Rational Oven CM101E Service Manual

Training Manual

SCC Line

SelfCooking Center - Combi Master

Edition 09-2007

Training Manual

SCC Line

Edition 09 - 2007

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electric safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailedue gas analysis MUST be done using adequate CO and CO2 measuring equipment! This shall ONLY be done by trained technicians! Always check appliance for possible gas leakages!

Part1: CM Technology |

|

CM Technique from 04 - 2004 |

4 |

Water level control Steam Generator |

6 |

RATIONAL SC Automatic |

7 |

Steam Control CM |

8 |

Additionaly functions CM from 04 - 2004 |

10 |

CM PCB (42.00.004) |

12 |

Motor for CM 40.00.274 |

13 |

CM - Sequence of events |

14 |

Service level CM from 04 - 2004 |

19 |

Service level: dP -- Diagnostic Program |

20 |

Service Level: ER -- Error code history |

21 |

Failure Codes CM „ER“ |

22 |

Service Level: rt -- Running Time |

23 |

Service level: SE -- Basic settings |

24 |

Service level: SE -- Function test |

26 |

CM Gas from 04 - 2004 |

28 |

Identification of the different gas burners / Gas blowers: |

29 |

Sequence of events of Burner and Ignition control |

30 |

Changing installation altitude: CM gas |

32 |

Checking of dyn. input gas flow pressure |

33 |

Flue gas analysis |

34 |

Changing Gas blower speed |

37 |

Burner adjustment |

38 |

Part2: SCC Technology |

|

SCC Control Panel |

39 |

Display up to Software version SCC 01-07-12 |

40 |

Display since Software version SCC 02-01-01 |

42 |

Display Programming / CleanJet SCC 02-01-01 |

44 |

SCC Electric from 04-2004 |

46 |

SCC Operator pcb (42.00.002) |

48 |

I/O PCB SCC (40.00.049) |

49 |

Motor for CM 40.00.274 |

50 |

Humidity control SCC |

51 |

Service level SCC |

60 |

SCC Diagnostic Mode |

61 |

SCC Running Times |

65 |

Basic Settings |

69 |

RESET |

73 |

Function test |

74 |

Download of unit service data |

78 |

HACCP |

82 |

Service messages |

84 |

Calibration SCC |

88 |

Control Drain Valve 54.00.357 |

90 |

SCC Gas |

|

SCC Gas from 04-2004 |

92 |

Identification of the different gas burners / Gas blowers: |

94 |

Sequence of events of Burner and ignition control |

95 |

Gas conversion : SCC Gas |

96 |

Adjustment of installation altitude above sea level |

97 |

Flue gas analysis: SCC gas |

98 |

Burner adjustment |

100 |

Changing gas blower speed SCC Gas |

101 |

Part3: Common information |

|

Flash SCC Software |

102 |

Software update CM units |

104 |

User instruction electrical descaler pump |

108 |

RATIONAL Commissioning SCC-CM |

110 |

Preventative maintenance SCC / CM |

114 |

Water info |

118 |

Part4: Fault list SCC - CM |

120 |

Part5: Circuit diagram (Training version 3NAC 400V |

138 |

SCC Service reference |

192 |

S

C

M

CM Technique from 04 - 2004

Steam

Hot Air

Combi Steam

Low Temperature Steam

Finishing

Cool Down

Cabinet temperature display

Cabinet temperature display

Cabinet temperature setting

Timer

Core temperature

Time - Core temperature display

Time - Core temperature display

Time - Core temperature setting

-4-

CM Technique from 04 - 2004

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

S

C M

B1 |

Thermocouple cabinet |

B2 |

Thermocouple quenching / Steam control |

B3 |

Thermocouple core temperature |

B5 |

Thermocouple steam generator (preheating, 180°C (356°F) max) |

F3 |

Safety temperature limiter steam generator 160°C |

F4 |

Safety temperature limiter cabinet 360°C |

Y1 |

Solenoid valve lling |

Y2 |

Solenoid valve quenching |

M1 |

Fan motor (without jumper) |

M4 |

Pump SC-Automatic |

S2 |

Level electrode |

CM 201/202 only: |

|

M2 |

Fan motor top (with jumper) |

-5-

S

C |

Water level control Steam Generator |

M |

|

S2

B5 |

S2 |

V AC |

|

F3 |

|||

|

|

M4

M4

B2

Y1

Y2

Y2

Center S2 ==> Ground: |

2 - 6V AC: |

water level too low |

steam heating must switch OFF |

|

|

solenoid valve lling Y1 ON |

|

|

Center S2 ==> Ground: |

0V AC: |

water level reached |

steam heating can switch ON |

|

|

solenoid valve lling Y1 switched OFF |

X12 |

|

Every 2 minutes steam elements will switch off for water level control

Notes:

-6-

RATIONAL SC Automatic

During the production of steam, the concentration of minerals inside the steam generator will increase over time. These minerals settle on the heating elements and heat exchanger as well as the interior steam generator walls.

In order to reduce this effect the steam generator will be pumped off and ushed regularly depending on the duration of steam production. This process needs approximately 45 seconds.

After emptying the steam generator it will be lled automatically with fresh water.

There are 4 conditions to start this SC Automatic:

1.Heating time of the steam generator must exceed 60 min. (CM - 45 min.)* and

2.the temperature of the thermocouple inside steam generator (B5) must be below 65°C (149°F) and

3.the temperature of the thermocouple inside interior cabinet (B1) must be below 70°C (158°F) and

4.the unit is switched ON.

* - can be adjusted from 20-120min

In case the unit is used permanently the above mentioned temperature conditions can not be met.

S

C M

In this case the following 2 conditions apply:

1.The heating time of the steam generator reaches the twice the set duration*, i.e. 120 min. (CM - 90 min.) and

2.the unit door is open for longer than 30 seconds

After completion of the SC-Automatic the timer accumulating the steam heating time is re-set to zero.

-7-

S

C |

Steam Control CM |

M |

Intelligent steam control via quenching sensor |

|

|

B1 |

|

B2 |

Y1 |

Y2 |

1.Filling of interior cabinet based on time and temperature control of B2 quenching sensor

2.After steam saturation inside cabinet steam will also ll quenching chamber

°C / °F |

B1 - 100°C(212°F) |

3. Depending on the frequency of temperature |

70°C |

|

raise of the quenching sensor B2 the |

|

duration of the next steam supply is |

|

(158°F) |

B2 - 1 |

|

|

calculated. |

|

|

|

B2-1: B2 temperature with partial load |

|

B2 - 2 |

B2-2: B2 temperature with full load |

|

|

|

|

|

4. The amount of steam inside the cabinet is |

|

t (sec) |

|

|

directly depending on the temperature |

|

|

|

variation of quenching sensor B2. |

Notes:

-8-

|

|

|

S |

Notes: |

C |

||

|

|

|

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-9-

S |

C |

Additionaly functions CM from 04 - 2004 |

|

||

|

|

|

|

M |

|

Below are listed the additionaly functions for the user / operator:

1.Cleaning program

1)Cool down cabinet below 60°C

2)Spray inside cabinet with Rational cleaner

3)Close cabinet door

4)Select „Cool Down

5)Press core temperature key for 10 sec.

6) „CLEn“ will show in cabinet temperature display

7) Press timer key 1x; Cleaning program starts automatically (open cabinet door and rinse interior cabinet after 40 min.) Close door again. Since Software version C1-06-05 a 10 min step hot air will follow to dry the interior cabinet.)

8) After end of program, leave cabinet door open over night.

2. Empty steam generator

This should be done after each installation to verify free drain connection and prior to disconnection the unit for storage.

1)Open cabinet door

2)Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „SC“ with temperature dial

6) Close water tap

7) Press timer key 1x and remain on „Cool Down“ position for about 45 sec.

3.Descaling program

1)Open cabinet door

2)Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „CALC“ with temperature dial

6) Press timer key 1x and follow procedure of the decalci cation instruction. (See user manual CM).

-10-

Additionaly functions CM from 04 - 2004

S

C

M

4.Changing temperature display from °C to °F

1)Select any mode

2) Press timer and core temperature key simultaneously for 10 sec. until Display changes from °C to °F or vice versa

3) Release both keys

Notes:

-11-

S |

CM PCB (42.00.004) |

|

C |

||

|

||

M |

CM PCB (42.00.047) from 02-2006 (without transformer) |

|

|

42.00.004 |

0,1 AT |

2 AT |

F1 |

F2 |

Transformer |

X7 |

|

|

|

X19 |

|

1 |

|

X20 |

|

1 |

42.00.047

|

|

|

|

|

|

|

2 AT |

|||

|

|

|

|

X16 |

|

F6 |

||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

2 AT |

|

|

|

|

|

|

|

|||

F6.1 |

|

|

|

|

|

|

X7 |

|||

|

|

|

|

|

|

|

|

|

|

X19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X63

|

1 |

|

off |

3 2 |

on |

|

4 |

|

1

|

X20 |

|

1 |

|

X18 |

|

X23 |

|

1 |

|

X31 |

X30 |

RS 485 |

RS 232 |

|

|

|

X8 |

Temperature |

|

X12 |

|

1 |

|

potentiometer |

|

|

|

|

X26 |

|

X50 |

X27 |

|

1 |

|

|

|

X2 B3 Core temperature

X3 B1 Interior cabinet

X4 B2 Quenching / Steam control

X6 B5 Steam generator

X7 ON - OFF switch

X8 Buzzer

X12 Level electrode

X 16power supply from transformer (42.00.047)

X18 SC - pump

X19 Solenoid valves

X20 Energy optimising / Sicotronic

X23 Vent hood (signal door open / closed)

X24 SSR

X26 SSR pulsing (USA version only)

X27 Door contact switch

X30 Serial interface (RS232)

X31 BUS interface

X32 Timer / Core Temp. Potentiometer

X50 external EEPROM

X63 Not used

1 Counting sequence

X2 X6 X4 X3

1 |

|

|

X24 |

1 |

X32 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Since February 2006 PCB 42.00.004 is replaced by 42.00.047. (Conversion kit: 87.00.139, pls. see Technical info 04-06)

The transformer on the new PCB 42.00.047 is no more existing and replaced by external transformer 40.00.227

-12-

Motor for CM 40.00.274

Jumper

Jumper

LED

Jumper 40.01.581 is used on oor model 201 and 202 for top position motor only! Jumper is not used on models 61 - 102 with one motor only! (Service 34 will be shown!)

LED code fan motor SCC and CM from 04/2004

Reason |

|

|

1x |

Motor doesn’t start, no changing |

Check for motor blockage or change motor. |

|

signal from hallsensor |

|

2x |

Voltage too low on motor pcb |

Check supply voltage or |

|

|

change motor. |

3x |

Voltage too high on motor pcb |

Check supply voltage or |

|

|

change motor. |

4x |

rpm measurement defective |

Change motor. |

5x |

Motor pcb temperature >105°C |

Check cooling system (cooling fan, air intake |

|

|

filter), otherwise change motor |

6x |

Supply voltage <80V |

Check power supply |

|

|

(F1-F2) |

7x |

Motor pcb defective |

Change motor. |

8x |

Motor pcb defective |

Change motor. |

Remedy |

|

|

S

C M

-13-

S |

CM - Sequence of events |

C M

Mode: Steam 100°C (212°F)

Temp. preset, not adjustable

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

Function Step |

Responsible sensor |

1.Select Steam mode

2.Select time or core temperature

|

3. |

Close cabinet door |

Reed switch S3 |

|

4. |

Check water level inside steam generator |

Level electrode S2 inside Steam Generatorr |

|

5. |

Preheat steam generator, |

Thermocouple B5 inside Steam Generator |

|

|

if B5 is below 85°C (185°F); |

|

|

6. |

Timer starts after successful preheating |

Logic on PCB |

|

|

(blinking dot in Display) |

|

|

7. |

Steam supply up to steam saturation |

Quenching sensor B2 |

|

|

inside cabinet |

(Steam control) |

|

8. |

Hot Air supply (only 50%) when set |

Cabinet sensor B1 |

|

|

temperature (100°C/212°F) can not be |

|

|

|

reached in time by Steam alone |

|

|

9. |

Quenching (set to 70°C/158°F) |

Quenching sensor B2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-14-

CM - Sequence of events |

S |

Mode: Low temperature steam

Temp. range 30-99°C (86-210°F)

C M

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

Function Step

1.Select Low temperature steam mode Set temperature 30-99°C (86-210°F)

2.Select time or core temperature

3.Close cabinet door

4.Check water level inside steam generator

5.Preheat steam generator, if B5 is below 85°C (185°F);

6.Timer starts after successful preheating (blinking dot in Display)

7.Steam supply until set temperature inside cabinet is reached

8.Hot Air supply (only 50%) when set temperature can not be reached in time by Steam alone

Responsible sensor

Reed switch S3

Level electrode S2 inside Steam Generatorr Thermocouple B5 inside Steam Generator

Logic on PCB

Cabinet sensor B1

Cabinet sensor B1

9. Quenching (set to 70°C/158°F) |

Quenching sensor B2 |

Note: Reduction of fan motor speed

In case the actual temperature is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-15-

S |

CM - Sequence of events |

C M

Mode: Combination

Temp. range 30-300°C (86-572°F)

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

Function Step |

Responsible sensor |

1.Select Combi mode

Set temperature 30-300°C (86-572°F)

2.Select time or core temperature

3. |

Close cabinet door |

Reed switch S3 |

4. |

Check water level inside steam generator |

Level electrode S2 inside Steam Generatorr |

5. |

Preheat steam generator, |

Thermocouple B5 inside Steam Generator |

|

if B5 is below 85°C (185°F); |

|

6. |

Timer starts after successful preheating |

Logic on PCB |

|

(blinking dot in Display) |

|

7. |

Hot Air supply until set temperature |

Cabinet sensor B1 |

|

inside cabinet. Hot air has priority |

|

8. |

Steam supply up to steam saturation |

Quenching sensor B2 |

|

inside cabinet |

(Steam Control) |

9. |

Quenching (set to 70°C/158°F) |

Quenching sensor B2 |

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-16-

CM - Sequence of events |

|

S |

|

F |

C |

Mode: Finishing |

|

|

|

M |

|

Temp. range 30-300°C (86-572°F) |

|

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

Function Step |

Responsible sensor |

1.Select Finishing mode

Recommended temperature 100-140°C (212-284°F)

2.Select time or core temperature

3. |

Close cabinet door |

Reed switch S3 |

4. |

Check water level inside steam generator |

Level electrode S2 inside Steam Generatorr |

5. |

Preheat steam generator, |

Thermocouple B5 inside Steam Generator |

|

if B5 is below 85°C (185°F); |

|

6. |

Timer starts after successful preheating |

Logic on PCB |

|

(blinking dot in Display) |

|

7. |

Hot Air supply |

Cabinet sensor B1 |

|

Electric units: 12 sec on - 6 sec off |

|

|

Gas units: 30 sec on - 15 sec off |

|

8. |

Steam supply |

Quenching sensor B2 |

|

Electric units: 6 sec on - 12 sec off |

(Steam Control) |

|

Gas units: 15 sec on - 30 sec off |

|

9. |

Quenching (set to 70°C/158°F) |

Quenching sensor B2 |

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-17-

S |

CM - Sequence of events |

C M

Mode: Hot Air

Temp. range 30-300°C (86-572°F)

B1 F4

B3

S2

B5

F3

M1

M4

S3

B2

Y1 Y2

Function Step |

Responsible sensor |

1.Select Hot Air mode

Set temperature 30-300°C (86-572°F)

2.Select time or core temperature

3. |

Close cabinet door |

Reed switch S3 |

4. |

Hot Air supply unitl set temperature |

Cabinet sensor B1 |

|

is reached |

|

8. |

Quenching (set to 90°C/194°F) |

Quenching sensor B2 |

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-18-

|

|

|

|

|

|

Service level CM from 04 - 2004 |

|

|

|

|

|

1) |

Switch unit ON |

|

|

|

|

|

2) |

On operator PCB set DIP switch 1 to „ON“ position |

|

on |

|

|

|

||

|

1 |

2 |

3 |

4 |

||

|

|

|

||||

|

|

|

|

|

3) |

Select service package with timer dial: |

|

|

|

|

|

|

Diagnostic Program |

|

|

|

|

|

|

Error code history |

|

|

|

|

|

|

Running times |

|

|

|

|

|

|

Basic settings |

|

|

|

|

|

4) |

Activate with core temperature key the desired service package |

|

|

|

|

|

5) |

Select with timer dial the desired step |

|

|

|

|

|

6) |

Activate selected step by pressing timer key |

|

|

|

|

|

|

|

|

on |

|

|

|

7) |

To de-activate service package set DIP switch 1 to „OFF“ position. |

|

1 |

2 |

3 |

4 |

||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Function Test |

|

|

|

|

|

|

1) |

Switch unit ON |

|

|

|

|

|

|

|

|

on |

|

|

|

2) |

Auf Bedienplatine DIP Schalter 3 auf „ON“ Stellen |

|

1 |

2 |

3 |

4 |

||

|

|

|

|

|

|

First step of function test is displayed. |

|

|

|

|

|

3) |

Select desired step of function test with timer dial |

|

|

|

|

|

4) |

Activate selected step by pressing timer key |

|

|

|

|

|

5) |

Activate selected step with core temperature key |

|

|

|

|

|

6) To de-activate function test set DIP switch 3 to „OFF“ position. |

|

|

on |

|

|

|

||

|

1 |

2 |

3 |

4 |

||

|

|

|

||||

S

C

M

42.00.004

0,1 AT 2 AT

F1 F2

Transformer

X7

X19

1

X20

X20

1

42.00.047

|

|

2 AT |

|

X16 |

F6 |

|

||

|

|

2 AT

F6.1

X63

|

1 |

|

|

off |

3 2 |

on |

X30 |

|

|

|

|

|

4 |

|

RS 232 |

X7

X19

1

X20

X20

1

X18

X23

1

X31

RS 485

X8

X12

1

|

X26 |

|

X50 |

X27 |

|

1 |

||

|

X2 X6 X4 X3

1 |

X24 |

1 |

X32 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes:

-19-

S

C

M

Service level: dP -- Diagnostic Program

dP # |

Description |

Connector Cabinet display Timer display Comment |

|

|

|

|

Software |

Software |

dP 1 |

Software Version |

|

|

version: C - 1 - |

Version:06.05 |

dP 2 |

B1 Cabinet sensor |

X 3 |

|

actual value |

max value |

|

|

|

|

||

dP 3 |

B2 Quenching sensor |

X 4 |

|

actual value |

max value |

|

|

|

|

||

dP 4 |

B3 Core sensor |

X 2 |

|

actual valuet |

max value |

|

|

|

|

||

dP 5 |

B5 Steam generator sensor |

X 6 |

|

actual value |

max value |

|

|

|

|

||

dP 6 |

PCB temperature |

|

|

actual value |

max value |

|

|

|

|

||

dP 7 |

S3 Door contact |

X27:(1-2) |

S3: 1 - 0 |

1 - 0 |

|

X12:(1-4) |

S2 |

|

Y1: 1 - 0 |

||

|

|

|

|||

dP 8 |

S2 Water level steam |

X19:(1-3) |

Y1 |

|

|

|

generator |

|

|

Temp. B5 |

0 - 1 - 2 |

dP 9 |

Steam elements |

|

|

||

|

|

|

|

||

|

0 - off; 1 - 50%; 2 - 100% |

|

|

Temp. B1 |

0 - 1 - 2 |

dP 10 |

Hot Air elements |

|

|

||

|

|

|

|

||

|

0 - off; 1 - 50%; 2 - 100% |

BUS |

|

Set rpm |

actual rpm |

dP 11 |

Speed fan motor top |

|

|||

BUS |

|

Set rpm |

actual rpm |

||

dP 12 |

Speed fan motor bottom |

|

|||

X 20 |

|

|

1 - 0 |

||

dP 13 |

Energy optimising |

|

|

||

|

|

|

|

||

|

(Sicotronic) |

X 26 |

|

|

1 - 0 |

dP 14 |

SSR pulsing (US version) |

|

|

||

|

|

61 - 202 |

ELE - GAS |

||

dP 15 |

Unit size and type |

|

|

||

|

|

|

|

||

dP 16 |

Flame Current Steam |

|

|

|

x.x A* |

|

|

|

|

||

dP 17 |

Flame Current Hot Air top |

|

|

|

x.x A* |

dP 18 |

Flame Current Hot Air bottom |

|

|

|

x.x A* |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Reset by pressing

for 5 sec.

+

Reset by pressing

for 5 sec.

+

+

Reset by pressing

for 5 sec.

+

+

Reset by pressing

for 5 sec.

+

+

Reset by pressing

for 5 sec. |

+ |

|

USA version only

since SW Version: C1-06-05 ( ame current)

since SW Version: C1-06-05 ( ame current)

since SW Version: C1-06-05 ( ame current)

*With SW Version C1-06-05 the ame current will show as 20-24 A

(This value must be divided by 4 to get the correct ame current e. g. 22:4 = 5,5 A.) Starting with SW version C1-07-01 the actual ame current is shown .

-20-

Service Level: ER -- Error code history

Since software version C1-07-01 the last 10 general error messages are

shown (applies for electric and gas models)

Er |

When timer key is pressed the error code will be displayed. i.e.: |

|

Er1 |

3 |

B1 Cabinet sensor defective |

Er2 |

14 |

Y1 Filling solenoid defective |

Er3 |

|

|

---- |

|

|

ER10 |

|

|

Note: Er1 - Er10 is a consecutive counting

Number 1-24 are error codes which are generated by the pcb

Gas error GE: (gas units only!)

Since software version C1-07-01 the last 16 gas error messages are shown in addition to the general error messages

GE11 |

20 |

No rpm signal |

GE12 |

32 |

No ame after 5 ignition sequences |

GE13 |

|

|

--- |

|

|

GE25 |

|

|

Note: GE11 - 25 is a consecutive counting

Number 1-43 are internal error codes which are generated by the ignition box

Indication of ignition box error messages (1-32 is shown to the operator as „rES“):

1 |

Hot air or Steam |

no gas, gas valve or electrode defective |

|

14 |

Hot air |

gas valve controll, change ignition box |

|

19 |

Hot air |

no ame because ame current is too low |

|

|

|

check burner setting, ame current, ignition cable and plug |

|

20 |

Hot air |

wrong or no rpm signal from gas blower |

|

|

|

check gas blower, power supply gas blower and control harness of gas blower |

|

22 |

Hot air |

no ame after 5 ignition sequences |

|

|

|

no gas, gas valve or electrode defective |

|

24 |

Steam |

gas valve controll, change ignition box |

|

29 |

Steam |

no ame because ame current is too low |

|

|

|

check burner setting, ame current, ignition cable and plug |

|

30 |

Steam |

wrong or no rpm signal from gas blower |

|

|

|

check gas blower, power supply gas blower and control harness of gas blower |

|

32 |

Steam |

no ame after 5 ignition sequences |

|

|

|

no gas, gas valve or electrode defective |

|

Possible failure in case of „E21“ |

|||

33, 36 |

|

Change ignition box |

|

35 |

|

Check frequency of main |

|

39 |

Hot air |

Check burner setting, ignition electrode and distance,and ame current |

|

40 |

Hot air |

Check ignition cable |

|

42 |

Steam |

Check burner setting, ignition electrode and distance,and ame current |

|

43 |

Steam |

Check ignition cable |

|

Is shown on display „CHnG PoL“ |

|||

34 |

|

Change polarity of mains |

|

All other numbers (2-13, 15-18, 21, 23, 25-28, 31): change ignition box

S

C M

-21-

S

C M

Failure Codes CM „ER“

Int. cab. |

Timer |

Failure explanation |

Description |

display |

display |

|

|

H2o |

OPEn |

H2O open |

Lack of water / open water tap |

CHnG |

PoL |

Change Polarity |

Phase / Neutral (only gas units) |

|

|

|

|

Timer |

Int. cab. |

Part concerned |

Description |

display |

display |

|

|

|

(E -press |

|

|

|

core temp. |

|

|

|

key) |

|

|

E1 |

|

external EEPROM |

Not initialised |

E2 |

|

Timeout of external |

Heating blocked by the extern. energyopti- |

|

|

power optimising system |

mising system for longer 2 min. |

|

|

(Sicotronic) |

|

E3 |

|

B1 Interior cabinet sensor |

Sensor broken |

E4 |

|

B2 Quenching sensor |

Sensor broken |

E5 |

|

B3 Core sensor |

Sensor broken |

E6 |

|

B5 Sensor steam generator |

Sensor broken |

E7 |

|

Thermocouple on PCB |

Sensor broken |

E8 |

|

Poti interior cabinet |

Defective |

E9 |

|

Poti timer/core temperature |

Defective |

E10 |

|

External EEPROM |

Defective |

E11 |

|

Mode switch |

After 5 sec switching on the unit, a cooking |

|

|

|

mode couldn‘t be identi ed |

E12 |

1 St |

Fan motor 1 (bottom) |

St = Status (probably Motor defect) |

|

1 Co |

Fan motor 1 (bottom) |

Co = Communication,(Bus failure) |

E 12 |

2 St |

Fan motor 2 (top) |

St = Status (probably Motor defect) |

|

2 Co |

Fan motor 2 (top) |

Co = Communication,(Bus failure) |

E13 |

|

M4 SC-pump |

Mal function |

E14 |

|

Solenoid valve lling Y1 |

Mal function |

E15 |

|

PCB temperature |

above 85°C (185°F) |

E16 |

|

Steam generator |

Temperature B5 above |

E17 |

|

Steam generator |

180°C (356°F) |

|

Temperature B5 below -5°C (23°F) |

||

E18 |

|

Interior cabinet temp. |

Temperature B1 above 340°C (644°F) |

E19 |

|

free |

|

E20 |

1_ |

Ignition box 1 |

Ignition box does not reply, Bus failure |

E20 |

2_ |

Ignition box 2 |

Ignition box does not reply, Bus failure |

E21 |

1xx |

Ignition box 1 Steam |

Ignition box defective (change box) |

E21 |

2xx |

Ignition box 1 Hot air |

Ignition box defective (change box) |

E21 |

3xx |

Ignition box 2 Hot air |

Ignition box defective (change box) |

E22 |

1xx |

Ignition box 1 Steam |

Testing of ignition and monitoring |

|

|

|

necessary |

E22 |

2xx |

Ignition box 1 Hot air |

Testing of ignition and monitoring |

|

|

|

necessary |

E22 |

3xx |

Ignition box 2 Hot air |

Testing of ignition and monitoring |

|

|

|

necessary |

E23 |

|

free |

|

E24 |

|

EEPROM |

Actual data structure of the EEPROM does |

|

|

|

not match with the software; flash pcb first |

-22-

Service Level: rt -- Running Time

rt # |

Description |

Timer display: 1-999 |

Comment |

|

|

|

|

Temp. display: >1000 |

|

rt 1 |

Total |

S3 door openings |

number |

Reset by pressing |

|

|

|

|

for 5 sec. |

rt 2 |

Total |

time Y1 valve lling |

min |

Reset by pressing |

|

|

|

|

for 5 sec. |

rt 3 |

Total |

time Y2 valve quenching |

min |

Reset by pressing |

|

|

|

|

for 5 sec. |

rt 4 |

Total time M4 SC-pump |

min |

Reset by pressing |

|

|

|

|

|

for 5 sec. |

rt 5 |

Total |

time steam heating time |

hrs |

Reset by pressing |

|

|

|

|

for 5 sec. |

rt 6 |

Total |

time hot air heating time |

hrs |

Reset by pressing |

|

|

|

|

for 5 sec. |

rt 7 |

Total |

time steam mode |

hrs |

Can not be reset |

rt 8 |

Total |

time hot air mode |

hrs |

Can not be reset |

rt 9 |

Total |

time combination mode |

hrs |

Can not be reset |

rt 10 |

Total |

time vario steam mode |

hrs |

Can not be reset |

rt 11 |

Total |

time nishing mode |

hrs |

Can not be reset |

rt 12 |

Total |

time cleaning program |

hrs |

Can not be reset |

rt 13 |

Total running time unit |

hrs |

Can not be reset |

|

|

|

|

|

|

|

|

|

|

|

+

+

+

+

+

+

+

+

+

+

+

+

Notes:

S

C M

-23-

|

|

Service level: SE -- Basic settings |

|

S |

|||

C |

|

|

|

M |

|

|

|

|

|

Select desired step with timer dial |

|

|

|

(fan motor and heating elements are automatically OFF) |

|

|

|

Activate selected step with timer key |

|

|

|

||

|

|

Steam heating time since last SC-Automatic |

|

+ |

Press time and core key simultaneously for 5 seconds to set steam heating time |

||

(SE2) to preset steam heating time plus 1 minute (default 45+1min) => test function |

|||

|

|

for SC-Automatic |

|

|

|

Preset Steam heating time until SC-Automatic (default 45min) |

|

+ |

Press time key and adjust preset steam heating time from 20 - 120 minutes with timer |

||

dial |

|

||

|

|

|

|

|

|

Flushing time SC-Automatik (default 45 seconds) |

|

+ |

Press time key and adjust ushing time of SC-automatik from 30 - 90 seconds with |

||

timer dial |

|

||

|

|

|

|

|

|

Operation steam generator pump (oFF - continous or on - pulsing) |

|

+ |

Press time key and select „on“ or „oFF“ with timer dial |

||

|

|

Show mode (on - oFF) |

SHO |

+ |

Press time key and select „on“ or „oFF“ with timer dial |

|

Setting new gas type (G20, G25, G30, G31, 13A)

|

Press time key, keep it pressed and select new gas type with timer dial |

|

+ |

Con rm new gas type by pressing core temperature key once. |

|

Corresponding gasblower speed is automatically adjusted |

||

|

||

|

NOTE: After changing gas type a waste gas analysis must be carried out in the func- |

|

|

tion test. |

Presetting of CO2 screw in mm on gas valve after gas type modi cation / changing gas valve

Press time key, keep it pressed and select with timer dial “ST“ for steam, “HA1“ for hot air top or “HA2“ for hot air bottom (only 201/202) with timer dial;

+Average lenght in mm of CO2 screw on gas valve is shown on timer display

-24-

+

+

+

+

+

+

+

+

Notes:

Service level: SE -- Basic settings |

S |

|

C |

|

M |

Adjustment of installation altitude above sea level (since SW C1-06-05)-500m - 4500m

Press time key, keep it pressed and select installaton altitude in 500m steps by timer dial. Con rm altitude setting by pressing simultaneously core temperature key once

Adjusting speed of blower motor steam (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial SE9 = MIN rpm; SE10 = Start rpm; SE11 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried out in the function test.

Adjusting speed of blower motor hot air top (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial SE12 = MIN rpm; SE13 = Start rpm; SE14 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried out in the function test.

Adjusting speed of blower motor hot air bottom (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial SE15 = MIN rpm; SE16 = Start rpm; SE17 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried out in the function test.

-25-

S |

Service level: SE -- Function test |

CNOTE: In Function test components are NOT protected against overload!

M

|

Function |

Connection |

Cabinet |

Time |

Comment |

|

|

|

I/O PCB |

Display |

Display |

|

|

|

|

|

|

|

|

|

F1 |

Steam 50%, |

X24:(1-2) |

actual temp.B5 |

1 / 0 |

Gas: no function |

|

|

Electric unit |

|

steam generator |

|

|

|

|

|

|

|

|

|

|

F2 |

Steam 100% |

X24:(1-2)+(5-6 |

actual temp.B5 |

1 / 0 |

Gas: no function |

|

|

Electric unit |

|

steam generator |

|

|

|

|

|

|

|

|

|

|

F3 |

Hot Air 50% |

X24:(7-8) |

actual temp. B1 |

1 / 0 |

Gas: no function |

|

|

Electric unit |

|

cabinet |

|

|

|

|

|

|

|

|

|

|

F4 |

Hot Air 100% |

X24:(7-8)+(3-4) |

actual temp. B1 |

1 / 0 |

Gas: no function |

|

|

Electric unit |

|

cabinet |

|

|

|

|

|

|

|

|

|

|

F5 |

Steam |

BUS |

actual temp.B5 |

1 / 0 |

Electric: no function |

|

|

Gas unit |

|

steam generator |

|

|

|

|

|

|

|

|

|

|

F6 |

Hot air top |

BUS |

actual temp.B1 |

1 / 0 |

Electric: no function |

|

|

Gas unit |

|

cabinet |

|

|

|

|

|

|

|

|

|

|

F/ |

Hot air bottom |

BUS |

actual temp.B1 |

1 / 0 |

Electric: no function |

|

|

Gas unit |

|

cabinet |

|

|

|

|

|

|

|

|

|

|

F8 |

Bottom Motor |

BUS |

Set rpm |

Act. rpm |

|

|

|

MAX speed |

|

|

|

|

|

|

|

|

|

|

|

|

F9 |

Bottom Motor |

BUS |

Set rpm |

Act. rpm |

|

|

|

MIN speed |

|

|

|

|

|

|

|

|

|

|

|

|

F10 |

Top Motor |

BUS |

Set rpm |

Act. rpm |

|

|

|

MAX speed |

|

|

|

|

|

|

|

|

|

|

|

|

F11 |

Top Motor |

BUS |

Set rpm |

Act. rpm |

|

|

|

MIN speed |

|

|

|

|

|

|

|

|

|

|

|

|

F12 |

Solenoid valve |

X19:(2-4) |

actual temp. |

Y2, 1 / 0 |

|

|

|

quenching |

|

B2 quenching |

|

|

|

|

|

|

|

|

|

|

F13 |

Solenoid valve |

X19:(2-4) |

Level electrode |

Y1, 1 / 0 |

|

|

|

lling |

|

S2, 1 / 0 |

|

|

|

|

|

|

|

|

|

|

F14 |

Steam generator |

X18:(1-2) M4 |

Level electrode |

M4,1 / 0 |

|

|

|

pump |

X12:(1-4) S2 |

S2, 1 / 0 |

|

|

|

|

|

|

|

|

|

|

F15 |

Buzzer |

|

|

1 / 0 |

|

|

|

|

|

|

|

|

|

F16 |

All Displays / LED |

|

|

|

|

|

|

|

|

|

|

|

|

F17 |

Relais Vent hood |

X 23: (1-2-3) |

|

1 / 0 |

|

|

|

(door open/close) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-26-

Function test

NOTE: In Function test components are NOT protected against overload!

|

Function |

Connection |

Cabinet |

Time |

Comment |

|

|

I/O PCB |

Display |

Display |

|

|

|

|

|

|

|

F19 |

Steam blower motor |

BUS |

Actual blower |

Set CO2 |

Check CO2 |

|

MIN rpm |

|

rpm |

value |

value only |

|

|

|

|

|

|

F20 |

Steam blower motor |

BUS |

Actual blower |

|

|

|

START rpm |

|

rpm |

|

|

|

|

|

|

|

|

F21 |

Steam blower motor |

BUS |

Actual blower |

Set CO2 |

Adjust CO2 value |

|

MAX rpm |

|

rpm |

value |

with C02 screw |

|

|

|

|

|

on gas valve |

|

|

|

|

|

|

F22 |

Hot Air blower motor |

BUS |

Actual blower |

Set CO2 |

Check CO2 |

|

TOP, MIN rpm |

|

rpm |

value |

value value only |

|

|

|

|

|

|

F23 |

Hot Air blower motor |

BUS |

Actual blower |

|

|

|

TOP, START rpm |

|

rpm |

|

|

|

|

|

|

|

|

F24 |

Hot Air blower motor |

BUS |

Actual blower |

Set CO2 |

Adjust CO2 value |

|

TOP, MAX rpm |

|

rpm |

value |

with C02 screw |

|

|

|

|

|

on gas valve |

|

|

|

|

|

|

F25 |

Hot Air blower motor |

BUS |

Actual blower |

Set CO2 |

Check CO2 |

|

TOP, MIN rpm |

|

rpm |

value |

value value only |

|

|

|

|

|

|

F26 |

Hot Air blower motor |

BUS |

Actual blower |

|

|

|

TOP, START rpm |

|

rpm |

|

|

|

|

|

|

|

|

F27 |

Hot Air blower motor |

BUS |

Actual blower |

Set CO2 |

Adjust CO2 value |

|

TOP, MAX rpm |

|

rpm |

value |

with C02 screw |

|

|

|

|

|

on gas valve |

|

|

|

|

|

|

|

|

|

|

|

|

S

C M

Notes:

-27-

S |

CM Gas from 04 - 2004 |

C |

|

|

|

|

M |

B5 |

F3 |

B1 |

F4 |

|

|

B3 |

||

|

S2 |

|

|

|

|

B11 |

|

|

|

|

|

|

M9 |

|

|

|

|

Y11 |

|

|

|

|

M1 |

|

|

|

|

A5 |

|

|

|

M4 |

B12 |

|

|

|

|

|

|

|

|

|

M8 |

|

|

|

|

Y12 |

|

|

|

|

S3 |

|

|

B2 |

|

|

|

Y1 |

Y2 |

|

|

|

A5 |

Ignition module (Steam and Hot Air) (without jumper) |

B1 |

Thermocouple interior cabinet |

B2 |

Thermocouple quenching / Steam control |

B3 |

Thermocouple core temperature |

B5 |

Thermocouple steam generator |

B11 |

Ignition/monitoring electrode steam |

B12 |

Ignition/monitoring electrode hot air |

F3 |

Safety thermostat steam generator 135°C |

F4 |

Safety thermostat interior cabinet 360°C |

M1 |

Fan motor |

M4 |

SC-pump |

M8 |

Gas blower motor hot air |

M9 |

Gas blower motor steam |

Y1 |

Solenoid valve lling |

Y2 |

Solenoid valve quenching |

Y11 |

Gas valve steam |

Y12 |

Gas valve hot air |

S2 |

Level electrode |

S3 |

Door reed switch |

Only |

oor units 201 - 202 |

A6 |

Ignition module hot air bottom (with jumper) |

M2 |

Fan motor top (with jumper) |

M10 |

Gas blower motor hot air bottom |

Y13 |

Gas valve hot air bottom |

B13 |

Ignition/monitoring electrode hot air bottom |

-28-

Identification of the different gas burners / Gas blowers:

CM 61 - 62 - 101 - 102 |

CM 201 - 202 |

Steam Blower

Steam Gas valve with

common ignition box for

common ignition box for  Steam and Hot Air (top) tted

Steam and Hot Air (top) tted

Hot Air blower (top)

Hot Air (bottom) Gas valve with

second ignition box tted

second ignition box tted

Hot Air blower bottom (ignition box tted)

Ignition box of Hot Air Blower, Bottom (201-202):

Jumper must ONLY be set

on Ignition Box for  Ignition box Hot Air Blower Bottom (201 - 202)

Ignition box Hot Air Blower Bottom (201 - 202)

Gas valve components

Compensation hose

CO2 Srew

Measuring test point for dynamic gas ow pressure

Gas supply

S

C M

-29-

S

C

M

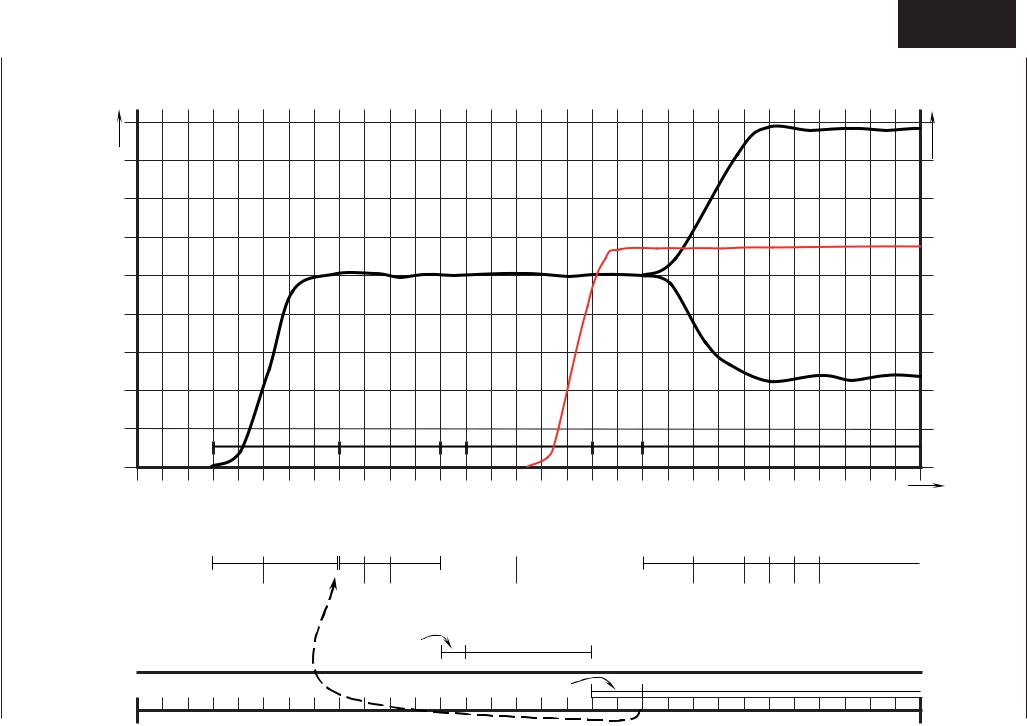

Sequence of events of Steam / Hot Air Burner (SCC as well as CM)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max RPM |

|

|

|

||

|

|

μA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RPM |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Speed |

|

A |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

rucr e n t in μ |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

blowerburner of |

|

4 |

|

|

|

|

|

|

|

|

|

Start RPM |

|

|

|

|

|

|

|

|

|

|

|

Flame current |

|

|||||||

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a m e |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min RPM |

|

|

motor |

||

-30- |

F l |

|

|

|

|

|

|

|

|

|

|

|

ignitionPre |

|

|

|

|

|

Flame control |

|

|

|

|

|

|

|

|

U/min in |

|||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start up |

|

|

Pre purge |

|

|

|

Ignition |

|

|

|

|

Burner running |

|

|

|

|

|

|

|

|||||||

|

|

Time |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

sec |

Ignition box gets heat demand over the BUS cable

Heat demand |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start - pre purge |

|

Pre purge, 4 sec |

|

Blower runs with Start RPM |

|

|

Blower runs with Max or Min RPM |

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

Burner blower motor |

|

|

|

|

about. 4-5 |

|

sec |

|

RPM monitored |

|

|

RPM |

|

monitoring |

|

by |

|

ignition |

|

box |

|

|

RPM |

|

monitoring by ignition box |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Energise Solenoids: Black coils ca 205V DC / orange coils ca 108V DC |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

Gas valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pre ignition, 1sec |

|

|

|

Ignition, 5 sec |

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Ignition, ca 20KV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Flame monitoring within. 2 sec |

|

|

|

continuous flame control |

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

Flame monitoring

control Ignition and Burner of events of Sequence

If no flame detected => new ignition sequence. After 5 th ignition without success => RESET

Loading...

Loading...