Page 1

The DreamStitcher

787

Portable Serger

INSTRUCTION MANUAL

Page 2

Page 3

1

TABLE OF CONTENTS

1. KNOWING YOUR MACHINE

Identification chart…………………………………………………………………………… 2

Accessories…………………………………………………………………………………… 3

Setting up your machine…………………………………………………………………… 4

Preparation for threading…………………………………………………………………… 5-6

Lint tray, Cutting width gauge……………………………………………………………… 7

Thread cutter, Changing presser feet…………………………………………………… 7

Changing needle, thread and fabric chart………………………………………………… 8

2. STARTING TO SEW

Threading your machine…………………………………………………………………… 9-12

Helpful hints………………………………………………………………………………… 12

Testing stitch overlock stitches…………………………………………………………… 13

Setting chart………………………………………………………………………………… 14

Three-thread overlock with one needle…………………………………………………… 15

Converting to two-thread use……………………………………………………………… 15

Narrow and rolled hem, picot stitch……………………………………………………… 16

Adjusting thread tensions…………………………………………………………………. 17

Adjusting stitch length, Adjusting overedge cutting width, Stitch finger(B)…………… 18

Differential feed……………………………………………………………………………… 19

Foot pressure regulator…………………………………………………………………… 20

Sewing with extra heavyweight fabric or multiple layers of fabric……………………… 20

Basic techniques

Turning outside corners without cutting threads…………………………………… 21

Turning curved edges, Removing stitches from sewn fabric……………………… 21

Corded overlock………………………………………………………………………. 22

Decorative effects……………………………………………………………………… 23

Differential feed applications………………………………………………………….. 24

3. CARING FOR YOUR MACHINE

Replacing moving cutter, Disengaging moving cutter……………………………………… 25

Removing face cover………………………………………………………………………… 25

Cleaning and oiling…………………………………………………………………………... 26

4. CHECKING PERFORMANCE PROBLEMS……………………………………………… 27

SPECIFICATION OF MACHINE

MODEL

300

320

Number of threads

3 or 4 threads

2, 3 or 4 threads

Overedge stitch width

6mm(left needle) and 3.8mm(right needle)

Needle

HA1-SP, HA ×1(130/705H)

Stitch length

1-5mm

Stitching speed

Up to 1300 stitches per minute

Dimensions

320 mm(W) ×280mm(P)×280mm(H)

Weight

8Kgs (17.6 1bs)

Page 4

2

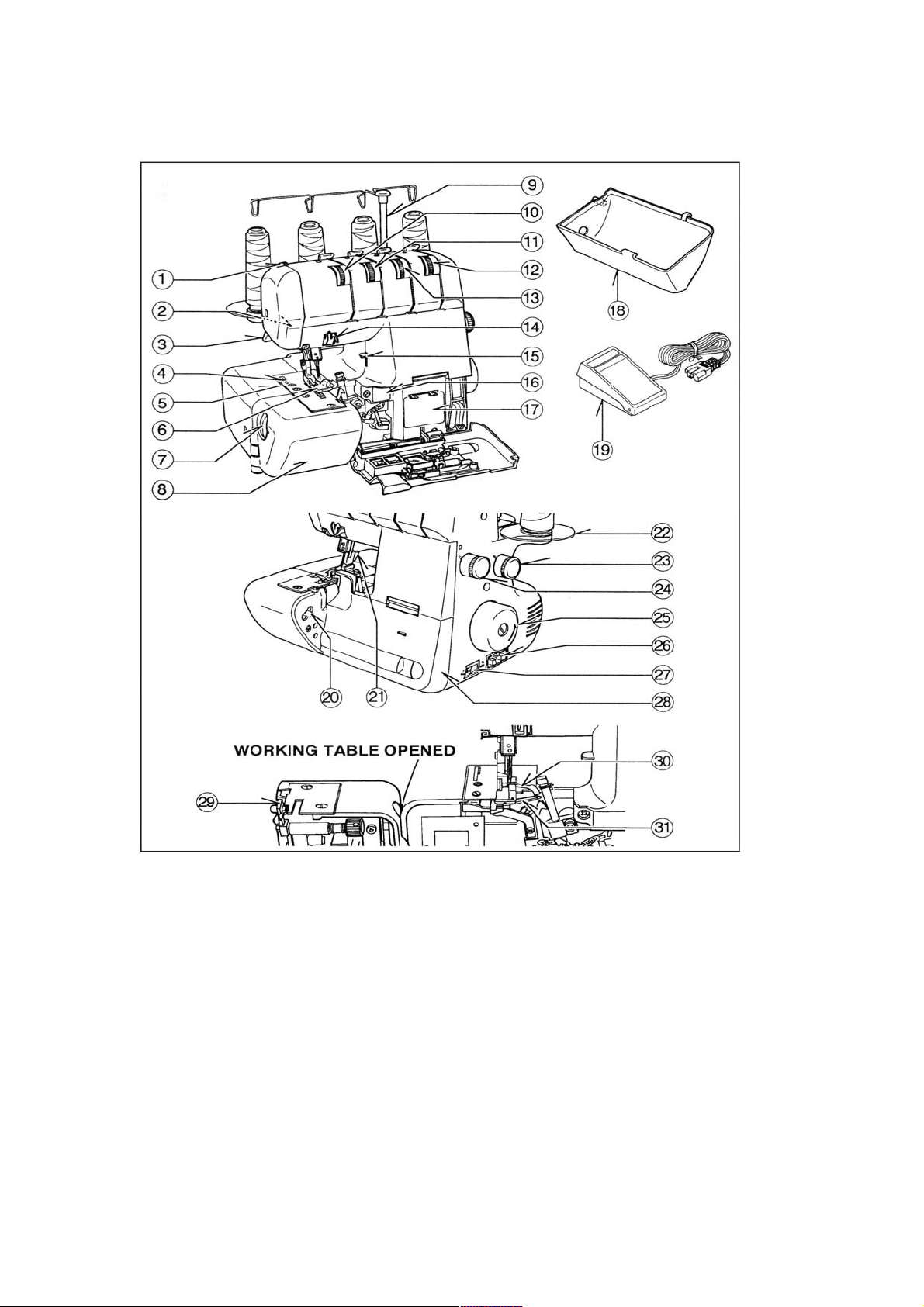

1. KNOWING YOUR MACHINE

IDENTIFICATION CHART

1. Foot pressure regulator

2. Sewing light

3. Presser foot lever

4. Thread cutter (Model 320 only)

5. Needle plate

6. Presser foot

7. Overedge cutting width dial

8. Working table

9. Thread guide pole

10. Left needle thread tension control

11. Right needle thread tension control

12. Lower Looper thread tension control

13. Upper looper thread tension control

14. Needle thread guides

15. Thread cutter lever (Model 320 only)

16. Two thread convertor instruction (Model 320 only)

17. Threading chart

18. Lint tray

19. Foot control

20. Release lever

21. Foot release lever

22. Spool disc

23. Differential feed control dial

24. Stitch length dial

25. Hand wheel

26. Plug connector socket

27. Light and power switch

28. Front cover

29. Moving cutter

30. Upper looper

31. Lower looper

Page 5

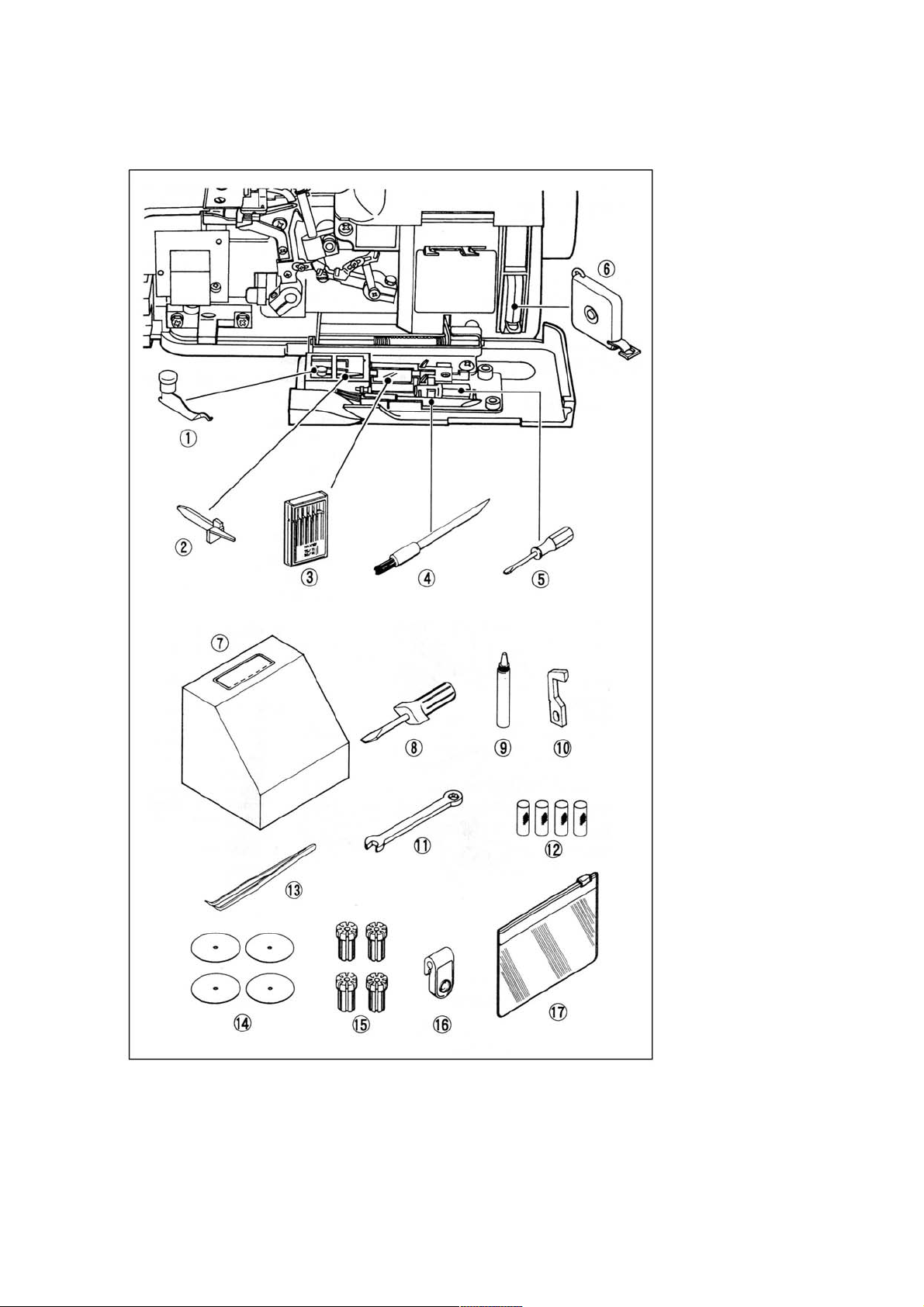

3

ACCESSORIES

All parts listed may be obtained from your nearest dealer.

1. Two-thread convertor

(Model 320 only)

2. Stitch finger (B)

(Model 320 only)

3. Needle set(option)

4. Brush(option)

5. Screwdriver (small)

6. Tape measure (option)

7. Machine cover

8. Screwdriver (large)

9. Oiler

10. Moving cutter

11. Spanner

12. Thread net

13. Tweezers

14. Spool disc

15. Spool holder

16. Cord guide

17. Accessory bag

* Only Model 320 has storage of accessories at the back of front cover.

Page 6

4

SETTING UP YOUR MACHINE

1. Wipe off excess oil in the needle

plate and bed areas.

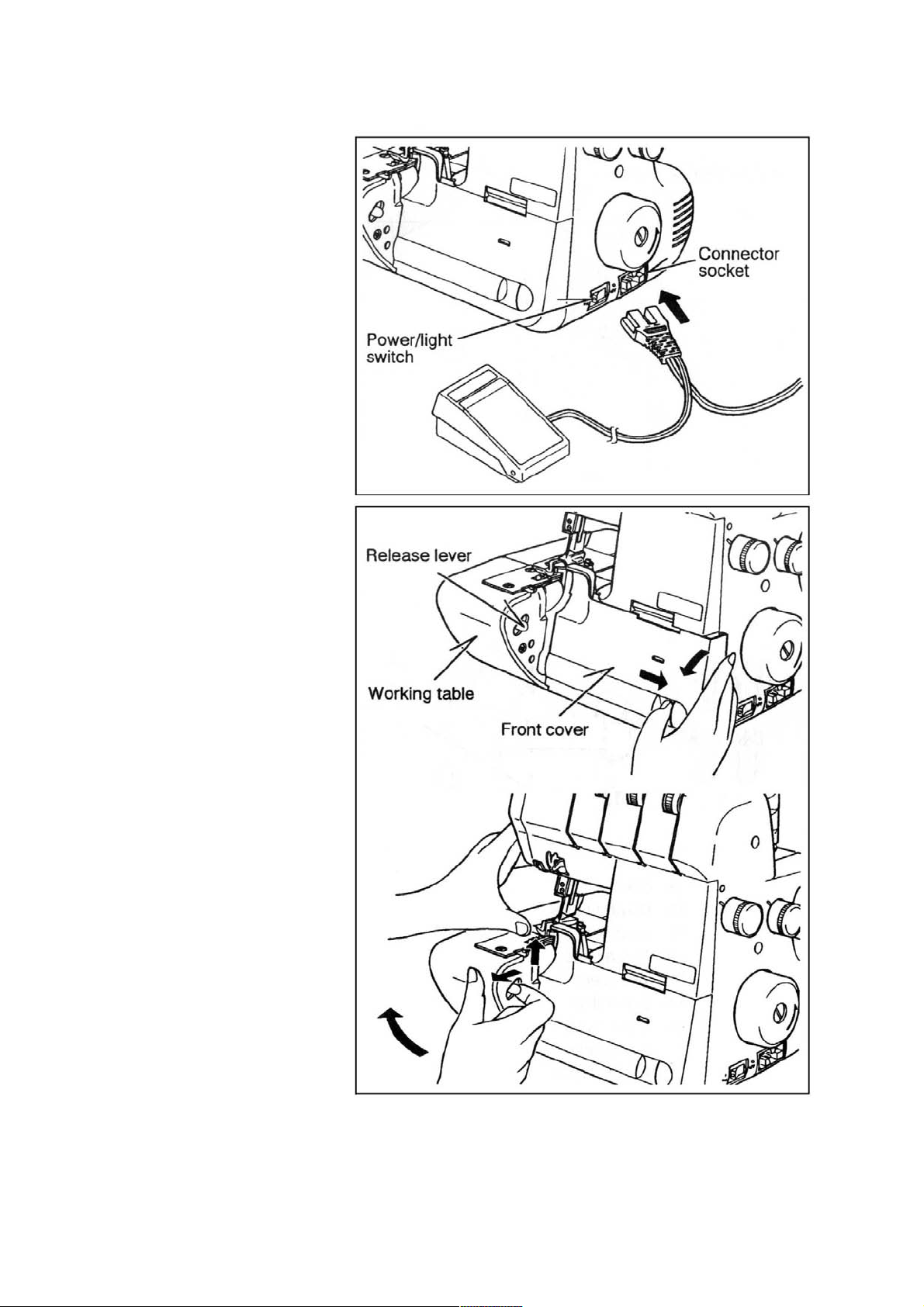

2. FOOT CONTROL

Push foot control plug into

connector socket, and connect

the power line plug into power

supply outlet.

3. POWER/LIGHT SWITCH

Your machine will not operate

unless the power/light switch is

turned on. This same switch

controls both machine power

and sewing light.

When leaving the machine

unattended, or servicing the

machine, remove the power line

plug from supply outlet..

4. OPENING FRONT COVER

To open front cover, pull it to the

right and down towards you.

5. OPENING WORKING TABLE

To open working table, pull the

release lever towards you with

your right hand, and lift the front

of presser foot up with your left

hand.

Page 7

5

PREPARATION FOR THREADING

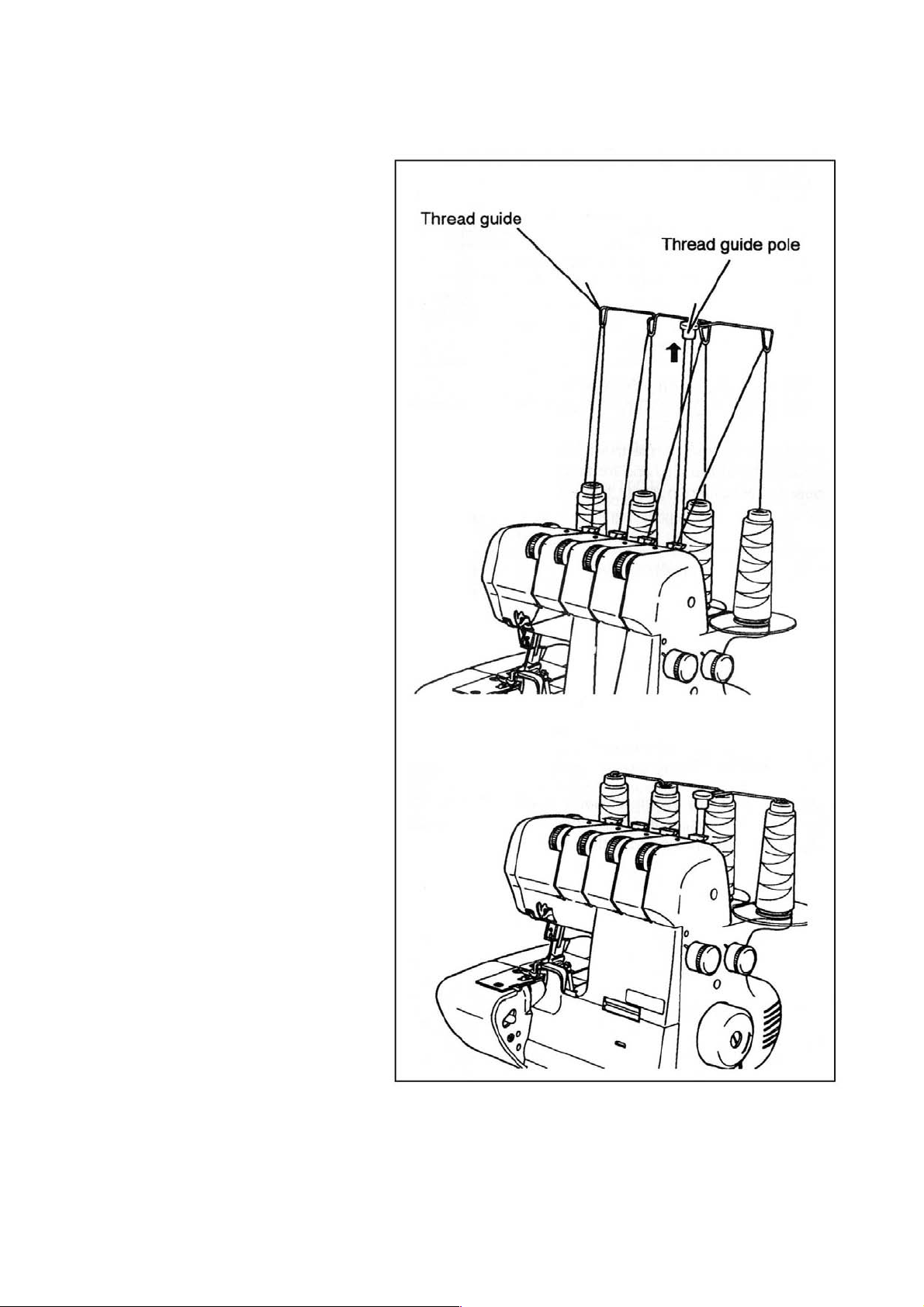

THREAD GUIDE POLE

Pull up thread guide pole to the

highest point until you hear it click.

Place thread spools on pins and

draw thread through thread

guides on the pole from rear to

front.

Thread guide of pole can hold

thread spools on the spool stand

by pulling down the pole as

illustrated.

Page 8

6

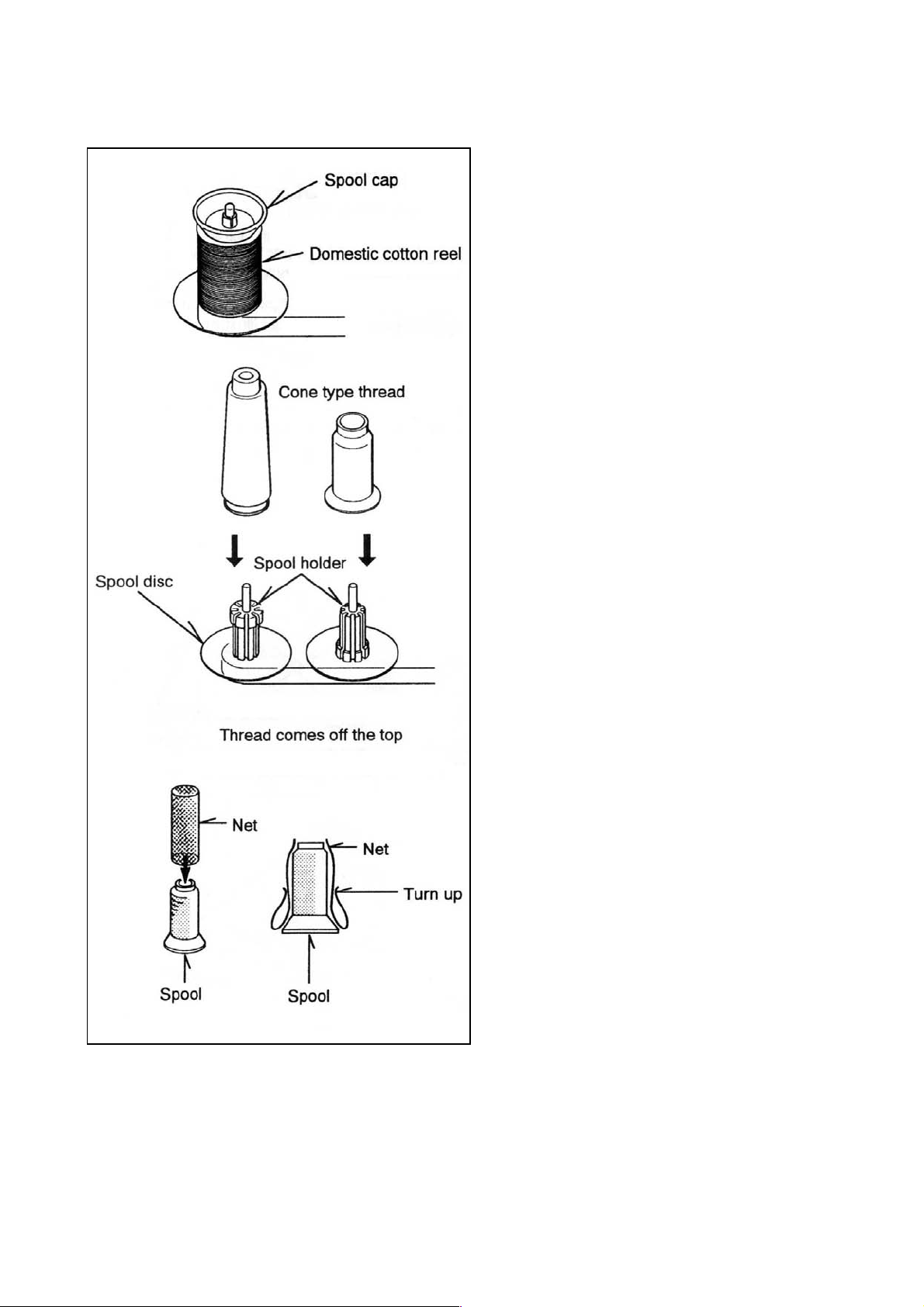

SPOOL CAPS FOR DOMESTIC TYPE

SPOOLS

SPOOL DISC AND SPOOL

HOLDERS FOR CONE SPOOLS

For large cone spools use the rubber spool

holders with the wide end at the top, and for

small ones, use the same rubber spool

holders but with the narrow end at the top.

SPOOL NETS

Polyester or bulky nylon threads become

loose while unwinding. To keep consistent

feeding of such threads, utilize spool net

sleeving over the spool.

Page 9

7

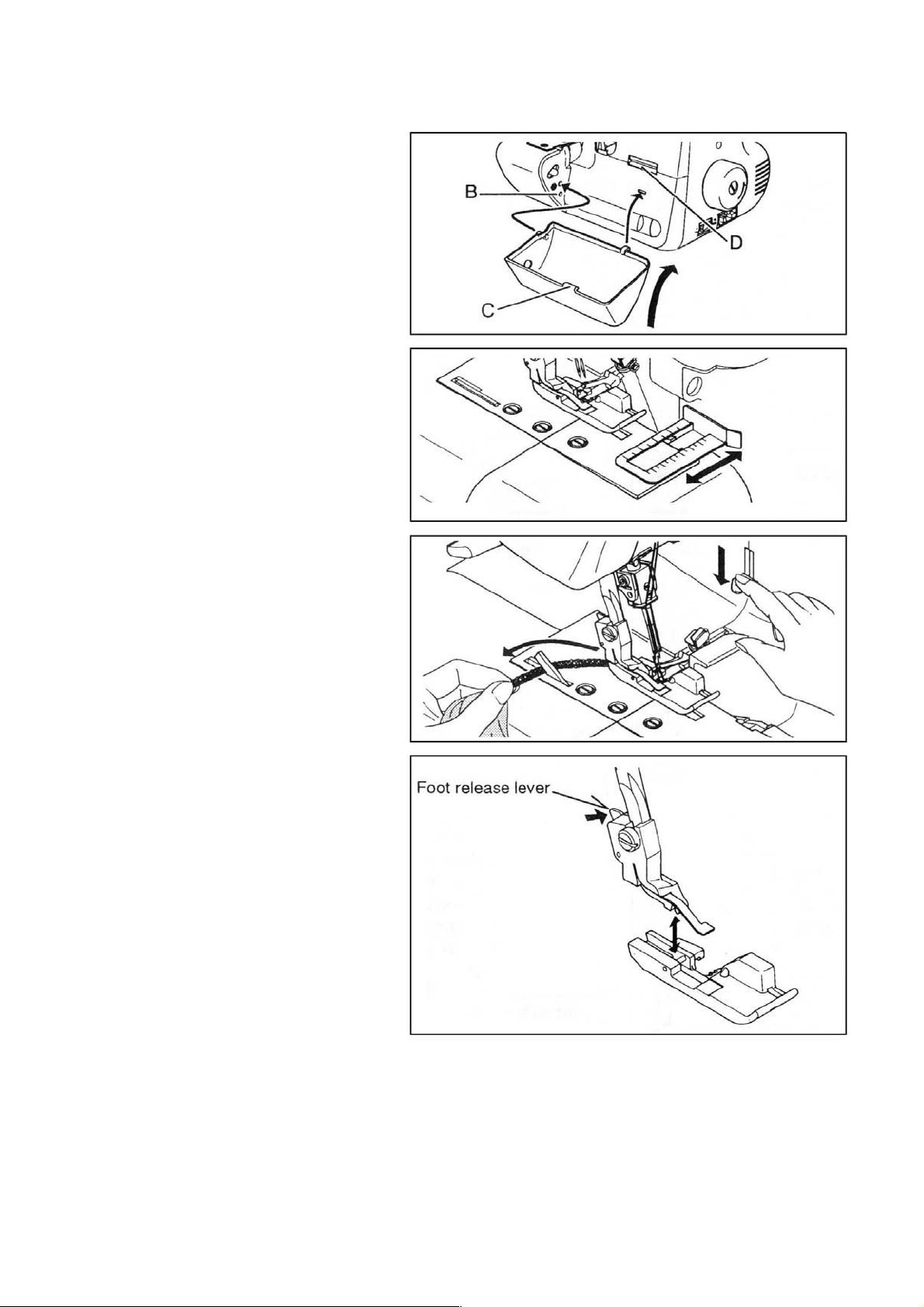

LINT TRAY

With the lint tray located in this position,

it will collect all your waste material.

After completion of work if you then turn

tray upwards in direction shown, finger

Ref C will locate in slot D and left hand

pin will slide into lower hole B.

CUTTING WIDTH GAUGE

When using cutting width gauge, the

fabric is cut down and sewn at same

distance from the edge of fabric.

Within the distance of the width

adjusted.

THREAD CUTTER (Model 320 only)

Thread cutter is built in needle plate.

Make sure that power switch is off, then

trim thread near the end of fabric by

pushing down lever as illustrated.

CHANGING PRESSER FEET

Be sure needle is in the up position.

Raise presser foot lever.

1. Push foot release lever to remove

the foot.

2. Place the desired foot on the needle

plate aligning needle holes.

3. Lower the presser foot lever and

push foot release lever so that the

foot holder snaps on the foot.

Page 10

8

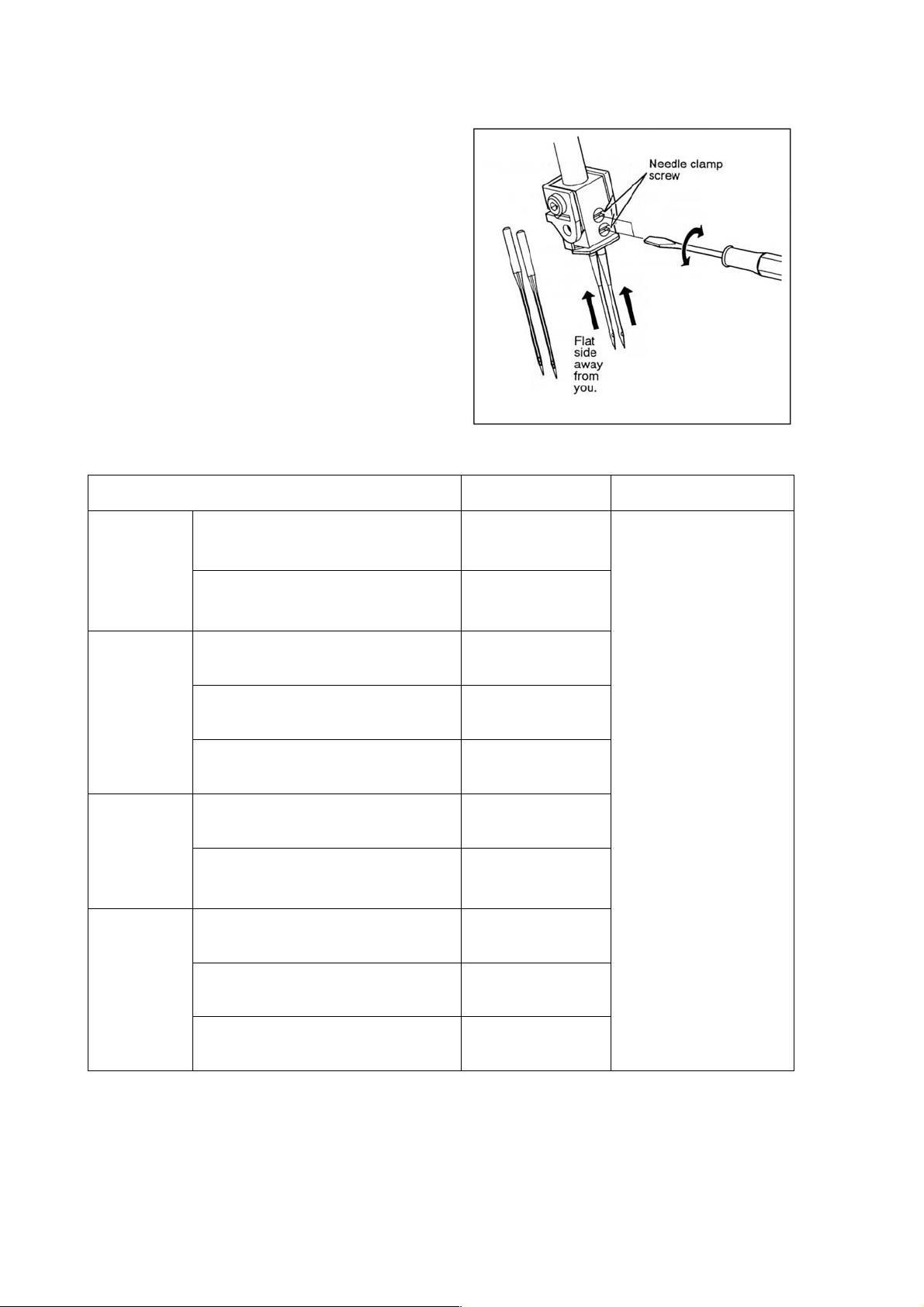

CHANGING NEEDLE

NEEDLE, THREAD AND FABRIC CHART

Use HA ×1 SP, HA ×1 (130/705H) Needles.

FABRIC

THREAD

NEEDLE

Light weight:

Organdy, Lawn, Gingham

Cotton No.100

COTTON

LINEN

Heavy weight:

Oxford, Denim, Cotton Gabardine

Polyester

No.60-50

Cotton No.60

Light weight:

Tropical, Wool, Poplin

Polyester

No.80

Cotton No.60

Serge, Gabardine, Flannel

Polyester

No.80-60

Cotton No.60

WOOL

Heavy weight:

Velours, Camelhair, Astrakhan

Polyester

No.60-50

Cotton No.60

Light weight:

Georgette Crape, Voile, Satin

Polyester

No.100-80

Cotton No.120-80

SYNTHETIC

FIBRE

Heavy weight:

Taffeta, Twills, Denim

Polyester

No.60

Cotton No.60

Tricot

Polyester

No.80-60

CottonNo.80-60

Jersey

Polyester

No.60-50

Cotton No.60

KNIT

Wool

Polyester

No.60-50

Bulk Nylon

90(14)

for general sewing

75(11)

for light weight fabrics

Raise needle bar to its highest point by turning

hand wheel towards you, but leave presser foot

down. Loosen needle clamp screw to remove the

needle, and place new needle with Flat Side

Away From you, into the needle bar as far as it

will go, and tighten screw.

*Synthetic threads are recommended for ordinary overlocking. Polyester thread, for example, is very

useful for different types of fabric.

NOTE: Keep in mind that the lower and upper loopers will use about twice the amount of thread as the

needles. When purchasing thread for sewing, therefore, especially if it is an unusual colour, you

should buy sufficient for your requirements.

Page 11

9

2. STARTING TO SEW

THREADING YOUR MACHINE

Wrong threading may cause shipped stitches,

breaking threads, or other problems.

Try to master the correct threading before

moving on to test sewing.

Threading must be carried out in the sequence

of Lower Looper – Upper Looper – Needle.

Open the front cover and the working table.

Raise needle to its highest point by turning hand

wheel towards you, and raise the presser foot.

Before re-threading lower looper, remove thread

from needle eye first, then re-thread the lower

looper. This will prevent tangling.

NOTE: Thread tension is released when the

presser foot is lifted up.

THREADING LOWER LOOPER

1. Feed the thread through the thread

guide as illustrated.

2. Pull the lower thread through tension

slot. Holding the thread with your left

hand, pull down with right hand firmly.

3. Draw the thread through thread guide

as illustrated.

4. Pass the thread through lower looper

eye, and hook it around part A as

indicated by the arrow. Leave about

4” (10cm) extra thread.

Page 12

10

THREADING UPPER LOOPER

1. Feed the thread through the thread guide as illustrated.

2. Pull the upper thread through the slot, holding the thread with your left hand.

3. Draw the thread through the thread guide as illustrated.

4. Pass the thread through wire thread guide and looper eye, leaving an excess length of

about 4”(10 cm)

Page 13

11

THREADING NEEDLES

1. Feed the thread through the thread guide as illustrated.

2. Draw the needle threads through left-hand tension slot. Holding the thread with your left hand, pull

down with right hand firmly.

3. Draw the thread through the thread guide as illustrated.

4. Thread the needles from front to back through needle eye and pull the threads towards the back

passing along the right side of presser foot, leaving an extra length of about 4”(10cm)

Page 14

12

HELPFUL HINTS

REPLACING THREAD SPOOLS

When replacing thread spools, the

following steps may be helpful for quick

changeover.

1. Cut off existing threads near the

spools. Tie the cut ends thread from

new spools as illustrated (seamen’s

knot).

2. Raise presser foot.

3. Lower needle bar to its lowest

position by turning hand wheel

away from you. Carefully pull the

existing threads until the connecting

knots pass through needle eye and

looper eyes.

CUTTING NEEDLE THREAD

Frayed thread may make needle

threading difficult.

Draw the thread near the thread cutter

on the needle plate and push the thread

cutter lever (model 320 only) or draw

the thread passing under the moving

cutter and turn hand wheel towards you

to obtain clear cut end as illustrated.

Page 15

13

TESTING STITCH OVERLOCK STITCHES

After threading is completed, use a

scrap of fabric that you plan to sew and

test to sew in the following order.

1. Gently pulling all the threads to the

left, lower the presser foot. Rotate

the hand wheel towards you a few

times to see if the lock stitches are

properly formed.

2. Start the machine at low speed and

feed in test fabric under the presser

foot by slightly pushing it forward.

(This can be done with the presser

foot down on most fabrics except

bulky materials.)

Guide the fabric gently as machine

automatically feeds the material.

3. Check thread tensions by test

sewing on spare fabric.

(See page 17.)

4. At fabric end, carry on running

machine at low speed, gently

pulling the fabric towards the back,

until about 5 to 6 cm of extra lock

stitches are produced without

fabric.

5. Cut thread by pushing thread cutter

lever down, or with scissors.

Page 16

14

Page 17

15

THREE-THREAD OVERLOCK WITH ONE NEEDLE

By threading the LEFT needle only a width of 6 mm will be produced and by threading the RIGHT

needle only a width of 3.8 mm will be produced.

Please keep the unused needle on the needle pad as illustrated.

CONVERTING TO TWO-THREAD USE (Model 320 only)

To convert to two thread use, first open the front cover and working table and raise needle to its

highest point by turning hand wheel towards you. Remove the right needle and use the left needle.

Please keep the unused needle on the needle pad.

Pull out the convertor as shown in Fig.1.

Attach the two-thread convertor onto the upper looper as shown in Fig. 2, Fig.3.

When not using convertor, insert it deep and keep as illustrated in Fig.4.

Page 18

16

NARROW AND ROLLED HEM, PICOT STITCH

Narrow and rolled edge is ideal for use on thin materials such as georgette crepe, crepe de chine,

silk etc.

Also, picot stitch can be produced particularly when sewing on fine ‘scarflike’ materials.

In view of the nature of these hems, they are unsuitable for use on ‘hard’ or ‘heavy’ materials.

1. Raise the presser foot.

2. Open the front cover and working table.

3. Remove the stitch finger from the needle plate by screw driver and keep it in the front cover as

illustrated (Model 320 only) or in the accessory bag.

4. Set the machine according to page 14.

NOTE:1.Please use following recommended thread for making ideal seams.

2.After finishing , reset the stitch finger in its place. Please ensure inserting it deep as

illustrated in Fig 1.

RECOMMENDED THREAD

Narrow overlock edge

Rolled edge

With Three Threads

With Three Threads

With Two Threads

Thread for needle

Polyester, Nylon, Silk No.50-100

Nylon No.100

Upper looper

-----------

Lower looper

Polyester, Nylon, Silk No.50-100

Bulk nylon (less stretchable)

Bulk nylon (less strechable)

Page 19

17

ADJUSTING THREAD TENSIONS

Turning tension dial to a higher number gives a tighter thread

tension. Turning tension dial to a lower number gives a looser

thread tension. The higher the number, the tighter the tension.

Test each thread tension on a scrap of the fabric you plan to

use.

TWO-THREAD USE

Just right

Lower looper thread pulled to under side

Needle thread Pulled to top side

Decrease needle tension Increase needle thread tension

FOUR-THREAD USE

Just right

Upper looper thread pulled to top side Lower looper thread pulled to top side

Increase Upper looper thread tension

and/or decrease lower looper tension

Increase lower looper thread tension

and/or decrease upper looper tension

Increase left needle thread tension and/or

decrease either or both looper threads.

Left needle thread loose and visible on

under side of fabric.

Right needle thread loose and visible on

under side of fabric.

Increase right needle thread tension.

Page 20

18

ADJUSTING STITCH LENGTH

Turn the stitch length dial until the

required length is indicated.

The higher the number, the longer

the stitch. This dial can adjust the

stitch length from 1 to 5 mm.

ADJUSTING OVEREDGE CUTTING WIDTH

Overedge cutting width can be adjusted from 4 to 7

mm by simply turning overedge cutting width dial

according to the kind of fabric.

It is set at standard width of 6 mm when delivered

from the factory.

Turn it towards “5” if fabric edge curls while

sewing.( Fig.1)

Turn it toward “7” if loops hang off the edge. (Fig.2)

Stitch finger (B) (Model 320 only)

Loops may hang off the edge, when you sew with lightweight fabric using 3 threads (right

needle only), and setting cutting width dial at 4-5(Fig.3). In such a case change the stitch

finger(A) to (B) to get neat stitching(Fig.4)

Page 21

19

DIFFERENTIAL FEED

The differential feed has two

independent feed dogs, one front (A) and

one rear (B).

Each feed dog has an individual feed

mechanism which enables the feeding of

material at a different ratio.

POSITIVE DIFFERENTIAL FEED

WHEN SET FOR POSTITVE DIFFERENTIAL

FEED, the front feed dog (A) makes a

longer stroke than the rear feed dog (B).

This has the effect of accumulating

material under the presser foot to offset

the wavering on the fabric.

NEGATITVE DIFFERENTIAL FEED

WHEN SET FOR NEGATIVE DIFFERENTIAL

FEED, the front feed dog (A) makes a

shorter stroke than the rear feed dog (B).

This has the effect of stretching material

under the presser foot to offset the

puckering on the fabric.

Page 22

20

EFFECT AND

APPLICATION

TYPE OF

FEEDING

SETTING

FEED RATIO

REAR:FRONT

Waver-free

seams,

Gathering

Positive

differential

feed

1-2

┠─╂───┨

No differential

feed

Neutral

feed

1

┠──╂──┨

Pucker-free

seams

Negative

differential

feed

0.7-1

┠───╂─┨

SETTING DIFFERENTIAL FEED

Set by simply turning the differential feed control dial in the direction desired referring to the chart

below.

The adjustment can be made between 0.7 (negative effect) and 2 (Positive effect). These settings give

the best ratio of feeding.

For normal sewing, the dial should be set at 1.

The dial can be reset even while sewing.

FOOT PRESSURE REGULATOR

Presser foot pressure has been correctly set at

the factory, so you do not need to adjust it for

most of ordinary sewing. If adjustment is

necessary, turn the foot pressure regulator to

higher number to increase or to lower number to

decrease pressure.

SEWING WITH EXTRA HEAVYWEIGHT

FABRIC OR MULTIPLE LAYERS OF FABRIC

A wide ranger of fabric can be overlocked on this

machine, but it is recommended to tighten screw

as illustrated, when sewing with extra

heavyweight fabrics or mulitiple layers of fabric.

Open working table for adjustment.

Loosen the screw when sewing with light to

normal weight fabric or turning overedge cutting

width dial, or otherwise fabric may not be well cut.

The machine is set for normal weight fabrics from

the factory.

Page 23

21

BASIC TECHNIQUES

TURNING OUTSIDE CORNERS

WITHOUT CUTTING THREADS

1. When you reach the fabric edge, stop

stitching with the needle above the fabric.

2. Raise the presser foot and gently pull on the

thread chain just enough to clear the stitch

finger.

3. Turn the fabric, lower the presser foot and

begin stitching in the new direction. Fig. 1.

NOTE: When overlocking and trimming at the

same time, cut the fabric along the new

stitching line for about 3 cm, before

turning the fabric. Fig. 2.

TURNING CURVED EDGES

For inside curves, guide fabric gently with

trimming line of the fabric under the right front of

the presser foot (or a little to the left), applying

pressure at point A in the direction of the arrow

with your left hand, and at the same time applying

a little opposite pressure at point B with your right

hand. Fig.3.

For outside curves place under the presser foot in

a similar manner but applying the pressure in the

opposite directions. Fig. 4.

REMOVING STITCHES FROM SEWN

FABRIC

To remove stitches already sewn, snip off needle

thread (s) at intervals and pull out looper threads.

Page 24

22

CORDED OVERLOCK,

Corded overlock can be used to strengthen

shoulder, sleeve or side seams when joining or

making up knitted garments. As a decorative

feature you can use knitting yarn of contrasting

colours to further enhance your garment. Your

machine is equipped with a presser foot which

has been designed to feed your cord or yarn to

the left of the safety stitch or to the right. Follow

instructions as follows:

1. Snap the detachable cord guide, in your

accessory set onto the thread guide pole

(Fig.1).

2. Place a “filler” cord, such as a crochet cotton,

gimp, wool, knitting yarn, or shirring elastic at

the rear of the machine spool pin. Pass the

cord through the cord guides (1) and (2) and

then through the left needle thread guide (3).

See Fig. 1.

3. Insert the cord through either the front or rear

hole (according to the operation, see

diagrams Figures 2 and 3), in the presser

soot and pass it under and to the rear of the

foot.

4. Place the material to be sewn as normal.

Start at slow speed observing if cord is

feeding correctly and increase speed as

needed.

FOR JOINING SHOULDERS OR SLEEVES, pass the

cord through the front hole, ensuring that it is

fixed between the left and right needle threads as

it is guided through the front hole. (Fig.2).

FOR JOINING SIDE SEAMS , pass the cord through

the rear hole, ensuring it is positioned to the right

needle thread. (Fig.3)

FOR DECORATIVE EFFECTS, you may pass

contrasting colours either through the front or rear

hole or if you desire, pass cord or yarn through

each hole.

FOR MAKING WAVED HEM WITH GUT (Fig.4), pass the

gut through the rear hole and start ROLLED HEM

(See page 16).

This is used for the hem of skirt, etc.

Page 25

23

DECORATIVE EFFECTS

In addition to normal overlocking which is fully

described in this instruction book, your machine can

also be used for a number of decorative applications

such as decorative top-stitching, butted

seams ,pin-tucking or making lengths of decorative

braid. See below.

Decorative top-stitching-using only two threads

or using three threads (flat seam)

Fold fabric along the line to be top-stitched and sew

over the folded edge, making sure not to cut into the

fold. Fig. A.

Unfold the fabric, pull the ends of the threads to the

underside and press flat.

The final appearance can be enhanced by using

buttonhole twist or embroidery thread on the lower

looper.

Butted seams-using only two threads or using

three threads (flat seam)

Place two pieces of fabric wrong sides together and

overlock along the edge. Unfold and press.

By using different coloured fabrics and thread a

pleasing ‘patchwork’ effect can be achieved.

Pin-tucking-using three threads

Fold fabric along a line to be pin-tucked and

overlock sew along the folded edge, making sure

hot to cut into the folded edge of the fabric. (See

page 25). Pull ends of threads to underside and

press.

Making decorative braid-using three threads

Overlock over a cord braid, holding it carefully with

both hands, making sure not to cut the edge. (See

page 25).

NOTE: *If you use blind hem foot (option),

decorative stitch is made easily.

**Reduce the upper looper tension when

you use thick thread.

Page 26

24

DIFFERENTIAL FEED APPLICATIONS

Please refer to pages 19,20 DIFFERENTIAL FEED,

Differential feed is designed to minimize puckering and

wavering.

It is also very effective for gathering.

1. Puckering

Puckering tends to occur on woven or sheer

fabrics.

To obtain pucker-free seams, set the differential

feed control dial at less than 1.

2. Wavering

Wavering tends to occur on knitted or stretchable

fabrics.

To obtain waver-free seams, set the differential

feed control dial at more than 1.

3. Gathering

Differential feed makes gathering easier on

lightweight fabric. Use it on waistlines, sleeve

heads, sleeve bottoms and ruffles, etc.

Set the differential feed control dial between 1.5

and 2 to obtain the best gathering effect for your

use.

IMPORTANT

The exact adjustment depends on the thickness and

elasticity of fabric. Even the stitch length can influence

the setting. The longer the stitches, the more the

fabric is contracted.

Always do a test run with a piece of actual fabrics you

use and find the best settings.

Page 27

25

3. CARING FOR YOUR MACHINE

REPLACING MOVING CUTTER

Replace a moving cutter if it becomes blunt as follows. A spare cutter will be found in your accessories.

NOTE:You should not need to replace fixed cutter, which is made of special hard alloy material.

FIRST REMOVE THE POWER PLUG FROM THE SUPPLY SOCKET-OUTLET.

1. Loosen screw and take out moving cutter.

2. Close the working table. Lower cutter driving

arm to its lowest position by turning the hand

wheel towards you by hand. In this position,

set replacement cutter in position and

secure it with screw, ENSURING THAT THE

EDGE OF THE MOVING CUTTER IS

APPROXIMATELY 0.5 MM BELOW THE

SURFACE OF THE FIXED CUTTER.

DISENGAGING MOVING CUTTER

If you want to sew without cutting, open the

working table and disengage the moving cutter

by pushing the cutter release knob to the left and

turning it towards you as illustrated.

Ensure that fabric edge is not wider than

overedge width selected or upper looper and

needle can be damaged.

REMOVING FACE COVER

Disconnect from power supply before removing

face cover.

Remove the screw and take off the face cover.

Page 28

26

CLEANING AND OILING

To keep the machine running smoothly, keep it clean and lubricated at all times.

FIRST DISCONNECT MACHINE FROM POWER SUPPLY BY REMOVING PLUG FROM

SOCKET-OUTLET.

1. Open the front cover and working table. Using the brush provided, remove dust and lint that have

accumulated.

2. Apply a few drops of oil to the points indicated by arrows.

ALWAYS USE A GOOD QUALITY SEWING MACHINE OIL.

3. Remove each top cover with screw driver and remove dust and lint of inside with the brush.

Page 29

27

4. CHECKING PERFORMANCE PROBLEMS

PROBLEM

PROBABLE CAUSE

CORRECTION

Irregular

Stitches

Incorrect Thread Tension(s).

Incorrect size Needle.

Improper Threading.

Pulling fabric.

Loose Presser Foot.

Reset thread tension (s).

Choose correct size Needle for

Thread and Fabric.

Re-thread machine.

Do not pull Fabric; guide it gently.

Reset Presser Foot.

Breaking

Needle

Pulling fabric.

Incorrect size Needle.

Incorrect setting of Needle.

Loose Presser Foot.

Do not pull Fabric; guide it gently.

Choose correct size Needle for

Thread and Fabric.

Reset Needle.

Reset Presser Foot.

Puckering

Incorrect Thread Tension (s).

Bent or blunt Needle.

Differential feed is set

Incorrectly.

Reset Thread Tension (s).

Insert new Needle.

Set it at less than 1.

Wavering

Differential feed is set

Incorrectly.

Set it at 1 or at more than 1.

For knitted fabrics.

Skipping

Stitches

Improper Threading.

Incorrect size Needle.

Bent or blunt Needle.

Incorrect setting of Needle.

Reset thread machine.

Choose correct size Needle for

Thread and Fabric.

Insert new Needle.

Reset Needle.

Page 30

28

Breaking

Threads

Improper Threading.

Bent needle.

Thread Tension (s) too tight.

Incorrect setting of Needle.

Thread Spool tangled.

Thread Guide Pole not extended.

Re-thread machine.

Insert new Needle.

Reset thread tension (s).

Reset needle.

Reset spool properly.

Fully extend Guide Pole.

Page 31

RELIABLE PRODUCTS WARRANTY

Reliable Corporation (“Reliable”) warrants to original purchaser of its products that every product sold by Reliable

(a “Reliable Product”) is free from defects in material and workmanship for a period of one year from the date of

purchase, if properly used and maintained. Subject to the conditions and limitations set forth below, Reliable will

either repair or replace any part of a Reliable Product that proves defective by reason of improper workmanship or

materials. If the defective Reliable Product is no longer available and cannot be repaired effectively or replaced

with an identical model, Reliable shall replace the defective Reliable Product with a current Reliable Product of

equal or greater value. Repaired parts or replacement products will be provided by Reliable on an exchange basis,

and will be either new or refurbished to be functionally equivalent to new. If Reliable is unable to repair or replace a

Reliable Product, it will refund the current value of that Reliable Product at the time the warranty claim is made.

This limited warranty does not cover any damage to a Reliable Product that results from improper installation, accident, abuse, misuse, natural disaster, insufficient or excessive electrical supply, abnormal mechanical or

environmental conditions, wear and tear resulting from normal use of the product, or any unauthorized disassembly, repair, or modification. This limited warranty does not extend to any indirect, consequential or incidental

damages that may be suffered by a user or from the use of a Reliable Product, including without limitation, any liability for third party claims for damage, and is limited to the amount paid by the original purchaser Reliable Product

with respect to which this limited warranty protection applies. This limited warranty does not apply with respect to

products that have been altered or which are missing serial numbers or for products not purchased directly from

Reliable or a dealer authorized by us to sell Reliable Products.

This limited warranty is the only warranty that applies to any Reliable Product, supersedes any and all terms that

may be contained in any other document or purchase order and may not be altered or amended except expressly

in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our customer service group at 1800-268-1649 or at support@reliablecorporation.com. You will be required to submit an original receipt via fax or

e-mail. The receipt must reflect that you are the original purchaser, the product was bought directly from us or from

an authorized Reliable dealer and that the warranty claim is being made within the warranty period. You will be

issued a return authorization number (RA#) and asked to ship the defective product together with proof of purchase and RA#, prepaid insured to the following address: Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON

M6B 4K7. Freight collect shipments will be refused. The risk of loss or damage in transit will be borne by the customer. Once Reliable receives the defective product, it will initiate the repair or replacement process.

If you have any questions regarding these warranties, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

Page 32

1 800 268 1649

www.reliablecorporation.com

Loading...

Loading...