Page 1

SPIRAL ICE ICEMAKER--DISPENSER

MODEL NUMBER:SID350A/35S

Operator’s Manual

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.CorneliusParts.COM

WWW.ICeCubes.NET

(866) 423-6253

(623) 869-8881

SID350W/35S,

SID350A/35S-B

SID350W/35S-B

Part No. 91626

Revised June, 1997

Revision

THIS DOCUMENT CONTAINS IMPORTANT INFORMA

This Manual must be read and understood before installing or operating this equipment

REMCOR INC: 8/95

B

TION

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1...................................................

DESCRIPTION 2............................................................

UNPACKING 2..........................................................

INSTALLATION 3............................................................

LOCATION 3............................................................

PLUMBING 3...........................................................

ELECTRICAL 3.........................................................

BEVERAGE SYSTEM 7..................................................

INSTALLATION 7......................................................

START UP 7............................................................

OPERATING INSTRUCTIONS 9...............................................

MAINTENANCE 13...........................................................

CLEANING INSTRUCTIONS 13...........................................

ICEMAKER SECTION 13.................................................

DISPENSER SECTION 14...............................................

BEVERAGE SYSTEM 14..................................................

MAINTENANCE AND ADJUSTMENTS 16.......................................

Page

THERMOSTAT ALTITUDE ADJUSTMENT 16................................

BIN STAT 16............................................................

ICE PRODUCTION ADJUSTMENT 16......................................

CLEARING EVAPORATOR FREEZE-UP 16.................................

SERVICE PROCEDURES 17..............................................

HIGH PRESSURE CONTROL 17..........................................

BIN THERMOSTAT 17...................................................

CONDENSER (AIR COOLED) 18.........................................

TROUBLESHOOTING GUIDE 23...............................................

WARRANTY 37..............................................................

LIST OF FIGURES

FIGURE 1. SID 350 / 35S 4...............................................

FIGURE 2. SID 350 / 35S-B 5.............................................

FIGURE 3. MOUNTING TEMPLATE SID 350A/35, SID 350W/35,

SID 350A/35S-B, SID 350W / 35S-B 6......................................

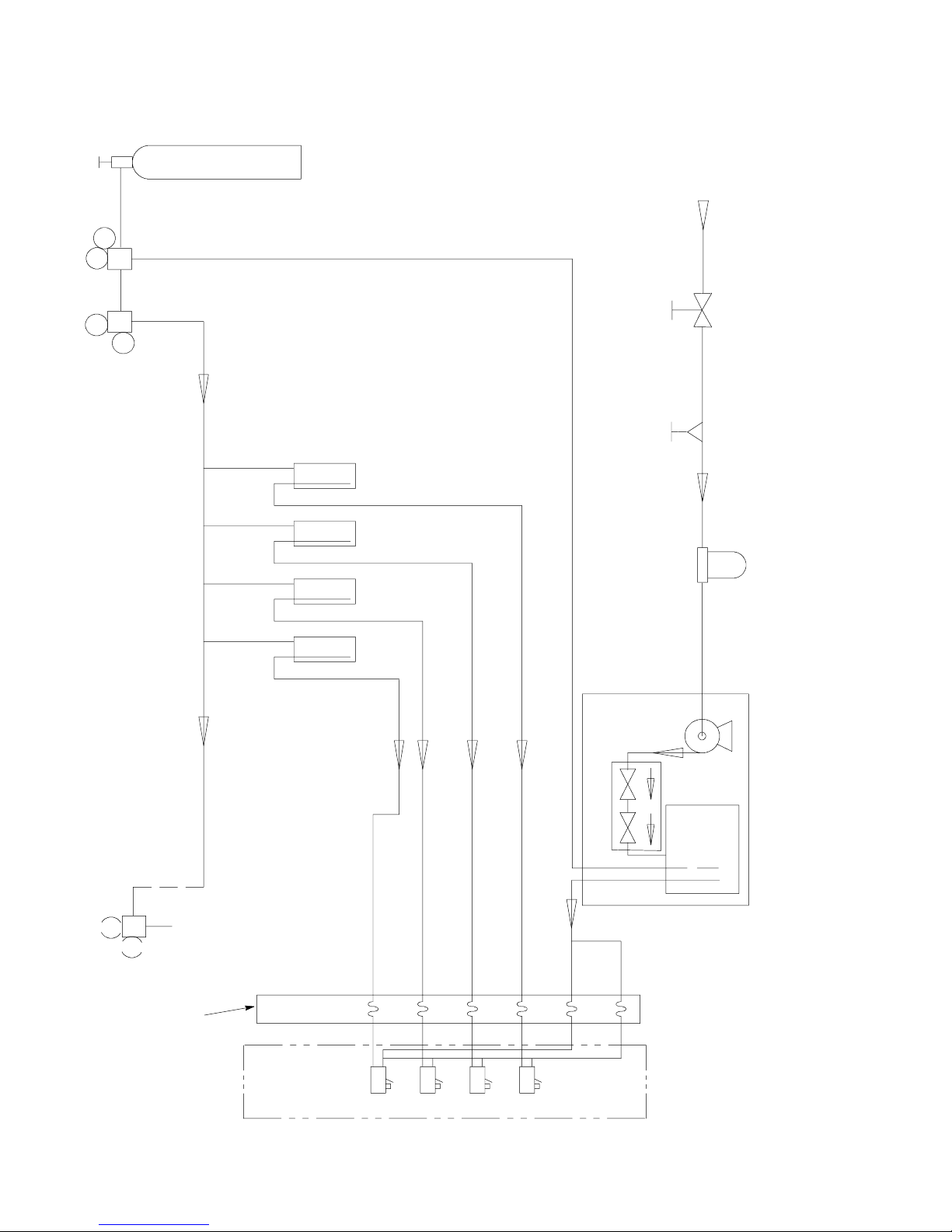

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC “-B”MODELS 8..............

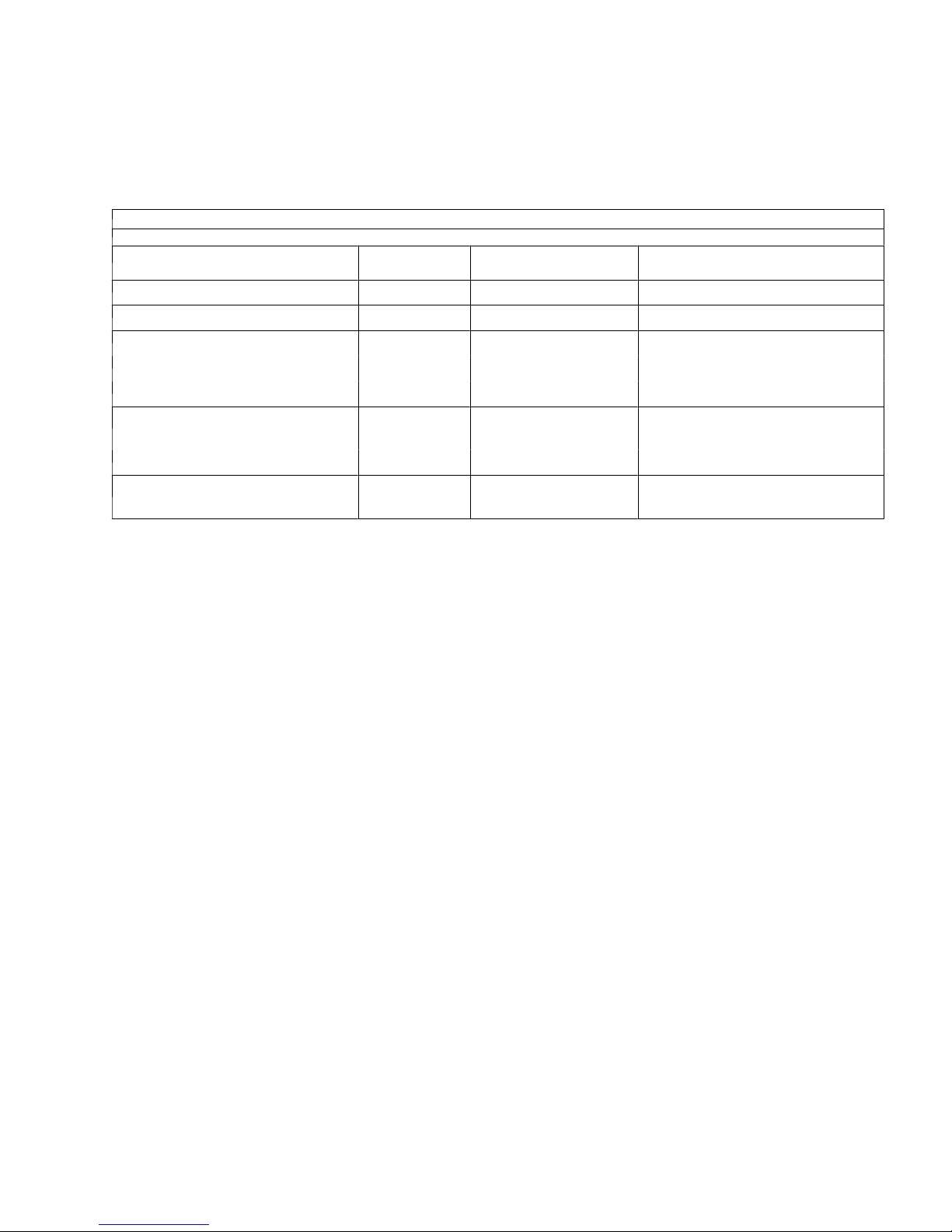

FIGURE 5. SID 350/35 115/1/ 60 HZ SCHEMATIC 10.........................

FIGURE 6. SID 350/35 115/1/60 HZ WIRING 1 1.............................

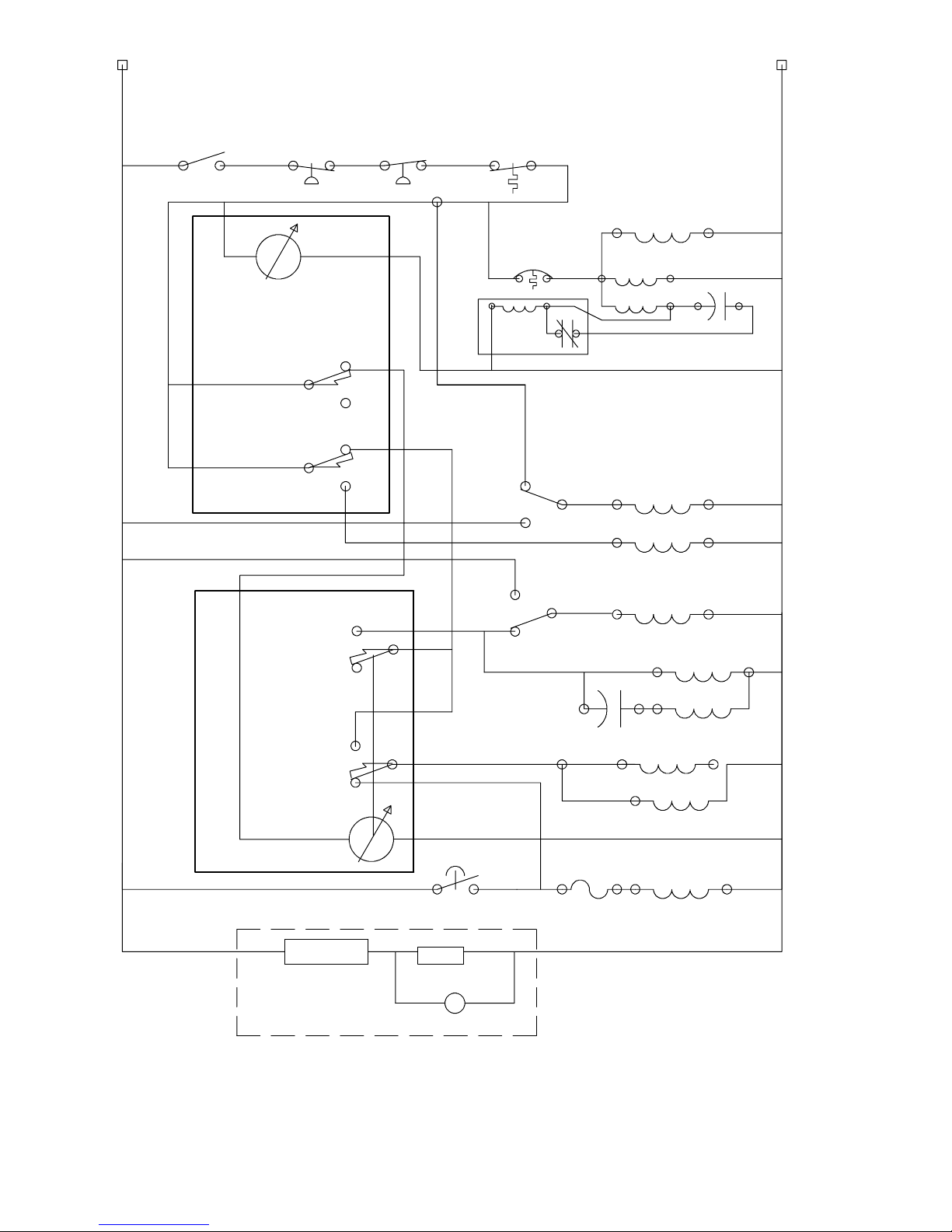

FIGURE 7. REFRIGERATION SCHEMATIC 12...............................

FIGURE 8. SERVICE PAR TS LIST CONDENSING UNIT 34...................

FIGURE 9. CABINET ASSEMBLY EXPLODED VIEW AND SERVICE PARTS 35.

FIGURE 10. SOLENOID ASSEMBLY - EXPLODED VIEW & PARTS LIST 36.....

i

91626

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF TABLES

Page

TABLE 1. SPECIFICATIONS 2............................................

TABLE 2. ICEMAKER CAPACITIES (LBS./DAY) 2...........................

TABLE 3. CONTROLLER 9...............................................

Manufactured Under One or More of the Following Patent Numbers:

3,211,336, 3,274,792, 3,393,839 , 3,517,860, 3,739,842, 4,215,803, 4,227,377, 4,300,3594,346,824

Canadian Patent Numbers912,514 (10/72), 936,855 (11,73), 4,429,543, 4,921,149

Other Patents Pending

91626

Page 4

SAFETY PRECAUTIONS

Always disconnect power to the dispenser before servicing or cleaning.

Never

occurs automatically when the dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice. To insure continued protection and sanitation, observe the following

IMPORTANT INSTALLATION NOTICE

An Everpure Model 9320-42, System IV Model DB900, or equal, icemaker quality water treatment unit MUST

BE INSTALLED in the water supply line to the icemaker. Failure to do so may result in poor quality ice, low production output and may cause premature failure of icemaker evaporator and void the extended evaporator warranty.

This icemaker is provided with a stainless steel evaporator, designed to last the life of the product. However,

some of the chemicals in treated and untreated water, specifically chlorine and sulfur (sulfide), have the ability to

attack stainless steel and cause premature failure. An initial investment in proper water treatment will pay for

itself in increased production, quality and long life of the product.

place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

ALWAYS be sure the removable lid is properly installed to prevent unauthorized access to the hopper interior and possible contamination of ice.

ALWAYS be sure the upper and lower front panels are securely fastened.

ALWAYS keep area around the dispenser clean of ice cubes.

1 91626

Page 5

DESCRIPTION

The REMCOR S.I.D. (Spiral Icemaker Dispenser) is a unique, self-contained, counter-top style unit which automatically makes hard, clear cube-quality ice and stores it in a sealed hopper for sanitary dispensing. The ice is

made by a new, patented process on a spiral shaped stainless steel evaporator and produces tube cube quality

ice on the outside of the tubes. There are no augers, no compressing of flaked ice, no bearings and no high

gear motor loads in the icemaking process. The unit has been designed to be simple, yet effective, to provide

many years of trouble free operation.

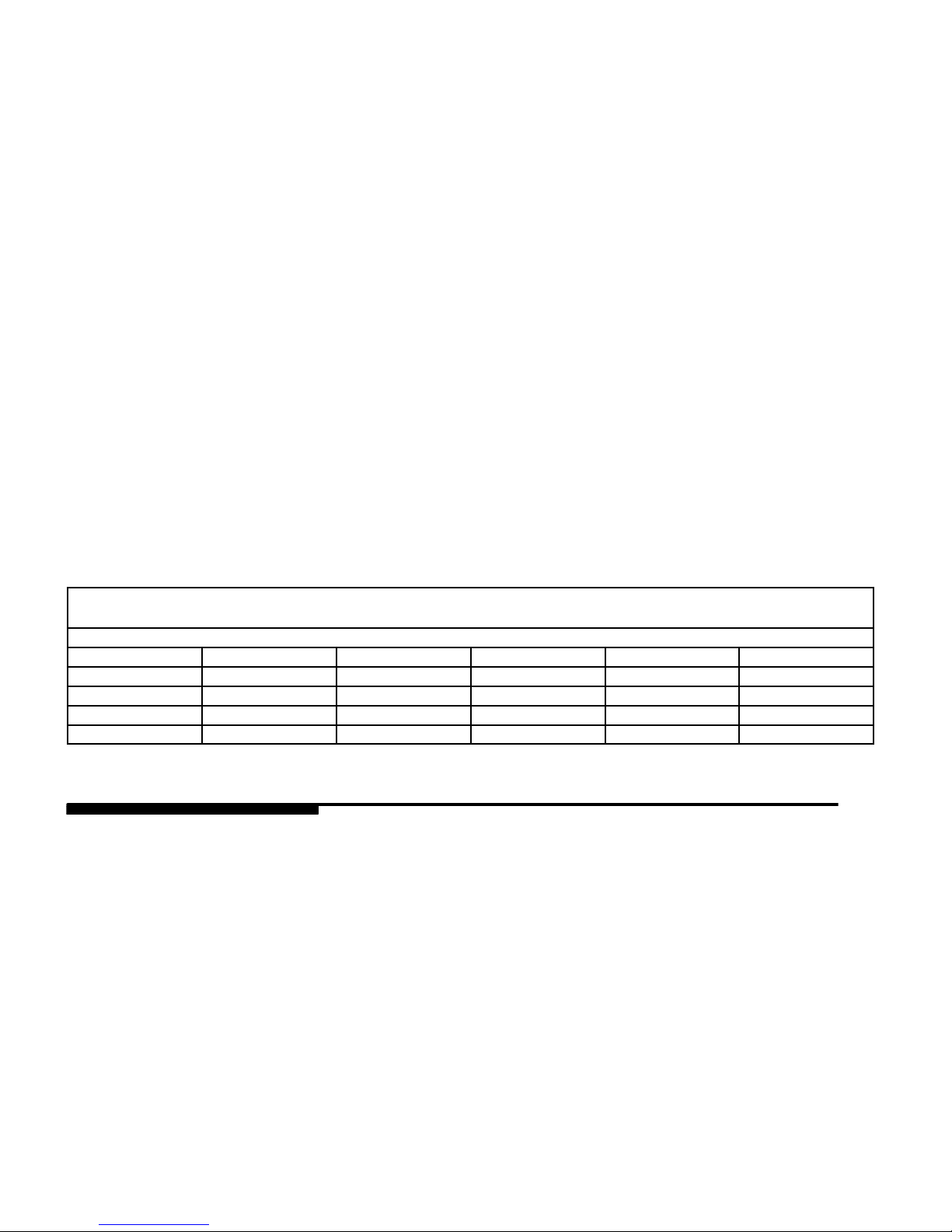

Table 1. Specifications

Compressor: HP 1/2

Refrigerant: R-22 1 lb.

Pressure Controls Setting: High: 400 Psig Low: 10 Psig

Voltage: 115 / 1 / 60

Amps: 16 Amps

Circuit Ampacity: 20 Amps

Fuse Size: 20 Amps

Ice Storage Capacity: 35 lbs.

Ice Making Capacity: Up to 350 lbs./24 hours

Shipping Weight: 170 lbs.

Ice Making Capacity Per 24 hr / lb at Given Conditions

Table 2. Icemaker Capacities (lbs./day)

Water Temperature °F

AIR TEMP. ° F 40 50 60 70 80

60 391 372 355 342 318

70 356 334 321 310 301

80 316 303 295 281 270

90 290 267 259 241 241

UNPACKING

1. With the unit upright carefully remove the shipping carton. Inspect for shipping damage and report any

such damage to the shipper immediately.

2. Unscrew and remove the top cover of the unit.

3. Remove shipping tape from storage hopper and agitator in storage hopper .

291626

Page 6

INSTALLATION

LOCATION

Locate the icemaker dispenser indoors in a well ventilated area. Avoid exposure to direct sunlight and/or heat

caused by radiation. Ambient room temperature must be in the range of 60° to 90° F. Do not install unit in an

enclosed area where heat build-up could be a problem. Note: Air flow direction and spacing required to Figure 1.

Consult Figure 1A and 1B for utility connection locations.

Consult Figure 2 for dimensions for mounting unit to the counter with the hardware provided. Note that the unit

must be level for proper operation.

The unit must be sealed

cut in the counter. Locate the desired position for the unit then mark the outline dimensions and cut-out locations using the template drawing cut openings in counter.

Apply a continuous bead of NSF listed silastic sealant (DOW 732 or equal) approximately 1/4”inside of the unit

outline dimensions, and around all openings. Then position the eater of the counter within the outline dimensions. All excess sealant must be wiped away immediately.

to the counter. The template drawing (Figure 2) indicates the openings which must be

PLUMBING

Connect the icemaker to a cold, potable water source, suitable for drinking. This water source must comply with

the basic plumbing code of the Building Officials and Code Administrators International Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and Drug Administration. Do not install unit on a water softener

line. It is recommended that a hand shut-off valve and strainer be used on the incoming supply line. (See Figure

2 for size and location.) For proper operation of the incoming water supply pressure must be in the range of

30-90 PSIG. Install a pressure regulating valve if above this range!

IMPORTANT: To insure proper icemaker operation and also to reduce the frequency of water-related

service problems, a water filter should be installed. REMCOR recommends the use of one of the

following basic systems.

1. Everpure inc.

660 N. Blackhawk drive

Westmont, IL 60559

(708) 654-4000

2. System IV

16632 Burke Lane

Huntington Beach, CA 92647

Insurice Twin System

For specific recommendations on these filter systems for your local water conditions, consult with a distributor in

your area or contact the filter manufacturer.

Connect separate drain lines to all drain connections. See Figure 2 for size and location. These lines must pitch

downward to and open drain and must contain no traps, or improper drainage will result. Separate, not joined

drain lines are required to prevent back flow.

NOTE: In areas where consistently warm water temperatures are encountered, the use of a pre-cooler

in the water line is recommended to maximize the ice production of this unit.

#9320-42

ELECTRICAL

Thisunitissuppliedwitha2wire-withground 6 foot long conductor and suitable plug for a standard 115 volt 20

amp circuit receptacle. This cord exits the unit through the base and should be routed per the National Electric

Code.

WARNING: Only qualified personnel should service internal components or electrical

wiring.

Basic Water System

3

#B1000

91626

Page 7

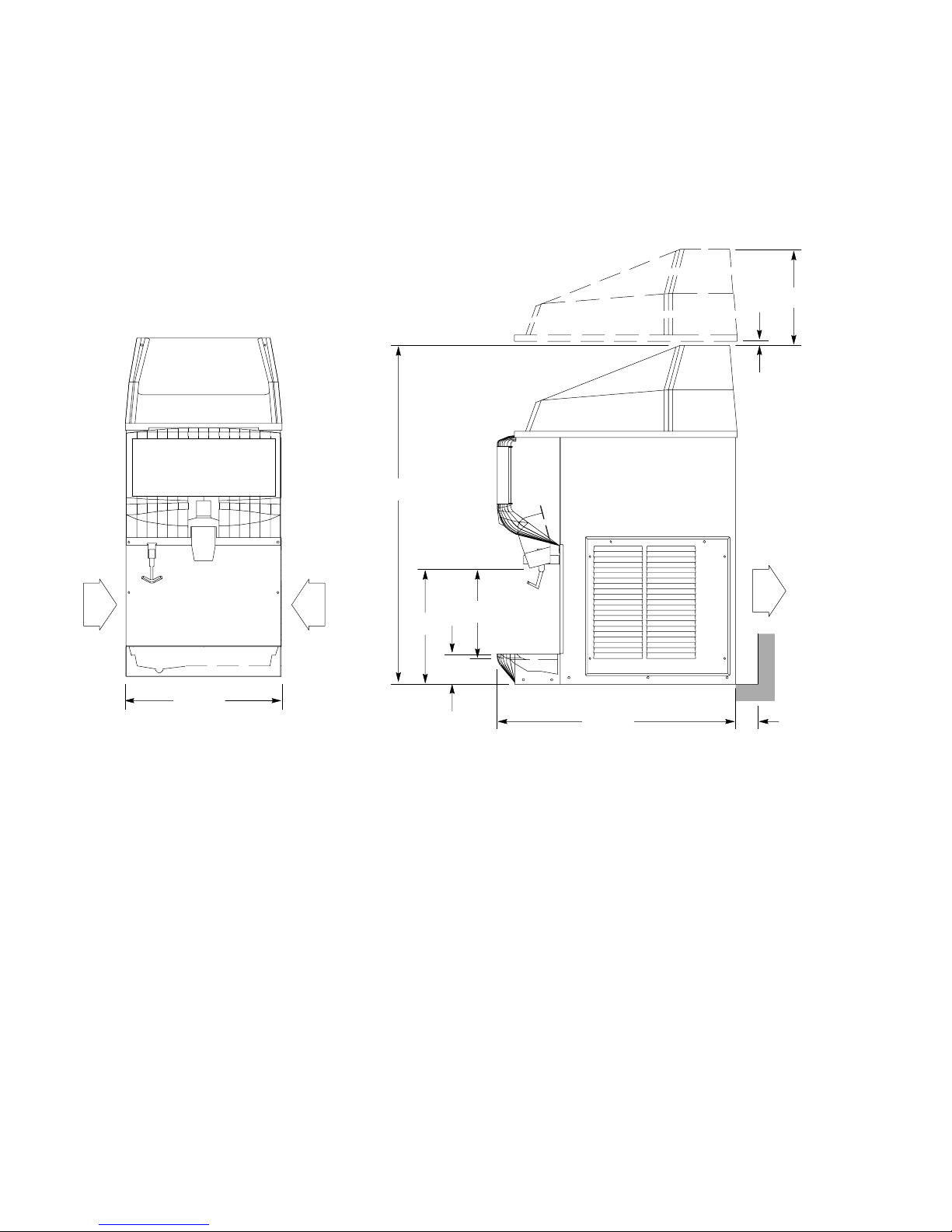

AIR

FLO

W

18.188

AIR

FLO

W

39.625

13.500

3.500

10.625

27.875

11.500

.500

AIR

FLO

W

3-MIN

1. Minimum 3”clearance must be provided at the rear of unit. (air flow out)

2. Inlet air flow may only be restricted on one side. (at least one side must be

open for proper performance)

3. Minimum top clearance must be 11.500.

FIGURE 1. SID 350 / 35S

491626

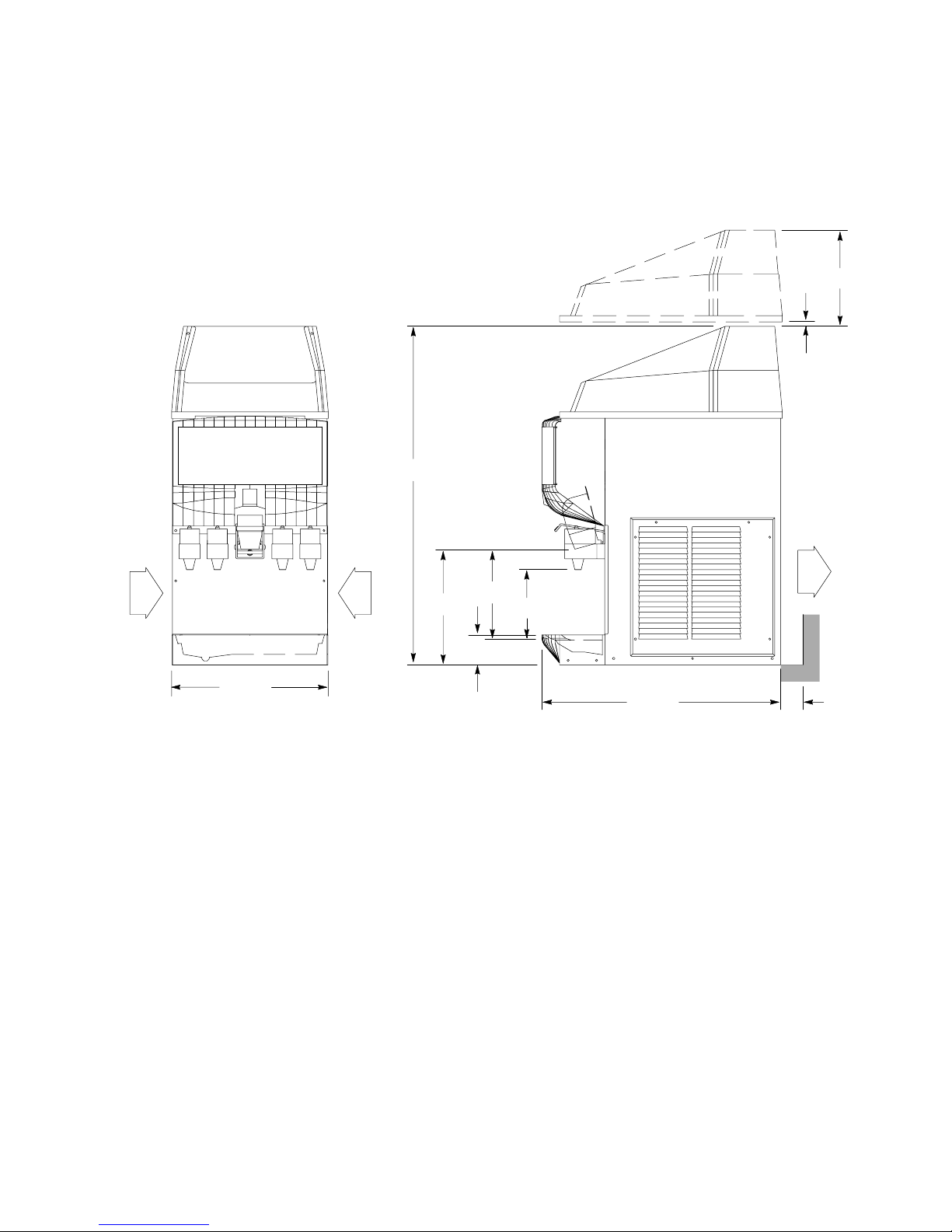

Page 8

AIR

FLO

W

18.188

AIR

FLO

W

39.625

13.500

10.625

3.500

8.250

27.875

11.500

.500

AIR

FLO

W

3-MIN

1. Minimum 3”clearance must be provided at the rear of unit. (air flow out)

2. Inlet air flow may only be restricted on one side. (at least one side must be

open for proper performance)

3. Minimum top clearance must be 11.500.

FIGURE 2. SID 350 / 35S-B

5 91626

Page 9

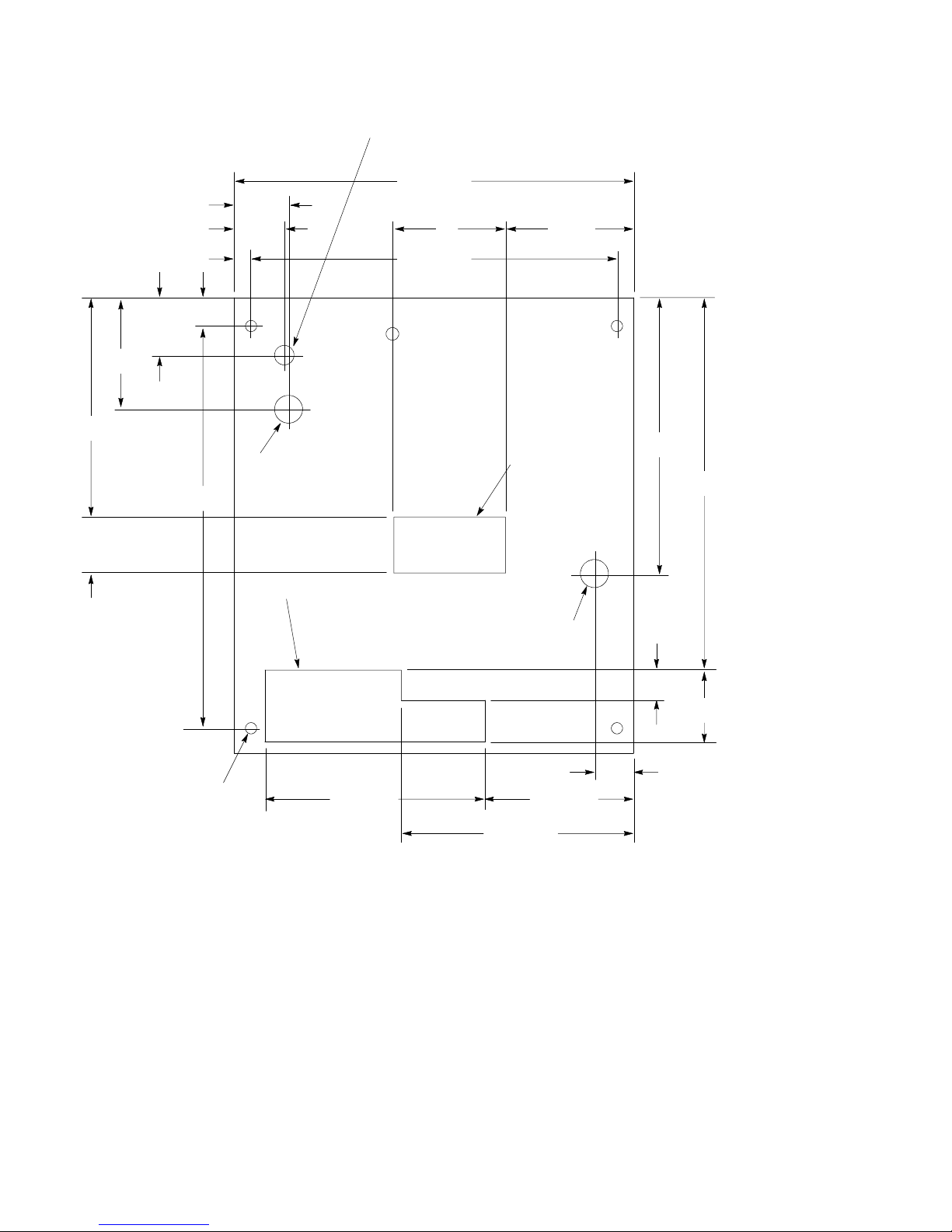

2 37/64

5

POWER CORD

1 5/8 MIN DIA.

CLEARANCE HOLE

17 29/32

27/16

21/4

5 53/4

3/4 16 13/32

1 17/64

9 27/32

18 1/32

21/2

3/8-16 THREADS (4) PLCS

FORLEGSORIFREQD.

1/2 DIA. HOLES IF

MOUNTED TO COUNTER

ICEMAKER WATER-IN

3/8 O.D. TUBE COMP

FITTING 1 1/4 DIA.

CLEARANCE HOLE

BEVERAGE TUBING CUTOUT

(FOR ”B”MODELS ONLY)

*SINK DRAIN AND

DRAIN COLLECTOR

OPENING

WATER COOLED CONDENSER

INLET 3/8 O.D. COMP. FITTING.

1 1/4-IN DIA. CLEARANCE HOLE

6 43/649 55/64

10 13/32

12 3/8

16 11/16

1 23/64

3 15/64

13/4

*NOTE:

DRAIN COLLECTOR REQUIRES

1-IN BARBBY MPT;

1-IN I.D. PLASTIC TUBING

FIGURE 3. MOUNTING TEMPLATE SID 350A/35, SID 350W/35, SID 350A/35S-B, SID 350W / 35S-B

691626

Page 10

BEVERAGE SYSTEM

“B”models contain beverage faucets only and must be supplied with cold product from any remote cold plate or

refrigerated soda factory.

Installation

1. Locate the required openings in the counter top for the beverage lines as shown in Figure 2.

2. Carefully pull the beverage tubes through the bottom opening in the unit and through the clearance opening

in the counter.

3. Connect the beverage system product lines as indicated in Figure 3. This work should be done by a qualified service person. Note that the hoses are marked with numbers 1 - 4 for syrup connections and “CW”for

carbonated water connection.

START UP

1. Remove front and side service panels and connect the water supply to the water valve.

2. Turn on water to icemaker. Depress fill switch to fill evaporator with water before starting unit.

3. Put the stop/rum switch in the “run”position. Observe that the icemaker goes through proper icemaking

and harvest cycle. If unit malfunctions, consult troubleshooting section.

NOTE: Do to meltage loss because of warm storage hopper, it will take longer to fill the hopper the

first time than when the icemaker has been operating continuously.

4. Depress the vend switch. Check that both the gate solenoid and agitator motor are energized simultaneously to lift the gas slid and rotate the agitator in the storage hopper, respectively. If either component

malfunctions, consult the troubleshooting section.

5. For beverage units, start up the beverage system and adjust the faucets to the proper brix. Contact your

local syrup distributor for complete information on the beverage system.

6. The bin thermostat is calibrated at an atmospheric pressure equivalent at 500 feet above sea level. For

locations at higher elevations, it may be necessary to re-adjust these controls. Consult the maintenance /

adjustment procedures section.

7 91626

Page 11

O

PTIONALFO

RDIET

R

EGULATORS

TANK

2

CO

WATER

SUPPLY

REGULATOR

FILTER

OPTIONAL PRESSURE

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC “-B” MODELS

CARBONATOR

SYRUP TANKS

S1 S2 S3 S4

15-50 PSIG

60-100 PSIG

VALVE

DOUBLE CHECK

5-15 PSIG

OR ROOT BEER

COLD PLATE OR

REFRIGERATED ICE BANK

91626

1

2

3

4

CW

CW

INCLUDED WITH UNIT

ITEMS OUTSIDE OF BROKEN LINES NOT

REMCOR ”B”ICE/BEVERAGE DISPENSER

8

Page 12

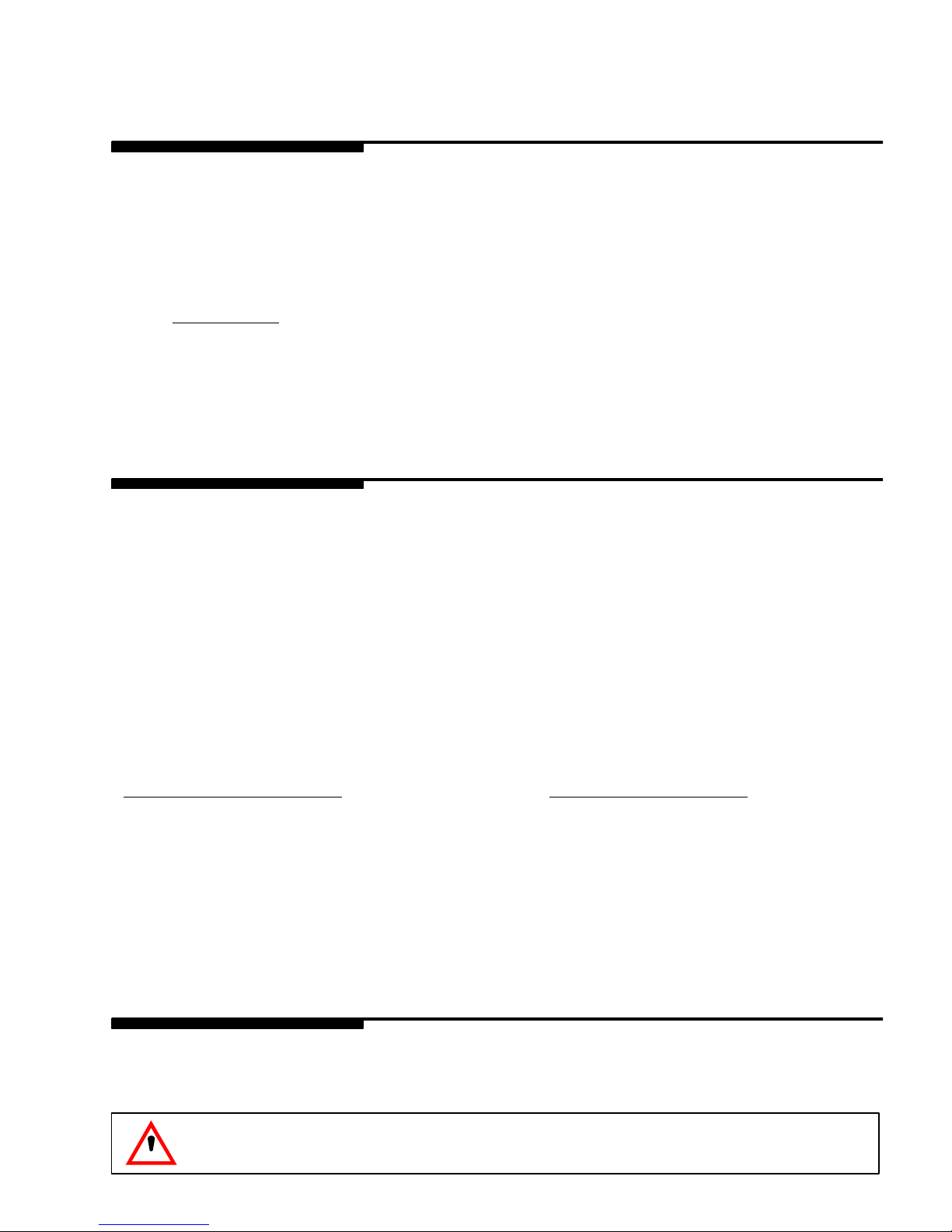

OPERATING INSTRUCTIONS

A temperature sensing control bulb, located in the storage hopper, starts and stop the icemaking process (compressor) in response to the ice level in the hopper. With this ice level control “calling”for ice (hopper ice level is

low), the total cycle timer is energized. This timer, in turn, energizes the harvest timer for its’respective “on”

times. The chart below details this sequence of events.

Table 3. CONTROLLER

TOTAL

TIME

Start - 35 seconds X 1. Hot gas solenoid valve open.

35 - 570 seconds

35 - 65 seconds X 1. Harvest motor one.

65 - 570 seconds (air-cooled)

65 - 510 seconds (water-cooled)

35 - 570 seconds (air-cooled)

35 - 510 seconds (water-cooled)

CYCLE TIME

X 1. Hot gas solenoid valve closed.

HARVEST TIME ACTION

2. Water fill valve on.

3. Agitator motor on.

X 1. Harvest motor and agitator

motors off.

2. Water fill valve off.

At the 35 second point in the cycle, the host gas solenoid valve closes and ice begins to form on the stainless

steel tubing coils of the evaporator. Ice will continue to form on these coils for the remainder of the cycle time.

At the end of the icemaking cycle, the total cycle timer (repeat starts sht harvest portion of the cycle again.

When ice contacts the control bulb in the storage hopper, the control switches the compressor off. This control

(thermostat) also switches off power to the total cycle timer. With power de-energized, the timer resets itself to

the “start”portion of the cycle. Therefore, the unit will always start with the hot gas/harvest portion of the ice

making cycle to ensure that the evaporator is cleared of any remaining ice.

991626

Page 13

L

STOP/

RUN

8

HPS

TOTAL CYCLE

ADJUSTMENT

1

NC

LPS

BIN T’STAT

1

START

RELAY

2

CONDENSER FAN

(AIR--COOLED)

TP

COMPRESSOR

C

R

S

START CAP

N

REPEAT

CYCLE

TIMER

(RCT)

INTERVAL

TIMER

(IT)

C

C

HARVEST

ADJUSTMENT

NO

NC

NC

8

NO

NO

NO

NC

C

C

1

VEND SWITCH

RUN

CLEAN

NO

NC

FILL

SWITCH

C

CAP

WATER FILL VALVE

F

AIR PUMP

HG SOL VALVE

HARVEST MOTOR

RED

BLUE

AGITATORMOTOR

BLUE

RED

GATE SOLENOID

BALLAST

LIGHTED DISPLAY OPTION

FIGURE 5. SID 350/35 115/1/ 60 HZ SCHEMATIC

LAMP

STARTER

10 91626

Page 14

RED

RED

WHT

RED

BLUE

HARVESTMOTOR

ORG

1

BIN

3

T”STAT

2

RUN

STOP

CLEAN

RUN

NC NO

20A

6A

B

L

U

E

B

R

N

C

BLK

BLK

BLK

PINK

PUR

YEL

BLK

B

L

K

G

W

B

H

R

L

T

N

K

WHT

L2

L1

BLK

WHT

W

H

T

W

H

T

NEUTRAL/WHITE

RED

RED

W

W

W

H

H

H

T

T

T

WHT

W

H

T

ORG

CNONC

L2

L1

RED

P

U

R

NCNOC

R

E

D

CNONC

PUR

BLK

115 V

20 A

WHT

NCNOC

P

U

R

W

H

PUR

BLUE

YEL

T

P

U

R

R

E

D

W

H

T

W

H

T

YEL

PUR

ORG

BLK

YEL

BRN

WHT

RED

GRN

HIGH PRESSURE

SAFETY CONTROL

WHT

RED

BLUE

WHT

WHT

BLK

RED

C

VEND

SWITCH

YEL

WHT

WHT

RED

C2

3S

R

RED

RED

HG SOLVALVE

NC

NO

BLK

BLK

GRN

AIR PUMP

GATE

SOLENOID

RED

1

YEL

WHT

WA TERFILL

VALV E

BLUE

YEL

BLK

RED

LOW PRESSURE

SAFETY CONTROL

WHT

COMPRESSOR ELECTRICBOX

S

C

R

RED

COMPRESSOR

MOTOR

BLUE

BALLAST

AGITA TOR

MOTOR

LPS

START

RELAY

RED

LIGHTED DISPLAY

BLUE

BLUE

LAMP

STARTER

COND.FAN

CF

AIR COOLED

COMPRESSOR

STARTCAP.

MOTOR

FIGURE 6. SID 350/35 115/1/60 HZ WIRING

1191626

Page 15

LOW PRESSURE

SERVICE PORT

PRESSURE

CONTROL

COMPRESSOR

TXV BULB

LOW

HIGH SIDE

SERVICE

PORT

TXV PRESSURE

TAP

HIGH

PRESSURE

CONTROL

HOT GAS

SOLENOID

VALVE

AIR--COOLED MODELS

A

CONDENSER

CONDENSER

FAN

B

FILTER/DRIER

EVAPORATOR

EXPANSION

VALVE(TXV)

SUCTION

ACCUMULATOR

WATER- -COOLED MODELS

PRESSURE

REGULATING

VALVE

A

B

CITY

WATER

DRAIN

FIGURE 7. REFRIGERATION SCHEMATIC

12 91626

Page 16

MAINTENANCE

It is recommended that the air cooled condenser be cleaned every 3 months or sooner depending on the operating environment for proper refrigeration system performance, Check that this condenser is free of dirt/foreign

material that could cause air flow blockage.

cleaning of the icemaker is recommended on a regular basis not only for sanitary reasons but also to maintain

the performance of the unit. Build-up of lime and scale can hinder icemaking production rates and interfere with

proper dispensing of the ice. See the cleaning section for the recommended procedure.

Periodically, check the vending area sink for proper water drainage. Remove any foreign material from the sink

to prevent drain blockage.

CLEANING INSTRUCTIONS

IMPORTANT: The icemaker should be cleaned at a minimum of 3 month intervals or more frequently

depending on local water conditions. The storage hopper interior should be cleaned at

least once a

WARNING: Do no use metal scrapers, sharp objects or abrasives on the surface of the

storage hopper, as damage may result. Do not use solvents or other cleaning agents as

they may attack the plastic surface. Use only the recommended chemicals and solutions

for both the icemaker and hopper

month.

Icemaker Section

1. Remove top cover, lower front panel and right side access panel.

2. Put toe stop/run switch in the “stop”position at the end of the harvest cycle. An alternate method would be

to stop the unit during the icemaking cycle and allow ice in the evaporator to melt by waiting for at least 1

hour before beginning the cleaning procedure. The flush switch can be depressed to bring in warmer water

to help the melting process.

WARNING: Electrical power is on to unit during icemaker cleaning mode. To avoid

possible injury, do not reach into hopper or into icemaker nozzle. Do not contact exposed

electrical wiring and components.

3. Plug icemaker drain line located in the drain collector at condenser fan motor. (1-1/4 OD hose).

4. Fill icemaker drain hose with water by pushing fill switch.

5. Add 4 oz. of Virginia Ice Machine Cleaner (or equivalent) through the evaporator outlet.

WARNING: Virginia Ice Machine Cleaner (or equivalent is a mild acid. Normal care should

be taken - keep out of eyes and cuts.

operate unit in the cleaning mode without the ice drop cover in place. There may be some

overflow of cleaning solution through the evaporator vent tube during the cleaning cycle.

Read warnings on package before using. Do not

6. Seal the evaporator outlet with plastic lug provided with the unit.

7. Push fill switch and fill evaporator (when fluid flows out of evaporator through vent tube) let go of fill switch.

8. Put the clean/run switch in the “clean”position. Allow unit to run in the cleaning mode for at least 30 minutes.

1391626

Page 17

9. Open drain line. To avoid splash, drain the drain line to a separate container.

10. Push fill switch and hold for 6 minutes to flush solution out of evaporator. Drain line should be in the drain

collector.

11. Plug drain line.

12. Push fill switch and hold for 1 minute to flush solution out of vent line

13. Open drain line. Put clean/run switch in the “run”position. Remove plug from evaporator.

14. Put the stop/run switch in the “run”position and allow unit to run through at least 3 complete icemaking and

harvest cycles, and until ice is free of “sweet”taste.

CAUTION: If unit fails to harvest, put the stop/run switch in the “stop”position and flush

the evaporator with hot water to melt remaining ice and repeat steps 10, 11, 12 and 13 to

clean out remaining solution.

15. Dispense all ice out of storage hopper and discard.

Dispenser Section

1. turn off main electrical power supply to machine.

2. Remove agitator assembly from storage hoper and wash and rinse it thoroughly.

3. Wash down all inside surfaces of the ice storage area including the top cover with a mild

and rinse

4. Replace agitator.

5. Sanitize the inside of the hopper and agitator with a solution of 1 ounce of household bleach in 2 gallons of

water. (200 PPM)

6. Replace the agitator disk. Sanitize as described in Step 5.

7. Remove Ice Chute cover as follows:

A. Flex sides outward to disengage lower pins.

B. Lift Ice Chute cover to disengage upper pins.

C. Lower Ice Chute cover down out of unit. Note: it may be helpful to twist cover slightly.

8. With brush provided clean the inside of the ice chute with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

9. Reverse steps above to reassemble ice chute.

10. Sanitize as described in Step 5.

thoroughly to remove all traces of detergent.

detergent solution

11. Turn on the electrical power supply. The icemaker is ready for normal operation.

BEVERAGE SYSTEM

1. Remove faucet spouts, wash in mild detergent, rinse and replace.

2. Disconnect electrical power to the carbonator. Shut off the water supply and close the CO

carbonator.

regulator to the

2

14 91626

Page 18

3. Disconnect the syrup tanks from the system.

4. Energize the beverage faucets to purge the remaining soda in the system.

5. Use a clean 5 gallon tank for each of the following.

A. Cleaning tank

B. Sanitation Tank

- fill with hot (120° - 140°) potable water.

- Fill with a chlorine sanitizing solution in the strength of 1/2 ounce of household

bleach (sodium hypochlorite) to 1 gallon of cold (ambient) potable water (200 PPM).

6. Repeat the following procedure on each of the units’syrup product lines:

A. Connect the cleaning tank to the syrup line to be sanitized and to the CO

system.

2

B. Energize the beverage faucet until the liquid dispensed is free of any syrup.

C. Disconnect the cleaning tank and hook-up the sanitizing tank to the syrup line and CO

system.

2

D. Energize the beverage faucet until the chlorine sanitizing solution is dispensed through the faucet.

Flush at least 2 cups of liquid to insure that the sanitizing solution has filled the entire length of the

syrup lines. Allow sanitizing solution to remain in product line for 15 minutes before processing.

E. Disconnect the sanitizing tank. Hook-up the product tank to the syrup line and to the CO

system.

2

F. Energize the faucet to flush the sanitizing solution from the syrup line and faucet. Continue to draw on

the faucet until only syrup is dispensed.

7. Repeat Step 2 in reverse order to turn on the carbonator. Dispense at lease 1 cup of beverage from each

faucet. Check taste. Continue to flush if needed, to obtain a satisfactory tasting drink.

1591626

Page 19

MAINTENANCE AND ADJUSTMENTS

THERMOSTAT ALTITUDE ADJUSTMENT

Bin Stat

IMPORTANT: Adjust the bin t’stat setting only if storage hopper overfill is a problem.

1. Remove the top plastic cover .

2. The adjustment screw is located at the right upper rear corner of the unit behind the hopper-evaporator

partition.

3. For altitudes up to 6000 ft., turn the adjustment screw COUNTERCLOCKWISE as follows:

ELEVATION (FT.) CCW TURN

2000 1/13

4000 1/6

6000 1/4

4. For altitudes above 6000 ft., consult the factory.

ICE PRODUCTION ADJUSTMENT

1. Remove the top cover and lower front panel.

2. Collect and weigh the ice produced during the harvest cycle. The amount of ice harvested should be 1.9 to

2.1 pounds.

A. Put the stop/run switch in the “stop”position. (if the unit is in the icemaking cycle, stop the unit at the

end of the harvest cycle.

3. If ice weight is not in the 1.9 to 2.1 pound range, make adjustments by adding or subtracting time to the

total cycle time. More time = more ice.

4. Return unit to normal icemaking mode and repeat steps 2 and 3 until proper amount of ice delivered per

cycle.

CLEARING EVAPORATOR FREEZE-UP

WARNING: To prevent possible injury, do not stick fingers or hand into icemaker nozzle or

hopper with power applied to unit.

1. Remove four (4) screws and remove the hopper cover.

2. Put the stop/run switch in the “stop”position.

3. Close the water supply valve to the icemaker.

4. Drain evaporator by disconnecting the water inlet tube at the bottom of the evaporator, when empty reconnect water inlet.

1691626

Page 20

5. Pour hot water into the evaporator ice exit opening. it will be necessary to use either a funnel or a container

with a spout. Fill the evaporator completely.

6. Drain the evaporator. Repeat steps 5 and 6 as required to insure that all of the ice in the evaporator is

melted.

7. Open the water supply valve and refill evaporator.

8. Consult the toubleshooting guide to determine cause of freeze-up before putting unit back in service.

SERVICE PROCEDURES

High Pressure Control

The high pressure control is factory set at 400 PSIG. To check the setting, install a refrigeration discharge pressure gauge on the service port located on the compressor discharge line. Remove the front and right side panels to access this port and high pressure control. Disconnect the electrical power to the condenser fan motor

leads in the control box. Run the icemaker to determine the control cut-out point. Adjust if necessary . this control is manual reset type; the reset lever is located behind the low pressure control next to the electric box on

top of the high pressure control. Push in to reset. If the icemaker will not run after the control has been reset

(with the refrigerant pressure less than 350 PSIG), replace the control. The adjustment screw is located on the

top of the control.

Bin Thermostat

1. The bin thermostat is located in the upper right rear corner of the unit under the cabinet flange.

2. To adjust the thermostat, remove the top plastic cover from the unit. The adjustment screw is located on

the top of the bin t’stat and is accessible through the hole in the cabinet flange. The factory setting is 35°F

cut-out/41°F cut-in. Before adjusting, check that the adjustment screw is turned clockwise to the stop

position (CCW adjustment will raise the cut-out/cut-in temperatures).

WARNING: Electrical power is on for the service procedure in item 3. Avoid contact with

uninsulated parts in the control box.

3. The thermostat sensing bulb is located in the ice storage hopper on the upper left side wall. With the adjustment screw in the full cold position and no ice contacting the sensing bulb, check that the thermostat is

closed (terminals 1 and 2). With ice contacting the t’stat bulb, terminals 1 and 2 should be open to perform

this check, use a voltmeter connected between t’stat #2 and neutral to determine the correct operation.

4. To replace a defective thermostat, disconnect electrical power to the unit. Remove the sensing bulb from

the storage hopper (2 thumbscrews). Remove the t’stat from under the flange (2 screws) by disconnecting

the two electrical leads. Install the new control, being careful not to kink the capillary tubing (sensing bulb)

when routing it to the storage hopper.

17 91626

Page 21

Condenser (air cooled)

The condenser should only have to be replaced if it has been physically damaged to the point that repair is not

practical. Use a fine comb to straighten bent/pushed-in areas. If replacement if necessary, the following equipment is required: vacuum pump, refrigeration manifold with gauges, brazing equipment and various hand tools.

The replacement procedure has two steps: CABINET REMOVAL and CONDENSER REPLACEMENT.

Cabinet

1. Remove ice from the hopper and all panels and plastic parts.

2. Disconnect electrical power to the unit.

3. Release refrigerant charge from the system through ports into an appropriate container/reclaim system.

4. Disconnect harness from gate solenoid (upper front) and dispenser push button switch.

5. Disconnect harness from the bin t’stat and air pump. Make sure that the harness is not secure to the cabi-

6. Remove clear hoses from the discharge and suction of the air pump.

7. Remove the pins from behind the front cabinet flanges at the sink.

8. Remove sink.

9. Remove bracket mounting evaporator assembly to the cabinet.

10. Loosen two (2) 1/4 x 20 hex head screws securing the evaporator mounting bracket to the base. Tilt evapo-

11. Remove partition (4 screws).

Removal

net.

rator assembly towards the back to remove the evaporator ice chute from the hopper partition.

12. Remove screw securing cabinet to the base.

13. Lift the cabinet.

Condenser Replacement

1. Remove screws mounting condenser shroud from the base and condenser.

2. Remove screws mounting condenser to the base.

3. Unbraze refrigerant lines from inlet and outlet of condenser.

4. Replace condenser.

5. It is also recommended to replace the filter drier.

6. After brazing, perform leak test of the new brazing joints.

7. Evacuate the system.

8. Charge the system to the name plate specification (1 lb. of r-22).

9. Install cabinet - Use reverse order of step 1.

10. Run the icemaker and check operation pressure in relation to the ambient temperature.

(air-cooled)

11. Install sink, panels and plastic parts.

1891626

Page 22

Cleaning the Condenser (air cooled)

1. Disconnect power to the unit.

2. Remove the right side and rear panels.

3. Remove all dirt/foreign matter build-upfrom the condenser fins (fan side). Be careful not to damage the

fins. It is recommended that a power vacuum cleaner with a “crevice”tool attachment be used.

Condenser Fan

Motor

WARNING: Electrical power is no to the unit fro the following procedure.

1. To check for a defective fan motor, remove the right and front panels.

2. Put the “stop/run”switch in the “stop”position. Verify that the fan blade is free to turn.

3. Put the “stop/run”switch in the “run”position. Refer to the wiring diagram for the following check (a voltmeter is required):

A. Verify that the high pressure safety control (HPS) is closed and the unit is “calling”for ice (no ice on

the bin t’stat sensing bulb in hopper).

CAUTION: The fan motor is connected in parallel to the compressor.

4. To replace the fan motor, disconnect the electrical power to the unit. Disconnect the electrical leads in the

compressor electric box. Remove the four (4) mounting screws securing the fan motor bracket to the condensing unit assembly base. Remove the complete motor/bracket/fan blade assembly from the unit for

ease of the motor replacement.

Expansion Valve

TXV

1. To check the TXV, hook-up a refrigeration suction pressure gauge to the appropriate access port.

2. While the icemaker is running, observe the gauge pressure. The nominal suction pressure range during the

icemaking cycle is 17 - 35 PSIG. The low pressure safety control LPS “trips”at 10 PSIG. The txv is operating properly if the suction pressure drop no lower than 16 PSIG.

TXV

3. To replace the TXV, the following items are required: vacuum pump, refrigeration manifold with gauges,

charging cylinder and various hand tools (wrenches, screwdrivers, etc). The Procedure is as follows.

A. Disconnect the electrical power from the unit.

B. Release refrigerant charge from system.

C. Remove insulation from TXV and sensing bulb.

D. Disconnect TXV from system (3 flare nut connections) and remove bulb from clamps on suction line.

E. Install replacement valve being careful to completely insulate TXV and bulb/suction line area.

F. Evacuate and recharge the system to name plate specifications.

19 91626

Page 23

Expansion Valve TXV (Cont’d)

4. Observe that the unit functions normally in both the icemaking and harvest cycle; specifically that suction

and discharge pressures are in the range of 37-17 PSIG and 200-280 PSIG.

water fill

valve

The water fill valve is located on the condensing unit assembly base, behind the compressor. To check for proper operation, put the “stop/run”switch in the “stop”position. Depress the fill switch and hold. Water should overflow out the evaporator and to the overflow tube and collector drain. If water doesn’t flow out the evaporator and

to the overflow tube and collector drain. If water doesn’t overflow and the water supply has been checked, then

the fill valve is defective.

To replace the fill valve:

1. Disconnect electrical power to the unit.

2. Disconnect the electrical wires from the solenoid.

3. Remove the water outlet line from the valve.

4. Remove the two (2) screws securing the valve to the condensing unit assembly base. Remove the valve.

5. With the valve “free”, remove the inlet fitting assembly (garden hose).

6. Install the inlet fitting assembly on the new valve. Repeat the above procedure in the reverse order to complete installation of the fill valve.

Compressor

The compressor can exhibit basically two types of malfunctions. It will run but the refrigeration system produces

little or no ice. In this case, check the suction and discharge pressures. A high suction pressure (greater than

the normal range of 17-35 PSIG) and low discharge pressure (less than the norma range of 200-280 PSIG) indicates an internal valve problem and loss if compression. The second type of failure is characterized b y the fact

that the compressor will not run but there is voltage at the terminals. The cause is a defective motor (check for

open or grounded windings).

In the case where the compressor is not operating, the electrical system can be checked as follows (a VOM

type instrument is required):

1. Remove the front panel and the compressor electric box cover.

2. Put the “stop/run”switch in the “run”position.

3. Verify that there is voltage at the compressor.

4. Disconnect electrical power to the unit.

5. disconnect wires so that continuity can be checked on the compressor electrical components.

6. Check continuity across the following:

A. Relay coil: If there is none, replace relay.

B. Compressor C & S - no continuity - replace compressor (open start winding).

C. Compressor C & R - no continuity - replace compressor (open run winding).

D. Start capacitor terminals

a. VOM on RX1 scale - continuity replace capacitor (shorted).

2091626

Page 24

b. VOM on RX100,000 scale - no continuity - replace capacitor (open).

E. Overload (TP) 1 & 3 - no continuity - replace TP (open).

F. Compressor C & shell - continuity replace compressor (grounded motor).

G. Check the continuity of the wires removed and reconnect to the proper terminals.

H. If all of the above tests prove satisfactory and compressor still fails to operate properly, change the

start relay as the new relay will eliminate and faulty electrical characteristics, such as improper pick-up

or drop-out which cannot be determined by the above tests. If the new relay fails to correct the difficul-

ty, the compressor shall be considered to be inoperative because of internal defects and must be re-

placed.

To replace the compressor, the following items are needed: vacuum pump, refrigeration manifold with gauges,

charging cylinder, brazing equipment and various hand tools. The procedure is as follows:

1. Disconnect electrical power to the unit and remove wires from the compressor terminals.

2. Release refrigerant charge from the system.

3. Unbraze discharge (next to service port) and suction lines.

4. remove mounting bolts (4) and hardware from old compressor.

5. Install new compressor following the above steps in reverse order.

6. Evacuate and recharge system to nameplate specifications.

7. Run icemaker and perform the following items:

A. Check that suction/discharge pressures are in the normal operating ranges. Nominal discharge pres-

sure 300 PSIG and suction pressure 17-35 PSIG at 70° F ambient air temperature and 50°F water

temperature.

B. Check ice production capacity (see ice thickness adjustment section for procedure).

Hot Gas Valve

(HGV)

There are three situations to monitor for determining the proper functioning of the HGV. Install suction and discharge pressure gauges on the access ports removing the front, left and right side panels. First, observe the

suction/discharge pressures during the icemaking cycle. the suction pressure (greater than 40 PSIG) range and

a low discharge pressure (less than 115 PSIG) indicate a leaking valve set problem and the HGV must be replaced. Secondly, observe the suction pressure during the hot gas portion of the harvest cycle. The minimum

suction pressure is 70 PSIG; pressures less then this indicate the HGV is not operating properly and must be

replaced. The third situation to analyze is the valve coil. If there is voltage but and audible “click”is not heard at

the valve, replace the HGV (defective coil - valve not opening). /The minimum suction pressure would also not

be attained in this third case.

To replace the HGV, the following equipment is needed: vacuum pump, refrigeration manifold with gauges,

charging cylinder, brazing equipment and various hand tools.

The replacement procedure is as follows:

1. Disconnect electrical power to the unit and the leads to the valve.

2. Release the refrigerant charge from the system.

3. Unbraze the line connections at the valve. Remove the nut that attaches the valve to the mounting bracket.

4. Install new valve.

5. Evacuate and recharge system to name plate specifications.

21 91626

Page 25

Cycle Timers

The following procedure is to check for the proper functioning of the cycle timers. (A voltmeter is required):

WARNING: Electrical power is on to the unit for this procedure. Avoid the contact with

uninsulated parts in the electrical control box.

1. Remove the lower front panel and the electrical control box cover.

2. Put the “stop/run”switch in the “stop”position. Allow system pressures to equalize before proceeding.

3. Put the “stop/run”switch in the “run”position. The repeat cycle time (RCT) should immediately start the hot

gas cycle (approx. 35 seconds).

A. If the hot gas valve is not energized, check for voltage between neutral (white on terminal board) and

the “NO”terminal (blue wire) of the RCT. If there is voltage, check the hot gas valve. If there is no voltage, replace timer.

4. After completion of the hot gas cycle, check for voltage at the “NC”terminals if the RCT and neutral. If

there is no voltage at either or both of these terminals, the timer is defective.

5. If voltage is found in step 4, then check for voltage at the “NO”terminals of the interval timer (IT) and neutral. If there is no voltage at either or both of these terminals, the timer is defective.

A. The timing range for the interval timer is normally set for 25 to 30 seconds. If voltage is found in step

5, then check the water fill valve, harvest motor and/or agitator motor, depending on which event is not

occurring.

6. Upon completion of the events in step 5A, check for voltage at the “NC”terminals of the interval timer. If

there is no voltage at either or both of these terminals, the timer is defective.

7. At the completion of the icemaking cycle (8 to 9 minutes), the repeat cycle timer should again initiate the

hot gas event. T o determine proper timer function, perform the voltage check of step 3A.

2291626

Page 26

TROUBLESHOOTING GUIDE

The following pages contain troubleshooting charts designed to aid and experienced service person in diagnosing any operating problems which may be experienced. It is assumed that normal service techniques and skill

are familiarly to the person doing the trouble shooting. In order to gain maximum benefit from these charts,

please note:

1. Start at the beginning of the chart and supply the appropriate answer to each question.

2. Dot not skip any section, unless instructed to do so. You might miss the solution to your

problem.

3. Evaluate the possible problem causes in the sequence in which they are presented. In general, they begin

with the most likely or easiest to check, and proceed to the less likely or more complicated.

4. If, after checking all indicated causes, the problem is not resolved, it is recommended that you retry a second time, carefully evaluating the symptoms and modifying your answers as necessary.

5. If you are unable to resolve a problem after several attempts, contact REMCOR customer service for assistance.

23 91626

Page 27

DOES

UNIT OPERATE

YES

IS ICEMAKER

O.K.

START

NO

NO

NO OPERATION OF

ANY COMPONENT

GO TO 1

ICEMAKER ABNORMAL.

DISPENSER AND BEVERAGE

WORK NORMALLY

GO TO 2

YES

IS

DISPENSER

O.K.

YES

IS

BEVERAGE

SYSTEM

O.K.?

NO

NO

DOES NOT DISPENSE.

ICEMAKER WORKS O.K.

GO TO 1

GO TO 3

PROBLEM WITH BEVERAGE

FAUCETS OR DRINK QUALITY.

GO TO 4

YES

DONE

2491626

Page 28

1. TOTALLYINOPERATIVE

YES

CHECK OR LOOSE CONNECTION

OR BROKEN WIRE INSIDE UNIT

IS LINE

NO

1. CHECK FOR SHORT CIRCUIT IN

WIRING INSIDE UNIT.

2. CHECK COMPONENTS FOR SHORT

CIRCUIT OR GROUNDED WIRING.

VOLTAGE

WITHIN ¦ 10% OF

NAMEPLATE

VOLTAGE?

YES

POWER

PRESENT AT

RECEPTACLE

YES

NO

IS

YES

CHECK FOR LOOSE CONNECTION

SUPPLY FUSE

BLOWN (OR C/B

TRIPPED)?

NO

OR BROKEN WIRE IN SUPPLY

WIRING TO UNIT.

IS

FUSE OR C/B

SIZE PROPER

IS

LINE VOLTAGE

HIGH OR

LOW

HIGH

INSTALL BUCKING TRANSFORMER

TO REDUCE LINE VOLTAGE.

1. REMOVE ALL OTHER EQUIPMENT

FROM ICEMAKER CIRCUIT

2. INSTALL NEW DEDICATED

CIRCUIT FOR ICEMAKER.

LOW

NO

REPLACE WITH CORRECT

SIZE DEVICE.

IS

YES

1. CHECK FOR LOOSE OR CORRODED

CONNECTION IN SUPPLY WIRING.

2. CHECK SUPPLY WIRING FOR UNDERSIZED WIRE, AND REPLACE.

3. INSTALL BOOSTING TRANSFORMER

TO RAISE LINE VOLTAGE.

OTHER EQUIP.

ON SAME

CIRCUIT

NO

25 91626

Page 29

2.A ICEMAKER INOPERATIVE

YES

1. CHECK THERMOSTAT ADJUSTMENT.

2. REPLACE BIN THERMOSTAT.

LEVEL NORMAL

IS

HOPPER

FULL?

NO

NORMAL SHUTOFF ON

BIN THERMOSTAT.

IS

WATER

IN EVAP.?

“RUN”

YESYES

YES

“RUN/STOP”

SWITCH

?

IS BIN

THERMOSTAT

OPEN

IS LOW

PRESSURE

SWITCH

OPEN?

“STOP”

NO

NO

PUT SWITCH IN

“RUN”POSITION.

IS HIGH

PRESSURE

SWITCH

OPEN?

NO

CHECK FOR LOOSE CONNECTION

OR BROKEN WIRE.

1. CHECK THAT WATER SUPPLY IS OPEN.

2. CHECK WATER SUPPLY FILTER.

3. CHECK FOR PLUGGED WATER INLET VALVE.

4. CHECK FOR PROPER TIMING ON TIMERS, INCREASE IF LOW WATER LEVEL OBSERVED.

5. CHECK IF DRAINS ARE PLUGGED, KINKED,

OR ARE NOT PROPERLY PITCHED TO AN OPEN

TRAP.

1. CHECK FOR REFRIGERANT UNDERCHARGE.

2. CHECK TXV VALVE.

NO

AIR COOLED UNITS

1. CHECK FOR RESTRICTED AIR FLOW TO

AIR CONDENSER.

2. CHECK FOR HOT AIR RECIRCULATING TO AIR

CONDENSER. ELIMINATE BY BAFFLING.

3. CHECK FOR DIRTY AIR COOLED CONDENSER.

4. CHECK CONDENSER FAN MOTOR.

5. CHECK FOR REFRIGERANT OVER-CHARGE.

WATER COOLED UNITS

1. CHECK EATER SUPPLY TO CONDENSER.

2. CHECK FOR FAULTY WATER REGULATOR

VALVE.

3. CHECK FOR REFRIGERANT OVER-CHARGE.

4. CHECK FOR FOULED CONDENSER.

YES

2691626

Page 30

IS

THERMAL

PROTECTOR

OPEN?

YES

2.B COMPRESSOR INOPERATIVE

IS

YES

LINE VOLTAGE

WITHIN ¦ 10%

OF NAMEPLATE

VOLTAGE

NO

NO

CHECK VOLTAGE PROBLEMS IN 1.

REPLACE

THERMAL

PROTECTOR.

IS

COMPRESSOR

BODY

COLD?

1. CHECK FOR LOOSE OR BROKEN

WIRING CONNECTION IN COMPRESSOR

NOYES

POWER CIRCUIT.

2. CHECK STARTING RELAY.

3. CHECK CAPACITOR(S).

4. CHECK COMPRESSOR MOTOR.

27 91626

Page 31

2.C NO ICE ON EVAPORATOR

IS

WATER LEVEL

NORMAL?

YES

CHECK

REFRIGERATION

SYSTEM

YES

NO

CHECK WATER

PROBLEM IN 2.A.

IS

EVAPORATOR

COLD

NO

YES

1. CHECK FOR REFRIGERANT UNDERCHARGE.

2. CHECK HOT GAS SOLENOID FOR LEAKING

SEAT.

3. GO TO 2.A.

HOT GAS SOLENOID

IS

ENERGIZED?

NO

CHECK HOT GAS

VALVE CIRCUIT

2891626

Page 32

2.DFROZENEVAPORATOR

1. SHUTOFF ICEMAKER AND THAW EVAPORATOR.

2. START ICEMAKER

IS

AMBIENT ABOVE

60°F?

YES

IS

VOLTAGE WITHIN

¦ 10%

YES

WAITAND TIME ONE FULL

FREEZING CYCLE, 10-11 MIN.

ARE ALL

TIMING FUNCTIONS

ACCURATE TO SETTINGS

¦ 10%

YES

NO

NO

NO

1. ARRANGE TO MAINTAIN MINIMUM 60° F

AMBIENT.

2. CONTACT REMCOR REGARDING SPECIAL

APPLICATION.

CHECK VOLTAGE ITEMS IN 1.

1. CHECK WIRING.

2. CHECK TIMERS.

DOES

HOT GAS VALVE

ENERGIZE

YES

DOES

HARVEST MOTOR

OPERATE

YES

DOES

ICE HARVEST

NORMALLY

YES

NO

NO

NO

CHECK HOT GAS VALVE AND

COMPONENT OPERATION.

CHECK HARVEST MOTOR

AND CAPACITOR.

1. REPEAT HARVEST COMPONENT TEST.

2. ADJUST ICE THICKNESS WITH TIME

ADJUSTMENTS, AFTER ALL OTHER

FACTORS HAVE BEEN CHECKED

THOROUGHLY.

29 91626

Page 33

2.E LOW ICE PRODUCTION

IS

WATER LEVEL

NORMAL?

YES

IS

WATER TEMP.

HIGH

NO

IS

AMBIENT TEMP.

HIGH

NO

YES

YES

CHECK WATER ITEMS IN 2.A.

NORMAL EFFECT. INSTALLPRE-

COOLER TO INCREASE CAPACITY.

NORMAL EFFECT. ARRANGE

FOR LOWER AMBIENT AIR

TEMP. IF POSSIBLE

NO

IS ICE THIN?

NO

YES

GO TO 2.C

CHECK REFRIGERATION

SYSTEM.

3091626

Page 34

2.F POOR ICE QUALITY

2.F POOR ICE QUALITY

YES

1. CHECK AIR PUMP.

2. CHECK ADJUSTMENT OF TIMER.

(WATER DUMP)

3. CHECK WATER FILTER.

4. INCREASE WATER DUMP BY ADJUSTING TIMER.

5. INSTALL ADDITIONAL WATER TREATMENT

DEVICES FOR SPECIFIC “PROBLEM”WATER.

IS

ICE CLOUDY?

NO

IS

ICE SOFT?

YES

NO

DONE

31 91626

Page 35

3. DISPENSER PROBLEM

YES

DOES

AGITATOR

ROTATE?

NO

1. CHECK MOTOR CAPACITOR.

2. CHECK AGITATOR MOTOR.

IS

HOPPER LEVEL

TOO HIGH

YES

YES

NO

IS

DOES

GATE OPEN?

1. CHECK FOR BLOWN SOLENOID FUSE IN ELECTRIC BOX.

IF FUSE IS BLOWN CHECK FOR STUCK GATE MECHANISM

BURNED OUT SOLENOID, OR LOW VOLTAGE.

2. CHECK VEND SWITCH

3. CHECK FOR LOOSE OR BROKEN WIRE CONNECTION IN

SOLENOID CIRCUIT.

4. CHECK VOLTAGE PROBLEM IN 1.

NO

1. CHECK FOR BURNED OUT SOLENOID.

2. CHECK FOR STUCK OR BINDING

GATE MECHANISM.

VOLTAGE AT

SOLENOID

103-126V.?

NO

YES

1. CHECK BIN THERMOSTAT

ADJUSTMENT.

2. REPLACE BIN THERMOSTAT.

IS

ICE SLUSHY?

DONE

NO

YES

1. CHECK HOPPER DRAINS.

2. CHECK LEVEL OF UNIT.

3. CHECK FOR WATER OVERFLOW FROM

EVAPORATOR. SEE SECTION 2.

3291626

Page 36

IS

ONE OR MORE

FAUCETS

INOPERATIVE?

NO

4. BEVERAGE SYSTEM PROBLEM

1. CHECK WIRING CONNECTIONS TO

YES

2. REPLACE INOPERATIVE FAUCETS.

3. CHECK WIRING CONNECTIONS FROM 24 V.

4. CHECK 24 V. TRANSFORMER.

INOPERATIVE FAUCETS.

TRANSFORMER.

IS

BEVERAGE

COLD?

YES

IS

BEVERAGE PROPERLY

CARBONATED?

YES

IS

BEVERAGE TOO

SWEET?

NO

IS

BEVERAGE TOO

WATERY?

NO

YES

YES

NO

1. CHECK REMOTE COOLING SYSTEM.

(-B MODELS)

2. CHECK FOR ICE ON COLD PLATE.

(-BC MODELS)

1. CHECK CO2PRESSURE.

2. CHECK CARBONATOR.

1. CHECK WATER SUPPLY PRESSURE.

2. CHECK SUPPLY FILTER.

3. CHECK CARBONATOR.

4. CHECK FAUCET BRIX.

1. CHECK IF SYRUP TANK IS EMPTY.

2. CHECK CO

3. CHECK FAUCET BRIX.

PRESSURE.

2

NO

DONE

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.CorneliusParts.COM

WWW.ICeCubes.NET

(866) 423-6253

(623) 869-8881

33 91626

Page 37

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.CorneliusParts.COM

WWW.IceCubes.NET

(866) 423-6253

13

16

14

15

(623) 869-8881

TXV TEMPERATURE

SENSOR

CAPILARY

TUBE

23

24

19

20

21

25

12

11

17

18

26

9

28

2

1

7

8

REFRIGERATION

LINE

3

4

56

27

10

TXV CAPILARY TUBING

MOUNT TXV SENSOR

AS SHOWN

22

CHARGING

FIGURE 8. SERVICE PARTS LIST CONDENSING UNIT

Item

No.

1 31572 --- ------- Fan Motor

2 31927 --- ------- Fan Blade

3 70404 --- ------- Tinnerman Clip

4 60962 60977 Condenser

5 52078 --- ------- Shroud

6 32778 32778 Capacitor-Start 270-324 MF, 110V

7 32576 32576 Hot Gas Solenoid Coil

8 60734 30734 Hot Gas Valve

9 60948 60948 TXV NIV-1/4-SP R22

10 70577 70577 Clamp

11 60369 60369 Low Pressure Control

12 60501 60501 High Pressure Control

13 51485 51485 Evaporator Shell Foamed

14 50481 50481 Gasket

15 51163 51163 Gasket. Shaft Sea;

16 51422 51422 Gasket. Evaporator

17 32777 32777 Compressor Starting Relay

18 60916 60916 Compressor

19 32719 32719 Electric Box Assembly

20 31924 31924 Timer, Total Cycle

21 31923 31923 Timer, Interval Cycle

22 52011 52011 Drain Assembly, Collector

23 51515 51515 Harvest Bar, Cut

24 60739 60739 Evaporator Coil

25 31673 31673 Capacitor Run, Harvest Motor

26 32779 32779 Overload Protector

27 60204 60623 Drier

28 27130 27130 Accumulator Assembly

29 40785 40785 Water Inlet Valve

30 --- ------- 40122 Water Regulating Valve

Part No.

Air-Cooled

Part No.

Water-Cooled Name

3491626

LINE

Page 38

14

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.CorneliusParts.COM

WWW.IceCubes.NET

(866) 423-6253

(623) 869-8881

4

10

25

11

24

8

9

7

FIGURE 9. CABINET ASSEMBLY EXPLODED VIEW AND SERVICE PARTS

Item

No. Part No. Name

1 31560 Harvest Motor

2 31568 Air pump

3 31001 Bin thermostat

4 27385 Panel, Access LS

5 27384 Panel, Back Removable

6 32778 Capacitor, Start

7 52009 Sink, Foamed Assy

8 10145 Pin, Sink Extension

9 27412 Grill, sink

10 52070 Merchandiser Assy

11 32838 Dispenser Switch Actuator

12 21517 Agitator

13 31093 Solenoid Assy

14 52005 Cover, Top

15 31106 Agitator Motor

16 27880 Panel, Access RS

17 31620 Starter FluorescentLight

18 31621 Ballast

19 31619 Base, Fluorescent Starter

20 32746 Fluorescent Light

21 30894 Dispense Switch, Red Button

22 53015 Ice Chute Back Section

53016 Ice Chute Cover

23 51374 Seal, Evaporator

24 27828 Panel, Lower Front

25 52074 Panel, Plexiglass Clear

22

21

18

13

20

35

12

1

23

3

5

2

16

15

17

19

6

91626

Page 39

22

17

19

22

4

1

4

18

21

16

15

14

19

13

9

2

3

5

22

20

6

8

11

10

12

7

FIGURE 10. SOLENOID ASSEMBLY - EXPLODED VIEW & PARTS LIST

Index

No.

1 21493 1 Solenoid Mounting Plate

2# 31551 1 Solenoid Service Kit

3 70171 2 8--32 x 3/8 Phil Tr HD Screws

4 70121 2 No. 8 Lockwasher

5 50752 3 Isolator

6* 50789 2 Bumper Assembly

7* 70423 1 Cotter Pin

8* 10080 1 Gate Lift Rod

9 10081 1 Gate Lift Rod Bushing

10 50754 1 Gate Arm Bearing

11 21492 1 Gate Lift Arm

12 70043 1 Flatwasher

13* 70422 1 Spring

14 70263 1 1/4-20 x 3/4 Hex Hd Screw

15 70048 1 1/4 Lockwasher

16 70066 1 1/4 Flatwasher

17 10077 1 Pivot Bearing

18 30227 1 1/4 Quick Connect Tab

19 50305 --- - Lubricant

20* 21592 1 Solenoid Linkage Pin

21* 70433 2 Retainer Ring

22 51088 --- - Loctite

--- -* 70438 ---- Rebuilding Kit

Part No. Qty. Name

NOTE: * Parts supplied with rebuilding kit.

# 31551 solenoid supplied with items 20 & 21.

3691626

Page 40

IMICORNELIUSINC

ONE CORNELIUS PLACE

ANOKA, MN.55303--6234

TELEPHONE (800) 238--3600

FACSIMILE (612) 422--3232

TECH SVC 1-800-535-4240

.

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.CorneliusParts.COM

WWW.IceCubes.NET

(866) 423-6253

(623) 869-8881

WARRANTY

IMI Cornelius Inc. and Remcor Products Company warrants that all equipment and parts are free from defects

in material and workmanship under normal useand service. For a copy of the warranty applicable to your

Cornelius and or Remcorproduct, in your country, please write, fax or telephonethe IMI Cornelius officenearest you. Please provide the equipmentmodel number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

BELGIUM

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

ENGLAND

FRANCE D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX(33) 1 34 28 6201

GERMANY

GREECE

HONG KONG

ITALY

NEW ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

SINGAPORE

SPAIN

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 48 8 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

Manual number

37

Page 41

CORPORATE HEADQUARTERS:

Remcor Incorporated

500 Regency Drive

Glendale Heights, IL 60139

708. 980.6900

Loading...

Loading...