Page 1

MSK-1341B

Industrial Sewing Machine

INSTRUCTION MANUAL

Page 2

1. Br ie f in tr od uc ti on 1. Ma in s pe ci fi ca ti on

T h i s c y l i n d e r b e d s e w i n g m a c h i n e a d o p t s s i n g l e

n e e d l e , s l i d e t y p e t h r e a d t a k e - u p l e v e r , a n d v e r t i c a l l a r g e

h o k . U p p e r a n d l o w e r s h a f t s a r e d r i v e n b y s y n c h r o n i z e d

t o o t h e d b e l t . C o m p o u n d f e e d b y f e e d d o g , n e e d l e a n d

wa lki n g fo ot; and h igh p re s se r f oo t st r ok e an d li fte r as sur e

i t s h i g h s w e i n g h e a v y a b i li ty a n d e a s y f or s e wi ng m u lt il a y e r l e a t h e r a n d u n e v e n m a t e r i a l s . S a f e t y c l u t c h d e v i c e

als o a ssur e s s afe op e ra ti on .

I t s w i d e l y u s e d f o r s e w i n g l e a t h e r p r o d u c t s , s u i t c a s e s ,

s h o e s a d c a p s . E sp e ci a l l y , i t s c y l i n d e r b e d i s s u i t a b l e f or

sew i ng vari o u s ar c a nd curv e d m at eria l s . .

Max . se wi ng spe e d

Max . st it ch len g t h

Nee d le b ar s trok e

Pre s se rf oot li f t

hei g ht

Thr e ad t ak e-up l e v er

Hoo k

Nee d le

Lub r ic at ion

Mot o r Po we r

Abb l ic at ion

MSK-1341 B

2000 s . p . m

6mm

33.3 6 m m

6.5m m b y h a n d

15mm b y k n e e

Slid e t y p e

Larg e h o o k

Dp×1 7 14 " ~ 24 " ( s ta n d ar d 2 3 ")

Oile d b y h a n d

400W ( s p e c i al f o r s e wi n g m ac h i n e 2P )

Medi u m , h e a vy , e x tr a h e av y

weig h t m a t e r ia l s

3. Op er at io n pr ep ar at io n

Bef re f irst o p erat e t he mac h ine, pl ease c l ean th e m achi n e thor o ughl y in o rder t o w eed ou t t he

dus t an d frll y l ubri c ate th e m achi ne .

Ple as e conf i rm if th e p ower w i ll be us ed i s suit a ble fo r t he des i gned v o ltag e.

The r ot atin g d irec t ion of t h e mach in e is cou n ter- c lock w i se whe n o bser ve d face t o t he han d w heel .

Bef or e turn o v er the m a chin e h ead, pl ease t a ke dow n t he kne e l ifte r c hain h oo k.

Bef or e tria l r unni n g,pl e ase ta ke d own th e b obbi n a nd nee d le.

Ple as e cont r ol the s e wing s p eed un de r 1800 s .p.m w i thin t h e firs t o pera ti on mon t h.

Onl y af ter th e m achi n e stop s ,the n th e hand w h eel ca n b e oper a ted.

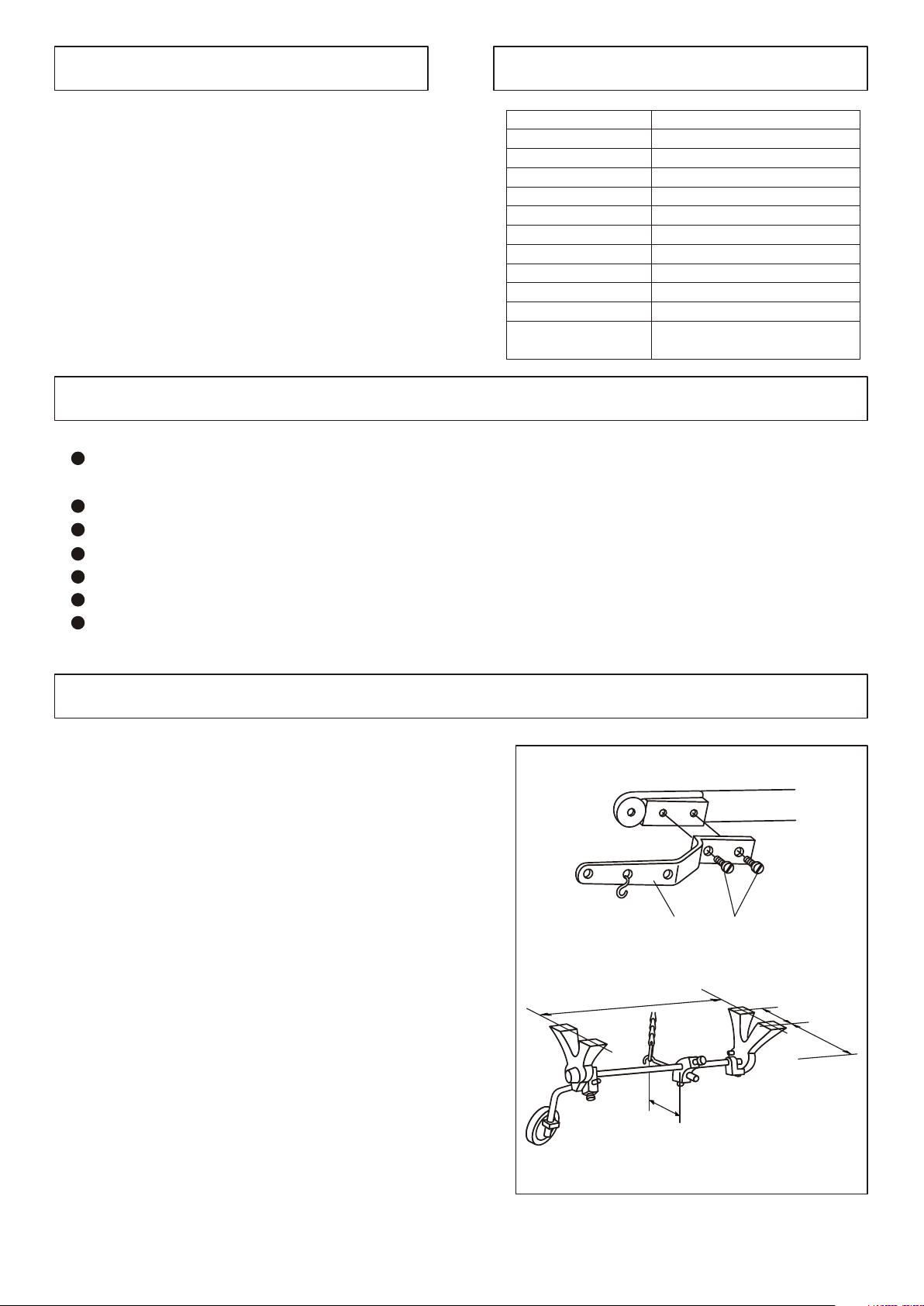

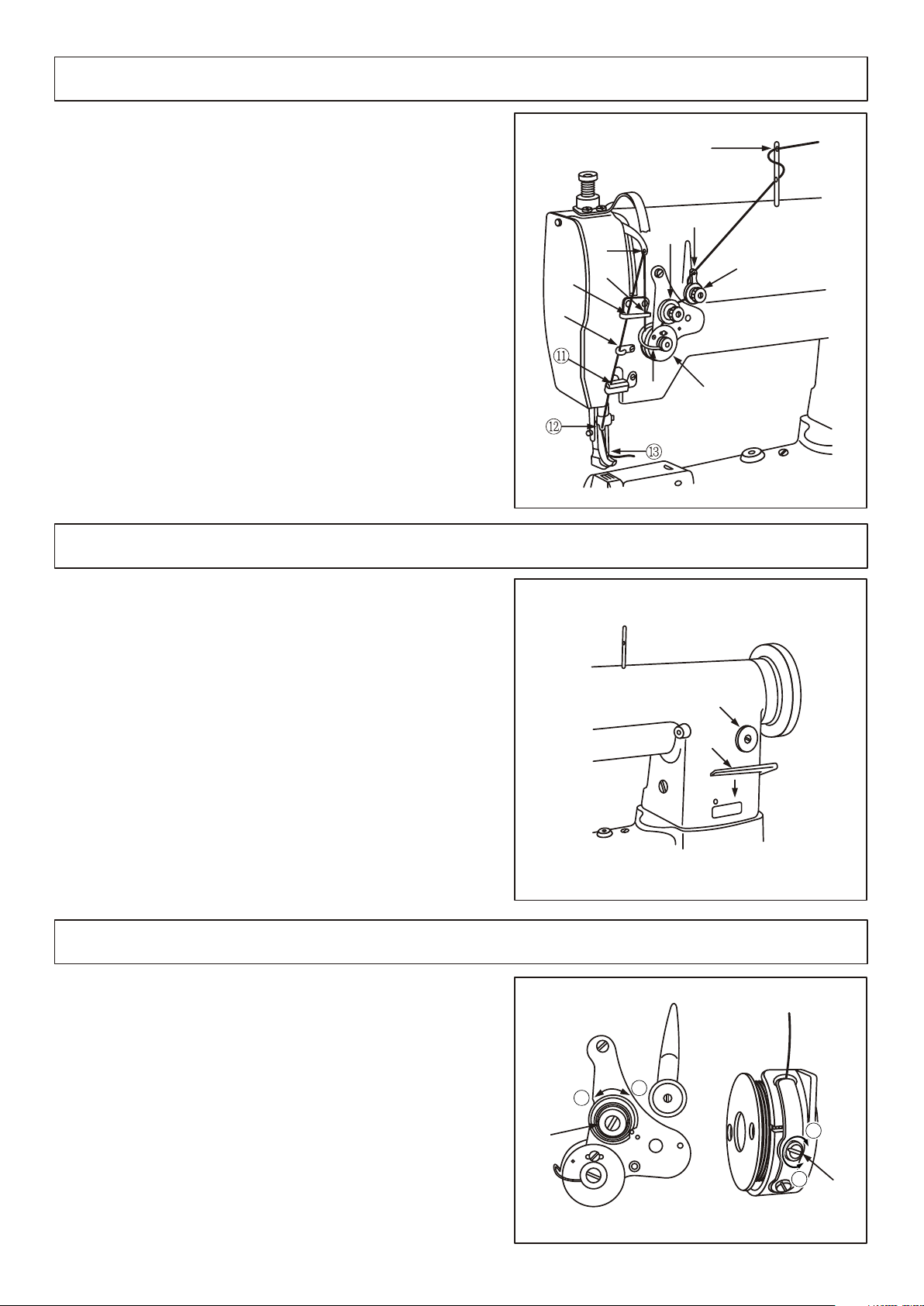

4. In st al li ng t he k ne e li ft er m ec ha ni sm (F ig .1 )

Whe n us e t he kn ee lifte r pe da l, pl ease u s e t he sc re w

to f i x t he kn ee li fter l e ve r .

Kne e li ft er le av er a n d sc re w ar e p ac ke d in th e ac -

ces s or y c ar to n.

272mm

① ②

61mm

100.5mm

To center of V-belt

33.5mm

Page 3

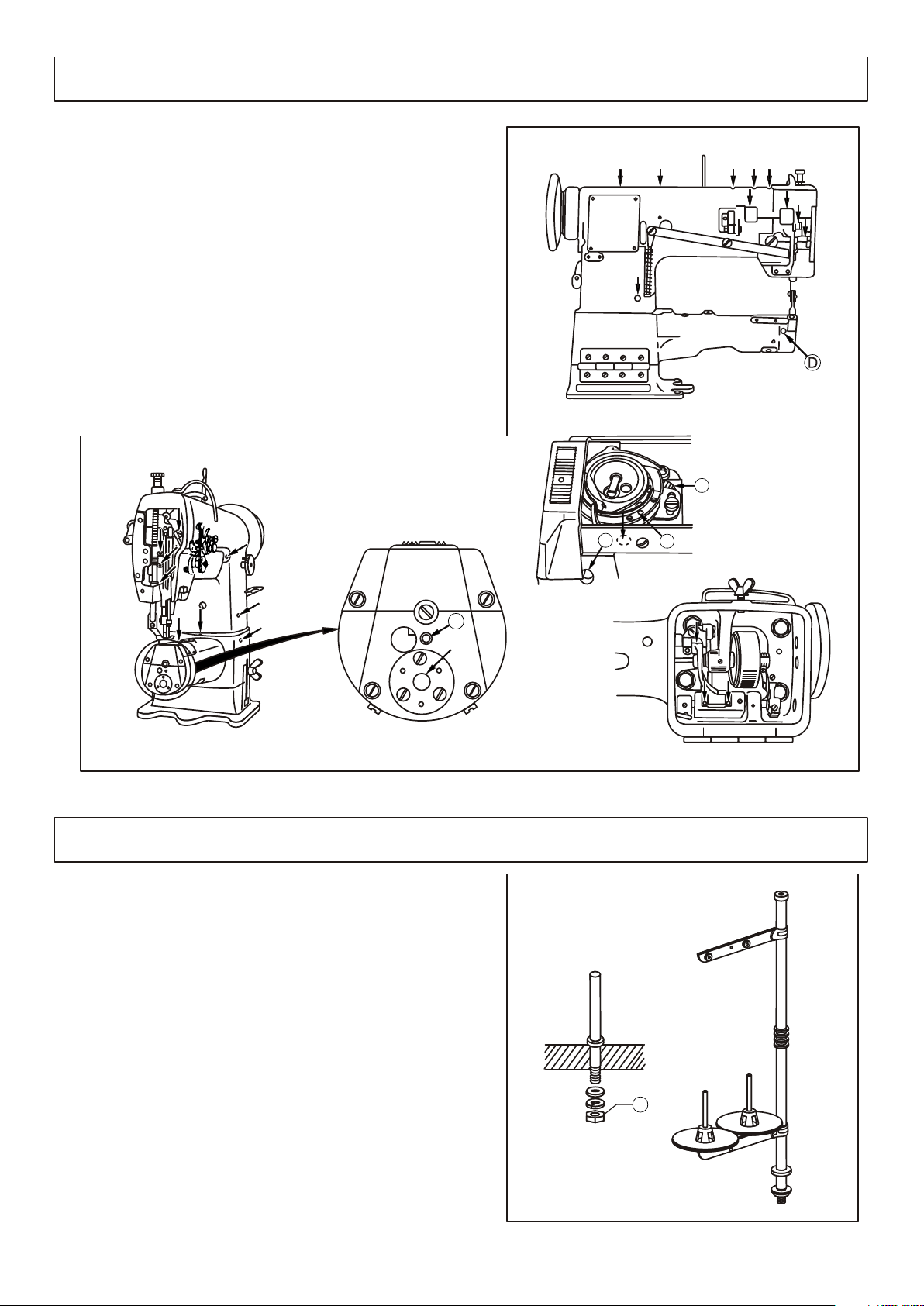

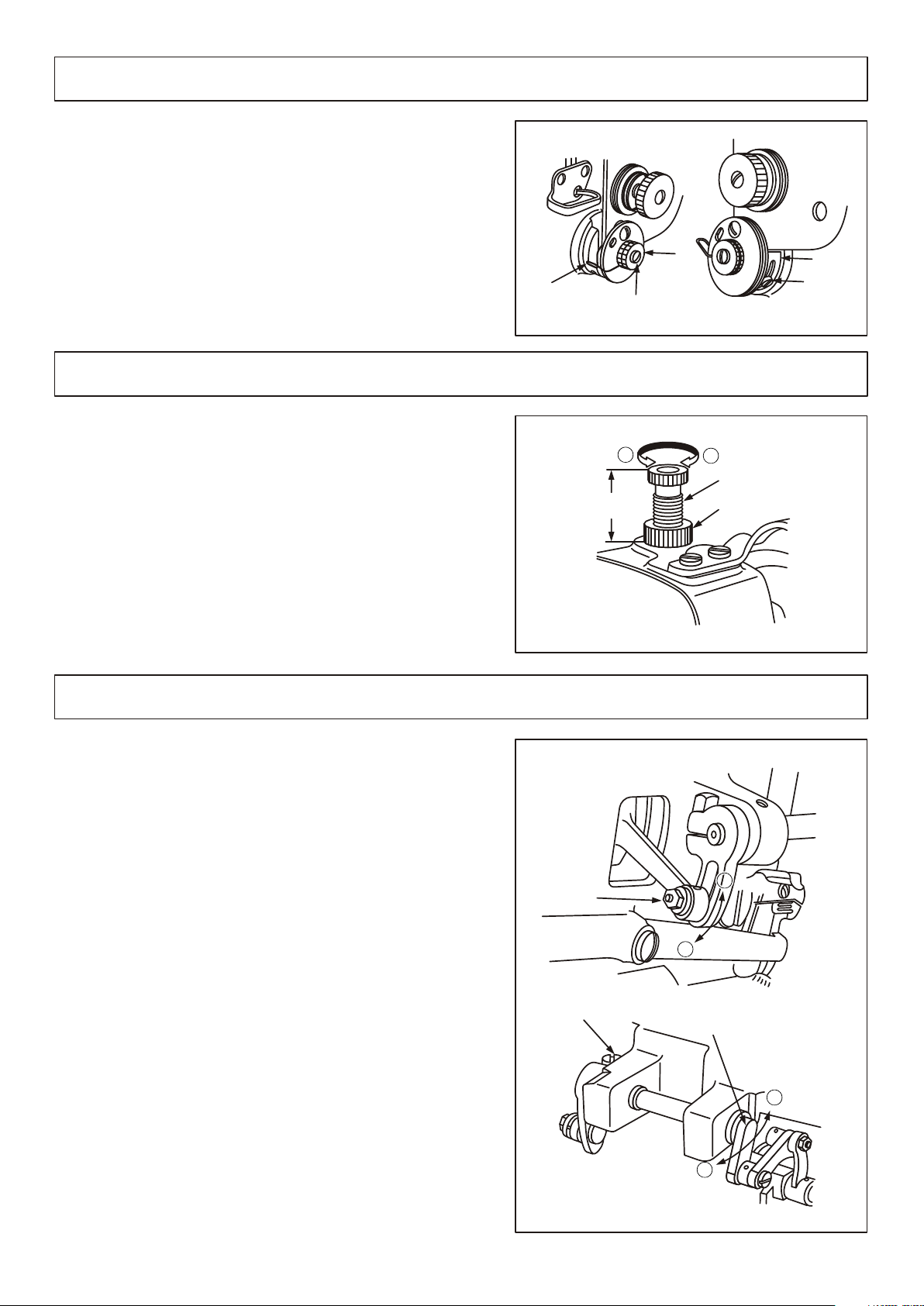

5. Lu br ic at io n( Fi g. 2)

1.B e fore r u nnin g ,ple a se f ill th e o il at th e p lace s a s

arr o w show n .

2.L u bric a ting t h e hook a n d ho ok sha f t sadd l e.

Mov e t he bed s l ide, f ill th e o il i nt the h o le A two o r

thr e e drop s e very d a y,fi l l th e oil in t o the fe l t B four

or fi v e drop s .

3.L u bric a ting t h e feed d o g su ppor t

Bef o re run n ing, p leas e f il l the oi l i nto ho l es C,D , E

two o r t hree d r ops.

B

C

6. In st al li ng t he t hr ea d st an d( Fi g. 3)

The t h re ad s ta nd s ho uld be lo c at ed o n th e ri ght bac k si de

of th e t ab le ,t he n ti ghten t h e nu t C.

E

A

C

Page 4

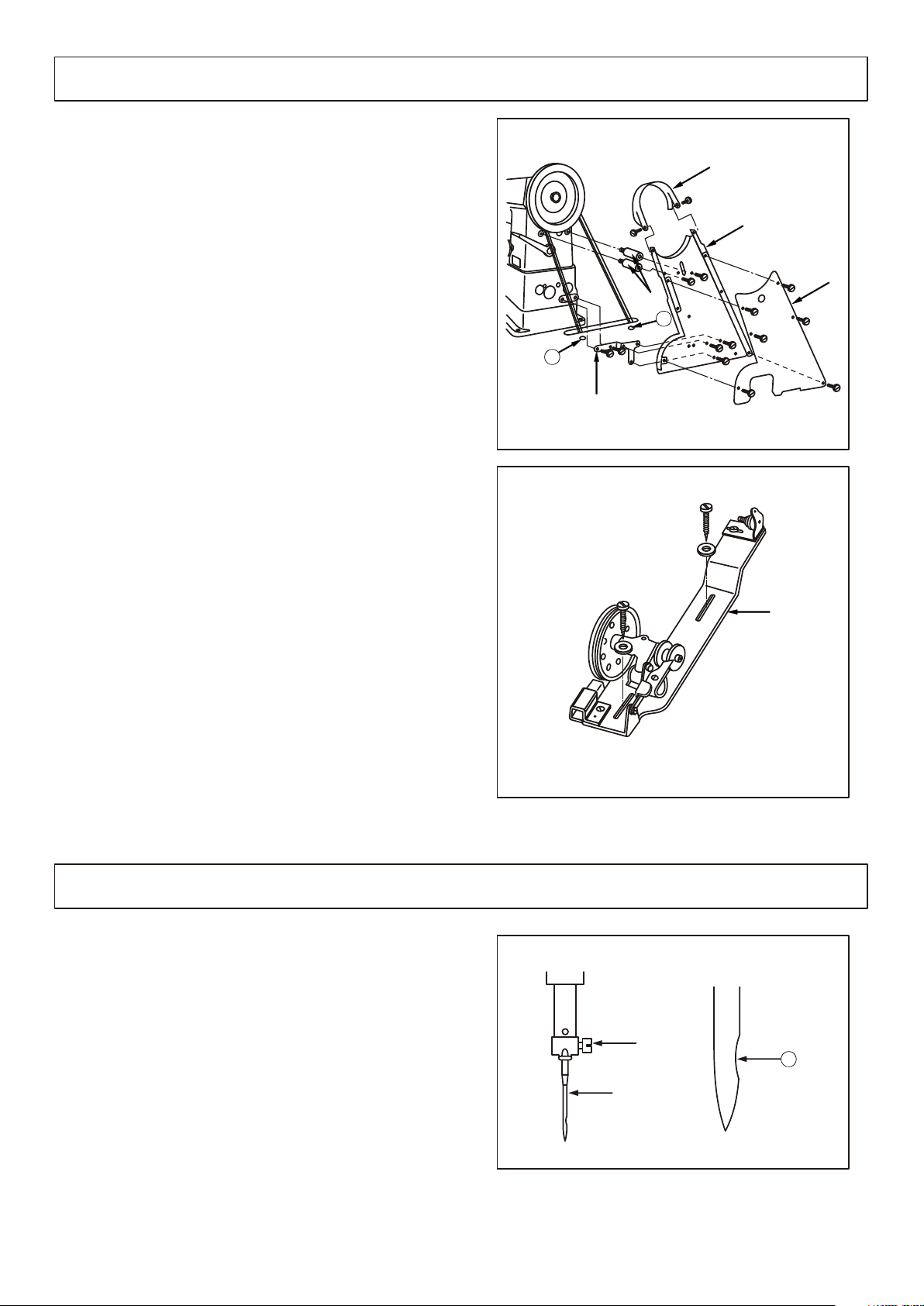

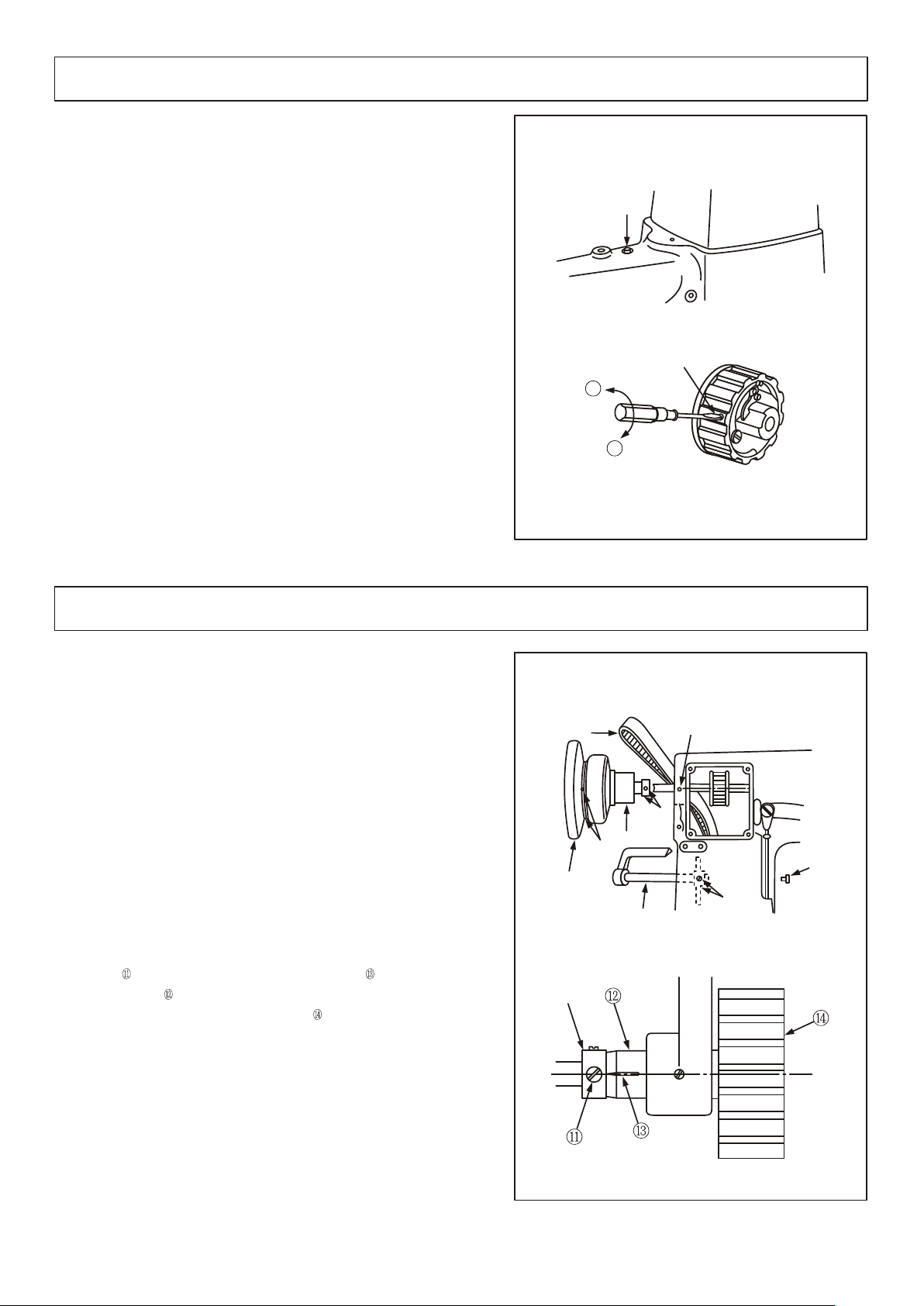

7.Installing the belt cover and bobbin winder(fig.4、5)

1.Install the belt cover support column into the screw

hole;

2.Install the belt cover support plate on the machine

casting;

3.Install the belt cover on the belt cover support

column and the belt cover support plate;

4.Install the bobbin winder into the cover and

adjust it to the proper position;

5.Fix the bobbin winder on the table;

6.Install the V-belt on the hand wheel,the n install the

belt cover and belt cover .

①

④ ⑤

③

⑥ ③

⑥

①

②

⑤

③

④

①

B

A

②

8. In st al li ng t he n ee dl e( fi g .6 )

1.T urn off the pow er;

2.T urn the han d whe el to lif t the nee dle bar to its

hig hes t pos iti on;

3.l oos en the nee dle set scr ew ,an d mak e the nee dle

①

gro ove Ato the rig ht sid e;

4.I nse rt the nee dle sha nk unt il to the bot tom of the

nee dle bar soc ket ;

5.T igh ten the scr ew .

②

②

⑥

②

A

①

Page 5

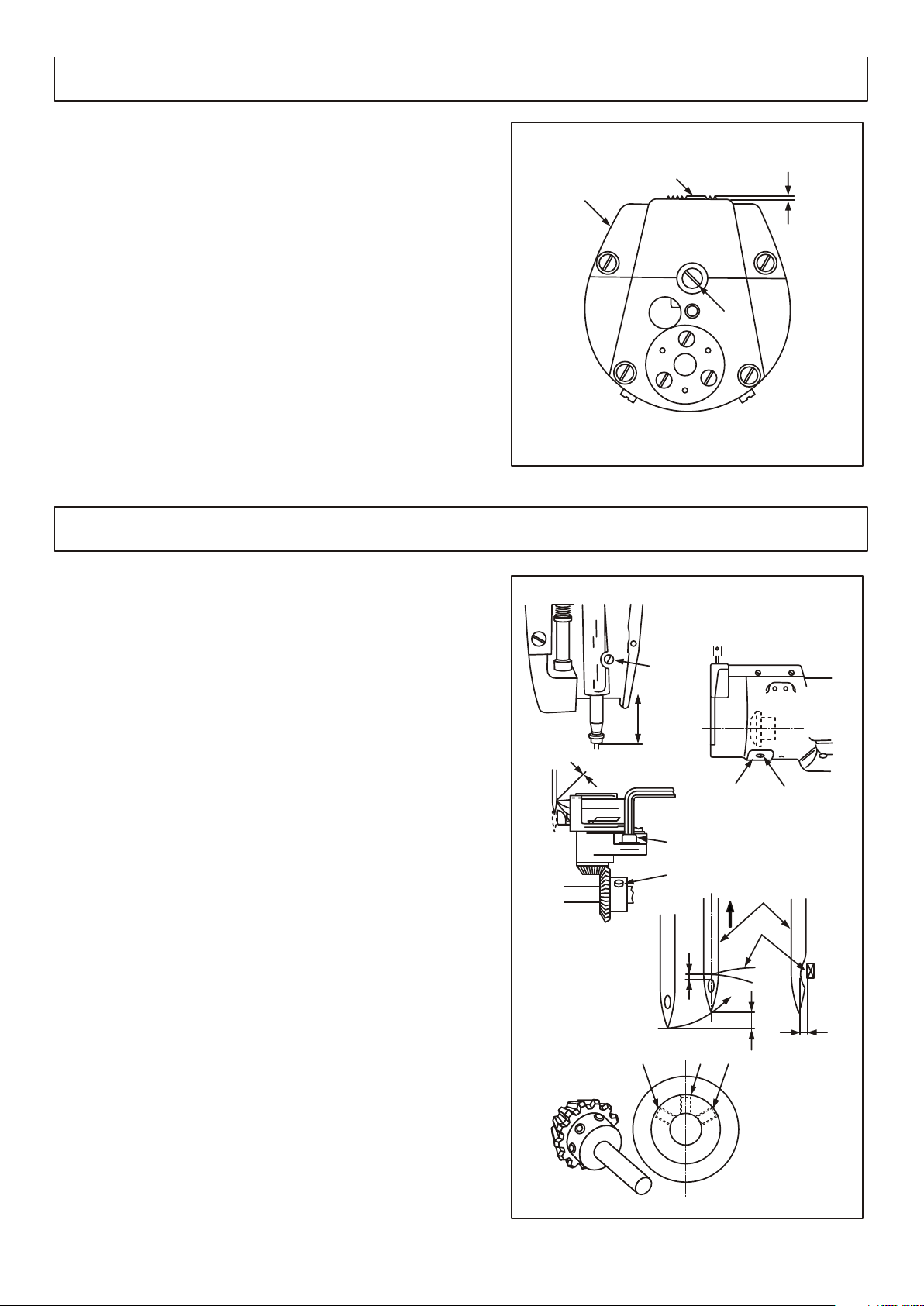

9. In st al li ng t he b ob bi n ca se (F ig .7 )

1.O p en t he h oo k co ve r,put t h e bo bb in a nd b obbin

Cas e i nt o th e ho ok ;

2.p u t th e bo bb in c as e on the ho o k dr iv in g sh aft,t h en

lay d o wn t he h oo k co ve r.

10 .W in di ng t he b ob bi n th re ad (F ig .8 )

1.T hre ad as fol low ing ord er A,B ,C, the n win d the thr ead

aro und bob bin sev era l cir cle s;

2.P res s dow n the bob bin pre ss pla te ,th e win din g

pul ley wil l be tou che d wit h the V-b elt ;

3.w ind ng amo unt can be adj ust ed by the scr ew ,th e

opt imu m cap aci ty of bob bin thr ead is fil l abo ut 80%

of bob bin out sid e dia met er. Tur n the scr ew clo ckw ise

to inc rea se the win din g amo unt ,co ntr ary ,to dec rea se

the amo unt ;

4.I f the thr ead is not nea t,p lea se mov e the bra cke t

to adj ust is;

5.W hen the win din g is ove r, the bob bin pre ss pla te

wil l be loo se and the bob bin win der wil l sto p aut oma tic all y.

①

②

③

①

A

B

③

C

②

①

11 .P ut t he b ob bi n in to b ob bi n ca se (f ig .9 )

1.D r aw th e t ip of bobbi n th re ad to the ri g ht ,t he n p ut the

bob b in in to bo bb in cas e ;

2.D r aw th e b ob bi n thre a d t hr ou gh the sl i t o n t he

bob b in ca se ,t he n pass t hr ou gh th e thre a d t en si on

spr i ng ,f in al ly ,draw t he th re ad out of t he sl it .

Rem i nd er :i f t he bobbi n is pu t c or rectl y ,t he n d ra w the

bob b in th re ad as A,the b ob bi n w il l rota t es as B.

①

②

②

A

B

①

Page 6

12 .T hr ea di ng t he n ee dl e th re ad (f ig .1 0)

P o s i t i o n t h e n e e d l e b a r o n i t s h i g h e s t , d r a w t h e t h r e a d

f r o m t h e t h r e a d s t a n d a n d t h r e a d a s s h o w n o r d e r

a c c o r d i n g t o F i g . 1 0 .

13 .A dj us ti ng t he s ti tc h le ng th (F ig .1 1)

⑩

⑨

⑦

⑧

⑥

①

②

④

③

⑤

Tur n th e s ti tc h d ial co u nt er -c lo ckwis e or cl oc kw ise to

adj u st th e s ti tc h leng t h. Th e f ig ure on t he di al is the

sti t ch le ng th .( mm)

Rev e rs e f ee d s ti tchin g

1.P r es s t he fe ed leave r do wn wa rd ;

2.W h en pr es s t he feed l e ve r d o wn wa rd , t he fee d in g i s

②

rev e rs e;

3.R e le as e t he fe ed lev e r, th e m ac hine r e co ve rs no rmal

fee d in g a ga in .

14 .T hr ea d te ns io n( Fi g. 12 )

1. Ad ju st in g th e te ns io n of ne ed le th re ad

Tu rn th e te ns io n ad ju st me nt nu t cl oc kw is e( A

di re ct io n) to in cr ea se th e te ns io n of ne ed le th re ad ;t ur n

th e nu t co un te r- cl oc kw is e( B di re ct io n) to de cr ea se th e

te ns io n.

2. Ad ju st in g th e te ns io n of bo bb in th re ad

Tu rn th e te ns io n ad ju st me nt nu t co lc kw is e( C di re cti on )t o in cr ea se th e te ns io n of bo bb in th re ad ; tu rn th e

nu t co un te r- cl oc kw is e( D di re ct io n) to de cr ea se th e

te ns io n.

①

②

①

①

6

5

0

4

3

2

②

B

A

1

C

D

②

Page 7

15 .T hr ea d ta ke -u p sp ri ng (f ig .1 3)

1. Ad ju st in g th e th re ad ta ke -u p sp ri ng st ro ke

a. Lo os en th e sc re w ,a nd mo ve th e di sc le ft wa rd

or ri gh tw ar d;

b. Mo ve th e di sc ri gh tw ar d to in cr ea se th e sp ri ng

st ro ke ,c on tr ar y, to de cr ea se th e sp ri ng st ro ke .

2. Ad ju st in g th e te ns io n of th re ad ta ke -u p sp ri ng

Ti gh te n th e nu t ,t ur n th e sp ri ng sh af t co un te rco lc kw is e to in cr ea se th e te ns io n, co tr ar y, to de cr ea se

th e te ns io n. Pl ea se us e a sc re wd ri ve r to ro ta te th e sp ro ng

sh af t to ge t th e re qu ir ed te ns io n.

⑤

② ③

④

①

①

⑤

16 .A dj us ti ng t he p re ss ur e of p re ss er f oo t( Fi g. 14 )

Adj ust the pre sse r foo t pre ssu re acc ord ing to the mat erial s.( the sta nda rd hei ght of pre ssu re adj ust men t scr ew

①

is 25m m).

1.T urn the scr ew clo ckw ise (A dir ect ion )to inc rea se

the pre ssu re, con tra ry, tur n the scr ew cou nte r-

clo ckw ise (B dir ect ion )to dec rea se the pre ssu re,

2.A fte r the pro per pre ssu re is got ,ti ght en the nut .

①

①

②

B

Standar d

25mm

④

③

②

A

①

②

17 .A dj us ti ng t he h ei gh t of p re ss er f oo t( fi g. 15 )

1.Th e optimum fixed position of presser foot is to adjust

The p res ser foo t to the “ 1/8” indication line on

The f eed cra nk.

Loosen the nut and adju st t he c am l ink ass embl ing

position.

a.At he highest position A, the max .Presser foot

Vertical stroke is got;

b.At the lowest position B, the mi n. Presser foot

vertical stroke is got.

2.Us ually, t he s rtoke of outer presser foot is same as that of

the inner presser foot.

A.Loosen the screw ;

b.When the thread take-up lever is at its highest

position,lay down the presser bar lever;

c.Ad just the feed crank to leftward( A dir ect on)

to increase the presser foot stroke.contrary,adjust

the feed crank to rightwa rd (b dir ect ion ) to

decrease the presser foot stroke.

①

③

②

①

②

③

AAA

B

③

B

A

Page 8

18 .A dj us ti ng t he h ei gh t of f ee d do g( Fi g. 16 )

The s ta nd ar d p os ition o f f ee d d og i s 1 mm highe r th an th e

sur f ac e o f t hr oa t plat e .

Ple a se ad ju st it as fol o wi ng or de r acco r di ng to se wing

req u ir em en t o r a fter c h an ge a n ew feed d o g:

1.P l ea se co nf ir m the h i gh es t p os ition o f f ee d d og ;

2.l o os en th e s cr ew ;

3.T h e h ei gh t c an be adj u st d b y t ur ning e c ce nt ri c p in(P2 2 ).

4.A f te r t he re qu red he i gh t i s g ot , tigh t en th e s cr ew .

②

③

①

③

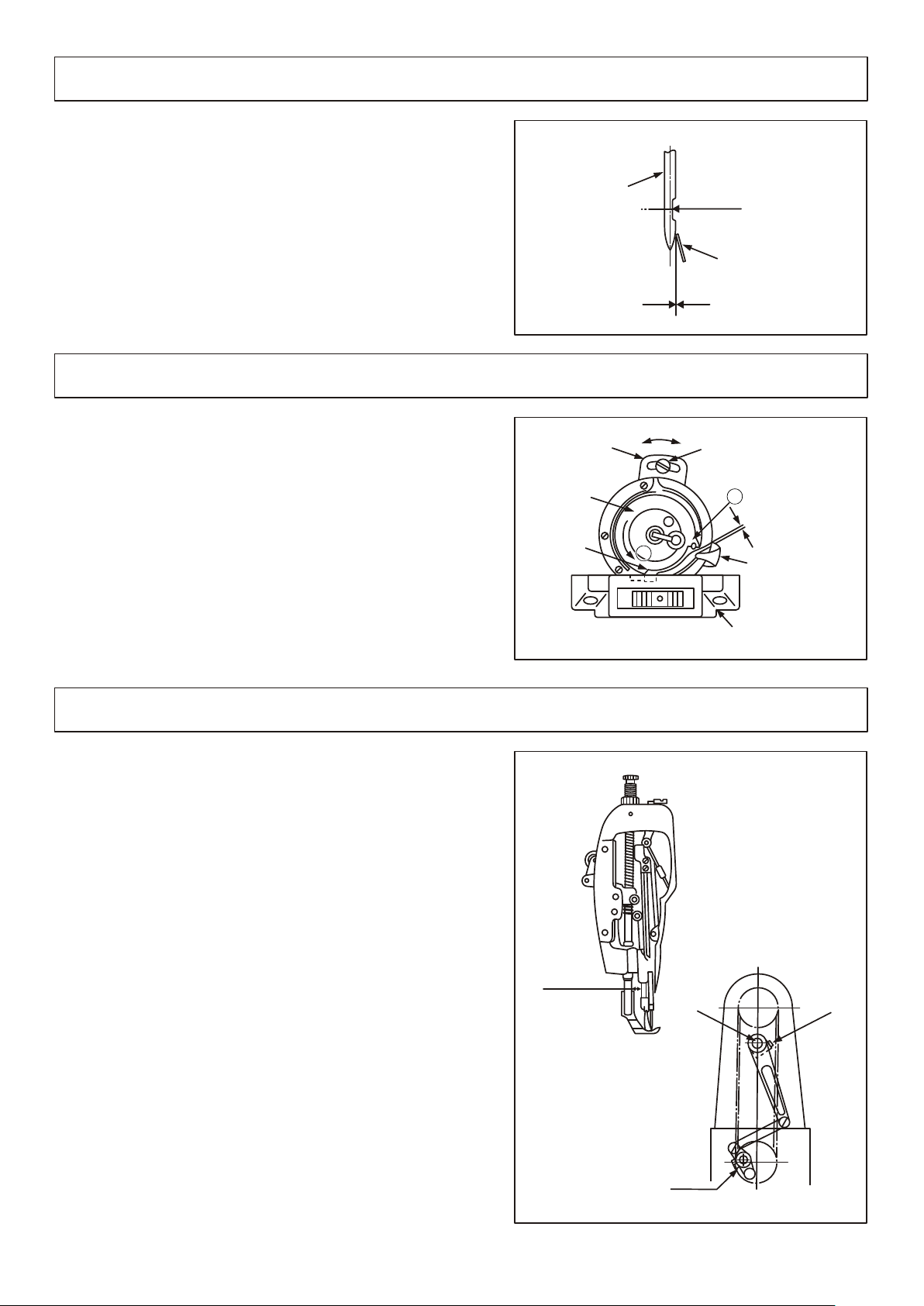

19 .A dj us ti ng t he n ee dl e an d ho ok (F ig .1 7)

②

①

1 mm

③

1.Adjust the stitch dial to figure“ 3”

2.Turn the hand wheel to lower the needle bar to its

lowest position, and loosen the scrwe ;

3.confirm the standard height of needle bar:Lif t th e

needle bar up to 2.4mm from its lowest position, there

should be1.7mm clearance hetween upside of n eed le

hole and the tip of hook blade ;the low est pos iti on

of needle bar is that there is a clearance of 55.2mm

from the bottom of needle bar rocking frame to the

bottom of needle bar.

4.Loosen the screw ,move the g ear cov er , an d

loosen the screw and screw ;

5.Loosen the screw ,move the h ook sha ft s add le l eft ward or rightward,assure the clearance between the

tip of hook blade and needle is 0~0 .5m m, a fte r

finish, tighten the screw;

6.Make the tip of hook blade align with the center of

needle bar,then tighten the screw ;

7.Turn the hand wheel clockwise, tighten the screws

alternately.

③ ②

④ ⑧

⑤

⑥

⑦

①

④

⑧

0~0.05m m

①

55.2mm

⑤

④

②

③

⑦

⑥

1.7mm

2.4mm

0~0.05m m

④ ⑧⑧

Page 9

20 .A dj us ti ng t he n ee dl e gu ar d pl at e( Fi g. 18 )

Aft e r c ha ng in g h ook , p l ea se co nf irm th e po si ti on of

nee d le gu ar d p la te. Th e st an da rd posit i on of ne ed le gua r d

pla t e i s t ha t n ee dle gu a rd pl at e i s to uc hed wi t h t he

fla n k s id e o f n ee dle sli g ht ly , i f not, b en d t he pl ate an d

adj u st th e p os it ion:

1.I f th e n ee dl e g uard p l at e b en ds inwar d , p le as e a djust

the p la te ou tw ar d with a sc re wd ri ver;

2.I f th e n ee dl e g uard p l at e b en ds outwa r d, pl ea se adjus t

the p la te in wa rd with a s cr ew dr iv er;

①

②

21 .A dj us ti ng t he i nn er h oo k gu id e( Fi g. 19 )

①

0~0.05m m

②

1.T u rn th e h an d w heel t o ma ke th e i nner h o ok gu id e

rea c h i ts fi na l p ositi o n;

2.T u rn th e b ob bi n case a s t he di re ction s ho wn by ar row

Bun t il to th e s li t of th r oa t p la te ;

3.L o os en th e s cr ew , th e move t he ad ju st ing pl a te

of i n ne r h oo k g ui de as a r ro w s ho wn direc t io n, as su re

the c le ar an ce be tween t he in ne r h ook gu i de an d t he

bob b in ca se fl an ge is a b ou t 0 .1 ~0 .15mm .

⑤ ⑥

④

①

③

②

⑥

⑤

A

0.1~0.1 5 m m

BB

B

①

④

22 .A dj us ti ng t he l en gt hw ay s po si ti on o f ne ed le b ar f ra me (F ig .2 0)

1.Adjusting the relationship between the inner presser

foot bar and pressing bar:

a.Adjust the stitch dial to min.figure;

③

①

7.5mm

②

①

b.Loosen the screw , adjust the distance between

theinner presser foot bar and pressing bar to

7.5mm.

Note:Dont make any clearance at axis direction of

needle bar frame.

2.Adjusting the relationship between the feed dog and

needle bar:

a.Adjust the stitch dial to min.figure;

b.Loosen the screw ;

c.Adjust the position of feed dog to make the needle

ali gn with the center of needle hole on the throat

plate(towards to the operator slightly).

③

Page 10

23 .S af et c lu tc h de vi ce (F .2 1)

If t h e h oo k b lo ck s the t h re ad wh en runni n g , th e s af ety

clu t ch de vi ce wi ll wor k , w hi ch ma ke the l ow er ti mi ng

pul l ey ro ta te wi thout l oa d.

1.R e st or e a s f ol lowin g or de r:

a.c l ea n t he th re ad blo c ke d i n t he hook;

b.P r es s t he bu tt on a nd turn t h e h an d w he el at r e ve rs e

dir e ct io n.

2.A d ju st in g t he force o f s af et y c lutch :

Tur n th e s cr ew c lockw i se (A di re ction ) to in cr ea se

the f or ce , c on ta ry, tu r n t he sc re w coun t er -c lo ck wise( B

dir e ct io n) to de creas e th e f or ce .

②

①

①

②

B

A

24 .R el oa di ng t he t im in g be lt (F ig .2 2)

1.U n lo ad in g t he timin g be lt :

a.L o os en th e s cr ew , , , , ;

b.T a ke th e h an d w heel an d b us hing do w n ;

c.P u ll th e f ee d l ever , o u t wa rd to m a ke th e t im ing

bel t ha v e en ough s p ac e t o p as s thro u gh ;

d.T a ke do wn th e b elt an d ta ke it ou t from t he bu sh lo le of

upp e r s ha ft .

2.R e lo ad in g t he timin g be lt ;

a.T h e l oa di ng or der of t im in g b el t is th e re ve rs e o rder

of u n lo ad in g;

b.A d ju st in g t he timin g re la ti on ship b e tw ee n u pp er

sha f t a nd lo we r s haft;

Tur n th e h an d w he el to l i ft th e t hr ead ta k e- up le ve r to

its h ig he st po si tion, t ur n t he lo wer sh a ft to ma ke the fi r st

scr e w o n t he co ll ar a li gn wit h th e m ar k o n the

rea r bu sh in g o f l ower s h af t, un de r this c on di ti on , inst a ll

the b el t o n t he lo wer ti m in g p ul le y .

⑧

① ② ③ ④ ⑤

⑥ ⑦

⑨

⑩

⑥

⑩

⑧

①

③

②

⑦

⑤

④

⑨

Page 11

25 .T ro ub le s ho ot in g

Tr oub le

1.T h re ad b re ak ag e

(th r ea d we ar a nd

tea r )

2.S k ip s ti tc h

Ca use s

① Thr e ad in g co ur se ,need l e ti p, h oo k bl ade

tip o r t hr ea d pa ss in g groov e o n th e th ro at

pla t e is r ou gh .

② Too l a rg e ne ed le t hr ead ten s io n.

③ Too b i g cl ea ra nc e of i nner ho o k gu id e.

④ col l is io n be tw ee n needl e a nd h oo k gu id e

tip .

⑤ Too s m al l ne ed le t hr ead ten s io n.

⑥ TOO l ar ge o r to o sm al l strok e t hr ea d ta ke

-up s p ri ng t en si on

⑦ Not t i mi ng b et we en n eedle a n d ho ok .

① Too b i g clea r ance b e twee n n ee dle an d

the t i p of inn e r hook b l ade.

② Not t i ming b e twee n n eedl e a nd h ook.

③ Too s m all pr e ssur e o n the ou t er p ress e r

foo t .

④ the h e ight o f n eedl e b ar is no t e no ugh.

⑤ No ef f ect of n e edle g u ard pl a te .

⑥ Wro n g need l e size .

⑦ Wro n g need l e thre a ding .

⑧ Rot a ry hoo k i s scra p ed.

So lut ion

Get r i d of t he b ur r on t he h ook bla d e ti p

and p o li sh t he t hr ea d passi n g gr oo ve o n

the t h ro at p la te w it h fine em e ry c lo th .

Adj u st t he n ee dl e th read to p r op er t en si on.

Dec r ea se t he c le ar ance, r ef er t o2 1.

Adj u st in g th e in ne r hook gu i de .

Rdf e r to 1 9. A dj us ti ng the ne e dl e an d

hoo k .

Adj u st t he n ee dl e th read to p r op er t en si on.

Dec r ea se t he t en si on of thr e ad t ak e- up

Spr i ng a nd i nc re as e the spr i ng s tr ok e.

Ref e r to 1 9. A dj us ti ng the ne e dl e an d ho ol .

Ref e r to 1 9. Ad ju st ing the n e ed le a nd h oo k.

Ref e r to 1 9. Ad ju st ing the n e ed le a nd h oo k.

Tig h te n th e pr es su re scre w .

Ref e r to 1 9. Ad ju st ing the n e ed le a nd h oo k.

Ref e r to 2 0. Ad ju st ing the n e ed le g ua rd

pla t e.

Cha n ge a p ro pe r ne ed le.

Ref e r to 1 2. Th re ad ing the n e ed le t hr ea d.

Get r i d of t he b ur r on t he h ook gui d e ti p

wit h f in e em er y cl ot h.

3.L o os e st it ch

① Th e thr e ad pa ssi ng pa rts a re no t smoo th.

② th e bob b in ca nno t rot ate s moo thly .

③ To o big c l ear anc e of in ner h ook g uide .

④ To o wea k t ens ion o f bob bin t hre ad.

⑤ to o tig h ten w hen w ind ing b obb in thr ead .

⑥ bo bbi n g thr ead d oes n't p ass t he thr ead

te nsi o n spr ing o n the b obb in ca se

Po lis h t hem w ith f ine e mer y c lot h.

Re set t h e bob bin a nd ro tar y h ook .

Re fer t o 2 1. Ad jus tin g the i n ner h ook

gu ide .

Ad jus t t he bo bbi n thr ead t e nsi on pr ope rly .

De cre a se th e ten sio n whe n w ind ing .

Th rea d ing t he bo bbi n thr e ad co rre ctl y.

Page 12

1.C ast ing c omp one nts

31

36

32

34

30

29

46

12

48

20

18

16

15

17

19

42

41

13

9

14

11

1

2

8

7

6

33

35

33

27

40

39

10

22

47

21

23

24

25

3

4

37

45

28

26

44

5

25

43

38

Page 13

1.C ast ing c omp one nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Pa rts N o .

50 W F2-0 04

16 W F1-0 59

50 W F2-0 05

13 W F2-0 08

50 W F2-0 08

50 W F2-0 09

1W F -038

50 W F2-0 10

16 W F2-0 12

7W F 5-01 7

50 W F2-0 13

50 W F2-0 12

50 W F2-0 11

50 W F2-0 19

50 W F2-0 20

7W F 4-00 4

50 W F2-0 14

16 W F2-0 15

50 W F2-0 21

19 W F4-0 02

50 W F2-0 22

1W F 1-02 6

16 W F2-0 15

50 W F2-0 15

50 W F2-0 16

50 W F2-0 23

10 6 WF2- 001

50 W F2-0 24

50 W F2-0 27

10 6 WF2- 002

50 W F2-0 28

50 W F2-0 29

50 W F2-0 31

50 W F2-0 32

50 W F2-0 30

50 W F2-0 25

50 W F2-0 26

50 W F2-0 03

50 W F3-0 90

50 W F3-0 91

50 W F1-0 55

50 W F2-0 06

50 W F2-0 07

1W F 1-01 6

22 W F5-0 27

Na me of p a rts

Fa c e plat e

Sc r ew

Ge a r cove r

Sc r ew

Sc r ew

Ru b ber pl ug

Th r ead ta ke-u p le ver c o ver

Sc r ew

Co n nect ing ho ok

Th r ead gu ide( mi ddl e )

Sc r ew

Si d e plat e

Wi n g bolt

Sc r ew

Oi l p an

Fe l t

Oi l a ick

Sc r ew

Th r ead gu ide( up per )

Sc r ew

Ta k e-up o il spl as her

Sc r ew

Ta k e-up s prin g ad jus t ing p l ate

Sc r ew

Sc r ew

Th r oat gu ide( lo wer )

Fe l t

Th r oat pa te bas e

Th r oat pl ate ba se

Sc r ew

Th r oat pl ate

Sc r ew

Le f t side p late

Sc r ew

Be d s lide

Ri g ht sid e plat e

Lo w er sha ft fro nt c ove r

Sc r ew

Ma c hine b ase

Ru b ber pl ug

Oi l t ube

Oi l t ube

Oi l t ube

hi n ge

Th r oat pl ate ba se

Sc r ew

Cy l inde r bed co ve r(l o wer )

Le f t scre w

Ri g ht scr ew

Qt y.

1

2

1

2

8

1

1

2

1

1

4

1

1

1

1

1

1

2

1

2

1

1

1

1

2

1

1

1

1

2

1

1

2

1

4

1

1

1

3

1

2

1

1

1

1

1

4

1

1

1

Re mar k s

SM9 / 64” ×40

SM9 / 64 ”×4 0

GB7 0 -8 5 M 8 × 2 0

SM1 5 /6 4” ×28

SM1 1 /6 4” ×40

SM1 1 /6 4” ×40

SM9 / 64 ”×4 0

SM9 / 64 ”×4 0

SM9 / 64 ”×4 0

SM9 / 64 ”×4 0

For 3 41

For 3 41 N

SM1 1 /6 4” ×40

SM1 1 /6 4” ×40

SM9 / 64 ”×4 0

SM1 1 /6 4” ×40

#1

#1S M 11 /6 4” ×40

SM9 / 64 ”×4 0

SM9 / 64 ”×4 0

Page 14

2.U ppe r sha ft an d thr ead t ake - up l e av e r com pon ent s

7

6

14

2

3

15

17

16

24

19

18

23

35

50

34

32

9

20

21

11

26

36

12

22

45

46

28

38

41

27

37

10

42

43

13

63

59

62

29

30

28

27

31

5

25

1

40

39

50

30

40

44

52

60

61

53

57

54

48

47

8

58

56

38

51

55

49

4

33

Page 15

2.U ppe r sha ft an d thr ead t ake - up l e ve r c omp one nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

Pa rts N o .

16 W F-0 1 0

50 W F1- 0 22

50 W F1- 0 04

50 W F1- 0 05

50 W F3- 0 43

18 2 27

50 W F1- 0 06

50 W F1- 0 62

50 W F1- 0 57

50 W F1- 0 15

50 W F1- 0 14

50 W F1- 0 08

50 W F1- 0 11

50 W F1- 0 09

50 W F1- 0 13

50 W F1- 0 12

50 W F1- 0 10

50 W F1- 0 16

50 W F1- 0 19

50 W F1- 0 17

50 W F1- 0 18

18 2 27

50 W F3- 0 34

50 W F1- 0 62

50 W F1- 0 24

50 W F1- 0 25

50 W F1- 0 13

50 W F1- 0 19

50 W F1- 0 35

50 W F1- 0 21

50 W F1- 0 22

50 W F1- 0 20

50 W F1- 0 23

50 W F1- 0 28

50 W F1- 0 19

50 W F1- 0 29

50 W F1- 0 27

50 W F1- 0 32

16 W F1- 0 43

21 W F6- 0 07

50 W F1- 0 30

50 W F1- 0 51

50 W F1- 0 53

50 W F1- 0 52

50 W F1- 0 34

16 W F3- 0 46

22 W F1- 0 13

22 W F1- 0 18

22 W F1- 0 16

22 W F1- 0 14

22 W F1- 0 17

Na me of p a rts

Pl u g

ta k e-u p l ever p in

Oi l w ick

Sc r ew

Oi l w ick

Sc r ew

Th r ead t a ke-u p leav er

Fe e d cam

Sc r ew

Oi l w ick

Ta k e-u p l ever s lidi ng blo ck

Oi l w ick

Hi n ge sc r ew

Ne e dle b a r cran k rod

Up p er sh a ft

Oi l w ick

Pl u g

Oi l w ick

Cr a nk pi n

Ne e dle b a r cran k

Sc r ew

Sc r ew

Sc r ew

Sc r ew

Up p er sh a ft bus h(fr ont)

Sc r ew

Oi l f elt

Oi l f elt

Up p er sh a ft bus h(mi ddle )

Sc r ew

Oi l f elt

Up p er sh a ft bus h(up per)

Se t s cre w

Sc r ew

Sc r ew

Sc r ew

Up p er sh a ft bea ring b ush

Sc r ew

Up p er sh a ft bus h(re ar)

Be a rin g

Re a tai n ing co llar

Ha n d whe e l

Sc r ew

Sc r ew

Ti m ing b e lt

Sp r ing p i n

Ti m ing p u lley (low er)

Sp r ing r i ng

Sc r ew

Sc r ew

Sa f ety c l utch p ush bu tton

Pu s h but t on cyl inde r

Sa f ety c l utch d isc

Sa f ety b a se

Sp r ing

Sa f ety c l utch s prin g

Sa f ety c l utch h ook

Sa f ety c l utch c ount er-h ook

Co u nte r -hoo k spri ng

Sa f ety c l utch l ink

Sa f ety c l utch l ink pi n

Qt y.

2

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

Re mar k s

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM1 / 4”×4 0

SM9 / 32” ×28

SM9 / 32” ×28

SM9 / 32” ×28

SM9 / 32” ×28

SM1 5 /6 4”×2 8

SM1 / 4”×4 0

GB8 9 4. 2- 86 2 6

15× 3 5 1 1 ( 20 2)×

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

GB8 7 9- 86 2×1 0

SM9 / 64” ×40

SM5 / 16” ×24

Page 16

3.N eed le ba r and h ook d riv ing s h af t c om p one nts

1

22

23

25

4

5

3

24

2

10.11.12

7

6

29

30

31

32

33

15

14

13

9

8

17

19

20

18

36

16

34

21

35

59

63

28

26

27

43.44.45.46.47

51

37

38

39

50

48

52

57

57

41

42

40

54

53

62

37

38

61

60

58

49

55

56

Page 17

3.N eed le ba r and h ook d riv ing s h af t c om p one nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

Pa rts N o .

50 W F3- 0 01

50 W F3- 0 02

50 W F3- 0 03

50 W F3- 0 04

50 W F3- 0 05

50 W F3- 0 06

50 W F3- 0 07

50 W F3- 0 08

50 W F3- 0 10

50 W F3- 0 09

50 W F3- 0 11

50 W F3- 0 12

50 W F3- 0 13

50 W F3- 0 14

34 T 5-5 4 0

36 T 5-0 0 8E5

50 W F1- 0 01

50 W F1- 0 03

22 - WF3 - 014

22 T 2-0 1 7

50 W F1- 0 02

33 T 1-0 2 7

50 W F1- 0 47

50 W F1- 0 48

50 W F1- 0 46

16 W F2- 0 17

50 W F1- 0 49

50 W F1- 0 50

10 6 WF1 - 001

50 W F5- 0 45

50 W F1- 0 44

50 W F1- 0 43

50 W F1- 0 31

50 W F3- 0 16

50 W F3- 0 17

50 W F1- 0 40

50 W F1- 0 36

50 W F1- 0 37

50 W F1- 0 38

50 W F1- 0 22

50 W F1- 0 41

50 W F1- 0 39

50 W F1- 0 42

17 0 27

Na me of p a rts

Ne e dle ba r rock ing fr a me as s emb l y

Ne e dle ba r rock ing fr a me sh a ft

Ne e dle ba r slid e bloc k Pin

Ne e dle ba r rock ing fr a me

Fe l t

Re t aine r

Ro c king s haft b ush( f ron t )

Ro c king s haft b ush( r ear )

Wa s her

Wa s her

Wa s her

Wa s her

Sc r ew

Ro c king s haft c rank

co n nect ing ro d

Hi n ger sc rew

Nu t

Fe e d shaf t cran k

Sc r ew

Sc r ew

Ne e dle ba r

Ne e dle ba r conn ecti o n

Fe l t

Sc r ew

Ne e dle

Sc r ew

Ne e dle ba r thre ad gui d e

Bo b bin

Ro t ary ho ok

In n er hoo k guid e

Sl i de blo ck

Sl i de blo ck pin

]S c rew

Sc r ew

Ad j usti ng pla te

Sc r ew

Wa s her

Ho o k shaf t sadd le ass e mbl y

Ho o k shaf t sadd le

Ho o k shaf t sadd le

Ho o k shaf t bush (upp e r)

Ho o k shaf t bush (low e r)

Wa s her

Wa s her

Wa s her

Wa s her

Wa s her

Ho o k shaf t gear

Lo w er sha ft

Fe e d cam

Sc r ew

Lo w er sha ft bev el gea r

Lo w er sha ft bus h(fr o nt)

Oi l f elt

Lo w er sha ft bus h(re a r)

Sc r ew

Sc r ew

Fe l t

Fe l t

Lo w er sha ft col lar

Sc r ew

Oi l w ick

Fe l t

Qt y.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

3

1

1

1

2

1

1

Re mar k s

GB1 1 7- 86 A 5×28

T=1 . 5

T=1 . 35 # 1

T=1 . 65 # 1

T=1 . 65

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM1 1 /6 4”×4 0

SM9 / 64” ×40

DP×17

SM1 / 8”×4 0

SKR T 34 1- NR

SM9 / 64” ×40

GB7 0 -8 5 M5×1 2

GB9 5 -8 5 5

For 3 41

For 3 41 N

T=1 . 88 # 1

T=1 . 92 # 1

T=1 . 96 # 1

T=2 . 00 # 1

T=2 . 04 # 1

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM1 / 4”×4 0

SM1 1 /6 4”×4 0

Page 18

4.P res ser f oot c omp one nts

9

8

24

1

10

12

13

14

15

22

23

18

16

21

20

7

3

2

11

6

17

19

4

5

Page 19

4.P res ser f oot c omp one nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Pa rts N o .

22 W F3-0 05

50 W F4-0 01

50 W F1-0 22

22 W F3-0 14

50 W F4-0 02

50 W F4-0 11

50 W F4-0 17

50 W F4-0 15

1K T 4-00 1

1K T 4-00 2

50 W F4-0 06

50 W F4-0 07

50 W F4-0 08

50 W F4-0 14

Na me of p a rts

Pr e sser b ar

Pr e sser b ar l owe r b ush

Sc r ew

Sc r ew

Ou t er pre ss er fo o t asse mbly

co n nect in g pin r o ller

Pr e sser b ar b rac k et gui de

Gu i de pla te b ase

Pr e ssur e ad jus t ment s crew

Nu t

Pr e sser s pr ing

Ha n d lift er

Ha n d lift er p in

Hi n ge scr ew

Qt y.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Re mar k s

SM1 5 /6 4” ×28

SM9 / 64 ”×2 8

15

16

17

18

19

20

21

22

23

16 0 34

50 W F4-0 09

50 W F4-0 10

50 W F4-0 13

50 W F4-0 12

50 W F4-0 18

50 W F4-0 19

22 W F2-0 17

50 W F4-0 16

Sc r ew

Pr e sser l if tin g l ever b ase

Sc r ew

Sp r ing

Th r ead re le ase g u ide as semb l y

Pr e sser b ar l ift i ng lev er

Hi n ge scr ew

Sc r ew

Sc r ew

1

1

1

1

1

1

1

3

1

SM1 1 /6 4” ×40

SM3 / 16 ”×3 2

SM1 5 /6 4” ×28

Page 20

5.U ppe r fee d mec han ism c omp o ne n ts

28

21

3

4

16

14

19

6

5

7

8

24

15

13

20

17

18

22

12

11

23

10

9

1

27

28

26

25

2

Page 21

5.U ppe r fee d mec han ism c omp o ne n ts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Pa rts N o .

55 W F3-0 18

50 W F3-0 19

50 W F3-0 21

50 W F3-0 22

50 W F3-0 23

50 W F3-0 25

50 W F3-0 26

50 W F3-0 27

50 W F3-0 31

50 W F3-0 32

50 W F3-0 36

22 W F4-0 40

50 W F3-0 35

50 W F3-0 38

50 W F3-0 37

50 W F3-0 40

50 W F3-0 41

50 W F3-0 42

50 W F3-0 24

50 W F3-0 20

50 W F3-0 39

50 W F3-0 33

16 W F1-0 59

50 W F3-0 29

50 W F3-0 30

17 0 78

1W F 1-01 1

Na me of p a rts

In n er pre sser f oot ba r

In n er pre sser f oot

Bu s hing

Up p er fee d shaf t

Sc r ew stu d

Up p er fee d conn ecti ng lin k

Up p er fee d sewi ng pla te

In n er pre sser f oot dr ivin g li nk

In n er pre sser f oot ro d

In n er pre sser f oot sp ring

Fe l t

Fe l t reta iner

Up p er fee d driv ing ro d

Up p er fee d cran k

co n nect ing st ud

Hi n g scre w

Wa s her

Nu t

Nu t

Sc r ew

Sc r ew

In n er pre sser f oot re atai ni ng pl a te

Sc r ew

Oi l w ick

Sl i de blo ck

Sl i der bl ock ho lder

Sc r ew

Sc r ew

Qt y.

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

Re mar k s

SM1 1 /6 4” ×40

SM1 / 4” ×40

SM1 1 /6 4” ×40

SM1 / 4” ×24

SM9 / 64 ”×4 0

SM1 1 /6 4” ×40

SM1 1 /6 4” ×40

Page 22

6.L owe r fee d mec han ism o mpo n en t s

53

54

4

58

1

59

10

7

8

9

6

11

5

14

52

2

23

24

22

15

16

21

51

56

3

40

44

25

41

20

60

42

19

18

13

17

63

28

25

50

61

10

62

11

29

12

60

57

30

38

37

36

34

39

33

37

31

35

36

32

44

43

45

25

46

27

47

26

64

65

48

55

49

Page 23

6.L owe r fee d mec han ism c omp one nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

Pa rts N o .

55 W F3-0 44

55 W F3-0 45

50 W F3-0 17

50 W F3-0 46

J0 . 0.40

50 W F3-0 47

50 W F3-0 49

50 W F3-0 17

50 W F3-0 15

50 W F3-0 51

50 W F3-0 50

50 W F3-0 53

50 W F3-0 52

50 W F3-0 59

50 W F3-0 56

50 W F3-0 55

50 W F3-0 57

17 W F4-0 35

50 W F3-0 58

50 W F3-0 62

50 W F3-0 66

16 0 56

50 W F3-0 17

50 W F3-0 68

50 W F3-0 69

50 W F3-0 74

10 6 WF3- 001

50 W F3-0 92

50 W F3-0 70

50 W F3-0 71

50 W F3-0 72

50 W F3-0 84

10 6 WF3- 003

50 W F3-0 85

50 W F3-0 86

10 6 WF3- 002

22 W F4-0 14

50 W F3-0 80

50 W F3-0 83

50 W F3-0 81

50 W F3-0 82

50 W F3-0 89

50 W F3-0 87

50 W F1-0 22

50 W F3-0 88

50 W F3-0 75

50 W F3-0 24

50 W F3-0 78

50 W F3-0 79

18 2 27

50 W F3-0 76

50 W F1-0 19

50 W F3-0 48

50 W F3-0 67

50 W F3-0 60

50 W F4-0 40

50 W F3-0 36

50 W F3-0 77

50 W F3-0 61

50 W F3-0 64

50 W F1-0 22

1W F 2-02 9

50 W F3-0 63

1W F 2-01 0

50 W F3-0 65

50 W F3-0 73

22 W F3-0 14

Na me of p a rts

Fe e d conn ecti on r od

Hi n ge pin

Sc r ew

Re v erse f eed dr iv ing r o cker

Sc r ew

Re v erse f eed dr iv ing r o cker s haft

Bu s hing

Sc r ew

Pi n

Sc r ew

Sl i de blo ck

Li n k

Sl i de blo ck sha ft

Fe e d regu lato r ba se

Sc r ew

St i tch di al

Sc r ew

Pi n

Sp r ing

Re v erse f eed le ve r sha f t

Re v erse f eed le ve r sha f t cran k

Sc r ew

Sc r ew

Re v erse f eed cr an k lin k

Hi n ge scr ew

Cr a nk

Cr a nk

Ec c entr ic pin

Te n sion s prin g

Sc r ew

Su s pens ion ho ok

Fe e d bar cr ank

Fe e d bar cr ank

Oi l f elt

Fe e d dog

Fe e d dog

Sc r ew

Fe e d dog su ppor t

Sc r ew

Fe n ce

Sc r ew

Sc r ew

Fe e d dog su ppor t cr ank

Sc r ew

Pi n

Fe e d shaf t bush in g(f r ont)

Nu t

Fe e dsha ft

Fe e d shaf t coll ar

Sc r ew

Fe e d shaf t bush in g(r e ar)

Sc r ew

Sc r ew

Co n nect ion ro d

Fe e d regu lato r bu shi n g

Fe l t reta iner

Oi l f elt

Oi l f elt

Hi n ge pin

Re v erse f eed le ve r

Sc r ew

Sc r ew

Sc r ew

Sc r ew

Sc r ew

Oi l w ick

Wa s her

Sc r ew

Qt y.

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

4

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

Re mar k s

SM1 1 /6 4”×2 8

SM1 5 /6 4”×2 8

SM9 / 64” ×40

SM3 / 16” ×28

SM3 / 64” ×28

SM1 5 /6 4”×2 8

For 3 41

For 3 41 N

For 3 41

For 3 41 N

For 3 41

For 3 41 N

SM1 / 8”×4 4

SM1 1 /6 4”×4 0

SM1 5 /6 4”×2 8

SM1 / 4”×4 0

SM1 / 4”×4 0

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM1 5 /6 4”×2 8

SM3 / 16” ×32

SM1 / 4”×4 0

SM1 / 4”×4 0

SM9 / 64” ×40

Page 24

7.T hre ad th nsi on co mpo nen t s

2

30

31

1

3

4

5

6

7

11

9

12

10

8

13

21

14

25

15

22

16

23

17

24

18

19

20

26

27

Page 25

7.T hre ad th nsi on co mpo nen t s

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Pa rts N o .

55 W F2-0 35

1W F 5-02 2

50 W F2-0 35A2

50 W F2-0 35A1

50 W F2-0 35A4

50 W F2-0 35A3

50 W F2-0 35A5

16 W F2-0 47

16 W F2-0 46A1 4

16 W F2-0 46A1 5

16 W F2-0 46A1 2

16 W F2-0 20

50 W F2-0 33

Na me of p a rts

Th r ead te nsio n cont roll e r ass e mbl y

Sc r ew

Th r ead gu ide

Fi r st ten sion p ost

th r ead te nsio n disc

Sp r ing

Th r ead te nsio n nut

Th r ead te nsio n cont roll e r ass e mbl y

Th r ead te nsio n rele ase ba r

Th r ead te nsio n rele ase le v er

Hi n ge scr ew

Th r ead te nsio n stud

Sc r ew

Th r ead te nsio n cont roll e r bas e

Qt y.

1

1

1

1

2

1

1

1

1

1

2

1

1

1

Re mar k s

SM1 1 /6 4” ×40

SM1 1 /6 4” ×32

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

16 W F2-0 46A1 3

16 W F2-0 46A6

16 W F2-0 46A5

16 W F2-0 46A4

15 3 029

16 W F2-0 46A3

16 W F2-0 15

16 W F2-0 46A1 0

16 W F2-0 46A7

16 W F2-0 46A8

16 W F2-0 33

16 W F2-0 46A9

16 W F2-0 46A1 1

16 W F2-0 49

16 W F2-0 50

Th r ead re leas e pin

Th r ad ten sion c isc

Th r ead te nsio n cisc

Te n sion s prin g

St o pper

Th r ead te nsio n stud n ut

Sc r ew

Th r ead ta kee- up spr ing sh a ft

Th r ead ta ke-u p spri ng

Th r ead te nsio n guid e disc

Sc r ew

Sc r ew

Nu t

Th r ead ta ke-u p spri ng fen c e

Fe n ce set scre w

1

2

1

1

1

1

SM1 1 /6 4” ×32

1

1

1

1

1

1

SM1 1 /6 4” ×32

SM1 / 8” ×44

1

1

1

SM9 / 64 ”×4 0

Page 26

8.B elt c ove r and b obb in si nde r c om p on e nts

3

2

3

4

5

6

1

3

3

7

3

8

9

10

Page 27

8.B elt c ove r and b obb in wi nde r c om p on e nts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

Pa rts N o .

50W F 5- 00 7

50W F 5- 00 5

40T 2 -2 02

50W F 5- 00 9

50W F 5- 00 8

22T 4 -0 15

50W F 5- 00 6

33T F -0 17

33T F -0 11

S14 4 20 02 0

Na me of p a rts

Bel t c ov er (3 )

Bel t c ov er (1 )

Scr e w

Sup p or t sc re w

Bel t c ov er s up po rt p late

Scr e w

Bel t c ov er (2 )

Woo d en s cr ew

Was h er

Bob b in w in de r as se mbly

Qt y.

1

1

12

2

1

2

1

2

2

1

Re mar k s

SM1 1 /6 4” ×40

SM1 1 /6 4” ×40

Page 28

9.K nee l ift er co mpo nen ts

5

11

12

10

11

13

14

2

6

4

3

1

16

15

9

7

8

9

18

23

17

16

19

11

20

21

10

22

Page 29

9.K nee l ift er co mpo nen ts

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Pa rts N o .

50W F 4-02 0

50W F 4-02 3

50W F 4-02 1

50W F 4-02 2

50W F 4-02 4

50W F 4-01 8

36T 5 -008 E 5

606 0 82

33T 5 -005

33T 5 -006

33T 5 -007 B 1

50W F 6-00 1

50W F 6-00 2

33T 5 -009

33T 5 -008

33T 5 -011 E

33T 5 -010 F

Na me of p a rts

Hangin g rod

Bar connec tion

Spring

Spring holdr

Hinge screw

Nut

Screw

Chain

“S”shaped hook

Knee lifter base

Wooden screw

Spring

Pin

Knee lifter shaft

Knee lifter crank

Set screw

Knee lifter crank hook

Screw

Knee lifter plate rod

Bracke t

Knee lifter adjust ment bracke t

Hexago nal screw

knee lifter press assemb ly

Qt y.

1

1

1

1

1

1

1

1

2

2

4

1

1

1

1

3

1

2

1

1

1

1

1

Re mar k s

Len g th 10 00 cm

GB9 S T5 ×8

GB1 1 9 2 ×31

GB8 2 1 M 8× 1 1

GB8 2 1 M 8× 1 1

GB5 7 81 -8 6- M6 ×10

Page 30

10. Acc ess ori es

1

2

3

4

11

1

1

9

9

5

10

11

6

8

7

9

18

12

13

15

14

16

17

Page 31

10. Acc ess ori es

Re f.N O .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Pa rts N o .

1F- 0 09

33T F -0 10

4F- 0 07

33T 1 -0 27

33T F -0 11

50W F 5- 01 0

1F- 0 13

33T F -0 14

33T F -0 13

33T F -0 12

50W F 5- 01 1

50W F 2- 01 7

50W F 2- 01 8

Na me of p a rts

Oil b o x

Par t s ba g

Wre n ch

Thr e ad s ta nd a ss em bly

Bob b in

Oil p o t

Nee d le

V-b e lt

Scr e w

Was h er

Nut

Hex a go na l wr en ch 3

Hex a go na l wr en ch 4

Mac h in e co ve r

Scr e w dr iv er (s ma ll)

Scr e w dr iv er (m il ddle)

Scr e w dr iv er (b ig )

Oil p a n

Thr e ad g ui de p in

Loc k nu t

Qt y.

11

1

1

6

1

5

1

4

4

4

1

1

1

1

1

1

1

1

1

1

Re mar k s

DP×17

M6×70

GB5 2 87 -8 56

GB4 1 -8 5 M6

S=3

S=4

Page 32

CONT ENTS

Oper a tion ins t ructio n

1 . B r i e f i n s t r u c t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 . M a i n s p e c i f i c a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 . O p e r a t i o n p r e p a r a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4. In st al li ng th e kn ee li ft er me ch an is m. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .1

5 . L u b r i c a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 . I n s t a l l i n g t h e t h r e a d s t a n d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7. In st al li ng th e be lt co ve r an d bo bb in wi nd er .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .3

8 . I n s t a l l i n g t h e n e e d l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

9 . I n s t a l l i n g t h e b o b b i n c a s e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 0 . W i n d i n g t h e b o b b i n t h r e a d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 1 . P u t t h e b o b b i n i n t o b o b b i n c a s e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 2 . T h r e a d i n g t h e n e e d l e t h r e a d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 3 . A d j u s t i n g t h e s t i t c h l e n g t h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 4 . T h r e a d t e n s i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 5 . T h r e a d t a k e - u p s p r i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1 6 . A d j u s t i n g t h e p r e s s u r e o f p r e s s e r f o o t . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . 6

1 7 . A d j u s t i n g t h e h e i g h t o f p r e s s e r f o o t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1 8 . A d j u s t i n g t h e h e i g h t o f f e e d d o g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 9 . A d j u s t i n g t h e n e e d l e a n d h o o k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 0 . A d j u s t i n g t h e n e e d l e g u a r d p l a t e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 1 . A d j u s t i n g t h e i n n e r h o o k g u i d e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 2 . A d j u s t i n g t h e l e n g t h w a y s p os i t i o n o f n e e d l e b a r f r a m e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 3 . S a f e t y c l u t c h d e v i c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 4 . R e l o a d i n g t h e t i m i n g b e l t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 5 . T t r o u b l e a n d r e m e d y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Part s l ist

1 . C a s t i n g c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1 - 1 2

2 . U p p e r s h a f t a n d t h r e a d t a k e - u p l e v e r c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3 - 1 4

3 . N e e d l e b a r a n d h o o k d r i v i n g s h a f t c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5 - 1 6

4 . P r e s s e r f o o t c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7 - 1 8

5 . U p p e r f e e d m e c h a n i s m c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9 - 2 0

6 . L o w e r f e e d m e c h a n i s m c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1 - 2 2

7 . T h r e a d t e n s i o n c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3 - 2 4

8. Be lt co ve r an d bo bb in wi nd er co mp on en ts .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 25 -2 6

9 . K n e e l i f t e r c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 7 - 2 8

1 0 . A c c e s s o r i e s . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 9 - 3 0

Page 33

www.reliablecorporation.com

Loading...

Loading...