TECHNICAL MANUAL

IL-211-D

Replaces (IL-211-C)

NO. 2 PROCESS™

HANDGUN

SPRAY

TECHNIQUES

Ransburg calls it

No.2...

but you'll say it

does an...A-1 job!

IMPORTANT: Before using this equipment, carefully

read all instructions in this manual. Keep this Technical Manual for future reference.

Technical Manual Price: $20.00 (U.S.)

NOTE: This manual has been changed from revision IL-211-C to revision IL-211-D. Reasons for

this change are noted under “Manual Change Summary” inside the back cover of this manual.

IL-211-D

No. 2 Process Handgun Spray Techniques

CONTENTS

NO. 2 PROCESS HANDGUN SPRAY TECHNIQUES:

PAGE

1-11

ANGLES AND RECESSES.........................................................................................................

SPRAY PATTERNS.....................................................................................................................

FLAT SURFACES........................................................................................................................

TUBULAR WORK.......................................................................................................................

USE THE RIGHT TECHNIQUE..................................................................................................

SAFETY REQUIREMENTS.........................................................................................................

2

3-4

5-7

8

9-10

11

IL-211-D

No. 2 Process Handgun Spray Techniques

DO NOT GAMBLE!

Reggie Ransburg says: “Before you get into the game, nd out what the rules are.”

Before operating, maintaining, or servicing any Ransburg electrostatic coating system, read and

understand all of the technical and safety literature provided with Ransburg products. If you do not have

the manuals and safety literature for your Ransburg system, contact your Ransburg representative.

Reggie says: “Why gamble? If you know how to play the game, you’ll be a winner.”

IL-211-D1

No. 2 Process Handgun Spray Techniques

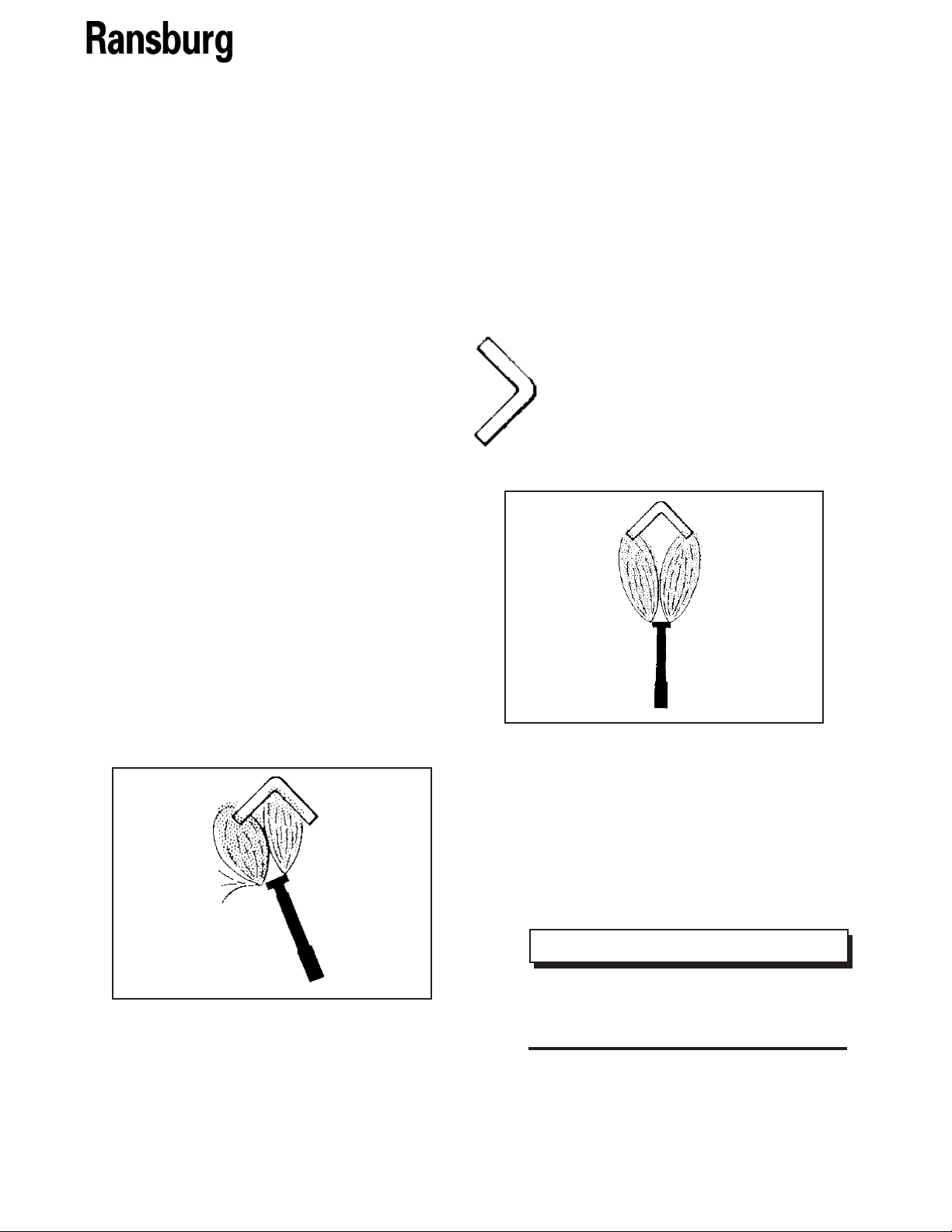

ANGLES AND RECESSES

General Rule: "Coat the most difcult areas rst."

While you work on the more difcult areas, wrap-around may take care of the less difcult areas on

the target.

A simple angle iron shape illustrating "difcult" and "easy" areas to coat.

One characteristic of electrical charges is their attraction to the closest ground. The paint is attracted

to the closest edges and will have only light or no coverage in the recess.

→ ←

DIFFICULT

EASY

SOLUTION: Move the gun in closer so that the

paint may be pulled directly from edge of the bell

to the part.

NOTE

IL-211-D

> Targets with very narrow and/or deep r

ecesses are difcult to coat. Care must be

taken to provide adequate coverage.

2

No. 2 Process Handgun Spray Techniques

SPRAY PATTERNS

The spray pattern varies in size from 10 inches minimum to 18 inches maximum (approximately).

Variations depend on bell size, paint delivery, and paint electrical resistance.

Minimum

Maximum

Voltage contactBrush out of

position.

Bell center probe has

poor contact or damaged shaft resistor.*

Large pattern with fair or poor

atomization may be caused by

excessive paint delivery.*

* Insulating hub of bell has become conductive, i.e., moisture

or conductive wash solvent.

Fair pattern with "Slugs" - Possible causes: dam-

aged bell edge or poor paint mixture.

IL-211-D3

A good spray pattern - Has ne atomization at

the edges and a small center hole.

No. 2 Process Handgun Spray Techniques

Fair pattern with poor atomization - Excessive

paint delivery or poor paint mixture.

No pattern - Paint thrown from edge of bell;

possible causes may be no gun voltage or paint

grounding out.

IL-211-D

4

Tune-Up Your System the RansCrafted Way

FLAT SURFACES

Poor Technique

When the gun is moved in an arc, heavier lms will

result in the center of the target and lighter lms

at the edges. Also, more overspray is produced.

Good Technique

When the gun is moved parallel with the surface

of the target, the operator has better control of

the paint. Film uniformity is more easily controlled. "Normally, keep the gun at right angles

to the target and move the gun parallel with the

target surface."

IL-211-D5

Tune-Up Your System the RansCrafted Way

C A U T I O N

!

> If the gun is held too far from the target,

the paint tends to "wrap-back" onto the gun

and operator.

The normal gun to target distance should be ap-

proximately 4 to 6 inches. This allows a good

spray pattern to form and helps produce more

uniform lms.

If the gun is held too close to the target (1 to

2 inches), the paint may not disperse properly,

causing runs, sags, poor uniformity, and can also

ground out the gun voltage.

IL-211-D

6

No. 2 Process Handgun Spray Techniques

FLAT SURFACES (Continued)

On at work, patterns may be overlapped as

much as 50%.

Another suitable technique, which is often used,

is to move the gun in a slow spiraling path across

the part, barely overlapping on the passes.

Some overstroke at the edge of the target will help

produce more wrap-around and better edge coverage.

Attention: Chain-link fence, or other expanded metalware, is normally sprayed the same as at work.

Fences are coated easiest by spraying from the post side.

IL-211-D7

TUBULAR WORK

The gun should normally be positioned about 4 to 6

inches from the part and held almost perpendicular

to the target surface. Spraying too close to the

part may cause runs and sags. Spraying too far

away from the part may cause overspray or allow

paint to wrap-back towards the gun.

No. 2 Process Handgun Spray Techniques

Moving the gun in a straight line may not always

produce the most complete coverage or uniformity.

(See example "A".)

A

B

C

NOTE

> Small tubes (up to about 2-1/2 inches)

often may be coated by wrap-around from

one side. Larger parts are harder to wrap

completely from one side because paint

must miss target to wrap-around

Example: Not complete wrap-around, but

still good attraction and efciency.

A slight waving or rotation of the gun can help

to spread the paint around the part better and

improve coverage. (See examples "B" and "C".)

IL-211-D

8

No. 2 Process Handgun Spray Techniques

USE THE RIGHT TECHNIQUE

No. 2 Process Handgun

Overspray and drift are almost totally eliminated by the No. 2 Process Handgun. Using the same pro-

cess as the automatic disk and bell systems, this gun delivers electrostatic wrap-around so effectively

that many small, open targets can be painted from one side only, and nishing material savings can

run 50% to 85% over conventional air spray.

The following are basic electrostatic spray techniques. Depending on the type of work being sprayed,

it may be necessary to change the technique slightly.

IL-211-D9

No. 2 Process Handgun Spray Techniques

Coating the outside of the target rst puts little paint on

the inside. If the inside is coated last, double coating

of the edges can result.

The difcult area is coated rst. While concentrating on the difcult area, much of the rest of

the part is also coated. Thus, only the remaining

uncoated areas need to be sprayed for adequate

coating of the entire target area.

AND NOW

LET US

SPRAY!

IL-211-D

10

No. 2 Process Handgun Spray Techniques

SAFETY REQUIREMENTS

All conductive objects in the spray area MUST be grounded!

• Keep all work holders and hooks free of coating material. The article being coated, work holders,

and hooks MUST be grounded through the conveyor or other supporting structure.

• Handgun operators MUST NOT wear gloves that insulate them from the gun handle.

• All persons, including the operators, in spraying areas must NOT wear shoes that insulate them

from the grounded conductive ooring.

• All loose objects in the spraying area MUST be connected to ground. All solvents in the spraying

area MUST be kept in an approved safety container that is connected to ground.

In addition to these requirements, Operator MUST:

• Turn off power supply prior to cleaning or working on equipment.

• Never immerse guns in any liquid.

• Have exhaust fans operating when spraying.

Check That:

• The spray booth, coating reservoir, and conveyor are grounded.

• The power supply is grounded and located outside of the spraying area.

• The oor in the spraying area is conductive and is grounded.

• Fire extinguishing equipment is provided and is operative.

• The spraying area is clean and free of accumulated coating material. Good housekeeping must

be maintained at all times.

• No more than one gallon of solvent is kept in each solvent safety container and the total quantity

of solvent in the spraying area is kept to the minimum consistent with operation.

• The guns are operating properly (the short circuit currents are within the limits set forth in the

instruction manual).

11

IL-211-D

MANUAL CHANGE SUMMARY

This manual was published to replace Technical

Manual IL-211-C No. 2 Process Handgun Spray

Techniques, to make the following changes:

1. Document created in standard booklet

formatting.

IL-211-D

Service Manual Price: $20.00 (U.S.)

Manufacturing

1910 North Wayne Street

Angola, Indiana 46703-9100

Telephone: 260/665-8800

Fax: 260/665-8516

Technical/Service Assistance Telephone: 800/ 233-3366 Fax: 419/ 470-2071

Technical Support Representative will direct you to the appropriate telephone number for ordering

Spare Parts.

© 2013 Ransburg. All rights reserved.

Models and specications subject to change without notice.

Form No. IL-211-D

Litho in U.S.A.

03/13

Loading...

Loading...