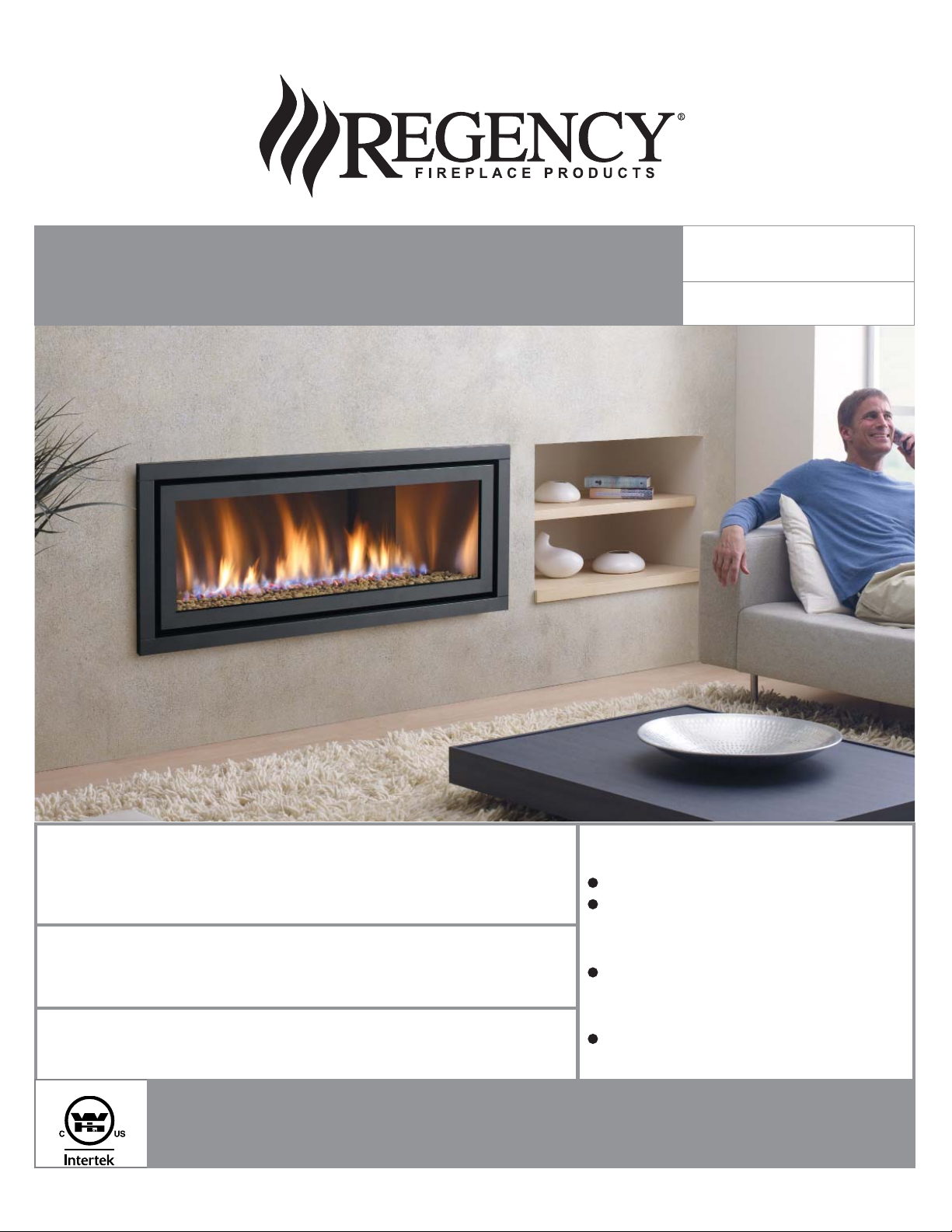

Regency Horizon HZ54 Installation Manual

Regency Horizon

™

HZ54

Owners &

Installation Manual

Gas Fireplace

MODELS: HZ54-NG Natural Gas

HZ54-LP Propane

www.regency-fi re.com

WARNING:

If the information in these instructions are not followed exactly,

a fi re or explosion may result causing property damage,

personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other fl ammable vapors and

liquids in the vicinity of this or any other appliance.

Installation and service must be performed by a qualifi ed

installer, service agency or the gas supplier.

Tested by:

918-751b

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4

Installer: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

FOR YOUR SAFETY

What to do if you smell gas:

Do not try to light any appliance

Do not touch any electrical switch:

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbour's phone. Follow

the gas supplier's instructions.

If you cannot reach your gas

supplier, call the fi re department.

10/08/09

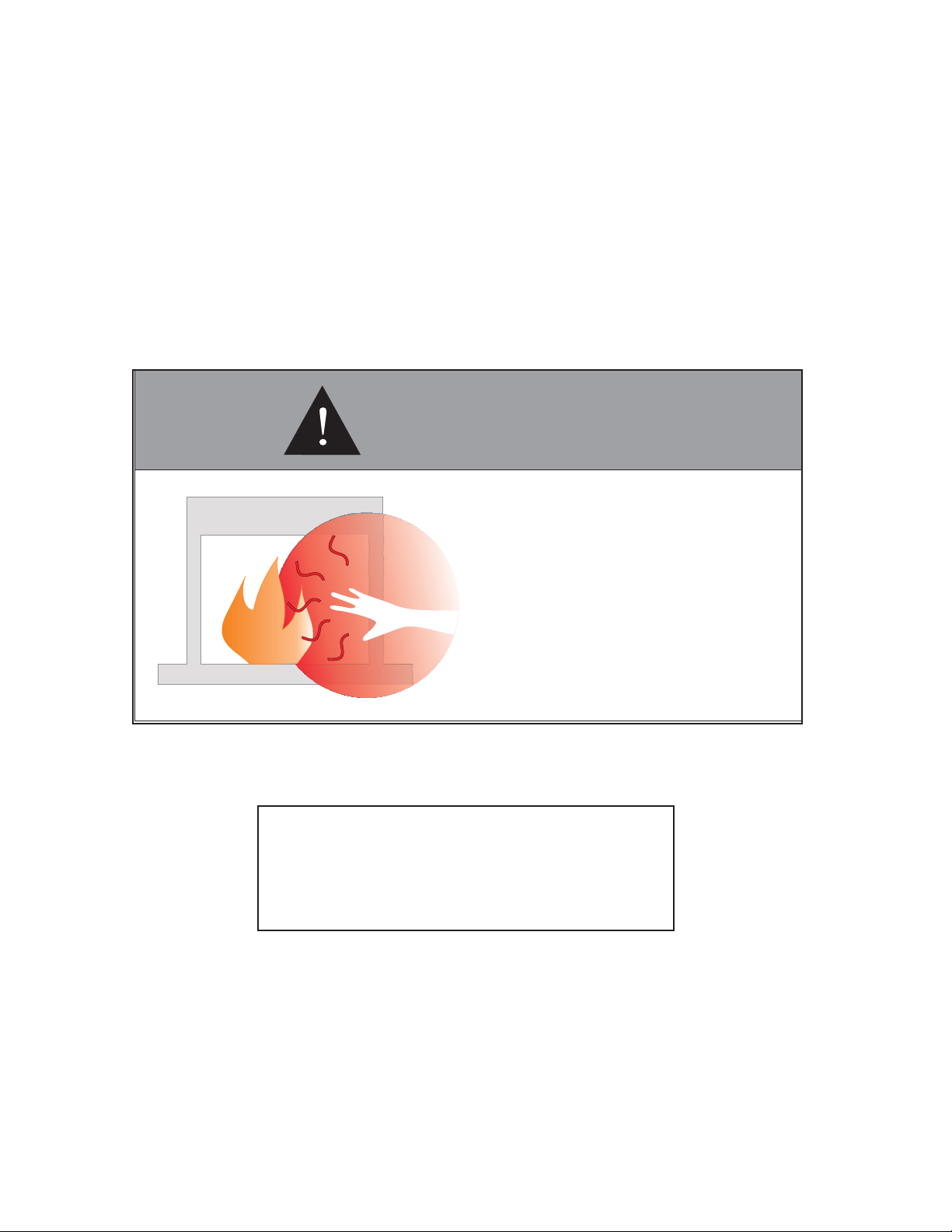

WARNING

HOT GLASS

CAUSE BURNS

DO NOT TOUCH

UNTIL COOLED

NEVER

TO TOUCH GLASS

CHILDREN AND ADULTS SHOULD BE ALERTED TO

THE HAZARDS OF HIGH SURFACE TEMPERATURES,

ESPECIALLY THE FIREPLACE GLASS, AND SHOULD

ST AY AWA Y TO AVOID BURNS OR CLOTHING IGNITION.

ALLOW CHILDREN

WILL

GLASS

To the New Owner:

Congratulations!

You are the owner of a state-of-the-art Gas Fireplace by REGENCY®. The HZ54 has been

designed to provide you with all the warmth and charm of a wood fi replace at the fl ick of a

switch. The model HZ54 has been approved by Warnock Hersey/Intertek for both safety and

effi ciency. As it also bears our own mark, it promises to provide you with economy, comfort

and security for many trouble free years to follow . Please take a moment now to acquaint

yourself with these instructions and the many features of your Regency

MANUFACTURED MOBILE HOME REQUIREMENTS

INFORMATION FOR MOBILE/MANUFACTURED HOMES AFTER FIRST SALE

This Regency® product has been tested and listed by Warnock Hersey/Intertek as a Direct Vent Wall Furnace to the following

standards: VENTED GAS FIREPLACE HEATERS ANSI Z21.88a-2007 / CSA 2.33a-2007 and GAS-FIRED APPLIANCES FOR

USE AT HIGH ALTITUDES CAN / CGA 2.17-M91.

This Direct Vent System Appliance must be installed in accordance with the manufacturer's installation instructions and the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or the current Standard of Fire Safety Criteria for

Manufactured Home Installations, Sites, and Communities ANSI/NFPA 501A, and with CAN/CSA Z240-MH Mobile Home Standard

in Canada.

®

Fireplace.

This appliance installation must comply with the manufacturer's installation instructions and local codes, if any. In the absence of

local codes follow the current National Fuel Gas Code, ANSI Z223.1 and the current National Electrical Code ANSI/NFP A 70 in the

U.S.A., and the current CAN/CGA B149 Gas Installation Code and the current Canadian Electrical Code CSA C22.1 in Canada.

This appliance comes equipped with a dedicated #8 Ground Lug for attachment of the ground wire to the steel chassis as applicable

to local codes.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

This appliance may only be installed in an aftermarket permanently located, manufactured (U.S.A only) or mobile home, where not

prohibited by local codes.

This appliance can only be used with the type of gas indicated on the rating plate. This appliance is not convertible for use with

other gases.

Ensure that structural members are not cut or weakened during installation.

2

HZ54 Regency HorizonTM Gas Fireplace

TABLE OF CONTENTS

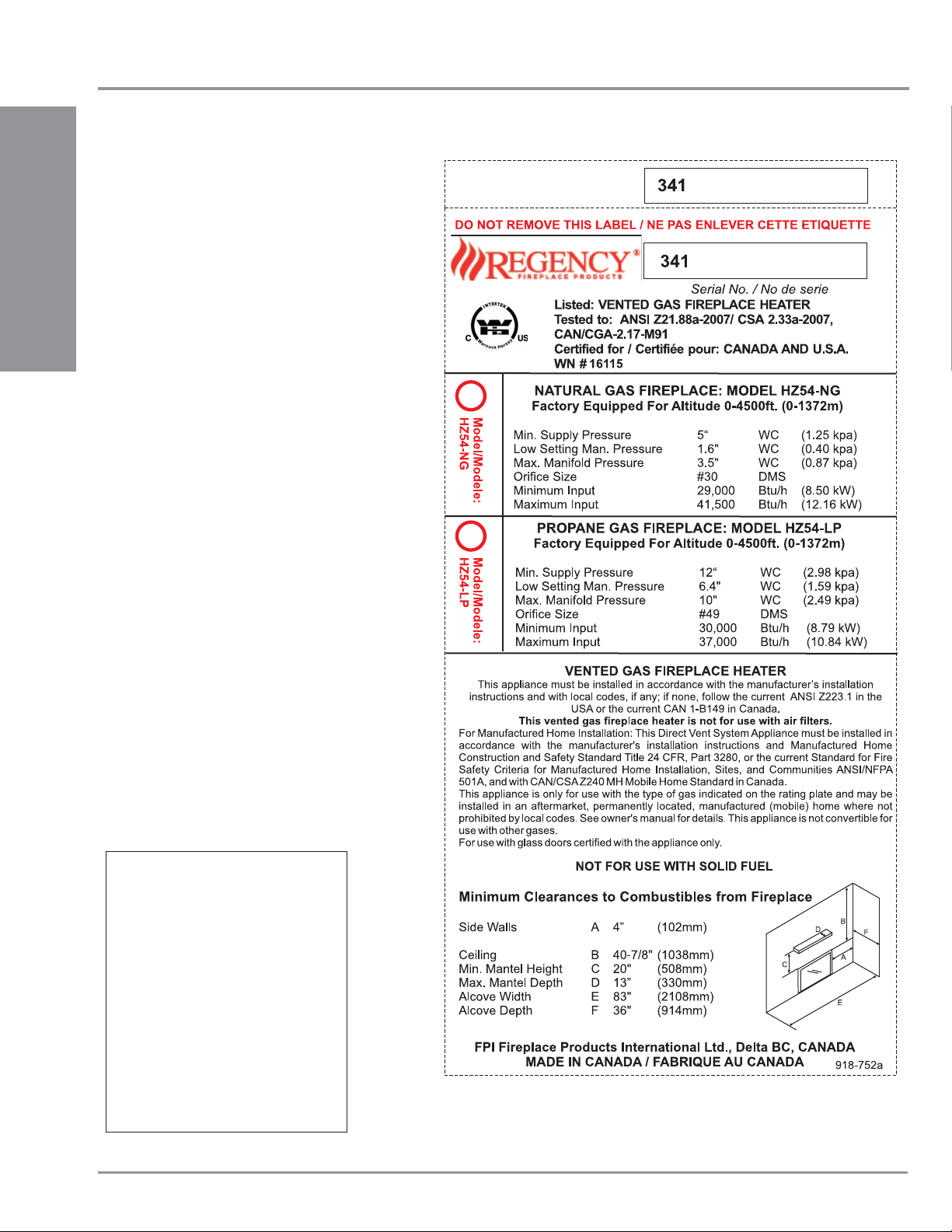

SAFETY LABEL

Copy of Safety Decal .....................................................4

REQUIREMENTS

MA Code - CO Detector.................................................5

DIMENSIONS

Unit Dimensions ............................................................6

Faceplate & Door frame overlay Dimensions ................6

INSTALLATION

Important Message ......................................................7

Before You Start ............................................................7

General Safety Information............................................7

Installation Checklist ......................................................8

Locating Your Gas Fireplace .........................................8

Clearances ....................................................................9

Non-Combustible Requirements ...................................9

Top non-combustible facing board...............................10

Mantel Clearances.......................................................11

Mantel Leg Clearances................................................11

Framing & Finishing.....................................................12

Unit Assembly Prior To Installation ..............................14

Standoff Assembly ...............................................14

Nailing Strips ........................................................14

Venting Introduction .....................................................14

Vent Restrictor Position ...............................................15

Exterior Vent Termination Requirements .....................16

Venting Arrangements ................................................17

Horizontal Termination (Flex) ...............................17

Rigid Pipe Venting Systems ........................................18

Basic Horizontal & Vertical Terminations .............18

5” x 8” Rigid Pipe Cross Reference Chart ...................19

Venting Arrangements ................................................21

Allowable Horizontal Terminations for HZ54-ng ...21

Venting Arrangements ................................................21

Allowable Horizontal Terminations for HZ54-lp ....21

Venting Arrangements ................................................24

Allowable Vertical Terminations for HZ54-ng .......24

Venting Arrangements ................................................25

Allowable Vertical Terminations for HZ54-lp ........25

Unit Installation with Horizontal Termination ................26

Unit Installation with Vertical Termination ....................27

Unit Installation ............................................................28

Horizontal Termination .........................................28

with Flex Vent System .........................................28

High Elevation .............................................................29

Gas Line Installation ....................................................29

Pilot Adjustment ...........................................................29

Gas Pipe Pressure Testing ..........................................29

S.I.T. Valve Description ................................................29

Aeration Adjustment ....................................................30

Wiring Diagram ...........................................................30

Optional Wall Thermostat ...........................................31

Optional Remote Control .............................................31

GT remote features .....................................................31

Optional Wall Switch ....................................................31

GT remote wiring Diagram ..........................................32

Optional Log set Installation ........................................33

OptionaL Refl ective Panel Installation .........................36

Glass Crystals or optional ceramic stones ..................37

Faceplate & Door frame overlay Installation................39

OPERATING INSTRUCTIONS

Operating Instructions .................................................41

First Fire ......................................................................41

Lighting Procedure ......................................................41

Shutdown Procedure ...................................................41

Normal Operating Sounds of Gas Appliances .............41

Copy of Lighting Plate Instructions ..............................42

MAINTENANCE

Maintenance Instructions.............................................43

General Vent Maintenance ..........................................43

Thermopile / Thermocouple .........................................43

Glass Gasket ...............................................................43

Glass Door...................................................................43

Glass Replacement .............................................43

Glass Door Removal ...................................................44

DC Spark Box Battery Replacement ...........................45

DC Spark Box Replacement........................................45

V alve Tray Replacement ..............................................46

HZ54-NG unit ..............................................................47

HZ54-LP unit ...............................................................48

PARTS LIST

Main Assembly ............................................................49

Accessories .................................................................50

WARRANTY

The Warranty: Limited Lifetime ...................................51

HZ54 Regency HorizonTM Gas Fireplace 3

SAFETY LABEL

This is a copy of the label that accompanies

each HZ54-NG and HZ54-LP Direct Vent Gas

Fireplace. We have printed a copy of the contents

here for your review.

NOTE: Regency

improved. Check the label on the unit and if

there is a difference, the label on the unit is the

correct one.

INSTALLATION

®

units are constantly being

For the State of Massachusetts, installation

and repair must be done by a plumber or

gasfi tter licensed in the Commonwealth of

Massachusetts.

For the State of Massachusetts, fl exible

connectors shall not exceed 36 inches in

length.

For the State of Massachusetts, the appliances individual manual shut-off must be a

t-handle type valve.

The State of Massachusetts requires the

installation of a carbon monoxide alarm in

accordance with NFPA 720 and a CO alarm

with battery back up in the same room where

the gas appliance is installed.

COPY OF SAFETY DECAL

4

HZ54 Regency HorizonTM Gas Fireplace

REQUIREMENTS

MA Code - CO Detector

(for the State of Massachusetts only)

5.08: Modifications to NFPA-54, Chapter 10

(2) Revise 10.8.3 by adding the following additional requirements:

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled

equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is

installed on the floor level where the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a battery

operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure

served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of

qualified licensed professionals for the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period of

thirty (30) days to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

INSTALLATION

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions

shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight

(8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA 54 as adopted by

the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product

Approved side wall horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the

instructions provided by the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a

Product Approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies

"special venting systems", the following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and

detailed installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions,

all parts lists for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of

the installation.

HZ54 Regency HorizonTM Gas Fireplace 5

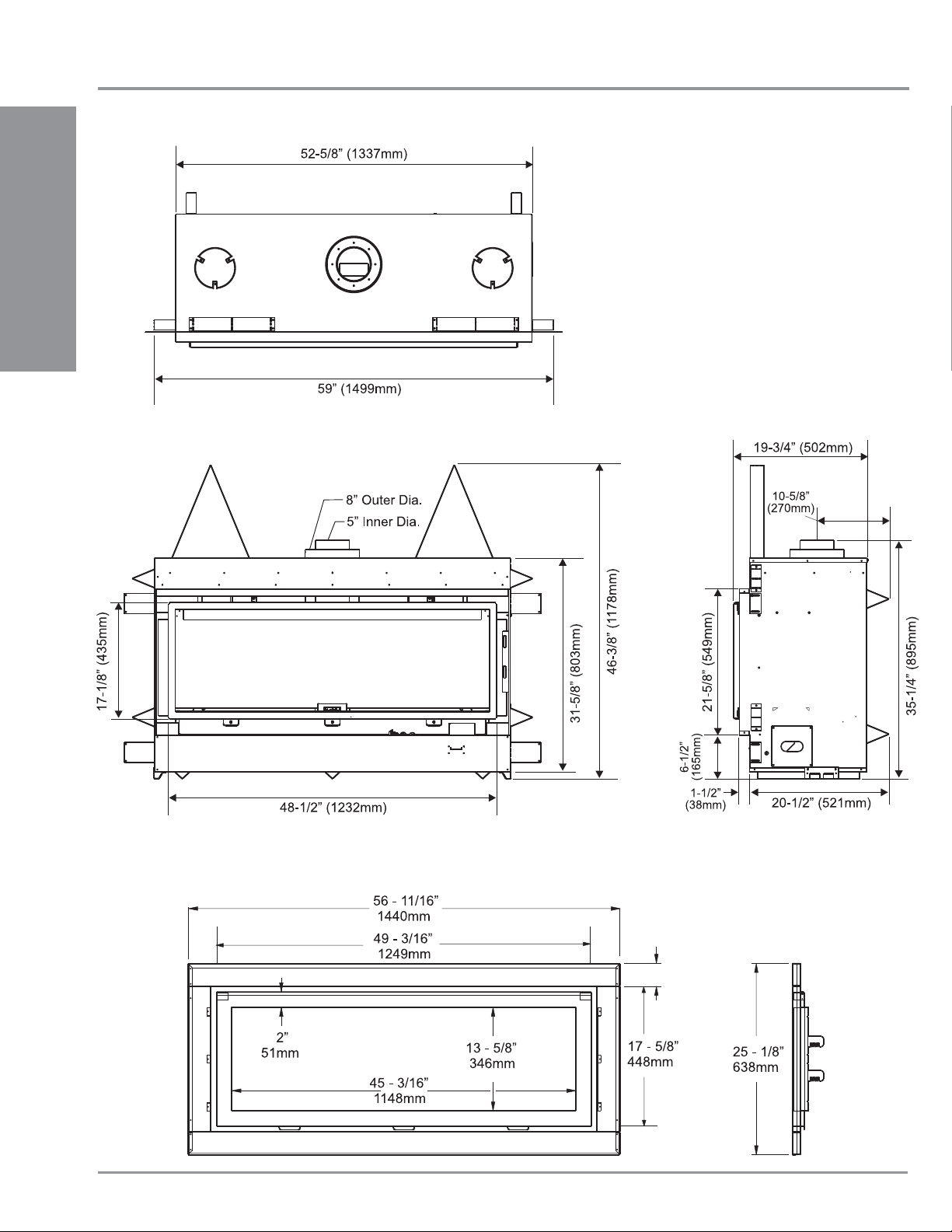

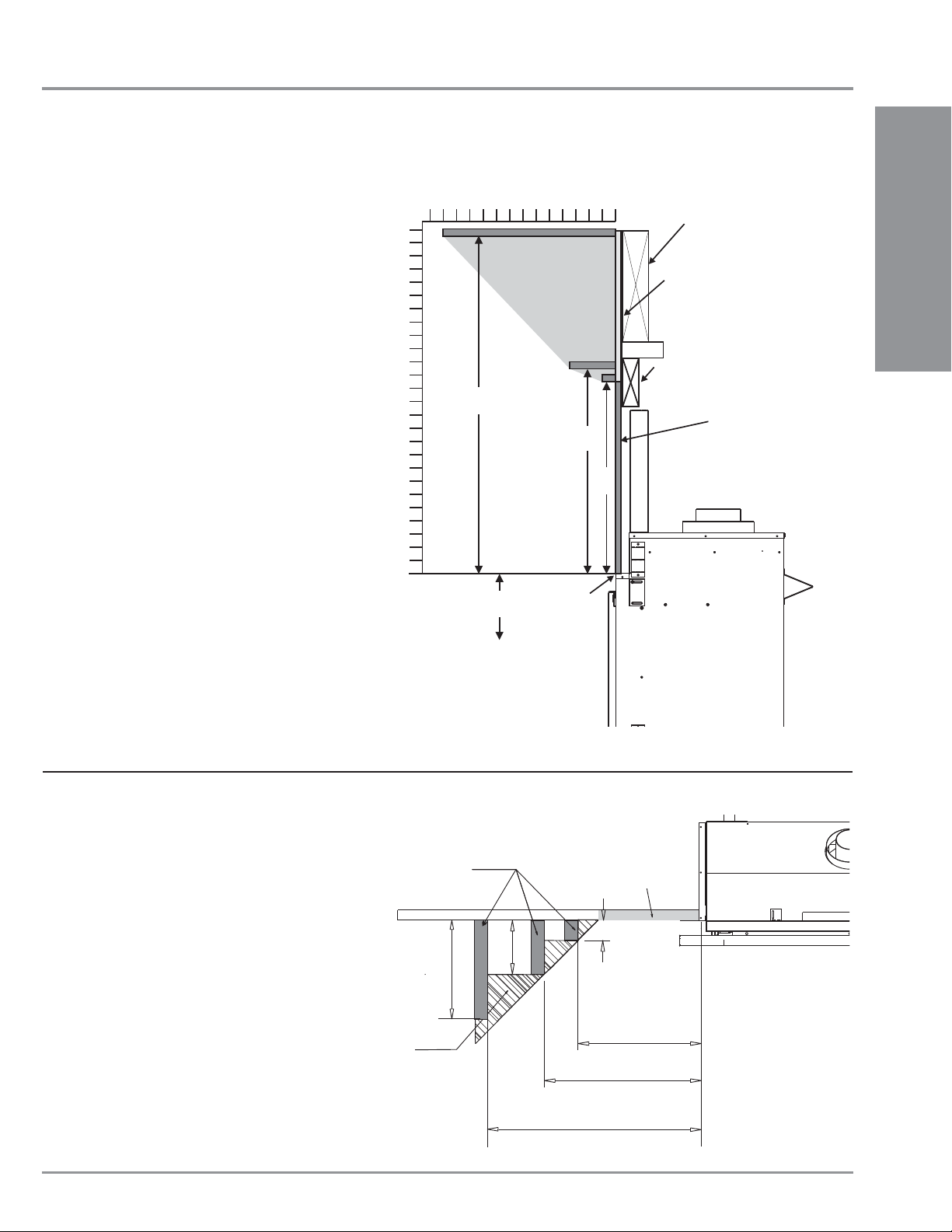

DIMENSIONS

INSTALLATION

UNIT DIMENSIONS

FACEPLATE & DOOR FRAME OVERLAY DIMENSIONS

6

HZ54 Regency HorizonTM Gas Fireplace

INSTALLATION

IMPORTANT MESSAGE

SAVE THESE

INSTRUCTIONS

The HZ54 Direct Vent Fireplace must be installed

in accordance with these instructions. Carefully

read all the instructions in this manual fi rst.

Consult the "authority having jurisdiction" to

determine the need for a permit prior to starting

the installation. It is the responsibility of the

installer to ensure this fi replace is installed in

compliance with manufacturers instructions and

all applicable codes.

BEFORE YOU ST ART

Safe installation and operation of this appliance

requires common sense, however, we are

required by the Canadian Safety Standards

and ANSI Standards to make you aware of

the following:

INST ALLATION AND REPAIR SHOULD

BE DONE BY AN AUTHORIZED

SERVICE PERSON. THE APPLIANCE

SHOULD BE INSPECTED BEFORE

USE AND AT LEAST ANNUALLY BY A

PROFESSIONAL SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TO EXCESSIVE

LINT FROM CARPETING, BEDDING

MATERIAL, ETC. IT IS IMPERATIVE

THAT CONTROL COMPARTMENTS,

BURNERS AND CIRCULATING AIR

PASSAGEWAYS OF THE APPLIANCE

BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED

OUT OF TRAFFIC AND AWAY FROM

FURNITURE AND DRAPERIES.

WARNING: F AILURE TO INST ALL THIS

APPLIANCE CORRECTLY WILL VOID

YOUR WARRANTY AND MAY CAUSE

A SERIOUS HOUSE FIRE.

YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISED WHEN

THEY ARE IN THE SAME ROOM AS

THE APPLIANCE.

CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED

ON OR NEAR THE APPLIANCE.

GENERAL SAFETY

INFORMATION

1) The appliance installation must conform

with local codes or, in the absence of local

codes, with the current Canadian or National

Gas Codes, CAN1-B149 or ANSI Z223.1

Installation Codes.

2) The appliance when installed, must be

electrically grounded in accordance with

local codes, or in the absence of local codes

with the current National Electrical Code,

ANSI/NFPA 70 or CSA C22.1 Canadian

Electrical Code.

3) See general construction and assembly

instructions. The appliance and vent should

be enclosed.

4) This appliance must be connected to the

specifi ed vent and termination cap to the

outside of the building envelope. Never vent

to another room or inside a building. Make

sure that the vent is fi tted as per Venting

instructions.

5) Inspect the venting system annually for

blockage and any signs of deterioration.

6) Venting terminals shall not be recessed into

a wall or siding.

7) Any safety glass removed for servicing

must be replaced prior to operating the

appliance.

8) To prevent injury, do not allow anyone who

is unfamiliar with the operation to use the

fi replace.

10) Be aware of electrical wiring locations in walls

and ceilings when cutting holes for termination.

11) Under no circumstances should this appliance

be modifi ed. Parts that have to be removed

for servicing should be replaced prior to

operating this appliance.

12) Installation and any repairs to this appliance

should be done by an authorized service

person. A professional service person should

be called to inspect this appliance annually.

Make it a practice to have all of your gas

appliances checked annually.

13) Do not slam shut or strike the glass door.

14) Under no circumstances should any solid

fuels (wood, paper, cardboard, coal, etc.) be

used in this appliance.

15) The appliance area must be kept clear and

free of combustible materials, (gases and

other fl ammable vapours and liquids).

Emissions from burning wood or gas could

contain chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

INSTALLATION

CHILDREN AND ADUL TS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

9) Wear gloves and safety glasses for protection

while doing required maintenance.

SURFACE TEMPERATURES, ESPECIALL Y THE FIREPLACE GLASS, AND

SHOULD ST AY AWA Y TO A VOID BURNS

OR CLOTHING IGNITION.

HZ54 Regency HorizonTM Gas Fireplace 7

INSTALLATION

INSTALLATION

CHECKLIST

1) Locate appliance

a) Room location (Refer to "Locating Your

Gas fi replace" section)

b) Clearances to Combustibles (Refer to

"Clearances" section)

c) Mantle Clearances (Refer to "Mantel

Clearances" section)

d) Framing & Finishing Requirements (Refer

INSTALLATION

to "Framing & Finishing" section)

e) Venting Requirements (Refer to "Venting"

section)

2) Assemble Top and Side Standoffs (Refer to

"Unit Assembly Prior to Installation).

3) Slide unit into place.

4) Install vent (Refer to "Venting Arrangement"

sections).

5) Make gas connections (Refer to "Gas Line

Installation section).

6) Install 1 AA battery into DC spark box.

7) Test the pilot (Refer to "Pilot Adjustment"

section).

8) T est Gas Pressure (Refer to "Gas Pipe Pressure Testing" section).

9) Install standard and optional features. Refer

to the following sections:

This includes:

1) Clocking the appliance to ensure the correct

firing rate (rate noted on label 41,500

Btu/h (NG), after burning appliance for 15

minutes.

2) If required, adjusting the primary air to ensure

that the fl ame does not carbon. First allow

the unit to burn for 15-20 min. to stabilize.

CAUTION: Any alteration to the product that

causes sooting or carboning that results

in damage is not the responsibility of the

manufacturer.

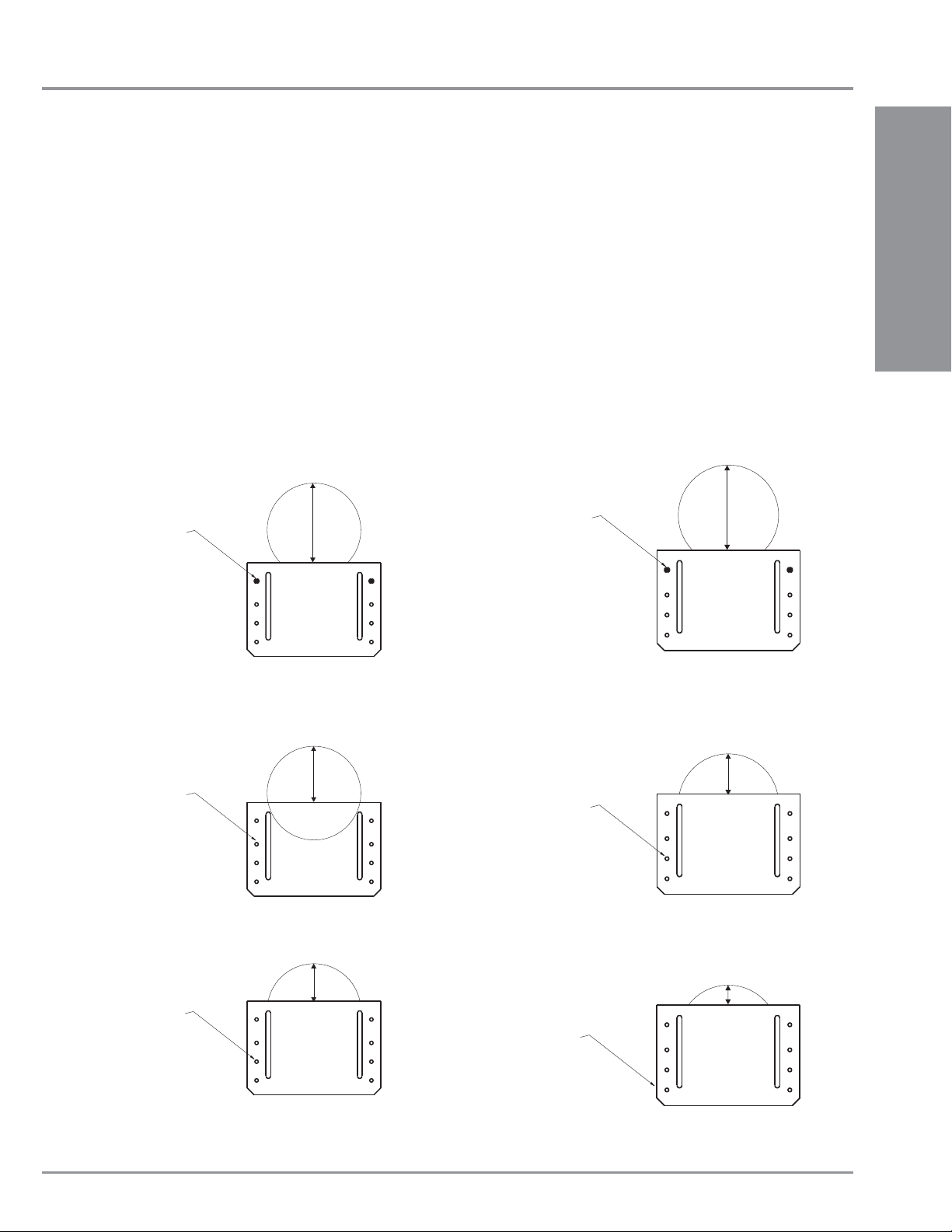

LOCATING YOUR

GAS FIREPLACE

1) When selecting a location for your fi replace,

ensure that the clearances are met.

2) The appliance must be installed on a fl at,

solid, continuous surface For example a

wood, metal or concrete fl oor or in a raised (on

the wall) application. The appliance must be

installed on a metal or wood panel extending

the full width and depth of the appliance.

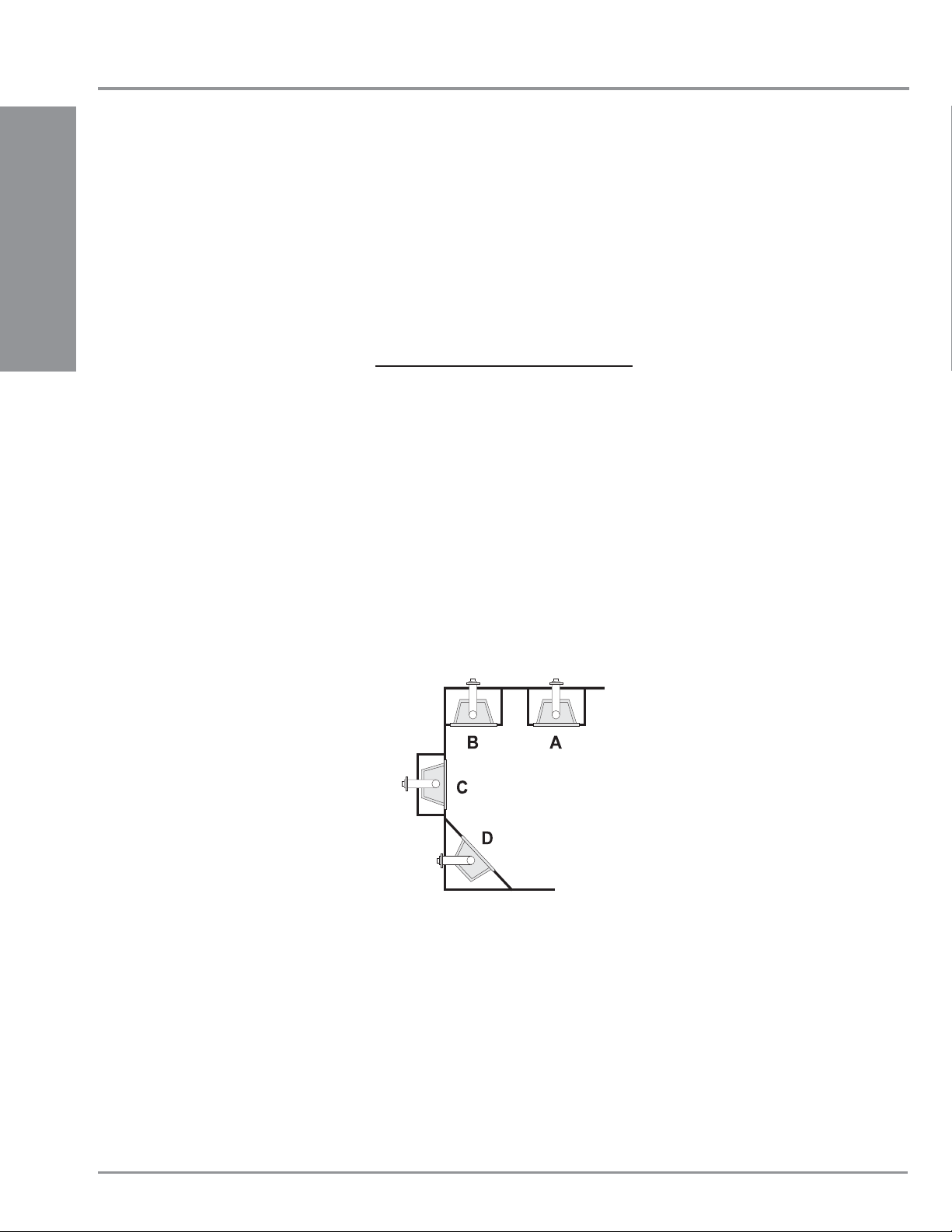

3) The HZ54 Direct V ent Gas Fireplace can be

installed in a recessed position or framed

out into the room as in A, B, C and D. See

4) This appliance is Listed for bedroom

installations using the standard Remote

(millivolt thermostat system). Some areas

may have further requirements, check local

codes before installation.

5) The HZ54 Direct Vent Gas Fireplace is

approved for alcove installations, see

"Clearances" section for details.

6) We recommend that you plan your installation

on paper using exact measurements for

clearances and floor protection before

actually installing this appliance. Have an

authorized inspector, dealer, or installer

review your plans before installation.

Note: For vent terminations refer to

"Exterior Vent T ermination Locations"

section.

a) Optional Log Set Installation

b) Glass Crystals/ Optional Ceramic

Stones

c) Optional Firebox Base Pebbles

d) Optional Refl ective Panels

e) Faceplate / Door Frame Overlay

f) Remote Control or Wall Thermostat

10) Wall Mounted ON/OFF Switch:

Use the toggle wall switch supplied with the

manual package. Use of a “decor” switch

causes higher resistance which is a problem

on gas fi replaces.

11) Final check.

Before leaving this unit with the customer, the

installer must ensure that the appliance is fi ring

correctly and operation fully explained to

customer.

Diagram 1

Diagram 1.

A) Flat on Wall

B) Flat on Wall Corner

C) Recessed into Wall/Alcove

D) Corner

8

HZ54 Regency HorizonTM Gas Fireplace

INSTALLATION

CLEARANCES

The clearances listed below are Minimum distances unless otherwise stated:

A major cause of chimney related fi res is failure to maintain required clearances (air space) to combustible materials. It is of the greatest

importance that this fi replace and vent system be installed only in accordance with these instructions.

INSTALLATION

The top, back and sides of the fi replace are defi ned by

Caution Requirements

standoffs. The metal ends of the standoff may NOT be

recessed into combustible construction.

if these clearances (air space) to combustible materials are not

adhered to. It is of greatest importance that this fi replace and vent

system be installed only in accordance with these instructions.

Clearance: Dimension Measured From:

A: Mantel Height (min.) 20" (508mm) Top of Fireplace Opening

B: Sidewall (on one side) 4" (102mm) Side of Fireplace Opening

C: Ceiling

(room and/or alcove)

D: Mantel Depth (max.) 13" (330mm) 30" Above Fireplace Opening

E: Alcove Width 83" (2108mm) Sidewall to Sidewall (Minimum)

F: Alcove Depth 36" (914mm) Front to Back Wall (Maximum)

G: To Floor 28 - 7/8" (733mm) Top of Fireplace Opening

Note 0" No hearth required

D

A

40-7/8" (1038mm) Top of Fireplace Opening

C

F

B

Fire hazard is an extreme risk

WARNING

Flue Clearances to Combustibles

Horizontal - Top 3"

Horiztonal - Side 2"

Horiztonal - Bottom 2"

Vertical 2"

Passing through wall/

floor/ceiling - when

fi restop is used.

F

B

1-1/2"

G

E

Installed Close

to Floor

Installed Close

to Ceiling

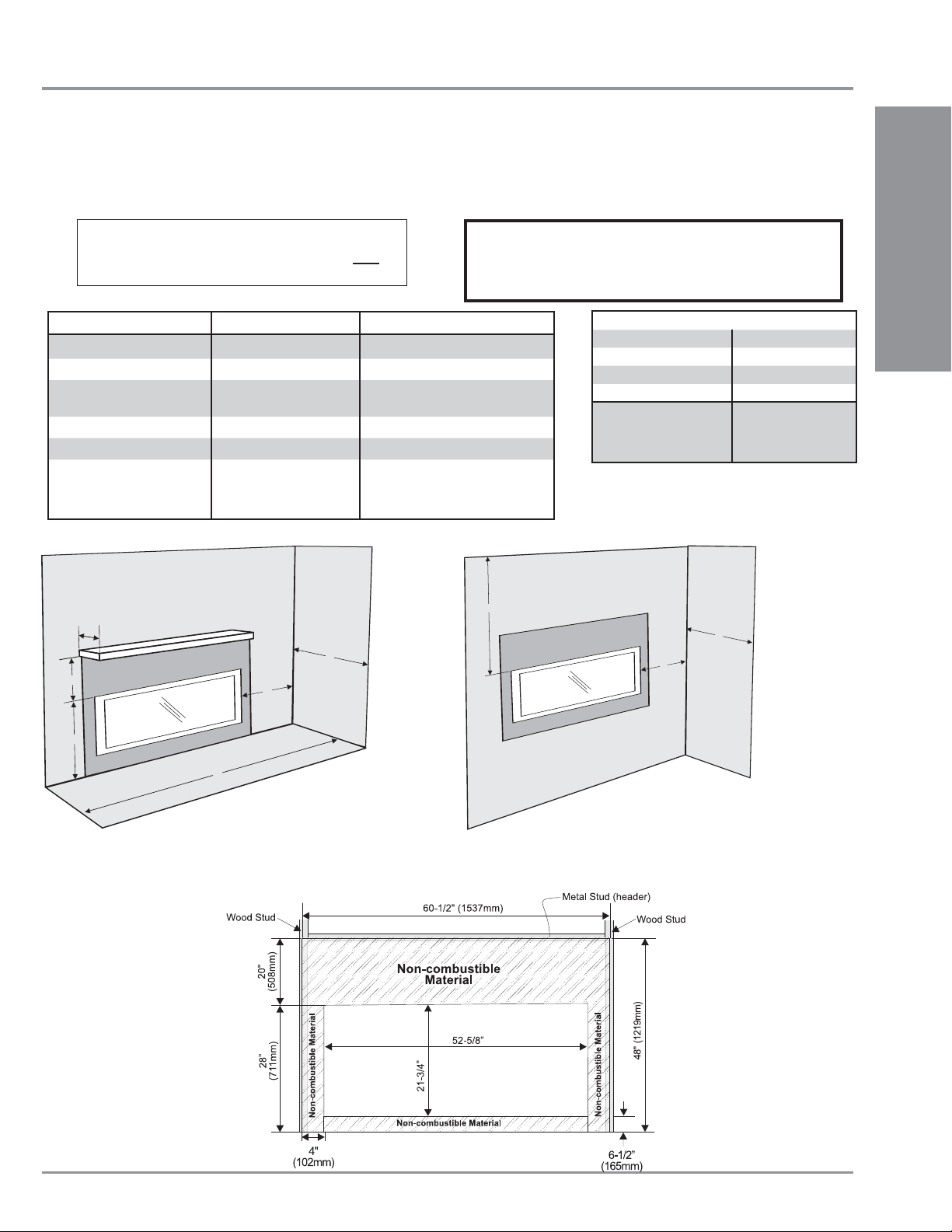

NON-COMBUSTIBLE REQUIREMENTS

HZ54 Regency HorizonTM Gas Fireplace 9

INSTALLATION

If fi nishing the wall above the unit with paint the top non-combustible board (Part # 476-936

- shipped separately from the unit) should be

installed.

Calcium silicate board is a high - grade material

with cement, quartz, natural and selected

minerals as the main raw materials. It is widely

INSTALLATION

used for partitions and ceilings in buildings.

It is fi re proof and earthquake proof.

If fi nishing the wall above the unit with materials

such as tile, brick, marble, etc. non-combustible

board available from the building supply store

can be used.

TOP NON-COMBUSTIBLE FACING BOARD

(PART # 476-936)

Wood Stud

20"

(508mm)

28”

(711mm)

Non-combustible Material

61-1/2" (1537mm)

Non-combustible

Facing Board

52-5/8”

21-3/4”

Non-combustible Material

Metal Stud (header)

Wood Stud

48" (1219mm)

Non-combustible Material

4"

(102mm)

INSTALLATION OF TOP FACING

Caution: This non-combustible board can be damaged if dropped or

struck. Handle with care.

1) Using drywall screws - secure non combustible material

around unit, framing and top nailing strip every 6 inches.

Important Note: To avoid cracking the board - pre-drill holes prior to

securing to unit/ framing.

2) Wipe any debris/dust from the non combustible

material and drywall.

3) Prior to taping and mudding it is highly recommended

to prime the facing using a quality primer. This will

ensure proper adhesion of both the tape and mud.

The optional board is very porous.

4) Tape the seams using a mesh type tape.

5) Mud seams as normal. We recommend using a

product called Durabond high strength compound - for the fi rst coat

This product can be found at any hardware store.

Mud must be cured as per manufacturer’s recommendations.

6) Prime wall for a second time for proper adhesion of paint

20”

Non-combustible board

(from buildingsupply store)

61-1/2”

6-1/2”

(165mm)

Non- combustible board

(calcium silicate)

½”

7) Paint walls using a high quality paint which will withstand

the high temperatures being emitted from this appliance.

Note: Due to the high temperatures being emitted from

this appliance, mudded joints may crack.

Note: In addition to the top piece of non-combustible board -

other non-combustible boards will be required to complete this

installation. These materials can be found at most building

supply stores.

10

Non-combustible board

MUST BE PRIMED.

HZ54 Regency HorizonTM Gas Fireplace

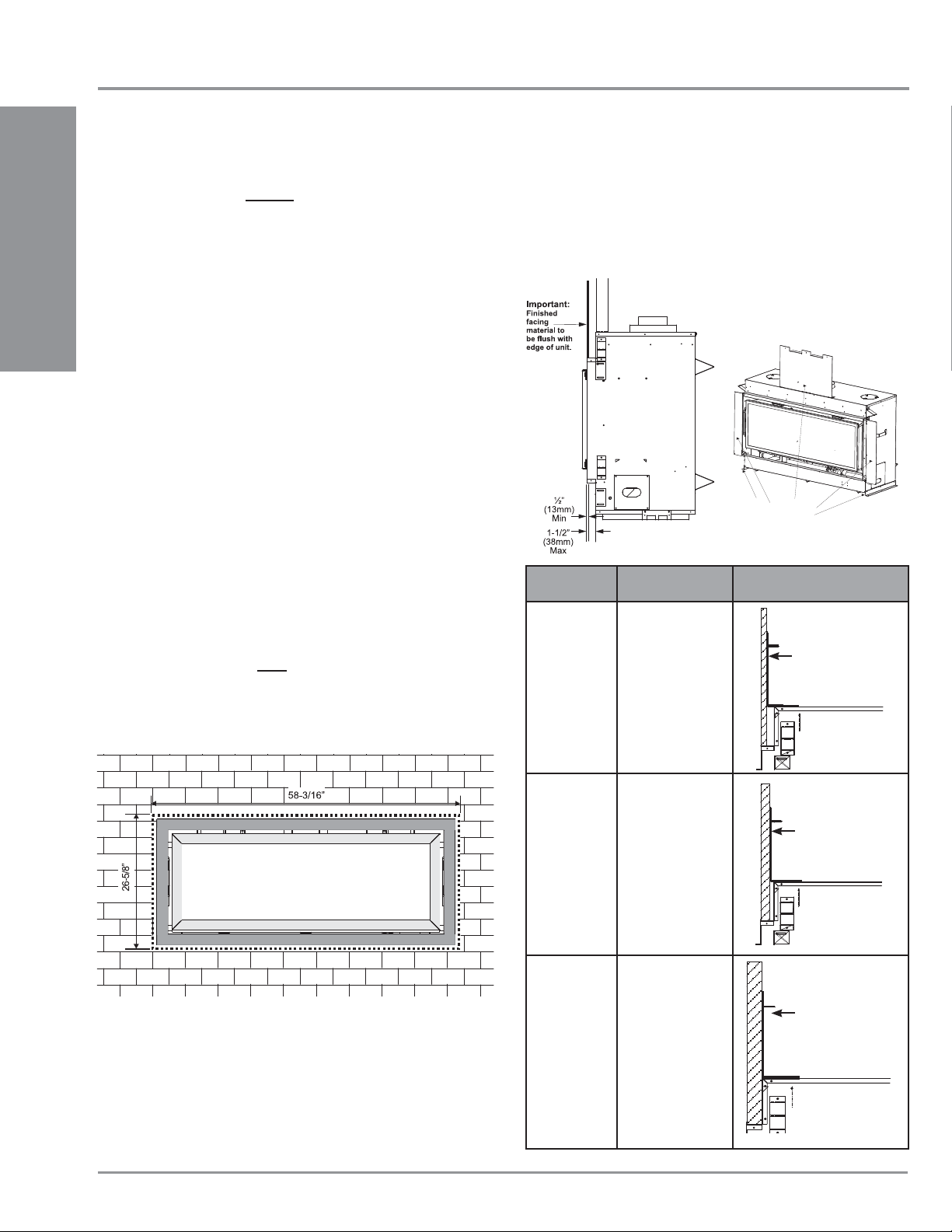

MANTEL CLEARANCES

4"

7”

INSTALLATION

Due to the extreme heat this fi replace emits, the

mantel clearances are critical. Combustible mantel

clearances from top of front facing are shown in the

diagram on the right.

Note: A non-combustible mantel may be

installed at a lower height if the framing

is made of metal studs covered with a

non-combustible board.

Note: Ensure the paint that is used on the mantel

and the facing is "heat resistant" or the

paint may discolour.

14

0

To Unit

Base Legs

12

810

13" (330mm)

1" (25mm)

30”

28-1/8”

6

4

2

3 ½" (89mm)

21”

20”

To p o f

Fireplace

Opening

INSTALLATION

0

Combustible Materia

Drywall

Metal Stud

(On Edge)

Non-combustible

Facing

Standoff

MANTEL LEG CLEARANCES

Combustible mantel leg clearances as per diagram:

MANTEL LEG

HZ54 Regency HorizonTM Gas Fireplace 11

Allowable mantel

leg projection

4”(102mm)

Non-Combustible

1.5" (38mm)

5-1/2” (140mm)

8” (203mm)

11” (279mm)

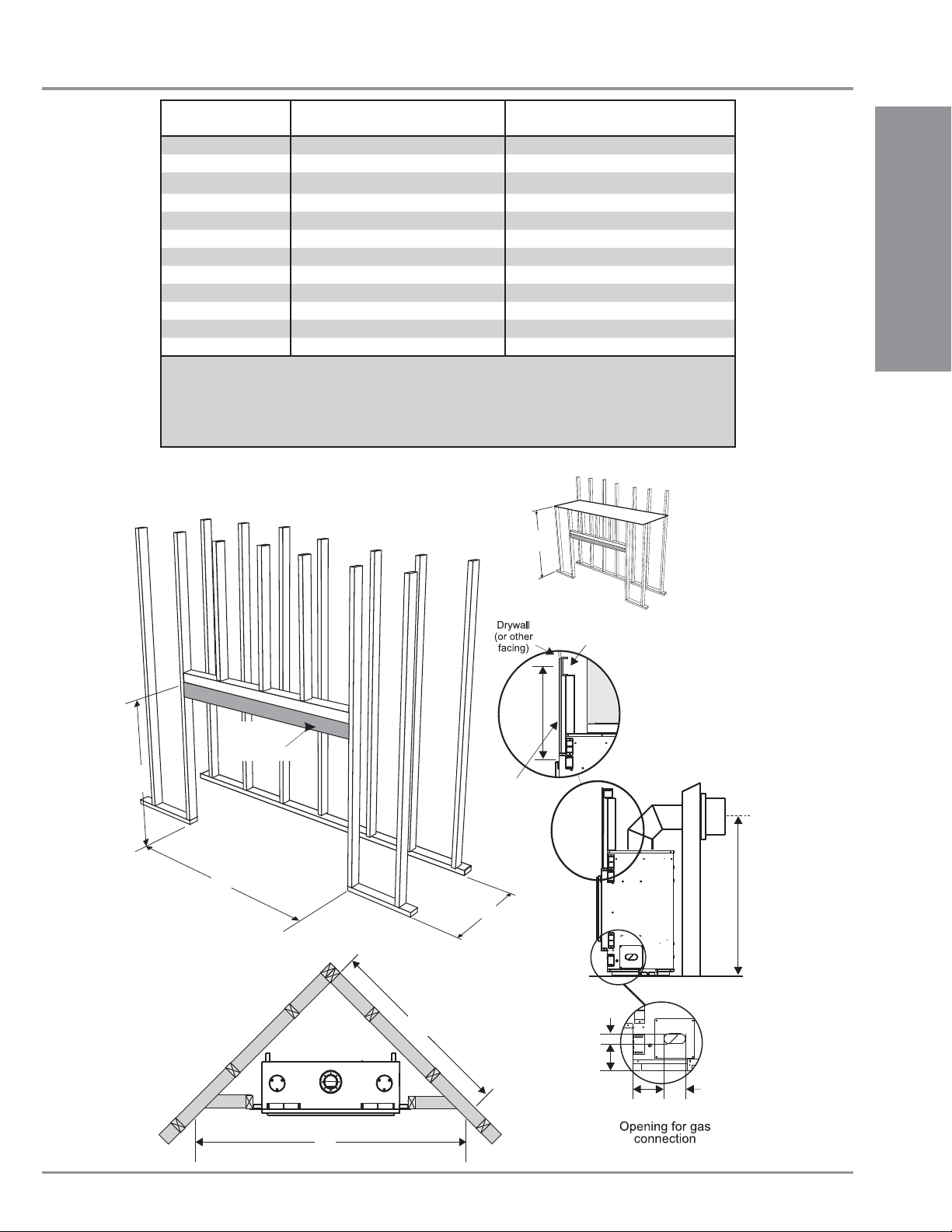

INSTALLATION

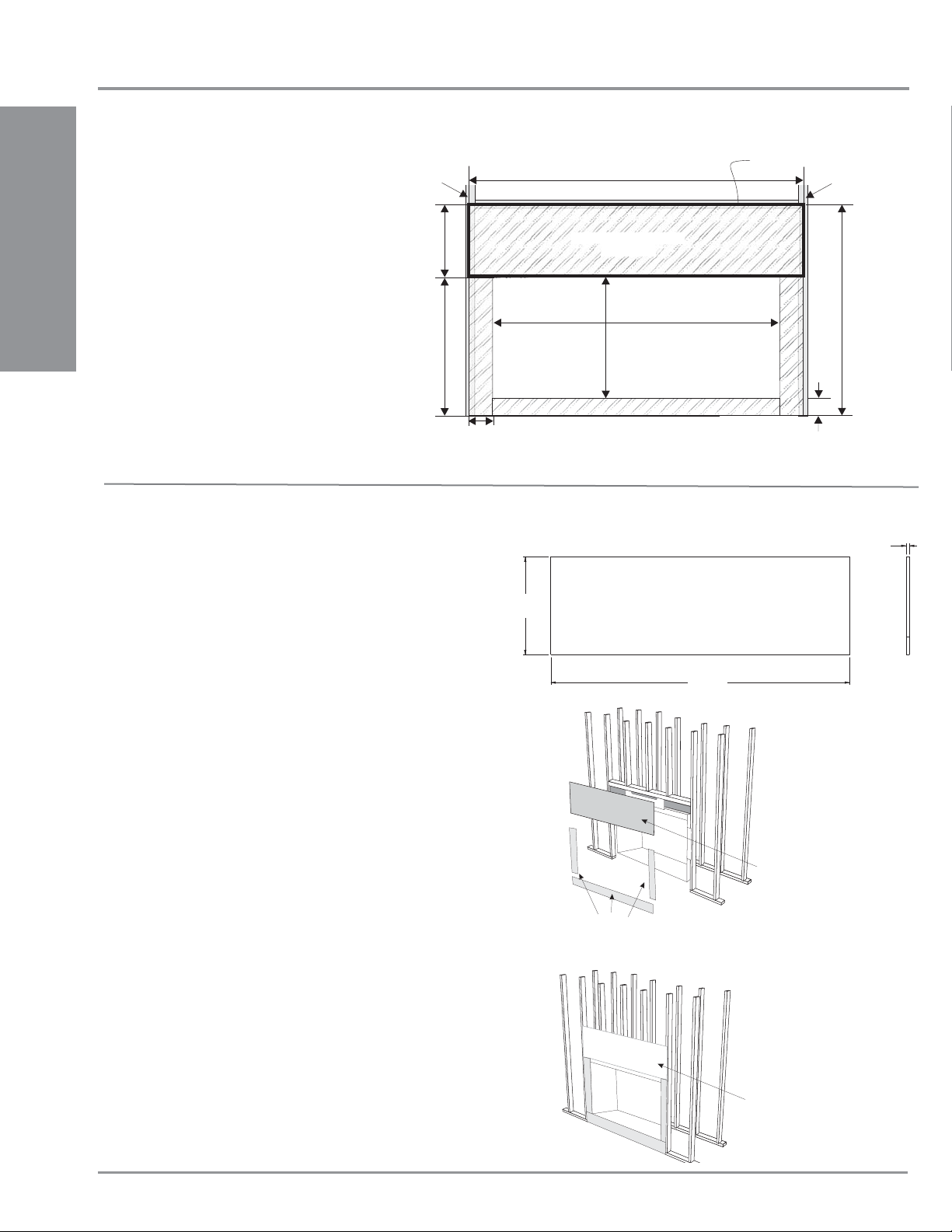

FRAMING & FINISHING

1) Frame in the enclosure for the unit with framing material.

IMPORTANT: Header must be metal stud. All other framing may

be of combustible type such as 2x4 / 2x6 framing materials.

Note: When constructing the framed opening, please ensure there

is access to install the gas lines when the unit is installed.

2) For exterior walls, insulate the enclosure to the same degree as the

INSTALLATION

rest of the house, apply vapour barrier and drywall, as per local installation codes. (Do not insulate the fi replace itself.)

WARNING: Failure to insulate and add vapor barriers to the inside

of the exterior wall will result in operational and performance

problems including, but not limited to: excessive condensation

on glass doors, poor fl ame package, carbon, blue fl ames etc.

These are not product related issues.

3) The unit does not have to be completely enclosed in a chase. You

must maintain clearances from the vent to combustible materials: See

"Clearances" section. Combustible materials can be laid against the

side and back standoffs and the stove base.

4) The combined total of non-combustible facing materials (ie. hardiboard + tile, slate, etc) may be brought up to and overlap the face of

the unit (top and bottom). The minimum thickness = 1/2"

to a maximum thickness = 1-1/2", as shown in the diagram below.

If material is thicker than 1-1/2" - it will not be possible to

mount the faceplace.

5) When fi nishing around the faceplate, if material such as brick, stone,

etc. extend past the faceplate depth - the minimum opening

dimensions noted below must be adhered to, this is to assure

removal of the faceplate.

6) Determine the total thickness of facing material (eg. hardiboard +

ceramic tile) to ensure the fi nished surface is fl ush with the front

edge of the unit (see diagram below). If necessary, side and top

nailing strips are adjustable, loosen the 1/4" screws and adjust.

Total non-combustible facing allowable: Min. = 1/2"

Max. = 1- 1/2"

See diagram below.

Nailing Strips

Finished

Material

Nailing Strip

Position

1/2" 1"

Nailing Strip

1” Forward

12

Unit

1" 1/2"

Nailing Strip

½” Forward

Unit

1-1/2" 0" (fl ush)

Nailing Strip

Flush w/unit

Factory Set

Unit

HZ54 Regency HorizonTM Gas Fireplace

INSTALLATION

Framing

Dimensions

A Framing Height 46-5/8” (1184mm)

B Framing Width 60” (1524mm)

* Framing Depth*

C

D Minimum Height to Combustibles 51” (1295mm)

E Corner Wall Depth 72" (1829mm)

F Corner Facing Wall Width 101-7/8 (2586mm)

G Vent Centerline Height 44” (1118mm)

H Non-combustible facing height 20” (508mm)

I Gas Connection Opening Height 1-1/2” (38mm)

J Gas Connection Height 4” (102mm)

K Gas Connection Inset 7-1/4” (184mm)

L Gas Connection Opening Width 3-1/4” (83mm)

Description HZ54

22” (559mm)

* Framing depth measurement is noted with the side nailing strips set as far forward on the fi rebox as possible.

The side nailing strips can be adjusted back up to 1” to allow for varying thicknesses in non-combustible material & wall fi nishes.

Important: The minimum framing dimensions given for height, width and depth must be maintained even if

using non combustible materials.

Dangerous operating conditions will occur if minimum framing dimensions are not adhered to.

D

INSTALLATION

A

Metal Stud

(Header)

on edge

B

E

Metal Stud (Header)

on edge

H

Non-Combustible

Facing

G

C

I

J

L

K

F

HZ54 Regency HorizonTM Gas Fireplace 13

(Located on the right side of the fireplace)

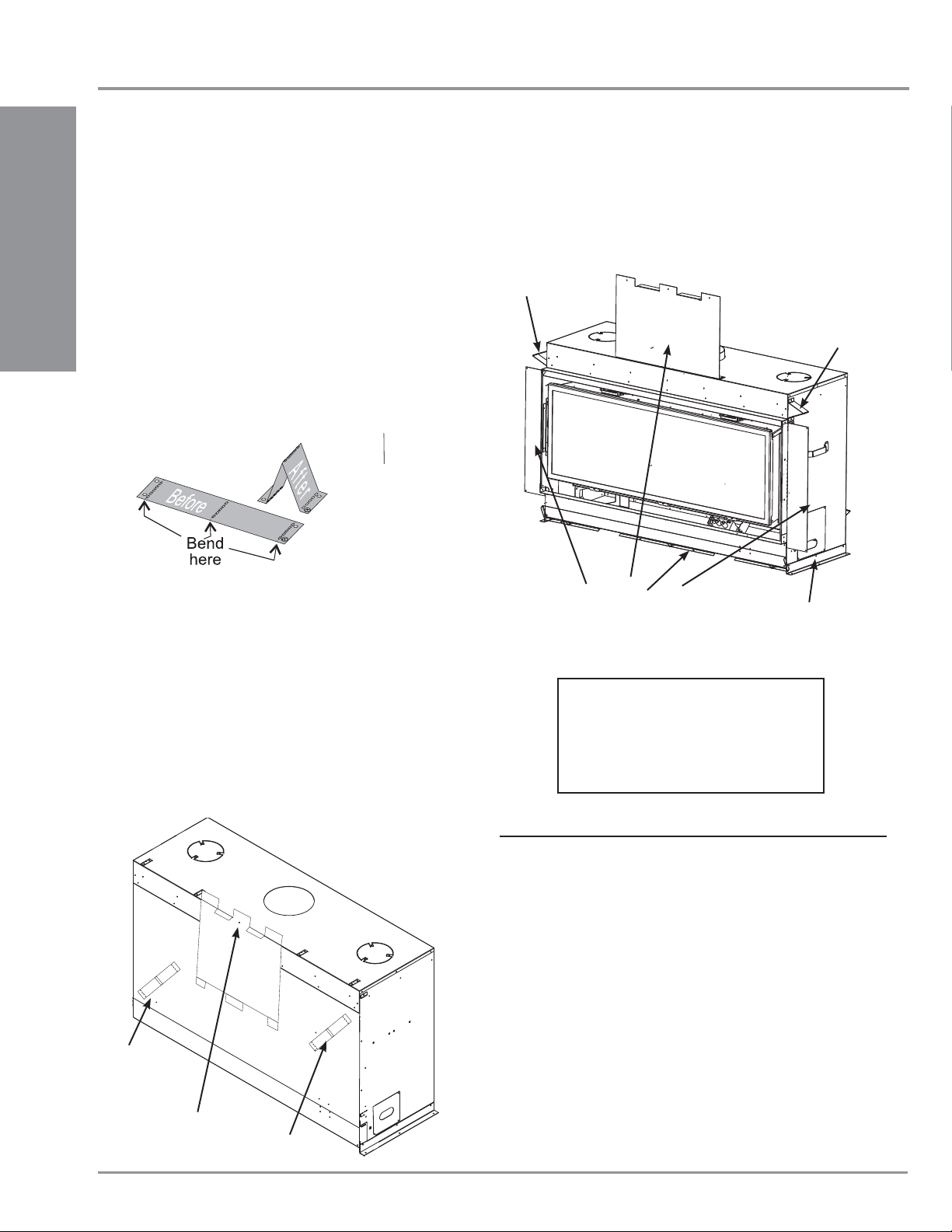

INSTALLATION

UNIT ASSEMBLY

PRIOR TO

INSTALLATION

The Top Standoff/ Nailing Strip, side nailing strips and standoffs must be

correctly positioned and attached to the unit before sliding the unit into

position.

ST ANDOFF ASSEMBLY

The top, side, rear and bottom standoffs are shipped in a fl at position and

INSTALLATION

must be folded into shape and attached - see diagram 1.

1) Remove the standoffs from the unit.

2) Take each standoff and bend into the correct shape. Bend up at the

bend lines until the screw holes in the standoff and the pre-punched

screw holes on the unit line up.

NAILING STRIPS

The nailing strips come attached to the unit. There is 1 plate on each

side,1 on the top, and one on the bottom that can be folded out as

required. The top and side nailing strips are secured to the framing.

The bottom nailing strip is secured to the unfi nished fl oor - if installing

the unit directly on the fl oor.

Note: The bottom nailing strip will need to be bent on site and

adjusted to accommodate the thickness of the facing material.

Standoff

Standoff

Diagram 1

The top stand off / nailing strip is shipped attached to the back of the

unit as shown below.

1) Remove one screw in location shown below.

Replace the screw on the back the unit after removing the

standoff / nailing strip.

2) Bend the 3 tabs at the bottom of the stand off / nailing strip to 90°,

bend in the same direction as the top tabs.

3) Install on the top front of the unit as shown in diagram 3. Do not fully

tighten the screws when installing - until the facing thickness has been

determined.

Nailing Strips

Diagram 3

Shipping brackets remove after shipped.

IMPORTANT NOTE

Framing depth measurement is noted with

the side nailing strips set as far forward on

the fi rebox as possible. The nailing strips can

be adjusted back up to 1” to allow for varying

thicknesses in non-combustible material & wall

fi nishes.

VENTING INTRODUCTION

The HZ54 uses the "balanced fl ue" technology Co Axial system. The

inner liner vents products of combustion to the outside while the outer

liner draws outside combustion air into the combustion chamber thereby

eliminating the need to use heated room air for combustion and losing

warm room air up the chimney.

Note: These fl ue pipes must not be connected to any other

appliance.

Standoff

Remove this screw to

release top standoff / nailing

strip

14

Standoff

The gas appliance and vent system must be vented directly to the outside

of the building, and never be attached to a chimney serving a separate solid

fuel or gas burning appliance. Each direct vent gas appliance must use

it's own separate vent system. Common vent systems are prohibited.

Diagram 2

HZ54 Regency HorizonTM Gas Fireplace

VENT RESTRICTOR POSITION

INSTALLATION

Vent restriction is required for certain venting installations, see the diagrams in the "Venting

Arrangements" section to determine if they are required for your installation.

The Vent Restrictor plate is located on the inside top of the fi rebox.

To set the vent restriction as indicated in the venting arrangements diagrams, refer to the following instructions;

1) Remove the glass door.

2) Remove the screws that hold the vent restrictor plate in place.

3) Adjust the vent restrictor plate to the required vent restrictor position as per the diagrams shown.

4) Once the vent restrictor plate is in the required position, secure with screws.

Vent Restrictor Settings for HZ54-NG

SET 1

THIS HOLE SETS THE

VENT RESTRICTOR

(factory setting)

AT 4.25”

4.25”

THIS HOLE SETS THE

VENT RESTRICTOR

Vent Restrictor Settings for HZ54-LP

SET 1

(factory setting)

AT 4.25”

INSTALLATION

4.25”

SET 2

THIS HOLE SETS THE

VENT RESTRICTOR

AT 3”

SET 3

THIS HOLE SETS THE

VENT RESTRICTOR

AT 2”

Vent Restrictor Set 1

Factory Set Vent Restrictor

(No adjustment required)

3”

Vent Restrictor Set 2

2”

Vent Restrictor Set 1

Factory Set Vent Restrictor

(No adjustment required)

2”

SET 3

THIS HOLE SETS THE

VENT RESTRICTOR

AT 2”

Vent Restrictor Set 3

1”

SET 4

THIS HOLE SETS THE

VENT RESTRICTOR

AT 1”

Vent Restrictor Set 3

Vent Restrictor Set 4

HZ54 Regency HorizonTM Gas Fireplace 15

Loading...

Loading...