Ransburg MICROPAK A11789 Service Manual

MICROPMICROP

MICROP

MICROPMICROP

AKAK

AK

AKAK

TM TM

TM

TM TM

CONTROLLERCONTROLLER

CONTROLLER

CONTROLLERCONTROLLER

SERVICE MANUAL

CP-06-01CP-06-01

CP-06-01

CP-06-01CP-06-01

January - 2007

MODEL: A1MODEL: A1

MODEL: A1

MODEL: A1MODEL: A1

I/O

17891789

1789

17891789

IMPORIMPOR

IMPOR

IMPORIMPOR

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

starting on page 1, and all instructions in this

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

manual. Keep this Service Manual for future

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

reference.reference.

reference.

reference.reference.

TT

ANTANT

T

ANT

TT

ANTANT

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

: Before using this equipment,: Before using this equipment,

Service Manual Price: $30.00 (U.S.)Service Manual Price: $30.00 (U.S.)

Service Manual Price: $30.00 (U.S.)

Service Manual Price: $30.00 (U.S.)Service Manual Price: $30.00 (U.S.)

CP-06-01

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

MicroPak Controller - Contents

PAGEPAGE

PAGE

PAGEPAGE

1-41-4

1-4

1-41-4

SAFETY PRECAUTIONS............................................................................................................

HAZARDS/SAFEGUARDS.........................................................................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

GENERAL DESCRIPTION..........................................................................................................

SAFETY FEATURES...................................................................................................................

DISPLAYS....................................................................................................................................

CURRENT CONTROL................................................................................................................

SPECIFICATIONS.......................................................................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

MICROPAK INPUT POWER.......................................................................................................

SAFETY GROUND......................................................................................................................

LOW VOLTAGE CABLE..............................................................................................................

INTERLOCKS AND I/O...............................................................................................................

DESCRIPTION OF TABLE 1 INTERLOCK &

I/O TERMINALS...........................................................................................................................

CURRENT CONTROL................................................................................................................

DIP SWITCH SUMMARY............................................................................................................

MICROPAK GROUND THEORY................................................................................................

OPERATION:OPERATION:

OPERATION:

OPERATION:OPERATION:

OPERATING CONTROLS..........................................................................................................

OPERATING PROCEDURES....................................................................................................

1

2-4

5-65-6

5-6

5-65-6

5

5

5

5

6

7-157-15

7-15

7-157-15

7

8

8

9

11

11-13

13-14

15

16-1816-18

16-18

16-1816-18

16-17

17-18

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

TROUBLESHOOTING................................................................................................................

CABLE CONTINUITY TEST........................................................................................................

TROUBLESHOOTING GUIDE...................................................................................................

TABLE 2 OHMMETER MEASUREMENTS................................................................................

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

MICROPAK CONTROLLER PARTS DIAGRAM / PARTS LIST...............................................

A11789-01 STAND-ALONE CONTROL / POWER SUPPLY

ASSEMBLY/PARTS LIST............................................................................................................

MICROPAK STAND-ALONE CONTROL / POWER SUPPLY

MODEL IDENTIFICATION..........................................................................................................

A11789-01 STAND-ALONE CONTROL / POWER SUPPLY SCHEMATIC.............................

WARRANTY POLICIES:WARRANTY POLICIES:

WARRANTY POLICIES:

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

CP-06-01

19-2219-22

19-22

19-2219-22

19

19

20-21

22

23-2923-29

23-29

23-2923-29

23-24

25-28

28

29

3131

31

3131

31

MicroPak Controller - Safety

SAFETYSAFETY

SAFETY

SAFETYSAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

Before operating, maintaining or servicing any

ITW Ransburg electrostatic coating system, read

and understand all of the technical and safety

literature for your ITW Ransburg products. This

manual contains information that is important for

you to know and understand. This information

relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize

this information, we use the following symbols.

Please pay particular attention to these sections.

A WARNING!A WARNING!

A WARNING!

A WARNING!A WARNING!

to a situation that might cause serious injuryto a situation that might cause serious injury

to a situation that might cause serious injury

to a situation that might cause serious injuryto a situation that might cause serious injury

if instructions are not followed.if instructions are not followed.

if instructions are not followed.

if instructions are not followed.if instructions are not followed.

A CAUTION!A CAUTION!

A CAUTION!

A CAUTION!A CAUTION!

how to prevent damage to equipment or howhow to prevent damage to equipment or how

how to prevent damage to equipment or how

how to prevent damage to equipment or howhow to prevent damage to equipment or how

to avoid a situation that might cause minorto avoid a situation that might cause minor

to avoid a situation that might cause minor

to avoid a situation that might cause minorto avoid a situation that might cause minor

injury.injury.

injury.

injury.injury.

A NOTE is information relevant to theA NOTE is information relevant to the

A NOTE is information relevant to the

A NOTE is information relevant to theA NOTE is information relevant to the

procedure in progress.procedure in progress.

procedure in progress.

procedure in progress.procedure in progress.

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements, etc.,

make such variations inevitable. Compare this

manual with your system installation drawings

and appropriate ITW Ransburg equipment manuals

to reconcile such differences.

states information to alert youstates information to alert you

states information to alert you

states information to alert youstates information to alert you

states information that tellsstates information that tells

states information that tells

states information that tellsstates information that tells

> The user

the Safety Section in this manual and the

ITW Ransburg safety literature therein identified.

> This manual

understood by

clean or maintain this equipment! Special

care should be taken to ensure that the

WARNINGSWARNINGS

WARNINGS and safety requirements for

WARNINGSWARNINGS

operating and servicing the equipment are

followed. The user should be aware of and

adhere to

and ordinances as well as

SAFETY STANDARD, SAFETY STANDARD,

SAFETY STANDARD, prior to installing,

SAFETY STANDARD, SAFETY STANDARD,

MUSTMUST

MUST read and be familiar with

MUSTMUST

MUSTMUST

MUST be read and thoroughly

MUSTMUST

ALLALL

ALL personnel who operate,

ALLALL

ALLALL

ALL local building and fire codes

ALLALL

NFPA-33NFPA-33

NFPA-33

NFPA-33NFPA-33

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> The hazards shown on the following page

may occur during the normal use of this

equipment. Please read the hazard chart

beginning on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efficient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your ITW Ransburg system,

contact your local Ransburg representative or

ITW Ransburg.

11

1

11

CP-06-01

MicroPak Controller - Safety

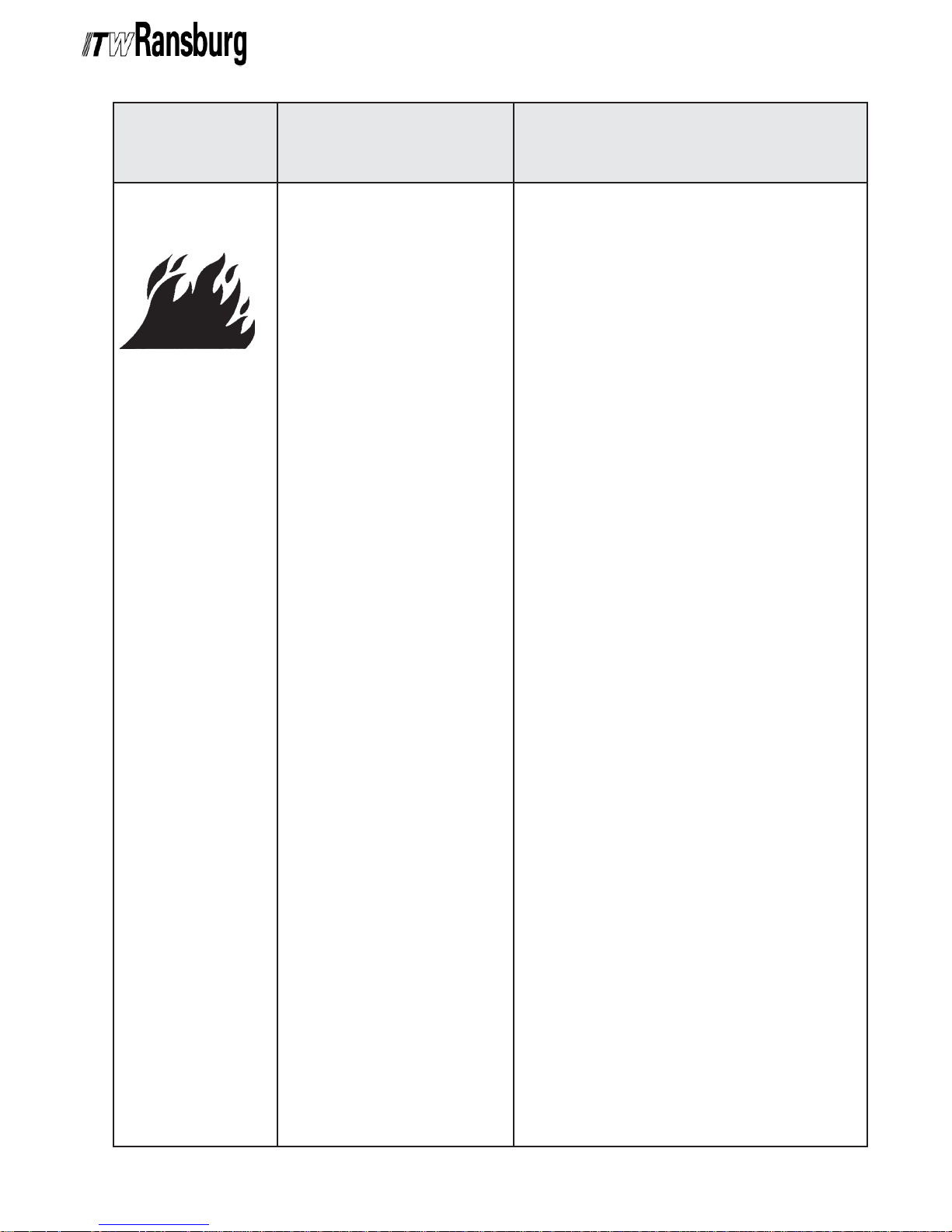

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate opera-tion

and maintenance procedures will

cause a fire hazard.

Protection against inadvertent

arcing that is capable of causing

fire or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

Those used for equipment flushing should have flash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have flash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using flammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized

equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only

during set-up operations. Production should never be

done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA- 33, NED, and

OSHA requirements.

CP-06-01

22

2

22

MicroPak Controller - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

ElectricalElectrical

Electrical

ElectricalElectrical

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Improper operation or maintenance

may create a hazard.

Personnel must be properly trained

in the use of this equipment.

High voltage equipment is utilized.

Arcing in areas of flammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and

maintenance.

Protection against inadvertent

arcing that may cause a fire or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shut-down

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating

materials and cause a fire or

explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read and

understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, fire protection, operation

maintenance, and housekeeping. Reference OSHA,

NFPA-33, and your insurance company requirements.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of flammable or combustible

material.

Testing may require high voltage to be on, but only as

instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

ExplosionExplosion

Explosion

ExplosionExplosion

Hazard /Hazard /

Hazard /

Hazard /Hazard /

IncompatibleIncompatible

Incompatible

IncompatibleIncompatible

MaterialsMaterials

Materials

MaterialsMaterials

33

3

33

Halogenated hydrocarbon solvents

for example: methylene chloride

and 1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equipment

during spraying, flushing, or cleaning. Read the label

or data sheet for the material you intend to spray. If

in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Any other type of solvent may be used with aluminum

equipment.

CP-06-01

MicroPak Controller - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray Area /Spray Area /

Spray Area /

Spray Area /Spray Area /

High VoltageHigh Voltage

High Voltage

High VoltageHigh Voltage

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

This is a high voltage device that

can produce electrical arcs capable

of igniting coating materials.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

(Reference NFPA- 33.)

A safe distance must be maintained between the

parts being coated and the atomizer bell. A distance

of at least 1 inch for each 10 KV of power supply

output voltage is required at all times.

Parts must be supported so that they will not swing

and reduce the clearance specified above.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

equipment must not be used in Class I, Division 1 or

2 locations.

CP-06-01

44

4

44

MicroPak Controller - Introduction

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

TMTM

TM

MicroPakMicroPak

The

MicroPak

MicroPakMicroPak

voltage to the cascade inside the Spray Gun

Assembly.

The MicroPak Controller together with the Spray

Gun Assembly and it’s Low Voltage Cable is a

System. It is unique in that it contains a built-in DC

Power Supply and is capable of operating either 1

or 2 MicroPak control units.

The MicroPak uses a combination of proven high

voltage generation technology including

microprocessor-based control with diagnostic and

communication functions. The processor circuitry

provides the maximum in applicator transfer

efficiency.

SAFETYSAFETY

SAFETY

SAFETYSAFETY

TMTM

Controller Controller

Controller

Controller Controller

FEA FEA

FEA

FEA FEA

, is used to provide

TURESTURES

TURES

TURESTURES

CURRENT CONTROLCURRENT CONTROL

CURRENT CONTROL

CURRENT CONTROLCURRENT CONTROL

The current setpoint limits the maximum current

that the cascade can produce. The voltage

setpoint sets the maximum voltage the cascade

can produce. The MicroPak will first attempt to

achieve current output setpoint. If the voltage

setpoint is set low, then the voltage setpoint will not

allow the current setpoint to be achieved.

VV

oltage Controloltage Control

V

oltage Control

VV

oltage Controloltage Control

The Over-Current setpoint can be monitored on

the μa Display by pressing the SET push-button

and holding for one second. It does provide a hard

shut-down if the output current exceeds the

setpoint. The kV setpoint is also displayed on the

kV display when the SET push-button is pressed

for one second.

DISPLADISPLA

DISPLA

DISPLADISPLA

The front panel displays for output voltage and

current indicate the true outputs from the cascade

or the tip voltage for indirect charge, and waterborne

applications. They are derived from feedback

signals in the low voltage cable between the

controller and the cascade.

YSYS

YS

YSYS

55

5

55

CP-06-01

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

(A(A

t Sea-Level Conditions)t Sea-Level Conditions)

(A

t Sea-Level Conditions)

(A(A

t Sea-Level Conditions)t Sea-Level Conditions)

Environmental / PhysicalEnvironmental / Physical

Environmental / Physical

Environmental / PhysicalEnvironmental / Physical

Temp. Operating:Temp. Operating:

Temp. Operating: (0

Temp. Operating:Temp. Operating:

TIONSTIONS

TIONS

TIONSTIONS

o

to 55o C)

MicroPak Controller - Introduction

NOTESNOTES

NOTES

NOTESNOTES

Storage:Storage:

Storage: (-40

Storage:Storage:

Humidity:Humidity:

Humidity: (95% Non-Condensing)

Humidity:Humidity:

Cabinet Size:Cabinet Size:

Cabinet Size: 13” Wide

Cabinet Size:Cabinet Size:

Weight:Weight:

Weight: 19 lbs.

Weight:Weight:

ElectricalElectrical

Electrical

ElectricalElectrical

DC Power Required: *DC Power Required: *

DC Power Required: *

DC Power Required: *DC Power Required: *

(per MicroPak)(per MicroPak)

(per MicroPak) 24VDC at 2.5A

(per MicroPak)(per MicroPak)

AC Electrical Requirements:AC Electrical Requirements:

AC Electrical Requirements:

AC Electrical Requirements:AC Electrical Requirements:

90-264 VAC @ 1.5 amps @

47/63 Hertz

**

DC power supplied from 24VDC built-in,DC power supplied from 24VDC built-in,

*

DC power supplied from 24VDC built-in,

**

DC power supplied from 24VDC built-in,DC power supplied from 24VDC built-in,

regulated power supy which has over-currentregulated power supy which has over-current

regulated power supy which has over-current

regulated power supy which has over-currentregulated power supy which has over-current

(40%) and over-voltage (20%) protection.(40%) and over-voltage (20%) protection.

(40%) and over-voltage (20%) protection.

(40%) and over-voltage (20%) protection.(40%) and over-voltage (20%) protection.

o

C to 85o C)

19” Deep

7” Height

(fully loaded output),

HP404 Cascade

Controls: Controls:

Controls:

Controls: Controls:

Discrete signals available via I/O Module

(Part #76037-03)

Analog In: Analog In:

Analog In: KV SET (0-10VDC)

Analog In: Analog In:

OVER-CURRENT SET

(0-10VDC)

Discrete Out: Discrete Out:

Discrete Out: HV ON (+24V)

Discrete Out: Discrete Out:

HV READY (+24V)

OVER-CURRENT FAULT

(+24V)

Discrete In: Discrete In:

Discrete In: HV RESET (+24V)

Discrete In: Discrete In:

HV ON (+24V)

CP-06-01

66

6

66

MicroPak Controller - Installation

INSTINST

INST

INSTINST

MICROPAK INPUTMICROPAK INPUT

MICROPAK INPUT

MICROPAK INPUTMICROPAK INPUT

POWERPOWER

POWER

POWERPOWER

For non-conduit installations, plug the detachable

AC line cord into the receptacle on the rear of the

MicroPak Controller. Plug the other end of the line

cord into a properly grounded 120 VAC outlet.

ALLAALLA

ALLA

ALLAALLA

NOTENOTE

NOTE

NOTENOTE

TIONTION

TION

TIONTION

> In general, conduit must be used for

approved AC installation, however, if national and local codes permit, the AC power

may be supplied via the factory supplied

line cord.

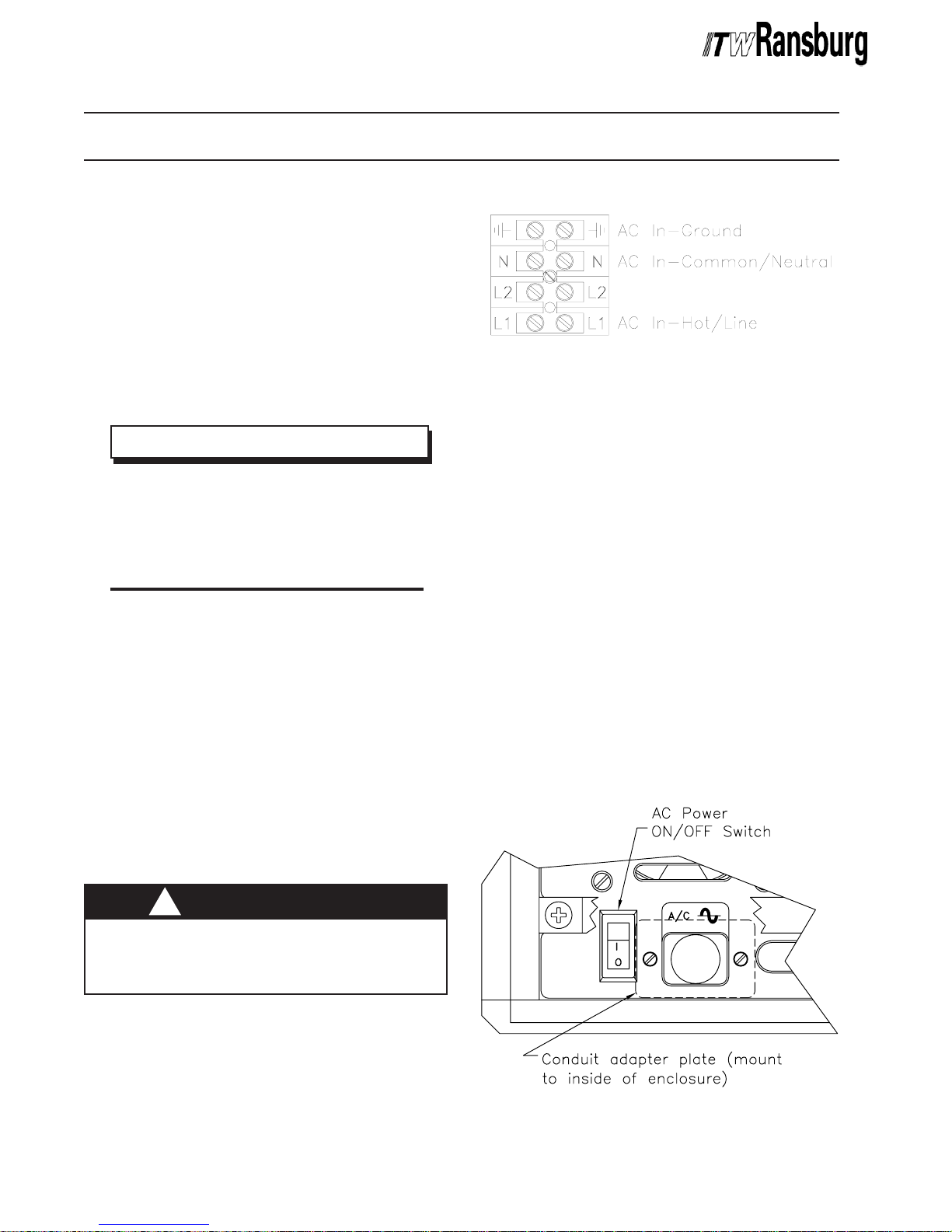

For installations where it is required to run the AC

input wiring in conduit, perform the following:

1. Ensure the AC line cord is unplugged and

remove the top cover from the controller (see

Figure 9).

Figure 1: Terminal Block 1 (1TB)Figure 1: Terminal Block 1 (1TB)

Figure 1: Terminal Block 1 (1TB)

Figure 1: Terminal Block 1 (1TB)Figure 1: Terminal Block 1 (1TB)

3. Remove the mounting hardware from the AC

Inlet Receptacle and remove it from the rear of the

control unit.

4. Install the Conduit Adapter Plate (supplied)

(76453) in the hole where the AC Inlet Receptacle

was removed (see Figure 2).

5. Install the AC line cord through the Conduit

Adapter Plate using conduit and wire to 1TB as

follows:

Hot/Line to 1TB-L1

Neutral/common to 1TB-N

Ground to 1TB-Ground

6. Reinstall top cover on controller.

2. Remove the AC Inlet Receptacle wiring from

1TB-L1, 1TB-N, and 1TB-Ground (see Figure 1

for AC input wiring locations).

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Always double check that the control

unit is unplugged from its AC outlet before

working with any internal wiring.

77

7

77

Figure 2: Installation of Conduit Adapter PlateFigure 2: Installation of Conduit Adapter Plate

Figure 2: Installation of Conduit Adapter Plate

Figure 2: Installation of Conduit Adapter PlateFigure 2: Installation of Conduit Adapter Plate

CP-06-01

MicroPak Controller - Installation

SAFETY GROUNDSAFETY GROUND

SAFETY GROUND

SAFETY GROUNDSAFETY GROUND

Install the ground wire assembly supplied with the

MicroPak Controller from the ground stud on the

rear of the controller to a true earth ground. For

maximum noise immunity, cut the ground wire

assembly to the shortest length required and

reinstall the end lug before making connections.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> The ground wire assembly

connected from the MicroPak Controller

ground stud to a true earth ground.

LOW VOLLOW VOL

LOW VOL

LOW VOLLOW VOL

Standard Low VStandard Low V

Standard Low V

Standard Low VStandard Low V

(A1(A1

1791-XX)1791-XX)

(A1

1791-XX)

(A1(A1

1791-XX)1791-XX)

Plug the connector of the low voltage cable

assembly into the appropriate receptacle on the

rear of the controller (see Figure 3). P1 is the

output for the leftmost MicroPak control unit, when

viewed from the front, and P2 is the output for the

rightmost MicroPak control unit, if installed. When

making the connection, line the red dot on the

connector with the red mark on the receptacle and

push in until it clicks. To remove, simply pull back

on the knurled portion of the connector. Attach the

low voltage cable(s) to the stress relief bar using

TR-SSEM-200 cable ties (supplied) as shown in

Figure 3.

Junction Box CablesJunction Box Cables

Junction Box Cables

Junction Box CablesJunction Box Cables

(A1(A1

1498-XX and A11498-XX and A1

(A1

1498-XX and A1

(A1(A1

1498-XX and A11498-XX and A1

The spray gun can be ordered with special low

voltage cables (A11498-XX and A11356-XX) for

splicing to a junction box. This is sometimes done

in the field, to reduce the amount of cable that has

to be replaced if a failure of the cable occurs. The

TT

AGE CABLEAGE CABLE

T

AGE CABLE

TT

AGE CABLEAGE CABLE

oltage Cableoltage Cable

oltage Cable

oltage Cableoltage Cable

MUSTMUST

MUST be

MUSTMUST

1356-XX)1356-XX)

1356-XX)

1356-XX)1356-XX)

control unit and gun ends of these cables attach

as described in the standard low voltage cable

section above. Follow the instructions below to

wire the junction box ends of these cables:

Junction Box in Hazardous LocationJunction Box in Hazardous Location

Junction Box in Hazardous Location

Junction Box in Hazardous LocationJunction Box in Hazardous Location

If the junction box is in the hazardous location, an

explosion-proof junction box must be used. In this

case, connect the numbered wires of cable

A11356-XX to the same numbered wire of cable

A11498-XX using a terminal strip inside the

explosion-proof junction box. Ensure the junction

box is grounded to earth ground. Connect wire 18

(braid) of cable A11498-XX to the junction box

(ground). Seal the cable in the explosion-proof

junction box using appropriate explosion-proof

fittings and sealing compound. The exposed area

of the cable braids must be located on the junction

box side of the sealing compound.

Junction Box in Non-HazardousJunction Box in Non-Hazardous

Junction Box in Non-Hazardous

Junction Box in Non-HazardousJunction Box in Non-Hazardous

LocationLocation

Location

LocationLocation

If the junction box is in a non-hazardous location,

then it is not necessary to use an explosion-proof

junction box. In this case, use the supplied cable

gland (A11357-02) and gland nut (A11358-02) to

secure the cables at their entry and exit to the

junction box. Install the cable gland in the junction

box and position the cable so that the spring of the

gland makes contact to the exposed braid of the

cable when the gland nut is tightened. Ensure the

junction box is grounded to earth ground. Connect

the numbered wires of cable A11356-XX to the

same numbered wire of cable A11498-XX using a

terminal strip inside the junction box. The braid of

cable A11498-XX will be grounded through its

contact to the cable gland spring and the grounded

junction box. Wire 18, therefore is unnecessary

and may be trimmed off. Connection in this

manner will ensure maximum noise immunity.

CP-06-01

88

8

88

Loading...

Loading...