Remcor Venture Installation Manual

VENTURE

CARBONATED & NONCARBONATED

Installation Manual

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of the Installer to

ensure that the water supply to the

dispensing equipment is provided with

protection against backflow by an air gap

as defined in ANSI/ASME A112. 1.2-1979; or

an approved vacuum breaker or other such

method as proved effective by test.

Water pipe connections and fixtures

directly connected to a potable water

supply shall be sized, installed, and

maintained according to Federal, State,

and Local laws.

POST-MIX DISPENSERS

Part No. 318832000

September 22, 1981

Revised: February 17, 1997

Control Code B

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1981-97Ó

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDARD UNIT (REQUIRES CONNECTION TO A REMOTE

CARBONATOR) 3. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

UNIT WITH BUILT-IN COLD CARBONATOR 3. . . . . . . . . . . . . . . . . . . . . . . . . .

NONCARBONATED UNIT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATED UNITS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NONCARBONATED UNITS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

UNPACKING AND INSPECTION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLACING UNIT IN OPERATING POSITION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILL WATER TANK AND STAR T REFRIGERATION SYSTEM 13. . . . . . . . . . . . . . .

INSTALLATION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING DRIP TRAY DRAIN HOSE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING PLAIN WATER SOURCE LINE(S) TO UNIT 14. . . . . . . . . . . . .

CONNECTING CARBONATED WATER SOURCE LINE TO UNIT 15. . . . . . .

CONNECTING CO2 SOURCE LINE TO UNIT 15. . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING SYRUP SOURCE LINES TO UNIT 15. . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDARD UNIT REQUIRING CONNECTION TO A REMOTE

CARBONATOR 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH BUILT-IN COLD CARBONATOR 16. . . . . . . . . . . . . . . . . . . . . . . . . .

NONCARBONATED UNIT 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT OPERATION 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLEEDING SYRUP AND APPLICABLE PLAIN OR CARBONATED

WATER SYSTEMS 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUST WATER-TO-SYRUP “RATIO” OF DISPENSED PRODUCT 17. . . . .

INSTALL DECALS 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERA TOR’S INSTRUCTIONS 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING CONTROLS 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSING VALVE LEVER 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSING VALVE WITH WATER LEVER 21. . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSING VALVES KEYED LOCK-OUT SWITCH 21. . . . . . . . . . . . . . . . . .

UNIT POWER SWITCH (IF APPLICABLE) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

318832000

TABLE OF CONTENTS (cont’d)

CARBONATOR WATER PUMP MOTOR POWER SWITCH (UNIT WITH

BUILT-IN COLD CARBONATOR) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY PRE-OPERATION CHECK 21.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT OPERATION 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 22. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

REPLENISHING SYRUP SUPPLY 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF UNIT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING SYRUP SYSTEMS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING DROP-IN REFRIGERATION ASSEMBLY CONDENSER COIL

FOR RESTRICTIONS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ICE WATER BATH 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATOR WATER PUMP YEARLY MAINTENANCE OR AFTER WATER

SYSTEM DISRUPTIONS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REQUIRING CONNECTION TO A REMOTE CARBONATOR

(STANDARD UNIT) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH BUILT-IN COLD CARBONATOR 23. . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CO2 GAS CHECK VALVES 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

PREPARING UNIT FOR SHIPPING, STORING, OR RELOCATING 25. . . . . . . . . .

HOOD AND FRONT PANEL REMOVAL 25.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

HOOD REMOVAL 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT ACCESS PANEL REMOVAL 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC INSPECTION 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 REGULATORS ADJUSTMENTS 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSING VALVE WATER FLOW RATE 27. . . . . . . . . . . . . . .

ADJUSTING DISPENSING VALVES FOR WATER-TO-SYRUP “RATIO” (BRIX)

OF DISPENSED PRODUCT 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF UNIT 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING POST-MIX SYRUP SYSTEMS 28. . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING DROP-IN REFRIGERATION ASSEMBLY CONDENSER COIL 30. . . .

CHECKING ICE WATER BATH 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING WATER TANK 31.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATOR WATER PUMP YEARLY MAINTENANCE OR AFTER WATER

SYSTEM DISRUPTIONS 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT CONNECTED TO REMOTE CARBONATOR (STANDARD UNIT) 33. . .

UNIT WITH BUILT-IN COLD CARBONATOR 33. . . . . . . . . . . . . . . . . . . . . . . . . .

NO. 3 DISPENSING VALVE CONVERSION FROM STILL TO CARBONATED

DRINK 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDARD UNIT 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH BUILT-IN COLD CARBONATOR 36. . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 36. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

REPLENISHING SYRUP SUPPLY 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYRUP TANK SYSTEM 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

318832000

ii

TABLE OF CONTENTS (cont’d)

BAG-IN-BOX SYRUP SYSTEM 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYRUP FLAVOR CHANGE 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CO2 SYSTEM CO2 GAS CHECK VALVES 37. . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDARD UNIT (REQUIRES CONNECTION TO A REMOTE CARBONATOR) 43

WATER-TO-SYRUP “RATIO” TOO LOW OR TOO HIGH 43. . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT INCREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 43. . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT DECREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 44. . . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO LOW. 44. . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT

FOAMS IN CUP OR GLASS. 44.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

DISPENSED PRODUCT PRODUCES FOAM AS IT LEAVES DISPENSING

VALVE. 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED. 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY CARBONATED WATER DISPENSED. 45. . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH BUILT-IN COLD CARBONATOR 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER-TO-SYRUP “RATIO” TOO LOW OR TOO HIGH 46. . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT INCREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 46. . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT DECREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 46. . . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO LOW. 46. . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR GLASS. 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT PRODUCES FOAM AS IT LEAVES

DISPENSING VALVE. 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED FROM ALL DISPENSING VALVES. 47. . . . . . . .

ONLY CARBONATED WATER DISPENSED. 48. . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NONCARBONATED UNIT 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER-TO-SYRUP “RATIO” TOO LOW OR TOO HIGH 49. . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT INCREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 49. . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT DECREASE TO DESIRED WATER-TO-SYRUP “RATIO”. 49. . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT

FOAMS IN CUP OR GLASS. 49.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

DISPENSED PRODUCT PRODUCES FOAM AS IT LEAVES

DISPENSING VALVE. 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED FROM ALL DISPENSING VALVES. 50. . . . . . . .

ONLY PLAIN WATER DISPENSED. 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION SYSTEM 50.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

COMPRESSOR DOES NOT OPERATE. 50.. .. .. .. .. .. .. .. .. .. .. .. .. .. .

Page

iii

318832000

TABLE OF CONTENTS (cont’d)

COMPRESSOR WILL NOT STOP AFTER SUFFICIENT ICE BANK IS

PRODUCED.. 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR OPERATES CONTINUOUSLY BUT DOES NOT FORM

SUFFICIENT ICE BANK. 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGITATOR MOTOR NOT OPERATING. 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

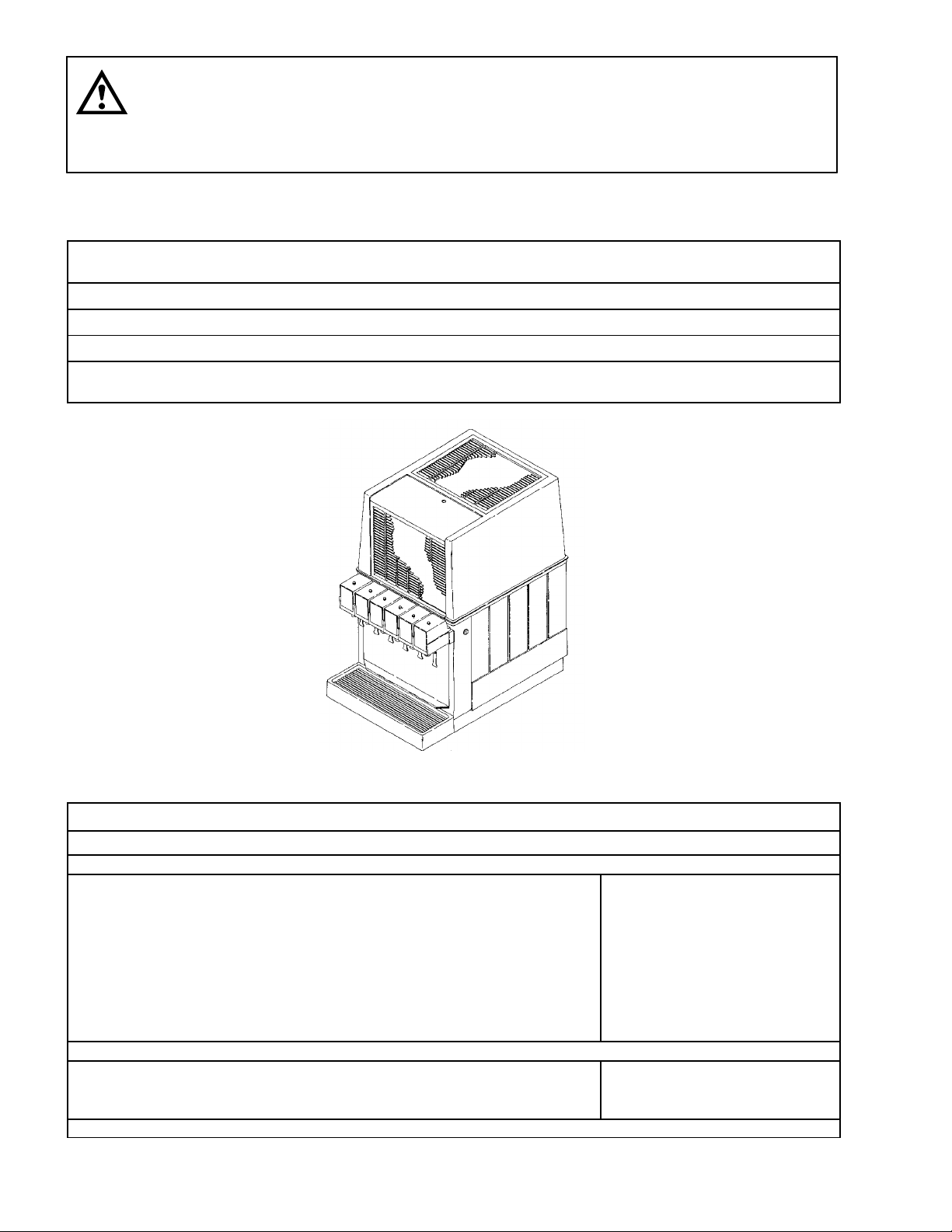

FIGURE 1. VENTURE SIX-FLAVOR POST-MIX DISPENSER 4. . . . . . . . . . . . . . .

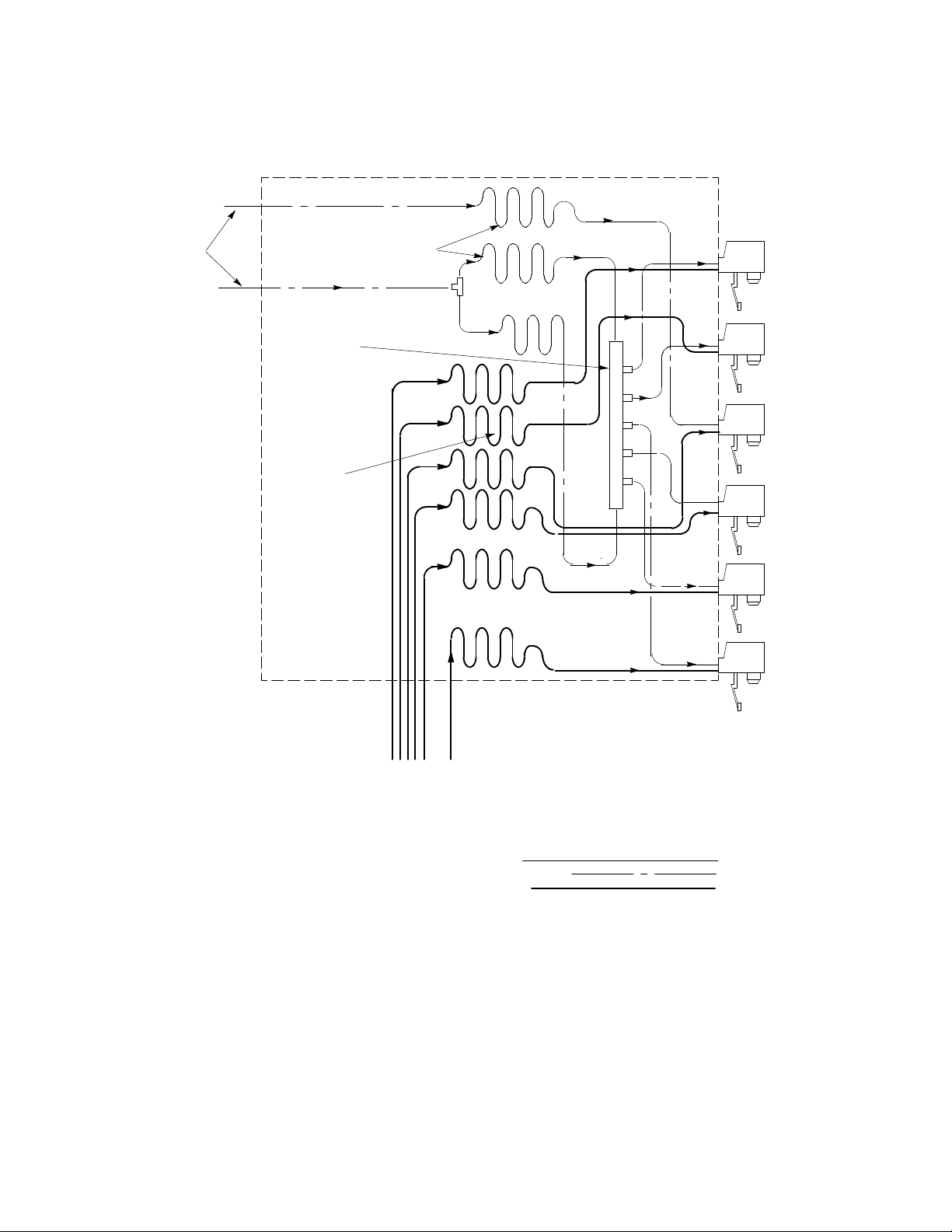

FIGURE 2. FLOW DIAGRAM (SIX FLAVOR UNIT REQUIRING CONNECTION TO

A REMOTE CARBONATOR) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. FLOW DIAGRAM (SIX-FLAVOR UNIT BUILT-IN COLD

CARBONATOR) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. FLOW DIAGRAM (SIX-FLAVOR NON-CARBONATED UNIT) 10. . . . .

FIGURE 5. INLET SUPPLY LINE CONNECTIONS (STANDARD UNIT) 18. . . . . . .

FIGURE 6. INLET SUPPLY LINE CONNECTIONS (UNIT WITH BUILT-IN COLD

CARBONATOR) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. INLET SUPPLY LINE CONNECTIONS (NONCARBONATED UNIT) 20

FIGURE 8. DISPENSER COMPONENTS (UNIT WITH BUILT-IN CARBONATOR

SHOWN) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. WATER TANK (UNIT WITH BUILT-IN COLD CARBONATOR

SHOWN) 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 10. WATER STRAINER SCREEN AND DOUBLE LIQUID CHECK

VALVE 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 11. LIQUID CHECK VALVE ASSEMBLY 34. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 12. CO2 GAS CHECK VALVE ASSEMBLY 38. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 13. WIRING SCHEMATIC FOR GERMAN ICE BANK CONTROL

(OPTIONAL) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 14. WIRING DIAGRAM (60 HZ UNIT WITH 1/3 H.P. REFRIGERATION

ASSEMBLY) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 15. WIRING DIAGRAM (50 HZ UNIT WITH 1/3 H.P. REFRIGERATION

ASSEMBLY) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 16. WIRING DIAGRAM (60 HZ UNIT WITH 1/4 H.P. REFRIGERATION

ASSEMBLY AND BUILT-IN COLD CARBONATOR) 41. .. .. .. .. .. .. .. .. .. .. .. .

FIGURE 17. WIRING DIAGRAM (50 HZ UNIT WITH 1/4 H.P. REFRIGERATION

ASSEMBLY AND BUILT-IN COLD CARBONATOR) 42. .. .. .. .. .. .. .. .. .. .. .. .

Page

LIST OF TABLES

TABLE 1. DESIGN DATA 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

318832000

iv

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly . Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2(Carbon Dioxide) Warning

CO2Displaces Oxygen. Strict Attention must be observed in the prevention of CO2(carbon dioxide)

gas leaks in the entire CO2and soft drink system. If a CO2gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must also be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1 318832000

THIS PAGE LEFT BLANK INTENTIONALLY

318832000

2

GENERAL INFORMATION

IMPORTANT: To the user of this manual - This manual is a guide for installing, operating, and maintaining this equipment. Refer to the Table of Contents for page location for detailed information pertaining to questions that arise during installation, operation, service, or maintenance of this

equipment.

GENERAL DESCRIPTION

This section gives the Unit description, theory of operation, and design data for the four-, five-, and six-flavor

Venture Post-Mix Dispensers (hereafter referred to as Units).

This Unit must be installed and serviced by a qualified Service Person. This Unit contains no User serviceable

parts.

UNIT DESCRIPTION

The Units are compact with high-impact and corrosion-resistant moulded lower housings and may be islandmounted or installed on a front or rear counter. Their refrigeration assemblies are the drop-in type that can be

removed for service and maintenance. Adjustable syrup flow regulators, located on dispensing valves, are

easily accessible to control Water-To-Syrup “Ratio” of dispensed product. All Units have electric dispensing

valves.

NOTE: Optional 4-inch Legs (P/N 314744000) that will elevate the Unit 4-inches above the countertop

are available. When ordering legs, order a quantity of four.

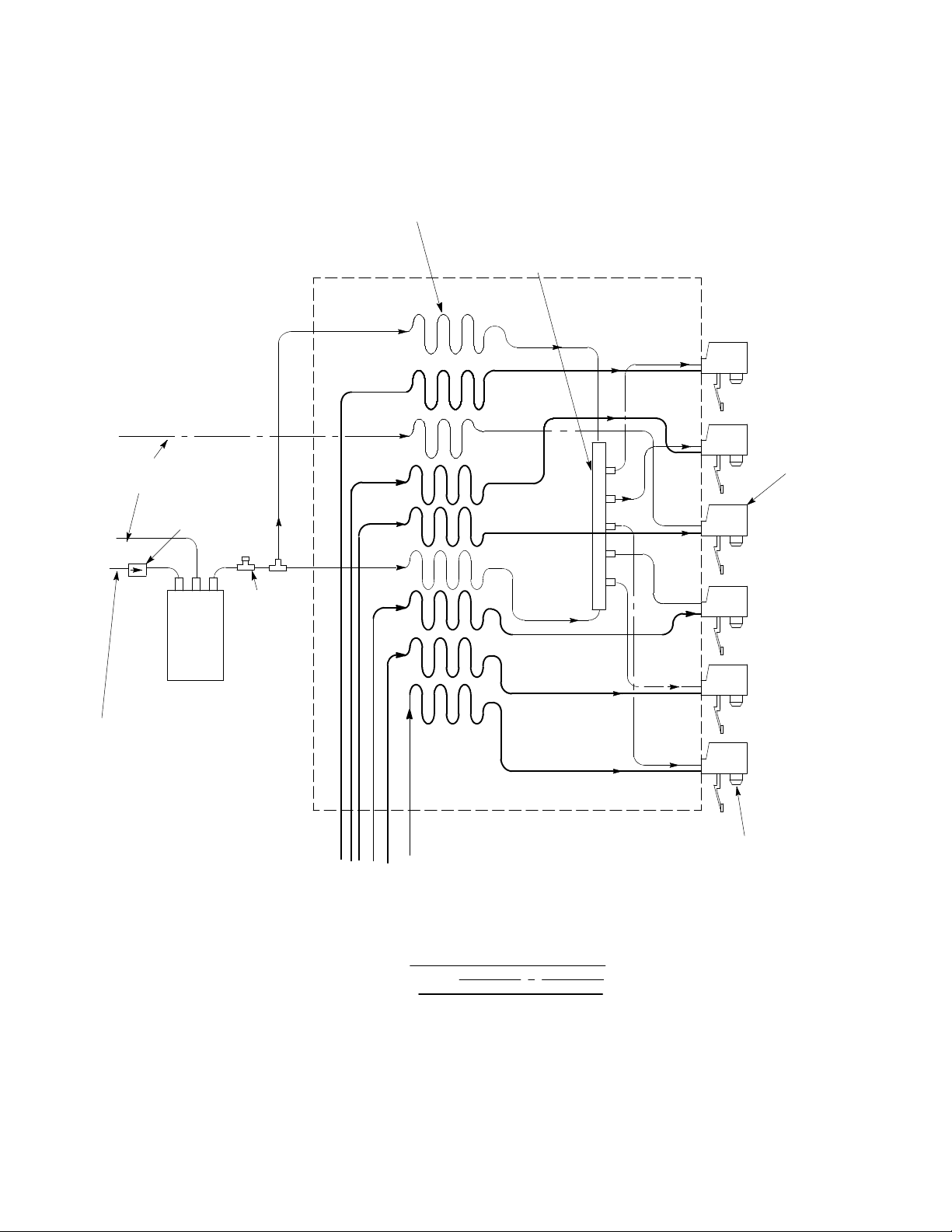

STANDARD UNIT (REQUIRES CONNECTION TO A REMOTE CARBONATOR)

This Unit (see Figure 2) is equipped with a 1/3 H.P. refrigeration assembly and requires connection to a remote

carbonator. Installation of Unit on a countertop, installation of LOOSE-SHIPPED PARTS, connection of remote

carbonator and plain water and syrup supplies, adjustment of CO2regulators, filling water tank with water, and

plugging Unit power cord into an electrical outlet is all that is required for operation.

UNIT WITH BUILT-IN COLD CARBONATOR

This Unit (see Figure 3) is equipped with a 1/4 H.P. refrigeration assembly and has a built-in cold carbonator

located inside the water tank. Installation of Unit on a countertop, installation of LOOSE-SHIPPED PARTS,

connection of plain water and syrup supplies, adjustment of CO2regulators, filling water tank with water, and

plugging Unit power cord into an electrical outlet is all that is required for operation.

NONCARBONATED UNIT

This Unit (see Figure 4) is equipped with a 1/3 H.P. refrigeration assembly and dispenses all noncarbonated

(still) drinks. Installation of Unit on a countertop, installation of LOOSE-SHIPPED parts, connection of plain water and syrup supplies, adjustment of CO2regulators, filling water tank with water, and plugging Unit power cord

into an electrical outlet is all that is required for operation.

3

318832000

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be

sanitized and all sanitizing solution must be purged from the syrup systems. All water must

also be purged from the plain and carbonated water systems. A freezing ambient

environment will cause residual water in the Unit to freeze resulting in damage to internal

components.

WARRANTY REFERENCE INFORMATION

Warranty Registration Date

(to be filled out by customer)

Unit Part Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

FIGURE 1. VENTURE SIX-FLA VOR POST-MIX DISPENSER

Table 1. Design Data

CARBONA TED UNITS:

60 HZ Unit:

1/3 HP refrigeration 115 V, 60 HZ (Requires a Remote Carbonator)

Four Flavor 417354XXX

Five Flavor 417351XXX

417355XXX

417365XXX

418355XXX

427355XXX

Six Flavor 417356XXX

417366XXX

1/4 HP refrigeration 115V 60 HZ w/built-in Cold Carbonator

Five Flavor 417405XXX

Six Flavor 417406XXX

318832000

4

Table 1. Design Data (cont’d)

50 HZ Unit:

1/3 HP refrigeration 230V, 50 HZ (Requires a Remote Carbonator)

Four Flavor 497354XXX

Five Flavor 497355XXX

497400XXX

498355XXX

498400XXX

Six Flavor 497356XXX

497401XXX

498356XXX

1/4 HP refrigeration 230V 50 Hz w/built-in Carbonator

Four Flavor 497404XXX

Five Flavor 497405XXX

Six Flavor 497416XXX

NONCARBONA TED CARBONATED UNITS:

60 HZ Unit:

1/3 HP refrigeration 115 V, 60 HZ

Five Flavor 412155XXX

412165XXX

Six Flavor 412156XXX

412166XXX

Overall Dimensions:

Width 16 1/4 inches

Height 27 5/8 inches

Depth 24 1/2 inches

Weight: Four, Five or Six-Flavor Standard and NonCarbonated Unit with

1/3 HP refrigeration.

Shipping (one carton) approx. 124 Pounds

Dry Weight (approx.) 115 Pounds

Ice Bank Weight 31 Pounds

Drop in Refrigeration Assembly 58 Pounds

Weight: Four, Five, or Six Flavor Unit with 1/4 HP refrigeration and built-in

cold carbonator.

Shipping (one carton) approx. 130 Pounds

Dry Weight (approx.) 125 Pounds

Ice Bank Weight 24 Pounds

Drop in Refrigeration Ass’y 71.6 Pounds

Water Tank Capacity (no ice bank approximate)

Four, Five, or Six-Flavor 9 3/4 Gallons

1/3 H.P. Refrigeration Ass’y

Standard Unit 1/3 HP Refrigeration Five, or Six-Flavor Unit with built-in

9 1/4 Gallons

Cold Carbonator and 1/4 HP Refrigeration

Refrigerant Requirement See Unit

Nameplate

Ambient Operating Temperature 40° F to 100° F

5

318832000

Table 1. Design Data (cont’d)

Unit Water Inlet Pressure 25-30 PSI

Unit Electrical Requirements See Unit

Nameplate

No. of

Dispens-

ing

Valves

5 4 1/3 HP=650 1/4 HP=252

6 4 1/3HP =520 1/4HP = 248

NOTE: Number of 12-oz drinks dispensed 40° F or below @ 75° F syrup and water inlet temperature and 75° F

ambient.

No. of

12 Oz

Drinks/

Min.

No. of Drinks 40° F

Or Below

(see NOTE)

THEORY OF OPERATION

WARNING: CO2displaces oxygen. Strict attention must be observed in the prevention of

CO2(carbon dioxide) gas leaks in the entire CO2and soft drink system. If a CO2gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

CARBONATED UNITS

Standard Units (Requires Connection To a Remote Carbonator).

(see Figure 2)

The Unit was set up at the factory to dispense a still (non-carbonated) drink from No. 3 dispensing valve and

carbonated drinks from the remaining dispensing valves. No. 3 dispensing valve may be converted to also dispense a carbonated drink. Refer to TABLE OF CONTENTS for conversion instructions.

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to the applicable syrup

tanks or bag-in-box syrup pumps and also to a remote carbonator. Plain water enters the remote carbonator

carbonated water tank and is carbonated by regulated CO2gas pressure also entering the tank.When dispensing valve is opened, CO2gas pressure exerted upon the syrup tank or on the bag-in-box system syrup pump,

pushes syrup through the Unit syrup cooling coil, and on to the dispensing valve.

Carbonated water is propelled by CO2gas pressure which pushes carbonated water from the carbonated water

tank, through the Unit cooling coils, and on to the dispensing valve. Syrup and carbonated water meet simultaneously at the dispensing valve resulting in a carbonated drink being dispensed. A still (non-carbonated) drink is

dispensed from No. 3 dispensing valve in the same manner as the carbonated drink except plain water is substituted for carbonated water.

318832000

6

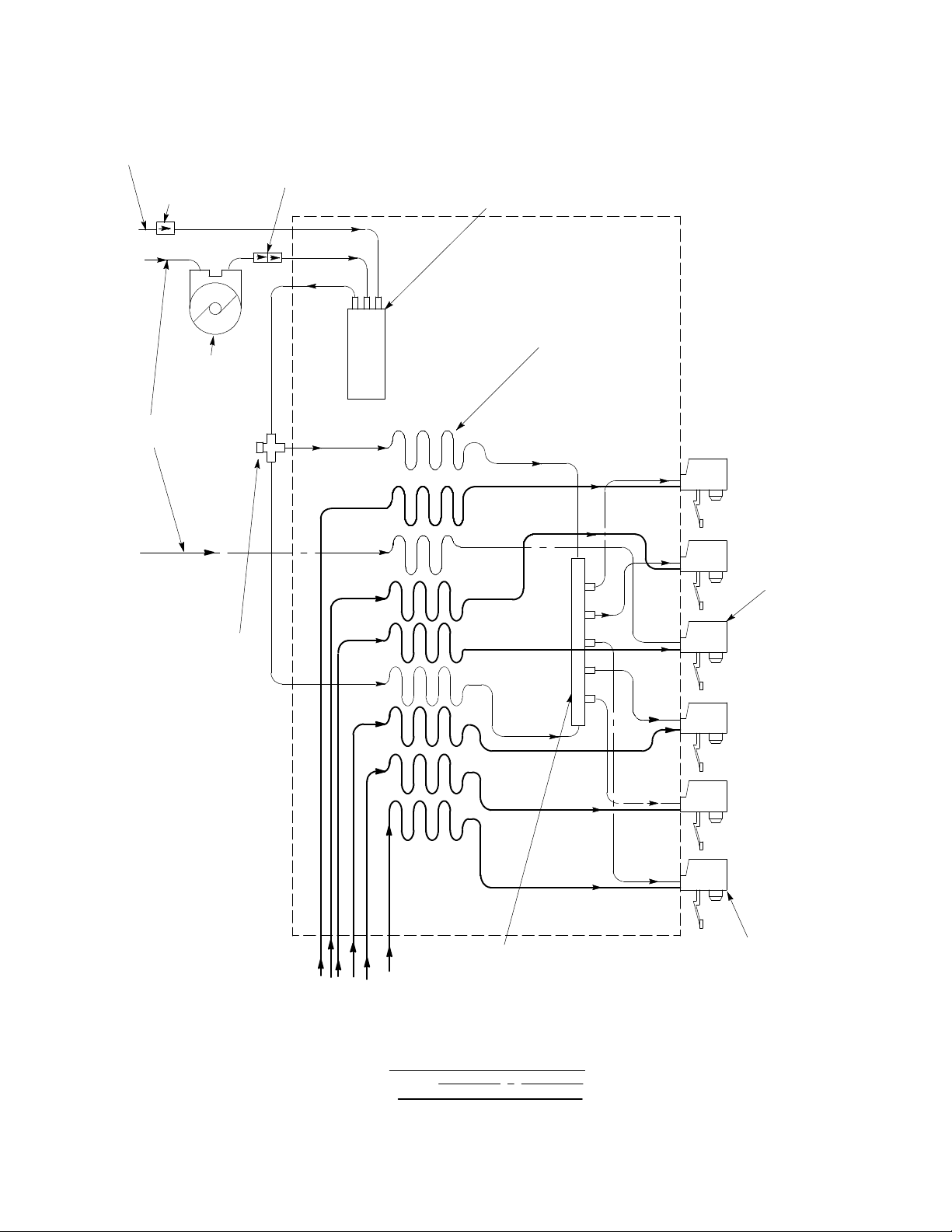

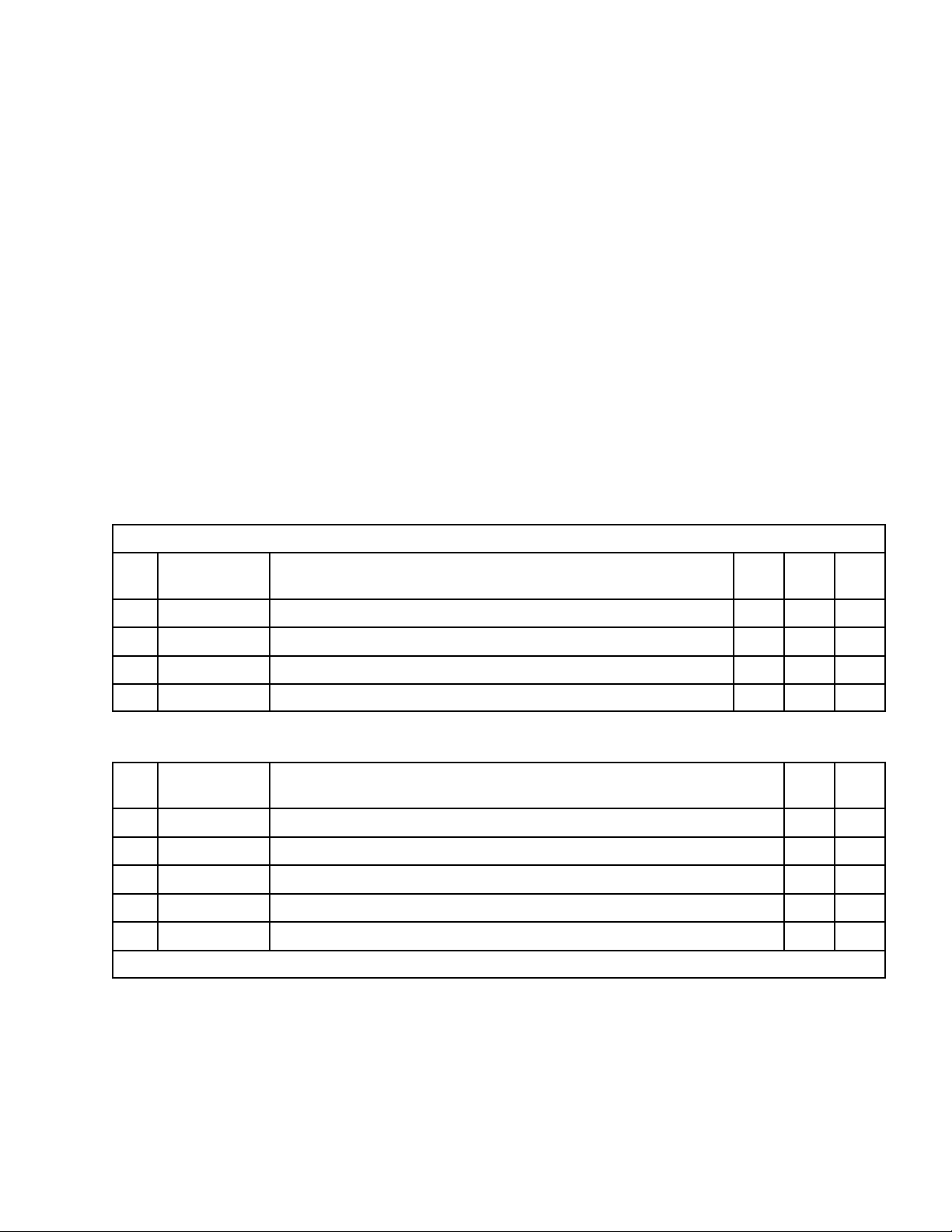

Units With Built-In Cold Carbonators.

(see Figure 3)

The Unit was set up at the factory to dispense a still (noncarbonated) drink from No. 3 dispensing valve and car-

bonated drinks from the remaining dispensing valves. No. 3 dispensing valve may be converted to also dispense a carbonated drink. Refer to TABLE OF CONTENTS for conversion instructions.

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to the applicable syrup

tanks or bag-in-box syrup pumps and to a built-in carbonator located inside the Unit. Plain water is pumped into

the carbonator carbonated water tank by a water pump and is carbonated by regulated CO2gas pressure also

entering the tank. When dispensing valve is opened, CO2gas pressure exerted upon the syrup tank or on the

bag-in-box system syrup pump, pushes syrup through the Unit syrup cooling coil, and on to the dispensing

valve. Carbonated water is pushed by CO

gas pressure from the carbonated water tank, through the Unit car-

2

bonated water cooling coils, and on to the dispensing valve.

Syrup and carbonated water meet simultaneously at the dispensing valve resulting in a carbonated drink being

dispensed. A still (noncarbonated) drink is dispensed from the No. 3 dispensing valve in the same manner as

the carbonated drink except plain water is substituted for carbonated water.

The carbonated water tank is replenished when the carbonated water level inside the tank drops, which in turn

automatically starts the carbonator water pump. When the carbonated water level inside the tank has been replenished, the carbonator water pump will stop.

NONCARBONATED UNITS

(see Figure 4)

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2gas regulators to the applicable syrup

tanks or bag-in-box syrup pumps. When dispensing valve is opened, CO2gas pressure exerted upon the syrup

tank or on the bag-in-box system syrup pump, pushes syrup through the Unit syrup cooling coils, and on to the

dispensing valve. Plain water enters the Unit and passes through the Unit plain water cooling coils on the way to

the dispensing valve. Syrup and plain water meet at the same time at the dispensing valve resulting in a still

(noncarbonated) drink being dispensed.

7

318832000

PLAIN

WATER

CO2 CHECK

VALVE

COOLING

COILS (9)

CARBONATEDWATER

MANIFOLD

1

2

NON--CARBONATED

DRINK

3

REGULATED

CO2 SUPPLY

REMOTE

CARBONATOR

CAPPED

TEE

FITTING

4

5

6

DISPENSER

DISPENSING VALVE (6)

SYRUP SUPPLY

(SYRUP TANKS OR

BAG-IN-BOX SYSTEM)

LINE LEGEND

CO2

PLAIN WATER

SYRUP

FIGURE 2. FLOW DIAGRAM (SIX FLAVOR UNIT REQUIRING CONNECTION TO A REMOTE CARBONATOR)

318832000

8

REGULATED

CO2 SUPPLY

PLAIN

WATER

CO2 CHECK

VALVE

WATER

PUMP

DOUBLE LIQUID

CHECK VALVE

BUILT--IN

CARBONATOR

COOLING

COILS (9)

1

2

NON--CARBONATED

DRINK

CAPPED

CROSS

FITTING

DISPENSER

SYRUP SUPPLY

(SYRUP TANKS OR

BAG-IN-BOX SYSTEM)

LINE LEGEND

CO2

PLAIN WATER

SYRUP

3

4

5

6

DISPENSING VALVE (6)

CARBONATEDWATER

MANIFOLD

FIGURE 3. FLOW DIAGRAM (SIX-FLAVOR UNIT BUILT-IN COLD CARBONATOR)

9

318832000

PLAIN

WATER

SUPPLY

PLAIN WATER

COOLING COILS

1

WATER

MANIFOLD

SYRUP

COOLING

COIL (5)

DISPENSER

2

3

4

5

6

SYRUP SUPPLY

(SYRUP TANKS OR

BAG-IN-BOX SYSTEM)

318832000

LINE LEGEND

CO2

PLAIN WATER

SYRUP

FIGURE 4. FLOW DIAGRAM (SIX-FLAVOR NON-CARBONATED UNIT)

10

INSTALLATION

This section covers unpacking and inspection, selecting location, installing Unit, preparing for operation, and

operation.

UNPACKING AND INSPECTION

NOTE: The Unit was thoroughly inspected before leaving the factory and the carrier has accepted and

signed for it. Any damage or irregularities should be noted at the time of delivery (or not later than 15

days from date of delivery) and immediately reported to the delivering carrier. Request a written inspection report from Claims Inspector to substantiate any necessary claim. File claim with the delivering

carrier, not with IMI Cornelius Inc.

1. After Unit has been unpacked, remove shipping tape and other packing material.

2. Lift hood straight up and off Unit.

3. Remove four shipping nuts that secure drop-in refrigeration assembly in Unit.

4. Remove two screws (if applicable) securing front access panel to Unit, then remove panel.

5. Unpack LOOSE-SHIPPED PARTS. Make sure all items are present and in good condition.

CARBONA TED UNITS WITH 1/3 H.P. REFRIGERATION

(REQUIRES CONNECTION TO A REMOTE CARBONATOR)

Table 2. Loose-Shipped Parts

Item

No. Part No. Name 4-FL 5-FL 6-FL

1 317659039 Drip Tray 1 1 1

2 317660000 Cup Rest 1 1 1

3 317792000 Line Outlet Plug 1 1 1

4 176193000 Fitting, 7/16-20 (2) 5 6 7

NONCARBONA TED UNITS WITH 1/3 H.P. REFRIGERATION

Item

No. Part No. Name 5-FL 6-FL

1 317659039 Drip Tray 1 1

2 317660000 Cup Rest 1 1

3 317792000 Line Outlet Plug 1 1

4 176193000 Fitting, 7/16-20 (2) 6 7

5 318523088 Test Baffle Ass’y, Dispensing Valve (see Note below) 1 1

NOTE: Temporarily used to adjust dispensing valves for Water-To -Syrup “Ratio” of dispensed product.

11

318832000

UNITS WITH 1/4 H.P. REFRIGERATION AND BUILT-IN COLD CARBONATOR

Item

No. Part No. Name 4FL 5FL 6FL

1 317659039 Drip Tray 1 1 1

2 317660000 Cup Rest 1 1 1

3 317792000 Line Outlet Plug 1 1 1

4 77070402 Fitting, Stainless Steel, 5/8-18 (2) 1 1 1

5 176017000 Swivel Nut, 7/16-20 1 1 1

6 311304000 Tapered Gasket, Black 3 3 3

7 77010400 Nipple, 7/16 Nut (for .265 Tube) 1 1 1

8 300200000 Tubing Clamp 1 1 1

SELECTING LOCATION

CAUTION: This Unit is intended for indoor installation only. Do not install this Unit in an

outdoor environment which would expose it to the outside elements.

This Unit may be island-mounted or installed on a front or rear counter. Locate the Unit so the following requirements are satisfied:

WARNING: To avoid possible fatal electrical shock or serious injury to the operator, it is

highly recommended that a GFCI (ground fault circuit interrupt) be installed in the

electrical circuit for the domestic Units. It is required that an ELCB (earth leakage circuit

breaker) be installed in the electrical circuit for the export Units

1. The Unit must be installed near a properly grounded electrical outlet with proper electrical requirements.The electrical circuit must be properly fused (slow-blow type fuse) or the circuit must be connected

through an equivalent HACR circuit breaker.The electrical outlet must be accessible for ease of connecting

and disconnecting the Unit power cord. No other electrical equipment should be connected to this circuit.

REFER TO UNIT NAMEPLATE FOR THE REQUIRED POWER CIRCUIT OPERATING VOLTAGE, HZ,

AND THE MINIMUM CIRCUIT AMPACITY OF THE UNIT. ALL ELECTRICAL WIRING MUST CONFORM

TO NATIONAL AND LOCAL ELECTRICAL CODES.

CAUTION: Do not place or store anything on top of the Unit.

2. A minimum of 15-inches clearance must be maintained above the Unit to the nearest obstruction (shelf,

cupboard, ceiling, etc.) and 6-inches clearance between back-side of the Unit and the wall. The front grille

of the Unit must be unobstructed to allow air to enter the hood.

3. Close to a permanent drain to route drip tray drain hose and water tank drain hose.

4. The top of the unit is to remain free of all objects. Do not place anything on top of unit.

318832000

12

PLACING UNIT IN OPERATING POSITION

NOTE: Some of the Units are manufactured with water and syrup inlet lines that are to be routed to outside of the Unit and be connected to water and syrup source lines. Some Units are also assembled at

the factory not equipped with water and syrup inlet lines and require water and syrup source lines to

be routed to inside of the Unit and be connected to labeled stainless-steel inlet tubes on front of the

Unit. For Units not equipped with factory installed water and syrup inlet lines, the water and syrup

source lines may be routed in through Unit back access hole or up through hole cut in the countertop

to inside of the Unit to be connected to labeled stainless-steel inlet tubes on front of the Unit.

Proceed as follows to place Unit manufactured with water and syrup inlet lines in operating position.

The Unit inlet supply lines, power cord, water tank drain hose, and drip tray drain hose must either be routed out

Unit base back access hole, under drip tray at front of the Unit, or if island-mounted, through hole cut in countertop under the Unit. Proceed to applicable installation procedure.

1. Unit Base Access Panel- Place Unit in location on the countertop. Route Unit inlet supply lines, power cord,

water tank drain hose, and drip tray drain hose out base back access hole. Area around inlet supply lines

at flanged hole behind front access panel must be closed and sealed.

Under Drip Tray At Front Of Unit- Place Unit in location on the countertop with drip tray

extended over the edge of the countertop approximately one inch. Route Unit inlet supply lines, power

cord, water tank drain hose. and drip tray drain hose out back access hole. Area around inlet supply lines

at flanged hole behind front access panel must be closed and sealed. Install LINE OUTLET PLUG, provided with the Unit, in Unit base back access hole.

Island-Mounted- Place Unit in location on the countertop flush with the countertop edge. Mark Unit center

line on edge of the countertop, then move Unit off to one side. Starting at center line mark on edge of the

countertop, measure back 12-inches for location of 2-inch hole to be cut in the countertop. Cut a 2-inch

hole in countertop where indicated. Place Unit in position over the hole. Route Unit inlet supply lines, power

cord, water tank drain hose, and drip tray drain hose down through hole in countertop. Install LINE

OUTLET PLUG, provided with the Unit, in Unit base back access hole. Area around inlet supply lines at

flanged hole behind front access panel must be closed and sealed.

2. To comply with NSF International (NSF) requirements within the United States, Unit base must be sealed

to countertop and all access holes to base must be sealed. Proceed as follows to seal Unit base.

NOTE: An alternate arrangement to avoid sealing the Unit base to the countertop as described, would

be to install four 4-inch Legs ( Leg P/N 314744000).

A. Tilt Unit up to expose bottom of base.

B. Liberally apply silastic sealant such as Dow Corning RTV 731 or equivalent on base bottom edges.

NOTE: Do not move Unit after positioning or seal from base to countertop will be broken.

C. Lower Unit into operating position on counter top to complete seal from base to countertop.

D. Apply additional sealant around bottom of base. Seal must have a minimum radius of 1/2-inch to pre-

vent crevices and to ensure a complete seal.

E. All access holes to inside of the Unit base must be closed and sealed.

FILL WATER TANK AND START REFRIGERATION SYSTEM

1. Make sure plug in water tank drain hose is secure.

NOTE: Use low -mineral-content water where a local water problem exists.

2. Remove plug from drop-in refrigeration assembly platform water fill hole. Fill water tank with clean water to

top of stainless steel coils located in coil basket.

3. Install plug in water fill hole.

13

318832000

Loading...

Loading...