Page 1

5000 SERIES

PROFESSIONAL STEAM PRODUCTS

PRODU ITS À VAPEUR PROFES SIONNELS

PRODU CTOS PROFESIO NALES DE VAPOR

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

Page 2

Page 3

ENGLISH 01

FRANÇAIS 13

ESPAÑOL 28

Page 4

THE 5000 SERIES

PROFESSIONAL STEAM STATION

INSTRUCTION MANUAL

ENGLISH

01

Page 5

RELIABLE. RIGHT THERE WITH YOU.

At Reliable, we do what we love, and take pride in doing it right.

You want what’s best for the people, places and things that matter

in your life – from where you live to what you wear. So do we. From

the start, we approach every product with a craftsman’s attention to detail and passion for making it right. Quality, functionality,

design and customer service play an equally important part in

delivering what’s right for you. With its stainless steel construction,

and professional grade components; the 5000 Series will allow

you to obtain the benefits of professional pressing or cleaning in a

compact and convenient format.

For your safety and to fully enjoy the advantages of this product,

please take a few minutes to read all the important safeguards and

care instructions. Keep this manual handy and review the product

warranty for your reference.

02

Page 6

IMPORTANT SAFETY INSTRUCTIONS –

SAVE THESE INSTRUCTIONS IN A SAFE

PLACE FOR FUTURE REFERENCE

READ ALL INSTRUCTIONS BEFORE USE

When using your Reliable™ steam station, basic safety precautions should always be

followed. Please read the following instructions carefully as they provide important information concerning how to install, use and care for this product.

1. To protect against the risk of electric shock, do not immerse the appliance

in water.

2. Do not allow the cord to touch hot surfaces.

3. Always allow the appliance to cool for at least thirty minutes before storing.

4. Always put the appliance in a secure place on a table or counter when using.

5. Do not move the appliance without unplugging it first.

6. Always disconnect the appliance from the outlet before filling with or removing water.

Be careful to avoid spilling water on the appliance when filling.

7. Use tap water or 50/50 tap/distilled water in the appliance. Do not use perfumed or

products containing alcohol in the appliance.

8. Always disconnect the appliance when not in use.

9. Do not use the appliance if the cord is damaged. Return the appliance or have the

cord repaired by the manufacturer, or their service agent.

10. Do not operate the appliance if it has been dropped or damaged. Do not disassemble

the appliance. Incorrect reassembly can cause a risk of electric shock. Send it to an

authorized service center for repair.

11. Do not operate another high wattage appliance on the same circuit.

12. This appliance must be grounded. Do not alter the plug or attempt to remove

this feature.

13. Be careful. Burns can occur from touching hot metal parts or steam.

14. This appliance is not intended for use by young children.

15. While using the appliance, never unscrew or remove the cap (1) while the boiler is

under pressure.

16. Before removing the cap, make sure there’s no more steam in the steam chamber by

shutting the boiler switch (4) to the off position, and pressing the steam iron button

(7) to release all of the remaining steam.

17. To ensure your safety, the safety cap (1) and all other components must be replaced

with original parts only.

03

Page 7

FOR HOUSEHOLD AND LIGHT

COMMERCIAL USE ONLY

FEATURES

• Low water light indicator

• Auto shut-off thermostat protection

• Regular tap water or 50/50 tap/distilled water

• 50 p.s.i operating pressure

• Ceramic terminal block

• 12-gauge heavy-duty wiring

• Up to 4 hours of steam

IRONING

• Your new ironing station provides clean, professional results every time

• The professional iron soleplate is made from durable, and fast heating aluminum

• Stainless steel outer shell construction for long life

• Adjustable thermostat allows for accurate temperature settings

• Cork handle iron is comfortable and stays cool

STEAM CLEANING

• Adjustable steam nozzle with foot pedal (5000CJ)

• Steam gun (5000CD)

IMPORTANT: When you want to dispose of the appliance, NEVER throw it in the garbage.

Instead, go to your closest recycling station or waste collection centre for subsequent

treatment. In this way, you will be contributing to looking after

the environment.

TECHNICAL DATA

Full aluminium-plated heating element at 800W –120V

Boiler power 5000IS: 1000W

Working pressure 5000IS: 3,5 bar

Tank nominal capacity of model 5000IS: 2,5 Litres

04

Page 8

HOW TO ASSEMBLE AND USE

1. Remove the steam station from its packing and make sure all packing has been

removed (including the protective bags). Put the station on a flat and solid surface.

2. A) 5000IS – It is recommended to put the iron on the iron pad, (supplied) as the pad

will withstand the temperature of the iron. B) 5000CJ – Screw the nozzle into the

steam fitting and plug in the 4-pin receptacle for the electronic foot pedal. C) 5000CD

– Connect the steam gun the same way using the quick disconnect for the steam hose.

3. Insert the two-piece wand (2) into the flange on top of the boiler, tighten with

the side screw and attach the spring on the iron hose to the coil end of the wand

(5000IS, 5000CD models only).

4. Unscrew the safety cap (1). Fill the boiler with a maximum of 8.45 cups (2 litres)

of water for the 5000IS series. Use the funnel supplied, making sure you do not overfill the tank (you can also use the water stick to determine the water level in the

steam tank).

5. Insert the plug into the electrical outlet; switch on the boiler (4) and steam button

(3). When the two button lights come on, the steam device and boiler are working.

6. For the 5000IS iron system, turn the iron plate’s temperature regulating knob (6) to

the position “cotton °°°” (indicated on the iron knob).

7. Wait 10 minutes for the boiler to reach maximum pressure. Once it reaches 50 psi,

the unit is now ready to operate. NOTE: The red light on the boiler switch (4) will

turn on and off during use, indicating that the heating element is activated or not.

8. NOTE: When you call for steam for the first time (after having turned the boiler on)

you might notice a fast decrease in pressure. This is normal for the first time.

9. The steam station is ready for use.

10. Push the steam button or the foot pedal for steam.

11. This steam product is equipped with a low water warning light (5) and the thermostat reset button (9 or 10). During operation, if the light comes on, it indicates that

the unit requires more water to operate. If this occurs, please follow these steps.

• Press the steam iron button or foot pedal to ensure there is no more steam

in the boiler.

• Slowly open the pressure cap (1) and refill to the required level with warm water.

• Replace the cap, tighten and press the thermostat reset button (9 or 10), wait

for it to build up pressure again.

IMPORTANT

When you are finished using the boiler for the day, unscrew the fill cap one-turn on the

unit to release the steam/air from the tank. This will eliminate the vacuum that may cause

damage to the pressure gauge.

05

Page 9

The boiler must be cleaned periodically and any sediment/mineral buildup removed

from inside the unit; otherwise, it may become clogged. The period between cleanings

depends on the frequency of use and the quality/hardness of the water used. If the unit

is in daily use with regular municipal tap water, we recommend a cleaning every two

weeks to a month.

TO CLEAN THE BOILER UNIT

1. Unplug the unit from the wall.

2. Disconnect the iron (5000IS), the steam gun (5000CD) or the steam nozzle

(5000CJ) from the boiler unit. (The steam nozzle on the 5000CJ may be left on

the unit if desired. It does not affect the cleaning instructions.)

3. Add a mixture of 1 part white vinegar to 5 parts water and pour inside the boiler

tank to capacity. Let the vinegar solution sit overnight.

4. Pick up the boiler unit and pour approximately half of the solution out of the boiler

tank. Vigorously shake/swirl the remaining solution around the tank to loosen and

pick up any softened sediment that may have accumulated inside. Pour the remaining solution out of the tank. You may see bits of sediment and mineral come out at

this point.

5. Rinse the tank with clean water until there is no smell of vinegar or any sediment

bits coming from inside the tank. NOTE: Sediment/mineral pieces can be blown into

the solenoid valve or the steam nozzle during operation so it is important that they

are not left in the tank after cleaning.

6. The unit is now ready for use.

WATER INSTRUCTIONS

Use tap water or 50/50 tap/distilled water in the appliance. Do not use perfume or products containing alcohol in the appliance.

06

Page 10

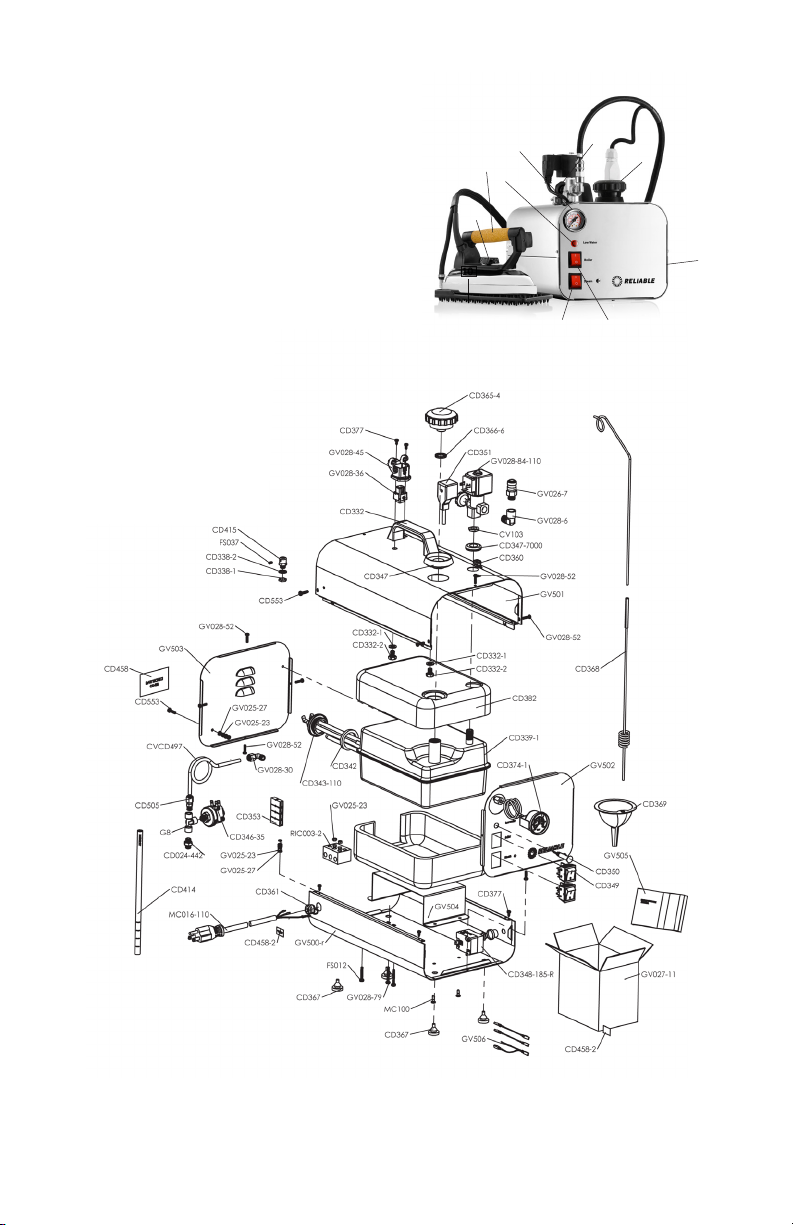

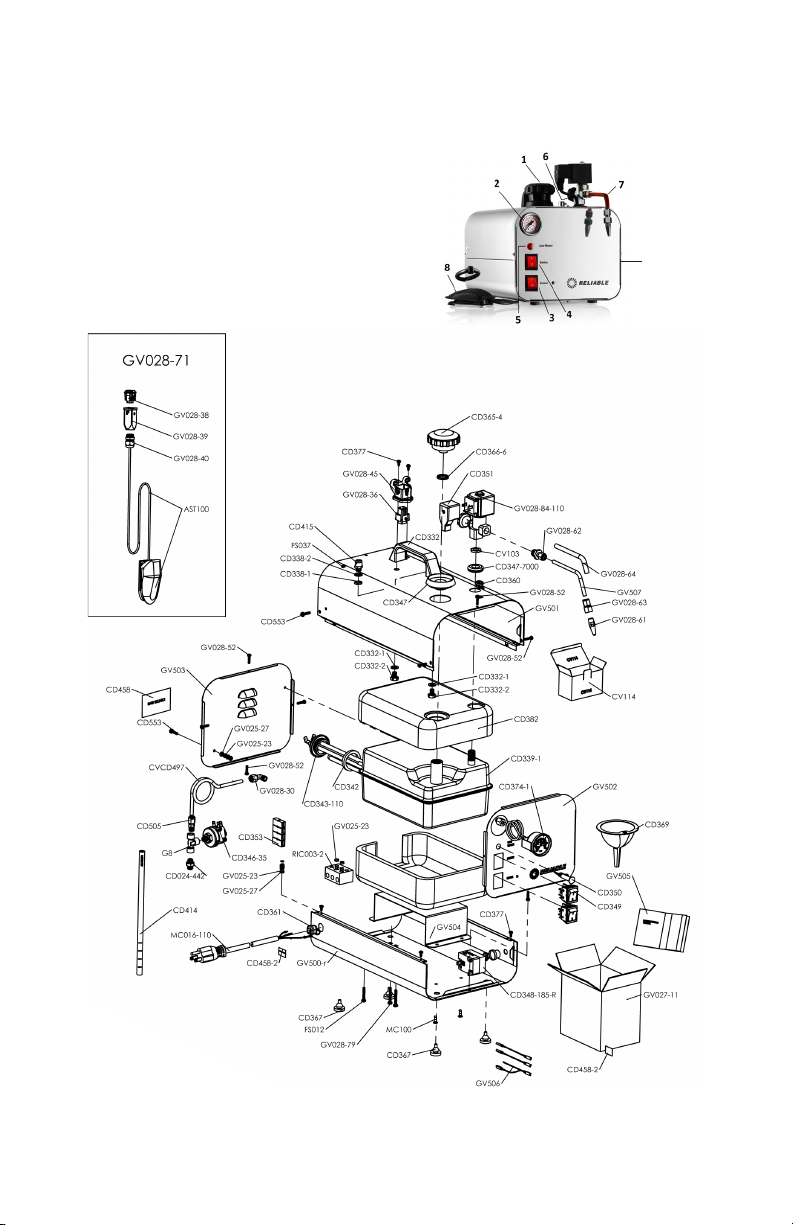

DESCRIPTION OF THE 5000IS

1. Safety cap

2. Iron power button

3. Boiler power button

4. Low water level light indicator

5. Temperature regulating knob

6. Steam button

7. Steam regulation knob

8. Pressure gauge

9. Thermostat reset button

8

6

4

5

10

7

1

9

32

07

Page 11

DESCRIPTION OF THE 5000CJ

1. Safety cap

2. Pressure gauge (manometer)

3. Steam button

4. Boiler button

5. Low water light indicator

6. Steam regulating knob

7. Adjustable nozzle

8. Pedal

9. Thermostat reset button

9

08

Page 12

DESCRIPTION OF THE 5000CD

1. Safety cap

2. Pressure gauge (manometer)

3. Steam button

4. Boiler button

5. Low water light indicator

6. Steam regulating knob

7. Cord support

8. Steam switch

9. Steam gun

10. Thermostat reset button

1700DA

10

09

Page 13

TROUBLESHOOTING

PROBLEM

The steam from the iron

is too wet.

Water is coming out from

the boiler.

There is no steam coming out

of the iron, nozzle or gun.

POSSIBLE CAUSES

1. While filling the tank you

may have poured too much

water into it.

2. The iron soleplate is not

getting hot enough.

1. There might be a leak in the

heating element gasket.

1. The steam knob might

be closed.

2. The iron switch might be off

3. The foot pedal is not

plugged in (5000CJ).

4. The boiler switch might

be off.

5. If the low water light is on,

the water in the tank is low

or empty.

REMEDY

1. The problem will go on

until the excess water is

emptied. Keep the steam

button pressed until the

water in the tank is at the

correct level.

2. Please check that the

temperature knob is

on the right position, if

not, increase the iron

temperature.

1. Contact technical support

as in most cases, the

gasket will need to be

replaced.

1. Open the steam knob

anticlockwise.

2. After the iron switch

comes on, wait for 4 minutes so that the iron plate

gets hot.

3. Plug the 4-pin receptacle

into the boiler.

4. After the boiler switch

comes on, wait for 10 minutes so the boiler produces

steam.

5. Refill the boiler carefully

following the instructions.

The steam is dirty.

Machine shuts off

automatically

1. When using the iron with a

ironing shoe, if not cleaned

regularly, calcium will form

between the shoe and the

iron base.

1. Machine is low on water.

1. Remove and rinse the

ironing shoe on a regular

(monthly) basis to avoid

scale build-up.

1. Press the steam iron button or foot pedal to ensure

there is no more steam

in the boiler.

2. Slowly open the pressure

cap (1) and refill to

the required level with

warm water.

3. Replace the cap, tighten

and press the thermostat

reset button (9 or 10),

wait for it to build up

pressure again.

10

Page 14

RELIABLE CORPORATION LIFETIME

PRODUCT WARRANTY POLICY FOR

PRESSURIZED STEAM BOILER TANKS

Reliable Corporation (“Reliable”) warrants to the original purchaser of the boiler noted

above from Reliable (the “Reliable Boiler Tank”) that it will be free from defects in materials

and workmanship when utilized for normal use by the original purchaser only. Should the

Reliable Boiler Tank need replacement, Reliable will do so at no parts and labor cost to the

original purchaser, exclusive of shipping.

Subject to the conditions and limitations set forth below, Reliable will either repair or replace

any part of a Reliable Boiler Tank that proves defective by reason of improper workmanship

or materials. If the defective Reliable Boiler Tank is no longer available and cannot be repaired

effectively or replaced with an identical model, Reliable shall replace the defective Reliable

Boiler Tank with a current Reliable Boiler Tank of equal or greater value. Repaired parts or

replacement products will be provided by Reliable on an exchange basis, and will be either new

or refurbished to be functionally equivalent to new. If Reliable is unable to repair or replace a

Reliable Boiler Tank, it will refund the current value of that Reliable Boiler Tank at the time the

warranty claim is made.

This limited warranty does not cover any damage to a Reliable Boiler Tank that results from

improper installation, accident, abuse, misuse, unreasonable use, natural disaster, insufficient

or excessive electrical supply, abnormal mechanical or environmental conditions or any

unauthorized disassembly, repair or modification. This limited warranty does not extend to

any indirect, consequential or incidental damages that may be suffered by a user from the

use of a Reliable Boiler Tank, including without limitation, any liability for third party claims

for damage, and is limited to the amount paid by the original purchaser for the Reliable Boiler

Tank with respect to which this limited warranty protection applies. This limited warranty does

not apply with respect to products that have been altered or which are missing serial numbers

or for products not purchased directly from Reliable or a dealer authorized by Reliable to sell

the Reliable Boiler Tank.

This limited warranty is the only warranty that applies to the Reliable Boiler Tank, supersedes

any and all terms that may be contained in any other document or purchase order and may

not be altered or amended except expressly in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our

customer service group at 1 800 268 1649 or at support@reliablecorporation.com. You will be

required to submit an original receipt via fax or e-mail. The receipt must reflect that you are

the original purchaser, the product was bought directly from Reliable or from an authorized

Reliable dealer and that the warranty claim is being made in compliance with the terms set

out in this document or any subsequent document issued by Reliable in connection with this

policy. You will be issued a return authorization number (RA#) and asked to ship the defective

product together with proof of purchase and RA#, prepaid insured to the following address:

Reliable Corporation, 5–100 Wingold Ave, Toronto, ON M6B 4K7.

Freight collect shipments will be refused. The risk of loss or damage in transit will be borne

by the customer. Once Reliable receives the defective product, it will initiate the repair or

replacement process.

11

Page 15

RELIABLE PRODUCTS WARRANTY

Reliable Corporation (“Reliable”) warrants to original purchaser of its products that

every product sold by Reliable (a “Reliable Product”) is free from defects in material and

workmanship for a period of one year from the date of purchase if properly used and

maintained. Subject to the conditions and limitations set forth below, Reliable will either

repair or replace any part of a Reliable Product that proves defective by reason of improper

workmanship or materials. If the defective Reliable Product is no longer available and cannot

be repaired effectively or replaced with an identical model, Reliable shall replace the defective

Reliable Product with a current Reliable Product of equal or greater value. Repaired parts or

replacement products will be provided by Reliable on an exchange basis, and will be either new

or refurbished to be functionally equivalent to new. If Reliable is unable to repair or replace

a Reliable Product, it will refund the current value of that Reliable Product at the time the

warranty claim is made.

This limited warranty does not cover any damage to a Reliable Product that results from

improper installation, accident, abuse, misuse, natural disaster, insufficient or excessive

electrical supply, abnormal mechanical or environmental conditions, wear and tear resulting

from normal use of the product, or any unauthorized disassembly, repair, or modification. This

limited warranty does not extend to any indirect, consequential or incidental damages that

may be suffered by a user or from the use of a Reliable Product, including without limitation,

any liability for third party claims for damage, and is limited to the amount paid by the original

purchaser Reliable Product with respect to which this limited warranty protection applies.

This limited warranty does not apply with respect to products that have been altered or which

are missing serial numbers or for products not purchased directly from Reliable or a dealer

authorized by us to sell Reliable Products.

This limited warranty is the only warranty that applies to any Reliable Product, supersedes any

and all terms that may be contained in any other document or purchase order and may not be

altered or amended except expressly in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our

customer service group at 1-800-268-1649 or at support@reliablecorporation.com.

You will be required to submit an original receipt via fax or e-mail. The receipt must reflect that

you are the original purchaser, the product was bought directly from

us or from an authorized Reliable dealer and that the warranty claim is being made within the

warranty period. You will be issued a return authorization number (RA#) and asked to ship the

defective product together with proof of purchase and RA#, prepaid insured to the following

address:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Freight collect shipments

will be refused. The risk of loss or damage in transit will be borne by

the customer. Once Reliable receives the defective product, it will initiate the repair or

replacement process.

If you have any questions regarding this warranty, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

12

Page 16

LES SÉRIES 5000

POSTE À VAPEUR PROFESSIONNEL

MODE D’EMPLOI

FRANÇAIS

13

Page 17

RELIABLE. PROCHE DE VOUS.

Chez Reliable, nous faisons ce que nous aimons et sommes fiers de

bien le faire. Vous voulez ce qu’il y a de mieux pour les personnes,

les lieux et les choses importantes de votre vie - depuis l’endroit

où vous vivez jusqu’aux vêtements que vous portez. Nous aussi.

Depuis le début, nous approchons chaque produit avec une

attention aux détails artisanale et la passion de le fabriquer. La

qualité, la fonctionnalité, la conception et le service à la clientèle

jouent des rôles également importants dans notre mission de

vous fournir ce qui vous correspond. Avec sa fabrication en acier

inoxydable et ses composants de qualité professionnelle ; la 5000

vous permettra d’obtenir les avantages du repassage ou d’un

nettoyage professionnel dans un format compact et pratique.

Pour votre sécurité et pour profiter pleinement des avantages de

ce produit, veuillez prendre quelques minutes pour lire toutes les

importantes mises en garde et les directives d’entretien. Gardez

ce manuel et la garantie du produit à portée de main pour vous y

référer ultérieurement.

14

Page 18

DIRECTIVES DE SÉCURITÉ IMPORTANTES

– CONSERVEZ CES INSTRUCTIONS

DANS UN ENDROIT SÉCURITAIRE POUR

RÉFÉRENCE FUTURE.

LISEZ TOUTES LES INSTRUCTIONS AVANT L’UTILISATION

Lorsque vous utilisez votre station à la vapeur Reliable™, les précautions sécuritaires

de base doivent toujours être suivies. Veuillez lire les instructions suivantes attentivement

car elles vous donneront de l’information importante sur l’installation, l’utilisation et

l’entretien de ce produit.

1. Pour protéger contre le risque de choc électrique, ne pas immerger l’appareil

dans l’eau.

2. Ne laissez pas le cordon électrique toucher de surfaces chaudes.

3. Laissez toujours l’appareil refroidir pendant au moins trente minutes avant de

le ranger.

4. Installez toujours l’appareil dans un endroit sécuritaire sur une table ou un

comptoir pendant l’utilisation.

5. Ne déplacez pas l’appareil sans l’avoir débranché avant.

6. Débranchez toujours l’appareil de la prise de courant électrique avant de remplir ou

retirer l’eau. Soyez prudent afin d’éviter d’éclabousser l’appareil avec de l’eau lors

du remplissage.

7. Utilisez l’eau du robinet ou un mélange d’eau distillée et du robinet à un mélange

de 50/50. Ne pas utiliser de parfum ou tout autre produit contenant de l’alcool

dans l’appareil.

8. Débranchez toujours l’appareil lorsque celui-ci n’est pas utilisé.

9. N’utilisez pas l’appareil si le cordon électrique est endommagé. Retournez l’appareil

ou faites réparer le cordon électrique par le manufacturier ou un agent autorisé.

10. Ne faites pas fonctionner l’appareil si celui-ci a été échappé ou endommagé. Ne

pas ouvrir l’appareil. Un réassemblage incorrect peut causer un risque de choc

électrique. Envoyez-le à un centre d’entretien autorisé pour réparation.

11. Ne pas faire fonctionner un autre appareil sur le même circuit électrique si celui-ci

est à haut voltage.

12. Cet appareil doit être mis à la terre. Ne pas modifier ou tenter de retirer cette

caractéristique de la fiche d’alimentation.

13. Soyez prudent. Des brûlures peuvent survenir si vous touchez des pièces métalliques

chaudes ou la vapeur.

14. Cet appareil n’est pas conçu pour être utilisé par des enfants.

15

Page 19

15. Lorsque vous utilisez l’appareil, ne jamais dévisser ou retirer le bouchon (1) pendant

que la bouilloire est sous pression.

16. Avant de retirer le bouchon, assurez-vous qu’il n’y a plus de vapeur présente dans la

chambre à vapeur. Pour ce faire, vous devez fermer l’interrupteur de la bouilloire (4)

et appuyez sur le bouton de vapeur (7) pour libérer toute la vapeur restante.

17. Pour assurer votre sécurité, le bouchon de sécurité (1) et toutes les autres

composantes doivent être remplacées avec des pièces d’origine seulement

POUR UNE UTILISATION RÉSIDENTIELLE

ET COMMERCIALE LÉGÈRE SEULEMENT

CARACTÉRISTIQUES

• Indicateur de bas niveau d’eau

• Arrêt automatique de protection du thermostat

• Utiliser avec de l’eau du robinet ou un mélange 50/50 d’eau du robinet et distillée

• Pression de fonctionnement à 50 psi

• Bloc terminal en céramique

• Câblage robuste de 12 Ga.

• Jusqu’à 4 heures de vapeur

REPASSAGE

• Votre nouveau poste de repassage vous donnera des résultats propres et profession-

nels à chaque fois

• La plaque d’assemblage du fer professionnelle est faite d’un aluminium durable,

à chauffage rapide

• Construction du corps extérieur en acier inoxydable pour une durée de vie prolongée

• Thermostat ajustable vous permettant de régler avec précision la température

• La poignée en liège est confortable et demeure froide

NETTOYAGE À LA VAPEUR

• Gicleur à vapeur ajustable avec pédale (5000CJ)

• Pistolet à vapeur (5000CD)

IMPORTANT : Lorsque vous désirez vous départir de l’appareil, NE JAMAIS le jeter aux

ordures. Rendez-vous plutôt à votre centre de recyclage le plus près ou à un centre

d’enlèvement des ordures ménagères pour un traitement adéquat. De cette façon, vous

contribuerez à protéger l’environnement.

16

Page 20

DONNÉES TECHNIQUES

Élément chauffant plaqué aluminium à 800W – 120V

Puissance de la bouilloire 5000IS : 1000 W

Pression de service du 5000IS : 3.5 bars

Capacité nominale du réservoir pour le modèle 5000IS : 2,5 litres

DIRECTIVES D’ASSEMBLAGE ET D’UTILISATION

1. Retirez le poste à vapeur de son emballage et assurez-vous que toutes les pièces

ont été retirées de l’emballage (y compris les sacs protecteurs). Installez le poste

sur une surface droite et solide.

2. A) 5000IS – Il est recommandé de mettre le fer sur le coussinet du fer (fourni)

puisque le coussinet résistera à la température du fer. B) 5000CJ – Vissez le

gicleur dans le raccord à vapeur et branchez le connecteur à 4 broches pour la

pédale électronique. C) 5000CD – Connectez le pistolet à vapeur de la même façon

en utilisant la déconnexion rapide pour le tuyau de vapeur.

3. Insérez les deux tringles rotatives (2) dans les rebords sur le dessus de la

bouilloire, serrez avec les vis latérales et fixez le ressort sur le tuyau du fer à

l’extrémité du serpentin de la tringle (modèles 5000IS et 5000CD seulement).

4. Dévissez le bouchon de sûreté (1). Remplissez la bouilloire avec un maximum de

8.45 tasses (2 litres) d’eau pour la série 5000IS. Utilisez l’entonnoir fournie en

vous assurant de ne pas trop remplir le réservoir (vous pouvez aussi utiliser la

baguette d’eau pour déterminer le niveau d’eau dans le réservoir à vapeur).

5. Insérez la fiche d’alimentation dans la prise électrique; allumez la bouilloire (4) et

le bouton de vapeur (3). Lorsque les lumières des deux boutons s’allument, le fer

et la bouilloire fonctionnent.

6. Pour le système 5000IS, tournez le bouton de réglage de la température de la

plaque du fer (6) à la position « coton » (inscrit sur le bouton du fer).

7. Attendez 10 minutes afin que la bouilloire atteigne la pression maximum. Une fois

qu’elle a atteint 50 psi, l’appareil est maintenant prêt à être utilisé. REMARQUE :

La lumière rouge sur le commutateur de la bouilloire (4) s’allumera et s’éteindra

pendant l’utilisation, indiquant que l’élément chauffant est activé ou non.

8. REMARQUE : Lorsque vous demandez de la vapeur pour la première fois (après

avoir allumé la bouilloire) vous pourriez remarquer une baisse de pression. Cela est

normal lors de la première utilisation.

9. Le poste à vapeur est maintenant prêt à être utilisé.

10. Appuyez sur le bouton de vapeur ou la pédale pour obtenir de la vapeur.

17

Page 21

11. Ce produit de vapeur est muni d’un témoin d’avertissement de bas niveau d’eau

(5) et le bouton de réinitialisation du thermostat (9 ou 10). Pendant le fonctionnement, si la lumière s’allume, cela indique que l’appareil nécessite davantage

d’eau pour fonctionner. Si cette situation se produit, veuillez suivre les étapes

suivantes.

• Appuyez sur le bouton de vapeur ou la pédale pour vous assurer qu’il n’y a

plus de vapeur dans la bouilloire.

• Ouvrez lentement le bouchon de pression (1) et remplissez au niveau

requis avec de l’eau tiède.

• Remplacez le chapeau, serrez et appuyez sur le bouton de

réinitialisation de thermostat (9 ou 10), attente lui pour accumuler la

pression encore.

IMPORTANT

Lorsque vous avez terminé d’utiliser la bouilloire pour la journée, dévissez le bouchon de

remplissage un – allumez l’appareil pour libérer la vapeur/air du réservoir. Cela éliminera

l’aspiration pouvant causer des dommages à la jauge de pression.

La bouilloire doit être nettoyée périodiquement et toute accumulation de sédiments/

minéraux doit être retirée de l’intérieur de l’appareil; autrement, elle pourrait créer une

obstruction. La période entre les nettoyages dépend de la fréquence d’utilisation et la

qualité/dureté de l’eau utilisée. Si l’appareil est utilisé quotidiennement avec de l’eau

régulière provenant du robinet, nous recommandons un nettoyage à toutes les deux

semaines ou une fois par mois.

POUR NETTOYER LA BOUILLOIRE

1. Débranchez l’appareil de la prise murale.

2. Débranchez le fer (5000IS), le pistolet à vapeur (5000CD) ou le gicleur de vapeur

(5000CJ) de l’unité de la bouilloire. (le gicleur à vapeur sur le 5000CJ peut demeurer sur l’appareil, si désiré. Cela n’affecte pas le nettoyage.)

3. Ajoutez un mélange de 1 partie de vinaigre blanc pour 5 parties d’eau. Versez à

l’intérieur du réservoir de la bouilloire. Laissez la solution de vinaigre reposer toute

la nuit.

4. Prenez la bouilloire et versez environ la moitié de la solution hors du réservoir de

celle-ci. Brassez/mélangez vigoureusement la solution restante autour du réservoir

afin de libérer et ramasser tout sédiment pouvant s’être accumulé à l’intérieur.

Versez le restant de la solution hors du réservoir. Vous pourriez voir à ce moment-ci

des particules de sédiments et minéraux sortir.

18

Page 22

5. Rincez le réservoir avec de l’eau clair jusqu’à ce que l’odeur de vinaigre ait disparue ou qu’aucune particule de sédiments ne sorte de l’intérieur du réservoir.

REMARQUE : Les particules de sédiments/minéraux peuvent faire surchauffer

l’électrovalve du gicleur de vapeur pendant le fonctionnement. Il est donc important qu’elles ne soient pas laissées dans le réservoir après le nettoyage.

6. L’appariel est maintenant prêt à être utilisé.

MODE D’EMPLOI POUR L’EAU

Utilisez l’eau du robinet ou un mélange d’eau distillée et du robinet à un mélange

de 50/50. Ne pas utiliser de parfum ou tout autre produit contenant de l’alcool

dans l’appareil.

19

Page 23

DESCRIPTION DU 5000IS

1. Bouchon de sûreté

2. Bouton d’alimentation du fer à repasser

3. Bouton d’alimentation de la bouilloire

4. Indicateur de bas niveau d’eau

5. Bouton de réglage de la température

6. Bouton de vapeur

7. Bouton de réglage de la vapeur

8. Jauge à pression

9. Bouton de réinitialisation de thermostat

8

6

4

5

10

7

1

9

32

20

Page 24

DESCRIPTION DU 5000CJ

1. Bouchon de sûreté

2. Jauge à pression (manomètre)

3. Bouton de vapeur

4. Bouton de la bouilloire

5. Indicateur de bas niveau d’eau

6. Bouton de réglage de la vapeur

7. Gicleur ajustable

8. Bouton de réinitialisation de thermostat

9

21

Page 25

DESCRIPTION DU 5000CD

1. Bouchon de sûreté

2. Jauge à pression (manomètre)

3. Bouton de vapeur

4. Bouton de la bouilloire

5. Indicateur de bas niveau d’eau

6. Bouton de réglage de la vapeur

7. Support du cordon électrique

8. Interrupteur à vapeur

9. Pistolet à vapeur

10. Bouton de réinitialisation de thermostat

1700DA

10

22

Page 26

DÉPANNAGE

PROBLÈME

La vapeur provenant du fer est

trop humide.

L’eau sort de la bouilloire.

Aucune vapeur ne sort du fer, du

gicleur ou du pistolet.

La vapeur est sale.

La machine a coupé

automatiquement.

CAUSES POSSIBLES

1. Pendant le remplissage du

réservoir, vous pourriez y

avoir mis trop d’eau.

2. La plaque d’assemblage du fer

ne devient pas suffisamment

chaude.

1. Il pourrait y avoir une fuite

dans le joint d’étanchéité de

l’élément chauffant.

1. Le bouton de vapeur pourrait

être fermé

2. L’interrupteur du fer à repasser

pourrait être fermé

3. La pédale n’est pas

branchée (5000CJ)

4. L’interrupteur de la bouilloire

pourrait être fermé

5. Si le témoin lumineux de bas

niveau d’eau est allumé, l’eau

dans le réservoir est à un bas

niveau ou vide.

1. Lorsque vous utilisez la

semelle de fer à repasser, si

vous ne la nettoyez pas, le

calcium se formera entre la

semelle et la base du fer.

1. La machine est basse sur

l'eau.

SOLUTION

1. Le problème continuera

jusqu’à ce que toute l’eau soit

vidée. Continuez d’appuyer sur

le bouton à vapeur jusqu’à ce

que l’eau du réservoir soit au

bon niveau.

2. Veuillez vous assurer que le

bouton de température est à

la bonne position. Si ce n’est

pas le cas, augmentez la

température du fer.

1. Contactez le service

technique car, dans la

plupart des cas, le joint

d’étanchéité nécessitera un

remplacement.

1. Ouvrez le bouton de vapeur

dans le sens contraire des

aiguilles d’une montre.

2. Après la mise en marche du

fer, attendez 4 minutes que la

plaque du fer devienne chaude.

3. Branchez le connecteur à 4

broches dans la bouilloire.

4. Après la mise en marche de la

bouilloire, attendez 10 minutes

afin que la bouilloire produise

de la vapeur.

5. Remplissez la bouilloire

soigneusement en suivant les

directives.

1. Retirez et rincez la semelle

de fer à repasser sur une

base régulière (mensuellement) pour éviter toute

accumulation d’écaille.

1. Appuyez sur le bouton de

vapeur ou la pédale pour vous

assurer qu’il n’y a plus de

vapeur dans la bouilloire.

2. Ouvrez lentement le bouchon

de pression (1) et remplissez au

niveau requis avec de

l’eau tiède.

3. Remplacez le chapeau, serrez et

appuyez sur le bouton de réinitialisation de thermostat (9 ou

10), attente lui pour accumuler

la pression encore.

23

Page 27

POLITIQUE DE GARANTIE À VIE DES

RÉSERVOIRS DE CHAUFFE-EAU SOUS

PRESSION DE RELIABLE CORPORATION

Reliable Corporation (« Reliable ») garantit à l'acheteur original du chauffe-eau susmentionné

de Reliable (le « réservoir de chauffe-eau Reliable ») qu'il sera exempt de tout défaut de

fabrication et de main d'œuvre dans le cadre d'une utilisation normale par l'acheteur original

uniquement. Si un remplacement du réservoir de chauffe-eau Reliable s'avérait nécessaire,

Reliable y procédera sans aucun frais de pièces ni de main d'œuvre pour l'acheteur original, à

l'exclusion des frais d'expédition.

Soumis aux conditions et limitations établies ci-après, Reliable réparera ou remplacera toute

pièce d'un réservoir de chauffe-eau Reliable qui s'avère défectueux en raison d'un défaut de

fabrication ou de matériaux défectueux. Si le réservoir de chauffe-eau Reliable défectueux n'est

plus disponible et ne peut pas être réparé efficacement ou remplacé par un modèle identique,

Reliable remplacera le réservoir de chauffe-eau Reliable défectueux par un réservoir de chauffeeau Reliable actuel de valeur équivalente ou supérieure. Les pièces réparées ou les produits

remplacés seront fournis par Reliable sur la base d'un échange, et seront soit neufs ou remis

à neuf pour être fonctionnellement équivalents aux neufs. Si Reliable n'est pas en mesure de

réparer ou de remplacer un réservoir de chauffe-eau Reliable, elle remboursera la valeur actuelle

dudit réservoir de chauffe-eau Reliable au moment où la réclamation de garantie est réalisée.

Cette garantie limitée ne couvre aucun dommage subi par un réservoir de chauffe-eau Reliable

résultant d'une installation incorrecte, d'un accident, d'un abus, d'une mauvaise utilisation,

d'une utilisation déraisonnable, d'une catastrophe naturelle, d'une alimentation électrique

insuffisante ou excessive, de conditions mécaniques ou environnementales anormales, ou de

tout démontage, réparation ou modification non autorisé. Cette garantie limitée ne s'étend à

aucun dommage indirect ou direct dont peut être victime un utilisateur suite à l'utilisation d'un

réservoir de chauffe-eau Reliable, y compris mais sans s'y limiter, toute responsabilité pour des

réclamations de tiers pour des dégâts, et se limite au montant payé par l'acheteur original du

réservoir de chauffe-eau auquel cette protection de garantie limitée s'applique. Cette garantie

limitée ne s'applique pas aux produits qui ont été modifiés ou dont les numéros de séries sont

manquants, ou aux produits non achetés directement auprès de Reliable ou d'un revendeur

agréé par Reliable pour vendre des réservoirs de chauffe-eau Reliable.

Cette garantie limitée est l'unique garantie qui s'applique au réservoir de chauffe-eau Reliable,

elle remplace toutes conditions qui peuvent être contenues dans un autre document ou bon de

commande et ne peut être transformée ou modifiée, sauf dérogation expressément écrite de

Reliable.

Pour obtenir une réparation ou un remplacement en vertu des conditions de cette garantie,

veuillez contacter notre service à la clientèle au 1 800 268 1649 ou par courriel à support@

reliablecorporation.com. Il vous sera demandé d'envoyer le reçu original par fax ou courriel. Le

reçu doit prouver que vous êtes l'acheteur original, que le produit a été acheté directement chez

Reliable ou chez un revendeur agréé par Reliable et que la réclamation de garantie est effectuée

conformément aux conditions définies dans le présent document ou tout document subséquent

publié par Reliable en rapport avec la présente garantie. Un numéro d'autorisation de retour (Nº

AR) vous sera donné et il vous sera demandé d'expédier le produit défectueux accompagné de la

preuve d'achat et du Nº AR, les frais d'assurances étant prépayés à l'adresse suivante : Reliable

Corporation, 5–100 Wingold Ave, Toronto, ON M6B 4K7.

Les expéditions avec fret à destination seront refusées. Le risque de perte ou

d'endommagement lors du transport sera assumé par le client. Une fois que Reliable aura reçu le

produit défectueux, elle initiera la réparation ou le remplacement.

24

Page 28

GARANTIE DES PRODUITS RELIABLE

Reliable Corporation (« Reliable ») garantit à l'acheteur original de ce produit que chaque produit

vendu par Reliable (un « Produit Reliable ») est exempt de tout défaut de pièce et de main d'œuvre

pour une période d'un an à compter de la date d'achat, s'il est utilisé et entretenu correctement.

Sous réserve des conditions et des restrictions énoncées ci-dessous, Reliable réparera ou remplacera

toute pièce d'un produit Reliable qui s'avère défectueuse en raison d'un défaut de fabrication ou de

matériaux défectueux. Si le Produit Reliable défectueux n'est plus disponible et ne peut pas être

réparé efficacement ou remplacé par un modèle identique, Reliable remplacera le Produit Reliable

défectueux par un Produit Reliable actuel de valeur équivalente ou supérieure. Les pièces réparées

ou les produits remplacés seront fournis par Reliable sur la base d'un échange, et seront soit neufs

ou remis à neuf pour être fonctionnellement équivalents aux neufs. Si Reliable n'est pas en mesure de

réparer ou de remplacer le Produit Reliable, elle remboursera la valeur actuelle du Produit Reliable au

moment où la réclamation de garantie est réalisée.

Cette garantie limitée ne couvre aucun dommage subi par un Produit Reliable résultant d'une

installation incorrecte, d'un accident, d'un abus, d'une mauvaise utilisation, d'une catastrophe

naturelle, d'une alimentation électrique insuffisante ou excessive, de conditions mécaniques ou

environnementales anormales, de l'usure et de la détérioration résultant de l'usure normale du

produit, ou de tout démontage, réparation ou modification non autorisés. Cette garantie limitée ne

couvre pas les dommages directs, indirects ou consécutifs dont peut être victime un utilisateur ou

suite à l'utilisation d'un Produit Reliable, y compris mais sans s'y limiter, toute responsabilité pour des

réclamations de tiers pour des dégâts, et se limite au montant payé par l'acheteur original du Produit

Reliable auquel cette protection de garantie limitée s'applique. Cette garantie limitée ne s'applique pas

aux produits qui ont été modifiés ou dont les numéros de séries sont manquants, ou aux produits non

achetés directement auprès de Reliable ou d'un revendeur agréé pour vendre des Produits Reliable.

Cette garantie limitée est l'unique garantie qui s'applique à tout Produit Reliable, elle remplace toutes

conditions qui peuvent être contenues dans un autre document ou bon de commande et ne peut être

transformée ou modifiée, sauf dérogation expressément écrite de Reliable.

Pour obtenir une réparation ou un remplacement en vertu des conditions de cette garantie,

veuillez contacter notre service à la clientèle au 1-800-268-1649 ou par courriel à support@

reliablecorporation.com. Il vous sera demandé d'envoyer le reçu original par fax ou courriel. Le reçu

doit prouver que vous êtes l'acheteur original, que le produit a été acheté directement chez nous

ou chez un revendeur agréé par Reliable et que la réclamation de garantie est effectuée pendant

la période de garantie. Un numéro d'autorisation de retour (Nº AR) vous sera donné et il vous sera

demandé d'expédier le produit défectueux accompagné de la preuve d'achat et du Nº AR, les frais

d'assurances étant prépayés à l'adresse suivante :

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Les expéditions avec fret à

destination seront refusées. Le risque de perte ou d'endommagement lors du transport sera assumé

par le client. Une fois que Reliable aura reçu le produit défectueux, elle initiera la réparation ou le

remplacement.

Si vous avez des questions concernant la présente garantie, vous pouvez écrire à :

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

26

Page 29

27

Page 30

LA SERIE 5000

ESTACIÓN PROFESIONAL DE VAPOR

MANUAL DE INSTRUCCIONES

ESPAÑOL

28

Page 31

RELIABLE. JUNTO A USTED.

En Reliable, hacemos lo que nos encanta hacer y nos enorgullecemos de hacerlo bien. Quiere lo mejor para las personas, los

lugares y las cosas que importan en la vida: desde dónde vive a

la ropa que viste. Nosotros también. Desde el inicio, abordamos

cada producto con la atención al detalle de un artesano y la pasión

por hacerlo bien. La calidad, la funcionalidad, el diseño y el servicio al consumidor son igual de importantes para ofrecerle algo

adecuado para usted. Con su estructura de acero inoxidable y sus

componentes de calidad profesional, la 5000 le permitirá obtener

los beneficios de un planchado o un lavado al vapor de tipo profesional, en un formato compacto y conveniente.

Por su seguridad y para disfrutar al máximo las ventajas de este

producto, tómese unos minutos para leer todas las precauciones

importantes e instrucciones de cuidado. Conserve este manual a

mano y lea la garantía del producto para su referencia.

29

Page 32

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD – CONSERVE ESTAS

INSTRUCCIONES EN UN LUGAR SEGURO

PARA FUTURA REFERENCIA

LEA COMPLETAMENTE LAS INSTRUCCIONES ANTES DE UTILIZARLO

Siempre debe seguir algunas precauciones básicas de seguridad al utilizar su estación de

vapor Reliable™. Lea cuidadosamente las siguientes instrucciones ya que le proporcionan

información importante con respecto a cómo instalar, usar y cuidar de este producto.

1. Para protegerse contra el riesgo de sufrir una descarga eléctrica, no sumerja este

artefacto en agua.

2. No deje que el cable entre en contacto con superficies calientes.

3. Siempre permita que el artefacto se enfríe durante al menos treinta minutos antes

de guardarlo.

4. Siempre coloque el artefacto en un lugar seguro sobre una mesa o una mesada

cuando lo utiliza.

5. No mueva el artefacto sin desenchufarlo previamente.

6. Siempre desconecte el artefacto del tomacorriente antes de colocarle o quitarle el

agua. Tenga la precaución de no derramar agua sobre el artefacto cuando lo llena.

7. Use agua del grifo o 50% agua del grifo y 50% agua destilada en este artefacto. No

utilice perfume ni productos que contengan alcohol en el artefacto.

8. Siempre desenchufe el artefacto cuando no lo utilice.

9. No use el artefacto si el cable está dañado. Devuelva el artefacto o haga reparar el

cable por el fabricante o su agente de reparaciones.

10. No utilice el artefacto si se ha caído o dañado. No desarme el artefacto. Un armado

incorrecto puede provocar el riesgo de una descarga eléctrica. Envíelo a un centro

de servicio técnico autorizado para que lo reparen.

11. No utilice otro artefacto de alto consumo en el mismo circuito.

12. Este artefacto debe ser conectado a tierra. No modifique el cable ni intente remover

este dispositivo.

13. Tenga precaución. El tocar partes metálicas calientes o vapor puede causar

quemaduras.

14. Este artefacto no debe ser utilizado por los niños.

15. Mientras use el artefacto, nunca desenrosque o saque la tapa (1) mientras la caldera

esté con presión.

30

Page 33

16. Antes de sacar la tapa, verifique que no haya más vapor en la cámara de vapor colocando la llave de la caldera (4) en la posición de apagado y presionando el botón de

planchado con vapor (7) para liberar todo el vapor que haya quedado.

17. Para garantizar su seguridad, la tapa de seguridad (1) y todos los demás componentes deben ser reemplazados por partes originales únicamente.

PARA USO HOGAREÑO Y COMERCIAL

LIVIANO ÚNICAMENTE

FUNCIONES

• Indicador de bajo nivel de agua

• Apagado automático de protección del termostato

• Agua común del grifo o 50% agua del grifo y 50% agua destilada

• 50 psi de presión de funcionamiento

• Bloque de terminales cerámico

• Cableado industrial calibre 12

• Hasta 4 horas de vapor

PLANCHADO

• Su nueva estación de planchado brinda resultados limpios y profesionales cada

vez que se la usa

• La base de plancha profesional está hecha con aluminio duradero y de calentamiento

rápido

• Cubierta exterior hecha de acero inoxidable para mayor durabilidad

• Termostato ajustable que permite ajustar la temperatura con precisión

• Plancha con mango de corcho que es cómodo y se mantiene frío

LIMPIEZA A VAPOR

• Boquilla de vapor ajustable con pedal de control (5000IS)

• Pistola de vapor (1500B)

IMPORTANTE: Cuando desee desechar el artefacto, NUNCA lo arroje a la basura. En su

lugar, diríjase a la estación de reciclado o al centro de recolección de residuos mas cercano para su posterior tratamiento. De este modo, estará contribuyendo con la protección

del medio ambiente.

31

Page 34

DATOS TÉCNICOS

Elemento calefactor totalmente recubierto en aluminio de 800W – 120V

Potencia de la caldera del 5000IS: 1000W

Presión de funcionamiento del 5000IS: 3,5 bars

Capacidad nominal del tanque para el 5000IS: 2,5 Litros

CÓMO ARMARLA Y USARLA

1. Saque la estación de vapor de su caja y verifique que haya sacado todo el material

de empaque (incluyendo las bolsas protectoras). Coloque la estación sobre una

superficie plana y sólida.

2. A) 5000IS – Le recomendamos poner la plancha en su base de apoyo (incluida) ya

que soportará la temperatura de la plancha. B) 5000CJ – Atornille la boquilla en

el adaptador de vapor y enchufe el conector de 4 vías para el pedal electrónico. C)

5000CD – Conecte la pistola de vapor de la misma forma usando el conector rápido

para la manguera de vapor.

3. Inserte la varilla de 2 piezas (2) dentro de la pestaña en la parte superior de la

caldera, ajústela con el tornillo del costado y enganche el resorte de la manguera de

la plancha al extremo de la bobina de la varilla (únicamente para los modelos 5000IS

y 5000CD).

4. Desenrosque la tapa de seguridad (1). Llene la caldera con un máximo de 8,45 tazas

(2 litros) de agua para la serie 5000IS. Use el embudo incluido, asegurándose de no

llenar de más el tanque (también puede usar la varilla para determinar el nivel del

agua dentro del tanque).

5. Inserte el enchufe en un tomacorriente; encienda la caldera (4) y el botón de vapor

(3). Cuando las luces de los dos botones sen enciendan, el dispositivo de vapor y la

caldera estarán funcionando.

6. Para el sistema de planchado 5000IS, gire la perilla de ajuste de temperatura de

la placa de la plancha (6) hasta la posición “cotton °°°” (indicada en la perilla de la

plancha).

7. Espere 10 minutos para que la caldera alcance su presión máxima. Una vez que

llegue a los 50 psi, la unidad estará lista para usarse. NOTA: La luz roja de la llave de

la caldera (4) se encenderá y apagará durante el uso, indicando cuando el elemento

calefactor está activado y cuando no.

8. NOTA: Cuando use el vapor por primera vez (luego de haber encendido la caldera)

puede notar un rápido aumento en la presión. Esto es normal la primera vez.

9. La estación de vapor está lista para ser usada.

10. Presione el botón de vapor o el pedal de control para obtener vapor.

32

Page 35

11. Este producto viene equipado con una luz de advertencia de bajo nivel de agua (5)

y el botón de reinicio termostato (9 o 10). Durante el uso, si se enciende esta luz,

indica que la unidad necesita más agua para seguir funcionando. Si pasa esto, haga

lo siguiente.

• Presione el botón de vapor de la plancha o el pedal de control para asegurar

que no quede nada de vapor en la caldera.

• Abra lentamente la tapa de presión (1) y llénela hasta el nivel necesario

con agua tibia.

• Reemplazar la tapa, apretar y pulse el botón de reinicio del termostato

(9 o 10), espere a que se acumule presión de nuevo.

IMPORTANTE

Cuando termine de usar la caldera, desenrosque una vuelta de la tapa de llenado de

la unidad para liberar el vapor/aire del tanque. Esto eliminará el vacío que podría dañar

el medidor de presión.

La caldera debe limpiarse periódicamente y se debe remover toda acumulación de sedimento/minerales del interior de la unidad; de lo contrario, podría atascarse. El período

entre limpiezas depende de la frecuencia de uso y de la calidad/dureza del agua que se

utilice. Si la unidad se usa todos los días con agua normal del grifo, le recomendamos

limpiarla cada dos semanas o una vez por mes.

PARA LIMPIAR LA CALDERA

1. Desenchufe la unidad del tomacorriente.

2. Desconecte la plancha (5000IS), la pistola de vapor (5000CD) o la boquilla de

vapor (5000CJ) de la caldera. (la boquilla de vapor del 5000CJ se puede dejar

colocada en la unidad si lo desea. No afecta las instrucciones de limpieza).

3. Haga una mezcla de 1 parte de vinagre y 5 partes de agua y viértala dentro del

tanque de la caldera hasta llenar su capacidad. Deje la solución de vinagre durante

toda la noche.

4. Levante la caldera y vierta aproximadamente la mitad de la solución fuera del

tanque. Sacuda/agite vigorosamente lo que quede de solución en el tanque para

aflojar y remover todo el sedimento ablandado que se haya acumulado en el interior. Vierta el resto de la solución fuera del tanque. Puede llegar a ver que salen

trozos de sedimento y minerales en ese momento.

5. Enjuague el tanque con agua limpia hasta que no tenga más olor a vinagre o que

no salgan más trozos de sedimento del mismo. NOTA: Los trozos de sedimento/

minerales pueden llegar a entrar en la válvula del solenoide o en la boquilla de

vapor durante el funcionamiento, por lo que es importante que no queden en el

tanque después de limpiarlo.

6. La unidad está lista para ser utilizada.

33

Page 36

INSTRUCCIONES DEL AGUA

Use agua del grifo o 50% agua del grifo y 50% agua destilada en este artefacto.

No utilice perfume ni productos que contengan alcohol en el artefacto.

DESCRIPCIÓN DEL 5000IS

1. Tapa de seguridad

2. Llave de encendido de la plancha

3. Llave de encendido de la caldera

4. Indicador de bajo nivel de agua

5. Perilla de ajuste de temperatura

6. Botón de vapor

7. Perilla de regulación de vapor

8. Indicador de presión

9. Termostato botón de reinicio

8

6

4

5

10

7

1

9

32

3034

Page 37

DESCRIPCIÓN DEL 5000CJ

1. Tapa de seguridad

2. Indicador de presión (manómetro)

3. Botón de vapor

4. Botón de la caldera

5. Indicador de bajo nivel de agua

6. Perilla de regulación de vapor

7. Boquilla ajustable

8. Termostato botón de reinicio

9

31

35

Page 38

DESCRIPCIÓN DEL 5000CD

1. Tapa de seguridad

2. Indicador de presión (manómetro)

3. Botón de vapor

4. Botón de la caldera

5. Indicador de bajo nivel de agua

6. Perilla de regulación de vapor

7. Soporte del cable

8. Llave de vapor

9. Pistola de vapor

10. Termostato botón de reinicio

1700DA

10

36

Page 39

DIAGNÓSTICO DE PROBLEMAS

PROBLEMA

El vapor de la plancha es

demasiado húmedo.

Está saliendo agua de la caldera.

No sale vapor de la plancha, la

boquilla o la pistola.

El vapor está sucio.

La máquina se apaga

automáticamente.

POSIBLE CAUSA

1. Puede haber puesto

demasiado agua en el tanque

al llenarlo.

2. La placa base de la plancha

no se calienta lo suficiente.

1. Puede haber una pérdida

en el sello del elemento

calefactor.

1. La perilla del vapor puede

estar cerrada

2. La llave de la plancha puede

estar apagada

3. El pedal de control no está

enchufado (5000CJ)

4. La llave de la caldera puede

estar apagada

5. Si la luz de bajo nivel de agua

está encendida, el tanque

tiene poco agua o está vacío.

1. Al usar la plancha con una

base para plancha, si no la

limpia regularmente, se acumulará calcio entre la base y

la plancha.

1. La máquina es baja

en agua.

SOLUCIÓN

1. El problema persistirá hasta

que se elimine el exceso de

agua. Mantenga presionado

el botón del vapor hasta que

el agua del tanque llegue al

nivel correcto.

2. Verifique que la perilla

de temperatura esté en

la posición correcta, si

no lo está, aumente la

temperatura de la plancha.

1. Llame al soporte técnico

ya que en la mayoría de los

casos deberá reemplazar

el sello.

1. Abra la perilla de vapor en

sentido antihorario.

2. Después de que se encienda

la llave de la plancha, espere

unos 4 minutos para que

se caliente la base de la

plancha.

3. Enchufe el conector de 4

vías en la caldera.

4. Después de que se encienda

la llave de la caldera, espere

unos 10 minutos para que la

caldera

genere vapor.

5. Vuelva a llenar la caldera con

cuidado, siguiendo

las instrucciones.

1. Saque y enjuague la base de

la plancha de forma regular

(una vez por mes) para evitar

que se acumule sarro.

1. Presione el botón de vapor

de la plancha o el pedal de

control para asegurar

que no quede nada de vapor

en la caldera.

2. Abra lentamente la tapa de

presión (1) y llénela hasta el

nivel necesario

con agua tibia.

3. Reemplazar la tapa, apretar

y pulse el botón de reinicio

del termostato (9 o 10),

espere a que se acumule

presión de nuevo.

37

Page 40

RELIABLE CORPORATION – GARANTÍA DEL

PRODUCTO DE POR VIDA – PÓLIZA PARA

CALDERAS PRESURIZADAS A VAPOR

Reliable Corporation (“Reliable”) garantiza al comprador original de la caldera descrita arriba

vendida por Reliable (la “Caldera Reliable”) que se encuentra libre de defectos de material

y mano de obra si es utilizada correctamente solo por el comprador original. Si la Caldera

Reliable necesitara algún cambio, Reliable no le cobrará al comprador original el costo de las

piezas y la mano de obra, excepto el envío.

Conforme a las condiciones y limitaciones establecidas a continuación, Reliable reparará o

cambiará la pieza de la Caldera Reliable que demuestre estar defectuosa a causa de material o

fabricación inadecuadas. Si la Caldera Reliable defectuosa deja de estar disponible y no puede

ser reparada con eficacia o reemplazada por un modelo idéntico, Reliable cambiará la Caldera

Reliable defectuosa por otra Caldera Reliable vigente de igual o mayor valor. Las piezas de

recambio o repuestos serán suministrados por Reliable a cambio de las piezas originales, y

serán piezas nuevas o piezas que estarán reacondicionadas para convertirse en productos

funcionalmente equivalentes a piezas nuevas. Si Reliable no puede reparar o reemplazar una

Caldera Reliable, la compañía reembolsará el valor de la Caldera Reliable que esté vigente al

momento de reclamar la garantía.

Esta garantía limitada no cubre los daños que sufra una Caldera Reliable como resultado de

una instalación inadecuada, accidente, abuso, uso incorrecto o irrazonable, desastre natural,

suministro de energía eléctrica insuficiente o excesivo, condiciones mecánicas o ambientales

anormales, o cualquier desarme, reparación o modificación no autorizada. Esta garantía limitada

no se extiende a ningún daño indirecto, resultante o accidental que el usuario pueda sufrir por

el uso de una Caldera Reliable, incluyendo, entre otros, la responsabilidad ante los reclamos

presentados por terceros; y se limita al monto pagado por el comprador original de la Caldera

Reliable respecto del cual tiene aplicación esta protección de garantía limitada. Esta garantía

limitada no es válida para los productos que hayan sido modificados o que no tengan número de

serie, o para los productos que no hayan sido comprados directamente a Reliable o a través de

un vendedor autorizado por Reliable para comerciar la Caldera Reliable.

Esta garantía limitada es la única garantía que se aplica a la Caldera Reliable, reemplaza todos

los términos que puedan estar contenidos en cualquier otro documento u orden de compra, y no

puede ser alterada o modificada, excepto que Reliable así lo haya autorizado expresamente por

escrito.

Para obtener la reparación o cambio según los términos de esta garantía, comuníquese con

nuestro grupo de servicio al cliente al 1 800 268 1649 o escriba a support@reliablecorporation.

com. Usted deberá presentar, por fax o correo electrónico, el comprobante original. Este

comprobante debe demostrar que usted es el comprador original, que el producto fue

adquirido directamente de nuestras oficinas o de un vendedor de Reliable autorizado y que el

reclamo de la garantía se realiza dentro del período establecido en este documento o en un

documento posterior emitido por Reliable en relación con esta póliza. Usted recibirá un número

de autorización (RA#) y deberá enviar el producto defectuoso, junto con el comprobante

de compra, el RA# y los seguros pagados por adelantado, a la siguiente dirección: Reliable

Corporation, 5-100 Wingold Ave, Toronto, ON M6B 4K7.

Los costos de envío por cobrar serán rechazados. El riesgo de sufrir una pérdida o daño en

tránsito será asumido por el cliente. Una vez que Reliable reciba el producto defectuoso, la

compañía iniciará el proceso de reparación o cambio.

38

Page 41

GARANTÍA DE LOS PRODUCTOS RELIABLE

Reliable Corporation (“Reliable”) garantiza al comprador original de sus productos que todas las

unidades vendidas por Reliable (un “Producto Reliable”) se encuentran libres de defectos de material

y de mano de obra durante el período de un año a partir de la fecha de compra, si son utilizadas

correctamente y han recibido el mantenimiento adecuado. En virtud de las condiciones y limitaciones

establecidas a continuación, Reliable reparará o reemplazará la pieza de un Producto Reliable que

demuestre estar defectuosa a causa de material o fabricación inadecuadas. Si el Producto Reliable

defectuoso deja de estar disponible y no puede ser reparado efectivamente o reemplazado por un

modelo idéntico, Reliable cambiará el Producto Reliable defectuoso por un Producto Reliable vigente

de igual o mayor valor. Las piezas de recambio o repuestos serán suministrados por Reliable a cambio

de las piezas originales, y serán piezas nuevas o piezas que estarán reacondicionadas para convertirse

en productos funcionalmente equivalentes a piezas nuevas. Si Reliable no puede reparar o reemplazar

un Producto Reliable, la compañía reembolsará el valor del Producto Reliable que esté vigente al

momento de reclamar la garantía.

Esta garantía limitada no cubre los daños que sufra un Producto Reliable como resultado de una

instalación inadecuada, accidente, abuso, uso incorrecto, desastre natural, suministro de energía

eléctrica insuficiente o excesivo, condiciones mecánicas o ambientales anormales, desgaste provocado

por el uso normal del producto, o cualquier desarme, reparación o modificación no autorizada. Esta

garantía limitada no se extiende a ningún daño indirecto, resultante o accidental que el usuario pueda

sufrir o que pueda causar el uso de un Producto Reliable, incluyendo, entre otros, la responsabilidad

ante los reclamos presentados por terceros; y se limita al monto pagado por el comprador original

del Producto Reliable respecto del cual tiene aplicación esta protección de garantía limitada. Esta

garantía limitada no es válida para los productos que hayan sido modificados o que no tengan número

de serie, o para los productos que no hayan sido comprados directamente a Reliable o a través de un

vendedor certificado que cuente con nuestra autorización para comerciar los Productos Reliable.

Esta garantía limitada es la única garantía que tiene aplicación a todos los Productos Reliable,

reemplaza todos los términos que puedan estar contenidos en cualquier otro documento u orden

de compra, y no puede ser alterada o modificada excepto que Reliable así lo haya autorizado

expresamente por escrito.

Para obtener una reparación o un reemplazo bajo los términos de esta garantía, póngase en

contacto con nuestro grupo de servicio al cliente llamando al 1-800-268-1649 o escriba a support@

reliablecorporation.com. Se le pedirá que mande un recibo original por fax o por correo electrónico.

Este comprobante debe demostrar que usted es el comprador original, que el producto fue adquirido

directamente de nuestras oficinas o de un vendedor de Reliable autorizado y que el reclamo de la

garantía se realiza dentro del período correspondiente. Usted recibirá un número de autorización

(RA#) y deberá enviar el producto defectuoso, junto con el comprobante de compra, el RA# y los

seguros pagados por adelantado, a la siguiente dirección:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Los costos de envío por cobrar

serán rechazados. El riesgo de sufrir una pérdida o daño en tránsito será asumido

por el cliente. Una vez que Reliable reciba el producto defectuoso, la compañía iniciará el proceso de

reparación o reemplazo.

Si tiene preguntas sobre esta garantía, puede escribir a la siguiente dirección:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

39

Page 42

Page 43

Page 44

1 800 268 1649

www.reliablecorporation.com

Loading...

Loading...