Page 1

Pathfinder

Radar

Scanners

Owner’s

Handbook

Document number: 81154_4

Date: 25th October 2000

Page 2

Page 3

Pathfinder Radar Scanners i

Pathfinder Radar Scanners Owners Handbook

October 2000

SAFETY NOTICES

This radar equipment must be installed and operated in accordance with the instructions contained in this manual. Failure to do

so can result in personal injury and/or navigational inaccuracies.

In particular:

1. High Voltage. The scanner unit contains high voltages. Adjust-

ments require specialised service procedures and tools only available to qualified service technicians – there are no user

serviceable parts or adjustments. The operator should never

remove the scanner unit internal covers or attempt to service the

equipment.

2. Electromagnetic Energy. The radar scanner transmits electro-

magnetic energy. It is important that the radar is turned off whenever personnel are required to come close to the scanner to

perform work on the scanner assembly or associated equipment.

It is recommended that the radar scanner is mounted out of range

of personnel (above head height).

Do not look directly at the antenna at close range as your eyes are

the most sensitive part of the body to electromagnetic energy.

When properly installed and operated, the use of this radar will

conform to the requirements of ANSI/IEEE C95.1-1992 Standard

for Safety Levels with Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 Hz to 300 GHz and NRPB,

Board Statement on Restrictions on Human Exposure to Static

and Time Varying Electromagnetic Fields and Radiation, Doc

NRPB, No. 5 (1993).

3. Navigation Aid. This radar unit is only an aid to navigation. Its

accuracy can be affected by many factors, including equipment

failure or defects, environmental conditions, and improper handling or use. It is the user’s responsibility to exercise common

prudence and navigational judgements. This radar unit should not

be relied upon as a substitute for such prudence and judgement.

Page 4

ii Pathfinder Radar Scanners

RAYTHEON MARINE products are supported by a network of

Authorized Service Representatives. For information on Raytheon

products and services, contact either of the following:

United States Raytheon Marine Company

Recreational Products

22 Cotton Road, Suite 280

Nashua

NH 03063-4219, USA

Telephone +1 603 881 5200

Fax +1 603 864 4756

www.raymarine.com

Europe Raytheon Marine Limited

Anchorage Park

Portsmouth

Hampshire PO3 5TD

England

Telephone +44 (0)23 9269 3611

Fax +44 (0)23 9269 4642

www.raymarine.com

Copyright © Raytheon Marine Company 2000

The technical and graphical information contained in this handbook, to the best of our knowledge, was correct as it went to press.

However, the Raytheon policy of continuous improvement and

updating may change product specifications without prior notice.

As a result, unavoidable differences between the product and

handbook may occur from time to time, for which liability cannot

be accepted by Raytheon.

Raytheon is a registered trademark of Raytheon Company.

SeaTalk is a registered trademark of Raytheon Marine Europe

Limited.

HSB is a trademark of Raytheon Marine Company.

Pathfinder is a trademark of Raytheon Marine Company.

Page 5

Pathfinder Radar Scanners iii

Preface

This handbook describes the following Raytheon Pathfinder radar

scanners:

2D 18" 2 kW Radome Scanner

4D 24" 4 kW Radome Scanner

5S 48" 4 kW Open Array Scanner

7S 72" 4 kW Open Array Scanner

9S 48" 1 0 kW Open Array Scanner

11S 72" 10 kW Open Array Scanner

These scanner units may be connected to any HSB display unit. In

addition, the 2D and 4D radome scanner units may be connected

to SL70, or Autohelm 7" LCD display.

CAUTION:

The open array scanners must not be used with the SL70 or

Autohelm 7" LCD Display Unit. This may resu lt in damage to the

display due to the high power requirements of the open array

scanner.

The handbook contains very important information on the installation and operation of your new equipment. In order to obtain the

best results in operation and performance, please read this handbook thoroughly.

Raytheon’s Product Support representatives or your local dealer

will be available to answer any questions you may have.

Display Software Version

For full operation of the open array scanners, the display unit

requires an appropriate software version. For new displays, the

correct software version is normally already installed in the display unit and is fully compatible with the 2D and 4D radome

scanners.

Early display units may not have the correct software for use with

open array scanners and will therefore require upgrading.

The software version can be confirmed by switching-on the display and checking the version number during the magnetron

warm-up sequence.

Page 6

iv Pathfinder Radar Scanners

Note: If a scanner unit is not connected the version number i s only

displayed for 10 seconds.

Where, necessary Software Upgrade Kits are available from your

dealer, distributor or from Raytheon Marine.

We recommend that where a repeater display is fitted, both the

repeater and the master display are upgraded.

Warranty

To register your Pathfinder Radar Scanner ownership, please take

a few minutes to fill out the warranty registration card found at the

end of this handbook. It is very important that you complete the

owner information and return the card to the factory in order to

receive full warranty benefits.

The radome scanner package includes a barcode label indicating

the serial number of the unit. This label should be stuck to the

warranty registration card.

The open array scanner has two barcode labels indicating the

serial numbers of the pedestal and the antenna units. Both labels

should be stuck to the warranty registration card.

EMC Conformance

All Raytheon equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

The design and manufacture of Raytheon equipment and accessories conform to the appropriate Electromagnetic Compatibility

(EMC) standards, but correct installation is required to ensure that

performance is not compromised.

Page 7

Contents v

Contents

Preface ................................................................................. iii

W arranty ...........................................................................iv

EMC Conformance ..........................................................iv

Chapter 1: Overview ...............................................................................1

1.1 Introduction .......................................................................1

EMC installation guidelines .............................................2

1.2 Unpacking and inspecting the components ......................4

1.3 Selecting the scanner unit site ........................................... 5

1.4 Cable runs ....................................................................... 11

Radome scanner cables ...................................................13

Open array scanner cables ...............................................16

Chapter 2: Installing the Scanner .......................................................21

2.1 Radome scanner .............................................................. 21

Securing the radome scanner to the mounting surface .... 21

Connecting the radome scanner inter-unit cable ............. 22

2.2 Open array scanner .........................................................27

Securing the pedestal to the mounting platform ..............28

Connecting the open array scanner inter-unit cable ........29

Fitting the open array to the pedestal ...............................33

2.3 System connections ........................................................34

DC power connection .....................................................34

Scanner connection .........................................................35

Display unit connection .................................................. 37

Chapter 3: Post Installation Checks and Maintenance ....................39

EMC Conformance ......................................................... 39

3.1 System Checks and Alignment .......................................39

System check .................................................................. 39

Set up, alignment and timing checks ............................... 39

72" open array position alignment ..................................40

3.2 Maintenance ....................................................................41

Warnings ......................................................................... 41

Routine Checks ...............................................................41

Servicing and Safety ....................................................... 41

3.3 Problem Solving .............................................................42

How to Contact Raytheon (US) ...................................... 43

How to Contact Raytheon (Europe) ................................ 44

W orldwide Support .........................................................45

Page 8

vi Pathfinder Radar Scanners

Appendix A: Specification ...........................................................47

2D 18" Radome Scanner Unit ........................................47

4D 24" Radome Scanner Unit ........................................48

5S and 9S 48" Open Array Scanner Unit ........................50

7S and 11S 72" Open Array Scanner Unit ......................53

Index .......................................................................... i

Page 9

Chapter 1: Overview 1

Chapter 1: Overview

1.1 Introduction

This handbook provides instructions to assis t you in the installation

and set up of the following radar scanners:

2D 18" 2 kW Radome Scanner

4D 24" 4 kW Radome Scanner

5S 48" 4 kW Open Array Scanner

7S 72" 4 kW Open Array Scanner

9S 48" 10 kW Open Array Scanner

11S 72" 10 kW Open Array Scanner

These scanner units may be connected to any HSB display un it. In

addition the 2D and 4D radome scanner units may be connected to

SL70, or Autohelm 7" LCD display .

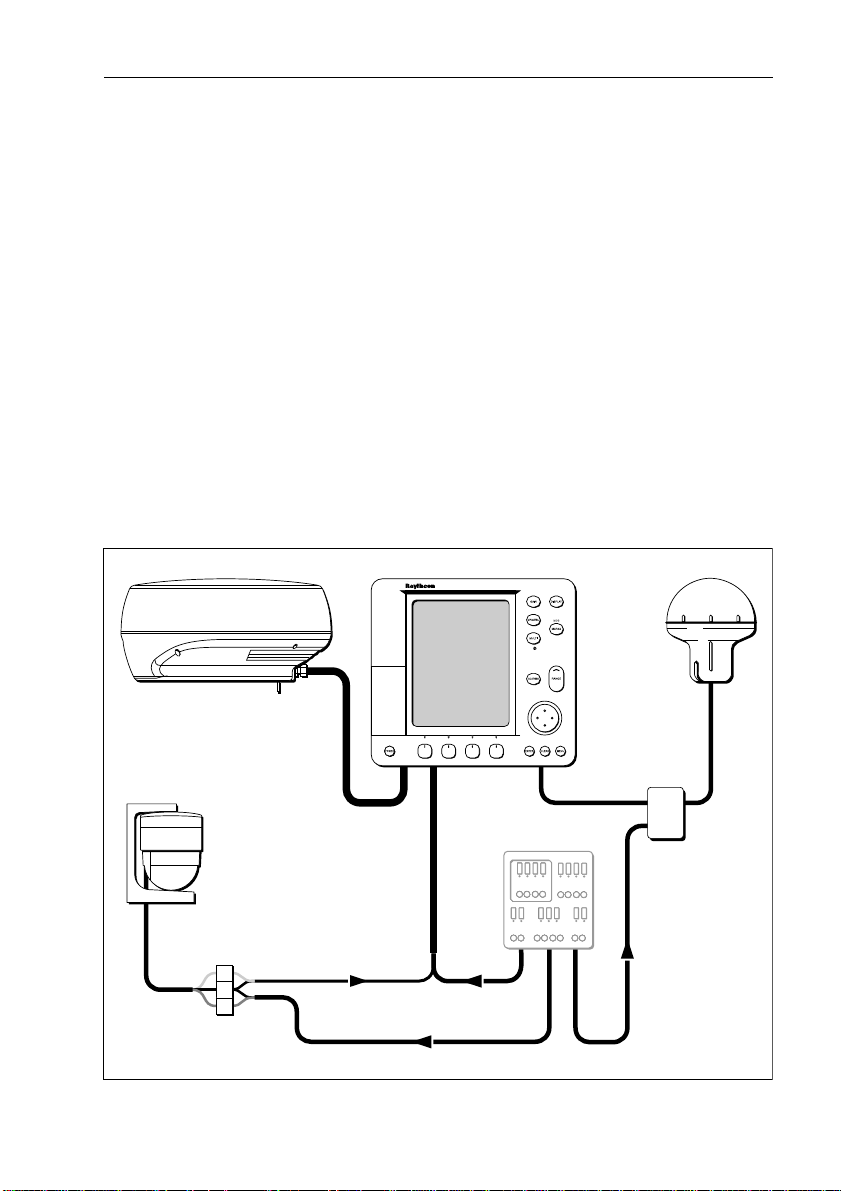

A typical Pathfinder Radar system is illustrat ed below .

Scanner

HSB Series Display

GPS

Compass

NMEA

Distribution Panel

12/24V Supply

12V Supply

SeaTalk

12V Supply

Junction

Box

D4288-3

Page 10

2 Pathfinder Radar Scanners

CAUTION:

Do not use the open array scanner with an SL70 or Autohelm 7"

LCD display unit. Failure to observe this may result in

permanen t damage to these disp lay units.

The 10 kW open array scanner requir es 24 V or higher; it will not

operate on 12 V systems.

This handbook is divided into three chapters as follows :

Chapter One provides an overview of the scanner installation. It

includes sections on Unpacking and Inspecting the Components,

Selecting the Scanner Site and a description of the Cable Runs.

Chapter Two pr ovides detailed instructions on how to mount and

connect each type of scanner.

Chapter Three provides instructions on how to perform the system

checks, alignment and adjustments. It also provi des information on

maintenance and what to do if you have problems.

EMC installation guidelines

All Raytheon equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

Their design and manufacture conforms to the appropriate

Electromagnetic Compatibility (EMC) standards, but correct

installation is required to ensure that performance is not

compromised. Although every effort has been ta ken to ensure that

they will perform under all conditions, it is importa nt to understand

what factors could affect the operation of the product.

The guidelines given here describe the conditions for opti mum EMC

performance, but it is recognized that it may not be possible to meet

all of these conditions in all situations. T o ensure the best possible

conditions for EMC performance within the constraints imposed by

any location, always ensure the maximum separation possible

between different items of electrical equipment.

For optimum EMC perform ance, it is recommended that wherever

possible:

• Raytheon equipment and cables connected to it are:

• At least 1 m (3 ft) from any equipment transmitting or cables

carrying radio signals e.g. VHF radios, cables and antennas.

Page 11

Chapter 1: Overview 3

In the case of SSB radios, the distance should be increased to

2 m (7 ft).

• More than 2 m (7 ft) from the path of a radar beam. A radar

beam can normally be assumed to spread 20 degrees above

and below the radiating element.

• The equipment is supplied from a separate battery from that used

for engine start. Voltage drops below 10 V (20 V for 10 kW open

array scanners) in the power supply to our products, and starter

motor tra nsients , can caus e the equip ment to re set. Thi s will not

damage the equipment, but may cause the loss of some information and may change the operating mode.

• Raytheon specified cables are used at all times. Cutting and

rejoining these cables can compromise EMC performance and so

must be avoided unless doing so is detail ed in the installation

manual.

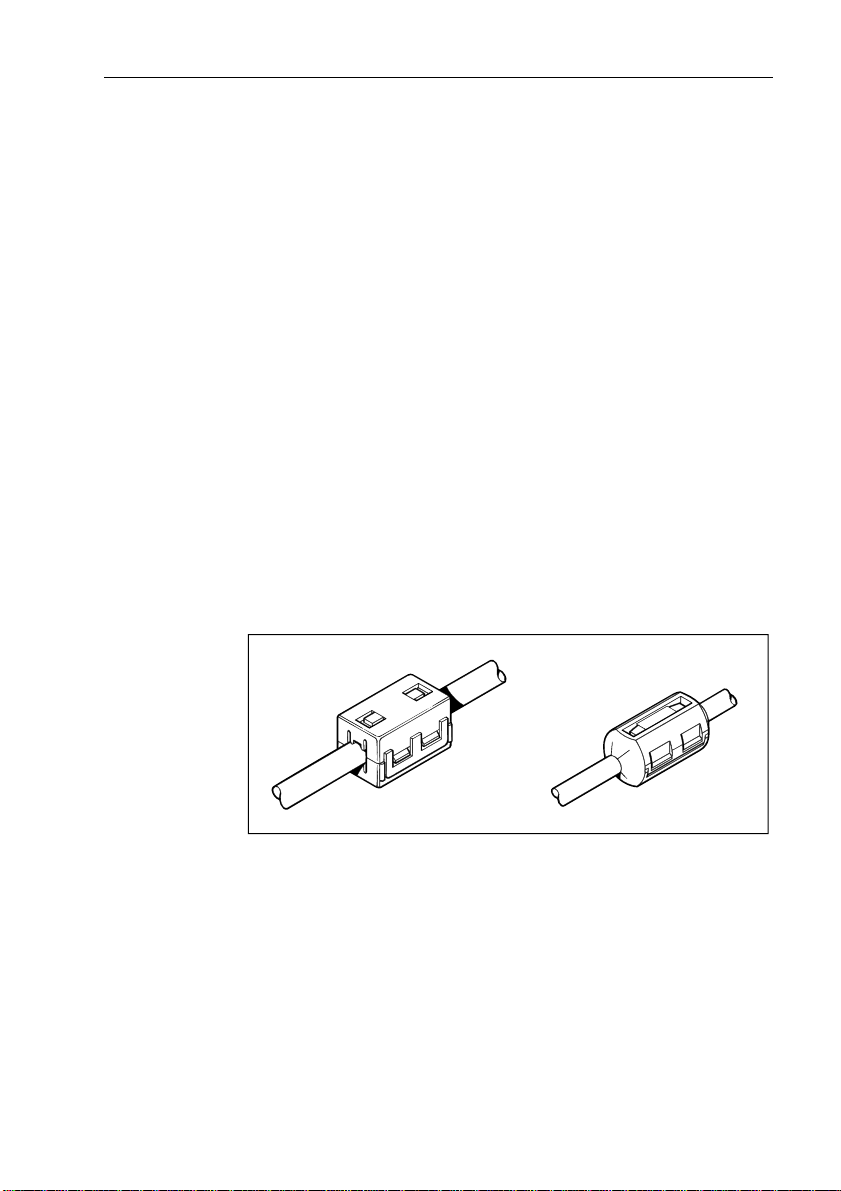

• If a suppression ferrite is attached to a cable, this ferrite should not

be removed. If the ferrite needs to be removed during installation

it must be reassembled in the same position. Section 2.1 Installing

the Radome Scanner includes instructions on fitting a ferri te.

The following illustration show s a typical range of suppression

ferrites fitted to Raytheon equipment.

D3548-2

Connections to Other Equipment

If your Raytheon equipment is to be connected to other equipment

using a cable not supplied by Raytheon, a suppressi on ferrite MUST

always be fitted to the cable close to the Raytheon unit.

Page 12

4 Pathfinder Radar Scanners

1.2 Unpacking and inspecting the components

Unpack your system carefully , to prevent damage to the equipment. It

is good practice to save the carton and packing for future use, in case

you need to return the unit for service. Check that you have all the

correct system components. These depend on your system package,

as detailed in the following tables.

Table 1-1: Radome scanners

Item Part No. Supplied with:

Option

for:

2D 18" 2 kW Radome Scanner

2DE 18" 2 kW Radome Scanner

4D 24" 4 kW Radome Scanner

Inter-unit cable 15 m heavy

Inter-unit cable 25 m heavy

Inter-unit cable 10 m light

Inter-unit cable 15 m light

Extension cable 5 m

Extension cable 10 m

Mast Mount 18" Scanner

Mast Mount 24" Scanner

Radar Interface adapter

(To fit radome to M88390 type 18"

mast mount)

Radome mounting interface plate M92731 - 2D

Supplied with HSB Series Display Unit

Supplied with HSB Series Display Unit

Supplied with HSB Series Display UnitSupplied with HSB Series Display Unit

Fer rite Cla mp

M92650

M92650E

M92652

M92668

M92669

M92692

M92720

M92699

M92700--

M92722

M92698--

M92721 - 2D

R55007 - Both

US Version

European Version

-

4D

2D (US version)

2D (Europe version)

-

-

-

Both

-

-

Both

Both

2D

4D

Table 1-2: Open array scanners

Item Part No. Supplied with: Option for:

4 kW Scanner Pedestal

10 kW Scanner Pedestal

48" Open Array

72" Open Array

Inter-unit cable 15 m heavy

Inter-unit cable 25 m heavy

Cable kit: 5 m +10 m extension

(To fit open array scanner on a

radar arch)

M92654

M92655

M92693

M92743

M92728

M92705

E55017

5S, 7S

9S, 11S

(

24/32V only)

5S, 9S

7S, 11S

-

-

-

-

-

-

-

5S,7S, 9S, 11S

5S, 7S, 9S, 11S

(

24/32V only)

5S, 7S, 9S,11S

Page 13

Chapter 1: Overview 5

Table 1-2:Open array scanners

Item Part No. Supplied with: Option for:

Extension cable 5m

Extension cable 10m

Software Upgrade Kit Please contact your authorized dealer or

M92699

M92700--

distributor for details

1.3 Selecting the scanner unit site

This section provides information that affects the possible locations

of the scanner, and its position relative to the display unit and t o the

power supply .

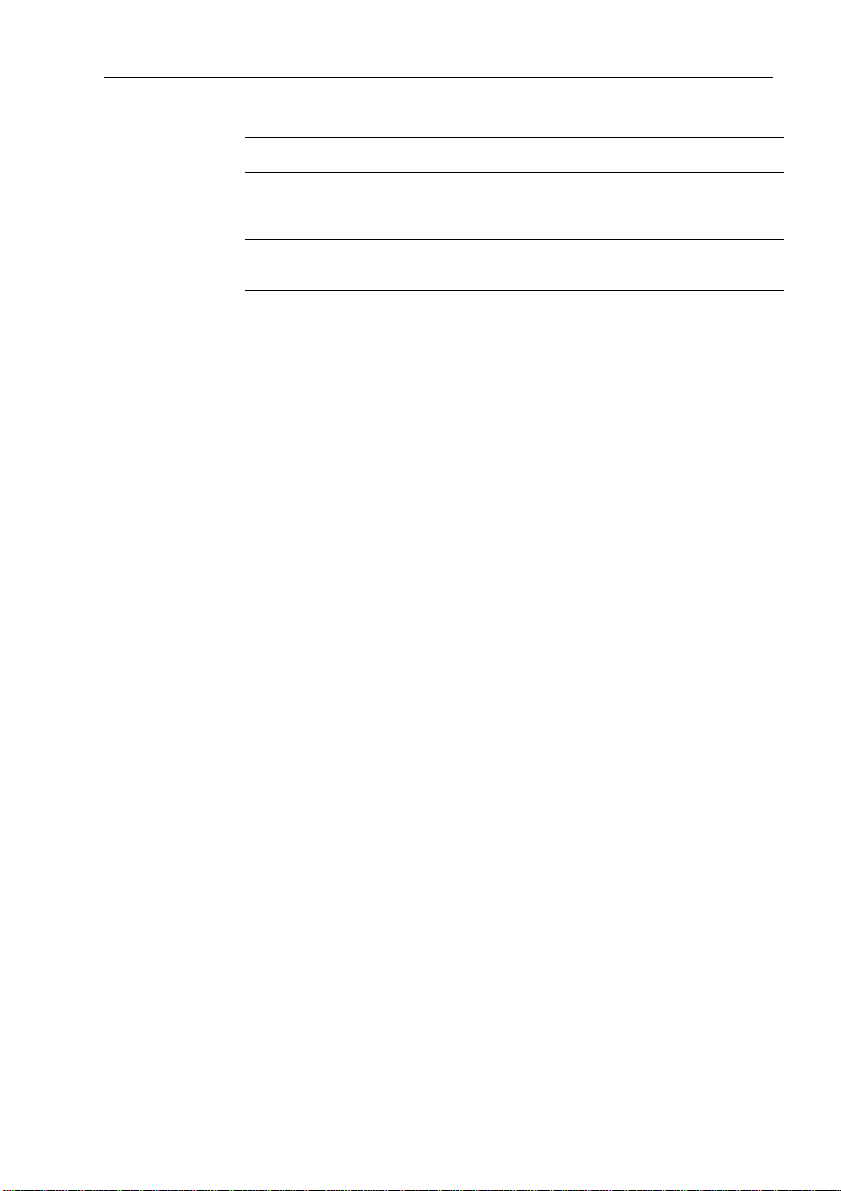

The dimensions of the each scanner unit are shown in the following

diagrams.

Selecting the best location for the scanner unit requires careful

consideration of the following points, to ensure reliable and trouble

free operation:

Note: In order to minimize potential interference to other sys tems on

board ship (EMC), it is advisable to mo unt the scanner on a part of

the boat that is insulated from the ship’s bat tery negative. If you cannot do this, and encounter problems, you can fit insulating bus hes between the scanner and its mounting bracket.

• Height: The scanner unit should normally be mounted as high as

practical above the waterline, for three reasons:

• For safety reasons the scanner should be out of range of per-

sonnel, preferably above head height. This avoids mechanical

danger and electromagnetic contact, particularly with the

eyes.

• Radar operates at the line-of-sight, so a high mounting posi-

tion gives better long range performance.

• Surrounding large objects, in the same horizontal plane, can

interfere with the radar signal and cause blind areas or shadow

sectors and false targets on the radar screen (see below).

However, do not mount the scanner so high that it is affected by

the pitching and rolling of the vessel. In addition, you may need to

lower the scanner to avoid creating a shadow sector underneath

the scanner’s beam.

5S, 7S, 9S, 11S

(24/32V only)

5S, 7S, 9S, 11S

Page 14

6 Pathfinder Radar Scanners

151.25 mm (5.95 in)

141.5 mm (5.6 in)

185.15 mm (7.3 in)

Rear

Rear

Rear

(4.6 in)

116.5 mm

302.5 mm (11.9 in)

468 mm (18.4 in) dia.

233 mm (9.2 in)

Weight: 6.5 kg (14.3 lbs)

Compass safe distance: 1 m (33 in)

18" Radome Scanner

402 mm (15.8 in)

599 mm (23.6 in) dia.

227 mm (8.9 in)

D3224_4

227 mm (8.9 in)

141.5 mm (5.6 in)

Rear

(4.6 in)

116.5 mm

233 mm (9.2 in)

Weight: 7.5 kg (16.5lbs)

Compass Safe Distance: 1m (33")

24" Radome Scanner

D3228_5

Page 15

Chapter 1: Overview 7

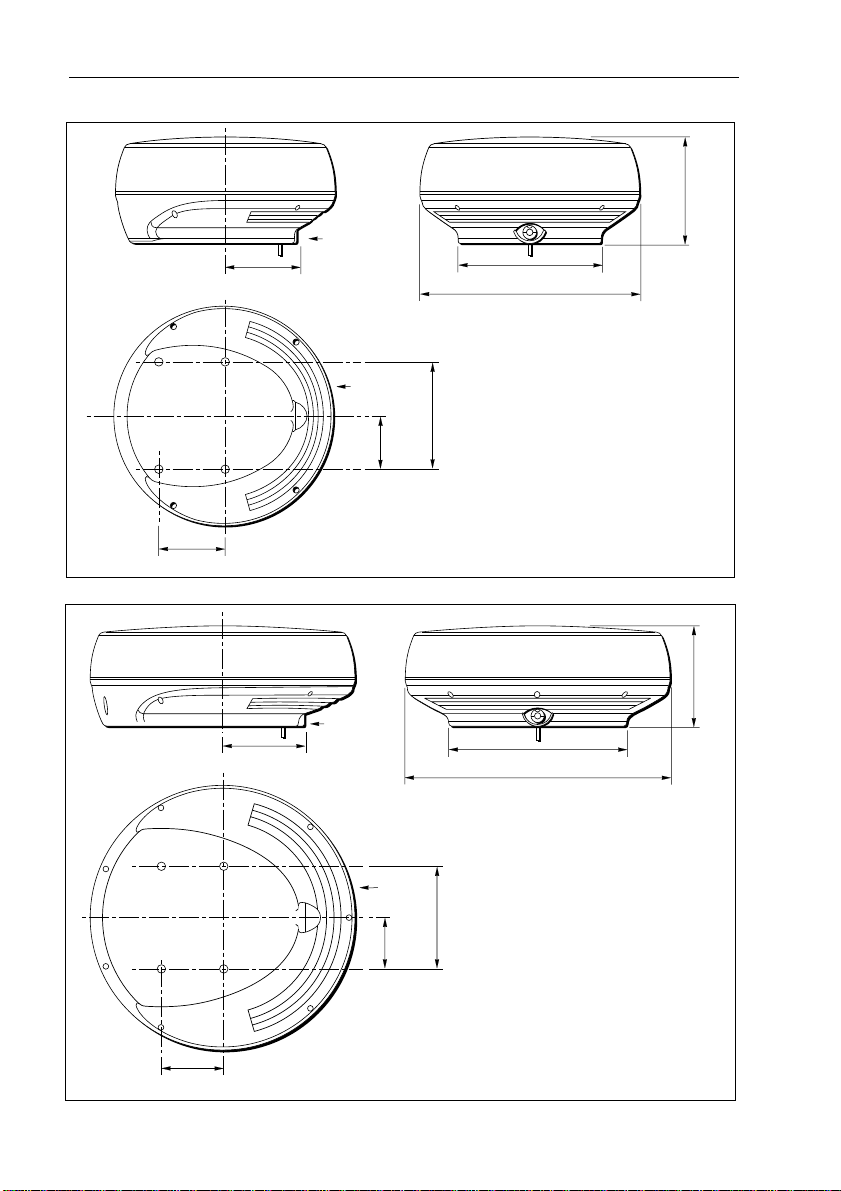

Open Array Scanners

48"- 1306 mm (51.4 in), 72"- 1918 mm (75.5 in)

Centre of rotation

100 mm (4 in)

427 mm (16.8 in)

140 mm (5.5 in)

Centre of rotation

406 mm (16 in)

296 mm (11.65 in)

150 mm (6 in)

Weight

Pedestal: 24 kg (53.0 lb)

48" Open Array: 6 kg (13.2 lb)

72" Open Array: 9.4 kg (20.7 lb)

Compass Safe Distance: 1 m (33 in)

Minimum clearance 630 mm (24.8 in)

70 mm

(2.75 in)

Minimum clearance height 510 mm (20.1 in)

D4572-3

Page 16

8 Pathfinder Radar Scanners

• Access: The scann er unit site sh ould be easily accessible to allow

maintenance to be carried out safely .

• Magnetic compass: Mount the scanner unit at least 1 m away

from a magnetic compass.

• Cable run: The maximum length of cable between the display

unit and the scanner unit should not normally exceed 20 m (60 ft)

for radome scanners, or 15 m (45 ft) for open array scanners. If

you need to use a longer cable power cable lengths must be considered, refer to Section 1.4 Cable Runs to determine appropriate

lengths.

• Shadow sectors and false echoes: Mount the scanner away from

large structures or equipment, such as the fly bridge, large engine

stacks, searchlights, horns, or masts. It is particularly important to

avoid shadow sectors near the bow . Raising or even lowering the

scanner may help to reduce these effects.

In shadow areas beyond the obstruction there will be a reduction

of the beam intensity , although not necessarily a complete cut-of f;

there will be a blind sector if the subtended angle is more than a

few degrees.

In some shadow sectors the beam intensity may not be suf ficient

to obtain an echo from a very small object, even at close range,

despite the fact that a large vessel can be detected at a much

greater range. For this reason the angular width and relative bearing of any shadow sector must be determined at installat ion.

Sometimes shadowing can be seen by increasing the radar gain

until noise is present. Dark sectors indicate possible shadowed

areas. This information should be posted near the display unit and

operators must be alert for targets in these blind sectors.

It should also be noted that wet s ails create shadow areas and thus

sail boat operators should be aware that radar performance may

reduce in rain.

If you mount the scanner on a mast, echoes from the mast may

appear on the radar display . These can be minimized by placing

absorbing material, such as a block of wood, between the scanner

and mast.

• Platform rigidity/stability: The scanner platform should not

twist (causing bearing errors) or be subject to excessive vibration.

• Heat/fumes: Mount the scanner away from the top of exhaust

stacks, since the scanner and cables can be damaged by excessive

heat and the corrosive effects of exhaust gases.

Page 17

Chapter 1: Overview 9

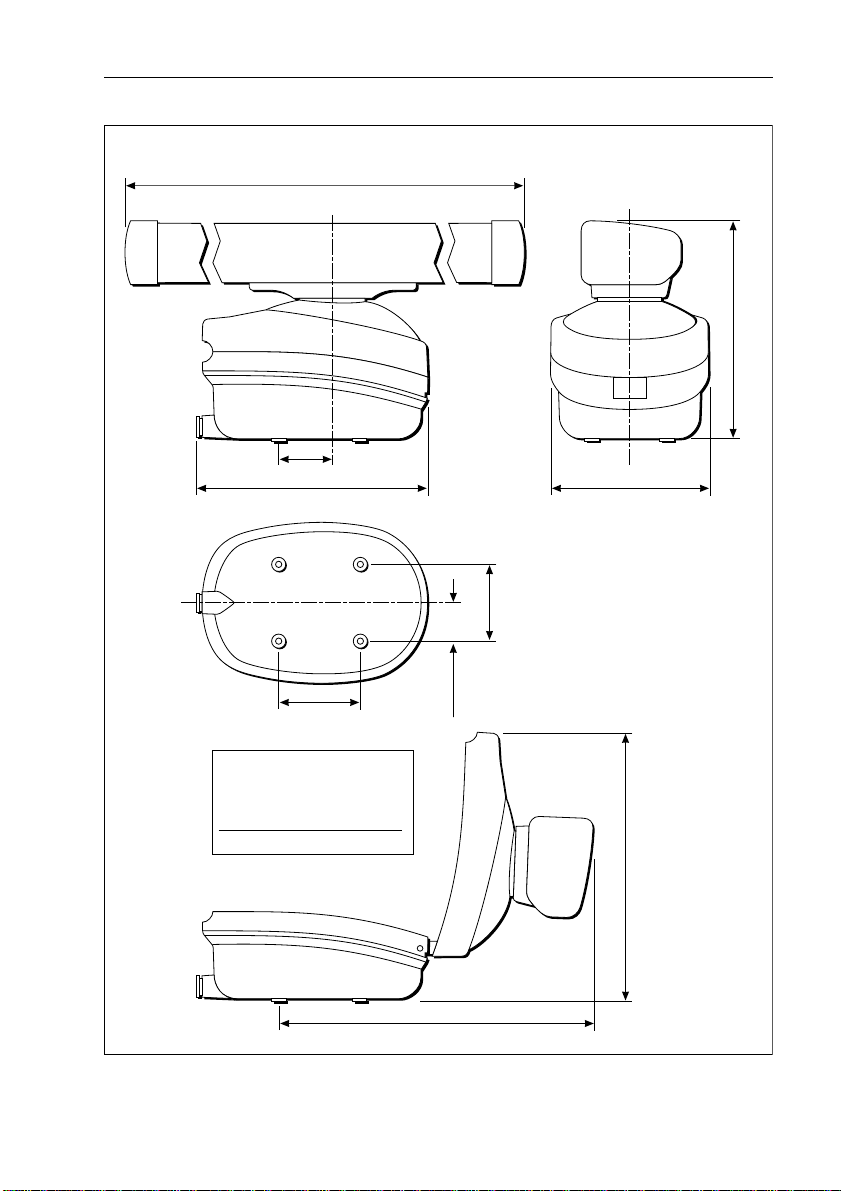

For open array scanners you should also consider the followi ng

points:

• Mounting Platform: The platform must be mechanically secure

and capable of supporting the mass and inertia of the open array

scanner. The complete unit weighs: 48" scann er - 30 kg (66.2 lb);

72" scanner - 33.4 kg (73.7 lb).

• The site must be clear of ropes and moving rigging.

• Sufficient clearance must be allowed to fully open the open array

pedestal for maintenance.

Mounting surface: sailboats

The scanner unit can be installed on a mast platform, an arch, or a

bridge structure. Make sure that the platform surface is flat and the

scanner unit drain hole (radome scanners) is not obstructed.

Raytheon recommends that radome scanner units are best suited for

sailboat operation as open array systems are more dif ficult to protect

from ropes and sails.

For sailboat installations, Raytheon offers a universal mast mount ki t

for each radome scanner type. This optional mount is used to fit a

radome scanner to a flat surface on a mast with a minimum diameter

of 60 mm (2½ in). When using the mast mount ki t, appropriate

hardware should be used for the style and structure of the mast aboard

the vessel. T ypically , the scanner will be mounted near the first set of

mast spreaders. If there is any doubt concerning the appropriate type

of hardware, consult your boat dealer or representative for their

recommendations.

Depending on the type of sailboat, a radar scanner guard should be

installed if the sails could touch the scanner or platform. W ithout a

proper radar guard the mounting platform an d the radar scanner could

be severely damaged.

Mounting surface: power boats

On many small vessels the scanner unit can be installed on a mast

platform, an arch, or a bridge structure, but take care to follow the

scanner site guidelines, particularly regarding height . If necessary ,

construct a radar mounting platform to obtain a suf ficiently high

mounting position. Make sure that the platform surface is flat and the

scanner unit drain hole (radome scanners) is not obstructed. Ensure

the platform is strong enough to support the maximum s hock loads

likely to occur.

Page 18

10 Pathfinder Radar Scanners

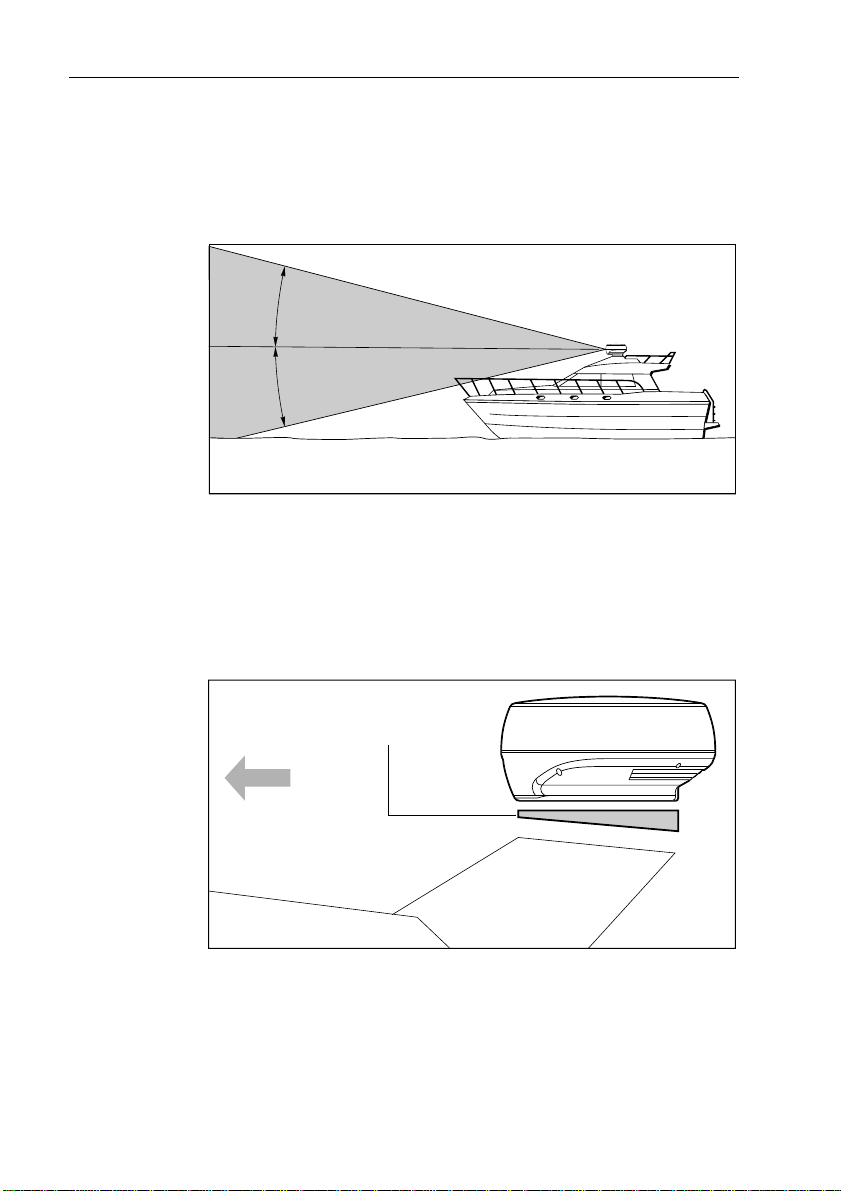

Setting the radiation plane

The scanner unit should be mounted so that the array rotates parall el

to the waterline. The radar beam is approximately 25° wide in the

vertical direction, providing good target det ection during the vessel’s

pitching and rolling.

12.5˚

12.5˚

Waterline

Ideal Radiation Plane

Planing hull vessels, and some displacement hull vessels, adopt a

higher bow angle when the vessel is at its cruising speed. In many

cases this substantially alters and raises the radar’s main radiation

plane, and can cause poor detection of nearby targets. It may be

helpful to lower the radar beam back towards the parallel, by

shimming th e rear of th e radar , so that the beam p oints slig htly

downwards with respect to the waterline when the vessel is at rest.

D3223-2

Wedge or

washers

Forward

Using shims to lower the main beam

D3229-3

The shims may be made from aluminium plate wedges, simple flat

washers, or an angled wooden block. For thick shims, you may need

longer securing bolts than the M8x40 bolts supplied with the radome

scanner, or the M10 studdi ng supplied with the open array scanners.

Page 19

Chapter 1: Overview 11

1.4 Cable runs

Y ou need to consider the following before installing the system

cables:

• Y ou need to fit the inter-unit cable and the power cable.

• All cables should be adequately clamped and protected from

physical damage and exposure to heat - avoid running cabl es

through bilges or doorways, or close to mo ving or hot objects.

• Acute bends must be avoided.

• Where a cable passes through an exposed bulkhead or deckhead,

a watertight gland or swan neck tube should be used .

• Avoid cutting and re-joining cables (if necess ary, refer to the notes

below).

Y ou need to run the following cables:

CAUTION:

Do not pull the cable through bulkheads using a cord attached to

the connector . This could damage the connections.

• Inter-unit cable. A vinyl-covered and shielded cable is supplied

with the radome scanner unit. The cable has a connector plug at

one end for connecting to the display unit or exten sion cable; the

other end of the radome scanner cable is fitted with an 8-wa y plug

and power cores (covered by a clear protective sleeve) for connecting to the scanner.

For open array scanners, various length cables are available.

These cables have a connector plug at one end for connecting to

the display unit or extension cable; th e other end is prepared ready

to fit to the power and signal connectors (see Section 2.2)

• Power cable. The scanner receives power via the display unit; the

power cable is supplied with the display unit. How ever, cable

details are provided in this section.

Rejoining Cables

Y ou should avoid cut ting and re-joining cables. If this is necessary

you must:

• Fit a ferrite on each side of the join. The specif ic ferrite to use

depends on the cable type - contact Raytheon Marine for details.

• Take care not to damage any of the wires. Make sure that all the

wires and, in particular, the screen are reconnected correctly .

Page 20

12 Pathfinder Radar Scanners

If you are mounting the scanner on the mast of a sailboat, and will

need to unstep the mast, you should inst all a suitable junction box

inside the boat.

On a radome scanner, the junction b ox should provide an 11 - or 13way terminal strip, depending on the number of power cores in your

cable, with a 10 A rating. Also, you should keep the length of t he unscreened coaxial cores to less than 30 mm to maintain EMC

conformance.

On an open array scanner, the j unction box should provide a 13-way

terminal strip with a 20 A rating for power cores. It is essential that all

4 power cores are connected and that the connection is of very low

resistance as considerable power passes through this connection.

Also, you should keep the length of the un-screened coaxial cores to

less than 30 mm to maintain EMC conformance.

Inter-unit cable

The inter-unit cable entrance is at the rear of the scanner unit. If the

unit is mounted on a holl ow mast the cable may be run inside the mast

and then fed through the radar’s cable entrance. Make sure that the

cable does not chafe where it enters and exits the mast.

Note: Rout e the cable from the display up t o the scanner , since this

will require the smallest clearance hole.

CAUTION:

The display connector on the inter-unit cable is a moulded plug

that cannot be replaced. DO NOT r emove this moulded plug.

The inter-unit cable, for connecting the scanner to the display unit,

depends on your scanner package as follows:

Table 1-3: Inter Unit Cables required for each Scanner Type

Scanner Package Inter-Unit Cable

2D (US) 10 m light (2 power cores)

2DE (European) 15 m light (2 power cores)

4D 15 m heavy (4 power cores)

5S, 7S (4 kW) and 9S, 11S (10 kW)

All 10 kW systems require a

Note:

minimum of 24 V.

15 m heavy or radar arch kit

(5 m + 10 m extension)

25 m heavy (24/32 V systems only)

The minimum bends permitted are:

Minimum bend, light cable 60 mm (~2.5 in) radius

Minimum bend, heavy cable 82 mm (~3.75 in) radius

Page 21

Chapter 1: Overview 13

Radome scanner cables

Inter-unit cable

The length of the supplied cable should be su fficient to complete the

cable run required on most small vessels. For longer runs, addi tional

or replacement cables are available, which have 4 power cores to

minimize voltage drops over the longer cable run: these optional

cables include 5 m and 10 m extension cables, and a 25 m

replacement cable.

The maximum inter-unit cab le length is limited by the minimum

supply voltage, the scanner type (18" radome or 24" radome), and the

cable type (2 or 4 power cores): if a mix of light and heavy cables is

used, only 2 power cores are connected through.

Note: For vessels with 24 V power systems, any combination of interunit cables can be used.

For vessels with 12 V power systems, the recommended cable(s) for

different run lengths are given in the fol lowing table, which assumes

a minimum supply voltage of 10.7 V (the lowest vol tage likely to be

reached by a 12 V battery in normal marine use). Do not use cable

combinations that are not included in the table.

Table 1-4: Recommended Radome Inter-Unit Cable(s) for Vessels with

12 V Power Systems

Inter-Unit Cable

Length Required (m

10 Std 10 m light N/A N/A

15 Std + 5 m ext Std 15 m light Std 15 m heavy

20 Std + 10 m ext 25 m assembly Std + 5 m ext

25 25 m assembly 25 m assembly Std + 10 m ext

30 25 m + 5 m ext 25 m + 5 m ext 25 m + 5 m ext

35 25 m + 10 m ext 25 m + 10 m ext 25 m + 10 m ext

)

2D (US) 2DE (Eur) 4D

Scanner Package

Refer to the packing list in Section 1 .2 for cable part numbers

Note: T his table applies to systems using t he standard 1.5 m power

cable. If you extend the power cable you may need to select different

inter-unit cable(s), as discussed in t he following section Power Cable.

Page 22

14 Pathfinder Radar Scanners

Power cable

The radome radar systems are intended for use on ships’ DC power

systems operating in the 10.7 to 32 V DC range (that is, 12 V and 24 V

systems, not 32 V systems). A 1.5 m (5 ft) power cable is s upplied

(with the display unit) for connect ing the ship’s DC power to the radar

scanner via the display unit. Refer to the HSB Series Display Owner’s

Handbook for details on connecting this cabl e. This section provides

details for extending the length of the power cable.

If a longer power cable run is required, use the supplied power cable

to connect to the display unit. Then use a suitable connector block to

connect the free end to the extension cable. The supplied power cable

has a cross-section of 2.0 mm

2

.

Note: For vessels with 24 V power systems, the power cable may be

extended by up to 20 m using a wire gauge of 1.5 mm

2

(AWG 16) or

greater, irrespective of the inter-unit cable length.

For vessels with 12 V power systems, longer power cable runs may

require larger wire gauges to minimize any voltage drop in the cable.

The scanner type and the length and type of the inter-unit cable (see

tables) also affect the wire gauge required for the extension pow er

cable. In order to determine the correct supply cable size if the power

cable must be extended, estimate the length of cable between the

ship’s main power source and the connector block, and then select the

wire size indicated by the distance and inter-unit cable in the

appropriate table following.

For example, you might have a 24" scanner, w ith 20 m between the

scanner and display unit, that you plan to connect by extending th e

supplied 15 m heavy inter-unit cable with a 5 m extension cab le. In

addition, your 12 V power supply might be 10 m from t he display

unit, requiring an extension of 8.5 m. T o determine the wire gauge

required for the power cable extension, refer to the table for the 24"

scanner, go to the row labelled 15 m Heavy + 5 m ext, and read across

until you come to a maximum cable length greater than 8.5 m. Th is is

the 10 m entry , in the column for 4.0 mm

2

wire gauge.

Page 23

Chapter 1: Overview 15

Table 1-5: Max. Extension Power Cable Lengths (m), 12 V Systems -

18" Radome Scanner

Inter-Unit Cable(s) Power Cable Core (each core)

mm2:

1.5162.0

AWG:

10 m Light 5.0 7.0 9.0 14.0 20.0 35.0

10 m Light + 5 m ext 1.0 2.0 3.0 4.5 7.0 12.0

10 m Light + 10 m ext Do NOT extend the power cable

15 m Light 1.0 2.0 3.0 4.5 7.0 12.0

15 m Heavy 7.0 10.0 13.0 20.0 30.0 50.0

15 m Heavy + 5 m ext 5.0 7.0 10.0 15.0 25.0 40.0

25 m Heavy 4.5 6.0 8.0 12.0 20.0 35.0

25 m Heavy + 5 m ext 3.5 4.5 6.0 9.0 15.0 25.0

25 m Heavy + 10 m ext 2.0 3.0 4.0 6.0 9.0 15.0

15

2.5

14

4.0

11

6.0

10

10.0

7

Note: If you have an 18" radome scanner, and the wire gauge required for your extended power cable is unacceptably large, you

should replace the supplied light (2 power core) inter-uni t cable with

the 25 m heavy (4 power core) inter-unit cable assembly (see t able).

Table 1-6: Max. Extension Power Cable Lengths (m), 12 V Systems -

24" Radome Scanner

Inter-Unit Cable(s) Power Cable Core (each core)

mm2:

1.5162.0152.5144.0

AWG:

15 m Heavy 5.0 7.0 9.0 14.0 20.0 35.0

15 m Heavy + 5 m ext 4.0 5.0 6.0 10.0 15.0 25.0

15 m Heavy + 10 m ext 2.0 3.0 4.0 7.0 10.0 17.0

25 m Heavy 2.0 3.0 4.0 7.0 10.0 17.0

25 m Heavy + 5 m ext 1.0 1.5 2.0 3.0 4.0 8.0

25 m Heavy + 10 m ext Do NOT extend the power cable

11

6.0

10

10.0

7

Page 24

16 Pathfinder Radar Scanners

Open array scanner cables

Inter-unit cable

Heavy duty cables are available in 15 m and 25 m lengths which

should be sufficient to complete t he cable run required on most small

vessels. For longer runs, 5 m and 10 m extension cables are available,

both have 4 power cores to minimize voltage dr ops over the cable run

and incorporate in-line moulded plugs.

The maximum inter-unit cable length is limited by the minimum

supply voltage and the scanner type.

CAUTION:

10 kW scanner systems cannot be used directly with 12 V

systems; they require a 12 V to 24 V converter rated to 180 W .

Contact your authorized Raytheon dealer or distributor for

details.

12 V Systems (4 kW scanners only)

For vessels with 12 V power systems, the recommended cable(s) for

different run lengths are given in t he following table, which assumes

a minimum supply voltage of 10.7 V (the lowest v oltage likely to be

reached by a 12 V battery in normal marine use). Do not use cable

combinations that are not included in the table.

Table 1-7: Recommended 4 kW Open Array Scanner Inter-Unit Cable(s)

for Vessels with 12 V Power Systems

Inter-Unit Cable

Length Required (m)

5 5m heavy

15

15

4 kW Scanners

15 m heavy

5 m heavy + 10 m extension

Refer to the packing list in Section 1.2 f or cable part numbers

24 V and 32 V Systems - 4 kW scanners

For vessels with 24 V and 32 V power systems, any combinat ion of

inter-unit cable up to a maximum length of 35 m can b e used.

Page 25

Chapter 1: Overview 17

24 V and 32 V Systems - 10kW scanners

10 kW open array scanners can use any combination of inter-unit

cable up to a maximum length of 35 m. However , these systems use

considerable power and installations sh ould be planned to minimize

all cable lengths. Refer to the tables on page 1-19, Max. Exte nsion

Power Cable Lengths (m) - 10 kW Scanner.

Power cable

The open array scanner systems are intended for use on ships’ DC

power systems operating in the following ranges:

4 kW 10.7 to 44 V DC range (that is, 12 V , 24 V and 32 V systems)

10 kW 20 to 44 V DC range (that is, 24 V and 32 V systems).

CAUTION:

10 kW open array scanner systems cannot be used directly with

12 V systems; they require a 12 V to 24 V converter rated to

180 W . Contact your authorized Raytheon de aler or distributor

for details.

Open array scanners draw considerable power from the vessels

power source, especially in high wind speeds. It is essential for

reliable operation that the unit is supplied with a low resistance power

cable system, especially when operated from a 12 V power system.

CAUTION:

Do not use the open array scanner with an SL70 or Autohel m 7"

LCD display unit. Failur e to observe this may r esult in

permanent damage to the display unit.

12 V systems (4 kW scanners only)

Extensions to the supplied power cable must be kept t o a minimum

and the power should be fed directly from the output of the battery

isolator switch via its own dedicated cable system. It is recommended

that no additional power switch is included in this power cable.

CAUTION:

The display unit does not include a fuse for scanner power, so an

in-line fuse or circuit breaker MUST be included in the power

cable.

All power connections must be of high quality to mi nimize their

resistance and to remove the risk of accidental shorts. Recommended

Page 26

18 Pathfinder Radar Scanners

maximum power cable extensions are given i n the table below . These

figures relate to the total cable extension, from the end of the supplied

1.5 m power cable to the system battery terminals. Do not exceed

these lengths as unreliable operation may result.

Table 1-8: Max. Extension Power Cable Lengths (m), 12 V Systems -

4 kW scanners

Power Cable Core Size (each core)

mm2:

4.0

AWG:

11

4 kW Scanners <3.0 4.5 6.0 7.5

6.0

10

8.0

8

10.0

7

Note: If the required extension results in unacceptably large diam eter cables, use two or more smaller gauge wir es to achieve the required copper wire cross-section. For exampl e, using two pairs of

2

2mm

is equivalent to using two single 4.0 mm2 cables.

24 V and 32 V systems

These systems are less sensitive than 12 V systems to voltage loss in

the power cables. However, it is still necessary to use adequate cables

to prevent excessive power loss. The table below gives the

recommended wire gauge for different power cable extension

lengths. Raytheon recommends that power is fed directly from the

output of the battery isolator switch via its own dedicated cable

system.

CAUTION:

The display unit does not include a fuse for scanner power, so an

in-line fuse or circuit breaker MUST be included in the power

cable.

Note: If the required extension results in unacceptably large diam e-

ter cables, use two or more smaller gauge wir es to achieve the required copper wire cross-section. For exampl e, using two pairs of 2

2

mm

is equivalent to using two single 4.0 mm2 cables.

Page 27

Chapter 1: Overview 19

Table 1-9: Max. Extension Power Cable Lengths (m), 24/32 V Systems -

4 kW Scanners

Power Cable Core Size (each core)

mm2:

2.0

AWG:

14

4 kW Scanners 8.0 16.0 24 32 35

4.0

11

6.0

10

8.0

8

10.0

7

Table 1-10:Max. Extension Power Cable Lengths (m), 24 V Systems -

10 kW Scanners

Inter-Unit Cable(s) Power Cable Core (each core)

mm2:

1.5

AWG:

16

5 m Heavy 12.0 16.0 20.0 32.0

10 m Heavy 10.5 14.0 18.0 28.0

15 m Heavy 9.0 12.0 16.0 24.0

15 m Heavy + 5 m ext 7.5 10.0 13.0 20.0

15 m Heavy + 10 m ext 6.0 8.0 10.0 16.0

25 m Heavy 6.0 8.0 10.0 16.0

25 m Heavy + 5 m ext 4.5 6.0 8.0 12.0

25 m Heavy + 10 m ext. 3.0 4.0 5.0 8.0

2.0

15

2.5

14

4.0

11

Table 1-11:Max. Extension Power Cable Lengths (m), 32 V Systems -

10 kW Scanners

Power Cable Core Size (each core)

mm2:

10 kW Scanners

AWG:

1.5

16

≤≤≤≤

15.0

2.0

15

≤≤≤≤

20.0

2.5

14

≤≤≤≤

25.0

Page 28

20 Pathfinder Radar Scanners

Page 29

Chapter 2: Installing the Scanner 21

Chapter 2: Installing the Scanner

2.1 Radome scanner

Securing the radome scanner to the mounting surface

CAUTION:

The drain tube must always be use d, but may be shor tened if

necessary

1. Using the paper template supplied with the scanner mounting kit,

mark the flat mounting surface with the mounting holes and drain

tube hole, and drill the holes as indicated on the template.

If it is impractical to drill a hole for the drain tube, then the scanner

unit should be mounted on 4 suitable spacers 10 mm high and the

drain tube length reduced by 10 mm. It will then be clear of the flat

surface and can still perform its function.

Note: If you are using a Raytheon mast mount bracket, the s urface is

pre-prepared.

Note: If you are mounting the scanner on a flat surface, you may find

it easier to fit the drain tube, as described in the following section, before securing the scanner.

2. Position the scanner on the mou nting surface, ensuring that the

cable inlet is pointing aft.

3. Locate the bolts and washers supplied with the scanner, grease the

bolts, and secure the scanner to the mounting surface as sh own in

the following diagram. Tighten t he bolts to 20 Nm (14.7 lb ft);

ensure the scanner is tightly fitted.

Page 30

22 Pathfinder Radar Scanners

Scanner base

Bitumen washer

Mounting bracket

or mounting surface

Greased mounting bolt

Y ou may need to use longer M8 mounting bolts to secure the scanner if you have used shims to lower the radar beam.

Connecting the radome scanner inter-unit cable

CAUTION:

Before wiring the scanner unit, make sure that the inter-unit

cable is not connected and power is not applied to the display

unit.

When you have run the inter-unit cable to the scanner location,

connect the cable as follows:

1. Loosen the 4 (18") or 7 (24") screws securing the scanner cover.

These screws are captive and should remain assembled to the

lower flange assembly. Press the radome inwards to release the

top. This breaks the seal and makes removal easier.

2. To avoid losing the scanner cover , tie the cord, attached to the

inside of the base of the scanner, to the eye provided i n the cover.

3. If you have a 24" scanner, unscrew and remove the inner cover:

D3995-3

Page 31

Chapter 2: Installing the Scanner 23

Inner cover

D4006-2

4. Remove the drain tube from inside the base of the scanner, and

insert it into the drain hole as shown in the following diagram.

Pull the tube gently from outside the scanner so that it clips into

place.

D3937-2

Page 32

24 Pathfinder Radar Scanners

5. Referring to the following illustration, remove the securing nut

(1) from the watertight gland and grommet (2), where the interunit cable (3) will enter the base.

8

7

6

5

4

11

White wire

2

1111 Securing nut 2222 Gland 3333 Inter-unit cable 4444 Eight-way plug 5555 Eight-way socket 6

7777 Terminal clamp 8

8 Screwdriver 9

8 8

9 Cable clamp 10

9 9

10 Cable clamp screws 11

1010

11 Ferrite clamp

1111

6. Slide the gland nut onto the inter-unit cable (3), and insert the

cable, still covered by its protective sleeve, through the gland into

the base.

7. Cut and remove the protective sleeve to expose the 8-way plug (4)

and power cores (6).

8. If the scanner is connected to an HSB Series Pathfinder Radar display, fit the ferrite clamp (11), supplied loose with the display

unit, as follows:

10

9

1

3

D3230-4

6 Power cores (2 or 4)

6 6

Page 33

Chapter 2: Installing the Scanner 25

CAUTION:

If any wires are damaged when the clamp is fitted, the scanner

unit will not function correctly .

• The ferrite clamp is supplied open. If the clamp has been

closed, insert a small, flat-blade screwdriver into the slots at

the end of the clamp opposite the hinge and twist gently .

• Position one-half of the clamp around the eight cores of the

inter-unit cable between the 8-way plug (4) and the cable

clamp, as close to the 8-way plug as possible. (It may be necessary to fit the clamp over the cable tie closest to the 8-way

plug – this will not af fect the ferrite clamp’s function).

Note: o n the 24" scanner, the clamp must be contained inside the inner cover.

• With the clamp positioned correctly, close the clamp ensuring

none of the cores are trapped by the hinge, latch or the ferrite

itself.

9. Connect the 8-way plug (4) to the connector (5). The correct fitting is with the small arrow marked on the body of the plug facing

upwards and to the left hand side. The grey wire will then be at the

left hand side and the white wire will be at the right hand side.

10. Connect the red and black power cores (6).

If you have a 10 m or light 15 m inter-unit cable, there is one pair

of cores. Connect the red cable lead to one of the terminal sockets

marked “+”, and the black cable lead to on e of the sockets marked

“-”.

If you have a heavy 15 m inter-unit cable, there are two pairs of

cores. Connect the red cable leads to the terminal sockets marked

“+”, and the black cable leads to the terminal sockets marked “-”,

with one lead in each socket.

The terminal clamps (7) are operated using a screwdriver (8), as

shown in the inset diagram on the previous page.

CAUTION:

Do not earth the cable screen to the scanner . The radar system is

earthed via the display unit.

11. Secure the nut (1) on the watertight gland, making sure that it

grips the cable’s outer s heath.

12. Secure the cable with the cable clamp (9), using the two screws

(10) provided. The clamp can be installed either way up, depend-

Page 34

26 Pathfinder Radar Scanners

ing on the thickness of the cable: use the position that matches the

profile of the cable.

CAUTION:

It is essential that the drain tube is fitted and that the nut on the

watertight g land is adequately tightene d. If this is not done, wat er

could become trapped in the scanner and cause irr eparable

damage.

13. Tighten the securing nut (1) again to ensure a waterproof seal.

14. If you have a 4D scanner, replace the inner cover over the connectors.

15.Untie the cord from the scanner cover , and coil it up in the

base of the scanner unit so that it cannot foul the rotat ing

antenna.

16. Replace the scanner cover , aligning the mark on the cover with

the mark on the scanner base above the cable gland, and tighten

the 4 or 7 captive screws. Do not over-tighten these screws.

Page 35

Chapter 2: Installing the Scanner 27

2.2 Open array scanner

Installation of the open array scanner should only be undertaken by a

competent installer . If you have any difficulty with t he installation,

please contact your local Raytheon Marine dealer or distributor .

The open array scanner is supplied in two sections; the pedestal unit

and the antenna. The pedestal unit is secured from below the

mounting platform. The open array is then secured to the pedestal.

Full details for mounting the scanner are given below .

CAUTION:

The pedestal unit has a cap fitted over the open array mounting

shaft to protect the protuding co-ax ial pin. This cap must be left

in place until the open array is fitted.

The pedestal base is fitted with a gasket: DO NOT gr ease this

gasket.

WARNING:

The open array scanner weighs: 48" scanner - 30 kg (66.2 lb); 72"

scanner - 33.4 kg (73.7 lb). For safety reas ons it is recommended

that the unit is not lifted by one person.

The unit is fitted with lifting eyes (maximum SWL 40 kg) to

facilitate the use of standard lifting accessories, e.g. ro pe, chain or

strop. The safe working load (SWL) of the lifting accesso ries

should be 150 kg. Suitable liftin g equipment could include a

crane, hoist, or an appropriate rigid, overhead structure.

Alternatively, the unit is suitable for a two person lift. Care

should be taken to ensure that each person is stan ding on a stable

surface, and that the pedestal is held carefully to ensure it cannot

slip.

The T-bar beneath the open array antenna can be used to aid

lifting.

Y ou should never lift the scanner by holding onto the open array

antenna.

Page 36

28 Pathfinder Radar Scanners

Securing the pedestal to the mounting platform

1. Using the paper template supplied with the scanner mounting kit,

mark the flat mounting surface with the holes and drill as indicated on the template. Refer to Section 1.2 when selecting the

scanner unit site.

2. Stick the four self-adhesive bitumen washers over the mounting

holes.

3. Ensure the lifting eyes are securely fitted to the top of the pedestal,

and the yellow protective cap is in place.

CAUTION:

T o prevent damage to the internal mounting bar , ensur e the stud

penetration is no more than 32 mm into the pedestal base. W e

recommend you mark each stud with tape, 32 mm from one end,

to act as a gauge.

4. Grease the studs. Using two nuts locked together on the stud,

screw each stud into the pedestal to a maximum of 32 mm, or

until they bottom out. Remove these two nuts.

Note: If the studding supplied is not long enou gh, use M10 stainless

steel, grade A4 studding of a suitable l ength. Refer to the following illustration for details .

5. Using suitable lifting equipment, raise the pedestal over the

mounting surface. Carefully lower into position, taking care that

the studs pass through the holes without damagi ng the threads.

Ensure that the cable inlet is pointing aft.

WARNING:

Support the pedestal unit until it has been secured to the

mounting platform. It is important that all four sets of nuts and

washers are used to secure the pedestal to the mounting platform.

6. Referring to the following illustration, use the four nuts and associated washers supplied to secure the pede stal. Tighten the nuts to

20 Nm (14.7 lb ft); ensure the scanner is tightly fitted.

Grease the nuts.

If required, cut-off any excess stud.

Page 37

Chapter 2: Installing the Scanner 29

Lifting eye

Pedestal

Bitumen washer,

sticky side down

on platform

Mounting

platform

M10 stud

length = 52 mm

32 mm Max.

plus platform depth

M10 plain washer

M10 spring washer

M10 nut

D4573-3

Connecting the open array scanner inter-unit cable

CAUTION:

Before wiring the scanner unit check that it is securely mounted

to the platform, then make sure that the inter-unit cable is not

connected and power is not applied to the display unit. The

scanner switch must be in the OFF position.

1. Loosen the fou r self-retaining bolts securing the pedestal lid to the

base. Pull -up and tu rn the bolts a nti-cloc kwise to lock them in th e

upright position. Remove the lifting eyes.

Note: It is important to remove lifting eyes to avoid corrosion. Retain

the lifting eyes: they will be required if the scanner is removed from its

platform.

2. Open the pedestal lid. Ensure the securing stay has automatically

locked into position.

Page 38

30 Pathfinder Radar Scanners

3. Referring to the following illustration, remove the cable gland

nut, washer and grommet from the watertight gland, where the

inter-unit cable will en ter the base.

Heatshrink

5mm (0.2in) 5mm (0.2in)

20mm (0.8in)

20mm (0.8in)

40mm (1.6in)

D4575-2

4. Slide the cable through the gland nut, washer and grommet, then

into the base. Clamp into position, ensuring th e section of main

cable covered in yellow heat shrink is clamped.

5. The cable is supplied prepared and ready to fit to the signal and

power connectors. If you need to cut the cable to length, strip of f

the protective outer sleeve then use the supplied kit to prepare the

cable as detailed in the following illustration

Page 39

Chapter 2: Installing the Scanner 31

1. Preparation of Wires

See Note A

See Note B

500mm ± 10mm

25mm

10mm

500mm ± 10mm

5-6mm strip length

Black power wires

Red power wires

Data wires

(6 off)

Coaxial

signal

Coaxial

screen

5-6mm

strip length

2. Heat Shrinking of Wires

5mm maximum

See Note CSee Note D

35mm

25mm

3. Heat Shrinking of Cable/Wires

40mm

20mm

Notes

A. Aluminium screen/polyester tape screen to remain.

B. Heat shrink sleeving fitted to keep the aluminium/polyester tape screen from unwinding

from the coaxial signal insulation.

C. The wires must be formed into two bundles with heat-shrink tubing (one containing the

four power wires and the other containing the eight signal wires).

D. The heatshrink shown in step 3 must be fitted to prevent the 'overall screen' from

shorting to base.

CAUTION:

If any of the wires are incorr ectly fitted, the scanner will not

function correctly.

Remove the 8-way plug from the signal connector and fit to the

cable as shown in the following diagram. The terminal clamps are

operated using a screwdriver as shown. Alternatively , you can

leave the connector in position whilst connecting the cable, you

should then remove the connector and visually check each wire

connection.

D4579-2

Page 40

32 Pathfinder Radar Scanners

Re-connect to the plug. When correctly fitted the white wire (coaxial) will be at the outer edge of the unit.

6. Connect the red and black power cores. Connect the red cable

leads to the terminal sockets marked “+”, and the black cable

leads to the terminal socket marked “-”, with one lead in each

socket. The terminal clamps are operated using a screwdriver as

shown in the inset diagram.

Signal connector

Grey

Purple

Blue

Green

Yellow

Orange

Coaxial Screen

(Black)

Coaxial Inner

(White)

Power connector

D4576-2

CAUTION:

Do not earth the cable screen to the scanner . The radar system is

earthed via the display unit.

7. Using the tie-wrap fitting on the pedestal lid, secure the cable.

8. Check the gasket in the pedestal lid is correctly seated.

Close the pedestal lid, ensuring that the cable does not become

trapped. Tighten the four s elf-retaining bolts.

CAUTION:

Do not grease the gasket in the pedestal li d.

Page 41

Chapter 2: Installing the Scanner 33

Fitting the open array to the pedestal

CAUTION:

The pedestal unit has a cap fitted over the open array mounting

shaft to protect the protuding co-ax ial pin. This cap must be left

in place until the open array is fitted to the pedestal.

1. Remove the cap from the open array shaft. Retain the cap, it will

be required if the open array is removed from the pedestal.

2. Grease the four securing studs.

CAUTION:

If the pin is damaged during the following operation you sh ould

contact your service dealer .

3. Lift the open array into position. Carefully lower the array - to prevent damage to the mounting pin, ensure the array remains parallel to the pedestal so that the studs slot into the holes on the

pedestal mounting bracket.

Note: The open array mounting bracket is designed so that the array

can only be fitted to the pedestal in the correct orientation.

4. Use the fou r nuts and associated washers supplied to secure the

array to the pedestal as shown in the diagram below .

Array

Pedestal

M8 plain washer

M8 spring washer

M8 nut

D4580-2

Page 42

34 Pathfinder Radar Scanners

2.3 System connections

DC power connection

Power is supplied to the scanner via the display unit; the power cable

is supplied with the display unit , refer to your display unit Owner’s

Handbook for details on connecting power. However , you should be

aware of the following.

The DC system should be either:

• Negative grounded, with the negative battery terminal connected

to the ship’s ground.

• Floating, with neither battery terminal connected to the ship’s

ground.

CAUTION:

This radar is not intended for use on “positive” ground vessels.

The power cable Earth screen connections must be connected to

the ship’s gr ound.

Grounding the radar system

It is important that an effective RF ground is connected to the radar

system. Y ou must ground the radar b y connecting the drain wire

(screen) of the Power/NMEA Input cable to the nearest ground point

of the ship’s RF ground system. Ref er to your display unit Owner’s

Handbook for details.

Note: Use on ly this ground connection.

Power Connections

The power connection to the radar should be made at either the output

of the battery isolator switch, or at a DC power distribution panel.

Raytheon recommends that power is fed directly to the radar via its

own dedicated cable system and MUST be protected by a thermal

circuit breaker or fuse, fitted close to the power connection. Refer to

the table below for isolator switch, circuit breaker or fuse value

ratings. Check all terminal connections are clean.

Page 43

Chapter 2: Installing the Scanner 35

CAUTION:

If you do not have a thermal cir cuit breaker or fuse in your power

circuit, e.g. fitted to the DC distribution panel, you MUST fit an

in-line breaker or fuse to the positive (red) lead of the power

cable.

Table 2-1: Isolator Switch/Thermal Breaker/Fuse Values

Vessels

Supply

12 V*

24/32 V**

* 1 0 kW sc anner s cann ot be d irect ly c on nec ted to 12 V

*

*Radome systems cannot use 32V.

Device Open Array Systems

4 kW 10 kW

Isolator Switch min. rating 30 A n/a 20A

Thermal Breaker rating 15 A n/a 10A

Fuse value 20 A n/a 15 A

Isolator Switch min. rating 15 A 15 A 15 A

Thermal Breaker rating 8 A 10 A 5 A

Fuse value 10 A 15 A 8 A

Radome

Systems

The open array scanner has a power switch fitted to the pedestal. This

switch can normally be left ON. However, if the scanner is being

serviced or if any personnel are in the vicinity of the open array , the

switch should be set to OFF .

Scanner connection

The inter-unit cable is connected to the scanner as described in

Sections 2.1 and 2.2. If you are using an int er-unit extension cable,

connect this to the display unit, and connect the supplied cable to the

extension cable. The scanner connector pins are shown in the

following diagram, together with the connections and core colors.

CAUTION:

The display connector on the inter-unit cable is a moulded plug

that cannot be replaced. DO NOT remove this moulded plug.

Page 44

36 Pathfinder Radar Scanners

Front view of

Display Cable Connector

2

86

11

13 12

Display Scanner

Video

Video RTN

*Battery --ve

Tx Trigger +

Battery --ve

Data I/O +

Tx Trigger --

Battery +ve

Data I/O --

*Battery +ve

Azimuth +

Azimuth --

1

35

4

7

10

1

2

3

4

5

6

7

8

9

10

11

12

13

9

White

Black

Black

Orange

Black

Green

Yellow

Shield

Red

Blue

Red

Violet

Grey

* Not present on 'light', 11 core cables.

Front view of Radome

Scanner Cable Connector

8

7

6

5

4

3

2

1

Battery +ve/--ve = 12 or 24v.

Not fitted on

Open Array Scanners

(refer to Section 2.2)

White

8

Black

Orange

Yellow

Green

Blue

Violet

Grey

Red

Red

Black

Black

Video

7

Video Rtn

6

Tx Trigger +

5

Tx Trigger --

4

Data I/O +

3

Data I/O --

2

Azimuth +

1

Azimuth --

Battery +ve

*Battery +ve

*Battery --ve

Battery --ve

D4290-3

Page 45

Chapter 2: Installing the Scanner 37

Display unit connection

CAUTION:

Do not use an open array scanner with an SL70 or Autohelm 7"

LCD display unit. Failur e to observe this may r esult in

permanent damage to the display unit.

10 kW open array scanners cannot be directly connected to 12 V

systems.

The rear of the Pathfinder display includes the following connection

sockets:

• Scanner connection

• Power/NMEA Input DC power connection, two NMEA 0183

inputs and one RF ground (screen) connection.

Note: If you have an integrated system that includes a rad ar display

with MARPA as a primary function, the scanner must be connected to

this display to enable the function. MARPA is then available on any

repeater display.

Connect the scanner cable to the scanner connector and power to the

power/NMEA input connector .

Power and all other connector details are supplied in the display unit

Owner’s Handbook.

Connector Panels

LCD Display

CRT Display

Power and NMEA Input

POWER/

NMEA

NMEA

HSB

ANTENNA/

TRANSDUCER

Scanner

SeaTalk

DISPLAY

FUSE

D4597-2

Page 46

38 Pathfinder Radar Scanners

Page 47

Chapter 3: Post Installation Checks and Maintenance 39

Chapter 3: Post Installation Checks and

Maintenance

Once you have installed your radar scanner and display u nit, and

made all the connections, you need to check your installation. You

can then set up the radar system, align the scanner and check the

display timing. In addition, for a 72" open array scanner you need to

set the antenna size to ensure the scanner rests in the correct position

when rotation stops.

Set up, alignment and timing checks are performed from the radar

system display unit. The procedures are outlined below; full det ails

are provided in the display unit Owner’s Handbook. Y ou should read

the Pathfinder radar display unit Owner’s Handbook and familiarise

yourself with the operation of the radar .

EMC Conformance

Always check the installation before going to sea to make sure that it

is not affected by radio transmissions, engine starting etc.

3.1 System Checks and Alignment

System check

Before performing the functional test, check the following:

• All securing bolts are fully tightened and mechanical locking

arrangements as specified are in place

• All connections have been made

• All connecting wires are secured and protected as necessary

Note: If you are the boat owner and have performed the installat ion

yourself, ask your authorised installation dealer to check the installation before going to sea.

Set up, alignment and timing checks

Switch on and initial set up

On the open array scanner , ensure the power switch on the pedestal is

set to ON.

T o switch on the display unit, press and hold the

unit beeps. The magnetron warm-up sequence should start, after

POWER

key until the

Page 48

40 Pathfinder Radar Scanners

which the unit should enter Standby mode.

If necessary , adjust the lighting and contrast.

If required, change the default language settings.

Checking transmission

WARNING:

The radar scanner transmits electromagnetic energy. Ensure

that the scanner has been installed according to the

recommendations given in Chapter 1, and that all personnel are

clear of the scanner , before switching to transmit mode.

Run through the radar operations described in the display uni t

Owner’s Handbook and check that all the expected data is displayed.

Bearing alignment

When the system is correctly installed, you must check th e bearing

alignment to ensure that targets appear at their correct bearing relative

to the ship’s bow , and adjust the alignment if necessary .

Display timing adjustment

The display timing can be affected by the length of the cable used to

connect the scanner to the display unit. This in turn affects the short

range accuracy shown on the display .

It is advisable to check the display timing before using the system for

navigation.

72" open array position alignment

T o ensure the 72" open array scanner rests in correct position when

rotation stops, you need to adjust the radar set up as follo ws:

1. With the display switched on in Radar mode, press

press the RADAR SET UP soft key.

2. Use the curso r to select the ANTENNA SIZE option, then press the

6ft softkey.

ENTER

press

If the Radar Set Up menu option ANTENNA SIZE is not available,

then you have an older version of di splay software. The 72" open

array scanner will operate correctly with this display. However,

for details on adjusting the open array stopping-p osition, please

contact your authorised Raytheon dealer or distributor .

twice to return to the default display .

MENU

then

Page 49

Chapter 3: Post Installation Checks and Maintenance 41

3.2 Maintenance

Warnings

The display unit and scanner unit co ntain high voltage.

Adjustments require specialised service procedures and tools

only available to qualified service technicians - there are no user

serviceable parts or adjustments and the operator should not

attempt to service the equipment. The operator should not remove

the rear cover of the display or any internal covers in the scanner.

Always turn the radar system off before carrying out any routine

maintenance on the scanner or nearby equipment. Switch off the

display unit befor e removing the power cord.

Routine Checks

The radar scanners are sealed units. Maintenance procedures are

therefore limited to the following periodical checks:

• Examine the cables for signs of damage, such as chafing, cuts or

nicks.

• Check that the cable connectors are firmly attached.

ake sure the scanner and pedestal are still attached

• M

securely to the mounting.

Once a year, remove, grease and re-attach the mounting

•

bolts securing the scanner and pedestal.

Servicing and Safety

• Raytheon equipment should be serviced only by authori sed Raytheon service technicians. They will ensure that service procedures and replacement parts used will not affect performance.

There are no user serviceable parts in any Raytheon product.

• Some products generate high voltages, so never handle the

cables/connectors when power is being supplied to the equipment.

• When powered, all electrical equipment produces electromagnetic fields. These can cause adjacent pieces of electrical equipment to interact with one another, with a conseq uent adverse

effect on operation. In order to minimise these effects and enable

you to get the best possible performance from your R aytheon

Page 50

42 Pathfinder Radar Scanners

equipment, guidelines are given in the installatio n instructions, to

enable you to ensure minimum interaction between different

items of equipment, i.e. ensure optimum Electromagnetic Compatibility (EMC).

• Always report any EMC-related problem to your nearest Raytheon dealer. We use such information to improve our quality

standards.

• In some installations, it may not be possible to prevent the equipment from being affected by external influences. In general this

will not damage the equipment but it can lead to spurious resetting

action, or momentarily may result in faulty operation.

3.3 Problem Solving

All Raytheon products are subjected to comprehensive test and

quality assurance programmes prior to packing an d shipping.

However, if this unit shou ld develop a fault, please refer to the

following table to identify the most likely cause and the corrective

action required to restore normal operation.

If you still have a problem after referring to the table below , contact

your local dealer, national dis tributor or Raytheon Product Support

Department for further advice.

Always quote the product serial numbers. The display unit seri al

number is printed on the back of the unit, and the scanner serial

number is on the back of the scanner near the gland.

Table 3-1: Common Problems and Their Solutions

Problem Correction

“Scanner not responding”

message.

The bearing displayed on the

radar display is not the same as

the actual

The 7 2” antenna stops in the

wrong position.

bearing

Check that the cable connecting the scanner

to the radar display unit is firmly attached and

undamaged.

Check that the polarity of the cables is correct.

Perform the bearing alignment procedure

described in the display unit

Section 8.7.

Refer to

72" open array position alignment

Owner’s Handbook

.

Page 51

Chapter 3: Post Installation Checks and Maintenance 43

How to Contact Raytheon (US)

For Marine Product and Services Information

Vi sit the Raytheon W orld Wi de W eb site for the latest information on

the newest Raytheon Marine electronic equipment and systems at:

www.raymarine.com

For Accessories and Parts

Many Raytheon accessory items and parts can be obtained directly

from your authorized Raytheon dealer . However, if you are in need of

an item not available from the retailer, please contact Raytheon

T echnical Services at:

1-800-539-5539 extension 2333 or

(603) 881-5200 extension 2333.

T echnical Services are available Monday through Friday 8:15 AM to

5:00 PM Eastern Standard Time.

Please have the Raytheon item or part number ready when calling if

placing an order . If you are not sure which item is appropriate for your

unit, you should first contact the T echnical Support Department at:

1-800-539-5539 ext. 2444 or

(603) 881-5200 extension 2444

to verify your requirements.

For Technical Support:

For technical support, call:

1-800-539-5539 extension 2444 or

(603) 881-5200 extension 2444.

Our T echnical Support Specialists are available to answer questions

about installing, operating and trouble-shooting all Raytheon

products. Questions may be addressed directly to our T echnical

Support Department via e-mail at:

rmc_tech_raytheon@raymarine.com.

Page 52

44 Pathfinder Radar Scanners

For Product Repair and Service

In the unlikely event your Raytheon unit should develop a p roblem,

please contact your authorized Raytheon dealer for assistance. The

dealer is best equipped to handle your service requirements and can

offer time saving help in getting the equipment back into normal

operation.

In the event that repairs can not be obtained conveniently , product

service may also be obta ined by re turning the unit to :

Raytheon Product Repair Center

22 Cotton Road, Suite 280

Nashua, NH03063-4219

The Product Repair Center is open Monday through Friday 8:15 a.m.

to 5:00 p.m. Eastern Standard T ime or Eastern Daylight Savings

Time. All products returned to the R epair Center are registered upon

receipt. A confirmation letter will be sent to you acknowledging the

repair status and the product’s reference number. Should you wish to

inquire about the repair status of your unit, contact the Product Repair

Center at:

1-800-539-5539 extension 21 18.

Please have the product reference number, or unit serial number ,

ready when you call. W e will do everything possible to make the

repair and return your unit as quickly as possible

How to Contact Raytheon (Europe)

In Europe, Raytheon support, service and accessories may be

obtained from your authorised dealer, or contact:

Raytheon Marine Company

Anchorage Park, Portsmouth

PO3 5TD, England

T el : +44 (0) 23 9269 361 1

Fax: +44 (0) 23 9269 4642

Or visit the Raytheon Marine W orld W ide W eb site:

www .r aymarine.com

Page 53

Chapter 3: Post Installation Checks and Maintenance 45

Technical Support

The T echnical Services Department handles enquiries concerning

installation, operation, fault diagnosis and repair . For technical

helpdesk contact:

T el: +44 (0) 23 9271 4713

Fax: +44 (0) 23 926 6 1228

Our technical support staff may also be reached via e-mail at:

techsupra@raytheon.com.

Accessories and Parts

Raytheon accessory items and parts are available through your

authorised Raytheon dealer . Please refer to the lists of component part

numbers and optional accessories in the Installation chapter of this

manual, and have the Raytheon part number ready when speaking

with your dealer.