Reliable 9000IS, 9000CJ, 9500BU, 9000CD User Manual

9000IS 9000CJ 9000CD9500IS

9000 SERIES

PROFESSIONAL STEAM PRODUCTS

PRODU ITS À VAPEUR PROFES SIONNELS

PRODU CTOS PROFESIO NALES DE VAPOR

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

ENGLISH 01

FRANÇAIS 16

ESPAÑOL 29

THE 9000

PROFESSIONAL STEAM PRODUCTS

INSTRUCTION MANUAL

ENGLISH

01

RELIABLE. RIGHT THERE WITH YOU.

At Reliable, we do what we love, and take pride in doing it right.

You want what’s best for the people, places and things that matter

in your life – from where you live to what you wear. So do we. From

the start, we approach every product with a craftsman’s attention

to detail and passion for making it right. Quality, functionality,

design and customer service play an equally important part in

delivering what’s right for you. With its stainless steel construction,

and professional grade components; the 9000 Series will allow

you to obtain the benefits of professional pressing or cleaning in a

compact and convenient format.

For your safety and to fully enjoy the advantages of this product,

please take a few minutes to read all the important safeguards and

care instructions. Keep this manual handy and review the product

warranty for your reference.

02

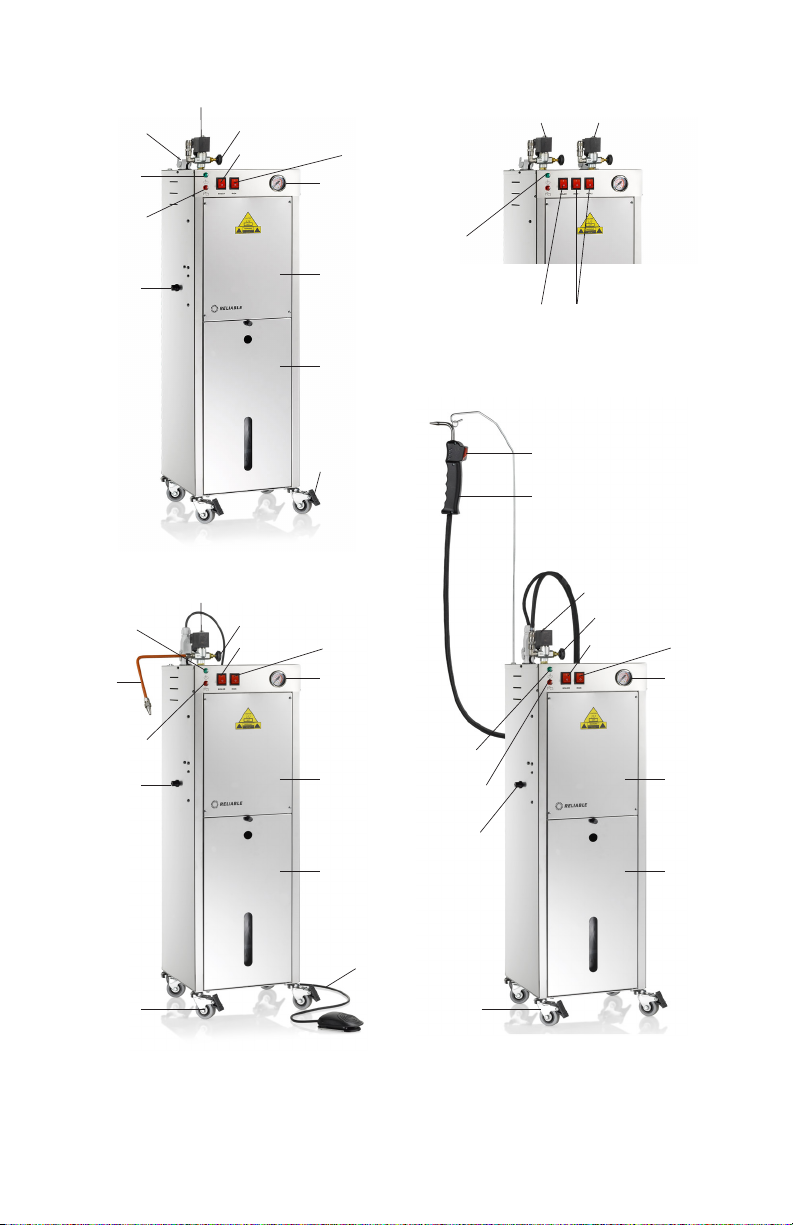

IRON PLUG

LOW WATER

PILOT LIGHT

STEAM READY

PILOT LIGHT (C)

ELECTRICAL

CABLE INLET

SOLENOID VALVE

STEAM REGULATION VALVE

STEAM SWITCH (B)

9000IS/9500IS 9500IS

BOILER SWITCH (A)

PRESSURE GAUGE

H

WATER DISCHARGE

BE

WATER INLET

LOW WATER

PILOT LIGHT

STEAM

NOZZLE

STEAM READY

PILOT LIGHT

ELECTRICAL

CABLE INLET

HEAVY DUTY

CASTERS

HEAVY DUTY

CASTERS

SOLENOID VALVE SOLENOID VALVE

STEAM REGULATION VALVE STEAM REGULATION VALVE

STEAM SWITCH STEAM SWITCH

BOILER SWITCH BOILER SWITCH

PRESSURE GAUGE PRESSURE GAUGE

LOW WATER

WATER

DISCHARGE

WATER INLET WATER INLET

FOOT PEDAL

PILOT LIGHT

STEAM READY

PILOT LIGHT

ELECTRICAL

CABLE INLET

HEAVY DUTY

CASTERS

STEAM GUN SWITCH

STEAM WAND

WATER

DISCHARGE

03

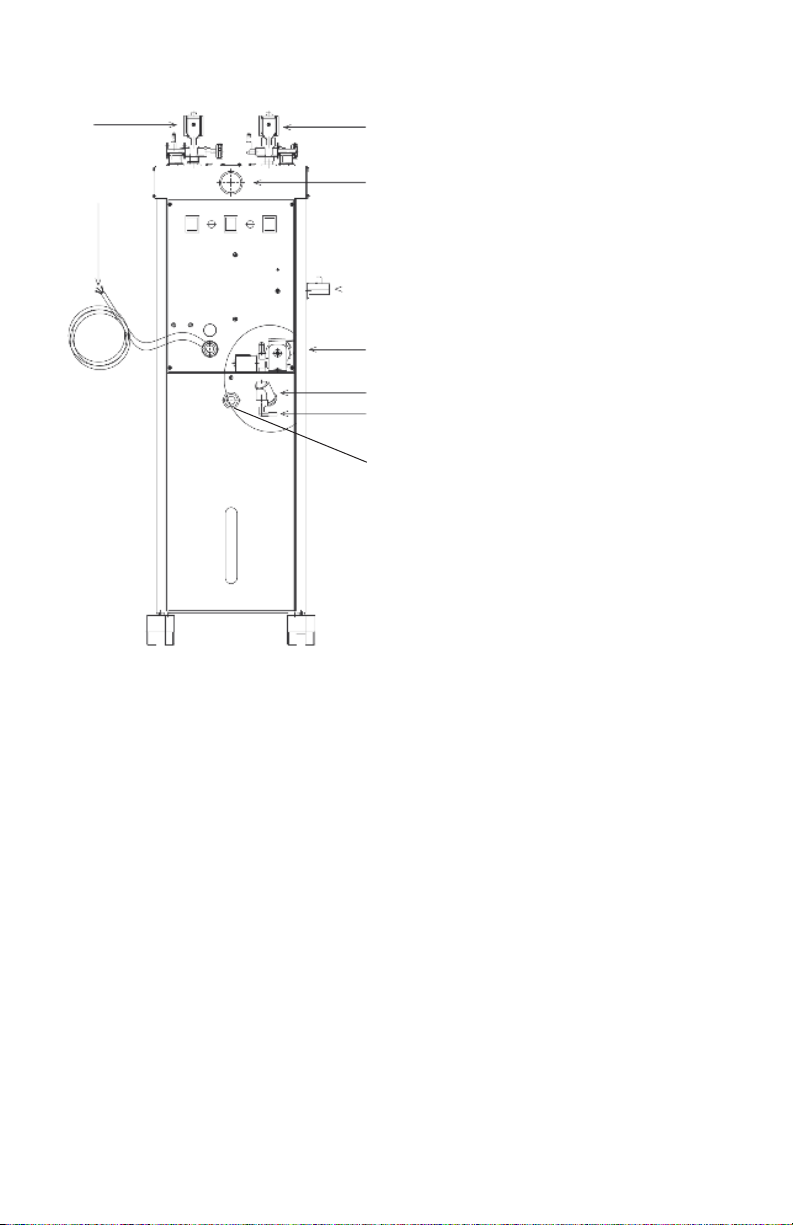

Fig. 5

6

1 = water inlet

77.1

2 = water filter

5

3 = pump

4 = water discharge

5 = pressure gauge

6 = power inlet

4

7 = solenoid valve

7.1 = solenoid valve

3

8 = water container valve

2

1

8

04

THE INSTALLATION AND USE OF THIS

PROFESSIONAL EQUIPMENT MUST BE DONE

BY COMPETENT AND TRAINED PERSONNEL

WITH APPROPRIATE TECHNICAL KNOWLEDGE

AND UNDERSTANDING OF APPLICABLE SAFETY

STANDARDS. BEFORE USING THIS EQUIPMENT

IT IS NECESSARY TO CONDUCT THE FOLLOWING

STEPS:

1. Water connection (tap with hose holder); the steam generator will be connected to the tap with hose holder labelled WATER INLET (fig. 5 #1), placed

on the Boiler, via a rubber tube which must have a pressure capacity of at

least 100 lbs. This rubber tube must be fixed tightly with 2 hose clamps.

(NOTE: before inserting the rubber tube into the water inlet, you must flush a

few litres of water in order to clean the conduit).

2. Protected electrical plug, suitable to the power voltage of the

steam generator.

3. 9000IS - Screw the nozzle into the steam fitting and plug in the 4-pin

receptacle for the electronic foot pedal. 9000CD - Connect the steam gun or

steam brush the same way using the quick disconnect steam hose.

4. 9000IS/9500IS - Insert the two-piece wand into the flange on top of the

boiler, tighten with the side screw and attach the spring on the iron hose to

the coil end of the wand.

PACKAGE OPENING

1. Remove the Boiler from the box, affix the wands, connect iron sockets and

steam tubes, fix the iron cable to cable/steam wand support hook.

ATTENTION: irons must be placed on their iron rests, on the ironing board.

CONNECTION TO WATER PIPE AND STARTING

1. Connect the rubber tube to the tube holder called WATER INLET placed on

the steam generator and turn the water tap on.

2. Connect the power supply cable to a protected plug with a grounded switch,

and a voltage suitable to the steam generator voltage.

3. After switching on the Boiler (A) and the irons and the steam switch (B), wait

for the Boiler green pilot light to switch off (C) and for the pressure gauge

to indicate 50-60 lbs. At this point press the steam button 3 or 4 times, so

that the steam comes out: this must be carried out in order to heat up the

05

hose that delivers steam to the iron steam wand/nozzle. This prevents water

leakage (the steam iron must always be held in such a way as not to harm the

operator.

4. To adjust steam flow, regulate the steam adjustment tap (fig. 5/7.1: solenoid

valve).

5. The Boiler is now ready for use. During use, the “steam ready” pilot light

switches on and off (C).

ATTENTION: Make sure that water is always available for the steam generator, the

lack of water can cause air bubbles inside the conduit, i.e. the water will not reach

the Boiler while the Boiler is under pressure. Without water, the pump will function

for about a minute; after that the alarm will sound and will cause the automatic

shut down of the entire unit.

6. Water pressure should never go over 3.5 lbs, otherwise the pump will stop

and, accordingly, the water will not reach the Boiler.

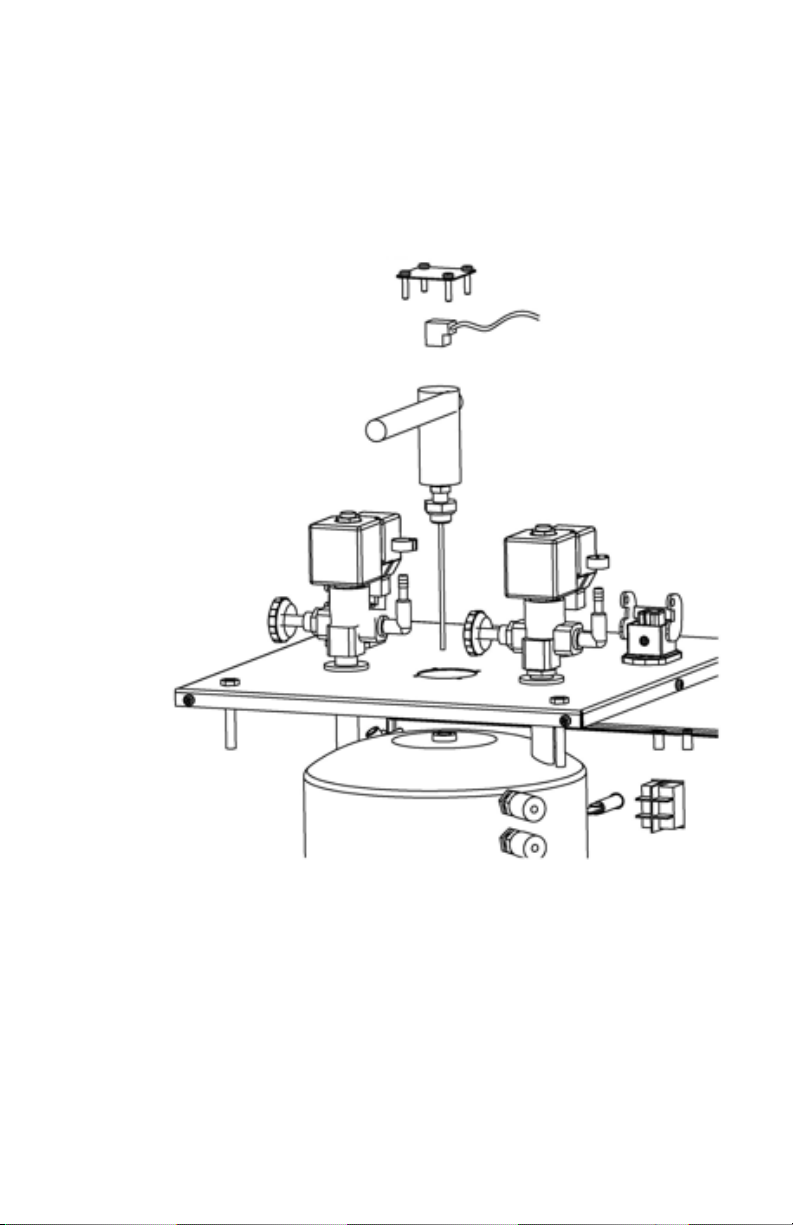

CONNECTION TO THE WATER TANK

1. The Boiler is designed to be connected to a direct waterfeed. If a direct waterfeed source is not available a water container kit is available.

*IF USING THE WATER CONTAINER KIT ENSURE THAT THE VALVE TO THE DIRECT FEED IS IN THE CLOSED POSITION.

2. To assemble the kit please proceed as follows:

• Open the front panel unscrewing the 4 screws.

• Insert the silicon hose on the valve MC111 and place the opposite end

into the water tank.

• Insert the other silicon hose on the water inlet (1), placing the other end

into the water tank.

06

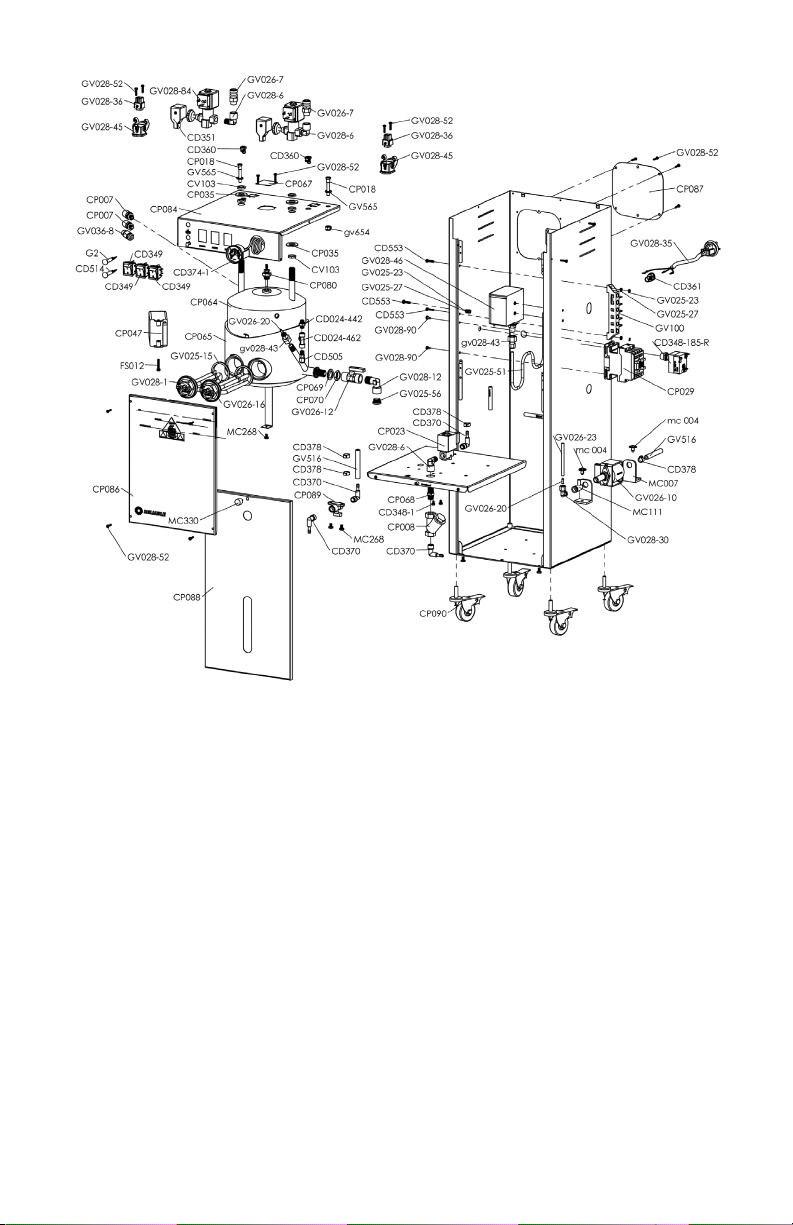

CPO89

07

IMPORTANT

1. Use only tap water.

2. Flush the Boiler once a week, making sure that the unit is shut off and that

the Boiler pressure is not over 0 lbs (pressure gauge). Open exhaust tap

slowly (water discharge). During this operation wear appropriate regulation

gloves, in order to avoid burns.

3. Never leave hot iron on the ironing board.

4. Connect the Boiler to suitable protected plug.

5. When not in use, switch the Boiler off and close the water tap; remember

to open the water tap before switching on the machine again (only for the

units connected to the direct waterfeed).

6. Always keep children away from the Boiler, both when it is on and off.

7. Make sure that during cold seasons the tubes that connect the Boiler to

water supply do not freeze.

8. Do not put additives in the water.

9. Standard and extraordinary maintenance must be carried out by authorized

personnel and all the components must be replaced only with original spare

parts.

08

WATER LEVEL PROBE CLEANING PROCEDURE

We recommend you clean the water level probe once a month. This cleaning operation must be carried out ONLY by authorized personnel. Please follow the cleaning

instructions as indicated below:

1. REMOVE THE COVER OF THE LEVEL PROBE

2. REMOVE THE CONNECTION PLUG

3. UNSCREW THE LEVEL PROBE WITH

A TUBE SPANNER DIAM. 18MM

4. TAKE OUT THE LEVEL PROBE

09

SPECIFICATIONS

Version 220V/110V Power supply:

Total Installed Power 1200W:

(Power Iron: W 800)

Boiler Power:

Pump Power: W 48-HZ 50 2/1 mm c f

Boiler Capacity: 5 L/1.3 Gal

Ironing Endurance: CONTINUOUS

Operating Steam Pressure: 3,5 / 4 BAR

Maximum Pressure: 5,5 BAR

IMPORTANT INFORMATION FOR CORRECT

DISPOSAL OF THE PRODUCT

This product must not be disposed of as urban waste. It must be taken to a special

local waste collection centre or to a dealer providing this service.

10

*

Foot Pedal – GVO28/71 (9000CJ)

Steam Nozzle – GVO28/67 (9000CJ)

Steam Gun – 1700DA (9000CD)

11

12

Loading...

Loading...