Page 1

The engine exhaust from

this product contains

chemicals known to the

State of California to cause

cancer, birth defects or

other reproductive harm.

Les échappements du

moteur de ce produit

contiennent des produits

chimiques connus par l’Etat

de Californie comme étant

responsables de cancers,

d’anomalies congénitales

et d’autres atteintes à

l’appareil reproducteur.

Los gases de escape del

motor de este producto

contienen sustancias

químicas conocidas por

el Estado de California

como causantes de cáncer,

malformaciones en recién

nacidos y otros problemas

de reproducción.

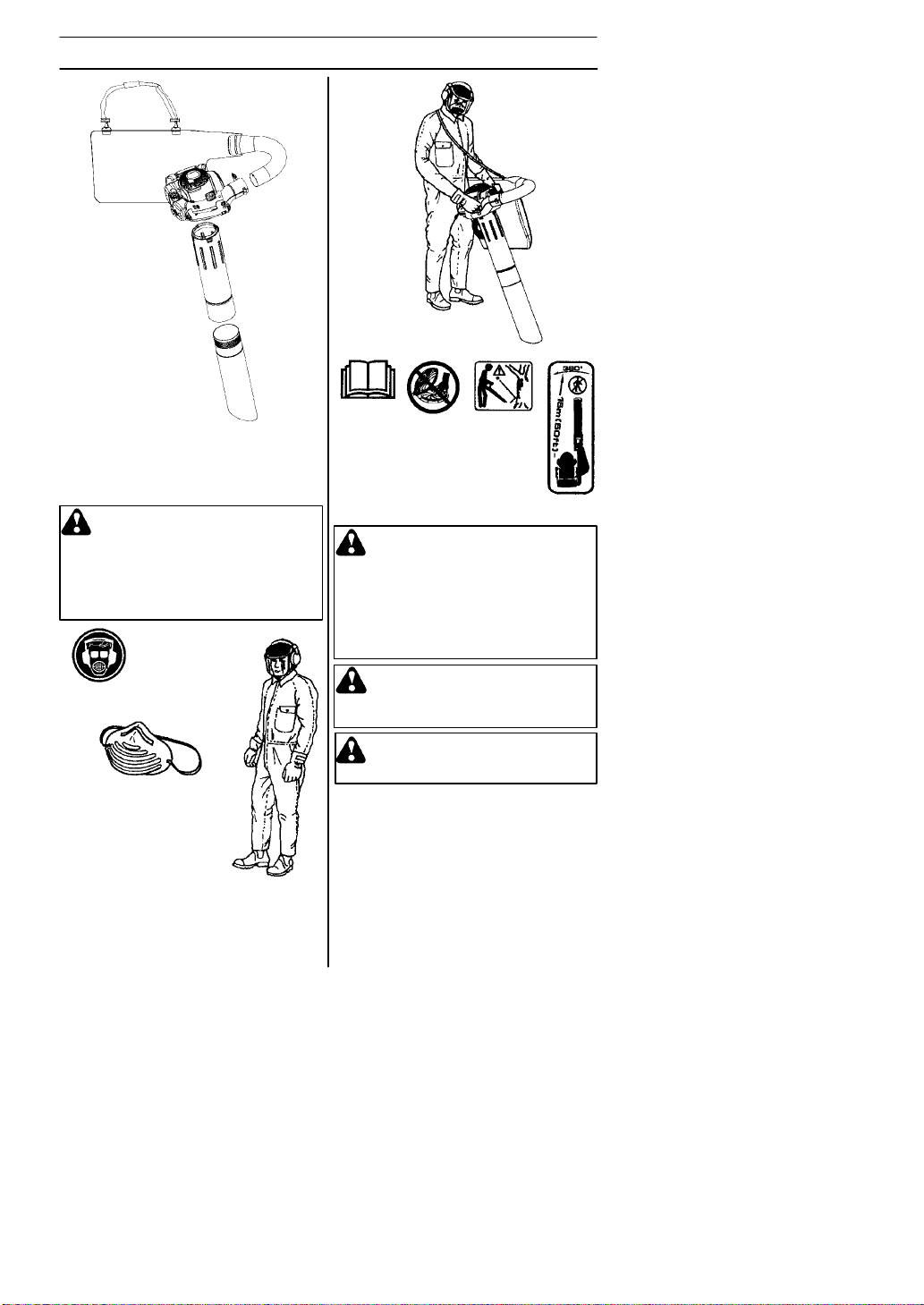

OWNER/OPERATOR MANUAL

MANUEL D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

HB280

BLOWER

SOUFFLEUR

Before using our products,

please read this manual

carefully to understand the

proper use of your unit.

Avant d’utiliser cette

ce produit, veuillez lire

attentivement ce manuel

afin de bien comprendre le

bon fonctionnement de cet

appareil

Antes de usar nuestros

productos, lea detenidamente este manual a fin de

familiarizarse con el uso

correcto de este aparato.

APPLICABLE SERIAL NUMBERS:

ENGINE UNIT 20085100001 and up

NUMEROS DE SERIE APPLICABLES:

MOTEUR 20085100001 et au-delà

NÚMEROS DE SERIE APLICABLES:

UNIDAD DE MOTOR 20085100001

y superior

SOPLADOR

WARNING

WARNING

AVERTISSEMENT

AVERTISSEMENT

545218616 Rev. 1 12/15/08 BRW

ADVERTENCIA

ADVERTENCIA

Page 2

CONTENTS

Contents

Introduction 2...................

Key to symbols 3..................

Safety instructions 4...............

Description 6.....................

Fuel handling 11....................

Starting and stopping 14............

Using the blower 15.................

Maintenance 18....................

Technical data 21...................

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any nonroad engine repair establishment or individual.

The blo wer is used for blowing away leaves

and other debris on the ground. When operating the blower, the operator must stand

with both feet firmly on the ground.

The Emissions Compliance Period referred

to on the Emissions Compliance label indicates the number of operating hours for

which the engine has been shown to meet

Federal emissions requirements.

Category C = 50 hours, B= 125 hours, and

A = 300 hours.

Note the following before

starting:

RedMax/ZENOAH has a policy of continuous product development and therefore

reserves the right to modify the design and

appearance of products without prior

notice. Long--term exposure to noise can

result in permanent hearing impairment.

Always use approved hearing protection.

This operator’s manual describes in detail

how to use and service the blower and

how to carry out regular maintenance. It

also describes which measures should be

taken to achieve maximum safety while

operating the blower, how the safety devices work and how they should be serviced.

Note! The section of the manual that deals

with safety, must be read and understood

by all persons who come in contact with

the blower.

This operator’s manual has been written

for those who need guidance when it

comes to fault tracing, thorough servicing

and carrying out corrective maintenance of

the blower.

There are warning symbols on the blower.

Should any of the warning symbols on the

blower become disfigured or worn, new ones

should be ordered and fitted to the blower as

soon as possible. Note that some of the

warning symbols may be molded in certain

components of the blower.

545218616 Rev. 1 12/15/08

For reference, please fill out the following

information that will be needed for future

servicing of your blower:

Model Number:

Serial Number:

Purchase Date:

Purchased From:

WARNING: Under no circum-

stances may the design of the

machine be modified without the

permission of the manufacturer.

Always use genuine accessories.

Non--authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

Your warranty may not cover

damage or liability caused by the

use of non--authorized accessories or replacement parts.

English---2

Page 3

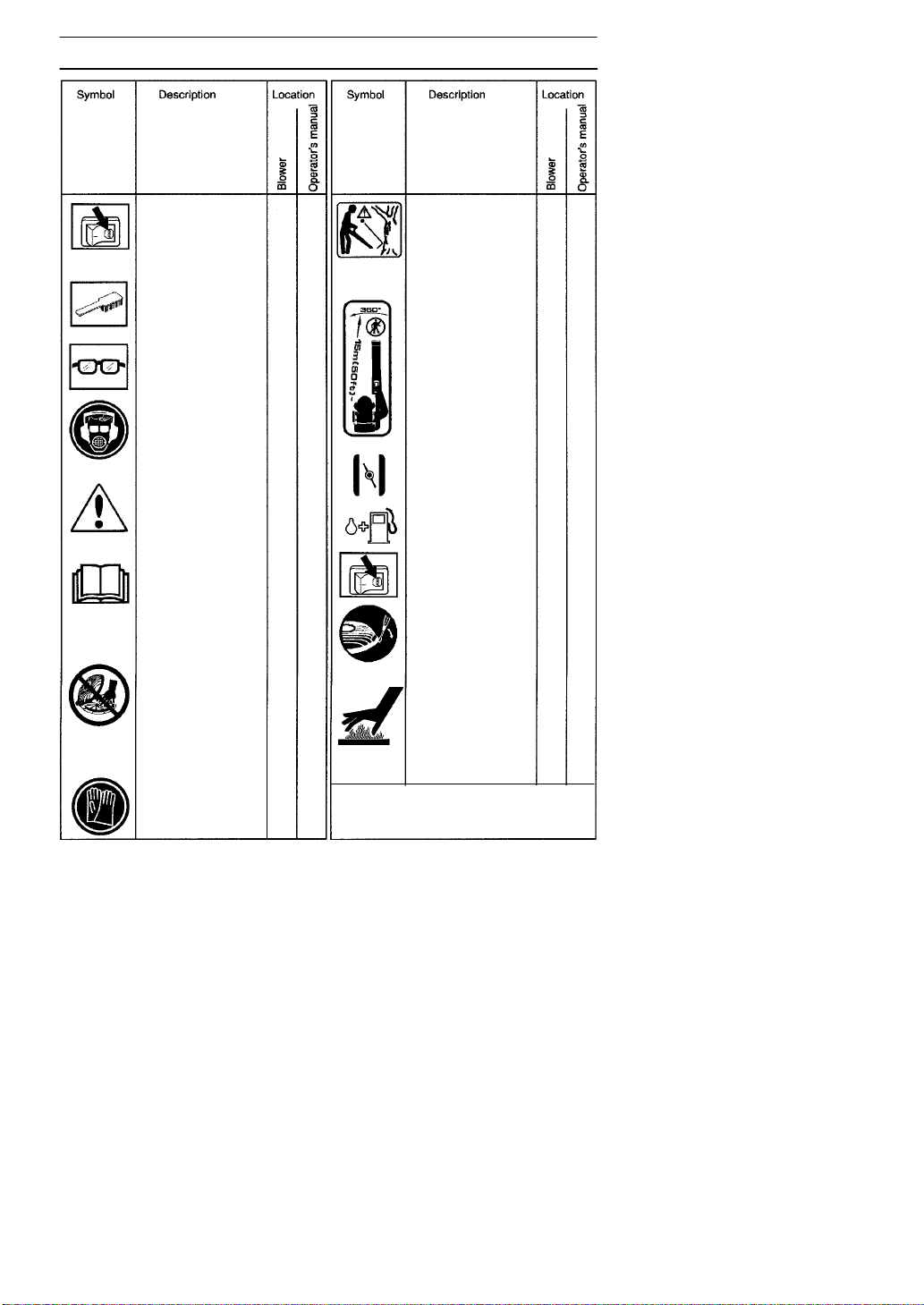

KEY TO SYMBOLS

Checks and/or maintenance shall be

carried out after

having switched off

the engine and disconnected the spark plug.

Cleaning at regular

intervals is required.

Approved protective

goggles or visor must

be worn.

Approved protective

goggles or visor, ear

protection, and face

mask in dusty envir onments must be worn.

WARNING! The blower can be dangerous!

Careless or improper

use can cause serious, even fatal injury.

Read the operator’s

manual carefully and

make sure that you

understand the

contents before using

the blower.

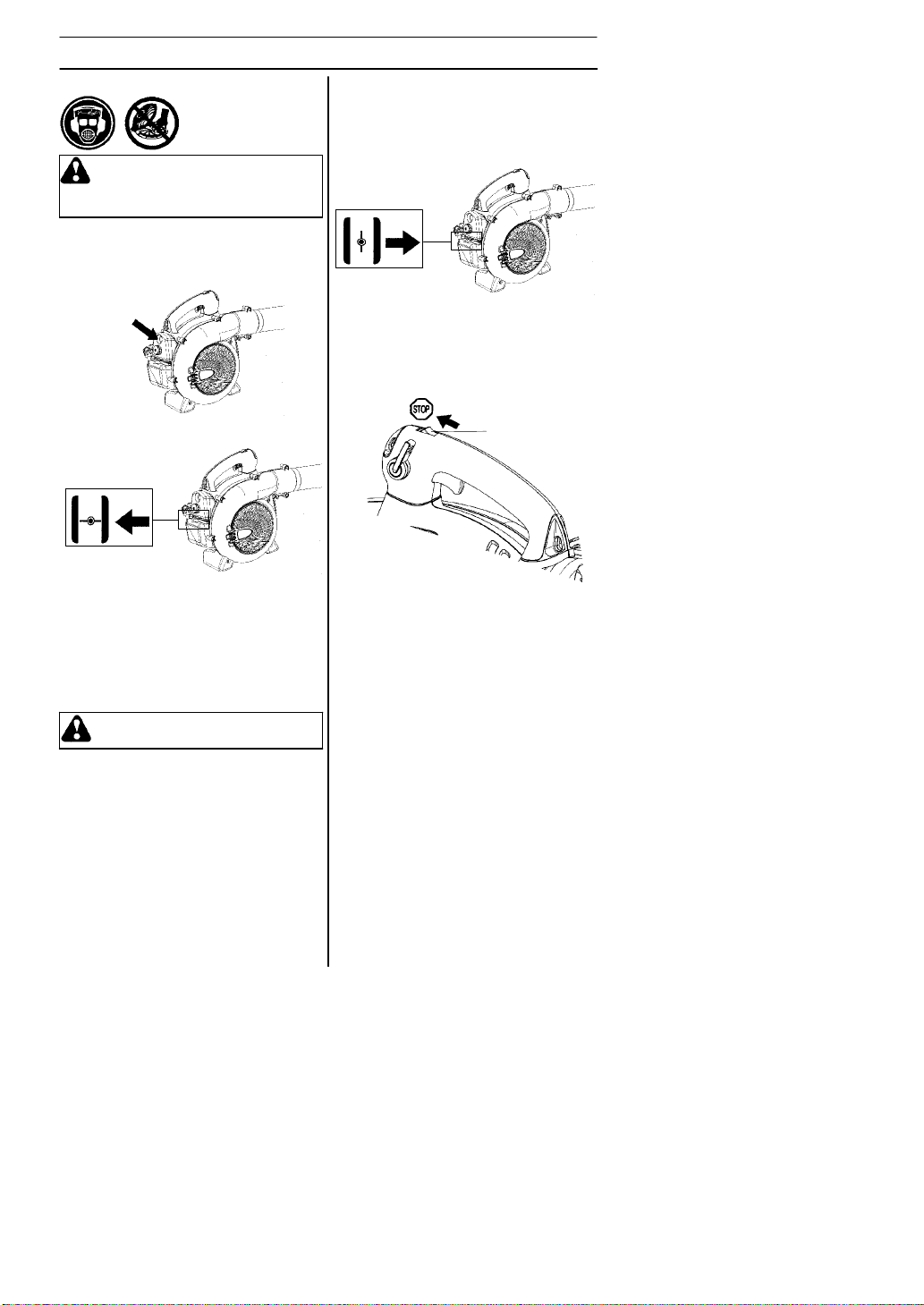

WARNING! Make sure

that the inlet cover is

locked in the closed

position or that the

vacuum tube is mounted on the blower. Never

touch the impeller unlesstheunitisoff,the

impeller has stopped

moving and the spark

plug is disconnected.

Always wear approved,

protective gloves.

X

X

X

XX

XX

XX

XX

XX

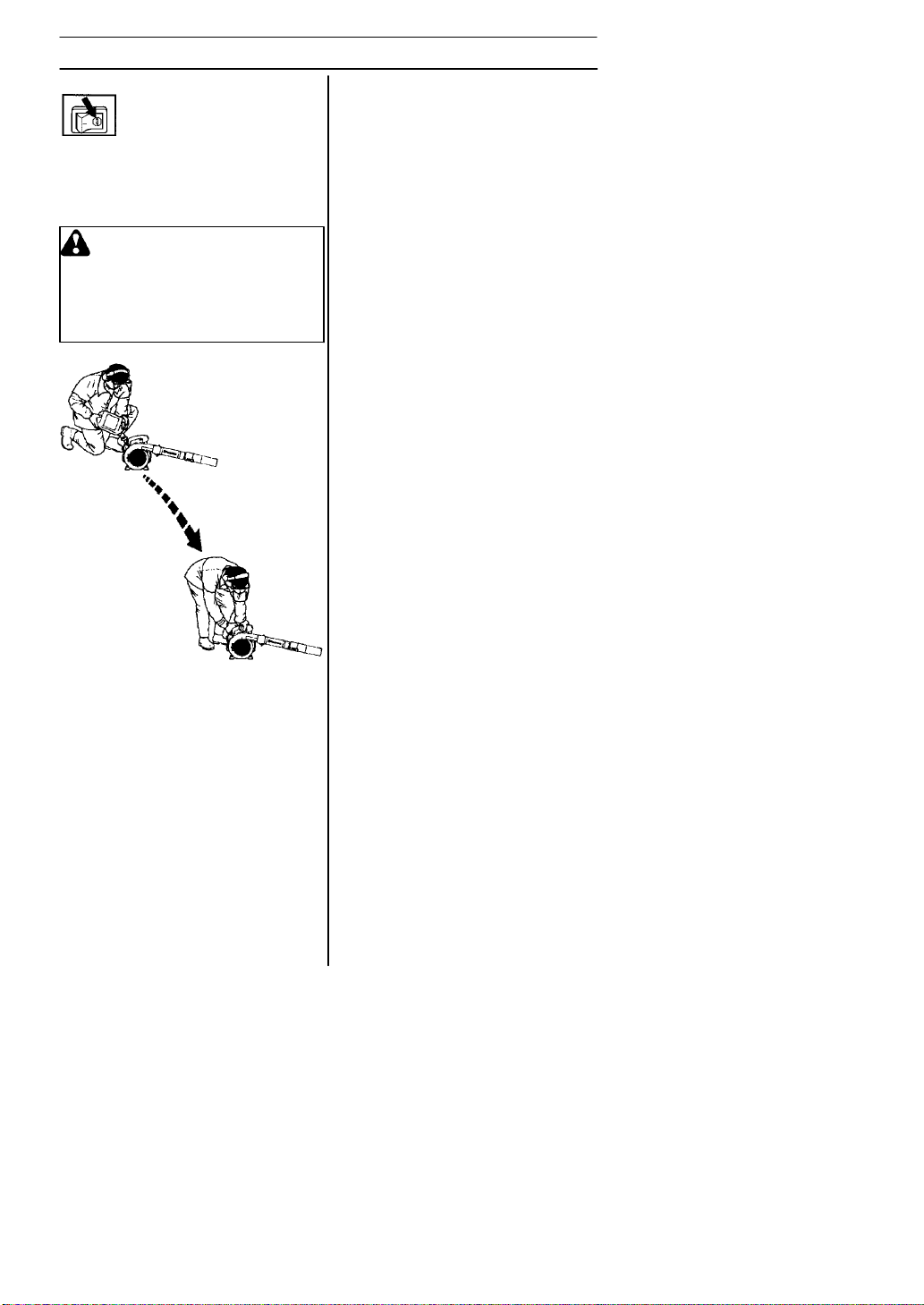

WARNING! The blower

may throw objects at

high velocity that can

ricoch et and hit the operator. This may cause

serious eye damage.

The blower operator

must make sure that

no bystanders or

animals come nearer

than 50 feet (15 meters).

Whenever several

operators are working

inthesameworkarea,

they should maintain a

safe distance of at

least 50 feet (15 meters) from one another.

Choke

Refueling

Stop switch

Instructions on how to

open the inlet cover.

WARNING! The muffler is very hot during

and after use. Do not

touch the muffler,

mufflerguard,orsurrounding surfaces, or

allow combustible

material such as dry

grass or fuel to do so.

Other symbols/decals on the machine

refer to special certification requirements

for certain markets.

XX

XX

X

X

X

X

545218616 Rev. 1 12/15/08

English---3

Page 4

SAFETY INSTRUCTIONS

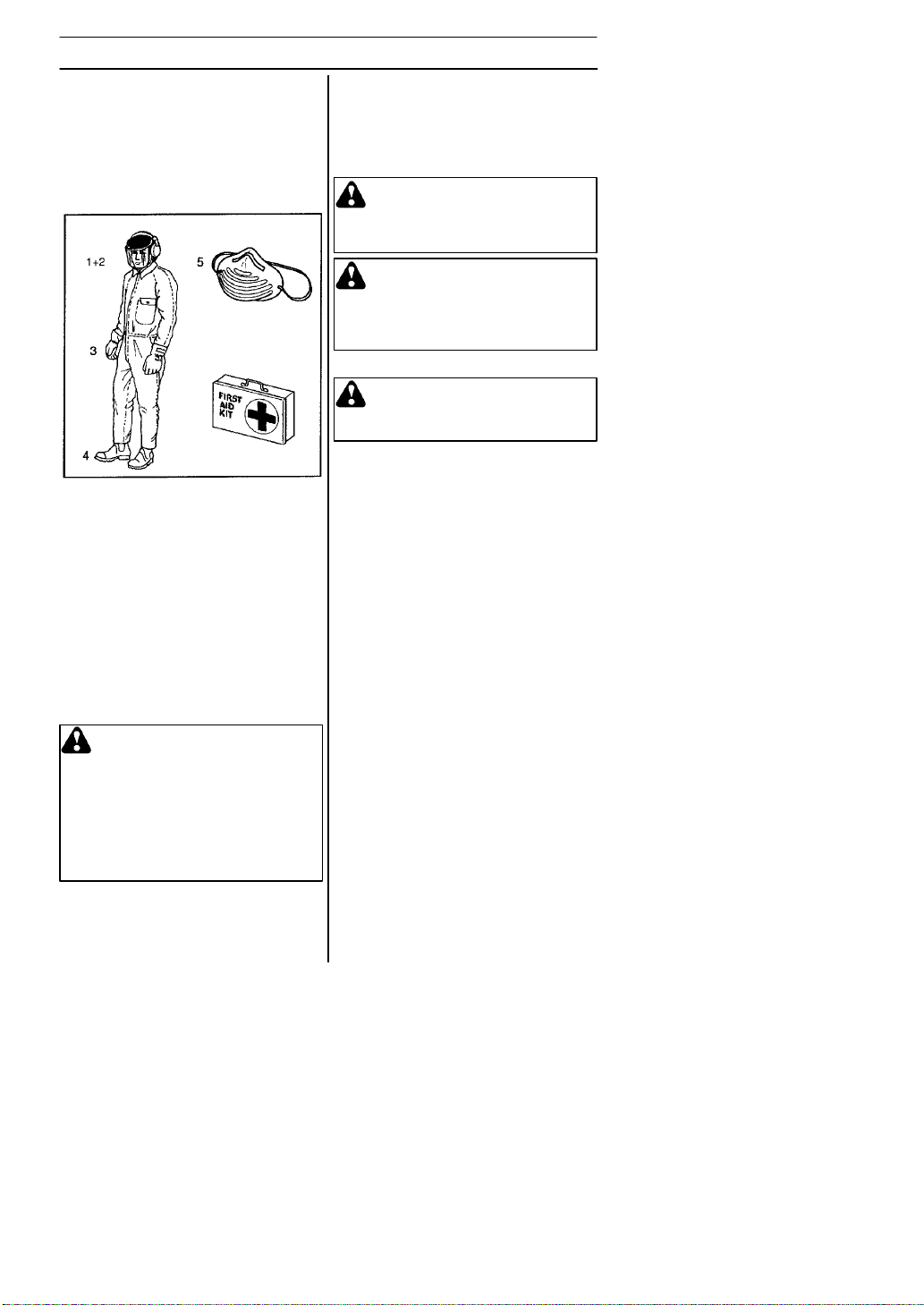

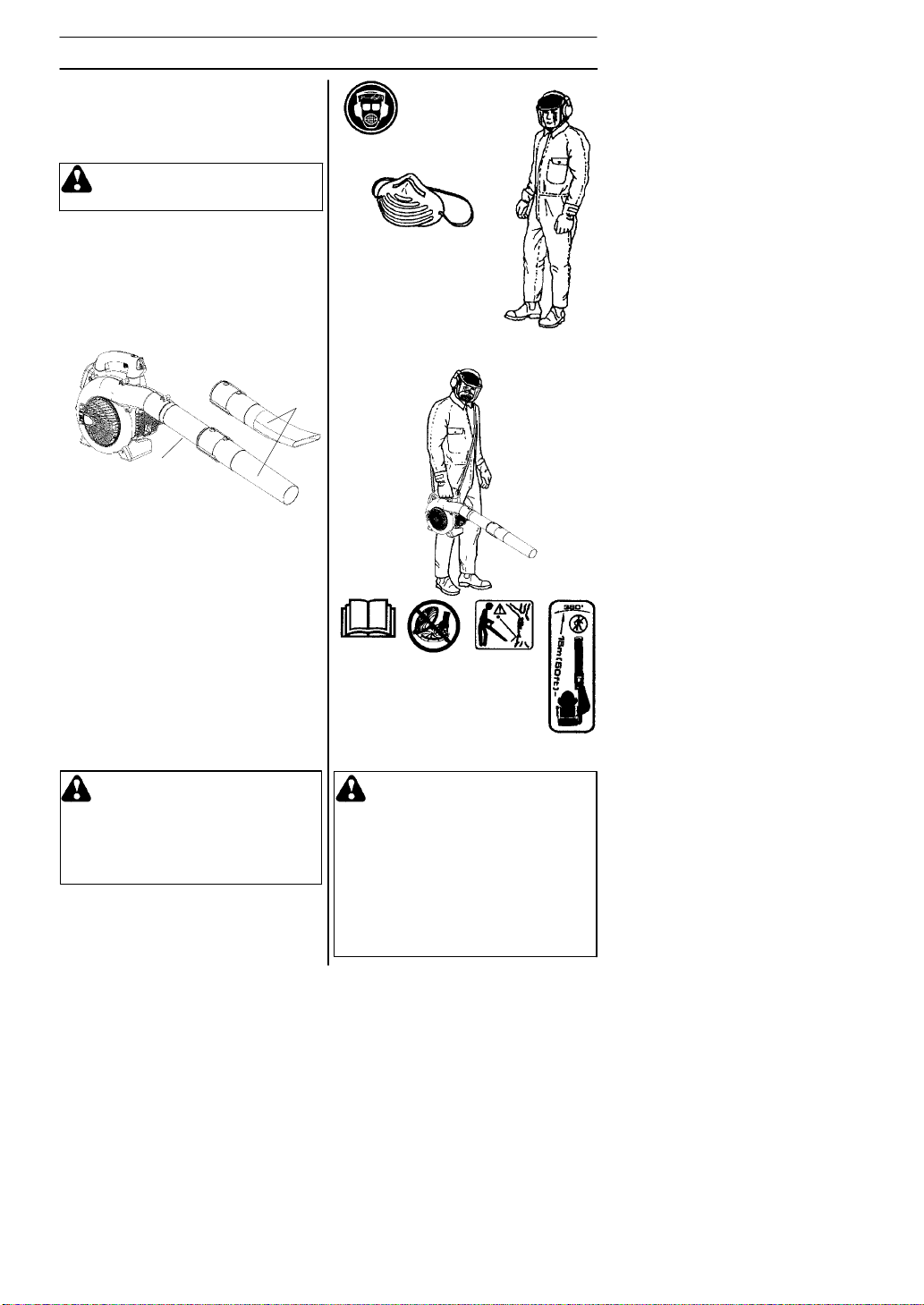

Personal safety equipment

Persons who use the blower shall wear the

following safety equipment:

1. Approved ear protection.

2. Approved eye protection.

3. Approved protective gloves.

4. Boots or work shoes with a non--slip sole.

5. Face mask when operating the blower in

dusty environments.

Personal safety

The following instructions apply to persons

operating the blower:

S The operator shall have read and under-

stood the contents of this manual.

S Do not wear loose clothing, scarves or

neckchains or let long hair hang loose,

since these can be drawn into rotating

parts of the blower and cause injury.

S Do not operate the blower while under

the influence of alcohol, drugs or when

you are tired.

S Do not allow minors to operate the

blower.

S Always have a first aid kit nearby.

Fuel safety

WARNING: The fuel used to run

the blower has the following

dangerous characteristics:

1. Volatile liquid: its vapor and

exhaust fumes are poisonous.

2. Direct contact can cause skin

irritation.

3. It is extremely flammable.

Special safety instructions apply to the type

of fuel used for the blower. These instructions are specified under the Fuel handling

section.

545218616 Rev. 1 12/15/08

Muffler

The muffler is designed to give the lowest

possible noise level and to direct the engine’s exhaust fumes away from the operator. Mufflers fitted with catalytic converters

are also designed to reduce harmful exhaust components.

WARNING: The exhaust fumes

from the engine are hot and may

contain sparks which can start a fire.

Never start the machine indoors or

near flammable material!

WARNING: Mufflers fitted with

catalytic converters become extremely hot during use and after stopping.

This also applies at idling speeds.

Contact can result in burns to the

skin.Beawareoftheriskoffire!

Safety equipment

WARNING: The blower must

never be used if any of the safety

devices or guards are missing,

damaged or not in working order.

The blower is equipped with a number of

safety devices and guards for the prevention of accidents. These are described in

the general description of the blower.

The safety devices and guards also require

regular inspection and maintenance. These

measures and the interval at which they

should be carried out are specified in the

Maintenance section.

Safety while operating the

blower

S Do not allow bystanders or animals to be

in the work area, i.e. 50 feet (15 meters)

from the operator.

S The blower may throw objects at high

velocity that can ricochet and hit the operator. This may cause serious eye damage.

S Never point the blower nozzle toward

people or animals.

S Stop the engine before fitting or disman-

tling accessories or other components.

S Never operate the blower if any of the

guards are missing.

S Never operate the blower in poorly venti-

lated spaces where exhaust fumes might

otherwise be inhaled.

S Stop the engine before refueling. Move

the unit at least 10 feet (3 meters) from

fueling site before attempting to start.

S The catalytic muffler is extremely hot

while the blower is running and after it

has stopped. The same applies when the

blower is running at idling speed. Be

aware of the danger of fire, especially

while operating the blower near flammable materials and/or where flammable

fumes are present.

English---4

Page 5

SAFETY INSTRUCTIONS

S Never touch the spark plug or plug cord

while the engine is in operation. Doing so

may result in being subjected to an electical shock.

S Never touch the muffler, spark plug, other

metallic parts of the engine or engine

cover while the engine is in operation or

immediately after shutting down the

engine. These metallic parts and engine

cover reach high temperatures during

operation and doing so could result in

serious burns.

S Be careful, particularly if left hand opera-

tion is applied. Avoid any direct body contact with inlet cover area. Keep jewelry,

loose clothing, or clothing with loosely

hanging straps, ties, tassels, etc., away

from inlet cover area.

S Do not operate the blower while standing

on a ladder or a stand.

Other safety measures

S Operate the blower only at reasonable

hours, i.e. not early in the morning or late

at night when people might be disturbed.

Comply with times listed in local ordinances. Usual recommendations are 9:00

a.m. to 5:00 p.m., Monday through Saturday.

S T o reduce sound levels, limit the number of

pieces of equipment used at any one time.

S Operate the blower at the lowest possible

throttle setting to do the job.

S Check the condition of the blower before

operation, especially the muffler, air intake

and air filter.

S Use a rake or a broom to loosen ground

debris before blowing.

S Under dusty conditions, slightly spray the

work area with a hose.

S Conserve water by using blowers instead

of hoses for many lawn and garden

applications, including areas such as roof

gutters, screens, patios and gardens etc.

S Watch out for children, pets, open windows

or vehicles, and blow debris safely away.

S Use the full nozzle extension so the air

stream can work close to the ground.

S After using the blower, clean up and

dispose of debris in trash receptacles.

Disposal

S When disposing of your machine and/or

fuel or oil for the machine, be sure to follow

all local regulations.

545218616 Rev. 1 12/15/08

English---5

Page 6

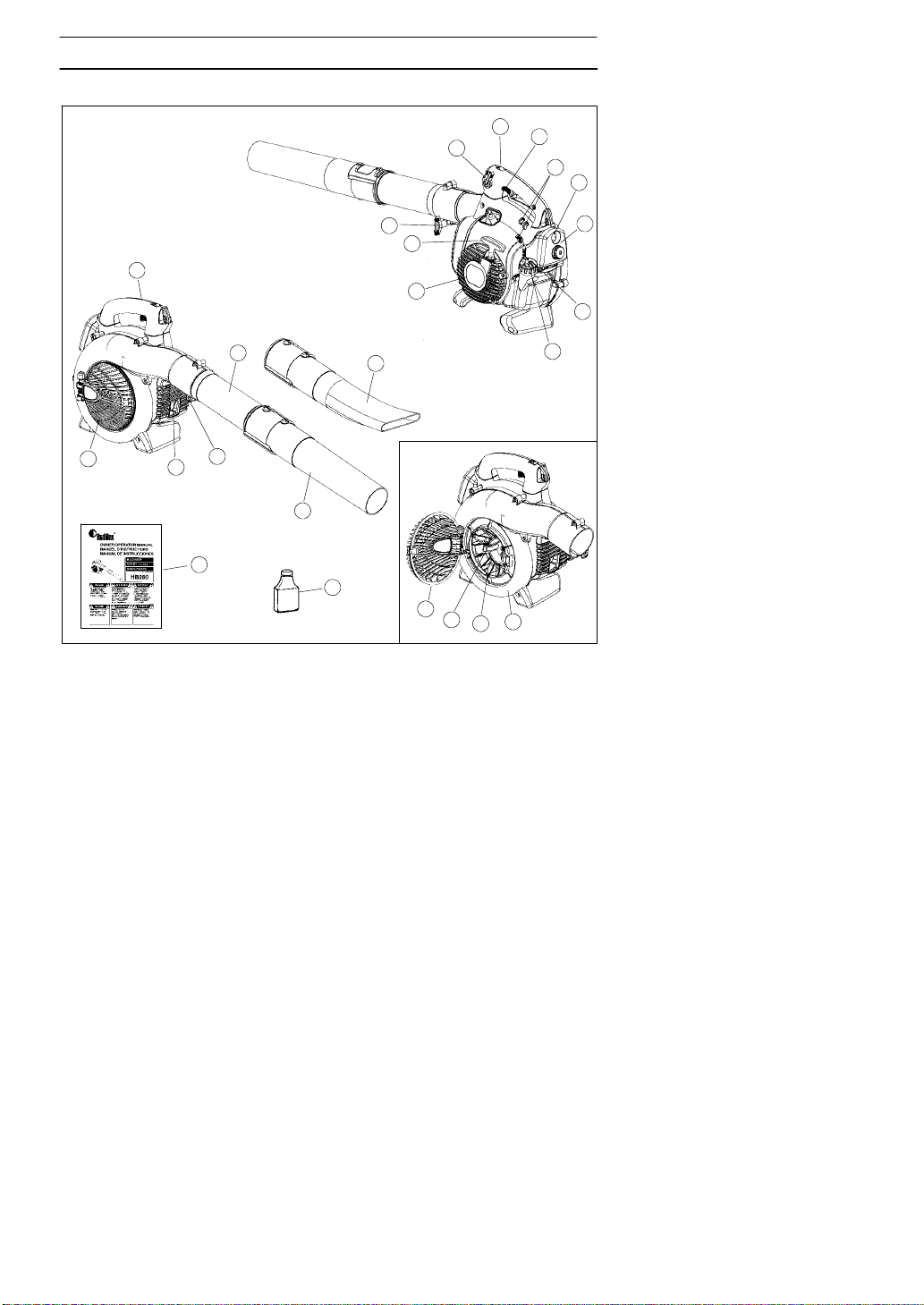

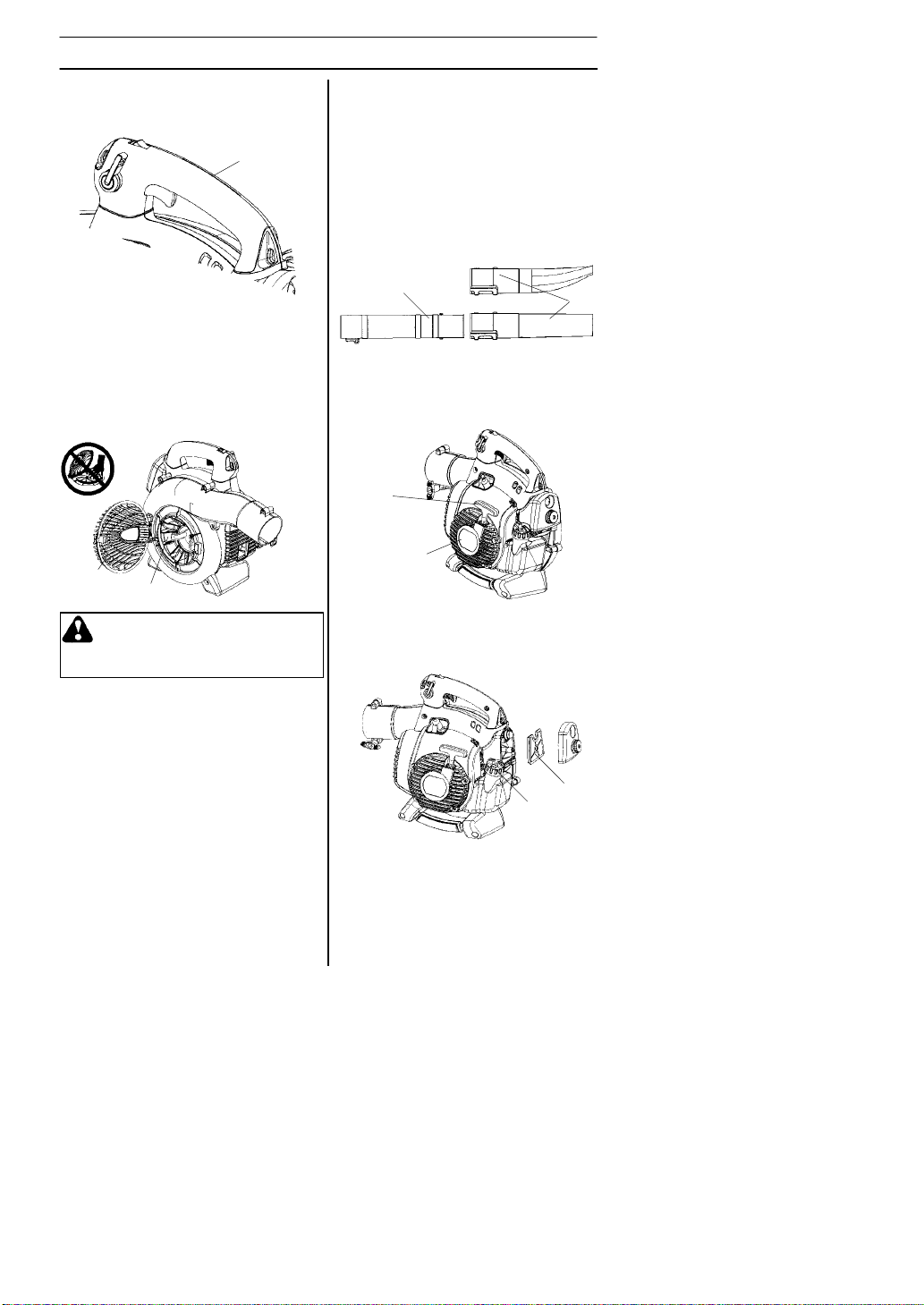

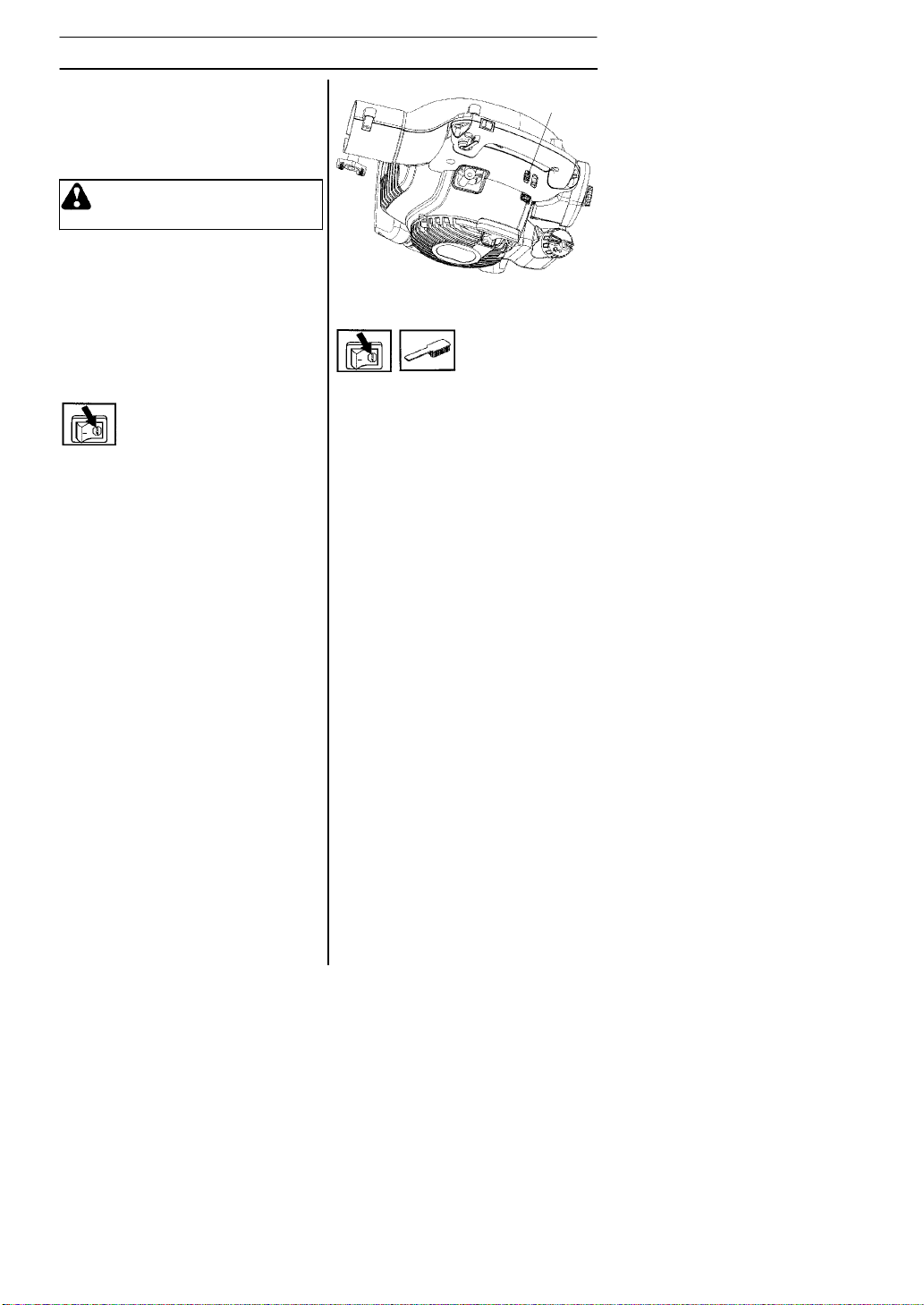

The blower

DESCRIPTION

2

3

1

21

8

15

19

18

20

14

9

1. Throttle trigger 12. Standard nozzle

2. STOP switch 13. High velocity nozzle

3. Variable speed control 14. Blower tube

4. Fan housing 15. Tube clamp bolt

5. Fuel cap 16. Tube clamp nut

6. Air filter 17. Muffler

7. Choke 18. Ground wire

8. Primer bulb 19. Starter handle

9. Inlet cover 20. Starter device

10. Cutters 21. Carburetor adjustment screws

11. Fan impeller 22. Operator’s manual

17

16

12

22

23. 2--stroke engine oil

23

13

9

10

11

6

7

5

4

545218616 Rev. 1 12/15/08

English---6

Page 7

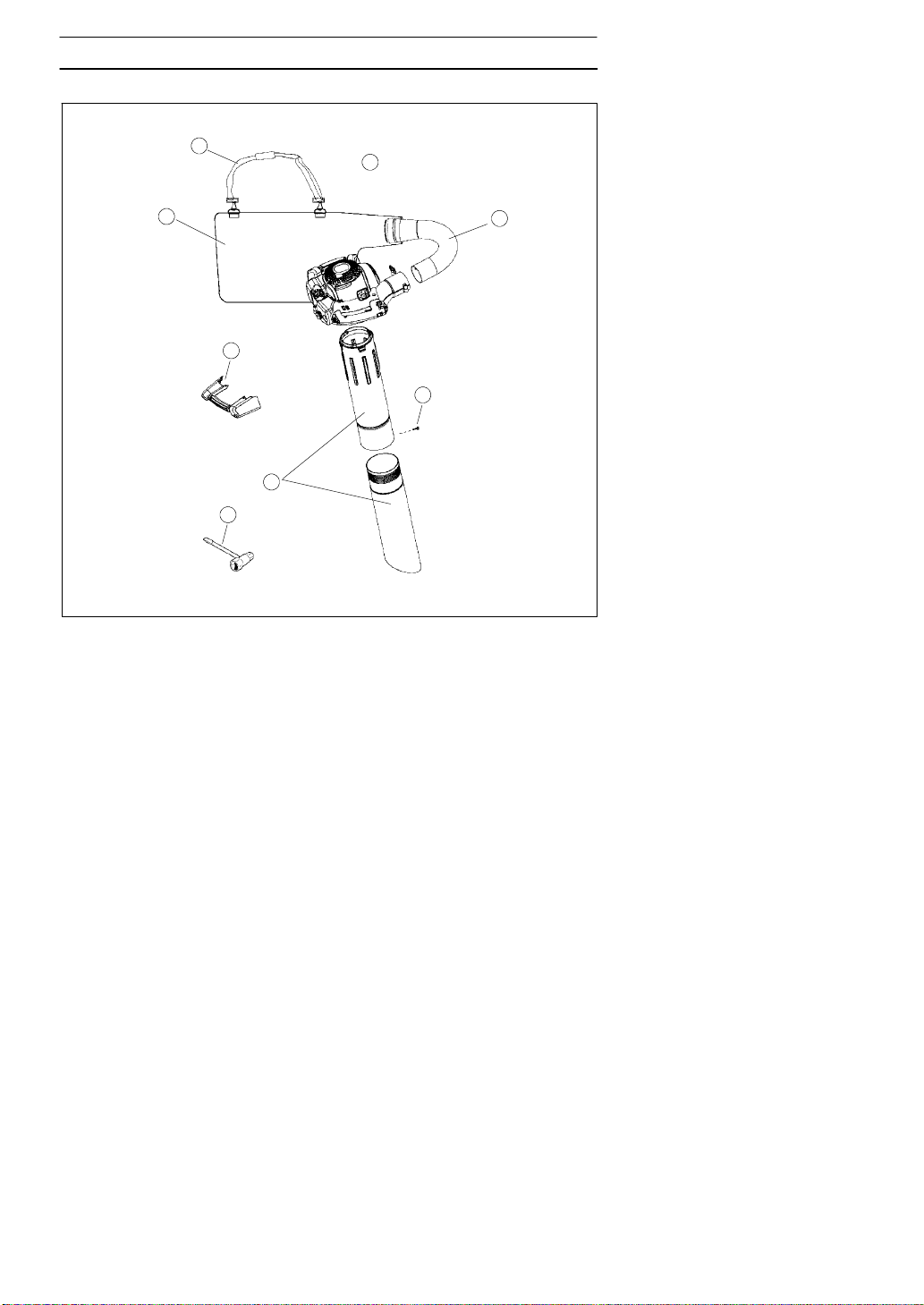

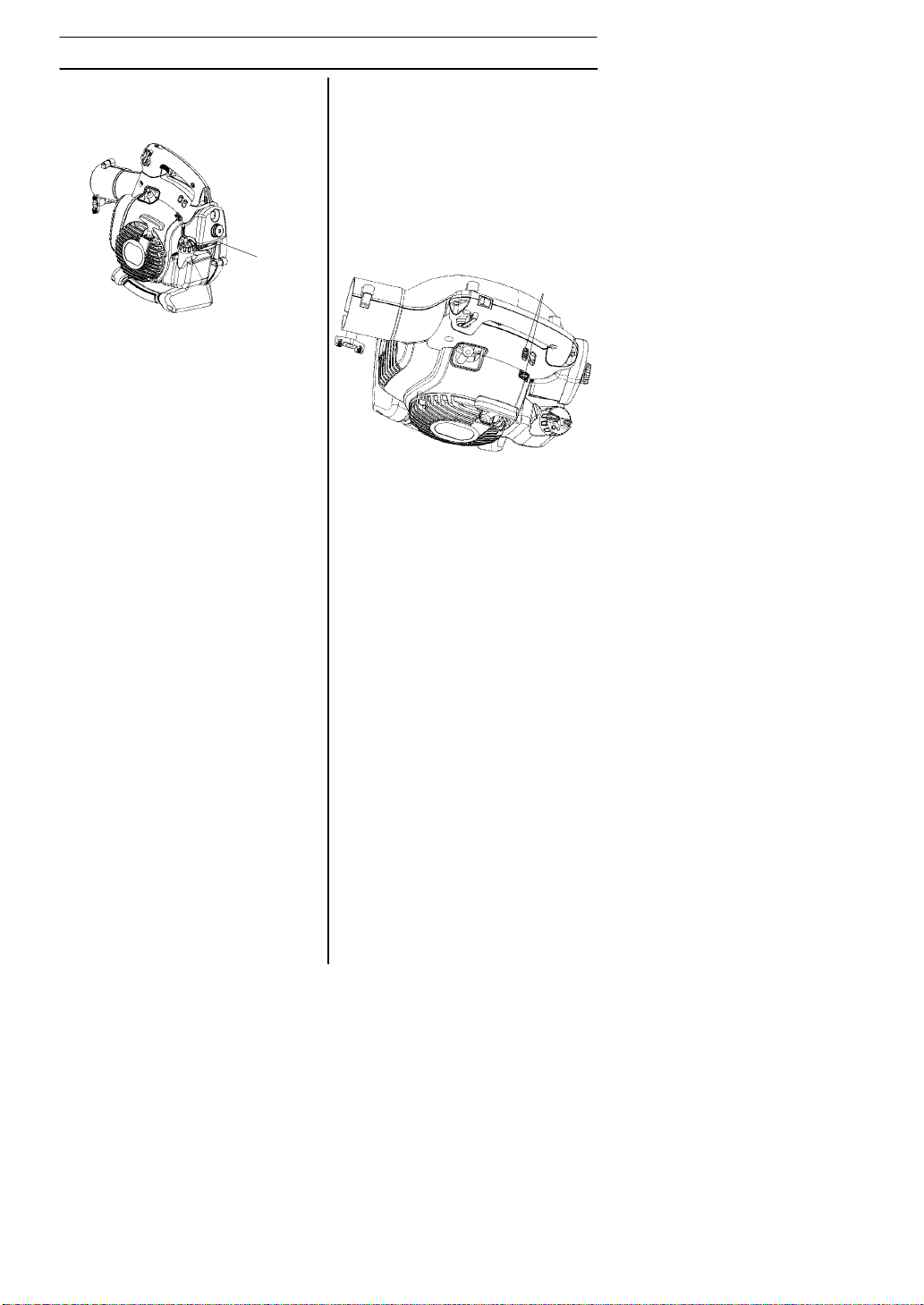

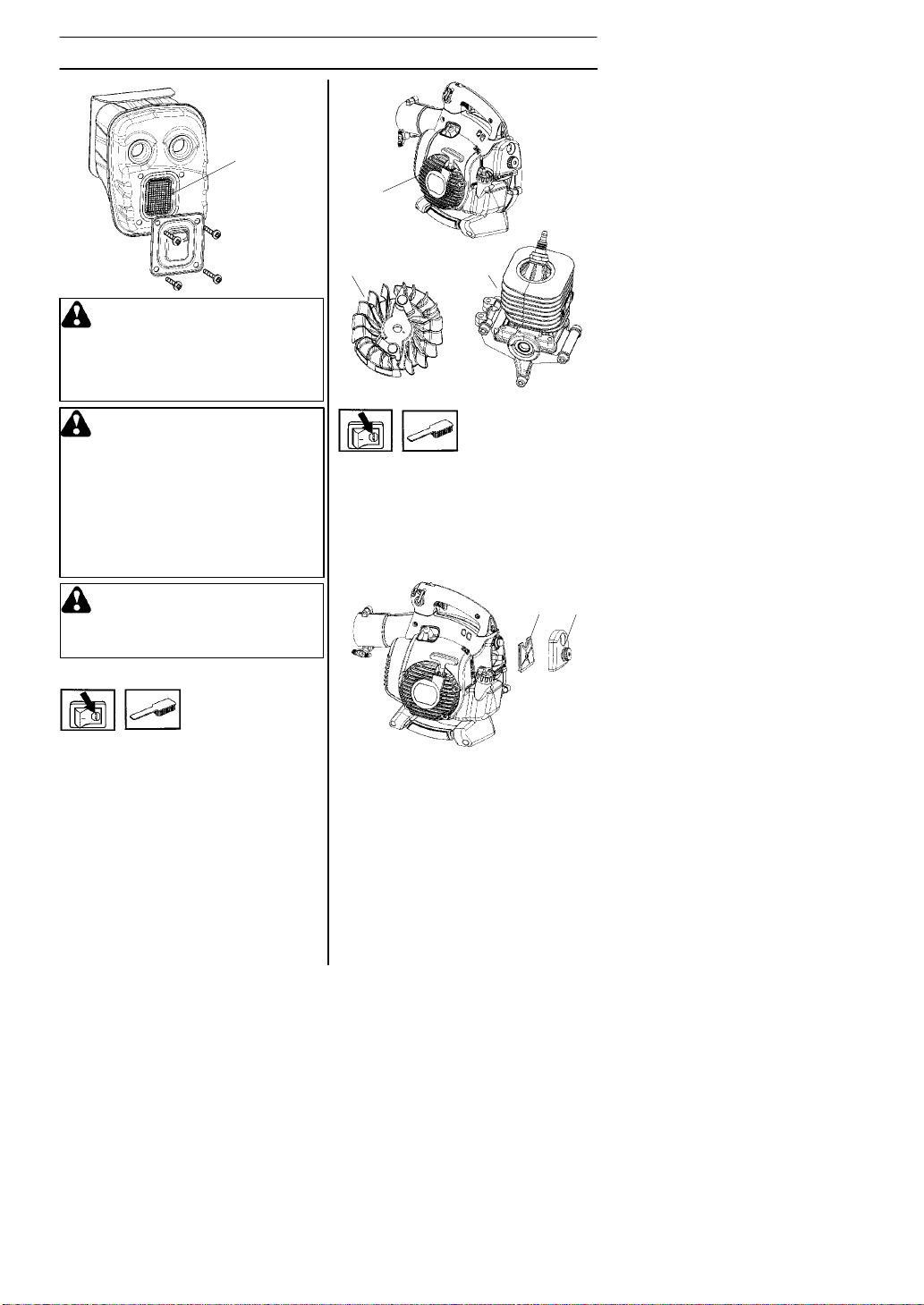

Optional accessory

DESCRIPTION

26

23

27

24

28

21. Vacuum accessory with collection components consisting of items 22--28 below

22. Collection bag tube

23. Collection bag

24. Vacuum tube in two sections

25. Screw

26. Shoulder strap

27. Vacuum assist handle

28. Scrench

21

22

25

545218616 Rev. 1 12/15/08

English---7

Page 8

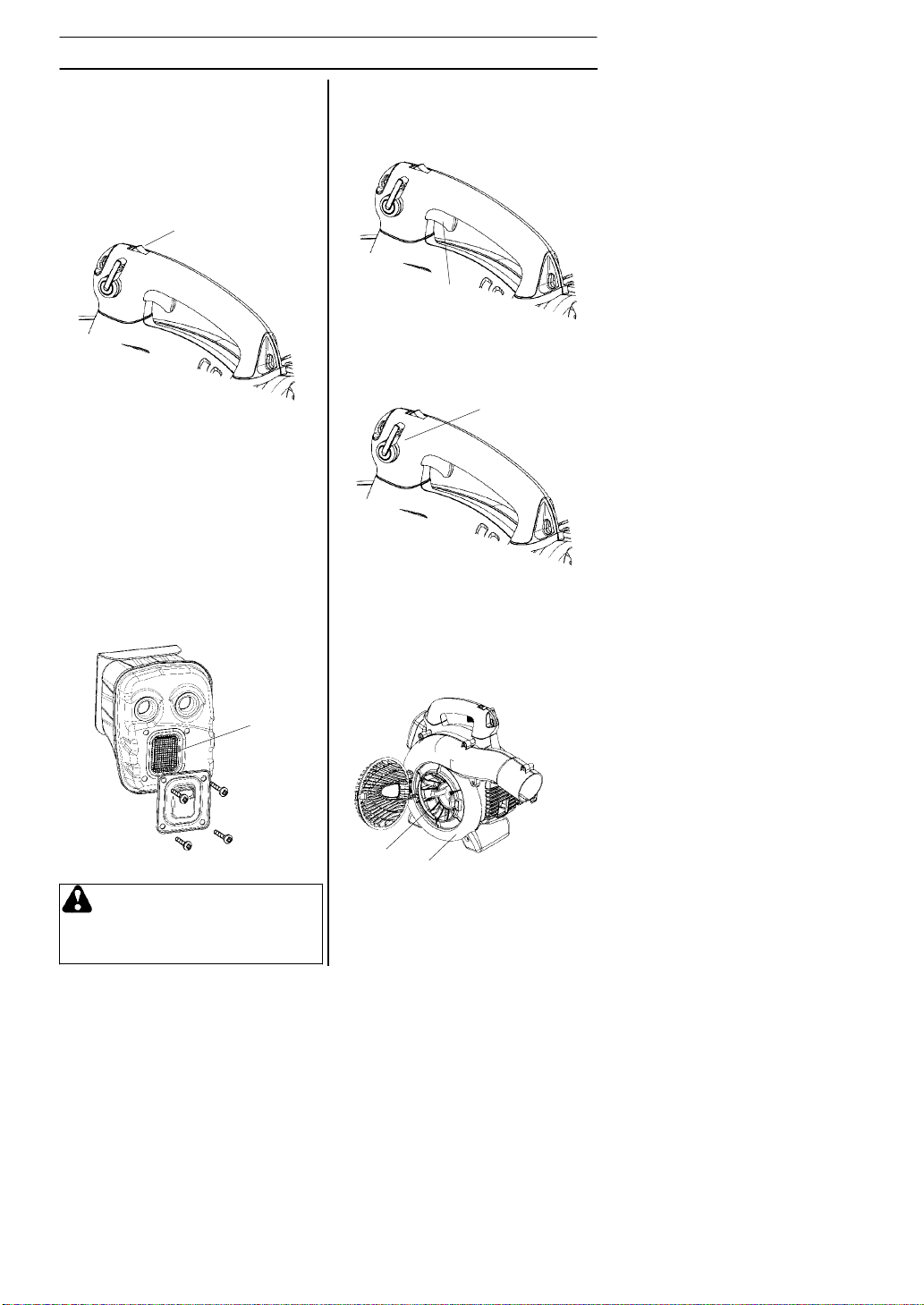

DESCRIPTION

Oth

Safety equipment

The following equipment on the blower is

designed for protecting personnel and

materials. These components should

receive special attention whenever you

operate, inspect and service the blower.

Stop switch

S The stop switch (A) is used to stop the

engine.

A

er equipment

Throttle trigger

S The speed and the output of the engine

are regulated by the throttle trigger (C).

C

Variable speed control

S The variable speed control (D) is de-

signed to allow setting engine speed as

necessary during blower use only.

Muffler

S The muffler is designed to give the low-

est possible noise level and to direct the

engine’s exhaust fumes away from the

operator. Mufflers fitted with catalytic

converters are also designed to reduce

harmful exhaust components.

S The engine exhaust fumes are hot and

can contain sparks, which may cause

fire if they come in contact with dry or

flammable material.

S Some blower models, especially those

sold in countries where the climate is

dry, are equipped with a spark arresting

screen (B). This screen must be cleaned

or replaced at specific intervals. See the

Maintenance section.

B

WARNING: The muffler is ex-

tremely hot while the engine is running and after it has stopped. DO

NOTTOUCHTHEMUFFLERIFITIS

HOT! This can cause severe burns.

D

S T o avoid causing damage to the unit, DO

NOT attempt to use the variable speed

control during starting or during vacuum

use.

Fan housing

S The blower fan housing (E) and the fan

impeller (F) provide high performance air

discharge.

F

E

545218616 Rev. 1 12/15/08

English---8

Page 9

Ground wire

L

S The ground wire (G) reduces static

build--up during operation in dry conditions.

G

DESCRIPTION

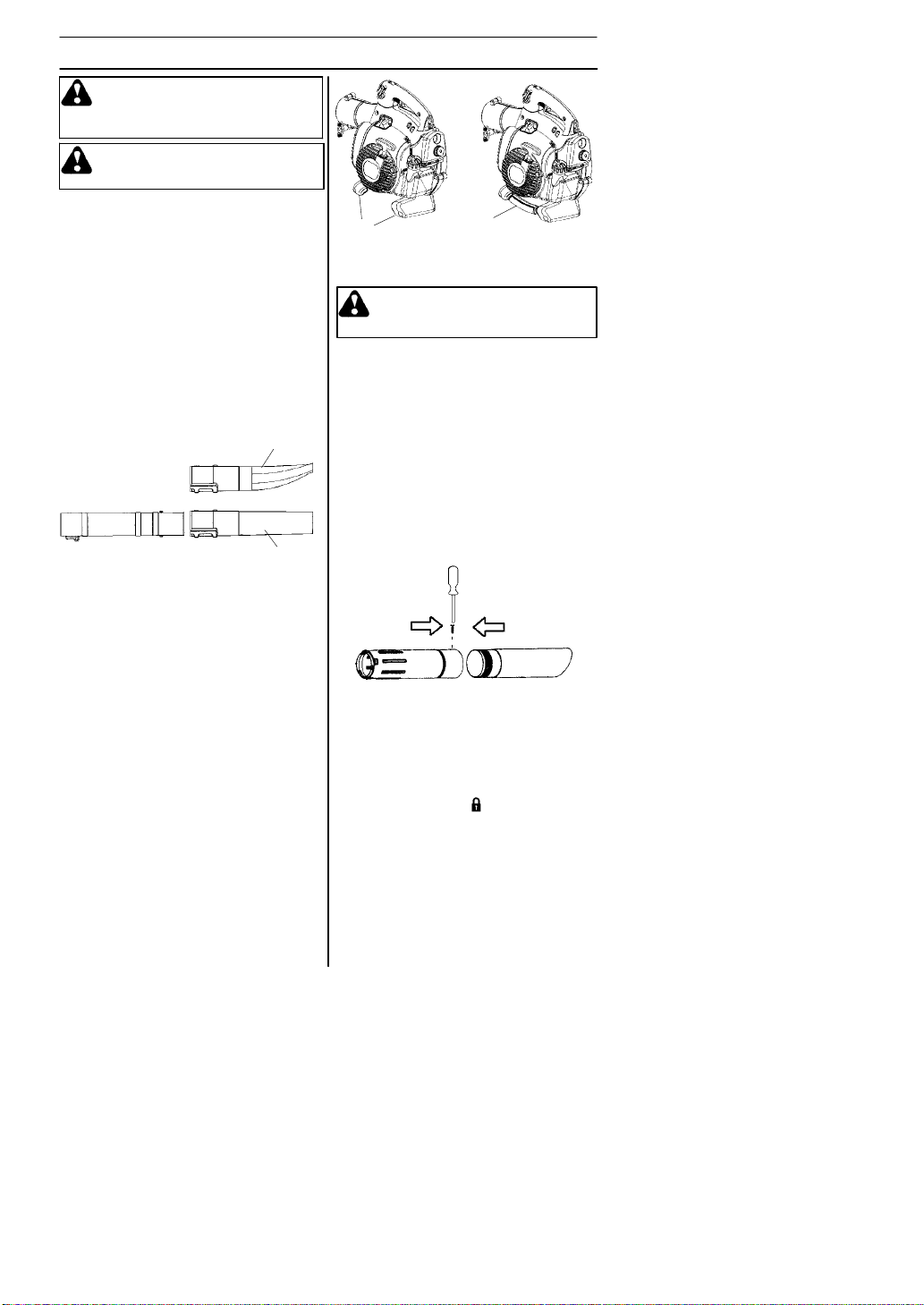

S The nozzles (

for connection to the blower tube. Air is

channeled through the blower tube to the

nozzles, where the air discharge velocity

increases and the air stream discharge

pattern is formed to provide best performance. The length of the blower tube

can be adjusted by twisting the nozzle to

the left to disengage the bayonet mount

and sliding the nozzle to the appropriate

position. Twist the nozzle to the right until

a click is felt to resecure the nozzle.

)have a bayonet mount

Inlet cover

S An inlet cover (H) is located on the side

of the fan housing. Opening this cover

allows access for cleaning and inspecting the impeller. If the optional vacuum

accessory is used, the vacuum tubes

must be fitted to the opening in the inlet

cover. To open the inlet cover, use a tool

to lift the edge of the cover opposite the

hinge (indicated by arrow on inlet cover).

H

J

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

Cutters

S Two cutters (J) are fastened to the impel-

ler. The cutters are there to mulch leaves

and other debris that have been vacuumed

before they enter the collection bag.

Blower tube and nozzle

The tube clamp bolt and nut must

NOTE:

be installed prior to initial use (see the general description of the blower on page 6).

S The blower tube (K) has a pegged slot

mounting system to the unit. T o install or

remove the blower tube (or collection bag

tube for the optional vacuum accessory),

the tube clamp bolt must be removed.

Align slot in the blower air outlet with the

raised rib on the tube and insert tube until

the holes in the tube and housing align.

Re--insert the tube clamp bolt and tighten.

545218616 Rev. 1 12/15/08

K

Starter device and starter handle

S The starter device (M) is located on the

side of the engine shrouding and engages the crankshaft only when the

starter handle (N) is pulled.

N

M

Fuel cap

S The fuel cap (O) is located at the rear of

the engine shrouding on the fuel tank

and has a seal to prevent fuel from leaking out.

O

Air filter

S The air filter (P) consists of a fiber filter

medium in a resilient frame. The air filter

should be cleaned at specific intervals

(see Maintenance section). Otherwise,

the blower will consume too much fuel,

the performance will be reduced and an

oily deposit may form on the spark plug

electrodes.

English---9

L

P

Page 10

DESCRIPTION

Choke

S The choke (Q) is located below the air

filter cover and should be used every

time the engine is cold--started.

Q

Adjusting the carburetor

NOTFORALLMODELS

S There are three adjusting screws (R) for

adjusting the carburetor:

S Low speed jet

S High speed jet

S Adjustment screw for idling

S Adjusting the carburetor involves adapt-

ing the engine to local operating conditions, e.g. climate, altitude, gasoline and

type of two--stroke engine oil used. For

details about carburetor adjustment, see

the Maintenance section.

R

545218616 Rev. 1 12/15/08

English---10

Page 11

FUEL HANDLING

f

Fuel

WARNING: Gasoline is very

flammable. Avoid smoking or

bringing any flame or sparks near

fuel. Make sure to stop the engine

and allow it cool before refueling

the unit. Select outdoor bare

ground for fueling and move at

least 10 feet (3 meters) away from

the fueling point before starting

the engine.

Gasoline requirements

S All 2--stroke RedMax products are pow-

ered by Zenoah professional--commercial

Duty, hi-- performance, hi-- RPM, air cooled

2--stroke engines. RedMax/ZENOAH

hi--performance 2--stroke engines produce

higher HP outputs as compared to standard home owner duty or light commercial

duty production engines offered by most

manufacturers.

S Exhaust emission are controlled by the

fundamental engine parameters and components (eq. carburation, ignition timing

and port timing) without addition of any

major hardware or the introduction of an

inert material during combustion.

S The RedMax/ZENOAH engines are regis-

tered and certified with CARB (California Air

Resources Board) and EPA (Environmental

Protection Agency) to operate on clean,

mid-- grade 89 octane or premium, unleaded

(lead- -free) gasoline and RedMax air- -cooled

“Max Life” synthetic blend premium two-stroke engine oil mixed at 50:1 ratio.

S Unleaded gasoline is recommended to re-

duce the contamination of the air for the

sake of your health and the environment.

S This hi--performance air cooled 2--stroke

engine requires the use of minimum 89

octane [R+M]/2 (mid--grade or premium)

clean gasoline. Gasoline may contain maximum of 10% Ethanol (grain alcohol) or up

to 15% MTBE (Methyl tertiary--butyl

ether). Gasoline containing Methanol

(Wood Alcohol) is NOT approved.

545218616 Rev. 1 12/15/08

NOTE: I

S

grade gasoline in your area is lower than

89 octane use premium unleaded

gasoline. The majority of all 2--stroke engine manufacturers in the USA and Canada recommend using gasoline with 89

octane or higher.

S Poor quality gasolines or oils may dam-

age sealing rings, fuel lines or fuel tank

of the engine.

NOTE: Failures caused by operating

S

engines on gasoline with octane rating

lower than 89 are not covered by the

RedMax 2--stroke engine warranty.

the octane rating ofthe mid--

WARNING: Gasoline with an

octane rating lower than 89 will

greatly increase the engines operating temperature. Low octane

gasoline will cause detonation

(knock) resulting in piston seizures

and major internal engine components damage.

WARNING: Alternative fuels

(not gasoline) such as E--15 (15%

ethanol), E--20 (20% ethanol), E--85

(85% ethanol) are NOT classified

as gasoline and are NOT approved

for use in RedMax 2--stroke gasoline engines. Use of alternative

fuels will cause major engine performance and durability problems

such as: improper clutch engagements, overheating, vapor lock,

power loss, lubrication deficiency,

deterioration of fuel lines, gaskets

and internal carburetor components, etc. Alternative fuels cause

high moisture absorption into the

fuel/oil mixture leading to oil and

fuel separation.

Oil requirements

S Use only RedMax “Max Life” synthetic

blend premium air--cooled 2--stroke engine oil or oil certified to ISO-- L-- EGD

(ISO/CD 1378) standard and one that is

JASO--FD registered. RedMax air-- cooled

“Max Life” synthetic blend premium

2--stroke engine oil and ISO--L--EGD

(ISO/CD 1378) AND JASO--FD oils are

fully compatible with gasoline’s containing

10% Ethanol. RedMax air--cooled “Max

Life” synthetic blend premium 2--stroke

engine oil and ISO--L--EGD (ISO/CD

1378) AND JASO--FD oils are universal

and should be mixed at 50:1 ratio for all

2--stroke air cooled engines sold in the

past regardless of mixing ratios specified

in those manuals.

English---11

Page 12

FUEL HANDLING

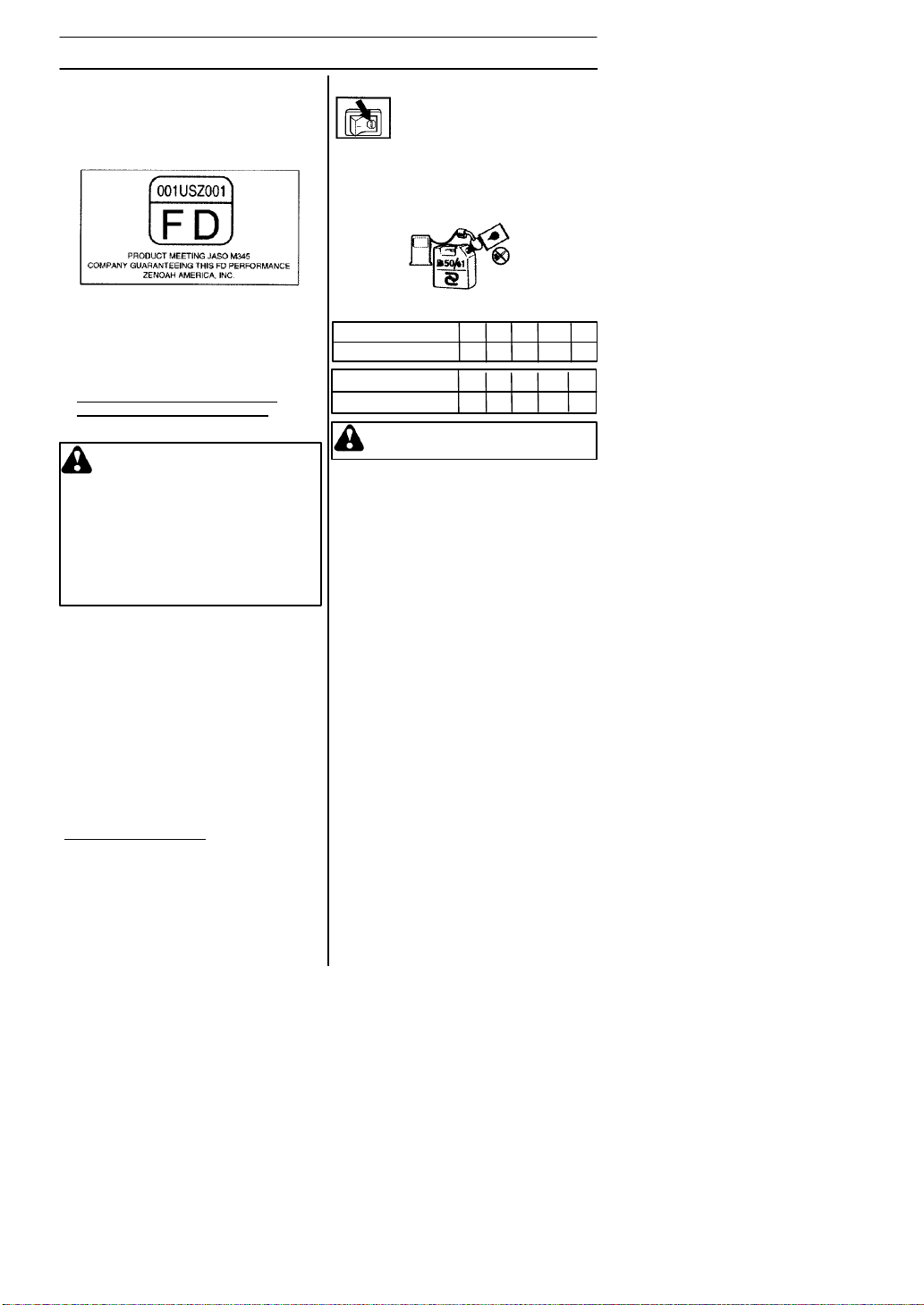

S Ifthe oil is registered with JASO, the JASO

Logo with FD and registration number will

be displayed on the container. The highest

JASO rating is “FD”, which equals the

ISO-- L--EGD rating. Lower ratings are

“FC”, “FB”, and “FA”.

How to mixfuel

Recommended mixing ratio:

Gasoline50:Oil1

(when using RedMax air--cooled

“Max Life” synthetic blend premium

2--stroke engine oil)

S Engine problems due to inadequate lu-

brication caused by failure to use ISO-L--EGD certified and JASO FD registered

oil such as RedMax air--cooled “MaxLife”

synthetic blend premium 2--stroke oil

WILL VOID THE REDMAX

STROKE ENGINE WARRANTY

WARNING: Do not use NMMA

(National Marine Manufacturers

Association), BIA (Boating Industry

Association), and TCW (two-- cycle

water cooled) oils designed for

mopeds or outboard, water cooled

marine engines. Do not use API

(American Petroleum Institute), TC

(2--cycle) labeled oils. The API--TC

test standard has been discontinued

by API in 1995 and it no longer exists.

IMPORTANT: GASOLINE/OIL MIXTURE

STORAGE RECOMMENDATIONS

Store your gasoline or gasoline/oil mixture in a cool, dry area in a tightly sealed

approved container to limit the entry of

moisture and additional air (oxygen).

Moisture and air cause the development

of varnish and gum, making the fuel stale.

Stored gasoline and gasoline/oil mixture

ages and loses its octane rating and

volatility. Do not mix more gasoline/oil

than you intend to use in 30 days, and 60

days when fuel stabilizer is added. RedMax air--cooled “Max Life” synthetic

blend premium 2--stroke engine oil

contains fuel stabilizer

cally extend your gasoline/oil mixture life

up to 60 days.

TWO--

.

and will automati-

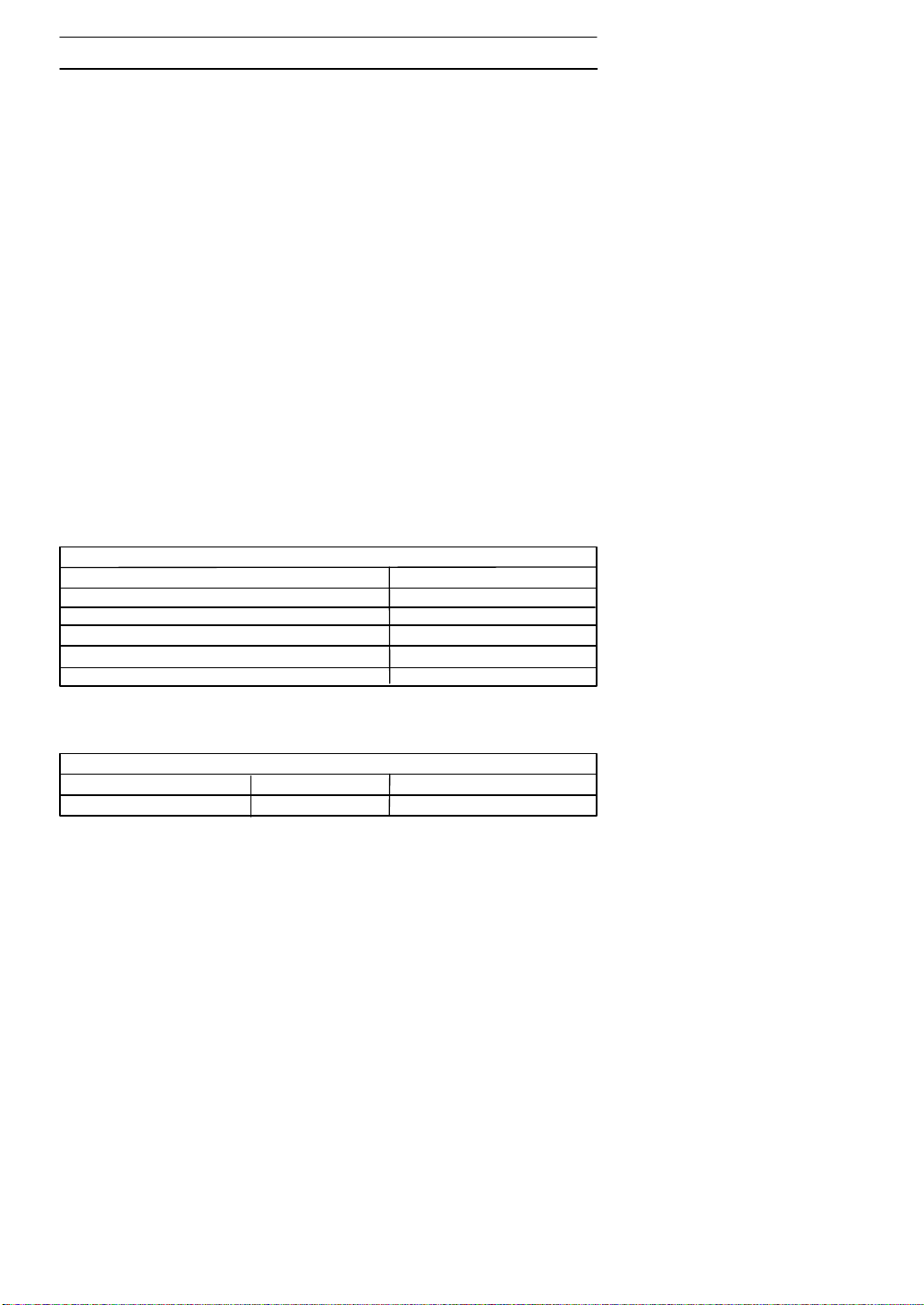

50:1 MIXING CHART

GASOLINE (gal.) 1 2 3 4 5

2-CYCLE OIL (fl.oz.) 2.6 5.2 7.8 10.4 13

GASOLINE (liter) 1 2 3 4 5

2-CYCLE OIL (mL) 20 40 60 80 100

WARNING: Pay attention to

agitation.

1. Measure out the quantities of gasoline and

oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well for 10

seconds.

4. Pour in the rest of gasoline and agitate again

for at least one minute. As some oils may be

difficult to agitate depending on oil ingredients, sufficient agitation is necessary. Be

careful that, if the agitation is insufficient,

there is an increased danger of early piston

seizure due to abnormally lean mixture.

5. Place a clear indication on the outside of the

container to avoid mixing up with gasoline or

other containers that don’t contain oil.

6. Indicate the contents on outside of container for easy identification.

545218616 Rev. 1 12/15/08

English---12

Page 13

FUEL HANDLING

Fueling your unit

1. Untwist and remove the fuel cap. Rest the

cap on a clean surface.

2. Put fuel into the fuel tank to 80% of the full

capacit y.

3. Fasten the fuel cap securely and wipe up

any fuel spillage around the unit.

WARNING: Select flat and bare

ground for fueling. Move at least 10

feet (3 meters) away from the fueling

point before starting the engine. Stop

the engine before refueling the unit.

At that time, be sure to sufficiently

agitate the mixed gasoline in the container.

Min. 10 ft.

(3 m)

To extend engine life, avoid:

1. FUEL WITH NO OIL (RAW GASOLINE) -It will cause severe damage to the internal

engine parts very quickly.

2. GASOHOL -- It can cause deterioration of

rubber and/or plastic parts and disruption of

engine lubrication.

3. OIL FOR 4--CYCLE ENGINE USE -- It can

cause spark plug fouling, exhaust port

blocking, or piston ring seizure.

4. Mixed fuels which have been left unused

for a period of one month or more may

clog the carburetor and result in the engine

failing to operate properly.

5. In the case of storing the product for a long

period of time, clean the fuel tank after rendering it empty. Next, Start the engine and

run the carburetor dry residual fuel.

6. In the case of scrapping the used mixed oil

container, scrap it only at an authorized

depository site.

545218616 Rev. 1 12/15/08

English---13

Page 14

STARTING AND STOPPING

Starting and stopping

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

Cold engine

Primer bulb: Press the primer bulb 10

times until fuel begins to fill the bulb. The

primer bulb need not be completely filled.

Warm engine

With a warm engine, squeeze and hold the

throttle trigger. Move choke to ½ position.

Pull starter rope sharply while squeezing

throttle trigger until engine runs. Move the

choke to the OFF CHOKE (opened)

position.

Stopping

To stop the engine, push and release the

engine STOP switch (S). The switch will

automatically return to the ON position.

Wait 7 seconds before attempting to restart

unit to allow switch to reset.

Choke: Move the blue engine choke lever

over to the FULL CHOKE (closed) position.

Starting: Hold the body of the machine on

the ground using your left hand

(CAUTION! Not with your foot!).

Firmly grip the starter rope handle with

your right hand. DO NOT squeeze

throttle trigger. Slowly pull out the cord

until you feel some resistance (the starter

pawls grip); then quickly and powerfully

pull the cord.

WARNING: Never wrap the starter

cord around your hand.

Pull starter handle until engine attempts to

run, but no more than 3 pulls. Move choke

to ½ position and pull the cord until the engine starts and runs. Allow the engine to

warm up for approximately 10 seconds;

then, move the choke to the OFF CHOKE

(opened) position.

NOTE: If engine dies, return blue engine

choke lever to the closed position and

repeat starting steps.

CAUTION! Do not pull the starter cord all

the way out and do not let go of the starter

handle when the cord is fully extended.

This can damage the machine.

S

545218616 Rev. 1 12/15/08

English---14

Page 15

USING THE BLOWER

To blow away debris on the

ground

Fitting the blower tube and noz zle

on the blower

WARNING: When fitting the blow-

er tube and nozzle, the engine must

be switched off.

The blower tube (T) has a pegged slot

mounting system to the unit. To install or

remove the blower tube, the tube clamp bolt

must be removed. Align slot in the blower

air outlet with the raised rib on the tube and

insert tube until the holes in the tube and

housing align. Re--insert the tube clamp bolt

and tighten.

U

T

The nozzles (U) have a bayonet mount for

connection to the blower tube. Air is channeled through the blower tube to the

nozzles, where the air discharge velocity

increases and the air stream discharge pattern is formed to provide best performance.

The length of the blower tube can be adjusted by twisting the nozzle to the left to

disengage the bayonet mount and sliding

the nozzle to the appropriate position.

Twist the nozzle to the right until a click is

felt to re--secure the nozzle.

Blowing

Before you begin blowing, put on the required safety equipment.

WARNING: When working with

the blower, wear the required personal safety equipment:

1. Hearing protection.

2. Eye protection.

3. Protective gloves.

4. Face mask in dusty environments.

545218616 Rev. 1 12/15/08

WARNING: Never point the blower

nozzle at people or animals. The

high--velocity air stream can contain

particles that may cause serious

injury, especially if the blower has

previously been used for vacuuming.

Be careful, particularly if left hand

operation is applied. Avoid any direct body contact with inlet cover

area. Keep jewelry, loose clothing,

or clothing with loosely hanging

straps, ties, tassels, etc., away from

inlet cover area.

English---15

Page 16

USING THE BLOWER

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

WARNING: Do not operate the

blower while standing on a ladder or

a stand.

Start the blower as described in the Starting

and Stopping section. Work according to the

following instructions:

1. Never blow air toward fixed objects such

as walls, large rocks, automobiles and

fences.

2. When working inside corners, blow from

the corner and inward toward the center of

the work area. Otherwise, debris can fly

up in your face and cause eye injury.

3. Never point the blower nozzle at delicate

plants.

Standard nozzle

The standard nozzle (V) is included with

the HB280. When greater accuracy and

high air stream concentration is desired,

use the standard nozzle.

High--velocity nozzle

The high--velocity nozzle (W) is also

included with the HB280 blower.

When a wider air stream and greater air

velocity is desired, use the high--velocity

nozzle.

To vacuum debris from the

ground (using optional vacuum

accessory)

The vacuuming device is an optional

accessory.

Fitting the vacuum assist handle

Before vacuuming, the assist handle (X)

must be assembled to the blower.

1. Loosen and remove screws from front

and rear impact feet (Y) of blower.

Remove both feet.

2. Install vacuum assist handle (X).

3. Reinstall two screws. Tighten securely.

W

V

Y

X

Fitting the collection bag with the

various vacuum tubes

WARNING: When fitting the

tubes to the blower, the engine

must be switched off.

1. Open the collection bag. Insert the

collection bag tube from inside the bag to

fit in the vacuum inlet opening of the bag

as shown. Ensure elastic is seated in

groove. Close the zipper on the bag.

2. Remove the blower tube and install the

collection bag tube. Install and tighten

tube clamp bolt. Attach the carrying strap

to the collection bag loops.

3. Align arrows on lower vacuum tube and

upper vacuum tube. Push low er vacuum

tube into upper vacuum tube until the lower

tube is securely seated in the upper tube

(about 3 inches/7 cm). Permanently assemble the two tubes together with the

supplied screw.

4. Open the cover on the side of the blower

by using a screwdriver to pry up under the

edge of the cover on the side opposite the

hinge (indicated by arrow on inlet cover).

5. Press the vacuum tubes in the large

opening at the underside of the blower

and align the tabs with the slots in the

tube. Turn it until the bayonet mount

locks (lock symbols align).

545218616 Rev. 1 12/15/08

English---16

Page 17

USING THE BLOWER

Vacuuming

Before vacuuming, put on the required

safety equipment.

WARNING: When working with

the blower, wear the required personal safety equipment:

1. Hearing protection.

2. Eye protection.

3. Protective gloves.

4. Face mask in dusty environments.

When operating the blower, the collection

bag must be supported by the shoulder

strap. The strap should be worn over the

shoulder as shown.

WARNING: Always check that

the collection bag is intact and the

zipper is closed before starting the

blower. Never use a damaged bag.

There is risk of injury due to flying

debris. Be careful, particularly if left

hand operation is applied. Avoid any

direct body contact with the exhaust outlet area.

WARNING: Never start the blower

if the inlet cover is not closed, is

damaged or cannot be closed

(except if the vacuum tube is fitted).

WARNING: Do not operate the

blower while standing on a ladder or

a stand.

Start the blower as described in the Starting

and Stopping section. Work according to the

following instructions:

1. Do not vacuum large solid objects that

can damage the fan, such as wood, cans

(tins) or lengths of string or ribbon.

2. Do not let the vacuum tube strike the

ground.

3. The collection bag can be emptied by first

stopping the unit and then opening the zipper on the side.

545218616 Rev. 1 12/15/08

English---17

Page 18

MAINTENANCE

Maintenance Safety

The owner is responsible for the performance of all required maintenance as

defined in the operator’s manual.

Disconnect the spark plug before performing maintenance, except carburetor adjustments.

WARNING: Improper mainte-

nance could result in serious engine

damage or in serious injury.

Carburetor

Your product has been designed and

manufactured to specifications that reduce

harmful emissions. After the engine has

used 8--10 tanks of fuel, the engine will be

run--in. To ensure that it continues to run at

peak performance and to minimize harmful

exhaust emissions after the run--in period,

ask your servicing dealer to adjust your carburetor.

Function

S The carburetor governs the engine’s

speed via the throttle control. Air and fuel

are mixed in the carburetor.

S The T--screw (Z) regulates the throttle

setting at idle speed. If the T-- screw is

turned clockwise this gives a higher idle

speed; turning it counterclockwise gives a

lower idle speed.

Basic setting

S The basic carburetor settings are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skilled technician.

Recommended idle speed:

See “Technical data” section.

Recommended max. speed:

See “Technical data” section.

Fine adjustment of the idle speed--T

Adjust the idle speed using the idle adjustment T--screw if it is necessary to readjust.

The idle speed is correctly adjusted when

the engine will run smoothly in every position.

Z

Muffler

Some mufflers are fitted with catalytic converters. See the Technical data section to

find out if your machine is equipped with a

catalytic converter.

The muffler is designed to dampen the

noise level and to direct the exhaust fumes

away from the user. The exhaust fumes

are hot and can contain sparks, which can

result in fire if the exhaust fumes are

directed towards a dry and flammable

material.

Some mufflers are equipped with a special

spark arresting screen (AA). If your machine is fitted with this type of screen, it

should be cleaned regularly. To access the

screen, remove the outlet cover on the

front of the muffler. Use a wire brush to

clean the screen. On mufflers without a

catalytic converter the screen should be

cleaned weekly, or replaced if necessary.

On mufflers fitted with a catalytic converter

the screen should be checked and cleaned

monthly. If the screen is damaged it

should be replaced. If the screen is frequently blocked, this can be a sign that the

function of the catalytic converter is impaired. Contact your dealer to inspect the

muffler. A blocked screen will cause the

engine to overheat resulting in damage to

the cylinder and piston.

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure the muffler

bolts are tight.

545218616 Rev. 1 12/15/08

English---18

Page 19

MAINTENANCE

AA

BB

WARNING: Mufflers fitted with

catalytic converters get very hot

duringuseandremainsoforsome

time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember

theriskoffire!

WARNING: Bear in mind that:

Engine exhaust fumes contain carbon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or anywhere that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near flammable material!

WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler.

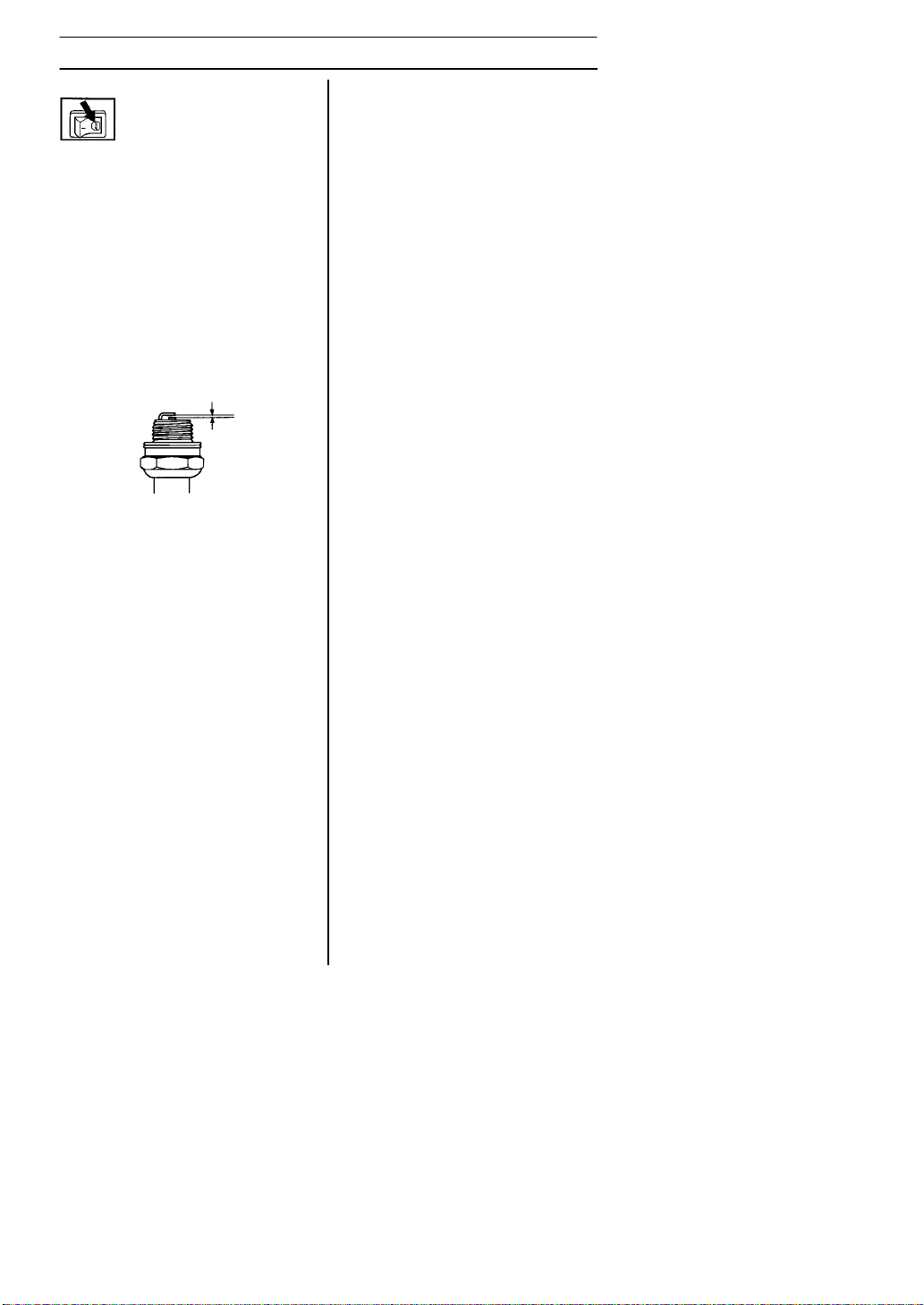

Cooling system

The engine is equipped with a cooling

system for maintaining the right operating

temperature.

The cooling system consists of the following components:

1. Air intake on the starter device (BB).

2. Fan blades on the flywheel (CC).

3. Cooling fins on the cylinder (DD).

4. Cylinder cowling (guides cooling air flow

against cylinder surfaces).

Clean the cooling system by brushing once

a week, or more often, if necessary.

A dirty or blocked cooling system will

cause the blower to overheat and this will

damage the cylinder and piston.

CC

DD

Air filter

The air filter (EE) must be regularly cleaned

to remove dust and dirt in order to avoid:

S Carburetor malfunctions

S Starting problems

S Loss of engine power

S Unnecessary wear to engine parts

S Excessive fuel consumption

S Elevated content of harmful exhaust

fumes.

FF

EE

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air filter cover (FF) and take out

the filter. Wash it clean in warm, soapy water.

Rinse thoroughly. Ensure that the filter is dry

before reinstalling it.

An air filter that has been in use for a long

time cannot be cleaned completely. The

filter must therefore be replaced with a new

one at regular intervals.

CAUTION! A damaged air filter must

always be replaced.

545218616 Rev. 1 12/15/08

English---19

Page 20

MAINTENANCE

Spark plug

The spark plug condition is influenced by:

S Incorrect carburetor adjustment.

S An incorrect fuel mixture (too much or in-

correct type of oil).

S Poor quality gasoline and/or oil

S A dirty air filter.

These factors cause deposits on the spark

plug electrodes, which may result in operating problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check the spark plug first before taking

any further action. If the spark plug is dirty,

clean it and check that the electrode gap is

0.024″ (0.6 mm). The spark plug should be

replaced after about a month in operation or

earlier if necessary.

0.024″ (0.6 mm)

CAUTION! Always use the recommended

spark plug type! Use of the wrong spark

plug can damage the piston/cylinder.

Maintenance schedule

Below you will find some general maintenance instructions.

Daily maintenance

S Clean the exterior surfaces of the blower.

S Check that the variable speed control and

the throttle trigger function in a safe manner. Replace damaged parts.

S Check that the stop switch works proper-

ly. Replace if necessary.

S Clean the air filter. Replace if necessary.

S Check that the inlet cover can be locked

in the closed position. Carefully check

that the fan impeller is clean, especially if

the blower has been used for collecting

debris (vacuuming).

S Check that all nuts and screws are prop-

erly tightened.

S Check that all the housings are free of

cracks. Replace damaged parts.

S Check that the collection bag is intact and

that the zipper works. Replace it if necessary.

Weekly maintenance

S Check the condition of the starter device,

the starter cord and the tensioning spring.

Replace damaged parts.

S Check the condition of the air intake at

the starter device. Remove debris if it is

clogged.

S Clean the outside of the spark plug. Re-

move it and check the electrode gap. Adjust the gap to 0.024″ (0.6 mm), or

replace the spark plug. Use resistor spark

plug Champion RCJ-- 8Y or equivalent.

S Clean the fan blades on the flywheel.

S Clean or replace the spark arresting

screen (not on mufflers with a catalytic

converter).

S Clean the carburetor area.

S Clean the air filter.

Monthly maintenance

S Clean the fuel tank.

S Clean the outside of the carburetor and

the area around it.

S Clean the fan blades on the flywheel and

the area around it.

S Check fuel lines for cracks or other dam-

age. Change if necessary.

S Change the fuel filter in fuel tank.

S Check all cables and connections. Re-

place damaged parts.

S Replace the spark plug. Use spark plug

Champion RCJ--8Y or equivalent.

S Change the air filter.

Storage

Before storing the blower:

S Drain the fuel tank and push the primer

bulb until it becomes empty of fuel.

S Remove the spark plug and drop a

spoonful of 2--cycle oil into the cylinder.

Crank the engine several times, then

install the spark plug.

S Store unit in a dry, dust free place, out of

the reach of children.

545218616 Rev. 1 12/15/08

English---20

Page 21

TECHNICAL DATA

Technical data

Engine

Cylinder volume, cu.in./cm

Cylinder bore, inch/mm 1.4/35

Stroke, inch/mm 1.130/28.7

Idle speed, rpm 2,800--3,200

Max. speed - blowing, rpm: 8,600

Max. speed - vacuuming, rpm*: 7,500

Max. engine output, acc. to ISO 8893, hp/kW 1.1/0.8

Catalytic converter muffler Yes

Speed--regulated ignition system No

Ignition system

Manufacturer/type of ignition system Phelon/CD

Spark plug Champion RCJ--6Y

Electrode gap, inch/mm 0.024/0.6

Fuel and lubrication system

Manufacturer/type of carburetor Zama

Fuel tank capacity, US pint/liter 1.05/0.5

Weight

Weight, without fuel but with blower tube

and standard nozzle fitted, lbs/kg 9.6/4.4

Sound levels

Equivalent sound pressure level, measured

according to ANSI B175.2--2000, dB(A) 70

Vibration levels

Vibration levels at handles, measured

according to ANSI B175.3--1997, m/s

At idle: 5.0

At max. speed: 11.8

3

2

Fan

Type Radial fan

Max. air velocity, mph (m/s), standard nozzle 134 (60)

Max. air velocity, mph (m/s), high velocity nozzle 170 (76)

3

Air volume with tube -- blowing, cfm (m

Air volume without tube -- blowing, cfm (m

Air volume with tubes -- vacuuming, cfm (m

/min.) 425 (12.0)

3

/min.) 470 (13.3)

3

/min.)* 445 (12.6)

*optional accessory

HB280

1.7/28

Model HB280

Approved accessories Model no. Part. no.

Vacuum kit VK--280 952 711 677

545218616 Rev. 1 12/15/08

English---21

Page 22

LIMITED WARRANTY

ANYISLIABL

EMISSIONS--RELATED PARTS: FOR

TWO (2) YEARS FROM THE DATE OF

ORIGINAL DELIVERY OF THE UNIT,

RedMax/ZENOAH AMERICA INC. (THE

COMPANY), THROUGH ANY RedMax

DEALER, WILL REPAIR OR REPLACE,

FREE OF CHARGE, FOR THE ORIGINAL

AND EACH SUBSEQUENT PURCHASER,

ANY PART OR PARTS FOUND TO BE

DEFECTIVE IN MATERIAL AND/OR

WORKMANSHIP. EMISSION--RELATED

PARTS ARE:

THE CARBURETOR ASSEMBLY, COIL

ASSEMBLY, ROTOR, SPARK PLUG,

AIR FILTER, FUEL FILTER, INTAKE

MANIFOLD, AND THE GASKETS

ALL OTHER PARTS EXCEPT ABOVE

PARTS, FOR 2 YEARS OF USE, 90 DAYS

FOR COMMERCIAL USE, 0 DAYS FOR

RENTAL USE, FROM THE DATE OF

ORIGINAL PURCHASE, THE COMPANY,

THROUGH ANY RedMax DEALER, WILL

REPAIR OR REPLACE, FREE OF

CHARGE, FOR THE ORIGINAL PURCHASER, ANY PART OF PARTS FOUND

TO BE DEFECTIVE IN MATERIAL AND/

OR WORKMANSHIP. THIS IS THE

EXCLUSIVE REMEDY.

THE PURCHASER SHALL BEAR COSTS

OF TRANSPORTING THE UNIT TO AND

FROM THE RedMax DEALER.

THE PURCHASER SHALL NOT BE

CHARGED FOR DIAGNOSTIC LABOR

WHICH LEADS TO THE DETERMINATION THAT A WARRANTED PART IS DEFECTIVE, IF THE DIAGNOSTIC WORK IS

PERFORMED AT THE RedMax DEALER.

THE PURCHASER OR OWNER IS RESPONSIBLE FOR THE PERFORMANCE

OF THE R EQUIRED MAINTENANCE AS

DEFINED BY THE MANUFACTURER IN

THE OWNER’S/OPERATOR’S MANUAL.

ANY WARRANTED PART WHICH IS NOT

SCHEDULED FOR REPLACEMENT AS

REQUIRED MAINTENANCE, OR WHICH

IS SCHEDULED ON LY FOR REGULAR

INSPECTION TO THE EFFECT OF “REPAIR OR REPLACE AS NECESSARY”

SHALL BE WARRANTED FOR THE WARRANTY PERIOD.

ANY WARRANTED PART WHICH IS

SCHEDULED FOR REPLACEMENT AS

REQUIRED MAINTENANCE SHALL BE

WARRANTED FOR THE PERIOD OF

TIME UP TO THE FIRST SCHEDULED

REPLACEMENT POINT FOR THE PART.

ANY REPLACEMENT PART THAT IS

EQUIVALENT IN PERFORMANCE AND

DURABILITY MAY BE USED IN NON-WARRANTY MAINTENANCE OR

REPAIRS, AND SHALL NOT REDUCE

THEWARRANTYOBLIGATIONOFTHE

COMPANY.

545218616 Rev. 1 12/15/08

THE COMP

DAMAGES TO OTHER ENGINE COMPONENTS CAUSED BY THE FAILURE OF

A WARRANTED PARTS STILL UNDER

WARRANTY.

THEWARRANTYDOESNOTAPPLY

TO THOSE UNITS WHICH HAVE BEEN

DAMAGED BY NEGLIGENCE OF

INSTRUCTION LISTED IN THE OWNER’S/

OPERATOR’S MANUAL FOR PROPER

USE AND MAINTENANCE OF THE

UNITS, ACCIDENTAL MISHANDLING,

ALTERATION, ABUSE, IMPROPER LUBRICATION, USE OF ANY PARTS OR

ACCESSARIES OTHER THAN THOSE

SPECIFIED BY THE COMPANY, OR

OTHER CAUSES BEYOND THE

COMPANY’S CONTROL.

THIS WARRANTY DOES NOT COVER

THOSE PARTS REPLACED BY NORMAL

WEAR OR HARMLESS CHANGES IN

THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS

WARRANTIES.

IMPLIED WARRANTIES INCLUDING

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PU RPOSE

ARE LIMITED TO TWO (2) YEARS OF

USE FROM THE ORIGINAL DELIVERY

DATE.

LIABILITIES FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGE UNDER

ANY AND ALL WARRANTIES ARE

EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS OR EXCLUSION OR LIMITATIO N OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMINATION OR EXCLUSION MAY NOT

APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

IF YOU NEED TO OBTAIN INFORMATION

ABOUT THE NEAREST SERVICE CENTER, PLEASE CALL RedMax/ZENOAH

AMERICA, INC., AT (770)--381--5147.

IMPORTANT: YOU WILL RECEIVE A

WARRANTY REGISTRATION CARD AT

TIME OF PURCHASE.

PLEASE FILL OUT THE CARD AND

SEND IT TO RedMax/ZENOAH AMERICA

WITHIN SEVEN (7) DAYS. BE SURE TO

KEEP A C OPY FOR YOUR RECORDS.

ZENOAH AMERICA, INC.

1100 Laval Blvd., Suite 110

Lawrenceville, GA 30043

EFOR

English---22

Page 23

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

Y

EMISSION CONT ROL WARRANTY STATEMENT

OUR WARRANTYRIGHTSAND

OBLIGATIONS:

The U.S. Environmental Protection Agency,

California Air Resources Board, Environment

Canada and RedMax/ZENOAH are pleased

to explain the emissions control system warranty on your year 2009 and later small off- road engine. In California, all small off- -road

engines must be designed, built, and

equipped to meet the State’s stringent anti- smog standards. RedMax/ZENOAH must

warrant the emission control system on your

small off--road engine for the periods of time

listed below provided there has been no

abuse, neglect, or improper maintenance of

your small off--road engine. Your emission

control system includes parts such as the carburetor, the ignition system and the fuel tank.

Where a warrantable condition exists, RedMax/ZEN OAH will repai r your small off--road

engine at no cost to you. Expenses covered

under warranty include diagnosis, parts and

labor.

MANUFACTURER’S WARRANTY

COVERAGE:

If any emissions related part on your engine

(as listed under Emissions Control Warranty Parts List) is defective or a defect in the

materials or workmanship of the engine

causes the failure of such an emission

related part, the part will be repaired or

replaced by RedMax/ZENOAH.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off--road engine owner, you are

responsible for the performance of the required maintenance listed in your operator’s

manual. RedMax/ZENOAH recommends

that you retain all receipts covering maintenance on your small off-- road engine, but

RedMax/ZENOAH cannot deny warranty

solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the small off--road

engine owner, you should be aware that

RedMax/ZENOAH may deny you warranty

coverage if your small off--road engine or a

part of it has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or the use of parts not made or approved by the original equipment manufacturer. You are responsible for presenting

your small off--road engine to a RedMax/

ZENOAH authorized repair center as soon

as a problem exists. Warranty repairs

should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized

service center, call RedMax/ZENOAH at

1-- 800- -291- -8251, or send e--mail correspondence to service@redmax.com.

545218616 Rev. 1 12/15/08

WARRANTYCOMMENCEMENT

DATE:

The warranty period begins on the date the

small off--road engine is purchased.

LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase.

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS.

Repair or replacement of any warranted part

will be performed at no charge to the owner at

an approved RedMax/ZENOAH servicing

center. If you have any questions regarding

your warranty rights and responsibilities, you

should contact your nearest authorized

service center, call RedMax/ZENOAH at

1-- 800--291-- 8251, or send e--mail correspondence to service@redmax.com.

WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance,

or which is scheduled only for regular inspection to the effect of “repair or replace

as necessary” shall be warranted for 2

years. Any warranted part which is scheduled for replacement as required maintenance shall be warranted for the period of

time up to the first scheduled replacement

point for that part.

DIAGNOSIS:

The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the

diagnostic work is performed at an approved RedMax/ZENOAH servicing center.

CONSEQUENTIAL DAMA GES:

RedMax/ZENOAH may be liable for damages

to other engine components caused by the

failure of a warranted part still under warranty.

WHAT IS NOT COVERED:

All failures caused by abuse, neglect, or

improper maintenance are not covered.

ADD--ON OR MODIFIED PARTS:

The use of add--on or modified parts can be

grounds for disallowing a warranty claim.

RedMax/ZENOAH is not liable to cover failures of warranted parts caused by the use

of add--on or modified parts.

HOW TO FILE A CLAIM:

If you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized service center, call RedMax/ZENOAH at

1-- 800- -291- -8251, or send e--mail correspondence to service@redmax.com.

English---23

Page 24

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONT ROL WARRANTY STATEMENT

WHERE TO GET WARRANTY SERVICE:

Warranty services or repairs shall be provided at all RedMax/ZENOAH service centers. Call RedMax/ZENOAH at

1-- 800- -291- -8251, or send e--mail correspondence to service@redmax.com.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RELATED PARTS:

Any RedMax/ZENOAH approved replacement part used in the performance of any

warranty maintenance or repair on emission

related parts will be provided without charge

to the owner if the part is under warranty.

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

EMISSION CONTROL WARRANTY

PARTS LIST:

Carburetor, air filter (covered up to maintenance schedule), ignition system: spark

plug (covered up to maintenance schedule),

ignition module, muffler including catalyst (if

equipped), fuel tank.

MAINTENANCE STATEMENT:

The owner is responsible for the performance of all required maintenance as defined in the operator’s manual.

545218616 Rev. 1 12/15/08

English---24

Page 25

SOMMAIRE

Sommaire

Introduction 25...................

Description symboles 26............

Consignes de sécurité 27............

Description 29.....................

Manipulation du carburant 34........

Démarrage et arrêt 37...............

Utilisation 38.......................

Entretien 41........................

Caractéristiques techniques 44......

L’entretien, le remplacement, ou la réparation des dispositifs d’émission et le

système peuvent être exécutés par n’importe quel distributeur ou individu de réparation de moteur tout--terrain.

Contrôler les points suivants

avant la mise en marche:

RedMax/ZENOAH travaille continuellement au développement de ses produits et

se réserve le droit d’en modifier, entre

autres, la conception et l’aspect sans

préavis. Une exposition prolongée au bruit

risque de causer des lésions auditives

permanentes. Toujours utiliser des protecteurs d’oreille agréés.

Ce mode d’emploi décrit en détail l’utilisation, l’entretien et la surveillance régulière

du souffleur. Il décrit aussi les précautions

à prendre pour limiter les risques pendant

l’utilisation, ainsi que le fonctionnement et

l’entretien des éléments de sécurité.

Attention! La section qui traite de la sécurité doit être étudiée et assimilée par toute

personne devant manipuler le souffleur.

Ce mode d’emploi a été écrit pour le personnel n’ayant pas les connaissances nécessaires pour la recherche de pannes,

l’entretien plus complexe et la réparation

du souffleur.

Les symboles d’avertissement indiqués à

la fois dans ce mode d’emploi et sur le

souffleur. En cas de déformation ou

d’usure d’un symbole d’avertissement, il

convient d’en commander un nouveau et

de le coller le plus rapidement possible.

Noter que des symboles d’avertissement

sont également coulés dans certains éléments du souffleur.

Le souffleur s’utilise pour faire envoler des

feuilles et autres salissures sur le sol. Pendant le travail l’opérateur doit se tenir debout

les pieds au sol.

La période de conformité d’émissions énuméré

sur l’étiquette de conformité d’émissions indique le nombre de temps d’exploitation l’où le

moteur a été montré pour répondre à des exigences fédérales d’émissions. Catégorie C =

50 heures, B = 125 heures, et A = 300 heures.

Pour la référence, veuillez enregistrer l’information suivante qui sera nécessaire

pour le futur entretien de votre appareil :

Numéro de Modèle :

Numéro de série:

Date d’achat:

Distributeur:

AVERTISSEMENT: Ne jamais

modifier sous aucun prétexte la machine sans l’autorisation du fabricant. N’utiliser que des accessoires

et des pièces d’origine. Des modifications non--autorisées et l’emploi

d’accessoires non--homologués

peuvent provoquer des accidents

graves et même mortels, à l’utilisateur ou d’autres personnes. Votre

garantie peut ne pas couvrir des

dommages ou la responsabilité

provoqués par l’utilisation des

accessoires ou des pièces de

rechange non--autorisés.

545218616 Rev. 1 12/15/08

French - -- 25

Page 26

DESCRIPTION SYMBOLES

Symbole Description Emplacement Symbole Description Emplacement

Les vérifications et/ou

opérations de maintenance doivent être réalisées après l’arrêt du

moteur et la déconnexiondelabougie.

Nettoyage régulier

indispensable.

Port de lunettes de

protection homologuées ou visière

obligatoire.

Port de lunettes de

protection homologuées

ou visière, ainsi que

protection auditive

obligatoire, et protection

respiratoire en cas de

risque de poussière.

AVERTISSEMENT!

Le souffleur peut être un

outil dangereux! Une

utilisation négligente ou

erronée peut provoquer

des blessures graves,

voire mortelles.

Etudier attentivement

ce mode d’emploi et

veiller à assimiler son

contenu avant d’utiliser

le souffleur.

AVERTISSEMENT!

Veiller à ce que le couvercle d’admission d’air

soit verrouillé en position

fermée ou que le tube

d’aspiration soit monté.

Ne jamais toucher la

roue du ventilateur tant

que l’appareil n’est pas

à l’arrêt, que la roue

n’est pas immobile et

que la bougie d’allumage n’est pas déconnectée.

X

X

X

XX

XX

XX

XX

AVERTISSEMENT!

Le souffleur peut

projeter violemment des

objets pouvant ricocher.

Cela peut provoquer

des blessures graves

aux yeux.

L’opérateur du souffleur doit veiller à ce

qu’aucune personne

ou animal ne se trouve

à moins de 15 mètres.

Lorsque plusieurs

opérateurs partagent

le même lieu de travail

la distance de sécurité

doit être de 15 mètres

au minimum.

Étrangleur

Remplissage de

carburant

Bouton d’arrêt

Instruction pour pour

ouvrir le couvercle

d’admission d’air

AVERTISSEMENT!

Le silencieux est très

chaud pendant et

après utilisation. Ne

touchez pas le silencieux, le couvercle de

silencieux, ou les surfaces environnantes,

ou ne permettez pas

le matériel qui est

combustible (sèche

herbe, carburant) pour

entrer en contact avec

le silencieux.

XX

XX

X

X

X

X

Toujours porter des

gants de protection

homologués.

545218616 Rev. 1 12/15/08

XX

Les autres symboles/autocollants présents sur la machine concernent des

exigences de certification spécifiques à

certains marchés.

French - -- 26

Page 27

CONSIGNES DE SÉCURITÉ

Equipement de protection personnel

Les personnes qui utilisent le souffleur doivent

porter l’équipement protecteur suivant:

1. Protection auditive homologuée.

2. Visière ou lunettes de protection homologuées.

3. Gants de protection homologués.

4. Bottes ou grosses chaussures avec semelles antidérapantes.

5. Protection respiratoire en cas de risque de

poussière.

Personnel

Pour le personnel utilisant le souffleur, les

points suivants s’appliquent:

S Doit avoir étudié et assimilé le contenu de

ce mode d’emploi.

S Ne doit pas porter des vêtements amples,

écharpe, collier ou des cheveux longs

pouvant pénétrer dans la machine.

S Ne doit pas être sous l’influence de

l’alcool, de médicaments ou fatigué.

S Doit être majeur.

S Une trousse de premiers secours doit tou-

jours être disponible.

Sécurité de carburant

AVERTISSEMENT! Le carbu-

rant utilisé pour le souffleur a les

caractéristiques dangereuses

suivantes:

1. Le liquide, ses vapeurs et les

gaz d’échappement sont toxiques.

2. Peut provoquer des irritations

cutanées.

3. Est très inflammable.

Des consignes de sécurité spéciales

s’appliquent au carburant utilisé pour le

souffleur. Elles figurent à la section

Manipulation du carburant.

545218616 Rev. 1 12/15/08

Silencieux

Le silencieux sert à réduire au maximum

les émissions sonores et à éloigner de l’utilisateur les gaz libérés par la machine. Le

silencieux équipé d’un pot catalytique est

aussi conçu pour réduire la teneur des gaz

d’échappement en substances toxiques.

AVERTISSEMENT! Un silen-

cieux muni d’un catalyseur devient

très chaud soit lors de l’utilisation,

soit après arrêt. Ceci vaut pour le ré gime au ralenti. Tout contact peut

brûler la peau. Attention au risque

d’incendie !

AVERTISSEMENT! Les gaz d’é-

chappement du moteur sont brûlants

et peuvent produire des étincelles

susceptibles de provoquer un incendie. Ne jamais mettre la machine en

service à l’intérieur ou à proximité

d’un matériau inflammable!

Equipement de sécurité

AVERTISSEMENT! Le souffleur

ne doit jamais être utilisé si l’un des

dispositifs de sécurité ou l’une des

protections manque, est endommagé

ou ne fonctionne pas.

Afin d’éviter des accidents avec le souffleur, il existe’un certain nombre de dispositifs de sécurité et de protection, qui figurent

à la section concernant la description générale du souffleur. Les dispositifs de sécurité

et les protections exigent aussi une vérification et un entretien réguliers. Ces

mesures et intervalles sont indiqués à la

section Entretien.

Sécurité pendant l’utilisation

S Aucune personne non autorisée ou ani-

mal ne doit se trouver dans la zone de

travail qui est de 15 mètres.

S Le souffleur peut projeter violemment des

objets pouvant ricocher. Cela peut provoquer des blessures graves aux yeux.

S Ne jamais diriger le flux d’air vers des

personnes ou des animaux.

S Arrêtez le moteur avant le montage ou le

démontage d’accessoires ou d’autres

éléments.

S Ne jamais faire fonctionner le souffleur

sans que les protections prévues soient

en place.

S Ne jamais faire fonctionner le souffleur

dans les espaces mal ventilés afin d’éviter l’inhalation de gaz d’échappement.

S Arrêter le moteur avant le remplissage de

carburant. Avant de tenter de démarrer

l’appareil, éloignez--le d’au moins 3

mètres du lieu de remplissage du réservoir à carburant.

French - -- 27

Page 28

CONSIGNES DE SÉCURITÉ

f

f

S Faites attention, particulièrement sivous

travaillez de la main gauche. Evitez tout

contact direct du corps avec la zone

d’échappement.

S Le silencieux du catalyseur est brûlant

aussi bien lors de l’utilisation qu’après

l’arrêt. Cela s’applique également en cas

de fonctionnement au ralenti. Faire attention aux risques d’incendie en particulier

lors de manipulation à proximité de

matériaux inflammables et/ou gaz.

S Ne touchez pas la bougie d’allumage ou

le fil de la prise lorsque le moteur tourne.

Vous risquez de recevoir un choc électrique.

S Ne touchez pas le silencieux, la bougie

d’allumage, les autres pièces métalliques

ou le capot moteur lorsque le moteur

tourne ou vient d’être arrêté. Ces pièces et

le capot moteur atteignent des températures élevées et vous risqueriez de vous

brûler sérieusement.

S Faites attention, particulièrement si vous tra-

vail lez de la main gauc he. Éviter tout contact direct du corps sur le couvercle d’admission d’air. Attachez ou enlevez les bijoux, les vêtements amples ou les vêtements qui ont des bretelles, des attaches,

des pompons, etc., loin de le couvercle

d’admission d’air.

S Le souffleur ne doit pas être utilisé sur des

échelles ou des échafaudages.

Autres consignes de sécurité

S Ne pas utiliser le souffleur à des heures

indues, par ex. tôt le matin ou tard le soir.

Voir instructions locales. Heures normales

d’utilisation: 09h00--17h00 du lundi au vendredi.

S Pour réduire le niveau sonore de l’appareil

il est recommandé de limiter le nombre

d’accessoires utilisés en une seule fois.

S Ne pas utiliser plus d’accélération que

nécessaire pour exécuter le travail en

question.

S Vérifier le souffleur avant utilisation. Parti-

culièrement le silencieux, l’admission d’air

et le filtre à air.

S Détacher les éventuelles salissures à

l’aide d’un râteau ou d’une brosse avant

l’opération de soufflage.

S Humidifier légèrement la zone de travail

avant le soufflage en milieu poussiéreux.

S Economiser l’eau en utilisant le souffleur

au lieu d’arroser. Valable pour les gouttières, les façades, les lieux ouverts, les

jardins, etc.

S Prendre garde aux enfants, animaux

domestiques, fenêtres ouvertes et voitures

récemment lavées. Faire envoler les salissures de façon sûre.

S Utiliser le tube et l’embout du sou

que le flux d’air arrive aussi près que possible du sol.

S Nettoyer après le soufflage. Mettre les

salissures dans une poubelle.

Mise au rebut

S Lorsque vous mettez au rebut l’outil, le

combustible ou l’huile pour l’outil, veillez à

bien respecter la réglementation locale.

leur afin

545218616 Rev. 1 12/15/08

French - -- 28

Page 29

Le souffleur

DESCRIPTION

2

3

1

21

8

15

19

18

20

14

9

1. Commande des gaz 12. Embout standard

2. Bouton d’arrêt 13. Embout de grande vitesse

3. Commande de vitesse variable 14. Tube de souffleur

4. Carter de ventilateur 15. Boulon de fixation du tube

5. Bouchon du réservoir 16. Écrou de fixation du tube

6. Filtre à air 17. Silencieux

7. Levier de l’étrangleur 18. Fil de mise à la terre

8. Pompe à carburant 19. Poignée de démarrage

9. Couvercle d’admission d’air 20. Appareil de démarrage

10. Couteau x 21. Réglage du carburateur

11. Ventilateur 22. Manuel d’instructions

17

16

12

22

13

23

9

23. Huile à 2 temps

10

11

6

7

5

4

545218616 Rev. 1 12/15/08

French - -- 29

Page 30

Accessoire en option

DESCRIPTION

26

23

27

24

28

21. Dispositif d’aspiration avec collecte comportant les éléments 22--28 ci--dessous

22. Tube du sac collecteur

23. Sac collecteur

24. Tube d’aspiration (deux éléments)

25. Vis

26. Harnais

27. Poignée d’aspiration

28. Clé universelle

21

22

25

545218616 Rev. 1 12/15/08

French - -- 30

Page 31

DESCRIPTION

Equipement de sécurité

L’équipement suivant du souffleur est conçu

pour diminuer les risques pour l’utilisateur et

l’environnement. Il convient d’apporter une

attention toute particulière à ces éléments

lors de l’utilisation, la vérification et l’entretien.

Bouton d’arrêt

S Le bouton d’arrêt (A) est utilisé pour

couper le moteur.

A

Silencieux

S Le silencieux sert à réduire au maximum

les émissions sonores et à éloigner de l’utilisateur les gaz libérés par la machine. Le

silencieux équipé d’un pot catalytique est

aussi conçu pour réduire la teneur des gaz

d’échappement en substances toxiques.

S Les gaz d’échappement du moteur sont

brûlants et peuvent comporter des étincelles pouvant provoquer un incendie en

cas de contact avec des matériaux inflammables.

S Le silencieux destiné à certains pays ay-

ant un climat sec est équipé d’un écran

pare--étincelles (B), qui doit être nettoyé/

remplacé régulièrement. Voir la section

Entretien.

Equipment divers

Commande des gaz

S Le régime et la puissance du moteur se

règlent à l’aide de la commande des gaz

(C).

C

Commande de vitesse variable

S La commande de vitesse variable (D)

permet de régler le régime du moteur,

selon le besoin, pendant l’utilisation du

souffleur uniquement.

D

S Pour éviter l’endommagement de l’appa-

reil, NE TENTEZ PAS d’utiliser le commande de vitesse variable pendant l’utilisation de la fonction d’aspirat eur.

Carter de ventilateur

S Le carter du ventilateur (E) et le ventilateur

(F) assurent un courant d’air approprié à

travers le souffleur.

AVERTISSEMENT! Le silen-

cieux est très chaud pendant et quelque temps après l’utilisation. NE PAS

TOUCHER LE SILENCIEUX S’IL EST

CHAUD! Cela peut occasionner des

brûlures.

545218616 Rev. 1 12/15/08

B

F

E

Fildemiseàlaterre

S Le fil de mise à la terre (G) réduit l’accu-

mulation d’électricité statique pendant le

fonctionnement par temps sec.

French - -- 31

Page 32

DESCRIPTION

f

f

G

Couvercle d’admission d’air

S Un couvercle d’arrivée d’air (H) est situé

sur le côté du boîtier du ventilateur.

L’ouverture du couvercle permet d’accéder

à la ventilateur pour nettoyage et inspection. Si le accessoire d’aspiration en

option est utilisé, il doit être fixé le tubes

d’aspiration sur l’ouverture du couvercle

d’arrivée d’air. Pour ouvrir le couvercle

d’arrivée d’air, soulever le bord opposé à

la charnière (indiqué par une flèche sur

le couvercle d’arrivée d’air) à l’aide d’un

tournevis.

SLe tube sou

de montage à fente et à taquet de fixation.

Pour installer ou retirer le tube souffleur (ou

le tube du sac collecteur pour le accessoire d’aspiration en option), retirez le boulon de fixation du tube. Alignez la fente de

la sortie d’air du souffleur avec la nervure

en relief du tube, puis enfoncez le tube de

façon à aligner les perçages du tube avec

ceux du carter de l’appareil. Réinstallez et

serrez le boulon de fixation du tube.

S Les embouts (L) sont doté d’un dispositif

de montage à baïonnette pour son raccordement au tube souffleur. L’air est soufflé via le tube souffleur jusqu’à l’embouts,

où le débit de soufflage augmente et le

schéma de l’air soufflé est formé de façon

à permettre l’obtention de performances

optimales. Pour régler la longueur du tube

souffleur, déverrouillez le système à baïonnette de l’embout en tournant ce dernier

vers la gauche, puis faites glisser l’embout

jusqu’à la position appropriée. Pour reverrouiller l’embout, tournez--levers la droite

jusqu’ à ce qu’un clic soit émis.

leur (K) est doté d’un système

H

J

AVERTISSEMENT! Le souffleur

ne doit jamais être démarré si le

couvercle d’admission d’air n’est pas

fermé, est endommagé ou s’il n’est

pas possible de le fermer. Ceci ne

s’applique quand les tubes d’aspiration soyez branchée.

Couteaux

S Il y a deux couteaux (J) sur la roue du

ventilateur. Les couteaux ont pour fonction de décomposer les feuilles et autres

déchets avant qu’ils passent dans le sac

collecteur.

Tubes souffleur et embouts

REMARQUE :

tube et l’écrou doivent être installés avant

l’utilisation initiale (référez--vous à la section

concernant la description générale du souffleur à la page 29).

Le boulon de fixation du

K

Appareil de démarrage et poignée

de démarrage

S L’appareil de démarrage (M) est situé sur

le côté du boîtier de moteur et s’engage

dans le vilebrequin uniquement lorsque la

poignée de démarrage (N) est tirée.

N

M

Bouchon de réservoir à carburant

S Le bouchon du réservoir à carburant (O)

est situé à l’arrière du boî tier du moteur

et est doté d’un joint d’étanchéité destiné

à éviter les fuites de carburant.

L

545218616 Rev. 1 12/15/08

French - -- 32

Page 33

DESCRIPTION

P