Page 1

Page 2

2

W

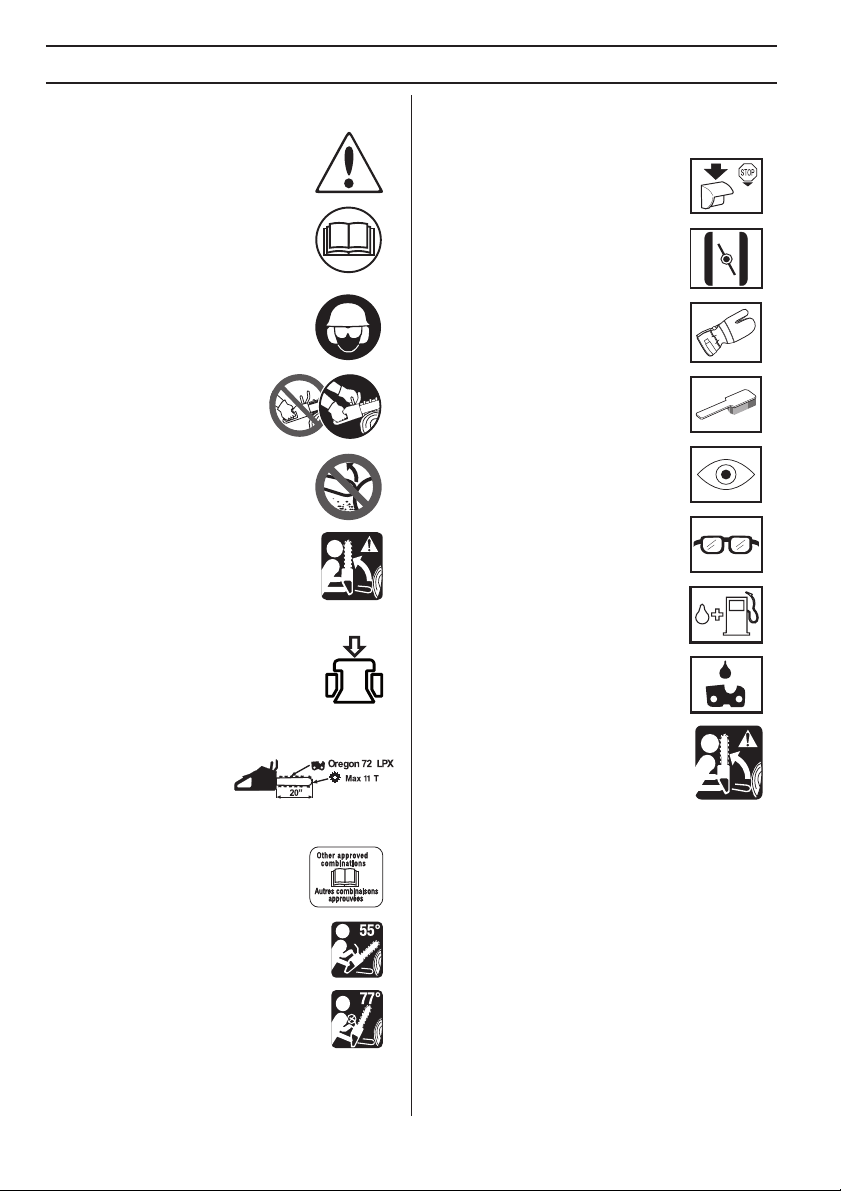

KEY T O SYMBOLS

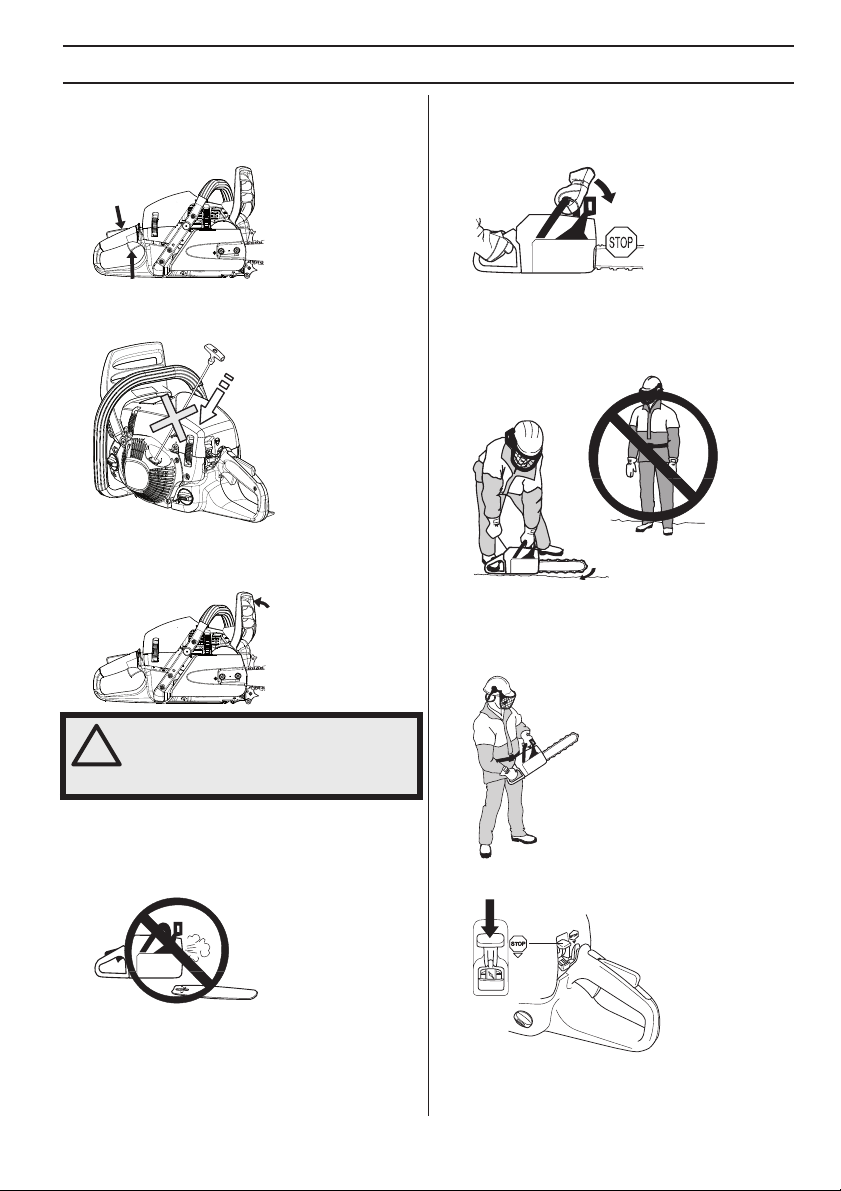

Symbols on the mac hine:

ARNING! Chain saws can be

dangerous! Careless or improper use

can result in serious or fatal injury to the

operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the

machine.

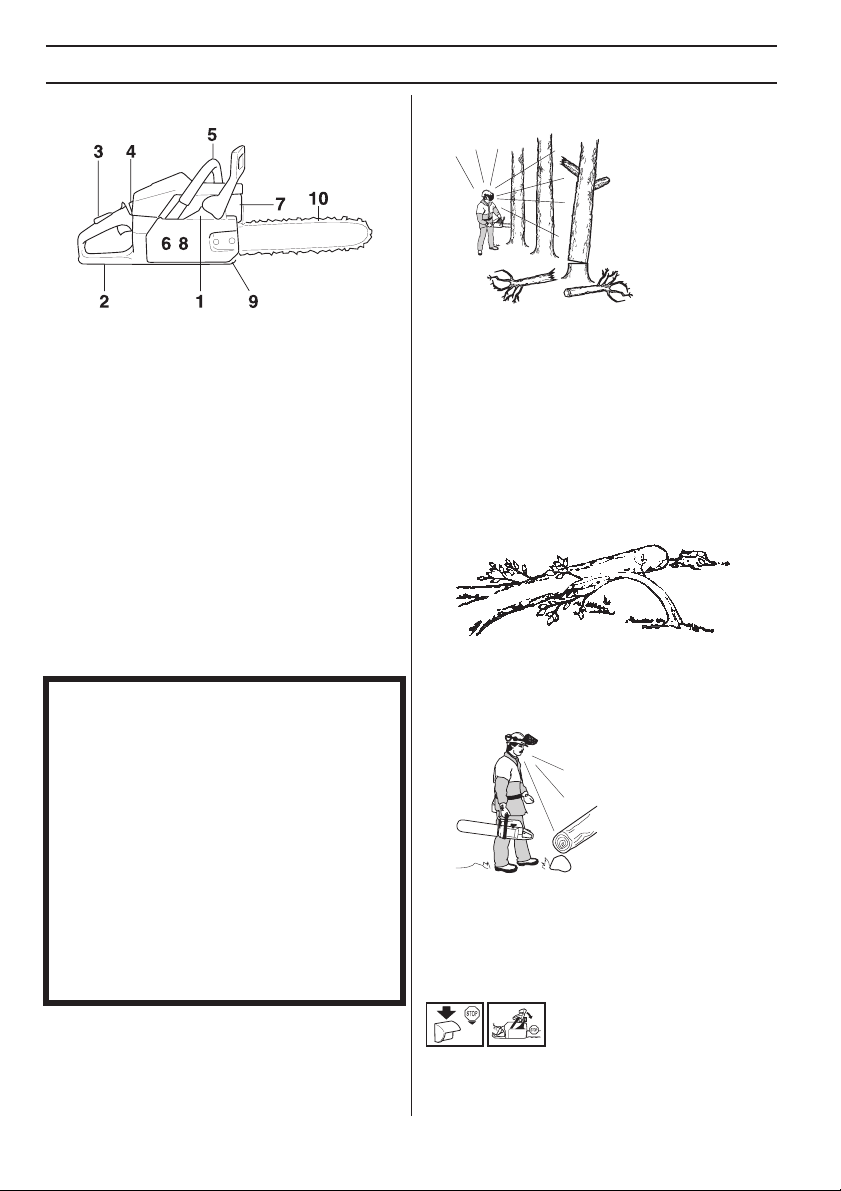

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

Both of the operator ′ s hands must

be used to operate the chain saw.

Never operate a chain saw

holding it with one hand only.

Contact of the guide bar tip with any

object must be avoided.

WARNING! Kickback may occur when

the nose or tip of the guide bar touches an

object, and cause a lightning fast reverse

reaction, kicking the guide bar up and

towards the operator. May cause serious

personal injury.

Decompression v alve: The valve is to

reduce the pressure in the cylinder and

make starting easier. You should always

use the decompression valve when

starting the machine.

Symbols f or Canada model:

Recommended cutting

equipment in this example:

- Bar length 20 inches

- Max. nose radius 11 Teeth

- Chain type Oregon 72LPX

Other approved bar and chain

combinations in Operator’s Manual.

Symbols in the operator’ s manual:

Switch off the engine b y moving the stop

switch to the STOP position before

carrying out any checks or

maintenance.

Ignition; choke: Set the choke control

in the choke position. This should

automatically set the stop switch to the

start position.

Always wear approved protective

gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

worn.

Refuelling.

Filling with oil and adjusting oil flow.

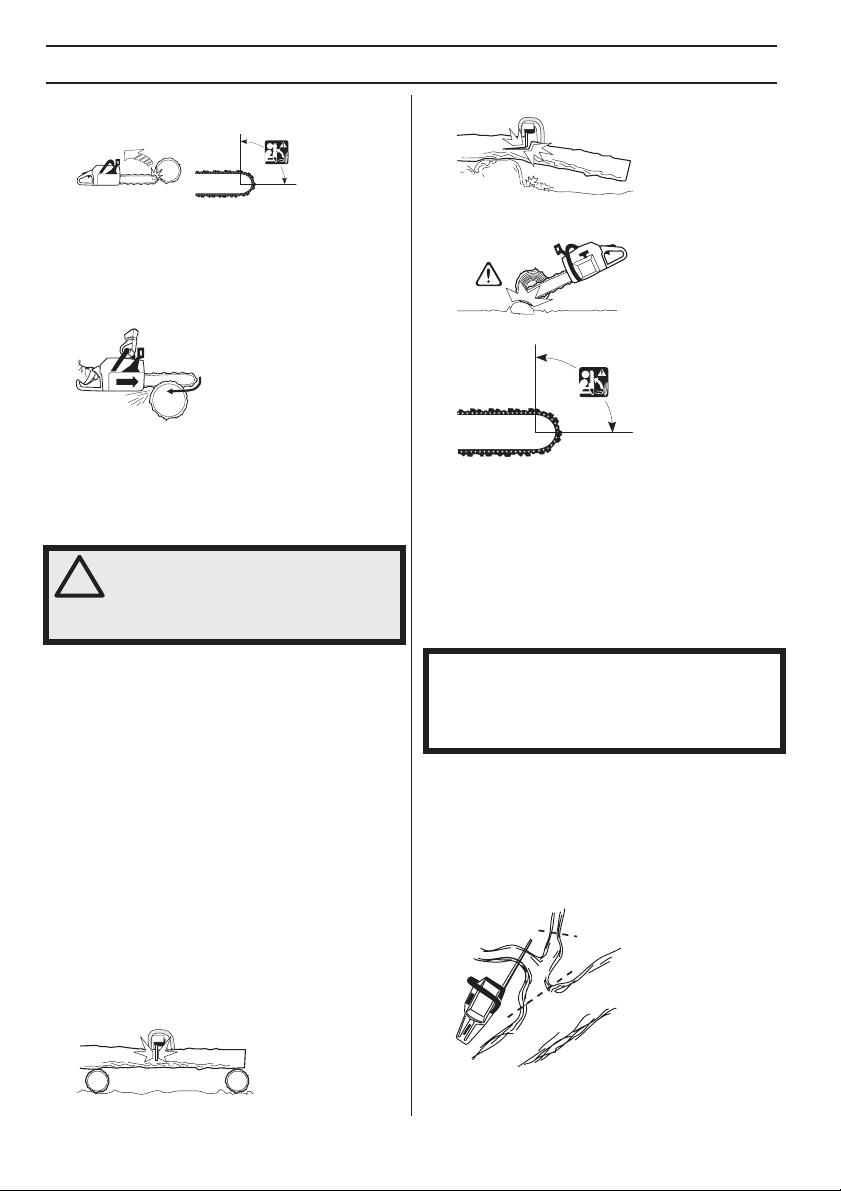

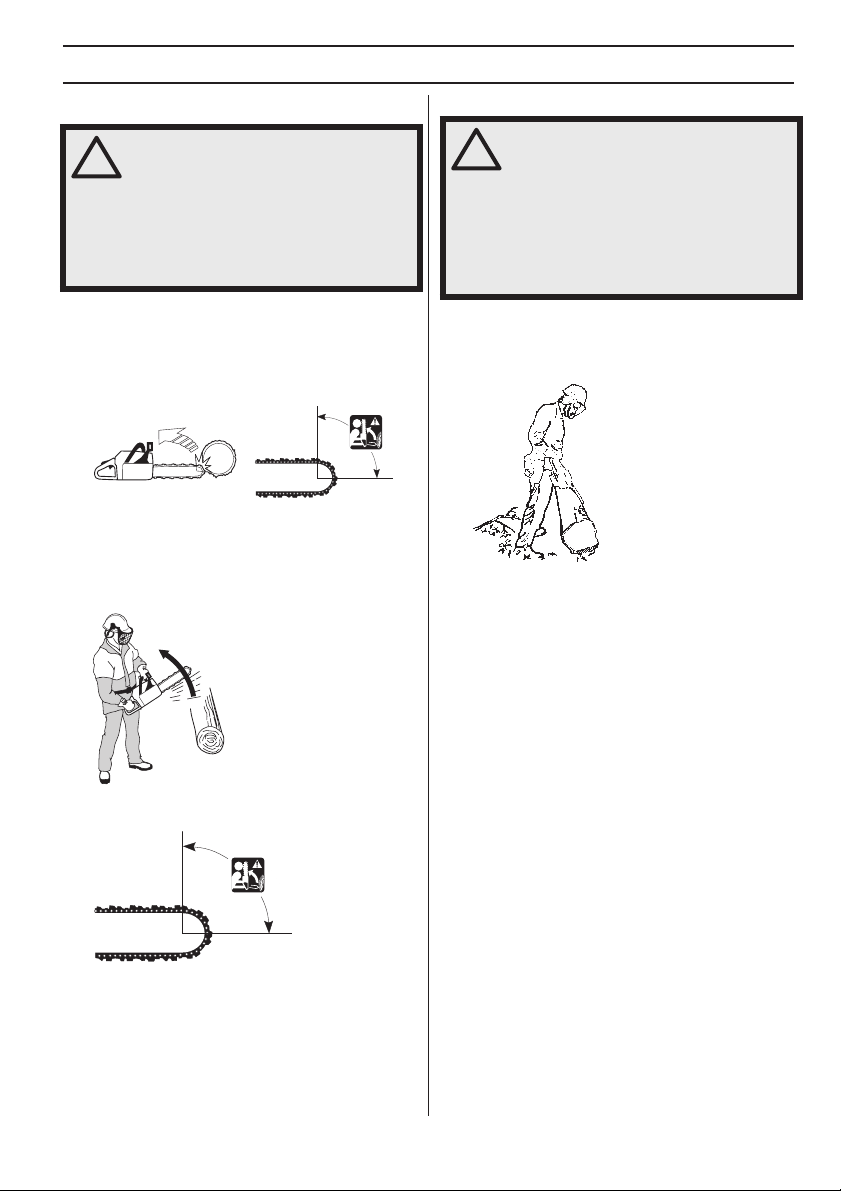

WARNING! Kickback may occur when

the nose or tip of the guide bar touches

an object, and cause a lightning fast

reverse reaction, kicking the guide bar up

and towards the operator. May cause

serious personal injury.

Measured maximum kickback value with

brake for the bar and chain combination on

the label.

Measured maximum kickback value without

triggering the brake, for the bar and chain

combination on the label.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

– English

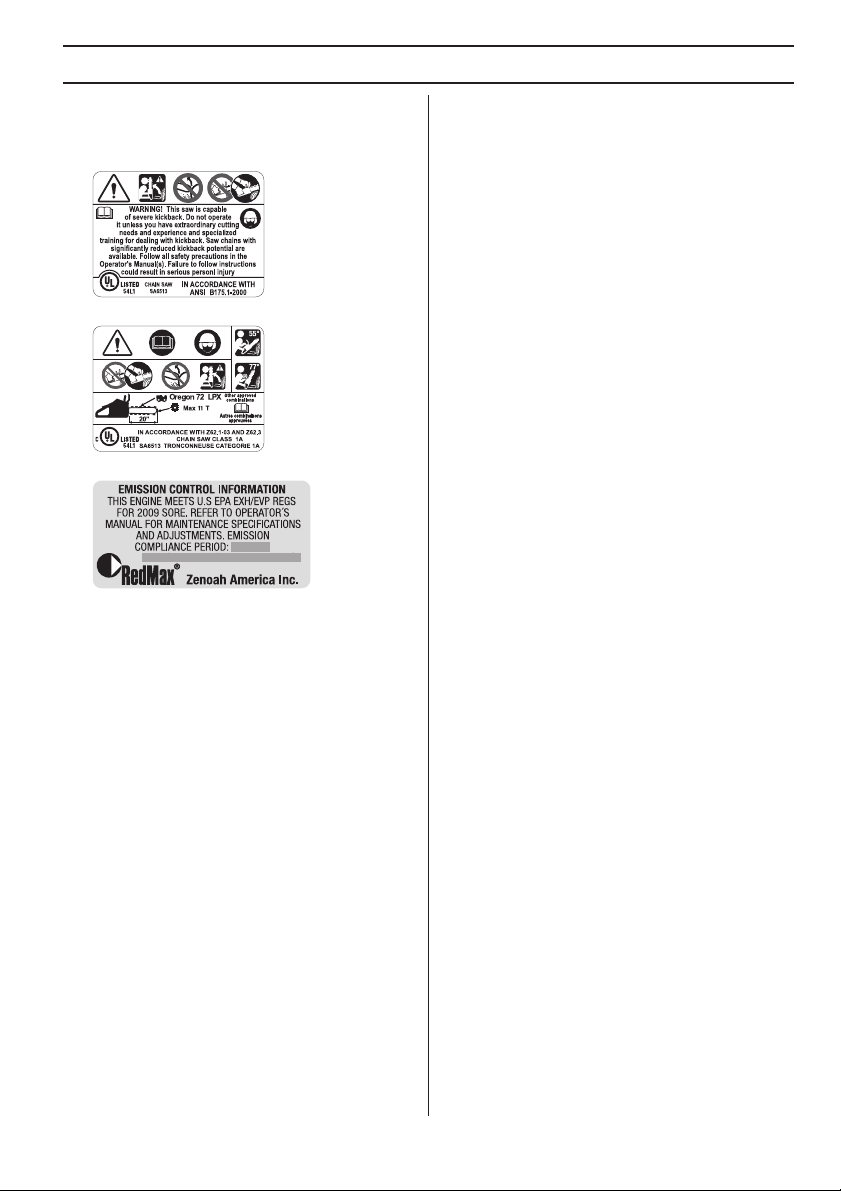

Page 3

Y

EP

KEY T O SYMBOLS

ou will find the following labels on your

chain saw:

USA:

Canada:

A III

The Emissions Compliance P eriod referred to on the

Emission Compliance label indicates the number of

operating hours for which the engine has been shown to

meet Federal emissions requirements.

Maintenance, replacement, or repair of the emission

control devices and system may be performed by any

nonroad engine repair establishment or individual.

English

–

3

Page 4

4

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ...................................... 2

Symbols for Canada model: .................................. 2

Symbols in the operator’s manual: ........................ 2

CONTENTS

Contents ............................................................... 4

WHA T IS WHAT?

What is what on the chain sa w? ........................... 5

AMERICAN ST ANDARD SAFETY

PRECAUTIONS

Saf ety precautions for chain saw users ................ 6

GENERAL SAFETY PRECA UTIONS

Bef ore using a new chain saw .............................. 7

Important .............................................................. 7

Always use common sense .................................. 8

Personal protective equipment ............................. 8

Machine ′ s safety equipment ................................. 8

Cutting equipment ................................................. 11

ASSEMBL Y

Fitting the bar and chain ....................................... 16

FUEL HANDLING

Fuel ....................................................................... 17

Fueling .................................................................. 19

Fuel safety ............................................................ 19

ARTING AND STOPPING

Star ting and stopping ............................................ 20

ORKING TECHNIQUES

Bef ore use: ............................................................ 22

General working instructions ................................ 22

How to avoid kickback ........................................... 29

MAINTENANCE

Gener al ................................................................. 30

Carburetor adjustment .......................................... 30

Checking, maintaining and servicing chain saw

safety equipment ..................................................

Muffler ................................................................... 33

Starter ................................................................... 33

Air filter .................................................................. 34

Spark plug ............................................................. 35

Lubricating the bar tip sprocket ............................. 35

Needle bearing lubrication .................................... 35

Adjustment of the oil pump ................................... 35

Cooling system ..................................................... 36

”Dust Free” centrifugal cleaning ............................ 36

Winter use ............................................................. 36

Maintenance schedule .......................................... 37

TECHNICAL D ATA

echnical data ....................................................... 38

Bar and chain combinations ................................. 39

LIMITED WARRANTY

Limited w arranty ................................................... 40

ARTS LIST .......................................................... 123

ST

W

T

P

31

– English

Page 5

1

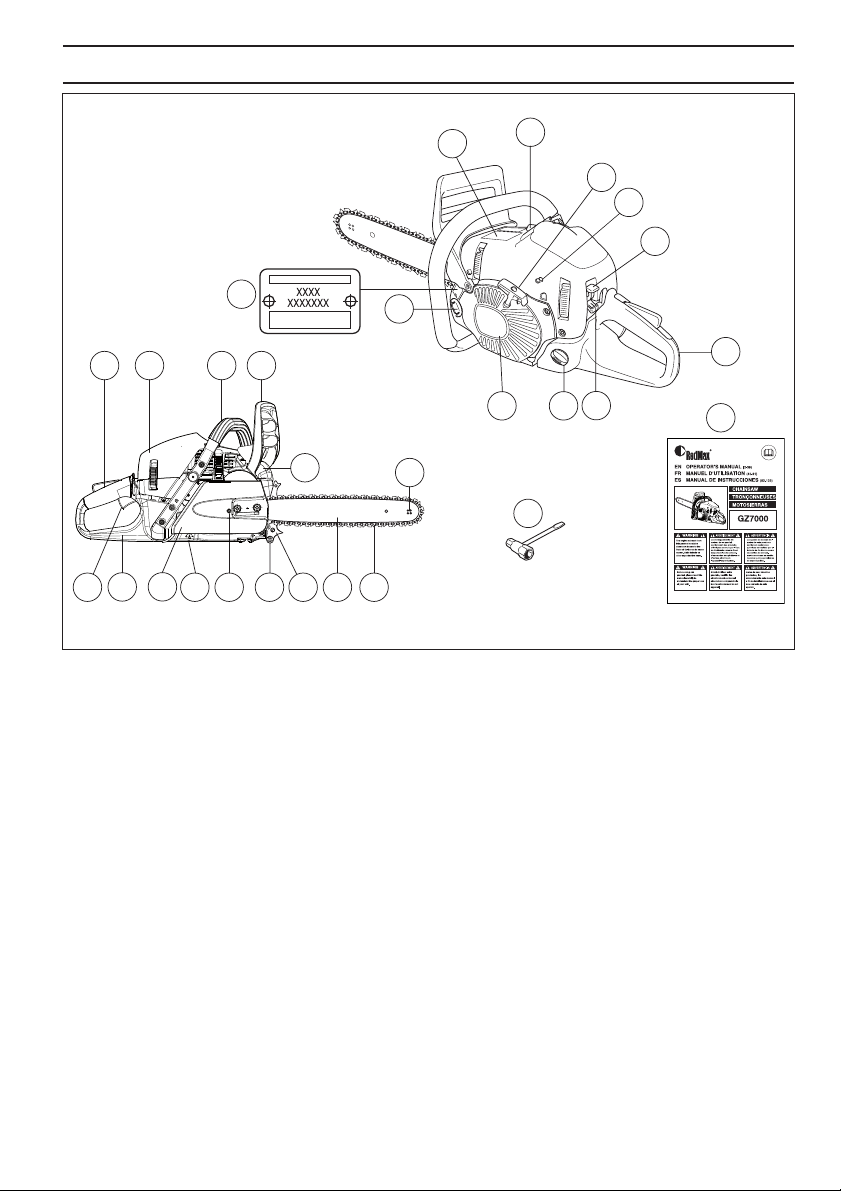

WHA T IS WHA T?

28

11

10

23

22

24

What is what on the c hain saw?

Decompression valve

2 Starter handle

3 Adjuster screws carburetor

4 Stop switch (Ignition on/off switch.)

5 Rear handle

6 Choke control/Start throttle lock

7 Fuel tank

8 Starter

9 Chain oil tank

10 Throttle lockout

11 Cylinder cover

12 Front handle

13 Front hand guard

14 Muffler

21

12

20

13

19

14

18

17

16

27

1

9

8

15

26

15 Bar tip sprocket

16 Chain

17 Bar

18 Bumper spike

19 Chain catcher

20 Chain tensioning screw

21 Oil pump adjustment screw

22 Clutch cover

23 Right hand guard

24 Throttle control

25 Operator’s manual

26 Combination wrench

27 Information and warning decal

28 Product and serial number plate

2

3

4

5

6

7

25

English – 5

Page 6

AMERICAN ST AND ARD SAFETY PRECA UTIONS

!

Saf ety precautions for chain saw users

(ANSI B175.1-2000 Anne x C)

Kic kback safety precautions

ARNING! Kickback may occur when

the nose or tip of the guide bar touches

!

an object, or when the wood closes in

and pinches the saw chain in the cut.

Tip contact in some cases may cause a

lightning fast reverse reaction, kicking

the guide bar up and back towards the

operator.

Pinching the saw chain along the top of

the guide bar may push the guide bar

rapidly back towards the operator.

Either of these reactions may cause you

to lose control of the saw which could

result in serious personal injury.

Do not rely exclusively upon the safety

devices built into your saw. As a chain

saw user, you should take several steps

to keep your cutting jobs free from

accident or injury.

With a basic understanding of kic kback, you can reduce

or eliminate the element of surprise. Sudden surprise

contributes to accidents.

Keep a good firm grip on the saw with both hands, the

right hand on the rear handle, and the left hand on the

front handle, when the engine is running. Use a firm grip

with thumbs and fingers encircling the chain saw handles.

A firm grip will help you reduce kickback and maintain

control of the saw. Don’t let go.

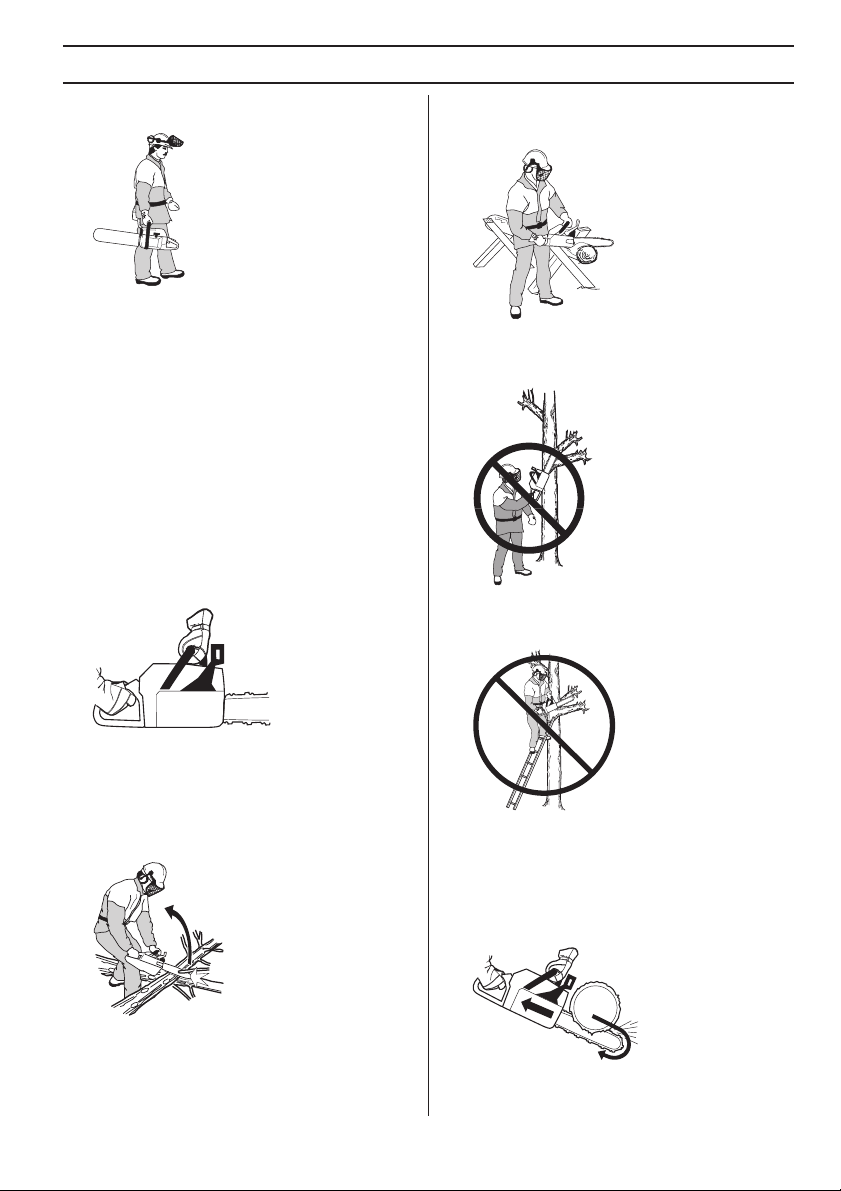

Make sure that the area in which you are cutting is free

from obstacles. Do not let the nose of the guide bar

contact a log, branch, or any other obstacle which could

be hit while you are operating the saw.

Cut at high engine speeds.

Do not overreach or cut above shoulder height.

Follow manufacturer’s sharpening and maintenance

instructions for the saw chain.

Only use replacement bars and chains specified by the

manufacturer or the equivalent.

6

W

W

Other saf ety precautions

ARNING! Do not operate a chain saw

with one hand! Serious injury to the

operator, helpers, bystanders or any

combination of these persons may result

from one-handed operation. A chain saw

is intended for two-handed use.

Do not oper ate a chain saw when you are fatigued.

Use safety footwear; snug-fitting clothing, protective

gloves, and eye, hearing and head protection devices.

Use caution when handling fuel. Move the chain saw at

least 10 feet (3 m) from the fueling point before starting

the engine.

Do not allow other persons to be near the chain saw when

starting or cutting with the chain saw. Keep bystanders

and animals out of the work area.

Do not start cutting until you have a clear work area,

secure footing and a planned retreat path from the falling

tree.

Keep all parts of your body away from the saw chain when

the engine is running.

Before you start the engine, make sure that the saw chain

is not contacting anything.

Carry the chain saw with the engine stopped, the guide

bar and saw chain to the rear, and the muffler away from

your body.

Do not operate a chain saw that is damaged, improperly

adjusted, or not completely and securely assembled. Be

sure that the saw chain stops moving when the throttle

control trigger is released.

Shut off the engine before setting the chain saw down.

Use extreme caution when cutting small size brush and

saplings because slender material may catch the saw

chain and be whipped toward you or pull you off balance.

When cutting a limb that is under tension be alert for

springback so that you will not be struck when the tension

in the wood fibers is released.

Keep handles dry, clean and free of oil or fuel mixture.

Operate the chain saw only in well-ventilated areas.

Do not operate a chain saw in a tree unless you have

been specifically trained to do so.

Do not operate a chain saw above shoulder height.

All chain saw service, other than the items listed in the

operator’s/owner’s safety and maintenance instructions,

should be performed by competent chain saw service

personnel. (For example, if improper tools are used to

remove the flywheel or if an improper tool is used to hold

the flywheel in order to remove the clutch, structural

damage to the flywheel could occur and subsequently

cause the flywheel to burst.)

When transporting your chain saw, use the appropriate

guide bar guard.

Note: This Annex is intended primarily for the consumer or

occasional user.

– English

Page 7

GENERAL SAFETY PRECA UTIONS

!

!

!

!

!

!

•

W

W

W

W

W

W

W

W

Bef ore using a new chain saw

Please read this manual carefully.

• Check that the cutting equipment is correctly fitted

and adjusted. See instructions under the heading

Assembly.

• Refuel and start the chain saw. See the instructions

under the headings Fuel Handling and Starting and

Stopping.

• Do not use the chain saw until sufficient chain oil has

reached the chain. See instructions under the

heading Lubricating cutting equipment.

• Long-term exposure to noise can result in permanent

hearing impairment. So always use approved hearing

protection.

ARNING! Under no circumstances may

the design of the machine be modified

!

without the permission of the

manufacturer. Always use genuine

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others. Your

warranty may not cover damage or

liability caused by the use of nonauthorized accessories or replacement

parts.

ARNING! A chain saw is a dangerous

tool if used carelessly or incorrectly and

!

can cause serious, even fatal injuries. It

is very important that you read and

understand the contents of this

operator’s manual.

ARNING! The inside of the muffler

contain chemicals that may be

!

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

ARNING! Long term inhalation of the

engine’s exhaust fumes, chain oil mist

!

and dust from sawdust can represent a

health risk.

ARNING! The ignition system of this

machine produces an electromagnetic

!

field during operation. This field may

under some circumstances interfere with

pacemakers. To reduce the risk of

serious or fatal injury, we recommend

persons with pacemakers to consult

their physician and the pacemaker

manufacturer before operating this

machine.

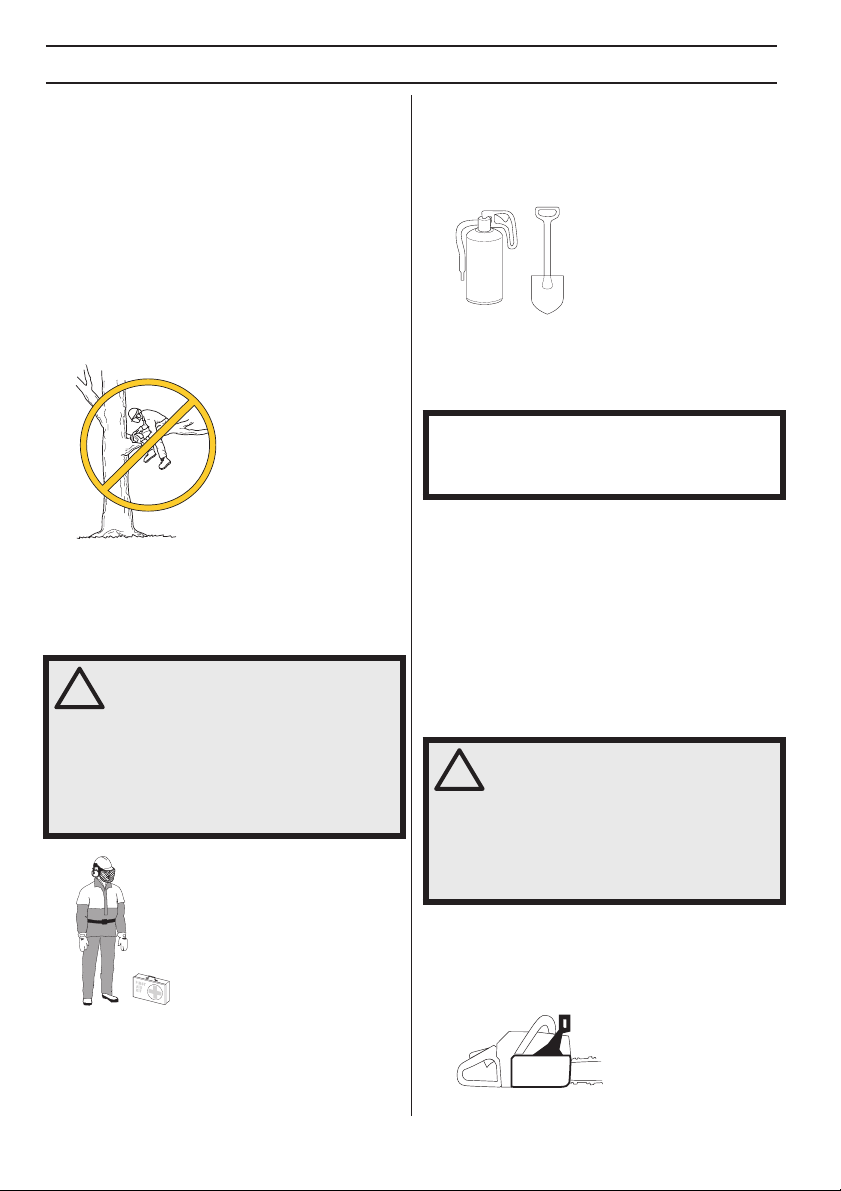

ARNING! When using a chain saw, a

fire extinguisher should be available.

ARNING! Keep handles dry, clean and

free of oil.

ARNING! Beware of carbon monoxide

poisoning. Operate the chainsaw in well

ventilated areas only.

WARNING! Do not attempt a pruning or

limbing operation in a standing tree

unless specifically trained to do so.

Impor tant

IMPORTANT!

The machine is only designed for cutting wood.

You should only use the saw with the bar and chain

combinations we recommend in the chapter Technical

data.

Never use the machine if you are fatigued, while under

the influence of alcohol or drugs, medication or anything

that could affect your vision, alertness, coordination or

judgement.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

Do not modify this product or use it if it appears to have

been modified by others.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the heading Maintenance.

Never use any accessories other than those

recommended in this manual. See instructions under

the headings Cutting equipment and Technical data.

CAUTION! Always wear protective glasses or a face

visor to reduce the risk of injury from thrown objects. A

chain saw is capable of throwing objects, such as wood

chips, small pieces of wood, etc, at great force. This can

result in serious injury, especially to the eyes.

WARNING! Running an engine in a

confined or badly ventilated area can

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Faulty cutting equipment or

the wrong combination of bar and saw

chain increases the risk of kickback!

Only use the bar/saw chain combinations

we recommend, and follow the filing

instructions. See instructions under the

heading Technical data.

English

–

7

Page 8

GENERAL SAFETY PRECAUTIONS

!

Always use common sense

It is not possible to cover every conceivable situation you

can face when using a chain saw. Always exercise care

and use your common sense. Avoid all situations which

you consider to be beyond your capability. If you still feel

uncertain about operating procedures after reading these

instructions, you should consult an expert before

continuing. Do not hesitate to contact your dealer or us if

you have any questions about the use of the chain saw.

We will willingly be of service and provide you with advice

as well as help you to use your chain saw both efficiently

and safely. Attend a training course in chain saw usage if

possible. Your dealer, forestry school or your library can

provide information about which training materials and

courses are available.

Work is constantly in progress to improve the design and

technology - improvements that increase your safety and

efficiency. Visit your dealer regularly to see whether you

can benefit from new features that have been introduced.

Personal protective equipment

WARNING! Most chain saw accidents

happen when the chain touches the

!

operator. You must use approved

personal protective equipment whenever

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment.

• Gloves with saw protection

• Trousers with saw protection

• Boots with saw protection, steel toe-cap and non-slip

sole

• Always have a first aid kit nearby.

• Fire Extinguisher and Shovel

Do not wear loose fitting clothing, scarves, neckties,

jewelry or any item that may become tangled in

surrounding growth or the chain saw itself. Generally

clothes should be close-fitting without restricting your

freedom of movement.

IMPORTANT! Sparks can come from the muffler, the bar

and chain or other sources. Always have fire

extinguishing tools available if you should need them.

Help prevent forest fires.

Machine′′′′s safety equipment

In this section the machine’s safety features and their

function are explained. For inspection and maintenance

see instructions under the heading Checking, maintaining

and servicing chain saw safety equipment. See

instructions under the heading, What is what?, to find

where these parts are located on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest servicing dealer.

WARNING! Never use a machine with

defective safety components. Safety

equipment must be inspected and

maintained. See instructions under the

heading Checking, maintaining and

servicing chain saw safety equipment. If

your machine does not pass all the

checks, take the saw to a servicing

dealer for repair.

• Approved protective helmet

• Hearing protection

• Approved protective goggles and a visor. The

approved protective goggles should comply with

standard ANSI Z87.1.

8 – English

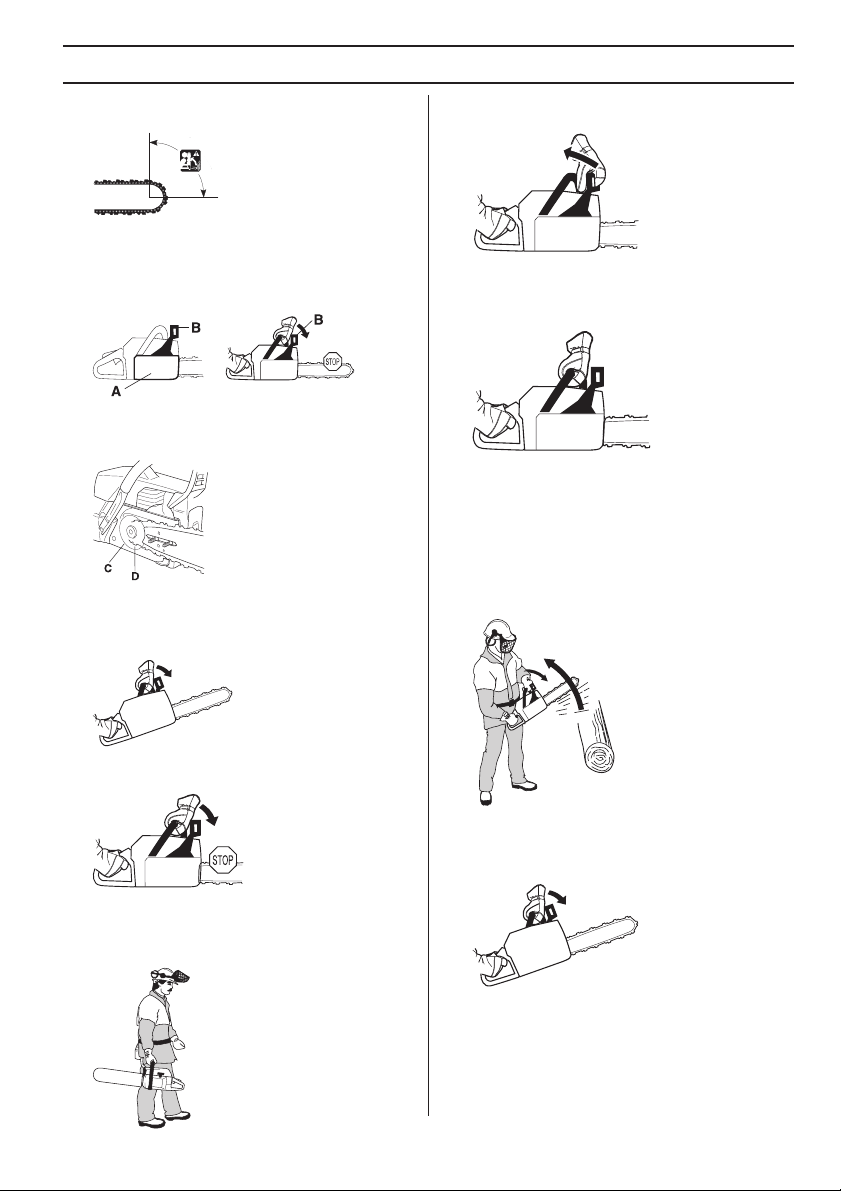

Chain brake and front hand guard

Your chain saw is equipped with a chain brake that is

designed to stop the chain. Should kickback occur, the

chain brake reduces the risk of accidents, but only you

can prevent them.

Page 9

GENERAL SAFETY PRECAUTIONS

Take care when using your saw and make sure the

kickback zone of the bar never touches any object.

• The chain brake (A) can either be activated manually

(by your left hand) or automatically by the inertia

release mechanism.

• The brake is applied when the front hand guard (B) is

pushed forwards.

• This movement activates a spring-loaded mechanism

that tightens the brake band (C) around the engine

drive system (D) (clutch drum).

• The front hand guard is not designed solely to activate

the chain brake. Another important feature is that it

reduces the risk of your left hand hitting the chain if

you lose grip of the front handle.

• To release the chain brake pull the front hand guard

backwards, towards the front handle.

• Kickback can be very sudden and violent. Most

kickbacks are minor and do not always activate the

chain brake. If this happens you should hold the chain

saw firmly and not let go.

• The way the chain brake is activated, either manually

or automatically by the inertia release mechanism,

depends on the force of the kickback and the position

of the chain saw in relation to the object that the

kickback zone of the bar strikes.

If you get a violent kickback while the kickback zone of

the bar is farthest away from you the chain brake is

designed to be activated by the inertia in the kickback

direction.

• The chain brake must be engaged when the chain

saw is started to prevent the saw chain from rotating.

• Use the chain brake as a ”parking brake” when

starting and when moving over short distances, to

reduce the risk of moving chain accidentally hitting

your leg or anyone or anything close by.

If the kickback is less violent or the kickback zone of

the bar is closer to you the chain brake is designed to

be activated manually by the movement of your left

hand.

• In the felling position the left hand is in a position that

makes manual activation of the chain brake

impossible. With this type of grip, that is when the left

hand is placed so that it cannot affect the movement

English – 9

Page 10

GENERAL SAFETY PRECAUTIONS

of the front hand guard, the chain brake can only be

activated by the inertia action.

original positions. This arrangement means that the

throttle control is automatically locked at the idle setting.

Will my hand always activate the chain brake during a kickback?

No. It takes a certain force to move the hand guard

forward. If your hand only lightly touches the front guard

or slips over it, the force may not be enough to trigger the

chain brake. You should also maintain a firm grip of the

chain saw handles while working. If you do and

experience a kickback, your hand may never leave the

front handle and will not activate the chain brake, or the

chain brake will only activate after the saw has swung

around a considerable distance. In such instances, the

chain brake might not have enough time to stop the saw

chain before it touches you.

There are also certain positions in which your hand

cannot reach the front hand guard to activate the chain

brake; for example, when the saw chain is held in felling

position.

Will my inertia activated chain brake always activate during kickback in the event of a kickback?

No. First your brake must be in working order. Testing the

brake is simple, see instructions under the heading

Checking, maintaining and servicing chain saw safety

equipment. We recommend you do before you begin each

work session. Second the kickback must be strong

enough to activate the chain brake. If the chain brake is

too sensitive it would activate all the time which would be

a nuisance.

Will my chain brake always protect me from injury in the event of a kickback?

No. First, the chain brake must be in working order to

provide the intended protection. Second, it must be

activated during the kickback as described above to stop

the saw chain. Third, the chain brake may be activated but

if the bar is too close to you the brake might not have

enough time to slow down and stop the chain before the

chain saw hits you.

Only you and proper working technique can eliminate

kickback and its danger.

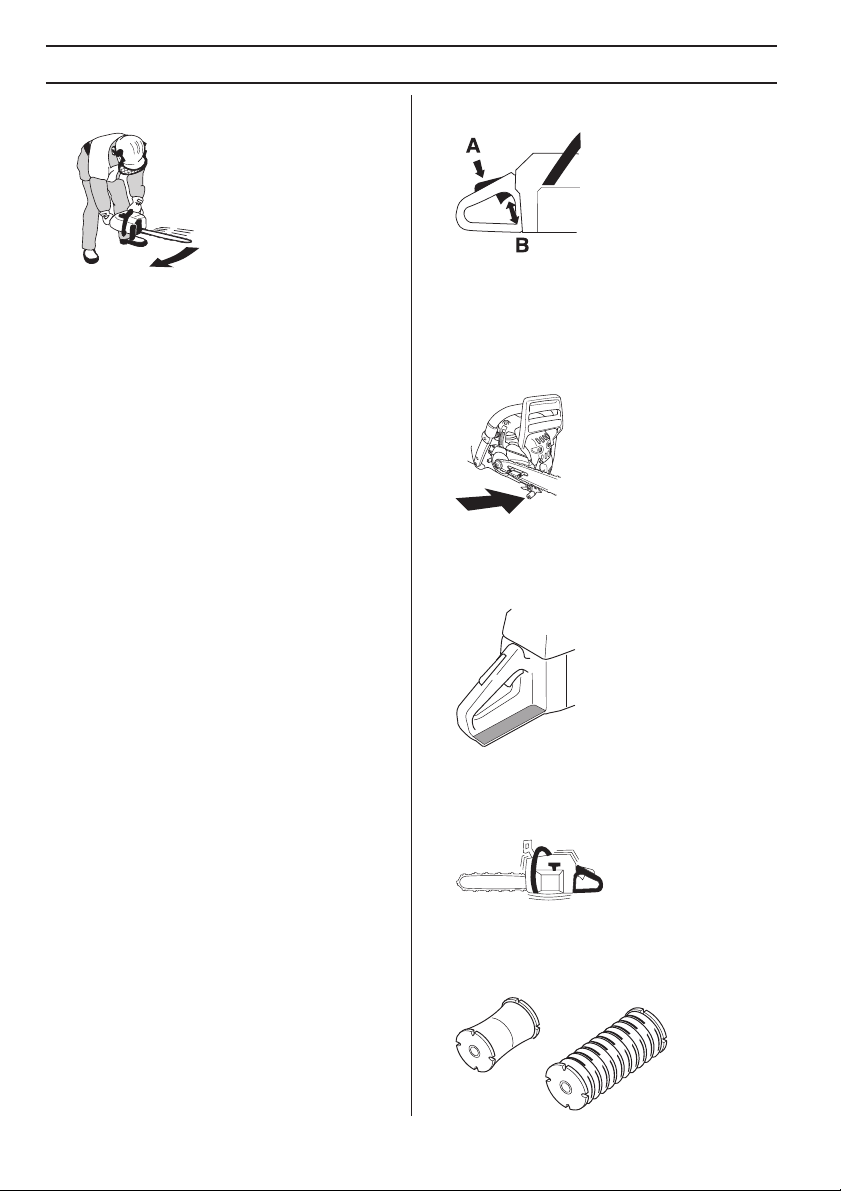

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

Chain catcher

The chain catcher is designed to catch the chain if it

snaps or jumps off. This should not happen if the chain is

properly tensioned (see instructions under the heading

Assembly) and if the bar and chain are properly serviced

and maintained (see instructions under the heading

General working instructions).

Right hand guard

Apart from protecting your hand if the chain jumps or

snaps, the right hand guard stops branches and twigs

from interfering with your grip on the rear handle.

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to reduce vibration and make

operation easier.

The machine′s vibration damping system reduces the

transfer of vibration between the engine unit/cutting

equipment and the machine

chain saw, including the cutting equipment, is insulated

from the handles by vibration damping units.

′s handle unit. The body of the

10 – English

Page 11

GENERAL SAFETY PRECAUTIONS

!

Cutting hardwoods (most broadleaf trees) creates more

vibration than cutting softwoods (most conifers). Cutting

with cutting equipment that is blunt or faulty (wrong type

or badly sharpened) will increase the vibration level.

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the fingers,

hands or wrists. These symptoms may be

increased in cold temperatures.

Stop switch

Use the stop switch to switch off the engine.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

WARNING! The exhaust fumes from the

engine are hot and may contain sparks

!

which can start a fire. Never start the

machine indoors or near combustible

material!

In areas with a hot, dry climate there is a high risk of fires.

These areas are sometimes subject to government rules

requiring among other things the muffler must be

equipped with an approved type of spark arrestor screen.

WARNING! Never use a saw without a

muffler, or with a damaged muffler. A

damaged muffler may substantially

increase the noise level and the fire

hazard. Keep fire fighting equipment

handy. If a spark arrestor screen is

required in your area, never use the saw

without or with a broken spark arrestor

screen.

Spark arrestor muffler

The spark arrestor muffler controls the exhaust noise and

prevents hot, glowing particles of carbon from leaving the

muffler. Make sure the spark arrestor screen is in good

repair and properly seated in the muffler.

Certain internal combustion engines operated on forest,

brush and/or grass-covered areas in some states, are

required to be equipped with a spark arrestor. This

requirement also applies to all US Forest Service lands.

In some of these areas, the spark arrestor system must

be certified per USDA Forest Service Regulation SAE

J335. Check with your local state authorities fo specific

regulations in your area. Failure to follow these

regulations is in violation of the law.

Cutting equipment

This section describes how to choose and maintain your

cutting equipment in order to:

• Reduce the risk of kickback.

• Reduce the risk of the saw chain breaking or jumping

off the bar.

• Obtain optimal cutting performance.

• Extend the life of cutting equipment.

• Avoid increasing vibration levels.

General rules

• Only use cutting equipment recommended by us!

See instructions under the heading Technical data.

• Keep the chain’s cutting teeth properly

sharpened! Follow our instructions and use the

recommended file gauge.

sharpened chain increases the risk of accidents.

A damaged or badly

CAUTION! During operation, the muffler or catalytic

muffler and surrounding cover become hot. Never

suspend the saw on a lanyard with the engine running.

Always wear proper protective clothing to protect your

lower body from sharp saw chain and hot muffler.

Always keep exhaust area clear of flammable debris

during transportation or when storing, otherwise serious

property damage or personal injury may result.

• Maintain the correct depth gauge setting! Follow

our instructions and use the recommended depth

gauge clearance.

the risk of kickback.

Too large a clearance increases

English – 11

Page 12

GENERAL SAFETY PRECAUTIONS

!

• Keep the chain properly tensioned! If the chain is

slack it is more likely to jump off and lead to increased

wear on the bar, chain and drive sprocket.

• Keep cutting equipment well lubricated and

properly maintained!

more likely to break and lead to increased wear on the

bar, chain and drive sprocket.

Cutting equipment designed to reduce kickback

WARNING! Faulty cutting equipment or

the wrong combination of bar and saw

!

chain increases the risk of kickback!

Only use the bar/saw chain combinations

we recommend, and follow the filing

instructions. See instructions under the

heading Technical data.

The only way to avoid kickback is to make sure that the

kickback zone of the bar never touches anything.

By using cutting equipment with ”built-in” kickback

reduction and keeping the chain sharp and wellmaintained you can reduce the effects of kickback.

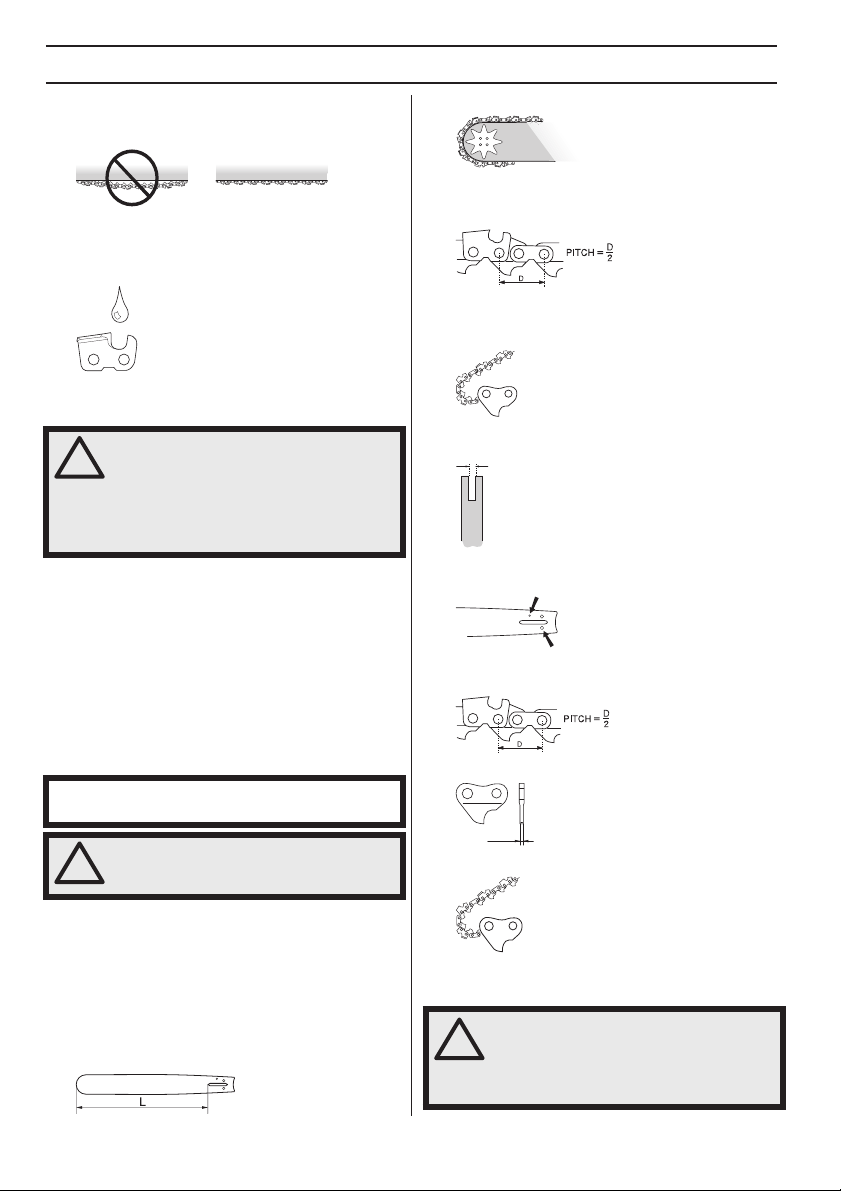

Bar

The smaller the tip radius the lower the chance of

kickback.

Chain

A chain is made up of a number of links, which are

available in standard and low-kickback versions.

IMPORTANT! No saw chain design eliminates the

danger of kickback.

A poorly lubricated chain is

• Number of teeth on bar tip sprocket (T).

• Chain pitch (inches). The spacing between the drive

links of the chain must match the spacing of the teeth

on the bar tip sprocket and drive sprocket.

• Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch

and the number of teeth on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar

must match the width of the chain drive links.

• Chain oil hole and hole for chain tensioner. The bar

must be matched to the chain saw design.

Chain

• Chain pitch (inches)

• Drive link width (mm/inches)

WARNING! Any contact with a rotating

saw chain can cause extremely serious

!

injuries.

Some terms that describe the bar and chain

To maintain the safety features of the cutting equipment,

you should replace a worn or damaged bar or chain with

a bar and chain combinations recommended by RedMax.

See instructions under the heading Technical Data for a

list of replacement bar and chain combinations we

recommend.

Bar

• Length (inches/cm)

12 – English

• Number of drive links.

Maintenance of saw chain and guide bar

Chain

WARNING! Keep the chain’s cutting teeth

properly sharpened! Follow our

instructions and use the recommended

file gauge. A damaged or badly sharpened

chain increases the risk of accidents.

Page 13

GENERAL SAFETY PRECAUTIONS

!

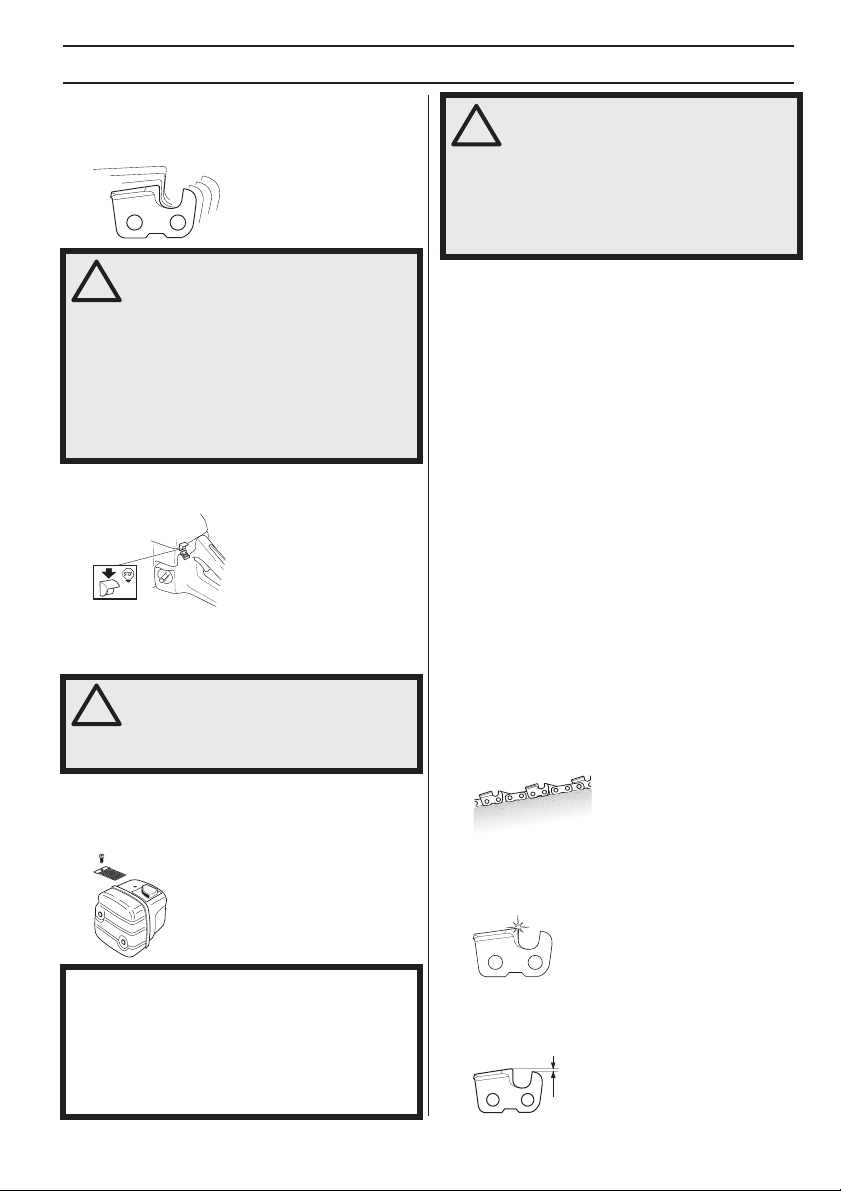

The cutting teeth need to be sharpened when:

• Sawdust becomes powder-like

• You need extra force to saw in

• The cut way does not go straight

• Vibration increases

• Fuel consumpion increases

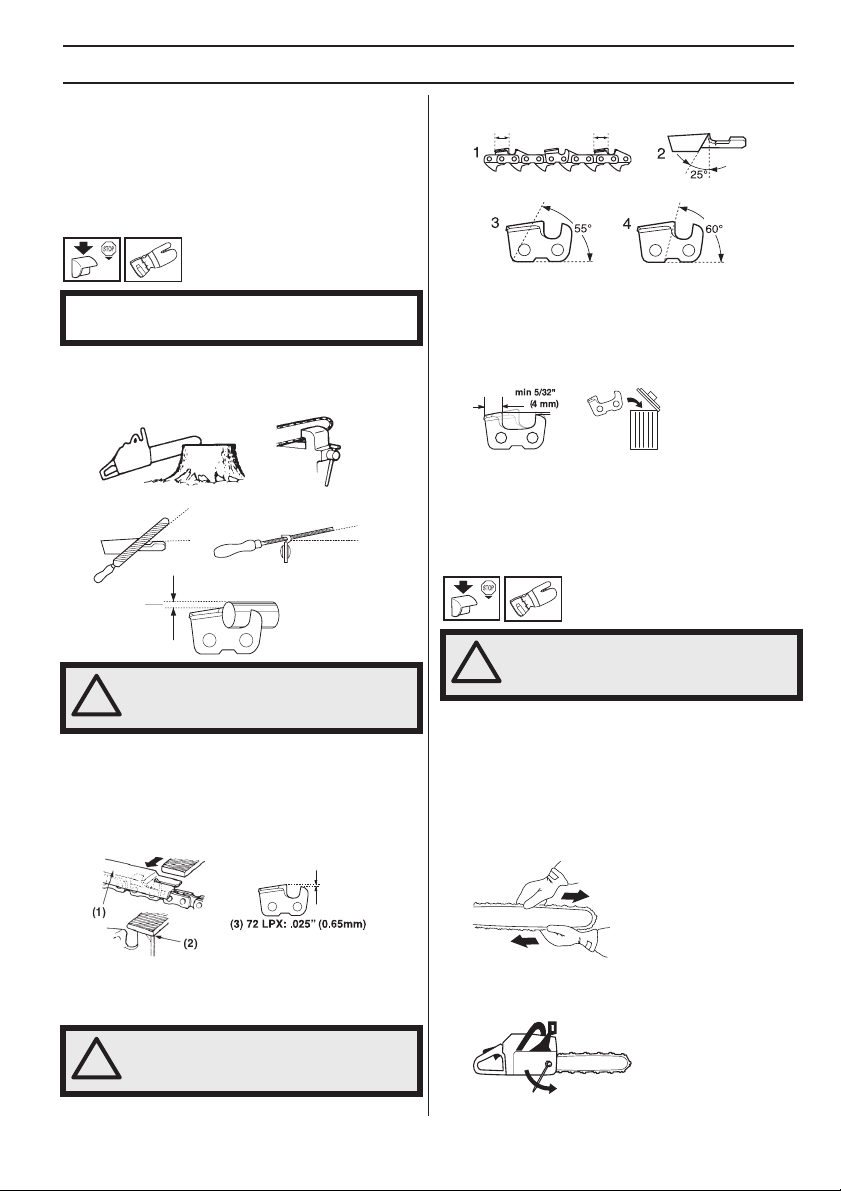

Sharpening cutting teeth

Important Always wear gloves, when working with the

chain, in order to protect your hands from injury.

Make sure the saw chain is held securely, before filing!

• Place your flle on the cutting teeth and push straight

forward. Keep the flle position as illustrated.

25°

1

5

WARNING! Departure from the

sharpening instructions considerably

!

increases the risk of kickback.

Use a round file of proper size for your chain.

Chain type 72 LPX

File size 7/32” /5,5mm

After every cutting tooth has been set, check the depth

gauge and flle it to the proper level as illustrated.

10°

Make sure every cutting tooth has the same lenght and

egde angels as illustrated.

1 Cutting teeth lenght

2 Filing angle

3 Side plate angle

4 Top plate cutting angle

When the length of the cutting teeth has worn down to

only 5/32 inch (4 mm) the chain must be replaced.

Bar

Reverse the bar occasionally to prevent partial wear.

The bar rail should always be square. Check for wear of

the bar rail.

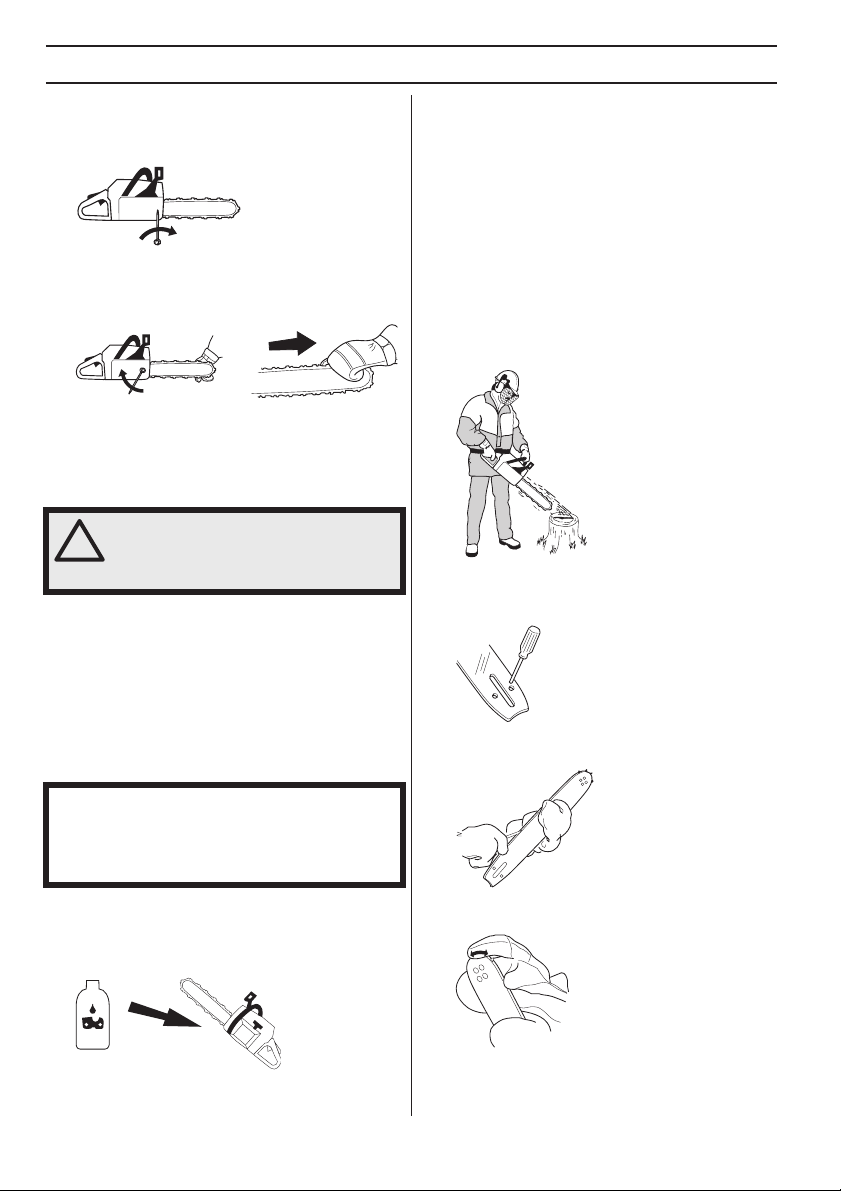

Tensioning the chain

WARNING! A slack chain may jump off

the bar and cause serious or even fatal

injury.

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up

the slack.

Check the chain tension every time you refuel. NOTE! A

new chain has a running-in period during which you

should check the tension more frequently.

Tension the chain as tightly as possible, but not so tight

that you cannot pull it round freely by hand.

1 Appropriate gauge checker

2 Make the shoulder round

3 Depth gauge standard

WARNING! The risk of kickback is

increased if the depth gauge setting is

!

too large!

• Loosen the bar nuts that hold the clutch cover/chain

brake. Use the combination spanner. Then tighten the

bar nuts by hand as tight as you can.

English – 13

Page 14

GENERAL SAFETY PRECAUTIONS

• Raise the tip of the bar and stretch the chain by

tightening the chain tensioning screw using the

combination spanner. Tighten the chain until it does

not sag from the underside of the bar.

• Use the combination spanner to tighten the bar nuts

while lifting the tip of the bar at the same time. Check

that you can pull the chain round freely by hand and

that it does not sag from the underside of the bar.

The position of the chain tensioning screw on our chain

saws varies from model to model. See instructions under

the heading What is what? to find out where it is on your

model.

Lubricating cutting equipment

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

!

which could lead to serious, even fatal

injuries.

Chain oil

Chain oil must demonstrate good adhesion to the chain

and also maintain its flow characteristics regardless of

whether it is warm summer or cold winter weather.

We recommend the use of our own oil for maximum chain

life. If our own chain oil is not available, standard chain oil

is recommended.

Never use waste oil! Using waste oil can be dangerous

to you and damage the machine and environment.

However, this safety feature requires that you use the

right sort of chain oil (if the oil is too thin it will run out

before the fuel), and that you adjust the carburetor as

recommended (a lean mixture may mean that the fuel

lasts longer than the oil) and that you also use the

recommended cutting equipment (a bar that is too

long will use more chain oil).

Checking chain lubrication

• Check the chain lubrication each time you refuel. See

instructions under the heading Maintenance of saw

chain and guide bar.

Aim the tip of the bar at a light coloured surface about

20 cm (8 inches) away. After 1 minute running at 3/4

throttle you should see a distinct line of oil on the light

surface.

If the chain lubrication is not working:

• Check that the oil hole in the bar is not obstructed.

Clean if necessary.

• Check that the groove in the edge of the bar is clean.

Clean if necessary.

IMPORTANT! When using vegetable based saw chain

oil, dismantle and clean the groove in the bar and saw

chain before long-term storage. Otherwise there is a risk

of the saw chain oil oxidizing, which will result in the saw

chain becoming stiff and the bar tip sprocket jamming.

Filling with chain oil

• All our chain saws have an automatic chain lubrication

system. On some models the oil flow is also

adjustable.

• The saw chain oil tank and the fuel tank are designed

so that the fuel runs out before the saw chain oil.

14 – English

• Check that the oil hole in the bar is not obstructed.

Clean if necessary.

If the chain lubrication system is still not working after

carrying out the above checks and associated measures

you should contact your servicing dealer.

Page 15

GENERAL SAFETY PRECAUTIONS

!

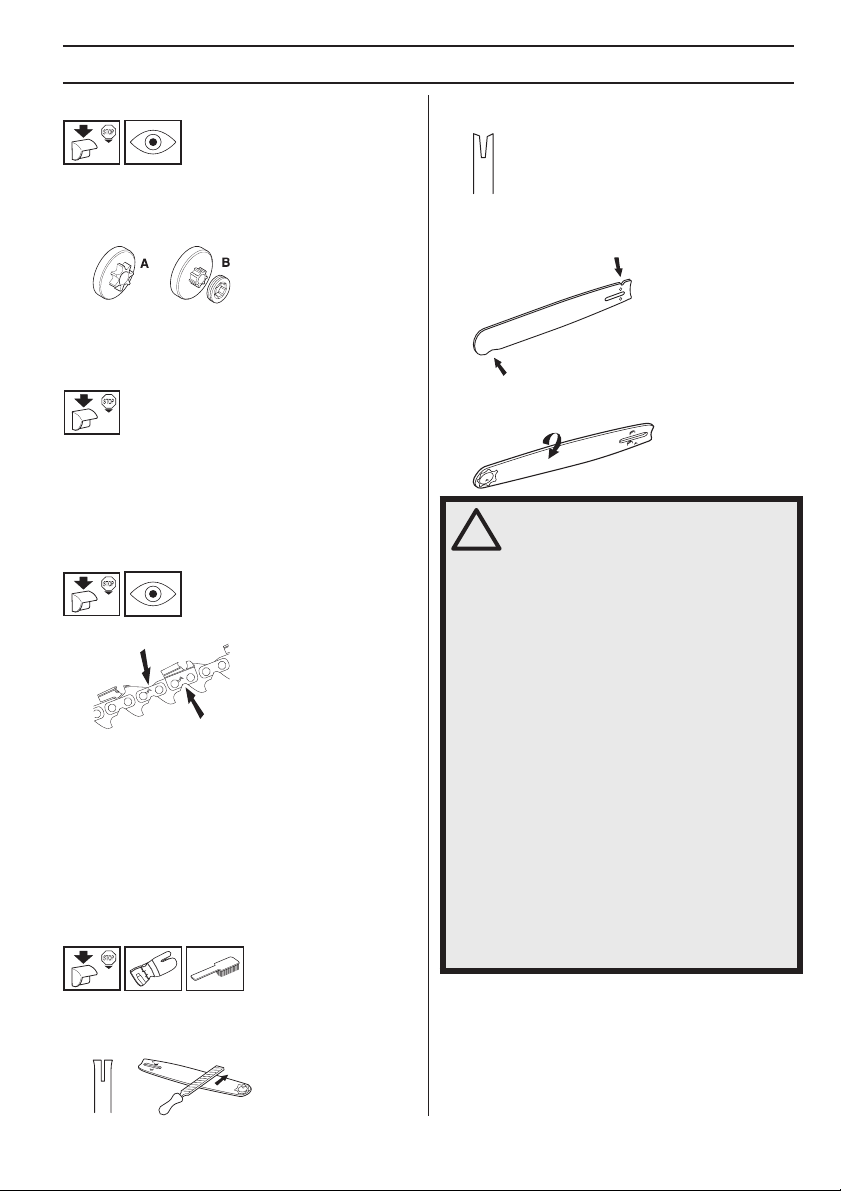

Chain drive sprocket

The clutch drum is fitted with one of the following drive

sprockets:

A Spur sprocket (the chain sprocket is welded on the drum)

B Rim sprocket (replaceable)

Regularly check the degree of wear on the drive sprocket.

Replace if wear is excessive. Replace the drive sprocket

whenever you replace the chain.

Needle bearing lubrication

Both versions of sprockets have a needle bearing on the

drive shaft, which has to be greased regularly (once a

week). CAUTION! Use only high quality bearing grease or

engine oil.

See instructions under the heading Maintenance, Needle

bearing lubrication.

Checking wear on cutting equipment

Check the chain daily for:

• Visible cracks in rivets and links.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points

above.

We recommend you compare the existing chain with a

new chain to decide how badly the existing chain is worn.

File all the teeth to the same length. When the length of

the cutting teeth is reduced to 5/32 inch (4 mm) the chain

is worn out and should be replaced.

Bar

• Whether the groove in the bar has become badly

worn. Replace the bar if necessary.

• Whether the tip of the bar is uneven or badly worn. If

a hollow forms on the underside of the bar tip this is

due to running with a slack chain.

• To prolong the life of the bar you should turn it over

daily.

WARNING! Most chain saw accidents

happen when the chain touches the

operator.

Wear personal protective equipment. See

instructions under the heading Personal

protective equipment.

Do not tackle any job that you feel you

are not adequately trained for. See

instructions under the headings

Personal protective equipment, How to

avoid kickback, Cutting equipment and

General working instructions.

Avoid situations where there is a risk of

kickback. See instructions under the

heading Machine

Use the recommended protective

equipment and check its condition. See

instructions under the heading General

working instructions.

Check that all the chain saw safety

features are working. See instructions

under the headings General working

instructions and General safety

precautions.

′′′′s safety equipment.

Check regularly:

• Whether there are burrs on the edges of the bar.

Remove these with a file if necessary.

English – 15

Page 16

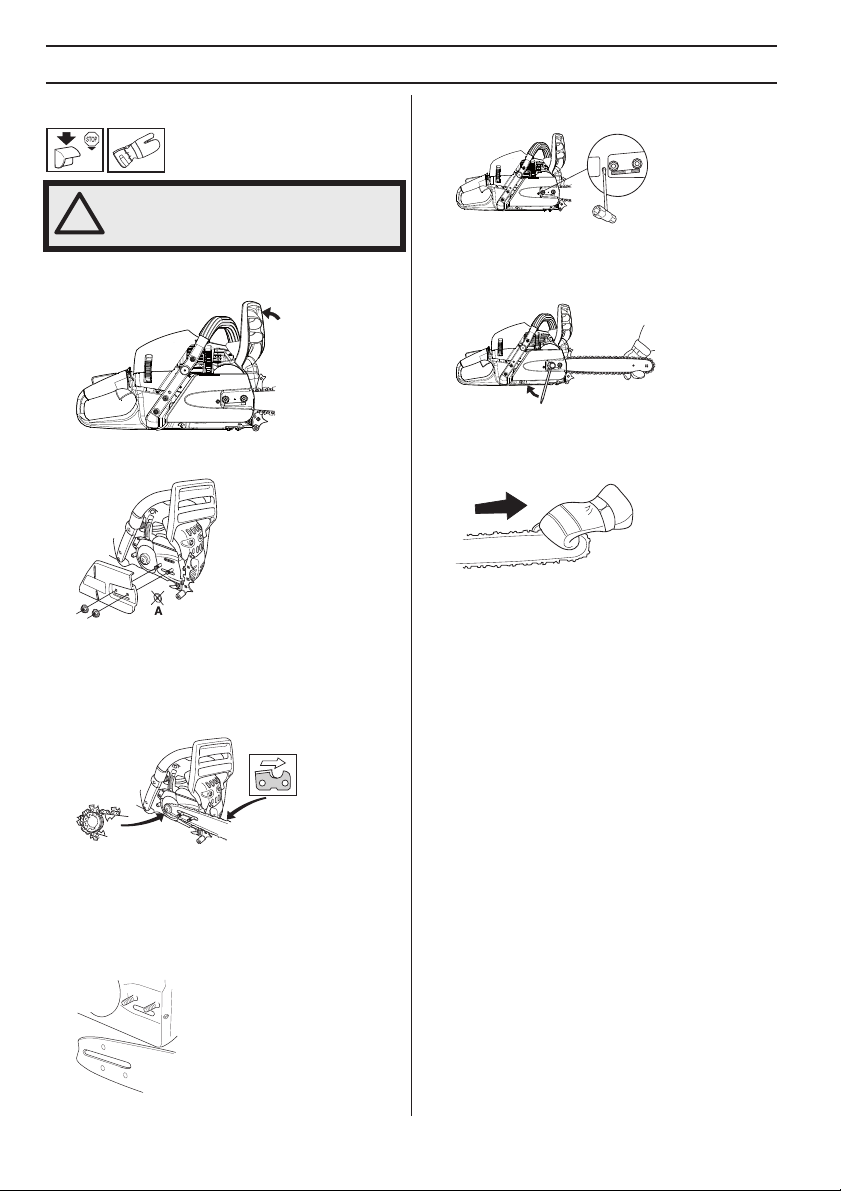

ASSEMBLY

Fitting the bar and chain

WARNING! Always wear gloves, when

working with the chain, in order to

!

protect your hands from injury.

Check that the chain brake is in disengaged position by

moving the front hand guard towards the front handle.

Remove the bar nuts and remove the clutch cover (chain

brake). Take off the transportation ring (A).

Note: If clutch cover is difficult to remove, replace bar

nuts, engage brake and rerelease (an audible click will be

heard if released properly).

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sprocket locate it

in the groove on the bar. Begin on the top edge of the bar.

Tension the chain by turning the chain tensioning screw

clockwise using the combination wrench.

The chain is correctly tensioned when it does not sag from

the underside of the bar, but can still be turned easily by

hand. Hold up the bar tip and tighten the bar nuts firmly

with the combination wrench.

When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life.

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Fit the clutch cover and locate the chain adjuster pin in the

hole in the bar. Check that the drive links of the chain fit

correctly over the drive sprocket and that the chain is

correctly located in the groove in the bar. Tighten the bar

nuts finger tight.

16 – English

Page 17

FUEL HANDLING

Fuel

Note! The machine is equipped with a two-stroke engine

and must always be run using a mixture of gasoline and

two-stroke oil. It is important to accurately measure the

amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

WARNING! Always ensure there is

adequate ventilation when handling fuel.

!

Gasoline

• Use good quality unleaded gasoline.

• CAUTION! Engines equipped with catalytic

converters must be run on unleaded fuel

mixtures.

converter and it will no longer serve its purpose.

Gasoline requirements

• All 2-Stroke RedMax products are powered by

Zenoah Professional-Commercial Duty, HiPerformance, Hi-RPM, Air Cooled 2-Stroke engines.

RedMax/Zenoah – Hi-Performance 2-stroke engines

produce higher HP outputs as compared to standard

Home Owner Duty or Light Commercial Duty

production engines offered by most manufacturers.

• Exhaust emission are controlled by the fundamental

engine parameters and components (eq. carburation,

ignition timing and port timing) without addition of any

major hardware or the introduction of an inert material

during combustion.

• The RedMax/Zenoah engines are registered and

certified with CARB (California Air Resources Board)

and EPA (Environmental Protection Agency) to

operate on CLEAN Mid-grade 89 octane or Premium,

unleaded (lead-free) gasoline and RedMax air-cooled

"MaxLife", synthetic blend Premium two-stroke engine

oil mixed at 50:1 ratio.

Leaded gasoline will destroy the catalytic

WARNING! Gasoline is very flammable.

Avoid smoking or bringing any flame or

!

sparks near fuel. Make sure to stop the

engine and allow it to cool before

refueling the unit. Select outdoor bare

ground for fueling and move at least 10 ft

(3 m) away from the fueling point before

starting the engine.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health and

the environment.

• This Hi-Performance Air Cooled 2-stroke Engine

requires the use of Minimum 89 Octane (R+M)/2

(Midgrade or Premium) clean gasoline. Gasoline may

contain maximum of 10% Ethanol (grain alcohol) or up

to 15% MTBE (Methyl tertiarybutylether). Gasoline

containing Methanol (Wood Alcohol) is NOT

approved.

IMPORTANT! If octane rating of the Mid Grade gasoline

in your area is lower than 89 Octane use Premium

Unleaded Gasoline. The majority of all 2-stroke engine

manufacturers in the USA and Canada recommend

using gasoline with 89 Octane or higher.

CAUTION! Gasoline with an octane rating lower than 89

will greatly increase the engines operating temperature.

Low octane gasoline will cause detonation (knock)

resulting in piston seizures and major internal engine

components damage.

Poor quality gasolines or oils may damage sealing rings,

fuel lines or fuel tank of the engine.

IMPORTANT! Failures caused by operating engines on

gasoline with octane rating lower than 89 are not

covered by the RedMax Two-Stroke engine warranty.

CAUTION! Alternative fuels, such as E-15 (15%

ethanol), E-20 (20% ethanol), E-85 (85% ethanol) are

NOT classified as gasoline and are NOT approved for use

in RedMax 2-stroke gasoline engines. Use of alternative

fuels will cause major engine performance and durability

problems such as: improper clutch engagements,

overheating, vapor lock, power loss, lubrication

deficiency, deterioration of fuel lines, gaskets and internal

carburetor components, etc... Alternative fuels cause high

moisture absorption into the fuel/oil mixture leading to oil

and fuel separation.

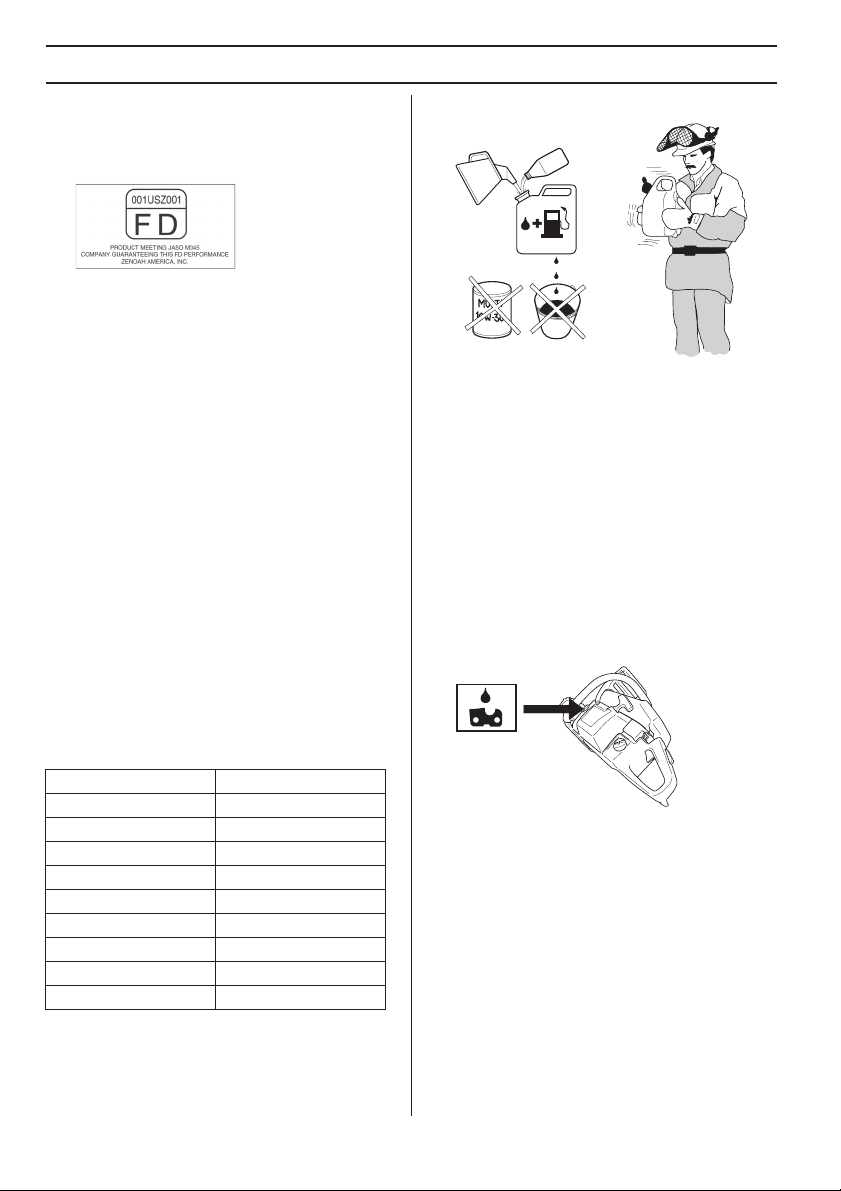

Oil requirements

• Use only RedMax "MaxLife", Synthetic blend

Premium air-cooled two-stroke engine oil or oil

certifiedto ISO-L-EGD (ISO/CD1378) standard AND

one that is JASO-FD registered. RedMax air-cooled

"MaxLife", Synthetic blend Premium two stroke

engine oil and ISO-L-EGD (ISO/CD1378) AND JASOFD oils arefully compatible with gasoline’s containing

10% Ethanol. RedMax air-cooled "MaxLife",

Synthetic blend Premium two stroke engine oil and

ISO-L-EGD (ISO/CD1378) AND JASO-FD oils are

Universal and should be mixed at 50:1 ratio for all 2

stroke air cooled engines sold in the past regardless

of mixing ratios specified in those manuals.

English – 17

Page 18

FUEL HANDLING

• If the oil is registered with JASO, the JASO Logo with

FD and registration number will be displayed on the

container. The highest JASO rating is "FD", which

equals the ISO-L-EGD rating. Lower ratings are "FC",

"FB" and "FA".

• Engine problems due to inadequate lubrication

caused by failure to use ISO-L-EGD certified and

JASO FD registered oil such as "MaxLife", RedMax

Synthetic blend Premium 2-stroke oil WILL VOID THE

REDMAX TWO-STROKE ENGINE WARRANTY.

CAUTION! Do not use NMMA (National Marine

Manufacturers Association), BIA (Boating Industry

Association), and TCW (two cycle water cooled) oils

designed for mopeds or outboard water cooled marine

engines. Do not use API (American Petroleum Institute),

TC (Two Cycle) labeled oils. The API-TC test standard

has been discontinued by API in 1995 and it no longer

exists.

Gasoline/oil mixture storage recommendations

Store your gasoline or gasoline/oil mixture in a cool dry

area in a tightly sealed approved container to limit the

entry of moisture and additional air (oxygen). Moisture

and air cause the development of varnish and gum,

making the fuel stale. Stored gasoline and gasoline/oil

mixture ages and loses its octane rating and volatility. Do

not mix more gasoline/oil than you intend to use in 30

days, and 60 days when fuel stabilizer is added. RedMax

air-cooled "Max Life" synthetic blend Premium two-stroke

engine oil "contains fuel stabilizer" and will automatically

extend your gasoline/oil mixture life up to 60 days.

Mixing ratio

1:50 (2%) for all engines.

Gasoline, litre Two-stroke oil, litre

2% (1:50)

5 0,10

10 0,43/0,20

15 0,30

20 0,40

US gallon US fl. oz.

1 2 1/2

2 1/2 6 1/2

5 12 7/8

Mixing

• Always mix the gasoline and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the gasoline

to be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

gasoline.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

Chain oil

• We recommend the use of special RedMax bar and

chain oil with good adhesion characteristics.

• Never use waste oil. This results in damage to the oil

pump, the bar and the chain.

• It is important to use oil of the right grade (suitable

viscosity range) to suit the air temperature.

• In temperatures below 32°F (0°C) some oils become

too viscous. This can overload the oil pump and result

in damage to the oil pump components.

• Contact your service agent when choosing chain oil.

18 – English

Page 19

FUEL HANDLING

!

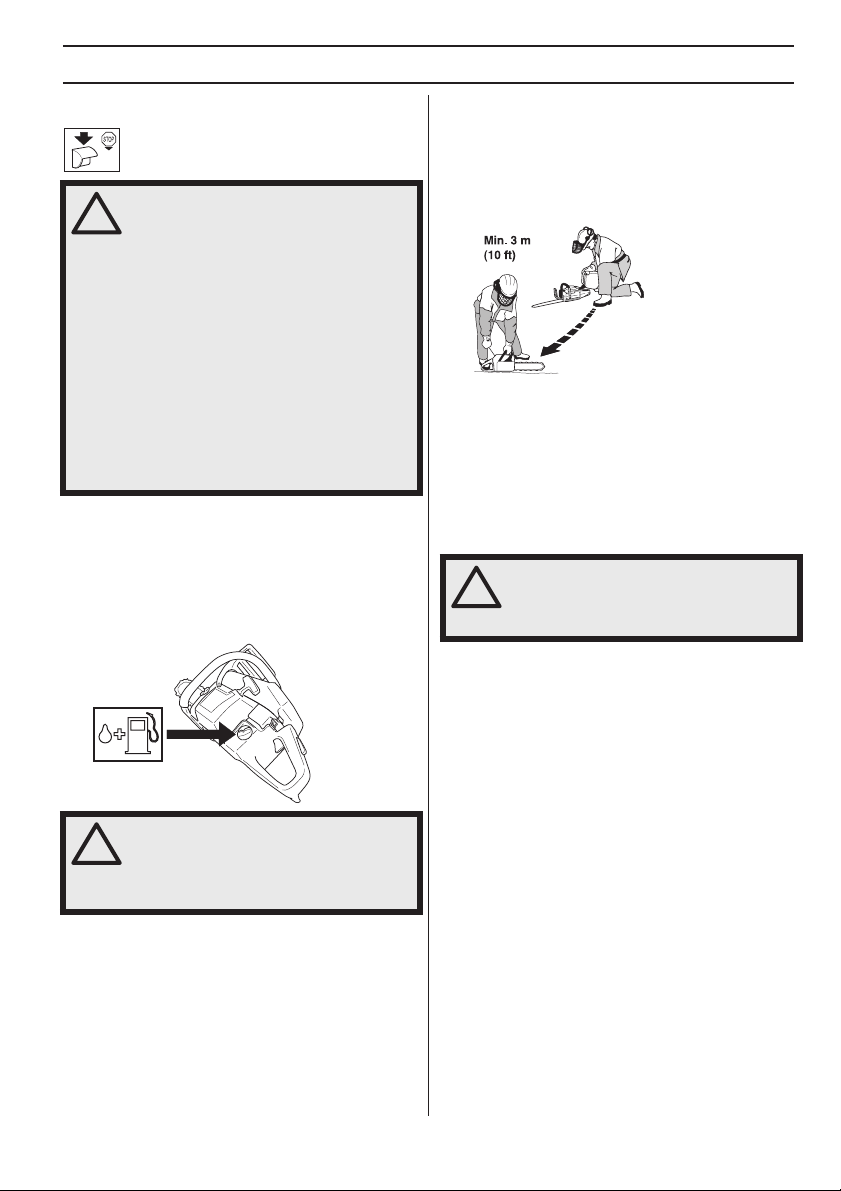

Fueling

WARNING! Taking the following

precautions, will lessen the risk of fire:

!

Do not smoke and do not place any hot

objects in the vicinity of fuel.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area before starting.

Clean the area around the fuel cap. Clean the fuel and

chain oil tanks regularly. The fuel filter must be replaced

at least once a year. Contamination in the tanks causes

malfunction. Make sure the fuel is well mixed by shaking

the container before refuelling. The capacities of the chain

oil tank and fuel tank are carefully matched. You should

therefore always fill the chain oil tank and fuel tank at the

same time.

WARNING! Fuel and fuel vapor are highly

flammable. Take care when handling fuel

!

and chain oil. Be aware of the risks of

fire, explosion and those associated with

inhalation.

Fuel safety

• Never refuel the machine while the engine is running.

• Make sure there is plenty of ventilation when refuelling

or mixing fuel (gasoline and 2-stroke oil).

• Move the machine at least 10 ft (3 m) from the

refuelling point before starting it.

• Never start the machine:

1 If you have spilled fuel or chain oil on the machine.

Wipe off the spillage and allow remaining fuel to

evaporate.

2 If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

WARNING! Never use a machine with

visible damage to the spark plug guard

and ignition cable. A risk of sparking

arises, which can cause a fire.

Transport and storage

• Always store the chain saw and fuel so that there is no

risk of leakages or fumes coming into contact with

sparks or naked flames from electrical equipment,

electric motors, relays/switches, boilers and the like.

• Always store fuel in an approved container designed

for that purpose.

• For longer periods of storage or for transport of the

chain saw, the fuel and chain oil tanks should be

emptied. Ask where you can dispose of waste fuel and

chain oil at your local gas station.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The bar guard must always be fitted to the cutting

attachment when the machine is being transported or

in storage, in order to prevent accident contact with

the sharp chain. Even a non-moving chain can cause

serious cuts to yourself or persons you bump into with

an exposed chain.

Long-term storage

Empty the fuel/oil tanks in a well ventilated area. Store the

fuel in approved cans in a safe place. Fit the bar guard.

Clean the machine. See instructions under the heading

Maintenance schedule.

English – 19

Page 20

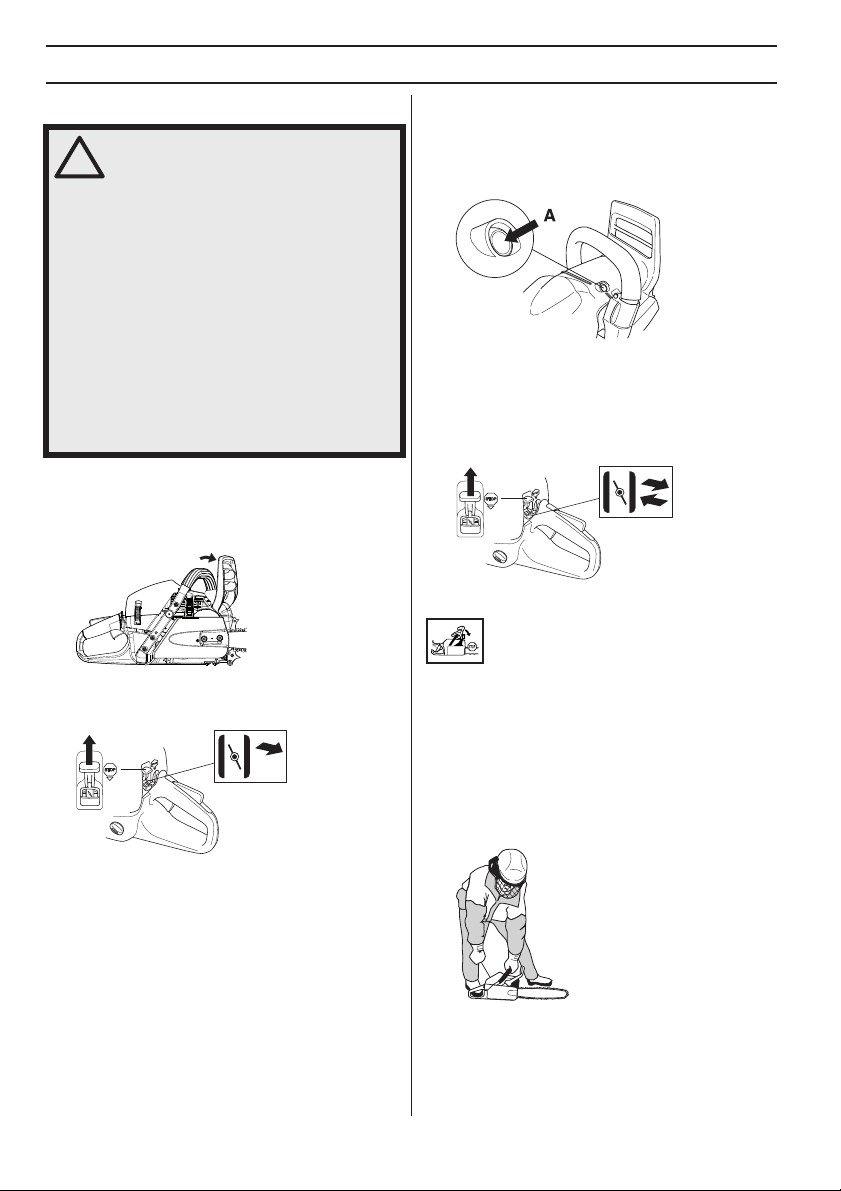

STARTING AND STOPPING

Starting and stopping

WARNING! Note the following before

starting:

!

The chain brake must be engaged when

the chain saw is started to reduce the

chance of contact with the moving chain

during starting.

Never start a chain saw unless the bar,

chain and all covers are fitted correctly.

Otherwise the clutch can come loose and

cause personal injuries.

Place the machine on firm ground. Make

sure you have a secure footing and that

the chain cannot touch anything.

Keep people and animals well away from

the working area.

Cold engine

Starting: The chain brake should be activated when

starting the chain saw. Activate the chain brake by

pushing the front hand guard forwards.

If the machine is fitted with a decompression valve (A):

Press the valve to reduce the pressure in the cylinder and

make starting easier. You should always use the

decompression valve when starting the machine. Once

the machine has started the valve will automatically return

to its closed position.

Warm engine

Use the same procedure as for starting a cold engine but

without setting the choke control in the choke position.

The correct choke/start throttle setting is obtained by

moving the choke control to the choke position and then

pushing it in again.

Starting

Ignition; choke: Set the choke control in the choke

position. This should automatically set the stop switch to

the start position.

Start throttle: The correct choke/start throttle setting is

obtained by moving the control to the choke position.

20 – English

Grip the front handle with your left hand. Hold the chain

saw on the ground by placing your right foot through the

rear handle. Pull the starter handle with your right hand

and pull out the starter cord slowly until you feel a

resistance (as the starter pawls engage) then pull firmly

and rapidly.

hand

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Push in the choke control as soon as the engine fires and

make repeated starting attempts. Immediately press and

release the throttle when the engine starts. That will

disengage the throttle latch.

Never wrap the starter cord around your

Page 21

STARTING AND STOPPING

As the chain brake is still activated the engine must return

to idling speed as soon as possible by disengaging the

throttle latch in order to avoid unnecessery wear on the

clutch assembly.

• The chain brake should be activated when starting.

Se instructions under the heading Start and stop. Do

not drop start. This method is very dangerous

because you may lose control of the saw.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Note!

Pull the front hand guard towards the front handle. The

chain brake is now disengaged. Your saw is ready for use.

WARNING! Long term inhalation of the

engine’s exhaust fumes, chain oil mist

!

and dust from sawdust can represent a

health risk.

• Never start a chain saw unless the bar, chain and all

covers are fitted correctly. See instructions under the

heading Assembly. Without a bar and chain attached

to the chain saw the clutch can come loose and cause

serious injury.

• Never start the machine indoors. Exhaust fumes can

be dangerous if inhaled.

• Observe your surroundings and make sure that there

is no risk of people or animals coming into contact

with the cutting equipment.

• Always hold the saw with both hands. The right hand

should be on the rear handle, and the left hand on the

front handle. All people, whether right or left handed,

should use this grip. Use a firm grip with thumbs and

fingers encircling the chain saw handles.

Stopping

The engine is stopped by pushing the stop switch to the

stop position.

English – 21

Page 22

Before use:

WORKING TECHNIQUES

• To make sure that none of the above might come

within reach of your saw or be injured by falling trees.

,

1 Check that the chain brake works correctly and is not

damaged.

2 Check that the rear right hand guard is not damaged.

3 Check that the throttle lockout works correctly and is

not damaged.

4 Check that the stop switch works correctly and is not

damaged.

5 Check that all handles are free from oil.

6 Check that the anti vibration system works and is not

damaged.

7 Check that the muffler is securely attached and not

damaged.

8 Check that all parts of the chain saw are tightened

correctly and that they are not damaged or missing.

9 Check that the chain catcher is in place and not

damaged.

10 Check the chain tension.

General working instructions

IMPORTANT!

This section describes basic safety rules for using a

chain saw. This information is never a substitute for

professional skills and experience. If you get into a

situation where you feel unsafe, stop and seek expert

advice. Contact your chain saw dealer, service agent or

an experienced chain saw user. Do not attempt any task

that you are not sure you can handle!

Before using a chain saw you must understand the

effects of kickback and how to avoid them. See

instructions under the heading How to avoid kickback.

Before using a chain saw you must understand the

difference between cutting with the top and bottom

edges of the bar. See instructions under the headings

How to avoid kickback and Machine’s safety equipment.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

CAUTION! Follow the instructions above, but do not use a

chain saw in a situation where you cannot call for help in

case of an accident.

2 Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and often brings

added risks, such as icy ground, unpredictable felling

direction, etc.

3 Take great care when removing small branches and

avoid cutting bushes (i.e. cutting many small branches

at the same time). Small branches can be grabbed by

the chain and thrown back at you, causing serious

injury.

4 Make sure you can move and stand safely. Check the

area around you for possible obstacles (roots, rocks,

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

5 Take great care when cutting a tree that is under

tension. A tree that is under tension may spring back

to its normal position before or after being cut. If you

position yourself incorrectly or make the cut in the

wrong place the tree may hit you or the machine and

cause you to lose control. Both situations can cause

serious personal injury.

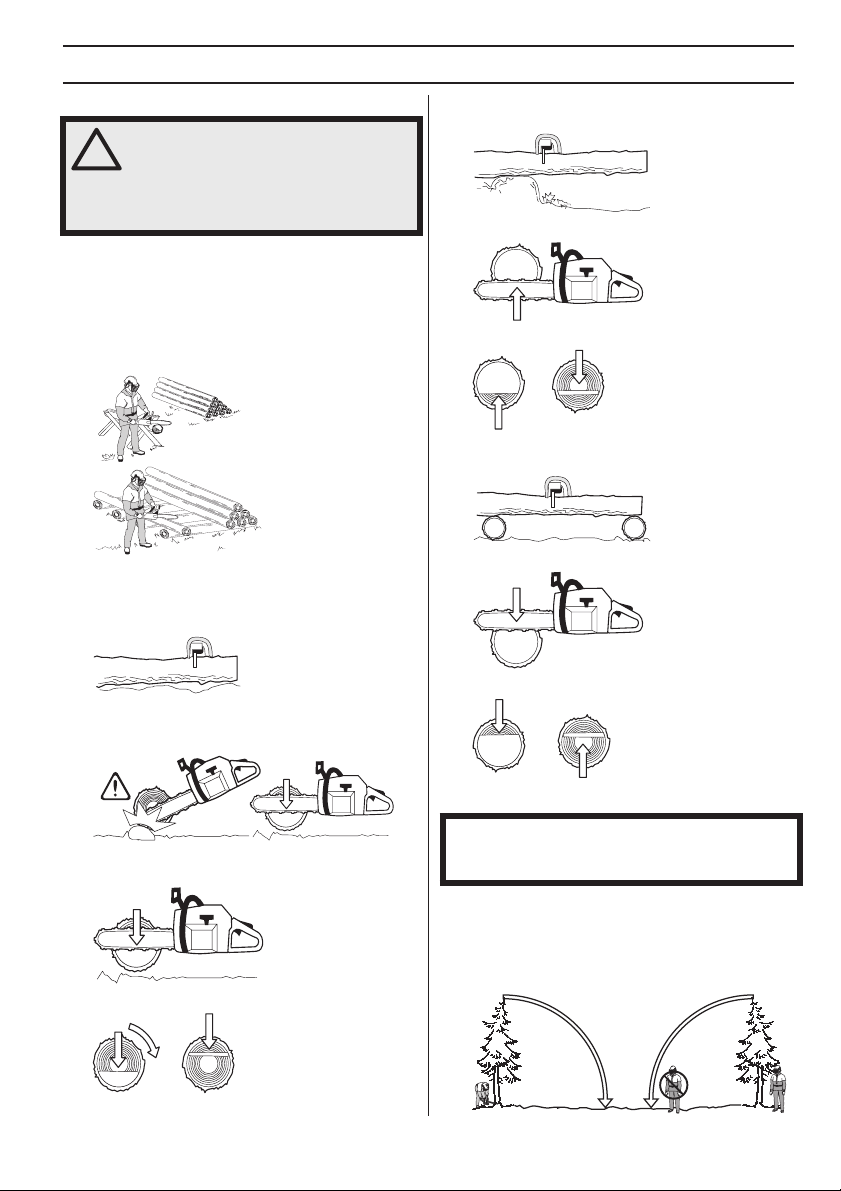

Basic safety rules

1 Look around you:

• To ensure that people, animals or other things cannot

affect your control of the machine.

22 – English

6 Before moving your chain saw switch off the engine

and lock the chain using the chain brake. Carry the

chain saw with the bar and chain pointing backwards.

Page 23

WORKING TECHNIQUES

Fit a guard to the bar before transporting the chain

saw or carrying it for any distance.

7 When you put the chain saw on the ground, lock the

saw chain using the chain brake and ensure you have

a constant view of the machine. Switch the engine off

before leaving your chain saw for any length of time.

General rules

1 If you understand what kickback is and how it happens

then you can reduce or eliminate the element of

surprise. By being prepared you reduce the risk.

Kickback is usually quite mild, but it can sometimes be

very sudden and violent.

2 Always hold the chain saw firmly with your right hand

on the rear handle and your left hand on the front

handle. Wrap your fingers and thumbs around the

handles. You should use this grip whether you are

right-handed or left-handed. This grip minimizes the

effect of kickback and lets you keep the chain saw

under control.

Do not let go of the handles!

branches without first separating them. Only saw one

log or one piece at a time. Remove the cut pieces to

keep your working area safe.

4 Never use the chain saw above shoulder height

and avoid cutting with the tip of the bar. Never use

the chain saw one-handed!

5 In order to keep control of your saw, always maintain

a firm foothold. Never work on a ladder, in a tree or on

any other insecure support.

3 Most kickback accidents happen during limbing. Make

sure you are standing firmly and that there is nothing

in the way that might make you trip or lose your

balance.

Lack of concentration can lead to kickback if the

kickback zone of the bar accidentally touches a

branch, nearby tree or some other object.

Have control over the workpiece. If the pieces you

intend to cut are small and light, they can jam in the

saw chain and be thrown towards you. Even if this

does not need to be a danger, you may be surprised

and lose control of the saw. Never saw stacked logs or

6 Always use a fast cutting speed, i.e. full throttle.

7 Take great care when you cut with the top edge of the

bar, i.e. when cutting from the underside of the object.

This is known as cutting with a pushing chain. The

chain tries to push the chain saw back towards the

user. If the saw chain is jamming, the saw may be

pushed back at you.

8 Unless the user resists this pushing force there is a

risk that the chain saw will move so far backwards that

English – 23

Page 24

WORKING TECHNIQUES

only the kickback zone of the bar is in contact with the

tree, which can lead to a kickback.

2 Make sure the object you are cutting will not split.

Cutting with the bottom edge of the bar, i.e. from the top

of the object downwards, is known as cutting with a

pulling chain. In this case the chain saw pulls itself

towards the tree and the front edge of the chain saw

body rests naturally on the trunk when cutting. Cutting

with a pulling chain gives the operator better control over

the chain saw and the position of the kickback zone.

9 Follow the instructions on sharpening and maintaining

your bar and chain. When you replace the bar and

chain use only combinations that are recommended

by us. See instructions under the headings Cutting

equipment and Technical data.

Basic cutting technique

WARNING! Never use a chain saw by

holding it with one hand. A chain saw is

!

not safely controlled with one hand.

Always have a secure, firm grip around

the handles with both hands.

General

• Always use full throttle when cutting!

• Reduce the speed to idle after every cut (running the

engine for too long at full throttle without any load, i.e.

without any resistance from the chain during cutting,

can lead to serious engine damage).

• Cutting from above = Cutting with a pulling chain.

• Cutting from below = Cutting with pushing chain.

Cutting with a pushing chain increases the risk of

kickback. See instructions under the heading How to

avoid kickback.

Terms

Cutting = General term for cutting through wood.

Limbing = Cutting branches off a felled tree.

Splitting = When the object you are cutting breaks off

before the cut is complete.

There are five important factors you should consider

before making a cut:

1 Make sure the cutting equipment will not jam in the

cut.

3 Make sure the chain will not strike the ground or any

other object during or after cutting.

Is there a risk of kickback?

4 Do the conditions and surrounding terrain affect how

safely you can stand and move about?

Two factors decide whether the chain will jam or the object

that you are cutting will split: the first is how the object is

supported before and after cutting, and the second is

whether it is in tension.

In most cases you can avoid these problems by cutting in

two stages; from the top and from the bottom. You need to

support the object so that it will not trap the chain or split

during cutting.

IMPORTANT! If the chain jams in the cut: stop the

engine! Don’t try to pull the chain saw free. If you do you

may be injured by the chain when the chain saw

suddenly breaks free. Use a lever to open up the cut and

free the chain saw.

The following instructions describe how to handle the

common situations you are likely to encounter when using

a chain saw.

Limbing

When limbing thick branches you should use the same

approach as for cutting.

Cut difficult branches piece by piece.

2

1

3

24 – English

Page 25

WORKING TECHNIQUES

Cutting

WARNING! Never attempt to cut logs

while they are in a pile or when a couple

!

of logs are lying together. Such

procedures drastically increase the risk

of kickback which can result in a serious

or fatal injury.

If you have a pile of logs, each log you attempt to cut

should be removed from the pile, placed on a saw horse

or runners and cut individually.

Remove the cut pieces from the cutting area. By leaving

them in the cutting area, you increase the risk for

inadvertently getting a kickback, as well as increasing the

risk of losing your balance while working.

The log is supported at one end. There is a high risk

that it will split.

Start by cutting from below (about 1/3 of the way through).

Finish by cutting from above so that the two cuts meet.

The log is supported at both ends. There is a high risk

that the chain will jam.

The log is lying on the ground. There is little risk of the

chain jamming or the object splitting. However there is a

risk that the chain will touch the ground when you finish

the cut.

Cut all the way through the log from above. Avoid letting

the chain touch the ground as you finish the cut. Maintain

full throttle but be prepared for what might happen.

If it is possible (can you turn the log?) stop cutting about

2/3 of the way through the log.

Turn the log and finish the cut from the opposite side.

Start by cutting from above (about 1/3 of the way through).

Finish by cutting from below so that the two cuts meet.

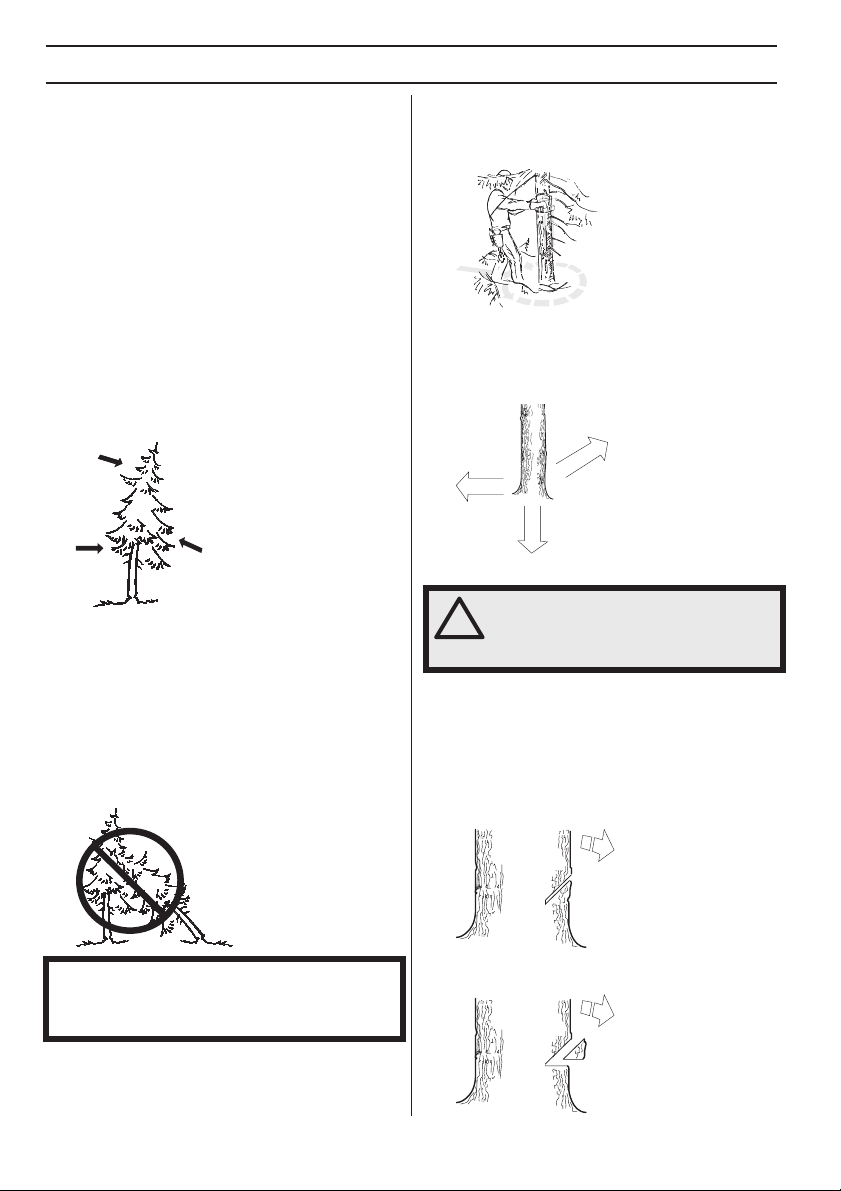

Tree felling technique

IMPORTANT! It takes a lot of experience to fell a tree.

Inexperienced users of chain saws should not fell trees.

Do not attempt any task beyond your experience level!

Safe distance

The safe distance between a tree that is to be felled and

anyone else working nearby is at least 2 1/2 tree lengths.

Make sure that no-one else is in this ”risk zone” before or

during felling.

English – 25

Page 26

WORKING TECHNIQUES

!

Felling direction

The aim is to fell the tree in a position where you can limb

and cross-cut the log as easily as possible. You want it to

fall in a location where you can stand and move about

safely.

Once you have decided which way you want the tree to fall

you must judge which way the tree would fall naturally.

Several factors affect this:

• Lean of the tree

• Bend

• Wind direction

• Arrangement of branches

• Weight of snow

• Obstacles within the reach of the tree: for example,

other trees, power lines, roads and buildings.

• Look for signs of damage and rot in the stem, this

makes it more probably that the tree will break and

start to fall before you expect it to.

You may find you are forced to let the tree fall in its natural

direction because it is impossible or dangerous to try to

make it fall in the direction you first intended.

Another very important factor, which does not affect the

felling direction but does affect your safety, is to make sure

the tree has no damaged or dead branches that might

break off and hit you during felling.

The main point to avoid is letting the tree fall onto another

tree. It is very dangerous to remove a trapped tree and

there is high accident risk. See instructions under the

heading Freeing a tree that has fallen badly.

Clearing the trunk and preparing your retreat

Delimb the stem up to shoulder height. It is safer to work

from the top down and to have the tree between you and

the saw.

Remove any undergrowth from the base of the tree and

check the area for obstacles (stones, branches, holes,

etc.) so that you have a clear path of retreat when the tree

starts to fall. Your path of retreat should be roughly 135

degrees away from the intended felling direction.

D

a

n

g

e

r

z

o

n

e

Retreat path

Danger zone

Felling direction

D

Retreat path

a

n

g

e

r

z

o

n

e

Felling

WARNING! Unless you have special

training we advise you not to fell trees

with a diameter larger than the bar length

of your saw!

Felling is done using three cuts. First you make the

directional cuts, which consist of the top cut and the

bottom cut, then you finish with the felling cut. By placing

these cuts correctly you can control the felling direction

very accurately.

Directional cuts

To make the directional cuts you begin with the top cut.

Stand to the right of the tree and cut on the pull stroke.

IMPORTANT! During critical felling operations, hearing

protectors should be lifted immediately when sawing is

completed so that sounds and warning signals can be

heard.

26 – English

Next make the bottom cut so that it finishes exactly at the

end of the top cut.

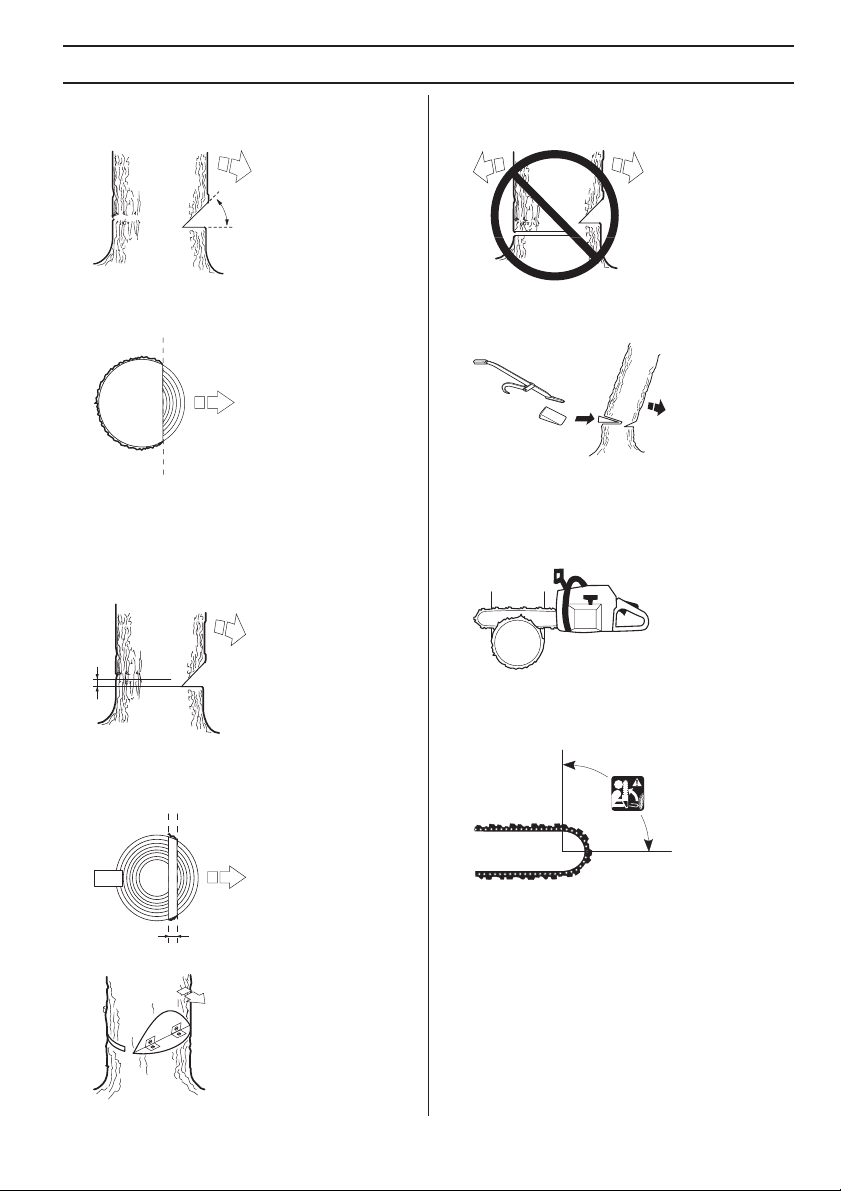

Page 27

WORKING TECHNIQUES

The directional cuts should run 1/4 of the diameter

through the trunk and the angle between the top cut and

bottom cut should be 45

°.

All control over the felling direction is lost if the felling

hinge is too narrow or non-existent, or if the directional

cuts and felling cut are badly placed.

The line where the two cuts meet is called the directional

cut line. This line should be perfectly horizontal and at

right angles (90

Felling cut

The felling cut is made from the opposite side of the tree

and it must be perfectly horizontal. Stand on the left side

of the tree and cut on the pull stroke.

Make the felling cut about 1.5-2 inches (3-5 cm) above the

bottom directional cut.

Finish the felling cut parallel with the directional cut line so

that the distance between them is at least 1/10 of the

trunk diameter. The uncut section of the trunk is called the

felling hinge.

°) to the chosen felling direction.

When the felling cut and directional cut are complete the

tree should start to fall by itself or with the aid of a felling

wedge or breaking bar.

We recommend that you use a bar that is longer than the

diameter of the tree, so that you can make the felling cut

and directional cuts with single cutting strokes. See

instructions under the heading Technical data section to

find out which lengths of bar are recommended for your

saw.

There are methods for felling trees with a diameter larger

than the bar length. However these methods involve a

much greater risk that the kickback zone of the bar will

come into contact with the tree.

The felling hinge controls the direction that the tree falls in.

English – 27

Page 28

WORKING TECHNIQUES

Freeing a tree that has fallen badly

Freeing a ”trapped tree”

It is very dangerous to remove a trapped tree and there is

high accident risk.

Never try to fell the tree that is trapped.

Decide which is the safest way to release the tension and

whether you are able to do it safely. In complicated

situations the only safe method is to put aside your chain

saw and use a winch.

General advice:

Position yourself so that you will be clear of the tree or

branch when the tension is released.

Make one or more cuts at or near the point of maximum

tension. Make as many cuts of sufficient depth as

necessary to reduce the tension and make the tree or

branch break at the point of maximum tension.

Never work in the risk zone of the hanging trapped tree.

The safest method is to use a winch.

• Tractor-mounted

• Portable

Cutting trees and branches that are in tension

Preparations: Work out which side is in tension and where

the point of maximum tension is (i.e. where it would break

if it was bent even more).

Never cut straight through a tree or branch that is in

tension!

If you must cut across tree/limb, make two to three cuts,

one inch apart, one to two inches deep.

Continue to cut deeper until tree/limb bends and tension

is released.

Cut tree/limb from outside the bend, after tension has

been released.

28 – English

Page 29

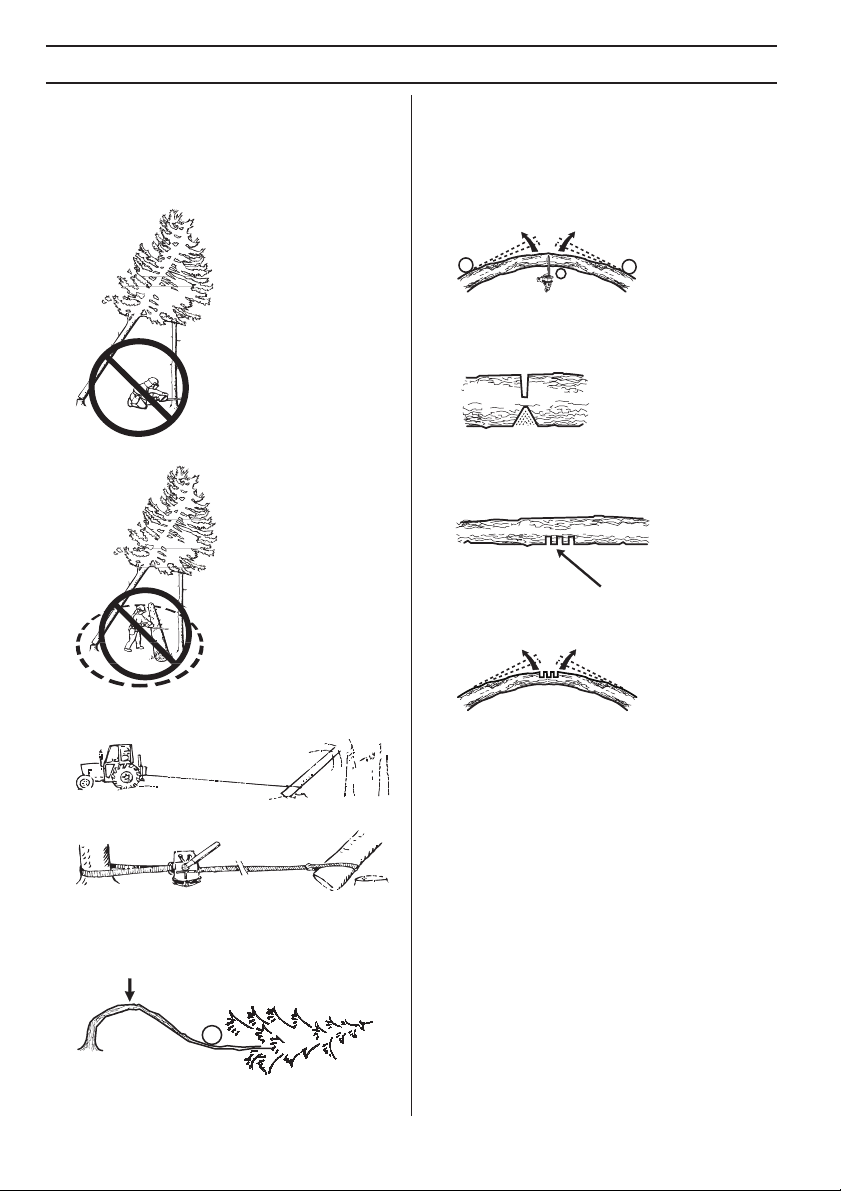

WORKING TECHNIQUES

!

How to avoid kickback

WARNING! Kickback can happen very

suddenly and violently; kicking the chain

!

saw, bar and chain back at the user. If

this happens when the chain is moving it

can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid

it by taking care and using the right

working technique.

What is kickback?

The word kickback is used to describe the sudden

reaction that causes the chain saw and bar to jump off an

object when the upper quadrant of the tip of the bar,

known as the kickback zone, touches an object.

Kickback always occurs in the cutting plane of the bar.

Normally the chain saw and bar are thrown backwards

and upwards towards the user. However, the chain saw

may move in a different direction depending on the way it

was being used when the kickback zone of the bar

touched the object.

Limbing

WARNING! A majority of kickback

accidents occur during limbing. Do not

use the kickback zone of the guide bar.

Be extremely cautious and avoid