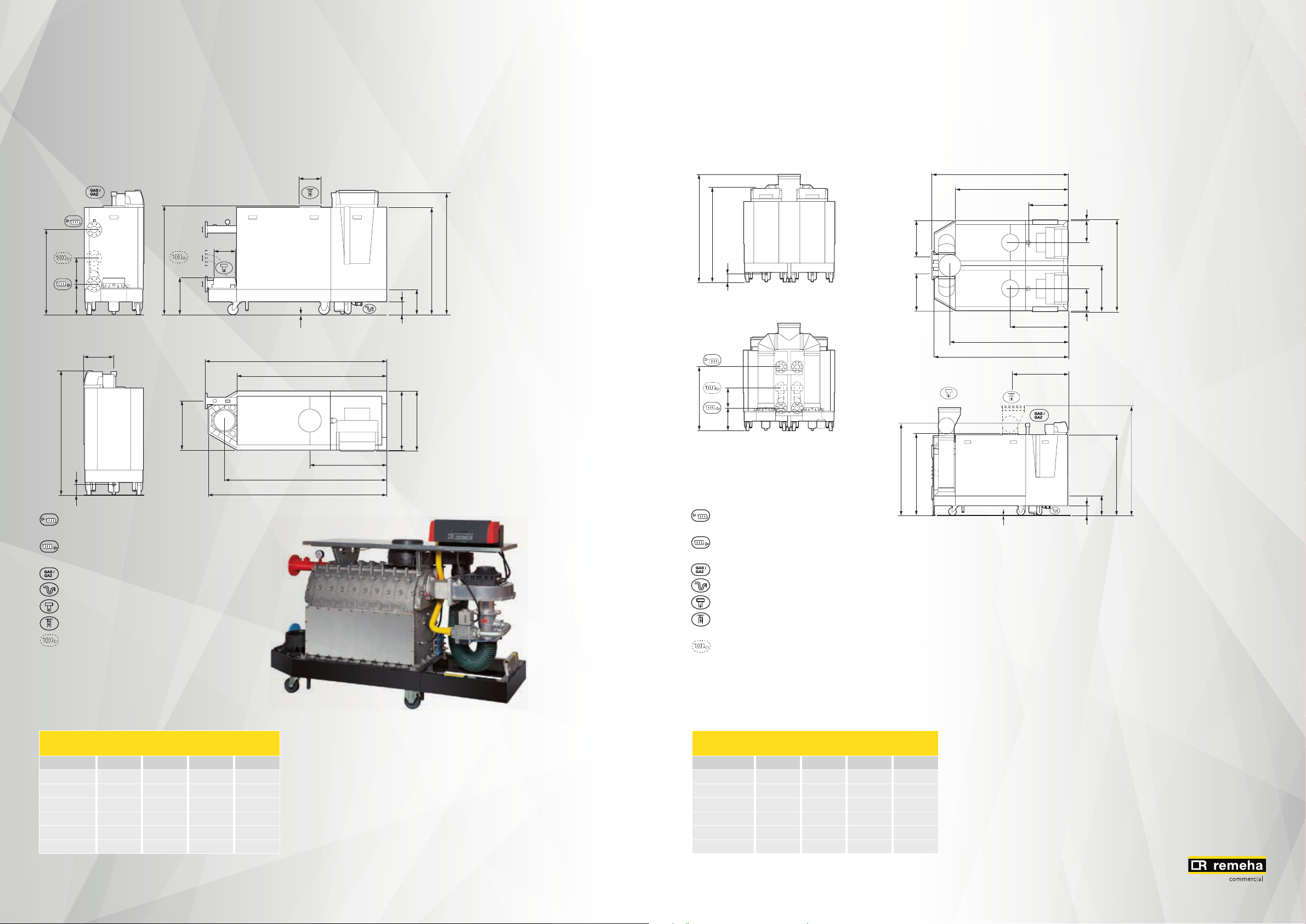

REMEHA GAS 310 ECO PRO

DIMENSIONS

80

Ø 250

65

65

1023

2

320

366

353

1310

2

447

C

Ø 250

2

REMEHA GAS 310/610 ECO PRO

OVERVIEW

REMEHA GAS 310/610 ECO PRO

OVERVIEW

REMEHA GAS 610 ECO PRO

DIMENSIONS

C

L

641

1726

1500

1477

1293

310

155

L

1023

130

2

320

592

592

920

B

A

894,5

8353353

1460

722

8

592

1500

130

Heating circuit flow (80mm) ” ;” Flange NW 80

(Standard DIN 2576)

Heating circuit return (65mm) ” ;” Flange NW 80

(Standard DIN 2576)

Gas connection” ;” G2” (Female thread)

Condensates discharge” ;” 1¼” (Internal)

Flue gas outlet” ;” Ø 250mm

Air intake” ;” Ø 250mm

2

Second return (optional)” ;” Flange NW 80

(Standard DIN 2576)

Remeha Gas 310 ECO PRO

Boiler type A (mm) B (mm) C (mm) D (mm)

310-285 (5) 1833 1635 1862 1490

310-355 (6) 1833 1635 1862 1490

310-430 (7) 1833 1635 1862 1490

310-500 (8) 2142 1944 2172 1800

310-575 (9) 2142 1944 2172 1800

310-650 (10) 2142 1944 2172 1800

706

716

920

B

A

T003472-G

NOTE: Heating flow pipe 80mm

with a mating flange NW 80 (PN16)

Return flow pipe 65mm with

a mating flange NW 80 (PN16)

The optional return pipe is also

65mm and fitted with a NW80

(PN16) mating flange

The service areas are shown on page 12/13.

366

1477

1310

Heating circuit flow (80mm) ” ;” Flange NW 80

(Standard DIN 2576)

Heating circuit return (65mm) ” ;” Flange NW 80

(Standard DIN 2576)

Gas connection” ;” G2” (Female thread)

Condensates discharge” ;” 1¼” (Internal)

Flue gas outlet” ;” Ø 350mm

Air intake” ;” Ø 250mm

Air supply collector (Optional)” ;” Ø 350mm

2

Second return (optional)” ;” Flange NW 80

(Standard DIN 2576)

Remeha Gas 610 ECO PRO

Boiler type A (mm) B (mm) C (mm) D (mm)

610-570 (5) 1833 1635 1862 1490

610-710 (6) 1833 1635 1862 1490

610-860 (7) 1833 1635 1862 1490

610-1000 (8) 2142 1944 2172 1800

610-1150 (9) 2142 1944 2172 1800

610-1300 (10) 2142 1944 2172 1800

310

2

155

NOTE: Heating flow pipe 80mm

with a mating flange NW 80 (PN16)

Return flow pipe 65mm with

a mating flange NW 80 (PN16)

The optional return pipe is also

65mm and fitted with a NW80

(PN16) mating flange

1760

1293

T003766-F

Loading...

Loading...