Page 1

SEWQUIET

6000SM

INDUS TRIAL DC BRUSH LESS SERVOMOTOR

SERVOMOT EUR INDUSTRI EL À COURANT CONTI NU SANS BALAI

SERVOMOTO R INDUSTRIAL SI N ESCOBILLA S DE CD

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

Page 2

Page 3

ENGLISH 01

FRANÇAIS

ESPAÑOL 15

08

Page 4

SEWQUIET 6000SM

INDUSTRIAL DC BRUSHLESS

SERVOMOTOR

INSTRUCTION MANUAL

ENGLISH

01

Page 5

RELIABLE. RIGHT THERE WITH YOU.

At Reliable, we do what we love, and take pride in doing it right.

You want what’s best for the people, places and things that matter

in your life – from where you live to what you wear. So do we. From

the start, we approach every product with a craftsman’s attention

to detail and passion for making it right. Quality, functionality,

design and customer service play an equally important part in

delivering what’s right for you. Whether you are an advanced

sewer or a beginner, the 6000SM’s microprocessor controller

gives the user an unparalleled connection to the sewing machine,

allowing for speed or detailed work.

For your safety and to fully enjoy the advantages of this product,

please take a few minutes to read all of the important safeguards

and care instructions. Keep this manual handy and review the

product warranty for your reference.

02

Page 6

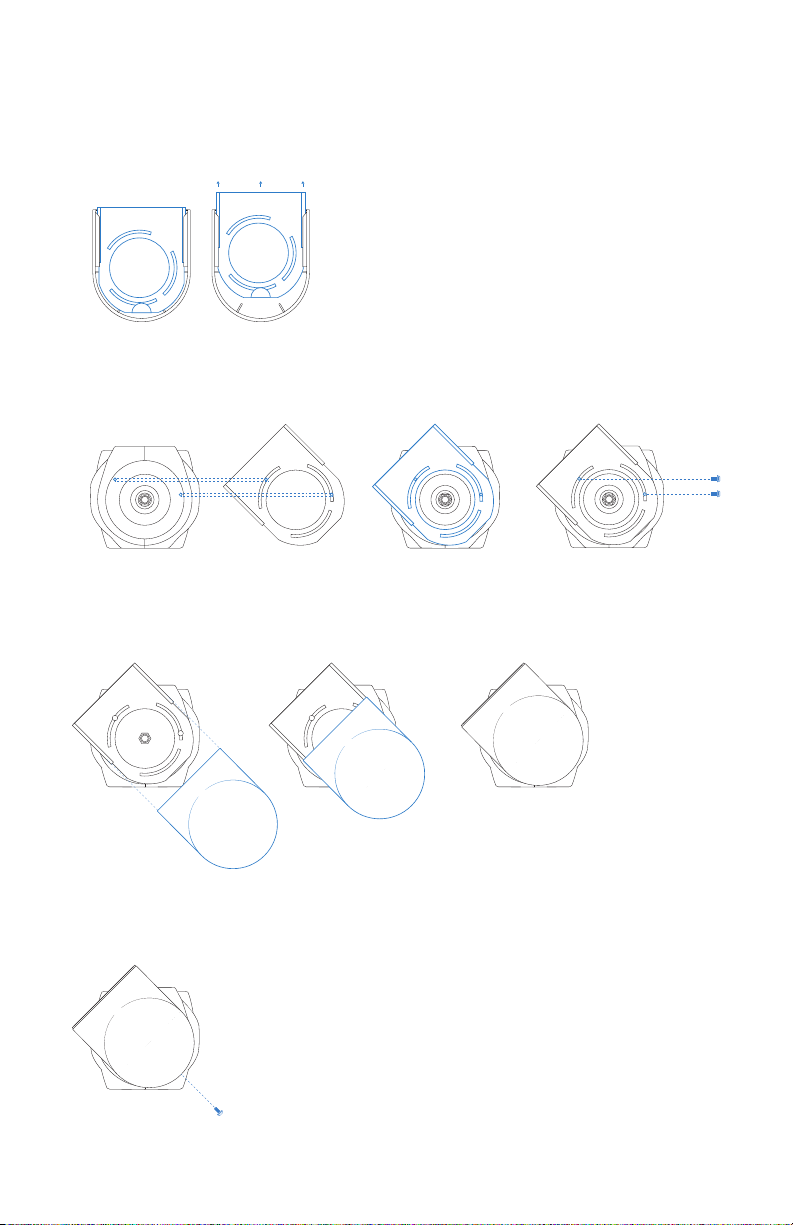

PULLEY COVER INSTALLATION INSTRUCTIONS

1. Slide the pulley cover off of the bracket.

2. Align the bracket to the screw holes on the motor. Place two mounting screws (sup-

plied) onto the bracket and fasten it to the motor. (Required angle indicated).

3. Slide the pulley cover onto the bracket.

4. Fasten the screw on the bottom of the pulley cover to secure it to the bracket.

03

Page 7

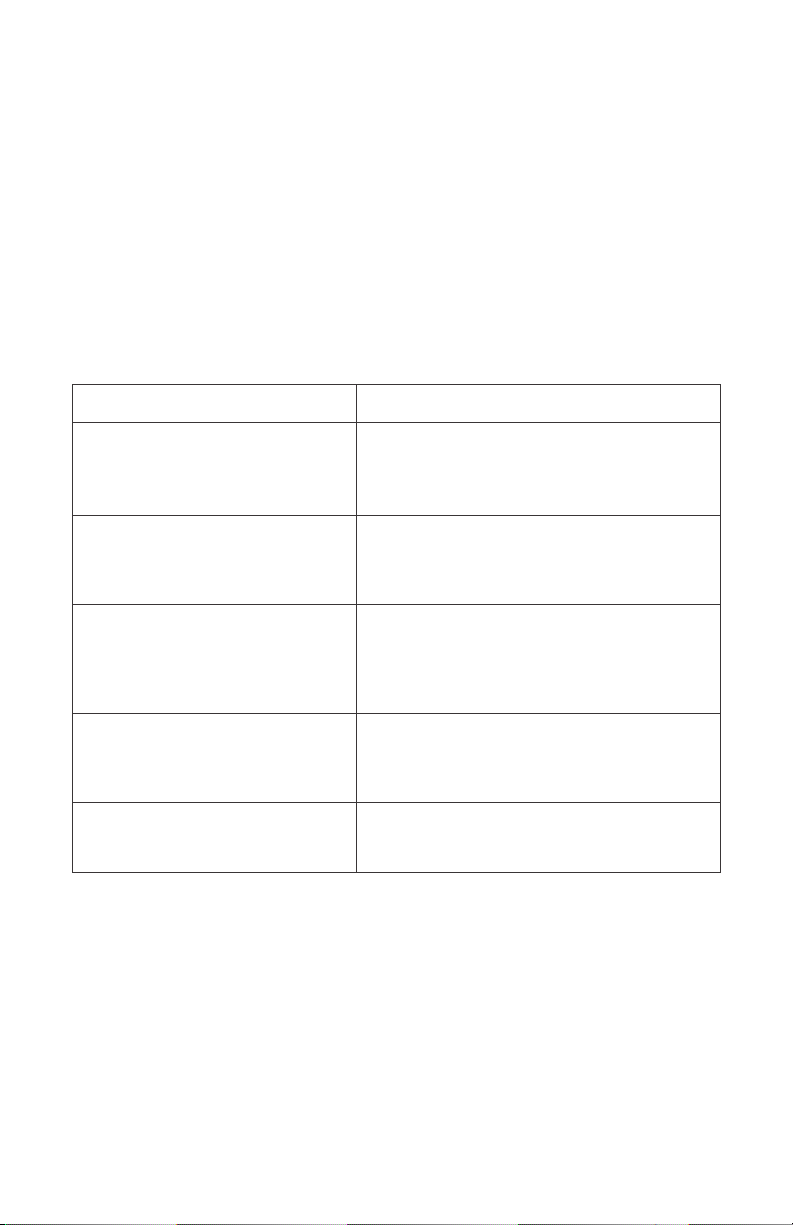

PROGRAMMING

MACHINE TYPE

Basic single needle

Basic two needle/needle feed

Walking foot (Except MSK-1541S)

Walking foot auto lubrication

MSK-1541S/4200SW

Sergers – overlock

Blindstitch

Zig-Zag (20U style)

Zig-Zag (High Speed)

Zig-Zag Walking foot

SPEED

SELECTOR

34

22

16

20

29

40

12

16

22

20

PULLEY

SIZE

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

APPROX.

SPEED RPM

4500

3000

1500

1720

2160

5260

1200

1650

2000

1925

SPECIFIC

SPEED

5000

3500

1800

2000

2500

6500

2500

2000

3000

2000

In order to prevent possible damage to your machine, if the machine you have

is not on the categories list, please call your dealer to obtain the correct speed

setting and pulley size.

HOW TO CHANGE THE SPEED

• Press the “P” button and the LED will change to n0

• Press the “S” button to change the speed in increments of 100rpm

• Continue to press the “S” button until the desired speed setting is displayed

• Press the “P” button to save the selection

HOW TO CHANGE THE DIRECTION

• Press the “P” button 4 times until the LED reads n3

• Press the “S” button to select between “0” and “1”

• Select “0” and the motor will run counterclockwise

• Select “1” and the motor will run clockwise

• Press the “P” button to save the selection.

04

Page 8

HOW TO ENABLE AND DISABLE THE NEEDLE

POSITIONING FUNCTION

• Press the “P” button 2 times and the LED will change to "n1"

• Press the “S” button to select between “0” and “1”

• Select “0” to disable the needle positioning function

• Select “1” to enable the needle positioning function

• Press the “P” button to save the selection

HOW TO SET THE STOP POSITION OF THE NEEDLE:

This programming should only be used when the OPTIONAL synchronizer is

installed. Order separately.

• Press the “P” button 3 times and the LED will change to "n2"

• Press the “S” button to select between “0” and “1”

• Select “0” and the needle will stop in the down position

• Select “1” and the needle will stop in the up position

• Press the “P” button to save the selection

SETTING THE “F” MODE N5 TO N6

STEP 1:

• First, press and hold the “S” button. Then press and hold the “P” button. Keep

both buttons pressed until “F” appears on the display.

• When “F” appears, release both buttons and then press the “P” button to

advance to parameter “5”.

• When “5” appears, keep pressing only the “S” button to advance to “0” (low

speed start disabled).

• Press the “P” button to save the value.

STEP 2:

• First, press and hold the “S” button. Then press and hold the “P” button and

keep both buttons pressed until “F” appears on the display.

• When “F” appears, release both buttons and then press the “P” button to

advance to parameter “6”.

• When “6” appears, keep pressing the “S” button only to advance to “9” (step

sewing higher value).

• Press the “P” button to save the value.

• Switch the power off and then switch the power back on to complete the

programming.

* Please note: When sewing dense materials (ex. Tooling leather), a size 22 leather

point needle is recommended.

05

Page 9

WHEN THE DISPLAY IS SHOWING E5

• Press and release the "S" button and the display will change to "P"

• Press the "P" button 2 times and the display will changes to "n1"

• Press the "S" button and the display will change to "1"

• Press the "S" button again and the display will change to "0"

• Press the "P" button to save the value

• Turn the power off and then on again to complete the programming.

ERROR CODES

ERROR CODE

E1: Operational failure.

E2: Over current or under voltage.

E3: The board cannot read the

parameter.

E4: Hall signal error.

E5: Needle position problem.

SOLUTION

E1: Machine is locked. Check to see if the

machine is difficult to turn, or if there is a

lack of lubrication.

E2: Check the power source to ensure that

the voltage is within range.

E3: Turn the power off and on twice, and

try again. If the problem still cannot be

solved, contact your dealer.

E4: Replace the main fuse. If the problem

continues to persist, please contact your

dealer.

E5: Check if the synchronizer is connected.

06

Page 10

RELIABLE PRODUCTS WARRANTY

Reliable Corporation (“Reliable”) warrants to original purchaser of its products that

every product sold by Reliable (a “Reliable Product”) is free from defects in material and

workmanship for a period of one year from the date of purchase if properly used and

maintained. Subject to the conditions and limitations set forth below, Reliable will either

repair or replace any part of a Reliable Product that proves defective by reason of improper

workmanship or materials. If the defective Reliable Product is no longer available and

cannot be repaired effectively or replaced with an identical model, Reliable shall replace

the defective Reliable Product with a current Reliable Product of equal or greater value.

Repaired parts or replacement products will be provided by Reliable on an exchange basis,

and will be either new or refurbished to be functionally equivalent to new. If Reliable is

unable to repair or replace a Reliable Product, it will refund the current value of that Reliable

Product at the time the warranty claim is made.

This limited warranty does not cover any damage to a Reliable Product that results from

improper installation, accident, abuse, misuse, natural disaster, insufficient or excessive

electrical supply, abnormal mechanical or envsteamermental conditions, wear and tear

resulting from normal use of the product, or any unauthorized disassembly, repair, or

modification. This limited warranty does not extend to any indirect, consequential or

incidental damages that may be suffered by a user or from the use of a Reliable Product,

including without limitation, any liability for third party claims for damage, and is limited

to the amount paid by the original purchaser Reliable Product with respect to which this

limited warranty protection applies. This limited warranty does not apply with respect to

products that have been altered or which are missing serial numbers or for products not

purchased directly from Reliable or a dealer authorized by us to sell Reliable Products.

This limited warranty is the only warranty that applies to any Reliable Product, supersedes

any and all terms that may be contained in any other document or purchase order and may

not be altered or amended except expressly in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our

customer service group at 1-800-268-1649 or at support@reliablecorporation.com.

You will be required to submit an original receipt via fax or e-mail. The receipt must reflect

that you are the original purchaser, the product was bought directly from

us or from an authorized Reliable dealer and that the warranty claim is being made within

the warranty period. You will be issued a return authorization number (RA#) and asked to

ship the defective product together with proof of purchase and RA#, prepaid insured to the

following address:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Freight collect

shipments will be refused. The risk of loss or damage in transit will be borne by

the customer. Once Reliable receives the defective product, it will initiate the repair or

replacement process.

If you have any questions regarding this warranty, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

07

Page 11

SEWQUIET 6000SM

SERVOMOTEUR INDUSTRIEL À

COURANT CONTINU SANS BALAI

MANUEL D’INSTRUCTIONS

FRANÇAIS

08

Page 12

RELIABLE. PROCHE DE VOUS.

Chez Reliable, nous faisons ce que nous aimons et sommes fiers de

bien le faire. Vous voulez ce qu’il y a de mieux pour les personnes,

les lieux et les choses importantes de votre vie - depuis l’endroit où

vous vivez jusqu’aux vêtements que vous portez. Nous aussi. Depuis

le début, nous approchons chaque produit avec une attention

aux détails artisanale et la passion de le fabriquer. La qualité, la

fonctionnalité, la conception et le service à la clientèle jouent des

rôles également importants dans notre mission de vous fournir ce

qui vous correspond. Que vous soyez une couturière expérimentée

ou débutante, le régulateur par microprocesseur de la 6000SM

donne à l’utilisateur une connexion incomparable à la machine à

coudre, permettant un travail rapide ou détaillé.

Pour votre sécurité et pour profiter pleinement des avantages de

ce produit, veuillez prendre quelques minutes pour lire toutes les

importantes mises en garde et les directives d’entretien. Gardez

ce manuel et la garantie du produit à portée de main pour vous y

référer ultérieurement.

09

Page 13

INSTALLATION DU CARTER DE COURROIE

1. Faites glisser le carter de courroie hors du support.

2. Alignez le support sur les trous de vis du moteur. Placez deux vis de montage

(fournies) sur le support et fixez-le au moteur. (Angle requis indiqué sur la photo).

3. Faites glisser le carter de courroie dans le support.

4. Serrez la vis située au bas du carter de courroie pour la fixer au support et termi-

nez l’installation.

10

Page 14

PROGRAMMATION

TYPE DE MACHINE

Aiguille simple de base

Deux aiguilles de base/

entrainement par aiguille

Pied portable (sauf MSK-1541S)

Pied portable lubrification

automatique

MSK-1541S/4200SW

Surjeteuses - remailer

Point invisible

Zigzag (style 20U)

Zigzag (haute vitesse)

Pied portable zigzag

SÉLECTEUR

DE VITESSE

34

22

16

20

29

40

12

16

22

20

TAILLE DE

LA POULUIE

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

TR/MIN

APPROX.

4500

3000

1500

1720

2160

5260

1200

1650

2000

1925

VITESSE

SPÉCIFIQUE

5000

3500

1800

2000

2500

6500

2500

2000

3000

2000

Afin d’éviter des dommages éventuels à votre machine, si la machine que vous

possédez n’apparaît pas dans la liste des catégories, veuillez appeler votre

revendeur pour obtenir le réglage de vitesse et la taille de poulie appropriés.

COMMENT CHANGER LA VITESSE :

• Appuyez sur la touche « P » et la LED passe à n0

• Appuyez sur la touche « S » pour changer la vitesse par paliers de 100 t/min

• Maintenez la touche « S » enfoncée jusqu’à ce que la vitesse désirée s’affiche

• Appuyez sur la touche « P » pour enregistrer la sélection

COMMENT CHANGER LA DIRECTION :

• Appuyez 4 fois sur la touche « P » jusqu’à ce que la LED affiche n3

• Appuyez sur la touche « S » pour choisir entre « 0 » et « 1 »

• Sélectionnez « 0 » et le moteur tourne dans le sens inverse des aiguilles

d’une montre

• Sélectionnez « 1 » et le moteur tourne dans le sens des aiguilles d’une montre

• Appuyez sur la touche « P » pour enregistrer la sélection

11

Page 15

COMMENT ACTIVER ET DÉSACTIVER LA FONCTION

DE POSITIONNEMENT DE L’AIGUILLE:

• Appuyez 2 fois sur la touche « P » et la LED passe à n1

• Appuyez sur la touche « S » pour choisir entre « 0 » et « 1 »

• Sélectionnez « 0 » pour désactiver la fonction de positionnement de l’aiguille

• Sélectionnez « 1 » pour activer la fonction de positionnement de l’aiguille

• Appuyez sur la touche « P » pour enregistrer la sélection

COMMENT RÉGLER LA POSITION DE L’AIGUILLE:

Cette programmation devrait uniquement être utilisée lorsque le synchroniseur

EN OPTION est installé. À commander séparément.

• Appuyez 3 fois sur la touche « P » et la LED passe à n2

• Appuyez sur la touche « S » pour choisir entre « 0 » et « 1 »

• Sélectionnez « 0 » et l’aiguille s’arrête en position vers le bas

• Sélectionnez « 1 » et l’aiguille s’arrête en position vers le haut

• Appuyez sur la touche « P » pour enregistrer la sélection

RÉGLAGE DU MODE « F » N5 À N6

ÉTAPE 1 :

• D’abord, appuyez et maintenez enfoncée la touche « S ». Puis, appuyez et

maintenez enfoncée la touche « P ». Maintenez les deux touches enfoncées

jusqu’à ce qu’un « F » apparaisse sur l’écran.

• Lorsque le « F » apparaît, relâchez les deux touches puis appuyez sur la touche

« P » pour avancer jusqu’au paramètre « 5 ».

• Lorsque le chiffre « 5 » apparaît, continuez d’appuyer sur la touche « S » pour

avancer jusqu’à « 0 » (désactivation du démarrage à vitesse réduite).

• Appuyez sur la touche « P » pour enregistrer la valeur.

ÉTAPE 2 :

• D’abord, appuyez et maintenez enfoncée la touche « S ». Puis appuyez et

maintenez enfoncée la touche « P » jusqu’à ce qu’un « F » apparaisse sur

l’écran.

• Lorsque le « F » apparaît, relâchez les deux touches puis appuyez sur la touche

« P » pour avancer jusqu’au paramètre « 6 ».

• Lorsque le chiffre « 6 » apparaît, continuez d’appuyer sur la touche « S » pour

avancer jusqu’à « 9 » (la plus haute valeur de couture).

12

Page 16

• Appuyez sur la touche « P » pour enregistrer la valeur.

• Éteignez puis rallumez la machine pour terminer la programmation.

* Veuillez noter : Lorsque vous cousez des tissus denses (par exemple : du cuir à

ciseler), l’utilisation d’une aiguille à pointe effilée 22 pour cuir est recommandée.

LORSQUE L’ÉCRAN AFFICHE E5

• Appuyez et relâchez la touche « S » et l’affichage passera à « P »

• Appuyez 2 fois sur la touche « P » et l’affichage passera à « n1 »

• Appuyez sur la touche « S » et l’affichage passera à « 1 »

• Appuyez à nouveau sur la touche « S » et l’affichage passera à « 0 »

• Appuyez sur la touche « P » pour enregistrer la valeur.

• Éteignez et rallumez l’appareil pour terminer la programmation.

CODES D'ERREUR

CODES D’ERREUR

E1: Défaillance opérationnelle.

E2: Surtension ou sous-tension.

E3: La plaque ne peut pas lire le

paramètre.

E4: Erreur de signal de Hall.

E5: Problème de positionnement

de l’aiguille.

SOLUTION

E1: La machine est verrouillée.Vérifiez si la

machine est difficile à tourner ou s’il y a

un manque de lubrification.

E2: Vérifiez la source électrique pour vous

assurer que la tension se trouve dans la

plage de variation.

E3: Éteignez et rallumez l’appareil deux-

fois, et réessayez. Si le problème n’est

toujours pas résolu, contactez votre

revendeur.

E4: Remplacer le fusible principal. Si le pro-

blème persiste, veuillez contacter votre

revendeur.

E5: Vérifiez si le synchroniseur est connecté.

13

Page 17

GARANTIE DES PRODUITS RELIABLE

Reliable Corporation (« Reliable ») garantit à l'acheteur original de ce produit que chaque

produit vendu par Reliable (un « Produit Reliable ») est exempt de tout défaut de pièce et

de main d'œuvre pour une période d'un an à compter de la date d'achat, s'il est utilisé et

entretenu correctement. Soumis aux conditions et limitations établies ci-après, Reliable

réparera ou remplacera toute pièce d'un produit Reliable qui s'avère défectueuse en raison

d'un défaut de fabrication ou de main d'œuvre. Si le Produit Reliable défectueux n'est plus

disponible et ne peut pas être réparé efficacement ou remplacé par un modèle identique,

Reliable remplacera le Produit Reliable défectueux par un Produit Reliable actuel de

valeur équivalente ou supérieure. Les pièces réparées ou les produits remplacés seront

fournis par Reliable sur la base d'un échange, et seront ou neufs ou remis à neuf pour être

fonctionnellement équivalents aux neufs. Si Reliable n'est pas en mesure de réparer ou de

remplacer le Produit Reliable, elle remboursera la valeur actuelle du Produit Reliable au

moment où la réclamation de garantie est réalisée.

Cette garantie limitée ne couvre aucun dommage subi par un Produit Reliable résultant

d'une installation incorrecte, d'un accident, d'un abus, d'une mauvaise utilisation,

d'une catastrophe naturelle, d'une alimentation électrique insuffisante ou excessive, de

conditions mécaniques ou environnementales anormales, de l'usure et de la détérioration

résultant de l'usure normale du produit, ou de tout démontage, réparation ou modification

non autorisé(e). Cette garantie limitée ne s'étend à aucun dommage indirect ou direct dont

peut être victime un utilisateur ou suite à l'utilisation d'un Produit Reliable, y compris mais

sans s'y limiter, toute responsabilité pour des réclamations de tiers pour des dégâts, et se

limite au montant payé par l'acheteur original du Produit Reliable auquel cette protection

de garantie limitée s'applique. Cette garantie limitée ne s'applique pas aux produits qui ont

été modifiés ou dont les numéros de séries sont manquants, ou aux produits non achetés

directement auprès de Reliable ou d'un revendeur agréé pour la vente de Produits Reliable.

Cette garantie limitée est l'unique garantie qui s'applique à tout Produit Reliable, elle

remplace toutes conditions qui peuvent être contenues dans un autre document ou bon de

commande et ne peut être transformée ou modifiée, sauf dérogation expressément écrite

de Reliable.

Pour obtenir une réparation ou un remplacement en vertu des conditions de cette garantie,

veuillez contacter notre service à la clientèle au 1-800-268-1649 ou par courriel à

support@reliablecorporation.com.

Il vous sera demandé d'envoyer le reçu original par télécopie ou courriel. Le reçu doit

prouver que vous êtes l'acheteur original, que le produit a été acheté directement chez

nous ou chez un revendeur agréé par Reliable et que la réclamation de garantie est

effectuée pendant la période de garantie. Un numéro d'autorisation de retour (Nº AR) vous

sera fourni et il vous sera demandé d'expédier le produit défectueux accompagné de la

preuve d'achat et du Nº AR, les frais d'assurances étant prépayés à l'adresse suivante :

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Les expéditions avec

fret payable à destination seront refusées. Le risque de perte ou d'endommagement lors du

transport sera assumé par le client. Une fois que Reliable aura reçu le produit défectueux,

elle initiera la réparation ou le remplacement.

Si vous avez des questions concernant la présente garantie, vous pouvez écrire à :

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

14

Page 18

SEWQUIET 6000SM

SERVOMOTOR INDUSTRIAL SIN

ESCOBILLAS DE CD

MANUAL DE INSTRUCCIONES

ESPAÑOL

15

Page 19

CONGRATULATIONS

En Reliable, hacemos lo que nos encanta hacer y nos

enorgullecemos de hacerlo bien. Quiere lo mejor para las personas,

los lugares y las cosas que importan en la vida: desde dónde vive

a la ropa que viste. Nosotros también. Desde el inicio, abordamos

cada producto con la atención al detalle de un artesano y la

pasión por hacerlo bien. La calidad, la funcionalidad, el diseño y

el servicio al consumidor son igual de importantes para ofrecerle

algo adecuado para usted. Sin importar si usted es un costurero

avanzado o principiante, el controlador del microprocesador de

la 6000SM le da al usuario una conexión sin incomparable con la

máquina de coser, permitiendo velocidad y trabajo detallado.

Por su seguridad y para disfrutar al máximo las ventajas de este

producto, tómese unos minutos para leer todas las precauciones

importantes e instrucciones de cuidado. Conserve este manual a

mano y lea la garantía del producto para su referencia.

16

Page 20

INSTALACIÓN DE LA CUBIERTA DE LA POLEA

1. Deslice la cubierta de la polea del soporte.

2. Alinee el soporte con los orificios para tornillos en el motor. Coloque dos tornillos de

montaje (provistos) en el soporte y ajústelos al motor. (En la fotografía, se indica el

ángulo requerido).

3. Deslice la cubierta de la polea en el soporte.

4. Ajuste el tornillo en la parte inferior de la cubierta de la polea para asegurarlo al

soporte y completar la instalación.

17

Page 21

PROGRAMACIÓN

TIPO DE MÁQUINA

Aguja simple básica

Aguja doble básica/

alimentación de la aguja

Pie móvil (excepto MSK-1541S)

Pie móvil automático de

lubricación

MSK-1541S/4200SW

Sobrehiladora - overlock

Puntada escondida

Zig-zag (style 20U)

Zig-zag (alta velocidad)

Pie móvil zig-zag

SELECTOR DE

VELOCIDAD

34

22

16

20

29

40

12

16

22

20

TAMAÑO DE

LA BOBINA

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

60MM

VELOCIDAD

APROX. EN

RPM

4500

3000

1500

1720

2160

5260

1200

1650

2000

1925

VELOCIDAD

ESPECÍFICA

5000

3500

1800

2000

2500

6500

2500

2000

3000

2000

Para evitar posibles daños en su máquina, llame a su distribuidor para obtener la

configuración de velocidad adecuada y el tamaño de la bobina, si la máquina que

tiene no está en la lista de categorías.

CÓMO CAMBIAR LA VELOCIDAD:

• Presione el botón «P» y el LED cambiará a n0

• Presione el botón «S» para cambiar la velocidad en incrementos de 100 rpm

• Continúe presionando el botón «S» hasta que se muestre la configuración de

velocidad deseada

• Presione el botón «P» para guardar la selección

18

Page 22

CÓMO CAMBIAR LA DIRECCIÓN:

• Presione el botón «P» 4 veces hasta que el LED indique n3

• Presione el botón «S» para seleccionar entre «0» y «1»

• Seleccione «0» y el motor funcionará en sentido antihorario

• Seleccione «1» y el motor funcionará en sentido horario

• Presione el botón «P» para guardar la selección

CÓMO HABILITAR Y DESHABILITAR LA FUNCIÓN DE

POSICIONAMIENTO DE LA AGUJA:

• Presione el botón «P» 2 veces y el LED cambiará a n1

• Presione el botón «S» para seleccionar entre «0» y «1»

• Seleccione «0» para deshabilitar la función de posicionamiento de la aguja

• Seleccione «1» para habilitar la función de posicionamiento de la aguja

• Presione el botón «P» para guardar la selección

CÓMO FIJAR LA POSICIÓN DE DETENCIÓN DE LA

AGUJA:

Solo debe utilizarse esta programación cuando se haya instalado el sincronizador

OPCIONAL. Realice el pedido por separado.

• Presione el botón «P» 3 veces y el LED cambiará a n2

• Presione el botón «S» para seleccionar entre «0» y «1»

• Seleccione «0» y la aguja se detendrá en la posición hacia abajo

• Seleccione «1» y la aguja se detendrá en la posición hacia arriba

• Presione el botón «P» para guardar la selección

CONFIGURACIÓN DEL MODO “F” DEL NÚMERO 5 AL

NÚMERO 6

PASO 1:

• Primero, mantenga presionado el botón “S”. Luego, mantenga presionado el

botón “P”.

• Mantenga presionados ambos botones hasta que aparezca “F” en la pantalla.

• Cuando aparezca “F”, libere ambos botones y luego presione el botón “P” para

avanzar al parámetro “5”.

19

Page 23

• Cuando aparezca “5”, solo mantenga presionado el botón “S” para avanzar a

“0” (inicio de velocidad baja desactivado).

• Presione el botón “P” para guardar la selección.

PASO 2:

• Primero, mantenga presionado el botón “S”. Mantenga presionado el botón “P”,

y mantenga presionados ambos botones hasta que aparezca “F” en la pantalla.

• Cuando aparezca “F”, libere ambos botones y luego presione el botón “P” para

avanzar al parámetro “6”.

• Cuando aparezca “6”, mantenga presionado el botón “S” para avanzar a “9”

(paso de costura con valor más alto).

• Presione el botón “P” para guardar la selección.

• Apague el dispositivo y luego vuelva a encenderlo para completar la

programación.

* Observe: Cuando cosa materiales densos (por ejemplo, cuero para estampado),

se recomienda una aguja con punta para cuero tamaño 22.

CUANDO APARECE EN LA PANTALLA “E5”:

• Presione y libere el botón “S” y la pantalla cambiará a “P”.

• Presione el botón “P” 2 veces y la pantalla cambiará a “n1”.

• Presione el botón “S” y la pantalla cambiará a “1”.

• Presione el botón “S” nuevamente y la pantalla cambiará a “0”.

• Presione el botón “P” para guardar la selección.

• Apague y vuelva a encender para completar la programación.

20

Page 24

CÓDIGOS DE ERROR

CODES D’ERREUR

E1: Fallo operativo

E2: Sobrecorriente o baja tensión

E3: El tablero no puede leer el

parámetro

E4: Señal de error de Hall

E5: Problema de posicionamiento de

la aguja

SOLUTION

E1: La máquina está trancada. Verifique

si es difícil girar la máquina o si hay

falta de lubricación.

E2: Verifique la fuente de energía para

asegurarse de que el voltaje esté

dentro del rango.

E3: Apague y encienda la máquina dos

veces, y vuelva a intentarlo. Si aún

no puede resolver el problema, contacte a su distribuidor.

E4: Reemplace el fusible principal. Si el

problema continúa, contacte a su

distribuidor.

E5: Verifique si el sincronizador está

conectado.

21

Page 25

GARANTÍA DE LOS PRODUCTOS RELIABLE

Reliable Corporation (“Reliable”) garantiza al comprador original de sus productos que todas

las unidades vendidas por Reliable (un “Producto Reliable”) se encuentran libres de defectos

de material y de mano de obra durante el período de un año a partir de la fecha de compra,

si son utilizadas correctamente y han recibido el mantenimiento adecuado. En virtud de las

condiciones y limitaciones establecidas a continuación, Reliable reparará o reemplazará

la pieza de un Producto Reliable que demuestre estar defectuosa a causa de material o

fabricación inadecuadas. Si el Producto Reliable defectuoso deja de estar disponible y no se

lo puede reparar en forma eficaz ni reemplazar por un modelo idéntico, Reliable cambiará el

Producto Reliable defectuoso por un Producto Reliable vigente de igual o mayor valor. Reliable

proporcionará piezas reparadas o de repuesto a cambio de las piezas originales, y serán piezas

nuevas o reacondicionadas para convertirse en productos funcionalmente equivalentes a piezas

nuevas. Si Reliable no puede reparar ni reemplazar un Producto Reliable, reembolsará el valor

del Producto Reliable que esté vigente al momento de reclamar la garantía.

Esta garantía limitada no cubre los daños que sufra un Producto Reliable como resultado de una

instalación inadecuada, accidente, abuso, uso incorrecto, desastre natural, suministro de energía

eléctrica insuficiente o excesivo, condiciones mecánicas o ambientales anormales, desgaste

provocado por el uso normal del producto, o cualquier desarme, reparación o modificación no

autorizada. Esta garantía limitada no se extiende a ningún daño indirecto, resultante o accidental

que el usuario pueda sufrir o que pueda causar el uso de un Producto Reliable, incluyendo,

entre otros, la responsabilidad ante los reclamos presentados por terceros; y se limita al monto

pagado por el comprador original del Producto Reliable respecto del cual tiene aplicación

esta protección de garantía limitada. Esta garantía limitada no es válida para productos que

hayan sido modificados o que no tengan número de serie, o para productos que no hayan sido

comprados directamente a Reliable o mediante un vendedor certificado que cuente con nuestra

autorización para vender Productos Reliable.

Esta garantía limitada es la única que se aplica a todos los Productos Reliable, reemplaza todos

los términos que puedan estar contenidos en cualquier otro documento u orden de compra, y no

puede ser alterada ni modificada excepto que Reliable así lo haya autorizado expresamente por

escrito.

Para obtener una reparación o cambio según los términos de esta garantía,

comuníquese con nuestro grupo de atención al cliente al 1-800-268-1649 o escriba a

support@reliablecorporation.com.

Usted deberá presentar, por fax o correo electrónico, el comprobante original. Este comprobante

debe demostrar que usted es el comprador original, que el producto fue adquirido directamente

en nuestras oficinas o a un vendedor de Reliable autorizado y que el reclamo de la garantía se

realiza dentro del período correspondiente. Usted recibirá un número de autorización (RA#) y

deberá enviar el producto defectuoso, junto con el comprobante de compra, el RA# y seguros

pagados por adelantado, a la siguiente dirección:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Los costos de envío por

cobrar serán rechazados. El riesgo de sufrir una pérdida o daño en tránsito será asumido por el

cliente. Una vez que Reliable reciba el producto defectuoso, la compañía iniciará el proceso de

reparación o reemplazo.

Si tiene preguntas sobre esta garantía, puede escribir a la siguiente dirección:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

22

Page 26

Page 27

Page 28

1 800 268 1649

www.reliablecorporation.com

Loading...

Loading...