Remcor UNIVERSAL 750 Installation Manual

Installation Instructions

UNIVERSAL 750 PRE-MIX

DISPENSER

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303--6234

Telephone(800) 238--3600

Facsimile (612) 422--3232

Part No. 189159000

August 20, 1964

Revised: January 22, 1991

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Installation Manual must be read and understood before starting to install or operate this equipment.

IMI CORNELIUS INC; 1964-91Ó

Printed in U.S.A.

TABLE OF CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . .

UNIT DESCRIPTION 1. . . . . . . . . . . . . . . . . . . .

THEORY OF OPERA TION 2. . . . . . . . . . . . . .

INSTALLA TION 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

UNP ACKING AND INSPECTION 5. . . . . . . . .

IDENTIFICA TION OF LOOSE--SHIPPED

P ARTS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 5. . . . . . . . . . . . . . . . .

INSTALLING UNIT 5. . . . . . . . . . . . . . . . . . . . . .

LOCA TING UNIT 5. . . . . . . . . . . . . . . . . . . . .

DRAIN CONNECTIONS 6. . . . . . . . . . . . . . .

ROUTING UNIT PRODUCT INLET LINES AND

DRIP TRAY DRAIN HOSE OUT OF UNIT CAB-

INET 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING UNIT PRODUCT INLET

LINES 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING DISPENSING VALVES

KNOBS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILL EVAPORATOR TANK AND STAR T REFRIG-

ERA TION SYSTEM 6.. . . . . . . . . . . . . . . . . . . .

PREP ARING UNIT FOR OPERATION 7. . . . .

UNIT OPERATION 7. . . . . . . . . . . . . . . . . . . . . .

OPERA TORS INSTRUCTIONS 9. . . . . . . . . . . . .

OPERA TING CONTROLS 9. . . . . . . . . . . . . . .

DISPENSING VALVE LEVER 9. . . . . . . . . . .

UNIT POWER SWITCH 9. . . . . . . . . . . . . . .

DAIL Y PRE OPERATION CHECK 9. . . . . . . . .

UNIT OPERATION 9. . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 9. . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING PRODUCT TANKS CO2 REG-

ULA TORS 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSED PRODUCT FLOW

RA TE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 9. . . . . . . . . . .

REPLENISHING PRODUCT SUPPLY 9. . . . .

CLEANING AND SANITIZING 9. . . . . . . . . . . .

DAIL Y CLEANING OF UNIT 9. . . . . . . . . . . .

WEEKL Y CLEANING OF DISPENSING

V ALVES 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING UNIT 9. . . . . . . . . . . . . . . . . . . .

CHECKING CONDENSER COIL FOR RESTRIC-

TIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ICE WATER BATH 9. . . . . . . . . . .

SERVICE AND MAINTENANCE 11.. . . . . . . . . . .

PREP ARING UNIT FOR SHIPPING, RELOCAT-

ING, OR STORING 1 1.. . . . . . . . . . . . . . . . . . . .

PAGE

TOP COVER, ACCESS GRILLES, AND DRIP

TRA Y REMOVAL ) 1 1.. . . . . . . . . . . . . . . . . . . . .

TOP COVER REMOV AL 1 1.. . . . . . . . . . . . . .

ACCESS GRILLES REMOVAL 1 1.. . . . . . . .

DRIP TRAY REMOVAL 11. . . . . . . . . . . . . . . .

PERIODIC INSPECTION 11.. . . . . . . . . . . . . . .

ADJUSTMENTS 1 1.. . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING PRODUCT TANKS CO2 REG-

ULA TORS 11.. . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSED PRODUCT FLOW

RA TE 1 1.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 1 1.. . . . . . . . . .

REPLENISHING PRODUCT SUPPLY 12. . . . .

PRODUCT FLAVOR CHANGE 12. . . . . . . . . . .

CLEANING CONDENSER COIL 12. . . . . . . . . .

CHECKING ICE WATER BATH ) 12.. . . . . . . . .

CLEANING EVAPORATOR TANK ) 14. . . . .

CLEANING AND SANITIZING 15. . . . . . . . . . . .

DAIL Y CLEANING OF UNIT 15. . . . . . . . . . . .

WEEKL Y CLEANING OF DISPENSING

V ALVES ) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING UNIT 16. . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 21. . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED. 21.. . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT FOAMS IN CUP

OR GLASS 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT FOAMS AS IT LEAVES

DISPENSING VALVE. 21. . . . . . . . . . . . . . . . . . .

REFRIGERA TION SYSTEM 22. . . . . . . . . . . . . .

COMPRESSOR DOES NOT OPERA TE. 22.

COMPRESSOR WILL NOT STOP AFTER

SUFFICIENT ICE BANK IS FORMED. 22. .

COMPRESSOR OPERATES CONTINUOUSLY

BUT DOES NOT FORM SUFFICIENT ICE

BANK. 22.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER FAN MOTOR NOT

OPERA TING. 23. . . . . . . . . . . . . . . . . . . . . . . .

AGITA TOR MOTOR NOT OPERATING. 23.

COMMERCIAL WARRANTY 25. . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. UNIVERSAL 750 PRE-MIX DISPENS-

ER 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. FLOW DIAGRAM 3. . . . . . . . . . . . .

FIGURE 3. PAR TS IDENTIFICATION 13. . . . . .

FIGURE 4. EVAPORATOR TANK (STANDARD

UNIT SHOWN) 14. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. CLEANING DISPENSING VALVE 15

FIGURE 6. WIRING DIAGRAM 18. . . . . . . . . . .

i

PAGE

189159000

TABLE OF CONTENTS CONT’D

FIGURE 7. INSTRUCTIONS FOR CRIMPING

TUBE CLAMPS 19. . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

PAGE

LIST OF TABLES

TABLE 1. DESIGN DA TA 1. . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED P ARTS 5.. . . . .

189159000

ii

GENERAL INFORMATION

IMPORTANT: To the user of this manual -- This

manual is a guide for installing, operating, and

maintaining this equipment. Refer to Table of

Contents for page location of detailed

information pertaining to questions that arise

during installation, operation, service and

maintenance, or troubleshooting this equipment.

GENERAL DESCRIPTION

This section gives the unit description, installation

requirements, theory of operation, design data, and

flow diagram for the Universal 750 Four-- Flavor Pre-Mix Dispenser (hereafter referred to as a unit).

UNIT DESCRIPTION

The dispenser (see Figure 1) is a compact unit that

may be installed free standing or under a

counter or bar.

Installation of the LOOSE-- SHIPPED PARTS, (see

Table 2-- 1), connection to a grounded electrical outlet

with proper electrical requirements, filling evaporator

tank with water, and connection to product tanks with

regulated CO2pressure are all that is required to set

unit up for operation. A 6--inch leg kit (P/N

187416-- 000) is available. Also available is a four

caster kit (P/N 316290-- 000) to make unit mobile.

CAUTION: Before shipping, storing,

or relocating this Unit, the syrup

systems must be sanitized and all

sanitizing solution must be purged from the

syrup systems. All water must also be

purged from the plain and carbonated water

systems. A freezing ambient environment

will cause residual water in the Unit to freeze

resulting in damage to internal components.

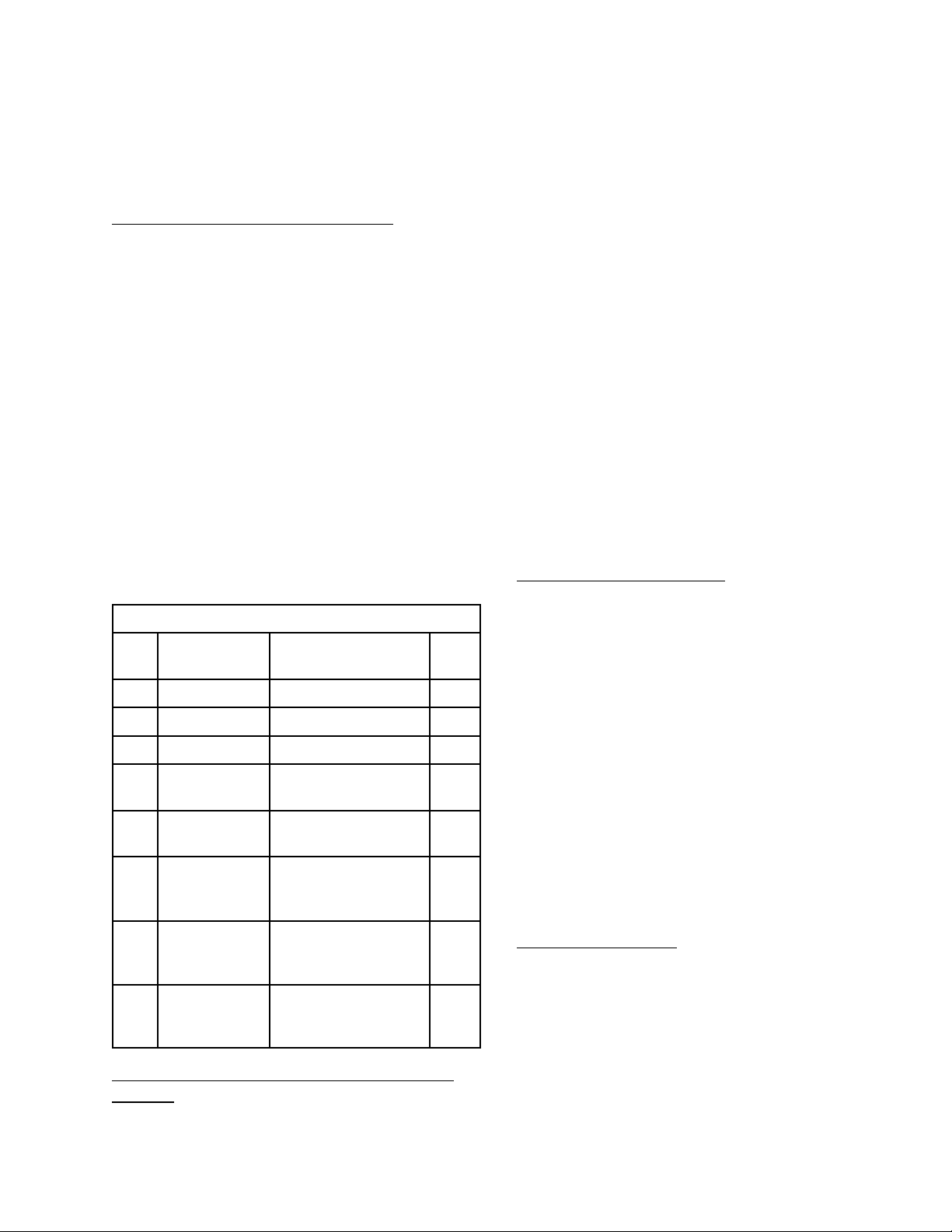

Table 1. Design Data

Model Numbers:

Universal 750 (domestic) 284729-- 000

Standard Unit

Universal 750 (domestic) with 284780-- 000

Sealed Evaporator Tank

Universal 750 (export) 494729-- 000

Overall Dimensions:

Height 37--1/4 inches

Width 16 inches

Depth (with drip tray) 22 inches

FIGURE 1. UNIVERSAL 750 PRE-MIX DISPENSER

Table 1. Design Data (cont’d)

Weights:

Shipping (1Carton) 159 pounds

Dry Weight 140 pounds

With Evaporator Tank full 225 pounds

of Water

Ice Bank Weight 46 pounds

Capacities:

Unit Water Bath (no ice bank)

approx.

Dispensing Rate:

6-- oz. drinks @ 4/minute *763

6-- oz. drinks @ 6/minute *507

Recovery Rate 3 drinks/minute

NOTE: *Number of 6-- oz. drinks that can be dispensed at 40° F or below with 75° F product inlet

temperature and 75° F ambient.

Ambient Operating Temperature 40°F to 100°F

Electrical Requirements:

Operating Voltage (domestic) 1 15 VAC, 60

Current Draw (domestic) 8.1 amps

Operating Voltage (export) 230 VAC, 50

Current Draw (export) 3 amps

1 189159000

10 gallons

Hz

Hz

THEORY OF OPERATION (see Figure 2)

A CO2cylinder delivers carbon dioxide gas (CO2)

through regulated CO2regulators to product tanks.

When dispensing lever is opened, CO2pressure exerted upon product tanks pushes product from tanks,

through unit cooling coils, to dispensing valves resulting in cold dispensed drinks.

When unit power cord has been plugged into electrical outlet and power switch on back of unit has been

flipped to ‘‘ON’’ (up) position, compressor, condenser

fan motor, and agitator motor will start and begin

forming an ice bank. When full ice bank has been

formed, compressor and condenser fan motor will

stop but agitator motor will continue to operate circulating ice water bath in evaporator tank. Evaporator

tank ice bank sensing bulb will cycle compressor and

condenser fan motor on and off as required to maintain full ice bank.

2189159000

FIGURE 2. FLOW DIAGRAM

CYLINDER

REGULATOR (2)

2

2

CO

CHECK VALVE (4)

CO

PRODUCT TANK (4)

DISPENSING

PRODUCT COIL (4)

ICE WATER

VALVE (4)

BATH DISPENSER

2

LINE LEGEND

PRODUCT

CO

3

189159000

THIS PAGE LEFT BLANK INTENTIONALLY

4189159000

INSTALLATION

This section covers unpacking and inspection, identification of LOOSE--SHIPPED PARTS, selecting location, installing unit, preparing unit for operation, and

unit operation.

UNPACKING AND INSPECTION (see Figure

3)

NOTE: The unit was thoroughly inspected before

leaving factory and carrier has accepted and

signed for it. Any damage or irregularities

should be noted at time of delivery and immediately reported to delivering carrier. Request a

written inspection report from Claims Inspector

to substantiate any necessary claim. File claim

with delivering carrier, not with IMI Cornelius Inc.

1. After unit has been removed from shipping carton, remove shipping tape and other packing

material. Inspect for shipping damage and follow

procedure in preceding NOTE if damage is evident.

2. Unpack item listed in LOOSE--SHIPPED

P ARTS. Make sure all items are present and in

good condition.

2. CUP REST (item 2) to be installed in DRIP

TRA Y

(item 3).

3. DRIP TRAY (item 3) to be installed on unit by

inserting rear edge of tray under lip of valve trim

panel and lifting up until bottom tray supports

are inserted in square holes provided in front

panel. Lock drip tray in place by slight downward pressure.

4. DECALS, DISPENSING VALVES KNOBS (item

7) to be installed on DISPENSING V ALVES

KNOBS (item 4)

5. DISPENSING VALVES KNOBS (item 4) to be

installed on dispensing valves by pushing knobs

down into place on valves levers.

6. Applicable ADAPTERS (item 5) to be used to

connect product inlet lines from product tanks to

unit product inlet lines. REDUCERS (item 6)

may be used to connect unit product inlet lines

directly to product tanks quick disconnects provided disconnects have 1/4-- inch flare (7/16--20)

male fittings.

SELECTING LOCATION

Table 2. Loose-Shipped Parts

Item

No. Part No. Name Qty.

1 188090 Leveling Legs 4

2 186642 Cup Rest 1

3 186573-- 039 Drip Tray 1

4 151741-- 039 Dispensing Valve

Knob

5 150807-- 100 Adapter, 7/16-- 20

Male by 1/2--16 Male

150807-- 200 Adapter, 1/2-- 16

Male by 1/2--16 Male

(domestic unit only)

6 31 1245 Reducer, 7/16--20

Female by 1/2--16

Male

7 317904-- 999 Decal, Dispensing

V alve Knob (as

ordered)

IDENTIFICATION OF LOOSE--SHIPPED

PARTS (see Figure 3)

1. LEVELING LEGS (item 1) to be installed in

threaded holes provided on unit base (only units

installed outside the United States).

NOTE: For identification purposes, side of unit

dispensing valves are on is designated ‘‘front’’ of

unit. This unit may be installed free standing or

under counter or bar. Locate unit so following

requirements are satisfied.

1. Near a properly grounded electrical outlet with

proper electrical requirements. No other electrical appliance should be connected to this circuit.

ALL ELECTRICAL WIRING MUST CONFORM

4

4

4

4

TO NATIONAL AND LOCAL ELECTRICAL

CODES.

2. Air circulation through condenser coil, required

for cooling coil, is drawn in through air intake

grille on front of unit and is exhausted out

through grilles on sides and back of unit. When

locating unit, make sure grilles are not restricted

to insure proper air circulation through unit.

INSTALLING UNIT

LOCATING UNIT

4

Areas Outside United States (Canada, Europe, etc.)

Install LEVELING LEGS (item 1) in threaded holes

on each corner of unit base. Adjust each leveling leg

until unit sits level and stands solid. Make sure all

leveling legs are in contact with floor.

Areas Within United States -- To comply with National

Sanitation Foundation (NSF) requirements, unit must

be sealed to floor and LEVELING LEGS (item 1)

may not be used. Perform following procedure to

install unit.

5 189159000

Loading...

Loading...