Page 1

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

WARNING

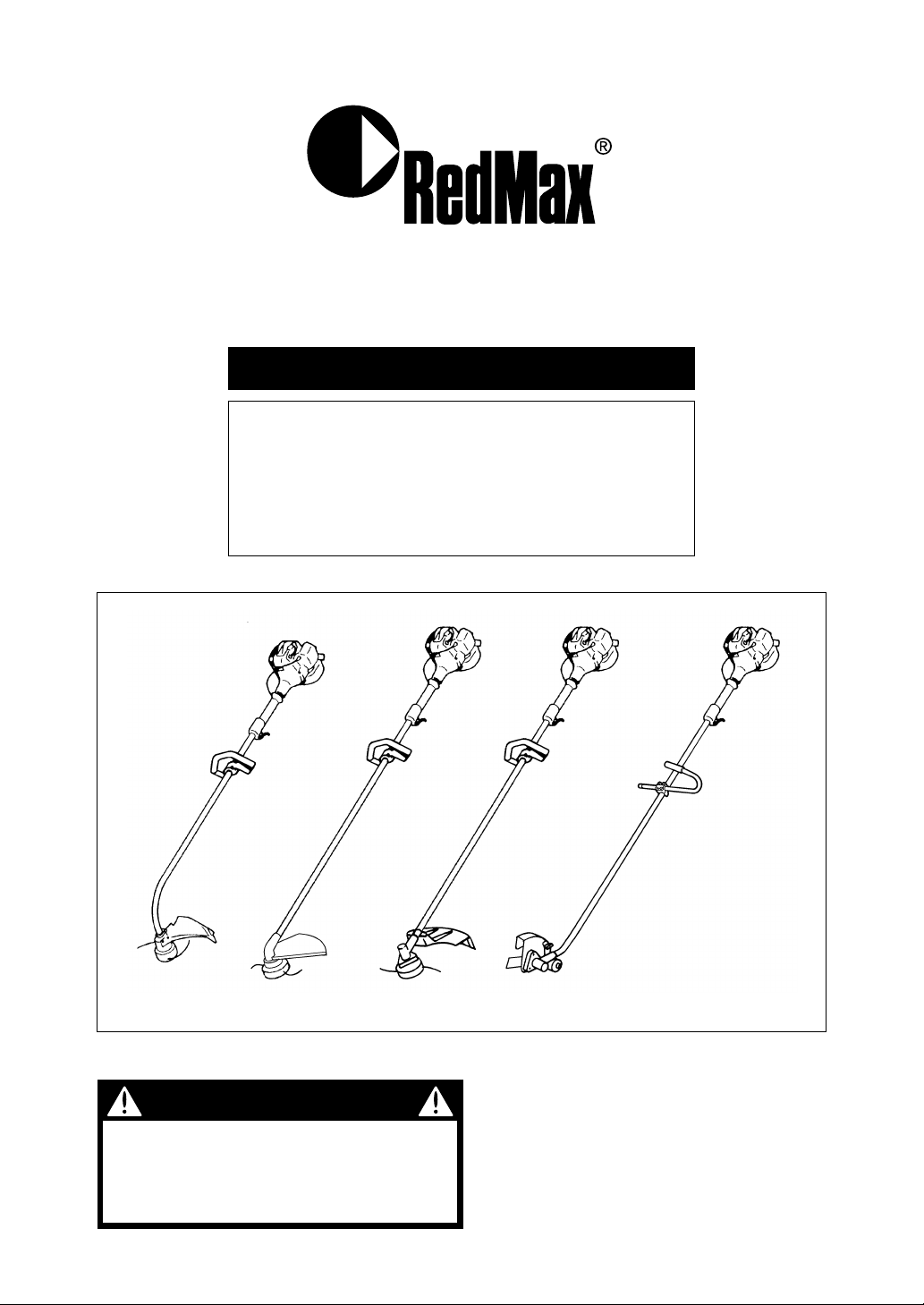

OWNER/OPERATOR MANUAL

TRIMMERS / STICK EDGERS

5850-93110 (9809)

IMPORTANT :

Before operating your RedMax product,

read this manual carefully and completely.

BT2200LDC

BC2200E

BC2200LDC

HE2200LDC

BT2200LDC BC2200E BC2200LDC HE2200LDC

Page 2

Page 3

Thank you for choosing a RedMax trimmer / stick edger.

This manual will provide you with full understanding of the

necessary instructions for assembly, operation and

maintenance of the equipment.

Please read this manual carefully before starting operation.

For continued safe and reliable operation, use ONLY

original RedMax parts and accessories, Adhere to all notes

and warnings.

CONTENTS

FOR SAFE OPERATION · · · · · · · · · · · · · · · · · · · · · · 2

SETUP · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

FUEL · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

OPERATION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

SPECIFICATIONS · · · · · · · · · · · · · · · · · · · · · · · · · · 13

PARTS LIST · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 14

Page 4

FOR SAFE OPERATION

■ KNOW YOUR UNIT

1.Read this Owner's Manual carefully until

you completely understand and can follow

all safety rules, precautions, and operating

instructions before operating the unit.

2.Restrict your unit to users who understand

and follow all safety rules, precautions, and

operating instructions found in this manual.

Children should not be allowed to operate

this unit.

■ PLAN AHEAD

1.Dress in a long-sleeved shirt and long

pants. Wear protective gloves and shoes.

Eye and ear protection should be worn at

all times. Do not wear loose clothing,

jewelry, short pants or sandals. Do not go

barefoot.

2.Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the work area. Establish

a safe method for gaining your attention

during operation. Be careful if you are

approached.

3.Do not operate the unit when you are tired,

ill or upset; or if you are under the influence

of alcohol, drugs, or medication.

4.Inspect the work site before each use.

Remove all debris and objects that could be

thrown, become entangled in the cutting

head, or cause damage during operation.

■ HANDLE FUEL WITH CAUTION

1.Eliminate all sources of sparks or flame

(including smoking, open flames, or work

that could cause sparks) in the area where

fuel is mixed, poured, or stored.

2.Mix, pour, and store fuel in an approved,

marked container and in a well ventilated

area.

3.Be sure to stop the engine before refueling

the unit.

4.Do not smoke while handling fuel or while

operating the unit.

5.Wipe up all spills before starting the engine.

Move at least 10 feet (3 meters) away from

fuel and refueling site before starting the

engine.

■ OPERATE YOUR UNIT SAFELY

1.Inspect the entire unit before each use for

worn, loose, or damaged parts. Do not use

until the unit is in proper working order.

2.Keep the handles free of oil and fuel.

3.Never start or run the engine inside a

closed room or building, Exhaust fumes

contain dangerous carbon monoxide.

4.Keep the engine idle speed adjusted

properly so that the cutting head comes to a

complete stop when trigger is released.

5.Be sure to stop the engine before refueling,

inspecting or leaving the unit unattended.

6.Always use both hands to hold the unit.

7.Do not use any accessory or attachment

other than those bearing the RedMax mark

and are recommended for the unit.

■ MAINTAIN YOUR UNIT PROPERLY

1.Disconnect the spark plug before

performing all maintenance except for

carburetor adjustment.

2.Use only recommended, genuine

replacement parts to avoid creating hazard

and/or voiding your warranty.

3.Wear protective gloves when handling or

performing maintenance on metal blades.

4.When transporting or storing the unit, drain

fuel from the fuel tank.

5.Do not store the unit or fuel in a closed area

where fuel vapors can reach an open flame

from hot water heaters, furnaces, and so

on.

6.Store the unit in a dry area out of the of

children.

7.All engine service, other than those

explained in this manual, should be

performed by competent service personnel.

Improper service to the muffler and flywheel

could cause serious accidents, resulting in

bodily injury.

2

Page 5

■ HE2200LDC

1.Install the blade guard to the gear case with

the provided 3 screws.

2.Place the blade between the cutter holders

(A) and (B) while locking the gear shaft by

putting the bar , one of the tools provided,

through the key holes on the holder(A) and

the gearcase. Use the socket and the bar

as shown in the picture below to tighten the

mounting nut.

3.Install the J-shaped handle to the shaft tube

and clamp at a position best for your job.

• ADJUSTING HANDLE POSITION

Loosen the handle bracket screws and

reposition the handle to your best operating

position. Re-tighten the screws.

1.Install the driveshaft assembly to the engine

unit. Clamp it securely with the attached

bolt and nut.

2.Connect the throttle cable to the engine.

3.Mount the handle to the driveshaft casing

and clamp it at a position suitable for

operation.

4.Install the debris guard to the bracket with

screws provided.

SETUP

BT2200LDC

Attach the guard above the clamp and slide

it down. Rotate it a half turn to set in place.

BC2200E

BC2200LDC

HE2200LDC

3

Page 6

FUEL

The RedMax engines are lubricated by oil

specially formulated for air-cooled 2-cycle

gasoline engine use. When RedMax oil is not

available, use an anti-oxidant added quality oil

formulated for air-cooled 2-cycle engine use.

RECOMMENDED MIXING RATIO

GASOLINE 32 : OIL 1

Exhaust emission are controlled by the

fundamental engine parameters and

components (eq., carburation, ignition timing

and port timing) without addition of any major

hardware or the introduction of an inert

material during combustion.

These engines are certified to operate on

unleaded gasoline.

The fuel is highly flammable. Do not

smoke or bring any flame or sparks near

fuel.

■ HOW TO MIX FUEL

1.Mix the fuel and oil at 32 : 1

2.Put some of the gasoline into a clean,

approved fuel container.

3.Pour in all of the oil and agitate well.

4.Pour in the rest of gasoline and agitate

again for at least one minute.

5.Put a clear indication on the outside of the

container to avoid mixing up with gasoline

or other containers.

WARING!!!

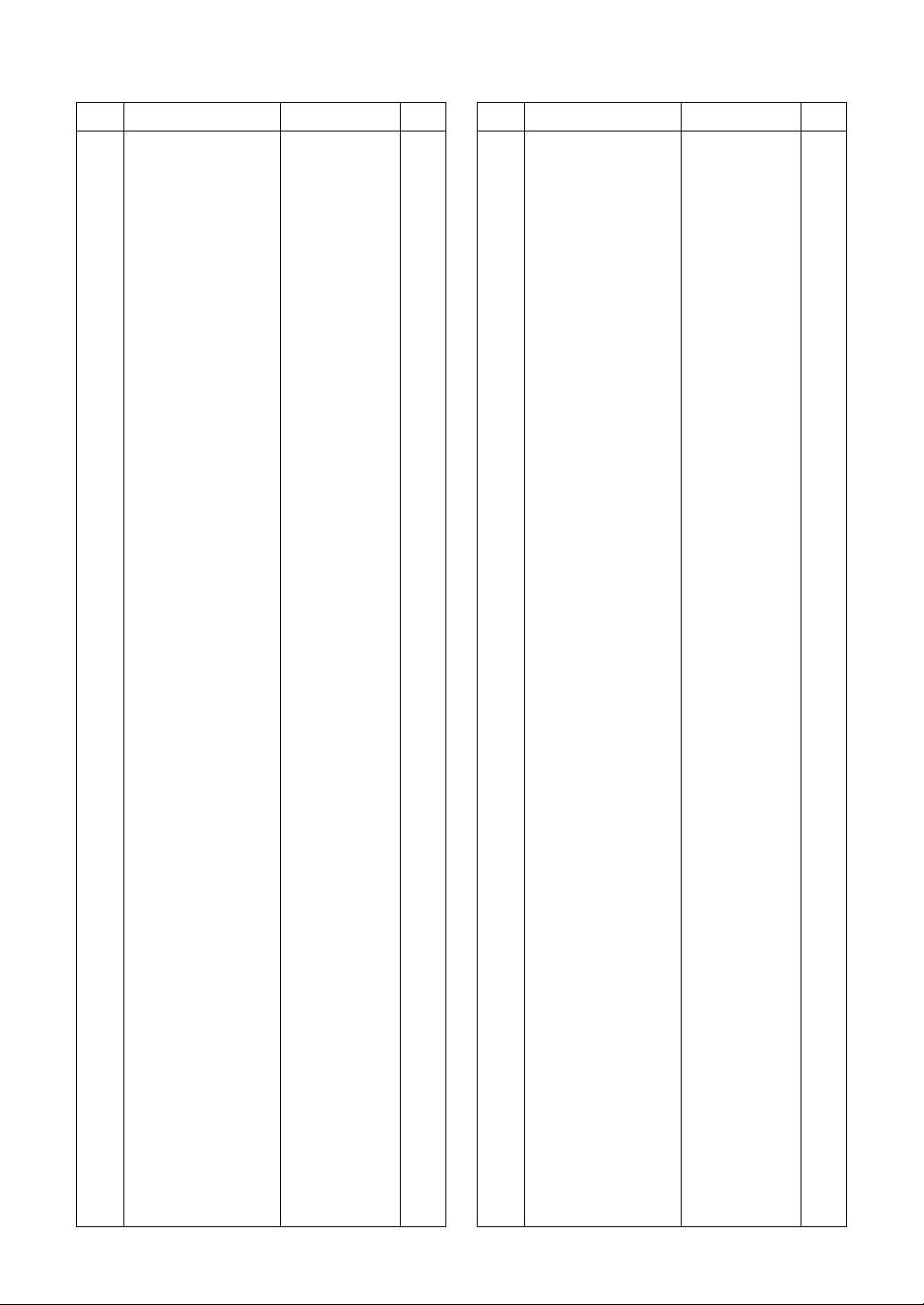

■ FUELING UNIT

1.Untwist and remove the fuel cap. Rest the

cap on a dustless place.

2.Put fuel into the fuel tank to 8O% of the full

capacity.

3.Fasten the fuel cap securely and wipe up

any fuel spillage around the unit.

CAUTION :

1.Select bare ground for fueling.

2.Move at least 10 feet (3 meters) away from

the fueling point before starting the engine.

3.Stop the engine before refueling the unit.

TO KEEP YOUR ENGINE WORKING

EFFICIENTLY

1.FUEL WITH NO OIL (RAW GASOLINE) —

It will cause severe damage to the system.

2.GASOHOL — It can cause deterioration of

rubber and/or plastic parts and disruption of

engine lubrication.

3.OIL FOR 4-CYCLE ENGINE USE or

WATER COOLED 2-CYCLE ENGINE USE

— It can cause spark plug fouling, exhaust

port blocking, or piston ring sticking.

4

Page 7

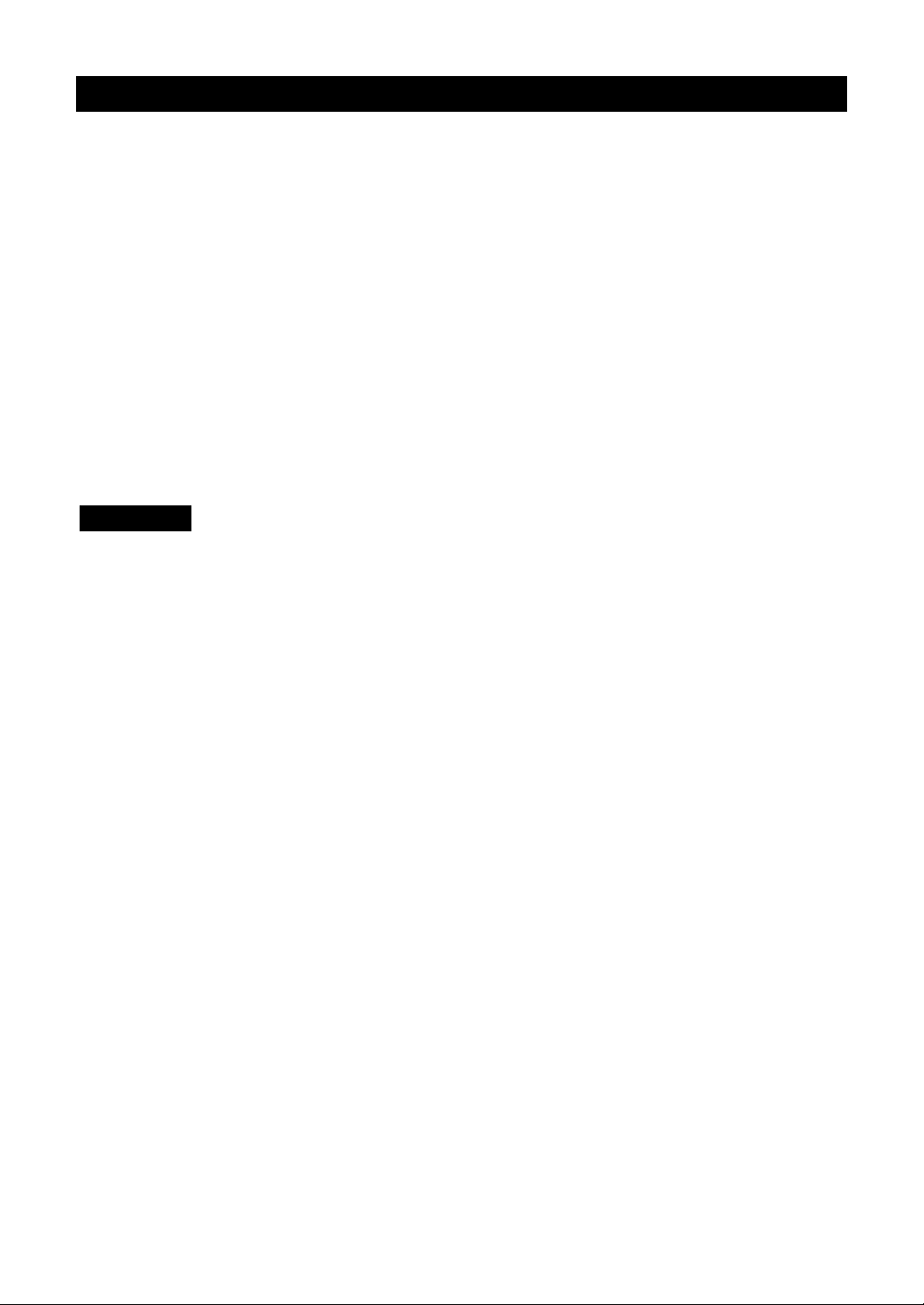

■ STARTING ENGINE

Keep the cutting head off the ground and

clear of surrounding objects as it will start

rotating upon starting of the engine.

1.Press the primer bulb until fuel flows out in

the clear tube (5 to 7 times). Lace the

choke lever in the full choke position. When

restarting the engine right after stopping it,

keep the choke open.

2.Put the ignition switch in the "ON" position.

3.Rest the unit on a flat, firm place. While

pulling the throttle trigger with the little

finger of your left hand, pull the starter rope

quickly.

WARING!!!

NOTE :

Avoid pulling the rope to its dead end or

returning it by releasing the knob. Such

actions can cause starter failures.

4.When the engine has started, move the

choke lever gradually upward to open

choke.

5.Allow the engine to warm up for a half

minute before starting operation.

NOTE :

1.When restarting the engine immediately

after stopping it, leave choke open.

2.Overchoking can make the engine hard to

start due to excess fuel. When the engine

fails to start after several attempts, open

choke and repeat pulling the rope or

remove the spark plug and dry it.

■ STOPPING ENGINE

1.Release the throttle trigger and run the

engine for a half minute.

2.Put the ignition switch in the "OFF" position.

NOTE :

Except for an emergency, avoid stopping the

engine while the trigger is on.

■ ADJUSTING IDLING SPEED

1.When the engine tends to stop frequently at

idling mode, turn the adjusting screw

clockwise.

Idling speed : 2800rpm

2.When the cutting head keeps rotating after

releasing the trigger, turn the adjusting

screw counter clockwise.

NOTE :

Warm up the engine before adjusting the

idling speed.

OPERATION

5

Page 8

■ LINE HEAD USAGE

• HOW TO USE

1.Always wear eye protection such as

safety goggles. Never lean over the

rotating cutting head. Rocks or other

debris could be thrown into eyes and

face and cause serious personal Injury.

2.Keep the debris guard attached in place

at all times when the unit is operated.

• TRIMMING GRASS AND WEEDS

Always remember that the TIP of the line

does cutting. You will achieve better results

by not crowding the line into the cutting area.

Allow the unit to trim at its own pace.

1.Hold the unit so the cutting head is off the

ground and tilted about 30 degrees toward

the sweep direction.

2.Use full throttle when cutting.

3.You can avoid thrown debris by sweeping in

the correct direction, I.e., from your right to

the left for BT2200LDC & BC2200E, and

from your left to the right for BC2200LDC.

4.Use a slow, deliberate action to cut heavy

growth. The rate of cutting motion will

depend on the material being cut. Heavy

growth will require slower action than will

light growth.

5.Never swing the unit too hard because you

may lose your balance or control of the unit.

6.Try to control the cutting motion with the hip

rather than placing the full workload on the

arms and hands.

7.Take precautions to avoid wire, grass and

dead, dry, long-stem weeds from wrapping

around the cutting head shaft. Such

materials can stall the cutting head and

cause the clutch to slip, resulting in damage

to the clutch system, if repeated frequently.

WARING!!!

• ADJUSTING LINE LENGTH

Your trimmer is equipped with a bump head

that allows the operator to advance the line

without stopping the engine. When the line

becomes short, lightly tap the head on the

ground while running the engine at full

throttle. Each time the head is bumped, the

line advances about 1 inch (25.4 mm). For

best results, tap the head on bare ground or

hard soil. If line release is attempted in tall

grass, the engine may stall.

NOTE :

Always keep the trimming line fully extended.

Line release becomes difficult as the cutting

line becomes shorter.

OPERATION

6

Page 9

OPERATION

■ METAL BLADE USAGE

NOTE :

Do not use the Metal Cutting Blade for

model BT2200LDC and BC2200E

• Always cut by guiding the head from your

right to left.

• When mowing a wide area, start working

from the left side to avoid interference of cut

grass.

• A metal blade cuts best up to the point 1/3

from the edge. Use that area for cutting

shrubs, tough and thick weeds. For cutting

young grass, you can use up to 2/3 from the

tip of blade.

Note :

Do not use the Metal Cutting Blade for

cutting trees or thick branches. The blade is

designed to cut grass, weeds or shrubs

only.

Working on a slope increases the danger

of losing your balance. Do not use your

unit on a slope until you have mastered its

operation.

FOR SAFE OPERATION ON A SLOPE:

1.Always use anti-slip shoes.

2.Do not work in and/or right after the rain

when the ground is wet and slippery.

3.Do not use your unit on a slope where firm

footholds are not secured.

4.Do not cut material above your waist or

below your ankle.

5.Be sure to stop the engine moving to the

next row.

WARING!!!

The operator must keep his own path of

advance clear due to the possibility of

swinging around and seriously injuring a

bystander or helper.

CONTROLLING BLADE BOUNCE

Blade bounce can cause serious personal

injury. Carefully study this section. It is

important that you understand what causes

bounce, how you can reduce the chance of

bounce and how you can remain in control of

the unit if bounce does occur.

1. What causes blade bounce:

Bounce can occur when the moving blade

contacts an object that it cannot cut.

This contact causes the blade to stop for an

instant and then suddenly move or “bounce”

away from the object that was hit. The

operator can lose control of the unit and the

blade can cause serious personal injury to the

operator or any person nearby if the blade

contacts any part of the body.

2. How you can reduce the chance of blade

bounce:

a.Recognize that bounce can happen. By

understanding and knowing about

bounce, you can help eliminate the

element of surprise.

b.Cut fibrous weeds and grass only. Do

not let the blade contact materials it

cannot cut such as hard, woody vines

and brush or rocks, fences, metal, etc.

c.Be extra prepared for bounce if you must

cut where you cannot see the blade

making contact such as in areas of

dense growth.

d.Keep the blade sharp. A dull blade

increases the chance of bounce.

e.Cut only at full throttle.

f.Avoid feeding the blade too rapidly. The

blade can bounce away from material

being cut if the blade is fed faster than its

cutting capability.

WARING!!!

Never cut with

this side

Tough weeds

Young grass

7

Page 10

g.Cut only from your right to your left.

h.Keep your path of advance clear of

material that has been cut and other

debris.

3. How you can maintain the best control:

a.Keep a good, firm grip on the unit with

both hands. A firm grip can help

neutralize bounce. Keep your right and

left hands completely around the

respective handles.

b.Keep both feet spread apart in a

comfortable stance and yet braced for

the possibility that the unit could bounce.

Do not overreach. Keep firm footing and

balance.

c.Always use the shoulder harness. Adjust

the harness for comfort before starting

the engine. The harness should be

adjusted so the left hand can

comfortably hold the handlebar grip

approximately waist high.

d.Do not cut material waist high or over to

avoid loss of unit control.

e.Do not swing the unit with such force that

you are in danger of losing your balance.

Stop engine before removing grass or

weed wrappings to avoid injury from

accidental blade rotation.

WARING!!!

TO SHARPEN BLADE :

1.Grind away each cutting edge and its back

evenly and maintain similar shape to

original.

2.Sharpen each cutting edge and make sure

the bottom corner is rounded.

• If edge bottom is finished square, the

blade will tend to crack from the corner

during operation.

• Do not cool the blade with water in case

of using grinder. It may cause cracks on

blade.

WARING!!!

OPERATION

.10"R

.15"R

8

Page 11

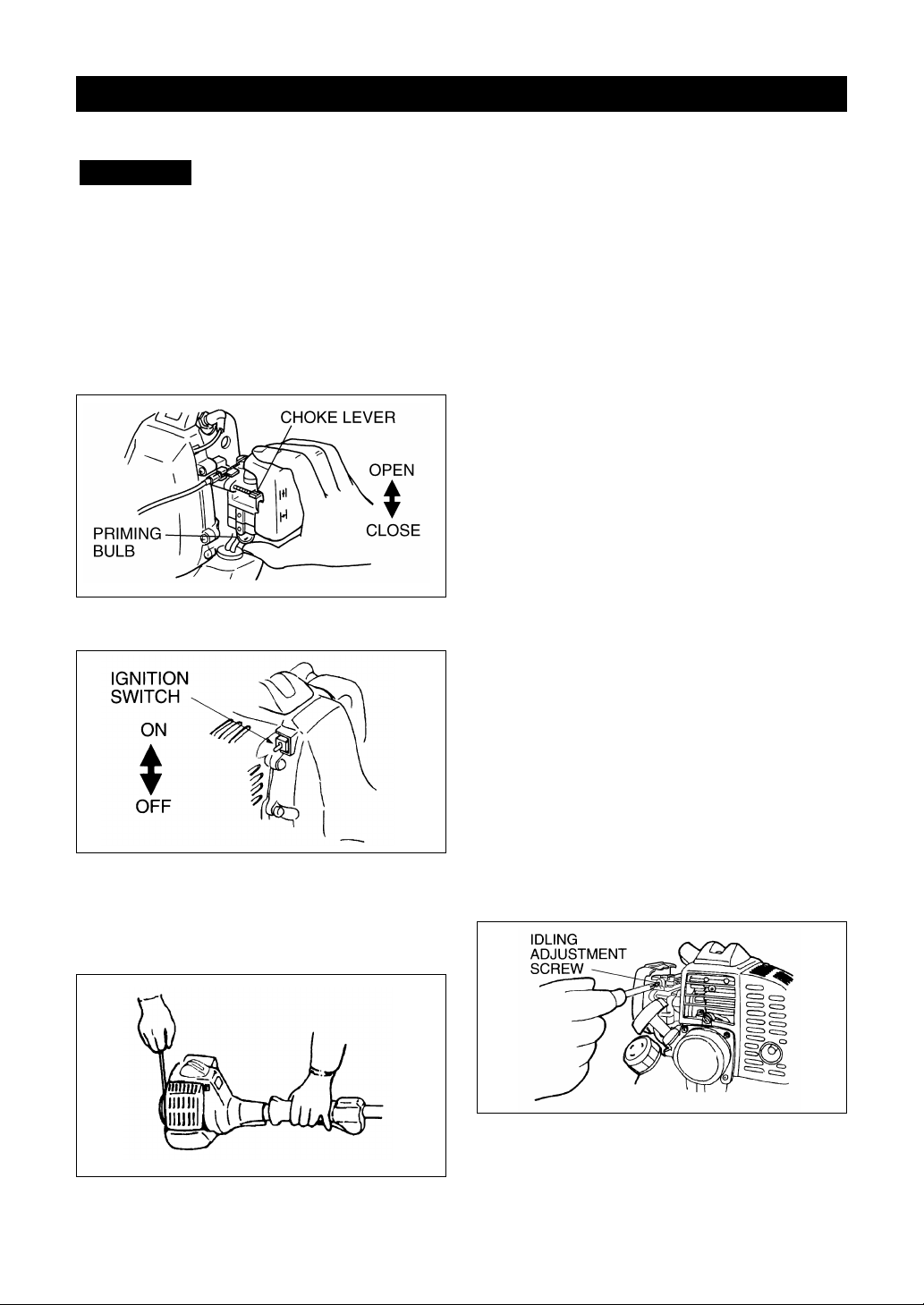

I.

Bump head for BT2200LDC and BC2200E

■ REPLACING TRIMMING LINE

To refill a new trimming line either ;

A : Install the prewound reel #153577 or

B : Rewind the existing reel.

For replacement line, use a diameter of .080

in (2.03 mm). The engine may overheat and

fail if you use a larger line. For safety reason,

do not use metal-reinforced line.

A : REWINDING THE EXISTING SPOOL

• DISASSEMBLING THE HEAD

1.Hold the outer spool with one hand and

unscrew the Bump Knob bolt (counterclockwise for BT2200LDC and BC2200E).

Inspect the captured bolt inside the Bump

Knob to make sure it moves freely. Replace

the Bump Knob if it is damaged.

2.Remove the inner reel. Use a clean cloth to

clean the inner reel, the inside of the outer

spool and the center shaft.

3.Inspect the indexing teeth on the inner reel

and outer spool for wear and, if necessary,

deburr or replace the reel and spool.

• WINDING NEW LINE

1.Take 25 ft (7.6 m) of new trimming line,

insert one end through either hole on the

inner reel and put the other end through

another hole. Hold the line where the both

ends are matching and pull it to make the

loop as small as possible.

2.Wind the line in the direction indicated on

the inner reel, in even and tight layers. Be

sure not to overlap the two ends of the line.

3.Insert each end of the line into the holding

slot.

MAINTENANCE

BT2200LDC

BC2200E

9

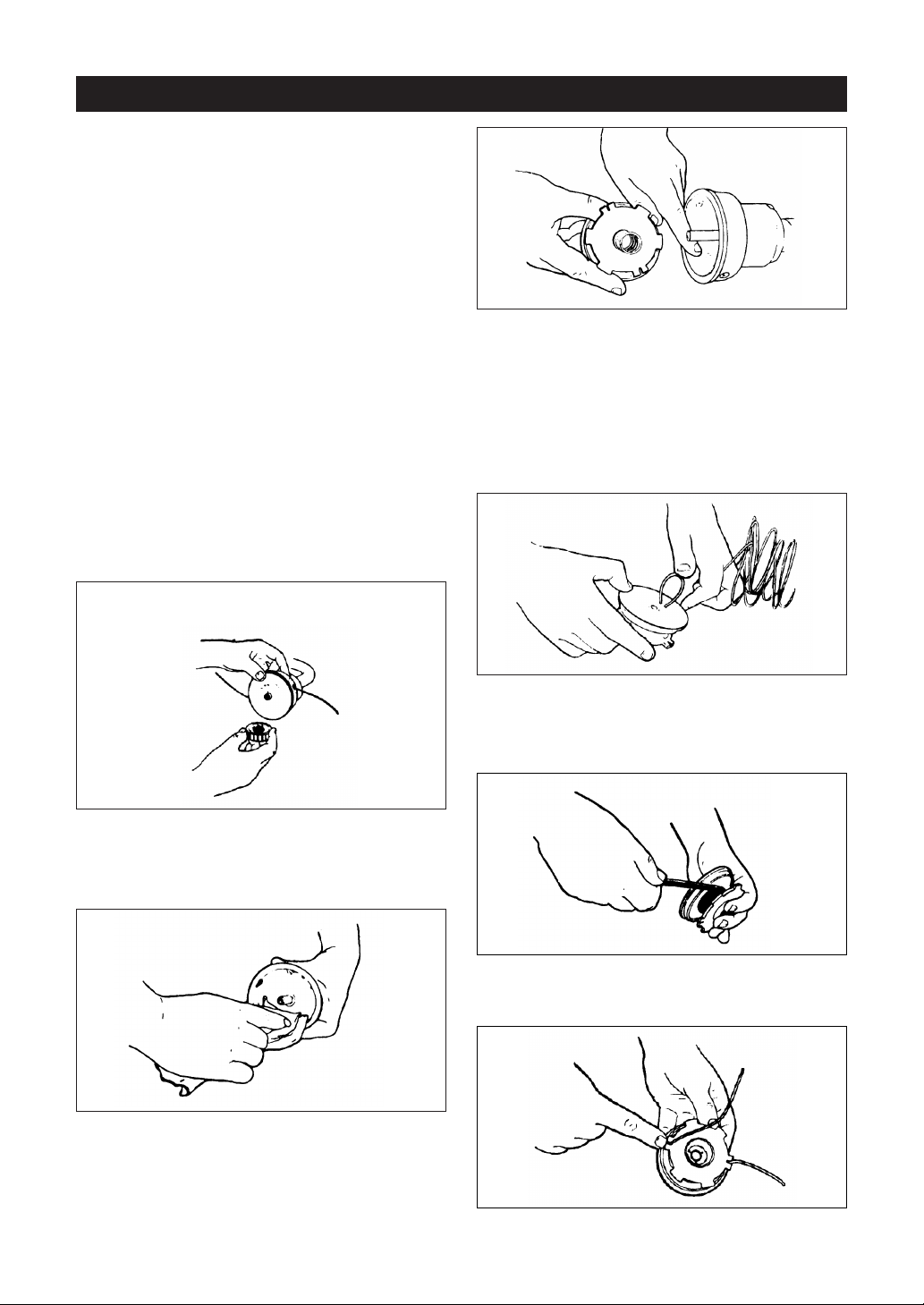

Page 12

• INSTALLING THE REEL

1.Insert each end of the line through the

eyelet on the outer spool. Then pull the end

firmly to release the line from the holding

slot.

MAINTENANCE

1 4 6

2 5 7

3

7.6m

(25')

3.8m

(12.5')

Ø2.4mm

0.095In

2.Hold the inner reel in place and screw in the

Bump Knob bolt in the correct direction

(clockwise for BT2200LDC and

BC2200E).

B : INSTALLING A PREWOUND REEL

1.Follow the instructions in DISASSEMBLING THE HEAD.

2.Follow the instructions in INSTALLING THE

REEL.

II. Bump head for BC2200LDC

10

Page 13

MAINTENANCE

8 11 14

1

2

9

10 12

13

15

THIS

SIDE UP

THIS

SIDE UP

WIND

LINE

11

Page 14

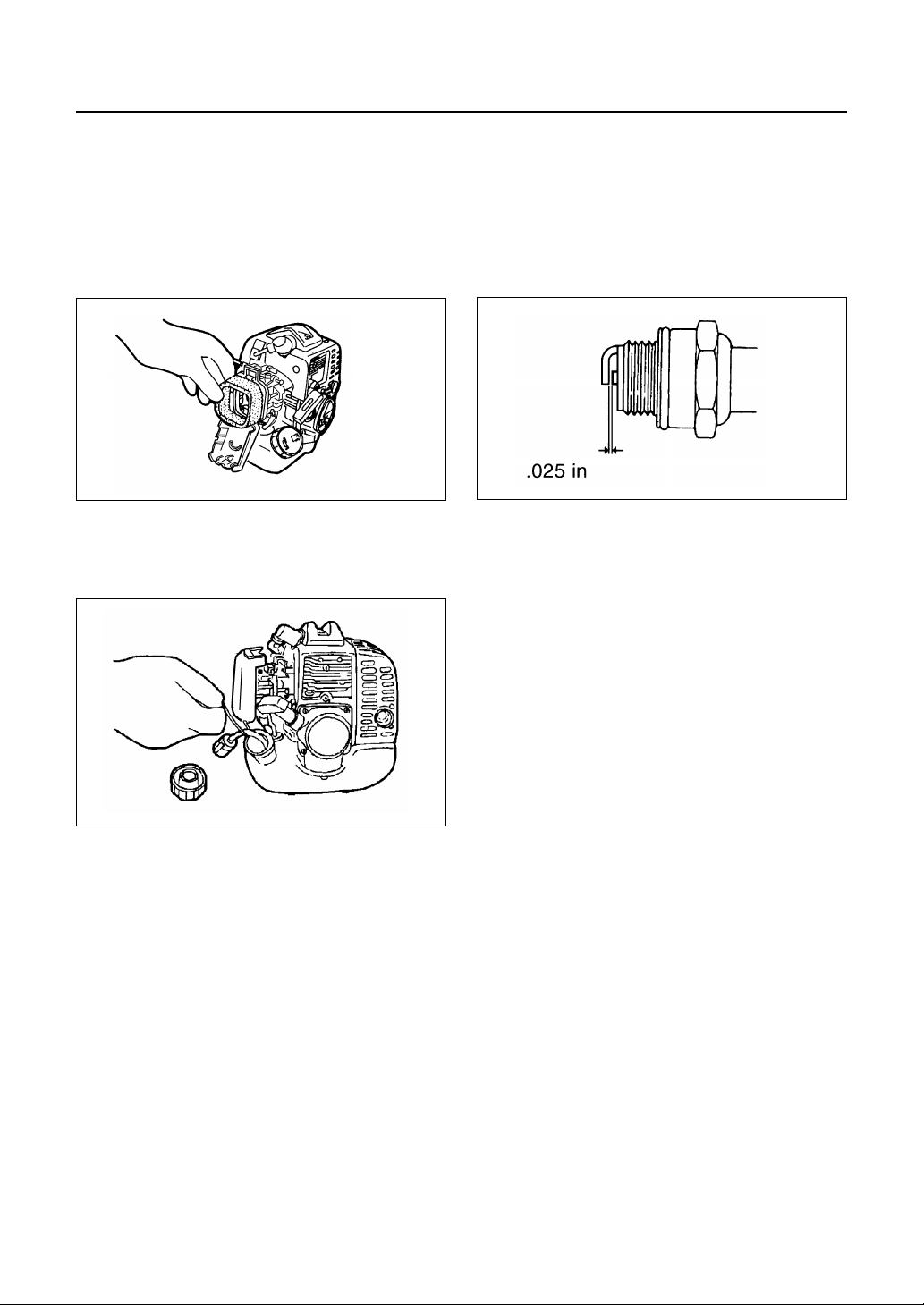

■ SPARK PLUG

Starting failure and mis-firing are often caused

by a fouled spark plug. Periodically clean the

spark plug and check that the spark gap is

within the correct range.

For a replacement plug, use Champion

RCJ6Y or the equivalent.

■ STORAGE

Old fuel left in the carburetor may cause

starting failure. Before storing the unit, empty

the fuel tank and start the engine and run it on

until it stops by itself.

■ AIR FILTER

The air filter, if clogged, will reduce the engine

performance. Every 30 days, check and clean

the filter element in warm, soapy water as

required. Dry completely before installing. If

the element is broken or shrunk, replace with

a new one.

■ FUEL FILTER

When the engine runs short of fuel supply,

check the fuel filter for blockage.

MAINTENANCE

12

Page 15

■ BT2200LDC

Overall size (LxWxH) ···························································································62.2x9.7x17.9 (in)

Dry weight ·························································································································10.1 (lbs)

Engine Type ························································································Air-cooled 2-stroke gasoline

Model ············································································································Zenoah G22L

Displacement ·······································································································22.5 (cc)

Max. output ························································································0.9 (HP) at 7000 rpm

Idling speed ·········································································································2800 rpm

Operating speed (with standard head) ·································································8300 rpm

Fuel ·························································································Mixture (Gasoline 32 : Oil 1)

Fuel tank capacity ···············································································································20 (fl.oz)

Transmission·Centrifugal clutch,Flex.driveshaft Reduction ratio ·································No reduction

Cutting head rotating direction ·······························································Clockwise (Operator view)

■ BC2200E

Overall size (LxWxH) ···························································································67.3x9.7x13.8 (in)

Dry weight ·························································································································10.6 (lbs)

Engine Type ························································································Air-cooled 2-stroke gasoline

Model ·············································································································Zenoah G22L

Displacement ········································································································22.5 (cc)

Max. output ························································································0.9 (HP) at 7000 rpm

Idling speed ·········································································································2800 rpm

Operating speed (with standard head) ·································································7600 rpm

Fuel ·························································································Mixture (Gasoline 32 : Oil 1)

Fuel tank capacity ···············································································································20 (fl.oz)

Transmission·Centrifugal clutch,Flex.driveshaft Reduction ratio ···············································1.00

Cutting head rotating direction ································································Clockwise (Operator view)

■ BC2200LDC

Overall size (LxWxH) ·························································································68.5x10.2x13.2 (in)

Dry weight ··························································································································11.8 (lbs)

Engine Type ························································································Air-cooled 2-stroke gasoline

Model ·············································································································Zenoah G22L

Displacement ········································································································22.5 (cc)

Max. output ························································································0.9 (HP) at 7000 rpm

Idling speed ·········································································································2800 rpm

Operating speed (with standard head) ·································································7000 rpm

Fuel ·························································································Mixture (Gasoline 32 : Oil 1)

Fuel tank capacity ···············································································································20 (fl.oz)

Transmission·Centrifugal clutch,Flex.driveshaft Reduction ratio ···············································1.23

Cutting head rotating direction ···················································Counter clockwise (Operator view)

■ HE2200LDC

Overall size (LxWxH) ·························································································63.6x16.7x14.2 (in)

Dry weight ·························································································································12.6 (lbs)

Engine Type ························································································Air-cooled 2-stroke gasoline

Model ·············································································································Zenoah G22L

Displacement ········································································································22.5 (cc)

Max. output ························································································0.9 (HP) at 7000 rpm

Idling speed ·········································································································2800 rpm

Operating speed (with standard blade)·····················································7000~11000 rpm

Fuel ·························································································Mixture (Gasoline 32 : Oil 1)

Fuel tank capacity ···············································································································20 (fl.oz)

Transmission·Centrifugal clutch,Flex.driveshaft Reduction ratio ···············································1.23

Cutting head rotating direction ···················································Counter clockwise (Operator view)

SPECFICATIONS

13

Page 16

Fig.1 TRIMMER UNIT FOR BT2200LDC

Key# Description Part Number Q'ty

PARTS LIST

Fig.1 TRIMMER UNIT FOR BT2200LDC

17 Guard mount screw 153318 1

18 Guard ass'y 683445 1

19 Blade ass'y 682061 1

20 Anti-rotation screw 145569 1

21 Spool shaft 153313 1

22 Outer spool ass'y 153619 1

23 Eyelet 145566 2

24 Retainer (10 pack) 610660 1

25 Spring 610317 1

26 Inner reel 153600 1

27 Bump head knob ass'y 153066 1

28 Throttle cable comp. 6502-82100 1

29 Decal

—————

1

Key# Description Part Number Q'ty

1 Curved shaft ass'y

—————

1

2Flex.drive shaft

—————

1

3 Throttle housing ass'y 181125 1

4 Throttle lever 180975 1

5Screw 145569 1

6Screw 147544 5

7 Spring 610314 1

8 Handle ass'y 6462-14100 1

9 Handle 6462-14310 1

10 Clamp 6462-14320 1

11 Screw 0263-90535 4

12 Cutting head ass'y 147823 1

13 Lower clamp ass'y 153597 1

14 Retaining ring 145570 1

15 Washer 145567 1

16 Bushing ass'y 153312 1

14

Page 17

Fig.2 TRIMMER UNIT FOR BC2200E

Key# Description Part Number Q'ty Key# Description Part Number Q'ty

1 Straight shaft ass'y

—————

1

2Flex drive shaft

—————

1

3 Throttle housing ass'y 181125 1

4 Throttle lever 180975 1

5 Spring 610314 1

6Screw 145569 1

7Screw 147544 5

8 Handle ass'y 6462-14100 1

9 Handle 6462-14310 1

10 Clamp 6462-14320 1

11 Screw 0263-90535 4

12 Gear box ass'y 180549 1

13 Guard, Cutting head 180548 1

(include item 14)

14 Blade assembly 180553 1

15

Heardware, guard mounting

180547 1

16 Clamp assembly 153597 1

17 Screw, Anti-rotation 145569 1

18 Spool, Outer w/eyelet 153619 1

(include item 20)

19 Eyelet 145566 1

20 Retainer 610660 1

21 Spring 610317 1

22 Reel, inner 153600 1

23

Bump head knob assembly

153066 1

24 Throttle cable comp 6502-82100 1

25 Decal

—————

1

Fig.2 TRIMMER UNIT FOR BC2200E

15

Page 18

Fig.3 TRIMMER UNIT FOR BC2200LDC

Key# Description Part Number Q'ty Key# Description Part Number Q'ty

1 Straight shaft ass'y

—————

1

2Flex.drive shaft

—————

1

3 Gear box ass'y 147488 1

4Screw

————— 1

5 Screw set 147677 1

6Blade driver 147489 1

7

Lower retaining washer

147490 1

8 Throttle housing ass'y 181125 1

9 Throttle lever 180975 1

10 Screw 145569 1

11 Screw 147544 5

12 Spring 610314 1

13 Handle ass'y 6462-14100 1

14 Handle 6462-14310 1

15 Clamp 6462-14320 1

16 Screw 0263-90535 4

17 Cutting head ass'y UBT-200 1

18 Housing UBTR-06 1

19 Eyelet UBT-9 2

20 NUT UBTR-F10 1

21 Spring UBT-4 1

22 Spool UBT-3 1

23 Button UBT-2 1

24 Cover UBT-1 1

25 Guard ass'y 6778-24000 1

26 Guard Comp. 6778-24100 1

27

Blade

6778-24140 1

28 Screw 0263-30512 2

29 Nut 3320-15310 2

30 Clamp 3541-24121 1

31 Bolt 3540-24130 2

32 Washer 0290-20615 2

33 Throttle cable comp. 6502-82100 1

34 Decal

—————

1

Fig.3 TRIMMER UNIT FOR BC2200LDC

16

Page 19

Fig.4 STICK EDGER UNIT FOR HE2200LDC

Key# Description Part Number Q'ty Key# Description Part Number Q'ty

1 Curved shaft ass'y

—————

1

2Flex drive shaft

—————

1

3 Throttle housing ass'y 181125 1

4 Throttle lever 180975 1

5 Spring 610314 1

6Screw 145569 1

7Screw 147544 5

8 Handle bracket ass'y 683295 1

9 Srew

————— 1

10 Tube closure 612021 2

11 Grip 612381 1

12 J-Handle ass'y 180687 1

13 Gear box ass'y 147488 1

14 Screw

————— 1

15 Driver, blade 613217 1

16 Blade 180064 1

17 Retaining washer 613222 1

18 Retaining nut 613221 1

19 Guard Ass'y

6779-24100

1

20 Plate, rubber 6779-24120 1

21 Plate 6779-24130 1

22 Bolt 00225-30512 2

23

Mounting Bolt assambly set

684070 1

24 Guide bracket

6779-24150

1

25 Wheel 613216 1

26

Wheel mounting bolt ass'y

684068 1

27 Adjustment knob set 684069 1

28 Throttle cable 6502-82100 1

29 Decal

————— 1

Fig.4 STICK EDGER UNIT FOR HE2200LDC

17

Page 20

Fig.5 ENGINE GROUP FOR BT2200LDC. BC2200E. BC2200LDC. HE2200LDC

18

Page 21

Fig.5 ENGINE GROUP FOR BT2200LDC. BC2200E. BC2200LDC.HE2200LDC

Key# Description Part Number Q'ty Key# Description Part Number Q'ty

1Cylinder 5850-12110 1

2 Gasket, base 5500-12211 1

3 Bolt 1850-12130 2

4 Insulator 5850-13160 1

5 Gasket, insulator 5850-13120 1

6 Gasket, carburetor 5850-13130 1

7Screw 5850-13210 2

8 Muffler ass'y 5850-15100 1

10 Arrester 5850-15140 1

11 Screw 5850-15130 2

12 Gasket, muffler 5850-15211 1

13 Plate, muffler 5850-15220 1

14 Screw 5850-15230 1

15 Crankcase comp 5850-21100 1

16 Gasket, case 5500-21140 1

17 Bearing 06030-06001 2

18 Oil seal 2169-21210 1

19 Oil seal 1850-21220 1

20 Snap ring 04065-02812 1

21 Screw 01252-30530 4

22 Piston 5600-41111 1

23 Ring 1100-41210 2

24 Pin 1101-41310 1

25 Snap Ring 1260-41320 2

26 Crankshaft comp 5850-42000 1

27 Key 1000-43240 1

28 Shoe-c 5850-51100 1

29 Washer 5850-51210 1

30 Spacer 5850-51220 1

31 Rotor 5850-71111 1

32 Coil ass'y 5850-71200 1

33 Spacer 1260-71261 2

34 Screw 5850-72160 2

35 Recoil ass'y 5850-75100 1

36 Case comp. 5850-75110 1

37 Reel 5850-75120 1

38 Spring, spiral 5850-75130 1

39 Screw 5850-75140 1

40 Washer 1400-86280 1

41 Rope 5850-75150 1

42 Knob 5850-75160 1

43 Pulley ass'y 5850-75200 1

44 Ratchet 5850-75220 1

45 Spring 5850-75230 1

46 Ring 0308-00040 1

47 Screw 5850-15230 4

48 Bracket 5850-83221 1

49 Carburetor ass'y 5850-81000 1

50 Screw 5850-81110 2

51 Ring 1751-81130 1

52 Swivel 1881-81140 1

53 Valve ass'y ————— 1

54 O-Ring 1751-81240 1

55 Jet 5516-81250 1

56 Diaphragm 3310-81260 1

57 Gasket, pump 1065-81410 1

58 Diaphragm, pump 1065-81420 1

59 Body, pump 1850-81450 1

60 Screen 3306-81380 1

61 Gasket, diaphragm 1850-81470 1

62 Body, purge 1850-81490 1

63 Pump, priming 1751-81510 1

64 Cover, pump 1850-81520 1

65 Screw 1850-81530 4

66 Screw 5850-82310 2

67 O-Ring 5850-83110 1

68 Body ass'y 5850-82100 1

69 Sleeve ————— 2

70 Plate, choke ————— 1

71 Lever, choke ————— 1

72 Screw ————— 1

73 Element 5850-82170 1

74 Cover 5850-82210 1

75 Housing comp 5850-31100 1

76 Bolt 0225-30635 1

77 Nut 0280-10605 1

78 Screw 5850-13210 4

79 Cover, engine 5850-32110 1

80 Screw 5850-15230 1

81 Screw 5850-32170 2

82 Spark plug 5602-73110 1

83 Switch comp 5850-72210 1

84 Tank 5850-85110 1

85 Cap ass'y 5850-85200 1

86 Pipe, Return 5850-85320 1

87 Grommet 5850-85330 1

88 Filter ass'y 5850-85400 1

89 Screw 5850-85510 3

90 Label, recoil 5850-91120 1

91 Tool set 5850-91000 1

92 Socket 3239-91310 1

93 Bar 3582-91330 1

94 Bar 3540-91110 1

19

Page 22

THE CALIFORNIA AIR RESOURCES BOARD AND KOMATSU ZENOAH Co. ARE PLEASED TO

EXPLAIN THE EMISSION CONTROL SYSTEM WARRANTY ON YOUR 1995 AND LATER LAWN AND

GARDEN EQUIPMENT ENGINE. IN CALIFORNIA, NEW UTILITY AND LAWN AND GARDEN

EQUIPMENT ENGINES MUST BE DESIGNED, BUILT AND EQUIPPED TO MEET THE STATE'S

STRINGENT ANTI-SMOG STANDARDS.

KOMATSU ZENOAH Co, MUST WARRANT THE EMISSION CONTROL SYSTEM ON YOUR LAWN AND

GARDEN EQUIPMENT ENGINE FOR THE PERIODS OF TIME LISTED BELOW PROVIDED THERE HAS

BEEN NO ABUSE, NEGLECT OR IMPROPER MAINTENANCE OF YOUR LAWN AND GARDEN

EQUIPMENT ENGINE.

YOUR EMISSION CONTROL SYSTEM. MAY INCLUDE PARTS SUCH AS THE CARBURETOR, THE

IGNITION SYSTEM, AND CATALYTIC CONVERTER. ALSO INCLUDED MAY BE THE HOSES, BELTS,

CONNECTORS AND OTHER EMISSION-RELATED ASSEMBLIES.

WHERE A WARRANTABLE CONDITION EXISTS, KOMATSU ZENOAH Co. WILL REPAIR YOUR LAWN

AND GARDEN EQUIPMENT ENGINE AT NO COST TO YOU INCLUDING DIAGNOSIS, PARTS AND

LABOR.

MANUFACTURER'S WARRANTY COVERAGE:

THE 1995 AND LATER UTILITY AND LAWN AND GARDEN EQUIPMENT ENGINES ARE

WARRANTED FOR TWO YEARS. IF ANY EMISSION-RELATED PART ON YOUR ENGINE IS

DEFECTIVE, THE PART WILL BE REPAIRED OR REPLACED BY KOMATSU ZENOAH Co.

OWNER'S WARRANTY RESPONSIBILITIES:

—AS THE LAWN AND GARDEN EQUIPMENT ENGINE OWNER, YOU ARE RESPONSIBLE FOR

THE PERFORMANCE OF THE REQUIRED MAINTENANCE LISTED IN YOUR OWNER'S

MANUAL. KOMATSU ZENOAH Co. RECOMMENDS THAT YOU RETAIN ALL RECEIPTS

COVERING MAINTENANCE ON YOUR LAWN AND GARDEN ENGINE, BUT KOMATSU

ZENOAH Co. CAN NOT DENY WARRANTY SOLELY FOR THE LACK OF RECEIPTS OR FOR

YOUR FAILURE TO ENSURE THE PERFORMANCE OF ALL SCHEDULED MAINTENANCE.

—AS THE LAWN AND GARDEN EQUIPMENT ENGINE OWNER, YOU SHOULD BE AWARE,

HOWEVER, THAT KOMATSU ZENOAH Co. MAY DENY YOU WARRANTY COVERAGE IF

YOUR LAWN AND GARDEN EQUIPMENT ENGINE OR A PART HAS FAILED DUE TO ABUSE,

NEGLECT, IMPROPER MAINTENANCE OR UNAPPROVED MODIFICATION.

—YOU ARE RESPONSIBLE FOR PRESENTING YOUR LAWN AND GARDEN EQUIPMENT

ENGINE TO A KOMATSU ZENOAH Co. DISTRIBUTION CENTER AS SOON AS A PROBLEM

EXISTS. THE WARRANTY REPAIRS SHOULD BE COMPLETED IN A REASONABLE AMOUNT

OF TIME, NOT TO EXCEED 30 DAYS.

IF YOU HAVE ANY QUESTIONS REGARDING YOU WARRANTY RIGHTS AND RESPONSIBILITIES,

YOU SHOULD CONTACT KOMATSU ZENOAH AMERICA INC. AT (770)-381-5147.

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 23

EMISSION-RELATED PARTS, FOR TWO (2) YEARS FROM THE DATE OF ORIGINAL DELIVERY OF THE MODEL

BT2200LDC OR BC2200E / BC2200LDC OR HE2200LDC UNIT, KOMATSU ZENOAH AMERICA INC. (THE COMPANY),

THROUGH ANY RedMax DEALER, WILL REPAIR OR REPLACE, FREE OF CHARGE, FOR THE ORIGINAL AND EACH

SUBSEQUENT PURCHASER, ANY PART OR PARTS FOUND TO BE DEFECTIVE IN MATERIAL AND/OR

WORKMANSHIP. EMISSION-RELATED PARTS ARE:

THE CARBURETOR ASSY, COIL ASSY, ROTOR AND THE SPARK PLUG,

AIR FILTER, FUEL FILTER, INTAKE MANIFOLD, GASKETS

ALL OTHER PARTS EXCEPT ABOVE PARTS, FOR TWO (2) YEARS OF HOME USE [ ONE (1) YEAR FOR ANY OTHER

USE ] FROM THE DATE OF ORIGINAL ANY DELIVERY OF THE MODEL BT2200LDC OR BC2200LDC OR HE2200LDC

UNIT AND FOR ONE (1) YEAR OF HOME USE [90 DAYS FOR ANY OTHER USE] FROM THE DATE OF ORIGINAL ANY

DELIVERY OF THE MODEL BC2200E UNIT,THE COMPANY, THROUGH ANY RedMax DEALER, WILL REPAIR OR

REPLACE. FREE OF CHARGE, FOR THE ORIGINAL PURCHASER, ANY PART OR PARTS FOUND TO BE DEFECTIVE

IN MATERIAL AND/OR WORKMANSHIP. THIS IS THE EXCLUSIVE REMEDY.

THE PURCHASER SHALL BEAR COSTS OF TRANSPORTING THE UNIT TO AND FROM THE RedMax DEALER.

THE PURCHASER SHALL NOT BE CHARGED FOR DIAGNOSTIC LABOR WHICH LEADS TO THE DETERMINATION

THAT A WARRANTED PART ID DEFECTIVE, IF THE DIAGNOSTIC WORK IS PERFORMED AT THE RedMax DEALER.

THE PURCHASER OR OWNER IS RESPONSIBLE FOR THE PERFORMANCE OF THE REQUIRED MAINTENANCE AS

DEFINED BY THE MANUFACTURER IN THE OWNER/OPERATOR MANUAL.

ANY WARRANTED PART WHICH IS NOT SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE, OR

WHICH IS SCHEDULED ONLY FOR REGULAR INSPECTION TO THE EFFECT OF "REPAIR OR REPLACE AS

NECESSARY" SHALL BE WARRANTED FOR THE WARRANTY PERIOD. ANY WARRANTED PART WHICH IS

SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE SHALL BE WARRANTED FOR THE PERIOD OF

TIME UP TO THE FIRST SCHEDULED REPLACEMENT POINT FOR THAT PART.

ANY REPLACEMENT PART THAT IS EQUIVALENT IN PERFORMANCE AND DURABILITY MAY BE USED IN NONWARRANTY MAINTENANCE OR REPAIRS, AND SHALL NOT REDUCE THE WARRANTY OBLIGATION OF THE

COMPANY.

THE COMPANY IS LIABLE FOR DAMAGES TO OTHER ENGINE COMPONENTS CAUSED BY THE FAILURE OF A

WARRANTED PARTS STILL UNDER WARRANTY.

THIS WARRANTY DOES NOT APPLY TO THOSE UNITS WHICH HAVE BEEN DAMAGED BY NEGLIGENCE OF

INSTRUCTION LISTED IN THE OWNER/OPERATOR MANUAL FOR PROPER USE AND MAINTENANCE OF THE UNITS,

ACCIDENT MISHANDLING, ALTERATION, ABUSE, IMPROPER LUBRICATION. USE OF ANY PARTS OR ACCESSORIES

OTHER THAN THOSE SPECIFIED BY THE COMPANY, OR OTHER CAUSES BEYOND THE COMPANY'S CONTROL.

THIS WARRANTY DOES NOT COVER THOSE PARTS REPLACED BY NORMAL WEAR OR HARMLESS CHANGES IN

THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE LIMITED TO

–TWO (2) YEARS OF HOME USE [ONE (1) YEAR FOR ANY OTHER USE] FROM THE ORIGINAL DELIVERY DATE FOR

THE MODEL BT2200LDC OR BC2200LDC OR HE2200LDC. AND

–ONE (1) YEAR OF HOME USE [90 DAYS FOR ANY OTHER USE] FROM THE ORIGINAL DELIVERY DATE FOR THE

MODEL BC2200E.

LIABILITIES FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE UNDER ANY AND ALL WARRANTIES

ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS OR EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

IF YOU NEED TO OBTAIN INFORMATION ABOUT THE NEAREST SERVICE CENTER, PLEASE CALL KOMATSU

ZENOAH AMERICA INC. AT (770)-381-5147.

IMPORTANT: YOU WILL RECEIVE A WARRANTY REGISTRATION CARD AT TIME OF PURCHASE. PLEASE FILL

OUT THE CARD AND SEND IT TO RedMax / KOMATSU ZENOAH AMERICA WITHIN SEVEN (7) DAYS. BE SURE TO

KEEP A COPY FOR YOUR RECORDS.

RedMax TRIMMER/ STICK EDGER

MODELS BT2200LDC/ BC2200E / BC2200LDC / HE2200LDC

2(1) -YEAR LIMITED WARRANTY

KOMATSU ZENOAH AMERICA INC.

1505 Pavilion Place Suite A

Norcross, Georgia 30093

Page 24

KOMATSU ZENOAH AMERICA INC.

1505 Pavilion Place Suite A

Norcross, Georgia 30093

© Printed in the USA

Loading...

Loading...