Remcor UCGR Installation Manual

IMI CORNELIUS INC g One Cornelius Place g Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (763) 422-3246

Installation/Service Manual

UCGR GLYCOL COOLING UNIT

Part No. 569000330

January 10, 2001

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COOLING UNIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING COOLING UNIT LOCATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING SYSTEM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLACING COOLING UNIT IN OPERATING LOCATION 8. . . . . . . . . . . . . . . . . . . .

FILLING COOLING UNIT TANK WITH FOOD GRADE PROPYLENE

GLYCOL-TYPE ANTIFREEZE 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING COOLING UNIT REFRIGERATION SYSTEM 8. . . . . . . . . . . . . . . . . . .

STARTING PROPYLENE GLYCOL ANTI-FREEZE CIRCULATING SYSTEM 9. .

OPERATORS INSTRUCTIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

OPERATING CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLYCOL CIRCULATING PUMP POWER SWITCH 11. . . . . . . . . . . . . . . . . . . . .

COOLING UNIT MAINTENANCE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CONDENSER COIL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING COOLING UNIT GLYCOL (COOLANT) TANK 11. . . . . . . . . .

CLEANING COOLING UNIT EXTERIOR 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING COOLING UNIT GLYCOL (COOLANT) TEMPERATURE 13. . . . . . . .

COOLING UNIT MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOVAL OF DROP-IN REFRIGERATION ASSEMBLY 13. . . . . . . . . . . . . . .

CLEANING CONDENSER COIL 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING COOLING UNIT EXTERIOR 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING COOLING UNIT GLYCOL (COOLANT) TANK 14. . . . . . . . . .

LUBRICATION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAIRY PRODUCT IN LINES TOO WARM 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR DOES NOT OPERATE. 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR WILL NOT STOP AFTER GLYCOL (COOLANT) HAS REACHED

RECOMMENDED 265° F TO 285° F TEMPERATURE. 18. . . . . . . . . . . . . . . . . . . . .

i 0622

TABLE OF CONTENTS (cont’d)

COMPRESSOR OPERATES CONTINUOUSLY BUT DOES NOT LOWER

GLYCOL (COOLANT) TO 265° F TO 285° F. 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER FAN MOTOR NOT OPERATING. 18. . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. PYTHON FOR DAIRY PRODUCT COOLING 9. . . . . . . . . . . . . . . . . . .

FIGURE 2. PARTS IDENTIFICATION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. WIRING DIAGRAM 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE 1. DESIGN DATA 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

0622

ii

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identi-

fies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2 (Carbon Dioxide) Warning

CO2 Displaces Oxygen. Strict Attention must be observed in the prevention of CO2 (carbon dioxide)

gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must also be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1 0622

THIS PAGE LEFT BLANK INTENTIONALLY

20622

GENERAL INFORMATION

IMPORTANT: To the user of this manual - This manual is a guide for installing, operating, and

maintaining this system. Refer to Table of Contents for page location of detailed information pertaining

to questions that arise during installation, operation, service and maintenance, or troubleshooting this

Cooling Unit.

GENERAL DESCRIPTION

This section gives the description and theory of operation for the UCGR Glycol Cooling Unit (hereafter referred

to as a Cooling Unit).

COOLING UNIT DESCRIPTION

The UCGR Glycol Cooling Unit consists basically of a refrigeration system with a 1/2 horsepower compressor, a

refrigerated glycol holding tank to cool the glycol/water solution, and a glycol circulating pump to circulate cold

glycol/water solution (coolant) out and back through the dairy products system.

Table 1. Design Data

Cooling Unit Model Number 111815

Overall Dimensions:

Width 16-1/4 inches

Height 27-5/8 inches

Depth 24-1/2 inches

Weights: (approximate)

Shipping Weight 106 Pounds

Dry Weight 102 Pounds

Capacity:

Glycol Tank 10 gallons

Refrigeration System:

Refrigerant Type and Charge See Cooling Unit Nameplate

Ambient Operating Temperature 40° F to 100° F

Electrical Requirements:

Operating Voltage 115VAC, 60Hz

Operating Current 12 Amps

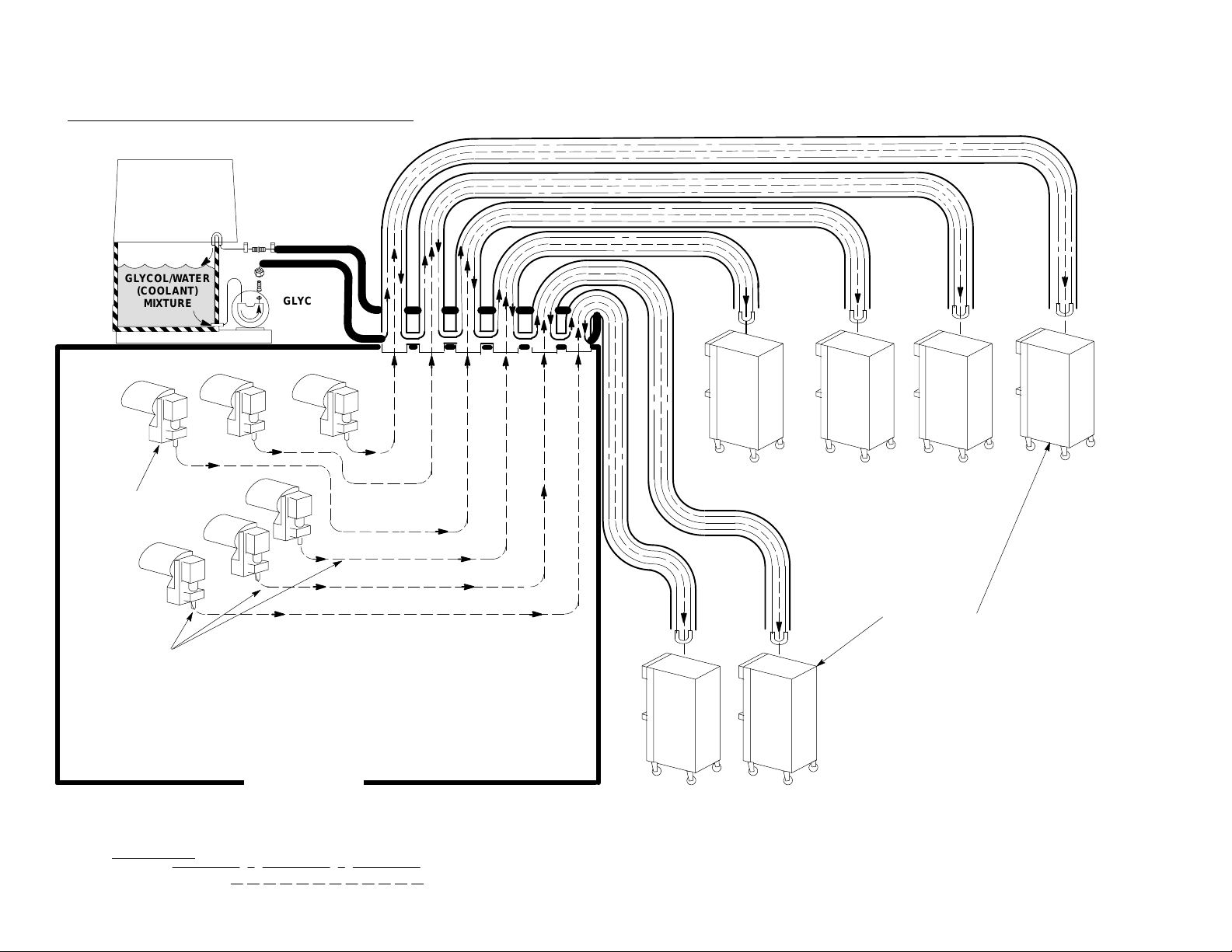

THEORY OF OPERATION

Food grade propylene glycol antifreeze/water solution (coolant) is cooled by the Cooling Unit and is circulated

through the glycol lines to each freezer. The glycol lines and the dairy product mix lines are covered with

insulation and the dairy product mix lines are kept cool by the glycol lines. Direction of glycol (coolant) flow is

from the Cooling Unit glycol tank, through glycol circulating pump, out through glycol feed line to each freezer,

and back through glycol return line to the Cooling Unit.

3 0622

0622

NOTE: FOR GLYCOL CONNECTION DETAIL SEE FIGURE B

*COMET GLYCOL

COOLING UNIT

INSTALLED ON TOP

OF COOLER

*COMET GLYCOL

COOLING UNIT

GLYCOL/WATER

(COOLANT)

MIXTURE

BOX (SUGGESTED

INSTALLATION

GLYCOL

(COOLANT)

CIRCULATING

PUMP

4

MIX

PUMP (6)

PRODUCT LINES (6)

LINE LEGEND

GLYCOL

DAIRY PRODUCT

FREEZER (6)

Walk-In Cooler

Dairy Product Cooling System

Loading...

Loading...