Rational Oven SCC101E Installation Manual

Installation Manual

Safety instructions

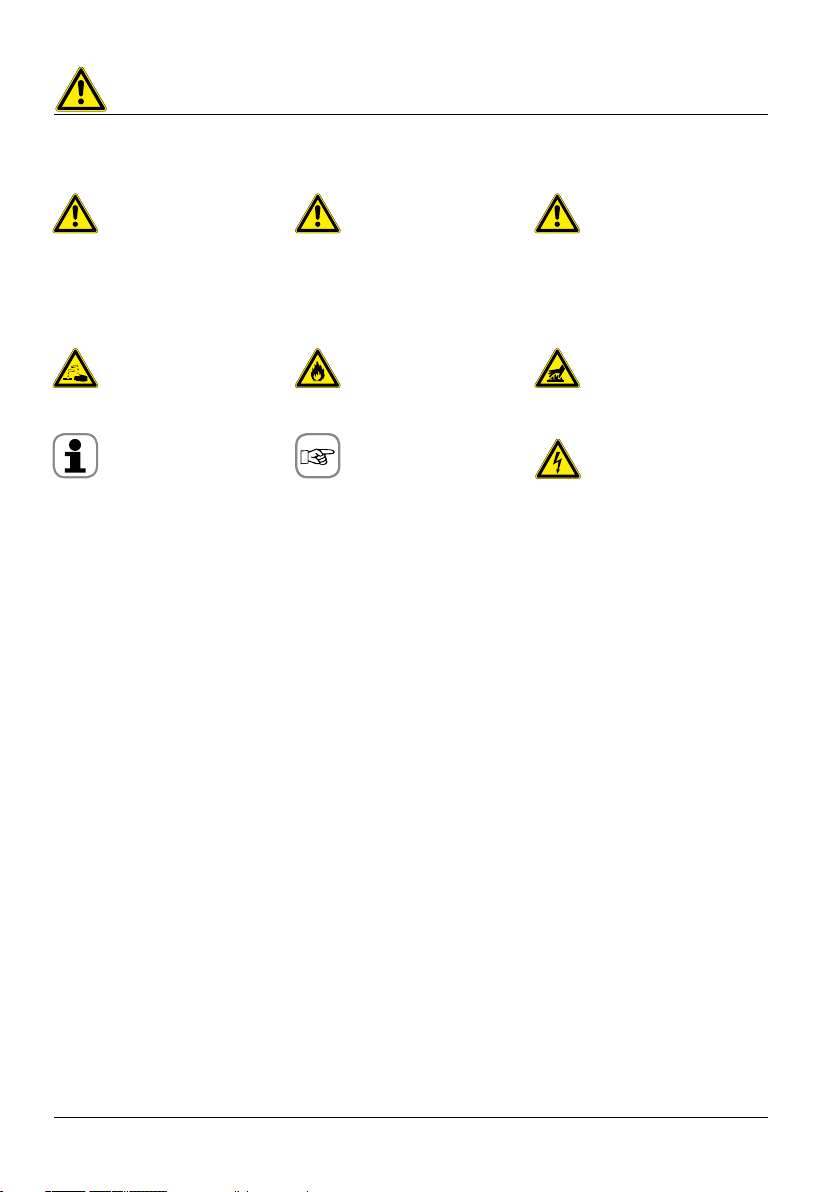

Explanations of the icon's

Danger!

Immediate dangerous situation,

that can endanger severe injury

or death

Corrosive substances

Attention: Inobservance can

cause material damages.

Warning!

Possibly dangerous situation,

that possibly can endanger

severe injury or death.

Fire hazard!

Tips and tricks for installation

Attention!

Possibly dangerous situation,

that can engender minor injury.

Danger of burning!

Danger!

High voltage.

Caution danger of life

Inobservance can endanger

severe injury or death.

- 2 -V-13

Safety instructions

Warning!

Wrong installation, service, maintenance or cleaning as well as unauthorized changes on the unit can

cause damages, injuries or even death. Read the installation manual carefully before installing the unit.

This unit may only be used for preparing food in commercial kitchens. Every other usage is against

definition and therefore dangerous.

Warning!

Only gas units

- As the unit must be installed underneath an extraction hood, it must be made sure that the hood is

switched on during operation of the unit – exhaust gases!

- Don't put any material on the exhaust pipes of the unit – Fire hazard!

- The area underneath the unit may not be blocked or closed by any material– Fire hazard!

- The unit may only be operated in a calm environment – Fire hazard!

Safety measures in case of smell of gas:

- Immediately close the gas supply.

- Don't touch any electrical switching element

- ventilation of the room.

- Avoid open flame or sparks

- Use an external telephone and inform your local gas authority (in case the local gas authority can not

be reached contact your local fire department immediately).

- 3 -

V-13

Dear customer

The warranty excludes glass damage, light bulbs and sealing material as well as damage caused by

improper use, installation, maintenance, repair or descaling

Quote in the event of a query:

Dealer

Appliance model:

Appliance no.:

______________________________________

Installer

Set to gas type:

______________________________________

Your appliance was checked by:

______________________________________

We reserve the right to make technical changes in the interest of progress!

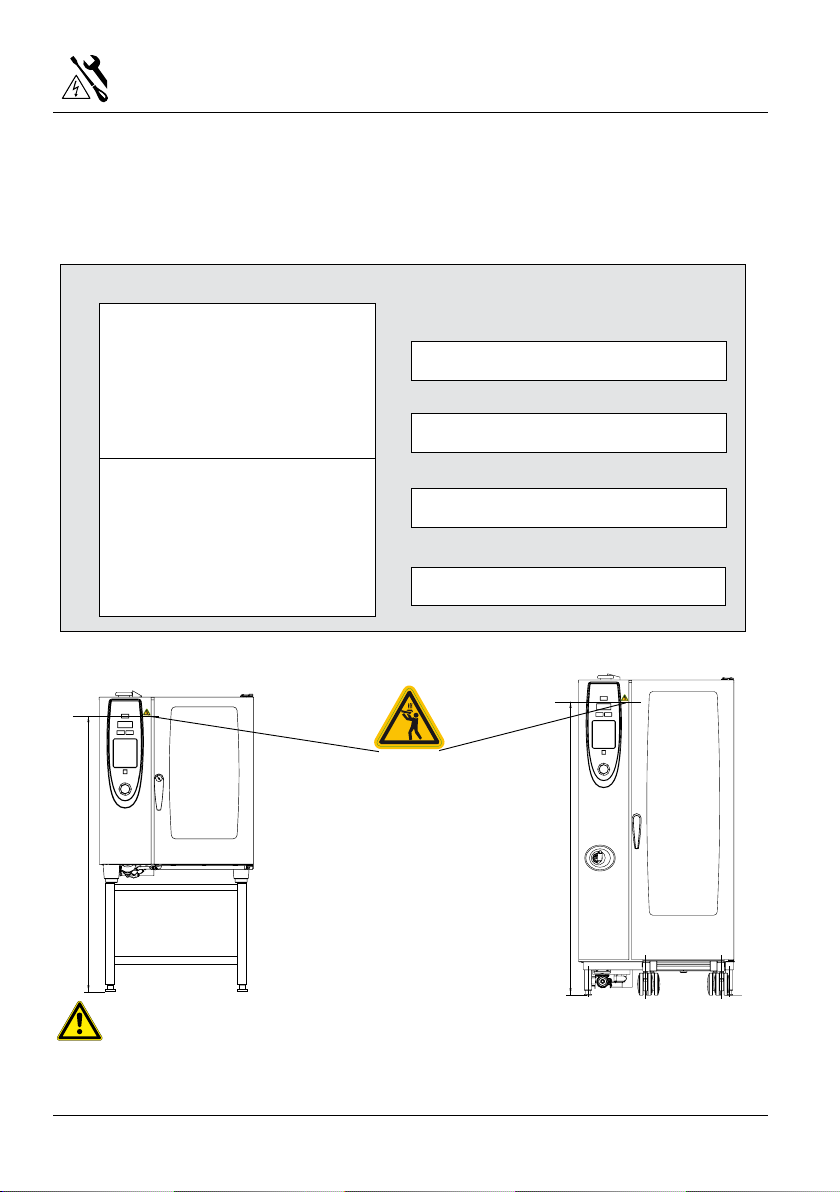

Safety stickers „Max. rack height for

)(63"1600

containers with liquid“ are in the Starter

)(63"1600

Kit.

After Installation of the unit, this sticker

has to be fixed to the unit in a height of

1600 mm (see examples)

Warning

To avoid scalding, do not use loaded containers with liquids or cooking goods which becomes fluid by

heating in higher levels than those which can be easily observed.

Danger of scalding!

- 4 -V-13

Installation instructions

Attention:

Follow the local standards and valid instructions. Damages based on installation not complying with the directives given hereunder are not covered by warranty terms.

The required connections (water, electric and gas) may only be carried out by trained/

qualified personal in accordance with the local regulations.

Check for any transport damage.

Should there be any signs of transport damage, inform your dealer/freight forwarder

immediately! Remove all cartons, packing materials, documents, etc. from the exterior AND

interior cabinet.

Dumping of old units.

At the end of its service life, the unit must not be disposed of with the general waste and must not be

placed in the recycling containers at local authority collection points.

We will be happy to help you with the disposal of your unit.

First time commissioning

valid for SelfCooking® Center with CleanJet+Care

When commissioning your new, intelligent SelfCooking Center® for the first time, you will be asked to

start an automatic self test. The duration of this self test is approximately 15 minutes and is necessary to

adapt the SelfCooking Center® to the specific environmental conditions.

m

Fire hazard!

Remove packing material, starter kit as well as

containers and grids from

intereior cabinet.

Leave hinged racks respectively mobile oven racks inside the cabinet, Interior cabinet door must not be

opened during the complete process of the self test. Opening the interior cabinet door interrupts the

self test and when switching on the unit the next time you will be asked to start the self test again.

This procedure does not apply to Combi Master units.

close cabinet door Press Start-key, Self test is run-

11:30 11:29

Start

s

Start

ning, remaining running time is

shown

- 5 -

m

s

V-13

Table of content

Safety instructions 2

Safety instructions 3

Dear customer 4

Installation instructions 5

Table of content 6

Table of content 7

Transport of units 8

Recommended minimum clearance 9

Installation type 6x1/1, 6x2/1, 10x1/1, 10x2/1 GN 10

Installation type 6x1/1, 6x2/1, 10x1/1, 10x2/1 GN 11

Installation Type 20x1/1 GN, 20x2/1 GN 12

Levelling mobile oven racks 20x1/1 and 20x2/1 GN 13

Electrical connection 14

Electrical connection 15

Water connection CareControl 16

Water connection 17

Selection of water filter 18

Selection of water filter 19

Gas consumption 20

Gas connection 20

Gas connection 21

Drain connection 22

Ventilation, technical data, heat emission 23

Option 24

Option 25

Option 26

Mobile floor models 20x1/1GN and 20x2/1GN 27

Mobile floor models 20x1/1GN and 20x2/1GN 28

Mobile floor models 20x1/1GN and 20x2/1GN 29

Mobile floor models 20x1/1GN and 20x2/1GN 30

Mobile floor models 20x1/1GN and 20x2/1GN 31

Mobile floor models 20x1/1GN and 20x2/1GN 32

Connection data USA/Canada 33

Connection data Europe 34

Conversion tables 35

- 6 -V-13

Table of content

Schematic drawing 6x1/1 GN CareControl 36

Schematic drawing 6x1/1 GN Gas CareControl 37

Schematic drawing 6x2/1 GN CareControl 38

Schematic drawing 6x2/1 GN Gas CareControl 39

Schematic drawing 10x1/1 GN CareControl 40

Schematic drawing 10x1/1 GN Gas CareControl 41

Schematic drawing 10x2/1 GN CareControl 42

Schematic drawing 10x2/1 GN Gas CareControl 43

Schematic drawing 6x1/1 GN 44

Schematic drawing 6x1/1 GN Gas 45

Schematic drawing 6x2/1 GN 46

Schematic drawing 6x2/1 GN Gas 47

Schematic drawing 10x1/1 GN 48

Schematic drawing 10x1/1 GN Gas 49

Schematic drawing 10x2/1 GN 50

Schematic drawing 10x2/1 GN Gas 51

Schematic drawing 20x1/1 GN 52

Schematic drawing 20x1/1 GN Gas 53

Schematic drawing 20x2/1 GN 54

Schematic drawing 20x2/1 GN Gas 55

Schematic drawing 20x1/1 GN Electric, mobile 56

Schematic drawing 20x1/1 GN Gas, mobile 57

Schematic drawing 20x2/1 GN Electric, mobile 58

Schematic drawing 20x2/1 GN Gas, mobile 59

- 7 -

V-13

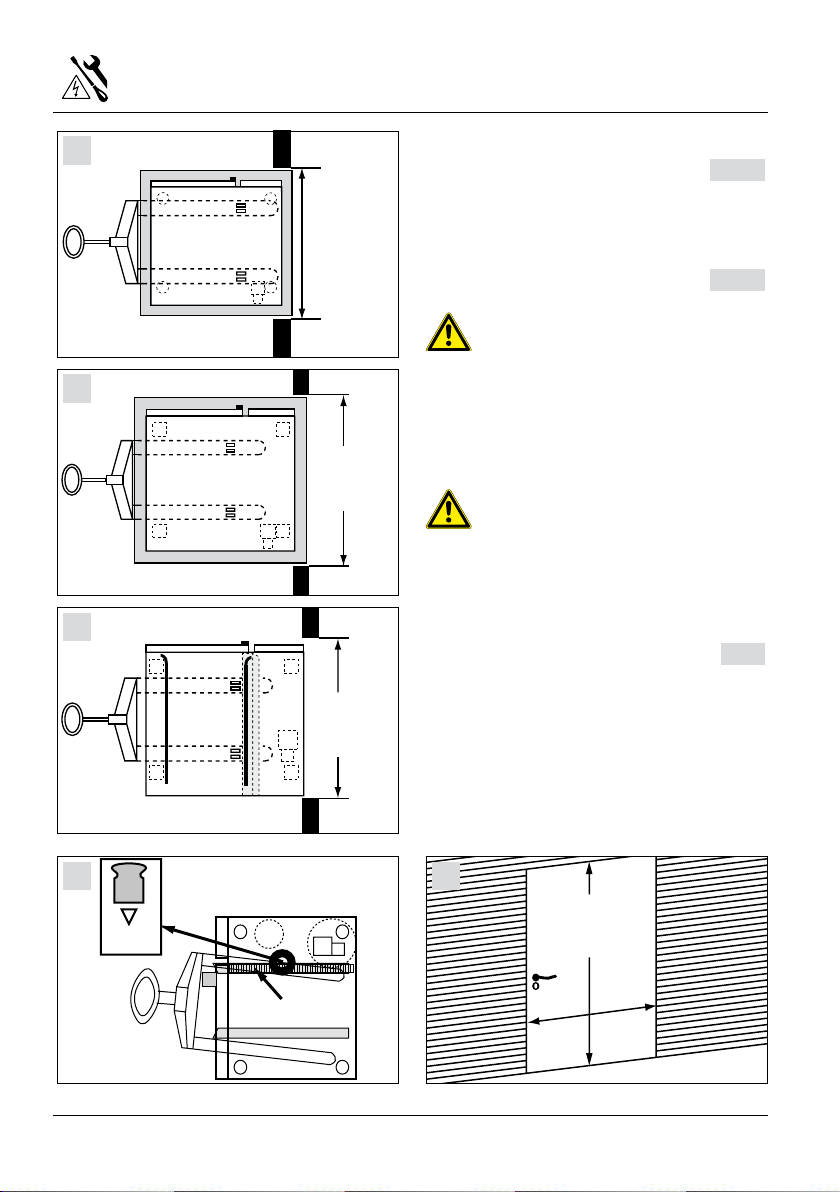

Transport of units

1

6x1/1 GN:

920mm/36 1/4"

6x2/1 GN:

1120mm/44 1/8"

10x1/1 GN:

920mm/36 1/4"

10x2/1 GN:

1120mm/44 1/8"

Transport of units

Transport of units using a pallet pic. 1,2

Transport of units without a pallet, 20x1/1 GN

and 20x2/1 GN units only. Put a piece of wood

between pallet jack and left guide rail of

the trolley pic. 3,4

Attention

Make sure that the unit is secured against

2

tilting, when transporting it.

Remove all containers/mobile oven racks from the

20x1/1 GN:

950mm/37 1/2"

20x2/1 GN:

1150mm/45 1/4"

cabinet. For floor model, remove corner mountings

from the pallet. Take unit off the pallet.

Attention

Observe the weight of the units.

Use carrying aid to avoid injuries.

Wear safety boots.

Weight see technical data on page 23

3

Observe door height pic. 5

X= Required door width when transporting units

20x1/1 GN:

920mm/36 1/4"

20x2/1 GN:

1140mm/45"

without pallet:

6x1/1GN 33 1/8” (840 mm)

6x2/1GN 41” (1040 mm)

10x1/1GN 33 1/8” 840 mm)

10x2/1GN 41” (1040 mm)

20x1/1GN 36 1/4” (920 mm)

20x2/1GN 45“ (1140 mm)

4

Center

of Gravity

F

r

o

n

t

D

o

o

r

2x2", 50x50mm

5

20x1/1 GN /

20x2/1 GN:

1900mm/75"

X (6x1/1 - 20x2/1GN)

- 8 -V-13

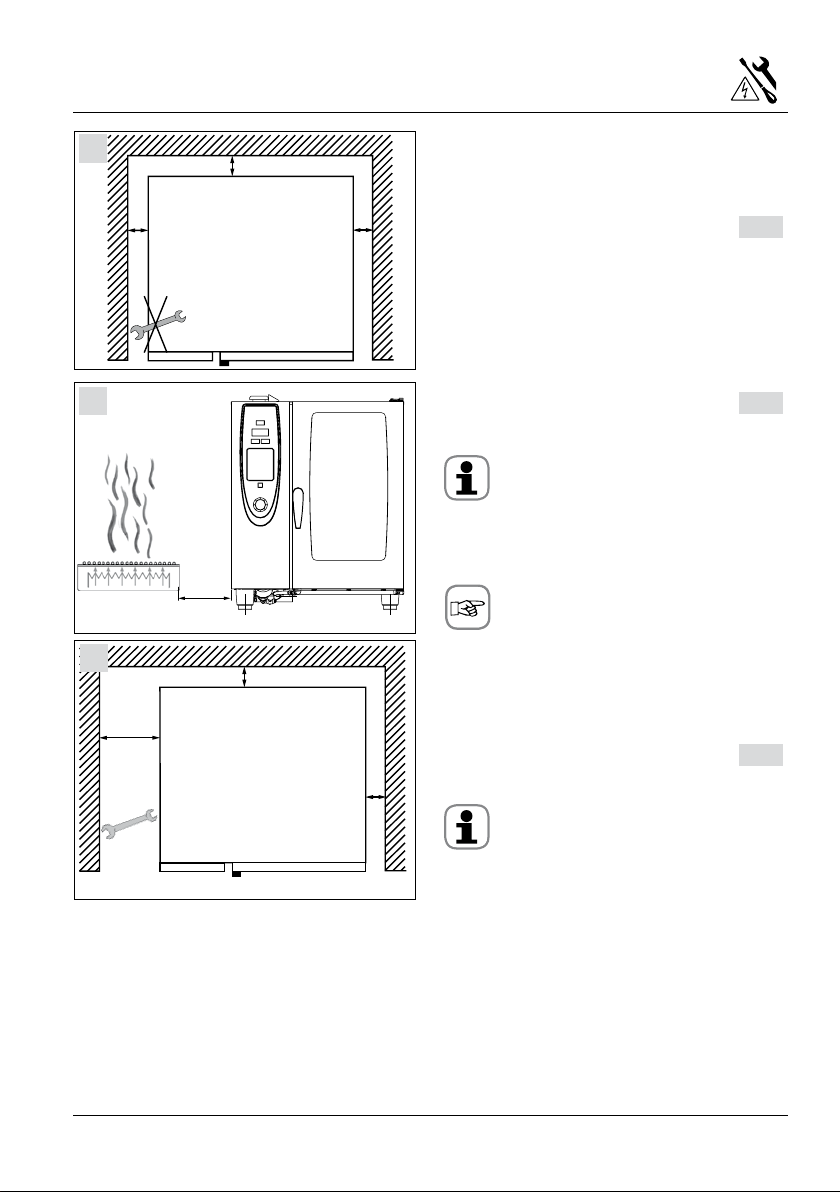

Recommended minimum clearance

1

2

3

50mm/2" 50mm/2"

≥ 350mm

14"

500mm/

20"

50mm/2"

50mm/2"

Minimum clearance left/ right/ rear 2” (50 mm)

(except floor models). If on castered stand with

flexible connections, that allow unit to be moved

forward while still connected to gas/ele. water

pic. 1

On floor models (20x1/1 GN and 20x2/1 GN) there

must be a minimum clearance of approx 20”

(500 mm) on the left side of the unit, for installing

the power cable.

Minimum clearance when there are heat sources

on the left-hand side is 14” (350 mm). pic 2

Attention:

A safety shut down can occur if the ambient

temperature on the left hand side of the unit is

too high.

Option:

Heat shield see page 24

We recommend a distance of 500 mm (20”) on the

left hand side of the unit for carrying out

maintenance work. pic. 3

50mm/2"

Attention:

- Do not install deep fat fryer at the rear of the

unit.

- The units must only be installed in frost-free

rooms.

- 9 -

V-13

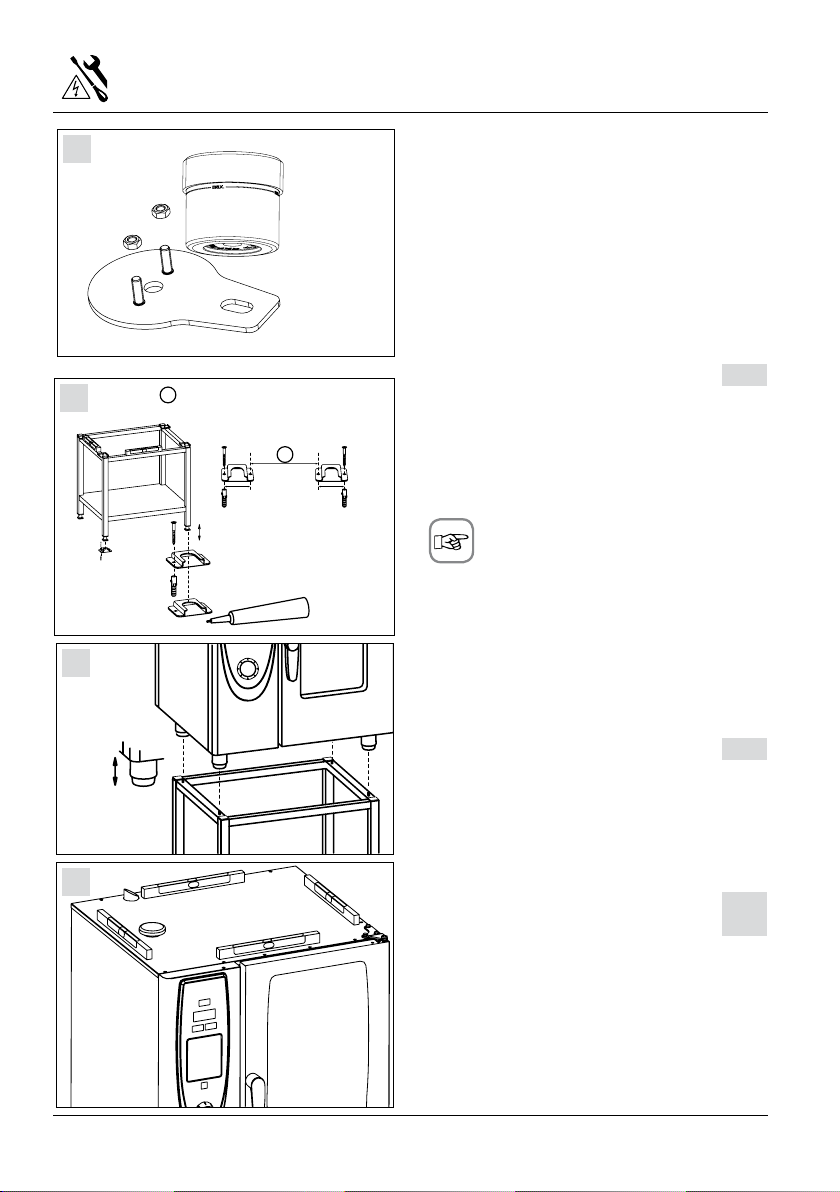

Installation type 6x1/1, 6x2/1, 10x1/1, 10x2/1 GN

1

2

3

+_ 10mm

A 6x1/1 /10x1/1 GN: 745,5mm (29 3/8")

6x2/1 10x2/1 GN: 965,5mm (38")

A

5006.0213

64,5mm

2 5/8"

64,5mm

2 5/8"

+_ 10mm

Because of safety reasons table units shall only be

installed on original stands of the manufacturer.

In this case the maximum rack height is

1600 mm (63")

If Gas units are installed on a table or on the

kitchen floor (combi duo) then:

a) press the retaining plates (ET-No.:12.00.519)

into the lower part of the pedestal and fasten

with the enclosed nuts.

b) the plate must be fitted to the surface using

either screws and dowels or studs and nuts or

the special adhesive. pic. 1

Retaining plates are not included in the scope

of supply

Attention: The center height of the drain pipe is

2 1/2” (63 mm). When installing combi duo

observe the drain height of the bottom unit.

Option:

Using 4” (100 mm) legs and height adjustable transport trolley for extended space

underneath unit. See page 24

Stands of gas appliances must be fixed to the floor

using the fixing set part no.: 8700.0317 either with

screws and dowels, or with the special

adhesive supplied unless unit is connected using

AGA/CGA approved flexible connections. pic. 2

Fixing set is not included in the scope of supply

Slide the stand into the fixing brackets and level it.

Place the unit on the stand. The feet of the unit

4

must be secured by means of the locating pins of

the stand pic. 3

Ensure that the unit is level pic. 4

Attention: When Installing a Combi Duo observe

the height of the drain pipe

.

- 10 -V-13

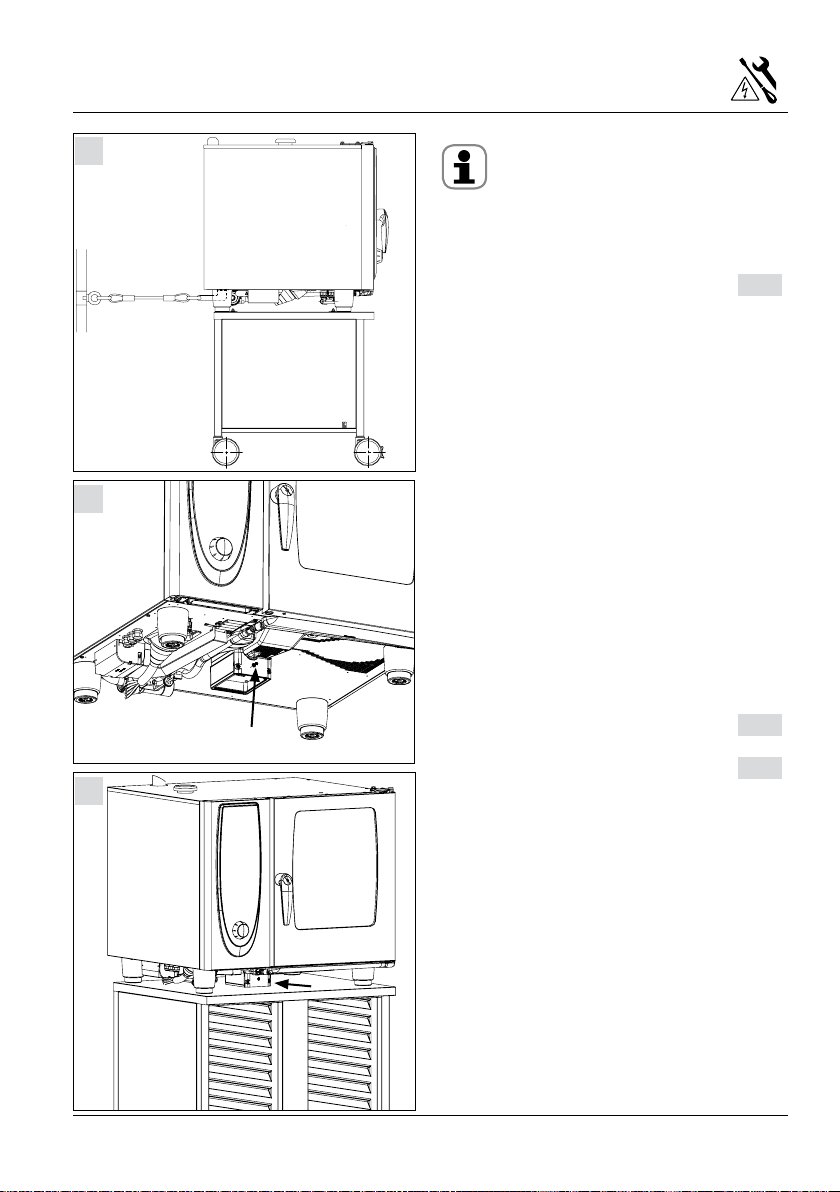

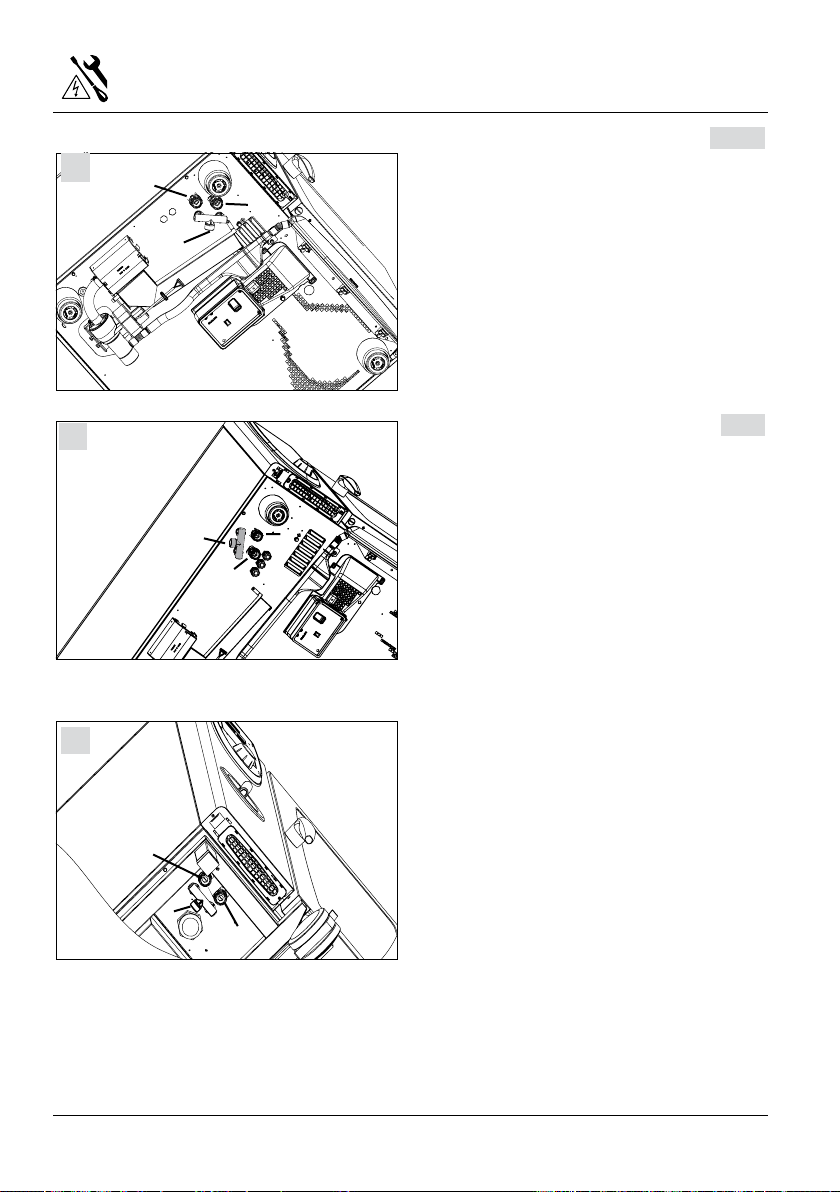

Installation type 6x1/1, 6x2/1, 10x1/1, 10x2/1 GN

1

Attention:

If the unit is mounted on a mobile stand or base

cabinet, the unit must be additionally secured

against slipping by a chain or cable in order to prevent damage to the electricity, water or gas supply

line pic. 1

2

Only valid for SelfCooking Center with Carecontrol

produced as of 28.09.2008:

At the bottom side of the SelfCooking Center a

cover over the care pump is installed. This cover is

secured in the upper position during transportation. If the SelfCooking Center will be installed on

a table or on base cabinet then the cover must be

lowered.

- Loose the screw at the front side of this cover

pic. 2

- Cover must lay on the table respectively on the

top of the base cabinet. pic. 3

3

- 11 -

V-13

Installation Type 20x1/1 GN, 20x2/1 GN

1

2

+_ 10mm

A 20x1/1 GN: 732,5 mm / 28 7/8"

20x2/1 GN: 937,5 mm / 37"

A

64,5mm

2 5/8"

64,5mm

2 5/8"

3

5006.0213

Ensure that the unit is level pic. 1

Fix the floor locks, of the supplied fixing set, to the

floor with either screws and pins or with the

special adhesive. pic. 2

Next slide the unit into the floor locks pic. 2

The mobile oven rack must be level when

standing inside the unit pic. 3

Attention: Observe height of the drain pipe

Option:

Using leg extension for more space underneath unit.

Install height extension for mobile oven

rack see page 25

- 12 -V-13

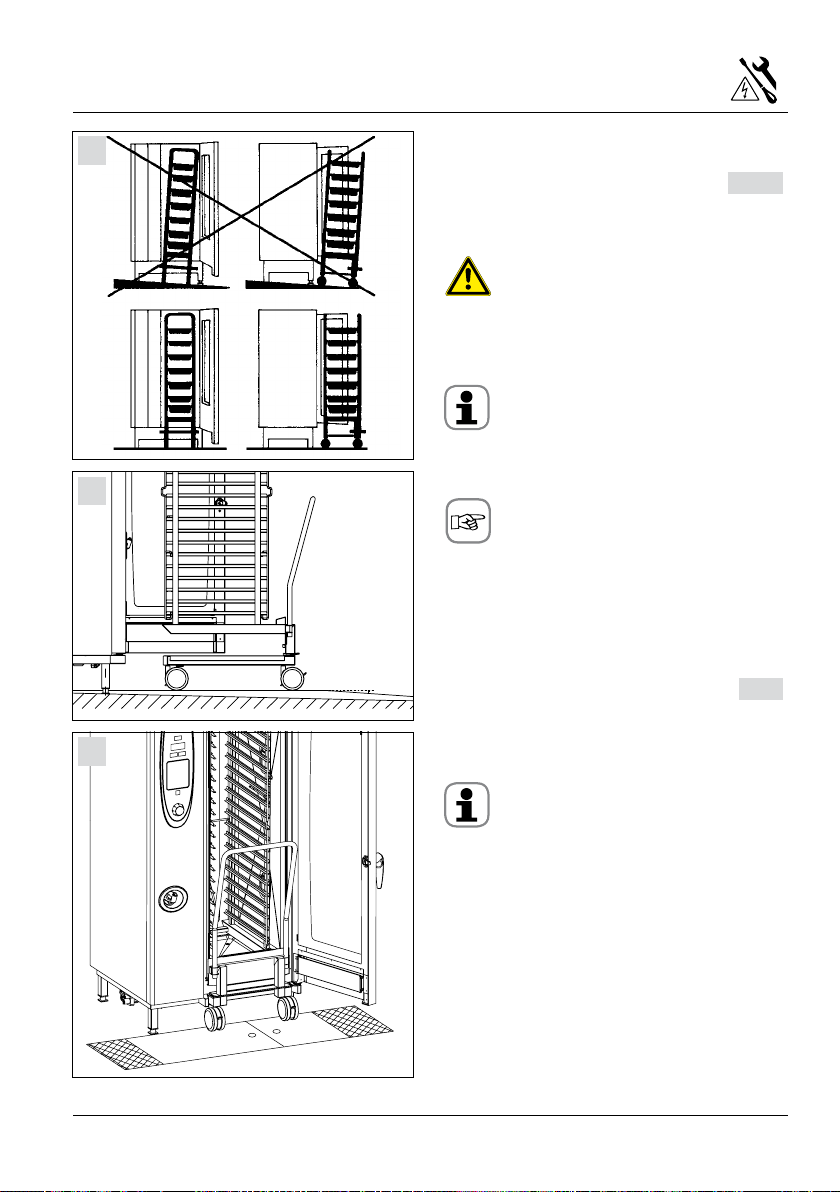

Levelling mobile oven racks 20x1/1 and 20x2/1 GN

1

If the floor is not level, an access ramp (not

supplied) will be required. The incline must not

exceed 4°. pic. 1,2

Warning:

If the incline exceeds 4°, hot cooking liquid

can spill out of the cooking containers.

Danger of scalding!

Attention:

An incorrect levelled trolley can cause malfunction

during operating the unit (e. g. during Cleanjet)

2

Option:

Access ramp see page 25

If there is a drain grill in front of the floor unit, a

max 4

ramp should be placed over it to enable the

mobile oven rack to be used. pic. 3

3

Attention:

Ensure that cover extends to left of the unit to prevent moisture (water, vapor) from entering air filter

- 13 -

V-13

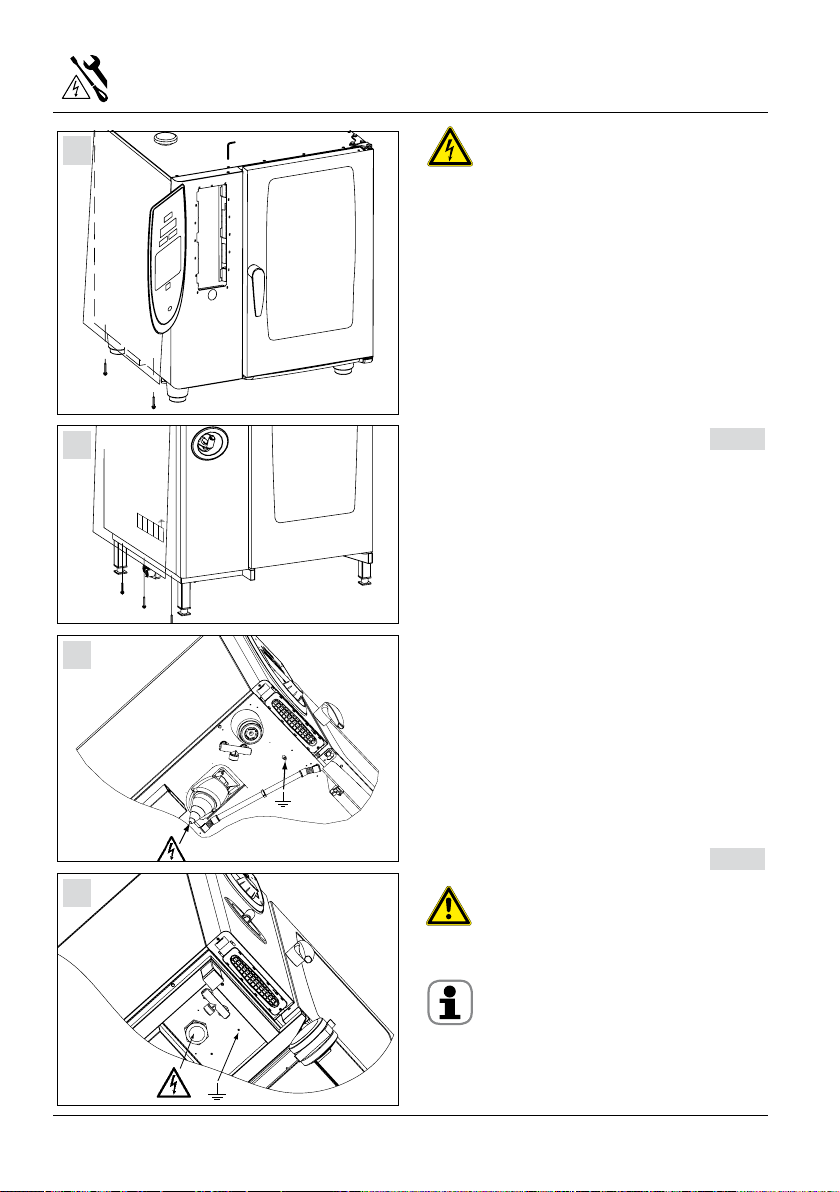

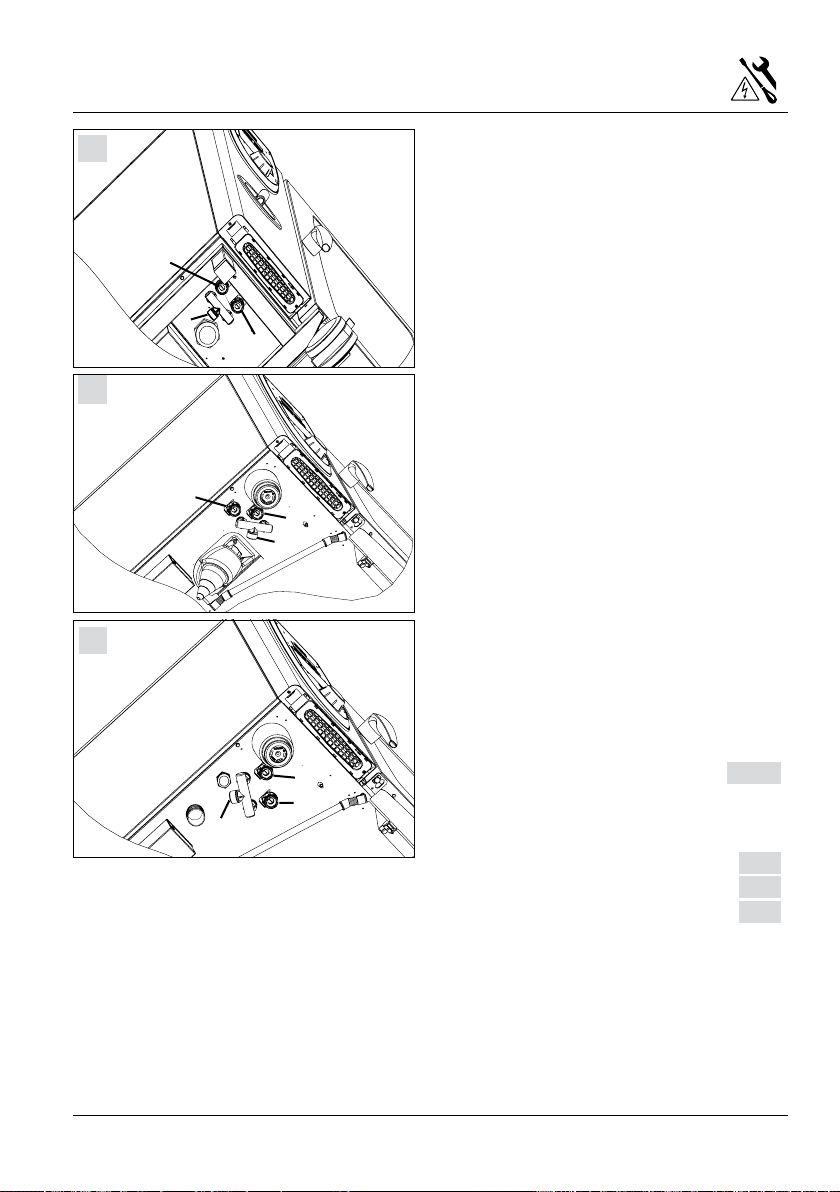

Electrical connection

1

5 mm

Attention:

Observe local regulations and standards

during installation!

Common information see next page

Electrical units

s¬¬%ACH¬APPLIANCE¬REQUIRES¬AN¬INDEPENDENT¬FUSED¬

power supply line (common phase circuit braker)

s¬¬!¬PERMANENT¬ELECTRICAL¬CONNECTION¬MUST¬BE¬PRO-

vided for the units.

s¬¬!LL¬UNITS¬ARE¬DELIVERED¬WITHOUT¬POWER¬CABLE

s¬&OR¬CONNECTION¬USE¬POWER¬CORD¬.%#¬5,¬STANDARD

s¬¬4HE¬MAIN¬CONTACTOR¬TABLE¬UNITS¬RESPECTIVELY¬THE¬

main terminals (floor models) are located in the

electrical compartment and are accessible after

2

removing the left side panel. pic. 1/2

Gas units

s¬ ¬7E¬RECOMMEND¬AN¬INDEPENDENT¬FUSED¬POWER¬

supply line

L

L

1

L

2

N

3

s¬ ¬!LL¬UNITS¬ARE¬EQUIPPED¬WITH¬A¬POWER¬CABLE¬

(standard 5-15P 120V IP) with plug, approx. 8 ft

(2,5 m) long

s¬¬3HOULD¬THE¬UNIT¬BE¬CONNECTED¬VIA¬A¬MAINS¬PLUG¬

make sure it is accessible. Otherwise provide

accessible all-pole disconnection device with a

minimum of a 3 mm contact gap.

3

s¬¬!TTENTION

Observe polarity of the mains!

No burner function with wrong polarity!

s¬¬#OLOUR¬CODING¬OF¬THE¬POWER¬CABLE¬

green = earth, white = Neutral

black = Phase L1

Gas and electrical units

s¬¬4HE¬STUD¬FOR¬THE¬EARTH¬BONDING¬IS¬LOCATED¬ON¬THE¬

bottom side, underneath the control panel, of the

unit. Connect the wire for the earth bonding

to this stud. pic. 3/4

4

Warning

Observe colour coding of the wires. Wrong

connection can cause electric shock

Attention:

Wrong connection can cause damages (e. g. fan

motor)

- 14 -V-13

Electrical connection

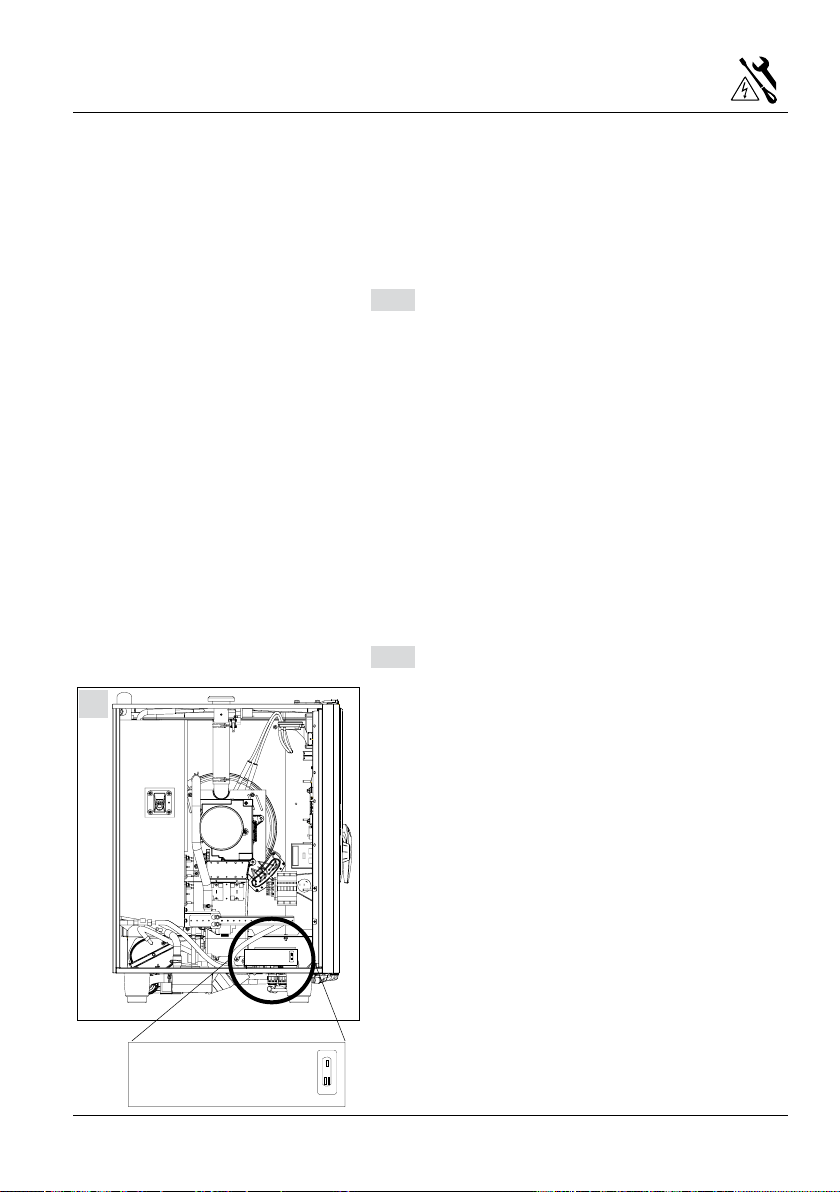

Voltage Conversion of electric units

208/240V units:

Units are set to 208 V ex works, but can be converted to 240 V.

To convert from 208V to 240 V proceed as follows:

- Disconnect unit from mains

- Remove left side panel.

- Set power switch S13 to desired voltage

(208 or 240 V) pic. 5

- On the control transformer change connection to

the desired voltage input (208 or 240 V)

- In the starter kit of the unit there is a sticker

which has to be filled in after voltage conversion.

After filling it in put the sticker next to the type

plate

440/480 V units

Units are set to 480 V ex works, but can be converted to 440 V.

To convert from 480V to 440 V proceed as follows:

- Disconnect unit from mains

- Remove left side panel.

Remove adapter cable W22 from input transformer

T3 and plug X72.

- Connect plug X72 to transformer T3.

- Set power input switch S 13 to 440 V pic. 5

5

Common information

s¬ ¬&OLLOW¬THE¬INSTALLATION¬INSTRUCTIONS¬AND¬THE¬

information on the rating plate when connecting the unit

s¬ ¬#OMPLY¬WITH¬ALL¬LOCAL¬REGULATIONS¬AND¬STANDARDS

which must conform to national, state and local

code requirements.

s¬ ¬7E¬RECOMMEND¬AN¬INDEPENDENT¬FUSED¬POWER¬

supply line for each appliance. Use of a common trip 2 pole or 3 pole circuit breaker or

3 pole fuse box with common trip is recommended to ensure safety.

s¬ ¬¬5NITS¬MUST¬BE¬CONNECTED¬TO¬AN¬EARTH¬LEAKAGE¬

circuit breaker. Consult with the NEC code for

specific values according to KW of attached

load for selection

s¬ ¬¬.OTE¬CONNECTION¬TO¬A¬RESIDENTIAL¬TYPE¬'&)¬OF¬

insufficient leakage current is not advisable,

random and or nuisance trips of the breaker

could result

s¬ ¬/NSITE¬INSTALLATION¬PROVIDE¬ACCESSIBLE¬ALLPOLE¬

disconnection device with a minimum of a 3

mm contact gap

s¬ ¬4HE¬CIRCUIT¬DIAGRAM¬IS¬LOCATED¬ON¬THE¬INNER¬SIDE¬

of the left side panel.

s¬ 3PECIAL¬VOLTAGE¬AVAILABLE¬ON¬REQUEST

s¬ ¬¬3EE¬CHART¬ON¬PAGE¬¬FOR¬WIRE¬SIZING¬

s¬ !PPLICABLE¬STANDARDS¬.&0!¬.%#¬#3!¬#

s¬ &OR¬ELECTRICAL¬CONNECTION¬DATA¬SEE¬PAGES¬

s¬¬"EFORE¬PULLING¬OUT¬MAINS¬PLUG¬OR¬RECONNECTING¬IT¬

again be sure the unit is switched off.

For appliance connections, precise dimensions and connection points, see pages 36

and following.

S 13

Power cable :

s¬¬4HE¬EXCHANGE¬OF¬THE¬POWER¬CABLE¬MAY¬ONLY¬BE¬

carried out by the service agents, qualified electricians or similar qualified personal

Electrical units

208V

440V

480V

240V

s¬¬&OR¬CONNECTION¬USE¬POWER¬CORD¬.%#¬5,¬STANDARD

s¬¬#ONNECT¬THE¬SUPPLY¬AS¬FOLLOWS

Grey terminal:

L1, L2, L3 (non-phase-sequence-dependent)

Yellow/green terminal: Earth connection

Gas units:

208 V

440 V

480 V

240 V

s¬¬)N¬CASE¬THE¬POWER¬CABLE¬HAS¬TO¬BE¬EXCHANGED¬

make sure to use one, that matches your local

standard (5-15P 120V IP)

- 15 -

V-13

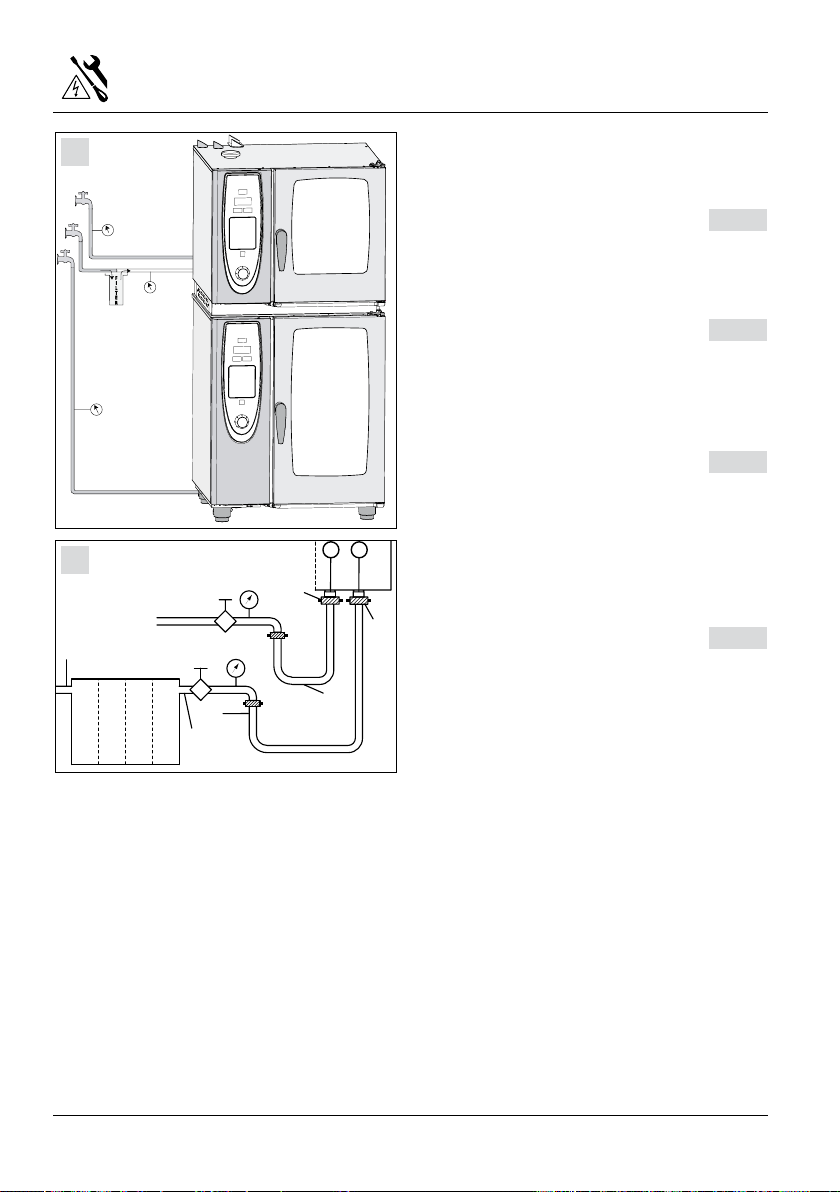

Water connection CareControl

6x1/1GN - 10x1/1GN E/G

1

3

2

1

6x2/1GN - 10x2/1GN E/G

2

1

20x1/1GN - 20x2/1GN E/G

3

2

3

3

1

2

Legend to water connections valid for: pic. 1/2

- SelfCooking Center table units with

Carecontrol manufactured as of

28.09.2008:

1 = Common water supply 3/4”

cold water 30°C/86°F

In case of split water connection

2 = Cold water supply 3/4”

(for quenching and hand shower 30°C/86°F).

3 = Treated water connection 3/4”

(steam generator, moistening, cleaning,

max. 60 °C/140°F).

Legend to water connections valid for: pic. 3

- SelfCooking Center table units with

Carecontrol manufactured as of

28.09.2008:

1 = Common water supply 3/4”

cold water 30°C/86°F

In case of split water connection

2 = Cold water supply 3/4”

(for quenching and hand shower 30°C/86°F).

3 = Treated water connection 3/4”

(steam generator, moistening, cleaning,

max. 60 °C/140°F).

The appliance must be connected to the facility

water supply with a supply hose that conforms to

EN 61770 resp. IEC 61770 or of similar quality.

The water supply hose must fulfill the local and/or

hygiene requirements for hoses in drinking water

systems for the respective area or municipality.

s¬¬)NSTALL¬INDIVIDUAL¬SHUTOFF¬VALVE¬FOR¬EACH¬

appliance

s¬¬¬2INSE¬THE¬WATER¬SUPPLY¬LINE¬PRIOR¬TO¬CONNECTION¬

to the unit!

s¬¬#ONNECTED¬WATER¬PRESSURE¬MUST¬BE¬IN¬THE¬RANGE¬

21,75 - 87 psi, recommended 43,5 psi

- 16 -V-13

Water connection

4

3

1

2

5

3

2

1

6

Maximum flow rate

6x1/1, 10x 1/1: 5,3 gal/min

6x2/1, 10x2/1, 20x1/1, 20x2/1: 6,6 gal/min

Average total water consumption is as follows (values excluding usage of hand shower)

6x1/1 6x2/1 10x1/1 10x2/1 20x1/1 20x2/1

3,2 8,5 6,6 11 13,1 15,8

gal/h gal/h gal/h gal/h gal/h gal/h

Note:

The manufacturer recommends especially on model

Combi Master a preventive check of your

equipment 6 months after installation to determine

actual scale build up.

This should be done by a trained technician.

s¬¬7ATER¬TREATMENT

For filter selection see pages 18/19

s¬¬4REATED¬WATER¬WITH¬A¬WATER¬HARDNESS¬LESS¬THAN¬

5 gr/gal must not be supplied, because such

water can react aggressive and corrosive which

can reduce the life cycle of the unit.

Connecting SelfCooking Center to water with

hardness less than 7,3 gr/gal.:

To avoid an excessive build up of foam the soft

water switch should be set to "ON" in the basic

settings. This can be done by a trained technician.

2

3

1

Legend to water connections valid for: pic. 4-6

- SelfCooking Center without Carecontrol

manufactured up to 27.09.2008:

- Combi Master

Floor models pic. 4

Table models electric pic. 5

Table models gas pic. 6

1 = Common water supply 3/4”

cold water max. 30°C/86°F

In case of split water connection

2 = Cold water, max 30°C/86°F, connection 3/4”

(quenching)

3 = Treated water connection 3/4”

(steam generator, moistening, hand shower,

max 60°C/140°F)

- 17 -

V-13

Selection of water filter

1

30C/86F

300 kPa

43,5 psi

F

I

L

T

E

300 kPa

R

43,5 psi

max. 60C/140F

30C/86F

300 kPa

43,5 psi

2

150-600kpa

21,75-87 psi

R 3/4"

2 3

Please consult your local water supply

provider for advise on chlorine (Cl2),

chloride (Cl-) and hardness of the water.

A)Particle filter pic. 1/2

When the water contains sand, iron particles or

suspended matter, we recommend a 5-15 μm

(micro meter) particle filter:

B)Active carbon filter pic. 1/2

When the level of chlorine (Cl2) in the water

exceeds 0,012 gr/gal (=0,2 ppm) (information

available from the water company), an active carbon filter should be installed.

C)Complete De-Ionization pic. 1/2

When the water has a chloride Cl- concentration

above 4.68 gr/gal (= 80 ppm), a complete

deionization system should be installed to avoid

corrosion.

Note: Make sure a remaining conductivity of

50 μS/cm (micro Siemens) remains in the water.

3/4"

A B C D

150-600kpa

21,75-87 psi

1/2"

3/4"

1/2"

max. 60°C

max. 140°F

R3/4"

D)Water softener: pic. 1/2

Valid for SelfCooking Center with

Carecontrol:

These models will remove scale all by itself providing that the units are used as prescribed.

These means a water softener is not needed.

Valid for SelfCooking Center without

Carecontrol and Combi Master:

A water softener is recommended when a high

level of scale (not containing chloride) is

experienced. Systems recommended: H+ Ion

Exchanger or Kleensteam. Sodium ion

exchangers (as used in dishwashers) must not

be used.

Treated water with a water hardness less than5

gr/gal must not be supplied, because such water

can react aggressive and corrosive which can

reduce the life cycle of the unit.

Amongst others the following filter manufacturers

offer adequate filter applications:

Britta, Cuno, Everpure, Selecto, Scientific

- 18 -V-13

Loading...

Loading...