Page 1

Type 150/400

Autopilot

System

Installation Guide

Document number: 81173-3

Date: June 2001

Page 2

ii Type 150/400 Autopilot System: Installation Guide

Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot

are registered trademarks of Raymarine Ltd.

Raymarine, AST (Advanced Steering T echnology), AutoAdapt,

AutoLearn, AutoRelease, AutoSeastate, AutoTack, AutoTrim,

FastTrim, GyroPl us, RayGyro, RayPilot and W indTrim are

trademarks of Raymarine Ltd.

Handbook contents © Raymarine Ltd 2001.

Page 3

Preface iii

Contents

About this handbook ............................................................v

Important Information ........................................................vi

Warranty .....................................................................................vi

Safety notices .............................................................................vi

EMC conformance ....................................................................vii

Handbook information ..............................................................vii

Step 1: Check the Installation Kit ............................................1

1.1 Read this handbook ...................................................................1

The autopilot system – core pack contents ................................1

The autopilot system – other key compone nts .......................... 3

The autopilot system – extended systems ................................. 3

1.2 Obtain installation tools ............................................................4

1.3 Check parts supplied ................................................................. 4

Step 2: Check Locations ............................................................6

2.1 Identify suitable locations .........................................................6

2.2 EMC installation guidelines ..................................................... 7

Step 3: Install the Course Computer .......................................9

3.1 Select the location ...................................................................10

Suitable locations ....................................................................10

Unsuitable locations ................................................................11

Orientation ..............................................................................11

3.2 Secure the course computer ....................................................12

3.3 Remove the connector cover ...................................................12

Connecting cables to the terminals .........................................14

Using the fuses ........................................................................14

3.4 Attach the power cables .......................................................... 15

Step 4: Install the Compass ....................................................17

4.1 Select the location ...................................................................18

4.2 Mount the compass ................................................................. 20

4.3 Connect to the course computer ..............................................20

4.4 Connecting SeaT alk or NMEA compasses ............................. 21

Step 5: Install the Rudder Position Sensor ...........................22

5.1 Rotary rudder position sensor - installation ............................ 22

Introduction ............................................................................ 22

Ensuring correct alignment .....................................................23

Securing the sensor to the boat ................................................24

Page 4

iv Type 150/400 Autopilot System: Installation Guide

Attaching the sensor to the tiller arm ...................................... 24

Checking alignment ................................................................25

Connecting to the course computer .........................................25

5.2 Linear rudder position sensor - installation ............................. 26

Introduction ............................................................................ 26

Mounting ................................................................................ 26

Step 6: Install the Drive Unit .................................................. 28

Step 7: Install the Control Unit ..............................................29

Step 8: Clamp the Cables ........................................................ 30

Step 9: Integrate the System ................................................. 31

9.1 Connecting SeaT alk equipment .............................................. 32

Possible systems .....................................................................32

9.2 Connecting NMEA equipment ............................................... 36

Course computer NMEA inputs/outputs ................................36

Control unit NMEA inputs ..................................................... 38

SeaTa lk/NMEA interface .......................................................38

Connecting several items of NMEA equipment .....................38

9.3 Connecting optional components ........................................... 40

GyroPlus yaw sensor .............................................................. 40

Handheld remotes ................................................................... 40

External alarm ......................................................................... 40

Wind vane (sail b oats) .............................................................40

Off switch ............................................................................... 41

Other manufacturers’ drive units ............................................ 41

9.4 Setting-up the autopilot ...........................................................42

Maintenance ........................................................................ 43

Regular checks ...........................................................................43

Fault-finding ..............................................................................43

Servicing ....................................................................................43

EMC, servicing and safety guidelines .................................... 44

Product support ..........................................................................44

Specifications ...................................................................... 45

Control unit functionality ..........................................................46

Glossary ................................................................................ 47

Index ..................................................................................... 49

Page 5

Preface v

About this handbook

W elcome to the installation guide for the Raymarin e Typ e 150/400

autopilot system. This autopilot system will steer your boat to a

heading automatically, accurately and reliably .

This handbook explains how to install the parts pro vided with

T ype 150, T ype 150G, Type 400 and T ype 400G autopilot system

core packs. The installation process involves the following steps:

Check the Installation Kit page 1

1

Check Locations page 6

2

Install the Course Computer page 9

3

Install the Compass page 17

4

Install the Rudder Position Sensor page 22

5

Install the Drive Unit page 28

6

Install the Control Unit page 29

7

Clamp the Cables page 30

8

Integrate the System page 31

9

At the end of this handbook we have also included:

• maintenance information

• product specifications

• glossary and index

• installation template

• the warranty statement

Note: T his handbook contains important information about the

installation and maintenance of your new Raymarine product. To get

the best from the product, please read this handb ook thoroughly.

Page 6

vi Type 150/400 Autopilot System: Installation Guide

Important Information

Warranty

T o register your new product, please take a few minutes to fill out the

warranty card. It is important that you return the card to the factory to

receive full warranty benefits.

Safety notices

WARNING: Product installation

This equipment must be installed and operated in accordance

with the instructions contained in this handbook. Failure to do so

could result in poor pr oduct performance, personal injury

and/or damage to your boat.

Because correct performance of the boat’s steering is critical for

safety , we STRONGLY RECO MMEND tha t an Autho rized

Raymarine Service Representative fits this product. Y ou will

only receive full warranty benefits if you can show that an

Authorized Raymarine Service Representative has installed or

commissioned this product.

WARNING: Electrical safety

Make sure the power supply is switched off befor e you make any

electrical connections.

WARNING: Calibration

We supply this pr oduct calibrated to default settings. To ensure

optimum performance on your boat, this product MUST be

calibrated before use. Do NOT use the product until it has been

calibrated using the instructions supplied.

WARNING: Navigation aid

Although we have designed this pr oduct to be accurate and

reliable, many factors can affect its performance. As a result, it

should only be used as an aid to n avigation and should never

replace common s ense and navigational judgement. A lways

maintain a permanent watch so you can respond t o situations as

they develop.

Page 7

Preface vii

Y our Raymarine autopilot will add a new dimension to your boating

enjoymen t. Howeve r, i t is the sk ipper’s responsibility to ensure the

safety of the vessel at all times by following these basic rules:

• Ensure that someone is present at the helm A T ALL TIMES, to

take manual control in an emergency .

• Make sure that all members of crew know how to disengage the

autopilot.

• Regularly check for other boats and any obstacles to navigation –

no matter how clear the sea may appear, a dangerous situation can

develop rapidly.

• Maintain an accurate record of the boat’s posit ion by using either

a navigation aid or visual bearings.

• Maintain a continuous plot of your boat’s position on a current

chart. Ensure that the locked autopilot heading will steer the boat

clear of all obstacles. Make proper allowance for tidal set – the

autopilot cannot.

• Even when your autopilot is locked onto the desired track using a

navigation aid, always maintain a log and make regular positional

plots. Navigation signals can produce signifi cant errors under

some circumstances and the autopilot will not be able to detect

these errors.

EMC conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the recreational marine environment.

The design and manufacture of Raymarine equipment and

accessories conform to the appropriate Electromagnetic

Compatibility (EMC) standards, but correct installation is required to

ensure that performance is not compromised.

Handbook information

T o the best of our knowledge, the information in this handbook was

correct when it went to press. However, Raymarine cannot accept

liability for any inaccuracies or omissions it may contain. In addition,

our policy of continuous product improv ement may change

specifications without notice. As a result, Raymarine cannot accept

liability for any differences between the product and th e handbook.

Page 8

viii Type 150/400 Autopilot System: Installation Guide

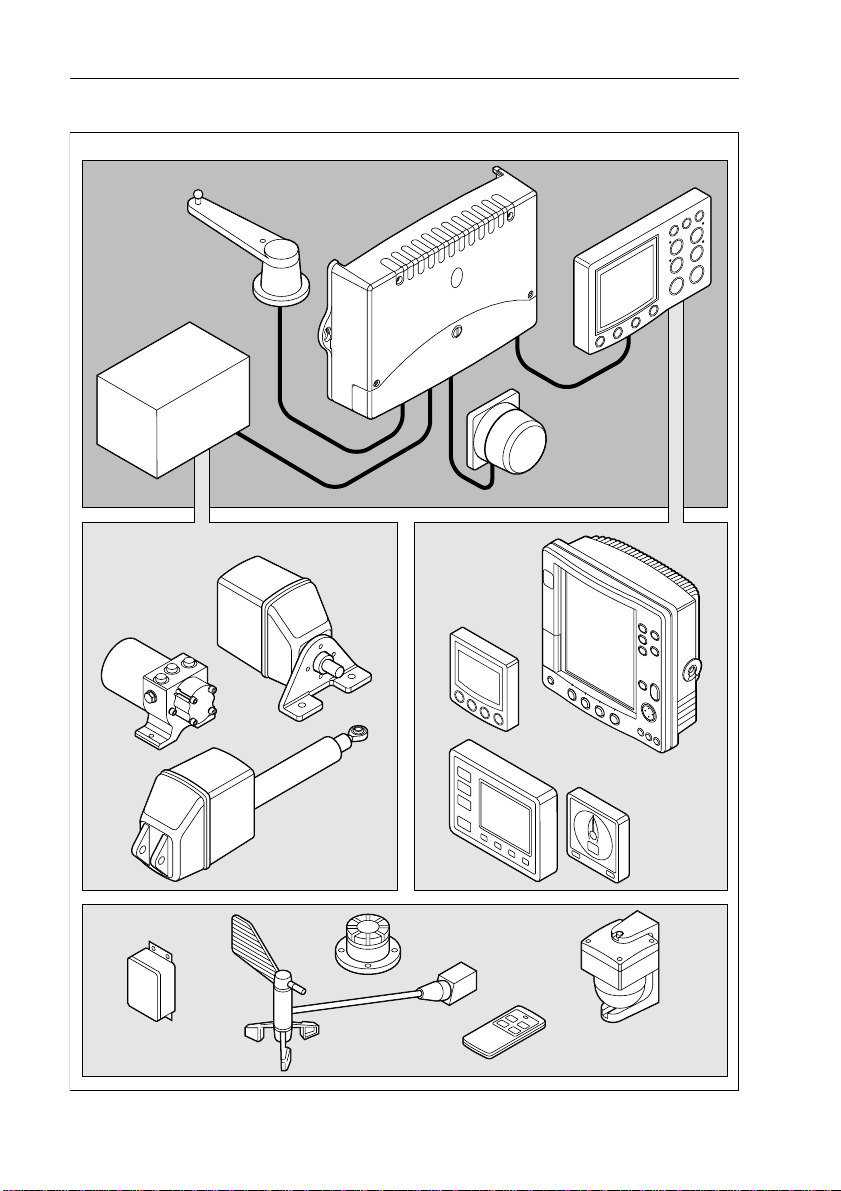

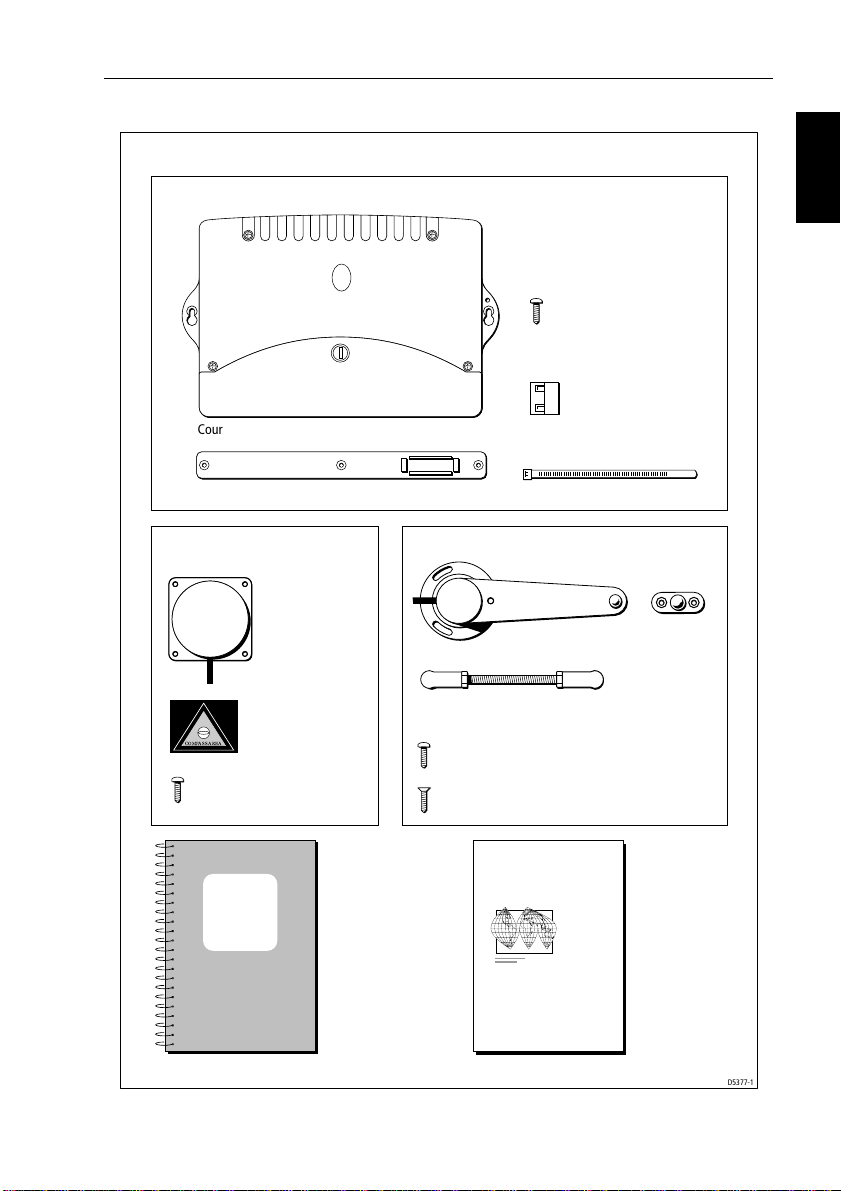

Type 150/400 autopilot system

Key components

Rudder

position sensor

Drive

unit

Course

computer

Standard

fluxgate

compass

Control

unit

Typical

drive units

Hydraulic

pump

Options

External GyroPlus

yaw sensor

Wind

vane

Linear drive

Rotary

drive

Other

equipment

External

alarm

SeaTalk

equipment

SeaTalk

handheld remote

NMEA

equipment

Active

compass

D5191-2

Page 9

Step 1: Check the Installation Kit 1

Step 1: Check the Installation Kit

The first step is to get ready for installation by:

• reading through all installation steps

• obtaining the necessary installation tools

• checking the parts supplied

WARNING: Product installation

This equipme nt must be inst alled and opera ted in accord ance

with the ins tructions containe d in this handboo k. Failure to do so

could result in poor p roduct performance, personal in jury

and/or damage to your boat.

Because correct performance of the boat’s steering is critical for

safety, we STRONGL Y RECOMMEND that an Authorized

Raymarine Service Representative fits this product. You will

only receive full warranty benefits if you can show that an

Authorized Raymarine Service Representative has installed or

commissioned this product.

1.1 Read this handbook

T o prepare for the system installation, read through the following

information and the rest of this handbook to familiarize yourself with

the autopilot system and how to install it.

Step 1

The autopilot system – core pack contents

Course computer

The course computer lies at the heart of the autopilot system. It

processes information from the sensors in the syst em (e.g. rudder

position and compass) so it can steer the boat using the drive unit:

• it contains a microprocessor, electronic circuitry to control the

drive unit and a powe r amplif ier for th e drive mo tor .

• it is the central distribution point for the autopilot system, with

terminals to take power from the boat’s distribution p anel and

inputs/outputs for all other autopilot componen ts

• it has inputs/outputs for SeaT alk and NMEA so you can connect it

to Raymarine and other manufacturer’s equipmen t.

Page 10

2 Type 150/400 Autopilot System: Installation Guide

Course computer versions

Version Supply voltage Drive unit compatibility

Step 1

Type 150

Type 150G

Type 400

Type 400G

*Note: The Raymarine GyroPlus yaw sensor measures the boat’s yaw (its rate of turn). The autopilot

system uses this informa tion to enhance course keeping in adverse weather and sai lin g conditions (such

as sailing downwind in following seas). The Type 150G and Type 400G course computers contain a

built-in GyroPlus yaw sensor as standard. The Type 150 and Type 400 course computers do not contain

a built-in GyroPlus, but have the option of an external GyroPlus or dealer-fitted internal GyroPlus.

12 V

12 V

12 V or 24 V

12 V or 24 V

All Raymarine Type 1 12 V drives and pumps

(including 12 V Constant Running pump).

All Raymarine Type 1 12 V drives and pumps

(including 12 V Constant Running pump).

All Raymarine 12 V and 24 V Type 1, Type 2 and

Type 3 drives and pumps. Drive voltage must be

matched to boat’s supply voltage.

All Raymarine 12 V and 24 V Type 1, Type 2 and

Type 3 drives and pumps. Drive voltage must be

matched to boat’s supply voltage.

Built-in

GyroPlus*?

No

Yes

No

Yes

CAUTION:

Before installing the course computer and drive unit, check that

they are the correct voltage for your boat’s supply.

For course computer installation information, see page 9

Í

For course computer specifications, see page 45

Compass

The compass is the direction sensor for the autopilot system. It

provides the course computer with precise information about the

boat’s heading.

Raymarine supplies a standard fluxgate compass for the autopilot

system.

For more information, see page 17

Í

Rudder position sensor

The rudder position sensor (or rudder reference transducer) provides

the course computer with the exact position of the boat’s rudder.

Page 11

Step 1: Check the Installation Kit 3

Raymarine produces two alternative types of rudder sensor:

• the rotary rudder position sensor is suitable for all steering

systems (apart from ‘bullhorn’ style hydraulic outboards)

• the linear rudder position sensor is specifically designed for

‘bullhorn’ style hydraulic outboard steering systems

For more information, see page 22

Í

The autopilot system – other key components

Drive unit

The drive unit translates instructions from the course computer into

rudder movement, so the course computer can steer the boat.

Raymarine produces a wide range of drive units to suit different types

of steering systems.

For more information, see page 28

Í

Control unit

The control unit is the your interface with the autopilot system. Y ou

can use it to:

• engage and disengage the autopilot

• adjust the boat’s course when the autopilot is engaged

• view information about the autopilot system’s status and perform

a range of other functions

Step 1

Raymarine produces a range of control units to suit di fferent boats

and user requirements.

For more information, see page 29

Í

The autopilot system – extended systems

Around these key components of the autopilot system, you can

extend the system by adding options su ch as:

• connections to additional control units, SeaT alk equipment or

other manufacturers’ equipment (via NMEA)

• a GyroPlus yaw sensor (if you have a T ype 150 or T ype 400

course computer without a built-in GyroPlus )

Page 12

4 Type 150/400 Autopilot System: Installation Guide

• handheld remotes (the ST600R full-function remo te control or

the SeaT alk handheld remote control)

Step 1

• pushpit or masthead wind vanes (for sail boats without a suitable

wind instrument)

• an external alarm (through an E85001 interface)

For more information about extended systems, see page 31.

Í

1.2 Obtain installation tools

T o install the core pack you will need the following items:

• tape measure (metric/imperial)

• screwdrivers:

• cross-head/pozi-drive

• flat-bladed (large and small)

• drill and 3 mm drill bit

• center punch, pencil and masking tape

• for the rudder position sensor:

• hacksaw

• small adjustable spanner

• bolts, nuts and lockwashers (if required for tiller pin)

• for the course computer power supply:

• suitabl e power ca ble (see page 16)

• suitable fuse/circuit breaker (see page 16)

Note: Y ou will also need the tools and equipment required to install

the control unit and drive unit. For full detai ls, refer the information

supplied with control unit and drive unit .

1.3 Check parts supplied

Use the diagram on the following page to check the parts supplied.

CAUTION:

Before you start installing the course computer, check that it is

the correct voltage for your boat’s power and your drive unit.

Page 13

Step 1: Check the Installation Kit 5

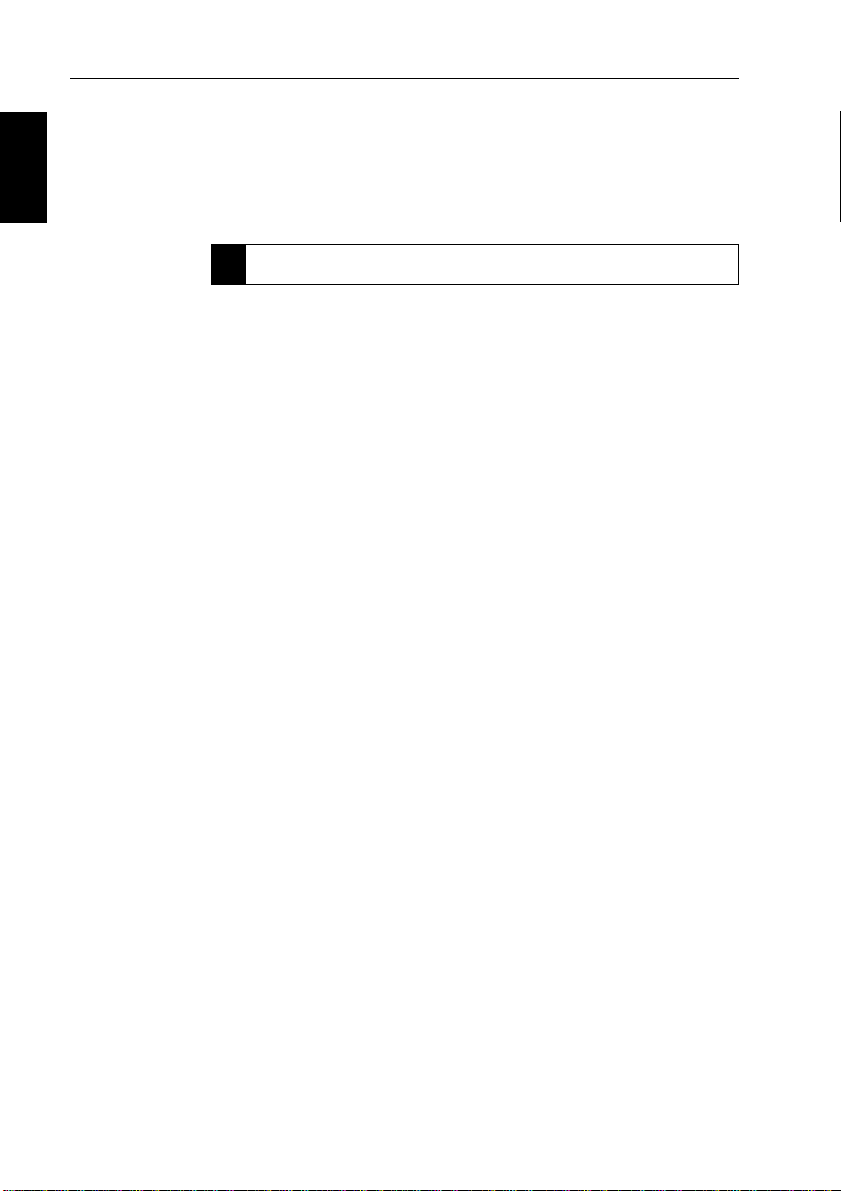

Core pack – parts supplied

Course computer components

No8 x 3/4 inch pan-head

self-tapping screws (x5):

• 2 for course computer

• 3 for cable clamp

Ferrite

(for power cable)

Course computer

Cable clamp Tie-wrap (for cable clamp)

Compass components Rudder position sensor components

Fluxgate compass

with 8 m (26 ft) cable

Step 1

Tiller pin

Worldwide

Distributor List

Compass

!

warning label

COMPASSAREA

No8 x 3/4 inch pan-head

self-tapping screws (x4)

Type 150/400

Autopilot

System

Installation

Guide

Installation Guide

(includes warranty

documents and

fitting templates)

Rudder position sensor

with 10 m (32 ft) cable

Connecting rod (M6), nuts (M6 x2)

and ball-pin sockets (x2)

No8 x 3/4 inch pan-head self-tapping screws (x3)

for rudder position sensor

No8 x 3/4 inch countersunk self-tapping screws (x2)

for tiller pin

Worldwide

Distributors

Note: This illustration shows the parts supplied with Type 150, 150G, 400 and 400G autopilot core packs.

D5377-1

Page 14

6 Type 150/400 Autopilot System: Installation Guide

Step 2: Check Locations

2.1 Identify suitable locations

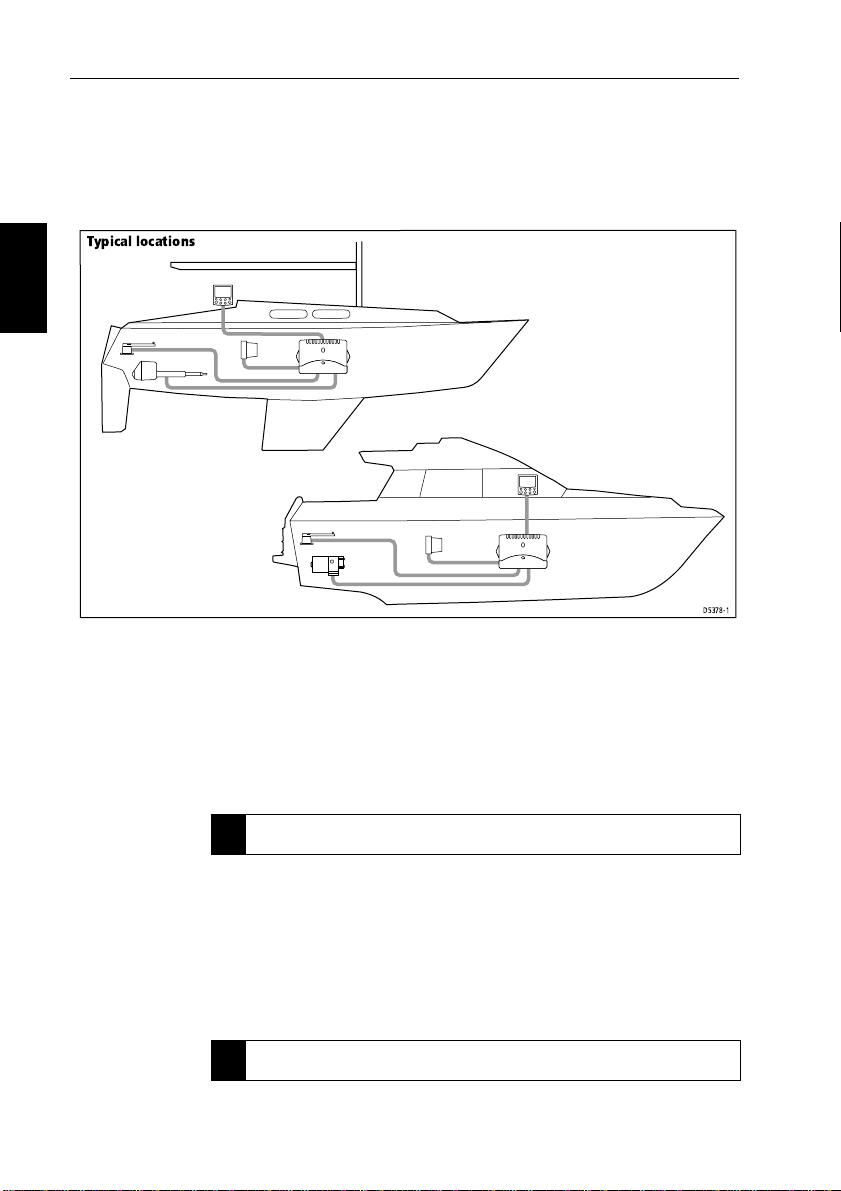

Typical locations

Step 2

After reading the following EMC installation guidelines (see page 7),

identify suitable locations for each part of the system.

D5378-1

Course computer location:

• mount vertically on a flat bulkhead below decks

• dry , protected and well-ventilated

• free from high operating temperatures and excessive vibration

For more information, see page 10

Í

Compass location:

• mount vertically, with cable exiting at the base

• as near as possible to the boat’s pi tch and roll center

• at least 0.8 m (2 ft 6 in) away from the boat’s steering compass

• in the back two-thirds of the boat

• away from potential sources of magnetic interference

For more information, see page 18

Í

Page 15

Step 2: Check Locations 7

Rotary rudder position sensor location:

• suitable base alongside the rudder stock and tiller arm.

• so the ball-joints at each end of the connecting rod are level

• so the sensor arm is between 75 mm (3 in) and 310 mm (12 in)

from the tiller arm

For more information, see page 23

Í

Drive unit and control unit locations

Refer to the information supplied with these units to identify suitable

locations.

Cabling:

• consider how you will run cables to and from each component

• avoid running cables through bilges where p ossible

• avoid running cables close to fluorescent lights, engi nes, radio

transmitting equipment etc.

Note: When cutting cables to length, we recommend that you include

a loop of extra cable so you can cut and strip the cables a few ti mes in

the future (if necessary).

Step 2

2.2 EMC installation guidelines

All Raymarine equipment and accessories are designed to the best

industry standards for use in the recreational marine environment.

Their design and manufacture conforms to the appropriate

Electromagnetic Compatibility (EMC) standards, but correct

installation is required to ensure that performance is not

compromised. Although every effort has b een taken to ensure that

they will perform under all conditions, it is important to understand

what factors could affect the operation of the product.

The guidelines given here describe the conditions for op timum EMC

performance, but it is recognized that it may not be possible to meet

all of these conditions in all situations. To ensure the best possible

conditions for EMC performance within the constraints imposed by

any location, always ensure the maximum separation possibl e

between different items of electrical equipment.

Page 16

8 Type 150/400 Autopilot System: Installation Guide

For optimum EMC perform ance, we recommend that wherever

possible:

• Raymarine equipment and cables connected to it are:

• At least 3 ft (1 m) from any equipment transmitting or cable s

carrying radio signals e.g. VHF radios, cables and antennas.

In the case of SSB radios, increases the distance to 7 ft (2 m).

• More than 7 ft (2 m) from the path of a radar beam. A radar

Step 2

beam can normally be assumed to spread 20 degrees above

and below the radiating element.

• The equipment is supplied from a separate battery from that used

for engine start. Voltage drops below 10 V , and starter motor

transients, can cause the equipment to reset. This will not damage

the equipment, but may cause the loss of some information and

may change the operating mode.

• Raymarine specified cables are used. Cutting and rejoining these

cables can compromise EMC performance and must be avoided

unless doing so is detailed in the installation manu al.

• If a suppression ferrite is attached to a cable, this ferrite should no t

be removed. If the ferrite needs to be removed d uring installation

it must be reassembled in the same position.

Suppression ferrites

This following illustration shows t ypical cable suppression ferrites

used on Raymarine equipment. Always use the ferrites supplied by

Raymarine.

D3548-2

Connections to other equipment

If your Raymarine equipment is to be connected to other equipment

using a cable not supplied by Raymarine, a suppression ferrite MUST

always be attached to the cable near to the Raymarine unit.

Page 17

Step 3: Install the Course Computer 9

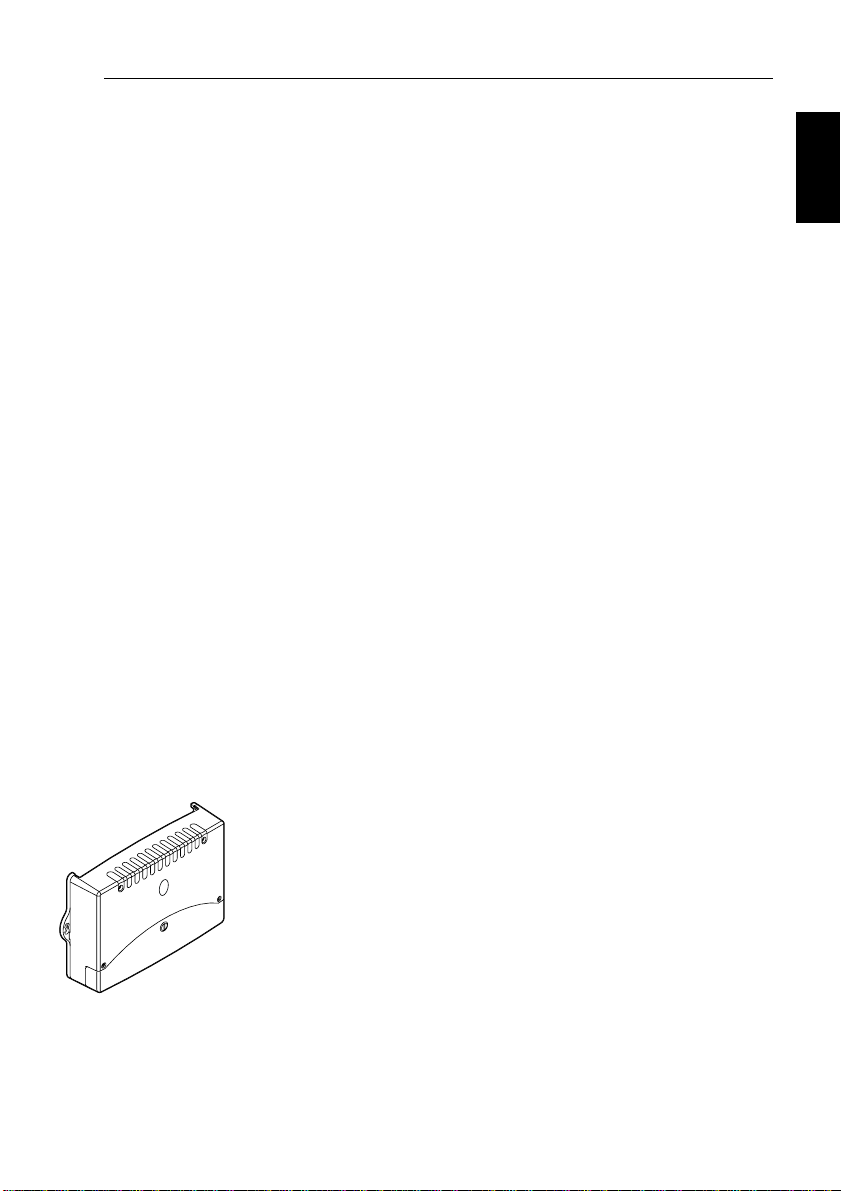

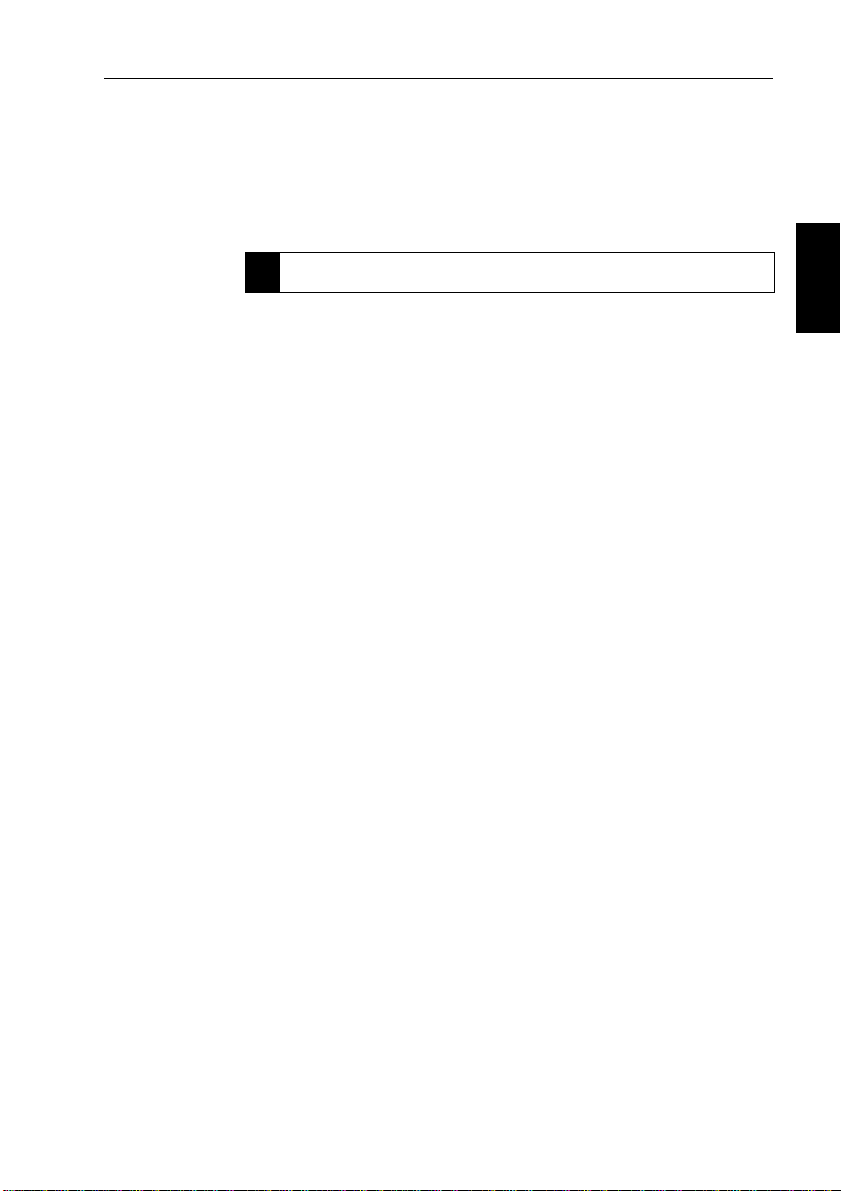

Step 3: Install the Course Computer

Installing the course computer involves these tasks:

Select the location page 10

3.1

Secure the course computer page 12

3.2

Remove the connector cover page 12

3.3

Attach the power cables page 15

3.4

Main cover

Step 3

Connector

cover catch

Connector

cover

Mounting screws,

No 8 x 3/4 in (x5)

Course computer - main parts

Mounting lug

Keyhole slot

Suppression ferrite

Tie-wrap

Cable clamp

Cables for autopilot

system components

and power

D5413-2

Page 18

10 Type 150/400 Autopilot System: Installation Guide

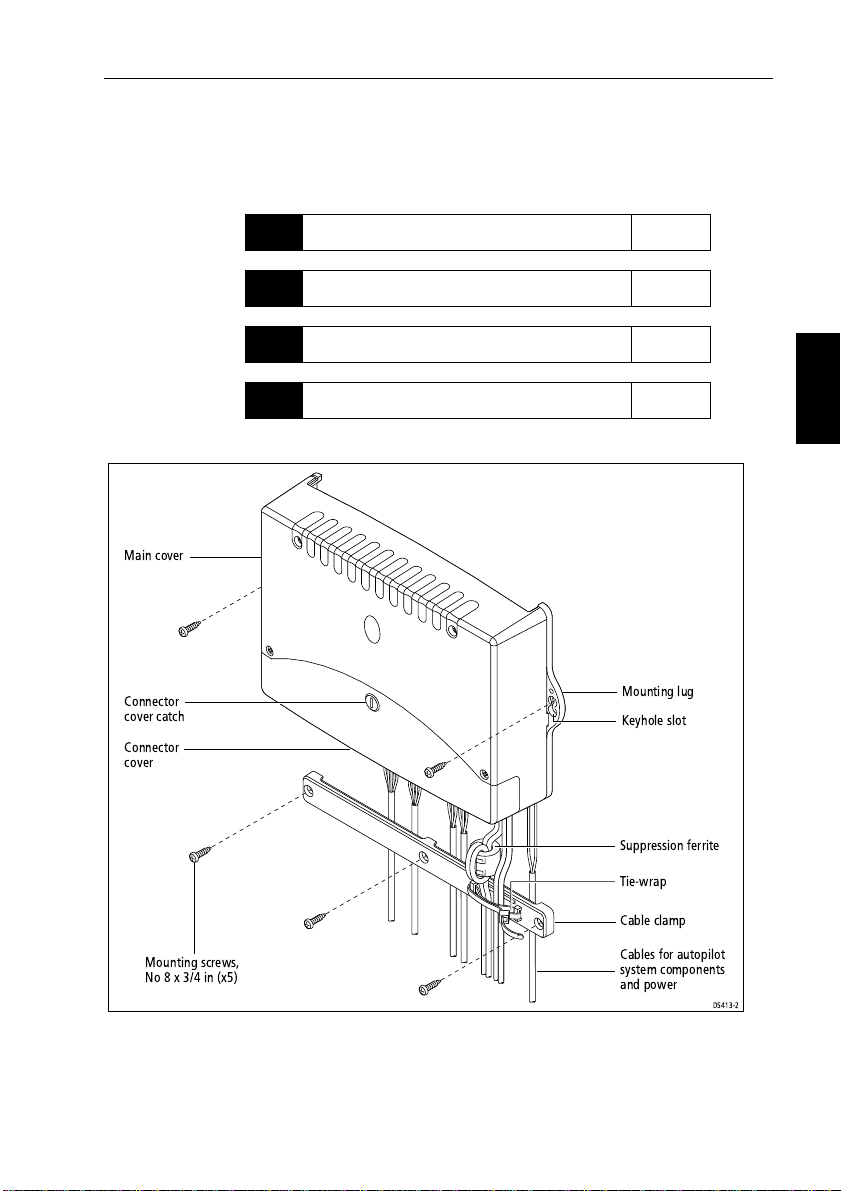

3.1 Select the location

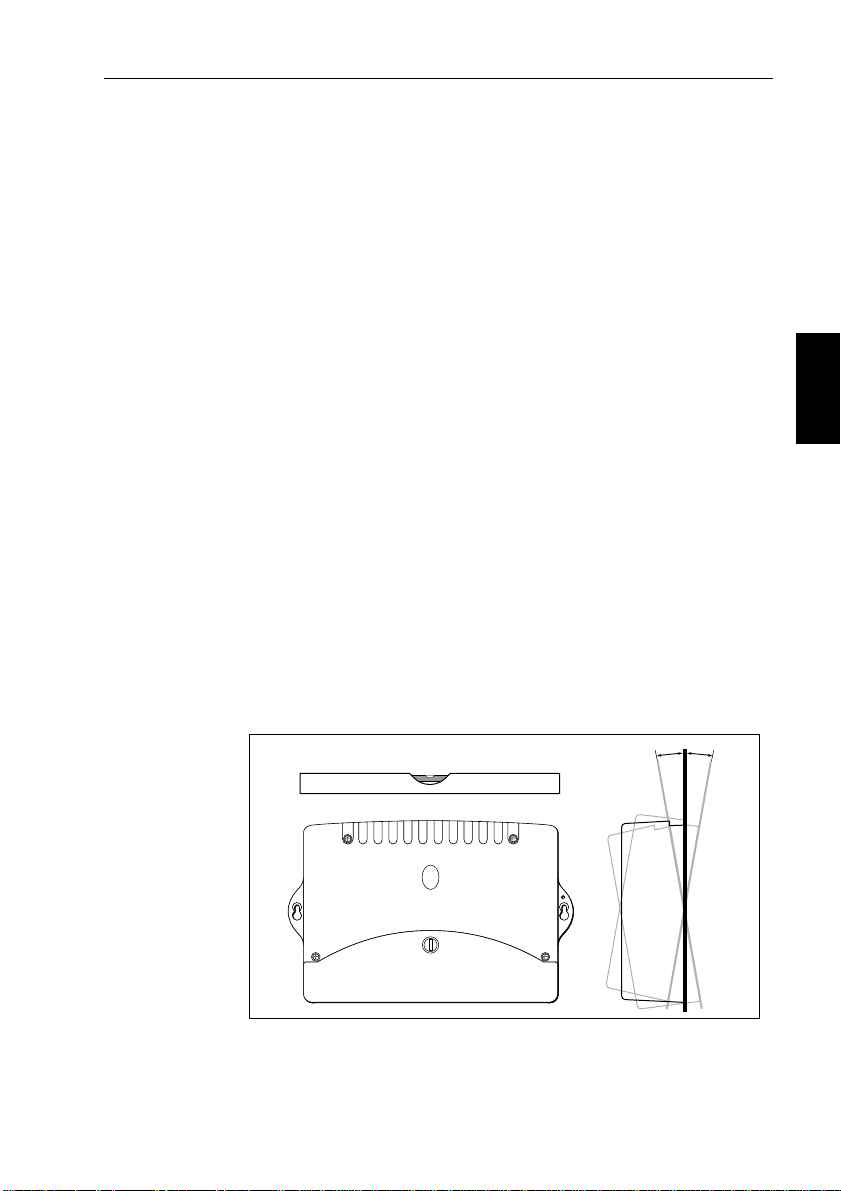

Course computer – installation dimensions

307 mm (12.1 in)

288 mm (11.3 in)

277 mm (10.9 in)

70 mm

(2.8 in)

Step 3

Keyhole slots

for No 8 screws

(pan-head)

133 mm (5.2 in) 133 mm (5.2 in)

26 mm

(1.0 in)

Suitable locations

The course computer is designed to be mounted on a vertical and flat

bulkhead below decks. Select a location that is:

• dry , protected and well-ventilated

• free from high operating temperatures

• free from excessive vibration

• non-metallic

• accessible for cable routing and sufficiently large to secure the

cable clamp under the computer

On sailboats, we also recommend mounting the course computer

across the boat on a transverse bulkhead.

Notes:

min 50 mm (1.9 in)

(recommended)

cable clearance:

min 50 mm (1.9 in)

(recommended)

195 mm (7.7 in)

D5260-1

1. If the only possible location has a meta llic surface, you must

insulate the base of course computer so it is not earthed.

2. When selecting the mounting location, also refer to the EMC

installation guidelines (on page 7).

Page 19

Step 3: Install the Course Computer 11

Unsuitable locations

WARNING:

The course computer is NOT designed to be mounted in engine

compartments.

Do NOT install the course computer:

• where there might be flammable vapors (such as in an engine

room or compartment, or in a fuel tank bay)

• where there is water splash or spray from bilges or hatches

• where it is at risk from physical damage from heavy items (such

as hatch covers, tool boxes, etc.)

• where it might be covered by other equipment

Orientation

CAUTION:

Y ou MUST mount the course computer so it is level and within

+/- 10° of the vertical.

The T ype 150G and T ype 400G course computers contain a buil t-in

GyroPlus yaw sensor that will NOT work correctly if you mount the

computer in any other orientation. This orientation also maximizes

the air flow to cool the course computer and provides optimum

resistance to dripping water .

±10˚

Step 3

level

D5379-1

Note: Type 150G and Type 400G course computers are supplied with

a temporary ‘Mount vertically’ label stuck to the case. Remove this

label after installation.

Page 20

12 Type 150/400 Autopilot System: Installation Guide

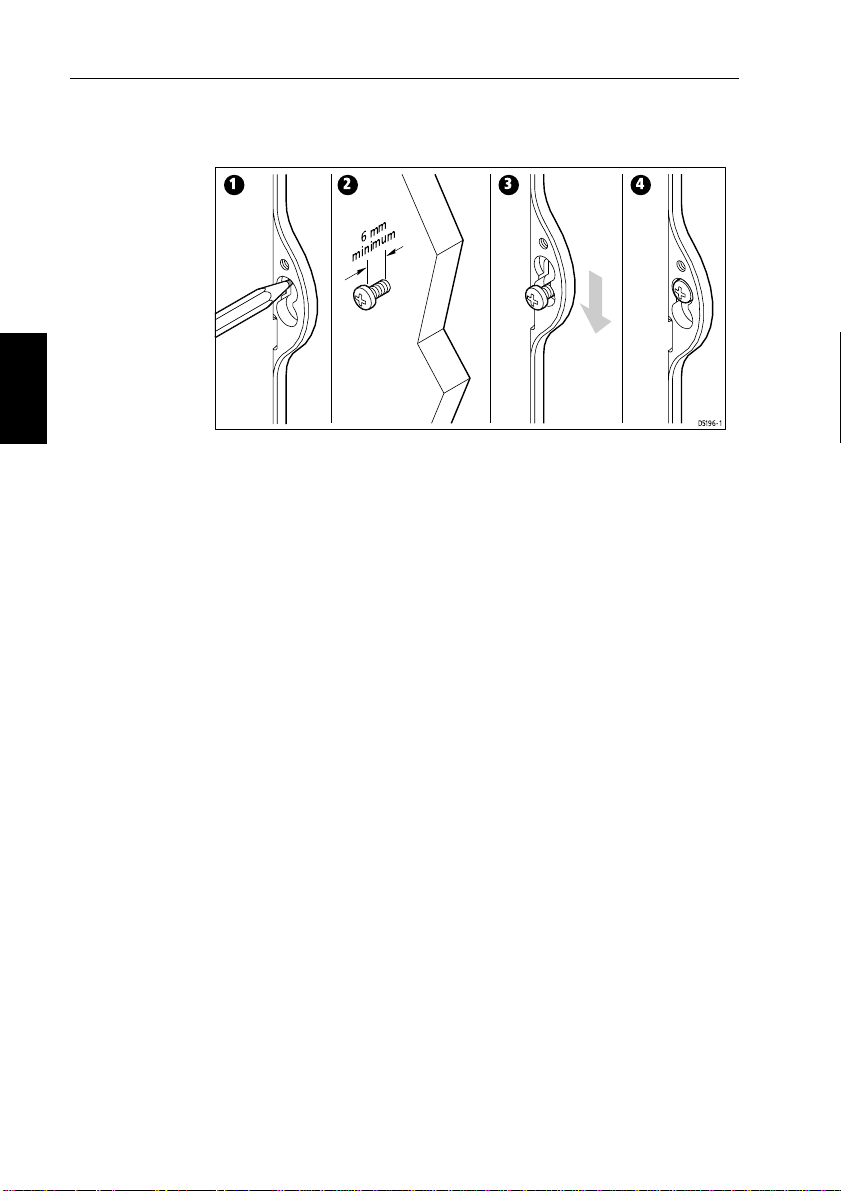

3.2 Secure the course computer

1 2 3 4

6mm

minimum

Step 3

Follow these steps to secure the course computer:

1. Hold the course computer in place against the mounting location

so you can mark the centre of the keyhole slots:

• these marks should be level and 288 mm (1 1.3 in) apart

• remove the course computer then drill the two pilot holes

using a 3 mm (

1

/8 in) drill bit

2. Screw the supplied self-tapping screws (No 8 x

into the holes, so the head of each screw is at least 6 mm (

from the surface.

3. Place the keyhole slots over the screw heads, then move the

course computer down, so the screw heads are at the top of the

keyhole slots.

4. Tighten the screws to hold t he course computer securely against

the mounting surface.

3.3 Remove the connector cover

To remove the connector cover:

• unlock the cover:

• use a flat-bladed screwdriver or small coin to rotate the catch

1

/

turn (90°) in either d irection – until you hear a click and the

4

slot is horizontal

• lift off the cover

D5196-1

3

/4 in, pan-head)

1

/4 in)

Page 21

Step 3: Install the Course Computer 13

Unlock

Lock

D5194-1

Spare connectors

for future upgrades

(Type 400 only)

Replacing the connector cover

To replace the connector cover:

• fit the cover

• lock the cover:

• turn the catch so the slot is vertical

• push in the catch until you hear it click

Course computer inputs, outputs and fuses

When you have removed the connector cover, you will see the course

computer inputs, outputs and fuses.

Spare fuses

Fluxgate

compass

inputs

External

GyroPlus

yaw sensor

inputs

sensor inputs

Fuse puller

Rudder

position

SeaTalk fuse

NMEA 0183

inputs/outputs

(5 A)

Clutch fuse

(4 A)

SeaTalk

inputs/

outputs

Type 150: 30 A

Type 400: 40 A

Off switch

inputs

Power inputs

Type 150: 12 V

Type 400:

12 V or 24 V

Power fuse

outputs

Drive

motor

Drive solenoid

return inputs

(for drives/pumps

with solenoids)

Drive clutch

outputs

Type 400:

selectable for

12 V or 24 V

D5193-2

Step 3

Page 22

14 Type 150/400 Autopilot System: Installation Guide

Connecting cables to the terminals

Power and Motor terminals

• The POWER and MOTOR terminals on T ype 150/150G course

computers accept stranded cable up to 4mm

• The

POWER and MOTOR terminals on Type 400/400G course

computers accept stranded cable up to 10 mm

T o secure cables in these terminals:

• strip 8–10 mm (

1

/2 in) of insulation from the end of each cable

• use a small screwdriver to loosen the screw on the terminal block

Step 3

• insert the stripped cable into the terminal

• tighten the screw

Other terminals

Note: All other terminals on the course computer will accept

stranded cable up to 2.5 mm

T o secure cables to the other terminals:

• strip at least 5 mm (

• use a small screwdriver to push the small plastic lever on top of

the terminal and release the cable clamp

• insert the stripped cable

• release the lever to grip the cable

2

(14 AWG).

1

/4 in) of insulation from the end of each cable

2

(12 A WG).

2

(8 AWG).

Using the fuses

The POWER, MOTOR and SeaTalk terminals are fuse protected

against short-circuits and misconnections. T o change the fuses:

• use the fuse puller (supplied in the case) to remove the fuse

• replace the fuse with an appropriate spare fuse

Note: The course computer is supplied with three spare fuses fitted in

the case. The fuses used in the course computer are standard

automotive blade fuses, so you can easily obtai n replacement fuses.

Your Raymarine dealer can also provide a replacement fuse pack

(part number: A18065).

Page 23

Step 3: Install the Course Computer 15

3.4 Attach the power cables

WARNING: Electrical safety

Make sure the power su pply is swi tched off befo re you make any

electrical connections.

Follow these steps to provide power to the course computer:

1. Measure the total length of cable run from the boat’s distribution

panel to the course computer, then use Table 3-1 to identify the

appropriate cable size.

Note: When s electing power cable you must use the gauge specified

in Table 3-1. If in doubt, use a heavier gauge cable than specified.

A lighter gauge cable might cause a voltage dr op between the supply

and the course computer. This could cause the course com puter to

malfunction and will reduce the power supplied to t he drive unit.

2. Route the cables back to the course computer, taking into account

the EMC installation guidelines (page 7).

3. Install a circuit breaker or fuse on the power supply to suit the

drive unit connected to your autopilot system (see Table 3-2).

4. Connect the cables to the

5. Attach the suppression ferrite (suppli ed) around both the positive

and negative power cables, between the cable clamp and course

computer. Wh en you attach the ferrite, you must loop both p ower

cables so that the ferrite encloses two passes of each cable.

Secure the ferrite with the small tie-wrap (supplied).

POWER inputs on the course computer.

Step 3

Course

computer

terminals

Power

supply

Fuse or

circuit breaker

Course computer – connecting power supply

Ferrite

D5380-2

Page 24

16 Type 150/400 Autopilot System: Installation Guide

Table 3-1: Recommended power supply cable sizes (stranded cables)

Cable length

(distribution panel to course computer)

Cable gauge

(AWG)

Copper area

(mm2)

Type 1 drive 12/24 V;

I/O drive; CR pump solenoids*

up to 3m (10ft)

up to 5m (16ft)

up to 7m (23ft)

up to 10m (32ft)

up to 16m (52ft)

14 AWG

12 AWG

10 AWG

8 AWG

6 AWG

Type 2 drive 12 V

Step 3

up to 7m (23ft)

up to 16m (52ft)

up to 5m (16ft)

10 AWG

8 AWG

6 AWG

Type 2 drive 24 V

up to 3m (10ft)

up to 5m (16ft)

up to 10m (32ft)

up to 16m (52ft)

12 AWG

10 AWG

8 AWG

6 AWG

Type 3 drive 12 V

up to 5m (16ft)

up to 7m (23ft)

up to 16m (52ft)

8 AWG

6 AWG

4 AWG

Type 3 drive 24 V

up to 5m (16ft)

up to 7m (23ft)

up to 16m (52ft)

Table 3-2: Recommended power cable fuse and circuit breaker sizes

10 AWG

8 AWG

6 AWG

2.5 mm

4 mm

6 mm

10 mm

16 mm

6 mm

10 mm

16 mm

4 mm

6 mm

10 mm

16 mm

10 mm

16 mm

25 mm

6 mm

10 mm

16 mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Drive unit Fuse (Amps)

Thermal over-current

circuit breaker (Amps)

Rotary, linear, hydraulic pump,

hydraulic linear

Type 1: 12 V and 24 V

Type 2: 12 V

Type 2: 24 V

Type 3: 12 V and 24 V

25 A

40 A

30 A

40 A

20 A

30 A

30 A

30 A

I/O drive 15 A 10 A

CR pump solenoids* 10 A 10 A

* These specifications apply to the cabling for CR pump solenoids. Power the

CR pump motor separately, as specified in the CR pump installation guide.

Page 25

Step 4: Install the Compass 17

Step 4: Install the Compass

This section provides installation instruct ions for the standard

Raymarine f luxgate comp ass (supplied in the core pack). This

involves the following tasks:

Select the location page 18

4.1

Mount the compass page 20

4.2

Connect to the course computer page 20

4.3

Note: This section also provides information about connecting other

SeaTalk or NMEA compasses to the course comput er (see page 21).

Compass description and dimensions

The compass contains a self-levelling mechanism. This enables the

compass to provide accurate readings with pitch and roll movements

up to +/- 35°.

76 mm (3 in)

Step 4

76 mm (3 in)

D5381-1

Fluxgate compass dimensions

Note: The rattle that the fluxgate compass makes when shaken is

normal. It is caused by the pendulum weight hitting the inside of

the case.

Page 26

18 Type 150/400 Autopilot System: Installation Guide

4.1 Select the location

The compass is primarily designed for mounting below deck on a

bulkhead. On steel-hulled boats you must moun t it above deck.

Standard location

T o achieve the best performance from the compass, mount it:

• as near as possible to the boat’s pitch and roll center to minimize

compass disturbance

• at least 0.8 m (2 ft 6 in) away from the boat’s steering compass to

prevent deviation of either compass

• away from the front third of the boat (otherwise shock motion will

affect compass performance)

• away from potential sources of magnetic interference, such as:

motors, drive units, loudspeakers, alternators/starters, electric

Step 4

cables, large ferrous objects (such as engines, ballast, keel, gas

bottles and tool boxes)

Note: Becaus e you align the compass after installation (see the

control unit handbook), you can mount it so it faces in any d irection.

0.3L to 0.5L

L

0.3L to 0.5L

L

Compass - recommended location for non-steel hulls

D5382-1

Page 27

Step 4: Install the Compass 19

Finding the most suitable location

T o identify the best compass location on your boat, start at the pi tch

and roll center then move the compass up and/or aft until you find a

location with minimal magnetic disturbance.

Note: To check if the intended mounting location is free from

magnetic influence, tape a handheld compass to the chosen location,

then turn the boat through 360°. The readi ngs on the handheld

compass and your boat’s main steering compass (if accurately

aligned) should not differ by m ore than10° at any heading.

Steel-hulled boats

On steel-hulled boats you must mount the compass at least 1 m (3 ft)

above the main deck or wheelhouse. Otherwise the compass will not

work correctly because the hull will prevent it from sensing the

Earth’s magn etic field. The following diagram shows recommended

mounting positions for steel-hulle d boats.

Note: The higher above the waterline you mount the compass, the

more the boat’s pitch and r oll will affect compass performance.

Step 4

6 ft (1.8 m)

4 ft (1.2 m)

4 ft (1.2 m)

Compass - recommended location for steel-hulled boats

D5383-1

Page 28

20 Type 150/400 Autopilot System: Installation Guide

4.2 Mount the compass

Vertical

Fluxgate compass - orientation

CAUTION:

Y ou must mount the fluxgate compass vert ically, with the cables

Step 4

exiting at the base.

1. Hold the compass against the mounting location.

2. Mark the four mounting holes, then remove the compass.

3. Drill four pilot holes using a 3 mm (

1

/8 in) drill bit.

4. Making sure the cable exits at the bottom of the compass, secure

the fluxgate compass using the self-tapping screws p rovided

(No 8 x

3

/4 in, pan-head).

538

4-1

D

Note: St ick the supplied warning label near to the co mpass, where it

is clearly visible.

4.3 Connect to the course computer

1. The compass is supplied with 8 m (26 ft) of cable. Route the cable

to the course computer, taking int o account the EMC installation

guidelines (page 7).

Note: Make sure you leave some spare cable so, if necessary, you can

re-position the compass to reduce deviation. If the standard cabl e is

not long enough, your Raymarine dealer can supply a 10 m (30 ft)

extension cable (part number: D174)

2. Connect the five cores of the cable to the

the course computer (as shown).

FLUXGATE terminals on

Page 29

Step 4: Install the Compass 21

Course

computer

terminals

Red Yellow

Screen Blue

Green

Compass cable

4.4 Connecting SeaTalk or NMEA compasses

Y ou can connect SeaT alk or NMEA compasses to the course

computer, either to replace the fluxgate compass or provide

supplementary compass signals.

When you connect more than one compass to the autopilot system,

the course computer processes their signals in this ord er of priority:

1. Fluxgate compass

2. NMEA compass

3. SeaTalk compass

This means that if you want to use a NMEA compass as the primary

compass, you need to disconnect the fluxgate compass .

T o connect a SeaTalk or NMEA compass to the autopilot system:

• NMEA compass: connect it to one set of NMEA inputs on the

course computer

• SeaT alk compass: connect it to the SeaT alk bus or the course

computer SeaTalk terminals

D5385-1

Step 4

Page 30

22 Type 150/400 Autopilot System: Installation Guide

Step 5: Install the Rudder Position Sensor

Note: Y our autopilot system must in clude either a rotary or linear

rudder position sensor, otherwise it will not function.

Refer to the following installation instructions to fit either a rotary or

linear rudder position sensor:

Rotary rudder position sensor - installation page 22

5.1

Linear rudder position sensor - installation

5.2

(on ‘bullhorn’ style hydraulic outboards only)

5.1 Rotary rudder position sensor - installation

Introduction

The rotary rudder position sensor is suitable for all steering s ystems

apart from ‘bullhorn’ style hydraulic out boards (which require a

linear rudder position sensor - see page26). The rotary rudder

Step 5

position sensor connects directly to the boat’s tiller arm or quadrant.

Installing the sensor involves five main tas ks:

• ensuring correct alignment

• securing the sensor to the boat

• attaching the sensor to the tiller arm

• checking alignment

• connecting to the course computer

187 mm (7.35 in)

140 mm (5.5 in)

page 26

Rudder position sensor - dimensions

60 mm (2.4 in)

70 mm (2.75 in)

D5386-1

Page 31

Step 5: Install the Rudder Position Sensor 23

Ensuring correct alignment

CAUTION:

T ake care to ensure correct rudder sensor alignment. If the

sensor is not correctly aligned, the autopilot system will not

perform accurately.

Vertical alignment

When viewed from the front of the boat, the connecting rod should:

• be as level as possible, so the ball-joints at each end are level

• remain parallel to the tiller arm’s plane of ro tation at all times

Note: If misalignment exceeds +/-5° the ball-joints will bind or fail.

Front view - rudder amidships

Ball joints (level)

Parallel

Tiller arm

or quadrant

Connecting rod

Sensor arm

Rudder position

sensor

Mounting base

Step 5

Top view - rudder amidships

Aft

Min: 101 mm (4 in)

Optimum: 140 mm (5.5 in)

Max: 190 mm (7.5 in)

Parallel

60˚ 60˚

90˚

Minimum: 75 mm (3 in)

Maximum: 310 mm (12 in)

Cable entry

Maximum

permitted

travel: +/- 60˚

D5387-1

Page 32

24 Type 150/400 Autopilot System: Installation Guide

Horizontal alignment

When viewed from above (as shown in the previous i llustration):

• the sensor arm must be between 75 mm (3 in) and 310 mm (12 in)

from the tiller arm

• with the rudder amidships, the sensor arm should be at 90° to th e

connecting rod and directly opposite the cable entry point o n the

sensor body

• when the rudder moves from hardover to hardover:

• the sensor arm and the tiller arm must remain parallel to each

other at all times

• sensor arm movement must not exceed +/- 60°: the rudder

position sensor may be damaged if th e steering system drives

the sensor arm beyond these limits onto its end stops

Securing the sensor to the boat

Mount the rudder position sensor on a suitable base alongs ide the

rudder stock and tiller arm:

1. Hold the sensor in place, mark the mounting holes, then remove

the sensor . (If required, use the template at the back of the book.)

Step 5

2. Drill the pilot holes using a 3 mm (

3. Attach the sensor to the mounting base using the self-tapping

screws supplied (No 8 x

3

/4 inch, pan-head).

1

/8 in) drill bit.

Note: To make minor adjustments to the sensor alignment, loosen th e

screws, rotate the sensor body, then re-tighten the screw s.

Attaching the sensor to the tiller arm

Attaching the tiller pin to the tiller arm

1. For optimum performance, mount the tiller pin on the tiller arm

140 mm (5.5 in) from the rudder stock.

Note: If necessary, you can fit the tiller pin anywhere between

101 mm (4 in) and 190 mm (7.5 in) from the rudder stock. This will

not affect autopilot performance, but will slightly alter the scaling of

the rudder angle display shown on the control unit.

2. Hold the tiller pin in place on the tiller arm, mark the mounting

holes then remove the tiller pin. Y ou can mo unt the tiller pin so it

is aligned either along or across the tiller arm.

Page 33

Step 5: Install the Rudder Position Sensor 25

3. Drill pilot holes using a 3 mm (1/8 in) drill bit.

4. Attach the tiller pin to the tiller arm using the two self-tapping

screws supplied (No 8 x

3

/4 inch, countersunk) or suitable bolts,

nuts and lock washers.

Attaching the connector rod

1. Use a hacksaw to cut the threaded connector rod to length.

2. Screw the lock nuts onto the rod and then the ball-pin sockets.

3. Press the sockets onto the pins on the sensor arm and t iller pin.

Note: T o give the precise rudder position, the rudder se nsor has a

built-in spring to remove any free play in the linkage to the tiller.

Checking alignment

Move the rudder from hardover to hardover and check that at all

rudder angles:

• all moving parts of the sensor remain free from any obs tructions

• the sensor and connecting rod remain accurately aligned

• the ball joints do not bind

Connecting to the course computer

Step 5

1. The rudder sensor is supplied with 10 m (32 ft) of cable. Route the

cable to the course computer, taking into account the EMC

installation guidelines (see page 7).

2. Connect to the

RUDDER terminals on the course computer.

Note: If you have mounted the rudder sensor upside down, you will

need to swap the red and green connections at the course computer.

Course

computer

terminals

Screen

BlueRed

Green

Rudder position sensor cable

D5388-1

Rudder position sensor - connecting to course computer

Page 34

26 Type 150/400 Autopilot System: Installation Guide

5.2 Linear rudder position sensor - installation

Introduction

The linear rudder position sensor (part number: M81 188) is designed

for ‘bullhorn’ style hydraulic outboard steering systems. It is totally

weatherproof and designed to be mounted on the bullhorn ram.

Note: You must use the linear rudder position sensor on all hydraulic

outboard installations.

425 mm (16.75 in)

Linear rudder position sensor - dimensions

Mounting

1. Use the steering system to position the bullhorn ram amidships.

Step 5

2. If necessary , release the hydraulic pressure from the boat’s

hydraulic steering system

Note: Contact your steering gear manufacture for advic e on this step,

and follow their instructions for r eleasing the hydraulic pressure .

32 mm

(1.3 in)

D5389-1

3. Loosen the starboard bolt that secures the bullhorn ram’s shaft to

the end bracket.

4. Fit the U-bracket (supplied) over the end bracket and th e bullhorn

ram’s s haft.

5. Hand tighten the starboard bolt to hold the U-bracket in place.

6. Fully open the hose clamps (supplied) using a flat bl aded

screwdriver, then hang them over the bullh orn ram.

7. Place the spacers (supplied) on the bullhorn ram and use adhesive

tape to sec ure them te mporaril y .

8. Pull out the rudder sensor’s shaft until its alignment mark is level

with the end of the barrel.

9. Position the rudder sensor against the spacers so the threaded rod

end of its shaft passes through the U-bracket.

Page 35

Step 5: Install the Rudder Position Sensor 27

10. Tighten the hose clamps around the bullhorn ram and the rudder

sensor’s barrel.

11. Tighten the starboard bullhorn bolt to secure the U-bracket.

12. Fit and tighten the supplied nut and washer to secure the threaded

rod end of the sensor’s shaft to the U-bracket.

Note: W e recommend installing the sensor with i ts shaft pointing to

starboard. If you cannot install the unit in this orientat ion, you can fit

it with the shaft pointing to port. If you do this, swap the red and green

connections at the course computer.

End

Starboard

bolt

bracket

Bullhorn

ram shaft

Nut and

washer

Threaded

rod

U-bracket

Sensor

shaft

Alignment mark

Sensor

shaft

Sensor

barrel

Hose clamp

Sensor

barrel

Spacer

Cable

Bullhorn

ram

D5390-1

Linear rudder position sensor - installation

Connecting to the course computer

1. Route the cable to the course computer, taking into account the

EMC installation guidelines (page 7).

2. Connect to the

to the illustration on page 25).

Note: To allow for the bullhorn’s movement, leave a loop of cable at

the end of the linear rudder position senso r. If the standard cable is

not long enough, your Raymarine dealer can supply a 1 0 m (30 ft)

extension cable (part number: D173).

RUDDER terminals on the course computer (refer

Step 5

Page 36

28 Type 150/400 Autopilot System: Installation Guide

rotary drive

linear drive

Step 6: Install the Drive Unit

Raymarine produces a wide range of drive units to suit different types

of steering systems:

• The rotary drive is designed for steering systems that can be

driven from the helm position through a chain and sp rockets.

• The linear and hydraulic linear drives are designed for boats

with existing mechanical steering systems, and drive the rudder

directly. The hyd raulic linear drive is suitable for larger boats and

heavier duty steering applications.

• The hydraulic pump and constant runn ing hydraulic p ump

(CR pump) are primarily designed for boats with existing

hydraulic steering systems. Alternatively , you can us e them in

combination with a secondary steering ram on boats with

mechanical steering. The CR pump is suitable for larger boats and

heavier duty steering applications.

pump

Step 6

• The I/O drive (the Inboard/Outboard or stern drive) is de signed

to drive cable operated, power assisted outbo ard steering systems.

T o control a Raymarine drive or pump, connect it to the motor

terminals on the course computer (and clutch terminals where

necessary). For Raymarine CR pumps, connect the solenoids to the

motor and solenoid terminals on the course computer .

For full information, see the installation guide packed with the drive.

Í

If you are connecting a non-Raymarine drive unit, see page 41.

Í

Page 37

Step 7: Install the Control Unit 29

ST7001+

ST6001+

Step 7: Install the Control Unit

Raymarine produce a range of control units to suit different boats and

user requirements.

The ST6001+ and ST7001+ control units have been design ed

specifically to provide access to all advanced functions on the

T ype 150, 150G , 4 00 and 400G course computes.

Y ou can also use the following control uni ts to operate the course

computer autopilot system, but they do not enable access to some of

its more advanced functions:

• ST6000+ control unit

• ST7000+ control unit

• ST600R remote control unit

• ST80 autopilot keypad (as part of an ST80 ins trument system)

• RayPilot 650 control unit

• ST6000 and ST7000 control units

For full information about control unit functionality, see page 46.

Í

Connecting to the course computer

If your system only includes a s ingle control unit, connect it to one set

of SeaT alk terminals on the course computer.

For full information, refer to the control unit owner’s handbook.

Í

If you are connecting mor e than one control unit or a combination of co ntrol

Í

units and SeaTalk instruments/equipment, see page 32 of this handbook.

Step 7

Page 38

30 Type 150/400 Autopilot System: Installation Guide

Step 8: Clamp the Cables

When you have connected all autopilot system components t o the

course computer, we recommend that you use the supplied cable

clamp to relieve any strain on the cable connections.

Secure the cables with the cable clamp as follows:

1. Hold the cable clamp in place below the course computer, making

sure:

• its center hole is below the center of the course computer (i.e.

in line with the connector cover catch)

• it is between at least 50 mm (2 in) from the bottom of the

course computer

• the hole locations are clear of any cables

2. Mark the position of the three holes, then remove the cable clamp.

3. Drill the three pilot holes using a 3 mm (

4. Secure the cable clamp using the self-tapping screws supplied

3

(No 8 x

/4 in, pan-head), making sure:

• the tie-wrap securing loops are on the right (below the

POWER and MOTOR terminals on the course computer)

• the clamp securely holds all cables

• the legs on cable clamp do not pinch any of the cables

Note: If the power and/or motor cables are larger than 5 mm (

diameter, secure them on top of the cable clamp with the tie-wrap

supplied. Make sure the tie-wrap sits ab ove the cables (as shown

below), so it pulls the cables against the clamp when tightened.

1 2

1

/8 in) drill bit.

1

/4 in)

Step 8

D5224-1

Page 39

Step 9: Integrate the System 31

Step 9: Integrate the System

This section explains how to connect the autopilot to other eq uipment

and integrate the system:

Connecting SeaTalk equipment page 32

9.1

Connecting NMEA equipment page 36

9.2

Connecting optional components page 40

9.3

Setting-up the autopilot page 42

9.4

Note: Before connecting other equipment, read the EMC installation

guidelines (see page 7).

Step 9

Page 40

32 Type 150/400 Autopilot System: Installation Guide

9.1 Connecting SeaTalk equipment

Y ou can use SeaT alk to connect the autopilot system to:

• additional SeaTalk control u nits: you can use any control units

to operate the autopilot and view autopilot information

• SeaT alk equipment (such as wind, navigation, radar and GPS):

• the autopilot system can use information from this equipment

to enhance course keeping and provide additional features

(such as waypoint navigation)

• you can also display information fr om the SeaT alk equipment

on the autopilot control unit

Possible systems

When connecting SeaT alk equipment, you have a range of options

depending on whether you want to:

• provide an ‘isolated’ control unit (for systems with more than one

control unit – see next page)

• provide power separately to the course computer and main

SeaT alk bus

The following illustrations show some typical ways to connect

simple SeaTalk systems.

CAUTION:

If your autopilot system includes more than one control unit,

we strong ly recomm end connect ing the mai n control unit to one

course computer SeaTalk port and the additional control unit(s)

to the other SeaT alk port. Th is will mean that if either SeaTalk

system fails, you will still have one operational control unit.

Single control unit, single power supply

The simplest type of system has the course computer prov iding

power to a single SeaT alk system that includes a single control unit

and several instruments.

Step 9

Page 41

Step 9: Integrate the System 33

Single control unit, single power supply

Course computer

power supply

SeaTalk A

(via breaker/fuse)

ST60

instruments

Control unit

Extra connection on larger SeaTalk systems*

SeaTalk bus

D5391-2

Isolated control unit, single power supply

If you have two control units, we recommend that you connect one to

each SeaTalk terminal. In the following illustration:

• the course computer provides power to the SeaT alk system

• one control unit is connected on its own to SeaTalk A so it is

isolated against any possible failure of SeaTalk B

If the SeaTalk B line fails, the isolated control unit will switch to

Standby mode as a safety measure. By pressi ng

control u nit you can regain f ull autopi lot contro l.

Isolated control unit, single power supply

SeaTalk B

SeaTalk A

auto on the isolated

Course computer

power supply

(via breaker/fuse)

ST60

instruments

Isolated

control unit

Second

control unit

Extra connection on larger SeaTalk systems*

SeaTalk bus

D5392-2

* Note: Depending on the n umber of SeaTalk units and the total length of SeaTalk

cabling, you may need to provide power supply to each end of the SeaTalk bus

(‘ring-main’ style). Refer to the instrument handbook for more information.

Step 9

Page 42

34 Type 150/400 Autopilot System: Installation Guide

Separate course computer and instrument power

Another option is to provide separate power supplies t o the course

computer and SeaT alk system so you can have independent, switched

instrument and pilot systems.

On the illustrated example, the behavior of the control unit on

SeaT alk A depends on whether you connect the red SeaT alk wire to

the SeaTalk B terminal:

• if the red wire is not connected, the control unit does not power up

when the course computer power is off

• if the red wire is connected, the control unit shows a

NO LINK message when the course computer power is off (as it will

still receive power from the SeaTalk B line)

Separate course computer and instrument power supplies

SeaTalk B

SeaTalk A

PILOT OFF or

Course computer

power supply

(via breaker/fuse)

ST60

instruments

Control unit

Red*

Screen

*Red wire not connected:

When course computer power supply is off,

control unit does not power up.

*Red wire connected:

When course computer power supply is off,

Yellow

control unit shows 'PILOT OFF' or 'NO LINK'

message.

Instrument SeaTalk bus

12 V power supply

for Instrument

SeaTalk bus

(via breaker/fuse)

D5393-2

Typical larger boat system

The following illustration shows a typical system layout for a

T ype 150G or T ype 400G course computer on a larger bo at. It has:

• separate course computer and SeaT alk power supplies

• an isolated control unit on SeaT alk A

• a NMEA 1 output so the radar/chartplotters can use the fast

heading output from the course computer to enable MARP A

Step 9

(see page 37)

Page 43

Step 9: Integrate the System 35

Typical larger boat system

Radar scanner

GPS receiver

Radar/

Chartplotter

Connect

NMEA

+ to Orange

NMEA

- to Yellow

SeaTalk A

Radar/Chartplotter

Control unit Instrument Instrument

SeaTalk B

HSB

(High Speed Bus)

Isolated control unit Instrument Instrument

Fast compass

output from

NMEA 1 out

SeaTalk B

Flybridge

Lower Helm

Separate power

feed for SeaTalk B

SeaTalk B

SeaTalk A (isolated control unit)

NMEA 1 out (fast compass heading)

Distribution

Panel

SeaTalk B

Step 9

D5394-3

Page 44

36 Type 150/400 Autopilot System: Installation Guide

9.2 Connecting NMEA equipment

If you have equipment on your boat that transmits NMEA 0183 dat a

(e.g. GPS), you can connect this equipment to the autopilot system.

Y ou can connect the NMEA equipment in any combination of these

ways:

• using the course computer NMEA inputs/outputs

• using the NMEA inputs on the back of either the ST6001+ or

ST7001+ control units (if your installation includes one of these

control units)

• using the SeaT alk/NMEA interface (part number: E85001) to

convert the NMEA data to SeaTalk dat a

WARNING: Connections to other equipment

If you are connecting Raymarine equipment to other equipment

using a non-Raymarine cable, you MUST a ttach an appropriate

suppression ferrite to the cable near to the Raymarine unit.

Course computer NMEA inputs/outputs

Note: Do NOT connect more than one piece of equipment to each of

the course computer NMEA inputs.

The course computer has two sets of NMEA in puts/outputs to receive

and transmit information from NMEA equipment. The course

computer decodes and transmits the following NMEA data:

Course computer NMEA 1 and 2 inputs

NMEA 0183 received Information extracted

APB

BWC

BWR

GGA

GLL

HDG

HDM

HDT

MWV apparent wind angle, apparent wind speed

Step 9

RMA

cross track error, bearing to waypoint, waypoint

number

bearing to waypoint, distance to waypoint,

waypoint number, time

latitude/longitude, time

heading

course over ground (COG), speed over ground

(SOG), latitude/longitude, variation

Page 45

Step 9: Integrate the System 37

Course computer NMEA 1 and 2 inputs

NMEA 0183 received Information extracted

RMB

RMC

VHW speed through water, heading

VTG

VWR

XTE cross track error

ZDA time, date

Note: When connected to a NMEA navigator, the course computer looks at

NMEA 1 first. If NMEA 1 has no data, the course computer looks at NMEA 2.

If both channels have the same type of navigation data, the course computer

uses NMEA 1.

Course computer NMEA 1 output*

NMEA 0183 transmitted Information sent

HDM heading

* Note: Type 150G and Type 400G course computers provide fast heading

(HDM) output from NMEA 1 at 10 Hz 0.1° resolution. This fast heading data is

suitable for use with the MARPA function on radar equipment.

cross track error, bearing to waypoint, distance to

waypoint, waypoint number

course over ground (COG), speed over ground

(SOG), latitude/longitude, time, variation

course over ground (COG), speed over ground

(SOG)

relative apparent wind angle, relative apparent

wind speed

Course computer NMEA 2 output

NMEA 0183 transmitted Information sent (* if available)

BWC

bearing to waypoint*, distance to waypoint*,

waypoint number*, time*

GLL latitude/longitude*, time*

HDG

HDM

heading

HDT

VTG

course over ground* (COG), speed over ground*

(SOG)

* Note: The course computer will only transmit these items if it has received the

appropriate data.

Step 9

Page 46

38 Type 150/400 Autopilot System: Installation Guide

Connect:

• the NMEA outputs from the equipment (such as navigators, wind

or speed instruments to the NMEA inputs on the course computer

• the NMEA outputs on the course computer to the NMEA inputs

on the equipment (such as radar)

Control unit NMEA inputs

Y ou can connect the outputs from a single item of NMEA equipment

to the NMEA inputs on the ST6001+ or ST7001+ cont rol units.

For more information, refer to the control unit owner’s handbook.

Í

SeaTalk/NMEA interface

The SeaTalk/NMEA interface (part number: E85001) enables you to

connect NMEA equipment to the SeaTalk system. It allows the

non-SeaT alk equipment to transmit and receive information to/from

the SeaTalk system.

The interface converts:

• NMEA data from the equipment into SeaT alk data

• SeaTalk data from the SeaT alk system into NMEA data

For more information about NMEA and SeaTalk received and transmitted,

Í

refer to the handbook supplied with the interface.

Connect:

• the NMEA equipment to the SeaTalk/NMEA interface

• the SeaTalk/NMEA interface to:

• one of the course computer SeaT alk terminals

• or, any other SeaT alk product (us ing one of the available

interface cables)

Connecting several items of NMEA equipment

If you need to connect several NMEA items to the course computer,

you will need to use an appropriate combination of:

• course computer NMEA inputs and outputs

Step 9

• control unit NMEA inputs

• SeaTalk/NMEA interface (part number: E85001)

Page 47

Step 9: Integrate the System 39

Typical NMEA connections

Option 1 – without SeaTalk/NMEA interface

Type 150/400 course computer terminals

Control unit (rear)

SeaTalk

Red

Screen

Yellow

SeaTalk

NMEA

GPS

Loran

Decca

NMEA

NMEA

radar

NMEA

NMEA

wind

instrument

Option 2 – with SeaTalk/NMEA interface

Type 150/400 course computer terminals

Red

Screen

Yellow

SeaTalk

NMEA

GPS

Loran

Decca

NMEA

radar

NMEANMEA

SeaTalk/

NMEA

interface

NMEA

wind

instrument

NMEA

NMEA

speed

instrument

Control unit (rear)

NMEA

SeaTalkSeaTalk

NMEA

speed

instrument

D5395-1

Step 9

Page 48

40 Type 150/400 Autopilot System: Installation Guide

9.3 Connecting optional components

To install any of these options, refer to the information supplied with the

Í

component.

GyroPlus yaw sensor

The T ype 150 and T ype 400 course computers do not contain a

built-in GyroPlus, but you have the opti on of adding:

• an external GyroPlus (part number: M81 162)

• or a dealer-fitted internal GyroPlus (part number: A1806 9)

Handheld remotes

Y ou can connect handheld remotes to the autopi lot system:

• the ST60 0R remote control unit (part number: A12016) can act

as the sole pilot control unit in your system or as a full-function

remote for systems with other fixed pilot cont rol units

• the compact SeaT alk handheld remote (part number: A15002)

gives you full course control away from the main steering

position

External alarm

The autopilot system sounds an off-cours e alarm from all control

units. On large and/or noisy boats you can fi t a Raymarine external

alarm (part number: Z035, connected though E85001 interface box)

as a high volume repeater.

Wind vane (sail boats)

The course computer can use wind angle information from a wind

vane or instrument to maintain a course relative to the wind. Y o u can

provide wind angle information to the autopilot sy stem by connecting

it to:

• a suitable SeaT alk or NMEA instrument (providing wind angle

and speed information)

or

• a Raymarine pushpit wind vane (part number: Z159) connected

Step 9

through an interface box (part number: M81189)

Page 49

Step 9: Integrate the System 41

Off switch

The course computer has inputs so you can fit an off s witch if

required. By closing a circuit, this switch will turn of f the course

computer power supply .

Connect a suitable off switch to the

computer.

OFF SWITCH inputs on the course

Course computer terminals

Connecting an off switch

Other manufacturers’ drive units

If you are connecting another manufacturer’s drive uni t, refer to the

specifications (on page 45) for information on the course computer’s

drive motor, drive clutch and drive solenoid terminals. Connect the

drive unit to these terminals as necessary.

For more information, contact the drive unit manufacturer.

Í

Connecting spool valves

If the drive has spool valves, connect them to the motor and solenoid

terminals on the course computer as shown below . The course

computer provides a negative ground for the spool valves even when

it is switched off.

Off switch (closes circuit to

turn off course computer power)

D5396-1

CAUTION:

Do NOT connect the solenoid return cables to boat’s negative

ground, as this will bypass the current protection devices inside

the course computer .

Step 9

Page 50

42 Type 150/400 Autopilot System: Installation Guide

Course computer connections

If electronic steering or jog lever

is used on the same solenoids, fit

diodes (suggested type: 1N4004)

as indicated to prevent

backfeeding the course computer.

Electronic steering

or jog lever

Diodes

Return cables

12 V

24 V

Selecting clutch voltage (Type 400/400G)

Note: Al l Raymarine 12 V and 24 V drive units with a clutch have a

12 V clutch so you do NOT need to re-position the clutch fuse.

Y ou can use the T ype 400/400 G course computers with other

manufacturers’ drives that have either 12 V or 24 V clutches.

Select the appropriate clutch voltage by positioning the clutch fuse to

the left (12 V clutch) or right (24 V clutch).

Fuse position: 12 V clutch Fuse position: 24 V clutch

4

9.4 Setting-up the autopilot

When you have installed and connected all components, you need to

check the system and then set-up the autopilot.

Spool valves

(diodes across

spool valves)

D5397-1

4

D5398-1

For more information about autopilot set-up, refer to the control unit

Step 9

Í

owner’s handbook.

Page 51

Maintenance 43

Maintenance

All Raymarine products are designed to provide many years of

trouble-free operation. W e also put them through comprehens ive

testing and quality assurance procedures before shipping.

Regular checks

On a regular basis:

• check that all connections and mountings are secure and

undamaged

• check the course computer for any signs of physical damage or

water damage

Note: Do not use chemical or abr asive materials to clean the course

computer. If the case is dirty, wipe it with a clean, damp cloth.

Fault-finding

Course computer fuses

Symptoms of a blown course computer fuse are:

Servicing

• if either the power fuse or SeaTalk fuse blows, the control unit

display will go blank

• if the clutch fuse blows and your drive has a clutch, the control

unit will show a

If your control unit shows either of these symptoms, check the

relevant fuse(s). If the fuse has blown, replace it with a fuse of the

same current rating (see page 14).

For more information about diagnosing faults on your autopilot system,

Í

refer to the Fault Finding section of the control unit owner’s handbook.

DRIVE STOPPED alarm message

CAUTION:

The course computer does NOT contain user-serviceable parts.

If you remove the main cover you will invalidate the warranty .

Page 52

44 Type 150/400 Autopilot System: Installation Guide

EMC, servicing and safety guidelines

• Raymarine equipment should be serviced only by authorized

Raymarine service technicians. They will ensure that service

procedures and replacement parts used will not affect

performance. There are no user serviceable parts in any

Raymarine product.

• Some products generate high voltages: never handle the

cables/connectors when power is being supplied to the

equipment.

• When powered up, all electrical equipment produces

electromagnetic fields. These can cause adjacent pieces of

electrical equipment to interact with one another, with a

consequent adverse effect on operation. In order to minimize

these effects and enable you to get the best possible performance

from your Raymarine equipment, guidelines are given in the

installation instructions, to enable you to ens ure minimum

interaction between different items of equipment, i.e. ensure

optimum Electromagnetic Compatibility (EMC).

• Always report EMC-related problems to your nearest Raymarine

dealer. W e use such information to improve our quality standards.

• In some installations, it may not be possible to preven t the

equipment from being affected by ext ernal influences. In general

this will not damage the equipment but it can lead to spurious

resetting action, or momentarily may result in faulty operation.

Product support

Raymarine products are supported by a worldwide network of

distributors and Authorized Service Representa tives. If you

encounter any difficulties with thi s product, please contact either

your national distributor , or your service representative, or the

Raymarine T echnical Services Call Center. Refer to the back cover

or the W orldwide Distributor List for contact detail s.

Page 53

Specifications 45

Specifications

Course computer specifications

Nominal supply voltage:

Type 150/150G

Type 400/400G

Operating voltage range:

Type 150/150G

Type 400/400G

Power consumption (standby) 300 mA

GyroPlus yaw sensor: • Type 150G/Type 400G: internal GyroPlus fitted onto circuit board

Operating conditions:

temperature range

relative humidity limit

water protection

Storage conditions:

temperature range

relative humidity limit

Dimensions:

width

height

depth

Weight 2.1 kg (4 lb 7.5 oz)

Inputs fluxgate compass, external GyroPlus yaw sensor, rudder position

Outputs NMEA 0183 v2.3 (x2), SeaTalk (x2), drive motor, drive clutch

Raymarine drive compatibility:

Type 150/150G

Type 400/400G

Drive motor output:

Type 150/150G

Type 400/400G

[specifications continue on next page]

12 V DC (fuse protected at 30 A)

12 V or 24 V DC (fuse protected at 40 A)

10 V to 16 V DC

10 V to 32 V DC