Page 1

INSTALLATION & OPERATING

CUS

®

INSTRUCTIONS

®

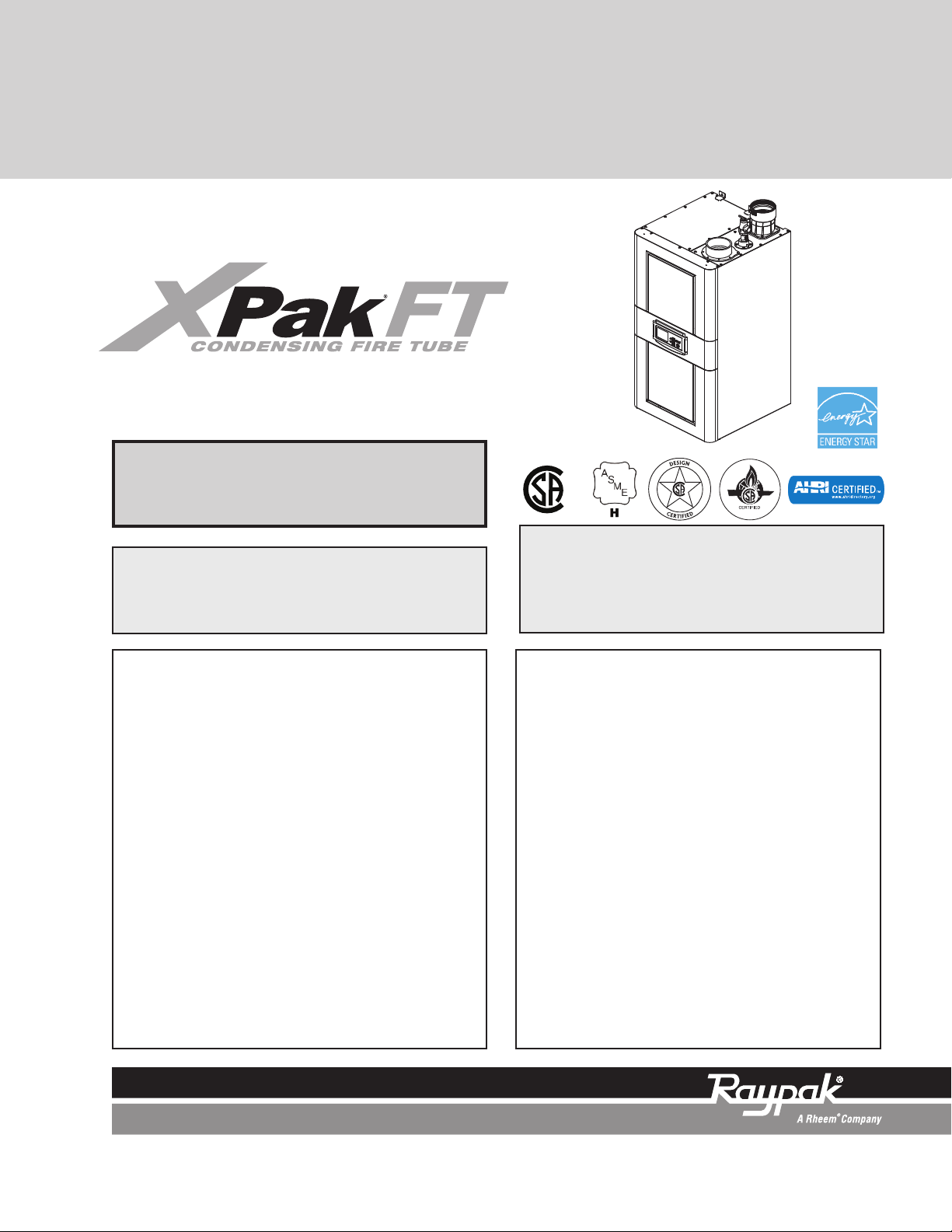

Models 88AR–398A

Type H

AVERTISSEMENT: Assurez-vous de bien suivre

WARNING: If the information in these instructions

are not followed exactly, a fire or explosion may

result causing property damage, personal injury or

death.

les instructions données dans cette notice pour

réduire au minimum le risqué d’incendie ou

d’explosion ou pour éviter tout dommage matériel,

toute blessure ou la mort.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids or other

combustible materials in the vicinity of this or any

other appliance. To do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.•

Do not touch any electrical switch; do not use•

any phone in your building.

Immediately call your gas supplier from a•

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the•

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Ne pas entreposer ni utilizer d’essence ou ni

d’autres vapeurs ou liquids inflammables à proimité de cet appareil ou de tout autre appareil.

CE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAS:

Ne pas tenter d’allumer d’appareil. •

Ne touchez á aucun interrupteur; ne pas vous•

server des téléphones se trouvant dans la

bâtiment.

Appelez immédiatement votre fournisseur de•

gaz depuis un voisin. Suivre les instructions

du fournisseur.

Si vous ne pouvez rejoinder le fournisseur,•

appelez le service es incendies.

L’installation et l’entretien doivent être assurés par

un installeur qualifié ou par le fournisseur de gaz.

Catalog No. 1000.66B Effective: 06-01-16 Replaces: 12-08-15 P/N 241556 Rev. 3

Page 2

Rev. 3 reflects the following:

Changes to: Minor changes to pages 8, 17, 22, 29, 37, 38, 39, 40, 52, 55, 58, 59, 66 and 67. Updated Wiring Diagram

on page 47.

Additions: Information under Condensate Management on page 37.

Deletions: Information under Ignition Control Functions on page 39.

2

Page 3

CONTENTS

WARNINGS 4

Pay Attention to These Terms 4

BEFORE INSTALLATION 5

Product Receipt 5

Model Identification 6

Ratings and Certifications 6

Installations at Elevation 6

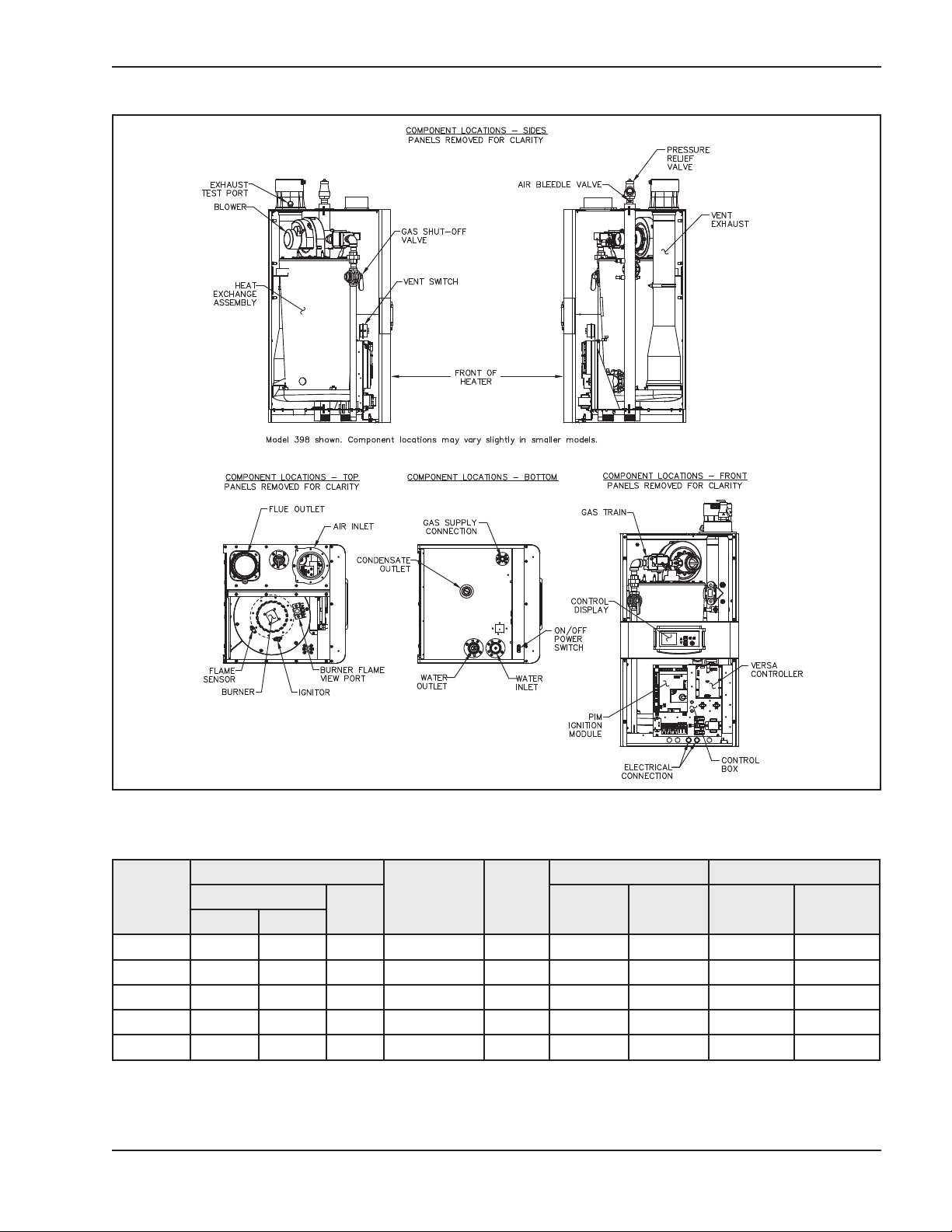

Component Locations 7

General Information 7

BOILER DIMENSIONS 8

Time/Temperature Relationships

in Scalds 9

INSTALLATION 9

Installation Codes 9

Equipment Room 10

Clearances 10

Combustion and Ventilation Air 11

Direct Vent 14

Conventional Combustion Air Supply 14

Water Piping 15

Hydronic Heating 16

System Sensor Installation 16

Applications and Modes 17

Heater Flow Rates and Pressure Drops 17

MODE 1 Water Plumbing 18

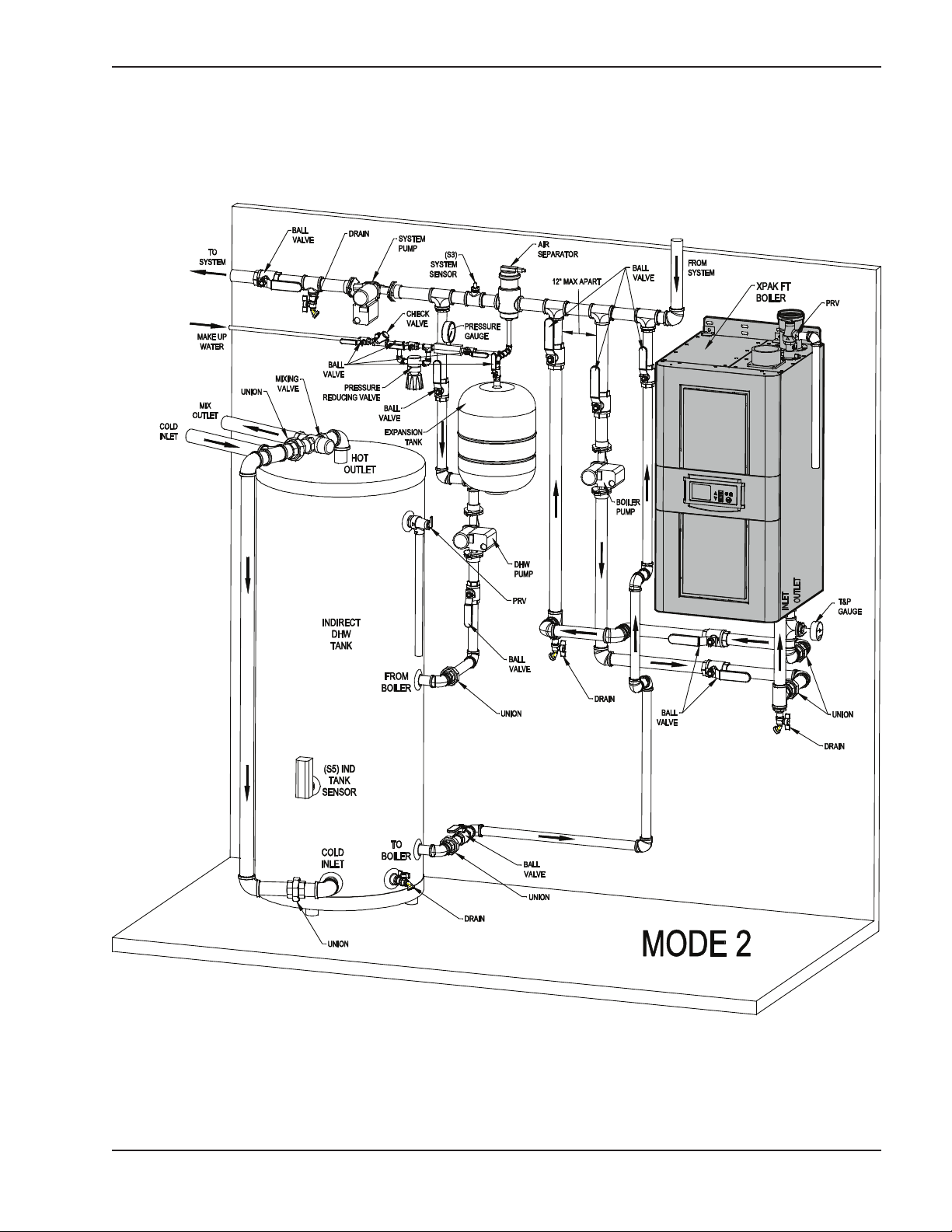

MODE 2 Water Plumbing 19

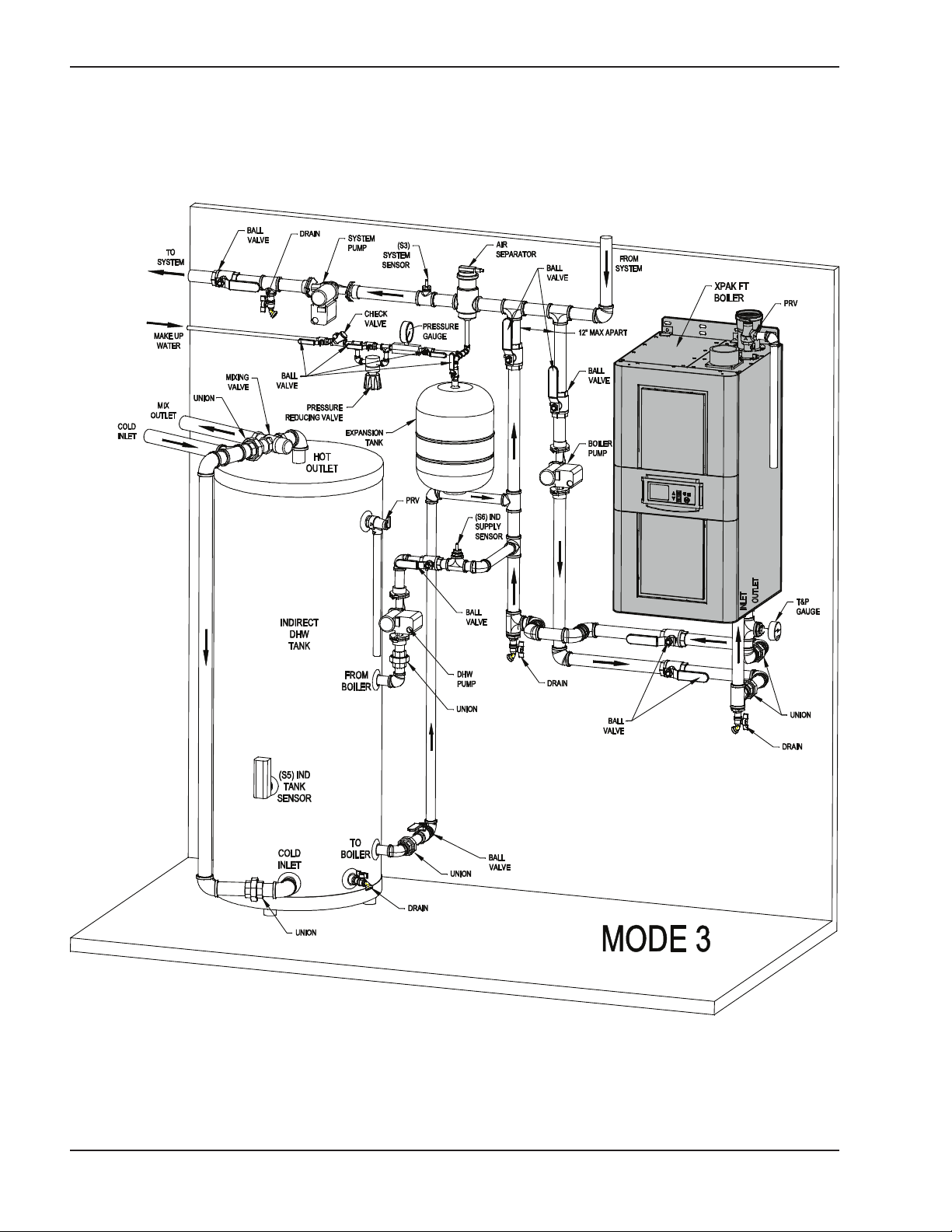

MODE 3 Water Plumbing 20

Gas Supply 21

Gas Supply Connection 21

Equivalent Pipe Length 21

Gas Supply Pressure 22

Electrical Power Connections 22

Making the Electrical Connections 23

Field Wiring Connections 24

Heating System Sensor Installation 25

Venting 28

Venting Installation Tips 31

Venting Configurations 31

Condensate Management 37

Freeze Protection 38

Controls 39

Outdoor Reset Concept 45

WIRING DIAGRAM 47

Converting Natural to Propane Gas 48

Gas Valve & Combustion Settings 49

START-UP 50

Pre Start-up 51

Pre Start-up Check 51

Initial Start-up 51

Preparation 51

Start-Up 52

Lighting Instructions 54

To Turn Off Gas to Appliance 54

TROUBLESHOOTING 55

XPak FT Error Codes 55

Heater Errors 55

Heater Faults 55

Sensor Resistance Values 55

XPak FT Fault Text 56

MAINTENANCE 58

Suggested Minimum

Maintenance Schedule 58

Preventive Maintenance

Schedule 58

Combustion Chamber Cleaning

Instructions 60

APPENDIX 61

Inside Air Contamination 61

Important Instructions for the

Commonwealth of Massachusetts 62

WARRANTY 63

START-UP CHECKLIST 64

ILLUSTRATED PARTS LIST 65

3

Page 4

WARNINGS

Pay Attention to These Terms

ndicates the presence of immediate hazards which will cause severe

DANGER:

I

personal injury, death or substantial property damage if ignored.

WARNING:

CAUTION:

NOTE:

DANGER: Make sure the gas on which the boiler

will operate is the same type as that specified on the

boiler rating plate.

WARNING: Should overheating occur or the gas

supply valve fail to shut, do not turn off or disconnect

the electrical supply to the boiler. Instead, shut off

the gas supply at a location external to the boiler.

WARNING: Do not use this boiler if any part has

been under water. Immediately call a qualified

service technician to inspect the boiler and to

replace any part of the control system and any gas

control which has been under water.

WARNING: To minimize the possibility of improper

operation, serious personal injury, fire, or damage to

the boiler:

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

WARNING: Both natural gas and propane have an

odorant added to aid in detecting a gas leak. Some

people may not physically be able to smell or

recognize this odorant. If you are unsure or

unfamiliar with the smell of natural gas or propane,

ask your local gas supplier. Other conditions, such

as "odorant fade," which causes the odorant to

diminish in intensity, can also hide, camouflage, or

otherwise make detecting a gas leak by smell more

difficult.

WARNING: UL-recognized fuel gas detectors are

recommended in all enclosed propane and natural

gas applications wherein there is a potential for an

explosive mixture of fuel gas to accumulate and their

installation should be in accordance with the

detector manufacturer's recommendations and/or

local laws, rules, regulations, or customs.

• Always keep the area around the boiler free of

combustible materials, gasoline, and other

flammable liquids and vapors.

• Boiler should never be covered or have any

blockage to the flow of fresh air to the boiler.

WARNING: Vent connectors serving any other

appliances shall not be connected into any portion of

mechanical draft systems operating under a positive

pressure. If an XPak FT

an existing unit, the vent system MUST be verified to

be of the correct size and of one of the Category IV

vent materials identified in this manual. If it is NOT,

it MUST be replaced.

®

boiler is installed to replace

WARNING - CALIFORNIA PROPOSITION

65: This product contains chemicals known to the

State of California to cause cancer, birth defects or

other reproductive harm.

WARNING: This appliance produces condensate

from the flue products that is acidic and highly

corrosive. Raypak recommends the use of a

condensate neutralizer kit to avoid long-term

damage to the drainage system and to meet local

code requirements.

WARNING: Risk of electrical shock. More than one

disconnect switch may be required to de-energize

the equipment before servicing.

4

Page 5

CAUTION: This boiler requires forced water

circulation when the burner is operating. See

minimum and maximum flow rates. Severe damage

will occur if the boiler is operated without proper

water flow circulation.

OTE: When the boiler has been filled for the first

N

time or the system has been drained and refilled, it

will be necessary to release any air that may have

become trapped within the appliance heat

exchanger. Open the bleedle valve until all air is

purged.

AVERTISSEMENT: N’utilisez pas cette Chaudière

si une partie de celle-ci s’est retrouvée sous l’eau.

Appelez immédiatement un technician de service

qualifié pour inspecter la Chaudière et pour

remplacer toute partie du système de contrôle et

toute commande de gaz s’étant retrouvée sous

l’eau.

OTE: Minimum 18 AWG, 105°C, stranded wire

N

must be used for all low voltage (less than 30 Volts)

xternal connections to the unit. Solid conductors

e

should not be used because they can cause

xcessive tension on contact points. Install conduit

e

as appropriate. All high voltage wires must be the

same size (105°C, stranded wire) as the ones on the

unit or larger.

AVERTISSEMENT: En cas de surchauffe ou de

non fermeture de la vanne d’alimentation en gaz,

n’éteignez ou ne débranchez pas l’alimentation électrique de la chaudière. Coupez plutôt l’alimentation

en gaz á l’extérieur de la chaudière.

BEFORE INSTALLATION

Raypak strongly recommends that this manual be reviewed thoroughly before installing your XPak FT boiler.

Please review the General Safety information before installing the unit. Factory warranty does not apply to units

that have been improperly installed or operated. (Refer to the warranty at the back of this manual.) Installation

and service must be performed by a qualified installer, service agency or gas supplier. If, after reviewing this

manual, you still have questions which this manual does not answer, please contact your local Raypak representative or visit our website at www.raypak.com.

Thank you for purchasing a Raypak product. We hope you will be satisfied with the high quality and durability of

our equipment.

Product Receipt

On receipt of your unit it is suggested that you visually check for external damage to the shipping carton. If the

carton is damaged, make a note to that effect on the Bill of Lading when signing for the shipment. Next, remove

the boiler from the carton. Report any damage to the carrier immediately.

On occasion, items are shipped loose. Be sure that you receive the correct number of packages as indicated on

the Bill of Lading.

Claims for shortages and damages must be filed with the carrier by consignee. Permission to return goods must

be received from the factory prior to shipping. Goods returned to the factory without an authorized Returned

Goods Receipt number will not be accepted. All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and serial number of the boiler. When ordering under warranty

conditions, you must also specify the date of installation.

Purchased parts are subject to replacement only under the manufacturer’s warranty. Debits for defective

replacement parts will not be accepted. Parts will be replaced in kind only per Raypak’s standard warranties.

5

Page 6

Model Identification

he model identification number and boiler serial num-

T

ber are found on the rating plate located on the inside

upper right panel and also on inlet air decal. The

model number has the form H7-198AR or similar

epending on the unit size and configuration. The let-

d

ter in the first group of characters identifies the

application (H = Hydronic Heating). The number which

follows identifies the firing mode (7 = electronic modulation). The second group of characters identifies the

size of the unit (three numbers representing the

approximate MBTUH input), and, where applicable, a

letter indicating the manufacturing series.

Ratings and Certifications

Standards:

• ANSI Z21.13 · CSA 4.9 - latest edition, GasFired Hot Water Boilers

• SCAQMD Rule 1146.2

All units are National Board Registered, and designcertified and tested by the Canadian Standards

Association (CSA) for the U.S. and Canada. Each boiler is constructed in accordance with Section IV of the

American Society of Mechanical Engineers (ASME)

Boiler and Pressure Vessel Code and bears the ASME

“H” stamp. This boiler also complies with the latest edition of the ASHRAE 90.1 Standard.

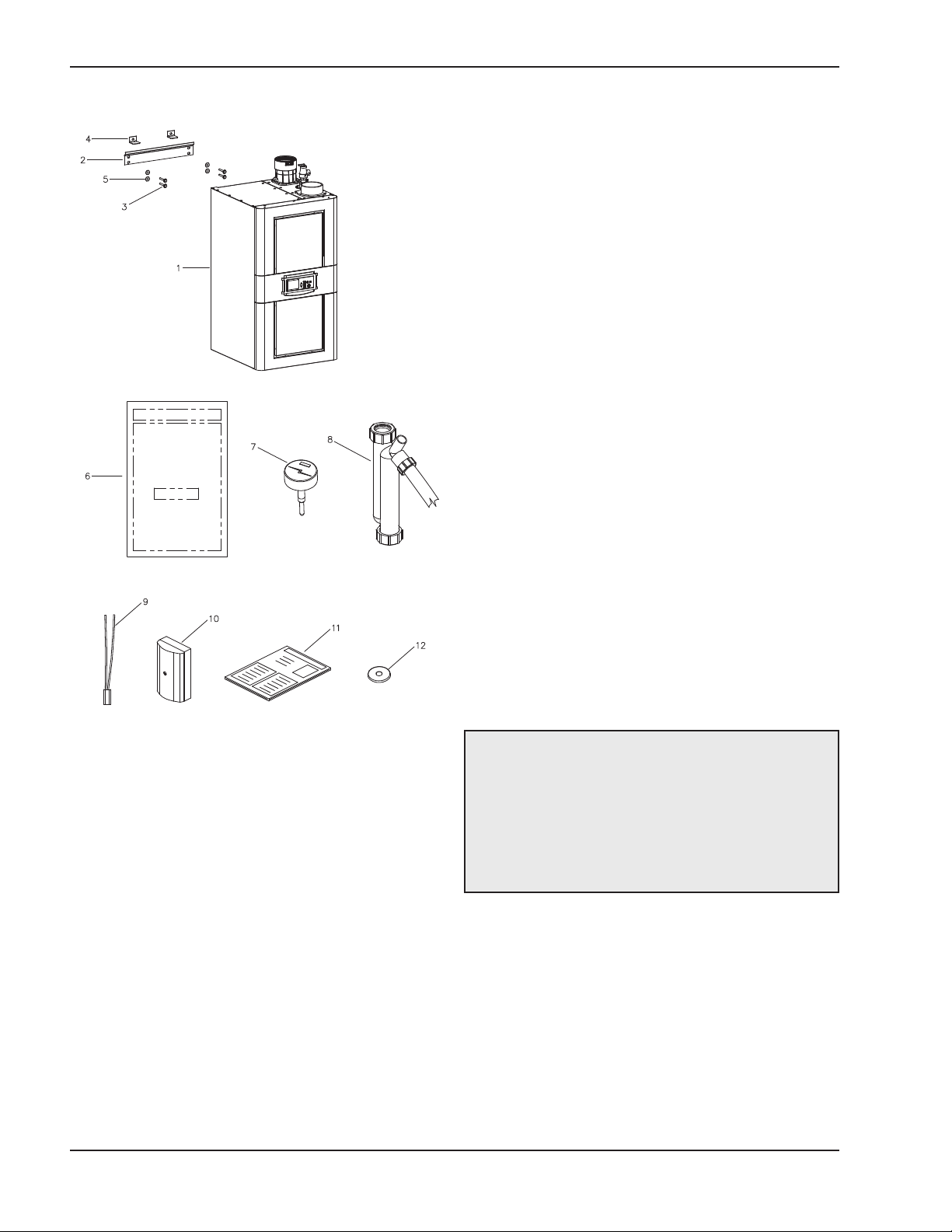

Fig 1: Boiler Carton Contents

Items Included:

1. (1) XPak FT Boiler

2. (1) Wall Mount Bracket

3. (6) Lag Screws

4. (2) Hold Down Brackets

5. (6) Washers

6. (1) Full-Scale Heater Template

7. (1) T & P Gauge

8. (1) Condensate Trap & Hose

9. (2) System Sensor

10. (1) Outdoor Sensor

11. (1) Installation & Operating Instructions Manual

12. (1) Propane Orifice Kit (Models 88AR & 108AR

ONLY)

Installations at Elevation

WARNING: Altering any Raypak pressure vessel

by installing replacement heat exchangers or any

ASME parts not manufactured and/or approved by

Raypak will instantly void the ASME and CSA ratings

of the vessel and any Raypak warranty on the

vessel. Altering the ASME or CSA ratings of the

vessel also violates national, state, and local

approval codes.

Rated inputs are suitable for up to 2,000 ft elevation

without de-rating. Consult your local representative or

the factory for installations at altitudes over 2,000 ft

above sea level. No hardware changes are required

to the boilers for installations up to 10,000 ft (adjustments may be required).

6

Page 7

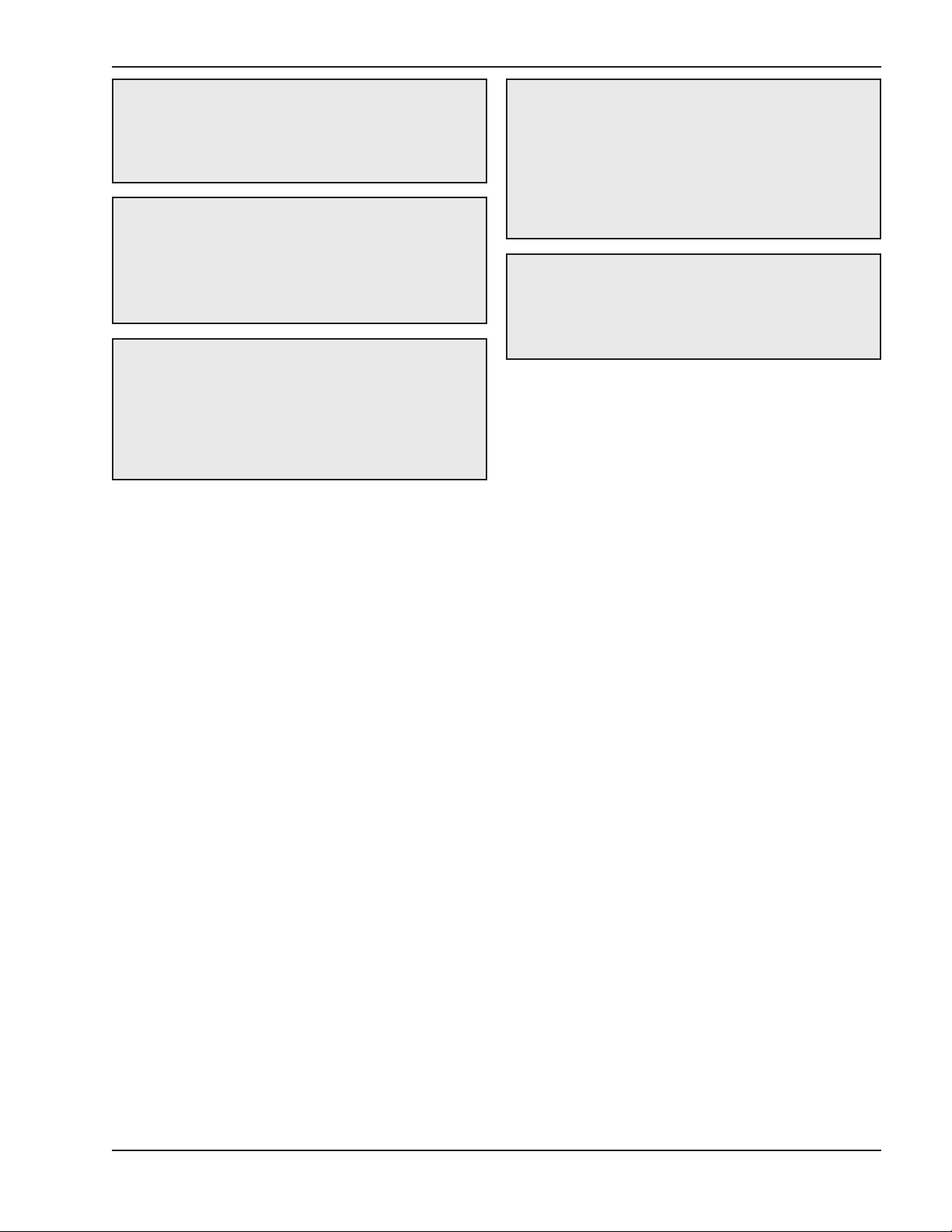

Component Location

Fig 2: Component Locations

General Information

AFUE Rating

Model

.

No

Input (MBH)

% Nat Pro Flue Intake

Min Max

88AR 17.0 85 95 12.0 1” ½” ½” 2”/3”** 2”/3”**

108AR 22.0 110 95 13.0 1” ½” ½” 3” 3”

198AR 39.8 199 95 28.4 1-1/4” ¾” ¾” 3” 3”

278AR 55.0 275 95 36.6 1-1/4” ¾” ¾” 3” 3”

398A 39.9 399 96* 39.9 1-1/2” ¾” ¾” 3”/4”*** 3”/4”***

*Model 398A value is a Thermal Efficiency.

**Model 88AR has a 3" standard vent size, but can be reduced to 2" with a shorter run. (See page 31 for details)

***Model 398A has a 4" standard vent size, but can be reduced to 3" with a shorter run. (See page 31 for details)

Minimum

Operating

Input

(MBH)

Table A: Basic Data

Water

Conn.

(NPT)

7

Gas conn. (NPT) Vent Size (inches)

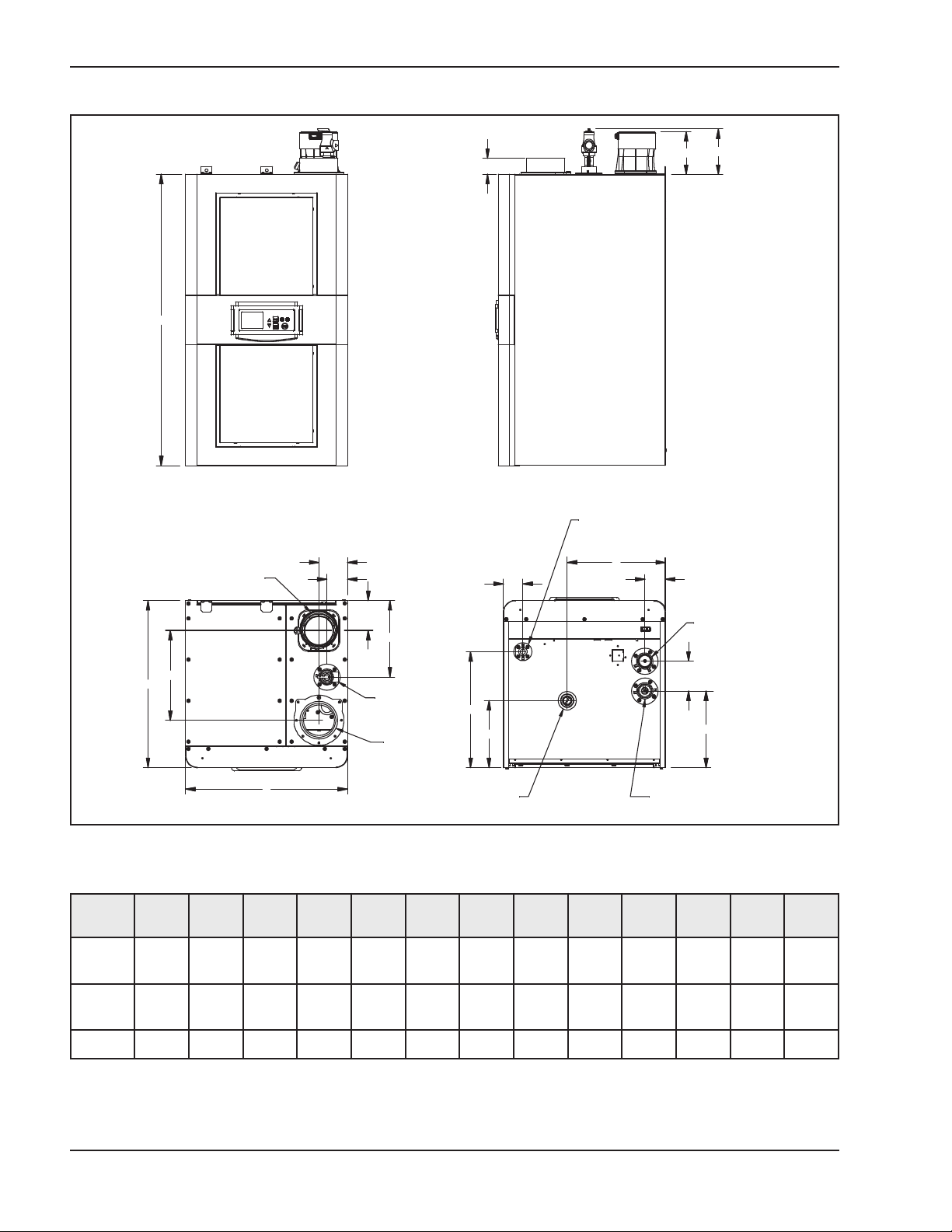

Page 8

Dimensions

B

P

L

J

D

N

M

F

A

C

H

E

D

3.79

K

F

WATER INLET

GAS SUPPLY CONNECTION

WATER OUTLET

CONDENSATE

OUTLET

AIR INLET

PRV

FLUE OUTLET

5

.6

6

.0

Fig 3: Boiler Dimensions

Model

No

88AR/

108AR

198AR/

278AR

398A 21.4 38.6 22.1 2.7 4.0 10.1 12.0 13.0 8.9 2.6 15.3 4.0 2.1

A B C D E F H J K L M N P

.

16.4 35.8 16.5 2.1 2.7 6.3 7.8 9.5 5.5 1.5 4.6 2.8 2.3

18.6 36.2 19.4 2.0 3.1 8.2 10.0 11.3 7.1 1.7 12.3 3.6 2.3

Table B: Basic Data

8

Page 9

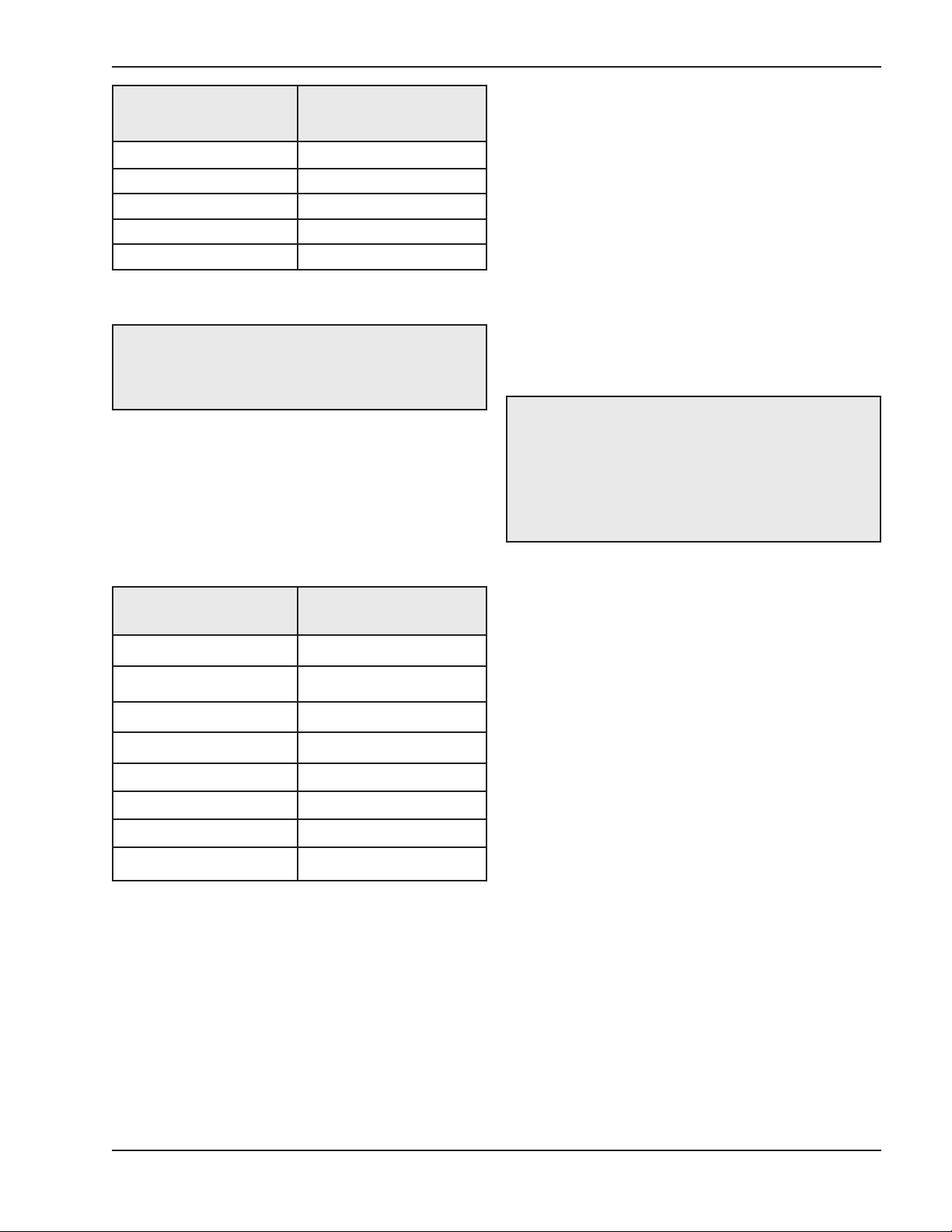

odel No.

M

8AR

8

Boiler Water Volume

(gallons)

.2

3

108AR 2.9

198AR 5.2

278AR 4.5

398A 5.9

Table C: Heater Water Volume

WARNING: This boiler cannot supply hot water for

use by individuals directly. A heat exchanger must

be used in conjunction with this boiler to meet DHW

needs.

Time/Temperature

Relationships in Scalds

The following chart details the relationship of water

temperature and time with regard to scald injury and

may be used as a guide in determining the safest

water temperature for your applications.

INSTALLATION

Installation Codes

Installations must follow these codes:

Local, state, provincial, and national codes, laws,•

regulations and ordinances

National Fuel Gas Code, ANSI Z223.1/NFPA 54 –•

atest edition (NFGC)

l

National Electrical Code, ANSI/NFPA 70 - latest•

edition (NEC)

Standard for Controls and Safety Devices for•

Automatically Fired Boilers, ANSI/ASME CSD-1,

(CSD-1) when required

For Canada only: CAN/CSA B149 Natural Gas•

and Propane Installation Code and CSA C22.1

C.E.C. Part 1 (C22.1)

CAUTION: This boiler should be located in an area

where water leakage will not result in damage to the

area adjacent to the appliances or to the structure.

When such locations cannot be avoided, it is

recommended that a suitable catch pan, adequately

drained, be installed under the appliance. The pan

must not restrict air flow.

Water Temp.

Time to Produce

Serious Burn

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table courtesy of The Shriners Burn Institute

Table D: Time to Produce Serious Burn

9

Page 10

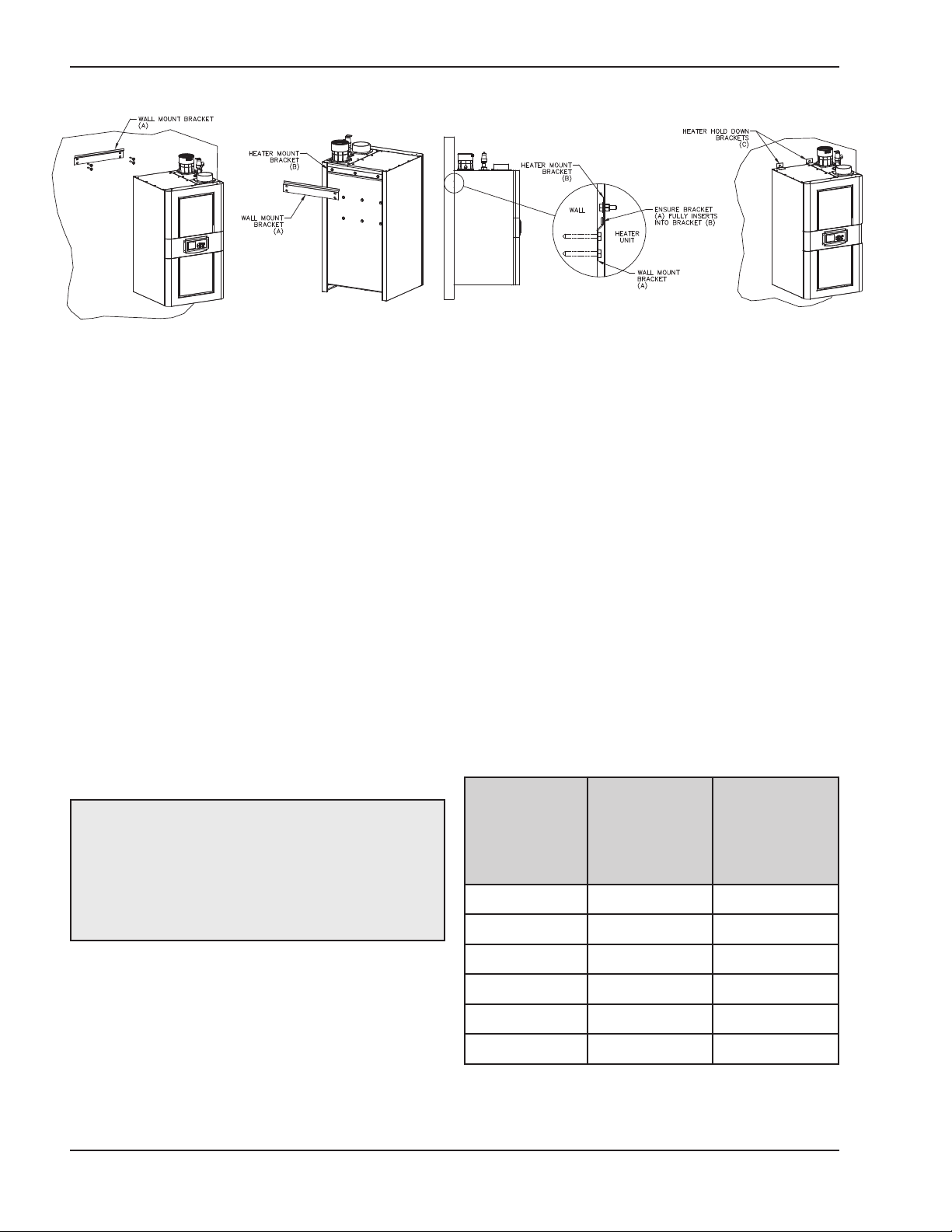

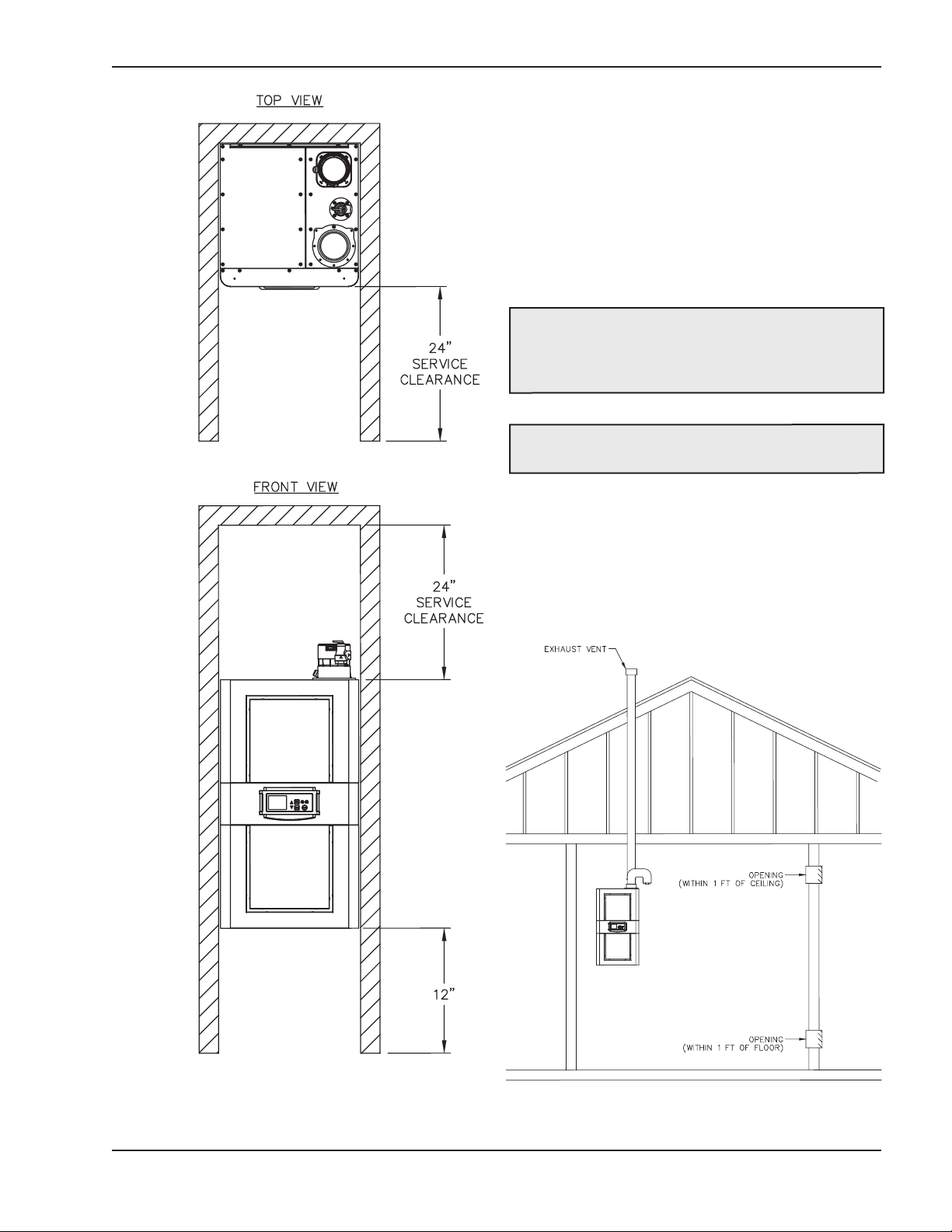

Fig 4: Wall Mount Installation

Equipment Room

Install CO detectors per local regulations. Boiler

requires yearly maintenance, see chapter “Checks,

adjustments and fault finding”.

Operating Limits of the boiler:

Max. Boiler Outlet Temperature: 200°F (99°C)

Max. Operating Pressure: 80 psi (5.5 bar)

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an

existing boiler, it is important to check the condition of

the entire hot water distribution system to ensure safe

operation.

In addition, the unit shall be installed such that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance operation or service.

NOTE: Use of this boiler in construction areas

where fine particulate matter, such as concrete or

dry-wall dust, is present may result in damage to the

boiler that is not covered by the warranty. If operated

in a construction environment, a clean source of

combustion air must be provided directly to the

boiler.

Clearances

Indoor Installations

When installed according to the listed minimum clearances from combustible construction, these boilers

can be serviced without removing permanent structural construction around the unit. However, for ease of

servicing, we recommend a clearance of at least 24 in.

in front, on the rear and 24 in. above the top of the boiler. This will allow the unit to be serviced in its installed

location without movement or removal of the heater.

Service clearances less than the minimum may

require removal of the unit to service either the heat

exchanger or the burner components. In either case,

the boiler must be installed in a manner that will enable

the unit to be serviced without removing any structure

around the boiler.

Min.

Boiler Side

Clearances

from

Combustible

Minimum

Service

Clearances

Surfaces

Right Side 0” 1”

Left Side 0” 1”

Top 0” 24”

Front Open 24”

Vent 1” 1”

Bottom 6” 12”

Table E: Clearances — Indoor Installations

10

Page 11

ombust

C

it

n

u

is

Th

t

n

o

c

-

n

o

n

ip

u

q

e

d

n

a

c

ia

v

d

lie

p

o

r

f

n

w

a

r

d

ia

v

r

o

,

r

e

r

f

ly

t

c

e

ir

d

u

q

e

r

e

h

t

a

d

a

n

a

C

(

T

AU

C

min

a

t

n

o

c

ma

a

d

n

a

c

p

p

A

e

h

t

TE: It

NO

ed

insulat

and

ion

p

p

u

s

e

b

t

s

mu

t

ir

a

d

e

t

a

min

a

t

ila

t

n

e

v

t

n

me

l me

a

n

io

t

n

e

v

n

o

imme

a

e

r

a

e

h

t

m

w

,

t

n

e

v

t

c

e

ir

d

A

.

e

id

s

t

u

o

m

o

f

o

s

t

n

me

e

ir

l c

a

c

ll lo

a

d

n

a

,

)

mb

o

C

:

N

O

I

r

o

c

y

b

d

e

t

a

ile

o

b

e

h

t

e

g

)

.

ix

d

n

e

is reco

in cold climates t

mmended that the in

Vent

h

it

w

d

lie

o

p

p

u

s

o

mb

o

C

.

n

io

w

s

n

a

e

t

ia

d

o

c

e

r

e

h

lla

a

t

s

in

ll

FG

N

e

h

t

.

s

e

d

o

a

n

io

t

s

u

c

e

iv

s

o

r

o

v

d

n

a

r

o minimize swe

s

h

ly

t

h

t

r

u

e

mb

io

e

id

u

s

ir

ic

f

f

r

p

io

t

s

c

e

r

r

r

u

s

u

s

n

C

mu

mic

e

h

t

ila

ie

p

o

a

n

o

u

o

io

t

mu

U

(

l

a

w

t

n

e

mb

n

n

s

S.

.

f

a

r

ir

s

t

ion

t

a

u

q

o

c

a

c

s

u

g

in

d

is

ir

a

mp

o

c

t

)

n

t

me

u

n

a

r

r

ke ven

a

ating.

n

mb

b

n

io

t

t

r

o

s

t

o

y.

t

h

it

n

d

A

ie

s

u

s

e

a

e

r

ly

B1

b

t

w

(

s

t

ir

b

a

w

h

S

be

t

ir

f

o

n

io

-

p

u

is

-

il

o

n

w

h

it

9

4

e

h

ic

e

e

Venting not shown for clarity. Boiler must be vented per

instructions in this manual

Fig. 5: Minimum Clearances from Combustible

Surfaces

Fig 6: Indoor Air Duct

11

Page 12

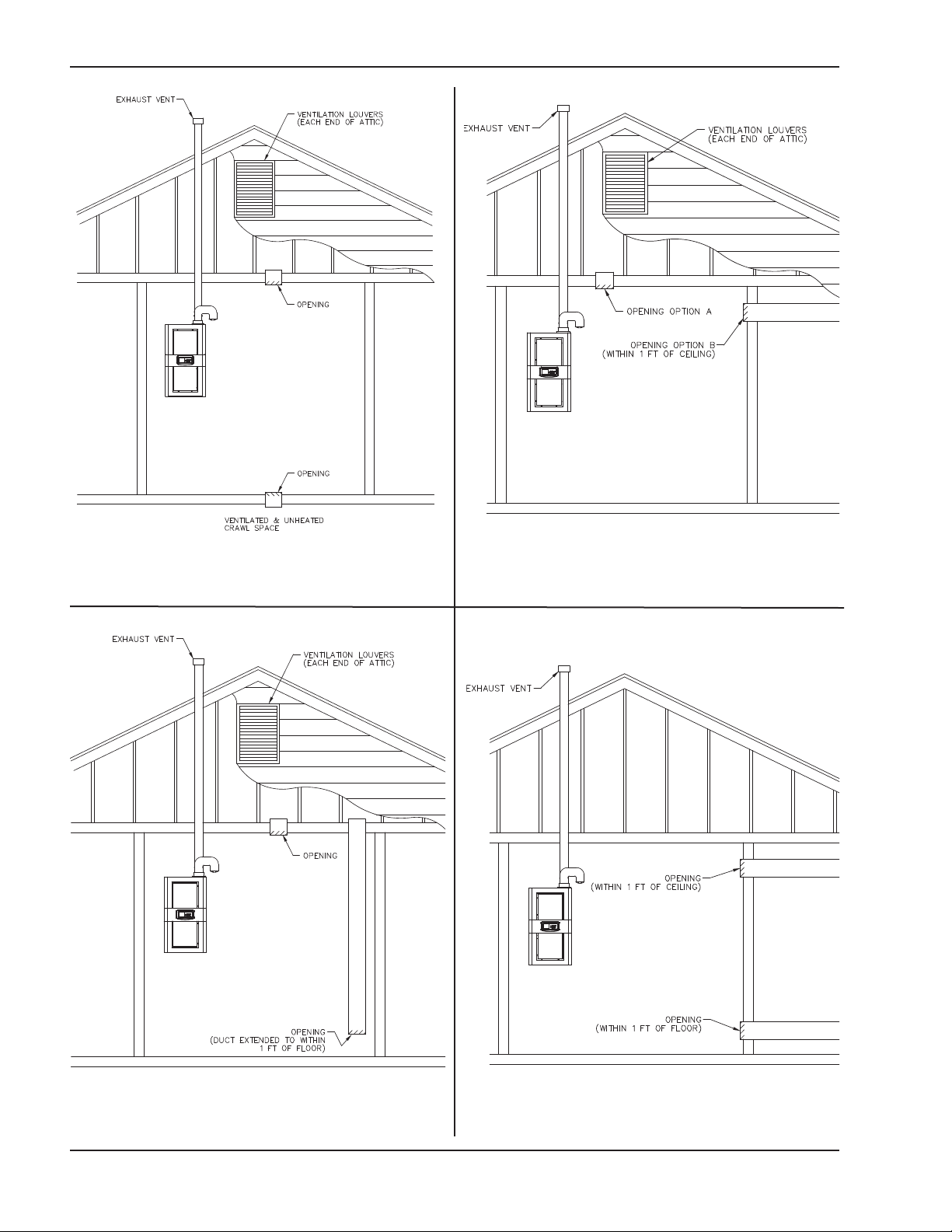

Fig 7: Two Vertical Air Ducts - Floor

Fig 8: Single Air Duct

Fig 9: Two Vertical air Ducts - Ceiling

Fig 10: Two Horizontal Air Ducts

12

Page 13

U.S. Installations

1

Canadian Installations

2

A

Clearance above grade, veranda, porch,

deck, or balcony

1 ft (30 cm) 1 ft (30 cm)

B

Clearance to window or door that may be

opened

4 ft (1.2 m) below or to side

of opening; 1 foot (30 cm)

above opening

3 ft (91 cm)

C Clearance to permanently closed window * *

D

Vertical clearance to ventilated soffit located

above the terminal within a horizontal distance of 2 ft (61cm) from the centerline of the

terminal

5 ft (1.5 m) *

E Clearance to unventilated soffit * *

F Clearance to outside corner * *

G Clearance to inside corner 6 ft (1.83 m) *

H

Clearance to each side of center line extended above meter/regulator assembly

*

3 ft (91 cm) within a height

15 ft above the me-

ter/regulator assembly

I Clearance to service regulator vent outlet * 6 ft (1.83 m)

J

Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any

other appliance

4 ft (1.2 m) below or to side

of opening; 1 ft (30 cm)

above opening

3 ft (91 cm)

K Clearance to mechanical air supply inlet

3 ft (91 cm) above if within

10 ft (3 m) horizontally

6 ft (1.83 m)

L

Clearance above paved sidewalk or paved

driveway located on public property

7 ft (2.13 m)

7 ft (2.13 m) t

M

Clearance under veranda, porch, deck or

balcony

* 12 in. (30 cm) TT

1

In accordance with the current ANSI Z223.1/NFPA 54 N ational Fuel Gas Code

2

In accordance with the current CAN/CSA-B149 Installation Codes

t Vent terminal shall not terminate directly above sidewalk or paved driveway located between 2 single-family dwellings that serves

both dwellings

TT Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor and top of term inal and

underside of veranda, porch, deck or balcony is greater than 1 ft (30 cm)

* Clearances in accordance with local installation codes and the requirements of the gas supplier

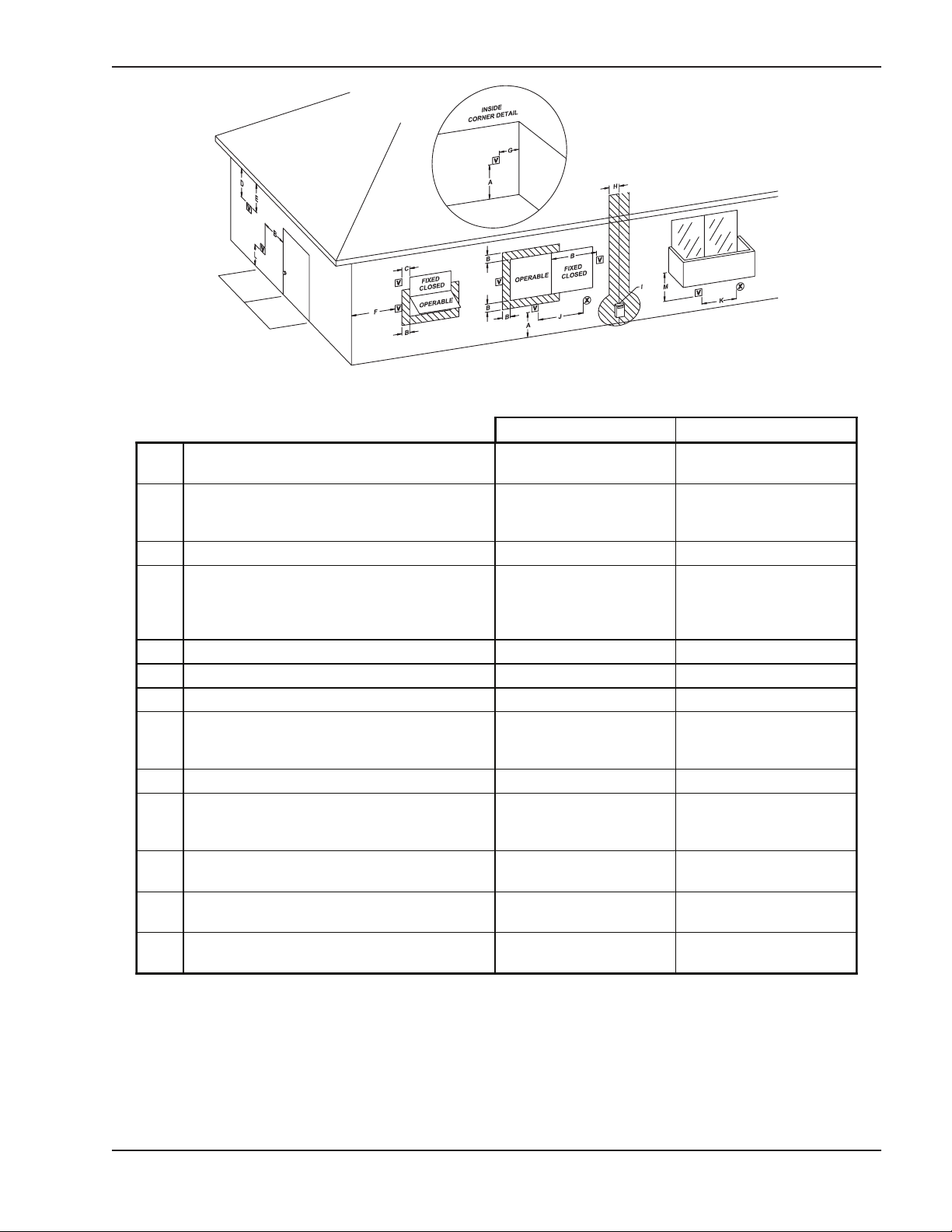

Fig. 11: Minimum Clearances from Vent/Air Inlet Terminations – Indoor and Outdoor Installations

Table F: Vent/Air Inlet Termination Clearances

13

Page 14

Direct Vent

If outside air is drawn through the intake pipe directly

o the unit for combustion:

t

1. Install the combustion air ducting kit.

. Install combustion air direct vent in accordance

2

with Fig. 24 (horizontal) or Fig. 26 (vertical) of this

manual.

3. Ventilation of the space occupied by the boiler(s)

is recommended and can be provided by an opening(s) for ventilation air at the highest practical

point communicating with the outdoors. The total

cross-sectional area should be at least 1 in² of free

area per 20,000 BTUH (111 mm² per kW) of total

input rating of all equipment in the room when the

opening is communicating directly with the outdoors or through vertical duct(s). The total

cross-sectional area should be at least 1 in² of free

area per 10,000 BTUH (222 mm² per kW) of total

input rating of all equipment in the room when the

opening is communicating with the outdoors

through horizontal duct(s). Damage to the equipment due to inadequate ventilation of the space is

not a warrantable failure.

4. In cold climates, and to mitigate potential freezeup, Raypak highly recommends the installation of

a motorized sealed damper on the air intake to

prevent the circulation of cold air through the boiler

during non-operating hours.

Conventional Combustion Air

Supply

U.S. Installations

All Air from Inside the Building

The confined space shall be provided with TWO permanent openings communicating directly with an additional room(s) of sufficient volume so that the combined volume of all spaces meets the criteria for a

room large in comparison (NFGC). The total input of all

gas utilization equipment installed in the combined

space shall be considered in making this determination. Each opening shall have a minimum free area

of 1 in.2 per 1,000 BTUH (2,225 mm2 per kW) of the

total input rating of all gas utilization equipment in the

con- fined space, but not less than 100 in.2 (645 cm2).

One opening shall commence within 12 in. (305 mm)

of the top, and one opening shall commence within 12

in. (305 mm) of the bottom of the enclosure. The minimum dimension of air openings shall be not less than

3 in. (76 mm) in any direction.

ll Air from Outdoors

A

The confined space shall communicate with the out-

oors in accordance with one of the methods below.

d

The minimum dimension of air openings shall not be

less than 3 in. (76 mm) in any direction. Where ducts

are used, they shall be of the same cross-sectional

rea as the net free area of the openings to which they

a

connect.

1. Two permanent openings, one commencing

within 12 in. (305 mm) of the top, and one commencing within 12 in. (305 mm) of the bottom of

the enclosure, shall be provided. The openings

shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely communicate with the outdoors.

a. Where directly communicating with the out-

doors or where communicating to the

outdoors through vertical ducts, each open-

ing shall have a minimum free area of 1 in.

per 4,000 BTUH (550 mm2per kW) of total

input rating of all equipment in the enclosure.

b. Where communicating with the outdoors

through horizontal ducts, each opening shall

have a minimum free area of 1 in.2per 2,000

BTUH (1,100 mm2per kW) of total input rating of all equipment in the enclosure.

2. One permanent opening, commencing within 12

in. (305 mm) of the top of the enclosure, shall be

permitted where the equipment has clearances of

at least 1 in. (25 mm) from the sides, top and bottom and 6 in. (152 mm) from the front of the

appliance. The opening shall directly communicate with the outdoors or shall communicate

through a vertical or horizontal duct to the outdoors or spaces that freely communicate with the

outdoors, and shall have a minimum free area of:

a. 1 in.2per 3,000 BTUH (740 mm2per kW) of

the total input rating of all equipment located in

the enclosure, and

b. Not less than the sum of the areas of all vent

connectors in the confined space.

WARNING: Do not use the “one permanent

opening” method if the equipment room is under

negative-pressure conditions.

2

14

Page 15

Canadian Installations

. Ventilation of the space occupied by the boiler

1

shall be provided by an opening(s) for ventilation

air at the highest practical point communicating

with the outdoors. The total cross-sectional area of

uch an opening(s) shall be at least 10% of the

s

area required in 2. and 3. (below), but in no case

shall the cross-sectional area be less than 10 in.2

(65 cm2).

CAUTION: All combustion air must be drawn from

the air outside of the building; the mechanical equipment room must communicate directly with the

outdoors.

2. For boilers using a barometric damper in the vent

system, there shall be a permanent air supply

opening(s) having a cross section area of not less

than 1 in.

to and including 1 million BTUH, plus 1 in.2per

14,000 BTUH (160 mm2per kW) in excess of 1

million BTUH. This opening(s) shall be either

located at or ducted to a point not more than 18 in.

(450 mm) nor less than 6 in. (152 mm) above the

floor level. The duct can also “goose neck” through

the roof. The duct is preferred to be straight down

and terminated 18 in. (450 mm) from the floor, but

not near piping. This air supply opening requirement shall be in addition to the air opening for

ventilation air required in 1. (above).

3. For heaters when air supply is provided by natural

air flow from outdoors for a power burner and

there is no draft regulator, drafthood or similar flue

gas dilution device installed in the same space, in

addition to the opening for ventilation air required

in 1., there shall be a permanent air supply opening(s) having a total cross-sectional area of not

less than 1 in.2for each 30,000 BTUH (74 mm2per

kW) of total rated input of the burner(s), and the

location of the opening(s) shall not interfere with

the intended purpose of the opening(s) for ventilation air referred to in 1. This opening(s) can be

ducted to a point not more than 18 in. (450 mm)

nor less than 6 in. (152 mm) above the floor level.

The duct can also “goose neck” through the roof.

The duct is preferred to be straight down 18 in.

(450 mm) from the floor, but not near piping.

WARNING: Care must be taken to ensure that the

equipment room is not under negative pressure

conditions.

2

per 7,000 BTUH (320 mm2per kW) up

Water Piping

NOTE: Refer to the VERSA IC®Applications Guide

(Catalog #5000.72) for detailed instructions regarding the various applications supported by the

ERSA IC control system.

V

General

The boiler should be located so that any water leaks

will not cause damage to the adjacent area or structures.

CAUTION: This boiler requires forced water

circulation when the burner is operating. See Table H

for minimum and maximum flow rates. The pump

must be interlocked with the boiler to prevent heater

operation without water circulation.

WARNING: Pressure relief valve discharge piping

must be piped near the floor and close to a drain to

eliminate the potential of severe burns. Do not pipe

to any area where freezing could occur. Refer to

local codes.

Relief Valve Installation and Piping

The boiler is supplied with a Section IV “H” stamped

relief valve sized for the full input of the unit. Relief

valve discharge piping shall provide no less than the

cross-sectional area of the relief valve outlet and must

be routed to a safe point of discharge. Installation must

comply with all national, state and local codes.

Temperature & Pressure Gauge

The temperature and pressure gauge is shipped loose

for field installation and must be installed within 12

inches of the boiler outlet (if possible) in an easily

readable location. Installation must comply with ASME

Section IV as well as all applicable national, state and

local codes.

Hydrostatic Test

Unlike many types of heaters, this boiler does not require hydrostatic testing prior to being placed in operation. The heat exchanger is ASME certified for 80 PSI

maximum working pressure. However, Raypak does

recommend hydrostatic testing of the piping connections to the unit and the rest of the system prior to

operation. This is particularly true for hydronic systems using expensive glycol-based anti-freeze.

Raypak recommends conducting the hydrostatic test

before connecting gas piping or electrical supply.

4. Refer to the B149 Installation Code for additional

information.

15

Page 16

eaks must be repaired at once to prevent damage to

L

the heater. NEVER use petroleum-based stop-leak

compounds.

o perform hydrostatic test:

T

. Connect fill water supply. With bleed valve open,

1

fill boiler with water. When water flows from bleed

valve, shut off water. Close bleed valve. Carefully

fill the rest of the system, making sure to eliminate

any entrapped air by using high-point vents. Close

feed valve. Test at standard operating pressure for

at least 24 hours.

2. Make sure constant gauge pressure has been

maintained throughout test.

3. Check for leaks. Repair if found.

Hydronic Heating

Pump Selection

In order to ensure proper performance of your boiler

system, you must install a correctly-sized pump. Raypak recommends designing for a ∆T within the range

of 20°F to 60°F (8°C to 19°C). See Table H for acceptable flow rates for each model (∆T is the temperature

difference between the inlet and outlet water when the

heater is firing at full rate).

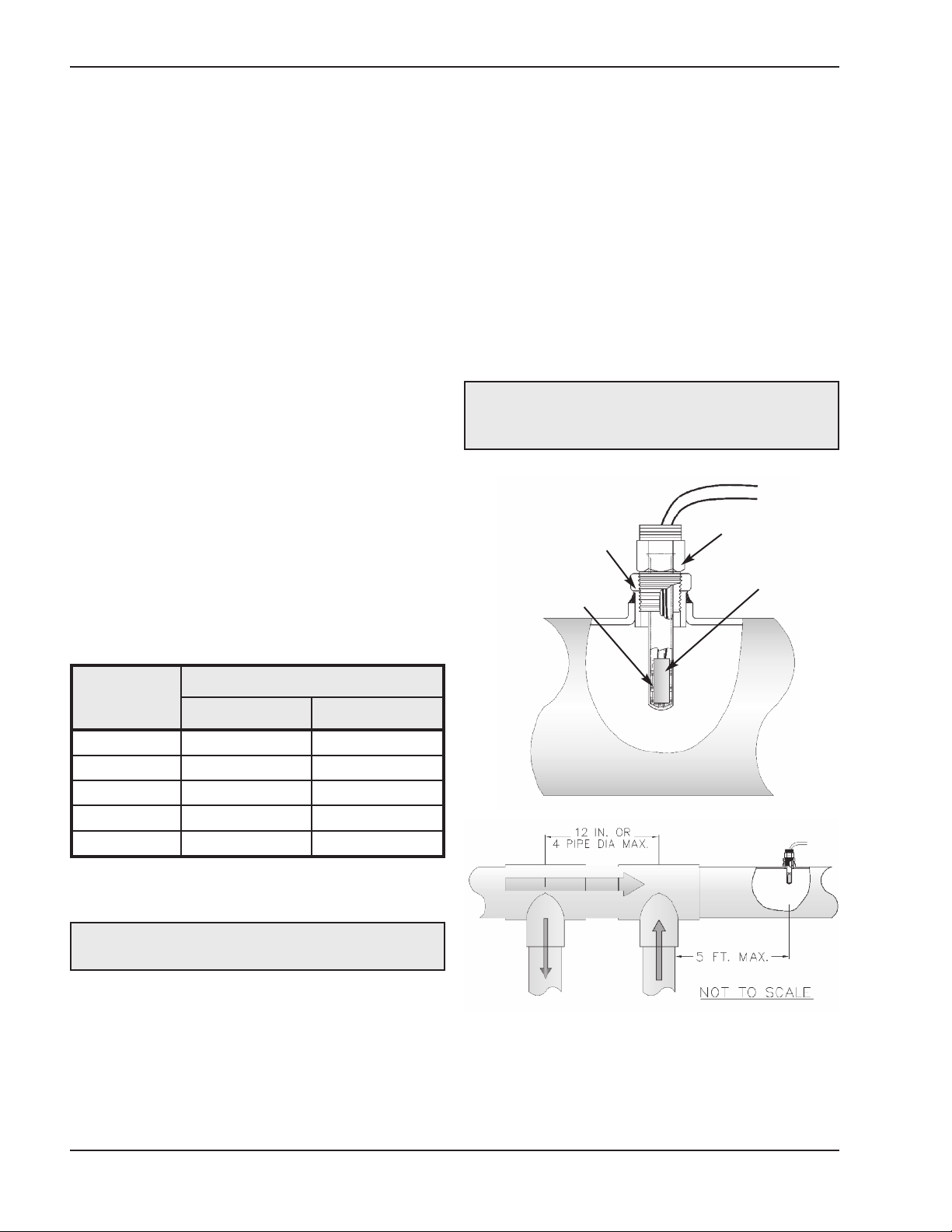

System Sensor Installation

The System Sensor (S3) is required for all selectable

modes unless the unit’s firing rate will be controlled by

an external source such as our Temp Tracker MOD+

Hybrid sequencer. Proper placement and method of

installation are critical for proper operation of the system. (See Fig. 12) The sensor must be installed in a

drywell in conjunction with heat conductive compound

as shown in the following images. The drywell must be

installed no more than 5 equivalent feet of pipe/tubing

downstream of the de-coupler and installed in such a

way that ensures the sensor bulb is in the flow path.

CAUTION: Be careful when installing the drywell

not to over-tighten the well as this can damage the

well and may prevent the sensor from fitting properly.

NPT

Fitting

Thermal

Paste

Drywell

System

Sensor (S3)

Boiler

Model

Standard Boiler Pump*

Pump HP

H7-88AR TACO 007 1/25

H7-108AR TACO 007 1/25

H7-198AR TACO 010 1/8

H7-278AR TACO 012 1/8

H7-398A TACO 012 1/8

* Pump selection based on 30° ∆T with up to 50 eq. ft. of tubing.

Table G: Pump Selection

NOTE: The 50 eq. feet of tubing typically represents

25 linear feet of tubing and 25 eq. feet of fittings.

Fig 12: System Sensor Installation

Three-Way Valves

Three-way valves intended to regulate system water

temperatures by reducing flow in the boiler should not

be used.

16

Page 17

Applications & Modes

The VERSA IC Control system is designed for a wide

range of applications. The installer/design engineer

should refer to the following Modes to determine which

best fits the intended application and functionality for

he unit being installed.

t

The XPak FT has three modes available to them to

address the various applications the units can be

applied to.

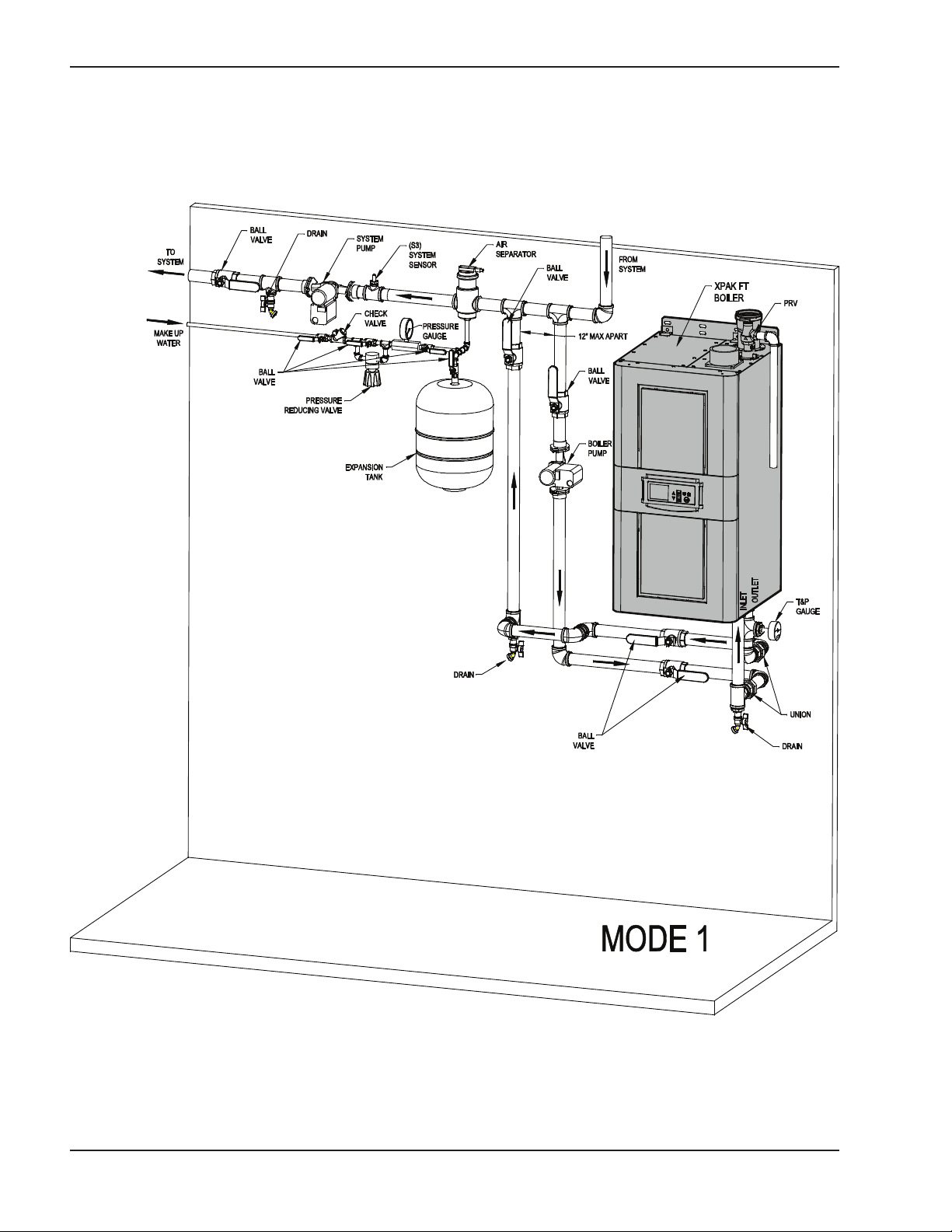

Mode 1

This mode is for hydronic heating systems with single

or multiple boilers (Maximum 4 boilers) in primary/secondary piping configuration with or without Outdoor Air

Reset (S4). The system temperature is controlled by

the System sensor (S3). The Boiler Pump (P1) runs

during any call for heat. The System Pump (P2) runs

whenever the system is enabled for heating and the

outdoor air temperature is lower than the warm weather shut down (WWSD) temperature setting (if utilized).

The Boiler Pump and System Pump are delayed “off”

as user-defined in the ADJUST menu. See Fig. 13 for

piping example.

Mode 2

This mode is for hydronic heating systems with single

or multiple boilers (Maximum 4 boilers) in primary/secondary piping configuration with or without Outdoor Air

Reset (S4) with indirect DHW on the system loop (with

or without priority). The system temperature is controlled by the System sensor (S3). The Indirect DHW

sensor (S5) determines the indirect call/tank setpoint.

The system temperature is boosted to Target Max

when using the Indirect DHW sensor (S5) during an

indirect call for heat. Priority mode toggles off the

System Pump (P2) when an indirect call for heat is

present. The Boiler Pump (P1) runs during any call for

heat. The Indirect DHW Pump (P3) runs during an

indirect call for heat with no “off” delay. The boiler

ump (P1) and System Pump (P2) delay “off” as user-

P

defined in the ADJUST menu. The System Pump (P2)

runs whenever the system is enabled for heating and

the outdoor air temperature is lower than the WWSD

emperature setting (if utilized) unless an indirect call

t

for heat is present with priority. See Fig. 14 for piping

xample.

e

Mode 3

This mode is for hydronic heating systems with single

or multiple boilers (Maximum 4 boilers) in primary/secondary piping configuration with or without Outdoor Air

Reset (S4) with indirect DHW on the boiler loop (with

priority). The system temperature is controlled by the

Supply sensor (S3) whenever the indirect call for heat

is not active. The DHW Supply sensor (S5) determines

the indirect call/tank setpoint. During an indirect call for

heat the boiler firing rate is determined by the water

temperature at the Indirect Supply sensor (S6) and the

Target Max setting when using the Indirect DHW sensor (S5).

The Boiler Pump (P1) runs during all heat calls regardless of priority. The Indirect DHW Pump (P3) runs

during an indirect call for heat with no “off” delay. The

Boiler Pump (P1) and System Pump (P2) delay “off” as

user-defined in the ADJUST menu. The system pump

(P2) runs whenever the system is enabled for heating

and the outdoor air temperature is lower than the

WWSD temperature setting (if utilized) unless an indirect call for heat is present. See Fig. 15 for piping

example.

WARNING: All potable water heating with this

boiler must be by an indirect heat exchanger. Only

non-potable water will go through the boiler.

System flow must exceed 120% of boiler flow.

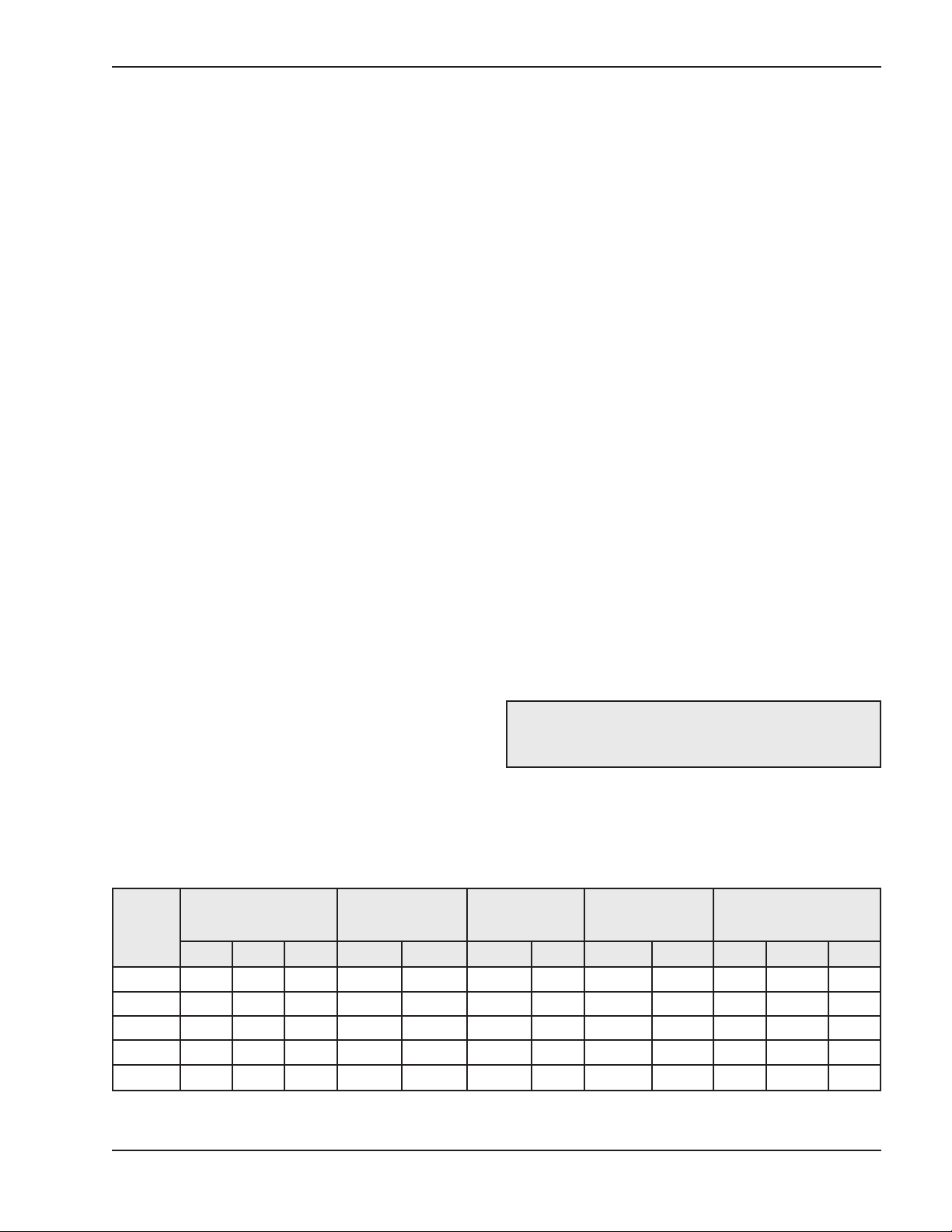

Water Flow Rates

Model

No.

H7-88A 8.1 5.4 20 5.4 3.3 4.0 2.3 3.2 1.8 2.7 1.4 60

H7-108A 10.5 7.4 20 7.0 4.5 5.2 3.2 4.2 2.4 3.5 2.0 60

H7-198A 18.9 11.6 20 12.6 6.2 9.5 4.3 7.6 3.5 6.3 3.0 60

H7-278A 26.1 20.3 20 17.4 10.1 13.1 6.5 10.5 4.9 8.7 4.0 60

H7-398A 38.3 14.1 20 25.5 7.4 19.2 5.0 15.3 4.0 12.8 3.4 60

Notes: Basis for minimum flow is ∆T . Basis for maximum flow is GPM.

MAXIMUM

FLOW

GPM ΔP (ft) ΔT GPM ΔP (ft) GPM ΔP (ft) GPM ΔP (ft) GPM ΔP (ft) ΔT

Table H: Heater Rates of Flow and Pressure Drops

30°F

∆T

17

40°F

∆T

50°F

∆T

MINIMUM

FLOW

Page 18

Fig 13: MODE 1 - Single Boiler - Primary/Secondary Piping

18

Page 19

Fig 14: MODE 2 - Single Boiler - Primary/Secondary Piping

with Indirect DHW on System Loop

19

Page 20

Fig 15: MODE 3 - Single Boiler - Primary/Secondary Piping

with Indirect DHW on Boiler Loop

20

Page 21

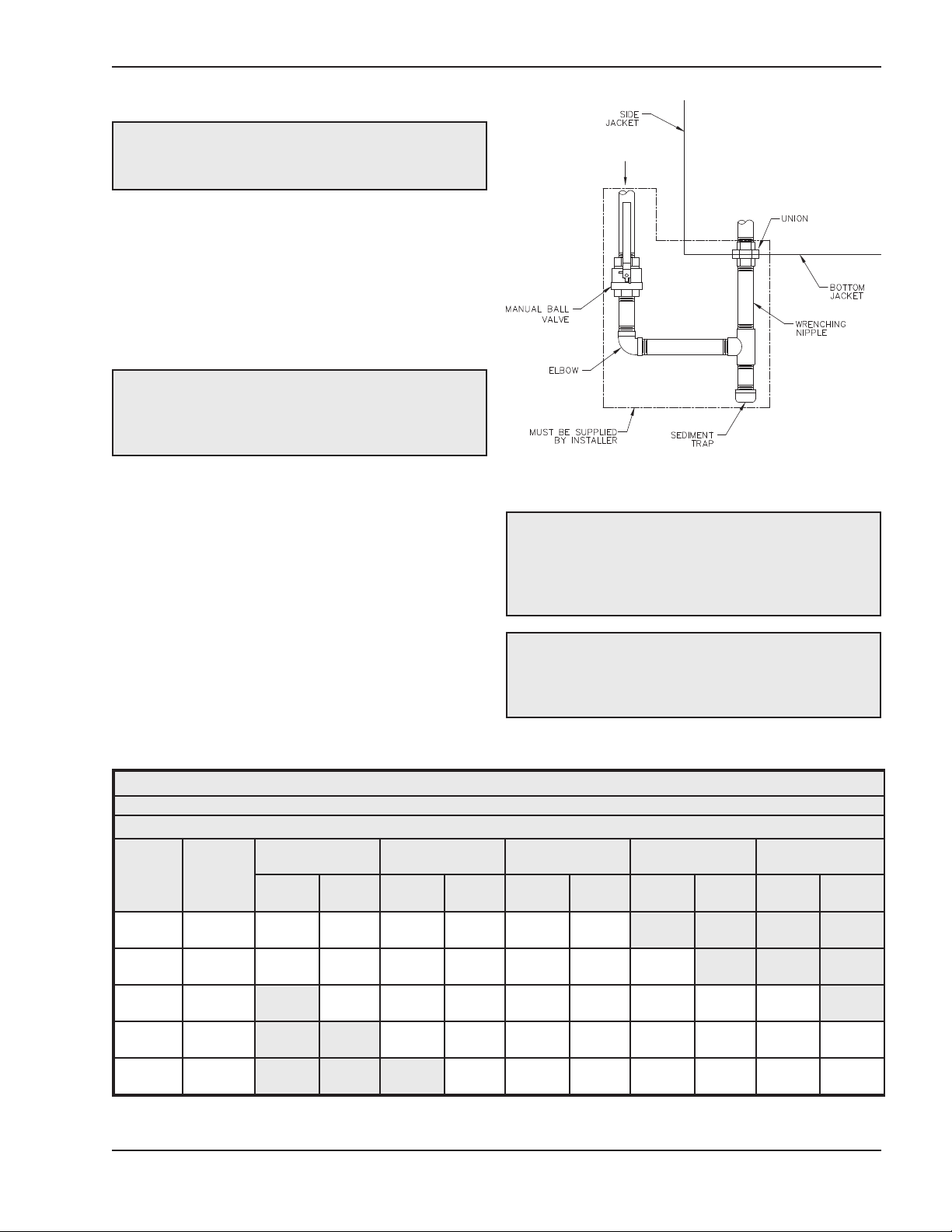

Gas Supply

ANGER: Make sure the gas on which the unit will

D

operate is the same type as specified on the rating

plate.

Gas piping must have a sediment trap ahead of the

boiler gas controls, and a manual shut-off valve located outside the boiler jacket. It is recommended that

a union be installed in the gas supply piping adjacent

to the boiler for servicing. Refer to Table J for maximum pipe lengths.

Gas Supply Connection

CAUTION: The boiler must be disconnected from

the gas supply during any pressure testing of the gas

supply system at test pressures in excess of 1/2 PSI

(3.45 kPa).

The boiler must be isolated from the gas supply piping system by closing the upstream manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or greater

than 1/2 PSI (3.45 kPa). Relieve test pressure in the

gas supply line prior to re-connecting the boiler and its

manual shut-off valve to the gas supply line. FAIL-

URE TO FOLLOW THIS PROCEDURE MAY

DAMAGE THE GAS VALVE. Over-pressurized gas

valves are not covered by warranty. The boiler and its

gas connections shall be leak-tested before placing

the appliance in operation. Use soapy water for leak

test. DO NOT use an open flame.

Fig. 16: Gas Supply Connection

CAUTION: Do not use Teflon tape on gas line pipe

thread. A pipe compound rated for use with natural

and propane gases is recommended. Apply

sparingly only on male pipe ends, leaving the two

end threads bare.

CAUTION: Support gas supply piping with

hangers, not by the boiler or its accessories. Make

sure the gas piping is protected from physical

damage and freezing, where required.

Model

88AR

108AR

198AR

278AR

398A

Maximum Equivalent Pipe Length

N: Natural Gas 1000 BTU/FT٨3 .60 Specific Gravity @ 0.5” WC pressure Drop

P: Propane Gas 2500 BTU/FT٨3 1.53 Specific Gravity @ 0.5” WC pressure Drop

Input

(KBTU)

88 35 75 135 305 440 990

110 20 50 90 205 290 720 1045

199 15 30 65 95 220 365 880 830

275 15 35 50 120 205 460 425 980

399 20 25 60 100 230 220 485

1/2” 3/4” 1” 1-1/4” 1-1/2”

N P N P N P N P N P

Table J: Maximum Equivalent Pipe Length

21

Page 22

Gas Supply Pressure

minimum of 4.5 in. WC upstream gas pressure

A

under full load and a maximum gas supply pressure

setpoint of 10.5 in. WC under load and no-load conditions for natural gas. A minimum of 8.0 in. WC

pstream gas pressure under full load and a maximum

u

gas supply pressure setpoint of 13.5 in. WC is required

or propane gas. The gas pressure regulator(s) sup-

f

plied on the boiler is for low-pressure service. If

upstream pressure exceeds 1/2 PSI at any time, an

intermediate gas pressure regulator, of the lockup

type, must be installed. This regulator should be

placed a minimum distance of 10 times the pipe diameter upstream of the boiler gas controls.

When connecting additional gas utilization equipment

to the gas piping system, the existing piping must be

checked to determine if it has adequate capacity for

the combined load. The gas valve pressure regulator

on the boiler is nominally preset as noted in Table K.

During normal operation, carbon dioxide should be 8.8

to 10.5% at full fire for natural gas and between 10.2

and 10.8% for propane gas. Carbon monoxide should

be ‹200 ppm.

Manifold Pressure (in. WC)

Model

No.

88AR -.1” WC -.1” WC

108AR -.1” WC -.1” WC

198AR -2.0” WC -1.4” WC

278AR -2.1” WC -2.0” WC

398A -3.4” WC -3.0” WC

Table K: Manifold Gas Pressure Settings

CAUTION: For proper operation, no more than a

30% drop in gas supply pressure from no-load to fullload conditions is acceptable. Under no

circumstances should the pressure be outside the

listed operational range.

Natural Gas Propane Gas

High High

Electrical Power Connections

Installations must follow these codes:

• National Electrical Code and any other national,

state, provincial or local codes or regulations having jurisdiction.

• Safety wiring must be NEC Class 1.

• Heater must be electrically grounded as required

by the NEC.

• In Canada, CSA C22. 1 C.E.C. Part 1.

The XPak FT 88AR-398A boilers are wired for 120

VAC single-phase 60 Hz power. Consult the wiring diagram shipped with the unit. Before starting the boiler,

check to ensure proper voltage to the boiler and

pump(s).

The expected current draw for the boiler is less than 5

amps. The pump load is additional.

The boiler pump (up to ¼ HP) and the indirect DHW

pump (up to ¼ HP) get their power supply directly from

the boiler power supply. The system pump relay is

rated for pilot duty only. An indirect DHW pump larger

than ¼ HP or 5A must use a separate power supply

and run the power through an external field-supplied

pump contactor. Use appropriately-sized wire as

defined by NEC, CSA and/or local codes. All primary

wiring should be 125% of minimum rating. The indirect and system pumps outputs are fuse-protected.

If any of the original wire as supplied with the boiler

must be replaced, it must be replaced with 105°C wire

or its equivalent.

All 120VAC field wiring connections to the XPak FT are

made inside the rear wiring box as shown in Fig. 17.

Low-voltage wiring is connected to the VERSA control

board and the Platform Ignition Module (PIM) at the

front of the unit. Sensors, enable/disable contacts,

(optional) 0-10 VDC control wiring, and cas- cade connections are wired into the VERSA and PIM field wiring

plugs. See the wiring diagram on page 47.

22

Page 23

Check the Power Source

CG

(12 AWG)

BW

(12 AWG)

ABK

(12 AWG)

NOTE: Minimum 18 AWG, 105°C, stranded wire

must be used for all low voltage (less than 30 volts)

external connections to the unit. Solid conductors

should not be used because they can cause

excessive tension on contact points. Install conduit

s appropriate. All high voltage wires must be the

a

same size (105°C, stranded wire) as the ones on the

unit or larger.

Fig. 18: Multi-meter

Making the Electrical Connections

Refer to Fig. 17–25.

1. Verify that circuit breaker is properly sized by

referring to the boiler’s rating plate. A dedicated

circuit breaker should be provided and sized for

the boiler and all pumps powered through it.

NOTE: Current draw noted on rating plate does not

include pump current.

Fig. 17: Wiring Connections

WARNING: Using a multi-meter, check the

following voltages at the circuit breaker panel prior to

connecting any equipment. Make sure proper

polarity is followed and house ground is proven.

(See Fig. 17.)

Check the power source:

AC = 108 VAC Minimum, 132 VAC MAX

AB = 108 VAC Minimum, 132 VAC MAX

BC = <1 VAC Maximum

2. Turn off all power to the boiler. Verify that power

has been turned off by testing with a multi-meter

prior to working with any electrical connections or

components at the J-box inside the unit.

3. Observe proper wire colors while making electrical connections. Many electronic controls are

polarity sensitive. Components damaged by improper electrical installation are not covered by

warranty.

4. Provide overload protection and a disconnect

means for equipment serviceability as required by

local and state code.

5. Install boiler controls, thermostats, or building

management systems in accordance with the

applicable manufacturers’ instructions.

6. Conduit must not be used as the earth ground.

NOTE: A grounding electrode conductor shall be

used to connect the equipment grounding

conductors, the equipment enclosures, and the

grounded service conductor to the grounding

electrode.

23

Page 24

Field Wiring Connections

DANGER: SHOCK HAZARD

Make sure electrical power to the boiler is disconnect-

d to avoid potential serious injury or damage to

e

components.

CAUTION: Wiring errors can cause improper and

dangerous operation. See the wiring diagram in this

manual. Verify proper operation after servicing.

Fig. 19: Electrical Wiring

Wiring the Thermostat

Connect the Enable/Disable terminals to the PIM (shown in Fig. 20). Alternately, any dry contact closure (including a remote thermostat) across these terminals will enable the XPak FT unit to run. Caution should be used to

ensure neither of the terminals becomes connected to ground.

Fig. 20: XPak FT Single Boiler Control

24

Page 25

Heating Sensor Installation

1. Only use the System sensor provided with the

unit.

2. The sensor wires can be extended up to 500'

sing a shielded 2-conductor cable.

u

3. Do not run sensor wires in conduit with line voltage

wiring.

4. Install a 3/8" ID 1/2 NPT immersion well.

5. If installing the system sensor on the supply, insert

the sensor in a well with heat paste no more than

5' feet past the boiler loop outlet on the common

supply header but before any major takeoffs. The

sensor must be located where it sees the output of

all the boiler stages. If a boiler is piped so that the

sensor does not see its output, the VERSA IC will

not sequence the boilers correctly.

Heating

System

Sensor

Sensor

Probe

Immersion Well

3/8” ID 1/2 NPT

Fig 21: System Sensor (S3)

Common

Supply Pipe

3. Use a minimum 18 AWG wire for runs of up to 150

feet.

4. Mount the outdoor sensor on an exterior surface of

he building, preferably on the north side in an

t

area that will not be affected by direct sunlight and

that will be exposed to varying weather conditions.

Wiring the Indirect Sensor (S5)

1. There is no indirect sensor connection required if

an indirect water heater is not used in the installation.

2. When the Indirect DHW call for heat is active, the

PIM communicates this to the VERSA. The

VERSA calculates the optimal operation and

sends the firing rate and pump output requests to

the PIM so it can activate the Indirect DHW pump

and Boiler pump if needed.

NOTE: Alternately, a thermostat contact closure can

be used in lieu of the sensor for indirect operation.

Connect the thermostat to the terminals marked IND

REMOTE THERMOSTAT.

CAUTION: Sensor and control wiring must NOT be

run in conduit or chases with line voltage.

If an optional Indirect DHW sensor is connected to

J2-1 and J2-2 the PIM will pass this signal to the

VERSA. This allows the VERSA to optimize the

Indirect DHW demand to maintain the Indirect

DHW setpoint. The Indirect DHW thermostat

switch closure is not required when using the

Indirect DHW sensor. If a VERSA is not present

the PIM shall activate the Indirect DHW pump

whenever the Indirect DHW call is active. The

Boiler pump may also be activated based on the

Indirect DHW piping configuration setting.

NOTE: If the System Sensor (S3) can not sense the

correct water temperature, the VERSA IC will not

provide comfortable heat levels.

WARNING: Use only the System and Outdoor Air

sensors included with the control.

Wiring the Outdoor Sensor (S4)

1. There is no connection required if an outdoor sensor is not used in this installation.

2. If using an Outdoor Sensor, connect the sensor

wires to the terminals marked OUTDOOR SENSOR (see wiring diagram). Caution should be

used to ensure neither of these terminals

becomes connected to ground.

3. Connect the indirect tank sensor to the terminals

marked INDIRECT DHW SENSOR (see wiring

diagram). Caution should be used to ensure neither of these terminals becomes connected to

ground.

Wiring the Optional 0–10 Volt

Building Control Signal

1. A signal from an energy management system may

be connected to the XPak FT boiler. This signal

should be a 0-10 volt positive DC signal, and an

energy management system can be used to control either the setpoint temperature or the firing

rate of the XPak FT boiler.

25

Page 26

VERSA

MASTER

Fig. 22: XPak FT Cascade System Wiring

2. To enable this remote control function, set dip

switch 5 to the UP position on the PIM. Dip switch

5 Toggles between an EMS (UP) signal or a

demand signal from the VERSA (DOWN). Dip

switch 2 on the PIM toggles between a Direct

Drive (UP) input and a Target Temperature

(DOWN) setpoint.

3. For a 4-20 mA application, refer to the VERSA IC

Applications Guide.

4. Connect an Energy Management system or other

auxiliary control signal to the terminals marked 010V (+ /-) on the PIM (see Fig. 20). Caution should

be used to ensure that the +0-10V connection

does not create a short to ground.

Wiring the Cascade System

Communication Bus

1. Designate the primary boiler as the master

boiler/boiler1 by leaving DIP switch 2 on the

VERSA in the ON position. All other VERSA controls require DIP switch 2 to be toggled OFF,

designating them as followers. Follower VERSA’s

are ignored by their corresponding PIM’s. Use

standard 18 AWG wire to connect the master

VERSA to the PIM on the followers. A total of 3 followers can be connected to the VERSA on the

master. For systems requiring more than 4 connected boilers, an external sequencer such as the

Raypak Temp-Tracker Mod+ Hybrid can be used.

2. It is recommended that the shortest length cable

possible be used to reach between the boilers. Do

not run unprotected cables across the floor or

where they will become wet or damaged. Do not

run communication cables parallel with, or close to

or against, high voltage (120 volt or greater)

wiring. Raypak recommends that the total maximum length of each set of communication bus

cables not exceed 200 feet.

3. Route the FT_BUS wires from the front along the

right rail and out the bottom of the cabinets.

4. Connect the FT_BUS wires to the PIM by pressing

down on the slots with a small screwdriver and

then inserting the wires into the holes. See Fig.

23.

Fig. 23: FT_BUS Wire Connection

26

Page 27

G

(12 AWG)

W

(12 AWG)

BK

G

W

BK

G

W

BK

G

W

BK

(12 AWG)

Fig. 24: XPak FT Cascade Master Pumps

G

(12 AWG)

W

(12 AWG)

BK

(12 AWG)

G

W

BK

-

Cascade System Pump and

Sensor Wiring

1. On the boiler designated as the Master, connect

the system pump wiring to the terminal block at the

rear of the unit. Connect to terminals 10, 11, and

12 (See Fig. 24). The output is rated for pilot duty

only (2A maximum).

Cascade Follower Pump

and Sensor Wiring

. Once the primary boiler has been identified, addi-

1

tional boilers will be designated as follower boilers.

Ensure DIP switch 2 on each follower VERSA is

set to the OFF/Down position (See Fig. 25)

2. For each follower boiler, connect the boiler pump

wires to the terminal block at the rear of each unit.

Connect to terminals 4, 5, and 6 as shown in Fig.

24.

2. Connect the boiler pump wires to the terminal

block at the rear of their unit. Connect to terminals

4, 5, and 6 (See Fig. 24).

3. Connect the system supply sensor to terminals 3

Fig. 25: VERSA Follower

and 4 on the J2 connector located on the Master

PIM (See Fig. 20).

Modbus BMS Communication

The VERSA IC control is equipped as standard with a

communications port for connectivity to building

automation via Modbus protocol. Refer to the VERSA

IC Applications Guide (Catalog No. 5000.72) for fur-

4. Connect the Outdoor sensor (if used) to terminals

5 and 6 on the J2 connector located on the Master

PIM (See Fig. 20).

ther information.

5. Connect the Enable/Disable wiring to terminals 9

and 10 on the J1 connector located on the Master

PIM (See Fig. 20). This connection must be provided through dry contacts closure.

NOTE: This dry contacts closure can come from a

room thermostat or a remote relay. No power of any

kind should be applied to either of these terminals.

27

Page 28

Alarm Connection

The Alarm Contacts are 3A rated dry contacts on a

normally-open relay that close during fault or lockout

conditions, and the maximum voltage across the contacts is 30 VAC or 30 VDC. Connections are made at

he supplied alarm contacts (spade terminals).

t

In a cascade system, the alarm output of the master

boiler will be active if either the master boiler or follower(s) have a lockout condition. The alarm output of

the follower boilers will only energize if a lockout condition occurs on that specific boiler.

Venting

CAUTION: Proper installation of flue venting is

critical for the safe and efficient operation of the

boiler.

WARNING: Contact the manufacturer of the vent

aterial if there is any question about the appliance

m

categorization and suitability of a vent material for

application on a Category IV vent system. Using

improper venting materials can result in personal

injury, death or property damage.

se only PVC or CPVC vent material (in Canada,

U

ULC-S636 approved plastic material must be used) or

special gas vent pipes listed for use with Category IV

gas burning heaters, such as the AL29-4C stainless

steel vents offered by Heat Fab Inc. (800-772-0739),

Protech System, Inc. (800-766-3473), Z-Flex (800654-5600) or American Metal Product (800-423-4270).

Pipe joints must be positively sealed. Follow the vent

manufacturer’s installation instructions carefully.

®

DuraVent

approved to be used on XPak FT products.

polypropylene vent material is also

General

Appliance Categories

Heaters are divided into four categories based on the

pressure produced in the exhaust and the likelihood of

condensate production in the vent.

Category I – A heater which operates with a non-positive vent static pressure and with a vent gas

temperature that avoids excessive condensate production in the vent.

Category II – A heater which operates with a non-positive vent static pressure and with a vent gas

temperature that may cause excessive condensate

production in the vent.

Category III – A heater which operates with a positive

vent pressure and with a vent gas temperature that

avoids excessive condensate production in the vent.

Category IV – A heater which operates with a positive

vent pressure and with a vent gas temperature that

may cause excessive condensate production in the

vent.

See Table M for appliance category requirements.

NOTE: For additional information on appliance

categorization, see the ANSI Z21.13 Standard and

the NFGC (U.S.), or B149 (Canada), or applicable

provisions of local building codes.

Vent installation shall be in accordance with Part 7,

Venting of Equipment, of the NFGC, ANSI

Z223.1/NFPA 54, Section 7, Venting Systems and Air

Supply for Appliances, of the B149 Code, or applicable

provisions of the local building codes.

WARNING: Do not use foam core or cellular core

PVC/CPVC pipe for venting.

WARNING: DO NOT insulate PVC or CPVC vent

pipe.

CAUTION: When using stainless steel vent in a climate where freezing may occur, a double wall vent

pipe must be used.

CAUTION: The inlet water temperature to the XPak

FT must not exceed 170ºF at any firing rate to use

the PVC venting option. The venting system must

conform to local codes and/or the current National

Fuel Gas Code ANSI Z223.1/NFPA 54. The system

setpoint must not exceed 180°F.

Support of Vent Stack

The weight of the vent stack or chimney must not rest

on the heater vent connection. Support must be provided in compliance with applicable codes. The vent

should also be installed to maintain proper clearances

from combustible materials. Use insulated vent pipe

spacers where the vent passes through combustible

roofs and walls.

28

Page 29

ombustion

COMBUSTIONCOMCOMBUCOMBUSCOMBUSTCOMBUSTICOMBUSTIOCOMBUSTION

TEST PORT

COMBUSTION

TEST PO

COMBUSTION

TEST PORT

3 O-RING

COMBUSTION

TEST PORT

3 O-RING

GASKETS

COMBUSTION

TEST PORT

3 O-RING

GASKETS

C

Air Supply

xhaust

E

Configuration

Heater

Venting

Category

Vertical Venting

From Inside Building

(Non-Direct Venting)

Horizontal Through-

the-Wall Venting

Vertical Venting

From Outside Building

(Direct Venting)

Horizontal Through-

the-Wall Venting

* Only Duravent®polypropylene is approved for the XPak FT product.

Table L: Venting Category Requirements

IV

ertified Vent

C

Materials

(Canada Only: ULC-

636 PVC and CPVC)

S

Stainless Steel,

AL29-4C,

Sch 40 PVC or CPVC

Polypropylene*

Combustion

Air Inlet

Material

Galvanized Steel,

PVC, ABS,

CPVC

WARNING: Condensate is acidic and highly

corrosive. The drain line must not be allowed to

freeze. Take appropriate measures.

NOTE: During winter months check the vent cap

and make sure no blockage occurs from build-up of

snow or ice.

Vent Terminal Location

1. Condensate can freeze on the vent cap. Frozen

condensate on the vent cap can result in a blocked

flue condition.

2. Give special attention to the location of the vent

termination to avoid possibility of property damage or personal injury.

3. Gases may form a white vapor plume in winter.

The plume could obstruct a window view if the termination is installed near windows.

4. The bottom of the vent terminal and the air intake

shall be located at least 12 in. above grade, including normal snow line.

5. Single-wall Category IV metal vent pipe shall not

be used outdoors in cold climates for venting gasfired equipment without insulation.

6. Through-the-wall vents for Category IV appliances shall not terminate over public walkways or

over an area where condensate or vapor could

create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or

other equipment.

Fig. 26: 3 in 1 Multi-Vent Connector

The Multi-vent connector is capable of using stainless

steel (SST), Polypropylene or PVC/CPVC pipe. Before

installing vent pipe, verify which o-ring gasket will be

used and dispose of the other two.

6. Locate and guard vent termination to prevent accidental contact by people or pets.

7. DO NOT terminate vent in window well, stairwell,

alcove, courtyard or other recessed area.

9. DO NOT terminate above any door, window, or

gravity air intake. Condensate can freeze, causing

ice formations.

10. Locate or guard vent to prevent condensate from

damaging exterior finishes. Use a 300-series

stainless steel backing plate against brick or

masonry surfaces.

29

Page 30

11. DO NOT extend exposed vent pipe outside of

VENT CAPS STACKED VERTICALLY

FLUE GASES MOVING IN PARALLEL

VENT CAPS ALL AT SAME ELEVATION

FLUE GASES MOVING TOWARD EACH OTHER

VENT CAPS AT STAGGERED ELEVATIONS

FLUE GASES MOVING TOWARD EACH OTHER

1” MINIMUM (TYP)

2” MINIMUM (TYP)

1” MINIMUM (TYP)

DISCHARGE

4’-0” MIN.

(TYP)

4’-0” MIN.

(TYP)

DISCHARGE

uilding beyond the minimum distance required

b

for the vent termination. Condensate could freeze

and block vent pipe.

.S. Installations

U

Refer to the latest edition of the National Fuel Gas

ode.

C

Vent termination requirements are as follows:

1. Vent must terminate at least 4 ft below, 4 ft horizontally from or 1 ft above any door, window or

gravity air inlet to the building.

2. The vent must not be less than 7 ft above grade

when located adjacent to public walkways.

3. Terminate vent at least 3 ft above any forced air

inlet located within 10 ft.

4. Vent must terminate at least 4 ft horizontally, and

in no case above or below unless 4 ft horizontal

distance is maintained, from electric meters, gas.

5. Terminate vent at least 6 ft away from adjacent

walls.

6. DO NOT terminate vent closer than 5 ft below roof

overhang.

7. The vent terminal requires a 12 in. vent terminal

clearance from the wall.

8. Terminate vent at least 1 ft above grade, including

normal snow line.

9. Multiple direct vent installations require a 4 ft

clearance between the ends of vent caps located

on the same horizontal plane.

Installations in Canada

Refer to latest edition of the B149 Installation Code.

A vent shall not terminate:

1. Directly above a paved sidewalk or driveway

which is located between two single-family dwellings and serves both dwellings.

2. Less than 7 ft (2.13 m) above a paved sidewalk or

paved driveway located on public property.

3. Within 6 ft (1.8 m) of a mechanical air supply inlet

to any building.

4. Above a meter/regulator assembly within 3 ft (915

mm) horizontally of the vertical centerline of the

regulator.

WARNING: The Commonwealth of Massachusetts

requires that sidewall-vented heaters, installed in

every dwelling, building or structure used in whole or

in part for residential purposes, be installed using

special provisions as outlined on page 62 of this

manual.

5. Within 6 ft (1.8 m) of any gas service regulator

vent outlet.

Fig. 26: Vent Cap Configurations

6. Less than 1 ft (305 mm) above grade level.

7. Within 3 ft (915 mm) of a window or door which

can be opened in any building, any non-mechanical air supply inlet to any building or the

combustion air inlet of any other appliance.

8. Underneath a verandah, porch or deck, unless the

verandah, porch or deck is fully open on a minimum of two sides beneath the floor, and the

distance between the top of the vent termination

and the underside of the verandah, porch or deck

is greater than 1 ft (305 mm).

30

Page 31

M

odel

No.

ertified Vent

C

Material

Vent and

ntake Air

I

Vent Size

(in.)

Vertical Vent Height1 (ft)

Min. Max.

Combustion

ir Intake

A

Pipe

Material

Vertical Air

Inlet Max.

Length* (ft)

88AR

(Canada Only:

ULC-S636 PVC

2

0

5

and CPVC)

108AR

198AR

278AR

Stainless Steel,

AL29-4C,

ANSI/ASTM D1785

Sch 40 PVC,

3 100 100

Galvanized

5

PVC, ABS,

ANSI/ASTM F441

398A

1

Vent lengths are based on a lateral length of 2 ft. Refer to the latest edition of the NFGC for further details.

* Subtract 10 ft per elbow. Max. 7 elbows.

** Only Duravent polypropylene is approved for the XPak FT product.

Model No.

Sch 40 CPVC

Polypropylene**

Table M: Category IV Vertical Vent & Vertical Direct Vent

Size

(in.)

3 60 60

4 100 100

Approved

Intakes

Approved Plastic

Terminals

Approved SS Terminals

88AR

3" PVC/CPVC Elbow

108AR

198AR

278AR

398A 4

3

PVC 90° Elbow,

Sch 40

Galvanized 90°

Elbow,

SS 90° Elbow,

ABS 90° Elbow

Sch 40*,

Duravent

Polypropylene

4" PVC/CPVC Tee

Sch 40*,

Duravent

FasNSeal®FSTT 3

FasNSeal®FSTT 4

Polypropylene

Steel,

CPVC

0

5

*Must be ULC-S636 materials in Canada.

Table N: Horizontal Vent and Air Intake Terminals

Venting Installation Tips

Support piping:

• Horizontal runs—At least every 5 ft (1.5 m)

• Vertical runs—Use braces

• Under or near elbows

NOTE: Ensure adequate clearances to allow annual

inspection of the venting system.

Venting Configurations

For heaters connected to gas vents or chimneys, vent

installations shall be in accordance with the NFGC

(U.S.), or B149 (Canada), or applicable provisions of

local building codes.

CAUTION: This venting system requires the

installation of a condensate drain in the vent piping

per the vent manufacturer’s instructions. Failure to

install a condensate drain in the venting system will

void all warranties on this boiler. Condensate is

acidic and highly corrosive. The drain line must not

be allowed to freeze. Take appropriate measures.

Vertical Venting (Category IV)

Installation

The maximum and minimum venting length for this

Category IV appliance shall be determined per the

NFGC (U.S.) or B149 (Canada).

31

Page 32

The minimum flue pipe diameter for conventional venting is: 3 in. (76 mm) for Models 88AR (2” optional),

108AR, 198AR and 278AR, and 4 in. (102 mm) for

Models 398A (3” optional).

The connection from the appliance vent to the stack

must be as direct as possible and shall be the same

diameter as the vent outlet. The horizontal breaching

of a vent must have an upward slope of not less than

1/4 inch per linear foot from the heater to the vent terminal. The horizontal portions of the vent shall also be

supported for the design and weight of the material

employed to maintain clearances and to prevent physical damage or separation of joints.

The vent terminal should be vertical and should terminate outside the building at least 2 ft above the highest

point of the roof that is within 8 ft. The vent cap should

have a minimum clearance of 4 ft horizontally from and

in no case above or below (unless a 4 ft hori-zontal

distance is maintained) electric meters, gas meters,

regulators and relief equipment.

WARNING: Vent connectors serving any other

appliances shall not be connected into any portion of

mechanical draft systems operating under a positive

pressure. If an XPak FT boiler is installed to replace

an existing boiler, the vent system MUST be verified

o be of the correct size and of Category IV AL29-4C

t

vent material, approved PVC/CPVC construction, or

DuraVent

®

polypropylene (in Canada, ULC- S636

approved plastic materials must be used). If it is

NOT, it MUST be replaced..

NOTE: For extractor sizing, typical CO2 levels are

9.0% for natural gas and 10.5% for propane gas and

flue temperatures of less than 180°F.

At the time of removal of an existing boiler, the following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining connected to the common venting system are not

in operation:

The distance of the vent terminal from adjacent public

walkways, adjacent buildings, open windows and

building openings must be consistent with the NFGC

(U.S.) or B149 (Canada). Vents supported only by

flashing and extending above the roof more than 5 ft

should be securely guyed or braced to withstand snow

and wind loads.

Common Venting

The NFGC does not address sizing guidelines for the

common venting of multiple Category IV heaters. This

is covered in the NFGC under “Engineered Vent Systems”. Table O provides volumes of flue products at

full fire for the calculation of appropriate vent and

extractor sizing for common venting.

CAUTION: A listed vent cap terminal suitable for

connection to the Cat IV vent materials, adequately

sized, must be used to evacuate the flue products

from the boilers.

WARNING: An extractor is required when multiple

heaters are vented through a common vent pipe.

The extractor must operate when one or more units

are firing.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and make sure there is no

blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

NOTE: Vent and intake piping must be supported so

that the weight of the venting is not transfered to the

unit. Horizontal runs of vent and intake piping must

be supported to prevent sagging.

NOTE: While a drain connection is required in the

vent of all XPak FT installations, the drain can be accomplished in several different ways. The figures in