Page 1

Installation Instructions

DRAFT ARM

WITH SF-1 VALVE

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303–6234

Telephone (800) 238–3600

Facsimile (612) 422–3232

Part No. 300168000

September 12, 1983

Revised: August 9, 1991

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Installation Manual must be read and understood before starting to install or operate this equipment.

IMI CORNELIUS INC; 1983-91

Printed in U.S.A.

Page 2

Page 3

TABLE OF CONTENTS

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . .

UNIT DESCRIPTION 1. . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 1. . . . . . . . . . . . . .

UNIT USED AS A TEA DISPENSER 1. . . .

UNIT CONNECTED TO A POST–MIX

SYSTEM 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 3. . . . . . . . . .

IDENTIFICATION OF LOOSE–SHIPPED

PARTS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 3. . . . . . . . . . . . . . . . .

INSTALLING UNIT 3. . . . . . . . . . . . . . . . . . . . . .

INSTALLING UNIT WITHOUT BASE 3. . . .

INSTALLING UNIT WITH OPTIONAL BASE

KIT (P/N 319314–039) 4. . . . . . . . . . . . . . . . .

CONNECTING INLET SUPPLY LINES TO

UNIT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT USED AS TEA UNIT 4. . . . . . . . . . . .

UNIT CONNECTED TO POST–MIX

SYSTEM 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING (IF USED) DRIP TRAY DRAIN

HOSE TO PERMANENT DRAIN 5. . . . . . . . . .

PREPARING FOR OPERATION 5. . . . . . . . . .

UNIT USED AS A TEA UNIT 5. . . . . . . . . . .

UNIT CONNECTED TO A POST–MIX

SYSTEM 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATORS INSTRUCTIONS 7. . . . . . . . . . . . .

DISPENSING VALVE OPERATION 7. . . . . . .

DAILY PRE–OPERATION CHECK 7. . . . . . . .

ADJUSTMENTS 7. . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSING VALVE WATER

FLOW RATE 7. . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING WATER–TO–CONCENTRATE

(TEA) OR SYRUP (POST–MIX) ‘‘RATIO’’ OF

DISPENSED PRODUCT 7. . . . . . . . . . . . . . .

ADJUSTING GAS PRESSURE

REGULATOR 7. . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING GAS SUPPLY 7. . . . . . . . . . .

TEA SYSTEM 7. . . . . . . . . . . . . . . . . . . . . . . .

POST–MIX SYSTEM 7. . . . . . . . . . . . . . . . . .

REPLENISHING CONCENTRATE (TEA SYSTEM) OR SYRUP (POST–MIX SYSTEM) SUP-

PLY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 7. . . . . . . . . . . .

DAILY CLEANING OF UNIT 7. . . . . . . . . . . .

WEEKLY CLEANING OF DISPENSING

VALVE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING SYSTEM 7. . . . . . . . . . . . . . . . .

PAGE

SERVICING WATER STRAINER SCREEN (TEA

SYSTEM) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 9. . . . . . . . . . . .

PERIODIC INSPECTION 9. . . . . . . . . . . . . . . .

ADJUSTMENTS 9. . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSING VALVE WATER

FLOW RATE 9. . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING WATER–TO–CONCENTRATE (TEA

SYSTEM) OR SYRUP (POST–MIX SYSTEM)

“RATIO’’ OF DISPENSED PRODUCT 9. . . . .

ADJUSTING GAS PRESSURE

REGULATOR 10. . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING GAS SUPPLY 10. . . . . . . . . . .

TEA SYSTEM 10. . . . . . . . . . . . . . . . . . . . . . . .

POST–MIX SYSTEM 11. . . . . . . . . . . . . . . . . .

REPLENISHING CONCENTRATE (TEA SYSTEM) OR SYRUP (POST–MIX SYSTEM)

SUPPLY 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONCENTRATE (TEA SYSTEM) OR SYRUP

(POST–MIX SYSTEM) FLAVOR CHANGE 11.

CLEANING AND SANITIZING 11. . . . . . . . . . . .

DAILY CLEANING OF UNIT (DO NOT USE

ABRASIVE TYPE CLEANERS) 11. . . . . . . . .

WEEKLY CLEANING OF DISPENSING

VALVE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING UNIT 12. . . . . . . . . . . . . . . . . . . .

SERVICING WATER STRAINER SCREEN 12

CLEANING GAS CHECK VALVE 12. . . . . . . . . .

REMOVE AND REPLACEMENT

PROCEDURES 13. . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSING VALVE ASSEMBLY 13. . . . . .

SYRUP, CONCENTRATE, OR WATER FLOW

REGULATOR 13. . . . . . . . . . . . . . . . . . . . . . . .

INLET VALVE 13. . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 17. . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING TEA SYSTEM 17. . . . .

ONLY WATER DISPENSED. 17. . . . . . . . . . .

ONLY CONCENTRATE DISPENSED. 17. . .

NO CONCENTRATE OR WATER

DISPENSED. 17. . . . . . . . . . . . . . . . . . . . . . . . .

WATER–TO–CONCENTRATE ‘‘RATIO’’ TOO

LOW OR TOO HIGH. 17. . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE CON-

CENTRATE FLOW REGULATOR DOES NOT

INCREASE TO DESIRED WATER–TO–CON-

CENTRATE ‘‘RATIO’’. 18. . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE CON-

CENTRATE FLOW REGULATOR DOES NOT

DECREASE TO DESIRED WATER–TO–CON-

CENTRATE ‘‘RATIO’’. 18. . . . . . . . . . . . . . . . .

TROUBLESHOOTING POST–MIX SYSTEM 18

i

PAGE

300168000

Page 4

TABLE OF CONTENTS CONT’D

PAGE

WATER–TO–SYRUP ‘‘RATIO’’ TOO LOW OR

TOO HIGH. 18. . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW REGULATOR DOES NOT INCREASE TO DESIRED WATER–TO–SYRUP

‘‘RATIO’’.19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW REGULATOR DOES NOT DECREASE TO DESIRED WATER–TO–SYRUP

‘‘RATIO’’.19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO

LOW. 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT FOAMS IN CUP

OR GLASS. 20. . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT PRODUCES FOAM

AS IT LEAVES DISPENSING VALVE. 20. . .

ONLY CARBONATED WATER

DISPENSED. 20. . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 21. . . . . . . . . . .

PAGE

LIST OF FIGURES

FIGURE 1. DRAFT ARM WITH SF-1 VALVE

(SHOWN WITH OPTIONAL BASE KIT0 1. . .

FIGURE 2. FLOW DIAGRAM

(TEA SYSTEM) 2. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. PARTS IDENTIFICATION (SHOWN

WITH OPTIONAL BASE KIT) 10. . . . . . . . . . . . .

FIGURE 4. RATIO CUP AND SYRUP DIVER-

SION TUBE ASSEMBLY 11. . . . . . . . . . . . . . . . .

FIGURE 5. WATER STRAINER 12. . . . . . . . . . .

FIGURE 6. GAS CHECK VALVE 13. . . . . . . . . .

FIGURE 7. DISPENSING VALVE ASSEMBLY 15

FIGURE 8. INSTRUCTIONS FOR CRIMPING

TUBE CLAMPS 16. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. TEA DRAFT ARM ASSEMBLY 24.

LIST OF TABLES

TABLE 1. DESIGN DATA 1. . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 3. . . . . .

300168000

ii

Page 5

GENERAL DESCRIPTION

IMPORTANT: To the user of this manual – This

manual is a guide for installing, operating, and

maintaining this equipment. Refer to Table of

Contents for page location of detailed

information pertaining to questions that arise

during installation,operation, service and

maintenance, or troubleshooting this equipment.

GENERAL DESCRIPTION

This section gives the description, theory of operation, and design data for the Draft Arm with SF–1

Valve (dispensing valve), hereafter referred to as a

unit.

UNIT DESCRIPTION

The unit (see Figure 1) is compact and may be island–mounted or installed on a countertop. The unit

may be used to dispense tea or may be connected

into a post–mix system to dispense a carbonated or

non–carbonated (still) drink. Adjustable water and

syrup flow regulators, located in the dispensing

valve, are easily accessible to control water flow rate

and to adjust Water–to–Concentrate (tea) or syrup

(post–mix) ‘‘Ratio’’ of dispensed product. An optional

Draft Arm Base Kit (P/N 319314–039) with drip tray

and drain hose is available.

Installation of unit on countertop, connection of unit

to tea or post–mix system, and adjustment of dispensing valve water and syrup flow regulators for

water flow rate and water–to–concentrate (tea) or

syrup (post–mix) ‘‘Ratio’’ of dispensed product is all

that is required for operation.

Table 1. Design Data

Unit Part Number 414019–000

Overall Dimensions:

Height without base kit 14–3/8 inches

Height with base kit 16–inches

Width without base kit 1–3/4 inches

Width with base kit 6–1/4 inches

Depth without base kit 4–3/4 inches

Depth with base kit 8–inches

Shipping Weight pounds

Dispensing Rate (continuous) nominal 1–1/2 oz/sec.

Ambient Operating Temperature 40°F to 100°F

FIGURE 1. DRAFT ARM WITH SF-1 VALVE

(SHOWN WITH OPTIONAL BASE KIT)

THEORY OF OPERATION (see Figure 2)

UNIT USED AS A TEA DISPENSER (see Figure

2)

A nitrogen (N) gas cylinder delivers gas through an

adjustable nitrogen gas regulator to the concentrate

tank. Gas pressure exerted upon contents inside

concentrate tank pushes concentrate from tank to

dispensing valve. At the same time, plain water is

pushed by city water line pressure to the dispensing

valve. Concentrate and plain water pass through adjustable water and syrup (concentrate) regulators in

the dispensing valve and meet simultaneously at the

valve nozzle resulting in finished product being dispensed.

UNIT CONNECTED TO A POST–MIX SYSTEM

The unit may be connected into a post–mix system

to dispense a carbonated or a non–carbonated (still

drink). The unit is shipped from the factory with

Baffle Tube Extension (P/N 300097–000) and Baffle

(P/N 318754–011) installed on the dispensing valve

and is intended to dispense tea. If unit will be connected into post–mix system, tube extension and

baffle should be removed and BAFFLE (item 12)

should be installed on valve for better mixing of dispensed product.

1 300168000

Page 6

300168000

WATER SOURCE

SHUTOFF VALVE

FILTER

WATER STRAINER

DRAFT ARM

WATER FILTER INSTALLATION

FOR FILTERS WITHOUT BUILT-IN

WATER SHUTOFF VALVE

PRIMARY REGULATOR

CONCENTRA T E TANK

GAS CHECK VALVE

NITROGEN (N)

CYLINDER

CONCENTRATE

TANK

2

FOR

LINE LEGEND

PLAIN WATER

CO

2

CONCENTRATE

FIGURE 2. FLOW DIAGRAM (TEA SYSTEM)

Page 7

INSTALLATION

This section covers unpacking and inspection, identification of LOOSE–SHIPPED PARTS, selecting location, installing unit, preparing for operation, and operation.

UNPACKING AND INSPECTION

NOTE: The unit was thoroughly inspected before

leaving the factory and the carrier has accepted and

signed for it. Any damage or irregularities should be

noted at time of delivery and immediately reported to

the delivering carrier. Request a written inspection

report from the claims inspector to substantiate any

necessary claim. File claim with delivering carrier, not

with IMI Cornelius Inc.

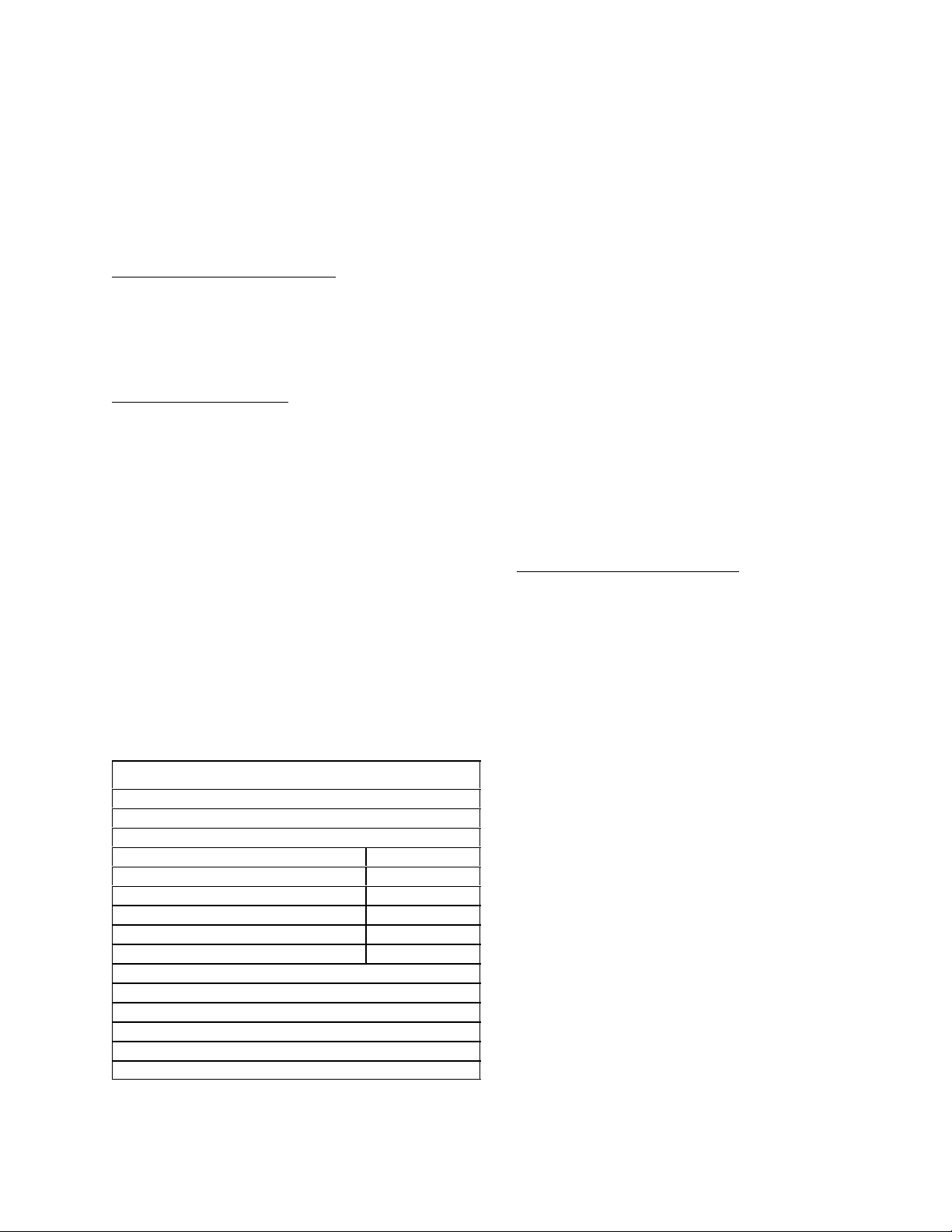

Table 2. Loose-Shipped Parts

Item

No. Part No. Name Qty.

1 317904–999 Flavor Decal (as

specified by

customer)

2 317905–999 Flavor Decal (as

specified by

customer)

3 311035 Water Strainer Ass’y1

4 176107 Adapter Fitting, 1/4

NPT by 7/16–20

5 178025–100 Tapered Gasket,

White

6 176035 Ferrule 2

7 176034 Nipple 2

8 176017 Nut 2

9 176193 Adapter Fitting,

7/16–20 male by

7/16–20 male

10 311577 Wing Nut 1

11 311584 Tube, Hold–Down 1

12 318523–027 Baffle (post–mix

application)

1

1

2

2

1

1

3. WATER STRAINER ASS’Y (item 3) to be

installed in plain water inlet supply line between

water filter and unit if used as tea unit.

4. ADAPTER FITTINGS (item 4) to be installed in

inlet and outlet of WATER STRAINER ASS’Y

(item 3) prior to installing water strainer if used

as tea unit.

5. TAPERED GASKETS, WHITE (item 5) are used

to seal connections when connecting water inlet

and outlet lines to WATER STRAINER ASS’Y

(item 3) if used as tea unit.

6. NUT (item 8), NIPPLE (item 7), and FERRULE

(item 6) to be installed on ends of unit inlet lines.

7. ADAPTER FITTINGS (item 9) used to connect

line to swivel nut connector on end of unit inlet

line.

8. TUBE, HOLD–DOWN (item 11) to be installed in

bottom of unit, then unit to be secured to countertop with WING NUT (item 10).

9. BAFFLE (item 12) to be installed on dispensing

valve if unit will be installed in post–mix system.

SELECTING LOCATION

This unit may be island–mounted or installed on a

front or rear counter. Locate unit so the following requirements are satisfied.

Close to a cold (100°F max) plain water source capable of supplying water at 20 to 125–psig if used as a

tea unit (see Figure 2). Water inlet supply line should

include a water shutoff valve and a water filter.

Close to a permanent drain for connection of drain

hose if optional Base Kit (P/N 319314–039) will be

used.

INSTALLING UNIT

INSTALLING UNIT WITHOUT BASE

1. Drill 3/4–inch hole in countertop.

IDENTIFICATION OF LOOSE–SHIPPED

PARTS

1. FLAVOR DECAL (item 1) to be installed on

back of dispensing valve cover.

2. FLAVOR DECAL (item 2) to be installed on front

of dispensing valve cover.

2. Route unit inlet lines out through hole in unit

base plate.

3. Route unit inlet lines through TUBE, HOLD–

DOWN (item 11).

4. Slide hold–down tube up on unit inlet lines, then

screw tube into base plate in bottom of unit.

5. Route unit inlet lines and hold–down tube down

through hole in countertop.

3 300168000

Page 8

6. To comply with National Sanitation Foundation

(NSF) requirements, unit base must be sealed

to countertop and all access holes to inside of

unit base must by sealed with Permagum or

other sealant material. Proceed as follows to

seal unit base.

8. To comply with National Sanitation Foundation

(NSF) requirements, unit base must be sealed

to countertop and all access holes to inside of

unit base must be sealed with Permagum or

other sealant material. Proceed as follows to

seal unit base.

A. Tilt unit up to expose bottom of base.

B. Liberally apply silastic sealant such as Dow

Corning RTV 731 or equivalent on base

bottom edges.

NOTE: Do not move unit after positioning or seal

from unit base to countertop will be broken.

C. Lower unit into operating position on coun-

tertop to complete seal from unit base to

countertop.

D. Slide WING NUT (item 10) up on unit inlet

lines to hold–down tube, then secure unit to

countertop with wing nut.

E. Apply additional sealant around bottom of

unit base. Seal must have a minimum radius of 1/2–inch to prevent crevices and to

insure a complete seal.

F. Seal all access holes to inside of unit base

with permagum or other sealant material.

7. Install NUT (item 8), NIPPLE (item 7), and FERRULE (item 6) on ends of unit inlet lines. Crimp

ferrules with IMI Cornelius Inc. crimping tool

(P/N 274261–300) and die set No. 31.

INSTALLING UNIT WITH OPTIONAL BASE

KIT (P/N 319314–039)

1. Tape loose–shipped template in place on coun-

tertop.

2. Drill holes indicated on template in countertop,

then remove template.

3. Route unit inlet lines out through hole in unit

base plate.

4. Route unit inlet lines through TUBE, HOLD–

DOWN (item 11).

5. Slide hold–down tube up on unit inlet lines, then

screw tube into base plate in bottom of unit.

6. Assemble base kit on unit.

7. Route unit inlet lines and drip tray drain hose

through holes in countertop.

A. Tilt unit up to expose bottom of base.

B. Liberally apply silastic sealant such as Dow

Corning RTV 731 or equivalent on base

bottom edges.

NOTE: Do not move unit after positioning or seal

from unit base to countertop will be broken.

C. Lower unit into operating position on coun-

tertop to complete seal from unit base to

countertop.

D. Fasten unit to countertop with loose–

shipped parts.

E. Apply additional sealant around bottom of

unit base. Seal must have a minimum radius of 1/2–inch to prevent crevices and to

insure a complete seal.

9. Install NUT (item 8), NIPPLE (item 7). and FERRULE (item 6) on ends of unit inlet lines. Crimp

ferrules with IMI Cornelius Inc. crimping tool

(P/N274261–300) and die set No. 31.

CONNECTING INLET SUPPLY LINES TO

UNIT

UNIT USED AS TEA UNIT (see Figure 2)

1. Connecting Water Inlet Supply Line.

IMI Cornelius Inc. recommends that a water shutoff

valve and a water filter be installed in the water inlet

supply line connected to unit. A IMI Cornelius Inc.

Water Filter (P/N 313860–000) and Quick Disconnect

Set (P/N 313867–000) are recommended.

NOTE: The unit must be connected to a cold

(100°F max) plain water source capable of supplying water at 20 to 125–psig. A Saddle Valve

(P/N 315664–000) or equivalent may be used to

tap into water source. Connect water inlet supply

line to unit as follows:

A. Install ADAPTER FITTINGS (item 4) in

WATER STRAINER ASS’Y (item 3) inlet

and outlet ports. Seal connections with

thread sealant compound.

B. Install water strainer assembly under coun-

tertop close enough to unit to allow unit water inlet line to be connected.

C. Connect unit water inlet line to water strain-

er assembly outlet fitting. Seal connection

with TAPERED GASKET, WHITE (item 5).

4300168000

Page 9

D. Before connecting water inlet supply line to

water strainer assembly, open water shutoff

valve for a period of time to flush out any

metal shavings resulting from installing fitting or saddle valve.

PREPARING FOR OPERATION

UNIT USED AS A TEA UNIT

1. Open water inlet supply line shutoff valve.

E. Connect water inlet supply line to water

strainer assembly inlet fitting. Seal connection with TAPERED GASKET, WHITE (item

5).

2. Connecting Concentrate Supply Line.

A. Install ADAPTER FITTING (item 9) in end

of unit concentrate inlet line.

B. Connect concentrate supply line from con-

centrate tank location to unit concentrate

inlet line.

UNIT CONNECTED TO POST–MIX

SYSTEM

NOTE: Unit is shipped from factory with Baffle

Tube Extension (P/N 300097–000) and Baffle (P/N

318754–011) installed on dispensing valve and is

intended for dispensing of tea. Remove tube extension and baffle and install BAFFLE (item 12)

for post–mix dispensing.

Connecting Water Inlet Supply Line.

Connect carbonated water for carbonated drink or

plain water for non–carbonated (still drink) water inlet

supply line from post–mix system to unit water inlet

supply line. Seal connection with TAPERED GASKET, WHITE (item 5).

Connecting Syrup Inlet Supply Line.

Connect syrup inlet supply line from post–mix system

to unit syrup inlet supply line. Seal connection with

TAPERED GASKET, WHITE (item 5).

2. Dispense from dispensing valve until air is

purged from water system. Check system for

leaks and tighten or repair any loose connections.

3. Check, and if necessary, adjust dispensing

valve for proper water flow rate as instructed.

4. Adjust concentrate tank nitrogen regulator as

instructed.

5. Connect concentrate tank into system.

6. Dispense from dispensing valve until air is

purged from concentrate system. Check for

leaks and tighten or repair any loose connections.

7. Install FLAVOR DECALS (items 1 and 2) on

dispensing valve cover.

UNIT CONNECTED TO A POST–MIX SYSTEM

1. Adjust post–mix system carbonator and syrup

tanks CO2 regulators as instructed.

2. Activate post–mix system carbonated water and

plain water supplies.

3. Dispense from dispensing valve until air is

purged from water system. Check for leaks and

tighten or repair any loose connections.

4. Check and if necessary, adjust dispensing valve

for proper water flow rate as instructed.

5. Activate post–mix system syrup supply.

CONNECTING (IF USED) DRIP TRAY

DRAIN HOSE TO PERMANENT DRAIN

NOTE: Drip tray drain hose routed to a waste container is not recommended due to sanitation and

cleaning problems. Connection of drain hose to permanent drain is recommended.

1. Preferably, route lower end of drip tray drain

hose and connect to permanent drain.

2. Place cup rest in drip tray.

6. Dispense from dispensing valve until air is

purged from syrup system. Check for leaks and

tighten or repair any loose connections.

7. Adjust Water–to–Syrup ‘‘Ratio’’ of dispensed

product as instructed.

8. Install FLAVOR DECALS (items 1 and 2) on

dispensing valve cover.

9. Using insulating tape, insulate water and syrup

or concentrate lines up to unit base.

5 300168000

Page 10

THIS PAGE LEFT BLANK INTENTIONALLY

6300168000

Page 11

OPERATORS INSTRUCTIONS

This section covers operators instructions for operating controls, daily pre–operation check, adjustments,

replenishing gas supply and concentrate or syrup

supplies, and cleaning and sanitizing.

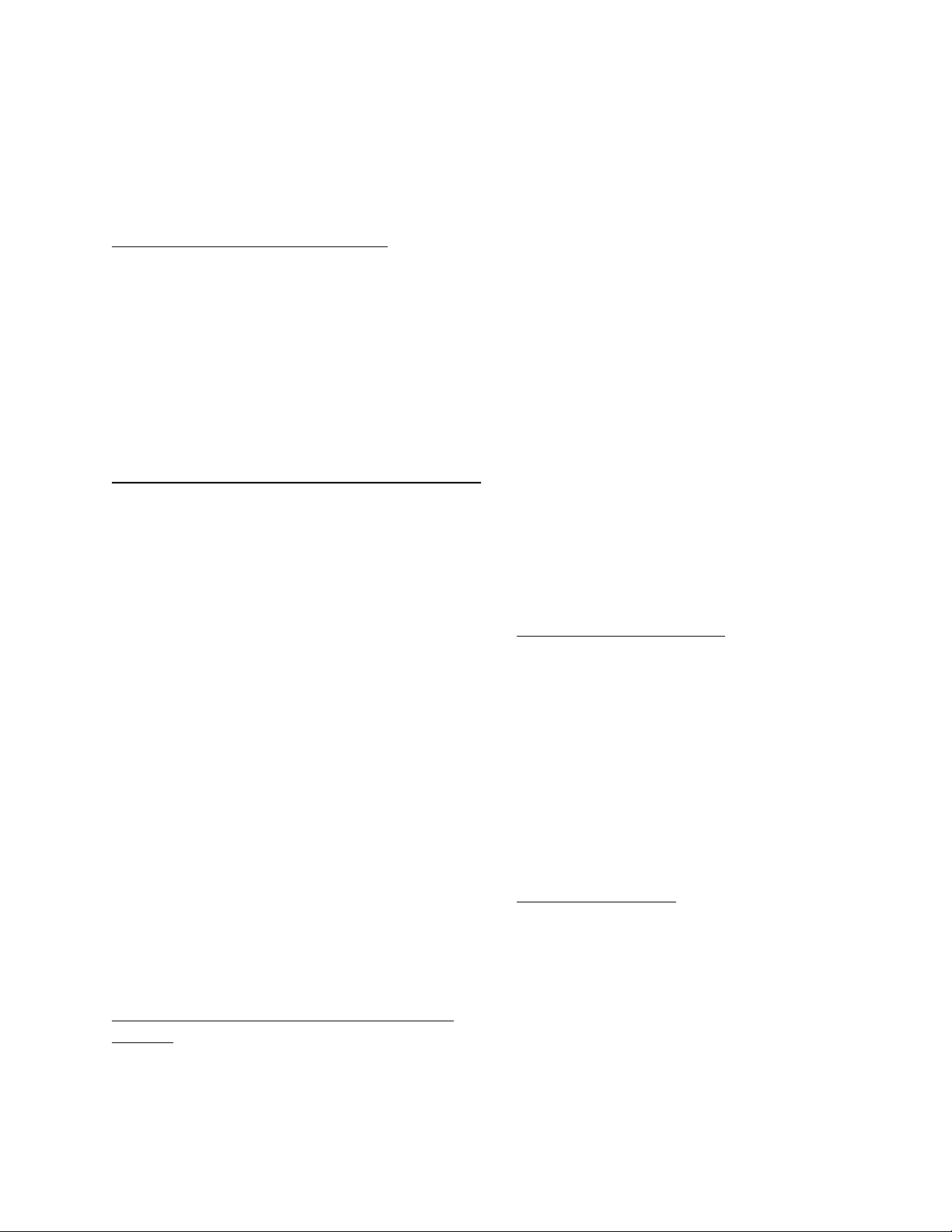

DISPENSING VALVE OPERATION (see

Figure 3)

Dispensing valve lever, located below dispensing

valve, need only to be pressed with cup or glass to

dispense product.

DAILY PRE–OPERATION CHECK

1. Tea System Nitrogen Gas Pressure Supply.

Note pressure reading on nitrogen gas pressure

regulator assembly high–side gage which indicates nitrogen cylinder pressure. When high–

side pressure gage reading approaches low–

side gage operating pressure reading, nitrogen

cylinder is almost empty and should be replaced.

Unit Connected to a Post–Mix System.

Water–to–Syrup ‘‘Ratio’’ of dispensed product should

be checked periodically and if necessary, adjusted as

instructed.

ADJUSTING GAS PRESSURE REGULATOR

Tea System.

Concentrate Tank Nitrogen Gas Pressure Regulator

–Nitrogen gas pressure regulator should be checked

periodically for proper pressure setting and if necessary, adjusted as instructed.

Post–Mix System.

Syrup tanks CO2 Gas Pressure Regulator – Syrup

tanks CO2 gas pressure regulator should be checked

periodically for proper pressure setting and if necessary, adjusted as instructed.

Carbonator CO2 Gas Pressure Regulator – Carbonator CO2 gas pressure regulator should be checked

periodically for proper pressure setting and if necessary, adjusted as instructed.

REPLENISHING GAS SUPPLY

Post–Mix System CO2 Gas Pressure Supply.

Make sure CO2 cylinder gas pressure regulator

assembly 1800–psi gage indicator is not in

shaded (‘‘change CO2 cylinder’’) portion of dial.

If so, CO2 cylinder is almost empty and must be

replaced.

2. Sufficient concentrate (tea) or syrup (post–mix).

If not, replenish concentrate or syrup supply.

3. If unit is equipped with base kit, make sure drip

tray is clean and cup rest is in place in drip tray.

ADJUSTMENTS

ADJUSTING DISPENSING VALVE WATER

FLOW RATE

Amount of water dispensed in four seconds should

be approximately five–ounces. If necessary to adjust

water flow rate, adjust as instructed.

ADJUSTING WATER–TO–CONCENTRATE

(TEA) OR SYRUP (POST–MIX) ‘‘RATIO’’ OF

DISPENSED PRODUCT

TEA SYSTEM

Nitrogen gas supply should be checked daily and if

necessary, replenished as instructed.

POST–MIX SYSTEM

CO2 gas supply should be checked daily and if necessary, replenished as instructed.

REPLENISHING CONCENTRATE (TEA

SYSTEM) OR SYRUP (POST–MIX

SYSTEM) SUPPLY

Concentrate (tea system) or syrup (post–mix system)

supply should be checked daily and if necessary, replenished as instructed.

CLEANING AND SANITIZING

DAILY CLEANING OF UNIT

Daily cleaning of unit should be performed at end of

daily operation as instructed.

WEEKLY CLEANING OF DISPENSING VALVE

Dispensing valve should be cleaned at least once a

week as instructed.

Unit Used as a Tea Dispenser.

Water–to–Concentrate ‘‘Ratio’’ of dispensed product

should be checked periodically and if necessary, adjusted as instructed.

SANITIZING SYSTEM

System should be sanitized as instructed every 90

days following Sanitizer Manufacturer’s recommendations.

7 300168000

Page 12

SERVICING WATER STRAINER SCREEN

(TEA SYSTEM)

CLEANING SYSTEM GAS CHECK VALVE (see Figure 2 and 6)

The water strainer screen (see Figure 2 and 5) must

be inspected and serviced at least once a year under

normal circumstances and after any disruptions

(plumbing work, earthquake, etc.) to the water supply

system that might cause turbulent (erratic) flow of

water through the system. Service water strainer

screen as instructed.

The CO2 system gas check valve must be inspected

and serviced at least once a year under normal

conditions and after any CO2 system servicing or

disruption as instructed.

8300168000

Page 13

SERVICE AND MAINTENANCE

This section covers service and maintenance procedures to be performed on the unit.

IMPORTANT: Only qualified personnel should

service unit or system components.

PERIODIC INSPECTION

1. Check dispensing valve for dripping that indicates a leak and repair as necessary.

2. Check concentrate (tea system) or syrup (post–

mix system) supply and if necessary, replenish

as instructed.

3. Tea System Nitrogen Gas Pressure Supply.

Note pressure reading on nitrogen gas pressure

regulator assembly high–side gage which indicates nitrogen cylinder pressure. When high–

side pressure gage reading approaches low–

side gage operating pressure reading, nitrogen

cylinder is almost empty and should be replaced

as instructed.

Post–Mix System Gas Pressure Supply.

Make sure CO2 cylinder gas regulator assembly

1800–psi gage indicator is not in shaded

(‘‘change CO2 cylinder’’) portion of dial. If so,

CO2 cylinder is almost empty and must be replaced as instructed.

ADJUSTMENTS

ADJUSTING DISPENSING VALVE WATER

FLOW RATE

1. Remove quick disconnect from concentrate (tea

system) or syrup (post–mix system) tank outlet.

2. Loosen dispensing valve cover screw until

screw disengages from valve, then remove cover.

3. Hold large chamber of ratio cup under dispensing nozzle.

4. Open dispensing valve for exactly four seconds.

Approximately 5–ounces of water should have

been dispensed in ratio cup.

(see Figure 4)

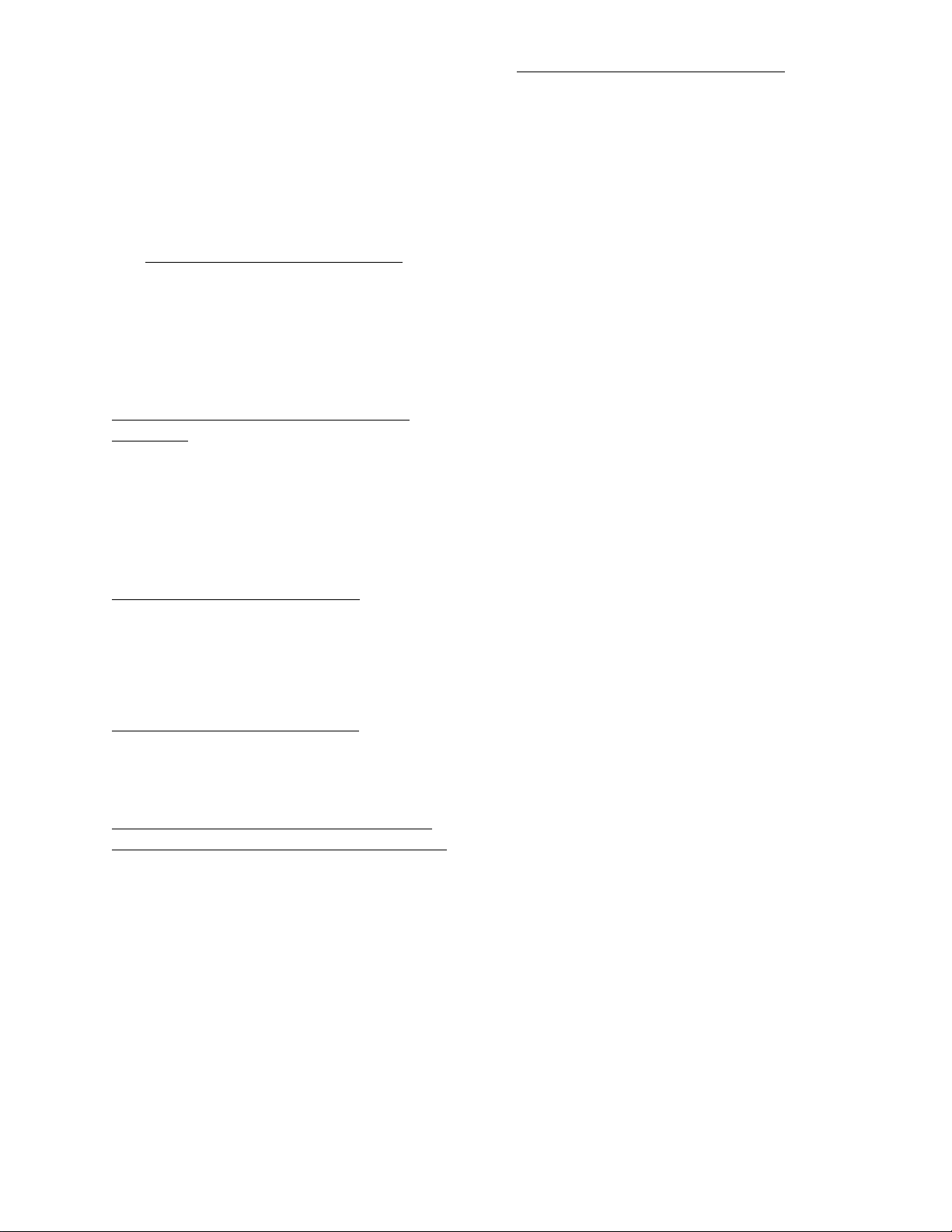

ADJUSTING WA TER–TO–CONCENTRATE

(TEA SYSTEM) OR SYRUP (POST–MIX

SYSTEM) “RATIO’’ OF DISPENSED

PRODUCT (see Figure 4)

NOTE: Make sure dispensing valve water flow

rate is as desired before adjusting valve for Water–to–Concentrate or Syrup ‘‘Ratio’’ of dispensed product.

Adjust Water–to–Concentrate (tea) or syrup (post–

mix) ‘‘Ratio’’ of dispensed product by using ‘‘Ratio’’

Cup (P/N 311100–000) and Syrup Diversion Tube

Assembly (P/N 319540–000) as follows (see Figure

4).

1. Loosen dispensing valve cover screw until

screw disengages from valve, then remove cover.

2. Install syrup diversion tube assembly on dispensing valve by pushing rubber end of syrup

diversion tube up on baffle inside nozzle.

NOTE: Refer to concentrate (tea) or syrup (post–

mix) manufacturer’s recommendations on package for Water–to–Concentrate (tea) or syrup

(post–mix)

‘‘Ratio’’.

3. Hold container under dispensing valve. Open

dispensing valve and dispense just enough to fill

syrup diversion tube with syrup or concentrate.

4. Hold large chamber of ratio cup under dispensing valve nozzle. Place free end of syrup diversion tube into syrup chamber marked for proper

ratio. Open dispensing valve and dispense

approximately five ounces of water into ratio

cup. Water and syrup or concentrate levels

should be even in ratio cup.

5. If water and syrup or concentrate levels are not

even in ratio cup, turn dispensing valve syrup

flow regulator labeled ‘‘SYRUP’’ adjusting screw

to the left (counterclockwise) no more than

1/4–turn at a time for less syrup or concentrate

or to the right (clockwise) no more than 1/4–turn

at a time for more syrup or concentrate.

5. If amount of water dispensed in four seconds

was incorrect, turn dispensing valve water flow

regulator labeled ‘‘WATER’’ adjusting screw to

the left (counterclockwise) no more than

1/4–turn at a time for less water or to the right

(clockwise) for more water.

6. Test for amount of water dispensed and adjust

dispensing valve water flow regulator until proper amount of water is dispensed.

6. Repeat Water–to–Concentrate (tea) or syrup

(post–mix) ‘‘Ratio’’ test and adjust syrup flow

regulator as many times as necessary until

proper ratio of dispensed drink is achieved.

7. Remove syrup diversion tube assembly from

dispensing valve.

8. Install dispensing valve cover and secure with

screw.

9 300168000

Page 14

COVER

COVER RETAINING

SCREW

DISPENSING

VALVE

DISPENSING

LEVER

CUP

REST

ADJUSTABLE WATER

FLOW REGULATOR

ADJUSTABLE CONCENTRATE

OR SYRUP FLOW REGULATOR

COUPLING NUT

OPTIONAL BASE KIT

(P/N 319314-039)

FIGURE 3. PARTS IDENTIFICATION (SHOWN WITH OPTIONAL BASE KIT)

ADJUSTING GAS PRESSURE REGULATOR

Tea System. (see Figure 2)

Set concentrate tank nitrogen gas regulator at 30–psi

plus one pound for every five feet over ten feet of

concentrate line length and one pound for every two

feet of vertical lift. For example: If total concentrate

line length is 20 feet and total vertical lift is 6 feet,

then 30–psi (initial) + 2–psi (1 pound for every 5 feet

over 10 feet of length which is 20 feet) + 3–psi (1

pound for every 2 feet of vertical lift which is 6 feet);

total equal 35–psi nitrogen regulator setting.

Post–Mix System.

Syrup tanks CO2 Regulator

Adjust syrup tanks CO2 regulator at 40–psig for syr-

up lines up to 10–feet in length plus one pound for

each 2–feet of vertical lift. For example: if syrup line

total length is 30–feet and total vertical lift is 6–feet,

then 40–psig + 2–psig (1–pound for every 10–feet of

length over 10–feet which is 20–feet) + 3–psig

(1–pound for every 2–feet of vertical lift which is

6–feet); total 40 + 2 + 3 = 45–psig CO2 regulator setting.

Carbonator CO2 Regulator.

Refer to manual provided with remote carbonator to

adjust carbonator CO2 regulator operating pressure.

REPLENISHING GAS SUPPLY

TEA SYSTEM

NOTE: Note pressure reading on nitrogen gas

pressure regulator assembly high–side gage

which indicates nitrogen cylinder pressure.

When high–side pressure gage reading approaches low–side gage operating pressure

reading, nitrogen cylinder is almost empty and

should be replaced.

1. Fully close (clockwise) nitrogen cylinder valve

shutoff valve.

2. Slowly loosen nitrogen regulator assembly coupling nut allowing nitrogen pressure to escape,

then remove regulator from empty nitrogen cylinder.

3. Unfasten safety chain and remove empty nitrogen cylinder.

4–2

300168–000

10300168000

Page 15

*Baffle (item 12) p/n 318523-027 is used

for post-mix application.

ADJUSTABLE WATER

FLOW REGULATOR

ADJUSTABLE SYRUP OR

CONCENTRA TE FLOW

REGULATOR

SYRUP DIVERSION TUBE

ASS’Y (P/N 319540-000)

RATIO CUP

(P/N 311100-000)

*BAFFLE

BAFFLE

WATER

CHAMBER

NOZZLE

WARNING: To avoid personal injury

and/or property damage, always

secure CO2 cylinder with safety chain

to prevent it from falling over. Should the

valve become accidentally damaged or

broken off, CO2 cylinder can cause serious

personal injury.

3. Position CO2 cylinder and secure with safety

chain.

4. Make sure gasket is in place inside CO2 regulator coupling nut, then install regulator on CO

2

cylinder.

5. Open (counterclockwise) CO2 cylinder valve

slightly to allow lines to slowly fill with gas, then

open valve fully to back–seat valve. (Back–seat-

ing valve prevents leakage around valve shaft.)

FIGURE 4. RATIO CUP AND SYRUP DIVERSION

TUBE ASSEMBLY

WARNING: To avoid personal injury

and/or property damage, always

secure nitrogen gas cylinder with

safety chain to prevent it from falling over.

Should the valve become accidentally

damaged or broken off, nitrogen cylinder can

cause serious personal injury.

4. Position nitrogen cylinder and secure with safety

chain.

5. Install nitrogen gas pressure regulator assembly

on nitrogen cylinder.

6. Open (counterclockwise) nitrogen cylinder shutoff valve slightly to allow lines to slowly fill with

gas, then open valve fully to back–seat valve.

(Back–seating valve prevents gas leakage

around valve shaft).

7. Check for nitrogen gas leaks and tighten any

loose connections.

6. Check CO2 connections for leaks. Tighten loose

connections.

REPLENISHING CONCENTRATE (TEA

SYSTEM) OR SYRUP (POST–MIX

SYSTEM) SUPPLY

1. Remove gas disconnect (grey) and syrup or

concentrate disconnect (black) from empty tank,

then remove tank.

2. Place full tank in position, then connect gas disconnect (grey) and syrup or concentrate disconnect (black)to tank.

CONCENTRATE (TEA SYSTEM) OR

SYRUP (POST–MIX SYSTEM) FLAVOR

CHANGE

Sanitize system as instructed, then install full tank of

new flavor concentrate or syrup.

CLEANING AND SANITIZING

DAILY CLEANING OF UNIT (DO NOT USE

ABRASIVE TYPE CLEANERS)

Unit should be thoroughly cleaned at end of daily operation as follows:

POST–MIX SYSTEM

NOTE: When indicator on CO2 cylinder regulator

assembly 1800–psig gage is in shaded (‘‘change

CO2 cylinder’’) portion of dial, CO2 cylinder is

almost empty and should be changed.

1. Fully close (clockwise) CO2 cylinder valve.

2. Slowly loosen CO2 regulator assembly coupling

nut allowing CO2 pressure to escape, then remove regulator assembly from empty CO2 cylinder.

11 300168000

1. If unit is equipped with base kit, remove cup rest

from drip tray. Wash cup rest in plain water, then

wipe dry with a clean soft cloth.

2. Wipe unit exterior and drip tray interior (if applicable) with damp cloth, then wipe dry with clean

soft cloth.

3. Install cup rest in drip tray.

WEEKLY CLEANING OF DISPENSING VALVE

1. Loosen dispensing valve cover screw until

screw disengages from valve, then remove cover.

Page 16

2. Remove nozzle, baffle, and baffle tube extension (if dispensing tea) from dispensing valve.

3. Wash removed parts, including valve cover, in

warm water.

WARNING: Flush sanitizing solution

from system as instructed. Residual

sanitizing solution left in system

could create a health hazard.

WATER STRAINER HOUSING

SCREEN (P/N 313253-000)

O-RING (P/N 310784-000)

SCREEN RETAINER

FIGURE 5. WATER STRAINER

4. Hold appropriate container under dispensing

valve, then slowly pour warm water over valve.

5. Install baffle, baffle tube extension (if applicable), nozzle, and cover on dispensing valve.

SANITIZING UNIT

IMPORTANT: Only qualified personnel should

perform sanitizing procedure.

The unit should be sanitized at least weekly following

Sanitizer Manufacturer’s recommendations. Use

Chlor–Tergent (Oakite Products, Inc.) or equivalent

sanitizer. Proceed as follows to sanitize unit.

1. Remove quick disconnects from concentrate to

syrup tank. Wash quick disconnects in warm

water.

2. Following Sanitizer Manufacturer’s instructions,

prepare two gallons of sanitizing solution in

clean empty concentrate or syrup tank.

7. Place waste container under dispensing valve.

Open valve to permit concentrate or syrup to

purge sanitizing solution from system and until

only syrup is dispensed, then close valve.

WARNING: To avoid possible

personal injury or property damage,

do not attempt to remove tank cover

until gas pressure has been released from

tank.

8. Thoroughly rinse inside and outside of tank that

was used for sanitizing solution to remove all

solution residue.

SERVICING WATER STRAINER SCREEN

(see Figures 2 and 5)

The water strainer screen must be inspected and

serviced at least once a year under normal circumstances and after any disruptions (plumbing work,

earthquake, etc.) to the water supply system that

might cause turbulent (erratic) flow of water through

the system. Service water strainer screen as follows:

1. Close unit water inlet line shutoff valve.

2. Loosen water strainer screen retainer, then pull

screen retainer and screen from water strainer

housing.

3. Pull screen from screen retainer. Clean any sediment from screen retainer and port in water

strainer housing.

4. Inspect screen for holes, restrictions, corrosion,

and other damage. Discard damaged screen.

3. Connect tank containing sanitizing solution into

tea or syrup system.

4. Place waste container under dispensing valve

nozzle. Dispense from dispensing valve to permit sanitizing solution to push concentrate or

syrup out of system and valve. Continue to dispense until only sanitizing solution is dispensed,

then close valve.

5. Follow Sanitizer Manufacturer’s application

instructions.

6. Remove tank containing sanitizing solution and

install tank containing concentrate or syrup into

concentrate or syrup system.

5. Install good or new screen (P/N 313253–000) in

screen retainer, then screw screen retainer into

water strainer housing. Tighten retainer only

finger tight.

6. Open unit water inlet line shutoff valve, then

check for water leaks.

CLEANING GAS CHECK VALVE (see

Figures 2 and 6)

The system gas check valve must be inspected and

serviced at least once a year under normal conditions and after any servicing or disruption of the system. ALWAYS REPLACE QUAD RING SEAL EACH

TIME GAS CHECK VALVES ARE SERVICED.

12300168000

Page 17

QUAD RING

183294-000

BALL

183296-000

SPRING

183297-000

RETAINER

183298-000

BODY

183295-100

*Quad ring seal must be replaced

each time check valve is serviced.

FIGURE 6. GAS CHECK VALVE

REMOVE AND REPLACEMENT

PROCEDURES

DISPENSING VALVE ASSEMBLY (see Figure 3)

Removal.

1. Loosen dispensing valve cover until screw disengages from valve, then remove cover.

2. Using spanner wrench, loosen and remove coupling nut from dispensing valve. Remove dispensing valve from unit.

Installation.

1. Install dispensing valve by reversing removal

procedure. Tighten coupling nut using spanner

wrench.

2. Adjust water flow regulator for water flow rate,

then adjust syrup flow regulator for Water–to–

Concentrate (tea) or syrup (post–mix) ‘‘Ratio’’ of

dispensed product as instructed.

SYRUP, CONCENTRATE, OR WATER FLOW

REGULATOR

Removal.

1. Loosen dispensing valve cover screw until

screw disengages from dispensing valve, then

remove cover.

2. Using spanner wrench, loosen and remove coupling nut from dispensing valve. Remove dispensing valve from unit.

(see Figures 3 and 7)

4. Pull TOP FLOW CONTROL (item 11), SPRING

(item 12), PISTON (item 13) up out of CYLINDER (item 14).

IMPORTANT: If more than one syrup or

concentrate or water flow regulator will be

disassembled at one time, do not mix pistons

and cylinders as they are precision matched

sets.

5. The CYLINDER (item 14) normally need not be

removed from BODY (item 15). If need to remove cylinder should arise, pull cylinder up out

of body, ALWAYS INSTALL NEW O–RING (item

10) P/N 317816–000 ON CYLINDER BEFORE

INSTALLING CYLINDER IN BODY.

Installation.

1. Install TOP FLOW CONTROL (item 11),

SPRING (item 12), and PISTON (item 13) in

CYLINDER (item 14).

2. Secure water flow or syrup or concentrate flow

regulator in dispensing valve BODY (item 15)

with PLATE (item 8) and SCREWS (item 9).

3. Install dispensing valve by reversing removal

procedure. Tighten coupling nut using spanner

wrench.

4. Water Flow Regulator Removed.

If water flow regulator was removed from dis-

pensing valve, water flow rate of valve must be

checked and if necessary, regulator must be

adjusted as instructed.

Syrup or Concentrate Flow Regulator Removed.

If syrup or concentrate flow regulator was re-

moved from dispensing valve, Water–to–Con-

centrate (tea) or syrup (post–mix) ‘‘Ratio’’ of dispensed product must be checked and if

necessary, adjusted as instructed.

5. Install dispensing valve cover and secure with

screw.

INLET VALVE (see Figures 3 and 7)

Removal.

1. Loosen dispensing valve cover screw until

screw disengages from dispensing valve, then

remove cover.

2. Using spanner wrench, loosen and remove coupling nut from dispensing valve. Remove dispensing valve from unit.

3. Turn dispensing valve upside down, then disconnect SPRINGS (item 3) from INLET

VALVES (item 4).

3. Remove two SCREWS (item 9) securing PLATE

(item 8) that secures water flow or syrup or concentrate flow regulator in dispensing valve

BODY (item 15), then remove plate.

13 300168000

4. Remove four SCREWS (item 1) securing dispensing valve BOTTOM COVER (item 2) and

VALVE BLOCK (item 6) to BODY (item 15),

then separate valve block from body.

Page 18

5. Remove inlet valve from valve block.

6. Remove NIB (item 5) from inlet valve.

2. Install dispensing valve by reversing removal

procedure. Tighten coupling nut using spanner

wrench.

NOTE: Short nib is for syrup or concentrate inlet

valve and long nib is for water inlet valve.

Installation.

1. Install inlet valve and assemble dispensing

valve by reversing disassembly procedure.

NOTE: It may be necessary to adjust inlet valves

so water and syrup or concentrate dispensing

start at same time and stop at same time by turning SETSCREWS (item 7).

3. Install dispensing valve cover and secure with

screw.

14300168000

Page 19

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

ADJUSTABLE CONCENTRATE OR SYRUP

AND WATER FLOW REGULAT ORS PARTS

TERMINOLOGY ARE THE SAME.

18

19

20

21

22

Item No. Description

1 Screw, Thread Cutting

2 Bottom Cover

3 Spring

4 Inlet Valve

5 Nib, Short, Syrup

Nib, Long, Water

6 Valve Block

7 Setscrew, Hex Socket

8 Plate

9 Screw, Thread Cutting

10 Screw, Thread Cutting

11 Top Flow Control

FIGURE 7. DISPENSING VALVE ASSEMBLY

*BAFFLE (P/n 318523-027), loose-shipped with unit,

is used in post-mix application of unit.

Item No. Description

12 Spring

13 Piston

14 Cylinder

15 Body

16 O–Ring

17 Baffle

18 O–Ring

19 Nozzle

20 Baffle Tube Extension

21 Cover Ass’y

22 Machine Screw

15 300168000

Page 20

FIGURE 8. INSTRUCTIONS FOR CRIMPING TUBE CLAMPS

16300168000

Page 21

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to carbonated water system, disconnect electrical

power to Cooling Unit, shut off plain water and CO2 supplies, and relieve the carbonated

water system pressure before proceeding. If repairs are to be made to syrup system,

remove quick disconnects from applicable syrup tank, then relieve the system pressure before

proceeding. If repairs are to be made to CO2 system, stop dispensing, shut off CO2 supply, then

relieve the system pressure before proceeding.

If repairs are to be made to an existing Remote Condensing unit, disconnect the power to the

condensing unit before proceeding

TROUBLESHOOTING TEA SYSTEM

Trouble Probable Cause Remedy

ONLY WATER DISPENSED. A. Quick disconnects not secure

on concentrate tank.

B. Out of concentrate. B. Replenish concentrate supply as

C. Concentrate tank nitrogen

regulator not properly

adjusted.

D. Inoperable dispensing valve. D. Repair dispensing valve.

E. Dispensing valve concentrate

flow regulator not properly

adjusted.

F. No nitrogen supply. F. Replenish nitrogen supply as

G. Dispensing valve concentrate

flow regulator, concentrate

tank quick disconnect, or

concentrate lines restricted.

IMPORTANT: If necessary to disassemble and clean dispensing valve

flow regulators, do not intermix their pistons and cylinders as they are

precision matched sets.

ONLY CONCENTRATE

DISPENSED.

A. Water inlet supply line shutoff

valve closed.

A. Secure quick disconnects on

concentrate tank.

instructed.

C. Adjust concentrate tank nitrogen

regulator as instructed.

E. Adjust dispensing valve

concentrate flow regulator as

instructed.

instructed.

G. Sanitize concentrate system as

instructed (see IMPORTANT

note).

A. Open water inlet supply line

shutoff valve.

NO CONCENTRATE OR

WATER DISPENSED.

WATER–TO–CONCENTRATE

‘‘RATIO’’ TOO LOW OR TOO

HIGH.

B. Water filter clogged. B. Replace water filter.

C. Water strainer clogged. C. Service water strainer as

instructed.

D. Inoperable dispensing valve. D. Repair dispensing valve.

A. Inoperable dispensing valve. A. Repair dispensing valve.

A. Dispensing valve concentrate

flow regulator not properly

adjusted.

B. Nitrogen gas pressure to

concentrate tanks insufficient

to push concentrate out of

tank.

17 300168000

A. Adjust Water–to–Concentrate

‘‘Ratio’’ as instructed.

B. Adjust nitrogen regulator for

concentrate tanks or replenish

nitrogen supply as instructed.

Page 22

Trouble RemedyProbable Cause

WATER–TO–CONCENTRATE

‘‘RATIO’’ TOO LOW OR TOO

HIGH. (cond’t)

ADJUSTMENT OF

DISPENSING VALVE

CONCENTRATE FLOW

REGULATOR DOES NOT

INCREASE TO DESIRED

WATER–TO–CONCENTRATE

‘‘RATIO’’.

C. Water pressure too low (must

be minimum of 20–psig).

A. No concentrate supply A. Replenish concentrate supply as

B. Concentrate tanks quick

disconnects not secure.

C. Concentrate tank nitrogen

regulator out of adjustment.

D. Dispensing valve concentrate

flow regulator, concentrate

tank quick disconnect, or

concentrate line restricted.

E. Water flowasher obstructed or

tapered nylon washer inside

tube swivel nut connection

distorted from being

over–tightened.

C. Correct water pressure problem.

instructed.

B. Secure concentrate tanks quick

disconnects.

C. Adjust concentrate tank nitrogen

regulator as instructed.

D. Sanitize concentrate system as

instructed.

E. Clean or replace flowasher or

replace tapered nylon washer and

make sure it seats properly.

F. Improper Baume of

concentrate.

G. Dirty or inoperative piston or

spring in dispensing valve

concentrate flow regulator.

IMPORTANT: If necessary to disassemble and clean dispensing valve

flow regulators, do not intermix their pistons and cylinders as they are

precision matched sets.

ADJUSTMENT OF

DISPENSING VALVE

CONCENTRATE FLOW

REGULATOR DOES NOT

DECREASE TO DESIRED

WATER–TO–CONCENTRATE

‘‘RATIO’’.

A. Dirty or inoperative piston or

spring in dispensing valve

concentrate flow regulator.

B. Water pressure too low (must

be minimum of 20–psig).

IMPORTANT: If necessary to disassemble and clean dispensing valve

flow regulators, do not intermix their pistons and cylinders as they are

precision matched sets.

TROUBLESHOOTING POST–MIX SYSTEM

F. Replace concentrate supply as

instructed.

G. Disassemble and clean

dispensing valve concentrate flow

regulator (see IMPORTANT note).

A. Disassemble and clean

dispensing valve concentrate flow

regulator (see IMPORTANT note).

B. Correct water pressure problem.

WATER–TO–SYRUP ‘‘RATIO’’

TOO LOW OR TOO HIGH.

A. Dispensing valve syrup flow

regulator not properly

adjusted.

B. CO2 gas pressure to syrup

tank insufficient to push syrup

out of tank.

18300168000

A. Adjust Water–to–Syrup ‘‘Ratio’’ as

instructed.

B. Adjust syrup tank CO2 regulator

as instructed.

Page 23

Trouble RemedyProbable Cause

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT INCREASE TO DESIRED

WATER–TO–SYRUP ‘‘RATIO’’.

A. No syrup supply. A. Replenish syrup supply as

instructed.

B. Syrup tank quick disconnects

B. Secure quick disconnects.

not secure.

C. Syrup tank CO2 regulator out

of adjustment.

D. Dispensing valve syrup flow

regulator, syrup tank quick

C. Adjust syrup tank CO2 regulator

as instructed.

D. Sanitize syrup system as

instructed.

disconnect, or syrup line

restricted.

E. Improper syrup Baume. E. Replace syrup supply as

instructed.

F. Dirty or inoperative piston or

spring in dispensing valve

syrup flow regulator.

F. Disassemble and clean

dispensing valve syrup flow

regulator (see IMPORTANT,

note).

G. Tapered nylon washer inside

tube swivel nut connector

G. Replace nylon washer and make

sure it seats properly.

distorted from being

overtightened.

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT DECREASE TO

DESIRED

WATER–TO–SYRUP ‘‘RATIO’’.

DISPENSED PRODUCT

CARBONATION TOO LOW.

IMPORTANT: If necessary to disassemble and clean dispensing valve

flow regulators, do not intermix their pistons and cylinders as they are

precision matched sets.

A. Dirty or inoperative piston or

spring in dispensing valve

syrup flow regulator.

A. Disassemble and clean

dispensing valve syrup flow

regulator (see IMPORTANT,

note).

IMPORTANT: If necessary to disassemble and clean dispensing valve

flow regulators, do not intermix their pistons and cylinders as they are

precision matched sets.

A. Carbonator CO2 regulator out

of adjustment for existing

water conditions or

A. Adjust carbonator CO2 regulator

(Reference manual provided with

carbonator).

temperature.

B. Air in carbonator tank. B. Vent air out of carbonator tank

through relief valve. Actuate

dispensing valve to make

carbonator pump cycle on.

C. Water, oil, or dirt, in CO

supply.

2

C. Remove contaminated CO2.

Clean CO2 system (lines,

regulators, etc.) using mild

detergent. Install clean CO

2

supply.

19 300168000

Page 24

Trouble RemedyProbable Cause

DISPENSED PRODUCT

COMES OUT OF

DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR

GLASS.

DISPENSED PRODUCT

PRODUCES FOAM AS IT

LEAVES DISPENSING VALVE.

A. Oil film or soap scum in cup or

A. Use clean cups and glasses.

glass.

B. Ice used for finished drink is

sub–cooled.

B. Do not use ice directly from

freezer. Allow ice to become ‘‘wet’’

before using. (Refer to following

NOTE).

NOTE: Crushed ice also causes dispensing problems. When finished

drink hits sharp edges of ice, carbonation is released from dispensed

drink.

A. Recovery rate of refrigeration

A. Allow ice bank to recover.

unit exceeded, ice bank

depleted.

B. Carbonator CO2 regulator

pressure adjusted too high for

existing water conditions or

B. Reduce carbonator CO2 regulator

pressure setting. Reference

manual provided with carbonator.

temperature.

C. Syrup over–carbonated with

CO2 as indicated by bubbles in

inlet syrup lines.

C. Remove syrup tanks quick

disconnects shake tank

vigorously, then relieve tank CO

pressure as many times as

necessary to remove

over–carbonation.

2

ONLY CARBONATED WATER

DISPENSED.

D. Dispensing valve restricted or

dirty.

E. Tapered nylon washer inside

carbonated water line swivel

D. Sanitize syrup system as

instructed.

E. Replace nylon washer. Make sure

it is properly seated.

nut connector distorted

restricting carbonated water

flow.

F. Dirty water supply. F. Check water filter. Replace

cartridge. (see NOTE)

NOTE: If water supply is dirty, be sure to flush lines and carbonator

completely. It may be necessary to remove lines to carbonator tank,

invert tank, and flush tank and all inlet lines to remove any foreign

particles or dirt.

A. Quick disconnects not secure

on syrup tank.

A. Secure quick disconnects on

syrup tank.

B. Out of syrup. B. Replenish syrup supply as

instructed.

C. Syrup tank CO2 regulator not

properly adjusted.

C. Adjust syrup tank CO2 regulator

as instructed.

D. Inoperable dispensing valve. D. Repair dispensing valve.

E. Dispensing valve syrup flow

regulator not properly

adjusted.

20300168000

E. Adjust dispensing valve syrup

flow regulator (Water–to–Syrup

‘‘Ratio’’) as instructed.

Page 25

Trouble RemedyProbable Cause

ONLY CARBONATED WATER

DISPENSED. (cont’d)

ONLY SYRUP DISPENSED. A. Water inlet supply line shutoff

F. Dispensing valve syrup flow

regulator, syrup tank quick

disconnect, or syrup lines

restricted.

IMPORTANT: If necessary to disassemble and clean dispensing valve

syrup flow regulators, do not intermix their pistons and cylinders as

they are precision matched sets.

valve closed.

B. Carbonator power cord

unplugged from electrical

outlet.

C. Carbonator CO2 regulator not

properly adjusted.

F. Sanitize syrup system as

instructed. (See IMPORTANT,

note).

A. Open water inlet supply line

shutoff valve.

B. Plug carbonated power cord into

electrical outlet.

C. Adjust carbonator CO2 regulator

(Reference manual provided with

carbonator).

21 300168000

Page 26

THIS PAGE LEFT BLANK INTENTIONALLY

22300168000

Page 27

ILLUSTRATED PARTS BREAKDOWN

DRAFT ARM WITH SF-1 VALVE

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303–1592

Telephone (800) 238–3600

Facsimile (612) 422–3232

Model Numbers

414019

September 12, 1983

Revised: October 8, 1986

IMI Cornelius Inc. 1983-86

23

Page 28

10

11

12

13

16

19

23

1

2

3

4

5

6

7

8

9

14

15

17

18

20

21

22

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

ITEM

NO.

1 176193 Fitting, 7/16–20

2 176034 Nipple

3 176017 Swivel Nut, 7/16–20

4 176035 Ferrule

5 176107 Fitting, 1/4 NPT by 7/16–20

6 178025–100 Tapered Gasket, White

7 311035 Strainer

8 311577 Wing Nut, 3/4–16

9 311584 Tube Hold Down

10 311580 Housing Cover

11 317884 Cover Ass’y (includes 12–14)

12 317881 Retaining Washer

13 317882 Machine Screw, Fl Sl Hd, Stainless

14 317647 Cover

15 319200 Dispensing Valve Ass’y (see

16 *187244 Machine Screw, Sl Pan Hd,

17 150199 Coupling Nut

18 319198 Adapter, Valve

**Zinc–plated steel unless indicated otherwise.

**Sold in bulk quantity only.

PART

NO.

319201 Draft Arm Ass’y, Tea

Steel, No. 8–32 by 3/8–in.

Figure 6–2)

No. 6–32 by 1/4–in.

NAME

FIGURE 9. TEA DRAFT ARM ASSEMBLY

ITEM

NO.

19 319199 Housing Ass’y (includes 20–27)

20 319197 Manifold and Tube Ass’y

21 150058 O–Ring, .301 I.D.

22 180020 Spring

23 178019 Retainer Washer

24 180018–013 Seal

25 314224 Stem, Poppet

26 180025 O–Ring, .364 I.D.

27 314488 Housing

28 316541 Column

29 319314–039 Base Kit, Optional (includes 30–41)

30 151447 Cup Rest

31 140133 Drain Hose Clamp

32 **140598 Drain Hose, 1/2 I.D. by 36–in.

33 319313 Flange

34 319315 Gasket, Rubber

35 *150774 Wing Nut, 3/8–16

36 151140 Mounting Clip

37 *150777 Hex Nut, Jam, 3/8–16

38 150447 Flat Washer, Rubber

39 *150724 Carriage Bolt, 3/8–16 by 5–in.

40 311587 Reinforcing Plate

41 151718–039 Base

PART

NO.

NAME

24300168000

Page 29

1

18

21

23

10

11

12

13

14

16

17

19

20

25

15

22

24

3

2

4

5

6

7

8

9

26

27

28

29

30

31

32

33

34

ITEM

NO.

1 317884 Cover Ass’y, w/o Lever , (includes 2–4)

2 317882 Machine Screw, Fl Sl Hd, Stainless

3 317881 Retaining Washer

4 317647 Cover, w/o Lever, Manual

5 317828 Thread Cutting Screw, Phil Rd Hd,

6 317718 Cover, B o t t o m

7 317649 Nozzle

8 300097 Extension, Baffle (tea application)

9 318754–011 Baffle (tea application)

10 398033–013 O–Ring, .799 I.D. by .103 C.S.

11 317723 Spring

12 311355 Valve Inlet

13 310788 Nib, Short, Syrup

14 317639 Valve Block

15 *314813 Setscrew, Headless Hex Soc.

16 317819 Pin

17 317646 Lever

NOTE 1: Items 27 and 28 are a matched pair and cannot be inter–

changed. Order item 26 for replacement.

**Zinc–plated steel unless indicated otherwise.

**Sold in bulk quantity only.

PART

NO.

319200 Post–Mix Valve Ass’y, Tea Draft Arm

Steel, No. 8–32 by 3/8–in.

Stainless Steel, No. 6–32 by 3/4–in.

318523–027 Baffle (see NOTE 2)

317782 Nib, Long, Water

Oval Pt., No. 8–32 by 1/2–in.

NAME

ITEM

NO.

18 317895 Thread Cutting Screw, Phil Pan Hd,

19 317645 Block, Threaded

20 317714 Plate

21 317784 Thread Cutting Screw, Phil Truss Hd,

22 310632–007 Adjusting Screw

23 180025 O–Ring, .364 I.D. by .070 C.S.

24 317429 Top, Flow Control

25 317816 O–Ring

26 310482 Spring

27 318664 Cylinder and Piston Ass’y, Syrup

28

29 317431 Cylinder (see NOTE 1)

30 317633 Body

31 319540 By–Pass Ass’y (includes 32 and 33)

32 319539 Nozzle

33 318755 Tube, By–Pass

34 319541 O–Ring, .157 I.D. by .038 C.S.

NOTE 2: If unit will be connected to post–mix system, remove existing tea baffle and baffle tube extension and install Baf fle (P/N

318523–000)

PART

NO.

Stainless Steel, No. 10–32 by 1/2–in.

Stainless Steel, No. 8–32 by 5/16–in.

(includes 28 and 29)

318665 Cylinder and Piston Ass’y, Water

(includes 28 and 29)

310754 Piston, Water (see NOTE 1)

310480 Piston, Syrup (see NOTE 1)

NAME

25

300168000

Page 30

THIS PAGE LEFT BLANK INTENTIONALLY

26300168000

Page 31

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or

Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you.

Please provide the equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

ENGLAND

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

LD004

4/21/98

27

Loading...

Loading...